Abstract

The worldwide application of geothermal energy for direct utilization is reviewed. This paper is based on the world update for direct-use presented at the World Geothermal Congress 2010 in Bali, Indonesia (WGC2010) [1] which also includes material presented at three world geothermal congresses in Italy, Japan and Turkey (WGC95, WGC2000 and WGC2005). This report is based on country update papers prepared for WGC2010 and data from other sources. Final update papers were received from 70 countries of which 66 reported some direct utilization of geothermal energy for WGC2010. Twelve additional countries were added to the list based on other sources of information. The 78 countries having direct utilization of geothermal energy, is a significant increase from the 72 reported in 2005, the 58 reported in 2000, and the 28 reported in 1995. An estimate of the installed thermal power for direct utilization at the end of 2009, reported from WGC2010 is 48,493 MWt, almost a 72 % increased over the 2005 data, growing at a compound rate of 11.4% annually with a capacity factor of 0.28. The thermal energy used is 423,830 TJ/year (117,740 GWh/yr), about a 55% increase over 2005, growing at a compound rate of 9.2% annually. The distribution of thermal energy used by category is approximately 47.2% for ground-source heat pumps, 25.8% for bathing and swimming (including balneology), 14.9% for space heating (of which 85% is for district heating), 5.5% for greenhouses and open ground heating, 2.8% for industrial process heating, 2.7% for aquaculture pond and raceway heating, 0.4% for agricultural drying, 0.5% for snow melting and cooling, and 0.2% for other uses. Energy savings amounted to 250 million barrels (38 million tonnes) of equivalent oil annually, preventing 33 million tonnes of carbon and 107 million tonnes of CO2 being release to the atmosphere which includes savings in geothermal heat pump cooling (compared to using fuel oil to generate electricity).

1. Introduction

Direct-use of geothermal energy is one of the oldest, most versatile and also the most common form of utilization of geothermal energy [2]. The early history of geothermal direct-use has been well documented for over 25 countries in the Stories from a Heat Earth–Our Geothermal Heritage [3], that documents geothermal use for over 2,000 years. The information presented here on direct applications of geothermal heat is based on country update papers submitted for the World Geothermal Congress 2010 (WGC2010) and covers the period 2005 to 2009. Papers from 70 countries have been received, 66 of which reported some geothermal direct-use with 12 additional countries added from other sources for a total of 78 countries—an increase of six countries from WGC2005 (Bosnia & Herzegovina, El Salvador, Estonia, Morocco, South Africa and Tajikistan). Data from WGC2010 are also compared with data from WGC95, WGC2000 and WGC2005.

Traditionally, direct-use of geothermal energy has been on small scale by individuals. More recent developments involve large-scale projects, such as district heating (Iceland and France), greenhouse complexes (Hungary and Russia), or major industrial use (New Zealand and the U.S.). Heat exchangers are also becoming more efficient and better adapted to geothermal projects, allowing use of lower temperature water and highly saline fluids. Heat pumps utilizing very low-temperature fluids have extended geothermal developments into traditionally non-geothermal countries such as Canada, France, Switzerland and Sweden, as well as areas of the mid-western and eastern U.S. Most equipment used in these projects are of standard, off-the-shelf design and need only slight modifications to handle geothermal fluids [4,5].

Worldwide [1], the installed capacity of direct geothermal utilization is 48,493 MWt and the energy use is 423,830 TJ/yr (117,740 GWh/yr) distributed among 78 countries presented in Table 1. This amounts to saving an equivalent 37.5 million tonnes of fuel oil per year (TOE) if it replaces electricity. For comparison, the installed capacity in the U.S. (2010) is 12,611 MWt and the annual energy use is 56,552 TJ (15,709 GWh), saving 20.2 million barrels of oils (3.04 million TOE). Internationally, the largest energy uses are for geothermal heat pumps (47%), and swimming, bathing and balneology (26%); whereas, in the U.S., the largest use is for geothermal heat pumps (84%). In comparison, Iceland’s largest geothermal energy use is 72% for district heating 17,483 TJ/yr (4,857 GWh/yr) [6]. As can be seen from Table 1 and Table 2, heat pumps have low capacity factors (USA), whereas industrial uses have high capacity factors (such as at the Tasman Pulp and Paper plant in Kawerau, New Zealand) due to the more continuous use in industrial processing (capacity factor = annual energy use/installed capacity—see Section 4 for more details).

