Comparison of Heavy-Duty Scuffing Behavior between Chromium-Based Ceramic Composite and Nickel-Chromium-Molybdenum-Coated Ring Sliding against Cast Iron Liner under Starvation

Abstract

:1. Introduction

2. Experimental Details

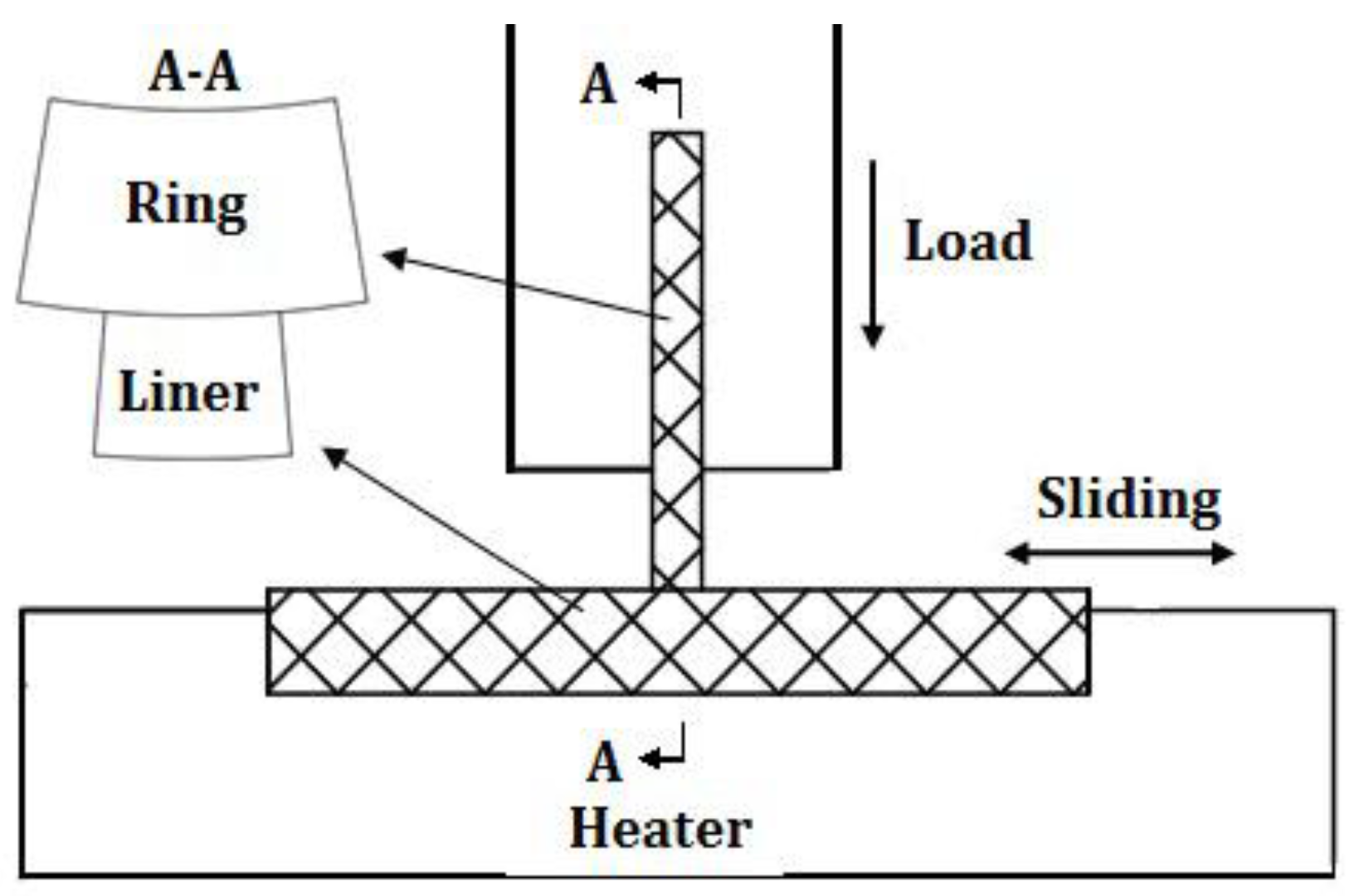

2.1. Test Rig Description

2.2. Experimental Materials

2.3. Experimental Procedure

3. Results and Discussion

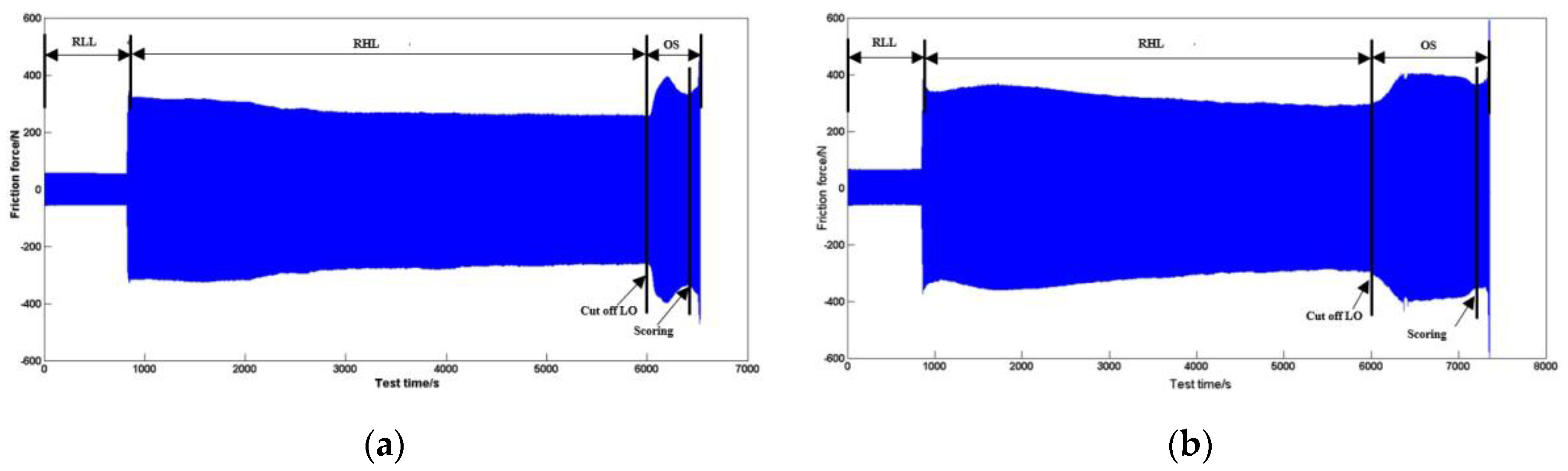

3.1. Friction Force Variation of the CKS Ring and NCM Ring

3.2. Effect of Nominal Pressure and Temperature on the Anti-Scuffing Time Duration

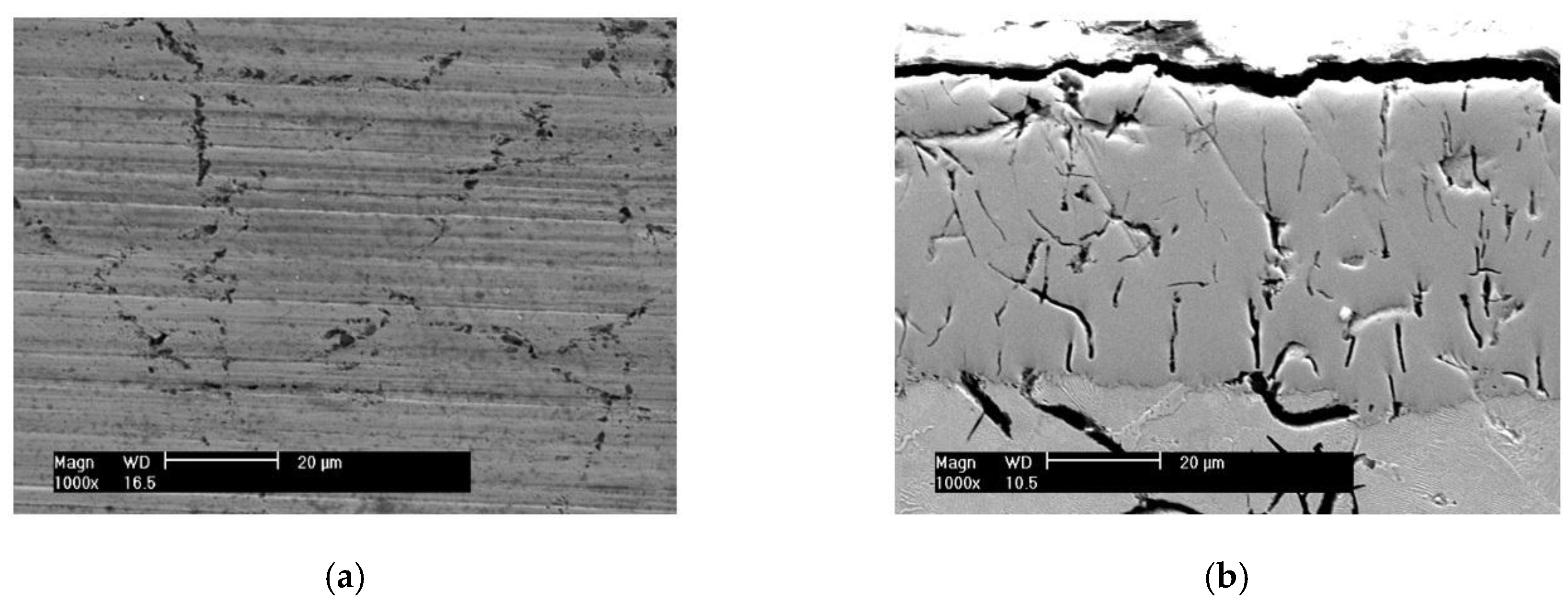

