On the Material Characterisation of Wind Turbine Blade Coatings: The Effect of Interphase Coating–Laminate Adhesion on Rain Erosion Performance

Abstract

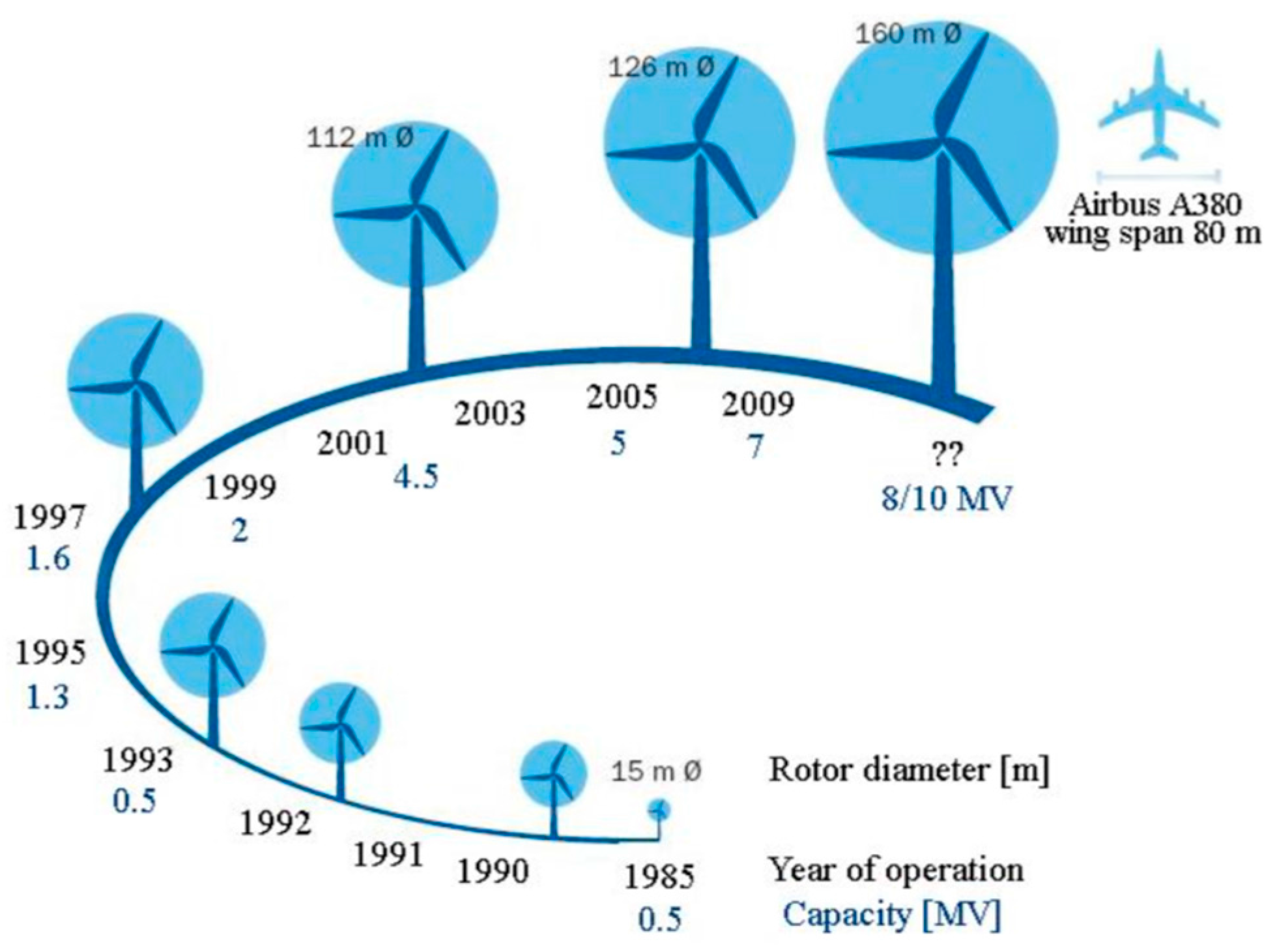

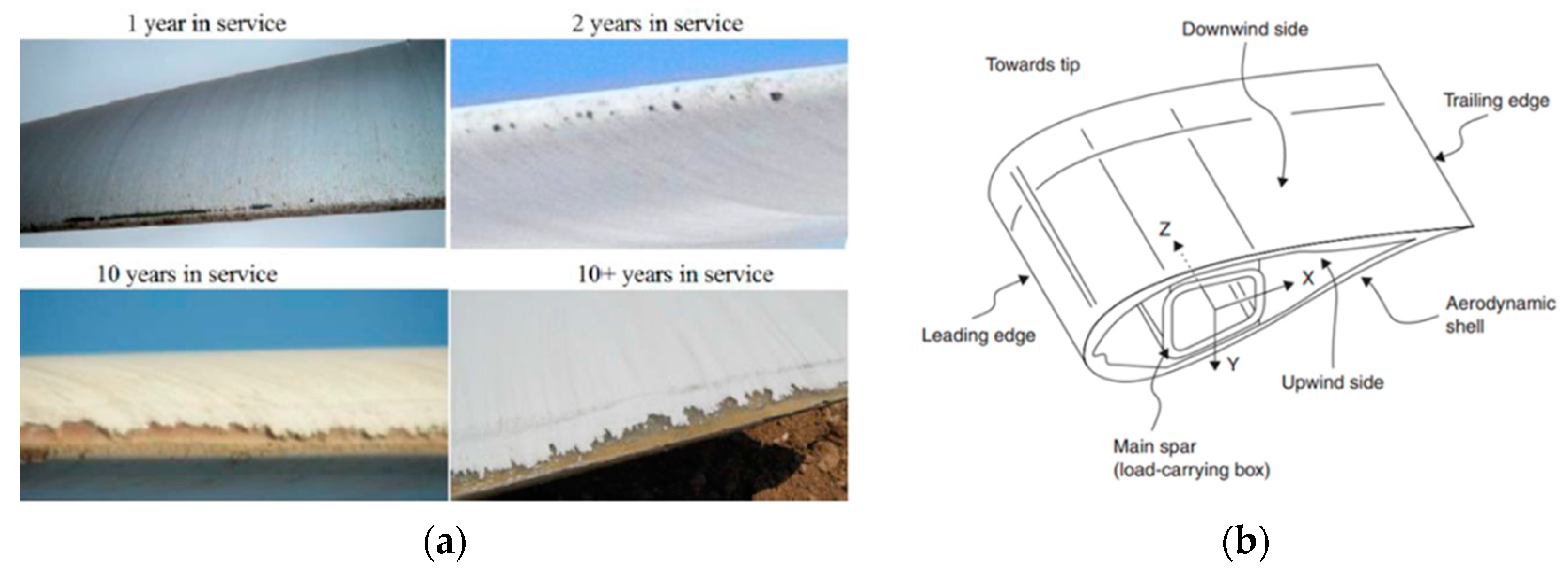

:1. Introduction

2. Materials and Manufacturing Approach

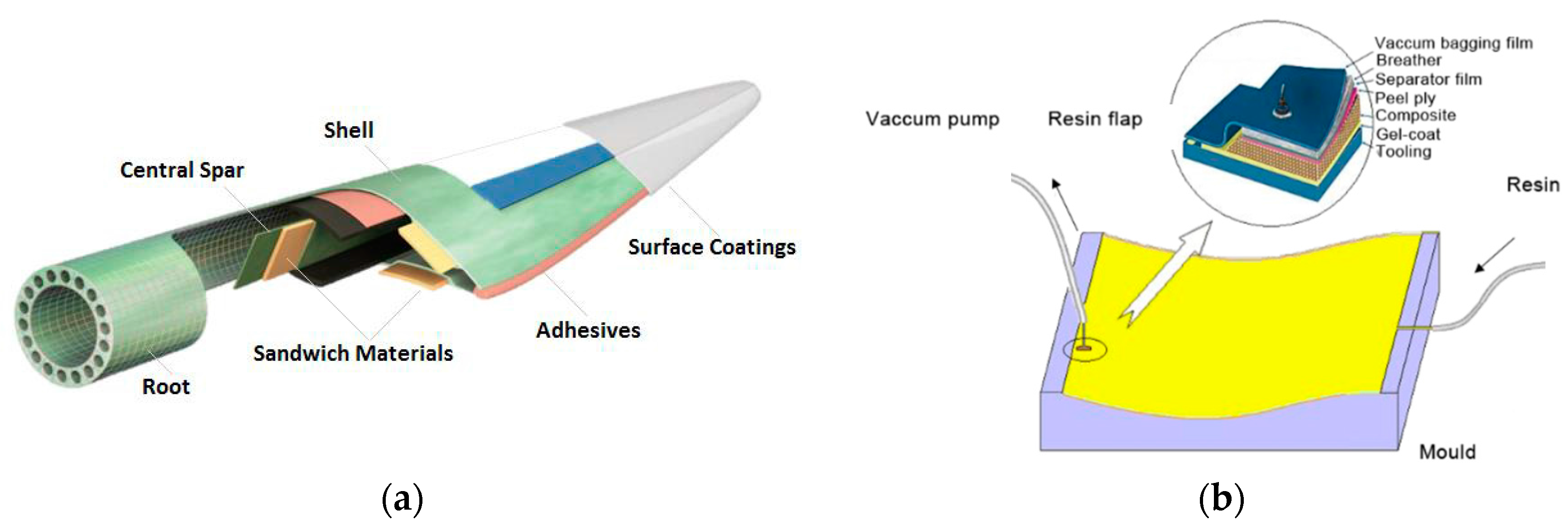

2.1. Infusion-Based Blade Manufacturing

2.2. Coating Technologies

- In-mould coatings use a similar material to the composite matrix substrate, i.e., epoxy/polyester. The in-mould coating plays a key role in the product performance of the whole blade part and is used in liquid composite moulding processes. The ease of integration into the blade manufacturing process makes it advantageous, as it simplifies and reduces the cost of applying the coating system. An appropriate in-mould gel coating needs to meet the blade processing window requirements. The finished product must be adequately bonded to the reinforcement, have an appropriate surface finish and provide long-term protection [18].

