Influence of Ultrasonic Surface Rolling on Microstructure and Wear Behavior of Selective Laser Melted Ti-6Al-4V Alloy

Abstract

:1. Introduction

2. Materials and Methods

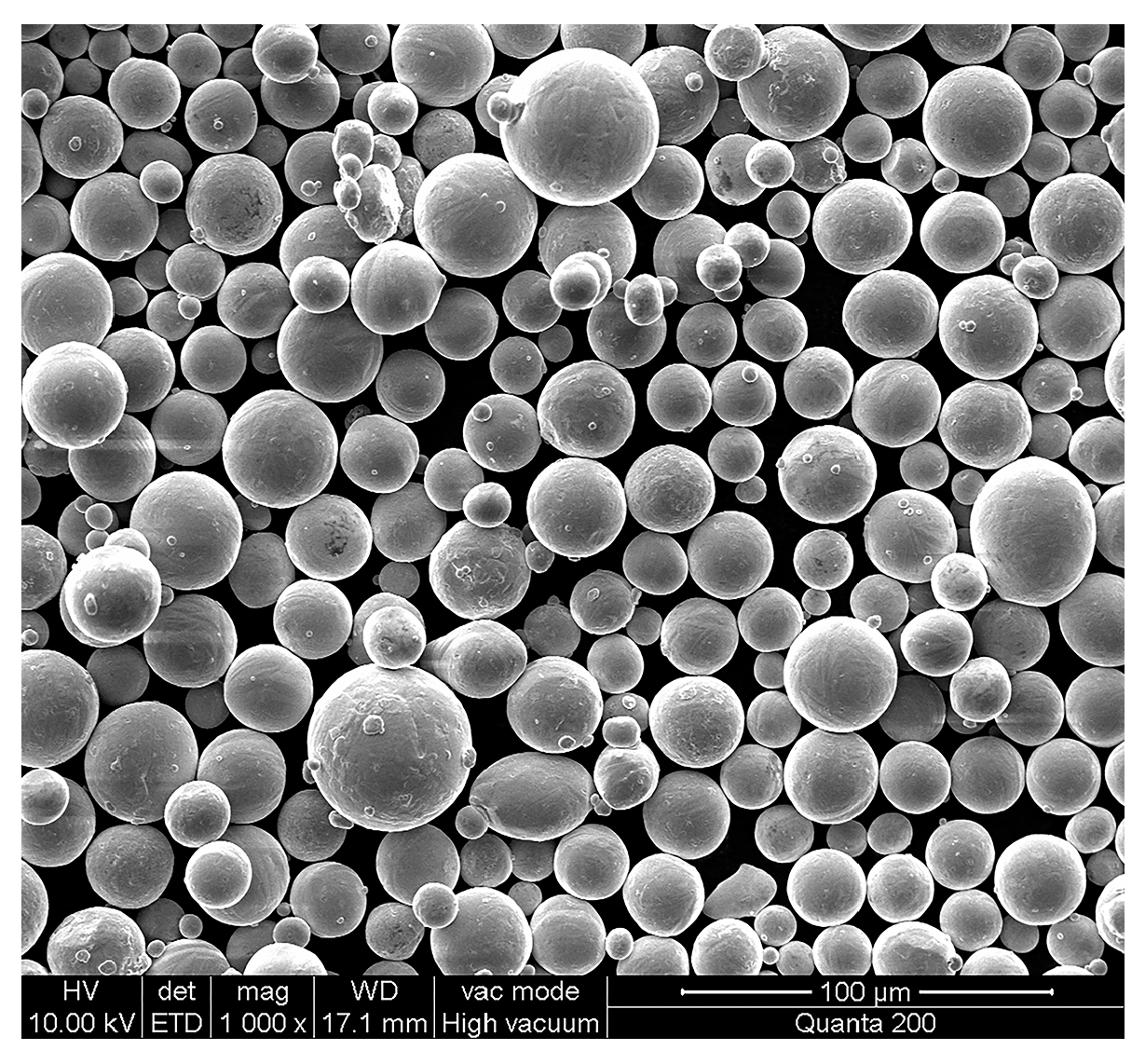

2.1. Materials

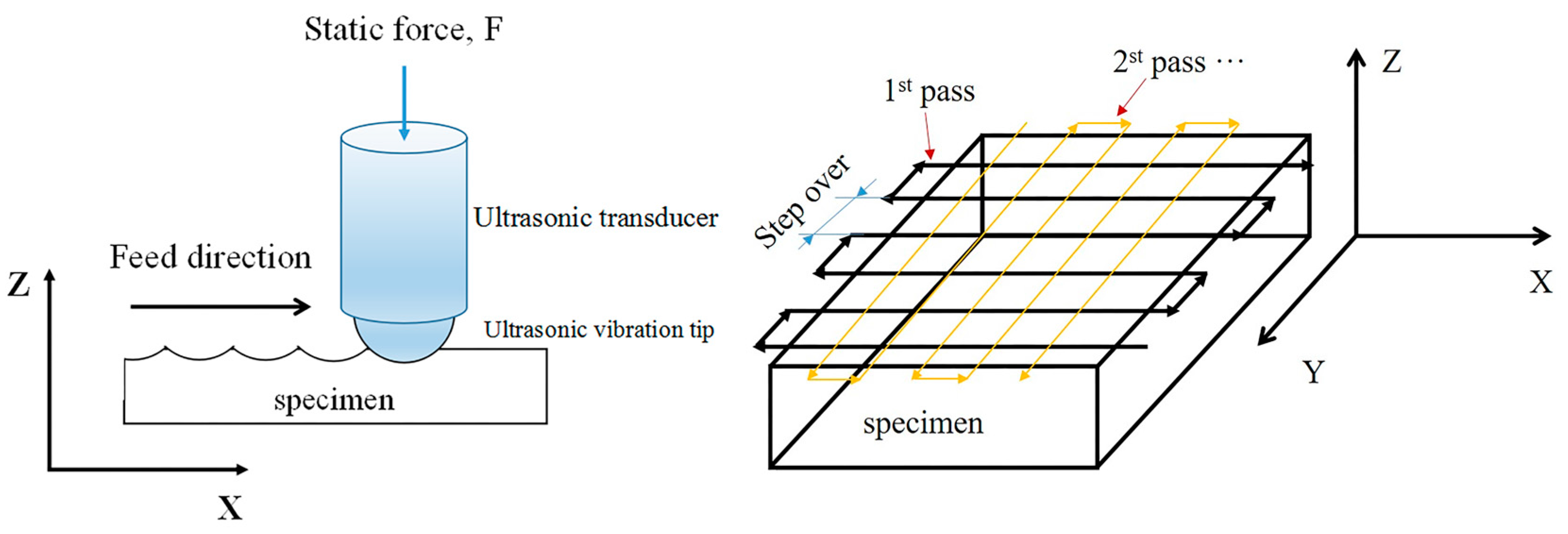

2.2. Ultrasonic Surface Rolling Process

2.3. Surface Characterization

2.4. Friction and Wear Tests

3. Result and Discussion

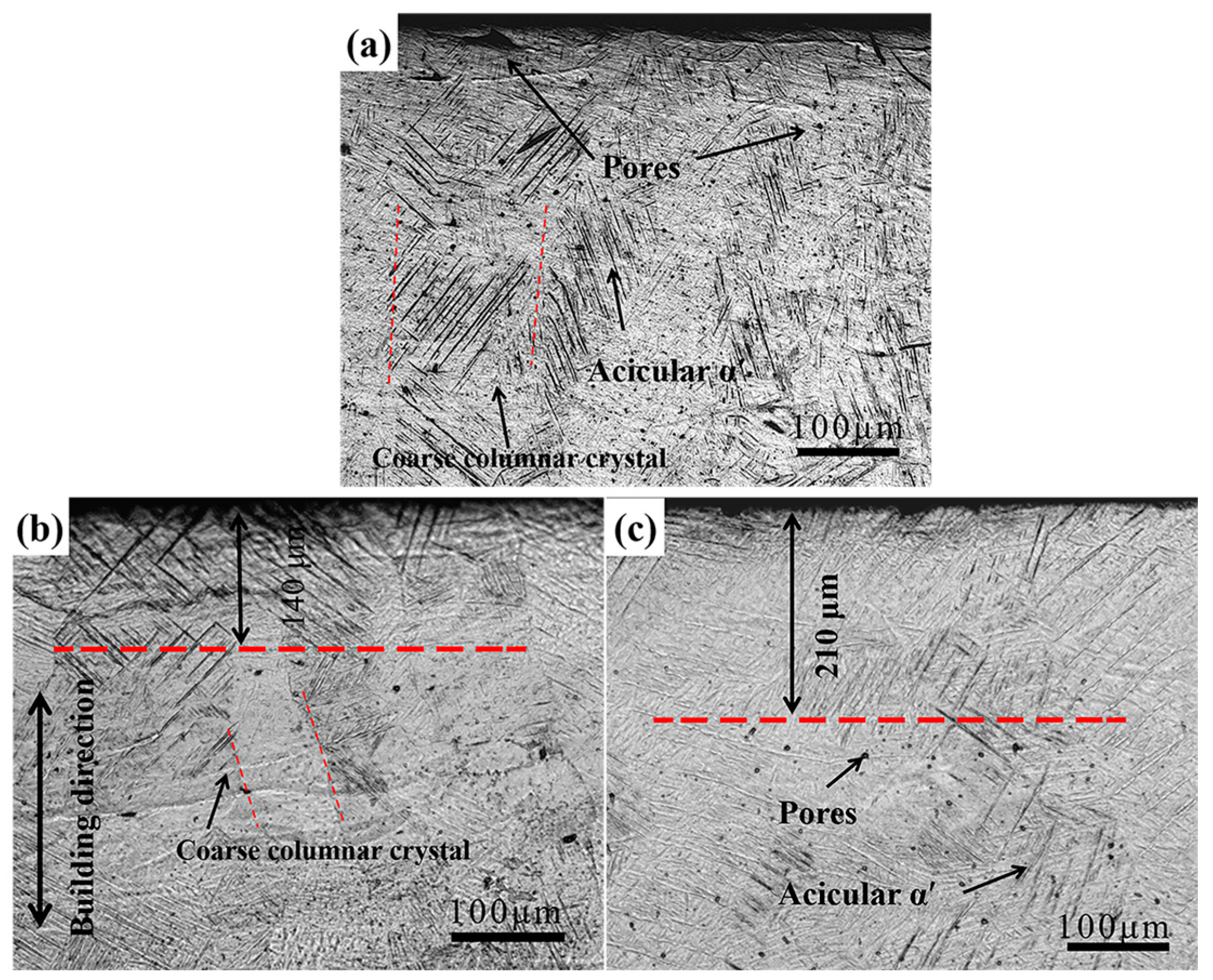

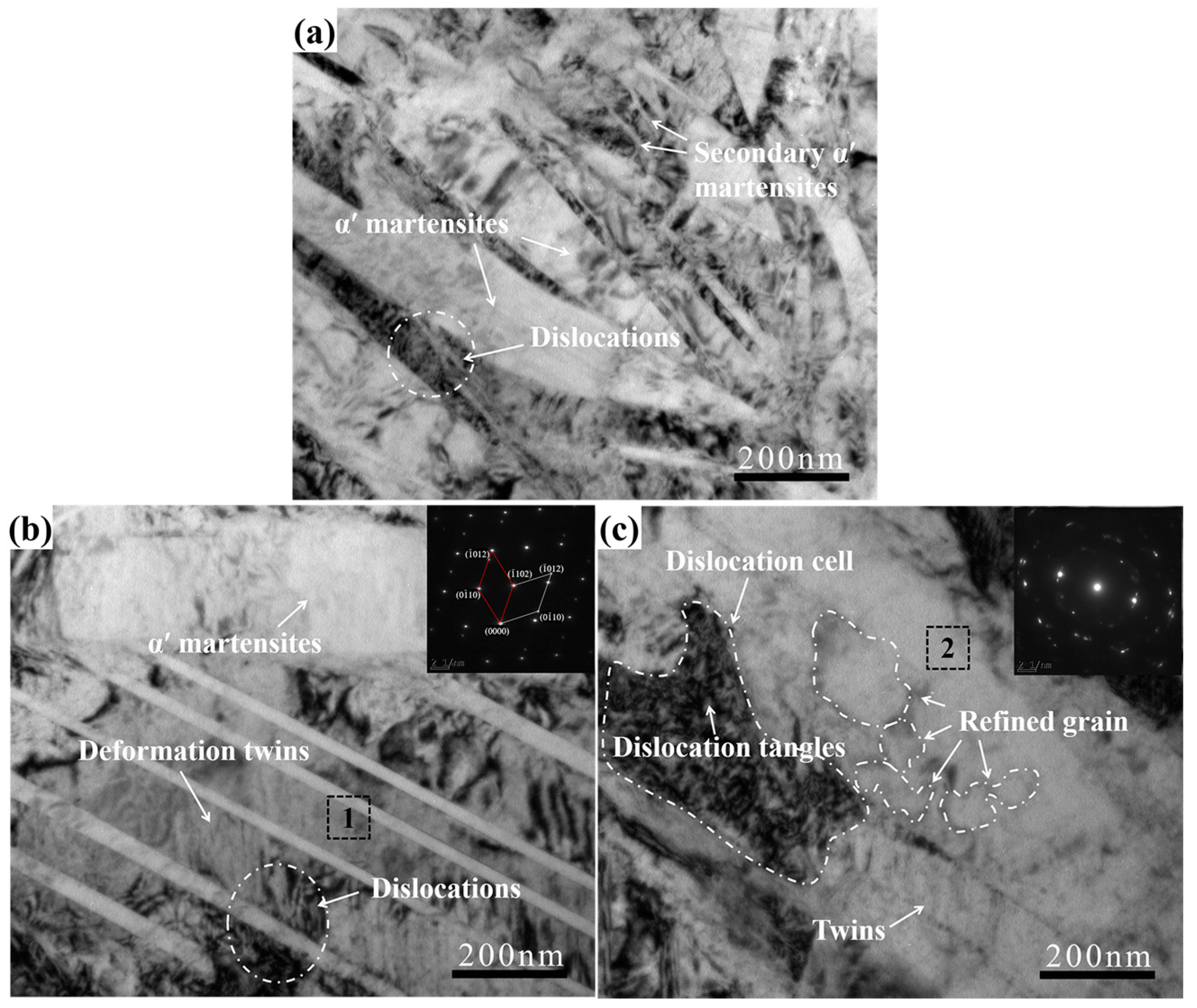

3.1. Microstructure Observation

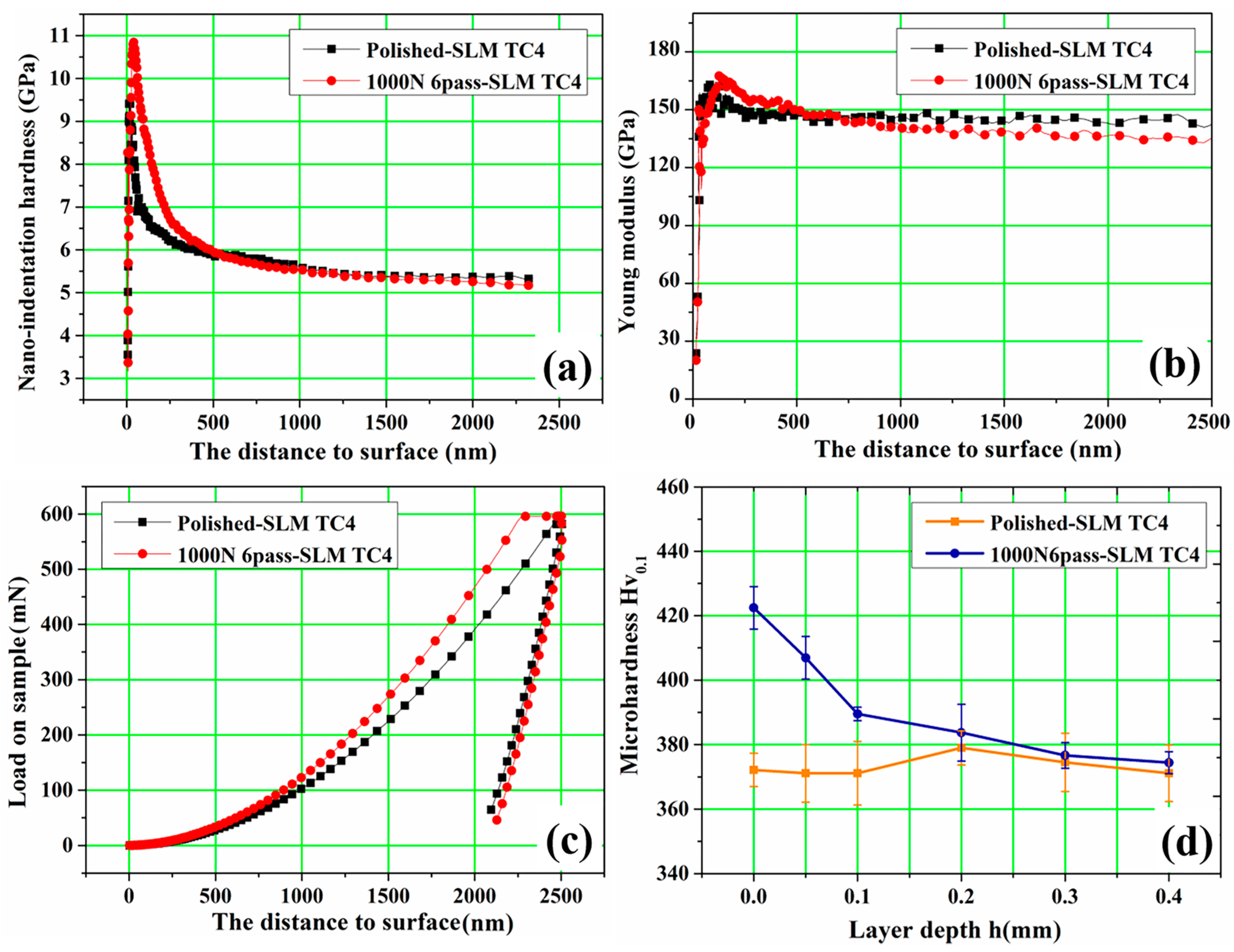

3.2. Nano-Indentation and Hardness

3.3. Friction and Wear Behavior

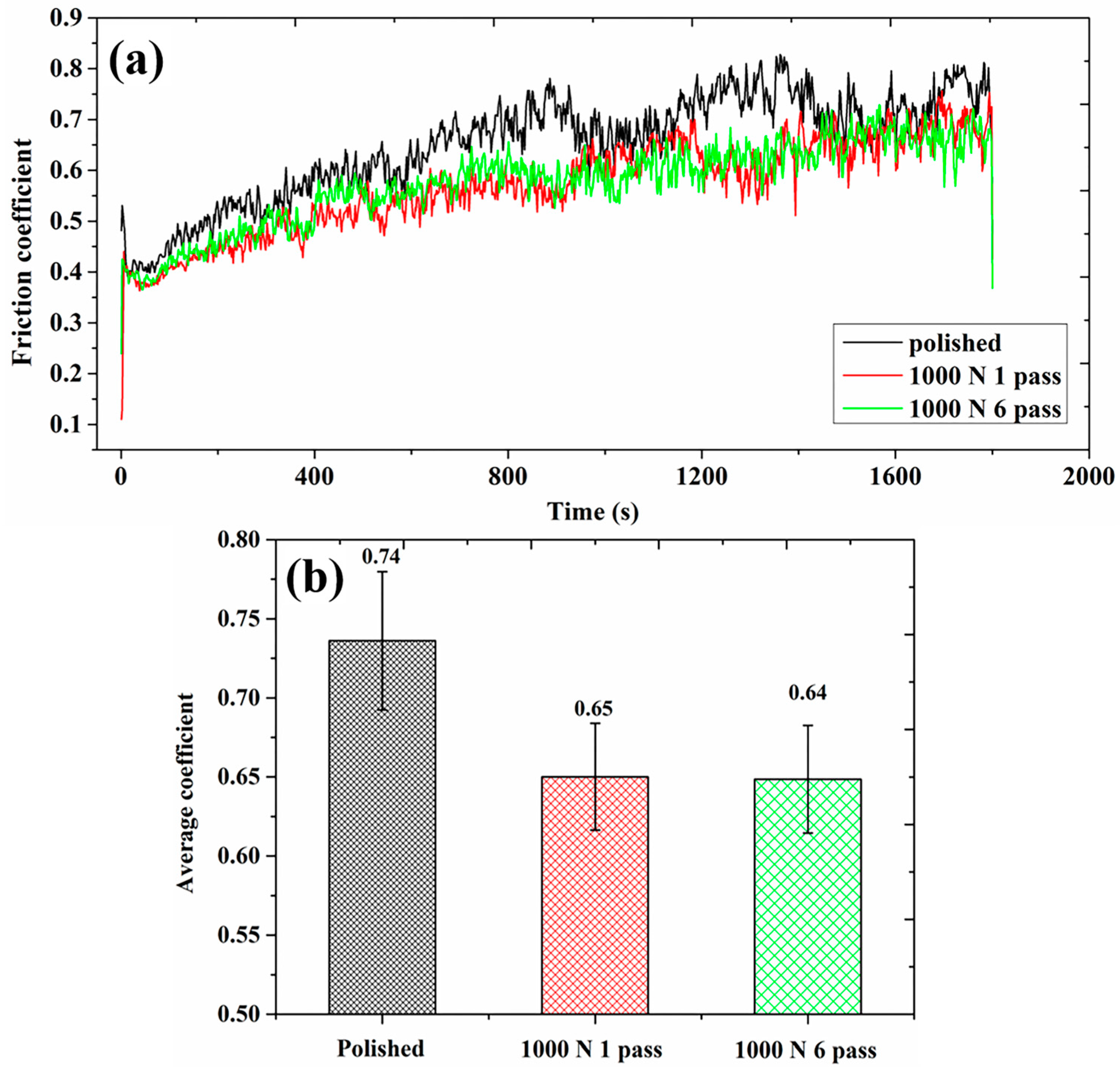

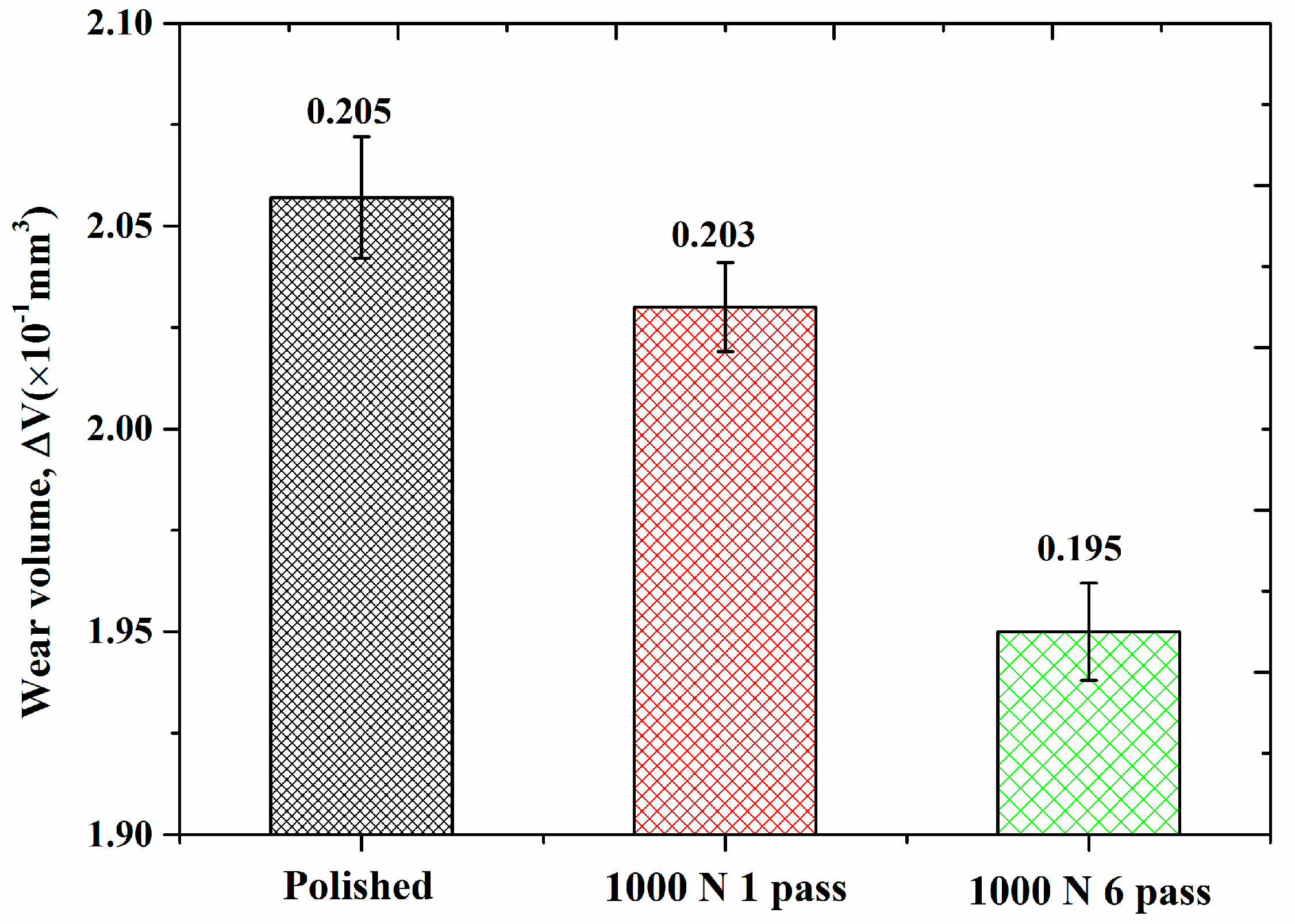

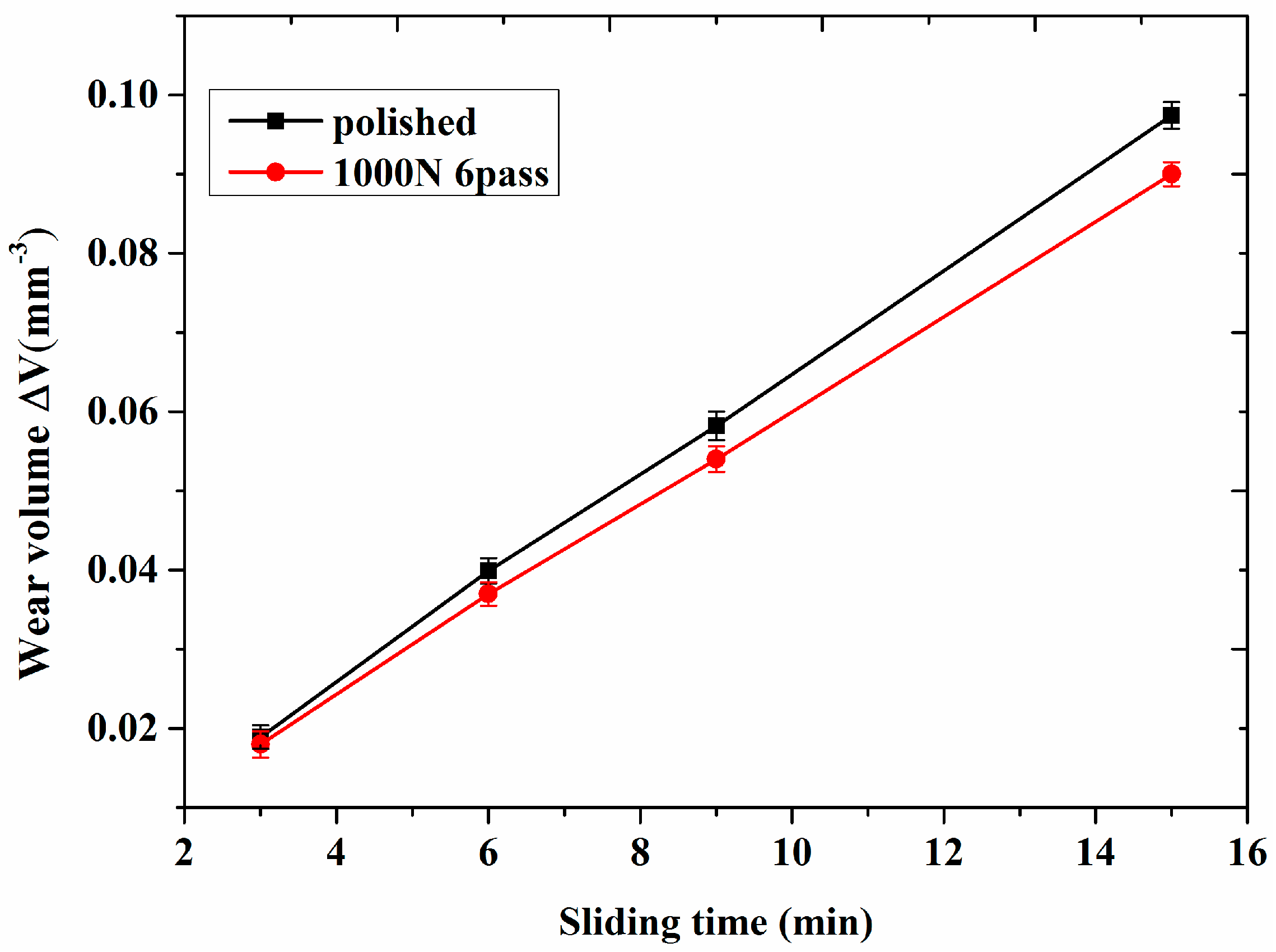

3.3.1. Friction Coefficient and Wear Volume

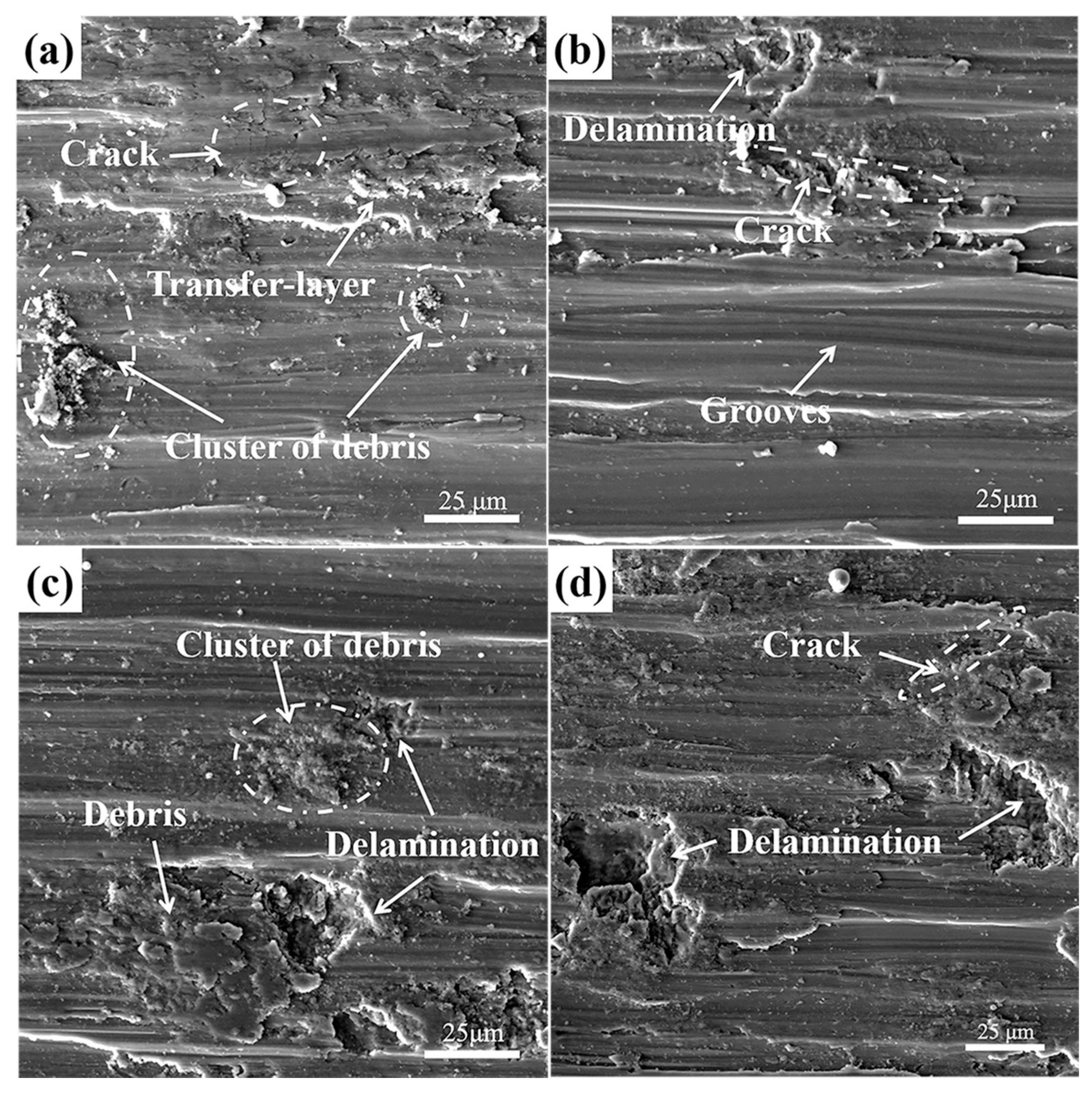