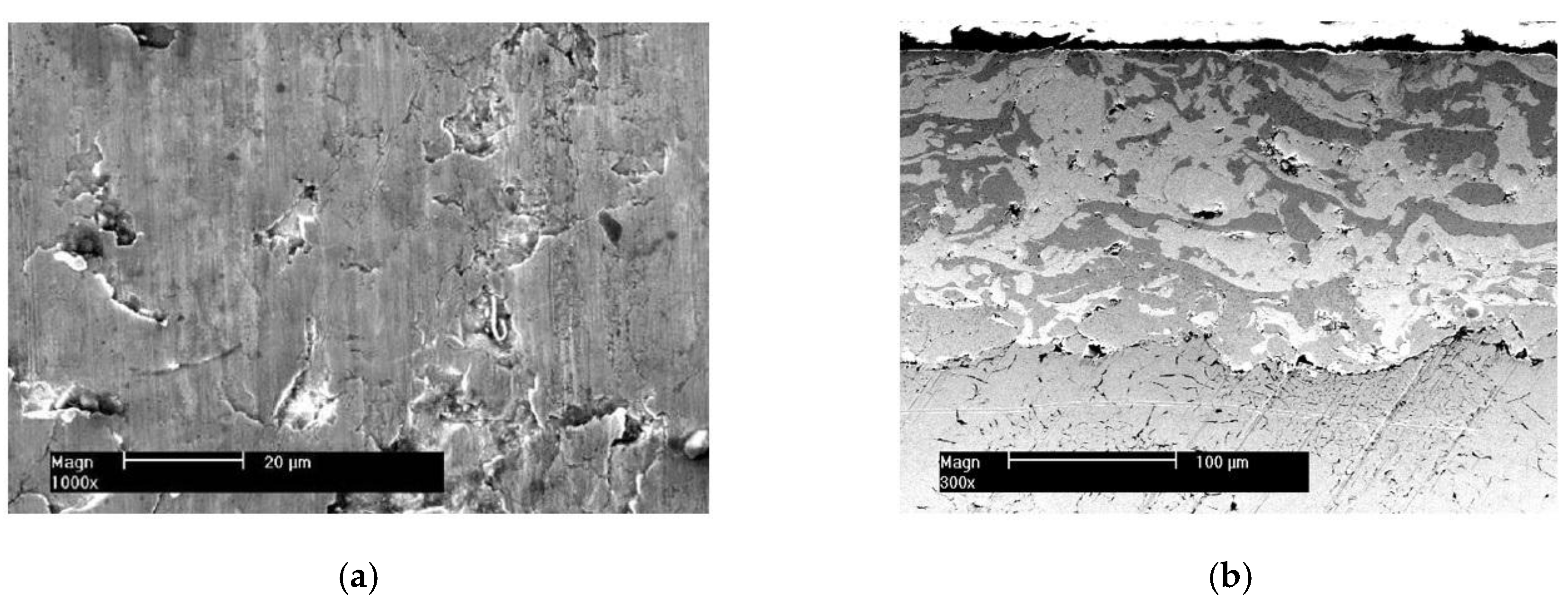

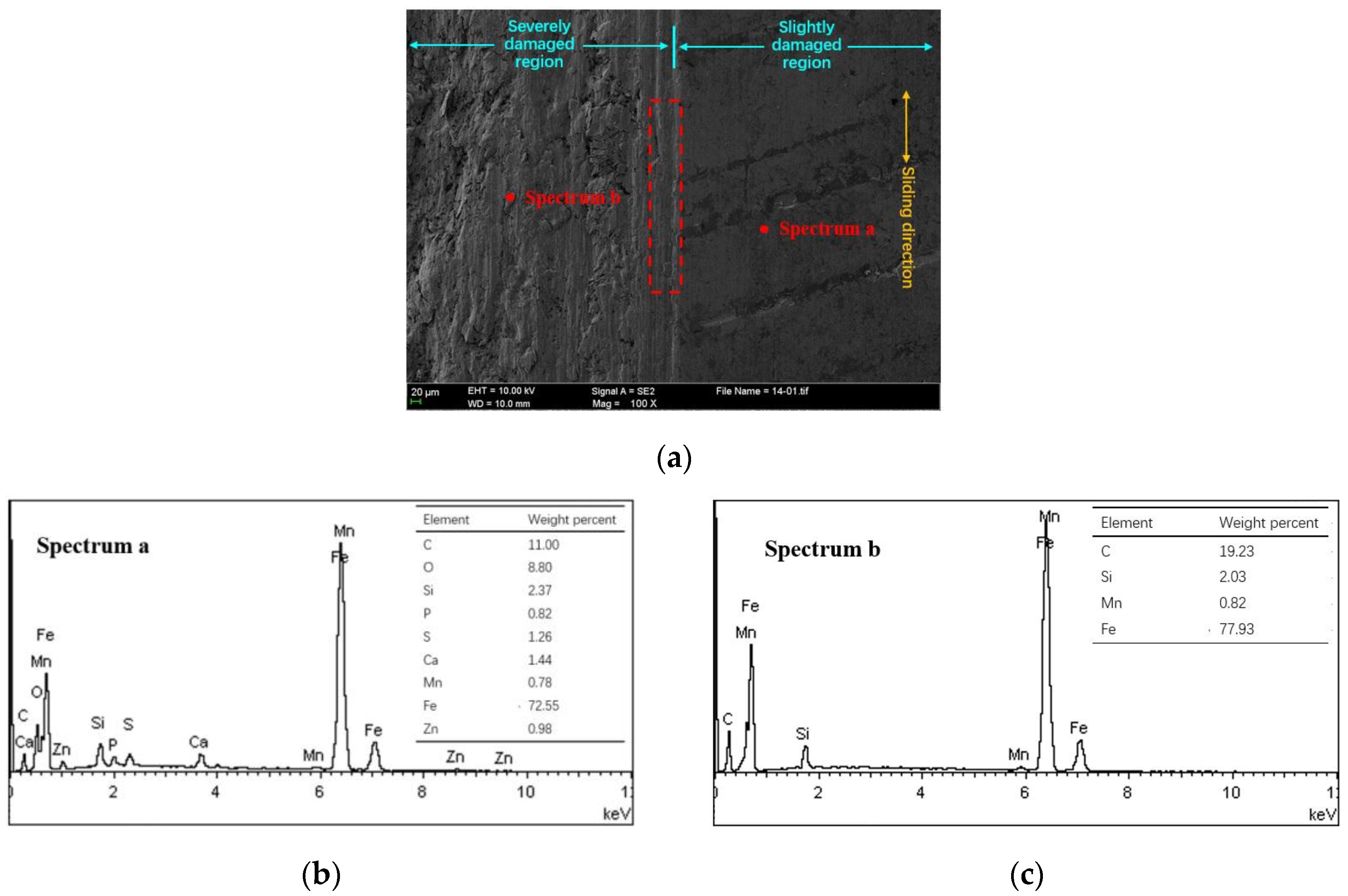

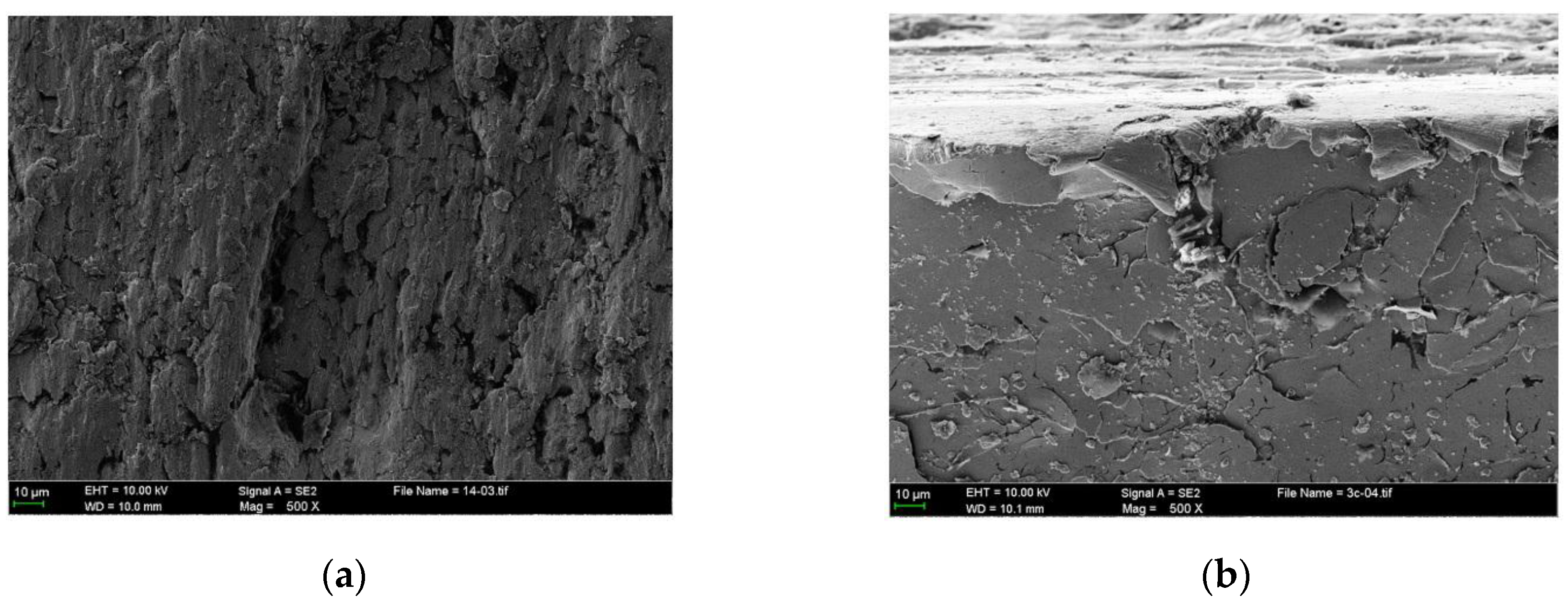

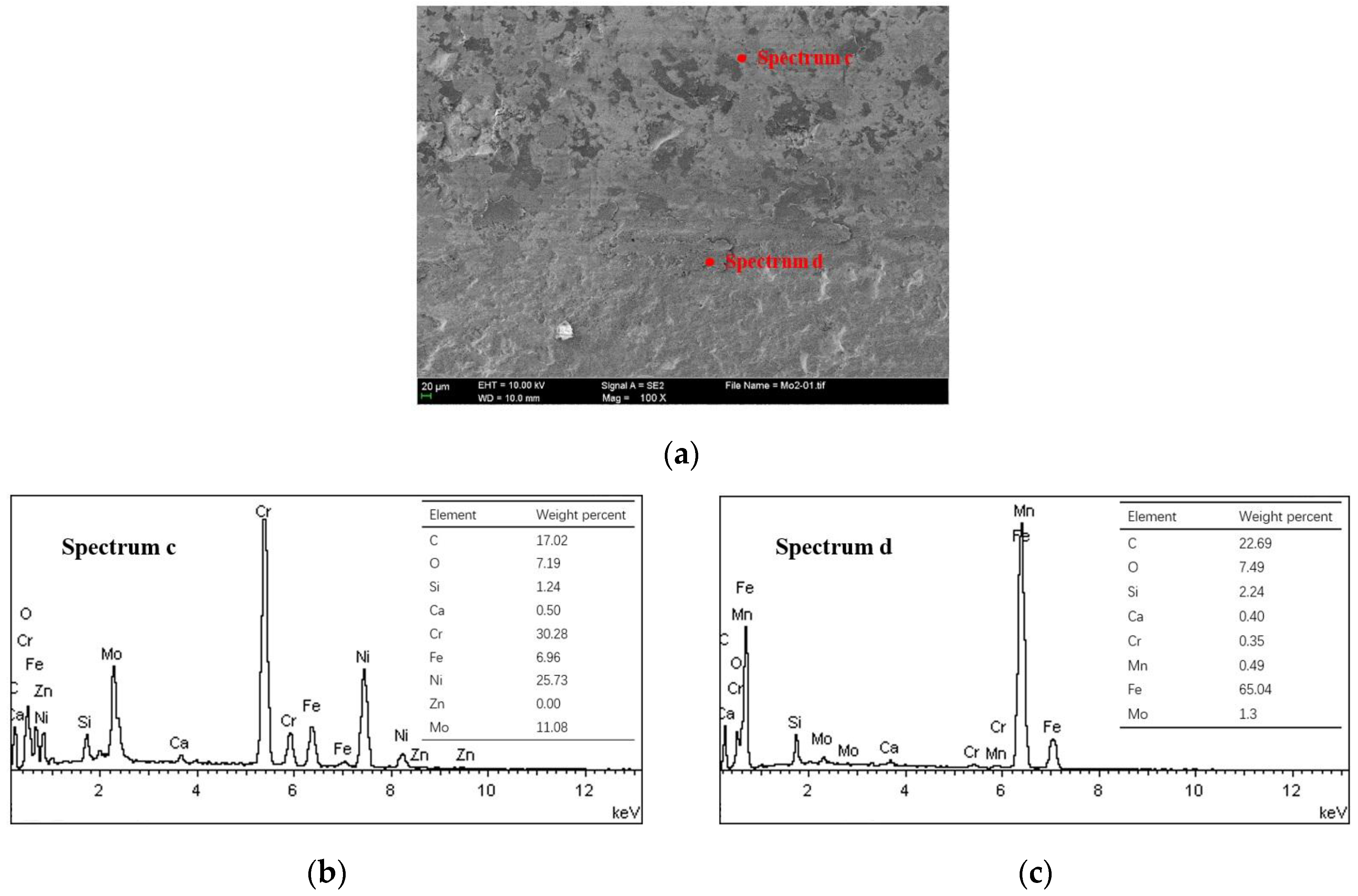

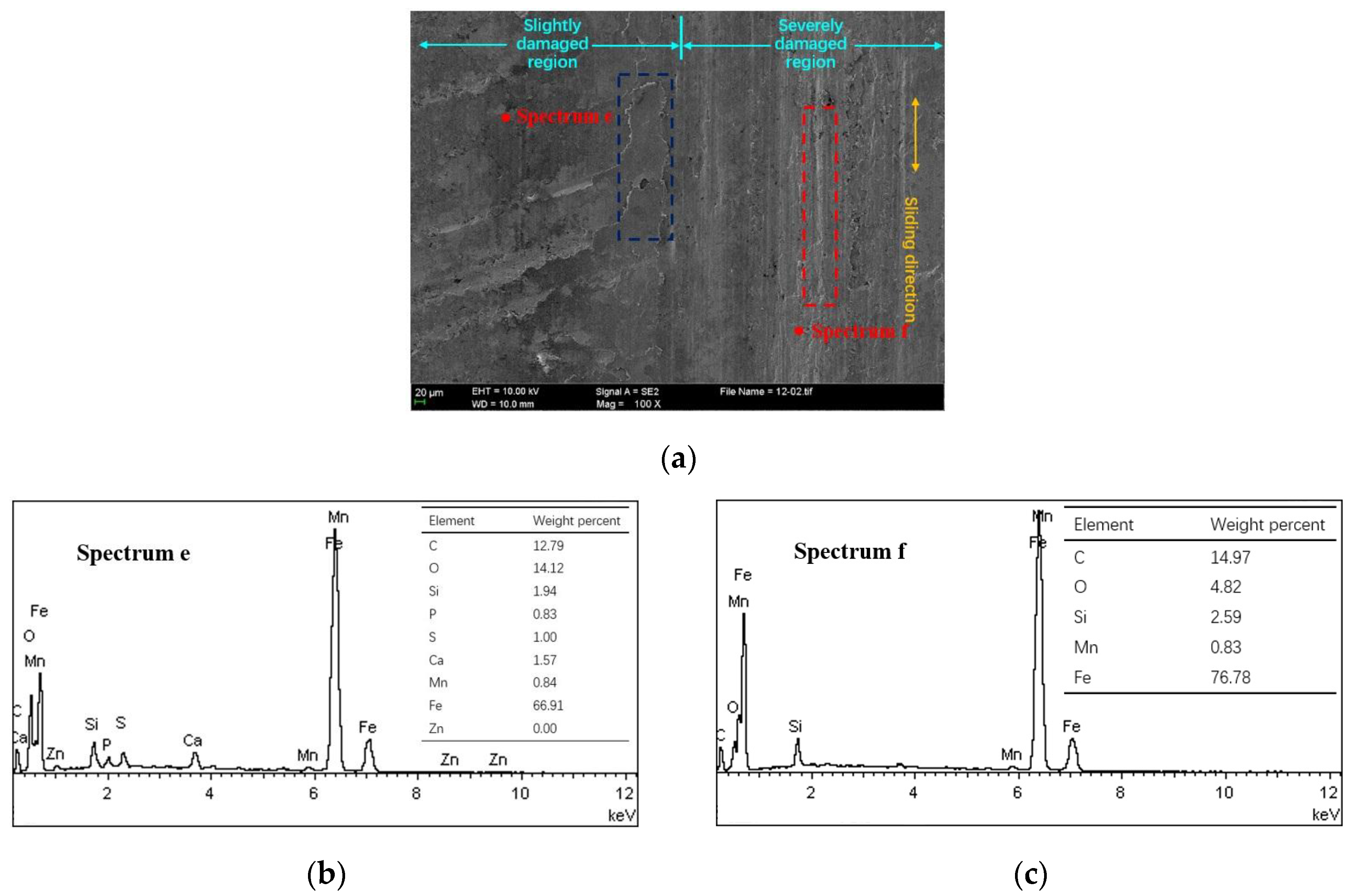

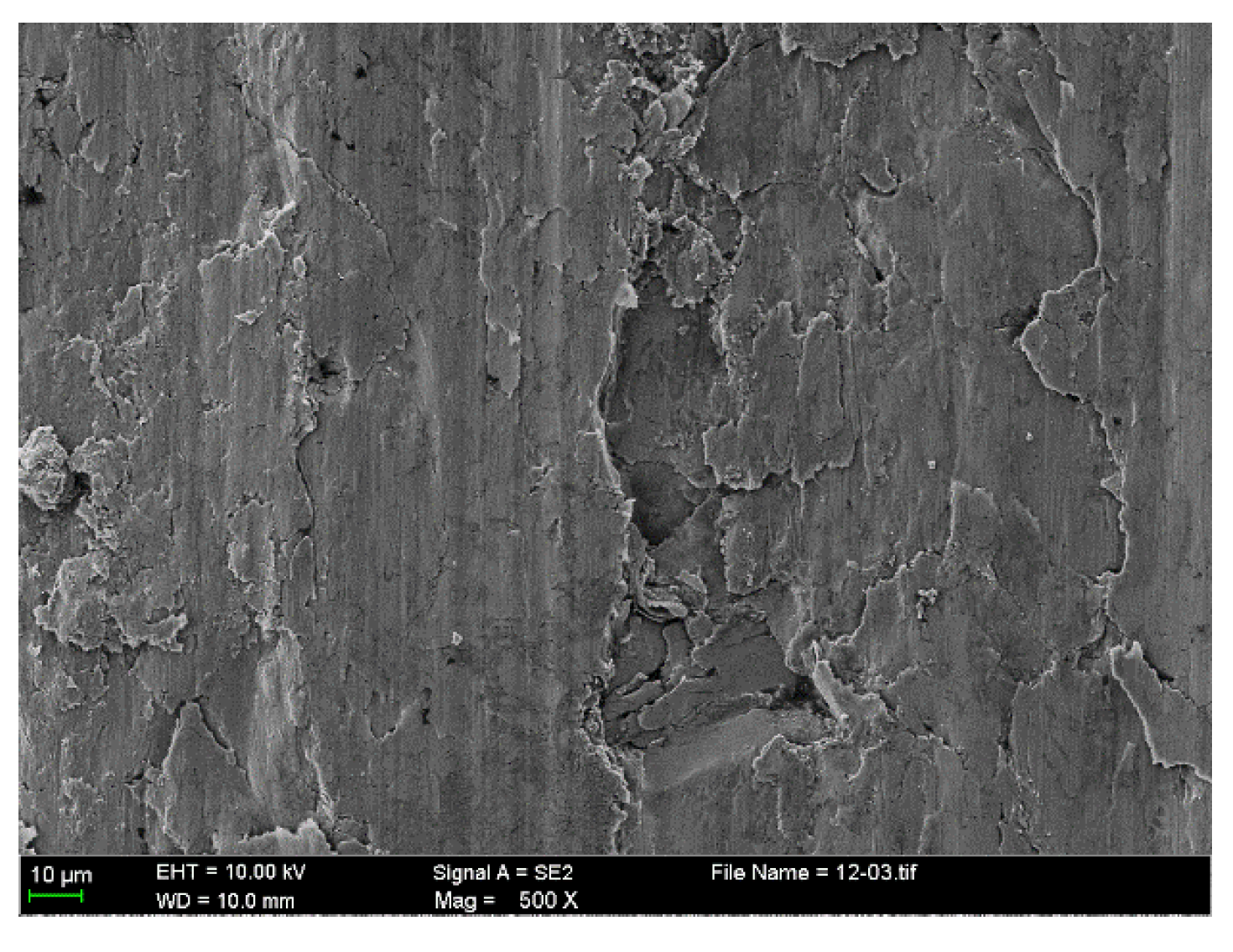

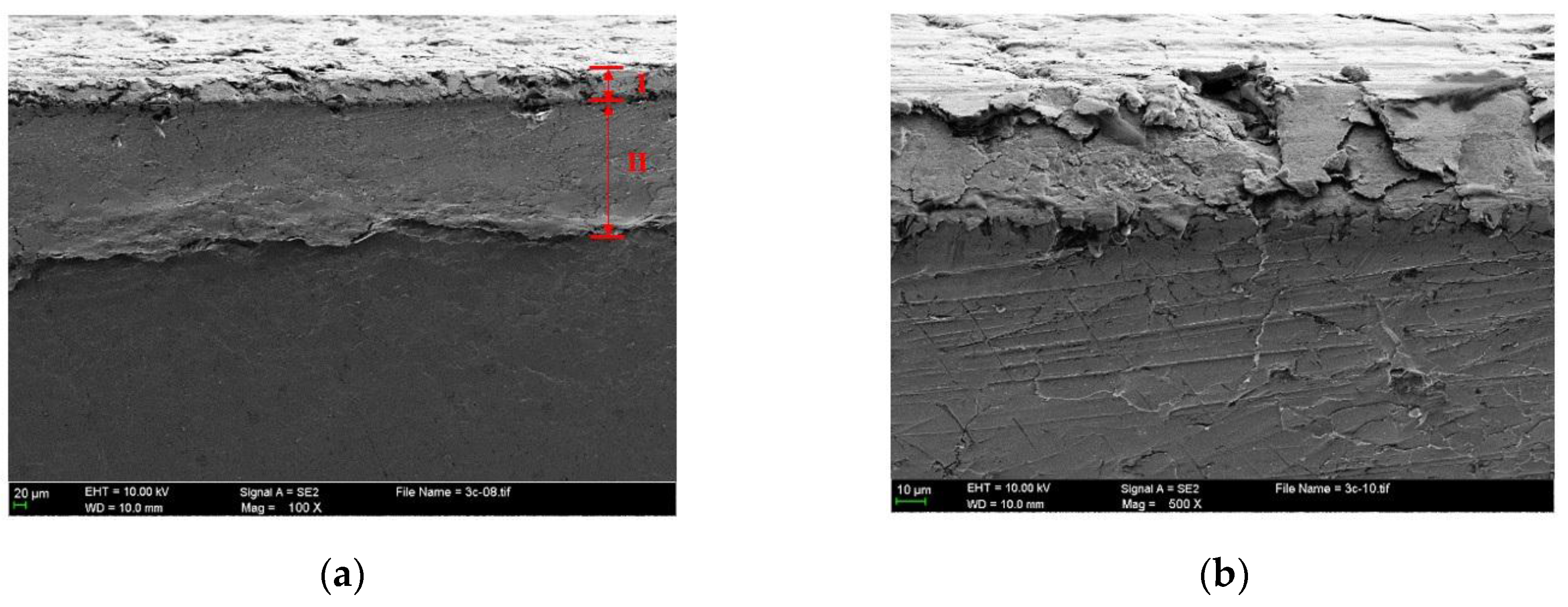

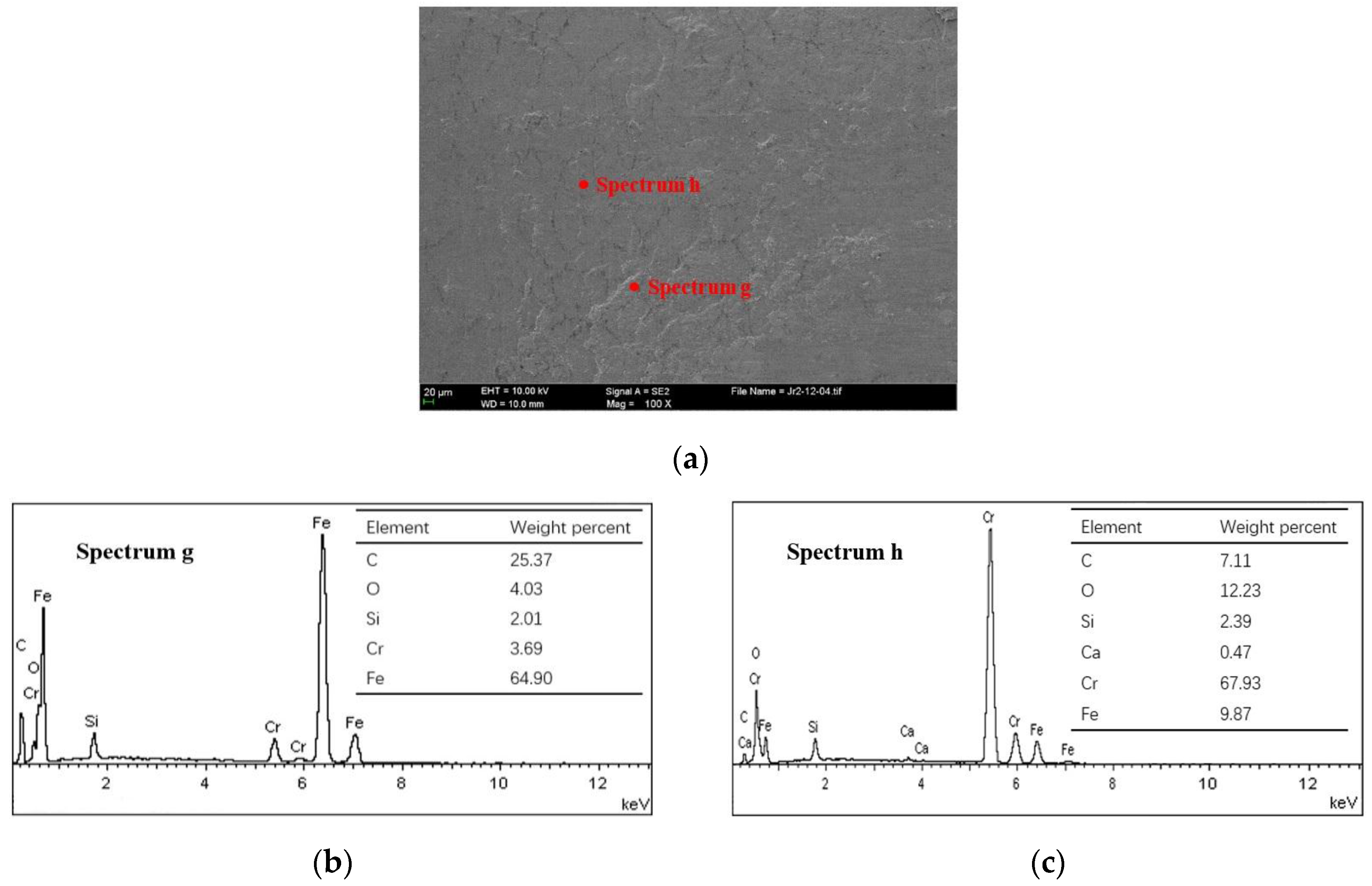

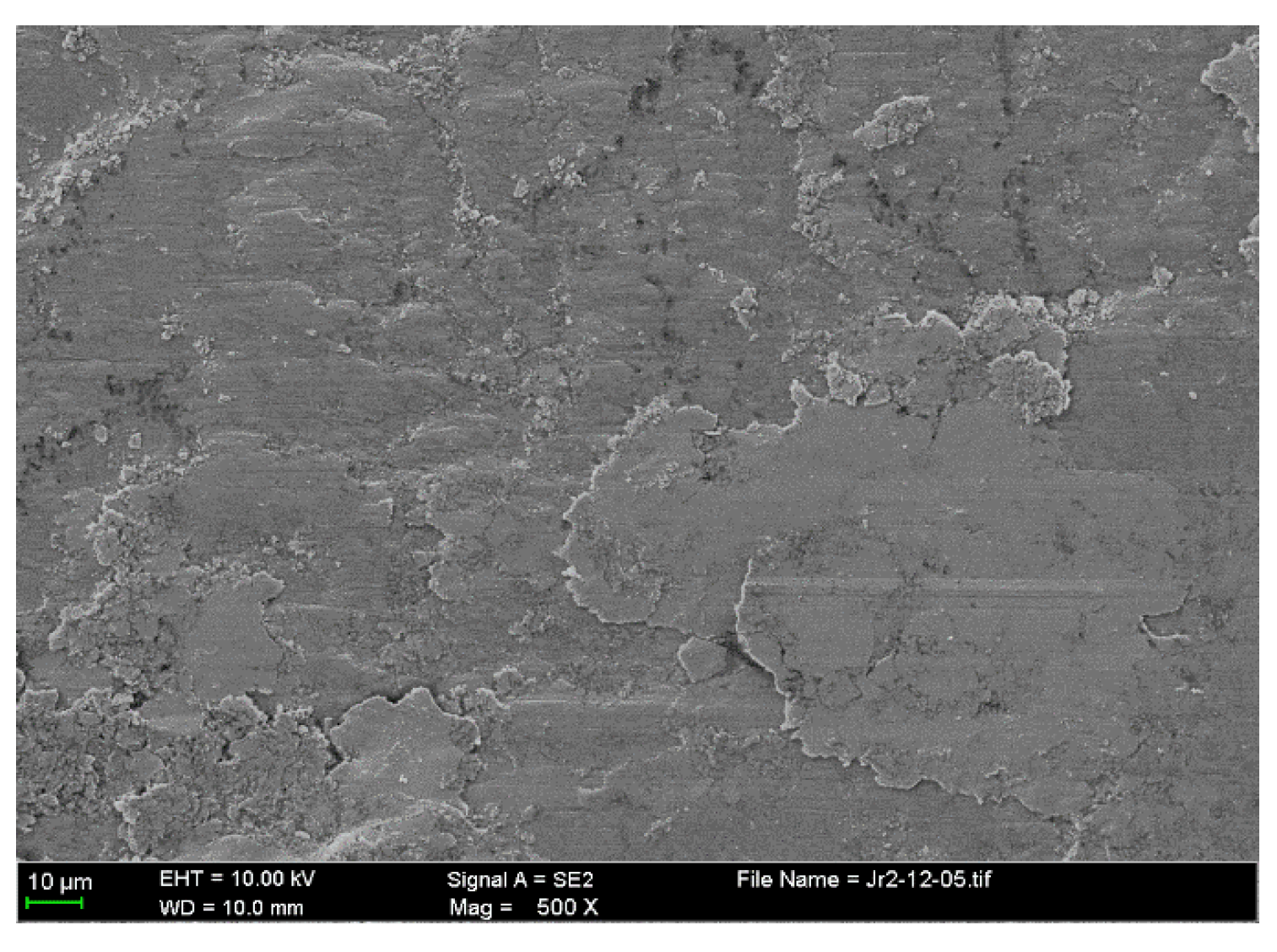

3.3. Scuffed Surface Analysis and Discussion

- (a)

- The surface honing textures of the cast iron cylinder liner gradually becomes shallow and its friction condition is in the “polishing wear” stage.

