Microstructure, Pitting Corrosion Resistance and Impact Toughness of Duplex Stainless Steel Underwater Dry Hyperbaric Flux-Cored Arc Welds

Abstract

1. Introduction

2. Experimental Procedure

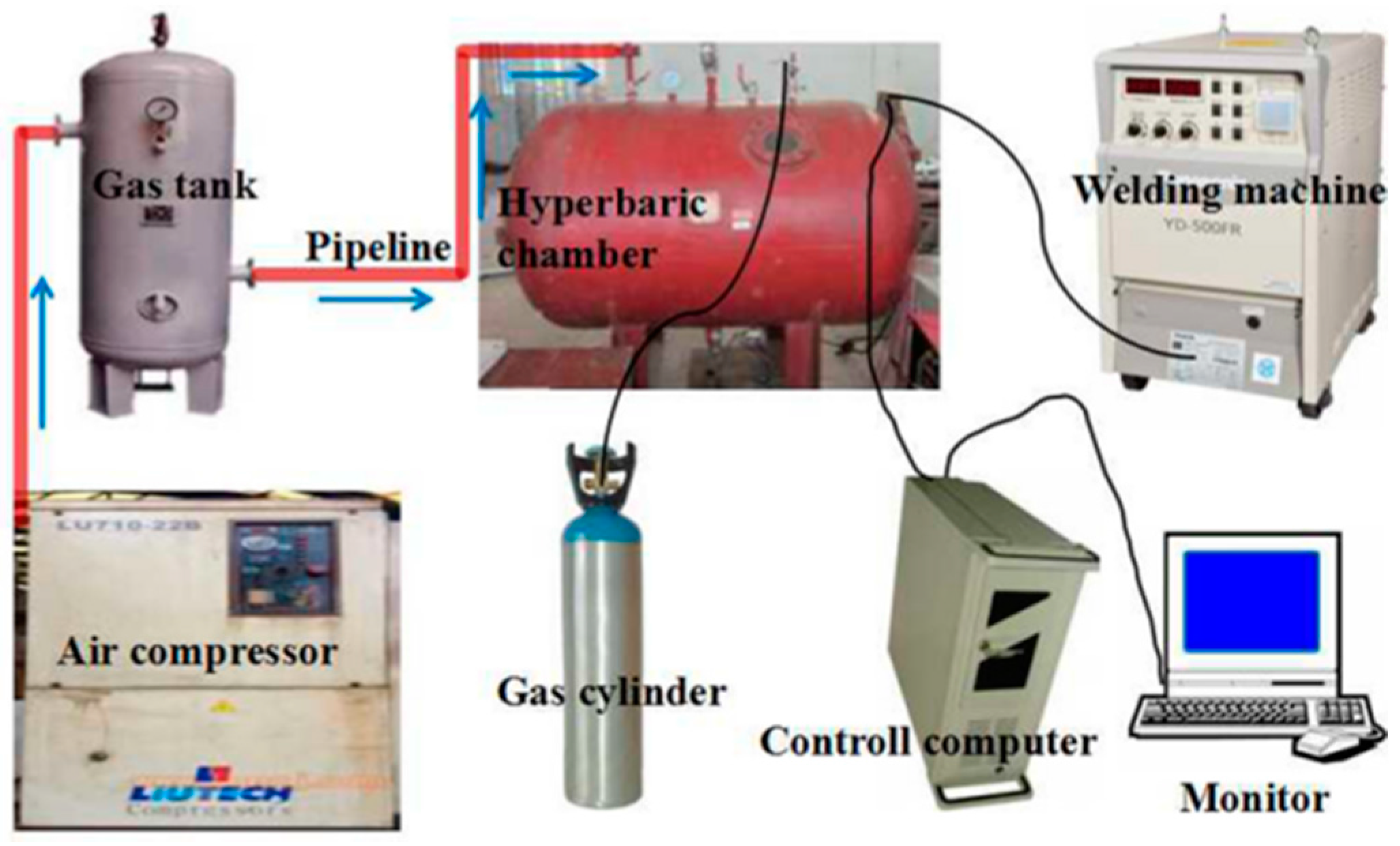

2.1. Welding Device and Materials

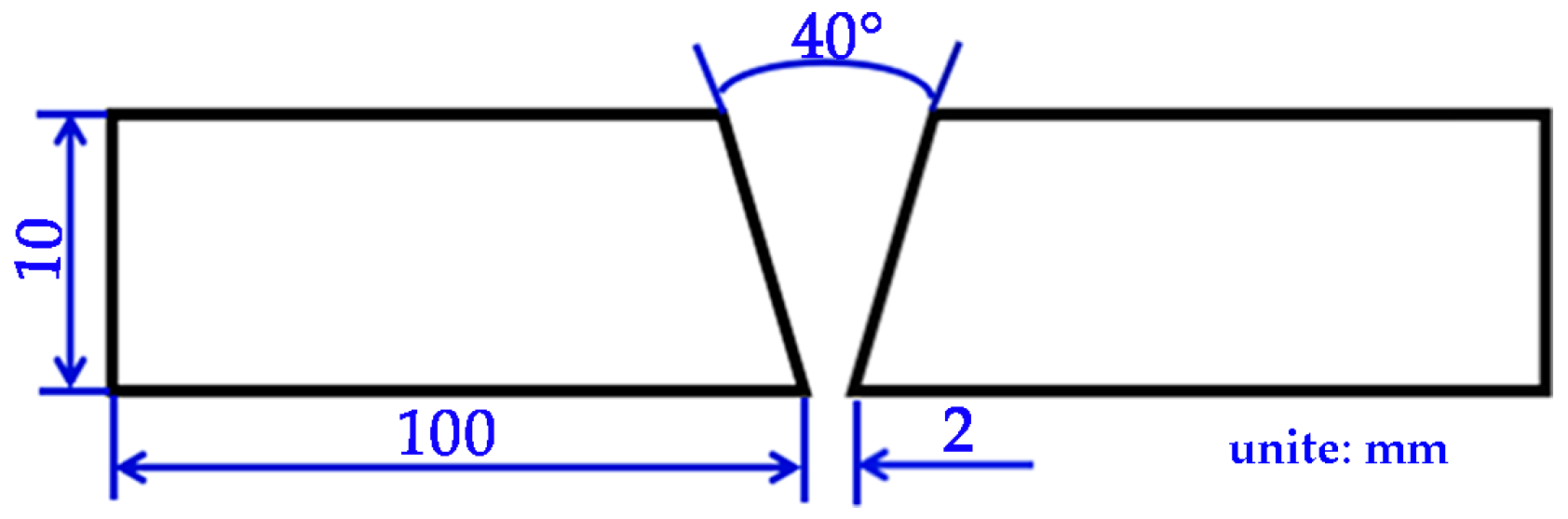

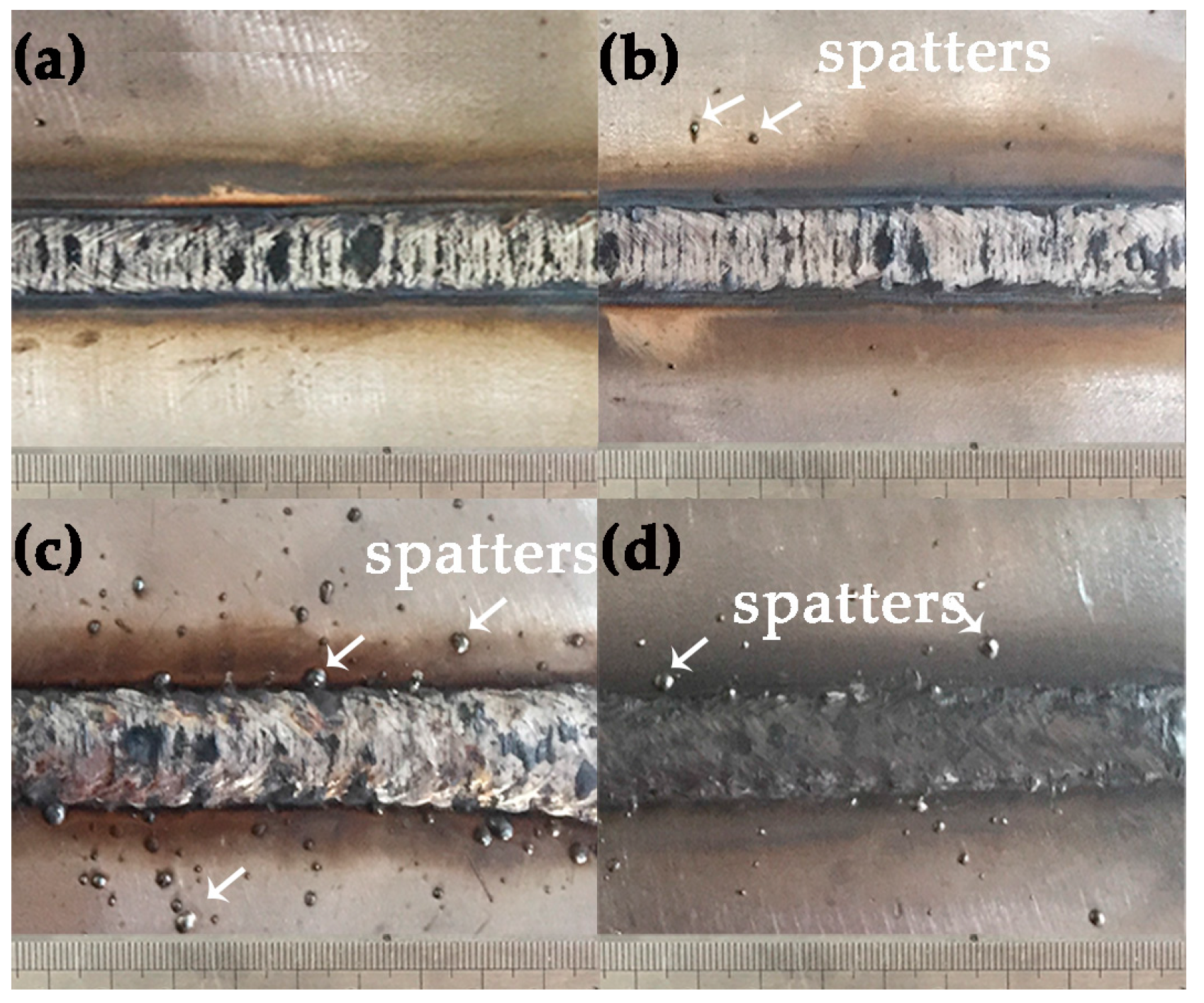

2.2. Welding Process

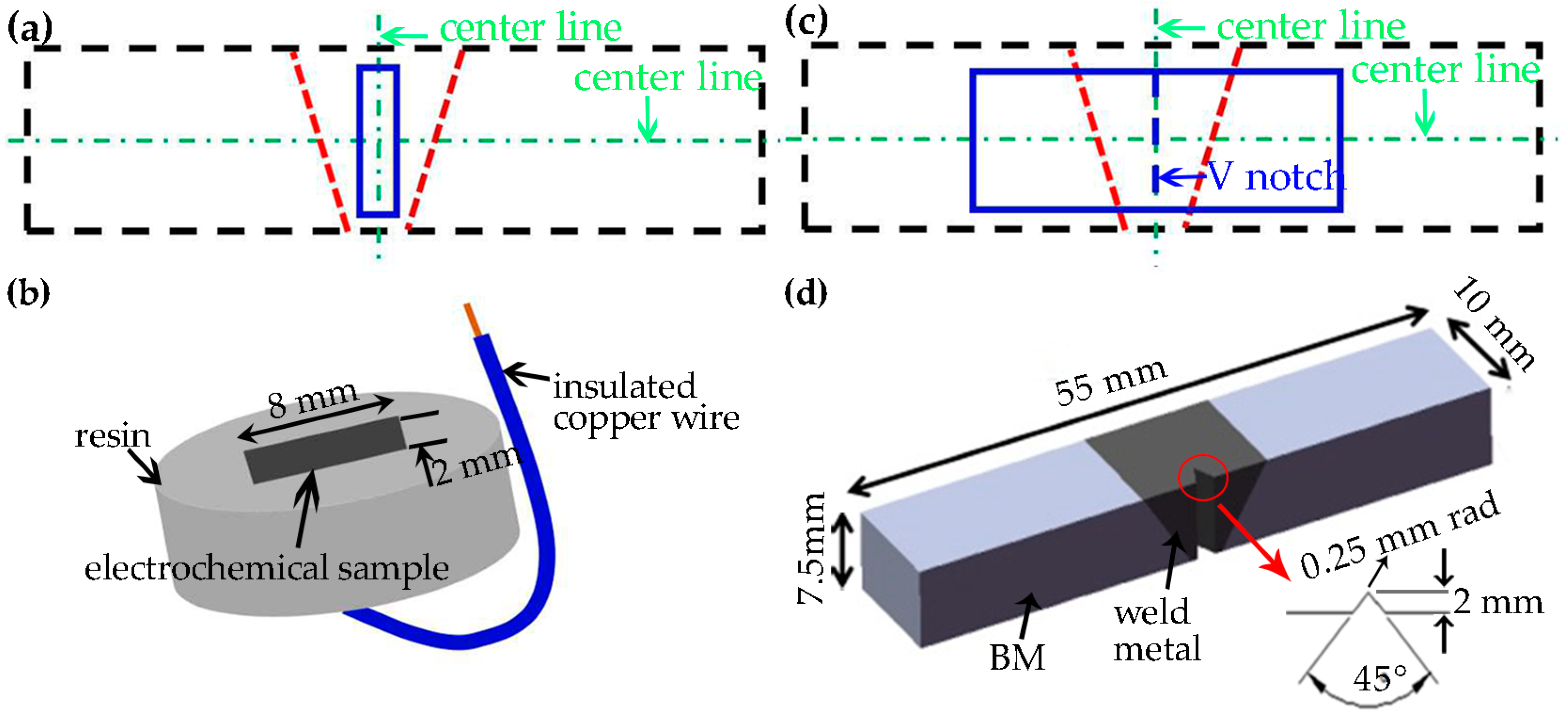

2.3. Microstructural Examination

2.4. Electrochemical Measurement and Impact Toughness Test

