3.1. Failure Characteristics

Figure 7a shows the failure characteristics of specimen W1. The failure process of specimen W1 was as follows: when the horizontal load was 195 kN, the horizontal short cracks formed at the base of the boundary elements. With the process of the loading, the cracks developed into the web region obviously and the inclined cracks developed and climbed along the height of the wall. With the development of the loading, the crush of the concrete at the base of the wall became significant. Other specimens W2 and W3 with RCA had almost identical failure characteristics with specimen W1. However, for specimen W4 with 100% RCA and 100% RFA, the damage of the concrete at the base of the wall was more serious than specimen W1 with natural aggregates, as shown in

Figure 7b,c, respectively. This indicated that more cumulative damages occurred for those specimens using the recycled aggregates. In order to prevent the serious damages, in the design of the RCA or RFA concrete shear walls, some strengthen method, such as the Fiber Reinforce Plastic (FRP) or steel plate strengthen method may be taken into account to reduce the concrete damages.

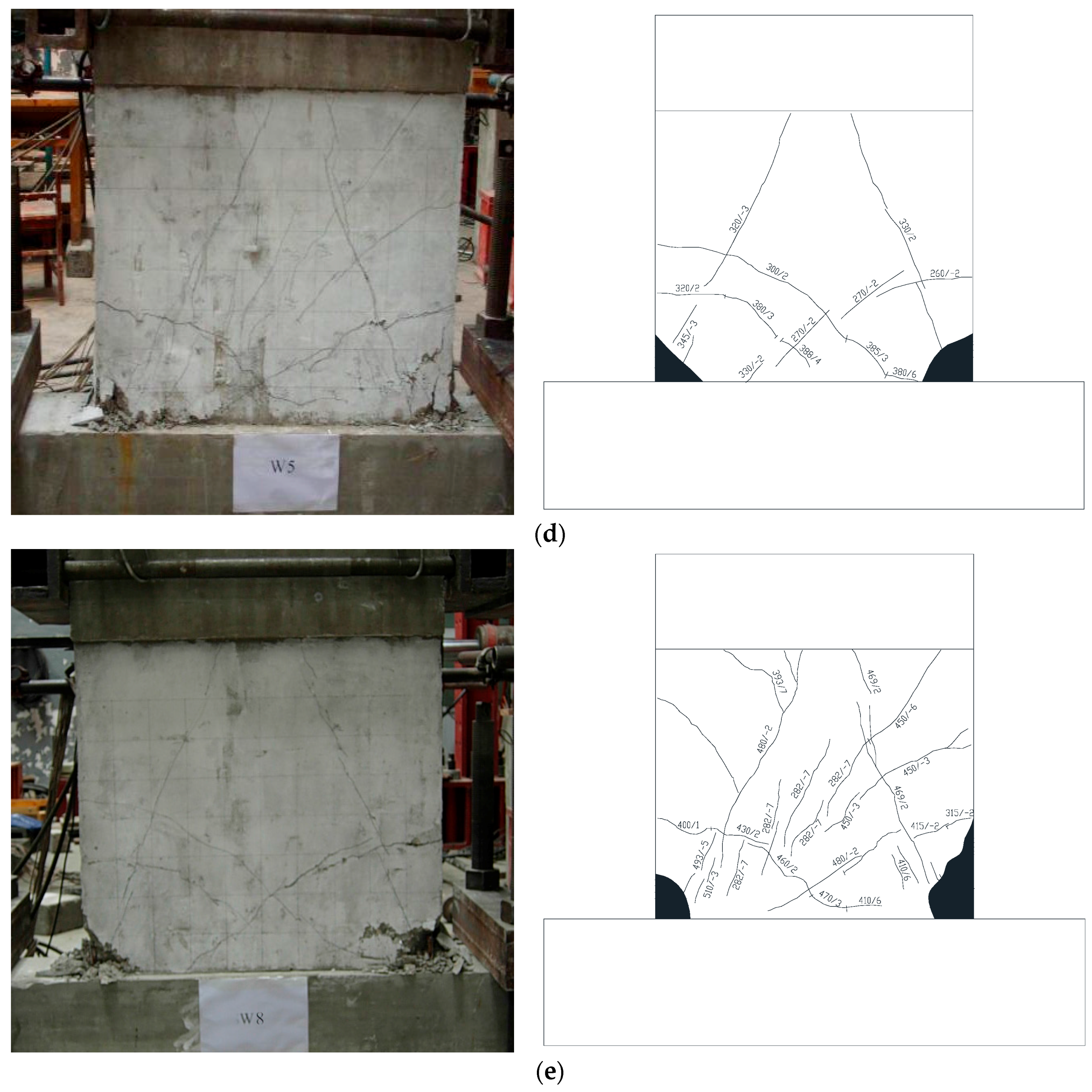

Figure 7d shows the failure characteristics of the specimen W5 with higher axial force ratio. As shown, compared with the specimen W1, no obvious 45° inclined cracks were found due to the higher axial force ratio.

Figure 7e shows the failure characteristics of the specimen W8 with the X-shaped brace. Different from specimens W1, W2, W3 and W4, no obvious 45° inclined cracks were found. It is confirmed that the brace had a positive effect on restraining the inclined cracks. Since the X-shaped brace is simple and economical during the design and construction of the concrete shear walls, when using RCA or RFA, it is suggested to install the X-shaped brace to reduce the damage of the concrete.