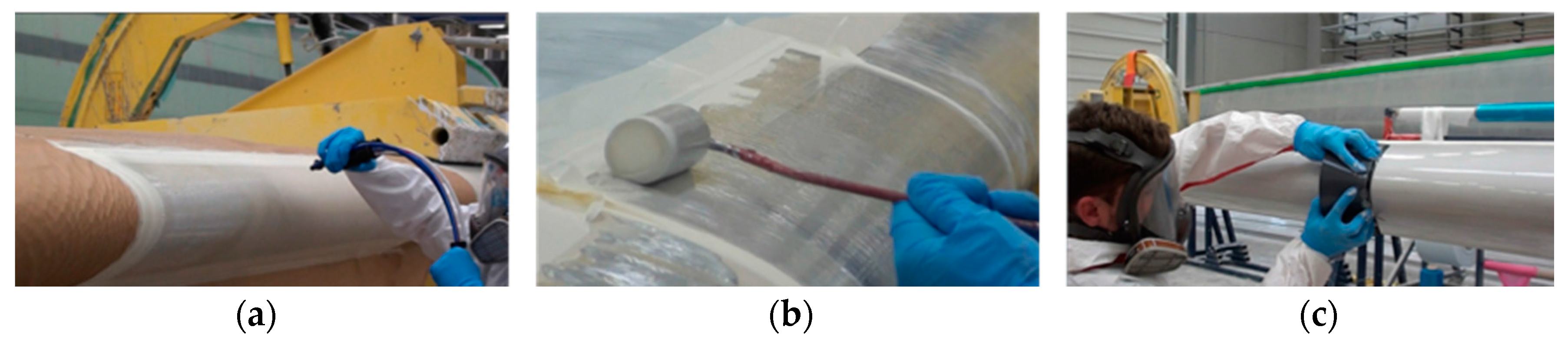

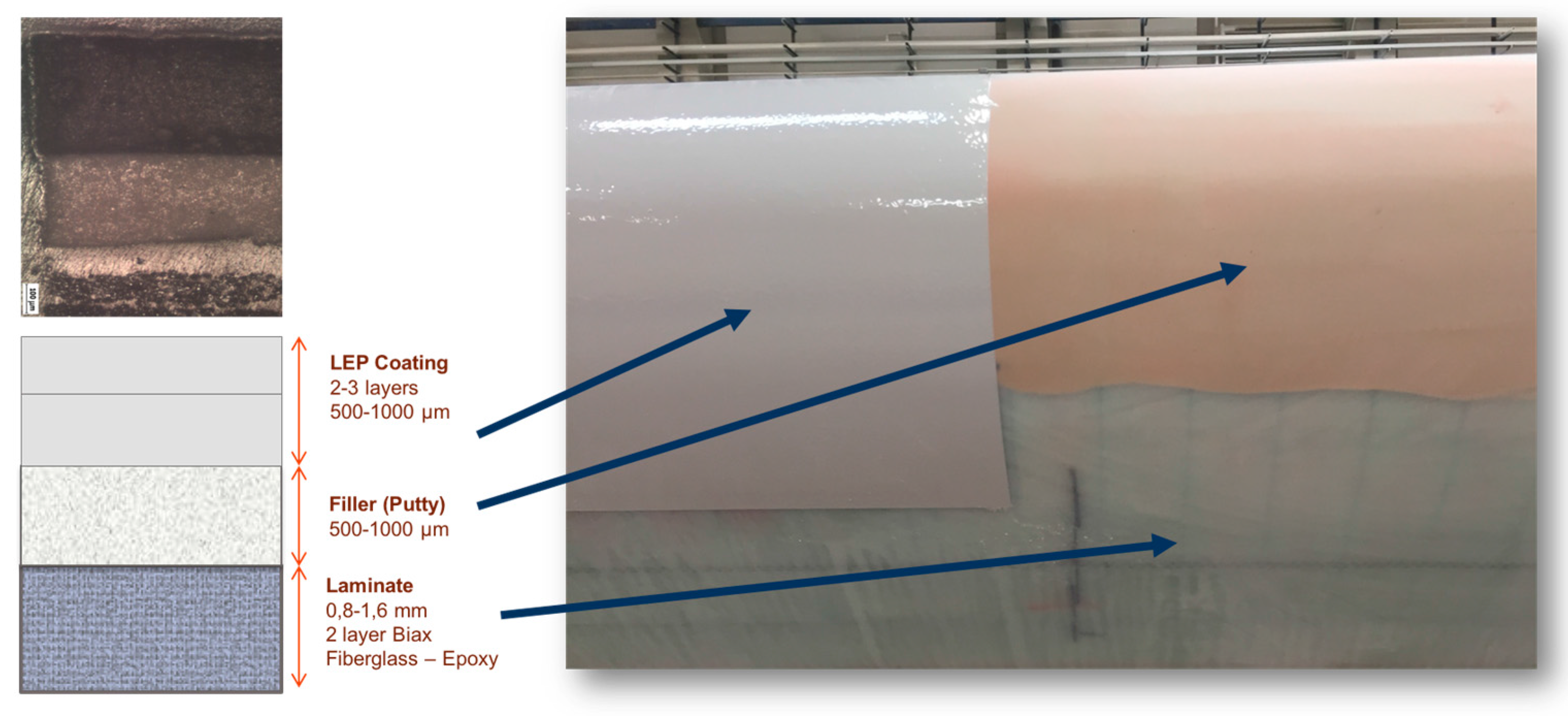

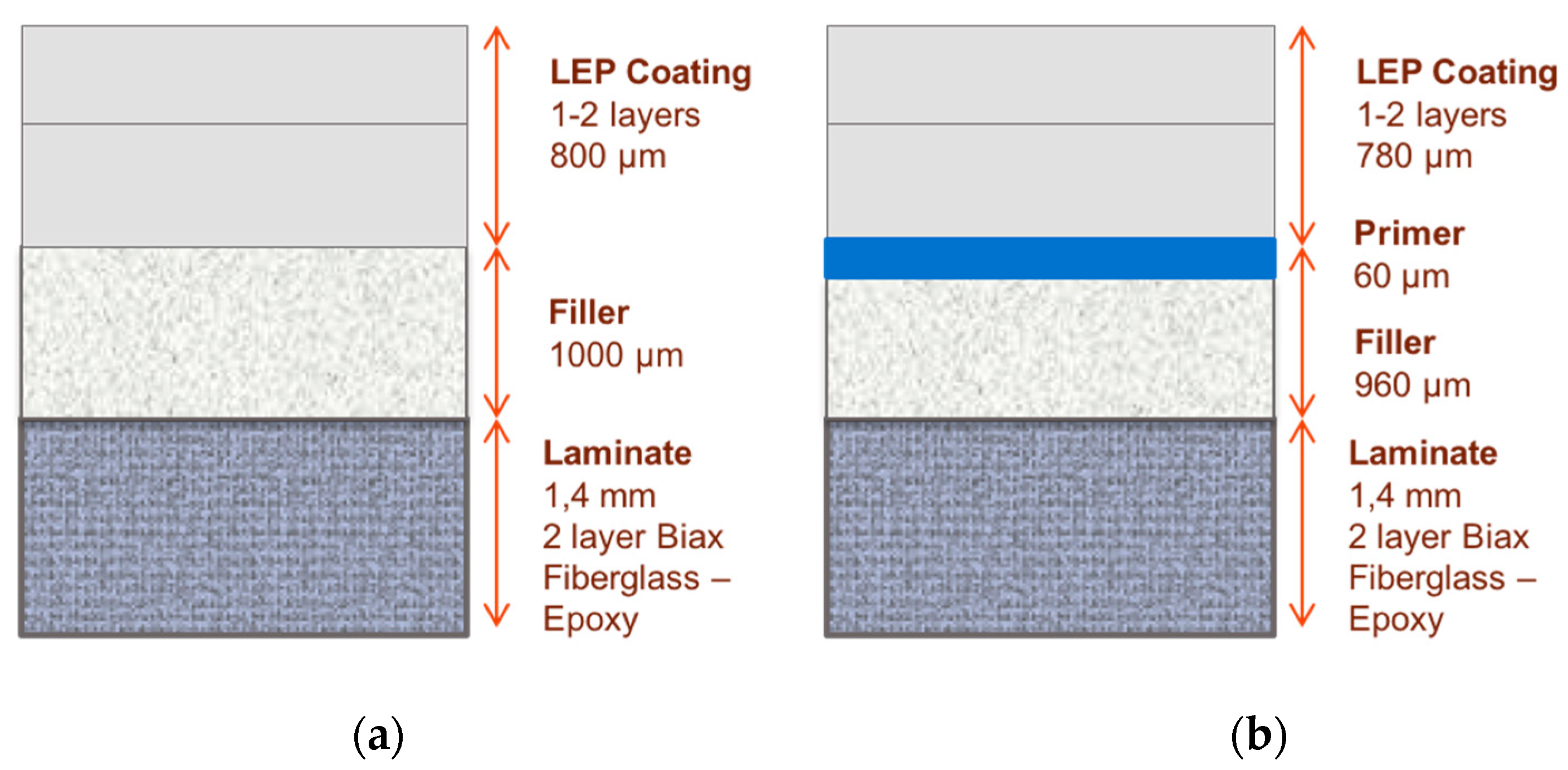

- A post-mould application, through painting or spraying, has different flexible materials to choose from, a polyurethane-based coating for example, see Figure 5. Post-mould application is typically used to apply Leading Edge Protection (LEP) in locations where the threat of rain erosion is a concern. Industrial processes state that LEP systems can be outlined as a multi-layered system, where some manufacturers include a putty layer between the laminate and the coating. Some manufacturers also include a primer layer under the coating and over the putty to improve adhesion. Depending on each industrial solution, the inclusion of interfaces may accelerate erosion by delaminating between layers (to be discussed further in the next section)—see Figure 6. Applications with fewer coating layers are recommended because of the robustness of the process and the reduction of interfaces. The coating application procedure is designed with the final material properties in mind (i.e., thickness, number of coating layers, surface roughness, temperature, humidity, viscosity, processing time, curing time, etc.)—see Figure 5. Specific post-mould application methods and materials are similarly employed when repairing a damaged area, during a service or as part of a prevention maintenance programme. The repair of the leading edge damage is most frequently achieved through the unsophisticated application of a primer-based layer and putty materials, smoothed over, and then cured to generate a new uniform and smooth surface finished to the affected blade zone—see Figure 7. The coating manufacturer, however, can only guarantee the performance of such materials when applied in very specific environmental conditions.

