Wind Turbines’ End-of-Life: Quantification and Characterisation of Future Waste Materials on a National Level

Abstract

:1. Introduction

1.1. Background

1.2. Problem

1.3. Aims and Objective

- (1)

- To develop and describe a generally applicable method for quantification of future waste amounts from wind turbines on a national level.

- (2)

- To apply the method to Sweden as a case and present and discuss the resulting amounts of waste material that will be generated from wind turbines in Sweden during the coming decades.

1.4. Significance

1.5. System Boundaries

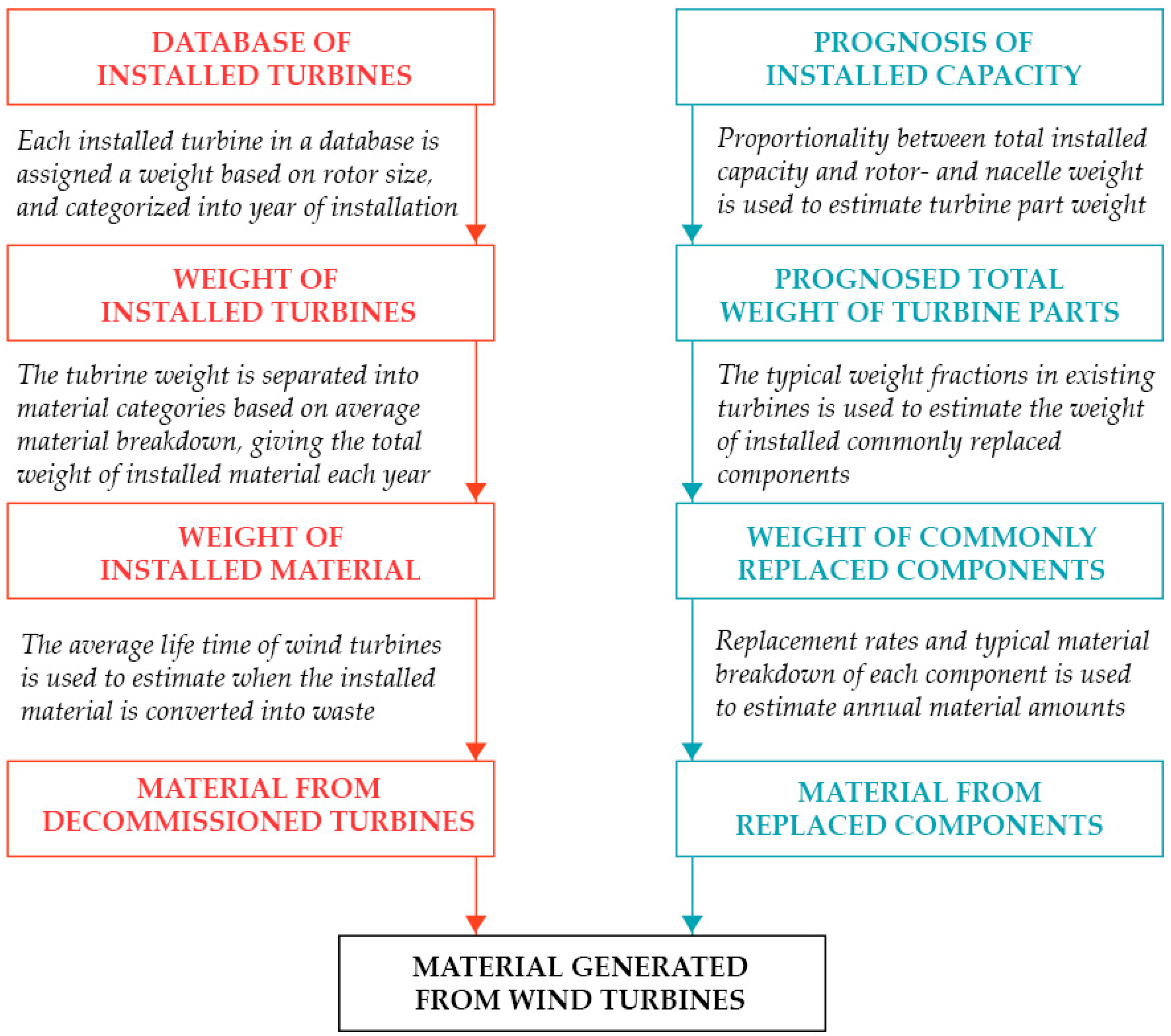

2. Materials and Methods

2.1. Material in Decommissioned Turbines

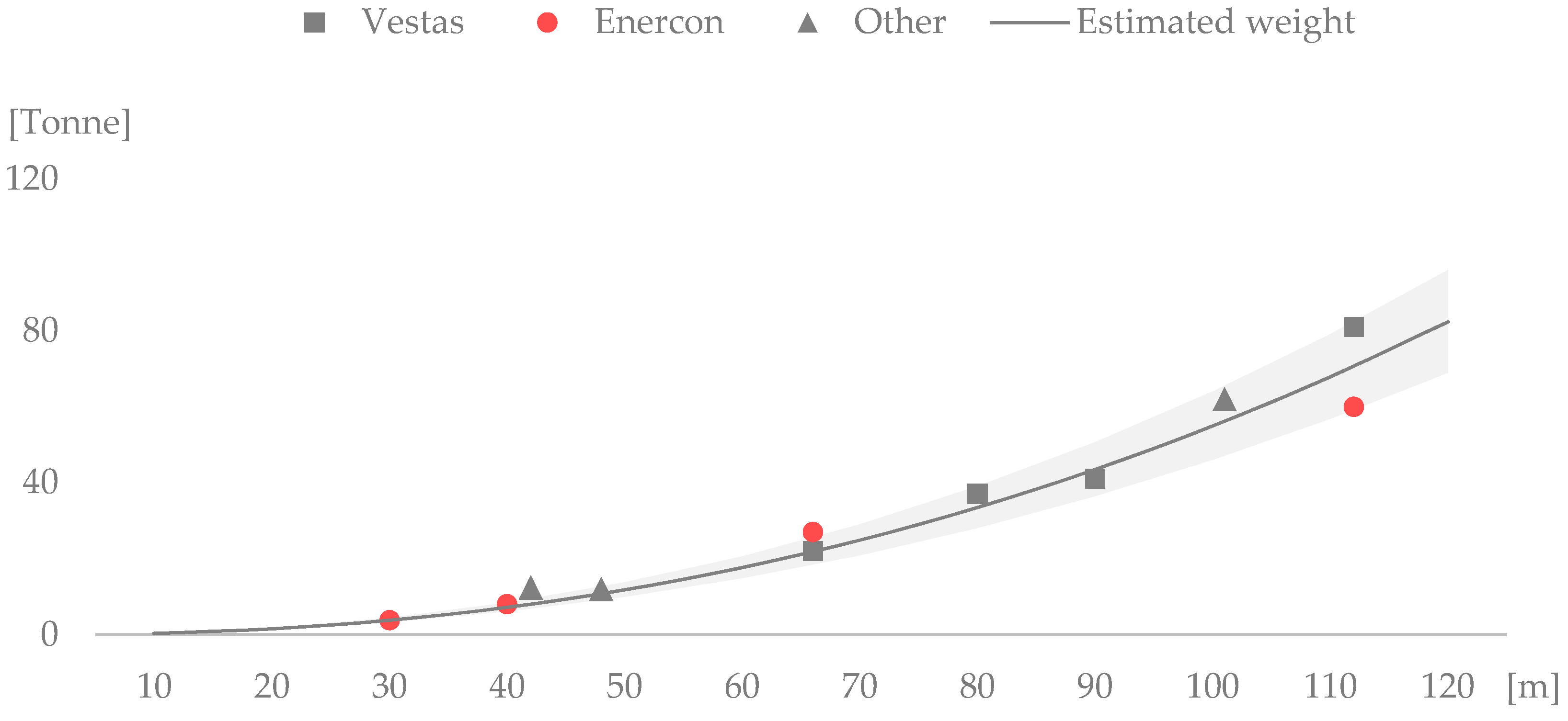

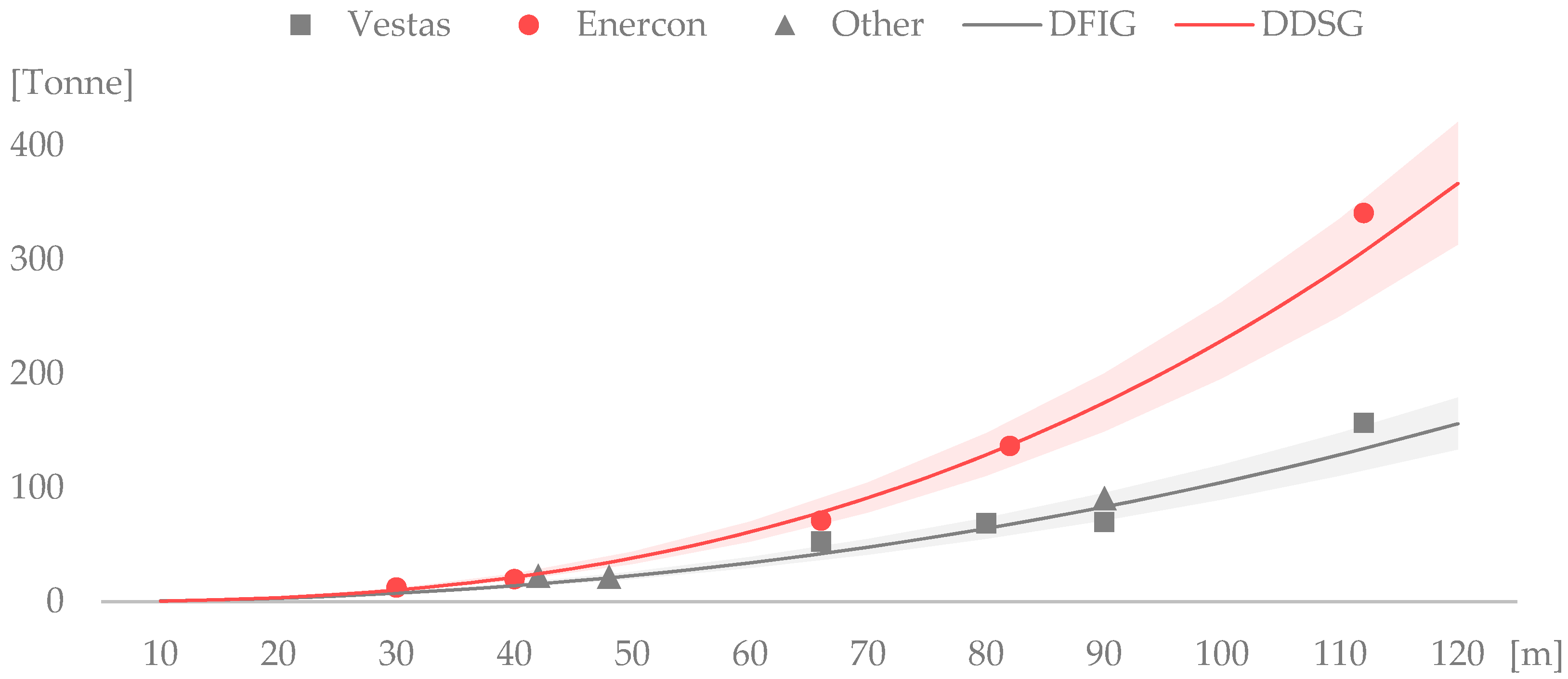

2.1.1. Estimating the Mass of Installed Turbines

- y = Calculated mass of turbine part (kg)

- x = Rotor diameter (m)

- log a = Intercept value

- b = Scaling factor

- mpart = Calculated mass of turbine part (kg)

- d = Rotor diameter (m)

- a = Intercept value

- b = Scaling factor

2.1.2. Material Specification in Wind Turbine Parts

- mm,t = Calculated total amount of a specific material in a wind turbine (kg)

- xm,part = Average fraction of a specific material in a turbine part (Appendix C)

- mpart = Calculated mass of the specific turbine part (kg)