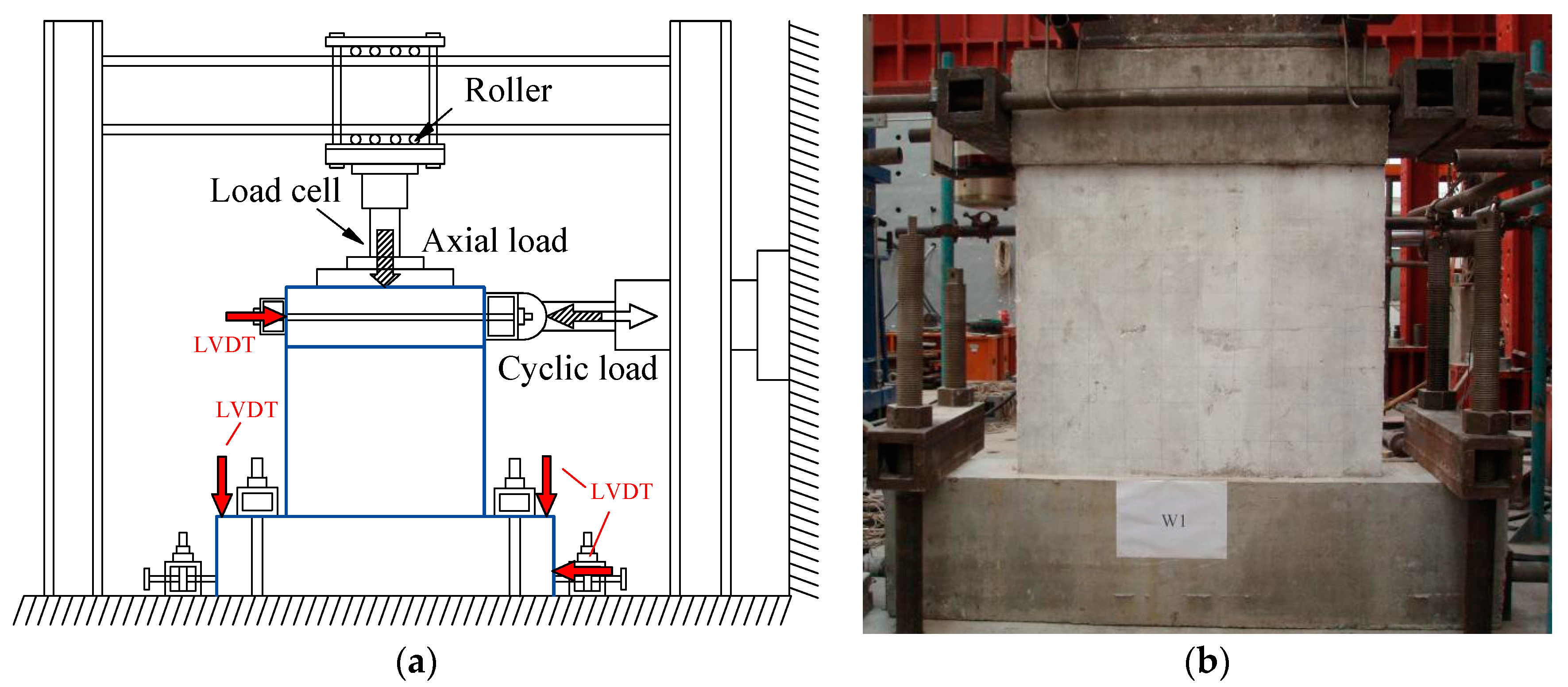

3.2. Hysteretic Behavior and Strengths

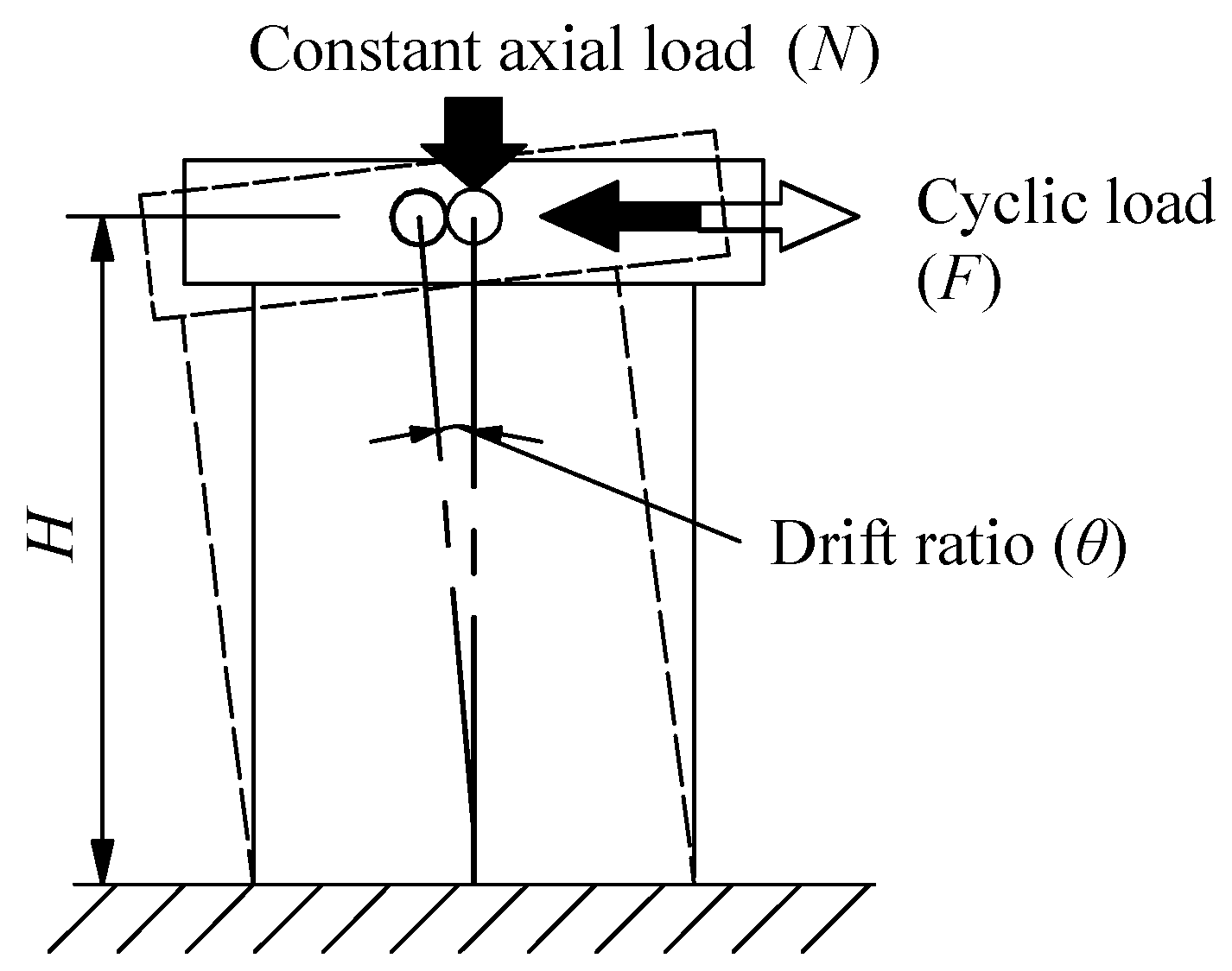

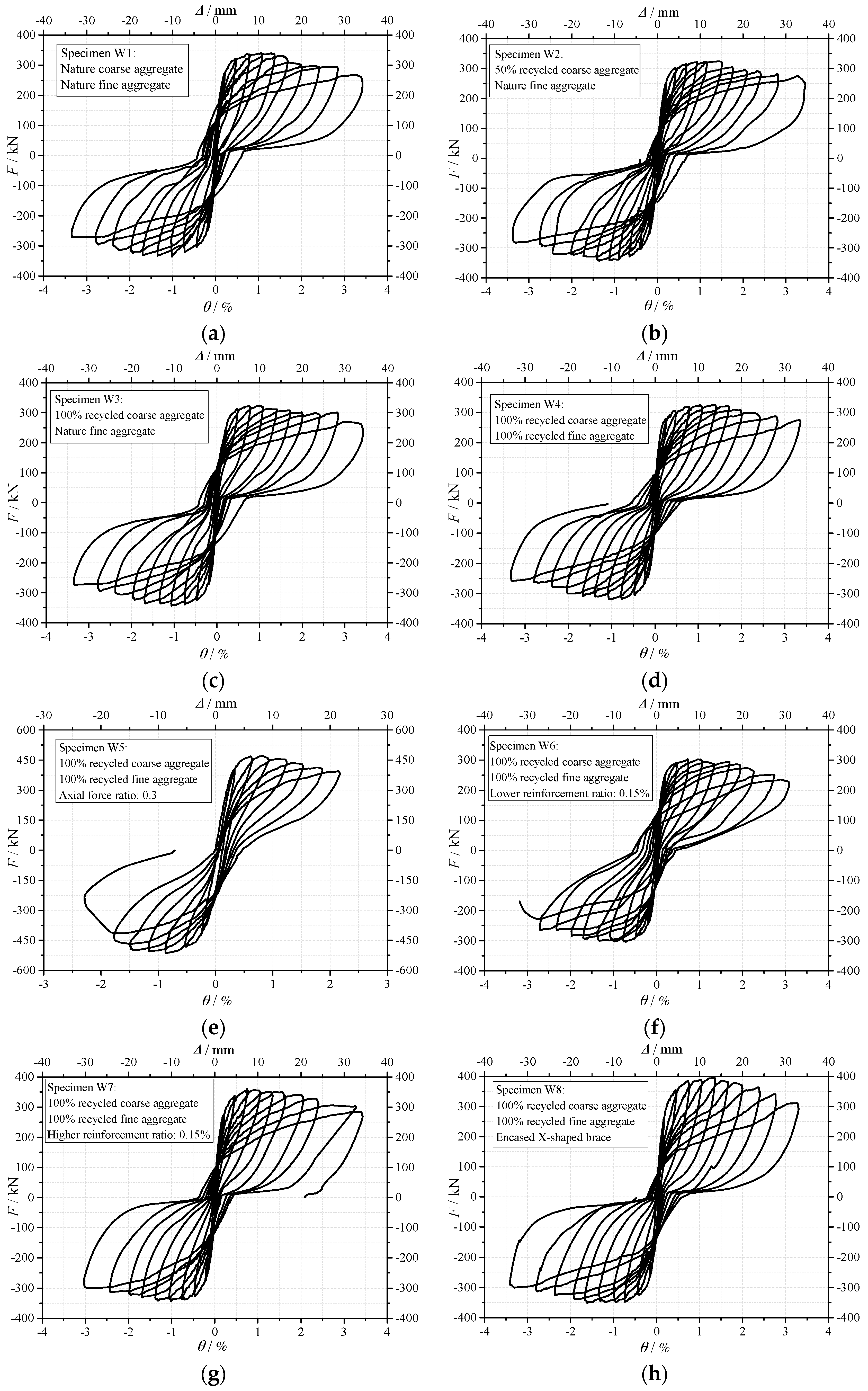

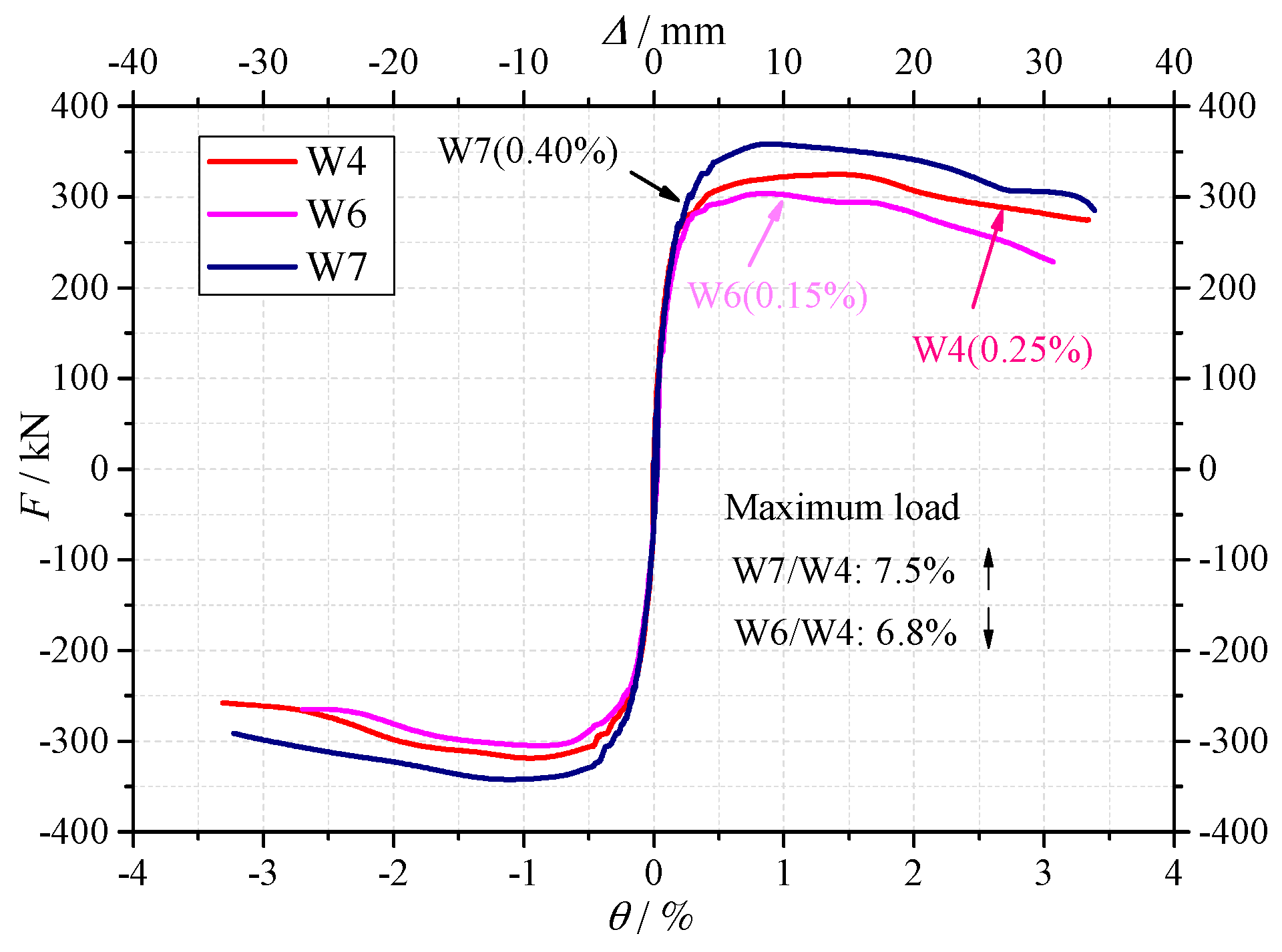

The “horizontal load

F-drift ratio

θ” hysteretic curves are shown in

Figure 8. During the loading process, from the start of the loading to 1.0% (0.8% for specimen W5) drift ratio, the ductility behavior was good for all the specimens, no obvious strength degradation occurred. From 1.0% to 2.0% drift ratio, the strength of the specimens degraded gradually. Pinch phenomenon can be observed in the hysteretic curves of all specimens, especially for specimen W5 with higher axial force ratio. It is proved that the specimens with recycled aggregates can have the stable and plump hysteretic behavior.

Table 6 shows the strength and deformation capacity of the specimens. In the table,

Fc is the crack load,

Fy is the yield load,

Fm is the maximum load,

θc is the crack drift ratio,

θy is the yield drift ratio and

θu is the ultimate drift ratio. Where, the

Fc and

θc was the load and drift ratio when the initial cracking occurred. The yield load