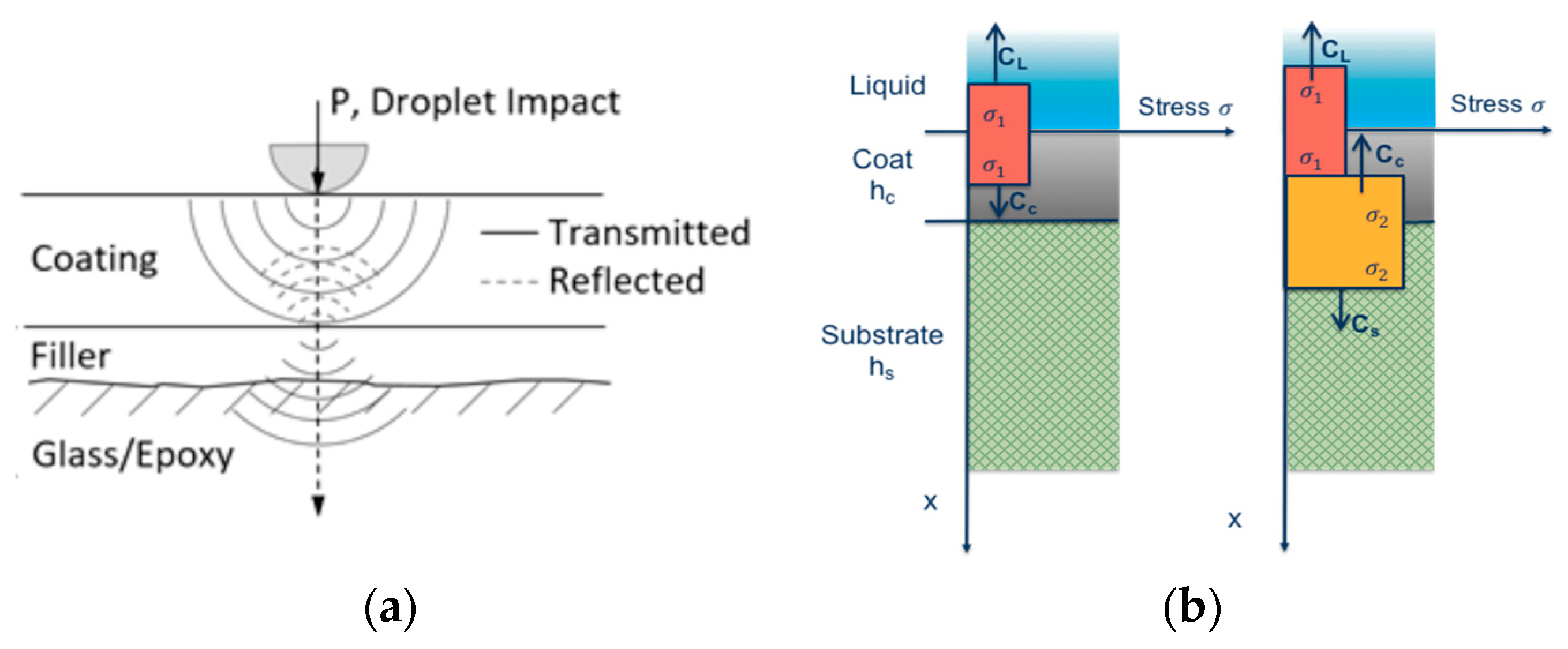

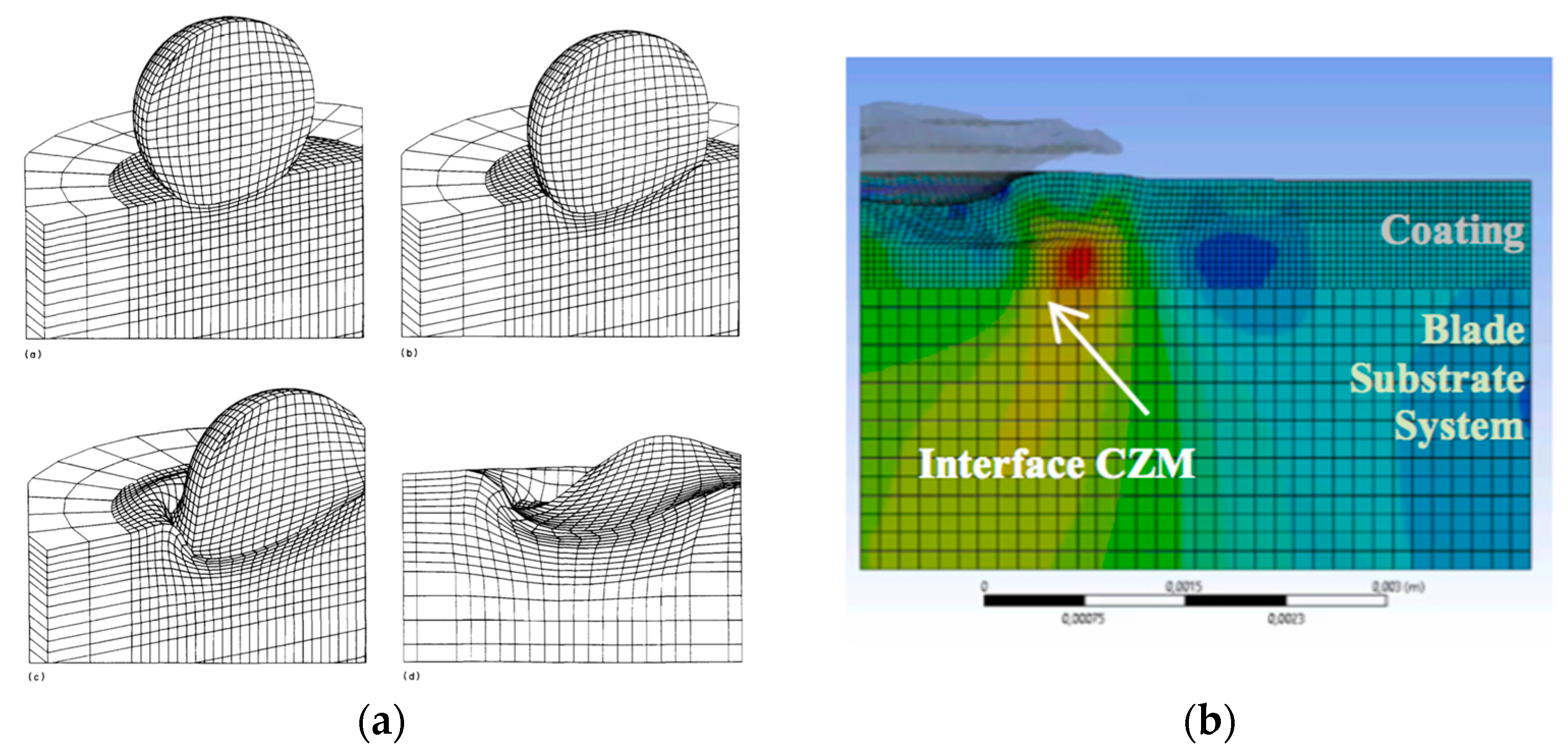

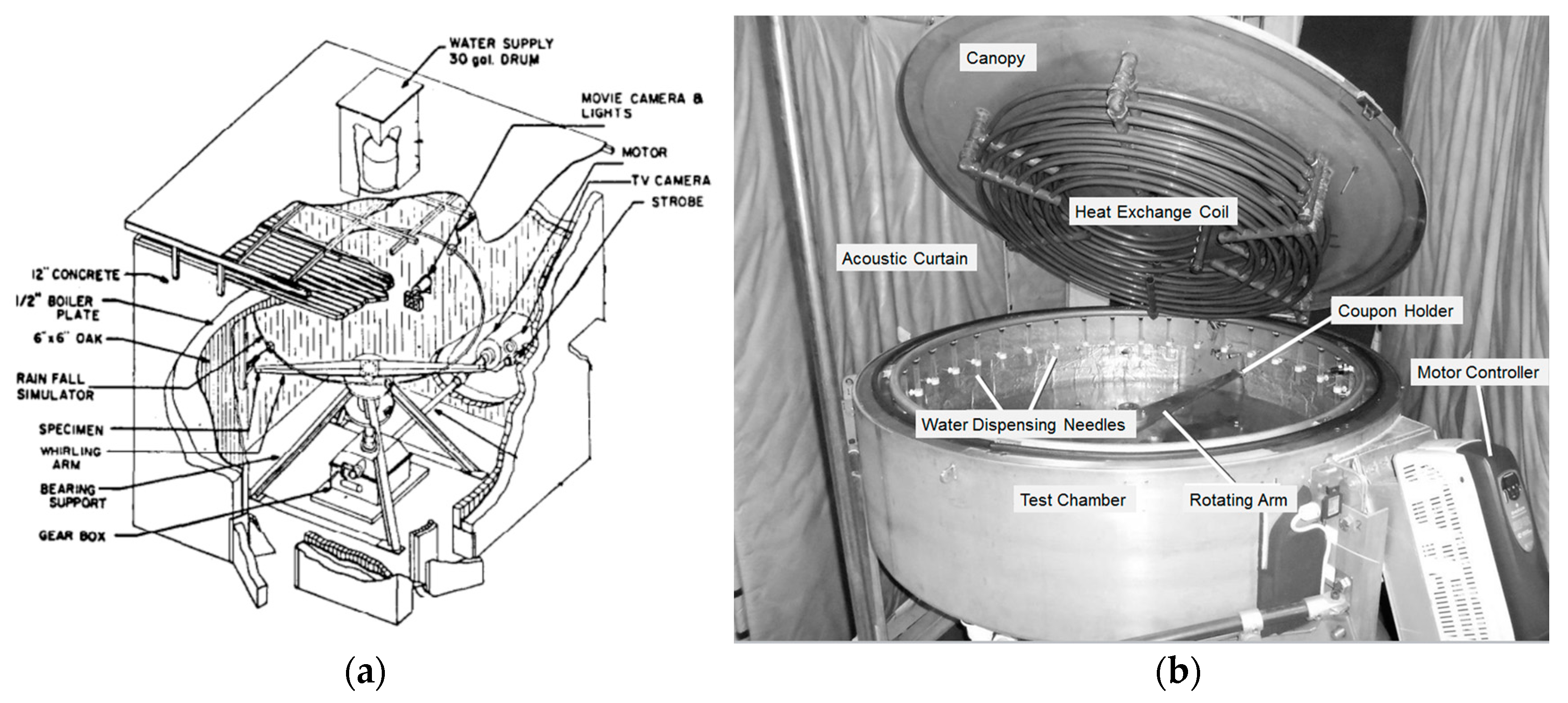

3. Modelling of a Liquid Drop Impact on Wind Turbine Blades

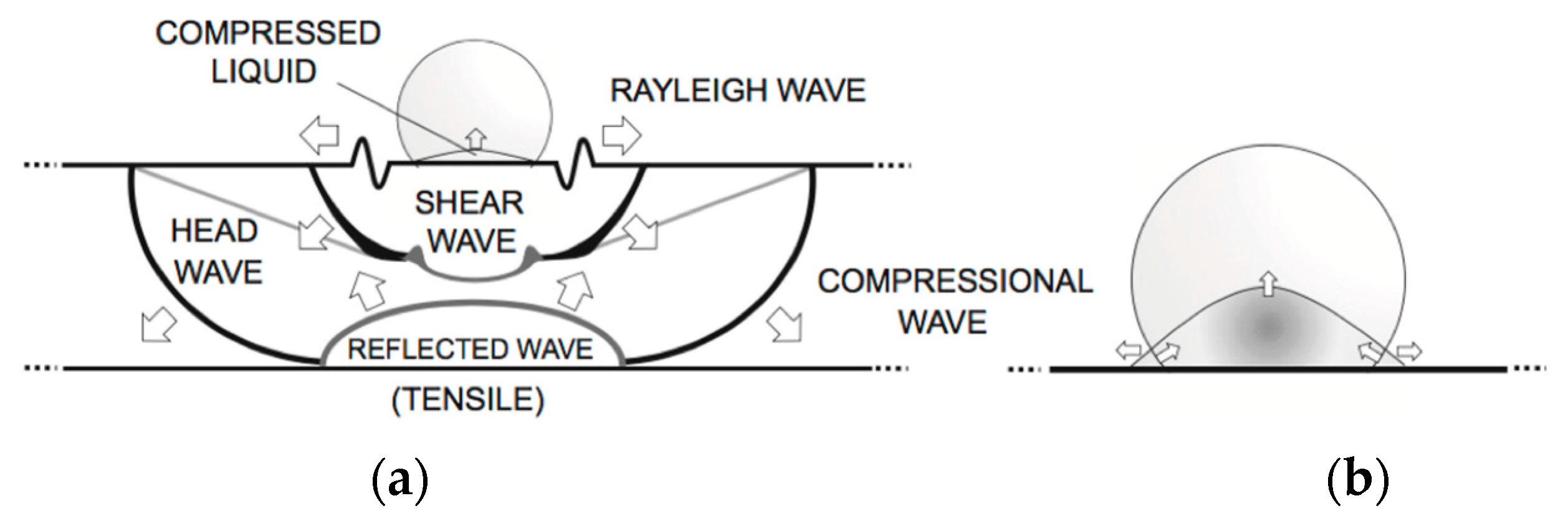

3.1. Liquid Impact Phenomena Affecting Erosion Failure

3.2. Identify Suitable Materials for Rain Erosion Coating Protection

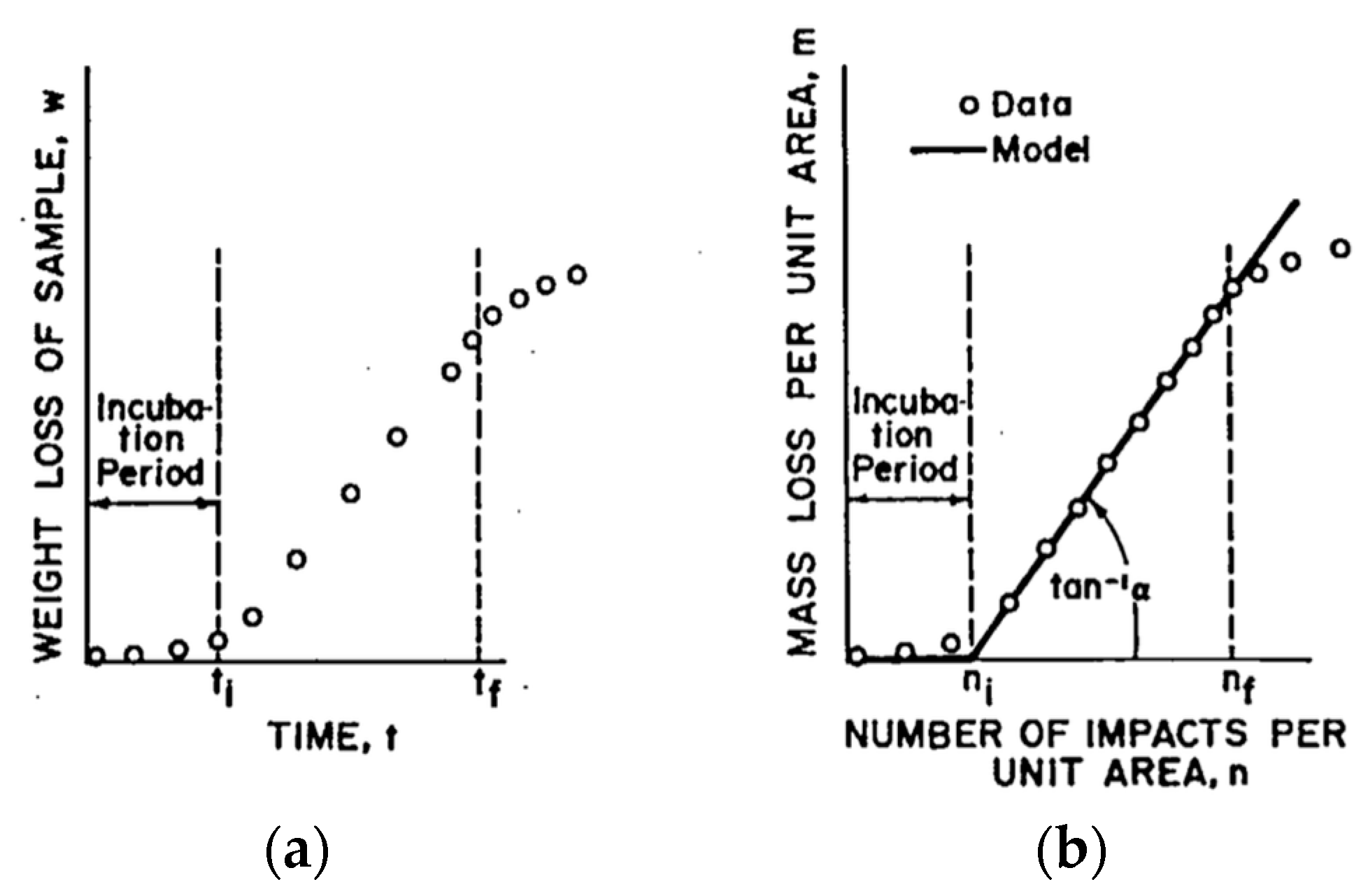

3.3. Erosion Lifetime Prediction Modelling

4. Case Studies: Effect of Interface and Adhesion Issues on Rain Erosion Performance

