1. Introduction

In China, the industrial sector is the largest consumer of electricity, accounting for approximately 72% of the total electricity consumption [

1]. In recent years, in line with efforts to reduce the need for generation and transmission, and in order to reach their ambitious fossil fuel consumption reduction targets, the Chinese government has promoted energy efficiency improvements in energy-intensive industries [

2]. A summary of energy consumption and intensity data from several Chinese energy-intensive industries in 2013 is shown in

Table 1. Although the energy intensity of the presented industrial products is approaching that of developed countries, the marginal benefits of further energy saving efforts might be limited. For this reason, in addition to increasing efficiency, managing load in energy intensive industries is a key focus for the long-term, low-carbon development of the future electric grid.

Table 1.

Energy intensity of major energy-intensive products in China (2013) [

2].

Table 1.

Energy intensity of major energy-intensive products in China (2013) [2].

| Industrial Products | Electricity Consumption (Billion kWh) | Electricity Consumption Intensity (kWh/t) a | Energy Consumption Intensity (kgce/t) b |

|---|

| China | Developed Countries c |

|---|

| Steel | 362.2 | 465 | 662 | 610 |

| Aluminum smelter | 303.1 | 13,740 | 13,740 | 12,900 |

| Cement | 210.2 | 87 | 125 | 118 |

| Ammonia | 59.5 | 1035 | 1532 | 990 |

| Calcium carbide | 76.5 | 3423 | 3423 | 3000 |

| Caustic soda | 66.5 | 2326 | 972 | 910 |

AS are required for reliable power system operations. With existing dispatching practices and grid infrastructure, different kinds of AS are mostly provided by coal-fired units in China. These units typically have slow response speeds and restricted ramp rates, and result in increasing pressure for energy conservation and emission reduction [

3,

4]. With the gradual development and implementation of smart grid infrastructure around the world, load flexibility has sparked research on the role that loads could play in the operation of an increasingly smarter power system [

5]. In recent years, public attention on demand response (DR) in the U.S. and Europe has been mainly focused on the commercial and residential sector due to the sectors’ high proportion of electricity consumption in their systems. Hao

et al. [

6] indicated that HVAC in existing commercial buildings in the U.S. could provide about 70% of the current national regulation reserve requirements in a specified frequency band. Nistor

et al. [

7] investigated the capability of dish washers and washing and drying machines equipped with communication modules, to act as operating reserves for the system operator. Keep

et al. [

8] performed similar work with using responsive refrigeration loads. Zakariazadeh

et al. [

9] presented a method for the integrated operational planning of a distribution system, electric vehicles were considered as responsive loads that could participate in AS programs by providing reserve to the system. Given the contribution from the residential and commercial sectors to the total electricity consumption in those systems, the papers aforementioned show potential for managing residential and commercial loads in the provision of AS. Although the contribution to the total electricity consumption from these sectors in China is growing, in the near term, industrial loads will continue to dominate the panorama. For this reason, research on the role and potential of industrial loads in the provision of AS is particularly important in China.

Traditional ideas hold that industrial loads should focus on maintaining a flat curve due to the pressure of maintaining economic production [

10]. Nevertheless, sparked interest on industrial load flexibility has occurred due to the growing share of electricity generation from renewable energy resources, which results in huge demands for AS capacities. Paulus and Borggrefe [

11] briefly estimated the technical and economic potential of energy-intensive industries to provide demand side management in German electricity and balance markets through 2030, including chloralkali processes, mechanical wood pulp production, aluminum electrolysis, electric arc furnaces, and cement mills. Olsen

et al. [

12] examined the characteristics of cement plants and their ability to shed or shift load to participate in DR. Swanepoel

et al. [

13] developed a computerized operations system that integrated all the components of the cement plant, and noticed that energy and emission reductions would be possible by changing the load profile of cement production plants. Todd

et al. [

14] investigated the available opportunities of one aluminum smelter facility in the AS market, and discussed the possibilities and capabilities of aluminum smelters to provide reliability services. Jiang

et al. [

15] designed a demand side frequency control scheme in an isolated wind power system, and evaluated the potential of aluminum smelting loads to participate in frequency regulation. Alcazar-Ortega

et al. [

16] analyzed the flexibility potential of customers in one meat industry based on the management of the most energy consuming process in this type of segment: cooling production and distribution, which is one of the most representative sectors in Spain.

However, previous analyses are mainly limited in that they are mainly case studies for a single industrial plant or sector and few researchers have considered models where multiple industrial users, together with conventional generators, aim at the provision of optimal AS scheduling. Furthermore, AS classifications and standards in different countries and regions are quite different due to different development levels, power system structures, pricing mechanisms and so on. Even in different regions of the same country, AS classifications and standards can vary. In addition, all power management methods in China’s AS scheduling only considered the participation of generators and neglected the flexibility of responsive loads. In this paper, based on the analysis of industrial users for AS according to their response mechanism, we propose an agent-based model to simulate the integrated power management of conventional generation and industrial loads in the existing Chinese AS mechanism, and verifies the capability of industrial loads to participate in the provision of AS scheduling.

The paper is organized as follows. In

Section 2, a brief summary of the framework and implementation rules for AS in China is presented. In

Section 3, the response mechanism of cement producers and aluminum smelters is established in consideration of their own production characteristics and requirements.

Section 4 presents an agent-based model and defines assumptions and settings of the simulations.

Section 5 discusses simulation results, followed by conclusions in

Section 6.

2. Overview of Ancillary Service in China

In order to guide the development for the provision of AS, in 2006, the Chinese government promulgated the “Interim Measures for AS Management of Grid-connected Power Plant” (“Interim Measures” for short), which defined the groups of AS that fitted with the Chinese electricity development reality [