Fy and

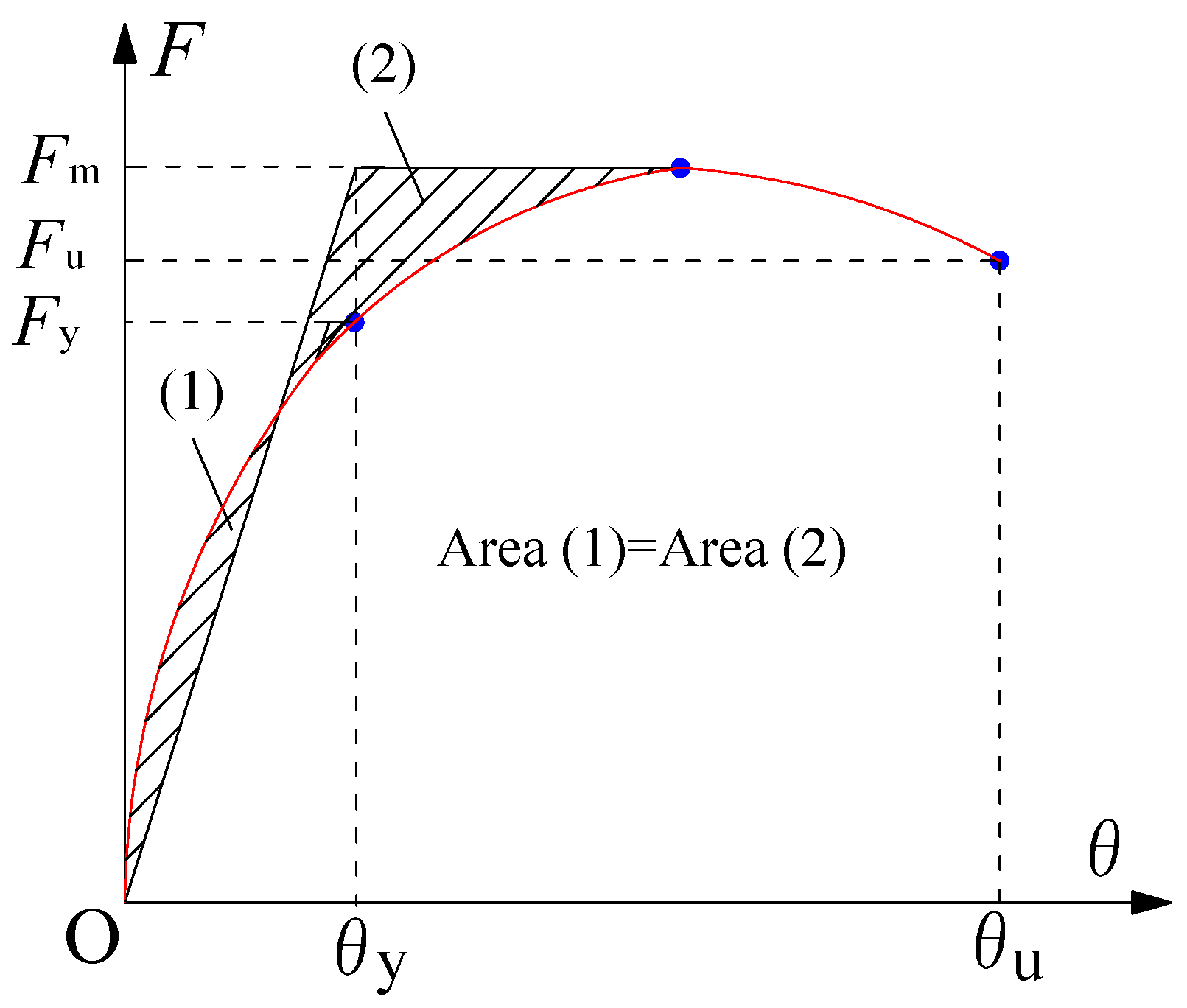

θy was determined by the energy equivalent method [

33], as shown in

Figure 9.

θu is the ultimate drift ratio, which is defined as the strength decreases to 85% of the maximum load.

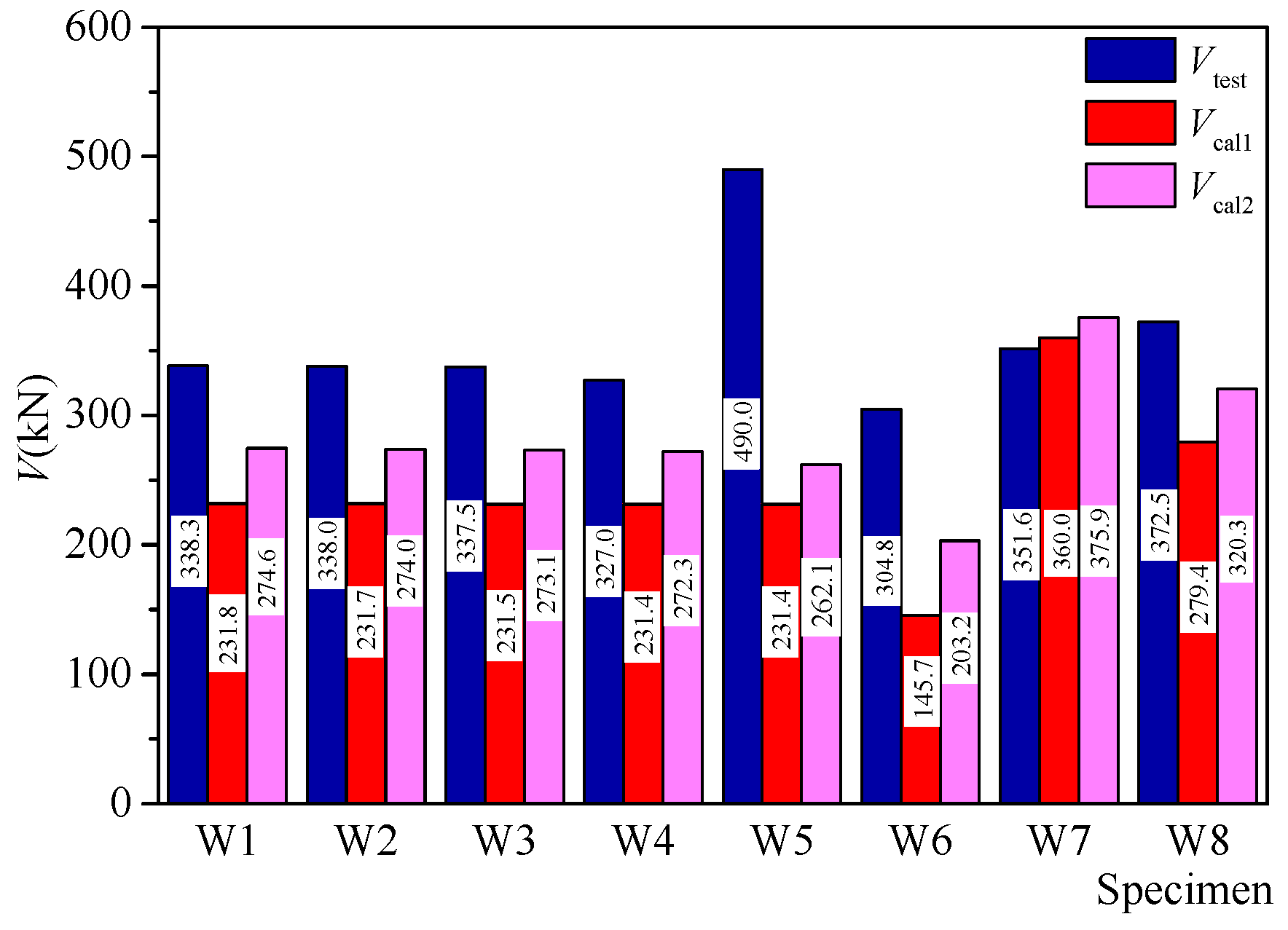

The parametrical studies are as follows:

(1) Influence of recycled aggregates

Figure 10 shows the comparison of the skeleton curves of the specimen W1, W2, W3 and W4. As shown in

Figure 10 and

Table 6, the observations are as follows.