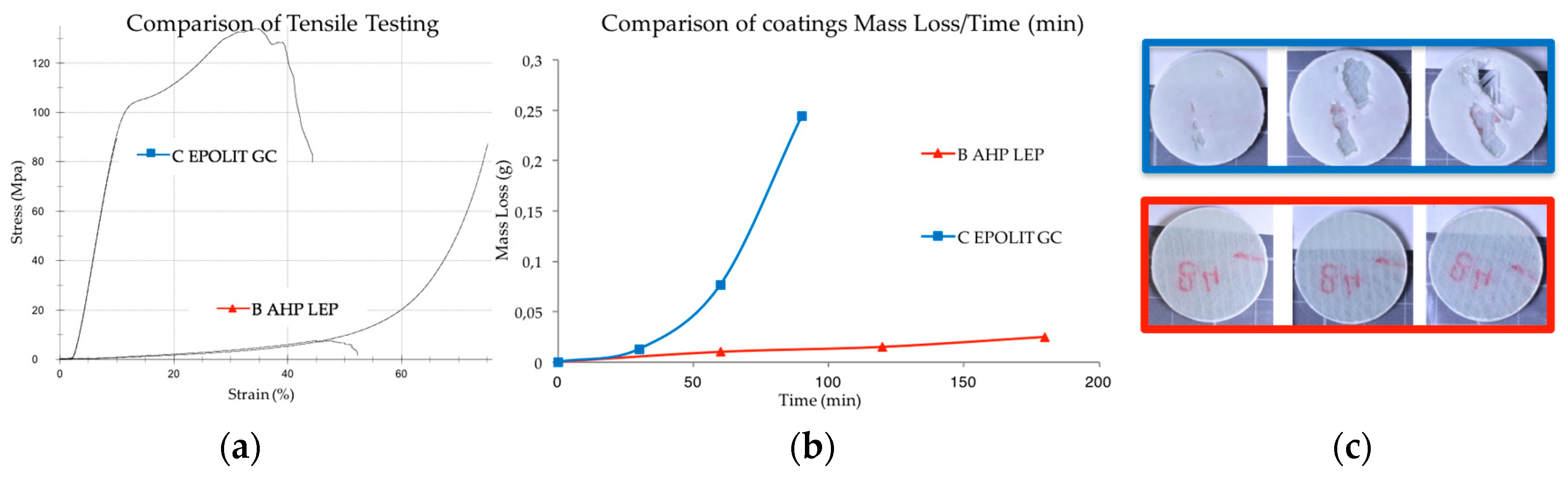

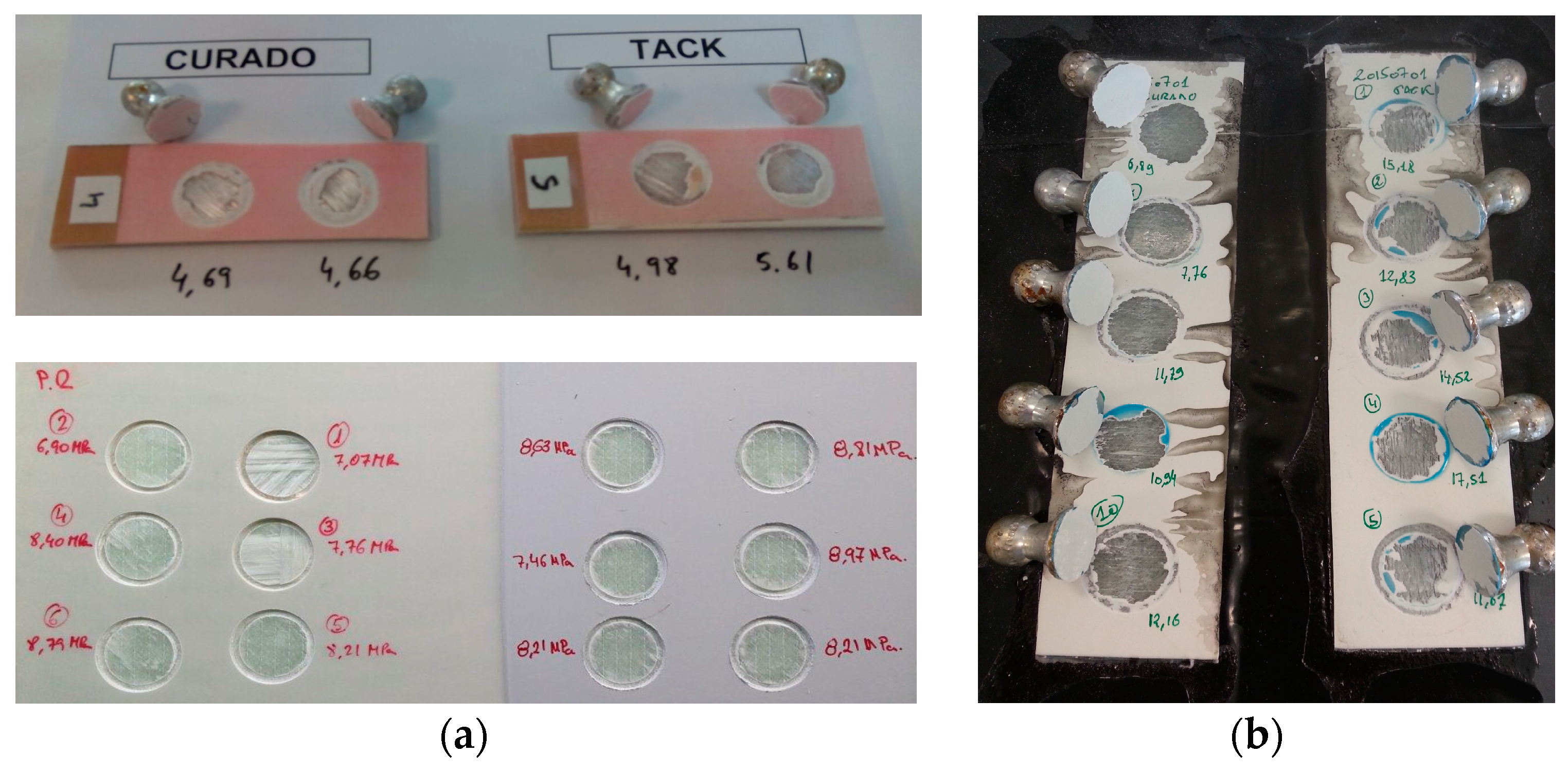

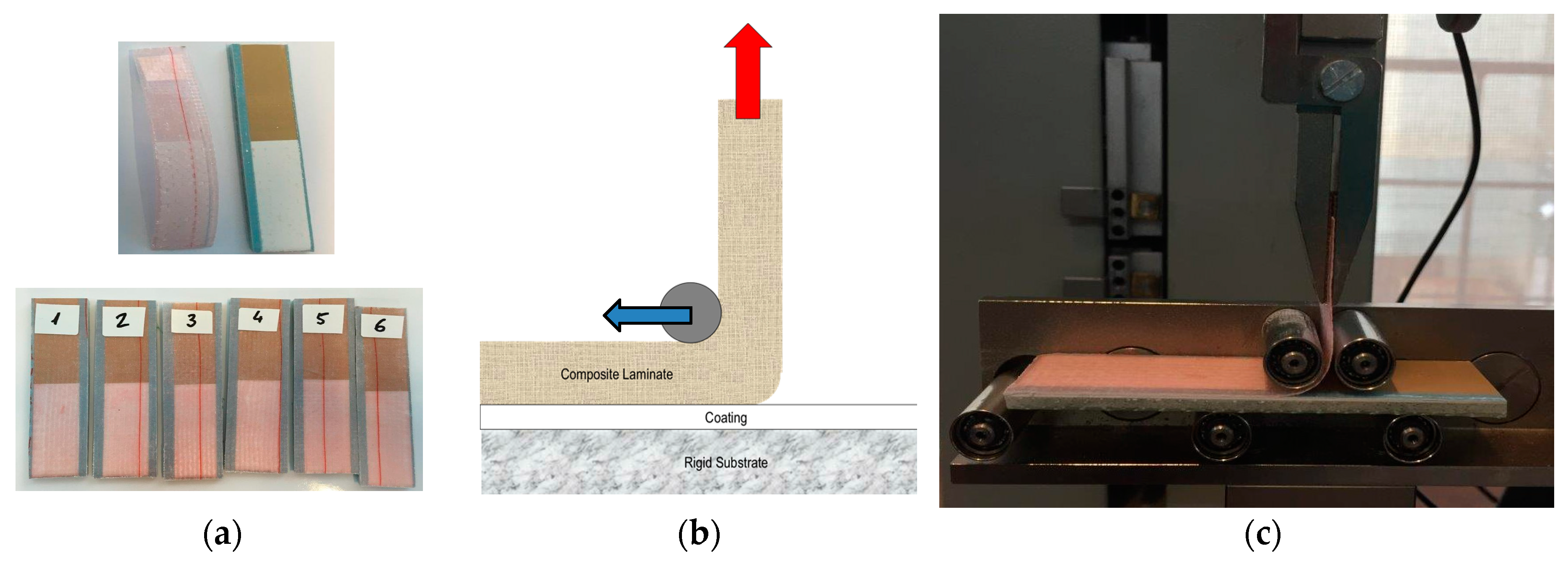

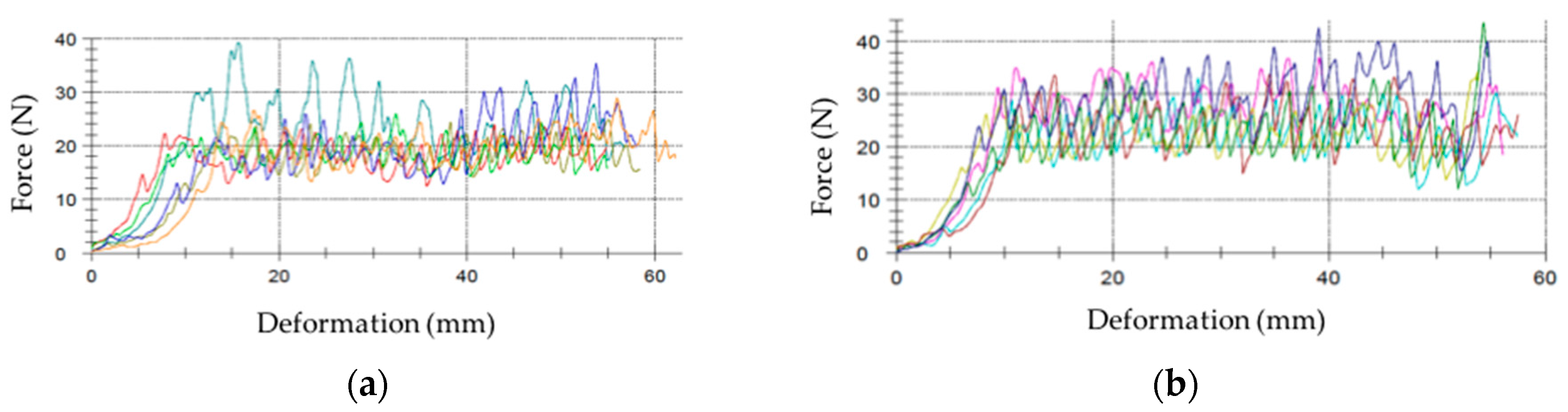

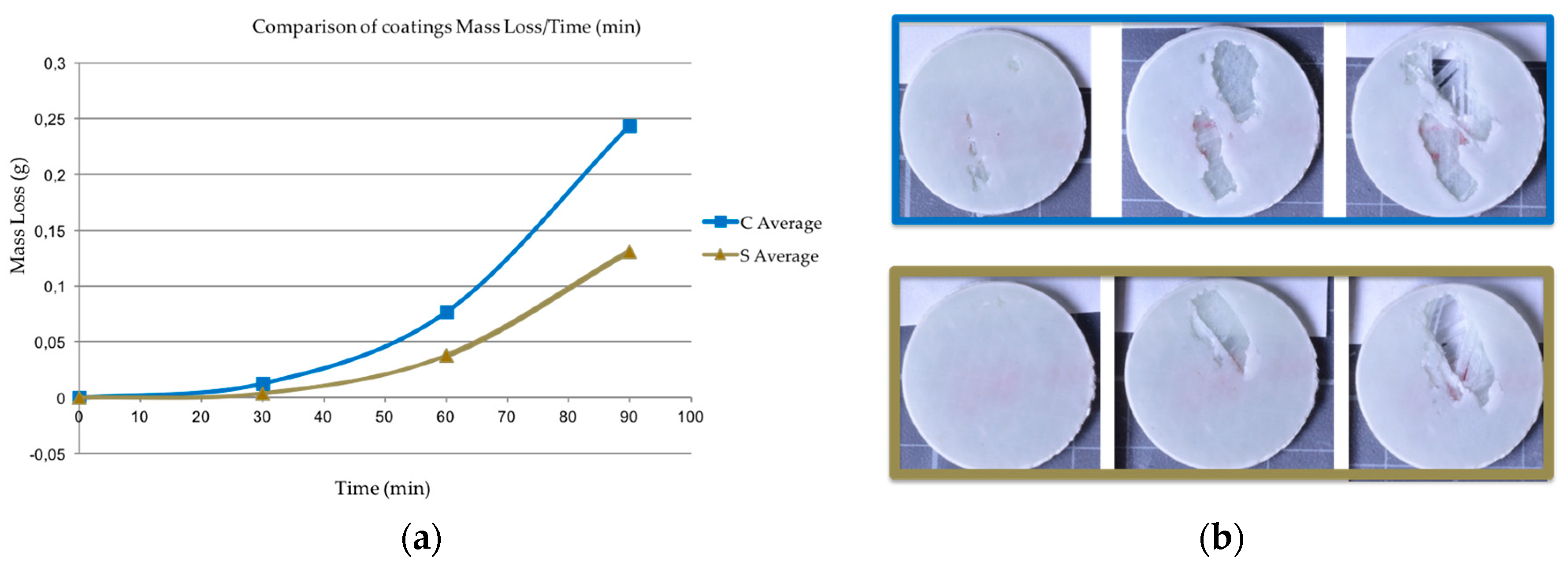

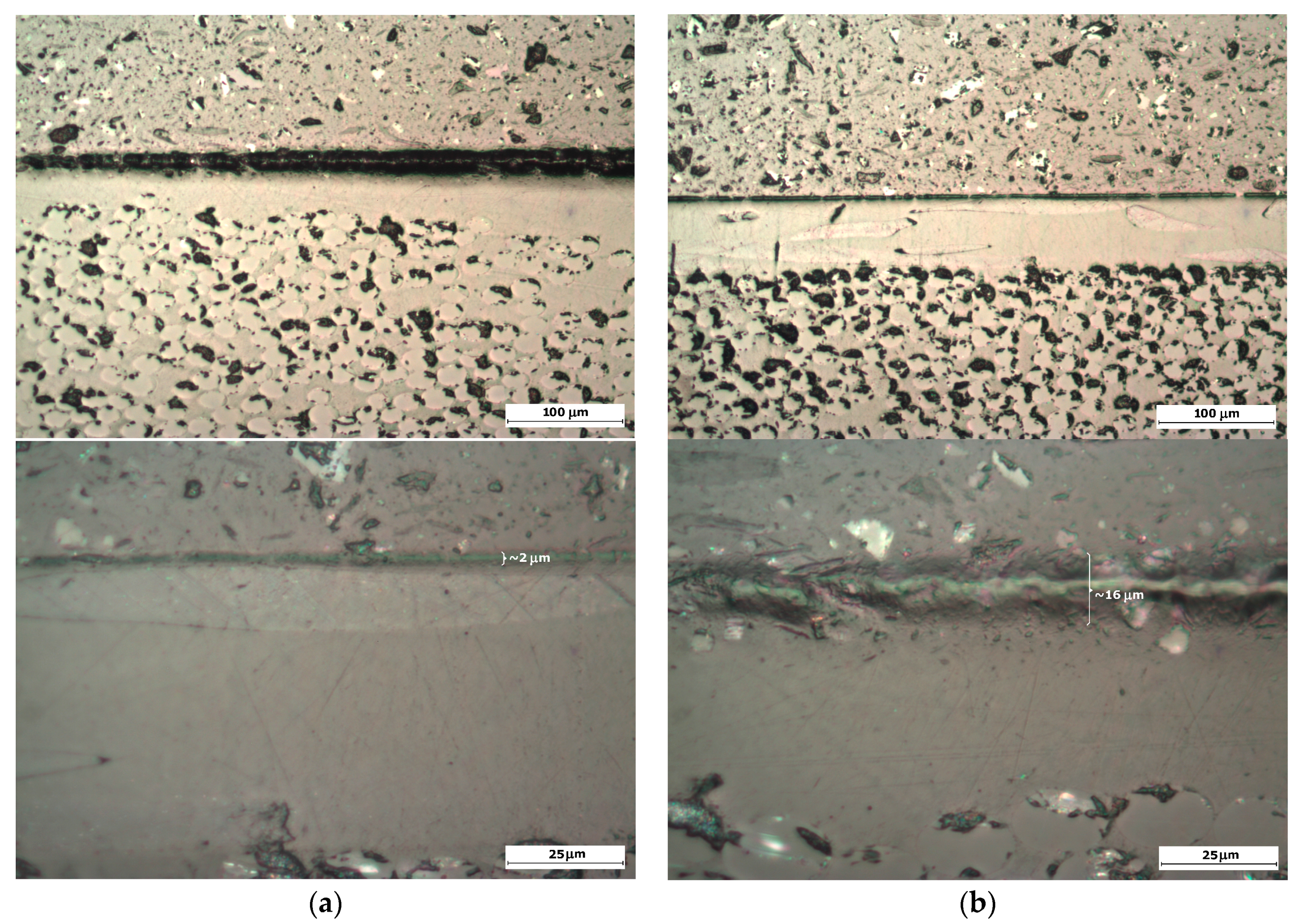

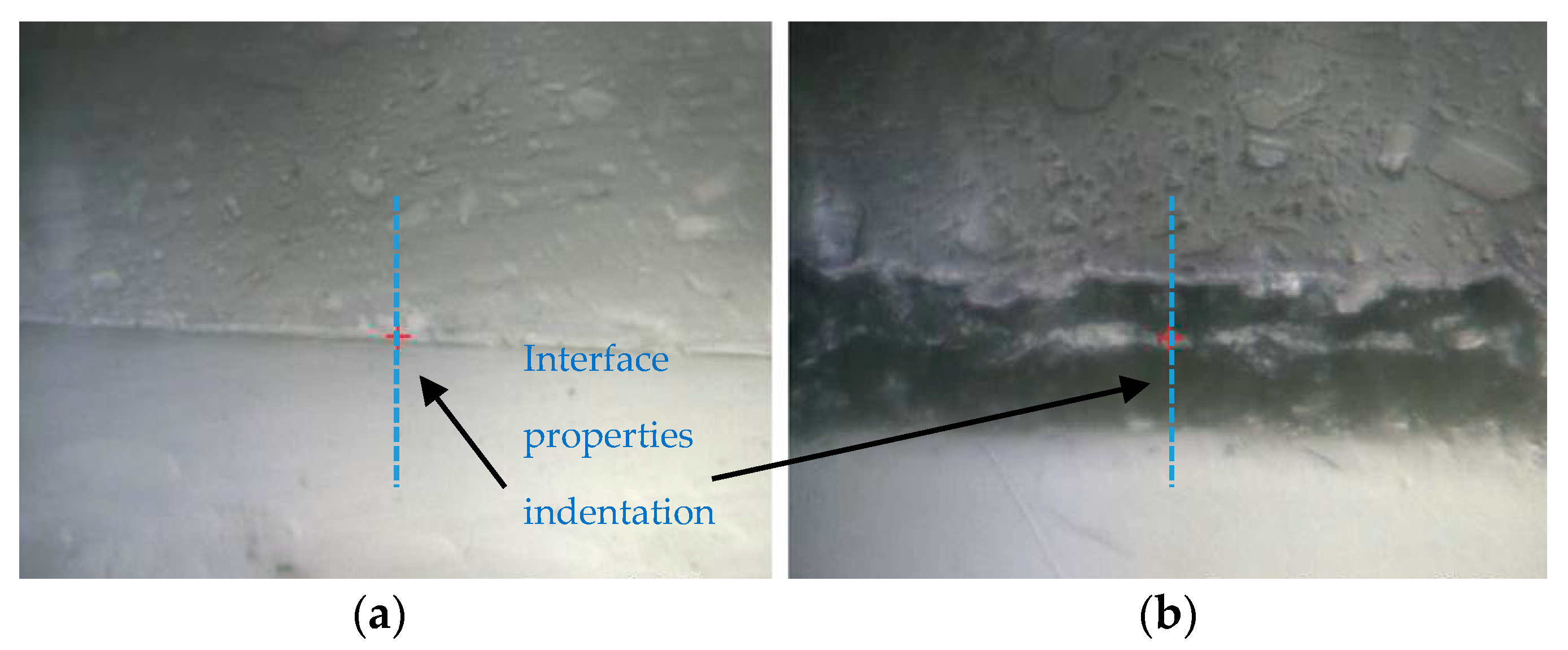

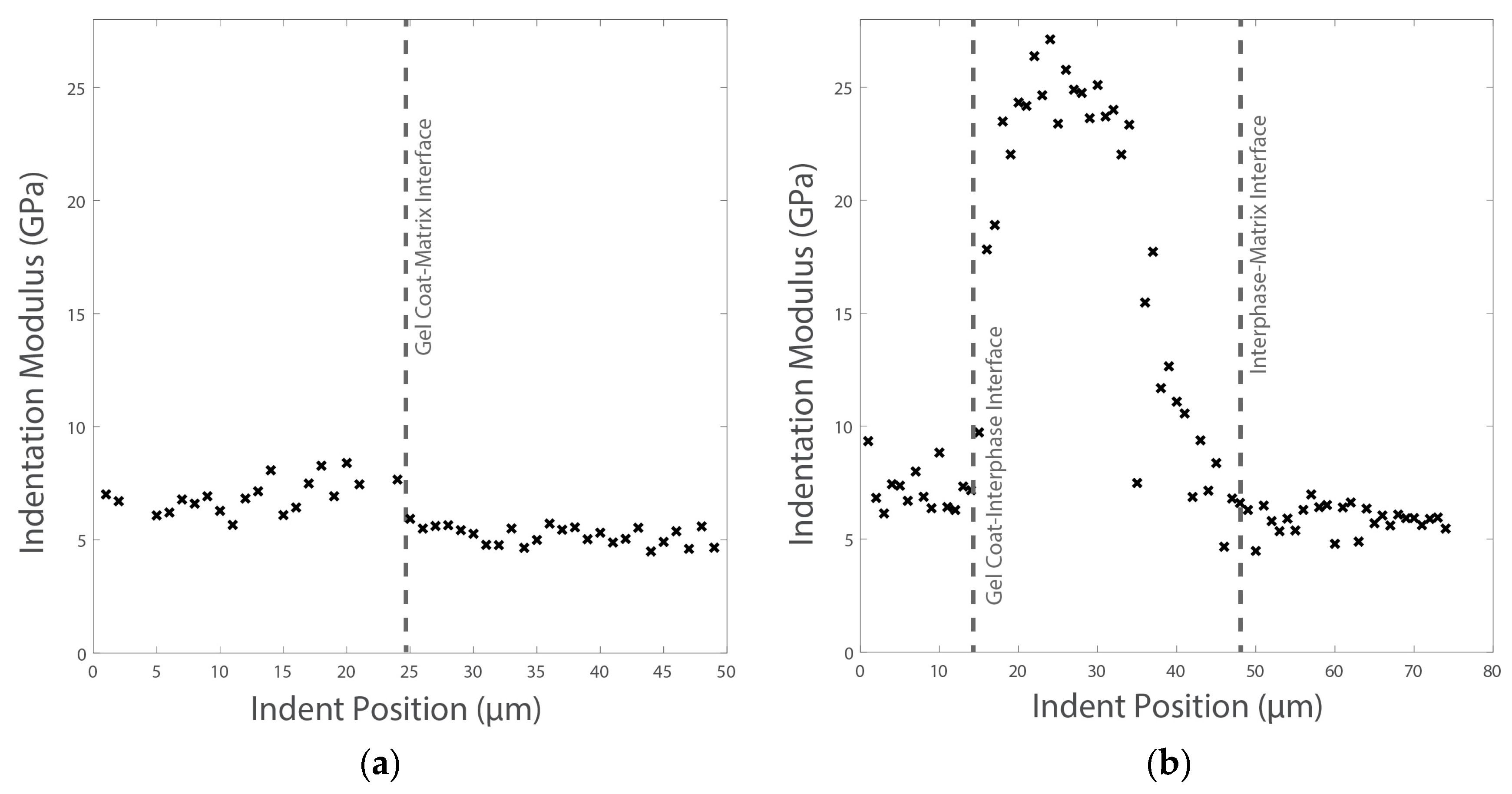

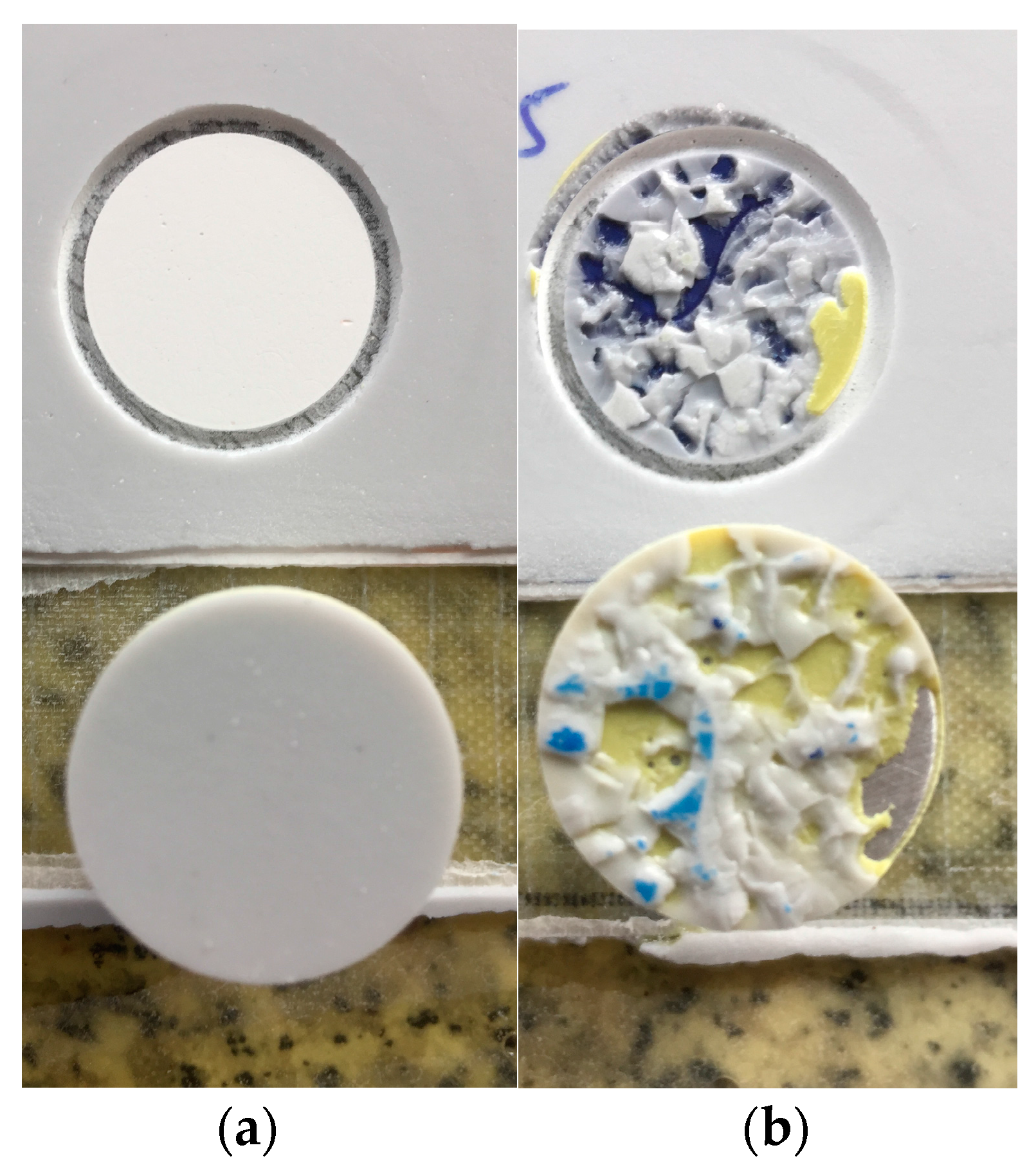

4.1. Comparison of Distinctive Polymer-Based Coating Technologies

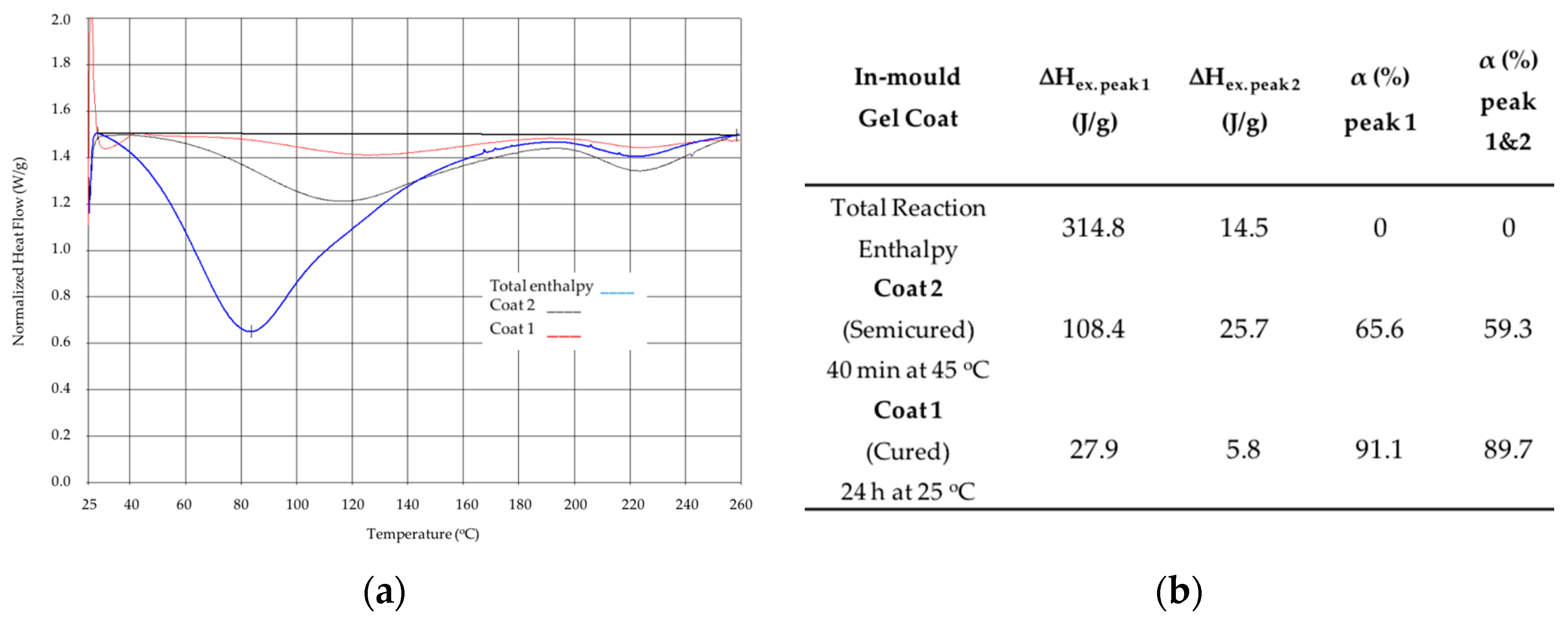

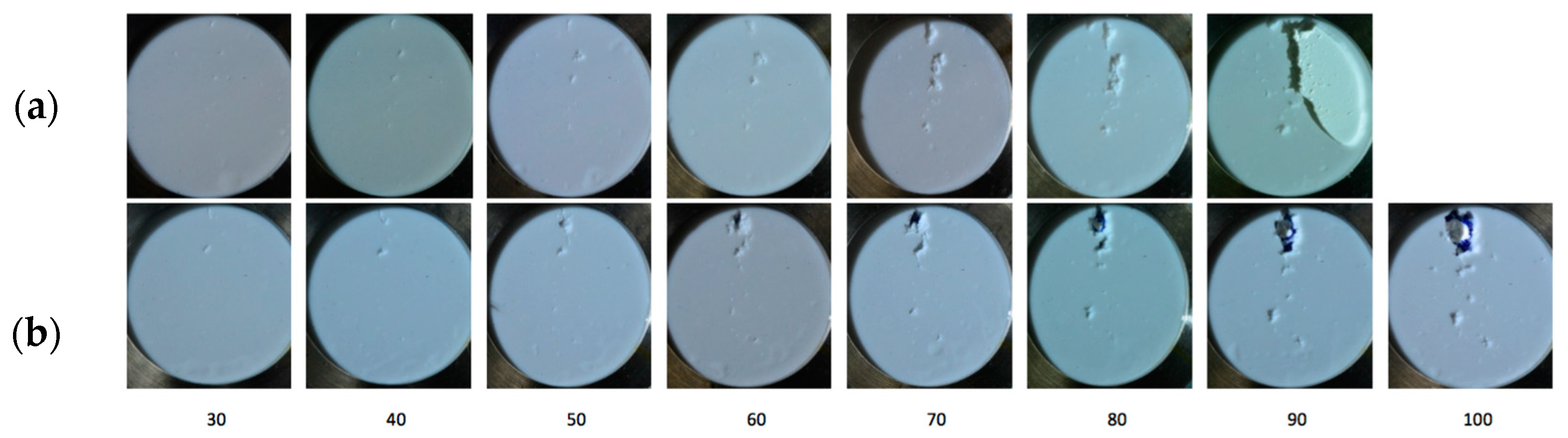

