Combined Biogas and Bioethanol Production: Opportunities and Challenges for Industrial Application

Abstract

:1. Introduction

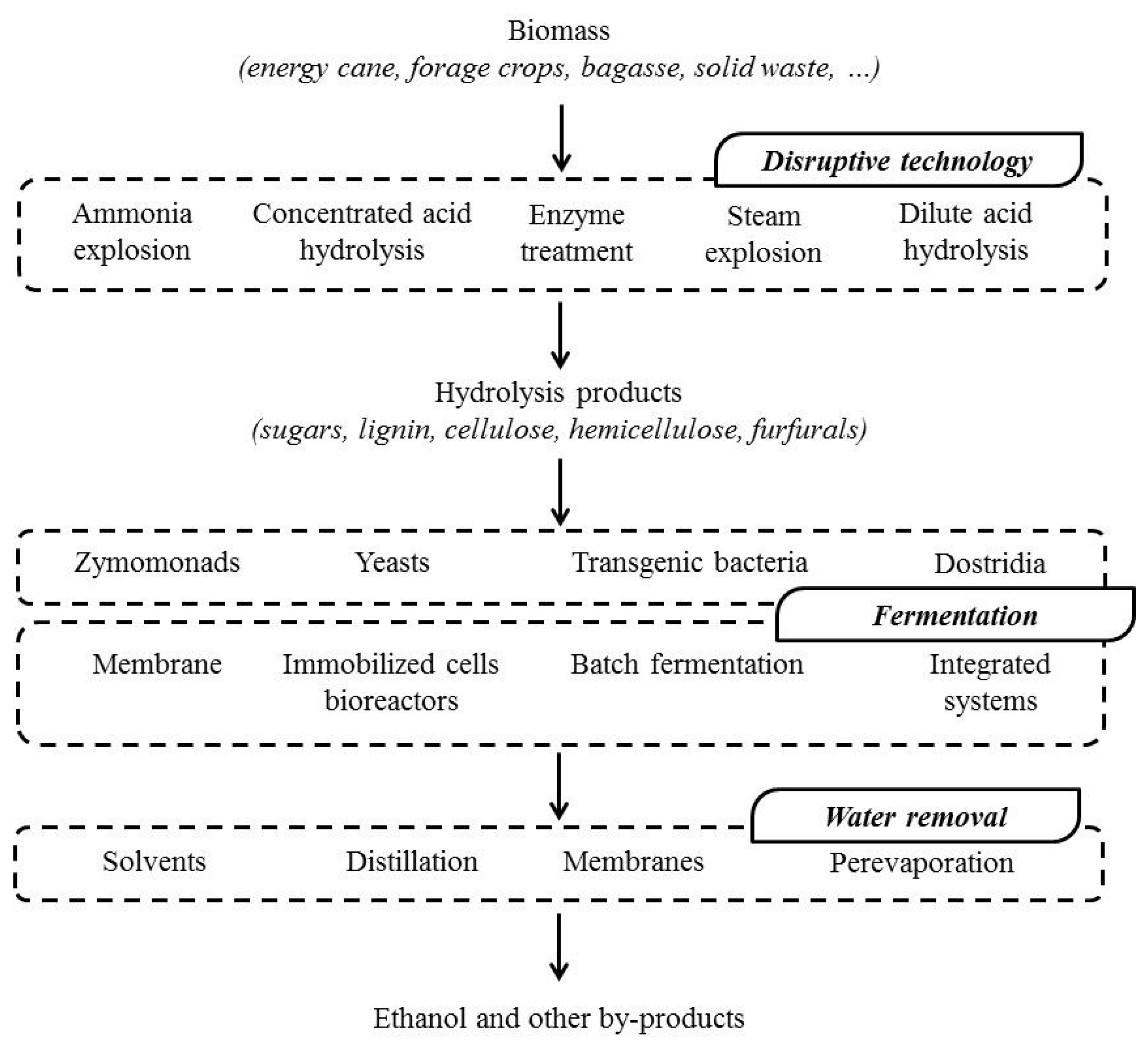

2. Bioethanol Production

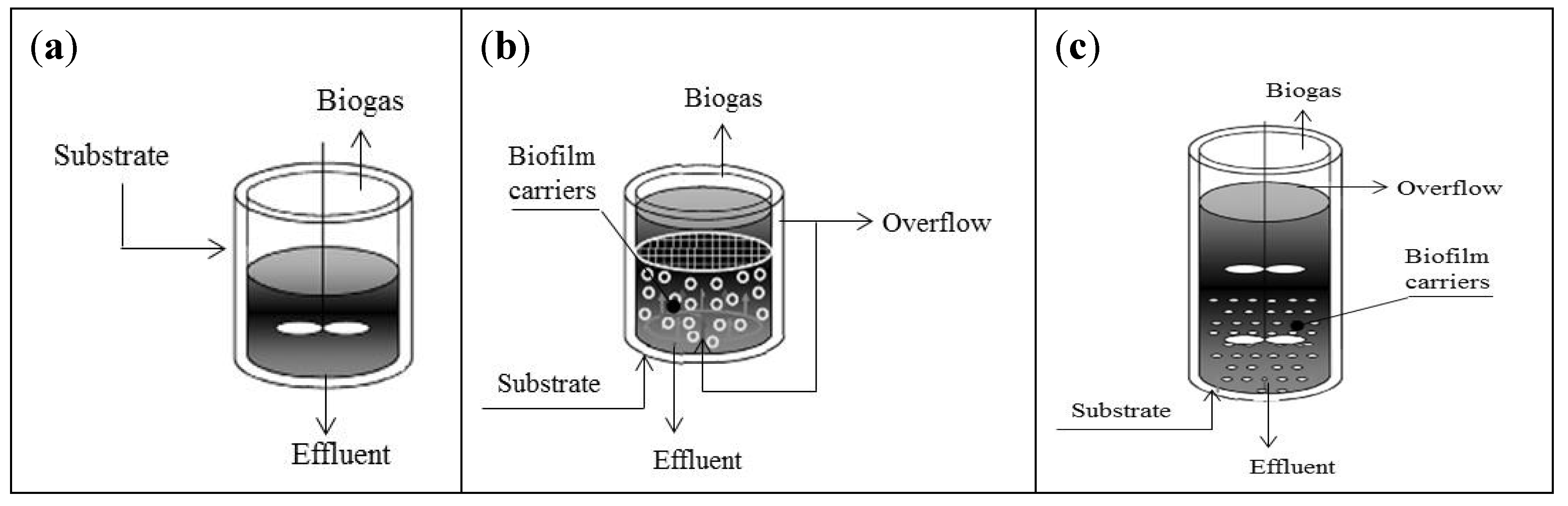

3. Biogas Production

| Constituent | Methane yield [Nm3/tTS] |

|---|---|

| Carbohydrates | 395–400 |

| Raw protein | 497 |

| Raw fat | 816–850 |

| Lignin | 0 |

| Biomass | Cellulose [%] | Hemicellulose [%] | Lignin [%] | Methane potential [Nm3CH4/tVS] | Ref. |

