A Review of Thermal Co-Conversion of Coal and Biomass/Waste

Abstract

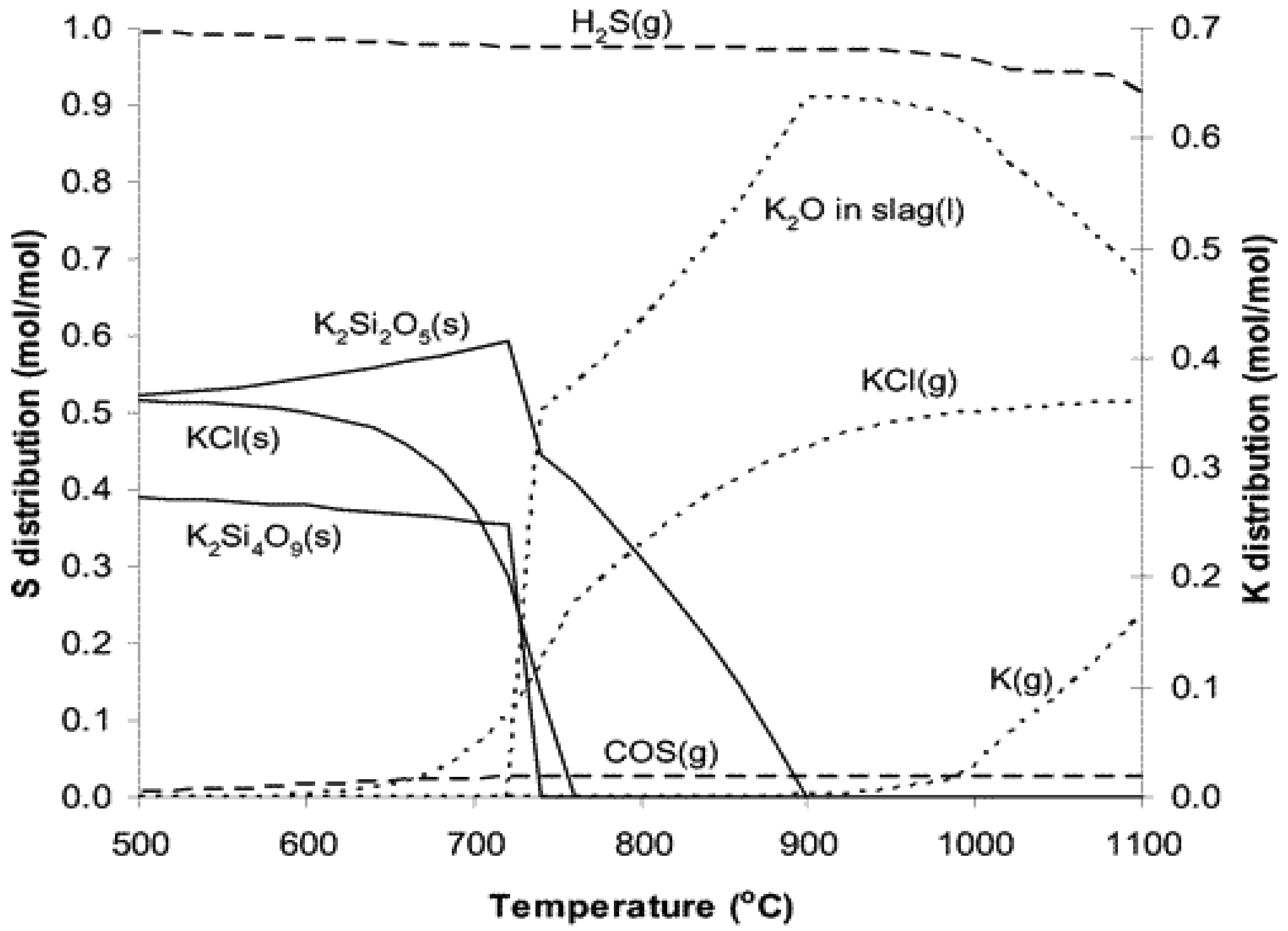

: Biomass is relatively cleaner than coal and is the only renewable carbon resource that can be directly converted into fuel. Biomass can significantly contribute to the world's energy needs if harnessed sustainably. However, there are also problems associated with the thermal conversion of biomass. This paper investigates and discusses issues associated with the thermal conversion of coal and biomass as a blend. Most notable topics reviewed are slagging and fouling caused by the relatively reactive alkali and alkaline earth compounds (K2O, Na2O and CaO) found in biomass ash. The alkali and alkaline earth metals (AAEM) present and dispersed in biomass fuels induce catalytic activity during co-conversion with coal. The catalytic activity is most noticeable when blended with high rank coals. The synergy during co-conversion is still controversial although it has been theorized that biomass acts like a hydrogen donor in liquefaction. Published literature also shows that coal and biomass exhibit different mechanisms, depending on the operating conditions, for the formation of nitrogen (N) and sulfur species. Utilization aspects of fly ash from blending coal and biomass are discussed. Recommendations are made on pretreatment options to increase the energy density of biomass fuels through pelletization, torrefaction and flash pyrolysis to reduce transportation costs.1. Introduction

Energy is the cornerstone to economic stability and development. Since the industrial revolution, fossil fuels have stimulated economic growth especially in the developed world. Only recently have we realized that this accelerated economic growth has not occurred without a penalty. Carbon dioxide emissions from fossil fuels combustion, combined with land-use changes, have driven the concentration of this most significant greenhouse gas (GHG) to levels in our atmosphere not seen for at least 800,000 years, and probably many millions of years [1]. Although somewhat controversial, the scientific evidence of global warming and climate change and their link to anthropogenic activities has been established. The concentration of GHG in the atmosphere and its consequences is expected to be exacerbated given the impressive world population growth as well as economic development expected in developing countries with a direct effect on competition for energy resources. The quest for substitutes to fossil fuels, the need to mitigate the negative environmental effects of fossil fuels utilization and the necessity to safely and economically dispose wastes have encouraged the development of alternative sources of energy and promotion of low quality fuels. Co-conversion of coal and biomass/wastes for energy purposes and chemicals are among these alternatives.

Coal fired power plants are still the largest source of electricity generation in the Unites States (contributing to about 42% of net electricity generation), and will keep their lead until 2040 [2]. According to the International Energy Agency (IEA), coal will continue to be a global energy solution throughout the 21st century [3]. The world's coal stock is still enormous. Coal has a low cost and a high energy density. It is expected to contribute significantly in the future energy needs in many nations [4,5], especially in fast-developing countries such as China and India. China alone uses nearly twice as much coal as all countries from the Organization for Economic Co-operation and Development (OECD) combined, while India has since 2011 become the third largest coal consumer in the world after china and the Unites States [5]. Conversion of coal-to-liquids and chemicals could become significant in the petrochemical industry. However, coal has a major drawback: it is responsible for the emission of environmentally harmful compounds [sulfur, nitrogen (N) and heavy metals]. Combustion of fossil fuels, which accounts for about 75% of total GHG emissions, together with land-use change is the main source of anthropogenic GHG emissions [4–7]. Combustion of coal alone accounts for 30% to 40% of the share of GHGs from fossil fuels combustion [4–7]; therefore, coal utilization deserves special attention given the likelihood of continued use for electricity generation and the potential for coal to partially replace petroleum for chemicals and transportation fuels as has recently occurred in China.

Biomass is any organic matter recently derived from plants through photosynthesis. It is a versatile feedstock encompassing forestry and agricultural residues, organic waste by-products, energy crops, sewage sludge and biosolids, woody plants and municipal green waste [8] and can be used simultaneously to generate heat, power, gaseous liquid fuels, materials, and chemicals. The estimation of the amount of biomass that can be generated as energy with minimum disturbance to the supply for food crop is controversial, estimated to about 35 EJ/year to 1135 EJ/year by Hoogwijk et al. [9] and to about 100–600 EJ/year by Slade et al. [10]; the former corresponds to about 6% to 189% of the current global primary energy usage while the later corresponds to about 17%–100%. Therefore, biomass is a precious resource which, if harnessed sustainably could be a meaningful contributor to meeting the future world energy needs. On a security point of view, large proportions of oil and gas reserves are concentrated in politically unstable regions, therefore, increasing the diversity in energy sources is important for many nations to secure a reliable and constant supply of energy [11], while contributing to a reduction in GHG emissions.

Biomass in general has a high content of hydrogen (H), making it suitable as a blend to compensate the often-low H content of coal. Biomass as gasification feedstock, although giving a high hydrogen yield, has the disadvantage of low energy density because of its high oxygen and moisture content. This shortcoming is compensated for when blended with a higher energy content coal. Other challenges such as the seasonal limitation of biomass are somewhat mitigated through co-conversion with coal. The higher tar release (due to excessive volatile release and low gasification temperature from biomass gasification) is also reduced as blending with coal increases the temperature, enhancing tar cracking. Blending biomass and coal as feedstock can reduce the shortcomings of each fuel and boost the efficacy of the overall system.