Typically, the agricultural and aquacultural uses require the lowest temperatures, with values from 25 to 90 °C. The amounts and types of chemicals such as arsenic and dissolved gases such as boron, are a major problem with plants and animals; thus, heat exchangers are often necessary. Space heating requires temperatures in the range of 50 to 100 °C, with 40 °C useful in some marginal cases and ground-source heat pumps extending the range down to 5 °C. Cooling and industrial processing normally require temperatures over 100 °C. The leading user of geothermal energy, in terms of market penetration, is Iceland, where more than 89% of the population enjoys geothermal heat in their homes from 30 municipal district heating services, and 54% of the country’s total energy use is supplied by direct heat and electrical energy derived from geothermal resources [6].

2. Data Summary

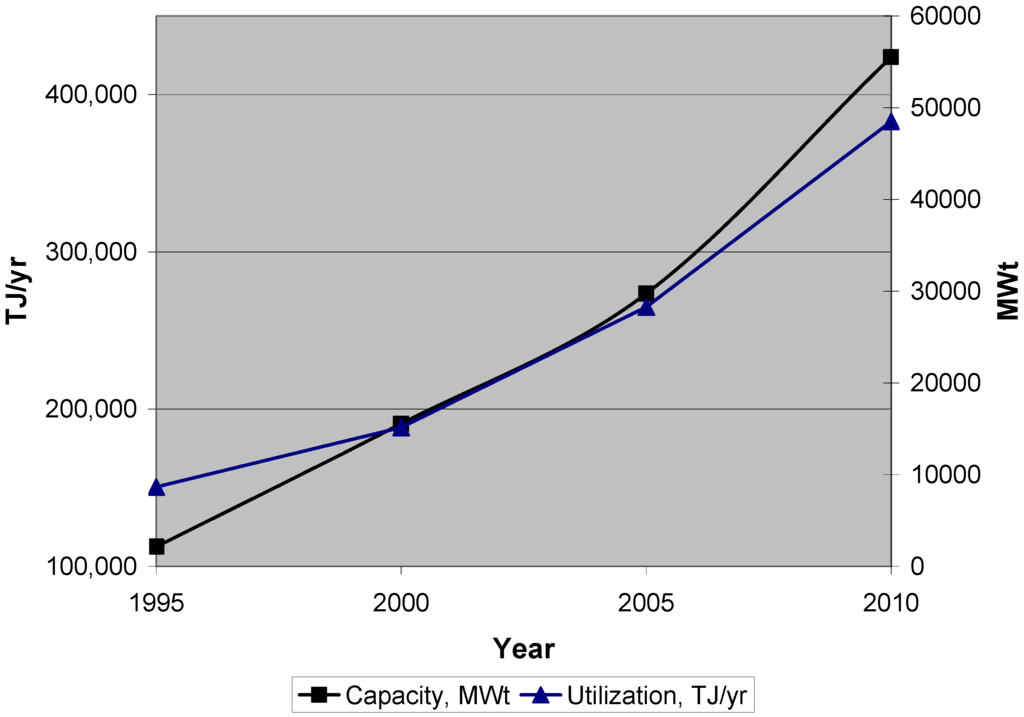

Table 1 is a summary, by country, of the installed thermal capacity (MWt), annual energy use (TJ/yr and GWh/yr) and the capacity factor to the end of 2009. The total installed capacity, reported through the end of 2009 for geothermal direct utilization worldwide is 48,493 MWt, a 71.5% increase over WGC2005, growing at an annual compound rate of 11.40%. The total annual energy use is 423,830 TJ (117,740 GWh), indicating a 55.0% increase over WGC2005, and a compound growth rate of 9.17%. The worldwide capacity factor is 0.28 (equivalent to 2,450 full load operating hours per year), down from 0.31 in 2005 and 0.40 in 2000. The growth rate of installed capacity and annual energy use over the past 15 years is shown in Figure 1. The lower capacity factor and growth rate for annual energy use is due to the increase in geothermal heat pump installations which have a low capacity factor of 0.19 worldwide.

Table 1.

Summary of direct-use data worldwide, 2010 [1].

| Country | Capacity (MWt) | Annual Use (TJ/yr) | Annual Use (GWh/yr) | Capacity Factor |

