A Microwave Thermostatic Reactor for Processing Liquid Materials Based on a Heat-Exchanger

Abstract

:1. Introduction

2. Methodology

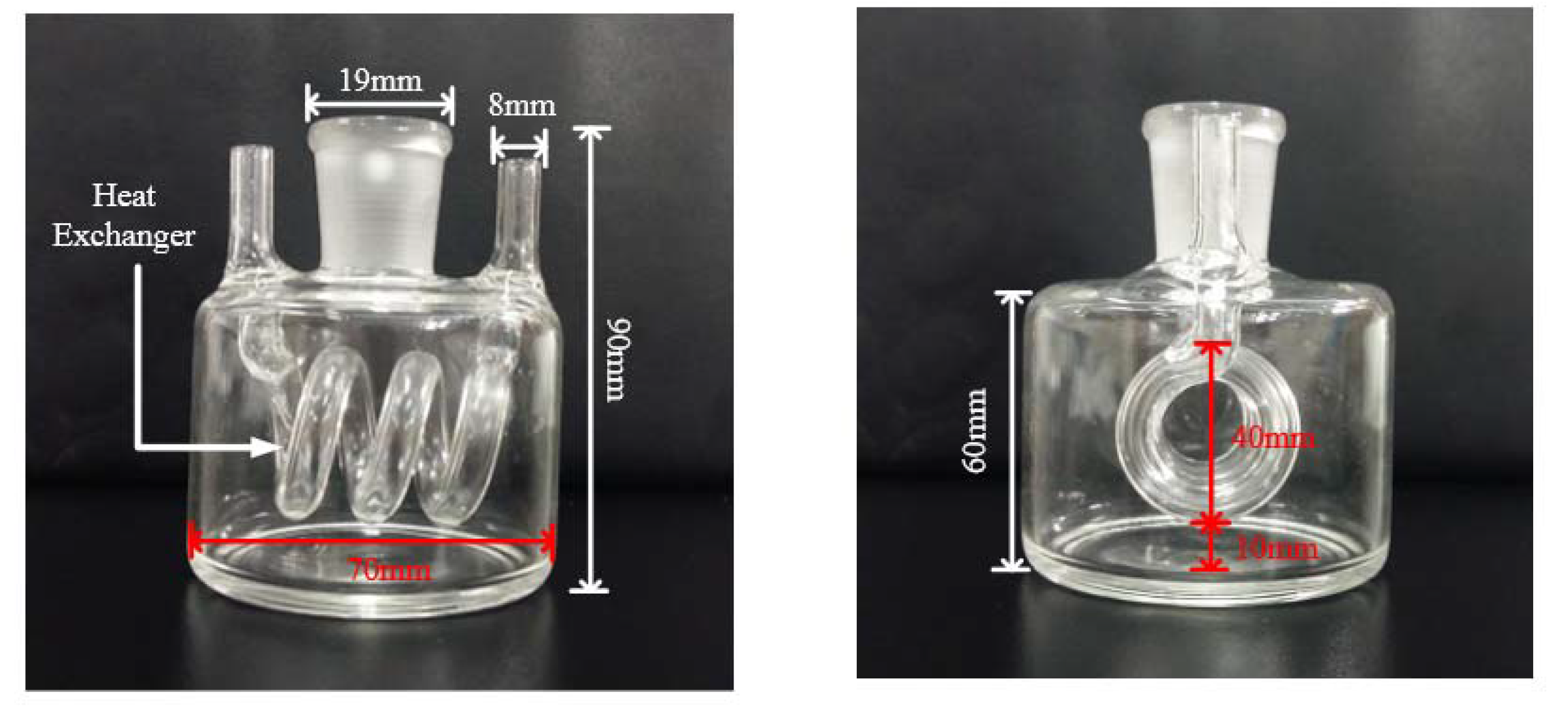

