Combined Turbine and Cycle Optimization for Organic Rankine Cycle Power Systems—Part A: Turbine Model

Abstract

:1. Introduction

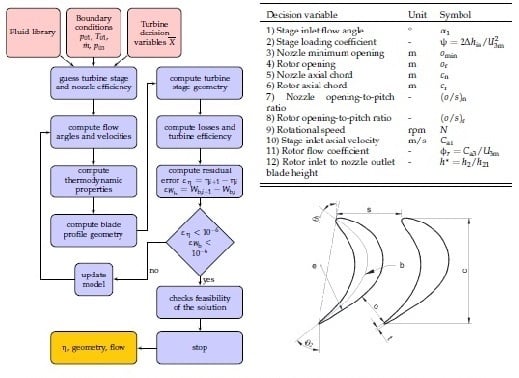

2. Axial Turbine Model

2.1. Modeling Approach

- a)

- A set of boundary conditions: inlet total pressure , inlet total temperature , mass flow rate , outlet total pressure . These are typically inputs from cycle calculations.

- b)

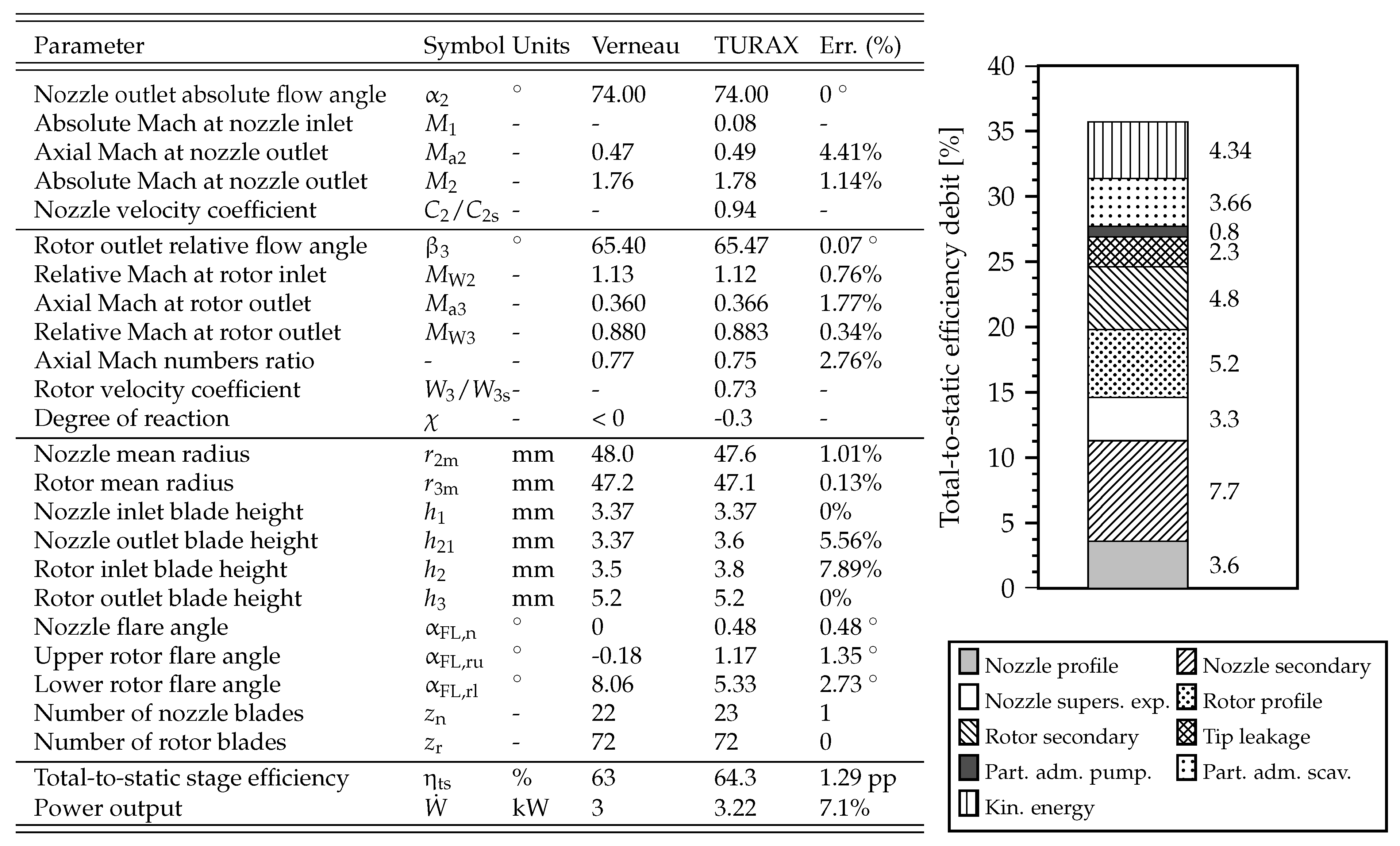

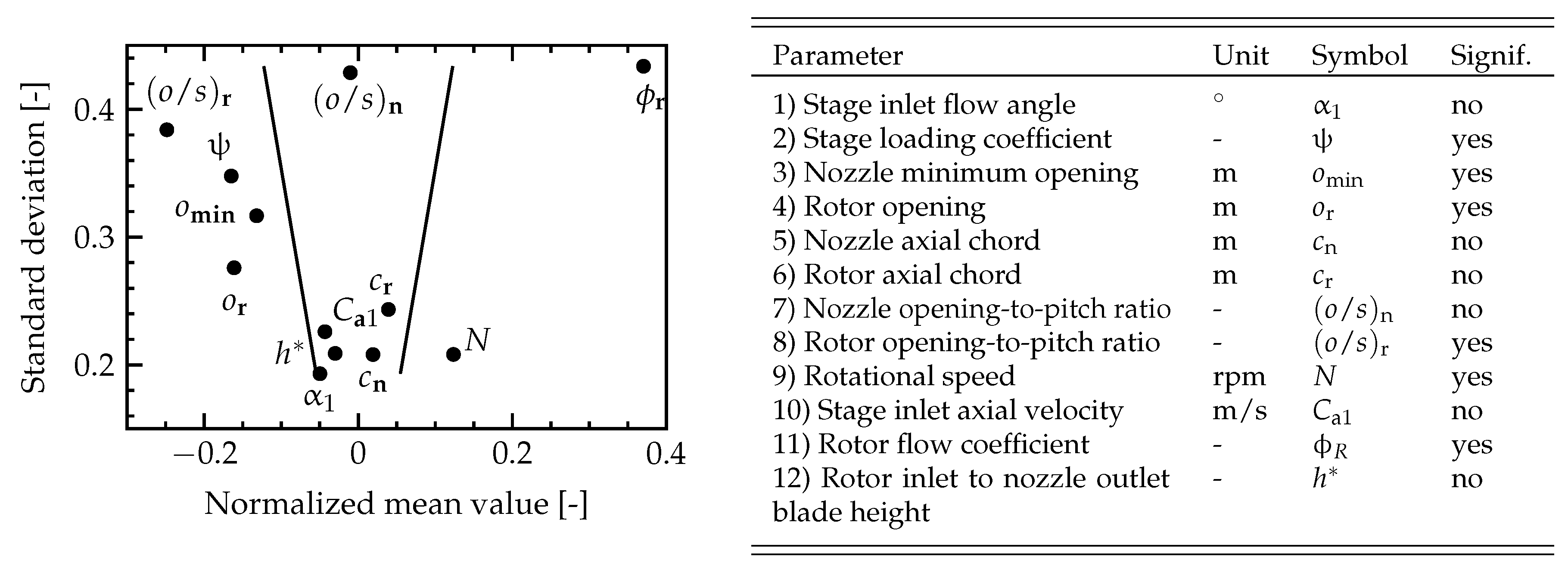

- An array of 12 turbine decision variables listed in the table of Figure 1.

- c)

- Specifications on blade shape geometry, clearance between nozzle and rotor , blade tip clearance , surface roughness , nozzle to rotor mean radius ratio .

- d)

- In the first iteration, assumption of the guessed values of turbine stage and nozzle efficiencies.

- Calculation of thermodynamic properties.

- Calculation of nozzle and rotor blade profile geometry and outlet flow angles. The Deich’s formula [27] is used to calculated the blade opening for converging-diverging nozzle. The profile loss correlations of Craig and Cox used for nozzle converging profiles are also adopted for a supersonic configuration. This approach, supported by Macchi [28], is based on the large number of efficient converging-diverging nozzles which were designed and tested according to Deich’s method.

- Calculation of turbine stage geometry.

- Estimation of losses and efficiency. The method by Craig and Cox [29] is used since it is considered by a number of references as one of the most complete and reliable [15,30,31]. Shock losses in a blade row are computed according to Kacker and Ockapuu [32]. Disk windage losses are estimated according to Balje and Binsley [33]. Partial admission losses are calculated using the method by Suter and Traupel [34], which is considered as one of the best available and comprehensive models [11,35].

- Calculation of the error on efficiency and blade work. The process iterates until the residual error between two consecutive iterations is below a predefined threshold value (i.e., ).

- In order to produce a feasible solution, the algorithm checks that the resulting turbine design satisfies a set of predefined constrains in the end of the iterative loop. The user can specify the values of the desired constraints in the model. An example of such constraints is provided in part B.