2.1.3. Turbine Life Time

2.2. Material in Replaced Components

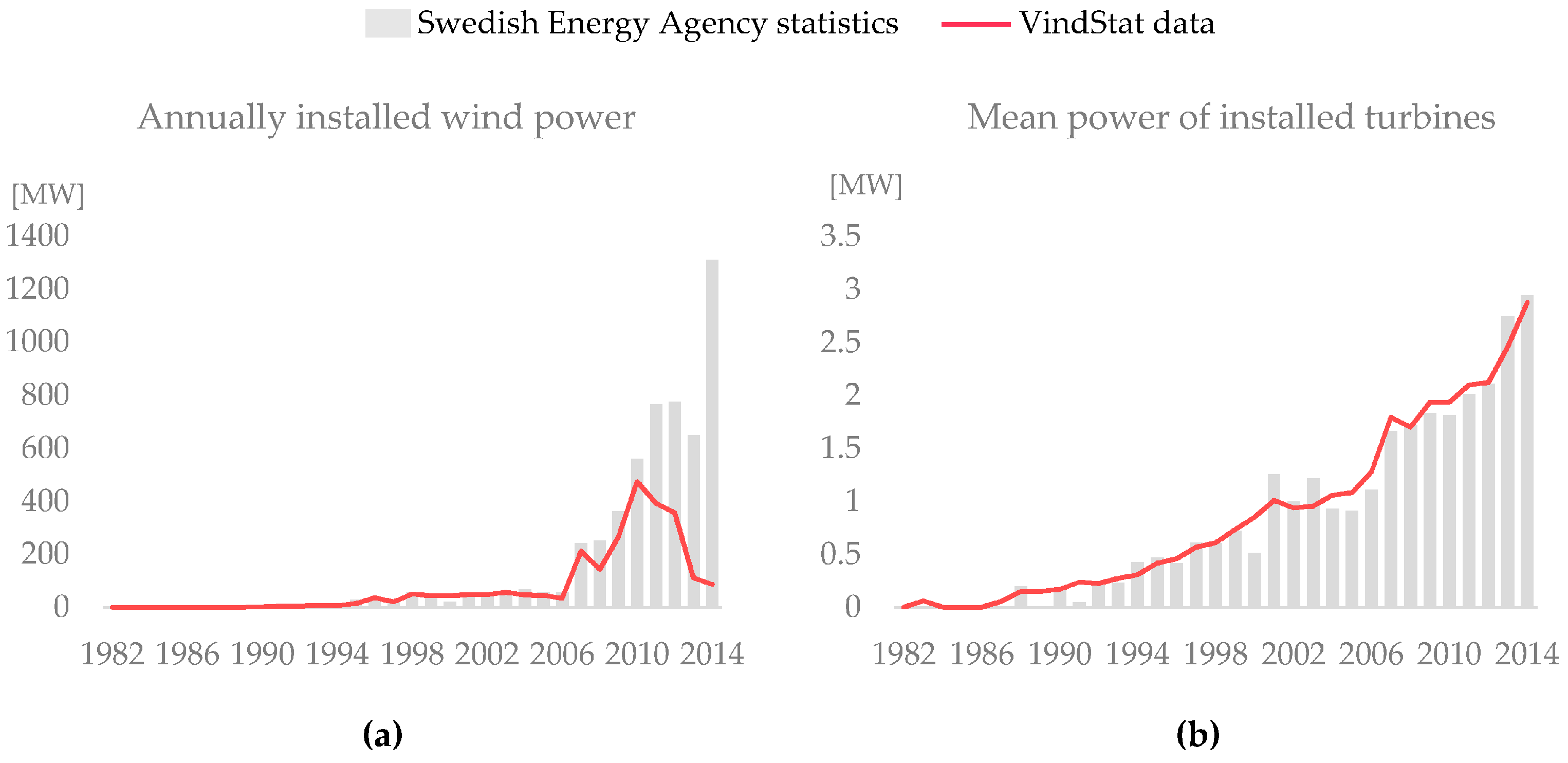

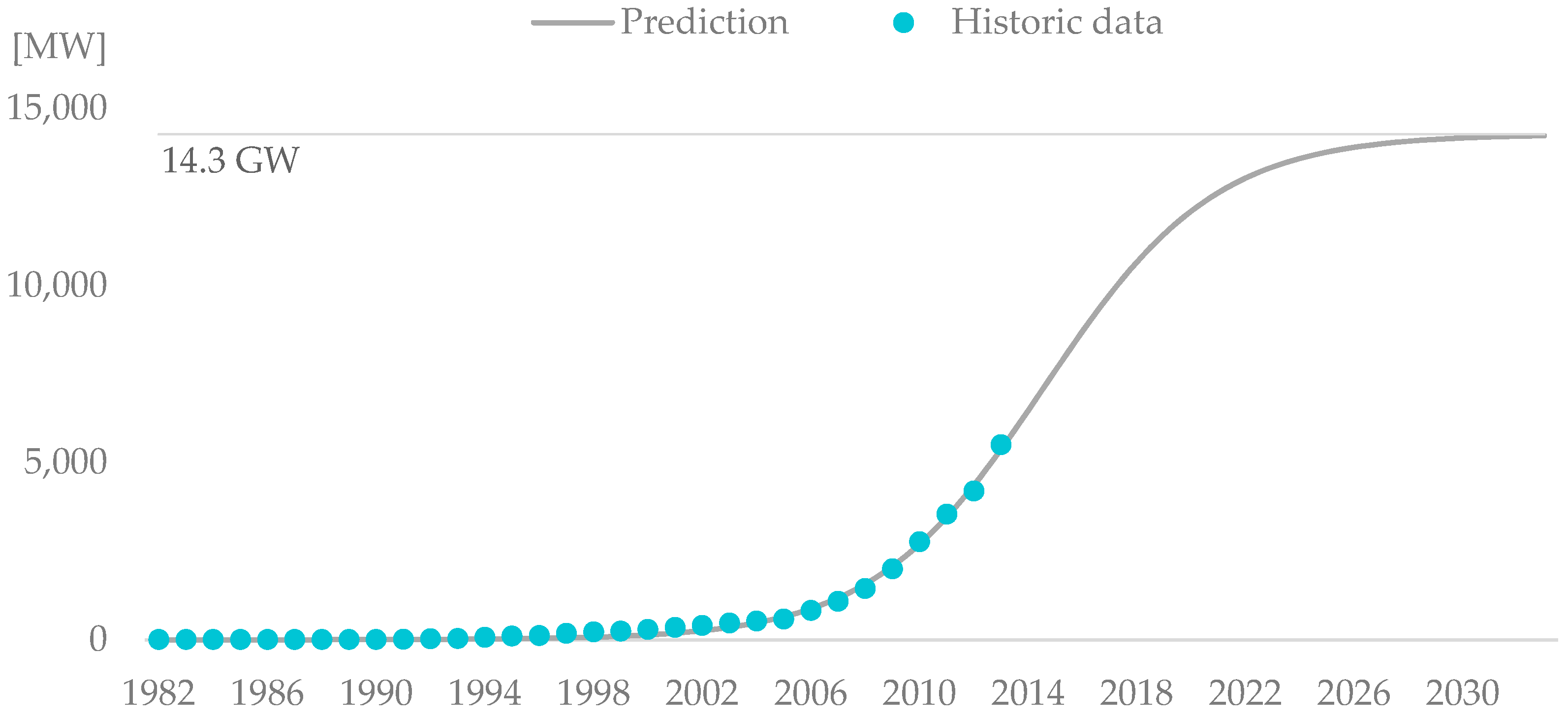

2.2.1. Wind Power Development

- P = Installed capacity

- A = The capacity at which the market is saturated

- k = Steepness factor for the growth curve

- t0 = The year when growth rate reaches its maximum

2.2.2. Mass of Installed Parts

- mrotor,year,tot = Calculated total mass of all installed rotors in a specific year (kg)

- mnacelle,year,tot = Calculated total mass of all installed nacelles in a specific year (kg)

- P = Installed power a specific year (W)

2.2.3. Components’ Mass, Material Specification and Replacement Rate

- mm,part,year,rc = Total mass of material generated from replaced components a specific year (kg)

- mpart,year,tot = Calculated total mass of installed nacelles/rotors in a specific year (kg)

- rc = Components replacement rate (Appendix E)

- xc = Components mass fraction of nacelle or rotor (Appendix E)

- xm,c = Material fraction of component mass (Appendix E)

- mm,rc,tot,year = Total amount of a specific material in replaced components (kg)

- mm,generator,tot,year = The amount of a specific material in replaced generators (kg)

- mm,gearbox,tot,year = The amount of a specific material in replaced gear boxes (kg)

- mm,rotorblade,tot,year = The amount of a specific material in replaced rotor blades (kg)

2.3. Material Generated from Wind Turbines

- mm,tot,year = Calculated amount of waste of a specific material from wind turbines (kg)

- mm,ins,tot,year = Total amount of material in installed turbines 20 years earlier (kg)

- mm,rc,tot,year = Total amount of material in replaced components (kg)