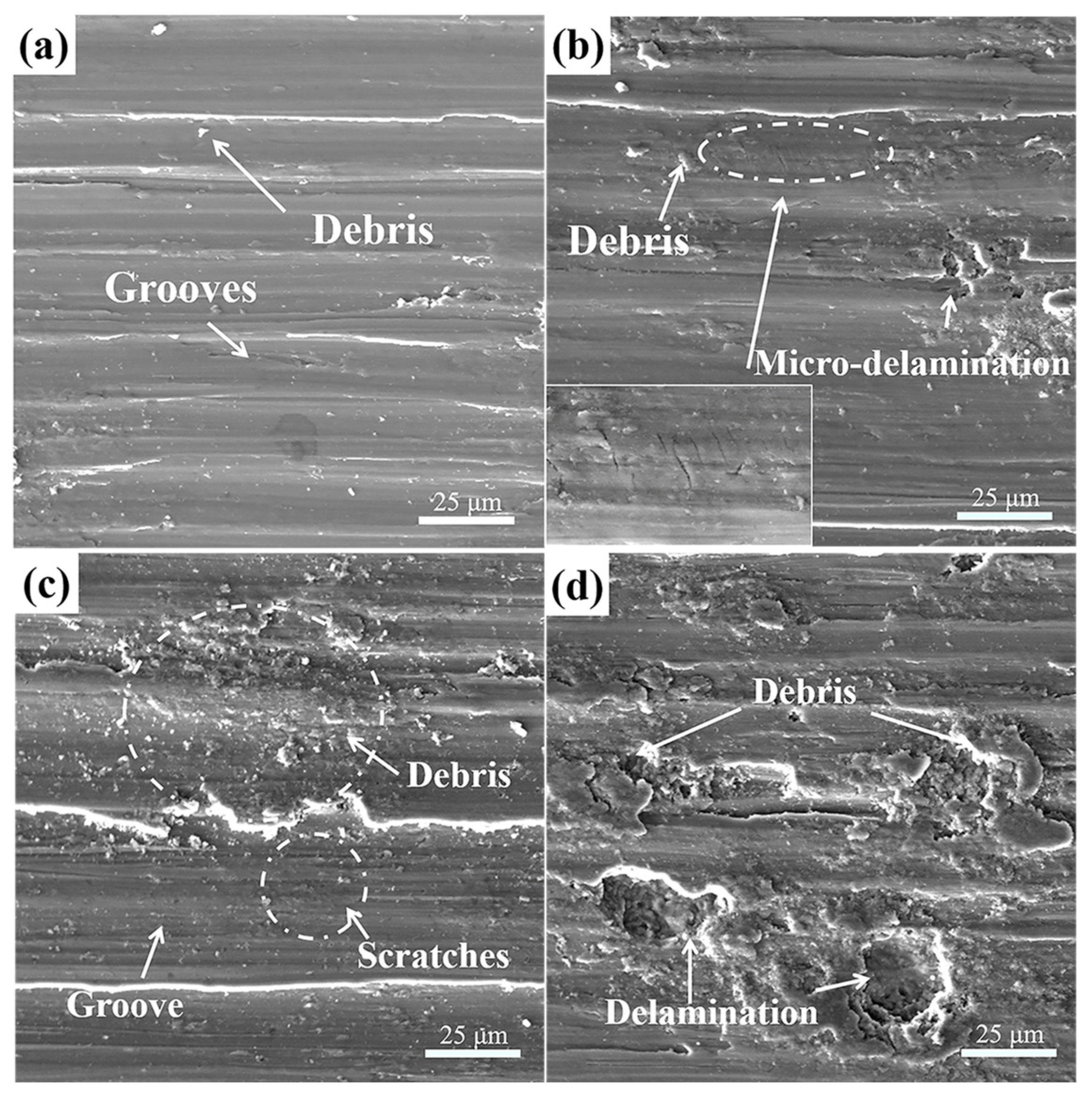

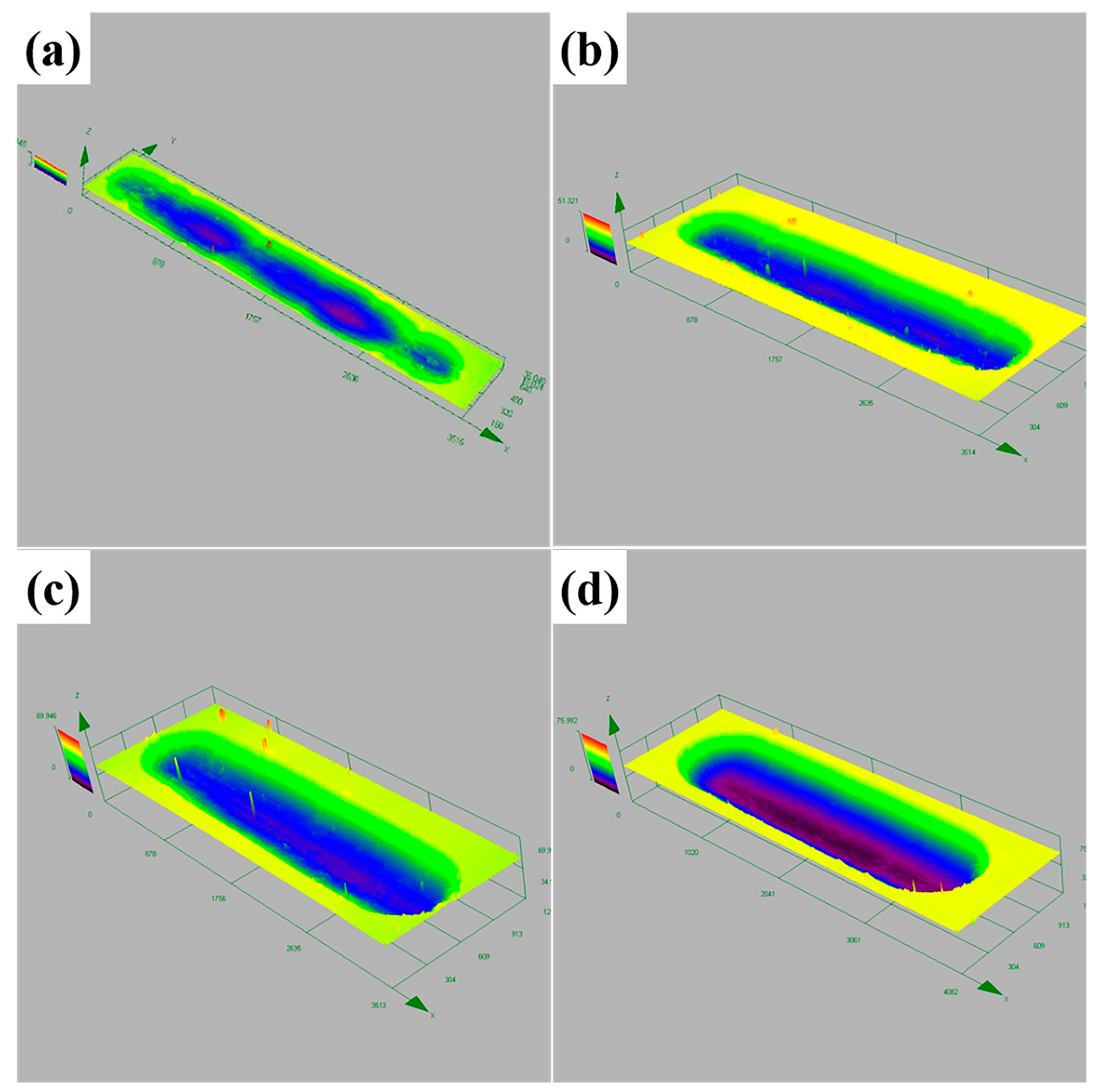

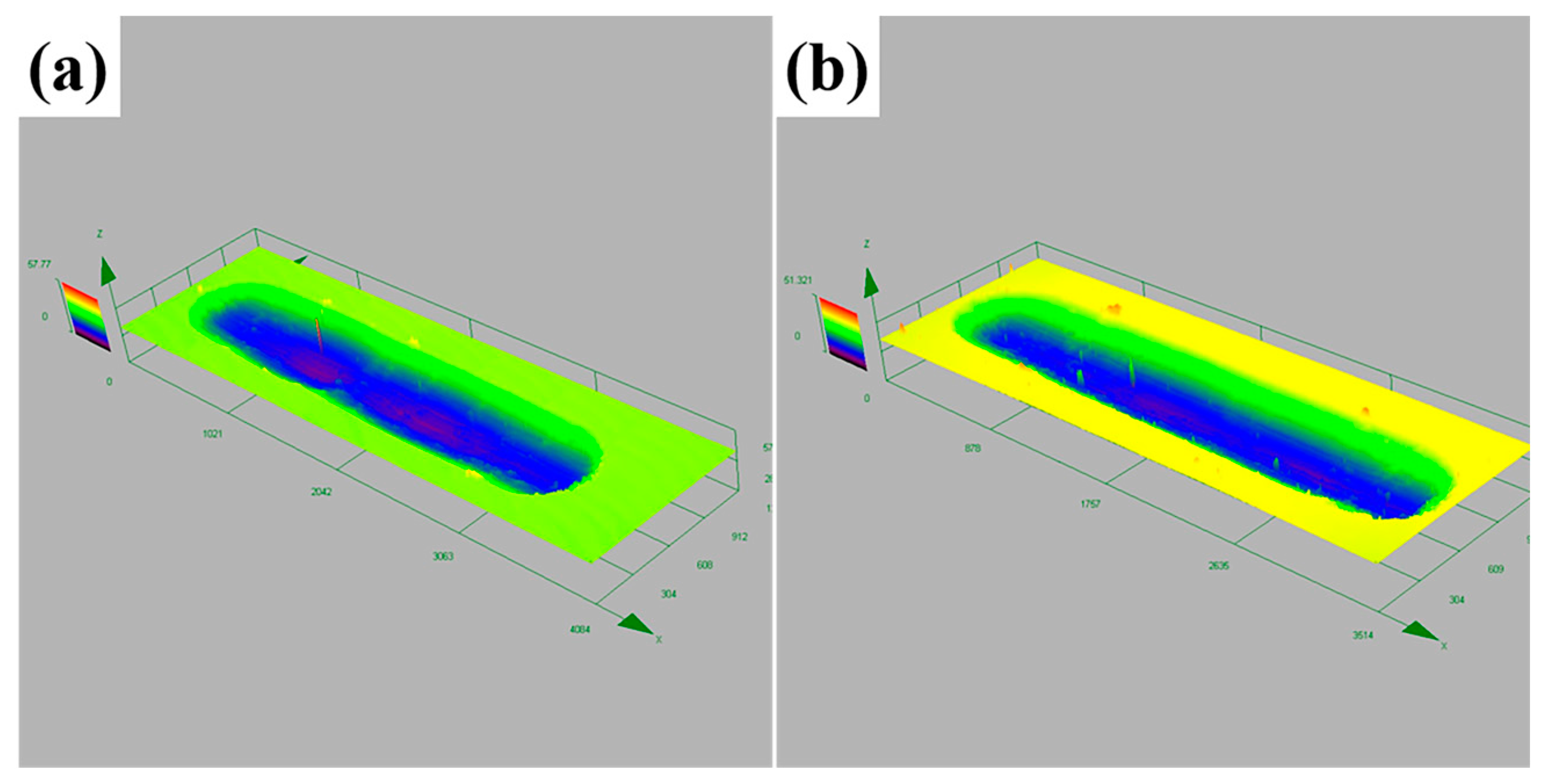

3.3.2. Analysis of Wear Mechanism

4. Conclusions

- (1)

- In this paper, samples of selective laser melted Ti-6Al-4V alloy were subjected to severe surface plastic deformation by using ultrasonic surface rolling process. The method could effectively increase the thickness of pore-free surface. Some substructures were formed after USRP treatment such as refined grains, dislocation wall and deformation twins, which improved the hardness and resistance to shear deformation of the modified surface.

- (2)

- Compared friction properties and wear volumes before and after USRP treated samples. The coefficient of friction was reduced from 0.74 to 0.64, the wear volume was decreased from 