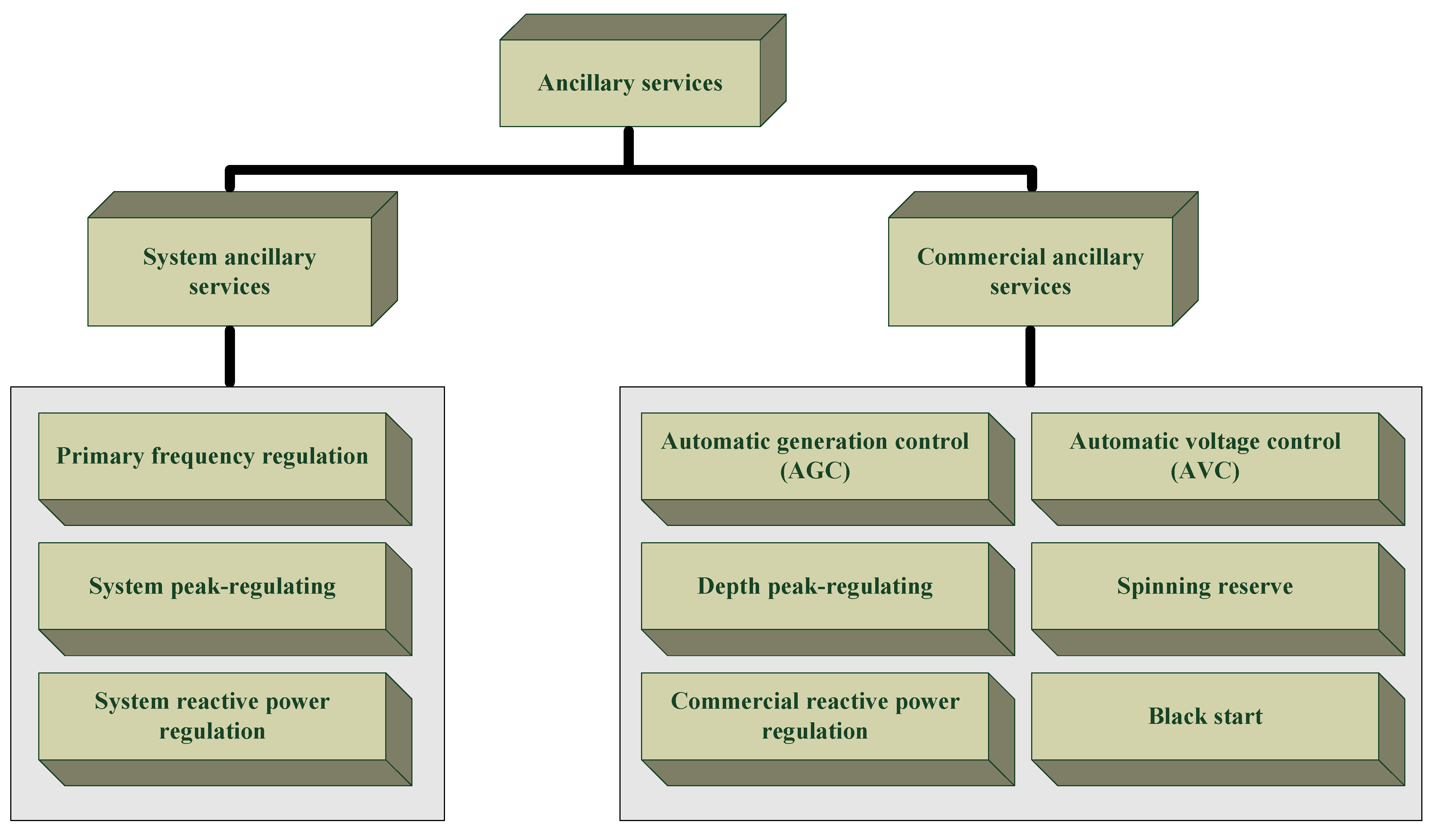

17]. The framework for the provision of AS is shown in

Figure 1. Although AS include system and commercial services and each of the type can be further subdivided into active and reactive power applications, considering the limitation of demand side resources, this paper focuses only on active power AS and covers the following:

Regulation service: Also called automatic generation control (AGC). Requires generators to provide continuous response to power system operator commands for minute-to-minute up and down fluctuations.

Peak-regulating service: Can be divided into system peak-regulating and commercial peak-regulating services. System peak-regulating services are provided by generators that track the load change between low demand and peak hours. Currently, this service is free in China, despite the revenue risk for power plants. Commercial peak-regulating services require generators to participate in shifting peak load or load fluctuation that makes them exceed the range of system peak regulating. It might require start-up/shut-down events within a fixed time. Commercial peak-regulating services need compensation from the dispatching regulator on account of the decreased efficiency of participating units.

Reserve service: Requires generators to reserve generating capacity in case of unplanned load increases or decreases. Reserve services can be divided into spinning and non-spinning reserve services. The Chinese government regulations stipulate that the compensation is due only to spinning reserves.

Figure 1.

AS framework in China.

Figure 1.

AS framework in China.