|---|---|---|---|---|---|

| Bagasse | 38.2 | 27.1 | 20.2 | NA | [69] |

| Barley straw | 37.5–45 | 24.2–31.7 | 9.0–26.1 | 226.4 | [69,72,73] |

| Corn stover | 33.7–41.3 | 22.4 | 15.2–18.6 | 80–157.3 | [69,74] |

| Eucalyptus | 38.0–45.0 | 12.0–13.0 | 25.0–37.0 | NA | [69] |

| Leaves | 11.1–12.2 | - | 22.7–23.1 | 47–75 | [69,74] |

| Maize | 37.5 | 30.0 | 10.3 | 418 | [70,75] |

| Pine wood | 26.0–44.15 | 30.5 | 24.3–28.3 | 20 | [69,74,76] |

| Rice straw | 32.0–39.6 | 18.5–24.0 | 13.0–22.7 | 302 | [69,70,77] |

| Sorghum | 22.2 | 19.4 | 21.4 | 286–319 | [69] |

| Sugarcane | 25.0 | 16.8–32.2 | 12.0–31.4 | 278 | [69,70,78] |

| Sunflower stalk | 31.0 | 15.6 | 29.2 | 231–297 | [69] |

| Switch grass | 31.0–45.0 | 20.0–31.0 | 12.0–18.0 | 125 | [69,74] |

| Wheat straw | 32.3–37.9 | 21.2–25.8 | 8.3–23.4 | 130–290 | [69,70,74,79] |

4. The Combination of Bioethanol and Biogas Production Processes

| Biomass | pH [-] | TS [%] | COD [g/L] | Soluble COD [g/L] | Ref. |

|---|---|---|---|---|---|

| Bagasse | - | 6.89 | - | 38.6 | [87] |

| Barley | 4.2 | 5.97 | 29.5 | - | [88,89] |

| Beet molasses | 4.3–6.7 | - | 55.5–147 | - | [89] |

| Cassava | 4.08 | 6.05 | 101.2 | 32.5 | [90] |

| Corn stover | 4.4 | 6.2-7.7 | 74.8 | 73.9 | [91,92] |

| Maize | 3.7 | 3.7–7.5 | 21.85–59.4 | - | [93] |

| Sugarcane | 3.9–4.6 | - | 31.5–45 | - | [94] |

| Sweet sorghum | 4.5 | - | 79.9 | - | [89] |

| Wheat straw | 3.6 | 12.0 | 150–154.2 | 61–76.8 | [95,96] |

| Stillage | AD operating conditions | Highlights | Reference |

|---|---|---|---|

| Algae | Batch tests (60 mL working volume); T = 35 °C | Methane yields in the range 239–283 L/kgVS, corresponding to energy potential 2.24 times higher than that from the ethanol produced in the main process. | [98] |

| Algae | Batch tests (100 mL working volume); T = 35 °C; Inoculum as 4.5 and 20 g VSS/L | The inhibition by dilute-acid hydrolysis byproduct was overcome by increasing inoculum concentration. Under optimal tested condition, 84.8% methane conversion rate was achieved. | [99] |

| Cassava | CSTR batch tests (37 °C and 60 °C) converted into semi-continuous (37 °C) | Under OLR higher than 10 gVS/ L d, the two-phase thermophilic CSTR was stable with hydrogen and methane yields of 56.6 mLH2/gVS and 249 mLCH4/gVS, respectively. | [100] |

| Cereal | Semi-continuous CSTR (5 L); T = 35 °C. Manure used as co-substrate (15% based on VS) | Anaerobic digestion of whole stillage turned to instability after 120 days of operation. Co-digestion with manure improved process stability and methane yield compared with theoretical values. | [101] |

| Corn | Anaerobic fluidized bed bioreactor (AFBR) employing zeolite as the carrier media; T = 37 °C | The AFBR showed up to 88% TCOD and 78% TSS removal at OLR of 29 kg COD/m3 d and HRT of 3.5 days. Methane production rates of up to 40 L/L stillage d was reached at the steady state. | [102] |

| Corn | BMP assays with alkalinity adjustment; T = 35 °C and 55 °C | Methane potential up to 1 L/gVS, with the best performances under thermophilic conditions. | [103] |

| ? | Semi continuous tests at SRT of 60, 45 and 35 days; T = 35 °C and 55 °C | Thermophilic digester was unable to cope with high organic loading rate at SRT of 60 days, whereas under mesophilic conditions, the digester was stable with 58 LCH4/kg stillage. | |

| Corn | BMP assays with alkalinity adjustment; T = 35 °C; ISR: 3.67–0.46 g/g | At the organic loading rate of 0.46 g/g, degradation was completed in 15–16 days. Methane potential in standard conditions was found in the range 401-458 mL/g VS added, with organic removals between 76% and 94% in batch mode. | [104] |

| Corn | Batch test (250 mL); T = 35 °C; ISR: 0.5–3.0 gVS/gVS; Mechanically shaking provided | Thin stillage, treated by centrifugation and lime addition, resulted in rapid production of high levels of biogas (763 mL biogas/gVS added), under the optimal ISR of 2.0 gVS/gVS. | [105] |

| Corn | Batch tests; T = 35 °C; Substrate/inoculum ratios: 4–8 gTCOD/gVSS | Two-stage process enabled 18.5% increase in total energy yield. | [106] |

| Corn | Batch tests (2.8 L working volume); T = 35 °C | Anaerobic digestion of corn stillage was able to improve the overall content utilization and extract a greater yield of lignocellulosic biomass compared to ethanol fermentation alone. | [107] |

| Grain | Continuous UASB reactor (working volume of 255 mL); HRT = 48 h; T = 55 °C | Maximum methane yield of 155 ml/gCOD was obtained at stillage mixtures with water of 25% (v/v) in the feed and at an OLR of 17.1 gCOD/L d. | [95] |

| Grain | CSTR (5 L), FBR (12.9 L) and ASBR (13 L); T = 38 °C; OLR up to 10 gVS/L d | At HRT as low as 6 days, good performances can be achieved by continuous grain anaerobic digestion when trace elements are supplemented, despite the reactor system. | [108] |

| Grain | Semi continuous CSTR digester; T = 38 °C and 44 °C; OLR up to 6 gVS/L d | Operation at 44 °C was the most successful strategy, resulting in up to 22% higher methane yield compared with the mesophilic reactor. | [109] |

| Grain | CSTR digester (12 L); T = 35 °C; OLR = 10 gVS/L d; HRT = 7–8.5 days | The depletion of Fe and Ni resulted in a rapid accumulation of volatile fatty acids while Co and W seem to have a long-term effect. | [110] |

| Grain | Semi continuous CSTR digester (4 L working volume); T = 35 °C; OLR = 2.5 and 4 gVS/L d | The solubility and speciation of supplemented Fe were controlled by precipitation of FeS(s) and formation of the aqueous complexes of Fe-sulfide and Fe-thiol. | [111] |

| Kitchen garbage | Semi continuous CSTR digester (8 L working volume) with biogas recirculation; T = 53 °C and 60 °C; OLR = 7 gVS/L d | A biogas recirculation ratio of 150 facilitated stable digestion performance and biogas production, while the ammonia removal efficiency increased 1.23-fold when the temperature increased from 53 °C to 60 °C. | [112] |

| Sugarcane bagasse | BMP assay, 55 °C | Methane potential over 80 days was approximately 10 mLCH4/mLstillage, with 85% of ultimate methane yield produced in 50 days. | [87] |

