Multiscale Analyses of Surface Failure Mechanism of Single-Crystal Silicon during Micro-Milling Process

Abstract

1. Introduction

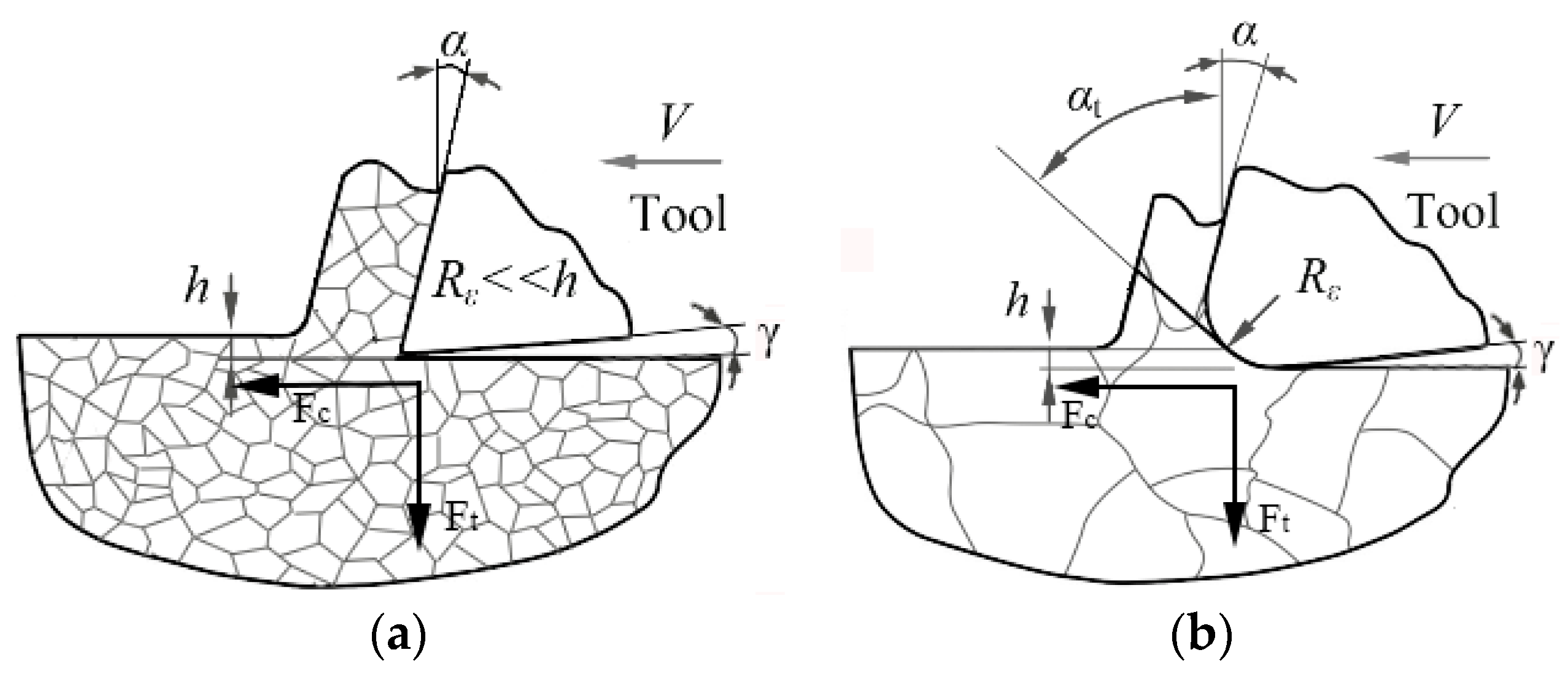

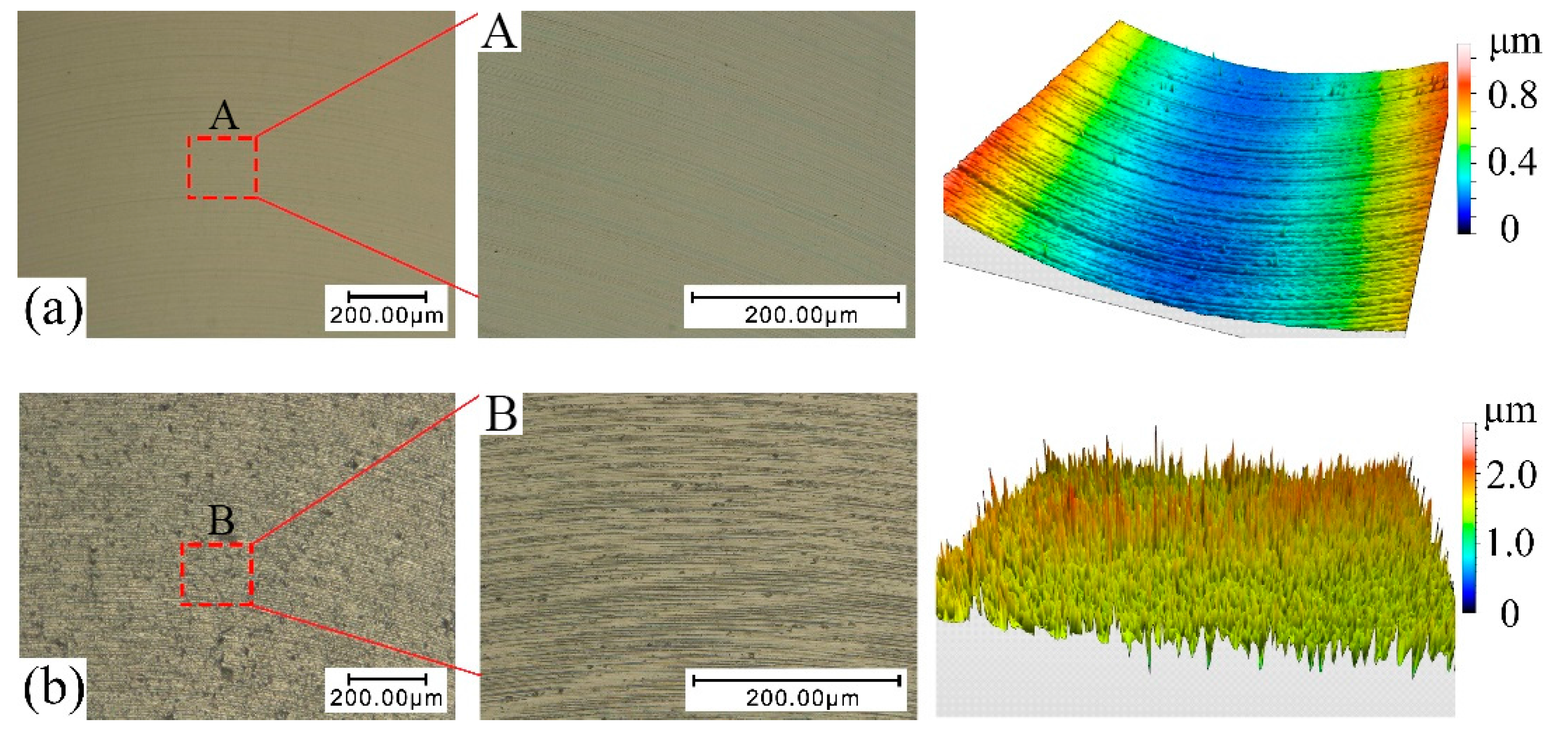