4.2. Effect of Curing Conditions of In-Mould Blade Coatings on Erosion Performance

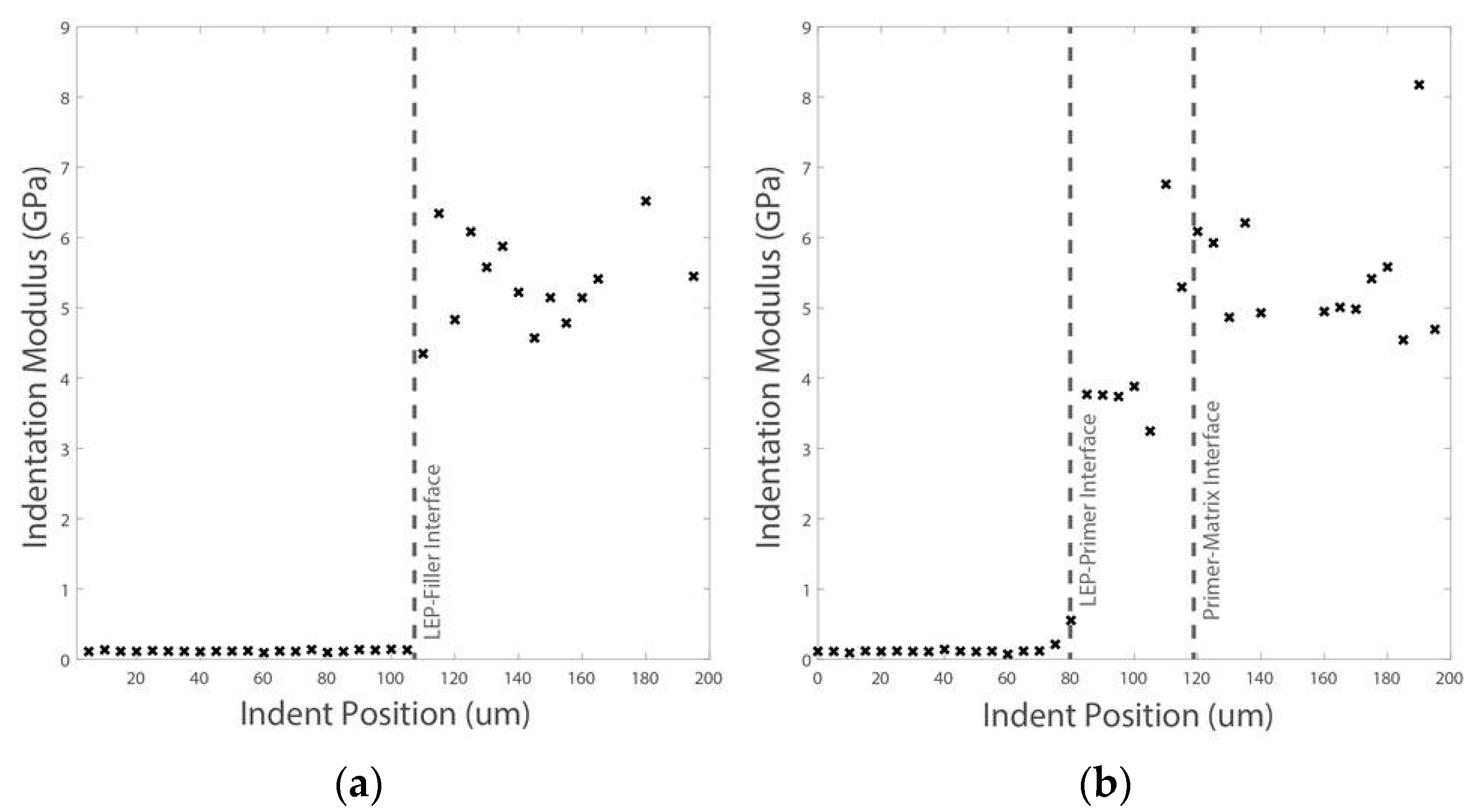

4.3. Effect of Primer on the Performance of Leading Edge Protection (LEP) Coatings

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- European Comission, 2012 Energy Roadmap 2050. Available online: https://ec.europa.eu/energy/sites/ener/files/documents/2012_energy_roadmap_2050_en_0.pdf (accessed on 27 July 2017).

- Linul, E.; Marsavina, L. Mechanical Characterization of Rigid PUR Foams Used for Wind Turbine Blades Construction. In Recent Advances in Composite Materials for Wind Turbines Blades; WAP-AMSA; 2013; ISBN 978-0-9889190-0-6. Available online: http://www.academicpub.org/amsa/chapterInfo.aspx (accessed on 28 September 2017).

- LM Wind Power. On the Leading Edge: Innovative Solutions to Reduce Rain Erosion. Available online: http://www.pes.eu.com/wind/on-the-leading-edge-innovative-solutions-to-reduce-rain-erosion/6236/ (accessed on 27 July 2017).

- Siemens Wind Power. Siemens Tackle Wind Power. Available online: http://renews.biz/102051/siemens-tackles-blade-erosion/ (accessed on 27 July 2017).

- Michael Legault, Wind Blades: Progress and Challenges. Available online: http://www.compositesworld.com/articles/wind-blades-progress-and-challenges (accessed on 27 July 2017).

- American Wind Energy Association. 2017 AWEA Market Report: U.S. Wind Industry First Quarter. Available online: http://www.awea.org (accessed on 27 July 2017).

- Nordex Acciona Windpower Corporate Brochure. Available online: http://www.acciona-windpower.es (accessed on 30 April 2016).