|---|---|---|---|---|

| Albania | 11.48 | 40.46 | 11.2 | 0.11 |

| Algeria | 66.84 | 2,098.68 | 583.0 | 1.00 |

| Argentina | 307.47 | 3,906.74 | 1,085.3 | 0.40 |

| Armenia | 1 | 15 | 4.2 | 0.48 |

| Australia | 33.33 | 235.1 | 65.3 | 0.22 |

| Austria | 662.85 | 3,727.7 | 1,035.6 | 0.18 |

| Belarus | 4.5 | 44.43 | 12.3 | 0.31 |

| Belgium | 117.9 | 546.97 | 151.9 | 0.15 |

| Bosnia & Herzegovina | 21.696 | 255.36 | 70.9 | 0.37 |

| Brazil | 360.1 | 6,622.4 | 1,839.7 | 0.58 |

| Bulgaria | 98.3 | 1,370.12 | 380.6 | 0.44 |

| Canada | 1126 | 8,873 | 2,464.9 | 0.25 |

| Caribbean Islands | 0.103 | 2.775 | 0.8 | 0.85 |

| Chile | 9.11 | 131.82 | 36.6 | 0.46 |

| China | 8,898 | 7,5348.3 | 20,931.8 | 0.27 |

| Columbia | 14.4 | 287 | 79.7 | 0.63 |

| Costa Rica | 1 | 21 | 5.8 | 0.67 |

| Croatia | 67.48 | 468.89 | 130.3 | 0.22 |

| Czech Republic | 216.5 | 1,290 | 358.4 | 0.19 |

| Denmark | 200 | 2,500 | 694.5 | 0.40 |

| Ecuador | 5.157 | 102.401 | 28.4 | 0.63 |

| Egypt | 1 | 15 | 4.2 | 0.48 |

| El Salvador | 2 | 40 | 11.1 | 0.63 |

| Estonia | 63 | 356 | 98.9 | 0.18 |

| Ethiopia | 2.2 | 41.6 | 11.6 | 0.60 |

| Finland | 994 | 7,966 | 2,213.0 | 0.25 |

| France | 1345 | 12,929 | 3591.7 | 0.30 |

| Georgia | 26.51 | 689.34 | 191.5 | 0.82 |

| Germany | 2,485.4 | 12,764.5 | 3,546.0 | 0.16 |

| Greece | 134.6 | 937.8 | 260.5 | 0.22 |

| Guatemala | 2.31 | 56.46 | 15.7 | 0.78 |

| Honduras | 1.933 | 45 | 12.5 | 0.74 |

| Hungary | 654.6 | 9767 | 2,713.3 | 0.47 |

| Iceland | 1,826 | 24,361 | 6,767.5 | 0.42 |

| India | 265 | 2,545 | 707.0 | 0.30 |

| Indonesia | 2.3 | 42.6 | 11.8 | 0.59 |

| Iran | 41.608 | 1,064.18 | 295.6 | 0.81 |

| Ireland | 134.45 | 691.91 | 192.2 | 0.16 |

| Israel | 82.4 | 2,193 | 609.2 | 0.84 |

| Italy | 867 | 9,941 | 2,761.6 | 0.36 |

| Japan | 2,099.53 | 25,697.94 | 7,138.9 | 0.39 |

| Jordan | 153.3 | 1,540 | 427.8 | 0.32 |

| Kenya | 16 | 126.624 | 35.2 | 0.25 |

| Korea (South) | 229.3 | 1,954.65 | 543.0 | 0.27 |

| Latvia | 1.63 | 31.81 | 8.8 | 0.62 |

| Lithuania | 47.6 | 411.52 | 114.3 | 0.27 |