2.1. Microwave Reactor with Heat-Exchanger

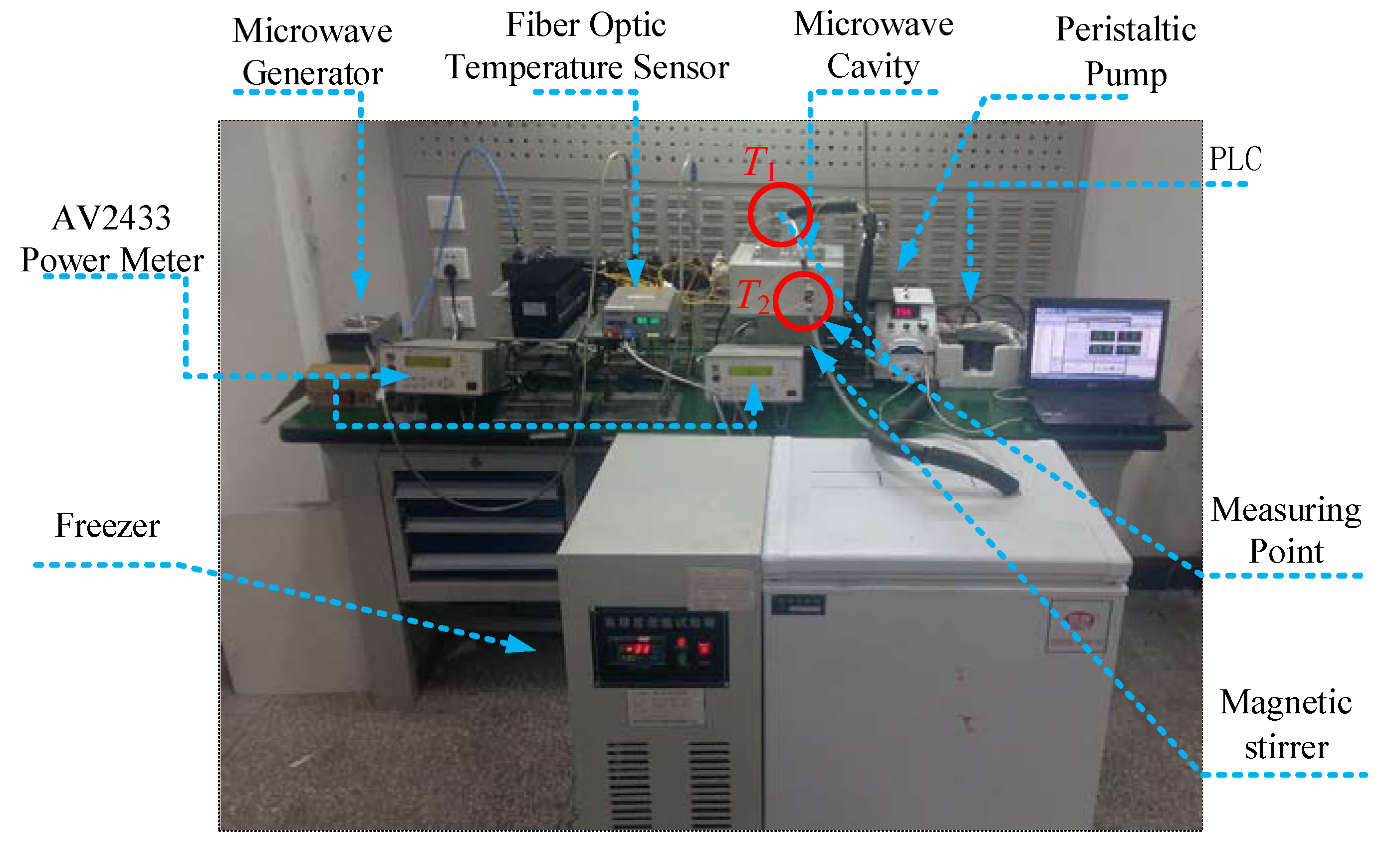

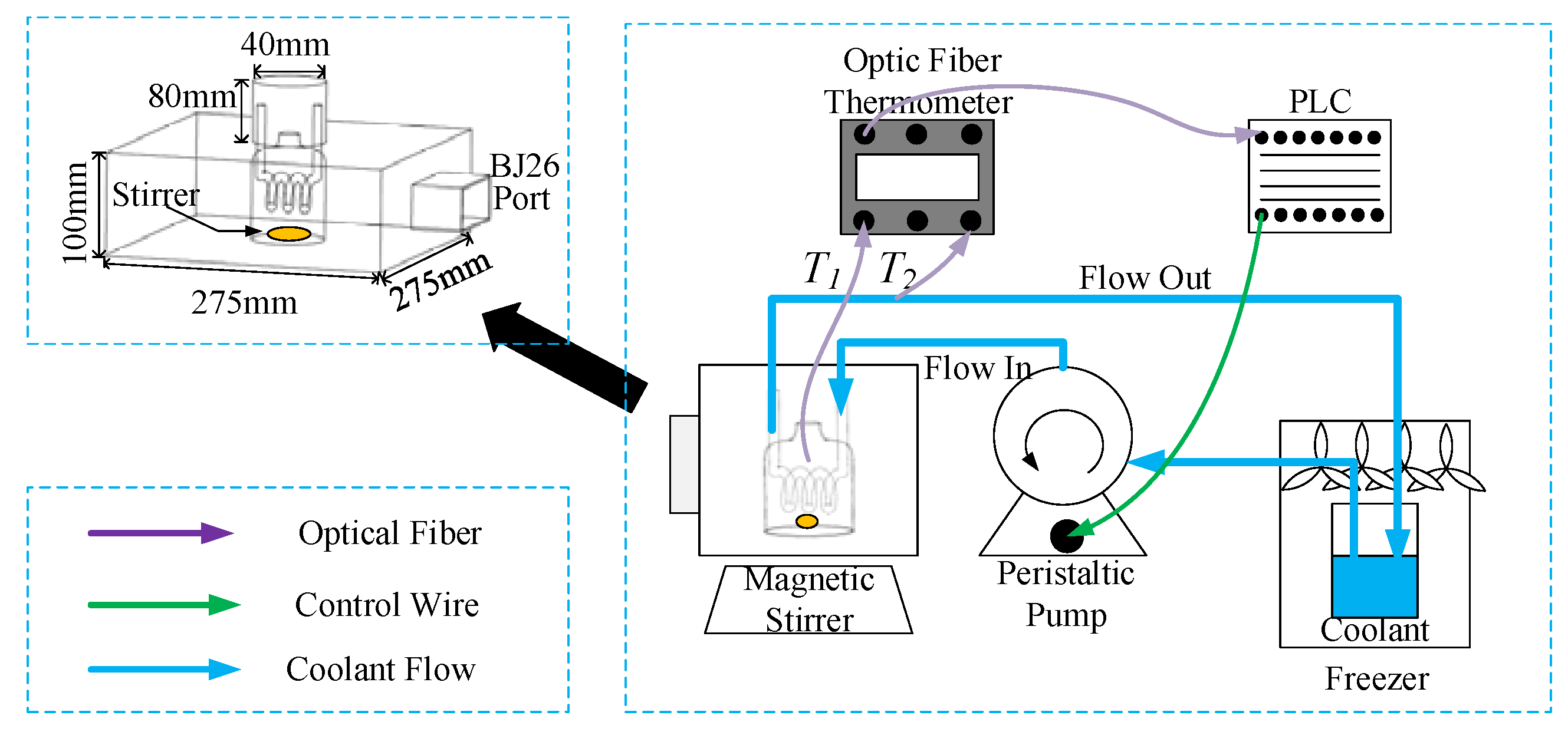

2.2. Experimental Setup

2.3. PID Controller