3. Results

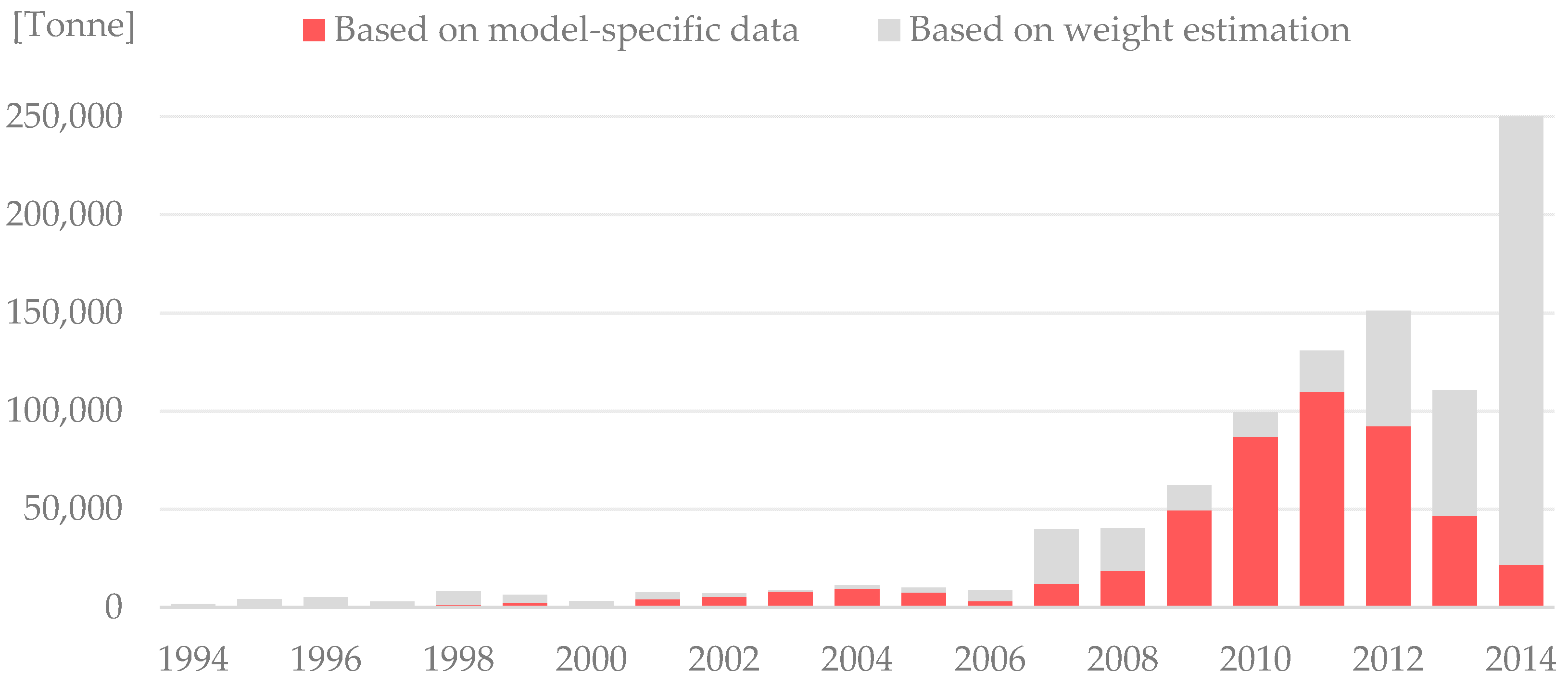

3.1. Calculated Mass of Installed Turbines

3.2. Prognosis of the Swedish Wind Power Development

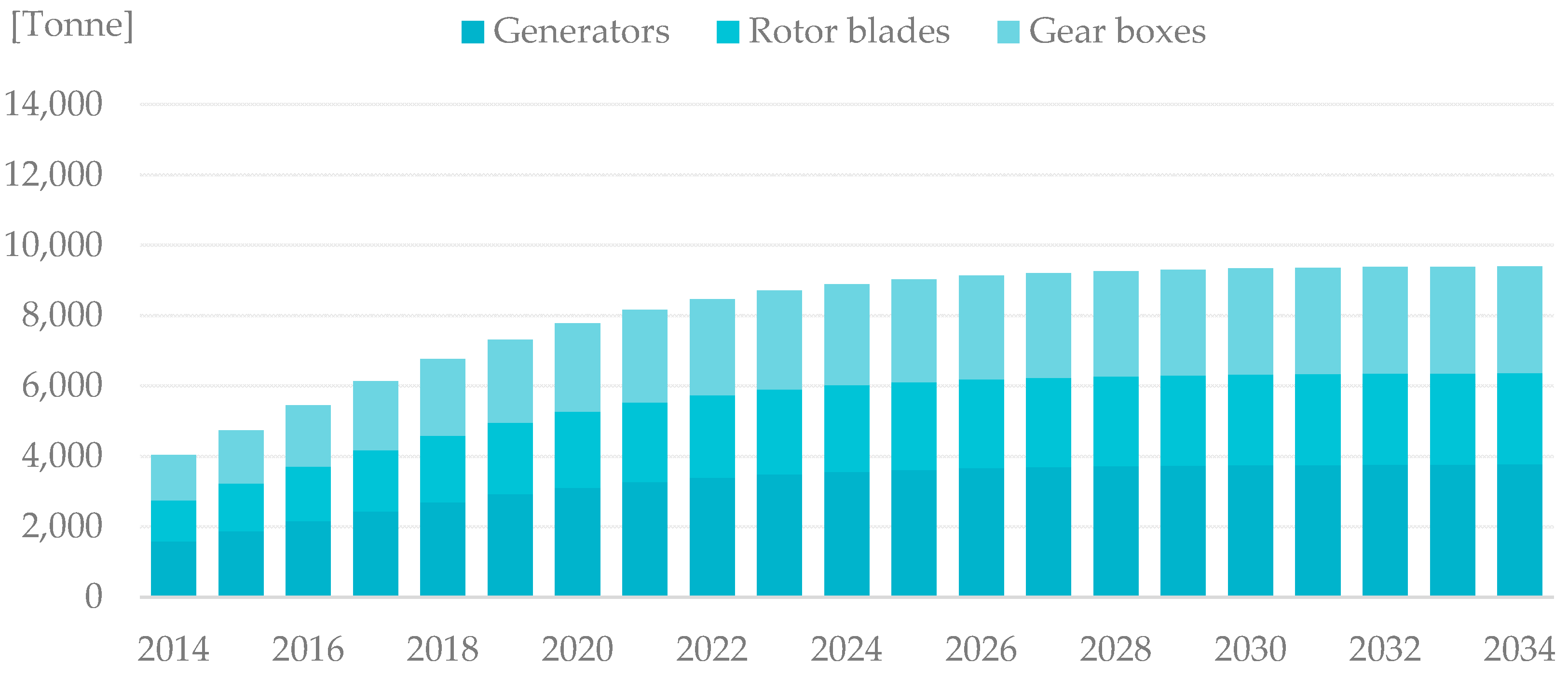

3.3. Mass of Replaced Components

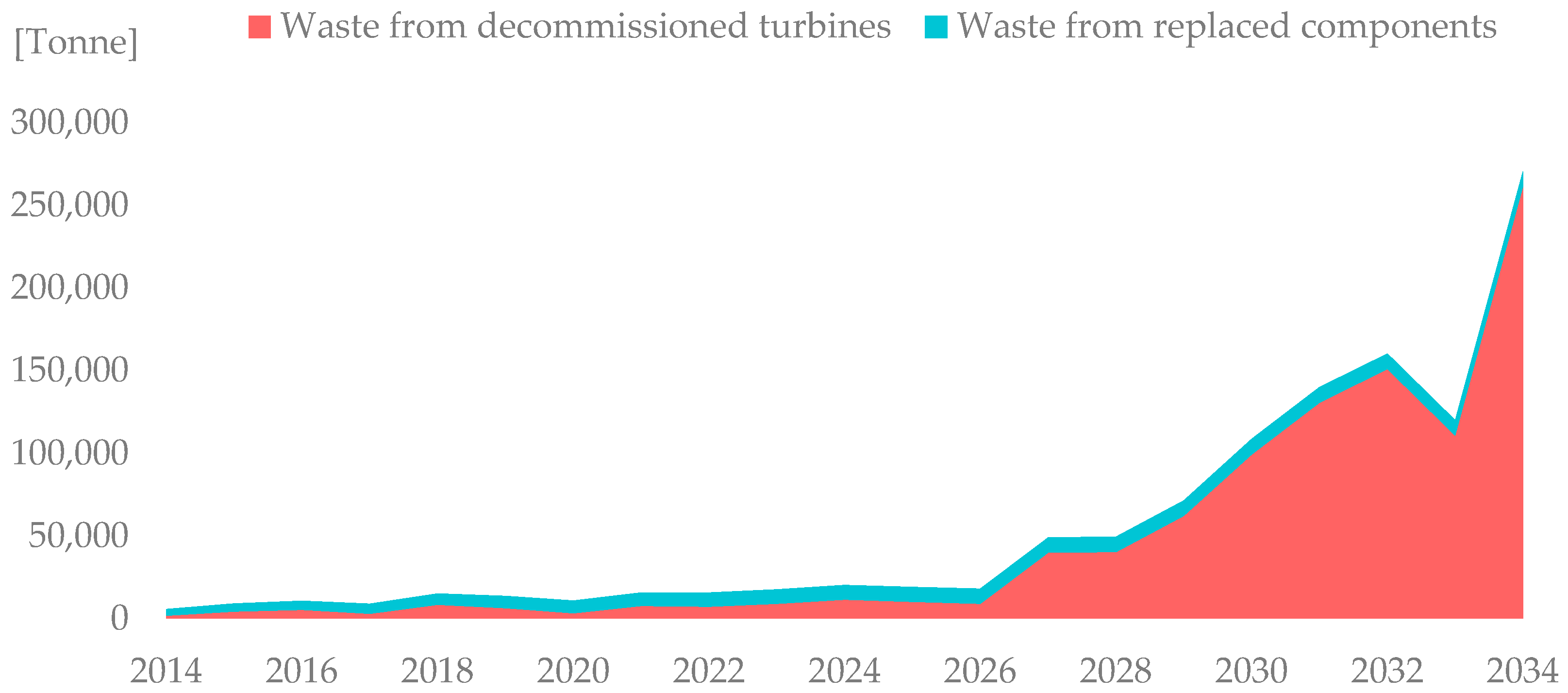