The most attractive benefit of co-converting coal and biomass is certainly the reduction of GHG emissions and environmental pollution. Biomass, compared to coal, has lower sulfur, N and heavy metals. It is also carbon-neutral if produced sustainably, thus co-conversion of biomass and coal can make significant contributions in mitigating GHG emission and other emissions. Compared to carbon capture and storage (CCS), co-converting biomass with coal is relatively cost-effective, given the high energy penalty of CCS which can range from 15% to 40% of the energy output [12]. Even if CCS were to be implemented as a means for GHG mitigation, it would not, alone, be able to meet the 50% emission reduction target by 2050 suggested by the International Panel on Climate Change (IPCC) [13]. Life cycle analyses of co-conversion are currently mostly limited to co-firing coal and biomass for combustion, while co-fired gasification investigations are scarce. Co-firing coal and biomass is currently among the most efficient renewable energy and climate change technologies available due to the high power generation efficiencies that are generally not achieved in smaller-scale dedicated biomass facilities. Considering biomass as a carbon-neutral resource, CO2 emission should decline proportionally to the amount of coal offset by biomass [14]; however, thermal conversion of biomass also prevents some biomass waste from occupying landfills and thus also reduces the landfill methane emission. Co-firing also results in lower N2O emission compared to coal alone [15], as both CH4 and N2O have higher global warming potentials (GWP) than CO2 (21 and 310, respectively) [16]. The overall outcome of co-firing is therefore a percentage reduction of CO2 equivalent higher than the percentage of biomass in the co-firing blend. The analysis of Mann and Spath [17] for combustion and gasification are illustrative. Pollutants from co-firing and co-gasification are different (e.g., SO2 from co-firing versus H2S and COS from co-gasification; NOx from co-firing versus NH3 and CHN from co-gasification), making co-combustion not suitable to appraise pollutants release during co-gasification. However, the relatively low sulfur and nitrogen contents of biomass compared to coal imply that lower amounts of H2S, NH3 and HCN are expected when co-gasifying.

Co-conversion of coal and biomass offers a better prospect for cleaner coal utilization and a way to dispose wastes/biomass in an economical, safe, and environmentally-acceptable manner. Some research on these systems has been performed, however, the wide variability of parameters (type of feedstock, type of gasifier, gasification conditions) in these systems requires additional research to identify the most important parameters and clarify how they affect the co-conversion efficiency and product yield.

This present work critically examines literature on thermal co-conversion (liquefaction, pyrolysis, gasification, combustion) of coal and biomass from pre-processing of feedstock to product utilization. Given the complexity of gasification compared to other processes, it will be the focal process during this analysis.

2. Feedstock Preprocessing and Feeding

Carbonaceous solid fuels, which include coal and biomass, are complex collections of organic polymers consisting of aromatic chains combined by hydrocarbons and other atoms such as oxygen, N, sulfur, potassium (K) and sodium (Na). Coals are mainly formed as the results of slow metamorphosis of biomass over a long period of time. The degree of that metamorphosis is among the criteria used to determine coal rank. For instance, the lower degree of metamorphosis is found in lignites and the maximum are found in low-volatile bituminous and anthracite coals. Intermediary stages are the subbituminous and other bituminous ranks [18]. Among thermal conversion processes, gasification is the most demanding in terms of end-use products (synthesis gas), which can be affected by the pre-processing steps for biomass fuels.

Gasification produces synthesis gas (syngas) and by-products such as ash and tars. Whether the syngas is used for power generation or for liquid fuel production, a clean gas free from tar and other contaminants is required. Biomass gasification has the drawback of producing a high amount of tar, therefore, tar avoidance or removal becomes important. Updraft gasifiers (fixed bed) produce more tar than fluidized beds, and fluidized beds more than entrained flow gasifiers [16–20]. Therefore, fixed bed and fluidized bed gasifiers produce the “dirtiest” syngas compared to entrained flow gasifiers [16–20] thus entrained flow gasification could be more suitable for co-gasification. Nonetheless, most large biomass gasifiers operate with fluidized bed technology.

Obtaining a relatively clean gas suitable for liquid fuel production from carbonaceous fuels requires operation at high temperature, which can be easily met with entrained flow gasifiers. At such temperatures (≈1573–1973 K), a gas with very low concentration of tar, methane, and carbon dioxide is obtained, which significantly decreases the gas cleaning cost.

Modern entrained flow gasifiers using solid feed operate at a pressure of between 15 bar and 60 bar. These elevated pressures are advantageous for gas to liquid synthesis. Pressurizing synthesis gas requires more energy than pressurizing ox0ygen; the reason being that the volume of synthesis gas is about double the volume of oxygen required for its production [19]. Improved ash handling also occurs with entrained flow gasifiers under slagging conditions. However, to render the biomass mineral matter, the gasifier should operate in a non-slagging mode such that the dried ash produced could be released back to the forest. This is challenging as some toxic minerals from coal may be applied to the soil. Ash from coal contains considerable amount of toxic elements including traces of mercury and lead.

The high reaction rates of entrained flow gasifiers demand very small feedstock input size (∼100 μm), easily achievable for friable materials like coal, but more challenging and energy-consuming for biomass due to its fibrous structure and hygroscopic nature. Therefore, the viability of entrained flow gasification of biomass relies on its pretreatment. Moreover, entrained flow gasifiers operate at high pressures and need injection of the fuel, which is usually introduced into the pressurized reactor through an alternating pressurized and depressurized lock system. The periodic procedure is suited for high bulk density fuels and moderate pressures. At low bulk densities (e.g., biomass) and higher pressures (>50 bar; e.g., operating pressure for subsequent liquid processes), the amount of lock gas can exceed the fuel weight. Therefore, a well-designed feeding system to withstand back pressure from the gasifier is required and this may be as expensive as the gasifier itself [20]. The fibrous nature of the biomass also prevents it from fluidizing and fluffs are formed that may plug piping. Among the pretreatment options available to palliate these biomass shortcomings are pelletization, torrefaction and fast pyrolysis [21].

Torrefaction is a thermal treatment at a temperature of 473–573 K, near atmospheric pressure and in the absence of oxygen. Ciolkosz and Wallace [22] have explored the key features for biomass torrefaction for bioenergy production. This mild thermal treatment not only destroys the fibrous structure and tenacity of the biomass (wood), but is also known to increase the calorific value and to invert its hydrophilic nature [23,24]. Therefore, Torrefaction increases its handling characteristics for storage, transportation and gasification purposes. Torrefaction can significantly decrease the power need for the processing operation (up to 85%) and at the same time the capacity of the milling plant can increase considerably (by a factor of 2–6) while nearly 85%–90% of the original biomass energy is retained in the solid product [23]; issues such as bridging and blockage of feeding systems as well as poor pulverization characteristics are resolved [25,26]. The ground torrefied biomass is pneumatically fed if a dried-coal fired system is used or slurry fed if slurry-coal fired system is in place.

Fast pyrolyis is a rapid heating process at about 773 K in an inert atmosphere. Rapid condensation of the vapors in one to a few seconds occurs, and more than half of the biomass mass can be obtained as liquid pyrolysis oil at the expense of low char and gas yield. In these conditions, the pyrolysis gases contain less than 10% of the biomass energy, which is consumed on-site as energy input to the pyrolysis process. The brittle char obtained is ground to a fine powder and suspended in the liquid pyrolysis oil to form the bioslurry, with an overall energy content of up to 80%–90% of the original biomass energy [27,28], and considerable volume reduction.

The dispersed nature of the biomass feedstock requires the pretreated fuel to be transported to a central plant where it is co-converted with coal. Important parameters in deciding which of the two pretreatment options to consider are the energy density and post processing of the pretreated fuel.

Bioslurry is denser (and less bulky) than torrefied biomass. Thus besides feeding bioslurry under pressure being easier; pneumatically feeding powdered torrefied wood requires pressurizing with an inert gas that reduces the calorific value and complicates the gas cleaning process. Another advantage of the fast pyrolysis process is that to avoid soil nutrients depletion, pyrolysis can be designed to optimize and obtain only an energy-rich bio-oil containing 60% to 70% of the original biomass energy [29], while the remaining char may be immediately returned to the soil. This approach may well be more efficient since it avoids transporting the ash from the gasification plant to the forest. Moreover, it ensures that almost all the ash extracted by biomass is returned to the soil and prevents possible toxic elements that might be present in coal ash to be applied to the soil. Additional savings could result from the simplicity associated with handling bio-oil at the plant site. Handling bio-oil at the plant site will require fewer and comfortable metering and handling equipment compared to handling solid feedstock.

3. Conversion Parameters

3.1. Feedstock

Biomass fuels usually have a low as-received fixed carbon value compared to coals while the volatile matter values are higher, therefore, when co-gasifying coal and biomass, a low release of carbon-containing compounds such as CO2, CO, CH4 and other light hydrocarbons are expected in comparison, to gasifying coal. This is contrary to results obtained by [30–35]; their experimental results show that increasing biomass ratio in the blend either increases concentration of carbon-containing compounds [CO2, CO, light hydrocarbon gases (C1 and C2) and tars] while H2 either decreases or stays constant. A screening of the experimental data can clarify this apparent contradiction. Kumabe et al. [33] added biomass on a carbon basis, not on a total weight basis; however, the hydrogen content in the biomass used was high enough so increasing the biomass ratio in the fuel blend would have increased the ration of hydrogen in the gas, instead a reduced concentration of hydrogen in the gas was observed. Using the ultimate analysis of the fuels the relative atomic compositions were CH1.548O0.737N0.002 for biomass (Japanese Cedar) and CH0.597O0.159N0.013 (Mulia coal). The authors observed an increase in CO2, a decrease in H2 and a constant concentration of CO. They also acknowledge the relatively high air-fuel ratio as compared to common gasification conditions and a lower temperature. Therefore, the lower temperature was more favorable to exothermic reactions, which were enhanced by the high air-fuel ratio, likely oxidizing part of hydrogen produced to steam, and hydrocarbons and a portion of carbon monoxide to carbon dioxide. Similar analysis can be made for [30–32,35]. This analysis also seems to explain why Cascarosa et al. [36] observed an increase of gas yield but a decrease of the gas calorific value when mixing 1% meat and bone meal (MBM) with coal in a fluidized bed gasifier.