0.206 mm−3 to 0.195 mm−3. As the sliding time increased, the difference of the wear volume before and after USRP treatment was gradually increased. The wear mechanism of surface was obviously changed from severe adhesive wear to abrasive wear. In the subsurface, the wear mechanism was same, which consisted of abrasion wear, adhesive and delamination.

- (3)

- The reasons for improvement of friction and wear resistance were attributed to the increase in hardness and shear resistance as well as inhibition of delamination initiation.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Yang, M.; Lin, X.; Xu, X.; Chen, J.; Huang, W. Microstructure and phase evolution in Ti60-Ti2AlNb gradient material prepared by laser solid forming. Acta Metall. Sin. 2009, 45, 729–736. [Google Scholar]

- Gurrappa, I. Characterization of titanium alloy Ti-6Al-4V for chemical, marine and industrial applications. Mater. Charact. 2003, 51, 131–139. [Google Scholar] [CrossRef]

- Wang, S.Q.; Liu, J.H.; Chen, D.L. Effect of strain rate and temperature on strain hardening behavior of a dissimilar joint between Ti-6Al-4V and Ti17 alloys. Mater. Des. 2014, 56, 174–184. [Google Scholar] [CrossRef]

- Budinski, K.G. Tribological properties of titanium alloys. Wear 1991, 151, 203–217. [Google Scholar] [CrossRef]

- Banerjee, D.; Williams, J.C. Perspectives on titanium science and technology. Acta Mater. 2013, 61, 844–879. [Google Scholar] [CrossRef]

- Dong, H.; Bell, T. Enhanced wear resistance of titanium surfaces by a new thermal oxidation treatment. Wear 2000, 238, 131–137. [Google Scholar] [CrossRef]