The Use of Digestate for Bioethanol Production

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Maity, S.K. Opportunities, recent trends and challenges of integrated biorefinery: Part I. Renew. Sustain. Energy Rev. 2015, 43, 1427–1445. [Google Scholar] [CrossRef] [Green Version]

- Nigam, P.S.; Singh, A. Production of liquid biofuels from renewable resources. Prog. Energy Combust. Sci. 2011, 37, 52–68. [Google Scholar] [CrossRef]

- Bazmi, A.A.; Zahedi, G. Sustainable energy systems: Role of optimization modeling techniques in power generation and supply—A review. Renew. Sustain. Energy Rev. 2011, 15, 3480–3500. [Google Scholar] [CrossRef]

- Cucchiella, F.; D’Adamo, I. Issue on supply chain of renewable energy. Energy Convers. Manag. 2013, 76, 774–780. [Google Scholar] [CrossRef]

- Long, H.; Li, X.; Wang, H.; Jia, J. Biomass resources and their bioenergy potential estimation: A review. Renew. Sustain. Energy Rev. 2013, 26, 344–352. [Google Scholar] [CrossRef]

- Angelis-Dimakis, A.; Biberacher, M.; Dominguez, J.; Fiorese, G.; Gadocha, S.; Gnansounou, E.; Guariso, G.; Kartalidis, A.; Panichelli, L.; Pinedo, I.; et al. Methods and tools to evaluate the availability of renewable energy sources. Renew. Sustain. Energy Rev. 2011, 15, 1182–1200. [Google Scholar] [CrossRef]

- Gabrielle, B.; Bamière, L.; Caldes, N.; De Cara, S.; Decocq, G.; Ferchaud, F.; Loyce, C.; Pelzer, E.; Perez, Y.; Wohlfahrt, J.; et al. Paving the way for sustainable bioenergy in Europe: Technological options and research avenues for large-scale biomass feedstock supply. Renew. Sustain. Energy Rev. 2014, 33, 11–25. [Google Scholar] [CrossRef]

- Chadwick, D.T.; McDonnell, K.P.; Brennan, L.P.; Fagan, C.C.; Everard, C.D. Evaluation of infrared techniques for the assessment of biomass and biofuel quality parameters and conversion technology processes: A review. Renew. Sustain. Energy Rev. 2014, 30, 672–681. [Google Scholar] [CrossRef]

- Fiorese, G.; Catenacci, M.; Bosetti, V.; Verdolini, E. The power of biomass: Experts disclose the potential for success of bioenergy technologies. Energy Policy 2014, 65, 94–114. [Google Scholar] [CrossRef]

- Tekin, K.; Karagöz, S.; Bektaş, S. A review of hydrothermal biomass processing. Renew. Sustain. Energy Rev. 2014, 40, 673–687. [Google Scholar] [CrossRef]

- Khan, A.A.; de Jong, W.; Jansens, P.J.; Spliethoff, H. Biomass combustion in fluidized bed boilers: Potential problems and remedies. Fuel Process. Technol. 2009, 90, 21–50. [Google Scholar] [CrossRef]

- Ward, J.; Rasul, M.G.; Bhuiya, M.M.K. Energy Recovery from Biomass by Fast Pyrolysis. Procedia Eng. 2014, 90, 669–674. [Google Scholar] [CrossRef]

- Abnisa, F.; Wan Daud, W.M.A. A review on co-pyrolysis of biomass: An optional technique to obtain a high-grade pyrolysis oil. Energy Convers. Manag. 2014, 87, 71–85. [Google Scholar] [CrossRef]

- Albertazzi, S.; Basile, F.; Brandin, J.; Einvall, J.; Hulteberg, C.; Fornasari, G.; Rosetti, V.; Sanati, M.; Trifirò, F.; Vaccari, A. The technical feasibility of biomass gasification for hydrogen production. Catal. Today 2005, 106, 297–300. [Google Scholar] [CrossRef]

- Batidzirai, B.; Mignot, A.P.R.; Schakel, W.B.; Junginger, H.M.; Faaij, A.P.C. Biomass torrefaction technology: Techno-economic status and future prospects. Energy 2013, 62, 196–214. [Google Scholar] [CrossRef]

- Van der Stelt, M.J.C.; Gerhauser, H.; Kiel, J.H.A.; Ptasinski, K.J. Biomass upgrading by torrefaction for the production of biofuels: A review. Biomass Bioenergy 2011, 35, 3748–3762. [Google Scholar] [CrossRef]

- Elliott, D.C.; Biller, P.; Ross, A.B.; Schmidt, A.J.; Jones, S.B. Hydrothermal liquefaction of biomass: Developments from batch to continuous process. Bioresour. Technol. 2015, 178, 147–156. [Google Scholar] [CrossRef] [PubMed]

- Brand, S.; Kim, J. Liquefaction of major lignocellulosic biomass constituents in supercritical ethanol. Energy 2015, 80, 64–74. [Google Scholar] [CrossRef]

- Srirangan, K.; Akawi, L.; Moo-Young, M.; Chou, C.P. Towards sustainable production of clean energy carriers from biomass resources. Appl. Energy 2012, 100, 172–186. [Google Scholar] [CrossRef]

- Kumar, A.; Kumar, N.; Baredar, P.; Shukla, A. A review on biomass energy resources, potential, conversion and policy in India. Renew. Sustain. Energy Rev. 2015, 45, 530–539. [Google Scholar] [CrossRef]

- Cherubini, F. The biorefinery concept: Using biomass instead of oil for producing energy and chemicals. Energy Convers. Manag. 2010, 51, 1412–1421. [Google Scholar] [CrossRef]

- Nallathambi Gunaseelan, V. Anaerobic digestion of biomass for methane production: A review. Biomass Bioenergy 1997, 13, 83–114. [Google Scholar] [CrossRef]

- Ward, A.J.; Lewis, D.M.; Green, F.B. Anaerobic digestion of algae biomass: A review. Algal Res. 2014, 5, 204–214. [Google Scholar] [CrossRef]

- Morales, M.; Quintero, J.; Conejeros, R.; Aroca, G. Life cycle assessment of lignocellulosic bioethanol: Environmental impacts and energy balance. Renew. Sustain. Energy Rev. 2015, 42, 1349–1361. [Google Scholar] [CrossRef]

- Manzetti, S.; Andersen, O. A review of emission products from bioethanol and its blends with gasoline. Background for new guidelines for emission control. Fuel 2015, 140, 293–301. [Google Scholar] [CrossRef]

- Yue, D.; You, F.; Snyder, S.W. Biomass-to-bioenergy and biofuel supply chain optimization: Overview, key issues and challenges. Comput. Chem. Eng. 2014, 66, 36–56. [Google Scholar] [CrossRef]