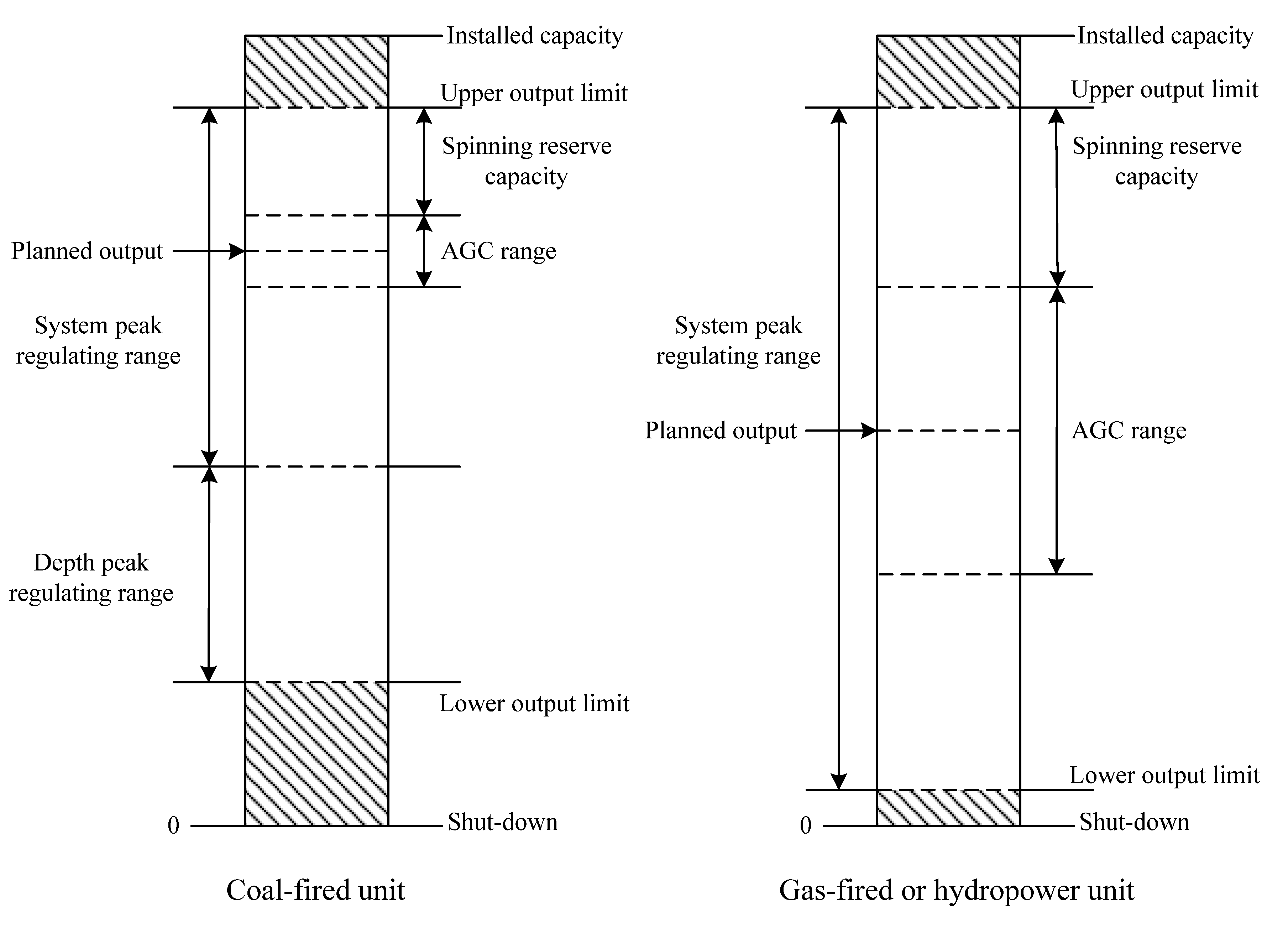

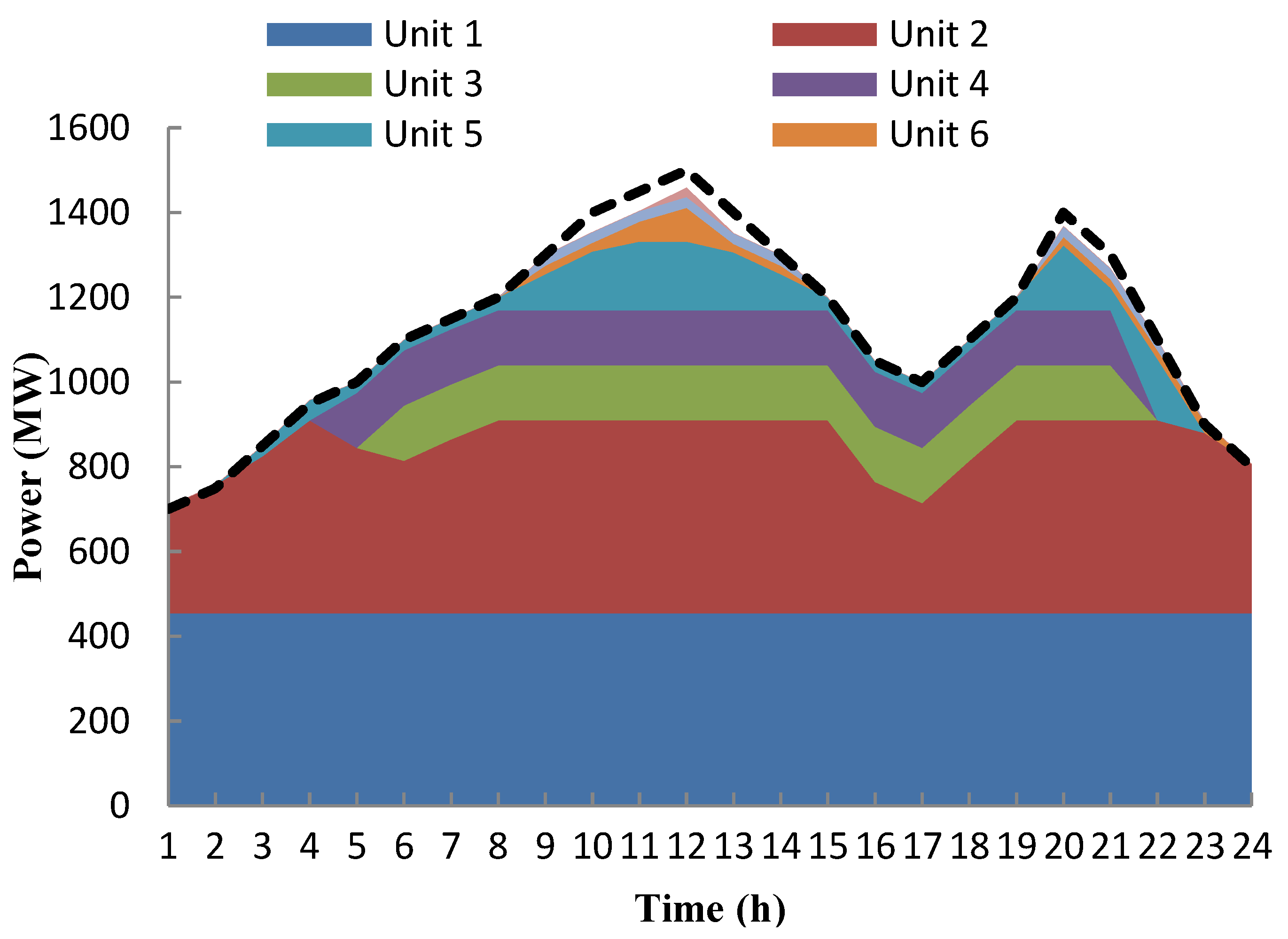

The capacity allocation of different types of units in China can be shown in

Figure 2. It is obvious that revenues from providing AS for coal-fired units come from three services: AGC, commercial peak-regulating and spinning reserve services. The revenue from commercial peak-regulating service also contains depth peak-regulating and start-up/shut-down compensations. Gas-fired and hydropower units are required to provide peak-regulating services in China because of their rapid ramp rate, and therefore they only obtain revenues from provision of AGC and spinning reserve services. Although a power system with higher share of gas-fired and hydropower units will have more flexibility, there are considerable gaps between the total installed capacity of these two types of units and that of coal-fired units in China. Therefore, coal-fired units are the primary provider of AS in China, which will result in significant ramp up/down costs and extra carbon emissions. Some units may also operate in uneconomic fashion, for example when the output of wind power unit unexpectedly fails [

18]. For this reason, in this paper, our model’s generation units are considered to be exclusively coal-fired power plants.

Figure 2.

The capacity allocation of different types of units.

Figure 2.

The capacity allocation of different types of units.

Based on the Interim Measures, the Chinese regional electric power regulators issued implementation guidelines separately, and different parameters and standards were set due to various power mixes at the different regional levels. These parameters and standards will be discussed in detail in

Section 4. Existing guidelines only considered the participation of generators and neglected the flexibility of responsive loads. The smart grid allows the real-time communication between supply and demand side based on modern information and communication technologies, as well as improved sensors and controls. It enables DR to participate as a resource with considerable potential apart from thermal generation. Technically, DR can be as effective as generation response for restoring the generation/load imbalances at the center of most power system reliability concerns [

19].

4. Agent-Based Integrated Power Management Model

4.1. Model Design

There is a long way to go before establishing an ideal power market mechanism in China. Fixed framework methods and models have limited usefulness in the research context of the Chinese power system and AS scheduling. Due to its inherent flexibility, we present, in this section, an agent-based model for AS dispatching that includes conventional generators, power grid and industrial agents.

