Design and Fabrication of a Novel Hybrid-Structure Heat Pipe for a Concentrator Photovoltaic

Abstract

:1. Introduction

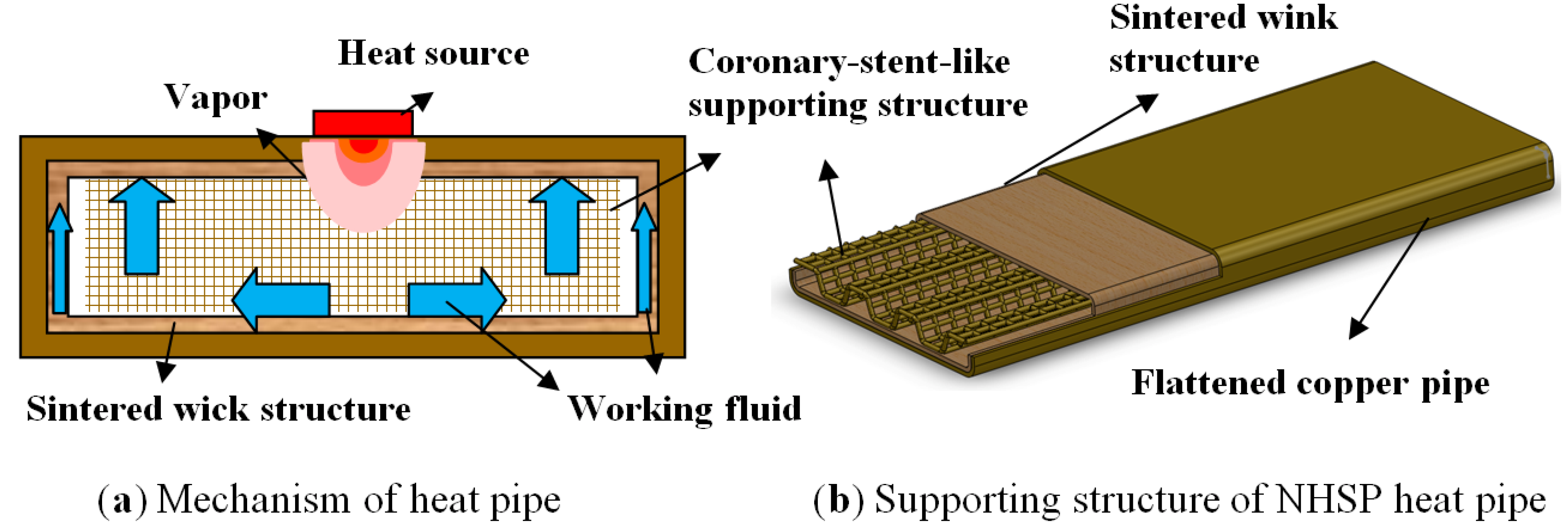

2. Design and Fabrication of the NHST Heat Pipe

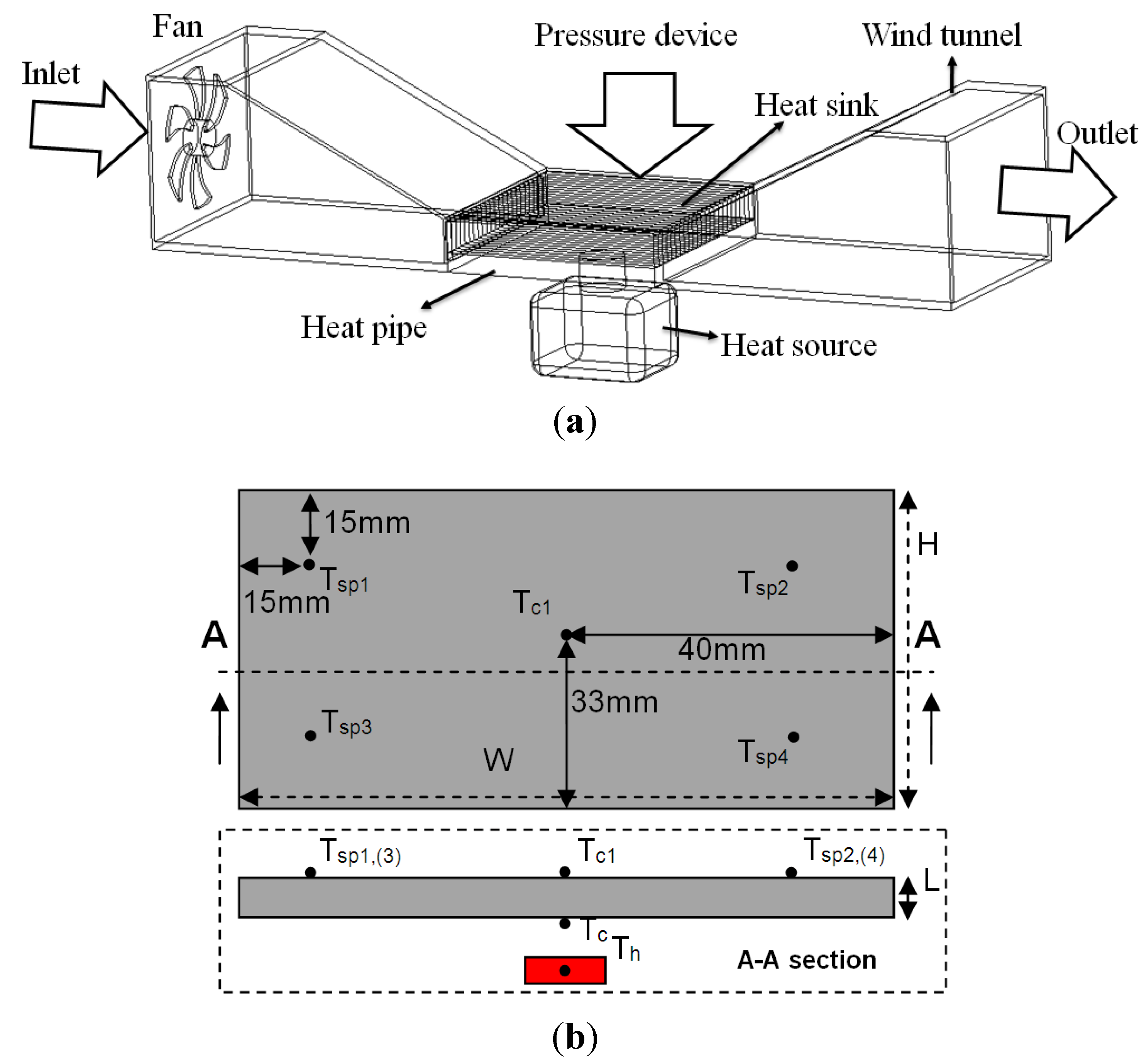