3. Results and Discussion

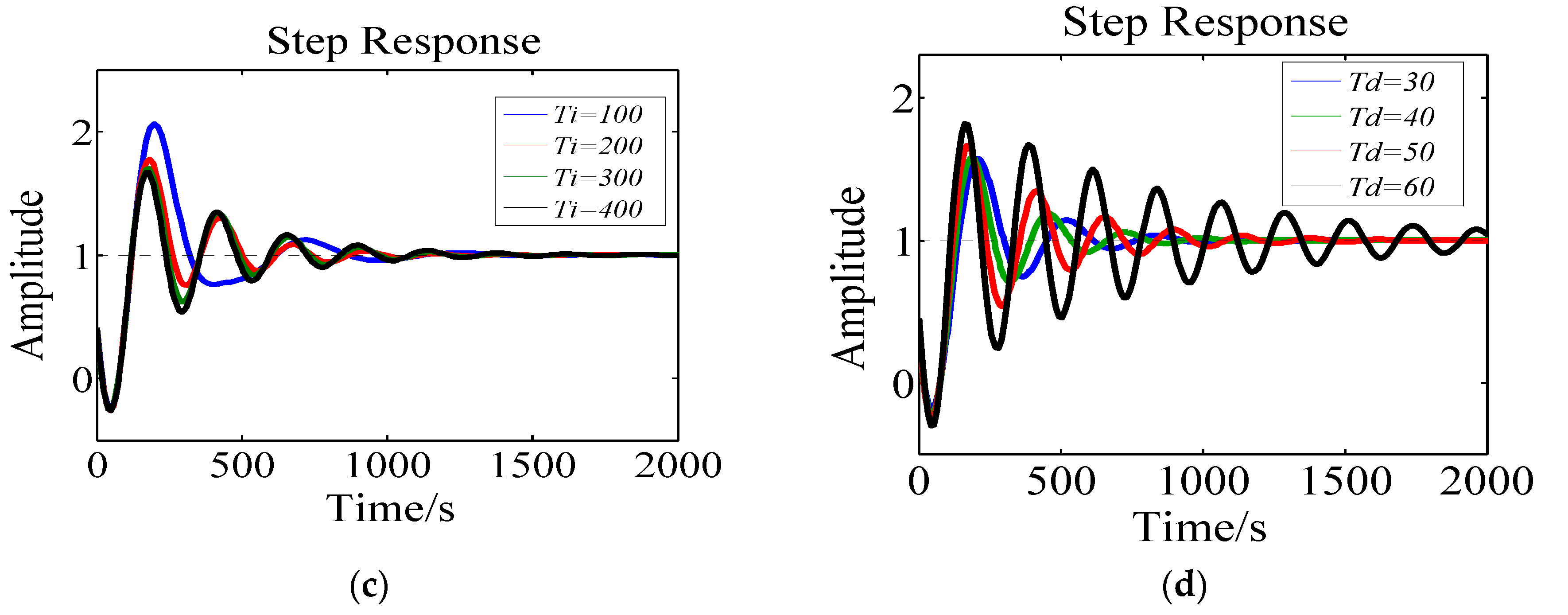

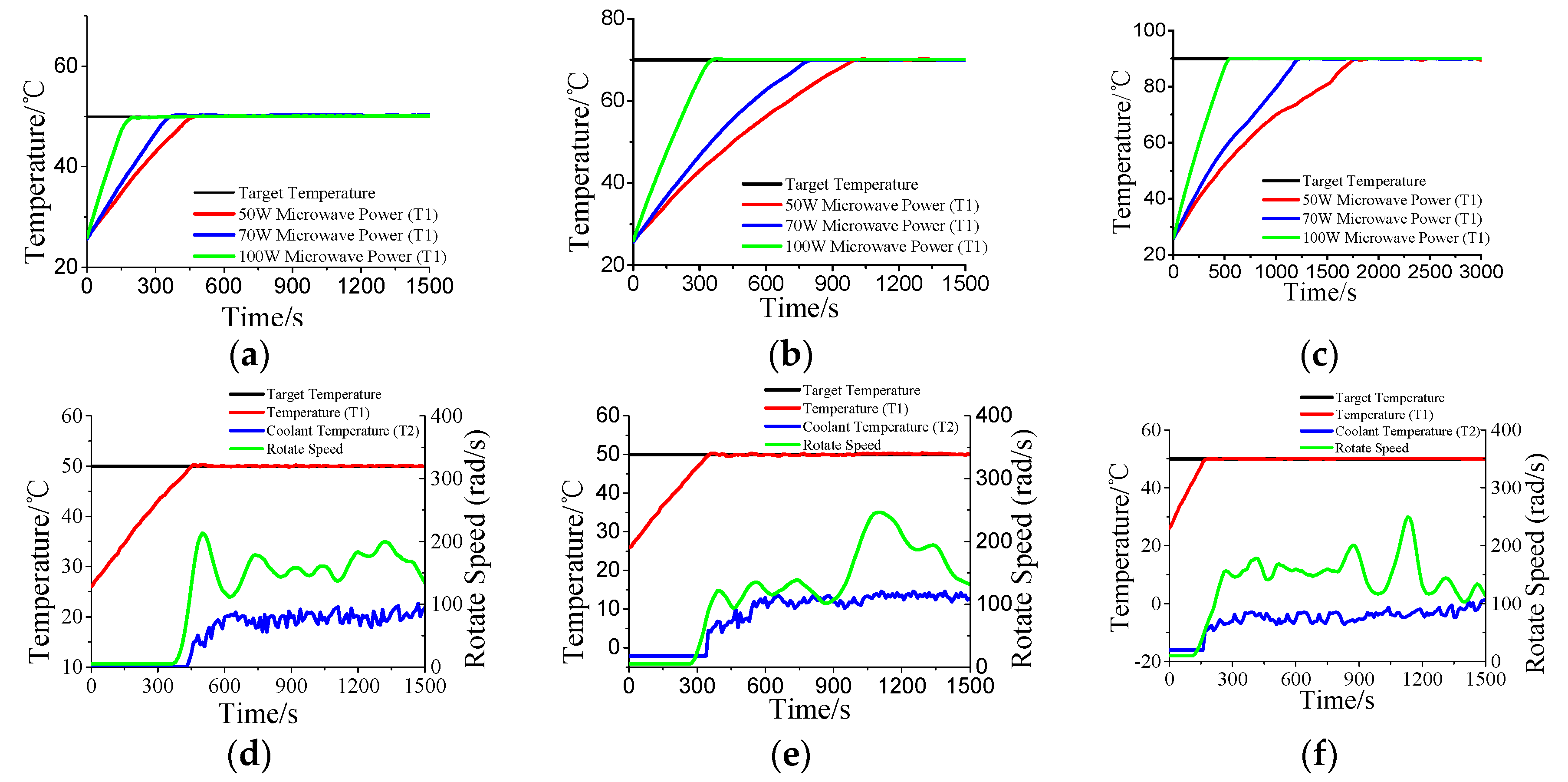

3.1. Parameter Tuning

3.2. Temperature Control for Water

3.3. Temperature Control for Other Liquid

4. Conclusions

- (1)

- A reactor for processing the liquid materials under the same temperature but different microwave power are designed.

- (2)

- Different materials are used to test the control performance of the reactor, indicating that it can control the system temperature accurately.