3. Results and Discussion

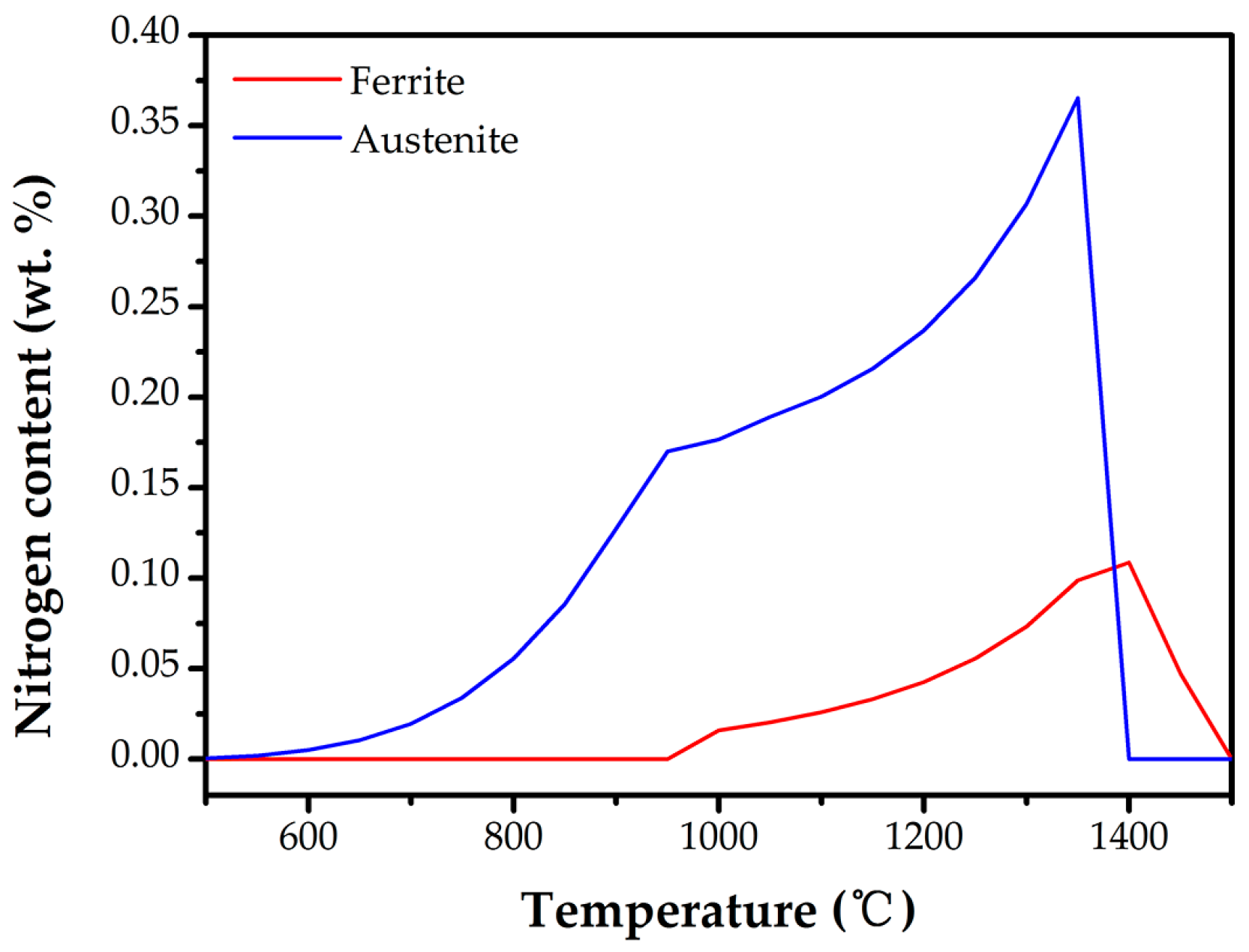

3.1. Thermodynamic Analysis

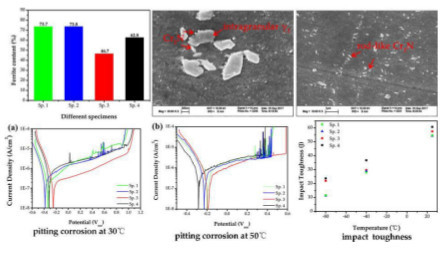

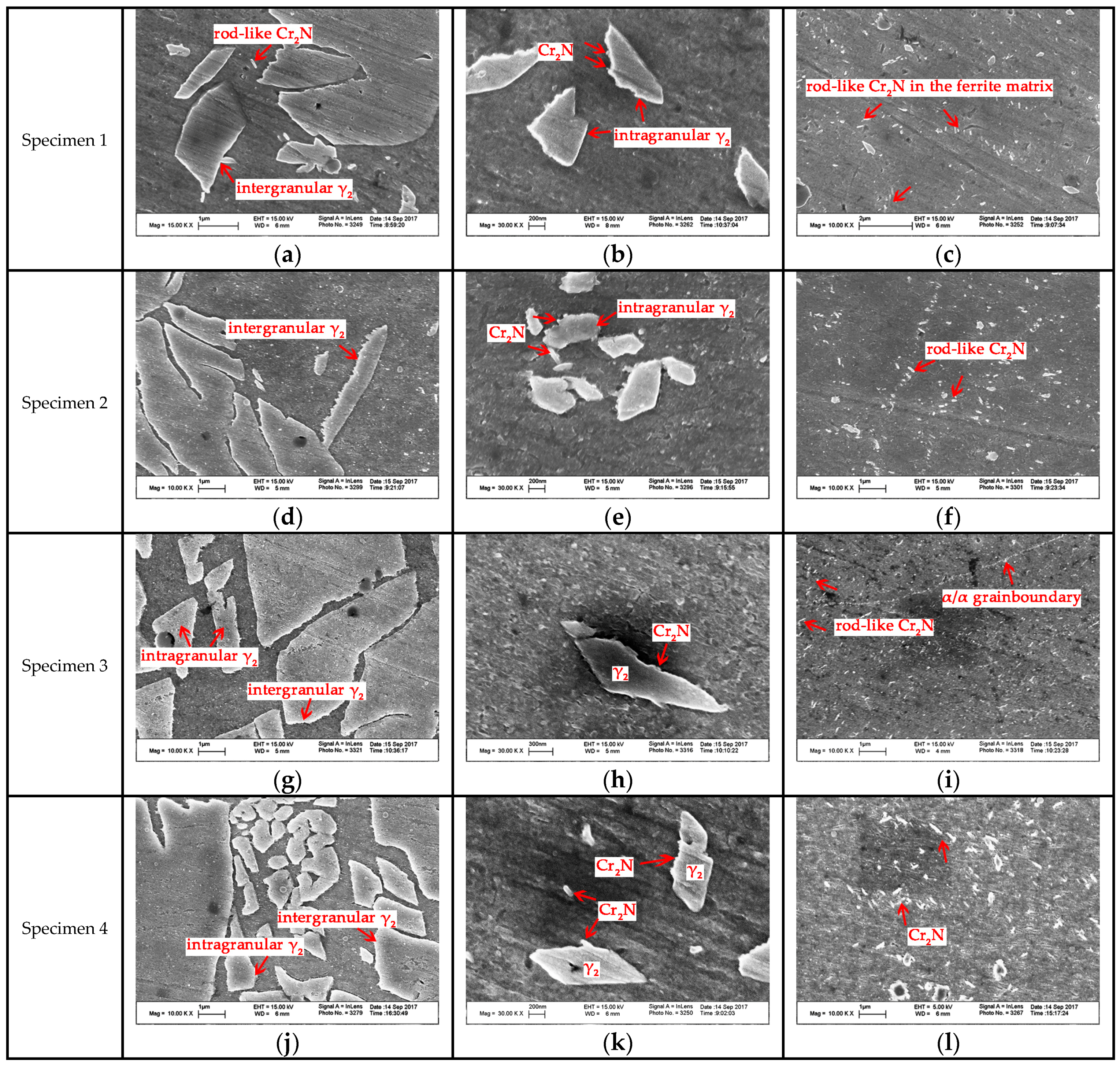

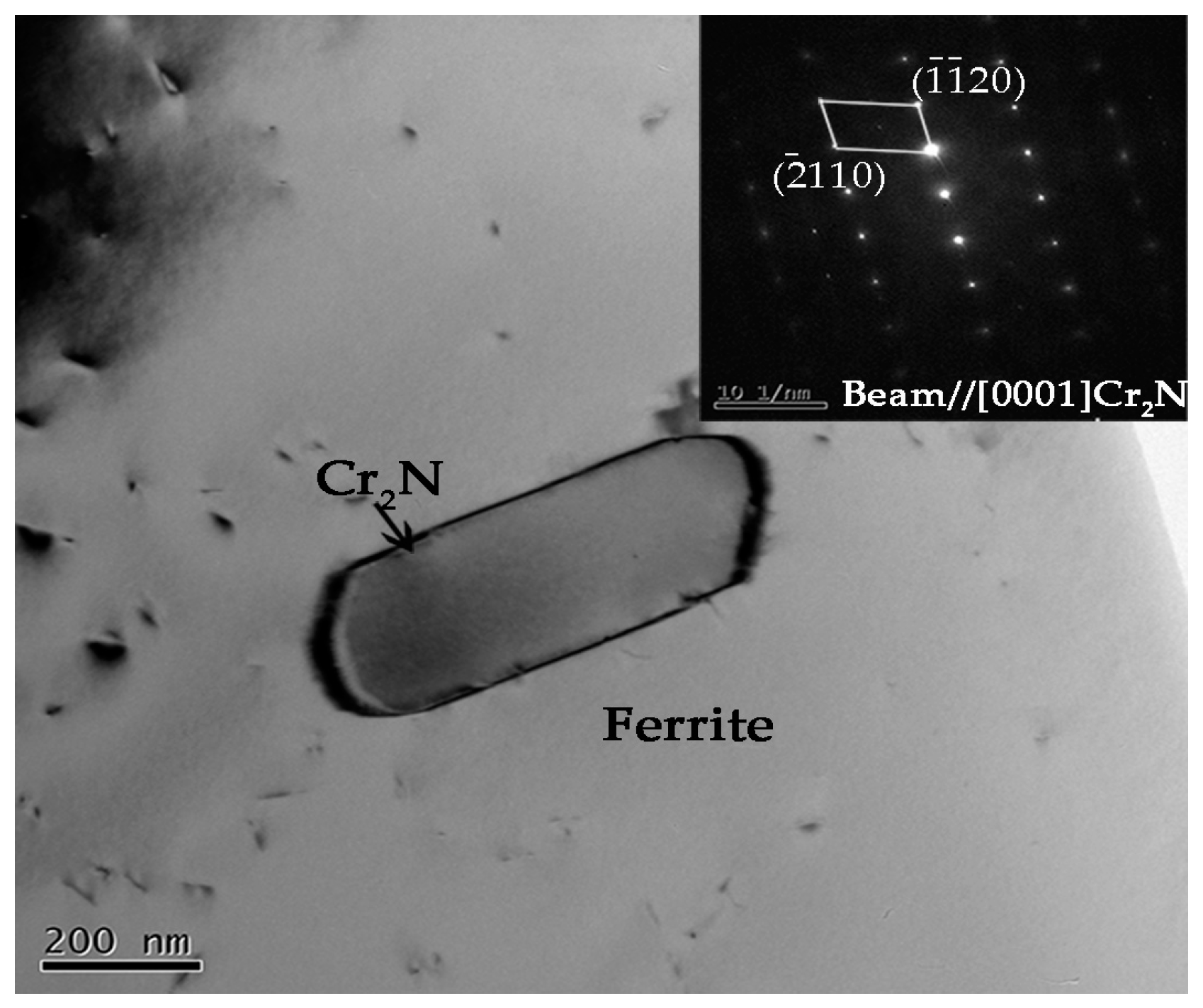

3.2. Microstructures Characterization

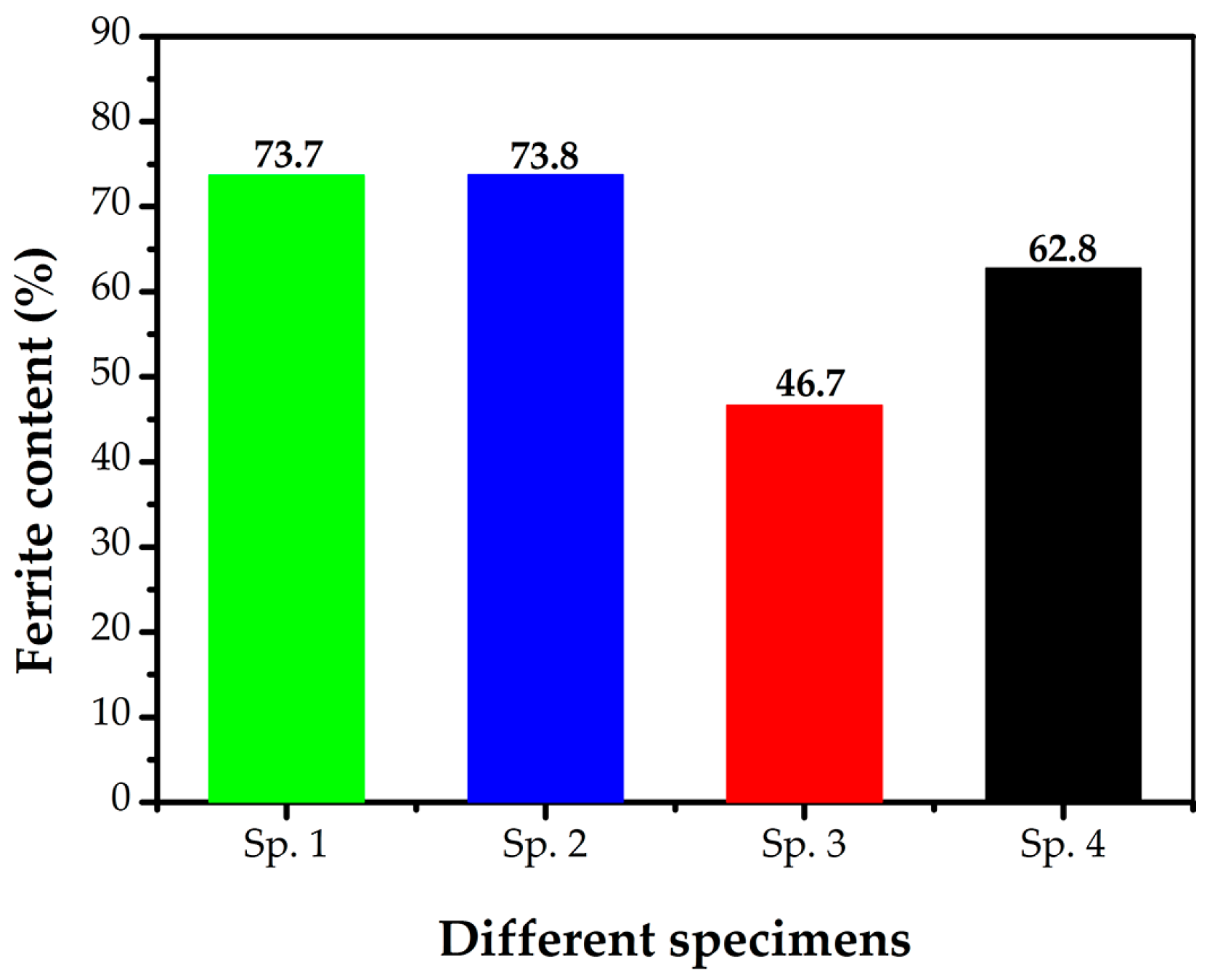

3.3. Effect of Ambient Pressure on the Microstructure

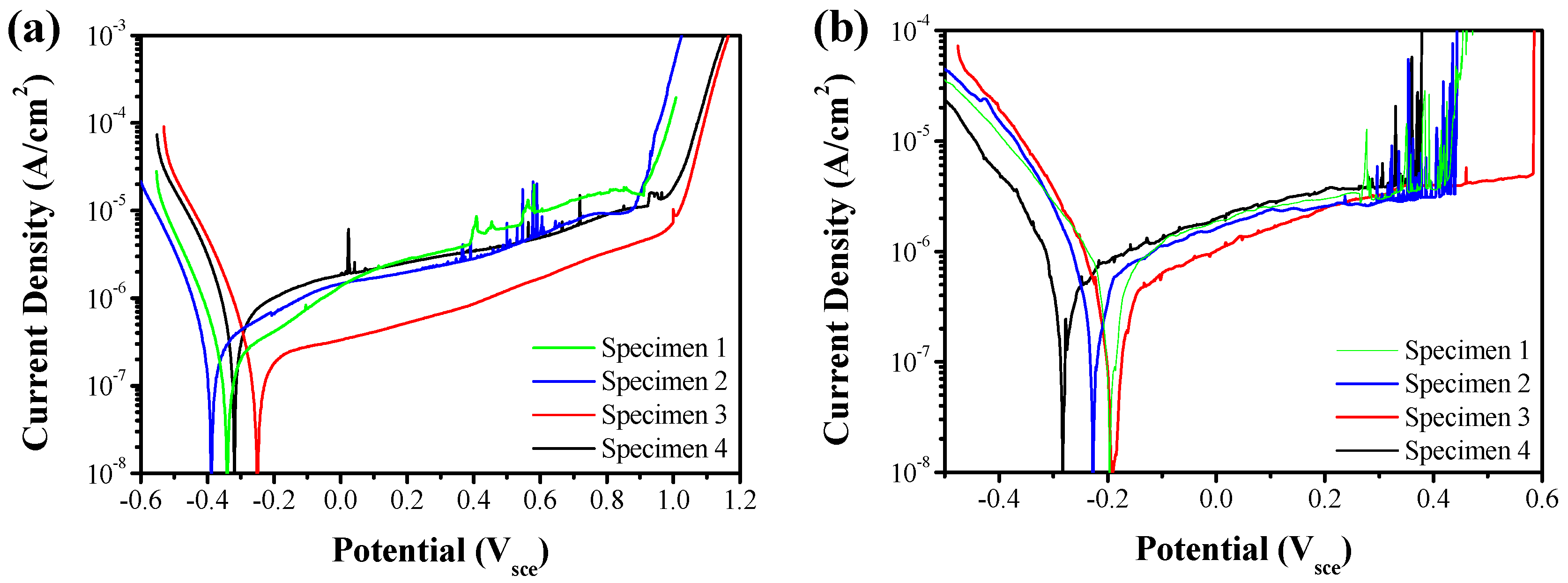

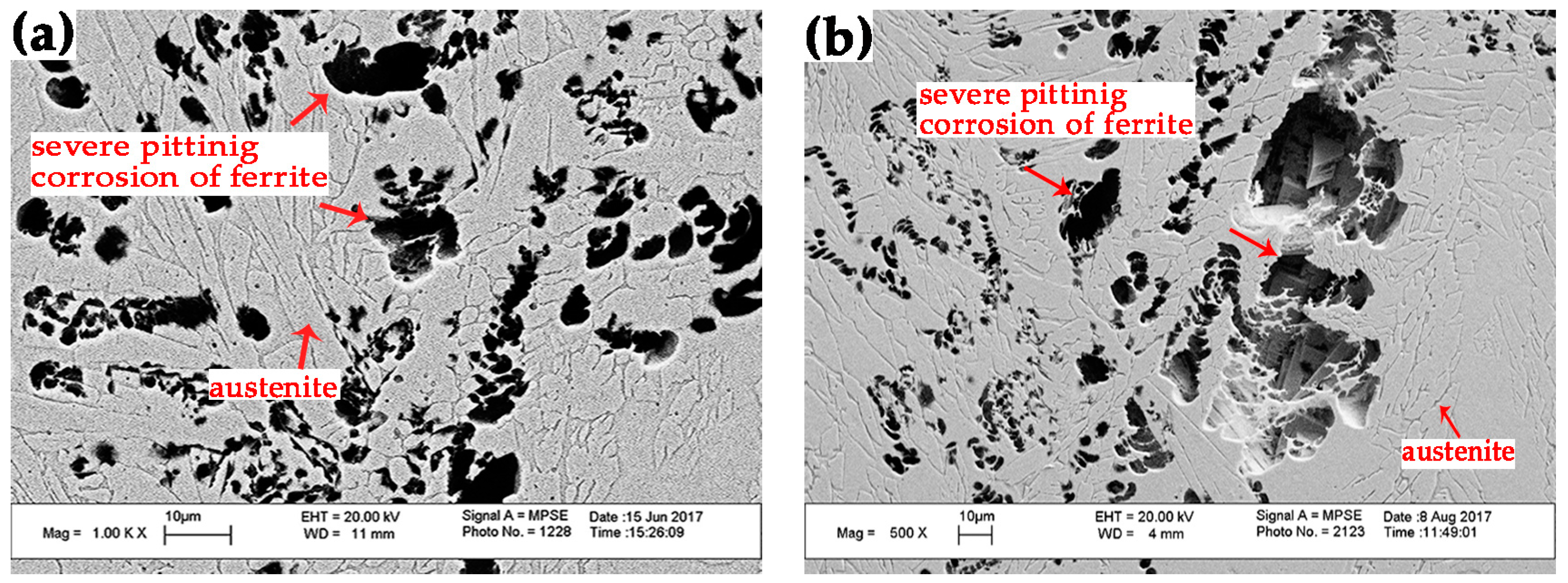

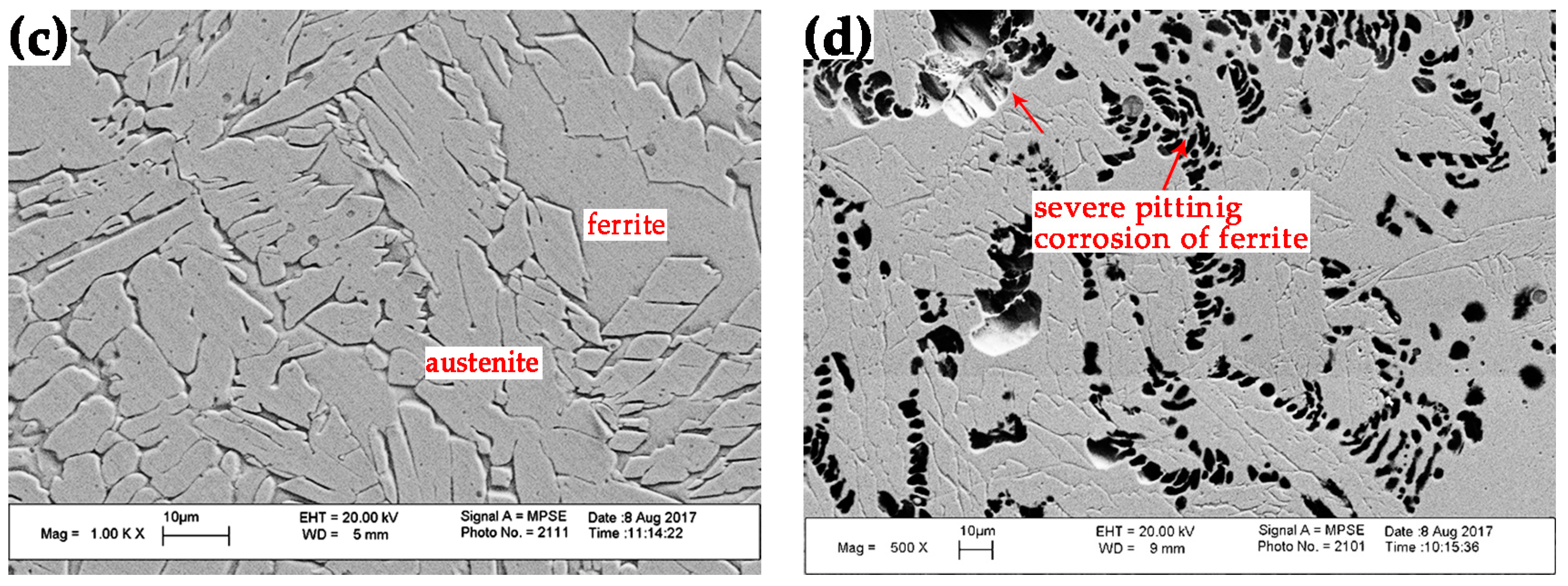