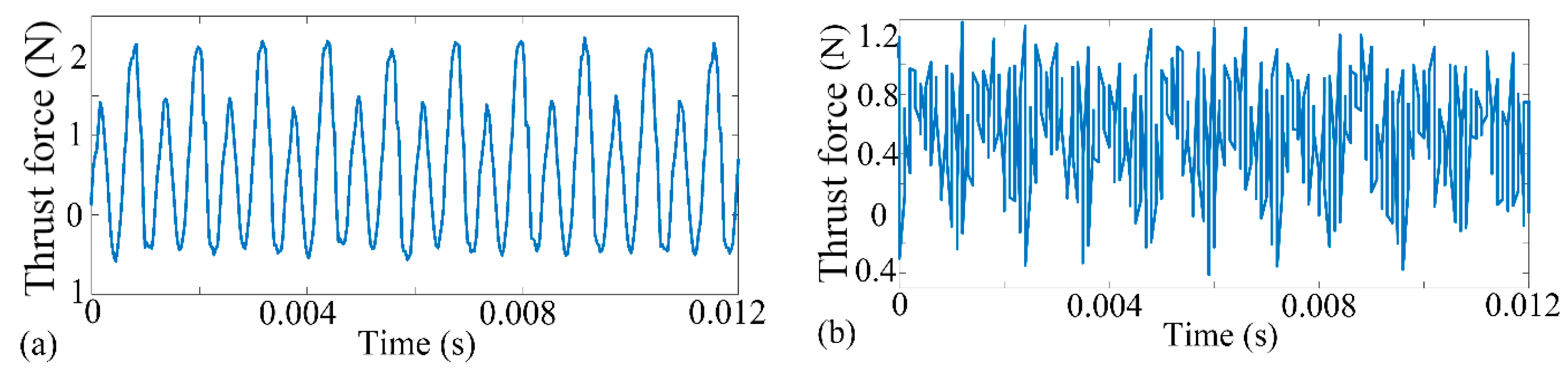

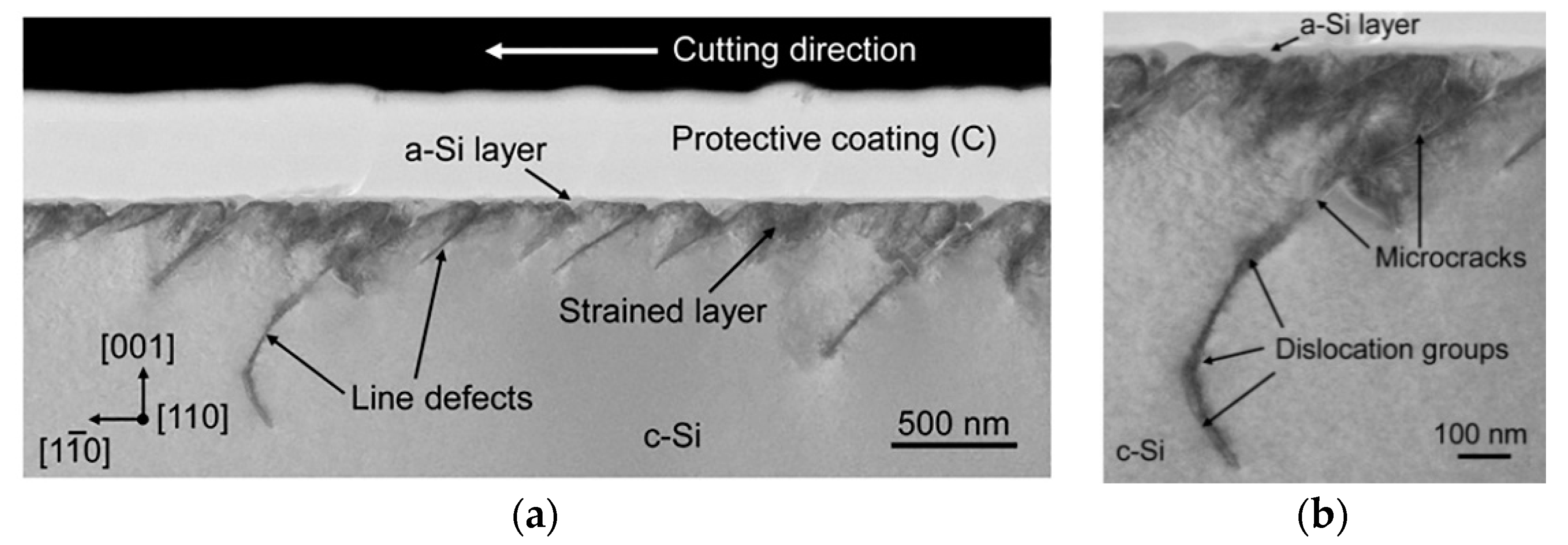

2. Experiment Set-Up and Results

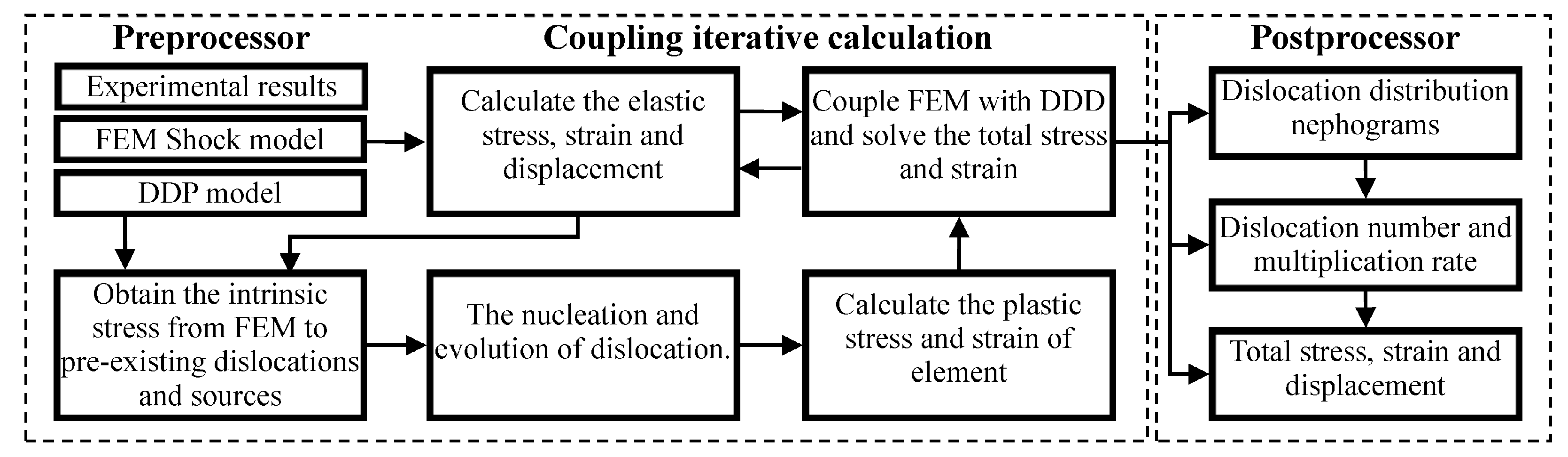

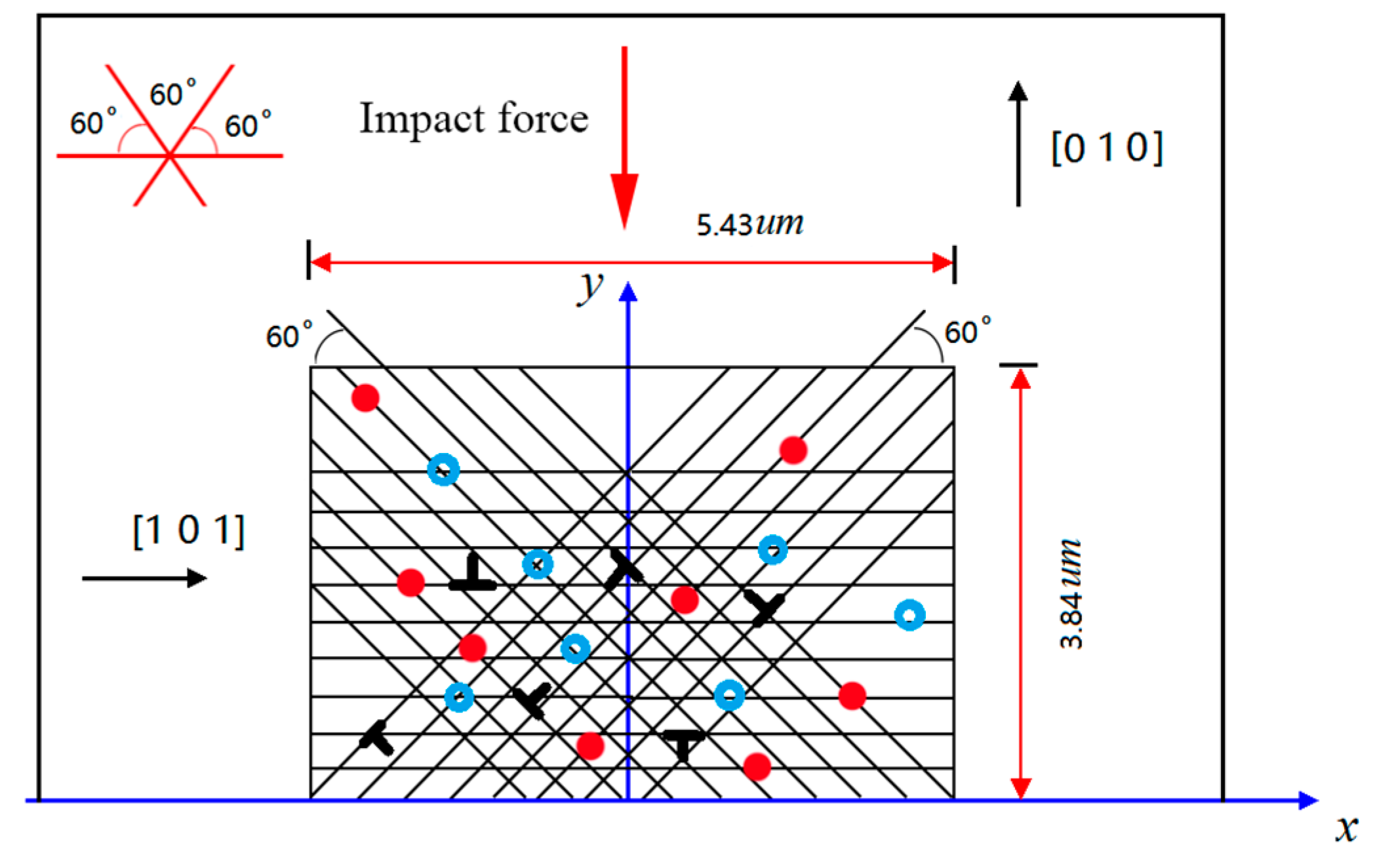

3. Multiscale Discrete Dislocation Plasticity Framework