3.4. Total Amount of Waste Material

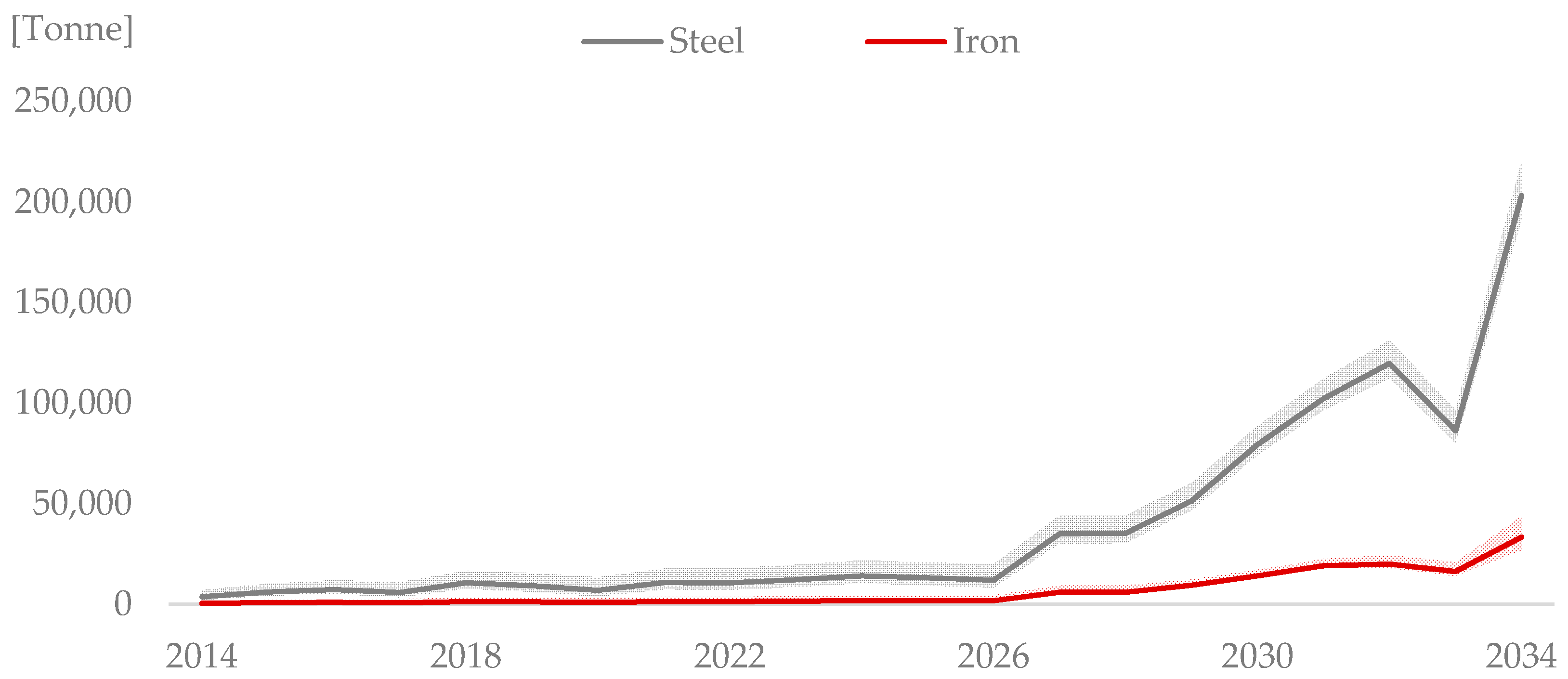

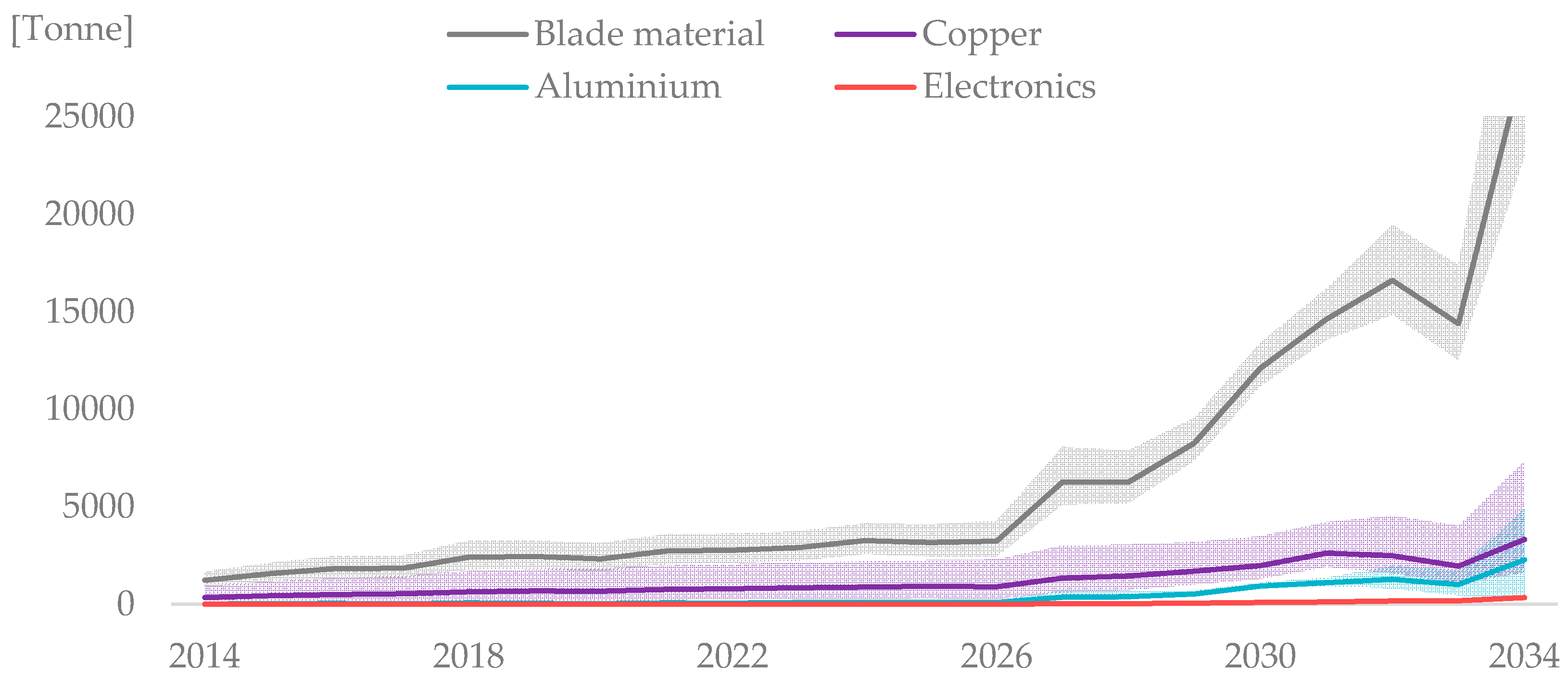

3.5. Estimated Waste Material Separated into Categories

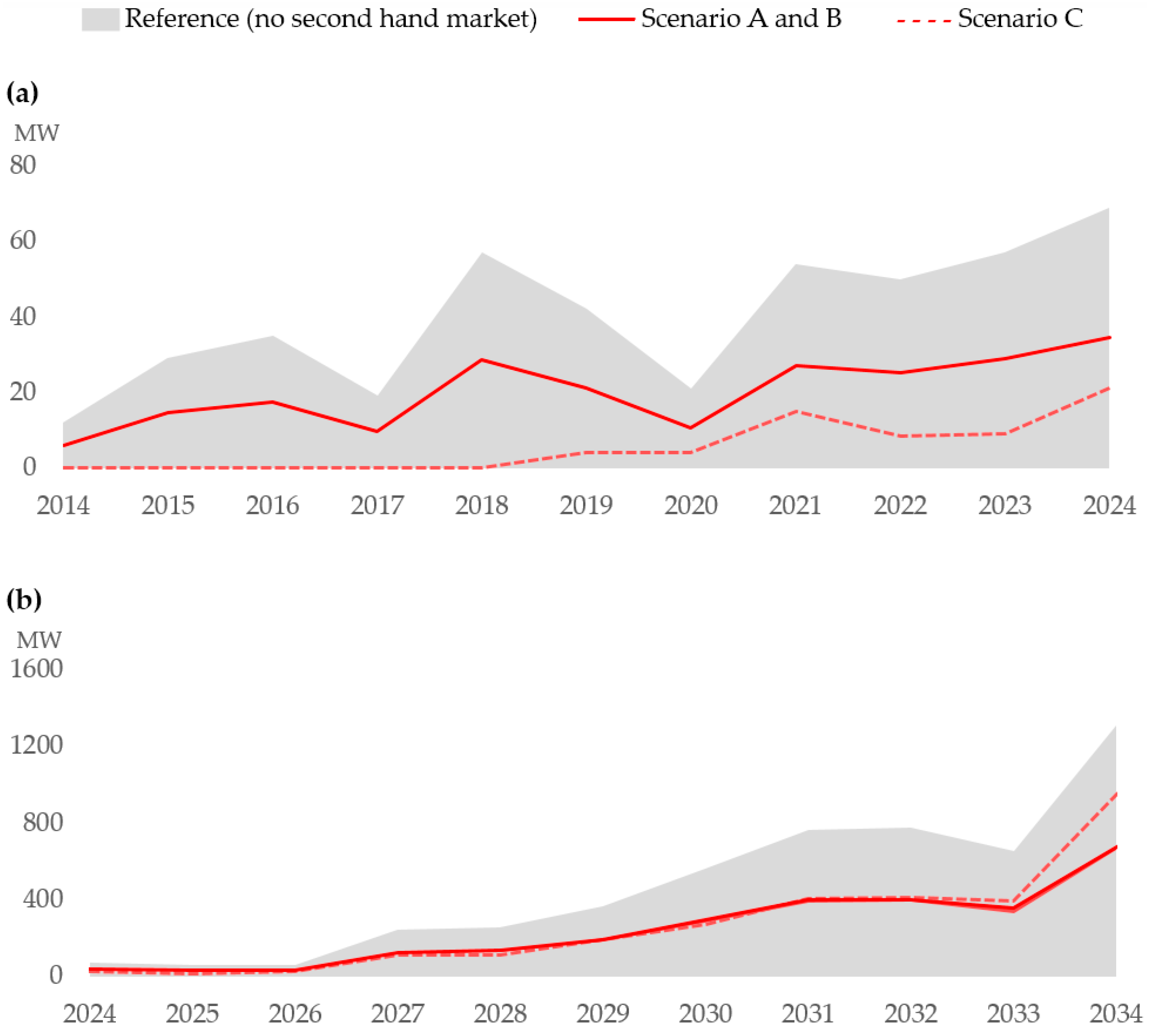

3.6. Re-Use Scenarios

4. Discussion

4.1. Future Waste Amounts in Sweden

4.2. Recycling Capacity

4.3. Climbing the Waste Hierarchy—from Recycling to Re-Use by Second Hand Markets

4.4. Uncertainties

4.5. Future Studies

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Appendix A. Material Specification of Specific Models