- (b)

- The formation of microscopic and macroscopic adhesions causes cast iron plastic shearing, resulting in different damage modes of the surface materials transfer. Meanwhile, the subsurface accompanied with the deformation contributes to the formation of abrasive particles.

- (c)

- Most transferred materials adhere to the piston ring surface with different particle aggregation patterns.

4. Conclusions

- (1)

- When mated with a cast iron cylinder liner, the NCM coating has better scuffing resistance properties than the CKS coating with the failure time criterion.

- (2)

- At the heavy-duty sliding conditions, when the nominal pressure and temperature exceed more than 60 MPa and 220 °C, respectively, the anti-scuffing performance exhibits an abrupt downward trend. Exceeding these harsh conditions, the anti-scuffing performances are maintained at a weak level.

- (3)

- Before the scoring occurs at the PRCL interface, the cast iron liner enters into a “polish wear” stage, and iron-based adhesive materials begin to form on the piston ring surface.

- (4)

- The plastic shearing cycle causes surface damages mainly due to adhesive effects for the NCM/Fe pairs, and abrasive effects for the CKS/Fe pairs.

Acknowledgements

Author Contributions

Conflicts of Interest

References

- Holmberg, K.; Andersson, P.; Nylund, N.; Makela, K.; Erdemir, A. Global energy consumption due to friction in trucks and buses. Tribol. Int. 2014, 78, 94–114. [Google Scholar] [CrossRef]

- Findik, F. Latest progress on tribological properties of industrial materials. Mater. Des. 2014, 57, 218–244. [Google Scholar] [CrossRef]

- Blok, H. The flash temperature concept. Wear 1963, 6, 483–494. [Google Scholar] [CrossRef]