Many co-conversion studies related to co-gasification studies have focused on parametric studies of the gasifier [31–35,37–43], mostly omitting the mechanisms by which mixtures of coal and biomass interact and how coal and biomass thermally degrade. The interaction between coal and biomass during thermal co-conversion is an issue yet to be solved; some devolatilization and pyrolysis results of coal and biomass blends have revealed no or very little synergy between the two fuels [44–56] while others have revealed significant synergy [43,57–71]. It is important to segregate the synergistic effect from the catalytic effect engendered by biomass mineral matters; most of the studies that found synergistic effects between the two fuels failed to segregate these two phenomena. Devolatilization/pyrolysis conditions as well as the type of feedstock [72–75] dictate the yield and composition of products during this stage, and therefore, influence the resulting char and the environment in which the char decomposes. The results of Yang et al. [74] for a packed bed reactor revealed that, at low heating rate (10 K/min), temperature of up to 1173 K, inert environment and atmospheric pressure, cellulose contributed mostly to the release of CO, whereas hemicelluloses contributed mostly to CO2, and lignin to H2 and CH4. Their explanation of this observation is that for lignin decomposition, H2 is released during cracking and deformation of the aromatic C=C and C–H bonds while CH4 is released during cracking of methoxyl groups; for cellulose which is high in carbonyl groups, CO is released and for hemicelluloses rich in carboxyl, CO2 is released. Very few studies have focused attention on pyrolysis/devolatilization conditions that pertain to gasification (high heating rate, high temperature, and pressurized atmosphere). Moreover the mechanism by which biomass components (cellulose, hemi-cellulose and lignin) interact under heating, the effect of mineral matter, as well as how these individual components and biomass as a whole would interact when blended with coal has not been elucidated. The effect of feedstock can thus influence the conversion behavior during the early stage of fuel decomposition (devolatilization/pyrolysis) as well as during char gasification.

3.1.1. Devolatilization/Pyrolysis

The generalized biomass pyrolysis model based on superimposed cellulose, hemicelluloses and lignin kinetics [76,77] has been questioned by recent developments in biomass thermal decomposition under pyrolysis conditions. Although Raveendran et al. [78] found no detectable interaction between biomass components during pyrolysis, and therefore agreed with the superimposed model, they acknowledged the influence of biomass ash on both pyrolysis characteristics and the product distribution. A study by Couhert et al. [79] demonstrated that because of the interactions between the structural components and the role of mineral matters in biomass, an additive law does not allow the gas yields of biomass to be correlated with its fractions of cellulose, hemicelluloses and lignin, thus suggesting a deeper analysis of the effect of biomass components interactions and ash on its decomposition. However, it is well known that cellulose is mainly responsible for volatiles, lignin is the main contributor of char while hemicellulose contributes to almost equally to both [74,80]. All these studies have been conducted at temperatures less than 1200 K; studies on behavior of biomass components at temperatures of 1600 K and higher reflecting the conditions of an entrained flow gasification process are scarce. Understanding the role of biomass ash and biomass components on volatile yield and composition and on char formation during thermal decomposition would facilitate the knowledge of how blends of coal and biomass behave under thermal decomposition.

The mineral matter in biomass (especially the ion-exchangeable alkali metals) is expected to further promote catalytic activity when blended with coal. Whether the influence of biomass has a greater impact during gasification than pyrolysis is unclear, but the type of feedstock appears to be a major factor in this partitioning. This remark is highlighted by Storm et al. [81] who did not find any interaction during co-pyrolysis of coal and straw, and instead found a lower release of pyrolysis products from blend of coal and sewage sludge as compared to unmixed fuels. Biagini et al. [44] found that thermal decomposition of biomass is not significantly affected by the presence of coal; in the same manner, coal is not affected by the release of volatile matter from biomass. It should be noted that in their study, the flow of nitrogen in a TGA did sweep the volatile products away from the devolatilizing fuels, therefore, the devolatilizing gas could not easily interact with the char, and thus the additive behavior of the products prevailed. These observations are well contrasted with results of [43,47,82,83] who identified some synergy.

Since blending coal and biomass/waste (heat input base) leads to an increase of the volatile products (CO, CH4 and CnHm) the energy content of the gas is expected to be higher than when gasifying coal alone because of the high heating value of CH4 and CnHm. The energy conversion efficiency is therefore supposed to be higher than when coal is gasified alone [31,33,35]. Kumabe et al. [33] reported an increase in conversion efficiency with increase in biomass ratio of the feedstock as well. Franco et al. [30] obtained similar results and observed that higher gas yield was observed when 40% of pine waste was used by mass in the coal-biomass blend. However, they noted that the higher energy conversion efficiency and heating value was obtained when higher amount of polyethylene (PE) was present in the mixture. This was explained by PE having a high content of C and H as compared to coal and pine waste. For mixtures of coal with equal amounts of pine and PE wastes, the gasification results were found to lie between those obtained for compositions with the same amount of only one waste.

3.1.2. Synergistic Effect during Coal and Biomass/Waste Co-Conversion

3.1.2.1. Synergy through Catalytic Effect

The merits of alkali (K+ and Na+) and alkaline earth (Ca2+) metals as catalysts for coal gasification have been extensively investigated [84–87], given the high content of these elements in some biomass, co-gasification of coal and biomass is expected to exhibit some catalytic behavior, whose significance will depend on the type of biomass and coal being used. In fact, Na is the principal alkali metal in lignite (low rank coal) and is said to be bonded to the oxygen anions in the carboxyl groups, while the amount of K is low [88]. In bituminous coals (high rank), K is said to be contained exclusively in illite or closely related clay structure [89], while Na is generally present as NaCl, usually as solution in moisture adsorbed in coal pores and capillaries [90]. As for calcium (Ca), it is present as exchanged ion with the hydrogen of the carboxyl group of low-rank coals; from low-rank coals to higher rank coals, Ca is systematically changed from carboxyl-bound to calcite [91], with decreasing catalytic activity [92]. The K present in the illite of bituminous coal is known to be transformed into a K-aluminosilicate glass [89] whereas the NaCl is highly volatilized. Therefore, mineral matters of high-rank coals have little catalytic activity during coal gasification. Moreover, the associated ion-exchangeable cations in low-rank coals are well distributed, at the atomic level. Therefore, any catalytically active ions such as Ca and Na are highly dispersed [93]. This is applicable to biomass fuels as well and sheds some light on why biomass mineral matter exerts some catalytic activity when blended with coal during thermal conversion. Ren et al. [94] compared co-gasification of MBM blended with a high-rank coal (anthracite), and MBM blended with a low-rank coal (lignite). Acid washed MBM samples blended with anthracite or lignite had a lower carbon conversion compared to the raw MBM blend. Thus, biomass mineral matter (Na, K and Ca) demonstrated catalytic influence during co-gasification, as reported by other authors [95,96]. They also found that the catalytic effect of MBM minerals was not perceivable on lignite but was significant for anthracite. This is in accordance with McKee et al. [97] and Srivastava et al. [98] who demonstrated the increased catalytic activity of alkali metals on gasification with increasing coal rank. The reaction rates of a blend of waste birch wood and Daw Mill coal was significantly increased and the char yields were lower than a simple blending prediction in a pressurized fluidized bed oxygen atmosphere gasifier with temperatures varying from 973 K to 1173 K at a pressure of 0.4 MPa [67]. Brown et al. [96] came to the conclusion that switchgrass char and switchgrass ash displayed catalytic activity in mixtures with coal char produced from Illinois No. 6 coal. The coal char gasification rate increased by eight fold at 1168 K in a mixture of 10:90 of coal char and switchgrass ash. In general, biomass is more reactive than any coal [99]. Its char is therefore continuously consumed during gasification, leaving very little remains at the end of the process, whereas coal char is less reactive and continuously accumulates in the bed during the course of the gasification. Blending biomass and coal takes advantage of both the high reactivity of biomass and its catalytic effect. However, some negative catalytic effects have been evidenced by Habibi et al. [100]. They observed an antagonism between switchgrass and a subbituminous coal while the mixture of switchgrass and fluid coke showed a synergy. They explain the antagonism by a deactivation of mineral catalysts due to sequestration of the mobile alkali elements by reaction with aluminosilicate minerals in coal to form inactive alkali aluminosilicates.

The catalytic effect of biomass in co-gasification with coal is also expected to play an important role for the abatement of environmentally harmful species containing sulfur and nitrogen. Biomass species with a high content of K, Na and Ca can form sulfate and capture sulfur from the gas phase when co-processed with coal [101]. During co-firing of straw and coal, Pedersen et al. [101] observed a net decrease of NO and SOx emission, due to the decrease of fuel- nitrogen conversion to NO and due to retention of sulfur in the ash. Sjöström et al. [67] also identified a lower ammonia yield during co-gasification of birch wood and Daw Mill coal. Cordero et al. [68] also showed enhancement in desulfurization when blending coal with different types of biomass during co-pyrolysis compared to coal pyrolysis. Haykiri-Acma and Yaman [57] showed that the addition of hazelnut shell to lignite contributed to the sulfur fixing potential of the resulting char in the form of CaS and CaSO4 during co-pyrolysis of these feedstocks.

3.1.2.2. Synergy through Other Mechanisms

The synergistic effect of co-conversion of coal and biomass can be viewed in terms of:

- -

increase in total volatiles (tars and light gases) release and decrease in char yield;

- -

overall decrease in pollutants (oxides of nitrogen and their precursors and well as SOx and their precursors).

The increase in total volatiles released and corresponding decrease in char production has received the most attention for synergistic evaluations. In the literature on thermal co-conversion of coal and biomass/waste, the non-catalytic mechanism responsible for this observation has been attributed to free radical/hydrogen transfer. However, the existence of non-catalytic synergistic effect remains controversial. Some researchers [43,57–71,101–108] have shown evidence of synergy between biomass and coal while others [44–56] found no evidence of synergy. Trevor and Kandiyoti [109] pointed out that the way biomass components are intermeshed affects the distribution of pyrolysis products. This important remark suggests that different biomass fuels may exhibit different behavior during co-conversion with coal, since the interlacing of biomass components (cellulose, hemicellulose and lignin) is unique for different biomass species.