| Model | Height | Steel | Iron 1 | Al. 2 | Copper | BM 3 | El. 4 |

|---|---|---|---|---|---|---|---|

| m | Tonne | Tonne | Tonne | Tonne | Tonne | Tonne | |

| Enercon | |||||||

| E40 | 44 | 59 | 9.3 | 0.2 | 2.7 | 1.7 | 0.0 |

| E44 | 55 | 72 | 10 | 0.2 | 2.8 | 7.0 | 0.0 |

| E66 | 98 | 247 | 21 | 0.2 | 9.3 | 18 | 0.1 |

| E70 | 100 | 359 | 46 | 6.9 | 10 | 23 | 0.1 |

| E82 | 107 | 246 | 73 | 1.3 | 11 | 29 | 0.2 |

| E112 | 120 | 642 | 100 | 0.9 | 44 | 68 | 0.6 |

| Vestas | |||||||

| V52 | 50 | 76 | 11 | 1.2 | 1.2 | 8.0 | 0.1 |

| V66 | 67 | 168 | 26 | 2.9 | 3.0 | 19 | 0.3 |

| V80 | 78 | 236 | 21 | 1.7 | 2.8 | 25 | 0.3 |

| V82 | 78 | 186 | 29 | 3.1 | 2.9 | 30 | 0.3 |

| V90 | 80 | 204 | 40 | 4.2 | 1.7 | 37 | 0.4 |

| V112 | 84 | 245 | 66 | 3.4 | 4.9 | 49 | 1.0 |

Appendix B. Turbine Parts’ Mass vs. Rotor Diameter

Appendix C. Material Specification for Generic Turbines

| DFIG | Rotor | Tower | Nacelle |

| Steel | 7% (0–14) | 98% (96–100) | 49% (41–54) |

| Iron | 27% (13–41) | - | 40% (36–47) |

| Aluminium | - | 1% (0–2) | 1% (0–3) |

| Copper | - | 0% (0–1) | 4% (2–8) |

| Blade material | 66% (58–87) | 1% (0–2) | 6% (5–8) |

| Electronics | - | - | 0.6% (-) |

| DDSG | Rotor | Tower | Nacelle |

| Steel | 5% (0–10) | 98% (95–100) | 48% (39–56) |

| Iron | - | - | 40% (30–53) |

| Aluminium | - | 0% (0–2) | 1% (-) |

| Copper | - | 0% (0–1) | 10% (7–13) |

| Blade material | 94% (89–100) | 1% (0–2) | 2% (0–5) |

| Electronics | - | - | 0.13% (0.1–0.17) |

Appendix D. Prognosis of Decommissioned Turbines

Appendix E. Component Properties

| Wind Power Plant Parts | Percent |

|---|---|

| Generator | |

| Percentage of nacelle mass | 30% (16–44) |

| Steel | 79% (68–90) |

| Copper | 21% (10–32) |

| Gear box | |

| Percentage of nacelle mass | 22% (14–31) |

| Steel | 75% (50–100) |

| Iron | 25% (0–50) |

| Rotor blades | |

| Percentage of rotor mass | 71% (58–84) |

| Blade material | 95% (91–100) |

| Steel | 3% (0–9) |

| Aluminium | 0.3% (0–1) |

Appendix F. Scaling up VindStat Data

- mm,ins,tot,year = The total mass of a specific material in installed turbines a specific year (kg)

- mm,ins,tot,year,VS = The total mass of a specific material in turbines present in VindStat (kg)

- xcoverage = VindStat coverage of installed power compared to other statistics (%)

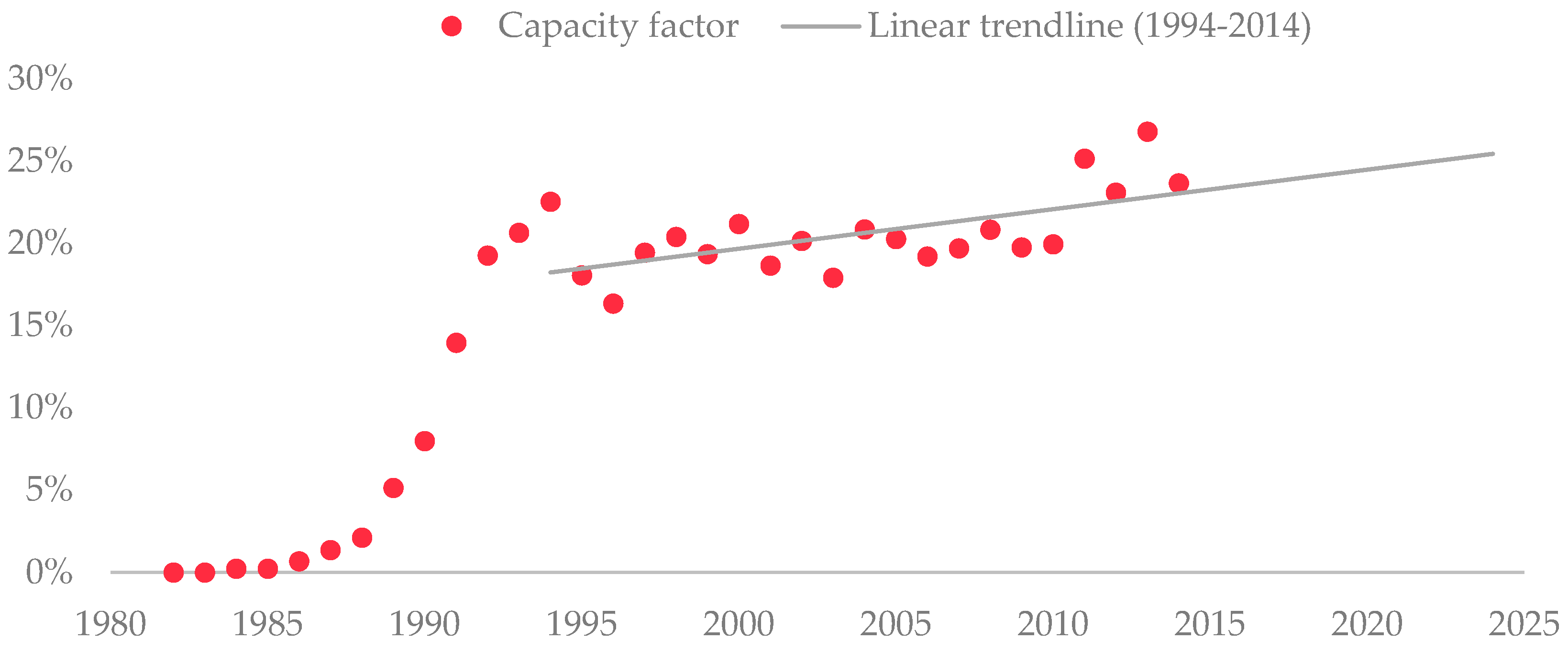

Appendix G. Converting Generated Energy to Installed Power

- E = Generated energy in a year (Wh)

- P = Total installed power that year (W)

- y = Capacity factor (%)

- x = Year

References

- Global Wind Energy Council. Global Wind Statistics. Available online: www.gwec.net/wp-content/.../vip/GWEC-PRstats-2015_LR.pdf (accessed on 25 August 2016).

- Energimyndigheten. Vindkraftstatistik 2014—Tabeller. February 2015. Available online: https://www.energimyndigheten.se/Global/Press/Pressmeddelanden/Vindkraftstatistik%202014.pdf (accessed on 7 July 2015).

- Svensk Vindenergi. Vindkraftstatistik och prognos: Kvartal 4 2014. 13 February 2015. Available online: http://www.vindkraftsbranschen.se/wp-content/uploads/2015/02/Statistik-vindkraft-kvartal-4-2014-20150213.pdf (accessed on 7 July 2015).

- Dolan, S.L.; Heath, G.A. Life cycle greenhouse gas emissions of utility-scale wind power. J. Ind. Ecol. 2012, 16, S136–S154. [Google Scholar] [CrossRef]

- Guezuraga, B.; Zauner, R.; Pölz, W. Life cycle assessment of two different 2 MW class wind turbines. Renew. Energy 2012, 37, 37–44. [Google Scholar] [CrossRef]

- Cherrington, R.; Goodship, V.; Meredith, J.; Wood, B.M.; Coles, S.R.; Vuillaume, A.; Feito-Boirac, A.; Spee, F.; Kirwan, K. Producer responsibility: Defining the incentive for recycling composite wind turbine blades in Europe. Energy Policy 2012, 47, 13–21. [Google Scholar] [CrossRef]

- Hossein Giahi, M.; Jafarian Dehkordi, A. Investigating the influence of dimensional scaling on aerodynamic characteristics of wind turbine using CFD simulation. Renew. Energy 2016, 97, 162–168. [Google Scholar] [CrossRef]

- Ashuri, T.; Zaaijer, M.B.; Martins, J.R.R.A.; Zhang, J. Multidisciplinary design optimization of large wind turbines—Technical, economic, and design challenges. Energy Convers. Manag. 2016, 123, 56–70. [Google Scholar] [CrossRef]

- Ahmadi-Baloutaki, M.; Carriveau, R.; Ting, D.S.K. A wind tunnel study on the aerodynamic interaction of vertical axis wind turbines in array configurations. Renew. Energy 2016, 96, 904–913. [Google Scholar] [CrossRef]

- Shaheen, M.; Abdallah, S. Development of efficient vertical axis wind turbine clustered farms. Renew. Sustain. Energy Rev. 2016, 63, 237–244. [Google Scholar] [CrossRef]

- Jalali, L.; Bigelow, P.; McColl, S.; Majowicz, S.; Gohari, M.; Waterhouse, R. Changes in quality of life and perceptions of general health before and after operation of wind turbines. Environ. Pollut. 2016, in press. [Google Scholar] [CrossRef] [PubMed]