3. Thermal Performance Measurement

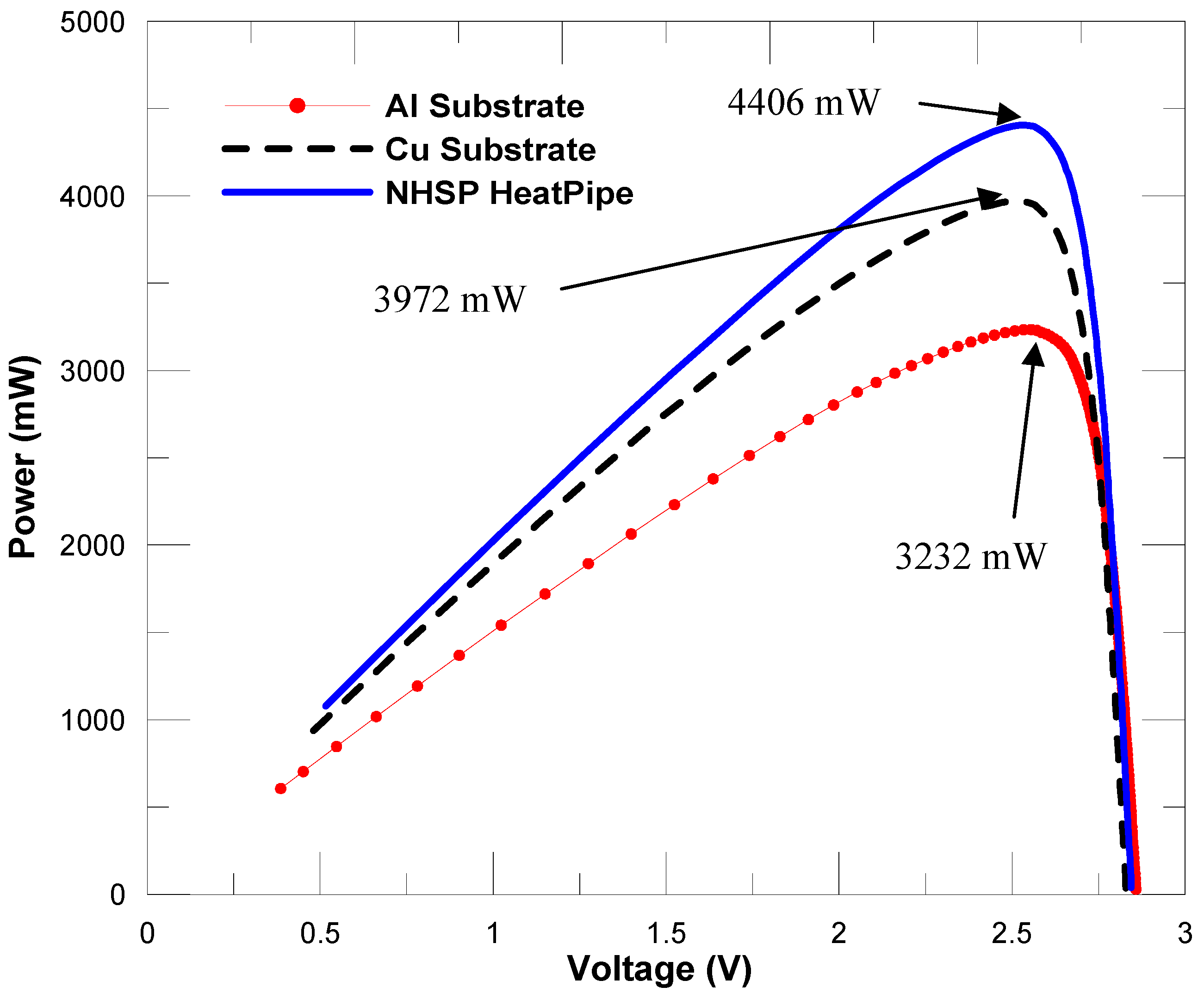

4. Results and Discussion of the Experiments

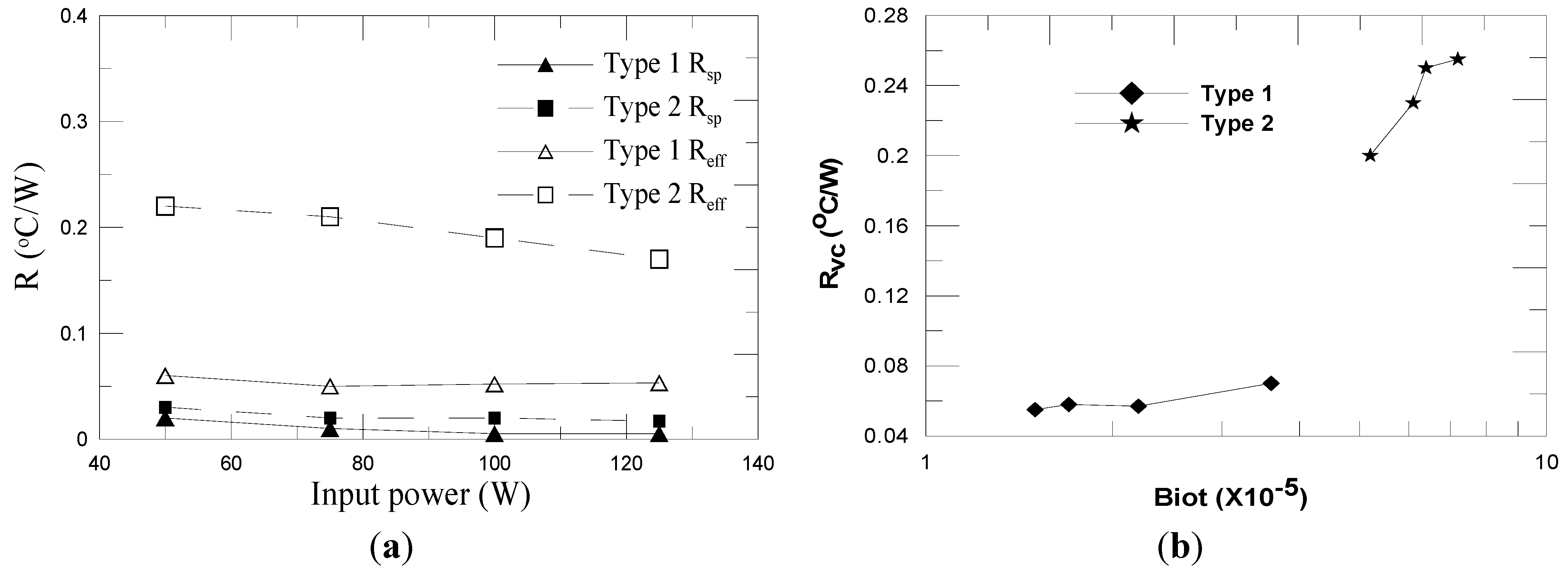

4.1. Experiments with Different Capillary Structures

| Sintered metal heat pipe (Type 1) | Copper mesh screen heat pipe (Type 2) | |

|---|---|---|

| Specifications | 80 mm × 65 mm × 4.0 mm (length × width × depth) | 80 mm × 65 mm × 4.0 mm (length × width × depth) |

| Working Fluid | pure water | pure water |

| Capillary Structure | 100-200-mesh sintered copper powder | 270-mesh copper screen |

| Thickness of Capillary Structure | 0.35 mm | 0.35 mm |

| Supporting Structure Specifications | 72 mm × 60 mm × 1.7 mm (rhombic multi-hole copper screen) | 72 mm × 60 mm × 1.7 mm (rhombic multi-hole copper screen) |