| Macedonia | 47.18 | 601.41 | 167.1 | 0.40 |

| Mexico | 155.82 | 4,022.8 | 1,117.5 | 0.82 |

| Mongolia | 6.8 | 213.2 | 59.2 | 0.99 |

| Morocco | 5.02 | 79.14 | 22.0 | 0.50 |

| Nepal | 2.717 | 73.743 | 20.5 | 0.86 |

| Netherlands | 1,410.26 | 10,699.4 | 2,972.3 | 0.24 |

| New Zealand | 393.22 | 9,552 | 2,653.5 | 0.77 |

| Norway | 1,000 | 10,800 | 3,000.2 | 0.34 |

| Papua New Guinea | 0.1 | 1 | 0.3 | 0.32 |

| Peru | 2.4 | 49 | 13.6 | 0.65 |

| Philippines | 1.67 | 12.65 | 3.5 | 0.24 |

| Poland | 281.05 | 1,501.1 | 417.0 | 0.17 |

| Portugal | 28.1 | 386.4 | 107.3 | 0.44 |

| Romania | 153.24 | 1,265.43 | 351.5 | 0.26 |

| Russia | 308.2 | 6,143.5 | 1,706.7 | 0.63 |

| Serbia | 100.8 | 1,410 | 391.7 | 0.44 |

| Slovak Republic | 132.2 | 3,067.2 | 852.1 | 0.74 |

| Slovenia | 115.6 | 1,015.1 | 282.0 | 0.28 |

| South Africa | 6.01 | 114.75 | 31.9 | 0.61 |

| Spain | 141.04 | 684.05 | 190.0 | 0.15 |

| Sweden | 4,460 | 45,301 | 12,584.6 | 0.32 |

| Switzerland | 1,060.9 | 7,714.6 | 2,143.1 | 0.23 |

| Tajikistan | 2.93 | 55.4 | 15.4 | 0.60 |

| Thailand | 2.54 | 79.1 | 22.0 | 0.99 |

| Tunisia | 43.8 | 364 | 101.1 | 0.26 |

| Turkey | 2,084 | 36,885.9 | 10,246.9 | 0.56 |

| Ukraine | 10.9 | 118.8 | 33.0 | 0.35 |

| United Kingdom | 186.62 | 849.74 | 236.1 | 0.14 |

| United States | 12,611.46 | 56,551.8 | 15,710.1 | 0.14 |

| Venezuela | 0.7 | 14 | 3.9 | 0.63 |

| Vietnam | 31.2 | 92.33 | 25.6 | 0.09 |

| Yemen | 1 | 15 | 4.2 | 0.48 |

| Total | 48,493 | 423,830 | 117,740 | 0.28 |

Figure 1.

The growth rate of the installed capacity and annual utilization from 1995–2010 [1].

The growing awareness and popularity of geothermal (ground-source) heat pumps have had the most significant impact on direct-use of geothermal energy. The annual energy use for these units grew 2.29 times at a compound annual rate of 18.0%. The installed capacity grew 2.15 times at a compound annual rate of 16.6%. This is due to better reporting and to the ability of geothermal heat pumps to utilize groundwater or ground-coupled temperatures anywhere in the world (see Table 2).