- Blanes-Vidal, V.; Schwartz, J. Wind turbines and idiopathic symptoms: The confounding effect of concurrent environmental exposures. Neurotoxicol. Teratol. 2016, 55, 50–57. [Google Scholar] [CrossRef] [PubMed]

- Jalali, L.; Nezhad-Ahmadi, M.-R.; Gohari, M.; Bigelow, P.; McColl, S. The impact of psychological factors on self-reported sleep disturbance among people living in the vicinity of wind turbines. Environ. Res. 2016, 148, 401–410. [Google Scholar] [CrossRef] [PubMed]

- Effiom, S.O.; Nwankwojike, B.N.; Abam, F.I. Economic cost evaluation on the viability of offshore wind turbine farms in Nigeria. Energy Rep. 2016, 2, 48–53. [Google Scholar] [CrossRef]

- Sarker, B.R.; Ibn Faiz, T. Minimizing maintenance cost for offshore wind turbines following multi-level opportunistic preventive strategy. Renew. Energy 2016, 85, 104–113. [Google Scholar] [CrossRef]

- Verdejo, H.; Escudero, W.; Kliemann, W.; Awerkin, A.; Becker, C.; Vargas, L. Impact of wind power generation on a large scale power system using stochastic linear stability. Appl. Math. Model. 2016, 40, 7977–7987. [Google Scholar] [CrossRef]

- Vasilj, J.; Sarajcev, P.; Jakus, D. Estimating future balancing power requirements in wind–PV power system. Renew. Energy 2016, 99, 369–378. [Google Scholar] [CrossRef]

- Da Rosa, W.M.; Rossoni, P.; Teixeira, J.C.; Belati, E.A. Insertion of wind generators in electrical power systems aimed at active losses reduction using sensitivity analysis. Int. J. Electr. Power Energy Syst. 2016, 80, 306–311. [Google Scholar] [CrossRef]

- Shazib Uddin, M.; Kumar, S. Energy, emissions and environmental impact analysis of wind turbine using life cycle assessment technique. J. Clean. Prod. 2014, 69, 153–164. [Google Scholar] [CrossRef]

- Ji, S.; Chen, B. LCA-based carbon footprint of a typical wind farm in china. Energy Procedia 2016, 88, 250–256. [Google Scholar] [CrossRef]

- Zhong, Z.W.; Song, B.; Loh, P.E. LCAs of a polycrystalline photovoltaic module and a wind turbine. Renew. Energy 2011, 36, 2227–2237. [Google Scholar] [CrossRef]

- Vargas, A.V.; Zenón, E.; Oswald, U.; Islas, J.M.; Güereca, L.P.; Manzini, F.L. Life cycle assessment: A case study of two wind turbines used in Mexico. Appl. Ther. Eng. 2015, 75, 1210–1216. [Google Scholar] [CrossRef]

- Wang, Y.; Sun, T. Life cycle assessment of CO2 emissions from wind power plants: Methodology and case studies. Renew. Energy 2012, 43, 30–36. [Google Scholar] [CrossRef]

- Bonou, A.; Laurent, A.; Olsen, S.I. Life cycle assessment of onshore and offshore wind energy-from theory to application. Appl. Energy 2016, 180, 327–337. [Google Scholar] [CrossRef]

- Demir, N.; Taşkın, A. Life cycle assessment of wind turbines in Pınarbaşı-Kayseri. J. Clean. Prod. 2013, 54, 253–263. [Google Scholar] [CrossRef]

- Ozoemena, M.; Hasan, R.; Cheung, W.M. Analysis of technology improvement opportunities for a 1.5 MW wind turbine using a hybrid stochastic approach in life cycle assessment. Renew. Energy 2016, 93, 369–382. [Google Scholar] [CrossRef]

- Martínez, E.; Jiménez, E.; Blanco, J.; Sanz, F. LCA sensitivity analysis of a multi-megawatt wind turbine. Appl. Energy 2010, 87, 2293–2303. [Google Scholar] [CrossRef]

- Ardente, F.; Beccali, M.; Cellura, M.; Brano, V.L. Energy performances and life cycle assessment of an Italian wind farm. Renew. Sustain. Energy Rev. 2008, 12, 200–217. [Google Scholar] [CrossRef]

- Crawford, R.H. Life cycle energy and greenhouse emissions analysis of wind turbines and the effect of size on energy yield. Renew. Sustain. Energy Rev. 2009, 13, 2653–2660. [Google Scholar] [CrossRef]

- Oebels, K.B.; Pacca, S. Life cycle assessment of an onshore wind farm located at the northeastern coast of Brazil. Renew. Energy 2013, 53, 60–70. [Google Scholar] [CrossRef]

- Tremeac, B.; Meunier, F. Life cycle analysis of 4.5 MW and 250 W wind turbines. Renew. Sustain. Energy Rev. 2009, 13, 2104–2110. [Google Scholar] [CrossRef]

- Kabir, M.R.; Rooke, B.; Dassanayake, G.D.M.; Fleck, B.A. Comparative life cycle energy, emission, and economic analysis of 100 kW nameplate wind power generation. Renew. Energy 2012, 37, 133–141. [Google Scholar] [CrossRef]

- Lenzen, M.; Munksgaard, J. Energy and CO2 life-cycle analyses of wind turbines-review and applications. Renew. Energy 2002, 26, 339–362. [Google Scholar] [CrossRef]

- Schleisner, L. Life cycle assessment of a wind farm and related externalities. Renew. Energy 2000, 20, 279–288. [Google Scholar] [CrossRef]

- Weinzettel, J.; Reenaas, M.; Solli, C.; Hertwich, E.G. Life cycle assessment of a floating offshore wind turbine. Renew. Energy 2009, 34, 742–747. [Google Scholar] [CrossRef]

- Hillman, K.M.; Sandén, B.A. Time and scale in Life Cycle Assessment: The case of fuel choice in the transport sector. Int. J. Altern. Propuls. 2008, 2, 1–12. [Google Scholar] [CrossRef]

- Hillman, K. Environmental Assessment and Strategic Technology Choice: The Case of Renewable Transport Fuels. Ph.D. Thesis, Chalmers University of Technology, Göteborg, Sweden, 2008. [Google Scholar]

- Kushnir, D. Environmental Assessment of Emerging Technologies: The Case of Nanomaterials for Energy Systems. Licentiate Thesis, Chalmers University of Technology, Gothenburg, Sweden, 2010. Available online: http://publications.lib.chalmers.se/publication/121684 (accessed on 28 September 2016). [Google Scholar]

- Arvesen, A.; Hertwich, E.G. Assessing the life cycle environmental impacts of wind power: A review of present knowledge and research needs. Renew. Sustain. Energy Rev. 2012, 16, 5994–6006. [Google Scholar] [CrossRef]

- Kolios, A.; Martínez-Luengo, M. The end of the line for today’s wind turbines. Renew. Energy Focus 2016, 17, 109–111. [Google Scholar] [CrossRef]

- Ortegon, K.; Nies, L.F.; Sutherland, J.W. Preparing for end of service life of wind turbines. J. Clean. Prod. 2013, 39, 191–199. [Google Scholar] [CrossRef]

- VindStat. Available online: http://www.vindstat.nu/stat/index.htm (accessed on 29 September 2016).

- VindStat. Driftuppföljning av Vindkraftverk: Årsrapport 2014; Energimyndigheten: Stockholm, Sweden, 2014. (In Swedish) [Google Scholar]

- Zimmermann, T.; Gößling-Reisemann, S. Influence of site specific parameters on environmental performance of wind energy converters. Energy Procedia 2012, 20, 402–413. [Google Scholar] [CrossRef]

- Garrett, P.; Ronde, K. Life Cycle Assessment of Electricity Production from a V90-2.0 MW Gridstreamer Wind Plant; Vestas Wind Systems A/S: Randers, Denmark, 2011. [Google Scholar]

- Eymann, L.; Stucki, M.; Fürholz, A.; König, A. Ökobilanzierung von Schweizer Windenergie; Bundesamt für Energie BFE: Bern, Switzerland, 2015. [Google Scholar]

- Gueder, M. Energetische Bewertung von Windkraftanlagen; Fachhochschule Würzburg-Schweinfurt: Schweinfurt, Germany, 2004. (In German) [Google Scholar]

- Vestas. Life Cycle Assessment of Electricity Produced from Onshore Sited Wind Power Plants Based on Vestas V82-1.65 MW turbines; Vestas Wind Systems A/S: Randers, Denmark, 2006. [Google Scholar]

- D’Souza, N.; Gbegbaje-Das, E.; Shonfield, P. Life Cycle Assessment of Electricity Production from a V112 Turbine Wind Plant; PE North West Europe ApS: Copenhagen, Denmark, 2011. [Google Scholar]