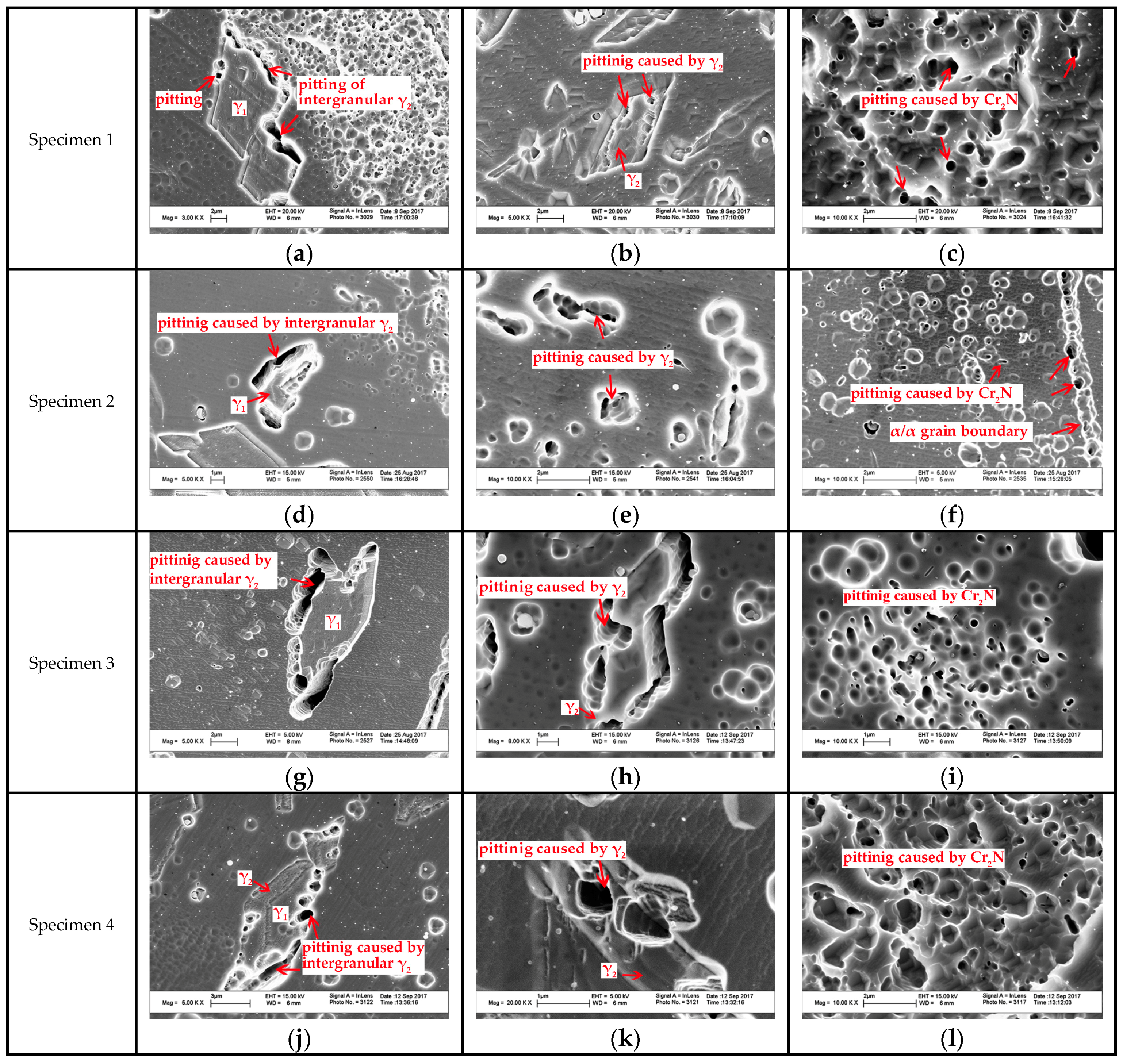

3.4. Electrochemical Test

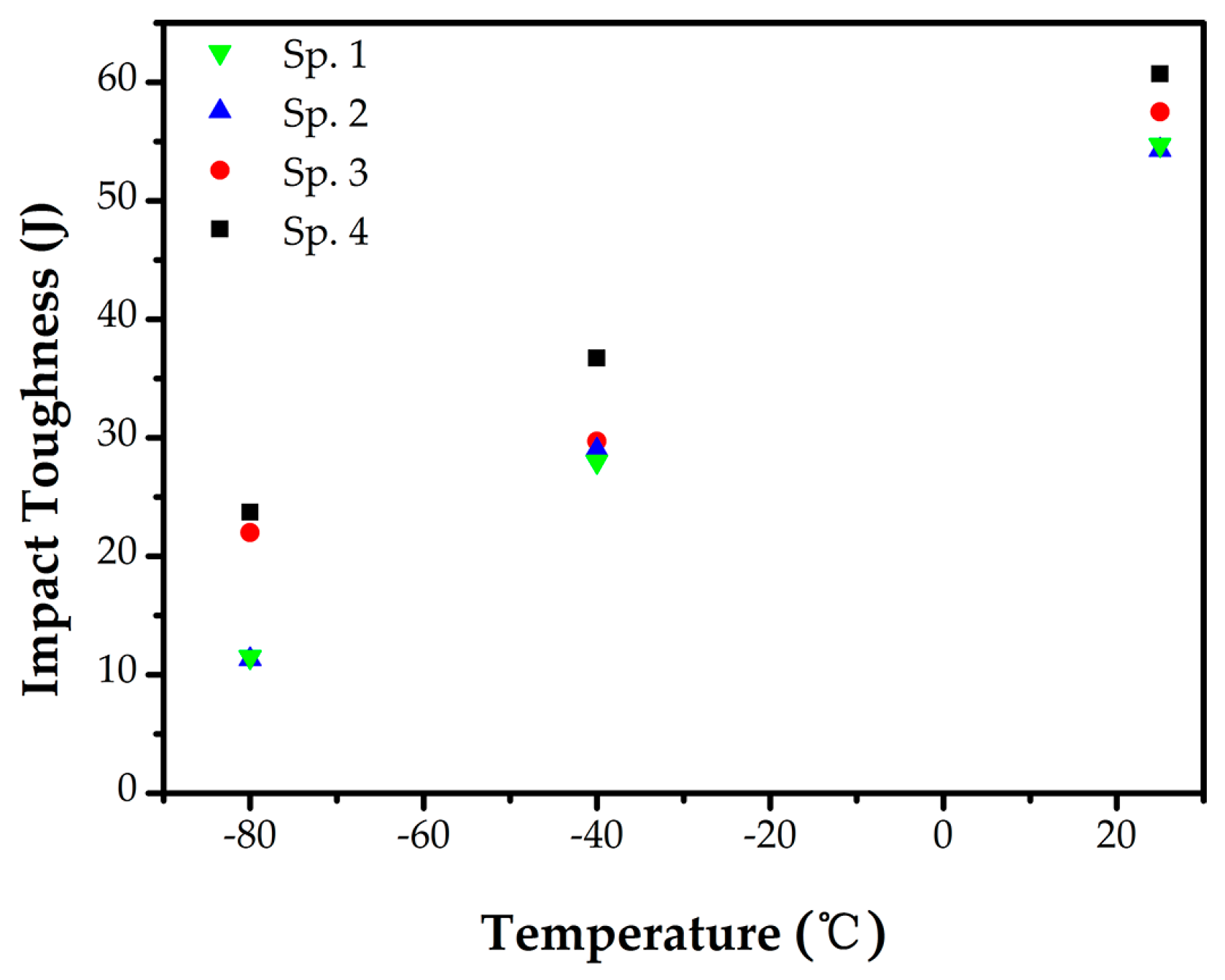

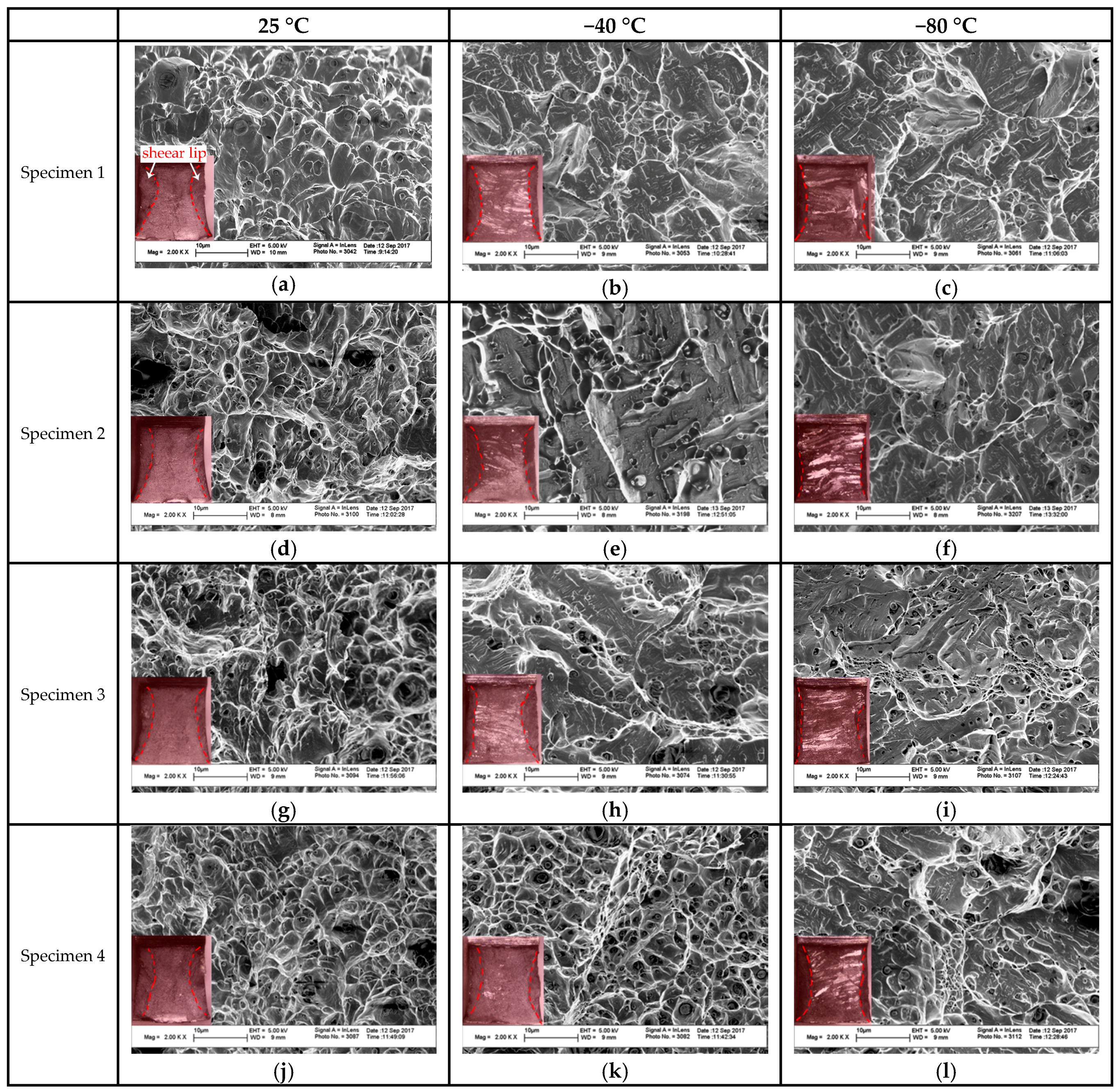

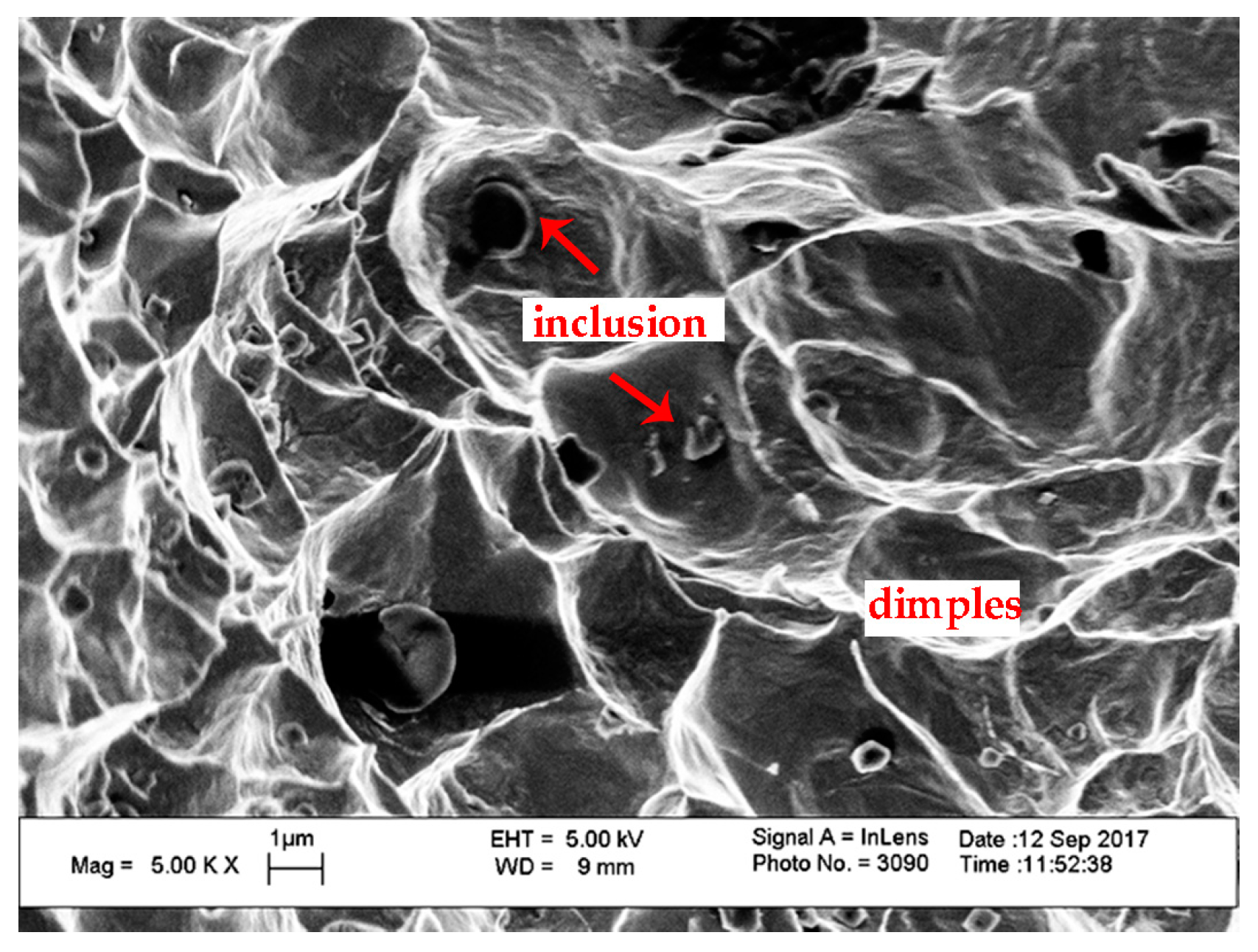

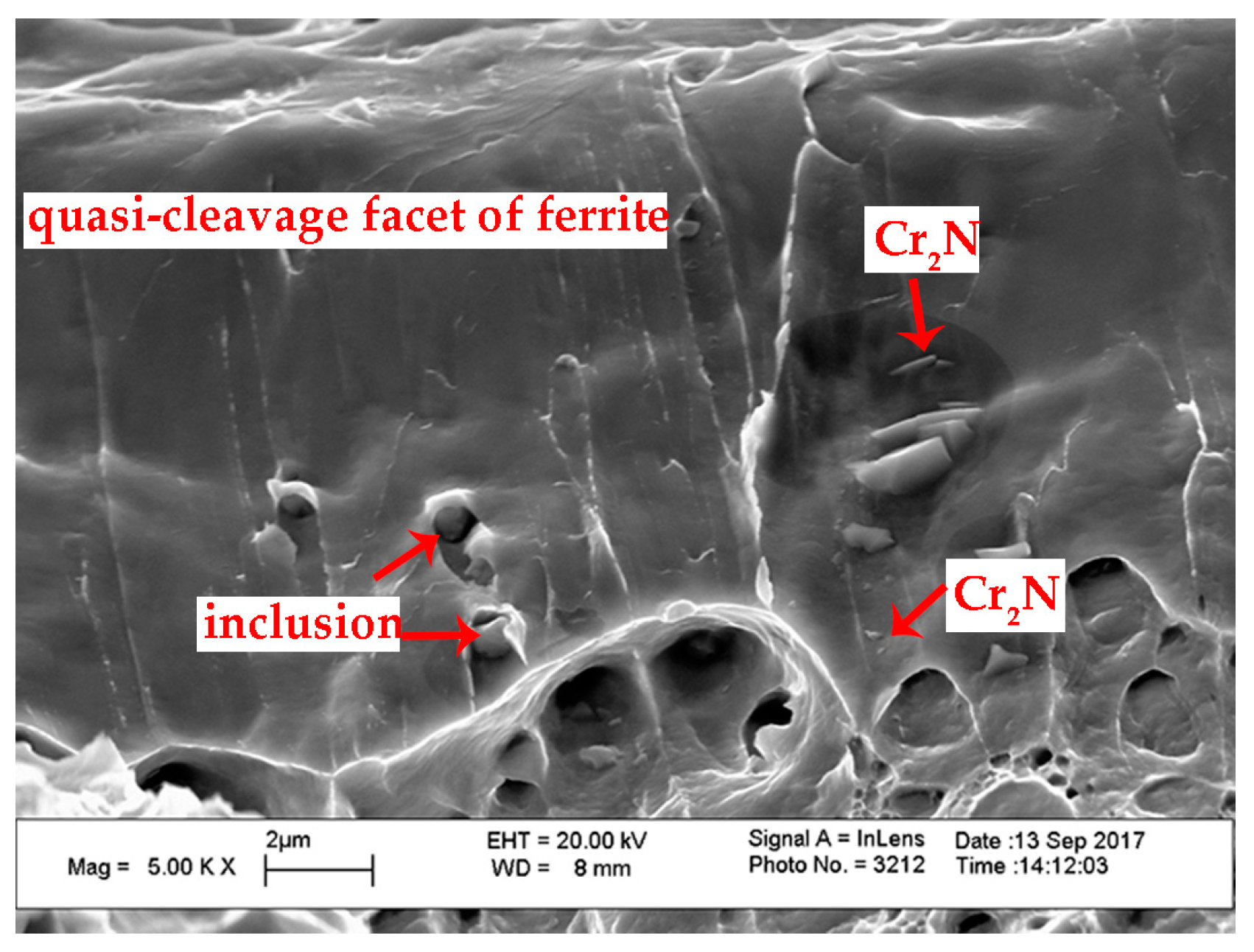

3.5. Impact Toughness

4. Conclusions

- (1)

- The heat input for root weld should decrease with the increase in ambient pressure to obtain a uniform weld shape, and consequently the number of weld layers to fulfill the groove’s needs to be increased, compared to welding at lower pressures with the same groove types.