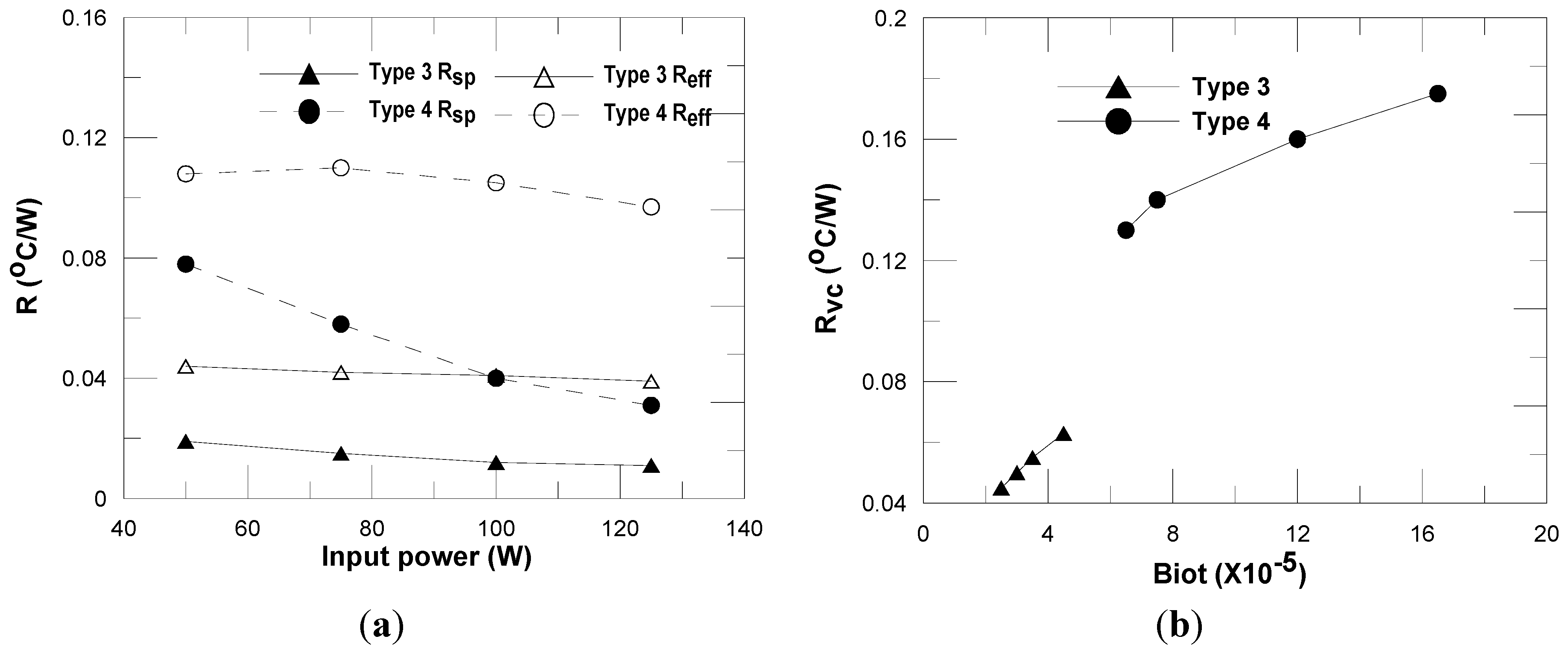

4.2. Experiments on the Effects of the Coronary-Stent-Like Supporting Structure

| With supporting structure (Type 3) | Without supporting structure (Type 4) | |

|---|---|---|

| Specifications | 80mm × 65mm × 4.0mm (length × width × depth) | 80mm × 65mm × 4.0mm (length × width × depth) |

| Working Fluid | pure water | pure water |

| Capillary Structure | 100-200-mesh sintered copper powder | 100-200-mesh sintered copper powder |

| Thickness of Capillary Structure | 0.3mm | 0.3mm |

| Supporting Structure Specifications | 72mm × 60mm × 1.7mm (rhombic multi-hole copper screen) | Unavailable |

4.3. Measurement of Thermal Performance with Different Substrate Using HCPV

5. Conclusions

Acknowledgments

References

- Lee, H.C.; Wu, S.C.; Yang, T.C.; Yen, T.J. Efficiently harvesting sun light for silicon solar cells through advanced optical couplers and a radial p-n junction structure. Energies 2010, 3, 784–802. [Google Scholar] [CrossRef]

- Ong, P.L.; Levitsky, I.A. Organic/IV, III-V semiconductor hybrid solar cells. Energies 2010, 3, 313–334. [Google Scholar] [CrossRef]

- Ho, T.; Mao, S.S.; Greif, R. The impact of cooling on cell temperature and the practical solar concentration limits for photovoltaics. Int. J. Energy Res. 2011, 35, 1250–1257. [Google Scholar] [CrossRef]

- He, W.; Chow, T.T.; Ji, J. Hybrid photovoltaic and thermal solar-collector designed for natural circulation of water. Appl. Energy 2006, 83, 199–210. [Google Scholar] [CrossRef]

- Quan, Z.H.; Li, N.J.; Zhao, Y.H. Experimental study of solar photovoltaic / thermal (PV / T) system based on flat plate heat pipe. In Proceedings of the 2011 Asia-Pacific Power and Energy Engineering Conference, Wuhan, China, 25–28 March 2011.