- Posada, J.A.; Patel, A.D.; Roes, A.; Blok, K.; Faaij, A.P.C.; Patel, M.K. Potential of bioethanol as a chemical building block for biorefineries: Preliminary sustainability assessment of 12 bioethanol-based products. Bioresour. Technol. 2013, 135, 490–499. [Google Scholar] [CrossRef] [PubMed]

- Sarkar, N.; Ghosh, S.K.; Bannerjee, S.; Aikat, K. Bioethanol production from agricultural wastes: An overview. Renew. Energy 2012, 37, 19–27. [Google Scholar] [CrossRef]

- Weiland, P. Biogas production: current state and perspectives. Appl. Microbiol. Biotechnol. 2010, 85, 849–860. [Google Scholar] [CrossRef] [PubMed]

- Oleskowicz-Popiel, P.; Kádár, Z.; Heiske, S.; Klein-Marcuschamer, D.; Simmons, B.A.; Blanch, H.W.; Schmidt, J.E. Co-production of ethanol, biogas, protein fodder and natural fertilizer in organic farming – Evaluation of a concept for a farm-scale biorefinery. Bioresour. Technol. 2012, 104, 440–446. [Google Scholar] [CrossRef] [PubMed]

- Parajuli, R.; Dalgaard, T.; Jørgensen, U.; Adamsen, A.P.S.; Knudsen, M.T.; Birkved, M.; Gylling, M.; Schjørring, J.K. Biorefining in the prevailing energy and materials crisis: A review of sustainable pathways for biorefinery value chains and sustainability assessment methodologies. Renew. Sustain. Energy Rev. 2015, 43, 244–263. [Google Scholar] [CrossRef] [Green Version]

- Martin, M.; Svensson, N.; Fonseca, J.; Eklund, M. Quantifying the environmental performance of integrated bioethanol and biogas production. Renew. Energy 2014, 61, 109–116. [Google Scholar] [CrossRef]

- Balat, M. Production of bioethanol from lignocellulosic materials via the biochemical pathway: A review. Energy Convers. Manag. 2011, 52, 858–875. [Google Scholar] [CrossRef]

- Scott, F.; Venturini, F.; Aroca, G.; Conejeros, R. Selection of process alternatives for lignocellulosic bioethanol production using a MILP approach. Bioresour. Technol. 2013, 148, 525–534. [Google Scholar] [CrossRef] [PubMed]

- Limayem, A.; Ricke, S.C. Lignocellulosic biomass for bioethanol production: Current perspectives, potential issues and future prospects. Prog. Energy Combust. Sci. 2012, 38, 449–467. [Google Scholar] [CrossRef]

- Saxena, R.C.; Adhikari, D.K.; Goyal, H.B. Biomass-based energy fuel through biochemical routes: A review. Renew. Sustain. Energy Rev. 2009, 13, 167–178. [Google Scholar] [CrossRef]

- Lin, Y.; Zhang, W.; Li, C.; Sakakibara, K.; Tanaka, S.; Kong, H. Factors affecting ethanol fermentation using Saccharomyces cerevisiae BY4742. Biomass Bioenergy 2012, 47, 395–401. [Google Scholar] [CrossRef]

- De Souza, C.J.A.; Costa, D.A.; Rodrigues, M.Q.R.B.; dos Santos, A.F.; Lopes, M.R.; Abrantes, A.B.P.; dos Santos Costa, P.; Silveira, W.B.; Passos, F.M.L.; Fietto, L.G. The influence of presaccharification, fermentation temperature and yeast strain on ethanol production from sugarcane bagasse. Bioresour. Technol. 2012, 109, 63–69. [Google Scholar] [CrossRef] [PubMed]

- Dragone, G.; Silva, D.P.; de Almeida e Silva, J.B. Factors influencing ethanol production rates at high-gravity brewing. LWT-Food Sci. Technol. 2004, 37, 797–802. [Google Scholar] [CrossRef]

- Wang, P.-M.; Zheng, D.-Q.; Chi, X.-Q.; Li, O.; Qian, C.-D.; Liu, T.-Z.; Zhang, X.-Y.; Du, F.-G.; Sun, P.-Y.; Qu, A.-M.; et al. Relationship of trehalose accumulation with ethanol fermentation in industrial Saccharomyces cerevisiae yeast strains. Bioresour. Technol. 2014, 152, 371–376. [Google Scholar] [CrossRef] [PubMed]

- Alkasrawi, M.; Abu Jrai, A.; Al-Muhtaseb, A.H. Simultaneous saccharification and fermentation process for ethanol production from steam-pretreated softwood: Recirculation of condensate streams. Chem. Eng. J. 2013, 225, 574–579. [Google Scholar] [CrossRef]

- Fujimoto, S.; Yanagida, T.; Nakaiwa, M.; Tatsumi, H.; Minowa, T. Pinch analysis for bioethanol production process from lignocellulosic biomass. Appl. Therm. Eng. 2011, 31, 3332–3336. [Google Scholar] [CrossRef]

- Haghighi Mood, S.; Hossein Golfeshan, A.; Tabatabaei, M.; Salehi Jouzani, G.; Najafi, G.H.; Gholami, M.; Ardjmand, M. Lignocellulosic biomass to bioethanol, a comprehensive review with a focus on pretreatment. Renew. Sustain. Energy Rev. 2013, 27, 77–93. [Google Scholar] [CrossRef]

- Tan, I.S.; Lee, K.T. Enzymatic hydrolysis and fermentation of seaweed solid wastes for bioethanol production: An optimization study. Energy 2014, 78, 53–62. [Google Scholar] [CrossRef]

- Doan, Q.C.; Moheimani, N.R.; Mastrangelo, A.J.; Lewis, D.M. Microalgal biomass for bioethanol fermentation: Implications for hypersaline systems with an industrial focus. Biomass Bioenergy 2012, 46, 79–88. [Google Scholar] [CrossRef]

- Vohra, M.; Manwar, J.; Manmode, R.; Padgilwar, S.; Patil, S. Bioethanol production: Feedstock and current technologies. J. Environ. Chem. Eng. 2014, 2, 573–584. [Google Scholar] [CrossRef]

- Carrier, M.; Loppinet-Serani, A.; Denux, D.; Lasnier, J.-M.; Ham-Pichavant, F.; Cansell, F.; Aymonier, C. Thermogravimetric analysis as a new method to determine the lignocellulosic composition of biomass. Biomass Bioenergy 2011, 35, 298–307. [Google Scholar] [CrossRef]

- Yang, L.; Xu, F.; Ge, X.; Li, Y. Challenges and strategies for solid-state anaerobic digestion of lignocellulosic biomass. Renew. Sustain. Energy Rev. 2015, 44, 824–834. [Google Scholar] [CrossRef]

- Bruni, E.; Jensen, A.P.; Pedersen, E.S.; Angelidaki, I. Anaerobic digestion of maize focusing on variety, harvest time and pretreatment. Appl. Energy 2010, 87, 2212–2217. [Google Scholar] [CrossRef]