It is obvious that interactions occurring between coal and biomass/waste during thermal conversion have not been sufficiently investigated and require further evaluation to elucidate the mechanism and conditions by which the two fuels interact when blended and converted.

3.1.3. An Analysis of Conditions Favorable to Synergy by Free Radical/Hydrogen Transfer during Thermal Conversion of Coal and Biomass/Waste Blends

3.1.3.1. Synergistic and Non-Synergistic Activities of Coal-Biomass Conversion Processes

3.1.3.1.1. Direct Liquefaction

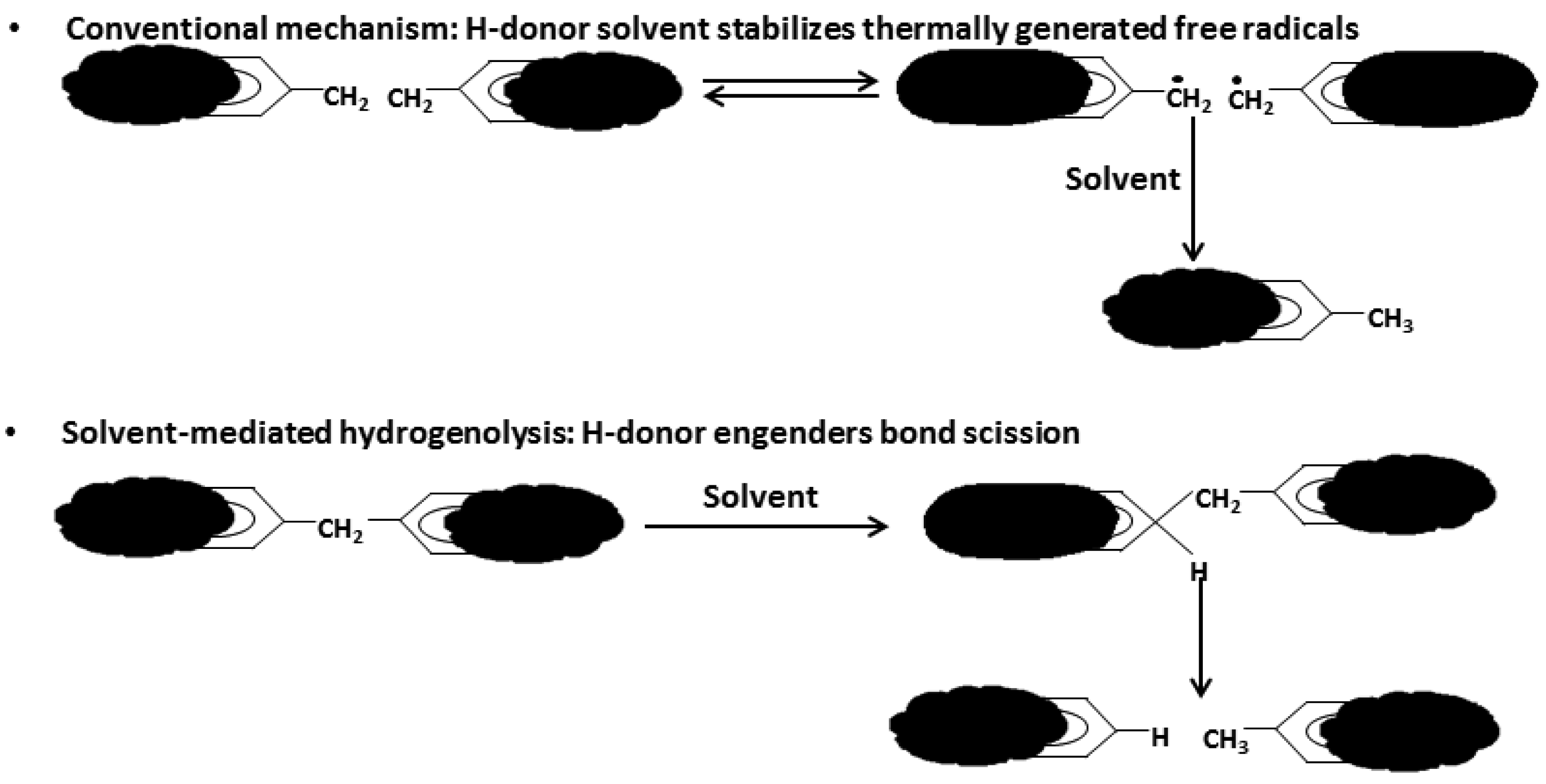

As depicted in Figure 1, liquefaction is a process by which a solid fuel (coal or biomass) is thermally ruptured into small radical fragments that are then stabilized by hydrogen atoms provided by a solvent or a hydrogen rich gas; the solvent also promotes bonds breaking, thereby allowing the process to occur at lower temperatures.

This process has been thoroughly investigated. There is clear evidence of the interaction during co-liquefaction of some fuels. The earliest depiction of synergy mechanisms during co-liquefaction is probably by Coughlin and Davoudzadeh [102]. In their experiment, they co-liquefied lignin and Illinois No. 6 bituminous coal using a series of catalysts with tetralin and phenol as solvents. They concluded that when coal and lignin react together in a solvent, they depolymerize under mild conditions to produce a filterable liquid product with yields greater than would be predicted based on a simple side-by-side, concurrent liquefaction of both components independently. One interesting finding was that the overall conversion of coal plus lignin increased as the fraction of lignin in the reaction mixture increased, while the opposite held true for increased proportion of coal in the reaction mixture. However, they noted that the overall conversion was not improved further by increasing lignin ratio beyond 0.7. Feng et al. [103] came to the same observation when catalytically co-liquefying coal and waste plastics. They used a mixture of subbituminous coal (Black Thunder), PE and polypropylene in a tubing reactor with catalysts: HZSM-5 zeolite catalyst, ferrihydrite treated with citric acid, co-precipitated A12O3-SiO, and a ternary ferrihydrite—A12O3-SiO containing 10% A12O3-SiO. They also measured synergy in terms of enhanced oil yield. Mastral et al. [104] also conducted co-liquefaction of a low rank coal (SAMCA coal, from Utrillas, Spain) and waste tires in tubing bomb reactors without solvent. They showed that the addition of tire to coal during co-liquefaction gives a positive interaction not by increasing the total conversion, but by influencing the mechanism of stabilization of the generated coal radicals. This assertion was made due to the high yield of asphaltenes, confirming the lower yield of light hydrocarbons (C1–C3) in the experiment as compared to the theoretical estimation. Another investigation by Mastral et al. [105] revealed that the slight synergy found can be due to the small free radicals from vulcanized rubber decomposition, which are able to stabilize coal radicals to light products. Taghiei et al. [106] also conducted co-liquefaction of PE and mixed plastic waste with a bituminous coal, a subbituminous coal and lignite in a tubing bomb reactor. Co-liquefaction of mixed waste plastics with a bituminous coal exhibited higher oil yields than obtained by liquefaction of either the waste plastics or the coal alone implying synergistic effects. Co-liquefaction of a 50:50 mixture of mixed waste plastic and an iron ion-exchanged subbituminous coal with the addition of 1.0 wt% of HZSM-5 zeolite catalyst gave a total conversion of over 90% and oil yield of approximately 70%. The oil yield of the mixture appeared to have been increased approximately 10% by synergistic effects. Co-liquefaction of iron ion-exchanged Beulah lignite with medium-density PE with no added solvent gave very good oil yields and total conversions at 723 K, indicating that the plastic plays the role of a hydrogen donor solvent for the coal under those conditions. It is interesting that the total conversion of lignite and plastic is possible at 723 K without a solvent. Kanno et al. [107] also observed synergy in the conversion of Yallourn coal (lignite) and PE under pressurized hydrogen using 1-methylnaphthalene and tetralin as solvent. The conversion and the oil yield were larger than the additive values of respective fuels processed separately and the observed values of residues for both Yallourn coal and PE during the co-liquefaction were evidently smaller than the estimated values. Anderson co-liquefied tires and a low-rank coal in a magnetically stirred autoclave under hydrogen pressures of 10, 5 and 1 MPa and nitrogen pressure of 0.1 MPa. They noted that the synergy was observed only at low hydrogen pressures. The oils obtained in the co-liquefaction showed a more aromatic nature than those obtained when each material was processed separately, a higher boiling point was also observed, suggesting that radicals from rubber and coal reacted between each other instead of reacting with hydrogen radicals. Although the existence synergy has been agreed upon and the mechanism has been somehow well understood during co-liquefaction, it has not been the case for other thermal conversion processes.

3.1.3.1.2. Pyrolysis

Pyrolysis is the decomposition of an organic material by heating in the absence of oxygen, but with inert gases or less reactive gases (argon and nitrogen) producing a viscous dark liquid (oil), gases and leaving a charring material composed mainly of carbon. Devolatilization on the other hand is the first step of combustion or gasification. It differs from pyrolysis with the presence of a reactive gas (O2, H2O, CO2, etc.) during heating, and both processes will be referred to as pyrolysis.

Unlike liquefaction, no solvent is added to the organic feedstock during pyrolysis. Therefore, the thermal breakdown of the organic feedstock is not chemically enhanced, nor is there any hydrogen donor (solvent as in the case of liquefaction) to stabilize the radicals involved during thermal bond breaking.