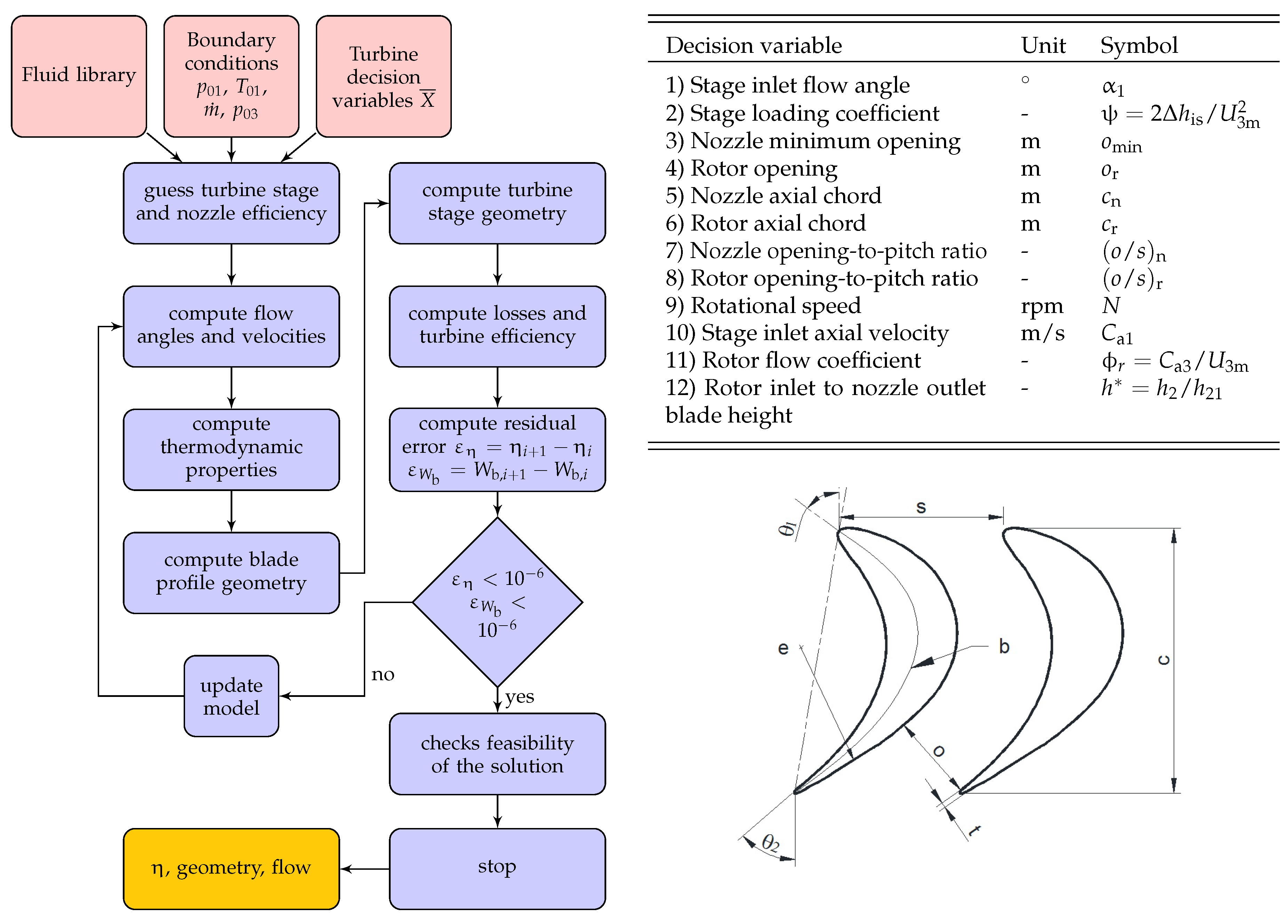

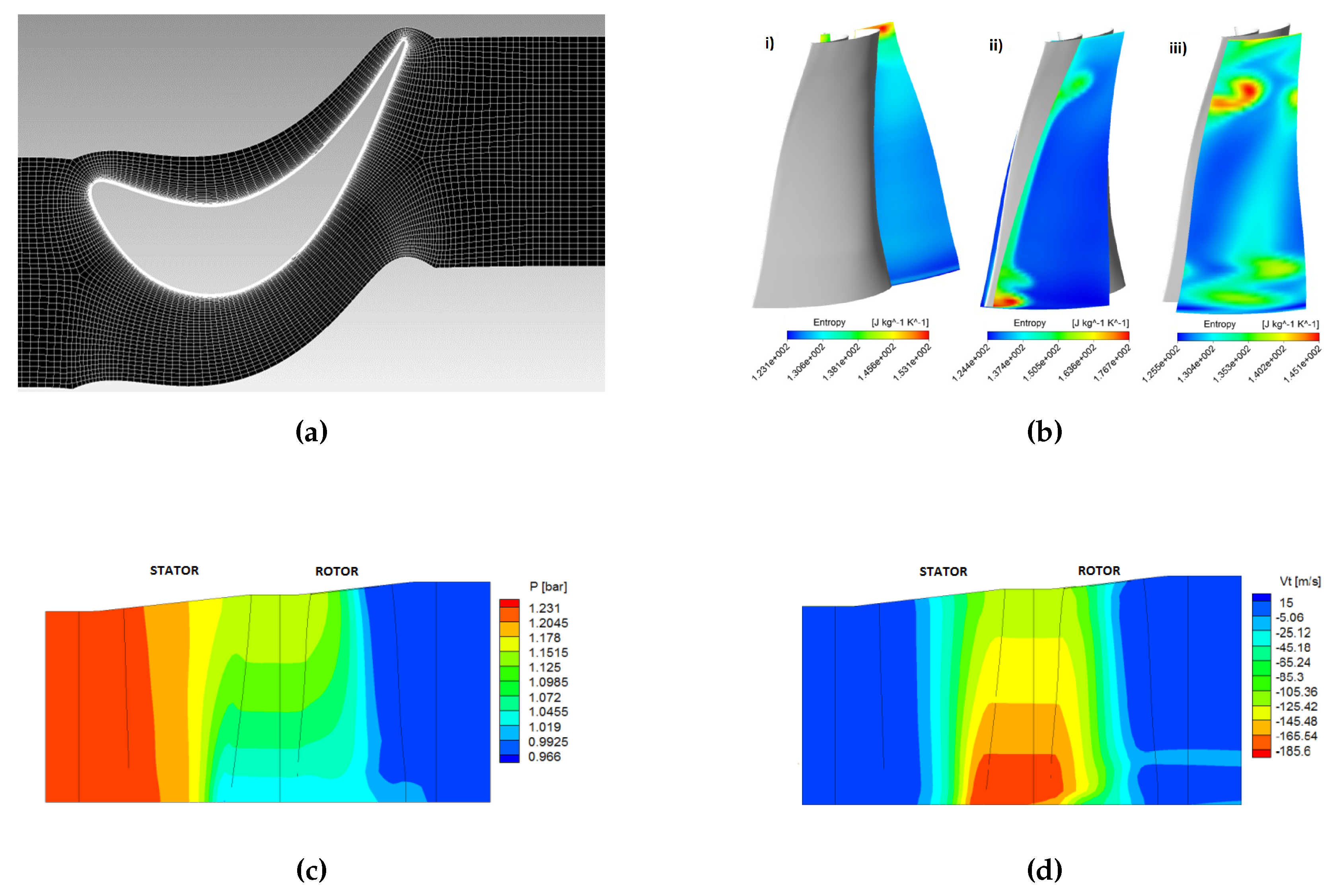

2.2. Validation

2.3. Sensitivity Analysis

3. Results

3.1. Hannover Turbine

3.2. Verneau Turbine

3.3. Sensitivity Analysis

- , , , , N, are indicated as significant parameters. Moreover, they tightly relate to the design features of the stage.

- The nozzle opening-to-pitch is not important according to the results. However, it is affected by a high standard deviation compared to the others, which implies strong interactions with the other parameters in the model. In addition, it cannot be disregarded from the design viewpoint since it relates to the estimation of nozzle pitch and outlet flow angle, and allows determining the number of nozzle blades.

- The stage inlet velocity is screened as an insignificant parameter for the performance of the turbine. However, the value of is strictly related to nozzle inlet blade height, which is a relevant aspect in the design and manufacturing of an axial turbine. This aspect becomes particularly critical for small-scale expanders, as highlighted, for example, by Klonowicz et al. [15]. Consequently, this variable was not excluded from the decision variables.

- Nozzle and rotor axial chords, and , do not significantly affect the efficiency according to Morris’s method. However, they tightly relate to the estimation of flaring angles. The optimization of the parameters and in the model would enable one to broaden the space of feasible design solutions. Furthermore, they relate to the actual length of the turbine and can be relevant for applications where compactness is a relevant decision criterion.

- The stage inlet flow angle does not provide a significant contribution to the efficiency. From the design point of view, it is a common practice to set it to the value of zero. Thus, it can be conveniently screened out from the decision variables of the model.

- The rotor inlet to nozzle outlet blade height ratio can be screened out in the model. Although related to tip clearance and annulus losses in the Craig and Cox correlations, it shows a limited impact on both preliminary design and efficiency of the turbine due to the short range of variation given by typical design constraints (i.e., 1.0–1.1) [29].