In a perfectly competitive electricity market, generators will withhold capacity from the energy market to sell into the AS markets. The bid price for the generator to supply an AS is based primarily on the difference between the generator’s production cost and the electricity sale price at that time. This means that costs for each AS are driven primarily by opportunity cost. Nevertheless, in China, there is no market mechanism to motivate supply and demand side resources to participate in the provision of AS. Instead, the AS prices are set by Chinese electricity regulators as shown in

Table 2 [

25,

26,

27,

28,

29], and they vary across different regions. In the north, central and northwest China grids, the compensation price for start-up/shut-down regulating service is dependent on the unit capacity. Meanwhile, in the northeast grid, a compensation factor is presented for the start-up/shut-down service and in eastern China, the continuously off-time duration is also considered. In this model, we choose the most widespread compensation standard of the north, central, and northwest China grids to design model parameters.

Table 2.

Compensation standard for AS in different regions of China.

Table 2.

Compensation standard for AS in different regions of China.

| Region | Depth Peak-Regulating ($/MWh) | Spinning Reserve ($/MWh) | Start-Up/Shut-Down ($/MW) |

|---|

| <100 MW | 100–400 MW | >400 MW |

|---|

| Northeast China | 83 | 3.3 | <200 | 200–800 | >800 |

| North China | 8.3 | 1.6 | 83 | 167 | 167 |

| Central China | 33 | 25 | 33 | 67 | 133 |

| East China | 17 | 8.3 | 133–300 | 167–667 | 333–833 |

| Northwest China | 20 | - | 67 | 133 | 133 |

For responsive loads, the participation model and evaluation criterion have not been established and their role in system operation is passive at present, for example, curtailment during instances of power rationing. To avoid production penalties for reduced efficiency, in the presented model, high responsive constraints for industrial users are set. One consequent model assumption is that industrial users are willing to participate in AS for benefits associated. Industrial users usually could not provide all types of AS and perform their basic function at the same time. Another assumption in the model is that industrial users can provide peak-regulating service by the dispatching operator. Aluminum smelters have a higher compensation than cement manufacturing plants in this model since they are able to provide up and down capacity from the smelting pot.

For evaluating the effect of integrated power management, daily system coal consumption is accounted in this model as shown in Equation (1):

where

Pi_t is the power output of unit

i at time

t,

fi is coal consumption factor of unit

i,

N is the total number of generator units,

T is the total number of hours to be studied, which tends to be 24 h.

4.2. Generation Agent

The generation agent represents conventional generators with different functional orientations, including base-load units, peak-regulating units and peak-load units, each of which has different fuel costs and start-up costs. For a given load demand from the grid agent, the generation agent will allocate power to each production unit in the following priority order: base-load units, peak-regulating units and peak-load units. In other words, base-load units are always producing the maximum output after start-up. Peak-regulating units are dispatched as flexible when needed to meet the supply and demand imbalance. And for following the rules given in Interim Measures, each peak-regulating unit will be just compensated for providing the depth peak-regulating service when its real-time power is out of the range of system peak-regulating service. For simplicity, this paper assumes the output of peak-regulating units keep unchanged within each hour, so the regulation up/down compensation for generation units can be ignored.

The aim of the generation agent in this model is set to maximize the total payoff. For conventional generator units, the objective includes the following benefits and costs,

(1) Generating benefit

Generating benefit of unit

i at time

t is,

where λ

i is the feed in tariff of unit

i.

(2) Fuel cost

Fuel cost of unit

i at time

t is,

where γ is the coal price.

(3) Start-up cost

where

is the duration of uninterrupted downtime for unit

i at time

t,

MDi is the minimum uninterrupted downtime of unit

i,

cshouri is the cold start hour of unit

i.

(4) AS compensation

where

ACi_t represents the AS revenue of unit

i at time

t,

,

and

are respectively the revenue of unit

i for offering depth peak-regulating, start-up/shut-down and spinning reserve services,

Pi_max and

Pi_min are the upper and lower output limit of unit

i,

qi is the depth peak-regulating service factor of unit

i,

CDP,

CUD and

CSR are respectively the relevant compensation price for depth peak-regulating, start-up/down and spinning reserves services respectively,

Ii_t is the on/off status of unit

i at time

t, where 1 represents on, 0 represents off.

To sum up, the revenue function of generation agent is,

the objective of generation agent is to maximize

FGA.

Assuming the normal operation of each unit, the generation limits and minimum on/off time constraints are included in this model:

where

MUi/MDi are minimum uninterrupted on/off time of unit

i,

is the duration of uninterrupted on/off of unit

i at time

t.