- (3)

- The reactor can be used to detect the special effect of electric field or microwaves on material properties, moreover, it will be helpful to detect the reaction kinetics parameters of the systems under microwaves.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Galema, S.A. Microwave chemistry. Chem. Soc. Rev. 1997, 26, 233–238. [Google Scholar] [CrossRef]

- Kappe, C.O. Microwave dielectric heating in synthetic organic chemistry. Chem. Soc. Rev. 2008, 37, 1127–1139. [Google Scholar] [CrossRef] [PubMed]

- Estel, L.; Poux, M.; Benamara, N.; Polaert, I. Continuous flow-microwave reactor: Where are we? Chem. Eng. Process. Process Intensif. 2017, 113, 56–64. [Google Scholar] [CrossRef]

- Patil, N.G.; Benaskar, F.; Meuldijk, J.; Hulshof, L.A.; Hessel, V.; Schoutern, J.C.; Esveld, E.D.C.; Rebrov, E.V. Microwave assisted flow synthesis: Coupling of electromagnetic and hydrodynamic phenomena. AIChE J. 2014, 60, 3824–3832. [Google Scholar] [CrossRef]

- Raner, K.D.; Strauss, C.R.; Trainor, R.W.; Thorn, J.S. A new microwave reactor for batchwise organic synthesis. J. Org. Chem. 1995, 60, 2456–2460. [Google Scholar] [CrossRef]

- Ye, J.; Hong, T.; Wu, Y.; Wu, L.; Liao, Y.; Zhu, H.; Yang, Y.; Huang, K. Model Stirrer Based on a Multi-Material Turntable for Microwave Processing Materials. Materials 2017, 10, 95. [Google Scholar] [CrossRef] [PubMed]

- Xia, T.; Zhang, C.; Oyler, N.A.; Chen, X. Hydrogenated TiO2 nanocrystals: A novel microwave absorbing material. Adv. Mater. 2013, 25, 6905–6910. [Google Scholar] [CrossRef] [PubMed]

- Hesas, R.H.; Daud, W.M.A.W.; Sahu, J.N.; Arami-Niya, A. The effects of a microwave heating method on the production of activated carbon from agricultural waste: A review. J. Anal. Appl. Pyrolysis 2013, 100, 1–11. [Google Scholar] [CrossRef]

- Kim, T.; Lee, J.; Lee, K.H. Microwave heating of carbon-based solid materials. Carbon Lett. 2014, 15, 15–24. [Google Scholar] [CrossRef]

- Rosana, M.R.; Hunt, J.; Ferrari, A.; Southworth, T.A.; Tao, Y.; Stiegman, A.E.; Dudley, G.B. Microwave-specific acceleration of a Friedel–Crafts reaction: Evidence for selective heating in homogeneous solution. J. Org. Chem. 2014, 79, 7437–7450. [Google Scholar] [CrossRef] [PubMed]

- Zhao, W.; Chen, J.; Chang, X.; Guo, S.; Srinivasakannan, C.; Chen, G.; Peng, J. Effect of microwave irradiation on selective heating behavior and magnetic separation characteristics of Panzhihua ilmenite. Appl. Surf. Sci. 2014, 300, 171–177. [Google Scholar] [CrossRef]

- Mitani, T.; Hasegawa, N.; Nakajima, R.; Shinohara, N.; Nozaki, Y.; Chikata, T.; Watanabe, T. Development of a wideband microwave reactor with a coaxial cable structure. Chem. Eng. J. 2016, 299, 209–216. [Google Scholar] [CrossRef]

- Bykov, Y.V.; Rybakov, K.I.; Semenov, V.E. High-temperature microwave processing of materials. J. Phys. D Appl. Phys. 2001, 34, R55. [Google Scholar] [CrossRef]

- Ma, C.; Liu, T.; Yang, L.; Zu, Y.; Chen, X.; Zhang, L.; Zhang, Y.; Zhao, C. Ionic liquid-based microwave-assisted extraction of essential oil and biphenyl cyclooctene lignans from Schisandra chinensis Baill fruits. J. Chromatogr. A 2011, 1218, 8573–8580. [Google Scholar] [CrossRef] [PubMed]

- Leadbeater, N.E.; Stencel, L.M. Fast, easy preparation of biodiesel using microwave heating. Energy Fuels 2006, 20, 2281–2283. [Google Scholar] [CrossRef]