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Nomenclature

| A | Cross-sectional area (m2) |

| C | Absolute velocity (m · s−1) |

Mean diameter of the stage (m) | |

Error (-) | |

| M | Mach number (-) |

| N | Rotational speed (rpm) |

Rotor to nozzle mean radius ratio (-) | |

Reynolds number (-) | |

| T | Temperature (K) |

| U | Peripheral velocity (m · s−1) |

Tip Speed (m · s−1) | |

| W | Relative velocity (m · s−1) |

Blade work (J · kg−1) | |

Mass flow rate (kg · s−1) | |

| b | Blade backbone length (m) |

| c | Axial chord (m) |

| e | Blade rear surface suction curvature (m) |

| h | Blade height [m]; specific enthalpy (J · kg−1) |

Ratio of Rotor inlet to nozzle outlet blade height (-) | |

Blade surface roughness (m) | |

| o | Blade opening (m) |

| p | Pressure (Pa) |

| r | radius (m) |

Nozzle to rotor axial clearance (m) | |

| t | Trailing edge thickness (m) |

Blade tip clearance (m) | |

| z | Number of blades (-) |

Abbreviations and acronyms

| CFD | Computational Fluid Dynamics |

| ORC | Organic Rankine Cycle |

Greek letters

Absolute flow angle (°) | |

Flaring angle (°) | |

Relative flow angle (°) | |

| χ | Stage degree of reaction (-) |

Degree of admission (-); residual error (-) | |

Turbine isentropic efficiency (-) | |

Flow coefficient (-) | |

Stage loading coefficient (-) | |

Density (kg · m−3) | |

Generic quantity (-) | |

| ζ | Kinetic energy loss coefficient (-) |

Subscripts

| 0 | Total conditions |

| 1 | Nozzle inlet |

| 2 | Rotor inlet |

| 21 | Nozzle outlet |

| 3 | Rotor outlet |

| a | Axial component |

| m | Referred to the mean diameter |

| min | Referred to the minimum opening |

| n | Nozzle |

| o | Outlet |

| r | Rotor |

| s | Isentropic conditions |

| ts | Total-to-static |

| tt | Total-to-total |

| W | Referred to the relative coordinate system |

References

- Stine, W.B.; Harrigan, R.W. Solar Energy Fundamentals and Design; John Wiley and Sons, Inc.: New York, NY, USA, 1985. [Google Scholar]

- Lecompte, S.; Huisseune, H.; van den Broek, M.; De Schampheleire, S.; De Paepe, M. Part load based thermo-economic optimization of the Organic Rankine Cycle (ORC) applied to a combined heat and power (CHP) system. Appl. Energy 2013, 111, 871–881. [Google Scholar] [CrossRef]

- Cayer, E.; Galanis, N.; Nesreddine, H. Parametric study and optimization of a transcritical power cycle using a low temperature source. Appl. Energy 2010, 87, 1349–1357. [Google Scholar] [CrossRef]

- Bao, J.; Zhao, L. A review of working fluid and expander selections for organic Rankine cycle. Renew. Sustain. Energy Rev. 2013, 24, 325–342. [Google Scholar] [CrossRef]

- Quoilin, S.; Broek, M.V.D.; Declaye, S.; Dewallef, P.; Lemort, V. Techno-economic survey of Organic Rankine Cycle (ORC) systems. Renew. Sustain. Energy Rev. 2013, 22, 168–186. [Google Scholar] [CrossRef]

- Fiaschi, D.; Manfrida, G.; Maraschiello, F. Design and performance prediction of radial ORC turboexpanders. Appl. Energy 2015, 138, 517–532. [Google Scholar] [CrossRef]

- Persico, G.; Pini, M.; Dossena, V.; Gaetani, P. Aerodynamics of Centrifugal Turbine Cascades. J. Eng. Gas Turbines Power 2015, 137. [Google Scholar] [CrossRef]

- Pini, M.; Persico, G.; Casati, E.; Dossena, V. Preliminary Design of a Centrifugal Turbine for Organic Rankine Cycle Applications. J. Eng. Gas Turbines Power 2013, 135. [Google Scholar] [CrossRef]

- Casati, E.; Vitale, S.; Pini, M.; Persico, G.; Colonna, P. Centrifugal Turbines for Mini-ORC Power Systems. J. Eng. Gas Turbines Power 2014, 136, 1–11. [Google Scholar] [CrossRef]

- Colonna, P.; Casati, E.; Trapp, C.; Mathijssen, T.; Larjola, J.; Turunen-Saaresti, T.; Uusitalo, A. Organic Rankine Cycle Power Systems: From the Concept to Current Technology, Applications, and an Outlook to the Future. J. Eng. Gas Turbines Power 2015, 137, 1–19. [Google Scholar] [CrossRef]

- Aungier, R.H. Turbine Aerodynamics; American Society of Mechanical Engineers Press: New York, NY, USA, 2006. [Google Scholar]

- Turboden. Turboden: Clean Energy Ahead. 2016. Available online: http://www.turboden.eu (accessed on 1 January 2016).

- Ormat Technologies. Green Energy You Can Rely On. 2016. Available online: http://www.ormat.com (accessed on 1 January 2016).