4.3. Industrial User Agent

4.3.1. Aluminum Smelter Agent

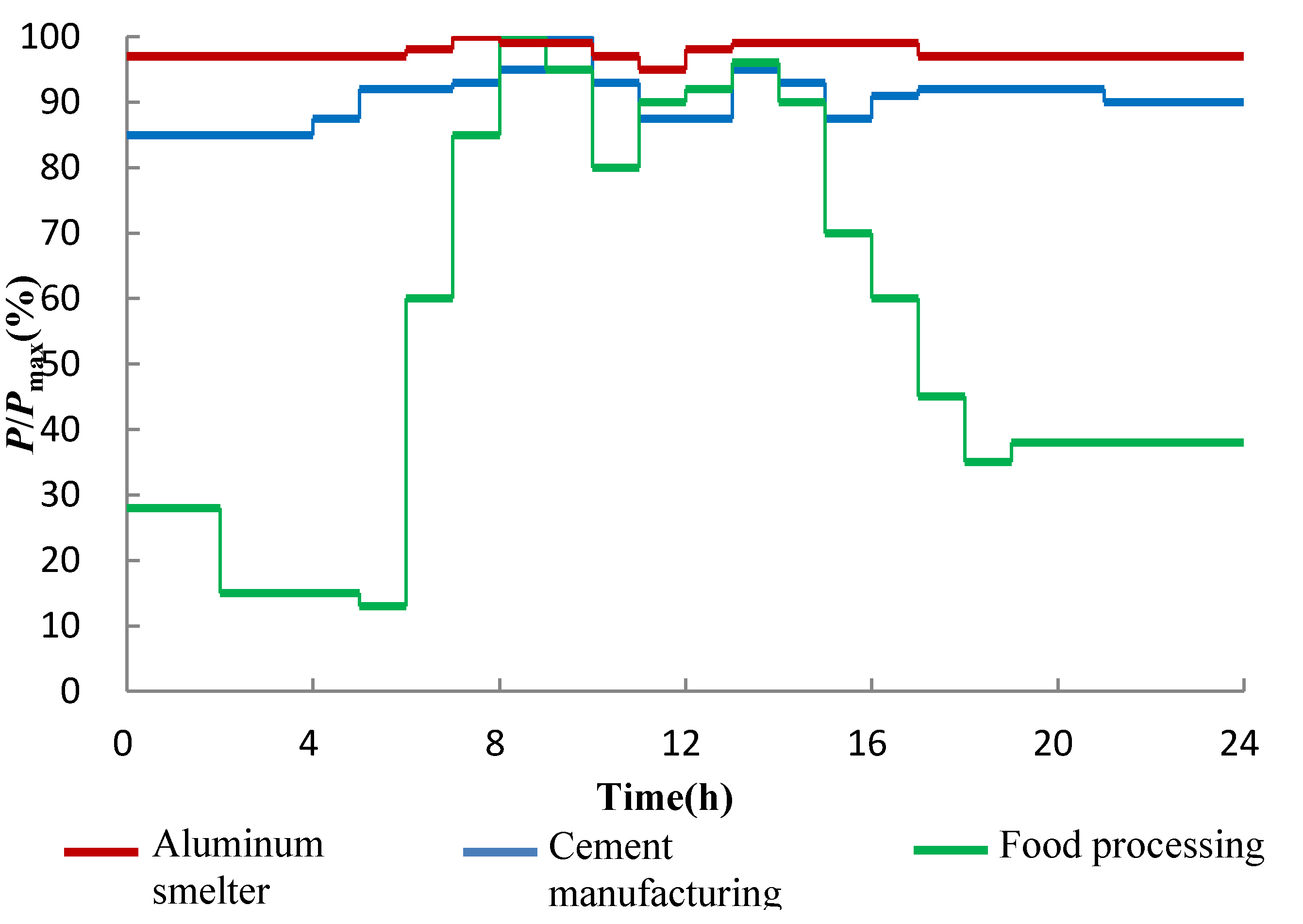

In this model, an aluminum smelter agent is designed as a flexible response resource by controlling the smelting pot. The smelting process power consumption is generally constant, typically operating at, or above, 95 percent load factor, as shown in

Figure 3, we assume that the power of smelter agent remains unchanged in daily operation if it doesn’t take AS into account. When considering AS benefits, the smelter will try to modify the smelting pot power for more benefits as shown in

Figure 5. And in this process, the response direction of the aluminum smelter agent is determined by the AS signal, but the actual response capacity of the aluminum smelter agent is determined by its own decision-making. Due to thermal inertia, if the power swings are small enough, the production of aluminum will not be affected by the provision of AS. The real-time power of smelter

k following the dispatching commands at time

t can be expressed as Equation (13):

where

Pk represents the daily baseline load of aluminum smelter

k without providing AS, and

ALk_t is the response capacity of smelter

k at time

t, which can be either positive or negative. The response capacity has a negative value when the smelter provides positive response capacity and vice versa.

Figure 5.

The load curve of aluminum smelter k.

Figure 5.

The load curve of aluminum smelter k.

On the basis of above analysis, the associated benefits and costs of aluminum smelter k to the provision of AS include the following:

(1) Load fluctuation cost

The movement of mechanical tap changers on the rectifiers necessary to adjust power could accelerate the wear and tear of these devices. This cost can be presented as a quadratic function of the response capacity as in Equation (14):

where

ak,

bk and

ck are wear coefficients of smelter

k,

Jk_t is the load change direction of smelter

k at time

t, with 1 representing provision of negative response capacity by increasing demand, −1 representing provision of positive response capacity by decreasing demand, and 0 representing no response.

(2) AS benefit

where

CIL_a is the compensation price of aluminum smelters for offering peak-regulating service.

(3) Production benefit

where

Mk is the aluminum production of smelter

k within time period

T,

Sa is the market price per ton of aluminum,

ecostk is the electricity consumption cost of smelter

k, Δμ

k is the average electricity price of smelter

k within

T,

dk is the electricity intensity of smelter

k, μ

t is the electricity price for energy-intensive users at time

t,

ocostk includes additional costs of smelter

k, including aluminum oxide, carbon block and labor cost,

etc.To sum up, the objective revenue function of aluminum smelter agent k is shown in Equation (18).

Some constraints of aluminum smelter are taken into account. Firstly, since the operation of aluminum smelters is subject to the thermal balance, so a response capacity limit within T is considered, as shown in Equation (19), to ensure that the positive capacity and negative capacity are equal. Secondly, since aluminum smelters tend to have a high stability and performance requirement, an upper limit on its supplying capacity is set, as shown in Equation (20). Thirdly, the duration of unidirectional positive or negative response duration should not be long, and it is constrained by Equation (21).

where η

max is the maximum responsive capacity factor that one smelter could provide,

MR is the maximum response duration limit of smelter, which tends to be 2 h.