4. Results and Discussion

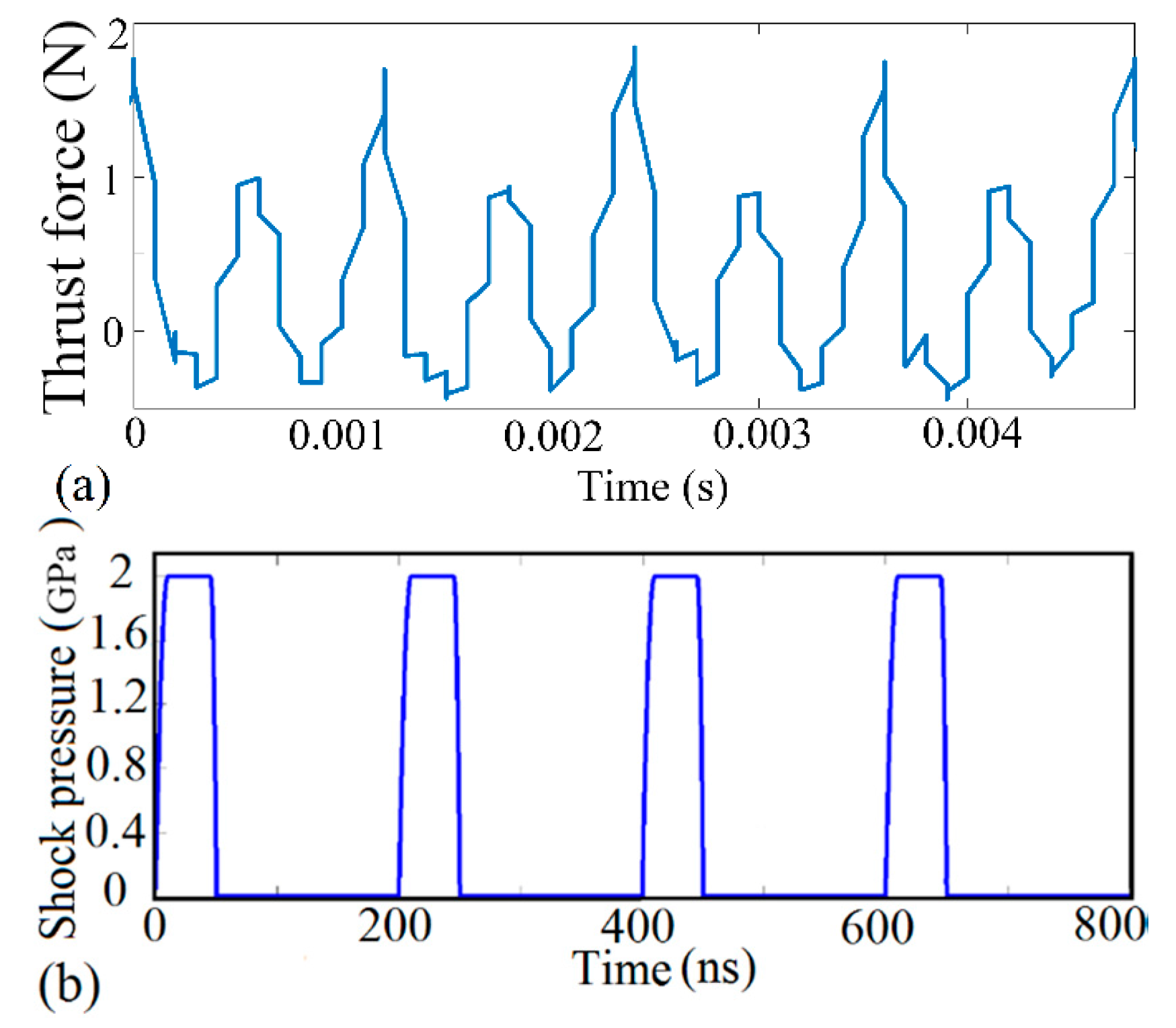

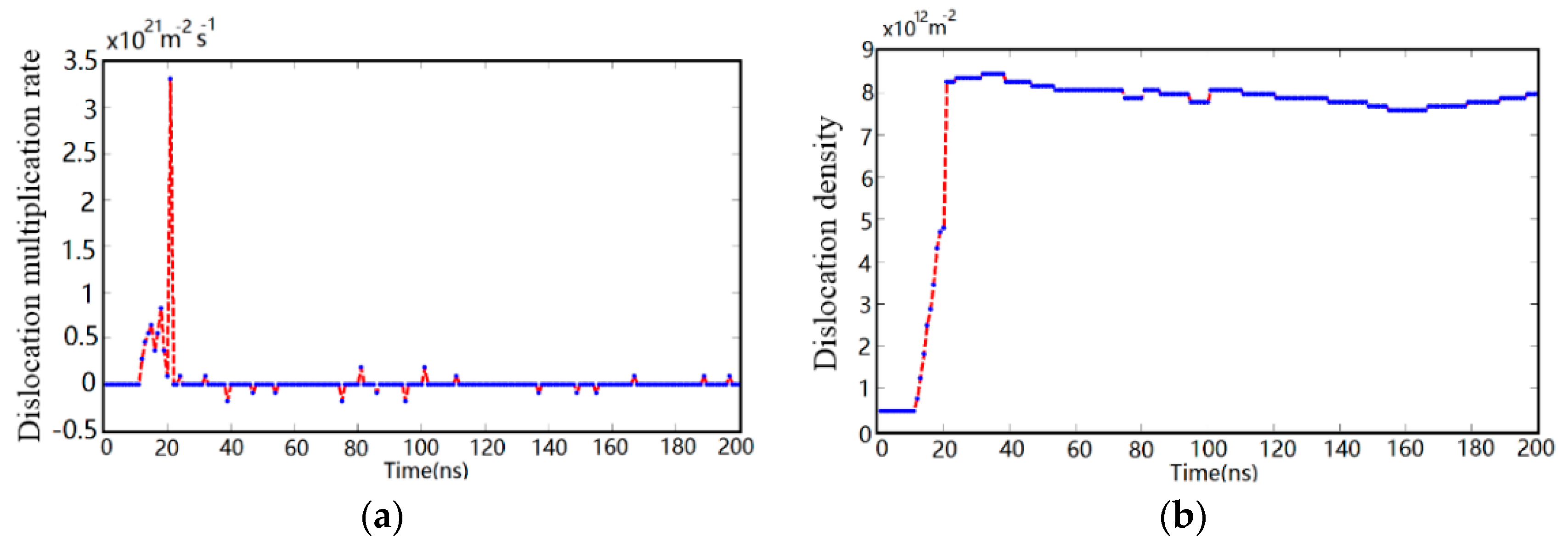

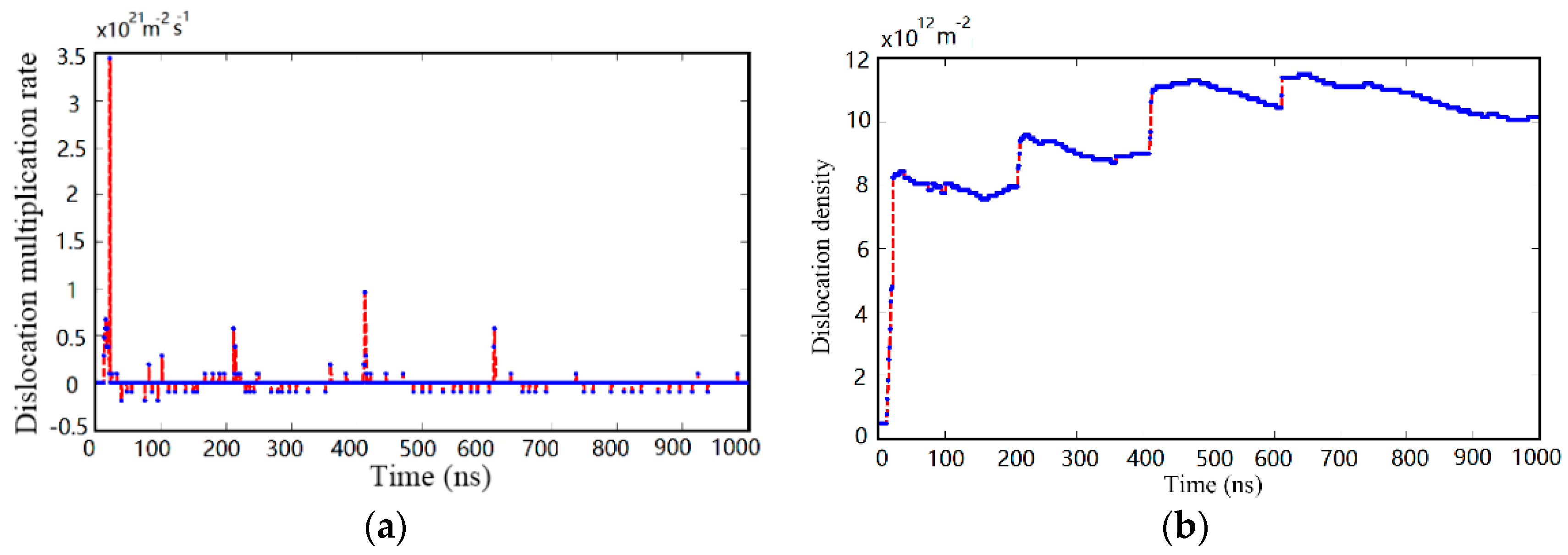

4.1. Dislocation Evolution in Silicon during Transient Irregular Cutting Process