Influence of RCA: The skeleton curves were almost identical for specimen W1, W2 and W3. The crack load, yield load and maximum load were almost identical. It is confirmed that the using of the RCA and its replacement percentage had almost no influences on the strength of the shear walls.

Influence of RFA: The yield load and maximum load of specimen W4 were 2.6% and 3.1% lower than specimen W3, respectively. Considering the cubic compressive strength of the concrete used in specimen W4 was slight lower than that of specimen W3, it is confirmed that the RFA also had almost no influence on the strength of the shear wall.

From above, it is indicated that for the limited configurations considered in this study, in the strength design of the recycled aggregates concrete shear wall, the strength design method for the normal concrete shear wall can be also applicable for the recycled aggregates concrete shear wall.

(2) Influence of axial force ratio

The axial force ratios of specimen W5 and specimen W4 were 0.3 and 0.15, respectively. The skeleton curves of the two specimens are shown in

Figure 11. As shown in

Figure 11 and

Table 6, the crack load, yield load and maximum load of specimen W5 were 61.4%, 47.5% and 49.9% higher than specimen W4, respectively. It is indicated that under higher axial force ratio, the shear resistance of the shear wall increased significantly. This is mainly due to two reasons: (1) with the increase of the axial force, the shear force carried by the concrete wall increases; (2) The development inclined cracks will be restrained, in consequence, the shear resistance increases.

(3) Influence of distributed web reinforcing bars

The reinforcement ratios of W4, W6 and W7 were 0.25%, 0.15% and 0.40%, respectively.

Figure 12 shows the skeleton curves of these three specimens. The reinforcement ratio had a certain influence on the strength of the shear walls. The crack load, yield load and maximum load of specimen W6 were 3.7%, 5.0% and 6.8% lower than specimen W4, respectively. While for specimen W7, the crack load, yield load and maximum load were 3.8%, 5.9% and 7.5% higher than specimen W4, respectively. In general, with the increasing of the reinforcing bars, the strength of the shear wall increased. It is confirmed that no matter the normal concrete or the recycled concrete are used in the shear wall, the reinforcement ratio is an important design factor.