- Czichos, H.; Kirschke, K. Investigations into film failure (transition point) of lubricated concentrated contacts. Wear 1972, 22, 321–336. [Google Scholar] [CrossRef]

- Rabinowicz, E. Friction seizure and galling seizure. Wear 1973, 25, 357–363. [Google Scholar] [CrossRef]

- Ludema, K.C. A review of scuffing and running-in of lubricated surfaces, with asperities and oxides in perspective. Wear 1984, 100, 315–331. [Google Scholar] [CrossRef]

- Enthoven, J.; Spikes, H.A. Infrared and visual study of the mechanisms of scuffing. Tribol. Trans. 1996, 39, 441–447. [Google Scholar] [CrossRef]

- Saeidi, F.; Taylor, A. A.; Meylan, B.; Hoffmann, P.; Wasmer, K. Origin of scuffing in grey cast iron-steel tribo-system. Mater. Des. 2017, 116, 622–630. [Google Scholar] [CrossRef]

- Kajita, S.; Yagi, K.; Izumi, T.; Koyamachi, J.; Tohyama, M.; Saito, K.; Sugimura, J. In situ X-ray diffraction study of phase transformation of steel in scuffing process. Tribol. Lett. 2015, 57, 6. [Google Scholar] [CrossRef]

- Yagi, K.; Ebisu, Y.; Sugimura, J.; Kajita, S.; Ohmori, T.; Suzuki, A. In situ observation of wear process before and during scuffing in sliding contact. Tribol. Lett. 2011, 43, 361–368. [Google Scholar] [CrossRef]