- Uusitalo, A. Working Fluid Selection and Design of Small-scale Waste Heat Recovery Systems Based on Organic Rankine Cycles. Ph.D. Thesis, Lappeenranta University of Technology, Lappeenranta, Finland, 2014. [Google Scholar]

- Klonowicz, P.; Heberle, F.; Preißinger, M.; Brüggemann, D. Significance of loss correlations in performance prediction of small scale, highly loaded turbine stages working in Organic Rankine Cycles. Energy 2014, 72, 322–330. [Google Scholar] [CrossRef]

- Lozza, G.; Macchi, E.; Perdichizzi, A. On the influence of the number of stages on the efficiency of axial-flow turbines. In Proceedings of the 27th American Society of Mechanical Engineers, International Gas Turbine Conference and Exhibit, American Society of Mechanical Engineers, London, UK, 18–22 April 1982.

- Da Lio, L.; Manente, G.; Lazzaretto, A. New efficiency charts for the optimum design of axial flow turbines for organic Rankine cycles. Energy 2014, 77, 447–459. [Google Scholar] [CrossRef]

- Ventura, C.A.D.M.; Rowlands, A.S. Design and performance estimation of radial inflow turbines coupled with a thermodynamic cycle analysis procedure. In Proceedings of the ASME ORC 2013: 2nd International Seminar on ORC Power Systems, Rotterdam, The Netherlands, 7–8 October 2013; pp. 1–5.

- Uusitalo, A.; Turunen-Saaresti, T.; Gronman, A.; Honkatukia, J.; Backman, J. Combined Thermodynamic and Turbine Design Analysis of Small Capacity Waste Heat Recovery ORC. In Proceedings of the ASME ORC 2015: 3nd International Seminar on ORC Power Systems, Brussels, Belgium, 12–14 October 2015; pp. 1–10.

- Gabrielli, P. Design and Optimization of Turbo-Expanders for Organic Rankine Cycles. Master’s Thesis, Technical University of Denmark, Copenhagen, Denmark, 2014. [Google Scholar]

- La Seta, A.; Andreasen, J.G.; Pierobon, L.; Persico, G.; Haglind, F. Design of Organic Rankine Cycle Power Systems Accounting for Expander Performance. In Proceedings of the 3rd International Seminar on ORC Power Systems, Brussels, Belgium, 12–14 October 2015; pp. 1–12.

- Mathworks. MATLAB 2015b Documentation. Available online: http://www.mathworks.com (accessed on 1 January 2016).

- Lemmon, E.W.; Huber, M.L.; McLinden, M.O. NIST reference fluid thermodynamic and transport properties–REFPROP; U.S. Department of Commerce: Gaithersburg, MD, USA, 2002.

- Bell, I.H.; Wronski, J.; Quoilin, S.; Lemort, V. Pure and pseudo-pure fluid thermophysical property evaluation and the open-source thermophysical property library CoolProp. Ind. Eng. Chem. Res. 2014, 53, 2498–2508. [Google Scholar] [PubMed]

- Ainley, D.G.; Mathieson, G.C.R. A Method of Performance Estimation for Axial-Flow Turbines; Technical Report; Aeronautical Research Council Great Britain: London, UK, 1951. [Google Scholar]

- Vavra, M. Axial Flow Turbines. Flow in Turbines. (VKI Lecture Series 15); Von Karman Institute For Fluid Dynamics: Rhode-Saint-Genése, Belgium, 1969; pp. 1–117. [Google Scholar]

- Deich, M. Atlas of Axial Turbine Blade Cascades; Deich, M.E., Filippov, G.A., Lazarev, L.Ya., Eds.; Maschinostroenie Publishing House: Moscow, Russia, 1965; pp. 4563–4564. [Google Scholar]

- Macchi, E. Design Criteria for Turbines Operating with Fluids having a Low Speed of Sound. Closed Cycle Gas Turbines. (VKI Lecture Series 100); Von Karman Institute For Fluid Dynamics: Rhode-Saint-Genése, Belgium, 1977; Volume 2, pp. 1–34. [Google Scholar]

- Craig, H.; Cox, H. Performance estimation of axial flow turbines. Proc. Inst. Mech. Eng. 1970, 185, 407–424. [Google Scholar] [CrossRef]

- Macchi, E.; Perdichizzi, A. Efficiency Prediction for Axial-Flow Turbines Operating with Nonconventional Fluids. J. Eng. Power 1981, 103, 718–724. [Google Scholar] [CrossRef]

- Lozza, G. A comparison between the Craig-Cox and the Kacker-Okapuu methods of turbine performance prediction. Meccanica 1982, 17, 211–221. [Google Scholar] [CrossRef]

- Kacker, S.C.; Okapuu, U. A Mean Line Prediction Method for Axial Flow Turbine Efficiency. J. Eng. Power 1982, 104, 111–119. [Google Scholar] [CrossRef]

- Balje, O.E.; Binsley, R.L. Axial Turbine Performance Evaluation. Part A Loss-Geometry Relationships. J. Eng. Gas Turbines Power 1968, 90, 341–348. [Google Scholar]

- Traupel, W. Thermische Turbomaschinen: Thermodynamisch-Strömungstechnische Berechnung; Springer: Berlin, Germany, 1966; Volume 1. [Google Scholar]

- Macchi, E.; Lozza, G. Comparison of Partial vs. Full Admission for Small Turbines at Low Specific Speeds. In Proceedings of the ASME 1985 International Gas Turbine Conference and Exhibit, Houston, Texas, 18–21 March 1985.