- Attar, H.; Prashanth, K.G.; Chaubey, A.K. Comparison of wear properties of commercially pure titanium prepared by selective laser melting and casting processes. Mater. Lett. 2015, 142, 38–41. [Google Scholar] [CrossRef]

- Yerramareddy, S.; Bahadur, S. The effect of laser surface treatments on the tribological behavior of Ti-6Al-4V. Wear 1992, 157, 245–262. [Google Scholar] [CrossRef]

- Mordyuk, B.N.; Prokopenko, G.I.; Milman, Y.V. Wear assessment of composite surface layers in Al-6Mg alloy reinforced with AlCuFe quasicrystalline particles: Effects of particle size, microstructure and hardness. Wear 2014, 319, 84–95. [Google Scholar] [CrossRef]

- Ye, C.; Telang, A.; Gill, A.S. Gradient nanostructure and residual stresses induced by Ultrasonic Nano-crystal Surface Modification in 304 austenitic stainless steel for high strength and high ductility. Mater. Sci. Eng. A 2014, 613, 274–288. [Google Scholar] [CrossRef]

- Wang, T.; Wang, D.; Liu, G. Investigations on the nanocrystallization of 40 Cr using ultrasonic surface rolling processing. Appl. Surf. Sci. 2008, 255, 1824–1829. [Google Scholar] [CrossRef]

- Wang, H.; Song, G.; Tang, G. Effect of electropulsing on surface mechanical properties and microstructure of AISI 304 stainless steel during ultrasonic surface rolling process. Mater. Sci. Eng. A 2016, 662, 456–467. [Google Scholar] [CrossRef]

- Amanov, A.; Cho, I.; Pyun, Y. Microstructural evolution and surface properties of nanostructured Cu-based alloy by ultrasonic nanocrystalline surface modification technique. Appl. Surf. Sci. 2016, 388, 185–195. [Google Scholar] [CrossRef]

- Amanov, A.; Penkov, O.V.; Pyun, Y.S. Effects of ultrasonic nanocrystalline surface modification on the tribological properties of AZ91D magnesium alloy. Tribol. Int. 2012, 54, 106–113. [Google Scholar] [CrossRef]

- Amanov, A.; Cho, I.S.; Kim, D.E. Fretting wear and friction reduction of CP titanium and Ti-6Al-4V alloy by ultrasonic nanocrystalline surface modification. Surf. Coat. Technol. 2012, 207, 135–142. [Google Scholar] [CrossRef]

- Li, G.; Qu, S.G.; Pan, Y.X. Effects of the different frequencies and loads of ultrasonic surface rolling on surface mechanical properties and fretting wear resistance of HIP Ti-6Al-4V alloy. Appl. Surf. Sci. 2016, 389, 324–334. [Google Scholar] [CrossRef]

- Li, G.; Qu, S.; Xie, M. Effect of ultrasonic surface rolling at low temperatures on surface layer microstructure and properties of HIP Ti-6Al-4V alloy. Surf. Coat. Technol. 2017, 316, 75–84. [Google Scholar] [CrossRef]