- Yagi, K.; Kajita, S.; Izumi, T.; Koyamachi, J.; Tohyama, M.; Saito, K.; Sugimura, J. Simultaneous synchrotron X-ray diffraction, near-infrared, and visible in situ observation of scuffing process of steel in sliding contact. Tribol. Lett. 2016, 61, 19. [Google Scholar] [CrossRef]

- Wojciechowski, L.; Kubiak, K.; Mathia, T.G. Roughness and wettability of surfaces in boundary lubricated scuffing wear. Tribol. Int. 2016, 93, 593–601. [Google Scholar] [CrossRef]

- Kamps, T.J.; Walker, J.C.; Wood, R.J.; Lee, P.M.; Plint, A.G. Scuffing mechanisms of EN-GJS 400-15 spheroidal graphite cast iron against a 52100 bearing steel in a PAO lubricated reciprocating contact. Wear 2017, 376, 1542–1551. [Google Scholar] [CrossRef]

- Ajayi, O.O.; Lorenzo-Martin, C.; Erck, R.A.; Fenske, G.R. Analytical predictive modeling of scuffing initiation in metallic materials in sliding contact. Wear 2013, 301, 57–61. [Google Scholar] [CrossRef]

- Öner, C.; Hazar, H.; Nursoy, M. Surface properties of CrN coated engine cylinders. Mater. Des. 2009, 30, 914–920. [Google Scholar] [CrossRef]

- Jisheng, E.; Gawne, D.T. Surface failure mechanisms of NCM steel under lubricated sliding. Wear 1997, 213, 123–130. [Google Scholar]

- Zeng, Z.; Zhang, J. Electrodeposition and tribological behavior of amorphous chromium-alumina composite coatings. Surf. Coat. Technol. 2008, 202, 2725–2730. [Google Scholar] [CrossRef]

- Lin, J.L.; Wei, R.H.; Bitsis, D.C.; Lee, P.M. Development and evaluation of low friction TiSiCN nanocomposite coatings for piston ring applications. Surf. Coat. Technol. 2016, 298, 121–131. [Google Scholar] [CrossRef]

- Wan, S.H.; Li, D.S.; Zhang, G.A.; Tieu, A.K.; Zhang, B. Comparison of the scuffing behaviour and wear resistance of candidate engineered coatings for automotive piston rings. Tribol. Int. 2017, 106, 10–22. [Google Scholar] [CrossRef]

- Shen, Y.; Jin, M.; Liu, Y.; Zhu, F. Characterization of friction condition transition by phase space trajectories. J. Tribol. Trans. ASME 2017, 139, 034501. [Google Scholar] [CrossRef]

- Bhushan, B. Principles and Applications of Tribology, 2nd ed.; Wiley: New York, NY, USA, 2013; pp. 315–396. [Google Scholar]

- Olander, P.; Jacobson, S. Scuffing resistance testing of piston ring materials for marine two-stroke diesel engines and mapping of the operating mechanisms. Wear 2015, 330, 42–48. [Google Scholar] [CrossRef]

| Elements | Fe | Cu | Al | Pb | Ni | Si | Ca | Mg | P | Zn |

|---|---|---|---|---|---|---|---|---|---|---|

| Content (ppm) | 24 | 13 | 5 | 3 | 7 | 19 | 7200 | 21 | 757 | 406 |

| Experimental Stage | Nominal Pressure (MPa) | Speed (r/min) | Temperature (°C) | Time (min) |

|---|---|---|---|---|

| RLL | 10 | 200 | 120 | ~15 |

| RHL | 40, 60, 80, 100 | 200 | 180, 200, 220, 250 | ~85 |

| OS | 40, 60, 80, 100 | 200 | 180, 200, 220, 250 | To scuffing |

| Temperature (°C) | Nominal Pressure (MPa) | |||

|---|---|---|---|---|

| 40 | 60 | 80 | 100 | |

| 180 | 36.0 ± 1.0 | 18.7 ± 2.7 | 6.0 ± 0.0 | 5.7 ± 0.7 |

| 200 | 29.7 ± 1.7 | 13.3 ± 2.3 | 5.3 ± 0.7 | 3.3 ± 0.7 |

| 220 | 9.3 ± 1.7 | 5.0 ± 0.0 | 4.7 ± 0.7 | 2.7 ± 0.7 |

| 250 | 5.3 ± 0.7 | 4.0 ± 0.0 | 3.3 ± 0.7 | 2.3 ± 0.7 |

| Temperature (°C) | Nominal Pressure (MPa) | |||

|---|---|---|---|---|

| 40 | 60 | 80 | 100 | |

| 180 | 79.3 ± 3.7 | 22.3 ± 1.7 | 11.0 ± 1.0 | 5.7 ± 0.7 |

| 200 | 32.7 ± 2.7 | 13.7 ± 1.3 | 6.3 ± 0.7 | 5.0 ± 0.0 |

| 220 | 10.7 ± 1.7 | 8.7 ± 0.7 | 5.3 ± 0.7 | 3.7 ± 0.7 |

| 250 | 7.3 ± 0.7 | 8.3 ± 0.7 | 5.0 ± 0.0 | 3.3 ± 0.7 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shen, Y.; Yu, B.; Lv, Y.; Li, B. Comparison of Heavy-Duty Scuffing Behavior between Chromium-Based Ceramic Composite and Nickel-Chromium-Molybdenum-Coated Ring Sliding against Cast Iron Liner under Starvation. Materials 2017, 10, 1176. https://doi.org/10.3390/ma10101176

Shen Y, Yu B, Lv Y, Li B. Comparison of Heavy-Duty Scuffing Behavior between Chromium-Based Ceramic Composite and Nickel-Chromium-Molybdenum-Coated Ring Sliding against Cast Iron Liner under Starvation. Materials. 2017; 10(10):1176. https://doi.org/10.3390/ma10101176

Chicago/Turabian StyleShen, Yan, Baihong Yu, Yutao Lv, and Bin Li. 2017. "Comparison of Heavy-Duty Scuffing Behavior between Chromium-Based Ceramic Composite and Nickel-Chromium-Molybdenum-Coated Ring Sliding against Cast Iron Liner under Starvation" Materials 10, no. 10: 1176. https://doi.org/10.3390/ma10101176

APA StyleShen, Y., Yu, B., Lv, Y., & Li, B. (2017). Comparison of Heavy-Duty Scuffing Behavior between Chromium-Based Ceramic Composite and Nickel-Chromium-Molybdenum-Coated Ring Sliding against Cast Iron Liner under Starvation. Materials, 10(10), 1176. https://doi.org/10.3390/ma10101176