4.3.2. Cement Agent

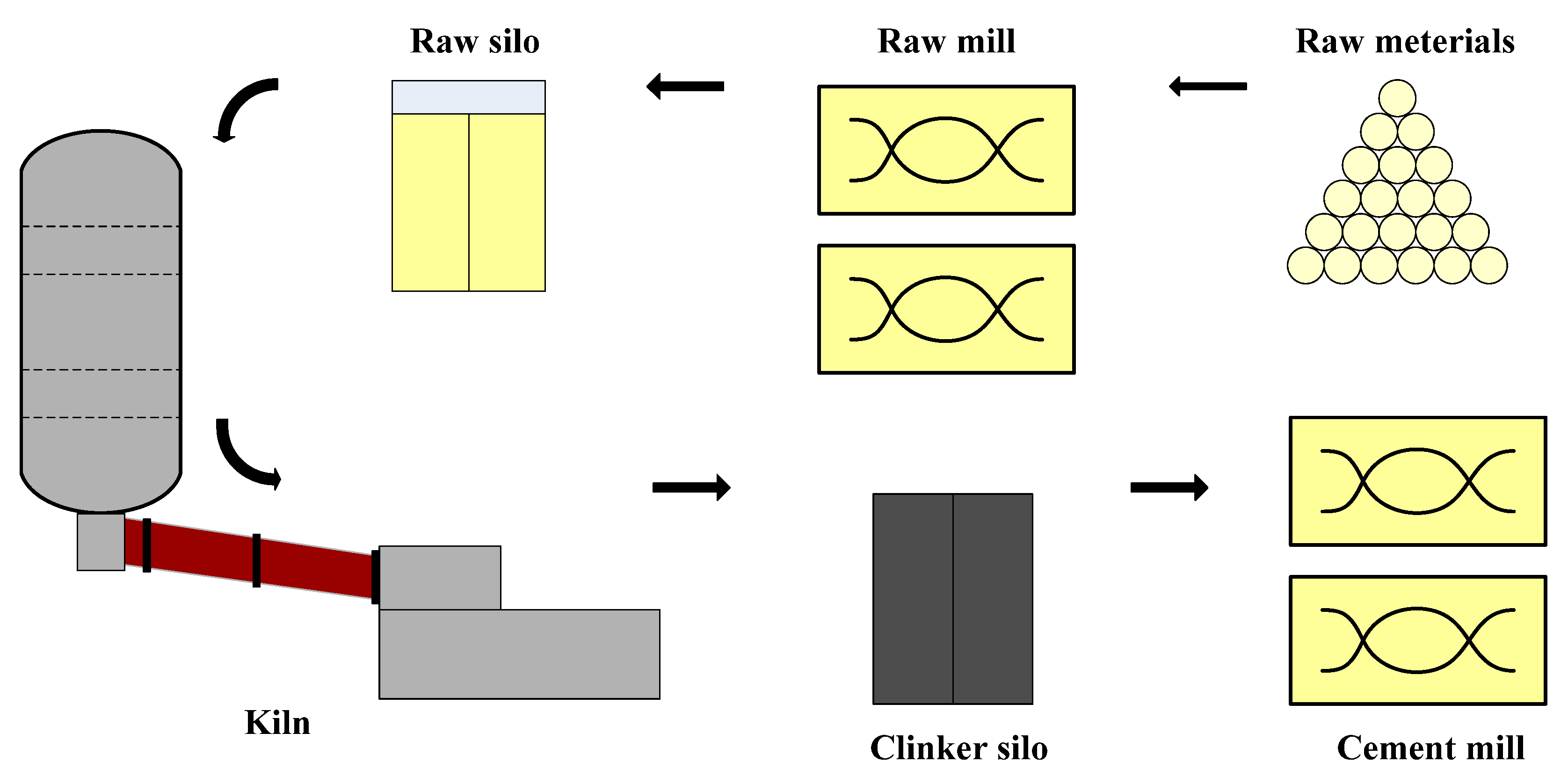

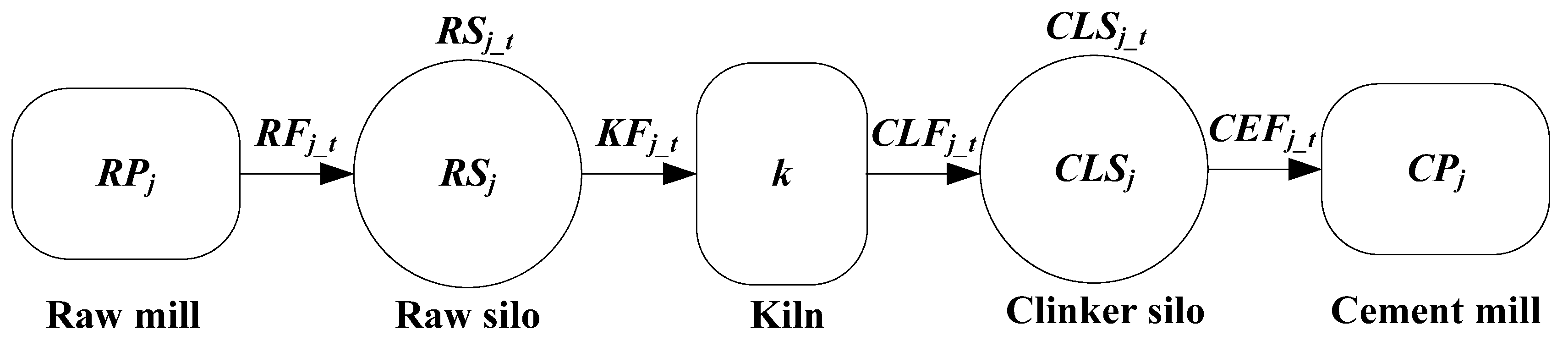

In this model, we assume that each cement agent just contains just two responsive devices: a raw mill and a cement mill, and that the responsive potential of each device is determined by the storage capacity and device configuration. Each cement agent can provide AS by controlling the curtailment of the raw mill and the cement mill. The agent’s cement production is based on the control of flows and stocks of its production process as shown in

Figure 6. These flows and stocks relationships are described in Equations (22)–(26):

Figure 6.

The diagram of flows and stocks in relation to AS in cement j.

Figure 6.

The diagram of flows and stocks in relation to AS in cement j.

where

RPj and

CPj are respectively the response capacity of raw mill and cement mill in cement

j respectively,

RFj_t,

KFj_t,

CLFj_t and

CEFj_t are the material flow of various production processes in cement

j at time

t,

RSj_t and

CLSj_t are the material stock of cement

j in the raw silo and clinker silos at time

t respectively,

RSj and

CLSj are the initial stock value of cement

j in its raw silo and clinker silo respectively,

k is the loss factor on ignition from the raw material to the clinker,

Xj_t and

Yj_t are the on/off status of raw mill and cement mill in cement

j at time

t, with 1 represents on, and 0 represents off.

Based on the above analysis, the associated benefits and costs of cement j for the provision of AS include the following,

(1) Interruption cost

where

cj is the interruption cost coefficient of cement

j.

(2) AS benefit

where

CIL_c is the compensation price of cements for offering peak-regulating service.

(3) Production benefit

where

Sc is the cement market price per ton,

ecostj is the electricity consumption cost of cement

j, Δμ

j is the average electricity price of cement

j within

T,

dj is the electricity intensity of cement

j,

BPj is the power of kiln in cement

j,

ocostj includes additional costs of cement

j, including limestone, coal and labor cost,

etc.Combining the associated costs and benefits presented above, the revenue function for a cement agent

j is shown in Equation (31):

Two types of constraints on cement agent in out model are set within

T: the storage and responsive times limits, as shown below,

where

RSj_max and

RSj_min are the upper and lower storage limit of the raw silos in cement

j respectively,

CLSj_max and

CLSj_min are the upper and lower storage limit of the clinker silos in cement

j,

RNmax and

CNmax are the maximum responsive times of raw mill and cement mill, respectively, in cement

j.

4.4. Grid Agent

The objective of the grid agent in this model is to regulate the power and AS markets in order to maintain reliability and support power system’s primary function of delivering energy to users. First, the grid agent forecasts the load demand for the next dispatching period, which includes the demand of industrial users based on the Chinese peak-valley price mechanism. It does not take strategic actions at this stage. Then the grid agent delivers demand messages to generators. After all the generators have finished their decision-making processes, the grid agent gathers and categorizes all of the supply and demand information. The grid agent, aiming at minimizing the system coal consumption, establishes feasible AS requirements of consumption for industrial users and considers the available capacity from industrial users as able to substitute coal-fired units. Once it receives a load fluctuation signal, the grid agent will dispatch responsive resources in the following priority order: aluminum smelter agents, cement agents and then generation agents. It is worth mentioning that whichever resources dispatched first will receive more challenging responsive signals than the others. Therefore, we choose to place aluminum smelters first, as smelters can instantaneously follow the responsive signal with higher accuracy. After the supply and demand is balanced, the grid agent informs the generation agent and industrial user agent of their generation schedule.