- Martinez, E.; Sanz, F.; Pellegrini, S.; Jimenez, E.; Blanco, J. Life cycle assessment of a multi-megawatt wind turbine. Renew. Energy 2009, 34, 667–673. [Google Scholar] [CrossRef]

- Ghenai, C. Life Cycle Analysis of Wind Turbine; InTech: Melbourne, FL, USA, 2012. [Google Scholar]

- Staffell, I.; Richard, G. How does wind farm performance decline with age? Renew. Energy 2014, 66, 775–786. [Google Scholar] [CrossRef]

- Echavirria, E.; Hahn, B.; van Bussel, G.J.W.; Tomiyama, T. Reliability of wind turbine technology through time. J. Sol. Energy Eng. 2008, 130, 031005. [Google Scholar] [CrossRef]

- Sheng, S. Report on Wind Turbine Subsystem Reliability—A Survey of Various Databases; National Renewable Energy Laboratory (NREL): Golden, CO, USA, 2013. [Google Scholar]

- Davidsson, S.; Grandell, L.; Wachtmeister, H.; Höök, M. Growth curves and sustained commissioning modelling of energy: Investigating resource constraints for wind energy. Energy Policy 2014, 73, 767–776. [Google Scholar] [CrossRef]

- Caduff, M.; Huijbregts, M.; Althaus, H.-J.; Koehler, A.; Hellweg, S. Wind power electricity: The bigger the turbine, the greener the electricity? Environ. Sci. Technol. 2012, 46, 4725–4733. [Google Scholar] [CrossRef] [PubMed]

- Polinder, H.; van der Pijl, F.F.A.; de Vilder, G.-J.; Tavner, P. Comparison of direct-drive and geared generator concepts for wind turbines. IEEE Trans. Energy Convers. 2006, 21, 725–733. [Google Scholar] [CrossRef]

- Wind Turbine Models. Turbines: Wind Turbine Models. Available online: http://en.wind-turbine-models.com/turbines (accessed on 28 September 2016).

- The Wind Power. SWT-2.3-101: The Wind Power. Available online: http://www.thewindpower.net/turbine_en_551_siemens_swt-2.3-101.php (accessed on 19 May 2015).

- Lindvig, K. The Installation and Servicing of Offshore Wind Farms; European Forum for Renewable Energy Sources: Brussels, Belgium, 2010. [Google Scholar]

- Recktenwald, G. Least Squares Fitting of Data to a Curve. In Numerical Methods with Matlab: Implementations and Applications; Department of Mechanical Engineering, Portland State University: Upper Saddle River, NJ, USA, 2007. [Google Scholar]

- Horste, A.; El-Thalji, I. Växellådshaverier på Landbaserade Vindkraftverk; Elforsk: Stockholm, Sewden, 2011. (In Swedish) [Google Scholar]

- Viberg, E.; Rasouli, A. Underhållet i en Vindkraftpark; Kungliga Tekniska Högskolan: Stockholm, Sewden, 2014. (In Swedish) [Google Scholar]

- Elforsk. Analys av Havererade Asynkrongeneratorer; Energimyndigheten: Stockholm, Sewden, 2002. (In Swedish) [Google Scholar]

- Axelsson, M.G. Tål Elnätet mer Vindkraft? Forskning Och Framsteg. Available online: http://fof.se/tidning/2012/7/tal-elnatet-mer-vindkraft (accessed on 23 June 2015). (In Swedish)

- Söder, L. På väg mot en Elförsörjning Baserad på Enbart Förnybar el i Sverige: En Studie om Behovet av Elkraft; Kungliga Tekniska Högskolan: Stockholm, Sweden, 2013. (In Swedish) [Google Scholar]

- Regeringen. Proposition 2008/09:163: En Sammanhållen Klimat- Och Energipolitik; Regeringskansliet: Stockholm, Sewden, 2009. (In Swedish) [Google Scholar]

- El-Kretsen, A.B. Our Operations 2015. Stockholm, Sweden. 2015. Available online: http://www.el-kretsen.se/sites/el-kretsen_se/files/insamlingsstatistik_2014.pdf (accessed on 8 November 2016).

- Sveriges Geologiska Undersökning. Uppdrag att Utföra en Kartläggning och Analys av Utvinnings- Och Återvinningspotential för Svenska Metall- Och Mineraltillgångar, Redovisning av Regeringsuppdrag; Sveriges Geologiska Undersökning: Uppsala, Sweden, 2014; Available online: http://resource.sgu.se/produkter/regeringsrapporter/utvinnings-och-atervinningspotential-metaller-mineral-2014.pdf (accessed on 8 November 2016). (In Swedish)

- Sandvik Materials Technology. Sandvik Duplex Stainless Steels; S-120-ENG. 01.2009; Sandvikens Tryckeri AB: Gävle, Sweden, 2009. [Google Scholar]

- Innoventum. Innoventum Offers Two Unique Wood Towers. Available online: https://www.innoventum.se/wooden-towers/ (accessed on 16 September 2016).

- Timbertower. Holztürme für Multimegawatt Windkraftanalgen. Available online: http://www.timbertower.de/de/ (accessed on 16 September 2016). (In German)

- New Atlas. Worlds-First Wooden Wind Turbine Starts Spinning in Germany. Available online: http://newatlas.com/timbertower-wooden-wind-turbine/25007/ (accessed on 16 September 2016).

- Arantegui, R.L. JRC Wind Status Report; European Commission: Petten, The Netherlands, 2012. [Google Scholar]

- Energistyrelsen. Master Data Register for Wind Turbines at End of March 2015; Energistyrelsen: Copenhagen, Denmark, 2015. [Google Scholar]

- Keuper, A. Wind energy use in germany—Status 31.12.1993. DEWI Mag. 1994, 25, 5–14. [Google Scholar]

- German Wind Energy Association. Wind Industry in Germany 2014; Bundesverband WindEnergie: Berlin, Germany, 2014. [Google Scholar]

- Deutsche WindGuard. Status of Land-Based Wind Energy Development in Germany; Deutsche WindGuard: Varel, Germany, 2014. [Google Scholar]

- Bruns, E.; Ohlhorst, D. Wind power generation in germany—A transdisciplinary view on the innovation biography. J. Transdiscipl. Environ. Stud. 2011, 10, 46–67. [Google Scholar]

- Lawson, J. Renewable Energy World: Repowering Gives New Life to Old Sites. Available online: http://www.renewableenergyworld.com/rea/news/article/2013/06/repowering-gives-new-life-to-old-wind-sites?cmpid=rss (accessed on 1 May 2015).

- Wizelius, T. Vindkraft i Teori och Praktik 2: A Upplagan; Studentlitteratur: Lund, Sweden, 2007. (In Swedish) [Google Scholar]

| Turbine Part | Intercept Factor | Scaling Factor | SE |

|---|---|---|---|

| Rotor | 0.30 | 2.22 | 0.17 |

| Nacelle (DFIG) | 0.64 | 2.19 | 0.15 |

| Nacelle (DDSG) 1 | 0.20 | 2.58 | - |

| Materials (Tonne) | Recycled Amounts in 2014 | Estimated Material Waste from Wind Turbines | |||

|---|---|---|---|---|---|

| 2024 | 2034 | ||||

| Steel & iron | 1,500,000 | 16,009 | (1%) | 236,656 | (16%) |

| Aluminum | 60,000 | 116 | (0%) | 2290 | (4%) |

| Copper | 65,000 | 891 | (1%) | 3333 | (5%) |

| Blade material 1 | 6000 | 3274 | (55%) | 28,060 | (468%) |

| Electronics | 79,000 | 11 | (0.01%) | 343 | (0.4%) |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Andersen, N.; Eriksson, O.; Hillman, K.; Wallhagen, M. Wind Turbines’ End-of-Life: Quantification and Characterisation of Future Waste Materials on a National Level. Energies 2016, 9, 999. https://doi.org/10.3390/en9120999

Andersen N, Eriksson O, Hillman K, Wallhagen M. Wind Turbines’ End-of-Life: Quantification and Characterisation of Future Waste Materials on a National Level. Energies. 2016; 9(12):999. https://doi.org/10.3390/en9120999

Chicago/Turabian StyleAndersen, Niklas, Ola Eriksson, Karl Hillman, and Marita Wallhagen. 2016. "Wind Turbines’ End-of-Life: Quantification and Characterisation of Future Waste Materials on a National Level" Energies 9, no. 12: 999. https://doi.org/10.3390/en9120999

APA StyleAndersen, N., Eriksson, O., Hillman, K., & Wallhagen, M. (2016). Wind Turbines’ End-of-Life: Quantification and Characterisation of Future Waste Materials on a National Level. Energies, 9(12), 999. https://doi.org/10.3390/en9120999