As stated earlier, the literature on synergy during co-pyrolysis of solid fuels is controversial. Among co-pyrolysis studies that resulted in no synergy are that of Vuthaluru [111] who conducted co-pyrolysis of a subbituminous (Collie coal) coal with waste wood and with wheat straw using a thermo gravimetric analyzer (TGA). The samples were heated at 20 K/min from ambient to 1523 K under atmospheric pressure using argon as the carrier gas. No synergy was found. Collot et al. [37] also did not find synergy in the co-pyrolysis of Daw Mill coal (bituminous) and Silver Birch Wood in a fluidized bed reactor. In a fixed bed reactor the degree of synergy was insignificant at 1123 K and 1273 K with a heating rate of 10 K/min, using helium as the carrier gas under pressure from 1 bar to 25 bar. It is however worth noting that they observed a slight increase (though not significant) of tar in the fixed bed reactor. Storm et al. [81] pyrolyzed blends of biomass (straw), sewage sludge of a high-volatile bituminous coal (Gottelborn hard coal) in a bench scale entrained flow reactor at 1473 K and atmospheric pressure, using nitrogen as the carrier gas. Neither coal/biomass nor coal/sewage sludge tests showed synergy. Meesri and Moghtaderi [45] co-pyrolyzed a high-volatile bituminous coal (Drayton coal) and Radiata pine sawdust in a horizontal tubular reactor at slow heating rate (10 K/min) and temperatures of 473–1173 K, and in a drop tube furnace at high heating rate and temperatures of 1173–1673 K. The pyrolysis products obtained from co-pyrolysis during their experiments correlated well with the weighted sum of the individual fuels, indicating a lack of synergy. Idris et al. [112] investigated the pyrolysis behavior of blends of a Malaysian subbituminous coal and empty fruit bunches, kernel shell, mesocarp fibers of palm tree in a TGA using nitrogen as the carrier gas. The heating was varied at 10, 20, 40 and 60 K/min and the temperature ranged from 298 K to 1173 K. No synergy was found. Another co-pyrolysis study that failed to depict synergy is that of Moghtaderi et al. [46]. The same high-volatile bituminous coal used in [45] was blended with Radiata pine and pyrolyzed. Two sets of experiments were conducted: slow heating conditions (10–50 K/min) and a temperature range of 473 K to 673 K and a high heating condition (10,000 K/min) and temperature range of 1173–1673 K with nitrogen as the carrier gas in both cases. No synergy was depicted in their investigation. Vamvuka et al. [83] modeled the devolatilization kinetics of lignite blends with olive kernels, forest residues and cotton residues using TGA in nitrogen gas. The heating rate in their experiment varied from 10 K/min to 100 K/min and the temperature ranged from 298 K to 1123 K. They concluded that the co-pyrolysis kinetic data followed a weighted average of the pyrolysis data of the individual fuels. In a similar study, Vamvuka et al. [47] modeled the co-pyrolysis kinetics of a high-volatile bituminous or lignite coals, blended with olive kernel and straw. Experimental conditions were similar to [83] and they came to the same conclusion: no synergy. Despite the lack of synergy in the co-pyrolysis studies cited above, many other investigators have found synergy during coal/biomass, coal/waste pyrolysis.

Jones et al. [113] conducted devolatilization studies of blends of some coals (Wujek, bituminous; Kaltim Prima, bituminous; Turoszow, lignite) with a variety of biomass (pinewood, cellulose, lignin, xylan and polywax model compounds) in pyrolysis-gas chromatography-mass spectrometry (GC-MS), TGA, and static batch pyrolysis reactors at slow and moderate heating rates and a temperature range of 673–1173 K. Synergy was observed only in the batch reactor while the py-GC-MS and TGA displayed additive behavior. Hayashi et al. [114] conducted co-pyrolysis of Yallourn coal (lignite), Taiheiyo coal (subbituminous), with fine powder of homo-polypropylene, low-density PE or high-density PE in a Curie-point pyrolyser. They found an increase of total volatiles (tar and light gases) and a decrease of char for all combinations of coal-polyolefin as compared to the sum of corresponding individual yields. Oney et al. [115] conducted co-pyrolysis of Seyitömer lignite and safflower seeds blends both in a TGA and in a fixed bed reactor. In the TGA, the sample was heated at 5 K/min from ambient temperature to 1073 K. In the fixed bed reactor, the samples were heated at a rate of 7 K/min to 723, 773, 823 and 973 K. In both reactors, nitrogen was used as the carrier gas. Their investigation revealed considerable synergy in the fixed bed reactor especially when the proportion of coal in the blend was <33%. Park et al. [64] conducted co-pyrolysis of Sawdust and a subbituminous coal in a TGA under nitrogen at 1.2 bar and in a fixed bed reactor. In the TGA, the samples were heated at 15 K/min from ambient to 1173 K, in the fixed bed reactor (the heating rate and temperature was not provided). They observed that char yield was lower than would be obtained from additive behavior. They also noted that the difference was more pronounced around 873 K and disappeared as the temperature approached 1073 K and higher. These observations are in accordance with Zhang et al. [59]; they pyrolyzed blends of Dayan coal (lignite) and legume straw in a free fall reactor under atmospheric pressure at temperatures ranging from 773 K to 973 K with nitrogen as the carrier gas. Their investigation revealed that synergy was pronounced at lower temperatures (around 873 K) but reduced as temperature increased and was less pronounced around 993 K. Gao et al. [116] made a similar observation. Park et al. [64] also noted as Oney et al. [115] as well as Gao et al. [116], that synergy was more pronounced at higher biomass blending ratio (around 70%). Ulloa et al. [117] conducted co-pyrolysis of blends of subbituminous (Bitsch Coal), bituminous (Lemington coal) coals, with Radiata Pine sawdust in a TGA under nitrogen at different heating rates (10, 30 and 50 K/min) to a maximum temperature of 1473 K. Their experiment depicted interaction between biomass and the two coals at temperatures higher than 673 K and up to 1473 K. Their explanation of the interaction was that the synergy between devolatilization of biomass and lignin (which spans from 673 K to 1173 K) coincides with that of coal. However, they identified the role of biomass mineral matter as catalytic agent favoring decomposition of coal/biomass blends by decreasing the formation of char and favoring the generation of more volatile material. Another comprehensive study of coal and biomass co-pyrolysis and co-combustion is that of Kubacki [118]. This investigation involved coals of different ranks with biomass (straw) in different reactors: TGA, Pyroprobe-GC/MS, batch pyrolysis reactor, and a heated wire mesh pyrolysis reactor coupled to a GC/MS. He found that the type of biomass can lead to a small change of the rate of coal pyrolysis; slight synergistic effects were seen for the TGA study, where co-pyrolyzed coals in blends often had lower peak temperatures compared to coal alone, and higher volatile matter yields were produced. Analysis of the gases evolved was consistent with higher gas yields. This effect was present for certain biomass (e.g., oat straw) even after minerals were removed, and so this is not purely the result of catalytic ash components. Regarding pollutants emission, it was [118] noted that synergy effects contributing to reduction in pollutants during co-gasification of coal and biomass is not solely attributed to interactions of volatiles in the vapor phase, rather, there is a strong linkage between the pyrolysis and combustion steps and as such, the two steps needs to be studied together. We can extend this remark to devolatilization/gasification as well. From this observation, we can infer that synergy seems to be dictated by the pyrolysis/devolatilization step. Therefore, any synergy observed during the gasification/combustion step is only the consequence of what has already taken place during pyrolysis/devolatilization:

cracking of tar to produce more gases in case of gasification;

more reactive char for gasification and combustion.

3.1.3.1.3. Gasification and Combustion

As mentioned in the previous section, synergy during gasification or combustion cannot be isolated from the pyrolysis/devolatilization step. Synergy during gasification/combustion is usually expressed in terms of the high amount of gases (gasification), high reactivity of the char (gasification and combustion), reduced pollutants (gasification and combustion). These observations occur as a consequence of the interactions occurred during pyrolysis/devolatilization. Kubacki [118] mentioned it in his thesis and suggested that pyrolysis and combustion need to be studied together.

3.1.3.2. Synergistic Effects by Free Radical/Hydrogen Donation

3.1.3.2.1. General Assessment

The following explanation for synergy between coal and biomass/waste has been postulated [119]:

The weak covalent bonds in biomass and the higher content of oxygen compared to coal causes its early reaction, therefore, releasing volatiles which break down and release free radicals or undergo combustion reactions with oxygen present in the system. The free radicals from biomass react with coal and enhance its decomposition. The gases resulting from cracking of the heavy volatiles from biomass, as well as light volatiles molecules from biomass are rich in hydrogen which react with coal's free radicals as hydrogen donors, therefore, preventing their recombination reactions and reduce the amount of less reactive secondary chars. This explanation is in accordance with similar conclusions made by Squire et al. [120], who found that polymers which undergo extensive tar-forming thermolysis have limited supplies of hydrogen available to donate thus tend to produce more char than polymers with abundant hydrogen. Coal volatiles are also commonly of high calorific value, thus their combustion further increases the temperature in the region around the particle. The high temperature is then favorable for cracking high molecular weight gaseous compounds (tar) produced by biomass and coal; the higher temperature is also favorable for endothermic conversion of biomass and coal char into gases. The overall effect is a net increase in volatiles yield, less char, and a higher fuel conversion rate. Similar suggestion have been reported in the literature; Ahmaruzzaman and Sharma [121] observed synergy in the thermal decomposition of polypropylene, petroleum vacuum residue and biomass blend. They explained the synergistic interaction by the generation of reactive free radicals from polypropylene cracking, which react with the thermal decomposition products from petroleum vacuum residue and biomass.