- Ye, X.; Ye, Y.; Tang, G. Effect of electropulsing treatment and ultrasonic striking treatment on the mechanical properties and microstructure of biomedical ti-6Al-4V alloy. J. Mech. Behav. Biomed. Mater. 2014, 40, 287–296. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Song, G.; Tang, G. Evolution of surface mechanical properties and microstructure of Ti6Al4V alloy induced by electropulsing-assisted ultrasonic surface rolling process. J. Alloys Comp. 2016, 681, 146–156. [Google Scholar] [CrossRef]

- Liu, Y.; Zhao, X.H.; Wang, D.P. Determination of the plastic properties of materials treated by ultrasonic surface rolling process through instrumented indentation. Mater. Sci. Eng. A 2014, 600, 21–31. [Google Scholar] [CrossRef]

- Ehtemam-Haghighi, S.; Cao, G.H.; Zhang, L.C. Nanoindentation study of mechanical properties of Ti based alloy with Fe and Ta additions. J. Alloys Comp. 2017, 692, 892–897. [Google Scholar] [CrossRef]

- Attar, H.; Bonisch, M.; Calin, M. Selective laser melting of in situ titanium-titanium boride composites: Processing, microstructure and mechanical properties. Acta Mater. 2014, 76, 13–22. [Google Scholar] [CrossRef]

- Attar, H.; Ehtemam-Haghighi, S.; Kent, D. Nanoindentation and wear properties of Ti and TiB composite materials produced by selectively laser melting. Mater. Sci. Eng. A 2017, 688, 20–26. [Google Scholar] [CrossRef]

- Attar, H.; Ehtemam-Haghighi, S.; Kent, D. Comparative study of commercially pure titanium produced by laser engineered net shaping, selective laser melting and casting processes. Mater. Sci. Eng. A 2017, 705, 385–393. [Google Scholar] [CrossRef]

- Xu, W.; Brandt, M.; Sun, S. Additive manufacturing of strong and ductile Ti-6Al-4V by selective laser melting via in situ martensite decomposition. Acta Mater. 2015, 85, 74–84. [Google Scholar] [CrossRef]

- Murr, L.E.; Gaytan, S.M.; Ramirez, D.A. Metal Fabrication by Additive Manufacturing Using Laser and Electron Beam Melting Technologies. J. Mater. Sci. Technol. 2012, 28, 1–14. [Google Scholar] [CrossRef]

- Qiu, C.; Adkins, N.J.E.; Attallah, M.M. Microstructure and tensile properties of selectively laser-melted and of HIPed laser-melted Ti-6Al-4V. Mater. Sci. Eng. A 2013, 578, 230–239. [Google Scholar] [CrossRef]

- Lu, S.L.; Tang, H.P.; Ning, Y.P. Microstructure and Mechanical Properties of Long Ti-6Al-4V Rods Additively Manufactured by Selective Electron Beam Melting Out of a Deep Powder Bed and the Effect of Subsequent Hot Isostatic Pressing. Metall. Mater. Trans. A 2015, 46, 3824–3834. [Google Scholar] [CrossRef]

- Dekhtyar, A.I.; Mordyuk, B.N.; Savvakin, D.G. Enhanced fatigue behavior of powder metallurgy Ti-6Al-4V alloy by applying ultrasonic impact treatment. Mater. Sci. Eng. A 2015, 641, 348–359. [Google Scholar] [CrossRef]

- Zhu, Y.; Chen, X.; Zou, J. Sliding wear of selective laser melting processed Ti6Al4V under boundary lubrication conditions. Wear 2016, 485–495. [Google Scholar] [CrossRef]

- Kruth, J.P.; Froyen, L.; Vaerenbergh, J.V. Selective laser melting of iron-based powder. J. Mater. Process. Technol. 2004, 149, 616–622. [Google Scholar] [CrossRef]

- Yang, J.J.; Yu, H.C.; Yin, J. Formation and control of martensite in Ti-6Al-4V alloy produced by selective laser melting. Mater. Des. 2016, 108, 308–318. [Google Scholar] [CrossRef]

- Fan, Y.; Zhao, X.; Liu, Y. Research on fatigue behavior of the flash welded joint enhanced by ultrasonic peening treatment. Mater. Des. 2016, 94, 515–522. [Google Scholar] [CrossRef]

- Mordyuk, B.N.; Prokopenko, G.I. Ultrasonic impact peening for the surface properties’ management. J. Sound Vib. 2007, 308, 855–866. [Google Scholar] [CrossRef]

- Ehtemam-Haghighi, S.; Prashanth, K.G.; Attar, H.; Zhang, L.C. Evaluation of mechanical and wear properties of Ti-xNb-7Fe alloys designed for biomedical applications. Mater. Des. 2016, 111, 592–599. [Google Scholar] [CrossRef]

- Toh, W.Q.; Wang, P.; Tan, X.P. Microstructure and wear properties of electron beam melted Ti-6Al-4V parts: A comparison study against as-cast form. Metals 2016, 6, 284. [Google Scholar] [CrossRef]

- Rosenfield, A.R. A fracture mechanics approach to wear. Wear 1980, 61, 125–132. [Google Scholar] [CrossRef]

- Long, M.; Rack, H.J. Subsurface deformation and microcrack formation in Ti-35Nb-8Zr-5Ta-O(x) during reciprocating sliding wear. Mater. Sci. Eng. C 2005, 25, 382–388. [Google Scholar] [CrossRef]

- Polasik, S.J.; Williams, J.J.; Chawla, N. Fatigue crack initiation and propagation in ferrous powder metallurgy alloys. In Proceedings of the Powder Metallurgy and Particulate materials, New Orleans, LA, USA, 13–17 May 2001; pp. 2042–2056. [Google Scholar]

- Farokhzadeh, K.; Edrisy, A. Transition between mild and severe wear in titanium alloys. Tribol. Int. 2016, 94, 98–111. [Google Scholar] [CrossRef]

| Ti | Al | V | O | C |

|---|---|---|---|---|

| Balance | 5.5~6.5 | 3.5~4.5 | <0.13 | <0.08 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Z.; Xiao, Z.; Huang, C.; Wen, L.; Zhang, W. Influence of Ultrasonic Surface Rolling on Microstructure and Wear Behavior of Selective Laser Melted Ti-6Al-4V Alloy. Materials 2017, 10, 1203. https://doi.org/10.3390/ma10101203

Wang Z, Xiao Z, Huang C, Wen L, Zhang W. Influence of Ultrasonic Surface Rolling on Microstructure and Wear Behavior of Selective Laser Melted Ti-6Al-4V Alloy. Materials. 2017; 10(10):1203. https://doi.org/10.3390/ma10101203

Chicago/Turabian StyleWang, Zhen, Zhiyu Xiao, Chuanshou Huang, Liping Wen, and Weiwen Zhang. 2017. "Influence of Ultrasonic Surface Rolling on Microstructure and Wear Behavior of Selective Laser Melted Ti-6Al-4V Alloy" Materials 10, no. 10: 1203. https://doi.org/10.3390/ma10101203

APA StyleWang, Z., Xiao, Z., Huang, C., Wen, L., & Zhang, W. (2017). Influence of Ultrasonic Surface Rolling on Microstructure and Wear Behavior of Selective Laser Melted Ti-6Al-4V Alloy. Materials, 10(10), 1203. https://doi.org/10.3390/ma10101203