- Khoo, H.H. Review of bio-conversion pathways of lignocellulose-to-ethanol: Sustainability assessment based on land footprint projections. Renew. Sustain. Energy Rev. 2015, 46, 100–119. [Google Scholar] [CrossRef]

- Mariano, A.P.; Dias, M.O.S.; Junqueira, T.L.; Cunha, M.P.; Bonomi, A.; Filho, R.M. Utilization of pentoses from sugarcane biomass: Techno-economics of biogas vs. butanol production. Bioresour. Technol. 2013, 142, 390–399. [Google Scholar] [CrossRef] [PubMed]

- Divya, D.; Gopinath, L.R.; Merlin Christy, P. A review on current aspects and diverse prospects for enhancing biogas production in sustainable means. Renew. Sustain. Energy Rev. 2015, 42, 690–699. [Google Scholar] [CrossRef]

- Cesaro, A.; Belgiorno, V. Pretreatment methods to improve anaerobic biodegradability of organic municipal solid waste fractions. Chem. Eng. J. 2014, 240, 24–37. [Google Scholar] [CrossRef]

- Kothari, R.; Pandey, A.K.; Kumar, S.; Tyagi, V.V.; Tyagi, S.K. Different aspects of dry anaerobic digestion for bio-energy: An overview. Renew. Sustain. Energy Rev. 2014, 39, 174–195. [Google Scholar] [CrossRef]

- Yan, Z.; Song, Z.; Li, D.; Yuan, Y.; Liu, X.; Zheng, T. The effects of initial substrate concentration, C/N ratio, and temperature on solid-state anaerobic digestion from composting rice straw. Bioresour. Technol. 2015, 177, 266–273. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.; Su, H.; Baeyens, J.; Tan, T. Reviewing the anaerobic digestion of food waste for biogas production. Renew. Sustain. Energy Rev. 2014, 38, 383–392. [Google Scholar] [CrossRef]

- El-Mashad, H.M.; Zeeman, G.; van Loon, W.K.P.; Bot, G.P.A.; Lettinga, G. Effect of temperature and temperature fluctuation on thermophilic anaerobic digestion of cattle manure. Bioresour. Technol. 2004, 95, 191–201. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.K.; Oh, B.R.; Chun, Y.N.; Kim, S.W. Effects of temperature and hydraulic retention time on anaerobic digestion of food waste. J. Biosci. Bioeng. 2006, 102, 328–332. [Google Scholar] [CrossRef] [PubMed]

- Deng, L.; Yang, H.; Liu, G.; Zheng, D.; Chen, Z.; Liu, Y.; Pu, X.; Song, L.; Wang, Z.; Lei, Y. Kinetics of temperature effects and its significance to the heating strategy for anaerobic digestion of swine wastewater. Appl. Energy 2014, 134, 349–355. [Google Scholar] [CrossRef]

- Chae, K.J.; Jang, A.; Yim, S.K.; Kim, I.S. The effects of digestion temperature and temperature shock on the biogas yields from the mesophilic anaerobic digestion of swine manure. Bioresour. Technol. 2008, 99, 1–6. [Google Scholar] [CrossRef] [PubMed]

- Noutsopoulos, C.; Mamais, D.; Antoniou, K.; Avramides, C.; Oikonomopoulos, P.; Fountoulakis, I. Anaerobic co-digestion of grease sludge and sewage sludge: The effect of organic loading and grease sludge content. Bioresour. Technol. 2013, 131, 452–459. [Google Scholar] [CrossRef] [PubMed]

- Gou, C.; Yang, Z.; Huang, J.; Wang, H.; Xu, H.; Wang, L. Effects of temperature and organic loading rate on the performance and microbial community of anaerobic co-digestion of waste activated sludge and food waste. Chemosphere 2014, 105, 146–151. [Google Scholar] [CrossRef] [PubMed]

- Esposito, G.; Frunzo, L.; Panico, A.; Pirozzi, F. Modelling the effect of the OLR and OFMSW particle size on the performances of an anaerobic co-digestion reactor. Process Biochem. 2011, 46, 557–565. [Google Scholar] [CrossRef]

- Wijekoon, K.C.; Visvanathan, C.; Abeynayaka, A. Effect of organic loading rate on VFA production, organic matter removal and microbial activity of a two-stage thermophilic anaerobic membrane bioreactor. Bioresour. Technol. 2011, 102, 5353–5360. [Google Scholar] [CrossRef] [PubMed]

- Motte, J.-C.; Escudié, R.; Bernet, N.; Delgenes, J.-P.; Steyer, J.-P.; Dumas, C. Dynamic effect of total solid content, low substrate/inoculum ratio and particle size on solid-state anaerobic digestion. Bioresour. Technol. 2013, 144, 141–148. [Google Scholar] [CrossRef] [PubMed]

- Kafle, G.K.; Bhattarai, S.; Kim, S.H.; Chen, L. Effect of feed to microbe ratios on anaerobic digestion of Chinese cabbage waste under mesophilic and thermophilic conditions: Biogas potential and kinetic study. J. Environ. Manage. 2014, 133, 293–301. [Google Scholar] [CrossRef] [PubMed]

- Kawai, M.; Nagao, N.; Tajima, N.; Niwa, C.; Matsuyama, T.; Toda, T. The effect of the labile organic fraction in food waste and the substrate/inoculum ratio on anaerobic digestion for a reliable methane yield. Bioresour. Technol. 2014, 157, 174–180. [Google Scholar] [CrossRef] [PubMed]

- Labatut, R.A.; Angenent, L.T.; Scott, N.R. Biochemical methane potential and biodegradability of complex organic substrates. Bioresour. Technol. 2011, 102, 2255–2264. [Google Scholar] [CrossRef] [PubMed]

- Sawatdeenarunat, C.; Surendra, K.C.; Takara, D.; Oechsner, H.; Khanal, S.K. Anaerobic digestion of lignocellulosic biomass: Challenges and opportunities. Bioresour. Technol. 2015, 178, 178–186. [Google Scholar] [CrossRef] [PubMed]

- Chandra, R.; Takeuchi, H.; Hasegawa, T. Methane production from lignocellulosic agricultural crop wastes: A review in context to second generation of biofuel production. Renew. Sustain. Energy Rev. 2012, 16, 1462–1476. [Google Scholar] [CrossRef]

- Davidsson, Å.; Gruvberger, C.; Christensen, T.H.; Hansen, T.L.; Jansen, J.C. Methane yield in source-sorted organic fraction of municipal solid waste. Waste Manag. 2007, 27, 406–414. [Google Scholar]

- Iroba, K.L.; Tabil, L.G.; Sokhansanj, S.; Dumonceaux, T. Pretreatment and fractionation of barley straw using steam explosion at low severity factor. Biomass Bioenergy 2014, 66, 286–300. [Google Scholar] [CrossRef]

- Sapci, Z. The effect of microwave pretreatment on biogas production from agricultural straws. Bioresour. Technol. 2013, 128, 487–494. [Google Scholar] [CrossRef] [PubMed]