Thus, hydrogen transfer between biomass and coal seems to be a plausible explanation of the synergistic effect between the two fuels. The hydrogen transfer mechanism between coal and solvents during coal liquefaction can provide some clue in the investigation of synergistic effects between coal and biomass during pyrolysis/devolatilization. In fact, co-liquefaction of coal and lignin [102], as well as coal and tire [105] have displayed significant synergies owing to the same mechanism. Similar mechanisms have been found during pyrolysis of solvent swollen coals [122–125] and coal impregnated with polyolefin [114]. Miura et al. [122] concluded that “to supply the radicals to coal effectively and to increase the total volatile matter, the formation rate of the radicals must match that of the radical fragments from coal at first. Furthermore, both radicals must be close enough spatially to react with each other, because the reaction rates among the radicals are much faster than the transport rate of the radicals.” One other important observation they made was the temperature dependence of the interaction between coal and solvent. The total volatiles yield of the solvent swollen coal increased with the increase of temperature and reached a maximum value. Further increase in temperature caused a decrease in the total volatiles yield of solvent swollen coal until it became equal to that of the raw coal. Thus, it can be inferred that synergy between coal and biomass is highly dependent on the process condition (temperature), the closeness (interaction) between coal and biomass particles, and the matching of the release of coal and biomass radical intermediates. The first two conditions imply that synergy may depend on the type of reactor being used. Therefore, it is expected to find more synergy in reactors operating at lower temperatures and favoring tight, intimate contact between fuel particles (fixed bed and fluidized bed) and little synergy in reactors that operate at higher temperatures and that segregate the fuel particles (entrained flow). However, these assumptions are somewhat contradicted by the results of Zhang et al. [59] and Lapuerta et al. [43]. The former [59] found synergy during co-pyrolysis of lignite and straw in a free fall reactor. The char collected was subjected to a CO2 reactivity test; results from the co-pyrolysis chars were about twice as high as those of coal char alone, and even higher than those of biomass alone while the latter [43] found synergies in a drop-tube reactor. Collot et al. [37] concluded in their pyrolysis experiments that neither intimate contact between fuel particles nor their relative segregation led to synergistic effects, making the case of fuels' interaction condition for synergy even more puzzling.

The temperature dependence of the interaction between the coal and biomass seems to be consistent with the results of some researchers [75,112–114], confirming that synergy is effective up to some optimum temperature and then disappears at higher temperatures.

A thorough understanding of free radical formation and evolution during pyrolysis seems to be the key to the possible interaction between coal and biomass. While extensive studies have been conducted on free radicals release during coal pyrolysis [115–124], such studies involving direct in situ observation of radicals released during biomass or biomass components (cellulose, hemicelluloses and lignin) pyrolysis are lacking. Understanding the mechanism of free radicals release during biomass/biomass components pyrolysis can pave the way to improvements in the modeling of coal and biomass blends during co-pyrolysis/co-gasification, and the synergistic effect between coal and biomass; therefore, providing an insight to the prediction of co-conversion of coal and biomass.

3.1.3.2.2. Hydrogen and Free Radicals Interaction

There is no doubt that hydrogen donation is a key factor in improving the yield of oil and increasing the conversion of the feedstock during liquefaction. Investigation of hydrogen transfer from a liquid carrier (tetralin) to coal was first described as a free radical reaction with thermal breakage of the coal molecules by Curran et al. [126]. They found that the degree of coal conversion was a function of the amount of hydrogen transferred and relatively independent of the solvent composition employed. Neavel [127] noted that the presence or lack thereof of a hydrogen donor vehicle had little effect on the thermal rupture of the coal fragment. This thermal cleavage results in the formation of highly reactive free radicals. In non-donor solvents, these free radicals react with surrounding molecules to form higher molecular weight compounds that become insoluble in subsequently employed extracting solvents. However, when a hydrogen donating solvent is employed, hydrogen is abstracted from the solvent and stabilizes pyrolysis-formed free radicals. Products are then relatively low molecular weight substances capable of being dissolved in most solvents. Progressively more donor hydrogen is abstracted for each increment of conversion as the reaction proceeds [127]. Vernon [128] conducted liquefaction of coal model compound dibenzyl and observed that when heated for 30 min at 723 K with an excess of a good donor solvent, tetralin, the conversion was 47% by mass and the only major product was toluene; very little benzene and ethyl benzene were produced. When the same experiment was carried out in the presence of high pressure hydrogen (× 11 MPa) the conversion increased to 58%. He then concluded that even molecular hydrogen could serve as a donor vehicle during liquefaction reactions. Li et al. [129] concluded that the primary factor inhibiting coal liquefaction is the consumption of hydrogen free radical (H●) from solvent or H2 and condensation of free radicals from coal pyrolysis after a period of reaction. So the essential approach for increasing oil yield and conversion of coal is to provide enough H● to stabilize the free radicals from coal pyrolysis. Unlike Neavel [127], McMillen [130] offered that the direct transfer of hydrogen atoms from solvent derived radicals to substituted positions in aromatic rings is substantial as preliminary steps in depolymerization of coal structures. Wei et al. [131] believe molecular hydrogen enhances the thermolysis, hydrogenation and hydrocracking of coal model compounds, as oppose to hydrogen donating solvents which inhibit these reactions. Although investigators opinions regarding liquefaction process may vary, there is a consensus that free radicals released during cleavage of the coal molecule needs to be stabilized by some hydrogen donor shuttle to suppress cross-linking reactions.

3.1.3.3. Enhanced Conversion of Solvent Swollen Coal

As the previous section described, the transfer of hydrogen to coal radicals is essential in achieving a higher yield of oil during liquefaction. It will be shown that improved pyrolysis is also achieved by effective transfer of hydrogen to free radicals. It has been suggested that the contact at the molecular level between the solvent and the fuel functional groups is essential in addition to the matching of the dehydrogenation rate of the solvent and the primary decomposition rate of coal. Miura et al. [132] ensured the contact at the molecular level was achieved by swelling the coal with solvent at 373–523 K under a pressurized atmosphere. The observed increase of both the total volatile matter and the tar yield was brought about by not only the effective hydrogen transfer from tetralin to the coal but by the effective utilization of small radicals such as OH● and H● from the coal for stabilizing the coal fragments. Mae et al. [133] used a similar technique by pyrolysing a pyridine vapor swollen coal. The suppression of cross-linking reactions significantly increased the volatile and tar yield. Awan et al. [134] conducted studies on tetralin treated coals. Similarly, he obtained a significant increase in tar and volatile yield and explained this observation in terms of the suppression of the cross-linking reactions of coal fragments due to the penetration of tetralin in to the micropores of coal, as well as the effective H● radicals transfer from tetralin to coal fragments during pyrolysis. Several experiments of this nature have been conducted to demonstrate the effectiveness of hydrogen transfer in the efficient release of gases during pyrolysis [123,132,135].

Non-catalytic synergistic effects observed in the release of volatiles and tar during coal biomass/waste co-conversion is evidenced by what precedes. The mechanism is a complex one, since in the case of biomass and coal, the release of hydrogen from biomass should match the free radical release from coal and the two fuels should be spatially close for the transfer to happen. The discrepancy observed in the scientific community about this topic is probably due to these constraints.

3.1.4. Effects of Co-Conversion of Coal and Biomass/Waste on Tar Release

Tar can be defined as the organics, produced under thermal or partial-oxidation regimes of any organic material, and generally assumed to be largely aromatic [136], condensing at ambient to lower temperatures. Tar is one of the most challenging constituents of the syngas. The tar content of the product gases from gasification of biomass is one of the major factors affecting the subsequent process stages. The type of feedstock used and gasification temperature are the main factors affecting tar yield during gasification [99]. Synergistic effects between coal and biomass particles are expected to lower the yield of tar compared to independent gasifying of these feedstocks. Kumabe et al. [33] obtained a slight decrease in tar yield by varying Japanese cedar (biomass) ratio of the feedstock from 0 to 100 when co-gasifying with Mulia (Indonesia) coal with air and steam in a downdraft fixed bed gasifier at 1173 K. Pinto et al. [137] observed a decrease in tar yield for a mixture of 80% coal (high-ash coal from Puertollano, Spain) and 20% pine wood waste compared to coal alone in a fluidized bed gasifier operating at atmospheric pressure and a temperatures of 1123–1173 K using a mixture of oxygen and steam as the gasifying agent. However, the addition of PE waste in the feed instead led to an increase in tar release; a probable reason for this behavior being the polymeric nature of PE which breaks into smaller fractions by thermal cracking, contributing to a greater amount of tars. A ternary blend of coal, PE and pine resulted in less tar release than when mixing coal and PE. They also found that dolomite was an efficient catalyst for reducing the tar yield during co-gasification of coal and biomass/waste mixtures containing PE. The presence of dolomite in the fluidized bed has the advantage of decreasing tar content and augmenting gas yield [35]. No evidence of synergetic effect however was found by Collot et al. [37] with Polish coal and forest residue mixture. Aznar et al. [32] and Andre et al. [35] also identified an increase in tar yield with an increase in biomass content of the feedstock, suggesting that synergetic effect during coal and biomass co-gasification might be highly dependent on biomass type as well as gasification conditions. One of the challenges emphasized by Mettler et al. [138] in their reviews of fundamental challenges of biomass pyrolysis for biofuels is the difficulty still encountered by researchers to identify and characterize nascent liquid intermediaries evolved during biomass pyrolysis. Therefore, the pertinence of these intermediates during co-conversion with coal is unknown. Further investigation is still needed to clarify the issue of synergy during coal and biomass/waste co-conversion.

3.2. Pressure

Pressure is among the conversion factors that depend on the reactor condition. Bahng et al. [139] provides a good update on available technologies for thermal conversion of biomass. The effects of pressure on biomass/waste and coal co-gasification have not been thoroughly investigated, which is the same as the effect of pressure on biomass gasification. However, many researchers have studied the effect of pressure on coal gasification alone. The pressure effect on gasification is depicted at different stages of the gasification process.