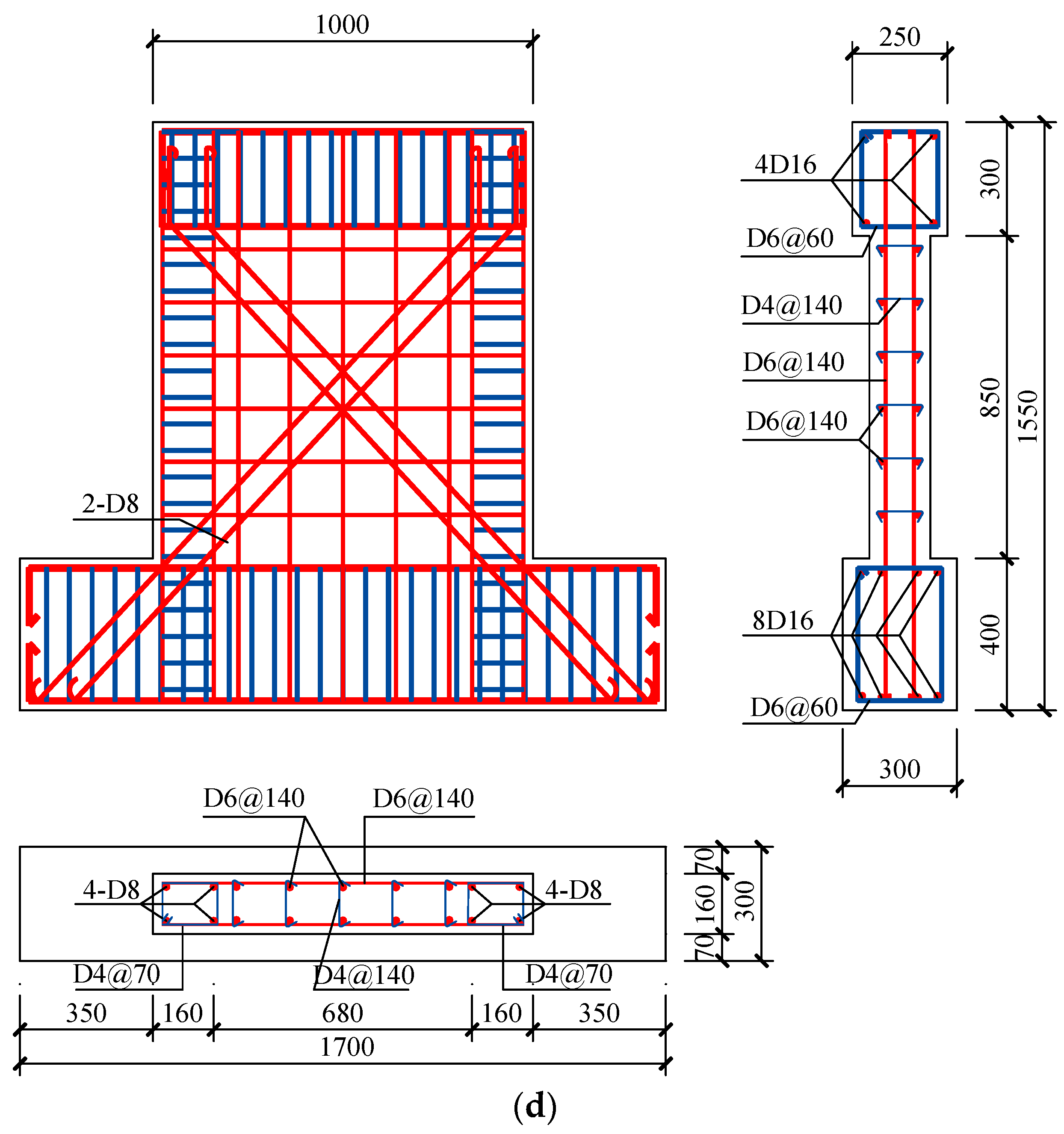

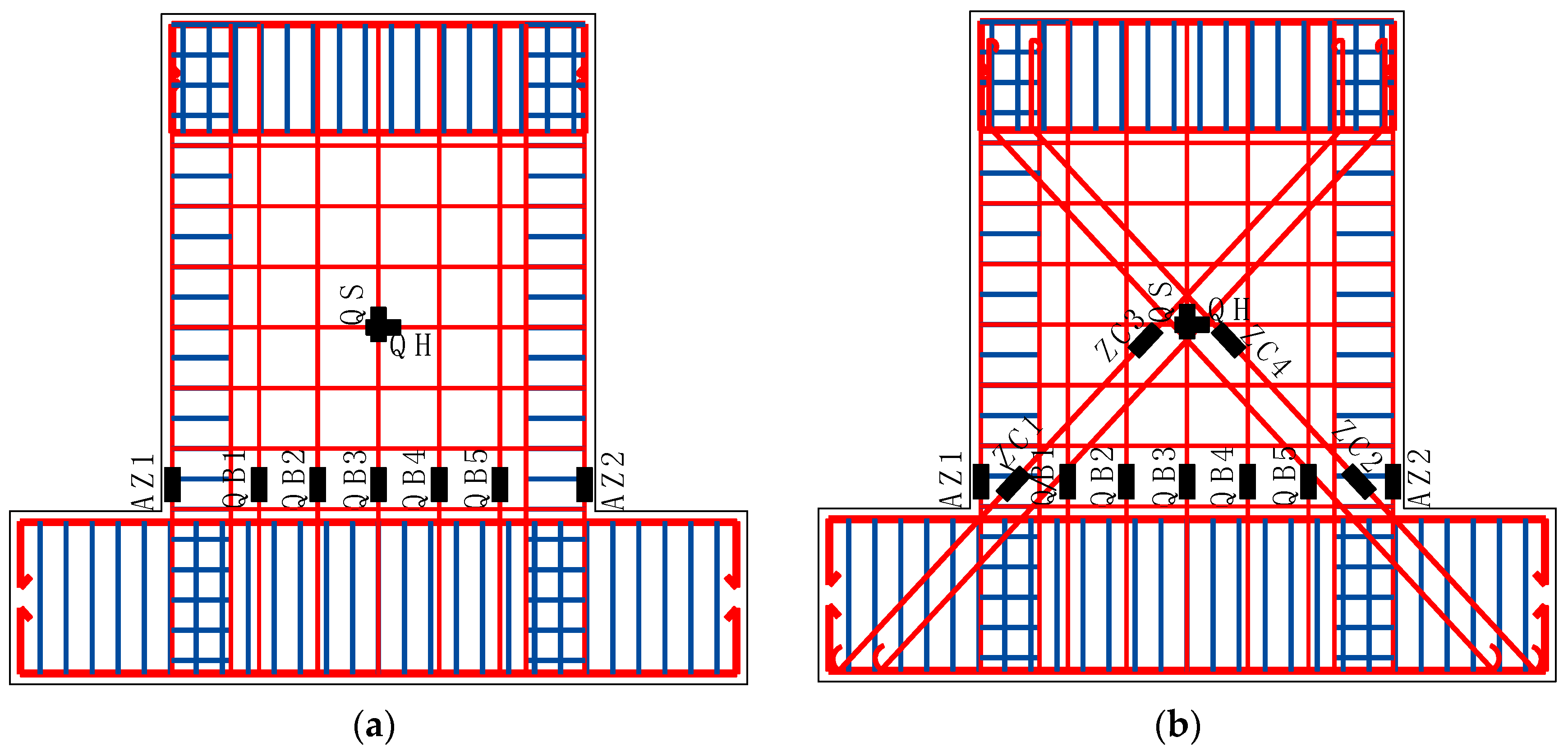

(4) Influence of encased X-shaped brace

As shown in

Figure 13, compared with specimen W4, specimen W8 was encased with the X-shaped rebars brace. It is confirmed that the crack load, yield load and maximum load increased by 3.9%, 11.5% and 13.9%, respectively. Even when compared specimen W8 with W7 which had a dense layout of the web reinforcing bars, the maximum load and yield load of specimen W8 were 6.0% and 5.0% higher than that of specimen W7, respectively. The encased X-shaped rebar brace was proved effective in enhancing the strength of the RAC shear wall. In the real engineering design and construction, the engineers always have a certain concern in using the RAC because of the mechanical behavior degradation of the RAC. By using the X-type rebars brace, which is low cost and simple in construction, the strength can increase significantly. The X-type rebars brace can be considered as an effective constructional measure to improve the application of the RAC shear wall.