- Xu, F.; Wang, Z.-W.; Li, Y. Predicting the methane yield of lignocellulosic biomass in mesophilic solid-state anaerobic digestion based on feedstock characteristics and process parameters. Bioresour. Technol. 2014, 173, 168–176. [Google Scholar] [CrossRef] [PubMed]

- Mayer, F.; Gerin, P.A.; Noo, A.; Foucart, G.; Flammang, J.; Lemaigre, S.; Sinnaeve, G.; Dardenne, P.; Delfosse, P. Assessment of factors influencing the biomethane yield of maize silages. Bioresour. Technol. 2014, 153, 260–268. [Google Scholar] [CrossRef] [PubMed]

- Kačík, F.; Šmíra, P.; Kačíková, D.; Veľková, V.; Nasswettrová, A.; Vacek, V. Chemical alterations of pine wood saccharides during heat sterilisation. Carbohydr. Polym. 2015, 117, 681–686. [Google Scholar] [CrossRef] [PubMed]

- Gao, J.; Chen, L.; Yuan, K.; Huang, H.; Yan, Z. Ionic liquid pretreatment to enhance the anaerobic digestion of lignocellulosic biomass. Bioresour. Technol. 2013, 150, 352–358. [Google Scholar] [CrossRef] [PubMed]

- Szczerbowski, D.; Pitarelo, A.P.; Zandoná Filho, A.; Ramos, L.P. Sugarcane biomass for biorefineries: Comparative composition of carbohydrate and non-carbohydrate components of bagasse and straw. Carbohydr. Polym. 2014, 114, 95–101. [Google Scholar] [CrossRef] [PubMed]

- Ji, W.; Shen, Z.; Wen, Y. Hydrolysis of wheat straw by dilute sulfuric acid in a continuous mode. Chem. Eng. J. 2015, 260, 20–27. [Google Scholar] [CrossRef]

- Bateni, H.; Karimi, K.; Zamani, A.; Benakashani, F. Castor plant for biodiesel, biogas, and ethanol production with a biorefinery processing perspective. Appl. Energy 2014, 136, 14–22. [Google Scholar] [CrossRef]

- Moshi, A.P.; Crespo, C.F.; Badshah, M.; Hosea, K.M.M.; Mshandete, A.M.; Elisante, E.; Mattiasson, B. Characterisation and evaluation of a novel feedstock, Manihot glaziovii, Muell. Arg, for production of bioenergy carriers: Bioethanol and biogas. Bioresour. Technol. 2014, 172, 58–67. [Google Scholar] [CrossRef] [PubMed]

- Gonela, V.; Zhang, J. Design of the optimal industrial symbiosis system to improve bioethanol production. J. Clean. Prod. 2014, 64, 513–534. [Google Scholar] [CrossRef]

- Taheripour, F.; Hertel, T.W.; Tyner, W.E.; Beckman, J.F.; Birur, D.K. Biofuels and their by-products: Global economic and environmental implications. Biomass Bioenergy 2010, 34, 278–289. [Google Scholar] [CrossRef]

- Latif, M.A.; Mehta, C.M.; Batstone, D.J. Low pH anaerobic digestion of waste activated sludge for enhanced phosphorous release. Water Res. 2015, 81, 288–293. [Google Scholar] [CrossRef] [PubMed]

- Riggio, V.; Comino, E.; Rosso, M. Energy production from anaerobic co-digestion processing of cow slurry, olive pomace and apple pulp. Renew. Energy 2015, 83, 1043–1049. [Google Scholar] [CrossRef]

- Maspolim, Y.; Zhou, Y.; Guo, C.; Xiao, K.; Ng, W.J. Comparison of single-stage and two-phase anaerobic sludge digestion systems–Performance and microbial community dynamics. Chemosphere 2015, 140, 54–62. [Google Scholar] [CrossRef] [PubMed]

- Tian, Z.; Mohan, G.R.; Ingram, L.; Pullammanappallil, P. Anaerobic digestion for treatment of stillage from cellulosic bioethanol production. Bioresour. Technol. 2013, 144, 387–395. [Google Scholar] [CrossRef] [PubMed]

- Mustafa, A.F.; McKinnon, J.J.; Christensen, D.A. Chemical characterization and in vitro crude protein degradability of thin stillage derived from barley- and wheat-based ethanol production. Anim. Feed Sci. Technol. 1999, 80, 247–256. [Google Scholar] [CrossRef]

- Wilkie, A.C.; Riedesel, K.J.; Owens, J.M. Stillage characterization and anaerobic treatment of ethanol stillage from conventional and cellulosic feedstocks. Biomass Bioenergy 2000, 19, 63–102. [Google Scholar] [CrossRef]

- Wang, W.; Xie, L.; Luo, G.; Zhou, Q. Enhanced fermentative hydrogen production from cassava stillage by co-digestion: The effects of different co-substrates. Int. J. Hydrog. Energy 2013, 38, 6980–6988. [Google Scholar] [CrossRef]

- Kim, Y.; Mosier, N.S.; Hendrickson, R.; Ezeji, T.; Blaschek, H.; Dien, B.; Cotta, M.; Dale, B.; Ladisch, M.R. Composition of corn dry-grind ethanol by-products: DDGS, wet cake, and thin stillage. Bioresour. Technol. 2008, 99, 5165–5176. [Google Scholar] [CrossRef] [PubMed]

- Wang, K.; Zhang, J.; Tang, L.; Zhang, H.; Zhang, G.; Yang, X.; Liu, P.; Mao, Z. Establishment and assessment of a novel cleaner production process of corn grain fuel ethanol. Bioresour. Technol. 2013, 148, 453–460. [Google Scholar] [CrossRef] [PubMed]

- Krzywonos, M.; Cibis, E.; Miśkiewicz, T.; Ryznar-Luty, A. Utilization and biodegradation of starch stillage (distillery wastewater). Electron. J. Biotechnol. 2009, 12. [Google Scholar] [CrossRef]

- Moraes, B.S.; Zaiat, M.; Bonomi, A. Anaerobic digestion of vinasse from sugarcane ethanol production in Brazil: Challenges and perspectives. Renew. Sustain. Energy Rev. 2015, 44, 888–903. [Google Scholar] [CrossRef]

- Kaparaju, P.; Serrano, M.; Angelidaki, I. Optimization of biogas production from wheat straw stillage in UASB reactor. Appl. Energy 2010, 87, 3779–3783. [Google Scholar] [CrossRef]

- Krzywonos, M.; Cibis, E.; Ryznar-Luty, A.; Miśkiewicz, T.; Borowiak, D. Aerobic biodegradation of wheat stillage (distillery wastewater) at an elevated temperature—Effect of solids separation. Biochem. Eng. J. 2010, 49, 1–6. [Google Scholar] [CrossRef]

- Cesaro, A.; Velten, S.; Belgiorno, V.; Kuchta, K. Enhanced anaerobic digestion by ultrasonic pretreatment of organic residues for energy production. J. Clean. Prod. 2014, 74, 119–124. [Google Scholar] [CrossRef]