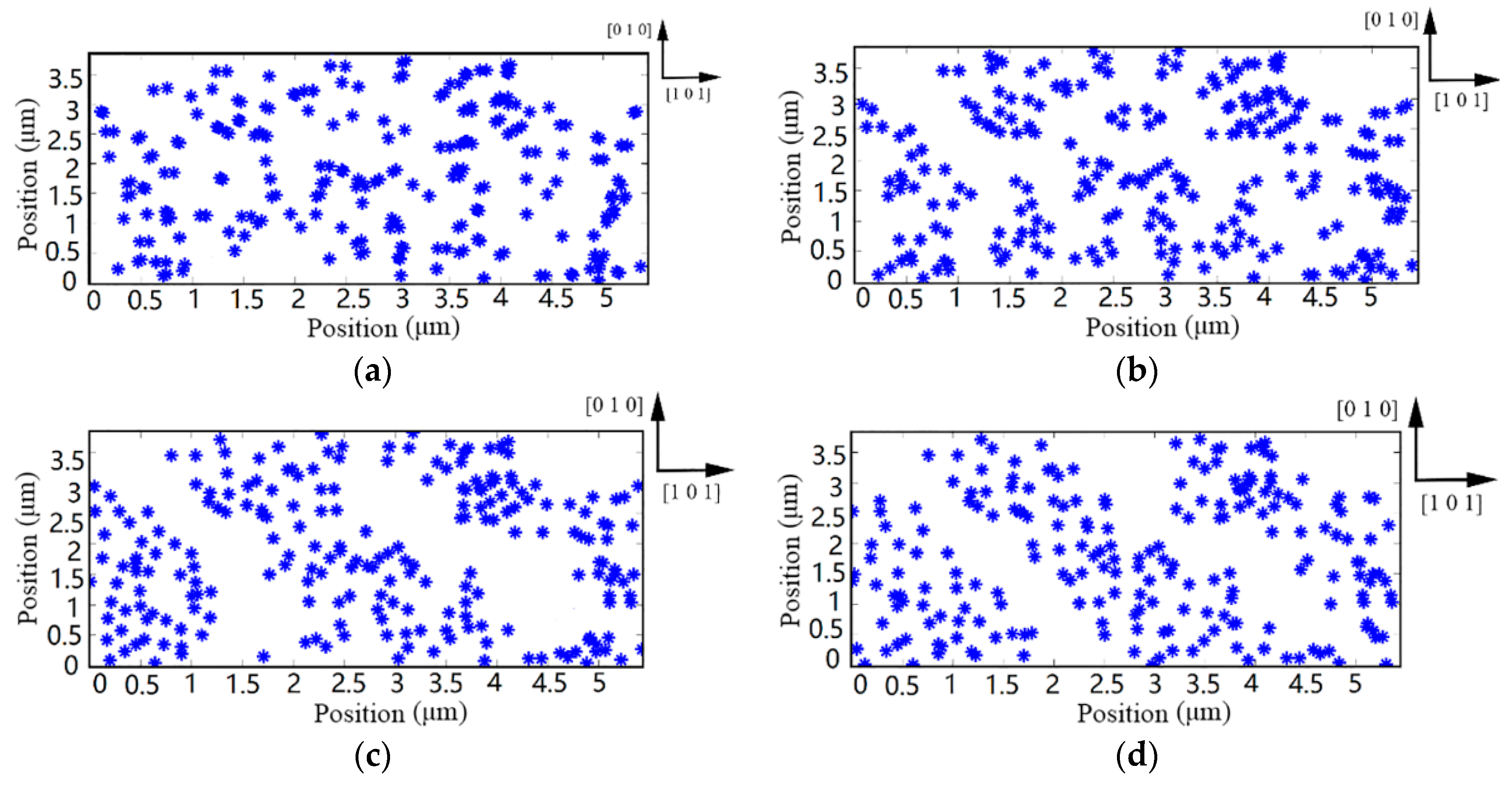

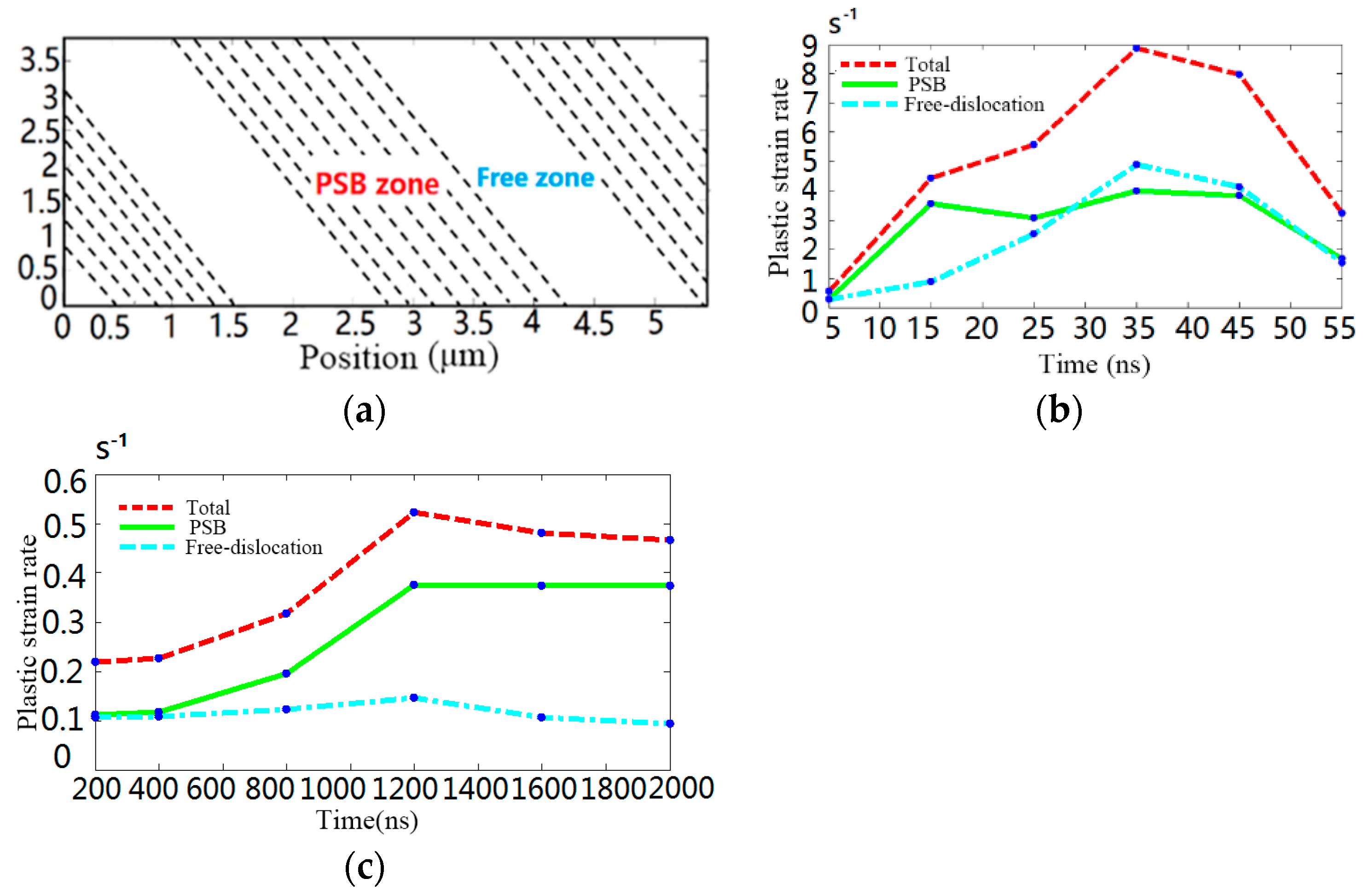

4.2. Dislocation Evolution in Silicon during Continuous Irregular Cutting Process

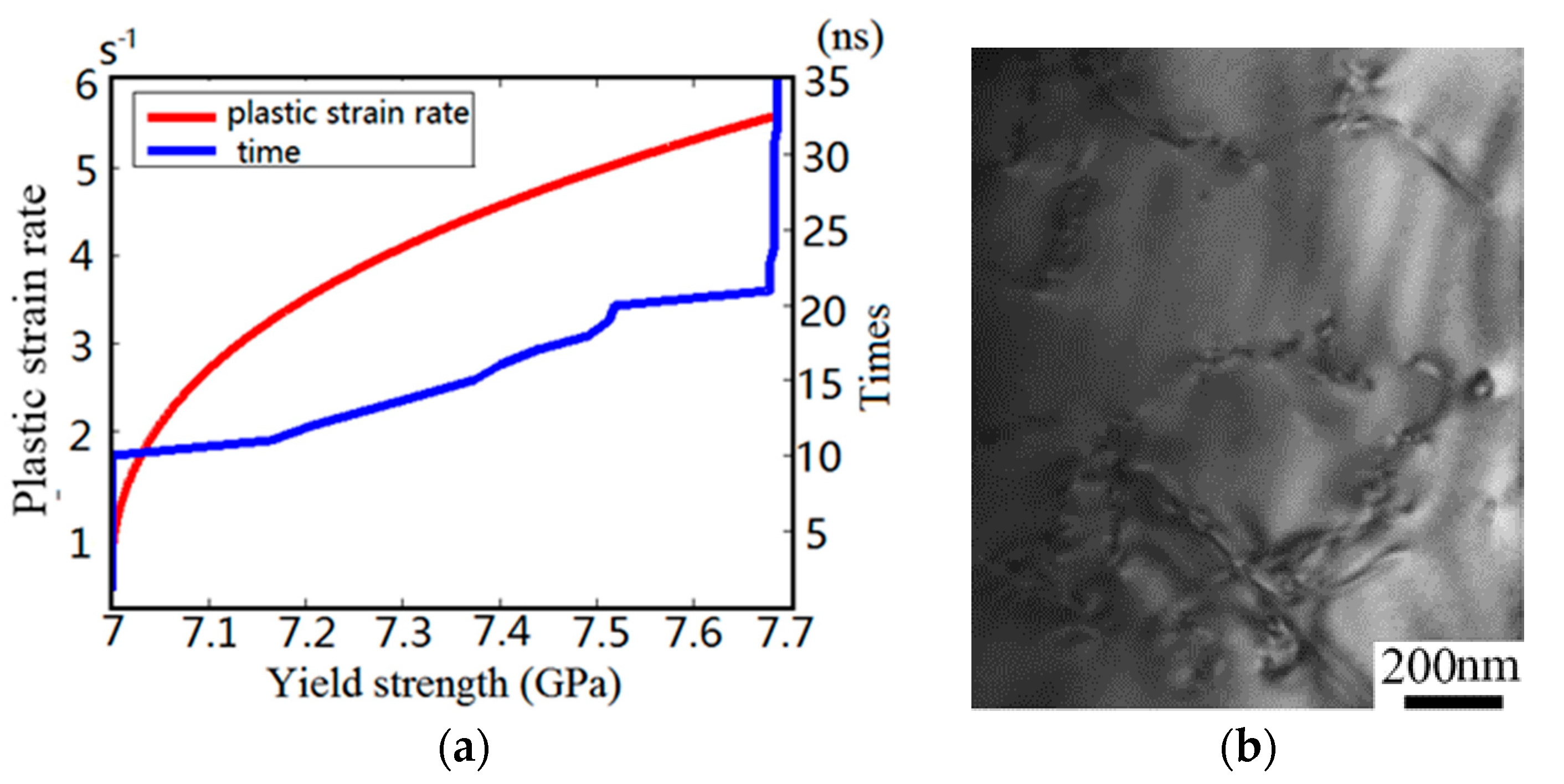

4.3. Mechanical Property and Damage Mechanism of Monocrystalline Silicon

5. Conclusions

- Experimental results show that the morphology and amplitude of cutting force are closely connected with machined surface quality and surface roughness during the micro-machining monocrystalline silicon process. Stable thrust force can enhance ductile mode milling. On the contrary, the vibration thrust force often results in the brittle model removal.