In addition, the constraints associated with the optimal scheduling problem by the grid agent include power balance and AS capacity, as shown in Equations (36) and (37).

(1) Power balance constraint

where

is the sum of generation agents output,

LDt is the original load demand at time

t,

PLt is network loss, while it is assumed that network loss has been considered within

LDt, so

PLt = 0.

(2) AS capacity constraint

where

is the sum of the maximum output capacity of all participating generation agents,

ASt is AS capacity at time

t.

6. Conclusions

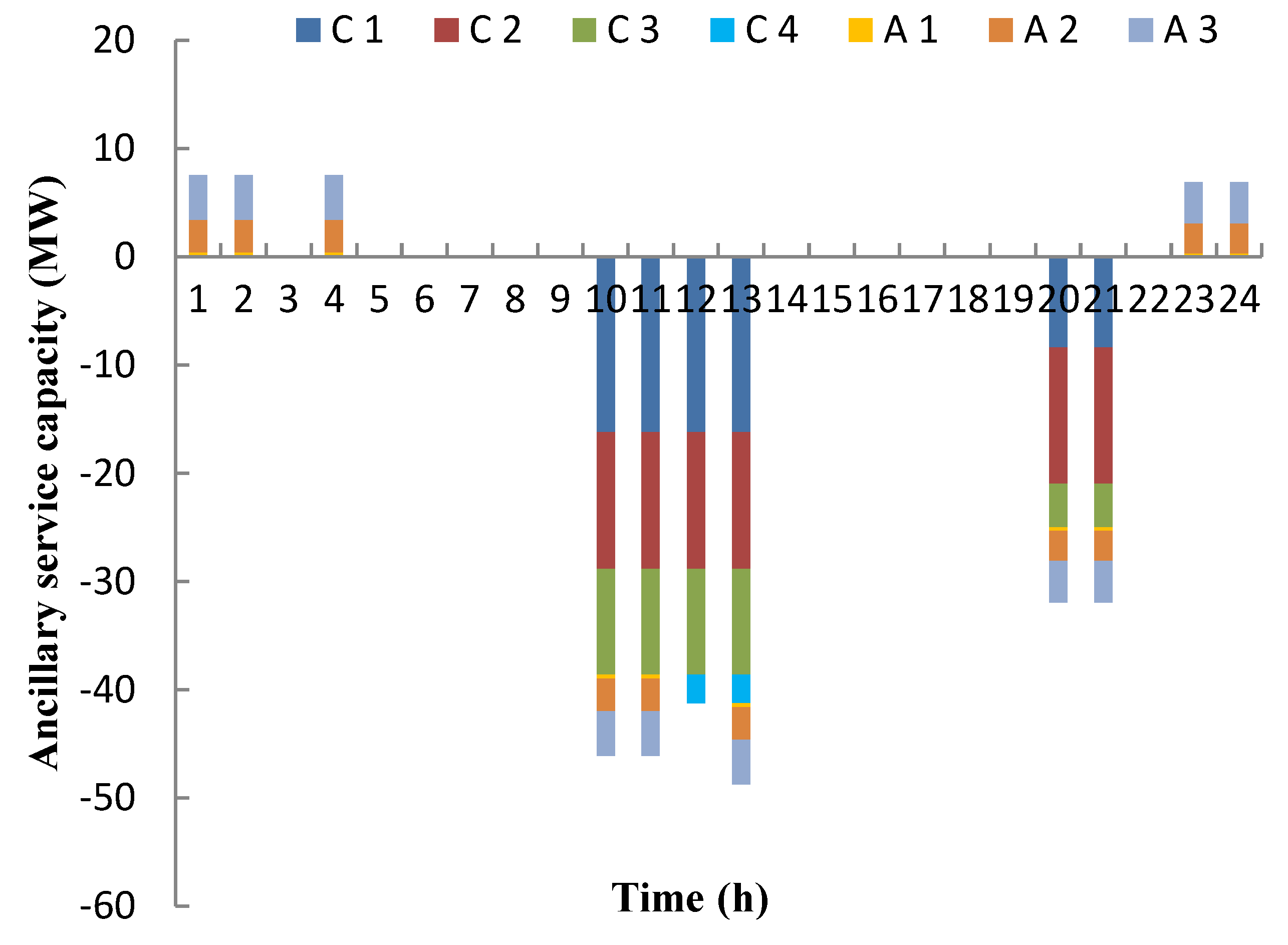

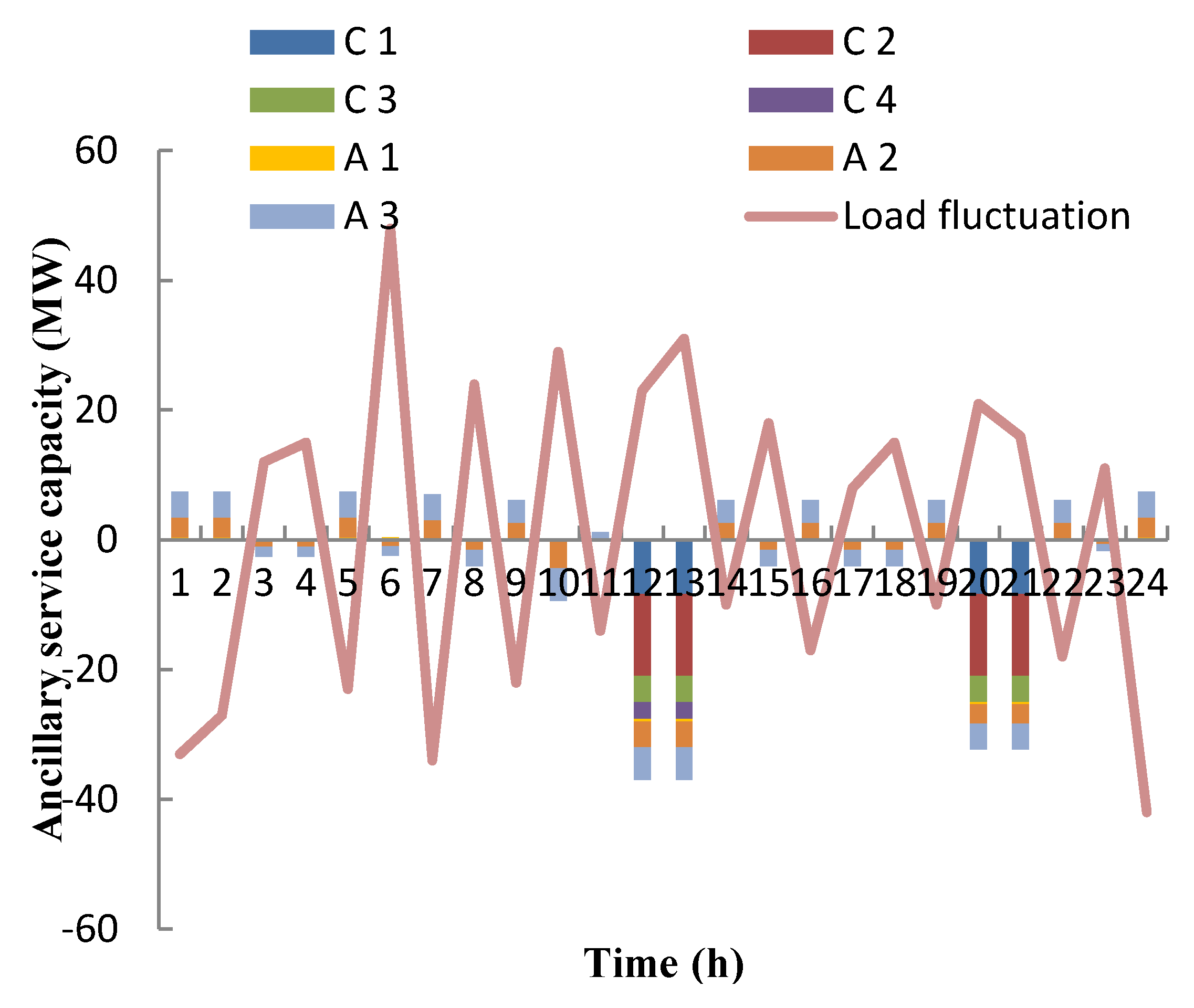

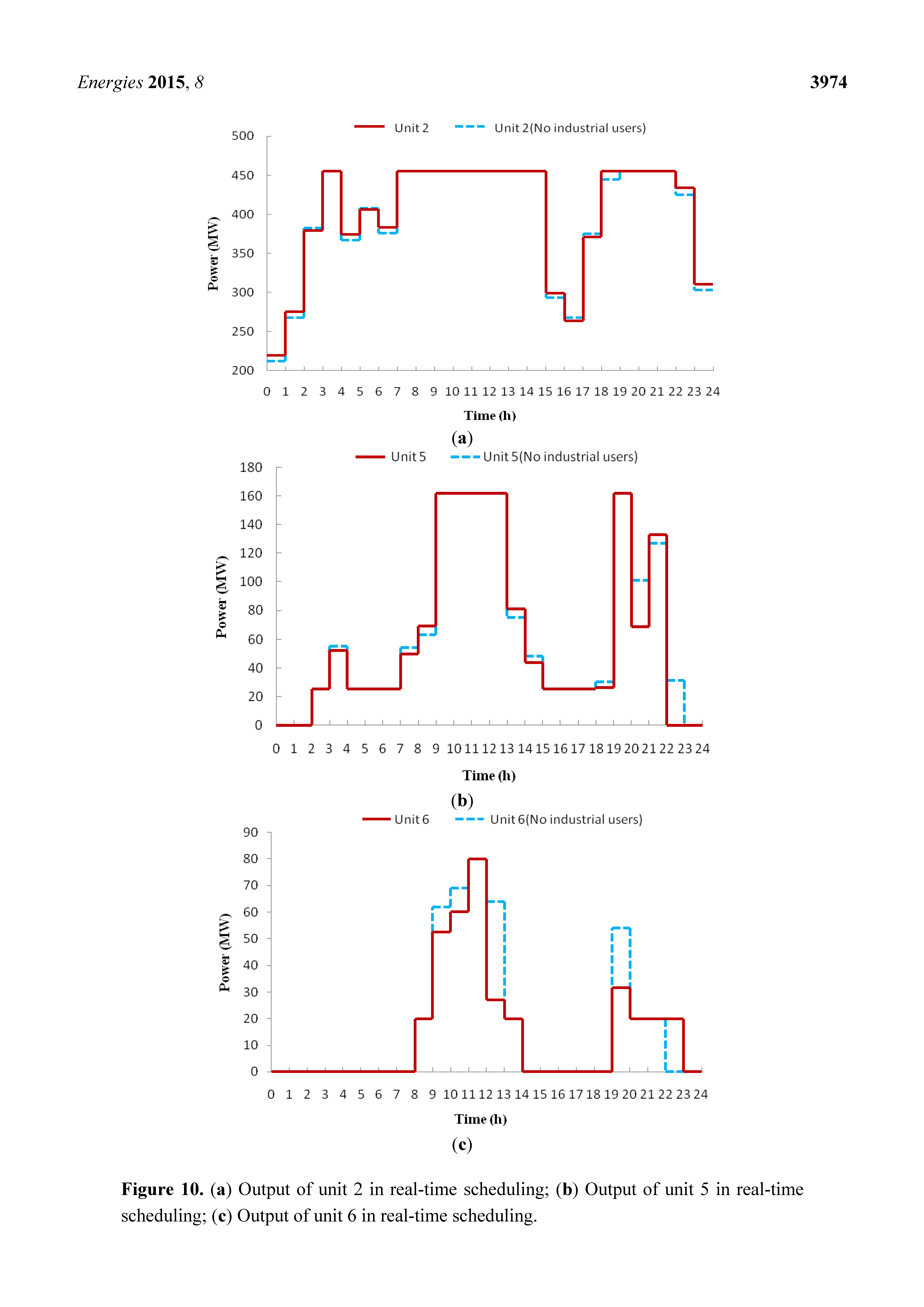

In this paper, we designed an integrated power management method that implements supply and demand side resources based on actual status of China’s AS scheduling, and proposed an agent-based model considering generation, industrial users and grid agents. Two case studies on day-ahead and real-time scheduling verified that the capability of industrial users to participate in the provision of AS.

In day-ahead scheduling, this paper considered the pricing mechanism of peak-valley electricity price and analyzed the impact of industrial responsive loads during the peak and valley periods. It was found, that the participation of industrial users replaced some of the output of the two peak-load units with the highest coal consumption rate and therefore reduced the total system cost associated to the provision of AS. In real-time scheduling case, peak-regulating units had more flexibility to respond to the load imbalances with the help from flexible industrial users, and the output from the higher coal consumption units decreased. In both of the two case studies, the coal consumption rate and load factors were both improved due to the contributions of demand side resources. Through this approach, it can be concluded that aluminum smelter plants are more suitable for participation in real-time AS scheduling, and cement plants, having more responsive devices and storage capacity have more flexibility in day-ahead AS scheduling. Without significant benefits, industrial users are unwilling to modify the existing production processes and therefore to provide flexibility to the grid. A relatively efficient incentive mechanism is essential, and it should be specially designed for industrial users.