3.2.1. Effect of Pressure on Pyrolsys/Devolatilization

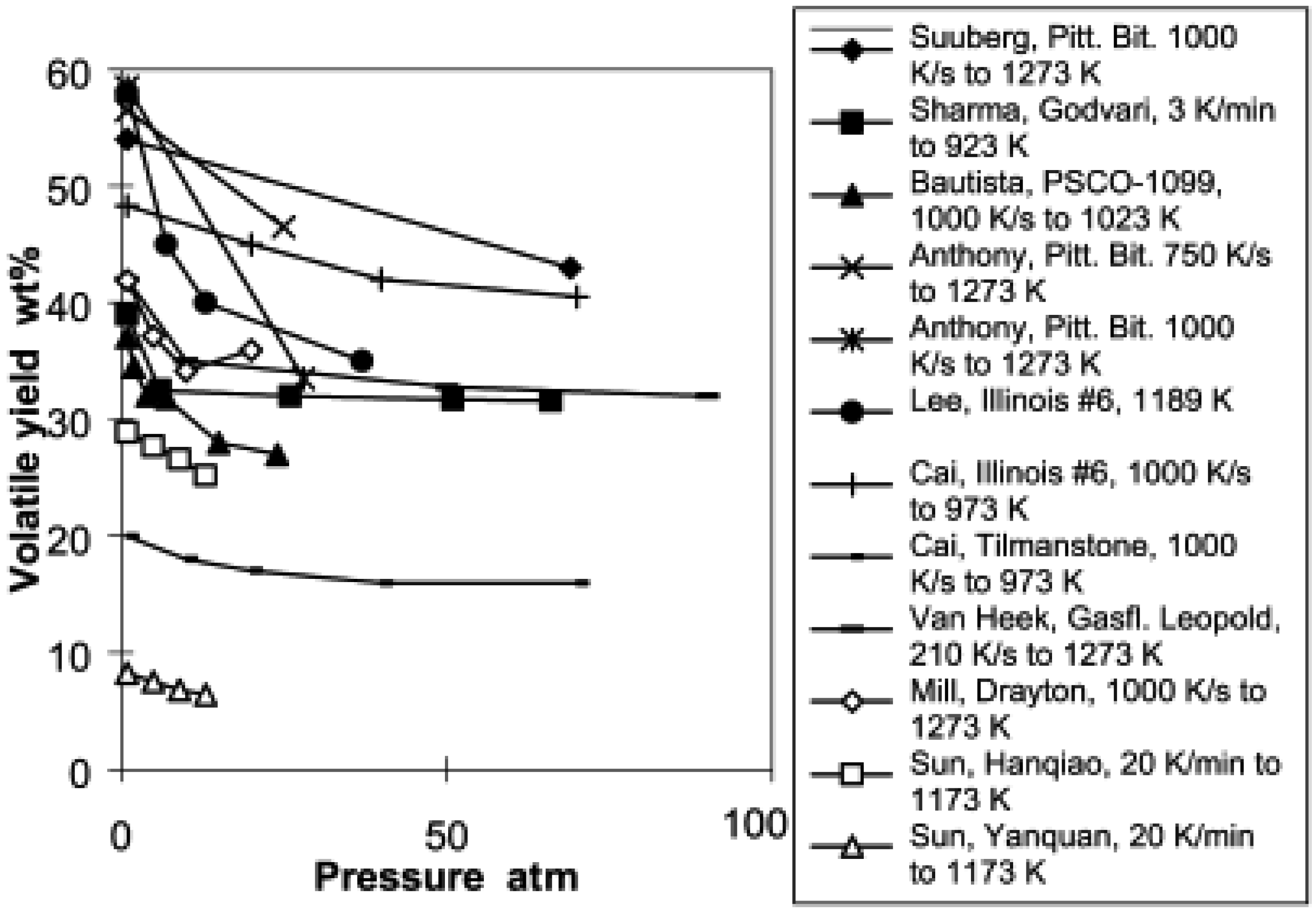

During the devolatilization phase of coal gasification, increasing the pressure decrease the total volatile yield. Lee et al. [140] conducted pyrolysis of a bituminous coal at pressures up to 0.39 MPa with a heating rate of 1000–10,000 K/s. They concluded that increasing pressure reduced the volatile release rate. The same observation is confirmed by Sun et al. [141] when pyrolysing two Chinese coals at 1173 K peak temperature and a heating rate of 20 K/min. They observed a significant decrease in total volatiles when increasing the operating pressure from 0.1 MPa to 1.3 MPa. However, their work emphasized that temperature affects the effect of pressure during coal devolatilization. They delineated two temperature ranges: one between 833 K and 953 K where the effect of pressure on devolatilization is insignificant, and one between 833 K and 953 K where increased pressure significantly reduces the devolatilization rate for Chinese bituminous and anthracite coals. Seebauer et al. [142] observed a similar trend on bituminous coal at pressure between 0.1 MPa and 4 MPa. Collot et al. [37] obtained the same trend on pyrolysis of Daw Mill coal at pressures ranging from 1 bar to 25 bar and temperatures of 1123–1273 K in a helium environment using a hot-rod reactor. It is important to note that the volatile decrease is sharp between 1 bar and 10 bar and remains almost constant for subsequent increase of pressure. However, when gasifying the same type of coal in a CO2 environment, keeping other parameters identical as in the pyrolysis, they instead observed an increase in total volatile at 1273 K and a decrease at 1123 K with increasing pressure. Gibbins et al. [143] obtained a decreased yield in a helium atmosphere while in a hydrogen atmosphere, an increase of total volatiles was observed during pyrolysis in a wire mesh reactor. Shan [144] cited by Wall et al. [145] computed the data for total volatile yield as a function of pressure from different authors and derived Figure 2.

The pressure effect during devolatization of biomass is similar to that of coal. Pindoria et al. [146] observed a decrease in total volatile yield as pressure increased from 0.25 MPa to 7 MPa during pyrolysis of Eucalyptus sawdust in a hot-rod reactor heated at 10 K/s to a peak temperature of 723 K. Collot et al. [37] also obtained a decrease in total volatiles yield on silver birch with pressure varying from 2 bar to 25 bar and temperatures of 1123–1273 K in a helium environment with a hot-rod reactor; it's important to note that the volatile decrease is sharp between 2 bar and 10 bar and remains almost constant for subsequent increases of pressure. When gasifying silver birch wood in a CO2 atmosphere, keeping all other parameters identical as in pyrolysis, the total volatile at 1273 K did not show any change with increased pressure while at 1123 K, a slight decrease was observed. All studies demonstrated that the effect of pressure on total volatile yield is less pronounced at higher pressures.

The decrease in total volatiles is mostly due to the decrease in tar as pressure is increased. Pressure suppresses the formation and release of tar and shifts the molecular weight of tar to a lighter fraction while promoting secondary reactions that decompose tar. Therefore, decreases in the tar output occur as well as increases in the total yield of light gases [147]. This observation is also well illustrated by Suuberg [148].

A high pressure inhibits the release of larger tar molecules that may easily evaporate at lower pressures, which is a plausible explanation why tar yield decreases and most of the tars shift toward lower molecular weights. Secondary reactions may explain why the effect of pressure on total volatiles is more pronounced at higher temperatures. The secondary repolymerization of the tar and the auto-hydrogenation phenomenon occurring at elevated pressure may also explain the increase of hydrocarbon gas yields, particularly methane.

Arendt and van Heek [145] obtained a significant decrease in tar yield during pyrolysis of five German hard coals in an inert gas (He) atmosphere as well as hydrogen atmosphere, with pressure varying from 0.1 MPa to 9 MPa and a temperature range of 1223–1273 K. They found that with increasing pressure, tar repolymerised and cracked more significantly, resulting in increased yields of char and hydrocarbon gases.

Similar results were obtained by Güell et al. [146] on pyrolysis of Pittsburgh No. 8 and Linby (UK) coals. Their experiment was conducted in a wired-mesh reactor with pressure ranging from atmospheric to 150 bar and peak temperatures of 973–1123 K under a helium and hydrogen atmosphere. Like total volatile yield, the effect of pressure on tar yield is less pronounced at higher pressures. Biomass reveals similar behavior; which is depicted by [142] on pyrolysis of eucalyptus wood waste.

3.2.2. Effect of Pressure on Char Characteristics

The effect of pressure on char formation and reactivity seems to be more complex. Reactivity of char is in fact highly dependent on the pyrolysis condition and pressure is one of the most important factors; it significantly affects the ash formation during char gasification as well. Under gasification conditions, one of the main parameters used for analyzing char reaction rate is its internal surface area. Higher pyrolysis pressures lead to lower surface area of char, and therefore, lower reactivity during gasification. Lee et al. [149] tested the reactivity of Illinois No. 6 bituminous coal chars obtained from different pyrolysis pressures and concluded that the char reactivity decreased slightly as the pyrolysis pressure increased. Sha et al. [150] also obtained a decrease in char's reactivity with increasing pyrolysis pressure in the range of atmospheric to 2 MPa on lignite, subbituminous and bituminous coals devolatilized at 1173 K in nitrogen. A previous study by Mühlen et al. [151] revealed similar observations; they investigated the reactivity of German bituminous coal chars pyrolysed under pressures of 0.2–4 MPa at 1173 K in helium. The reactivity of the chars was then evaluated at 4 MPa and 1173 K in hydrogen using a TGA.

Experiments with biomass show comparable results. Cetin et al. [152,153] tested the reactivity of chars from pyrolysis of Radiata pine, spotted gum (Eucalytus maculata) and sugar cane bagasse. They found that char particles produced at 20 bar reacted three times slower than the char generated at atmospheric pressure, thus the apparent gasification reactivity of biomass char decreases with increase pyrolysis pressure. Pindoria et al. [154] derived analogous results on the combustion reactivity of eucalyptus sawdust chars obtained at a peak temperature of 1123 K in helium, hydrogen and carbon dioxide atmosphere.