- The novel multiscale discrete dislocation dynamics modeling technique can reveal the interaction mechanism among dislocations and other defects. The predication for the evolution of dislocation structure falls within the existing experimental ranges, which indicates that the discrete dislocation simulation model developed in this study is robust and stable to study the plastic behavior of monocrystalline silicon in mesoscale.

- The dislocation multiplication rate of monocrystalline silicon increases rapidly with the rise of impact loading. In particular, transient impact loading can form dislocations entanglement structure to improve surface yield strength of monocrystalline silicon.

- The continuous irregular cutting process can induce persistent slip bands (PSBs) structure, which causes the inhomogeneous deformation and stress concentration within grains.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Du, J.; Wen, H.K.; Young, D.J. Monocrystalline silicon MEMS fabrication based on smart-cut technique. Sens. Actuators A-Phys. 2004, 112, 116–121. [Google Scholar] [CrossRef]

- Bai, J.X.; Bai, Q.S.; Hu, C.; He, X.; Pei, X.D. Research on the ductile-mode machining of monocrystalline silicon using polycrystalline diamond (PCD) tools. Int. J. Adv. Manuf. Technol. 2017, 1–9. [Google Scholar] [CrossRef]

- Choong, Z.J.; Huo, D.H.; Degenaar, P.; O’Neill, A. Effect of crystallographic orientation and employment of different cutting tools on micro-end-milling of monocrystalline silicon. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2016, 68, 51–80. [Google Scholar] [CrossRef]

- Cheng, X.; Li, L.; Huang, Y.; Yang, X.H.; Zhou, S.J. Theoretical modeling of the critical conditions for ductile-regime milling of single crystalline silicon. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2015, 229, 1462–1469. [Google Scholar] [CrossRef]

- Fang, F.Z.; Zhang, G.X. An experimental study of edge radius effect on cutting monocrystalline silicon. Int. J. Adv. Manuf. Technol. 2003, 22, 703–707. [Google Scholar] [CrossRef]

- Rusnaldy; Tae, J.K.; Hee, S.K. Micro-end-milling of single-crystal silicon. Int. J. Mach. Tools Manuf. 2007, 47, 2111–2119. [Google Scholar] [CrossRef]

- Rusnaldy; Tae, J.K.; Hee, S.K. An experimental study on microcutting of silicon using a micromilling machine. Int. J. Adv. Manuf. Technol. 2008, 39, 85–91. [Google Scholar] [CrossRef]

- Goel, S.; Luo, X.C.; Comley, P.; Reuben, R.L.; Cox, A. Brittle-ductile transition during diamond turning of monocrystalline silicon carbide. Int. J. Mach. Tools Manuf. 2013, 65, 15–21. [Google Scholar] [CrossRef]

- Wang, C.; Cheng, K.; Nelson, N.; Sawangsri, W.; Rakowski, R. Cutting force-based analysis and correlative observations on the tool wear in diamond turning of single-crystal silicon. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2015, 229, 1864–1873. [Google Scholar] [CrossRef]

- Wang, C.; Cheng, K.; Chen, X.; Minton, T.; Rakowski, R. Design of an instrumented smart cutting tool and its implementation and application perspectives. Smart Mater. Struct. 2014, 23, 035019. [Google Scholar] [CrossRef]

- Jiang, B.; He, T.T.; Gu, Y.P.; Wang, Q.L.; Cao, G.L. Method for recognizing wave dynamics damage in high-speed milling cutter. Int. J. Adv. Manuf. Technol. 2017, 92, 139–150. [Google Scholar] [CrossRef]

- Tanaka, H.; Shimada, S.; Ikaw, N. Brittle-ductile transition in monocrystalline silicon analysed by molecular dynamics simulation. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2004, 218, 583–590. [Google Scholar] [CrossRef]

- Korte, S.; Barnard, J.S.; Stearn, R.J.; Clegg, W.J. Deformation of silicon—Insights from microcompression testing at 25–500 °C. Int. J. Plast. 2011, 27, 1853–1866. [Google Scholar] [CrossRef]

- Cai, W.; Bulatov, V.V.; Justo, J.F.; Argon, A.S.; Yip, S. Intrinsic mobility of a dissociated dislocation in silicon. Phys. Rev. Lett. 2000, 84, 3346–3349. [Google Scholar] [CrossRef] [PubMed]

- Rabier, J.; Cordier, P.; Demenet, J.L.; Garem, H. Plastic deformation of Si at low temperature under high confining pressure. Mater. Sci. Eng. A 2001, 309–310, 74–77. [Google Scholar] [CrossRef]

- Minor, A.M.; Lilleodden, E.T.; Jin, M.; Stach, E.A.; Chrzan, D.C.; Morris, J.W. Room temperature dislocation plasticity in silicon. Philos. Mag. 2005, 85, 323–330. [Google Scholar] [CrossRef]

- Cheng, G.J.; Shehadeh, M.A. Multiscale dislocation dynamics analyses of laser shock peening in silicon single crystal. Int. J. Plast. 2006, 22, 2171–2194. [Google Scholar] [CrossRef]

- Zhang, L.C.; Zarudi, I. Towards a deeper understanding of plastic deformation in mono-crystalline silicon. Int. J. Mech. Sci. 2001, 43, 1985–1996. [Google Scholar] [CrossRef]

- Gerbig, Y.B.; Michaels, C.A.; Forster, A.M.; Cook, R.F. In situ observation of the indentation-induced phase transformation of silicon thin films. J. Mater. Res. 2015, 30, 390–406. [Google Scholar] [CrossRef]

- Cheng, G.J.; Shehadeh, M.A. Dislocation behavior in silicon crystal induced by laser shock peening: A multiscale simulation approach. Scr. Mater. 2005, 53, 1013–1018. [Google Scholar] [CrossRef]

- Goel, S.; Luo, X.C.; Reuben, R.L. Molecular dynamic simulation model for the quantitative assessment of tool wear during single point diamond turning of cubic silicon carbide. Comput. Mater. Sci. 2011, 51, 402–408. [Google Scholar] [CrossRef]

- Ghosh, A.; Kumar, V. Computational studies on fragmentation of brittle materials. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2012, 227, 1650–1664. [Google Scholar] [CrossRef]

- Tong, Z.; Xu, Z.W.; Wu, W.; Luo, X.C. Molecular dynamic simulation of low-energy FIB irradiation induced damage in diamond. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. Atoms 2015, 358, 38–44. [Google Scholar] [CrossRef]

- Erik, V.D.G.; Needleman, E. Discrete dislocation plasticity: A simple planar model. Model. Simul. Mater. Sci. Eng. 1995, 3, 689–735. [Google Scholar]