- (2)

- The weld metal made at 0.45 MPa had the most content of austenite followed by 0.75 MPa, and 0.15 MPa. The specimen obtained at 0.15 MPa behaved almost the same as the specimen of normal pressure. The most significant difference in the chemical composition is the much higher concentration of N in the weld metal made at 0.45 MPa than the other three specimens. The more the austenite content, the less presence of the chromium nitrides in ferrite.

- (3)

- The phases of lower PRENs reflected the pitting corrosion resistance of the weld metal measured by potentiodynamic polarization test in 1 mol/L NaCl solution at 30 °C and 50 °C. The metastable pits appearing at the α/γ2 boundaries, γ2 and around the Cr2N were viewed in all the specimens tested at the two test temperatures. Stable and clustered pits were not seen in specimens tested at 30 °C, while severely eroded pitting holes could be observed in ferrite of 0, 0.15 and 0.75 MPa tested at 50 °C. The weld metal made at 0.75 MPa had better pitting resistance than those made at 0 and 0.15 MPa at 30 °C because of higher PREN of secondary austenite of the 0.75 MPa weld metal, while the situation was reversed at 50 °C because the PREN of ferrite of the 0.75 MPa weld metal is smaller. Therefore, the weld metal made at 0.75 MPa experienced bad pitting resistance. The weld metal of 0.45 MPa presented the best resistance to pitting propagation in all the tests.