- Park, J.-H.; Yoon, J.-J.; Park, H.-D.; Lim, D.J.; Kim, S.-H. Anaerobic digestibility of algal bioethanol residue. Bioresour. Technol. 2012, 113, 78–82. [Google Scholar] [CrossRef] [PubMed]

- Park, J.-H.; Kim, S.-H.; Park, H.-D.; Lim, D.J.; Yoon, J.-J. Feasibility of anaerobic digestion from bioethanol fermentation residue. Bioresour. Technol. 2013, 141, 177–183. [Google Scholar] [CrossRef] [PubMed]

- Luo, G.; Xie, L.; Zou, Z.; Wang, W.; Zhou, Q.; Shim, H. Anaerobic treatment of cassava stillage for hydrogen and methane production in continuously stirred tank reactor (CSTR) under high organic loading rate (OLR). Int. J. Hydrog. Energy 2010, 35, 11733–11737. [Google Scholar] [CrossRef]

- Westerholm, M.; Hansson, M.; Schnürer, A. Improved biogas production from whole stillage by co-digestion with cattle manure. Bioresour. Technol. 2012, 114, 314–319. [Google Scholar] [CrossRef] [PubMed]

- Andalib, M.; Hafez, H.; Elbeshbishy, E.; Nakhla, G.; Zhu, J. Treatment of thin stillage in a high-rate anaerobic fluidized bed bioreactor (AFBR). Bioresour. Technol. 2012, 121, 411–418. [Google Scholar] [CrossRef] [PubMed]

- Eskicioglu, C.; Kennedy, K.J.; Marin, J.; Strehler, B. Anaerobic digestion of whole stillage from dry-grind corn ethanol plant under mesophilic and thermophilic conditions. Bioresour. Technol. 2011, 102, 1079–1086. [Google Scholar] [CrossRef] [PubMed]

- Eskicioglu, C.; Ghorbani, M. Effect of inoculum/substrate ratio on mesophilic anaerobic digestion of bioethanol plant whole stillage in batch mode. Process Biochem. 2011, 46, 1682–1687. [Google Scholar] [CrossRef]

- Alkan-Ozkaynak, A.; Karthikeyan, K.G. Anaerobic digestion of thin stillage for energy recovery and water reuse in corn-ethanol plants. Bioresour. Technol. 2011, 102, 9891–9896. [Google Scholar] [CrossRef] [PubMed]

- Nasr, N.; Elbeshbishy, E.; Hafez, H.; Nakhla, G.; Hesham El Naggar, M. Comparative assessment of single-stage and two-stage anaerobic digestion for the treatment of thin stillage. Bioresour. Technol. 2012, 111, 122–126. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Lv, Z.; Du, J.; Mo, C.; Yang, X.; Tian, S. Combined process for ethanol fermentation at high-solids loading and biogas digestion from unwashed steam-exploded corn stover. Bioresour. Technol. 2014, 166, 282–287. [Google Scholar] [CrossRef] [PubMed]

- Schmidt, T.; Pröter, J.; Scholwin, F.; Nelles, M. Anaerobic digestion of grain stillage at high organic loading rates in three different reactor systems. Biomass Bioenergy 2013, 55, 285–290. [Google Scholar] [CrossRef]

- Moestedt, J.; Nordell, E.; Schnürer, A. Comparison of operating strategies for increased biogas production from thin stillage. J. Biotechnol. 2014, 175, 22–30. [Google Scholar] [CrossRef] [PubMed]

- Schmidt, T.; Nelles, M.; Scholwin, F.; Pröter, J. Trace element supplementation in the biogas production from wheat stillage – Optimization of metal dosing. Bioresour. Technol. 2014, 168, 80–85. [Google Scholar] [CrossRef] [PubMed]

- Shakeri Yekta, S.; Lindmark, A.; Skyllberg, U.; Danielsson, Å.; Svensson, B.H. Importance of reduced sulfur for the equilibrium chemistry and kinetics of Fe(II), Co(II) and Ni(II) supplemented to semi-continuous stirred tank biogas reactors fed with stillage. J. Hazard. Mater. 2014, 269, 83–88. [Google Scholar] [CrossRef] [PubMed]

- Sun, Z.-Y.; Yamaji, S.; Cheng, Q.-S.; Yang, L.; Tang, Y.-Q.; Kida, K. Simultaneous decrease in ammonia and hydrogen sulfide inhibition during the thermophilic anaerobic digestion of protein-rich stillage by biogas recirculation and air supply at 60 °C. Process Biochem. 2014, 49, 2214–2219. [Google Scholar] [CrossRef]

- Patni, N.; Pillai, S.G.; Dwivedi, A.H. Wheat as a Promising Substitute of Corn for Bioethanol Production. Procedia Eng. 2013, 51, 355–362. [Google Scholar] [CrossRef]

- Dererie, D.Y.; Trobro, S.; Momeni, M.H.; Hansson, H.; Blomqvist, J.; Passoth, V.; Schnürer, A.; Sandgren, M.; Ståhlberg, J. Improved bio-energy yields via sequential ethanol fermentation and biogas digestion of steam exploded oat straw. Bioresour. Technol. 2011, 102, 4449–4455. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Q.-H.; Lu, X.; Tang, L.; Mao, Z.-G.; Zhang, J.-H.; Zhang, H.-J.; Sun, F.-B. A novel full recycling process through two-stage anaerobic treatment of distillery wastewater for bioethanol production from cassava. J. Hazard. Mater. 2010, 179, 635–641. [Google Scholar] [CrossRef] [PubMed]

- Demirel, B.; Yenigün, O. Two-phase anaerobic digestion processes: A review. J. Chem. Technol. Biotechnol. 2002, 77, 743–755. [Google Scholar] [CrossRef]

- Kobayashi, T.; Tang, Y.; Urakami, T.; Morimura, S.; Kida, K. Digestion performance and microbial community in full-scale methane fermentation of stillage from sweet potato-shochu production. J. Environ. Sci. 2014, 26, 423–431. [Google Scholar] [CrossRef]

- Moestedt, J.; Påledal, S.N.; Schnürer, A.; Nordell, E. Biogas Production from Thin Stillage on an Industrial Scale—Experience and Optimisation. Energies 2013, 6, 5642–5655. [Google Scholar] [CrossRef]

- García-Gen, S.; Rodríguez, J.; Lema, J.M. Optimisation of substrate blends in anaerobic co-digestion using adaptive linear programming. Bioresour. Technol. 2014, 173, 159–167. [Google Scholar] [CrossRef] [PubMed]

- Hamawand, I. Anaerobic digestion process and bio-energy in meat industry: A review and a potential. Renew. Sustain. Energy Rev. 2015, 44, 37–51. [Google Scholar] [CrossRef]

- Mata-Alvarez, J.; Dosta, J.; Romero-Güiza, M.S.; Fonoll, X.; Peces, M.; Astals, S. A critical review on anaerobic co-digestion achievements between 2010 and 2013. Renew. Sustain. Energy Rev. 2014, 36, 412–427. [Google Scholar] [CrossRef]