- Yildiz, A.; Ozgener, O.; Ozgener, L. Exergetic performance assessment of solar photovoltaic cell (PV) assisted earth to air heat exchanger (EAHE) system for solar greenhouse cooling. Energy Build. 2011, 43, 3154–3160. [Google Scholar] [CrossRef]

- Ganesha Prasad, M.S.; Drakshayani, D.N. Studies on passive cooling techniques in dry machining. Mater. Manuf. Process. 2010, 25, 360–369. [Google Scholar]

- Kuo, C.T.; Shin, H.Y.; Hong, H.F.; Wu, C.H.; Lee, C.D.; Lung, I.T.; Hsu, Y.T. Development of the high concentration III-V photovoltaic system at INER, Taiwan. Renew. Energy 2009, 34, 1931–1933. [Google Scholar] [CrossRef]

- Zhang, M.; Liu, Z.L.; Ma, G.Y.; Cheng, S.Y. The experimental study on flat plate heat pipe of magnetic working fluid. Exp. Therm. Fluid Sci. 2009, 33, 1100–1105. [Google Scholar] [CrossRef]

- Gillot, C.; Avenas, Y.; Cezac, N.; Poupom, G.; Schaeffer, C.; Fournier, E. Silicon heat pipes used as thermal spreaders. IEEE Trans. Compon. Packag. Technol. 2003, 26, 332–339. [Google Scholar] [CrossRef]

- Bai, P.F.; Tang, Y.; Tang, B.; Lu, L.S. Thermal performance of heat pipe with different micro-groove structures. J. Cent. South Univ. Technol. 2008, 15, 240–244. [Google Scholar] [CrossRef]

- Kempers, R.; Ewing, D.; Ching, C.Y. Effect of number of mesh layers and fluid loading on the performance of screen mesh wicked heat pipe. Appl. Therm. Eng. 2005, 26, 589–595. [Google Scholar] [CrossRef]

- Lin, L.; Ponnappan, R.; Leland, J. High performance miniature heat pipe. Int. J. Heat Mass Transf. 2002, 45, 3131–3142. [Google Scholar] [CrossRef]

© 2012 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license ( http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Huang, H.-J.; Shen, S.-C.; Shaw, H.-J. Design and Fabrication of a Novel Hybrid-Structure Heat Pipe for a Concentrator Photovoltaic. Energies 2012, 5, 4340-4349. https://doi.org/10.3390/en5114340

Huang H-J, Shen S-C, Shaw H-J. Design and Fabrication of a Novel Hybrid-Structure Heat Pipe for a Concentrator Photovoltaic. Energies. 2012; 5(11):4340-4349. https://doi.org/10.3390/en5114340

Chicago/Turabian StyleHuang, Hsin-Jung, Sheng-Chih Shen, and Heiu-Jou Shaw. 2012. "Design and Fabrication of a Novel Hybrid-Structure Heat Pipe for a Concentrator Photovoltaic" Energies 5, no. 11: 4340-4349. https://doi.org/10.3390/en5114340

APA StyleHuang, H.-J., Shen, S.-C., & Shaw, H.-J. (2012). Design and Fabrication of a Novel Hybrid-Structure Heat Pipe for a Concentrator Photovoltaic. Energies, 5(11), 4340-4349. https://doi.org/10.3390/en5114340