- (4)

- At the three tested temperatures (25 °C, −40 °C, and −80 °C), the impact toughness had no direct relation to the austenite content. The weld metal made at 0.75 MPa expressed the highest toughness value in comparison with the other weld metals and all the absorbed energy had a decline in different degrees along with a ductile-brittle transition. Whereas, the loss of toughness values were inversely proportional to the percentage of ferrite.

- (5)

- The ridiculously high ferrite content in the weld metals as well as the Cr2N precipitates had a serious effect on the pitting corrosion resistance and the absorbed energy. In addition, the weld metal made at 0.45 MPa had the best comprehensive performance of pitting corrosion resistance and impact toughness in this study.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Lippold, J.C.; Kotecki, D.J. Welding Metallurgy and Weldability of Stainless Steels, 1st ed.; John Wiley & Sons Inc.: Hoboken, NJ, USA, 2005; p. 234. [Google Scholar]

- Chan, K.; Tjong, S. Effect of secondary phase precipitation on the corrosion behavior of duplex stainless steels. Materials 2014, 7, 5268–5304. [Google Scholar] [CrossRef] [PubMed]

- Guo, Y.; Hu, J.; Li, J.; Jiang, L.; Liu, T.; Wu, Y. Effect of annealing temperature on the mechanical and corrosion behavior of a newly developed novel lean duplex stainless steel. Materials 2014, 7, 6604–6619. [Google Scholar] [CrossRef] [PubMed]

- Utu, I.; Mitelea, I.; Urlan, S.; Crăciunescu, C. Transformation and precipitation reactions by metal active gas pulsed welded joints from X2CrNiMoN22-5-3 duplex stainless steels. Materials 2016, 9, 606. [Google Scholar] [CrossRef] [PubMed]

- Moallemi, M.; Zarei-Hanzaki, A.; Eskandari, M.; Burrows, A.; Alimadadi, H. Comprehensive deformation analysis of a newly designed Ni-free duplex stainless steel with enhanced plasticity by optimizing austenite stability. Metall. Mater. Trans. A 2017, 48, 3675–3691. [Google Scholar] [CrossRef]

- Brytan, Z.; Niagaj, J.; Reiman, Ł. Corrosion studies using potentiodynamic and EIS electrochemical techniques of welded lean duplex stainless steel UNS S82441. Appl. Surf. Sci. 2016, 388, 160–168. [Google Scholar] [CrossRef]

- Maetz, J.; Cazottes, S.; Verdu, C.; Danoix, F.; Kléber, X. Microstructural evolution in 2101 lean duplex stainless steel during low- and intermediate-temperature aging. Microsc. Microanal. 2016, 22, 463–473. [Google Scholar] [CrossRef] [PubMed]

- Gao, H.; Jiao, X.; Zhou, C.; Shen, Q.; Yu, Y. Study on remote control underwater welding technology applied in nuclear power station. Procedia Eng. 2011, 15, 4988–4993. [Google Scholar] [CrossRef]

- Bal, M. The effect of aqueous environments on the quality of underwater-welded joints. Weld. Int. 1996, 10, 95–98. [Google Scholar]

- Shi, Y.; Zheng, Z.; Huang, J. Sensitivity model for prediction of bead geometry in underwater wet flux cored arc welding. Trans. Nonferrous Met. Soc. China 2013, 23, 1977–1984. [Google Scholar] [CrossRef]

- Łabanowski, J.; Fydrych, D.; Rogalski, G. Underwater welding—A review. Adv. Mater. Sci. 2008, 8, 11–22. [Google Scholar] [CrossRef]

- Łabanowski, J.; Prokop, K.; Rogalski, G.; Fydrych, D. The effect of wet underwater welding on cold cracking susceptibility of duplex stainless steel. Adv. Mater. Sci. 2016, 16, 68–77. [Google Scholar] [CrossRef]

- Shi, Y.H.; Hu, Y.; Yi, Y.Y.; Lin, S.Q.; Li, Z.H. Porosity and microstructure of underwater wet FCAW of duplex stainless steel. Metallogr. Microstruct. Anal. 2017, 6, 383–389. [Google Scholar] [CrossRef]

- Łabanowski, J.; Fydrych, D.; Rogalski, G.; Samson, K. Underwater welding of duplex stainless steel. Solid State Phenom. 2011, 183, 101–106. [Google Scholar] [CrossRef]

- Farrell, J. Hyperbaric Welding of Duplex Stainless Steel Pinpelines Offshore. Ph.D. Thesis, Cranfield University, Cranfield, UK, 1996. [Google Scholar]

- Akselsen, O.M.; Fostervoll, H.; Ahlen, C.H. Hyperbaric GMA welding of duplex stainless steel at 12 and 35 bar. Weld. J. 2009, 88, 21S–28S. [Google Scholar]

- Pramanik, A.; Littlefair, G.; Basak, A.K. Weldability of duplex stainless steel. Mater. Manuf. Process. 2015, 30, 1053–1068. [Google Scholar] [CrossRef]

- Brytan, Z.; Niagaj, J. Corrosion resistance and mechanical properties of TIG and A-TIG welded joints of lean duplex stainless steel S82441/1.4662. Arch. Metall. Mater. 2016, 61, 771–784. [Google Scholar] [CrossRef]

- Westin, E.M.; Olsson, C.O.A.; Hertzman, S. Weld oxide formation on lean duplex stainless steel. Corros. Sci. 2008, 50, 2620–2634. [Google Scholar] [CrossRef]

- Azar, A.S.; Lange, H.I.; Stby, E.; Akselsen, O.M. Effect of hyperbaric gas composition on mechanical properties of the weld metal. Mater. Sci. Eng. A-Struct. 2012, 556, 465–472. [Google Scholar] [CrossRef]

- Zhang, Z.; Jing, H.; Xu, L.; Han, Y.; Zhao, L. Investigation on microstructure evolution and properties of duplex stainless steel joint multi-pass welded by using different methods. Mater. Des. 2016, 109, 670–685. [Google Scholar] [CrossRef]

- Azar, A.S.; Ås, S.K.; Akselsen, O.M. Analytical modeling of weld bead shape in dry hyperbaric GMAW using Ar-He chamber gas mixtures. J. Mater. Eng. Perform. 2013, 22, 673–680. [Google Scholar] [CrossRef]

- American Society of Testing Materials for Standardization. Standard Test Methods and Definitions for Mechanical Testing of Steel Products; ASTM International: West Conshohocken, PA, USA, 2015. [Google Scholar]

- Garfias-Mesias, L.F.; Sykes, J.M.; Tuck, C.D.S. The effect of phase compositions on the pitting corrosion of 25 cr duplex stainless steel in chloride solutions. Corros. Sci. 1996, 1319–1330. [Google Scholar] [CrossRef]

- Li, K.; Gao, H.M.; Li, H.C. Arc Behavior of Dry Hyperbaric Gas Metal Arc Welding. Adv. Mater. 2014, 988, 245–248. [Google Scholar] [CrossRef]

- Muthupandi, V.; Bala Srinivasan, P.; Shankar, V.; Seshadri, S.K.; Sundaresan, S. Effect of nickel and nitrogen addition on the microstructure and mechanical properties of power beam processed duplex stainless steel (UNS 31803) weld metals. Mater. Lett. 2005, 59, 2305–2309. [Google Scholar] [CrossRef]

- Chen, L.; Tan, H.; Wang, Z.; Li, J.; Jiang, Y. Influence of cooling rate on microstructure evolution and pitting corrosion resistance in the simulated heat-affected zone of 2304 duplex stainless steels. Corros. Sci. 2012, 58, 168–174. [Google Scholar] [CrossRef]

- Ramirez, A.J.; Brandi, S.D.; Lippold, J.C. Secondary austenite and chromium nitride precipitation in simulated heat affected zones of duplex stainless steels. Sci. Technol. Weld. Join. 2004, 9, 301–313. [Google Scholar] [CrossRef]

- Geng, S.; Sun, J.; Guo, L.; Wang, H. Evolution of microstructure and corrosion behavior in 2205 duplex stainless steel GTA-welding joint. J. Manuf. Process. 2015, 19, 32–37. [Google Scholar] [CrossRef]

- De Lacerda, J.C.; Cândido, L.C.; Godefroid, L.B. Effect of volume fraction of phases and precipitates on the mechanical behavior of UNS S31803 duplex stainless steel. Int. J. Fatigue 2015, 74, 81–87. [Google Scholar] [CrossRef]

- Ramkumar, K.D.; Mishra, D.; Thiruvengatam, G.; Sudharsan, S.P.; Mohan, T.H.; Saxena, V.; Pandey, R.; Arivazhagan, N. Investigations on the microstructure and mechanical properties of multi-pass PCGTA welding of super-duplex stainless steel. Bull. Mater. Sci. 2015, 38, 837–846. [Google Scholar] [CrossRef]

- Deng, B.; Wang, Z.; Jiang, Y.; Sun, T.; Xu, J.; Li, J. Effect of thermal cycles on the corrosion and mechanical properties of UNS S31803 duplex stainless steel. Corros. Sci. 2009, 51, 2969–2975. [Google Scholar] [CrossRef]

- Wu, H.; Grabarnik, S.; Emadi, A.; de Graaf, G.; Wolffenbuttel, R.F. Characterization of thermal cross-talk in a MEMS-based thermopile detector array. J. Micromech. Microeng. 2009, 19, 074022. [Google Scholar] [CrossRef]

- Azar, A.S.; Woodward, N.; Fostervoll, H.; Akselsen, O.M. Statistical analysis of the arc behavior in dry hyperbaric GMA welding from 1 to 250 bar. J. Mater. Process. Technol. 2012, 212, 211–219. [Google Scholar] [CrossRef]

- Westin, E.M. Microstructure and Properties of Welds in the Lean Duplex Stainless Steel LDX 2101. Ph.D. Thesis, Royal Institute of Technology, Stockholm, Sweden, 2010. [Google Scholar]