- Lin, Y.C.; Yang, P.M.; Chen, S.C.; Lin, J.F. Improving biodiesel yields from waste cooking oil using ionic liquids as catalysts with a microwave heating system. Fuel Process. Technol. 2013, 115, 57–62. [Google Scholar] [CrossRef]

- Rosi, L.; Bartoli, M.; Undri, A.; Frediani, M.; Frediani, P. Synthesis of dianols or BPA through catalytic hydrolyisis/glycolysis of waste polycarbonates using a microwave heating. J. Mol. Catal. A Chem. 2015, 408, 278–286. [Google Scholar] [CrossRef]

- Booske, J.H.; Cooper, R.F.; Freeman, S.A. Microwave enhanced reaction kinetics in ceramics. Mater. Res. Innov. 1997, 1, 77–84. [Google Scholar] [CrossRef]

- Sun, H.; Huang, K. Experimental study of dielectric property changes in DMSO–primary alcohol mixtures under low-intensity microwaves. RSC Adv. 2015, 5, 61031–61034. [Google Scholar] [CrossRef]

- Clary, C.D.; Mejia-Meza, E.; Wang, S.; Petrucci, V.E. Improving grape quality using microwave vacuum drying associated with temperature control. J. Food Sci. 2007, 72, E023–E028. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Raghavan, G.S.V.; Orsat, V. Temperature and power control in microwave drying. J. Food Eng. 2010, 97, 478–483. [Google Scholar] [CrossRef]

- Yang, X.; Huang, K. Study on the key problems of interaction between microwave and chemical reaction. Front. Electr. Electron. Eng. China 2007, 2, 473–480. [Google Scholar] [CrossRef]

- De la Hoz, A.; Diaz-Ortiz, A.; Moreno, A. Microwaves in organic synthesis. Thermal and non-thermal microwave effects. Chem. Soc. Rev. 2005, 34, 164–178. [Google Scholar] [CrossRef] [PubMed]

- Huang, K.; Yang, X.; Hua, W.; Jia, G.; Yang, L. Experimental evidence of a microwave non-thermal effect in electrolyte aqueous solutions. New J. Chem. 2009, 33, 1486–1489. [Google Scholar] [CrossRef]

- Ahirwar, R.; Tanwar, S.; Bora, U.; Nahar, P. Microwave non-thermal effect reduces ELISA timing to less than 5 minutes. RSC Adv. 2016, 6, 20850–20857. [Google Scholar] [CrossRef]

- Hinrikus, H.; Lass, J.; Karai, D.; Pilt, K.; Bachmann, M. Microwave effect on diffusion: A possible mechanism for non-thermal effect. Electromagn. Biol. Med. 2015, 34, 327–333. [Google Scholar] [CrossRef] [PubMed]

- Bhattacharjee, M.K.; Delsol, J.K. Does microwave sterilization of growth media involve any non-thermal effect? J. Microbiol. Methods 2014, 96, 70–72. [Google Scholar] [CrossRef] [PubMed]

- Tang, Z.M.; Huang, K.M.; Liao, Y.H.; Hong, T.; Zhu, H.-C. Study on stability of electric field in multimode microwave heating cavity. Int. J. Appl. Electromag. Mech. 2016, 50, 321–330. [Google Scholar] [CrossRef]

- Ang, K.H.; Chong, G.; Li, Y. PID control system analysis, design, and technology. IEEE Trans. Control Syst. Technol. 2005, 13, 559–576. [Google Scholar]

- Baser, E.; Altun, Y. The estimation of PID controller parameters of vector controlled induction motor using Ziegler–Nichols method. J. Eng. Res. Appl. Sci. 2015, 4, 278–282. [Google Scholar]

- Azar, A.T.; Serrano, F.E. Design and modeling of anti wind up PID controllers. In Complex System Modelling and Control Through Intelligent Soft Computations; Springer: Cham, Switzerland, 2015; pp. 1–44. [Google Scholar]