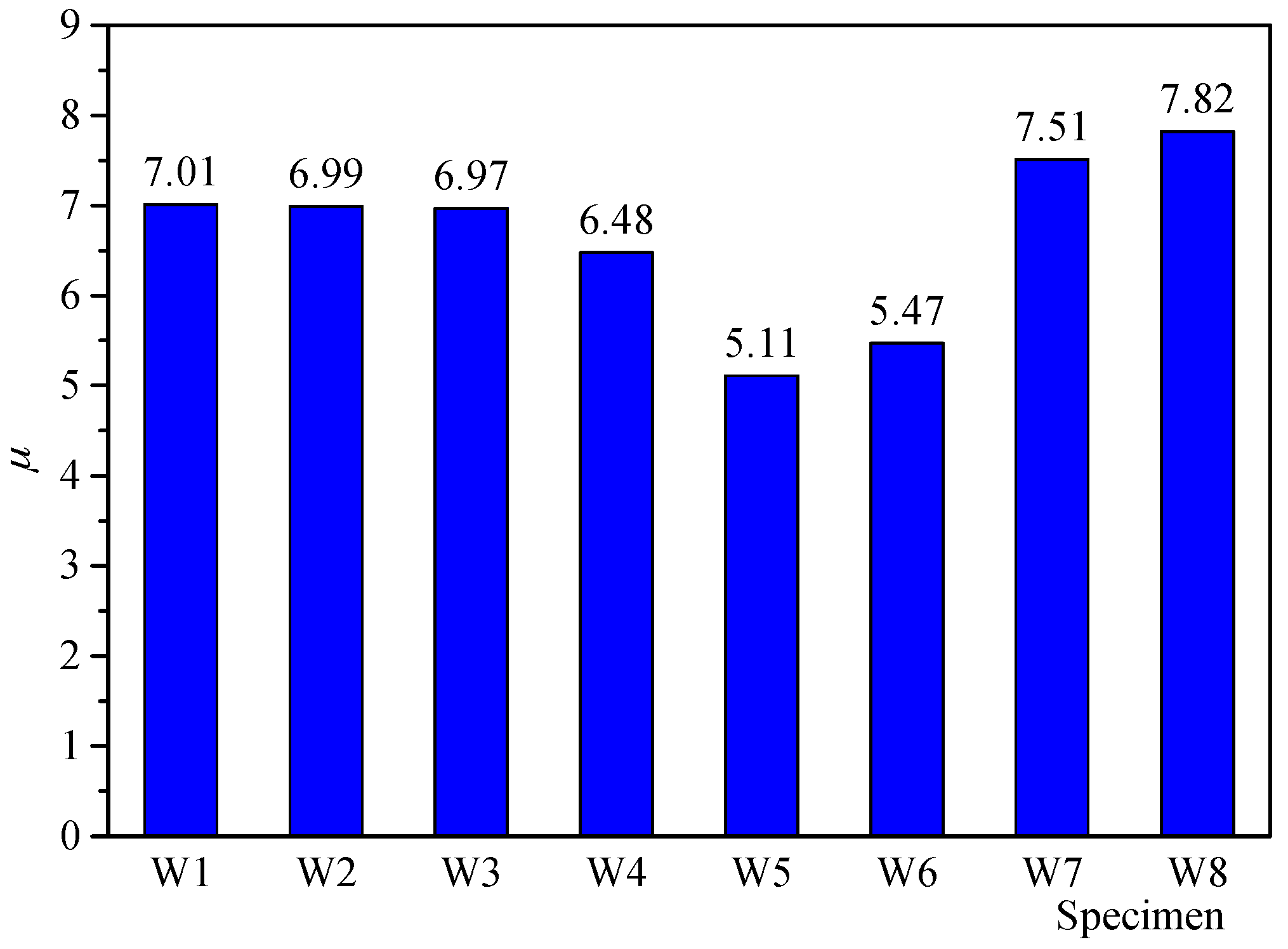

3.3. Ductility

Ductility ratio

μ is an index to describe the deformation capacity of the shear walls without significant strength degradation. Ductility ratio

μ is defined as

μ =

θu/

θy. The higher the ductility ratio is, the better deformation capacity becomes. The ductility ratio of each specimen is shown in

Figure 14. From

Figure 14, according to the limited configurations considered in this study, the following observations can be obtained.

The RCA replacement percentages of the specimens W1, W2 and W3 were 0%, 50% and 100%, respectively. However, the ductility ratios of these specimens were 7.01, 6.99 and 6.97, respectively. Almost identical ductility ratios were confirmed. The using of the RCA and its replacement percentage had no influence on the ductility of the shear wall.

The specimens W4 and W3 differed in the RFA replacement percentage, the percentage was 0% for specimen W3 and 100% for specimen W4. The ductility ratio of specimen W4 was 7.0% lower than that of specimen W3. It is indicated that compared with RCA, the using of RFA had noticeable influence on the ductility of the shear wall. When using the RFA, the ductility degradation should be taken into consideration.

When comparing specimen W8 with W4, the ductility ratio increased by 20.7%. It is an indication that the encased X-shaped brace had an obvious effect on enhancing the ductility of the shear wall. Even comparing specimen W8 with W1 using conventional concrete, the ductility increased by 11.4%. In the seismic design of the RAC shear wall, the X-shaped rebar brace was an efficient method to improve the ductility of the RAC shear wall. Especially when using the RFA in the shear walls, the using of the X-shaped brace is recommended.

With the increase of the axial force ratio, the ductility decreased significantly. The ductility ratio of specimen W5 decreased by 22.5% compared with specimen W4. It is indicated that in the seismic design of the RAC shear wall, the axial force ratio should be seriously restricted.

The ductility was significantly affected by the reinforcement ratio of the wall. The ductility ratio of specimen W6 was 15.5% smaller than that of specimen W4, due to the smaller reinforcement ratio of the specimen W6. Meanwhile, the ductility ratio of specimen W7 was 15.9% higher than that of specimen W4.

Above all, it is concluded that although the using of the recycled concrete have almost no effect on the strength of the shear wall, the ductility of the wall will be reduced when using the RFA. When the shear wall needs to be designed with high deformation capacity, the using of the RFA is suggested to be restrained. If the RFA must be used in some situations, some other construction measures, such as the X-type bar or the high ratio reinforcement, are needed.