- Gunn, R.N. Duplex Stainless Steels: Microstructure, Properties and Applications, 1st ed.; Woodhead Publishing: Cambridge, UK, 1997; p. 168. [Google Scholar]

- Shin, Y.T.; Shin, H.S.; Lee, H.W. Effects of heat input on pitting corrosion in super duplex stainless steel weld metals. Met. Mater. Int. 2012, 18, 1037–1040. [Google Scholar] [CrossRef]

- Sieurin, H.; Sandström, R. Austenite reformation in the heat-affected zone of duplex stainless steel 2205. Mater. Sci. Eng. A-Struct. 2006, 418, 250–256. [Google Scholar] [CrossRef]

- Kang, D.H.; Lee, H.W. Study of the correlation between pitting corrosion and the component ratio of the dual phase in duplex stainless steel welds. Corros. Sci. 2013, 74, 396–407. [Google Scholar] [CrossRef]

- Zhang, Z.; Jing, H.; Xu, L.; Han, Y.; Zhao, L. The influence of microstructural evolution on selective corrosion in duplex stainless steel flux-cored arc welded joints. Corros. Sci. 2017, 120, 194–210. [Google Scholar] [CrossRef]

- Zhang, Z.; Jing, H.; Xu, L.; Han, Y.; Zhao, L.; Zhang, J. Influence of microstructure and elemental partitioning on pitting corrosion resistance of duplex stainless steel welding joints. Appl. Surf. Sci. 2017, 394, 297–314. [Google Scholar] [CrossRef]

- Ha, H.; Jang, M.; Lee, T.; Moon, J. Interpretation of the relation between ferrite fraction and pitting corrosion resistance of commercial 2205 duplex stainless steel. Corros. Sci. 2014, 89, 154–162. [Google Scholar] [CrossRef]

- De Lacerda, J.C.; Cândido, L.C.; Godefroid, L.B. Corrosion behavior of UNS S31803 steel with changes in the volume fraction of ferrite and the presence of chromium nitride. Mater. Sci. Eng. A-Struct. 2015, 648, 428–435. [Google Scholar] [CrossRef]

- Muthupandi, V.; Bala Srinivasan, P.; Seshadri, S.K.; Sundaresan, S. Effect of weld metal chemistry and heat input on the structure and properties of duplex stainless steel welds. Mater. Sci. Eng. A-Struct. 2003, 358, 9–16. [Google Scholar] [CrossRef]

- Karlsson, L.; Arcini, H.; Bergquist, E.L.; Weidow, J.; Börjesson, J. Effects of alloying concepts on ferrite morphology and toughness of lean duplex stainless steel weld metals. Weld. World 2010, 54, 350–359. [Google Scholar] [CrossRef]

- Kang, D.H.; Lee, H.W. Effect of different chromium additions on the microstructure and mechanical properties of multipass weld joint of duplex stainless steel. Metall. Mater. Trans. A. 2012, 43, 4678–4687. [Google Scholar] [CrossRef]

- Komizo, Y.; Ogawa, K.; Azuma, S. HAZ embrittlement in high Cr-Mo duplex stainless steel and the effects of Ni and N. Weld. Int. 1991, 5, 277–282. [Google Scholar] [CrossRef]

- Wang, S.; Ma, Q.; Li, Y. Characterization of microstructure, mechanical properties and corrosion resistance of dissimilar welded joint between 2205 duplex stainless steel and 16MnR. Mater. Des. 2011, 32, 831–837. [Google Scholar] [CrossRef]

- Pilhagen, J.; Sandström, R. Influence of nickel on the toughness of lean duplex stainless steel welds. Mater. Sci. Eng. A-Struct. 2014, 602, 49–57. [Google Scholar] [CrossRef]

- Li, S.; Wang, Y.; Wang, X. Effects of Ni content on the microstructures, mechanical properties and thermal aging embrittlement behaviors of Fe-20Cr-xNi alloys. Mater. Sci. Eng. A-Struct. 2015, 639, 640–646. [Google Scholar] [CrossRef]

- Kaçar, R.; Acarer, M. Microstructure-property relationship in explosively welded duplex stainless steel–steel. Mater. Sci. Eng. A-Struct. 2003, 363, 290–296. [Google Scholar] [CrossRef]

- He, J.; Han, G.; Fukuyama, S.; Yokogama, K. Tensile behaviour of duplex stainless steel at low temperatures. Mater. Sci. Technol.-Lond. 1999, 15, 909–920. [Google Scholar] [CrossRef]

| C | Si | Mn | Cr | Ni | Mo | Cu | Co. | P | S | N | PREN | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| BM | 0.017 | 0.49 | 4.98 | 21.52 | 1.56 | 0.22 | 0.16 | 0.04 | 0.02 | <0.002 | 0.24 | 26.1 |

| FM | 0.024 | 0.63 | 1.57 | 22.07 | 8.17 | 3.05 | 0.019 | - | 0.021 | 0.009 | 0.15 | 34.54 |

| Specimen | Gauge Pressure (MPa) | No. of Layers | Current (A) | Voltage (V) | Welding Speed (mm·s−1) | Heat Input (J·mm−1) |

|---|---|---|---|---|---|---|

| Specimen 1 | 0 (normal atmosphere) | 1 (root) | 170 | 28 | 4 | 1190 |

| 2 (finishing) | 180 | 29 | 4.4 | 1186 | ||

| Specimen 2 | 0.15 | 1 (root) | 170 | 28 | 4 | 1190 |

| 2 (finishing) | 180 | 29 | 4.4 | 1186 | ||

| Specimen 3 | 0.45 | 1 (root) | 160 | 27 | 4 | 1080 |

| 2 (filling) | 170 | 28 | 4.8 | 992 | ||

| 3 (finishing) | 180 | 29 | 4.8 | 1088 | ||

| Specimen 4 | 0.75 | 1 (root) | 150 | 26 | 4.4 | 886 |

| 2 (filling) | 170 | 28 | 4.8 | 992 | ||

| 3 (finishing) | 180 | 29 | 4.8 | 1088 |

| Specimen | Phase | Cr | Ni | Mo | N | PREN |

|---|---|---|---|---|---|---|

| Specimen 1 | ferrite | 23.37 | 6.74 | 2.57 | 0.04 | 32.491 |

| primary austenite | 22.86 | 7.13 | 2.37 | 0.28 | 35.161 | |

| secondary austenite | 21.77 | 8.19 | 1.83 | 0.19 | 30.849 | |

| Specimen 2 | ferrite | 23.33 | 6.84 | 2.56 | 0.04 | 32.418 |

| primary austenite | 22.79 | 7.36 | 2.43 | 0.27 | 35.129 | |

| secondary austenite | 21.36 | 8.34 | 1.81 | 0.21 | 30.693 | |

| Specimen 3 | ferrite | 23.47 | 6.79 | 3.05 | 0.03 | 34.015 |

| primary austenite | 22.99 | 7.54 | 2.52 | 0.23 | 34.986 | |

| secondary austenite | 22.41 | 8.02 | 2.17 | 0.21 | 32.931 | |

| Specimen 4 | ferrite | 23.41 | 6.49 | 2.55 | 0.03 | 32.305 |

| primary austenite | 22.95 | 6.89 | 2.32 | 0.23 | 34.286 | |

| secondary austenite | 22.03 | 7.22 | 1.92 | 0.22 | 31.886 |

| Specimen | Si | Mo | Cr | Mn | Fe | Ni | N |

|---|---|---|---|---|---|---|---|

| Specimen 1 | 0.558 | 2.148 | 21.872 | 2.177 | 65.7 | 6.848 | 0.16 |

| (0.55–0.57) | (1.91–2.64) | (21.67–22.07) | (2–2.56) | (64.95–66.56) | (6.43–7.39) | ||

| Specimen 2 | 0.556 | 2.164 | 21.708 | 2.164 | 65.656 | 6.77 | 0.17 |

| (0.47–0.61) | (1.90–2.49) | (21.55–22.06) | (1.84–2.47) | (64.68–66.31) | (6.32–7.37) | ||

| Specimen 3 | 0.612 | 2.226 | 21.824 | 2.182 | 65.198 | 6.856 | 0.27 |

| (0.56–0.65) | (0.00–2.71) | (21.44–22.23) | (1.55–2.51) | (63.51–65.74) | (6.25–8.09) | ||

| Specimen 4 | 0.554 | 2.298 | 21.7 | 1.93 | 65.14 | 7.378 | 0.16 |

| (0.48–0.66) | (2.07–2.57) | (21.53–22.00) | (1.51–2.4) | (64.5–65.46) | (6.67–8.36) |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, Y.; Shi, Y.-H.; Shen, X.-Q.; Wang, Z.-M. Microstructure, Pitting Corrosion Resistance and Impact Toughness of Duplex Stainless Steel Underwater Dry Hyperbaric Flux-Cored Arc Welds. Materials 2017, 10, 1443. https://doi.org/10.3390/ma10121443

Hu Y, Shi Y-H, Shen X-Q, Wang Z-M. Microstructure, Pitting Corrosion Resistance and Impact Toughness of Duplex Stainless Steel Underwater Dry Hyperbaric Flux-Cored Arc Welds. Materials. 2017; 10(12):1443. https://doi.org/10.3390/ma10121443

Chicago/Turabian StyleHu, Yu, Yong-Hua Shi, Xiao-Qin Shen, and Zhong-Min Wang. 2017. "Microstructure, Pitting Corrosion Resistance and Impact Toughness of Duplex Stainless Steel Underwater Dry Hyperbaric Flux-Cored Arc Welds" Materials 10, no. 12: 1443. https://doi.org/10.3390/ma10121443

APA StyleHu, Y., Shi, Y.-H., Shen, X.-Q., & Wang, Z.-M. (2017). Microstructure, Pitting Corrosion Resistance and Impact Toughness of Duplex Stainless Steel Underwater Dry Hyperbaric Flux-Cored Arc Welds. Materials, 10(12), 1443. https://doi.org/10.3390/ma10121443