Several assumptions have been postulated to explain this observation. It's believed that high pressure may inhibit the transport effect during pyrolysis such as to reduce the release of volatile matters, causing large deposition on the pore surfaces, which creates secondary reactions, and therefore, deactivates active sites on the resulting char. Another assumption is that higher pyrolysis pressure enhances fluidity of coal, leading to a better mobility, alignment and ordering of carbon layers with reduction of micropores and subsequent loss of gasification reactivity. Concurrent influences of these two phenomena are also possible.

4. Co-Conversion and Emissions

4.1. Effect of Blending Coal and Biomass/Waste on NOx and N2O Precursors (HCN, NH3 and HNCO)

During combustion, nitrogen contained in solid fuels is converted to nitric oxides [NOx (NO and NO2)], gaseous nitrogen (N2) and nitrous oxide (N2O). The amount of fuel nitrogen retained in the char is generally insignificant. Life cycle assessment of biomass combustion in a heating furnace has revealed that 38.6% of the environmental impact is attributed to NOx, 36.5% to particulate matters, 2% to CO2 and 22.9% to all other pollutants [155]. It is known that NOx pollutants are formed in a two-step process: formation of the precursors (usually HCN and NH3) then combustion of the precursor. Therefore, a better understanding of the mechanism of formation of NOx precursors is essential to its in situ mitigation. Moreover, in oxygen-deprived environment (pyrolysis and gasification) NOx precursors are the main N2 compounds formed.

The origins, forms and modes of occurrence of nitrogen compounds (NH3 and HCN) during coal pyrolysis and gasification have been thoroughly investigated. Nitrogen in coal is mostly in pyrrolic and pyridinic forms [156–159]. Quaternary forms of nitrogen are also present, especially in low-rank coals. Amine functionalities are observed in low-rank coals [160], while they are present in biomass in diverse forms: proteins [161,162] (polymer of amino acids), alkaloids (heterocyclic nitrogen compounds), non-protein amino acids, nucleic acids, inorganic nitrogen and chlorophyll [163]. Chlorophyll, the green coloring matter in leaves and green stems, contains N in a magnesium-containing pyrrole derivative. Some biomass fuels are rich in nitrogen (sewage sludge, meat and bone mill, chicken liter, soya bean cake, slaughterhouse wastes, veterinary sanitation wastes, some agricultural wastes especially from legumes family [164]) impelling the need to investigate the release of NOx and N2O precursors during co-pyrolysis and co-gasification with coal. It is uncertain whether results from coal nitrogen investigations could be applied to biomass nitrogen, since this element is bound differently in the two types of fuel.

Reaction pathways involving nitrogen during pyrolysis/gasification is complex due to the overlapping of reaction stages, the influence of reaction conditions (residence time, temperature, pressure and gasification agent) and the differences between fuels. During pyrolysis, part of the fuel bound nitrogen (FBN) is released with the devolatilizing gases while the remainder is retained in the solid char to be released during subsequent gasification/combustion of the char [165,166]. The allocation of fuel-N to volatiles and char is dictated by temperature [160,167–170], particle size [168], fuel type [160], residence time [168,170], heating rate [171], and pressure [171]. Temperature, fuel type, and particle size, are the dominant factors in this allocation while heating rate and pressure only have a minor effect.

4.1.1. Fuel Nitrogen Behavior during Biomass Conversion

Given the predominance of proteins as the main nitrogen-containing compound in biomass, some researchers [172–177] have used amino acids as model compounds to study the behavior of nitrogen during thermal decomposition of biomass. Ren and Zhao [175] studied the pyrolysis and O2 and CO2 gasification behavior of phenylalanine, aspartic acid and glutamic acid in a TGA at temperatures ranging from 0 K to1073 K. The distinct structures of these amino acids cause them to behave slightly differently under argon pyrolysis as well as O2 and CO2 gasification. Ren et al. [176] found that the structure of the amino acids, the mineral matter content of biomass [178,179], the pyrolysis/gasification condition and the particle size [161,180] affects significantly the fate of nitrogen during pyrolysis of biomass. The thermal decomposition of amino acids and proteins proceeds mainly through dehydration with formation of cyclic amides, with diketopiperazine (DKP) being the common one [172–174,177].

Compared to coal, biomass has a higher content of oxygen, which enhances the direct release of NO and isocyanic acid (HNCO) as part of the devolatilizing gases during pyrolysis. The presence of CO2 suppresses the release of HNCO while enhancing formation of NH3 and NO [180] during gasification of amino acids, whereas HCN, HNCO and NO are promoted with the presence of O2.

Becidan et al. [181] found that HNCO can react with steam to give ammonia and carbon dioxide:

HNCO may also lose its hydrogen to give NCO, which then reacts with NO to give N2O and CO, it is therefore considered a precursor of N2O:

However, HCN is the main precursor of N2O [186,187] according to the following reactions:

The effect of particle size on FBN release is insignificant at lower temperatures (<673 K) but becomes considerable as the temperature increases. As the particle size increases, the yield of nitrogen species generally reduces [180]. This observation correlates with the fact that volatile release from a particle increases as the particle size decreases. With smaller particle sizes, volatile escape from the particle is fast enough to limit secondary reactions, resulting in high yield of volatile nitrogen.

Biomass also usually has a higher moisture content compared to most coals. Moisture can react with isocyanic acid to give ammonia and carbon monoxide, this reaction is known to be enhanced by the presence of CaO [188,189], which is present in most biomass:

Therefore, larger particles with longer diffusion path may favor reaction of HCN with H2O and enhance formation of NH3 as has been observed by some researchers [161,180]. It has also been observed that HNCO and NO release is higher for smaller particles. A probable explanation is that the temperature gradient within smaller particles is negligible during pyrolysis, therefore, the product of cracking of cyclic amides are quickly released as HNCO and NO [180]. Large particles retain more nitrogen in the solid phase than small particles because volatiles rebound to the solid phase during the transport out of the particles [190].

The effect of temperature on biomass fuel nitrogen has also been thoroughly investigated. Becidan et al. [181] observed an abrupt increase in N-conversion to HCN with temperature. They inferred that this observation is the result of tar and volatile cracking as well as secondary reactions. A similar inference has been made by Tian et al. [191]. NH3 also increase with temperature but reaches a maximum around 1023–1173 K as has been observed by many researchers [181,191]. It has also been observed that further increases in temperature cause a decrease in NH3 concentration in the gas [165,181,192,193] at temperatures higher than 1073–1173 K. This behavior could be explained by the conversion of ammonia into N2 and H2 as suggested by [165]:

It is further confirmed based on a thermodynamic point of view that NH3 destruction is endothermic, hence could be favored at higher temperatures [194] confirming the decrease of NH3 beyond a particular temperature.

Fuel oxygen usually forms OH radicals and other oxygen-containing radicals during the pyrolysis stage of solid fuel conversion. These radicals may promote secondary reactions including conversion of HCN to NH3. High heating rates suppress these secondary reactions, and hence favor formation of HCN [193]. This argument can be verified with slow heating rate pyrolysis where more NH3 is observed than HCN [194,195].

Higher heating rates appear to increase the HCN/NH3 ratio for both coal and biomass fuels [195–197]. However, the main product of most biomass thermal decomposition experiments under high heating rates is NH3, since biomass fuels contain significant amounts of quaternary and amine functionalities favoring NH3 formation [160]. At low heating rates NH3 is generally the dominant product, for both coals and biomass [198–200]. Minor amounts of isocyanic acid (HNCO) have been measured in fluidized bed pyrolysis [201] where the heating rate is usually low, while it has not been detected in entrained flow reactor experiments where the heating rate is usually high [199]. Contradicting results are however observed in literature where the dominant nitrogen specie during pyrolysis of biomass is HCN [202]. These authors (Yuan et al. [202]) investigated the fast pyrolysis of rice straw, chinar leaves, pine sawdust and soybean cake in a high frequency furnace. Volatile nitrogen of rice straw, chinar leaves and sawdust was dominated by HCN while that of soybean cake was dominated by NH3. They hypothesized that the presence or absence of lignin in those fuels could explain the difference observed. They suggested that the “microshells” formed by lignin around hemicellulose and cellulose in the cell wall of rice straw, chinar leaves and pine sawdust amplifies polymerization reactions between protein, cellulose and hemicellulose, resulting in formation of heterocyclic nitrogen which further decomposes into HCN. Whereas in soybean cake, the content of lignin and holocellulose is low, therefore, little heterocyclic nitrogen is formed, resulting in most of the fuel nitrogen being released as NH3.

The presence of Ca significantly reduces the emission of N2O probably by interfering with HCN chemistry [203]. In fact, it has been found that some alkali and alkaline earth metals (AAEM) can catalyze the conversion of fuel-N in the gas or solid phase. Therefore, Ca and K can promote formation of NH3 and N2 and suppress HCN [199,204]. These effects of Ca and K are in accordance with the reactions in Equations (3) and (2) listed earlier; since HCN is a precursor of N2O, and HCN is suppressed by Ca and K, then the presence of these elements reduces emission of N2O.

Pressure only has a minor effect on the chemistry of biomass nitrogen. Although many investigations have been conducted on the effect of pressure on coal nitrogen release, very few have been done for biomass. The equivalence ratio as well as the gasifying agent are also negligible factors in biomass nitrogen chemistry. However, it has been observed that CO2 as a gasifying agent reduces formation of HCN and suppresses formation of HNCO [180]. It was mentioned earlier that these two gases are precursors of N2O; it can be inferred that CO2 gasification of biomass could reduce formation of N2O. Jiachun et al. [165,194] found that within the range of 0.2–0.4, the equivalence ratio has a negligible effect on FBN conversion.

4.1.2. Fuel Nitrogen Behavior during Coal Conversion