- Bai, J.X.; Bai, Q.S.; Tong, Z. Dislocation Dynamics-Based Modeling and Simulations of Subsurface Damages Microstructure of Orthogonal Cutting of Titanium Alloy. Micromachines 2017, 8, 309. [Google Scholar] [CrossRef]

- Bai, J.X.; Bai, Q.S.; Tong, Z.; Hu, C.; He, X. Evolution of surface grain structure and mechanical properties in orthogonal cutting of titanium alloy. J. Mater. Res. 2017, 31, 3919–3929. [Google Scholar] [CrossRef]

- Shishvan, S.S.; Erik, V.D.G. Mode I crack analysis in single crystals with anisotropic discrete dislocation plasticity: I. Formulation and crack growth. Model. Simul. Mater. Sci. Eng. 2013, 21, 1163–1166. [Google Scholar] [CrossRef]

- Liao, Y.L.; Ye, C.; Gao, H.; Kim, B.J.; Suslor, S.; Stach, E.A.; Cheng, C.J. Dislocation pinning effects induced by nano-precipitates during warm laser shock peening: Dislocation dynamic simulation and experiments. J. Appl. Phys. 2011, 110, 023518. [Google Scholar] [CrossRef]

- Gurrutxaga-Lerma, B.; Balint, D.S.; Dini, D.; Eakins, D.E.; Sutton, A.P. A dynamic discrete dislocation plasticity method for the simulation of plastic relaxation under shock loading. Proc. Math. Phys. Eng. Sci. 2013, 469, 248. [Google Scholar] [CrossRef]

- Bai, J.X.; Bai, Q.S.; Tong, Z.; Chen, G.D. The influence of cutting parameters on the defect structure of subsurface in orthogonal cutting of titanium alloy. J. Mater. Res. 2017. [Google Scholar] [CrossRef]

- Ayas, C.; Deshpande, V.S.; Geers, M.G. Tensile response of passivated films with climb-assisted dislocation glide. J. Mech. Phys. Solid 2012, 60, 1626–1643. [Google Scholar] [CrossRef]

- Danas, K.; Deshpande, V.S. Plane-strain discrete dislocation plasticity with climb-assisted glide motion of dislocations. Model. Simul. Mater. Sci. Eng. 2013, 21, 45008–45033. [Google Scholar] [CrossRef]

- Davoudi, K.M.; Nicola, L.; Vlassak, J.J. Dislocations climb in two-dimensional discrete dislocation dynamics. J. Appl. Phys. 2012, 111, 103522. [Google Scholar] [CrossRef]

- Benzerga, A.A.; Brechet, Y.; Needleman, A.; Erik, V.D.G. Incorporating three-dimensional mechanisms into two-dimensional dislocation dynamics. Model. Simul. Mater. Sci. Eng. 2004, 12, 159–196. [Google Scholar] [CrossRef]

- Ohta, H.; Miura, H.; Kitano, M. A ball-indentation method to evaluate the critical stress for dislocation generation in a silicon substrate. Fatigue Fract. Eng. Mater. Struct. 2002, 24, 877–884. [Google Scholar] [CrossRef]

- Cai, M.B.; Li, X.P.; Rahman, M. Study of the mechanism of nanoscale ductile mode cutting of silicon using molecular dynamics simulation. Int. J. Mach. Tools Manuf. 2007, 47, 75–80. [Google Scholar] [CrossRef]

- Huo, D.H.; Lin, C.; Choong, Z.J.; Pancholi, K.; Degenaar, P. Surface and subsurface characterisation in micro-milling of monocrystalline silicon. Int. J. Adv. Manuf. Technol. 2015, 81, 1319–1331. [Google Scholar] [CrossRef]

- Bracht, H.; Haller, E.E.; Clark-Phelps, R. Silicon self-diffusion in isotope heterostructures. Phys. Rev. Lett. 1998, 81, 393–396. [Google Scholar] [CrossRef]

- Li, X.; Li, Z.; Tao, X.F.; Ren, L.L.; Gao, S.T.; Xu, G.F. Distribution of residual strain around nanoindentations in silicon. Mater. Lett. 2014, 132, 285–289. [Google Scholar] [CrossRef]

- Cheng, G.J.; Cai, M.; Pirzada, D.; Guinel, M.J.F.; Norton, M.G. Plastic deformation in silicon crystal induced by heat-assisted laser shock peening. J. Manuf. Sci. Eng. 2008, 130, 03508. [Google Scholar] [CrossRef]

- Yan, J.W.; Asami, T.; Harada, H.; Kuriyagaw, T. Crystallographic effect on subsurface damage formation in silicon microcutting. CIRP Ann. Manuf. Technol. 2012, 61, 131–134. [Google Scholar] [CrossRef]

| Test No. | Axial Depth of Cut (μm) | Feed Rate (μm/Tooth) | Spindle Speed (rpm) | Surface Roughness 1 Ra (nm) | Cutting Force Mode 2 (S/PS/C) | Milling Mode 3 (D/PD/B) |

|---|---|---|---|---|---|---|

| 1 | 10 | 0.075 | 50,000 | 9.292 | S | D |

| 2 | 30 | 0.075 | 50,000 | 12.835 | S | D |

| 3 | 60 | 0.075 | 50,000 | 13.352 | S | D |

| 4 | 120 | 0.075 | 50,000 | 127.724 | C | B |

| 5 | 30 | 0.3 | 50,000 | 19.671 | S | D |

| 6 | 30 | 0.6 | 50,000 | 15.984 | PS | PD |

| 7 | 60 | 0.3 | 50,000 | 89.999 | PS | PD |

| 8 | 60 | 0.6 | 50,000 | 108.877 | C | B |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bai, J.; Bai, Q.; Tong, Z. Multiscale Analyses of Surface Failure Mechanism of Single-Crystal Silicon during Micro-Milling Process. Materials 2017, 10, 1424. https://doi.org/10.3390/ma10121424

Bai J, Bai Q, Tong Z. Multiscale Analyses of Surface Failure Mechanism of Single-Crystal Silicon during Micro-Milling Process. Materials. 2017; 10(12):1424. https://doi.org/10.3390/ma10121424

Chicago/Turabian StyleBai, Jinxuan, Qingshun Bai, and Zhen Tong. 2017. "Multiscale Analyses of Surface Failure Mechanism of Single-Crystal Silicon during Micro-Milling Process" Materials 10, no. 12: 1424. https://doi.org/10.3390/ma10121424

APA StyleBai, J., Bai, Q., & Tong, Z. (2017). Multiscale Analyses of Surface Failure Mechanism of Single-Crystal Silicon during Micro-Milling Process. Materials, 10(12), 1424. https://doi.org/10.3390/ma10121424