- Saravanamuttoo, H.I.H.; Rogers, G.F.C.; Cohen, H. Gas Turbine Theory; Pearson Education Limited: Essex, UK, 2001. [Google Scholar]

- Dixon, S.L.; Hall, C.A. Fluid Mechanics and Thermodynamics of Turbomachinery; Butterworth-Heinemann: Waltham, MA, USA, 2010; pp. 105–107. [Google Scholar]

- Vavra, M.H. Aero-thermodynamics and Flows in Turbomachines; John Wiley & Sons: New York, NY, USA, 1960. [Google Scholar]

- Groschup, D.I.G. Strömungstechnische Untersuchung einer Axialturbinenstufe im Vergleich zum Verhalten der erben Gitter ihrer Beschaufelung. Ph.D. Thesis, Technische Universität Hannover, Hannover, Germany, 1977. [Google Scholar]

- Hirsch, C.; Denton, J. Through Flow Calculations in Axial Turbomachines. AGARD Advisory Report N.175; Technical Report; AGARD, Propulsion and Energetics Panel, Working Group 12: Neuilly Sur Seine, France, 1981. [Google Scholar]

- Kötzing, P.; Evers, B. Test Case e/tu-4, 4-stage Low Speed Turbine. AGARD Report No.275 AR-275; Technical Report; AGARD: Neuilly Sur Seine, France, 1990. [Google Scholar]

- Menter, F.R. Zonal Two Equation k – ω Turbulence Models for Aerodynamic Flows. In Proceedings of the 23rd Fluid Dynamics, Plasmadynamics, and Lasers Conference, Orlando, FL, USA, 6–9 July 1993.

- Persico, G.; Mora, A.; Gaetani, P.; Savini, M. Unsteady aerodynamics of a low aspect ratio turbine stage: Modeling issues and flow physics. J. Turbomach. 2012, 134. [Google Scholar] [CrossRef]

- Verneau, A. Supersonic turbines for organic fluid Rankine cycles from 3 to 1300 kW; Small High Pressure Ratio Turbines, (VKI Lecture Series 1987-2007); Von Karman Institute For Fluid Dynamics: Rhode-Saint-Genése, Belgium, 1987. [Google Scholar]

- Morris, M.D. Factorial Sampling Plans for Preliminary Computational Experiments. Technometrics 1991, 133, 295–302. [Google Scholar] [CrossRef]

- Saltelli, A.; Tarantola, S.; Campolongo, F.; Ratto, M. Sensitivity Analysis in Practice: A Guide to Assessing Scientific Models; John Wiley & Sons: Chichester, West Sussex, UK, 2004. [Google Scholar]

- Sin, G.; Gernaey, K.V.; Lantz, A.E. Good Modeling Practice for PAT Applications: Propagation of Input Uncertainty and Sensitivity Analysis. Biotechnol. Prog. 2009, 25, 1043–1053. [Google Scholar] [CrossRef] [PubMed]

- Calvi, S. Analisi e validazione di solutori CFD ad alta e bassa fedeltá per turbomacchine. Master’s Thesis, Politecnico di Milano, Milan, Italy, 2015. [Google Scholar]

| Hannover Turbine | Verneau Turbine | |||||

|---|---|---|---|---|---|---|

| Parameter | Symbol | Units | Nozzle | Rotor | Nozzle | Rotor |

| (1) Inlet flow angle | ° | 10 | 0 | |||

| (2) Stage loading coefficient | - | 2.1 | 4.4 | |||

| Nozzle (3) and rotor (4) throat opening | , | mm | 15 | 14 | 1.76 | 1.75 |

| Nozzle (5) and rotor (6) axial chord | , | mm | 48.2 | 37.1 | 12.5 | 12.5 |

| Nozzle (7) and rotor (8) opening to pitch ratio | , | - | 0.378 | 0.358 | 0.277 | 0.425 |

| (9) Rotational speed | N | rpm | 7200 | 18,000 | ||

| (10) Inlet axial velocity | m/s | 55.9 | 10.1 | |||

| (11) Rotor flow coefficient | - | 0.39 | 0.52 | |||

| (12) Rotor inlet to nozzle outlet blade height | - | 1 | 1.039 | |||

| Degree of admission | ε | - | 1 | 0.4 | ||

| Mass flow rate | kg/s | 6.786 | 0.18 | |||

| Total inlet temperature | K | 358.69 | 403 | |||

| Total inlet pressure | Pa | |||||

| Total outlet pressure | Pa | |||||

| Rotor to nozzle mean radius ratio | - | 1.019 | 0.99 | |||

| nozzle-rotor axial clearance | ss | mm | 34.36 | 6.3 | ||

| Radius of blade rear suction side curvature | , | mm | 109.00 | 166.57 | ||

| Trailing edge thickness to blade opening ratio | , | - | 0.0253 | 0.0357 | 0.07 | 0.172 |