- Valaker, E.A.; Armada, S.; Wilson, S. Droplet Erosion Protection Coatings for Offshore Wind Turbine Blades. Energy Procedia 2015, 80, 263–275. [Google Scholar] [CrossRef]

- Schmitt, G.F., Jr. Material Parameters that Govern the Rain Erosion Behaviour of Polymeric Coatings and Composites at Subsonic Velocities; AFML-TR-71-197; Technical Report Air Force Materials Lab.: Wright-Patterson AFB, OH, USA, 1971. [Google Scholar]

- Springer, G.S. Erosion by Liquid Impact; Scripta Technica Publishing Co.: Washington, DC, USA, 1976. [Google Scholar]

- Slot, H.M.; Gelinck, E.R.M.; Rentrop, C.; van der Heide, E. Leading edge erosion of coated wind turbine blades: Review of coating life models. Renew. Energy 2015, 80, 837–848. [Google Scholar] [CrossRef]

- Zhang, S.; Dam-Johansen, D.; Nørkjær, S.; Bernad, P.L., Jr.; Kiil, S. Erosion of wind turbine blade coatings—Design and analysis of jet-based laboratory equipment for performance evaluation. Prog. Org. Coat. 2015, 78, 103–115. [Google Scholar] [CrossRef]

- Keegan, M.H.; Nash, D.H.; Stack, M.M. On erosion issues associated with the leading edge of wind turbine blades. J. Phys. D App. Phys. 2013, 46. [Google Scholar] [CrossRef]

- Dalili, N.; Edrisy, A.; Carriveau, R. A review of surface engineering issues critical to wind turbine performance. Renew. Sustain. Energy Rev. 2009, 13, 428–438. [Google Scholar] [CrossRef]

- Attaf, B. Designing Composite Wind Turbine Blades from Cradle to Cradle. In Recent Advances in Composite Materials for Wind Turbines Blades; WAP-AMSA; 2013; ISBN 978-0-9889190-0-6. Available online: http://www.academicpub.org/amsa/chapterInfo.aspx (accessed on 28 September 2017).

- Schubel, P.J. Cost modelling in polymer composite applications: Case study—Analysis of existing and automated manufacturing processes for a large wind turbine blade. Compos. Part B Eng. 2012, 43, 953–960. [Google Scholar] [CrossRef]

- Hutchinson, J.R.; Schubel, P.J.; Warrior, N.A. A cost and performance comparison of LRTM and VI for the manufacture of large scale wind turbine blades. Renew. Energy 2011, 36, 866–871. [Google Scholar] [CrossRef]

- Rogers, W.; Hoppins, C.; Gombos, Z.; Summerscales, J. In-mould gel-coating of polymer composites: A review. J. Clean. Prod. 2014, 70, 282–291. [Google Scholar] [CrossRef] [Green Version]

- Keegan, M.H.; Nash, D.H.; Stack, M.M. Modelling Rain Drop Impact of Offshore Wind Turbine Blades. In Proceedings of the Turnine Technical Conference on ASME Turbo EXPO 2012, Copenhagen, Denmark, 11–15 June 2012. [Google Scholar]

- Gohardani, O. Impact of erosion testing aspects on current and future flight conditions. Prog. Aerosp. Sci. 2011, 47, 280–303. [Google Scholar] [CrossRef]

- Zhang, S.; Dam-Johansen, K.; Bernad, P.L., Jr.; Kiil, S. Rain erosion of wind turbine blade coatings using discrete water jets: Effects of water cushioning, substrate geometry, impact distance, and coating properties. Wear 2015, 328–329, 140–148. [Google Scholar] [CrossRef]

- Adler, W.F. Waterdrop Impact Modelling. Wear 1995, 186–187, 341–351. [Google Scholar] [CrossRef]

- Springer, G.S.; Lang, C.-I.; Larsen, P.S. Analysis of Rain Erosion of Coated Materials. J. Compos. Mater. 1974, 8, 229. [Google Scholar] [CrossRef]

- Stanley, S. Cook, Erosion by Water-Hammer, Proceedings of the Royal Society A: Mathematical. Phys. Eng. Sci. 1928. [Google Scholar] [CrossRef]

- Zahavi, J.; Nadiv, S. Indirect damage in composite materials due to raindrop impact. Wear 1981, 72, 305–313. [Google Scholar] [CrossRef]

- Busch, H.; Hoff, G.; Langbein, G.; Taylor, G.; Jenkins, D.C.; Taunton, M.A. Rain erosion properties of materials and discussion. Philos. Trans. R. Lond. A 1966, 260, 168–181. [Google Scholar] [CrossRef]

- ASTM. ASTM G73-10 “Standard Test Method for Liquid Impingement Erosion Using Rotating Apparatus”; ASTM: West Conshohocken, PA, USA, 2013. [Google Scholar]

- Eisenberg, D.; Steffen, S.; Stege, J. Leading Edge Protection Lifetime Prediction Model Creation and Validation. Available online: https://windeurope.org/summit2016/conference/allposters/PO078g.pdf (accessed on 27 July 2017).

- Cortés, E.; López, F.S.; Domenech, L.; Olivares, A.; Young, T.; O’Carroll, A.; Chinesta, F. Manufacturing issues which affect coating erosion performance in wind turbine blades. In Proceedings of the 20th International ESAFORM Conference on European Scientific Association Material Forming, Dublin, Ireland, 26–28 April 2017. [Google Scholar]

- Tobin, E.F.; Rohr, O.; Raps, D.; Willemse, W.; Norman, P.; Young, T.M. Surface topography parameters as a correlation factor for liquid droplet erosion test facilities. Wear 2015, 328–329, 318–328. [Google Scholar] [CrossRef]

- Tobin, E.F.; Young, T.M.; Raps, D.; Rohr, O. Comparison of liquid impingement results from whirling arm and water-jet erosion test facilities. Wear 2011, 271, 2625–2631. [Google Scholar] [CrossRef]

- Tobin, F.E.; Young, M.T. Analysis of Incubation Period Versus Surface Topographical Parameters in Liquid Droplet Erosion Tests. Mater. Perform. Charact. 2017, 6, 144–164. [Google Scholar] [CrossRef]

- Yang, B.; Sun, D. Testing, inspecting and monitoring technologies for wind turbine blades: A survey. Renew. Sustain. Energy Rev. 2013, 22, 515–526. [Google Scholar] [CrossRef]

- Schubel, P.J.; Crossley, R.J.; Boateng, E.K.G.; Hutchinson, J.R. Review of structural health and cure monitoring techniques for large wind turbine blades. Renew. Energy 2013, 51, 113–123. [Google Scholar] [CrossRef]

- García, V.; Cortés, E.; Domenech, L.; Sánchez, F.; Chinesta, F. Effect of surface coating on the characterization of the process dynamical behaviour during mould filling in Liquid Resin Infusion. In Proceedings of the 20th International Conference on Composite Materials (ICCM-20), Copenhagen, Denmark, 19–24 July 2015; pp. 102–110. Available online: www.iccm-central.org (accessed on 27 July 2017).

- Hardiman, M.; Vaughan, T.J.; McCarthy, C.T. The effects of pile-up, viscoelasticity and hydrostatic stress on polymer matrix nanoindentation. Polym. Test. 2016, 52, 157–166. [Google Scholar] [CrossRef]

| Material Combination: Coating-Substrate | ZL (kg/m2s) | ZC (kg/m2s) | ZS (kg/m2s) | ||||

|---|---|---|---|---|---|---|---|

| Gel Coat-GFRP | 1.48M | 3.04M | 5.64M | −0.345 | 1.345 | −0.300 | 1.300 |

| LEP-GFRP | 1.48M | 0.09M | 5.64M | 0.882 | 0.118 | −0.968 | 1.968 |

| Material | Indentation Modulus | Hardness |

|---|---|---|

| Gel Coating * | 6.85 ± 0.94 GPa | 275.11 ± 28.08 MPa |

| GFRP matrix | 4.64 ± 0.36 GPa | 175.41 ± 9.01 MPa |

| Material Combination: Coating–Substrate | ZL (kg/m2s) | ZC (kg/m2s) | ZS (kg/m2s) | ||||

|---|---|---|---|---|---|---|---|

| Gel Coating–GFRP | 1.48M | 3.04M | 5.65M | −0.345 | 1.345 | −0.300 | 1.300 |

| Gel Coating–GFRP Matrix * | 1.48M | 3.04M | 2.35M | −0.345 | 1.345 | 0.128 | 0.872 |

| Gel Coating *–Coat 2 interphase | 1.48M | 3.04M | 5.22M | −0.345 | 1.345 | −0.263 | 1.263 |

| Coat 2 interphase–GFRP ** | 5.22M | 5.65M | −0.040 | 1.040 |

| Material | Indentation Modulus | Hardness |

|---|---|---|

| LEP | 21.37 ± 0.45 MPa | 6.39 ± 0.8 MPa |

| Primer | 3.66 ± 0.29 GPa | 130.75 ± 47 MPa |

| Filler | 8.76 ± 0.87 GPa | 167.37 ± 14.17 MPa |

| Material Combination: Coating–Substrate | ZL (kg/m2s) | ZC (kg/m2s) | ZS (kg/m2s) | ||||

|---|---|---|---|---|---|---|---|

| LEP–GFRP | 1.48M | 0.09M | 5.65M | 0.882 | 0.118 | −0.968 | 1.968 |

| LEP–Filler | 1.48M | 0.09M | 2.83M | 0.882 | 0.118 | −0.936 | 1.936 |

| LEP–Primer | 1.48M | 0.09M | 2.28M | 0.882 | 0.118 | −0.922 | 1.922 |

| Primer–Filler * | 2.28M | 2.83M | −0.107 | 1.107 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cortés, E.; Sánchez, F.; O’Carroll, A.; Madramany, B.; Hardiman, M.; Young, T.M. On the Material Characterisation of Wind Turbine Blade Coatings: The Effect of Interphase Coating–Laminate Adhesion on Rain Erosion Performance. Materials 2017, 10, 1146. https://doi.org/10.3390/ma10101146

Cortés E, Sánchez F, O’Carroll A, Madramany B, Hardiman M, Young TM. On the Material Characterisation of Wind Turbine Blade Coatings: The Effect of Interphase Coating–Laminate Adhesion on Rain Erosion Performance. Materials. 2017; 10(10):1146. https://doi.org/10.3390/ma10101146

Chicago/Turabian StyleCortés, Enrique, Fernando Sánchez, Anthony O’Carroll, Borja Madramany, Mark Hardiman, and Trevor M. Young. 2017. "On the Material Characterisation of Wind Turbine Blade Coatings: The Effect of Interphase Coating–Laminate Adhesion on Rain Erosion Performance" Materials 10, no. 10: 1146. https://doi.org/10.3390/ma10101146

APA StyleCortés, E., Sánchez, F., O’Carroll, A., Madramany, B., Hardiman, M., & Young, T. M. (2017). On the Material Characterisation of Wind Turbine Blade Coatings: The Effect of Interphase Coating–Laminate Adhesion on Rain Erosion Performance. Materials, 10(10), 1146. https://doi.org/10.3390/ma10101146