- Thamma, M.; Homchat, K. Real-time implementation of self-tuning fuzzy PID controller for FOPDT system base on microcontroller STM32. In Proceedings of the 2017 2nd International Conference on Control and Robotics Engineering (ICCRE), Bangkok, Thailand, 1–3 April 2017; pp. 130–134. [Google Scholar]

- Padula, F.; Visioli, A. On the fragility of fractional-order PID controllers for FOPDT processes. ISA Trans. 2016, 60, 228–243. [Google Scholar] [CrossRef] [PubMed]

- Deshpande, S.S.; Kadu, C.B. Design of multi scale PID controller for Temperature process. In Proceedings of the International Conference on Automatic Control and Dynamic Optimization Techniques (ICACDOT), Pune, India, 9–10 September 2016; pp. 582–585. [Google Scholar]

- Neath, M.J.; Swain, A.K.; Madawala, U.K.; Thrimawithana, D.J. An optimal PID controller for a bidirectional inductive power transfer system using multiobjective genetic algorithm. IEEE Trans. Power Electron. 2014, 29, 1523–1531. [Google Scholar] [CrossRef]

- Åström, K.J.; Hägglund, T. PID controllers: theory, design, and tuning. Research Triangle Park, NC: Isa, 1995; Volume 2. [Google Scholar]

- Åström, K.J.; Hägglund, T. Revisiting the Ziegler–Nichols step response method for PID control. J. Process Control 2004, 14, 635–650. [Google Scholar]

- Liu, J. MATLAB Simulation of Advanced PID Control; Publishing House of Electronics Industry: Beijing, China, 2004. [Google Scholar]

- Scherlozer, A.; Orsini, M.; Patole, S. Simulation and Numerical Analysis and Comparative Study of a PID Controller Based on Ziegler–Nichols and Auto Turning Method. In Proceedings of the 12th IEEE International Conference on Control and Automation, Kathmandu, Nepal, 1–3 June 2016. [Google Scholar]

- Srivastava, N.; Tanti, D.K.; Ahmad, M.A. MATLAB simulation of temperature control of heat exchanger using different controllers. Autom. Control Intell. Syst. 2014, 2, 1–5. [Google Scholar] [CrossRef]

| Parameters | Kp | Ti | Td | |

|---|---|---|---|---|

| Power/W | ||||

| 50 | 70 | 650 | 185 | |

| 70 | 42 | 340 | 85 | |

| 100 | 30 | 200 | 50 | |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, Y.; Zhang, C.; Xie, T.; Hong, T.; Zhu, H.; Yang, Y.; Liu, C.; Huang, K. A Microwave Thermostatic Reactor for Processing Liquid Materials Based on a Heat-Exchanger. Materials 2017, 10, 1160. https://doi.org/10.3390/ma10101160

Zhou Y, Zhang C, Xie T, Hong T, Zhu H, Yang Y, Liu C, Huang K. A Microwave Thermostatic Reactor for Processing Liquid Materials Based on a Heat-Exchanger. Materials. 2017; 10(10):1160. https://doi.org/10.3390/ma10101160

Chicago/Turabian StyleZhou, Yongqiang, Chun Zhang, Tian Xie, Tao Hong, Huacheng Zhu, Yang Yang, Changjun Liu, and Kama Huang. 2017. "A Microwave Thermostatic Reactor for Processing Liquid Materials Based on a Heat-Exchanger" Materials 10, no. 10: 1160. https://doi.org/10.3390/ma10101160

APA StyleZhou, Y., Zhang, C., Xie, T., Hong, T., Zhu, H., Yang, Y., Liu, C., & Huang, K. (2017). A Microwave Thermostatic Reactor for Processing Liquid Materials Based on a Heat-Exchanger. Materials, 10(10), 1160. https://doi.org/10.3390/ma10101160