| Blade surface roughness | mm | |||||

| Rotor tip clearance | mm | 0.24 | - | |||

| Inlet width arc | - | mm | 29.60 | 34.95 | - | |

| Backbone length | , | mm | 62.10 | 57.63 | - | |

| Trailing edge thickness | , | mm | 0.38 | 0.50 | 0.3 | 0.3 |

| Parameter | Symbol | Units | Exp. Data [39,40,41] | TURAX | CFD [48] | Error TURAX | Error CFD |

|---|---|---|---|---|---|---|---|

| Nozzle outlet absolute flow angle | ° | 69.84 | 68.55 | 68.45 | 1.29 ° | 1.39 ° | |

| Nozzle outlet relative flow angle | ° | 7.13 | 4.60 | 4.82 | 2.53 ° | 2.31 ° | |

| Nozzle outlet absolute velocity | - | 170.8 | 150.8 | 153.84 | 11.8% | 9.95% | |

| Absolute Mach at nozzle outlet | - | 0.457 | 0.406 | 0.412 | 11.2% | 9.9% | |

| Static pressure at nozzle outlet | bar | 0.31% | 0.28% | ||||

| Static temperature at nozzle inlet | K | 357.4 | 357.4 | 357.4 | 0.0% | 0.0% | |

| Static temperature at nozzle outlet | K | 347.17 | 347.75 | 347.06 | 0.17% | 0.03% | |

| Rotor outlet relative flow angle | ° | 68.75 | 69.31 | 67.07 | 0.56 ° | 1.68 ° | |

| Rotor outlet absolute flow angle | ° | 2.45 | 5.91 | 7.58 | 3.46 ° | 5.13 ° | |

| Rotor outlet relative velocity | m/s | 166.3 | 153.9 | 157.51 | 7.43% | 5.30% | |

| Static pressure at rotor outlet | bar | 0.33% | 1.15% | ||||

| Static temperature at rotor outlet | K | 337.86 | 337.96 | 336.60 | 0.03% | 0.37% | |

| Nozzle mean radius | mm | 181.5 | 180.1 | 181.5 | 0.77% | 0% | |

| Rotor mean radius | mm | 185 | 183.5 | 185 | 0.81% | 0% | |

| Nozzle inlet blade height | mm | 89.2 | 89.2 | 89.2 | 0% | 0% | |

| Nozzle outlet (rotor inlet) blade height | mm | 97 | 100.2 | 97 | 3.3% | 0% | |

| Rotor outlet blade height | mm | 103 | 108.1 | 103 | 4.95% | 0% | |

| Nozzle flare angle | ° | 5.62 | 12.83 | 5.62 | 7.21 ° | 0 ° | |

| Rotor flare angle | ° | 7.89 | 12.04 | 7.89 | 4.15 ° | 0 ° | |

| Number of nozzle blades | - | 29 | 28 | 29 | 1 | 0 | |

| Number of rotor blades | - | 30 | 30 | 30 | 0 | 0 | |

| Nozzle kinetic energy loss coefficient | - | 3.79% | 6.48% | 5.82% | 2.69 pp | 2.03 pp | |

| Rotor kinetic energy loss coefficient | - | 9.08% | 6.76% | 6.66% | 2.32 pp | 2.42 pp | |

| Total-to-total stage efficiency | - | 91.62% | 92.84% | 93.32% | 1.22 pp | 1.70 pp |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Meroni, A.; La Seta, A.; Andreasen, J.G.; Pierobon, L.; Persico, G.; Haglind, F. Combined Turbine and Cycle Optimization for Organic Rankine Cycle Power Systems—Part A: Turbine Model. Energies 2016, 9, 313. https://doi.org/10.3390/en9050313

Meroni A, La Seta A, Andreasen JG, Pierobon L, Persico G, Haglind F. Combined Turbine and Cycle Optimization for Organic Rankine Cycle Power Systems—Part A: Turbine Model. Energies. 2016; 9(5):313. https://doi.org/10.3390/en9050313

Chicago/Turabian StyleMeroni, Andrea, Angelo La Seta, Jesper Graa Andreasen, Leonardo Pierobon, Giacomo Persico, and Fredrik Haglind. 2016. "Combined Turbine and Cycle Optimization for Organic Rankine Cycle Power Systems—Part A: Turbine Model" Energies 9, no. 5: 313. https://doi.org/10.3390/en9050313

APA StyleMeroni, A., La Seta, A., Andreasen, J. G., Pierobon, L., Persico, G., & Haglind, F. (2016). Combined Turbine and Cycle Optimization for Organic Rankine Cycle Power Systems—Part A: Turbine Model. Energies, 9(5), 313. https://doi.org/10.3390/en9050313