- Wang, W.; Xie, L.; Chen, J.; Luo, G.; Zhou, Q. Biohydrogen and methane production by co-digestion of cassava stillage and excess sludge under thermophilic condition. Bioresour. Technol. 2011, 102, 3833–3839. [Google Scholar] [CrossRef] [PubMed]

- Andalib, M.; Elbeshbishy, E.; Mustafa, N.; Hafez, H.; Nakhla, G.; Zhu, J. Performance of an anaerobic fluidized bed bioreactor (AnFBR) for digestion of primary municipal wastewater treatment biosolids and bioethanol thin stillage. Renew. Energy 2014, 71, 276–285. [Google Scholar] [CrossRef]

- Sharma, D.; Espinosa-Solares, T.; Huber, D.H. Thermophilic anaerobic co-digestion of poultry litter and thin stillage. Bioresour. Technol. 2013, 136, 251–256. [Google Scholar] [CrossRef] [PubMed]

- John, R.P.; Anisha, G.S.; Nampoothiri, K.M.; Pandey, A. Micro and macroalgal biomass: A renewable source for bioethanol. Bioresour. Technol. 2011, 102, 186–193. [Google Scholar] [CrossRef] [PubMed]

- Kemppainen, K.; Ranta, L.; Sipilä, E.; Östman, A.; Vehmaanperä, J.; Puranen, T.; Langfelder, K.; Hannula, J.; Kallioinen, A.; Siika-aho, M.; Sipilä, K.; von Weymarn, N. Ethanol and biogas production from waste fibre and fibre sludge – The FibreEtOH concept. Biomass Bioenergy 2012, 46, 60–69. [Google Scholar] [CrossRef]

- Narra, M.; Balasubramanian, V. Utilization of solid and liquid waste generated during ethanol fermentation process for production of gaseous fuel through anaerobic digestion–A zero waste approach. Bioresour. Technol. 2015, 180, 376–380. [Google Scholar] [CrossRef] [PubMed]

- Capecchi, L.; Galbe, M.; Barbanti, L.; Wallberg, O. Combined ethanol and methane production using steam pretreated sugarcane bagasse. Ind. Crops Prod. 2015, 74, 255–262. [Google Scholar] [CrossRef]

- Torry-Smith, M.; Sommer, P.; Ahring, B.K. Purification of bioethanol effluent in an UASB reactor system with simultaneous biogas formation. Biotechnol. Bioeng. 2003, 84, 7–12. [Google Scholar] [CrossRef] [PubMed]

- Uellendahl, H.; Ahring, B.K. Anaerobic digestion as final step of a cellulosic ethanol biorefinery: Biogas production from fermentation effluent in a UASB reactor—pilot-scale results. Biotechnol. Bioeng. 2010, 107, 59–64. [Google Scholar] [CrossRef] [PubMed]

- Global Solutions. Scale up history. Available online: http://www.inbicon.com/en/global-solutions (accessed on 20 July 2015).

- Maabjerg Energy Concept. Status Report. Moving towards realization 2013. Available online: http://www.maabjergenergyconcept.eu/ (accessed on 20 July 2015).

- Alburquerque, J.A.; de la Fuente, C.; Ferrer-Costa, A.; Carrasco, L.; Cegarra, J.; Abad, M.; Bernal, M.P. Assessment of the fertiliser potential of digestates from farm and agroindustrial residues. Biomass Bioenergy 2012, 40, 181–189. [Google Scholar] [CrossRef]

- Massaccesi, L.; Sordi, A.; Micale, C.; Cucina, M.; Zadra, C.; Di Maria, F.; Gigliotti, G. Chemical characterisation of percolate and digestate during the hybrid solid anaerobic digestion batch process. Process Biochem. 2013, 48, 1361–1367. [Google Scholar] [CrossRef]

- Abdullahi, Y.A.; Akunna, J.C.; White, N.A.; Hallett, P.D.; Wheatley, R. Investigating the effects of anaerobic and aerobic post-treatment on quality and stability of organic fraction of municipal solid waste as soil amendment. Bioresour. Technol. 2008, 99, 8631–8636. [Google Scholar] [CrossRef] [PubMed]

- Bustamante, M.A.; Restrepo, A.P.; Alburquerque, J.A.; Pérez-Murcia, M.D.; Paredes, C.; Moral, R.; Bernal, M.P. Recycling of anaerobic digestates by composting: effect of the bulking agent used. J. Clean. Prod. 2013, 47, 61–69. [Google Scholar] [CrossRef]

- Cesaro, A.; Belgiorno, V.; Guida, M. Compost from organic solid waste: Quality assessment and European regulations for its sustainable use. Resour. Conserv. Recycl. 2015, 94, 72–79. [Google Scholar] [CrossRef]

- Menardo, S.; Gioelli, F.; Balsari, P. The methane yield of digestate: Effect of organic loading rate, hydraulic retention time, and plant feeding. Bioresour. Technol. 2011, 102, 2348–2351. [Google Scholar] [CrossRef] [PubMed]

- Yue, Z.; Teater, C.; Liu, Y.; MacLellan, J.; Liao, W. A sustainable pathway of cellulosic ethanol production integrating anaerobic digestion with biorefining. Biotechnol. Bioeng. 2010, 105, 1031–1039. [Google Scholar] [CrossRef] [PubMed]

- Teater, C.; Yue, Z.; MacLellan, J.; Liu, Y.; Liao, W. Assessing solid digestate from anaerobic digestion as feedstock for ethanol production. Bioresour. Technol. 2011, 102, 1856–1862. [Google Scholar] [CrossRef] [PubMed]

- MacLellan, J.; Chen, R.; Kraemer, R.; Zhong, Y.; Liu, Y.; Liao, W. Anaerobic treatment of lignocellulosic material to co-produce methane and digested fiber for ethanol biorefining. Bioresour. Technol. 2013, 130, 418–423. [Google Scholar] [CrossRef] [PubMed]

- Gao, T.; Li, X. Using thermophilic anaerobic digestate effluent to replace freshwater for bioethanol production. Bioresour. Technol. 2011, 102, 2126–2129. [Google Scholar] [CrossRef] [PubMed]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cesaro, A.; Belgiorno, V. Combined Biogas and Bioethanol Production: Opportunities and Challenges for Industrial Application. Energies 2015, 8, 8121-8144. https://doi.org/10.3390/en8088121

Cesaro A, Belgiorno V. Combined Biogas and Bioethanol Production: Opportunities and Challenges for Industrial Application. Energies. 2015; 8(8):8121-8144. https://doi.org/10.3390/en8088121

Chicago/Turabian StyleCesaro, Alessandra, and Vincenzo Belgiorno. 2015. "Combined Biogas and Bioethanol Production: Opportunities and Challenges for Industrial Application" Energies 8, no. 8: 8121-8144. https://doi.org/10.3390/en8088121

APA StyleCesaro, A., & Belgiorno, V. (2015). Combined Biogas and Bioethanol Production: Opportunities and Challenges for Industrial Application. Energies, 8(8), 8121-8144. https://doi.org/10.3390/en8088121