The five countries with the largest installed capacity are: USA, China, Sweden, Germany and Japan accounting for 63% of the world capacity, and the five countries with the largest annual energy use are: China, USA, Sweden, Turkey, and Japan, accounting for 55% of the world use. Japan and Germany are new members of the “top five” as compared to WGC2005. However, an examination of the data in terms of land area or population shows that the smaller countries dominate, especially the Nordic ones. The “top five” then become for installed capacity: (MW/population) Iceland, Sweden, Norway, Finland, and Switzerland; (MW/area) Netherlands, Switzerland, Iceland, Sweden, and Hungary; for annual energy use: (TJ/yr/population) Iceland, Sweden, Norway, New Zealand, and Denmark; and (TJ/yr/area) Netherlands, Iceland, Switzerland, Hungary, and Sweden. The largest increase in geothermal installed capacity (MWt) over the past five years are: United Kingdom, Korea, Ireland, Spain and Netherlands; and the largest increase in annual energy use (TJ/yr) over the past five years are: United Kingdom, Netherlands, Korea, Ireland, and Argentina, mainly due to geothermal heat pump installations. In 1985, only 11 countries reported an installed capacity of more than 100 MWt. By 1990, this number had increased to 14, by 1995 to 15, by 2000 to 23, and by 2005 33 countries. At present (December, 2009), there are 36 countries reporting over 100 MWt, an increase of 3 countries over 2005.

3. Categories of Utilization

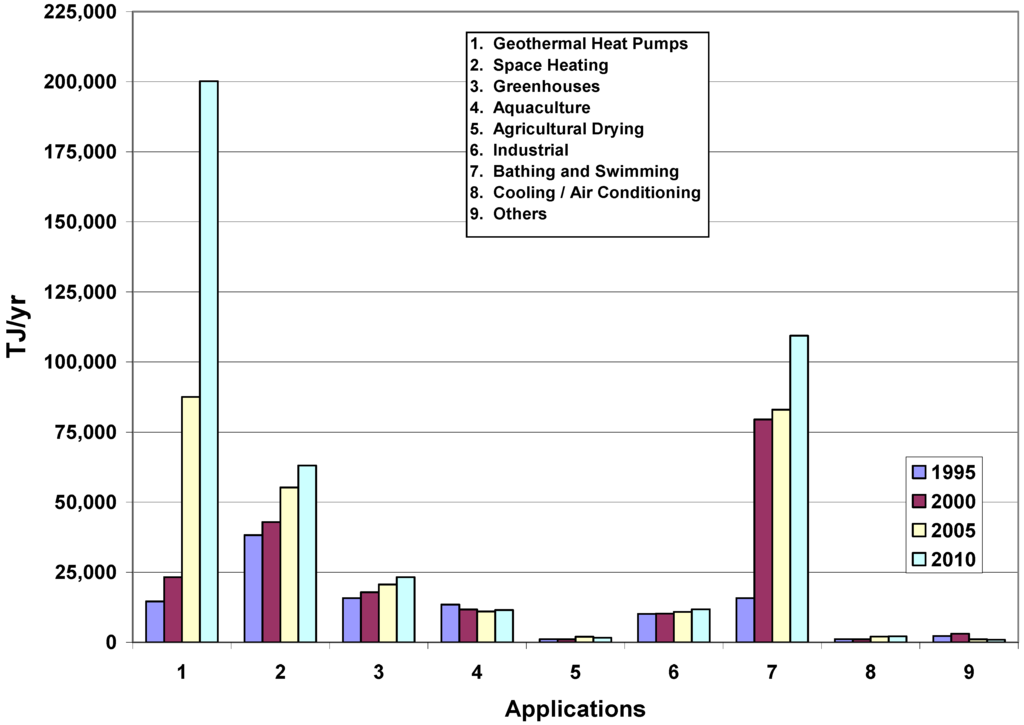

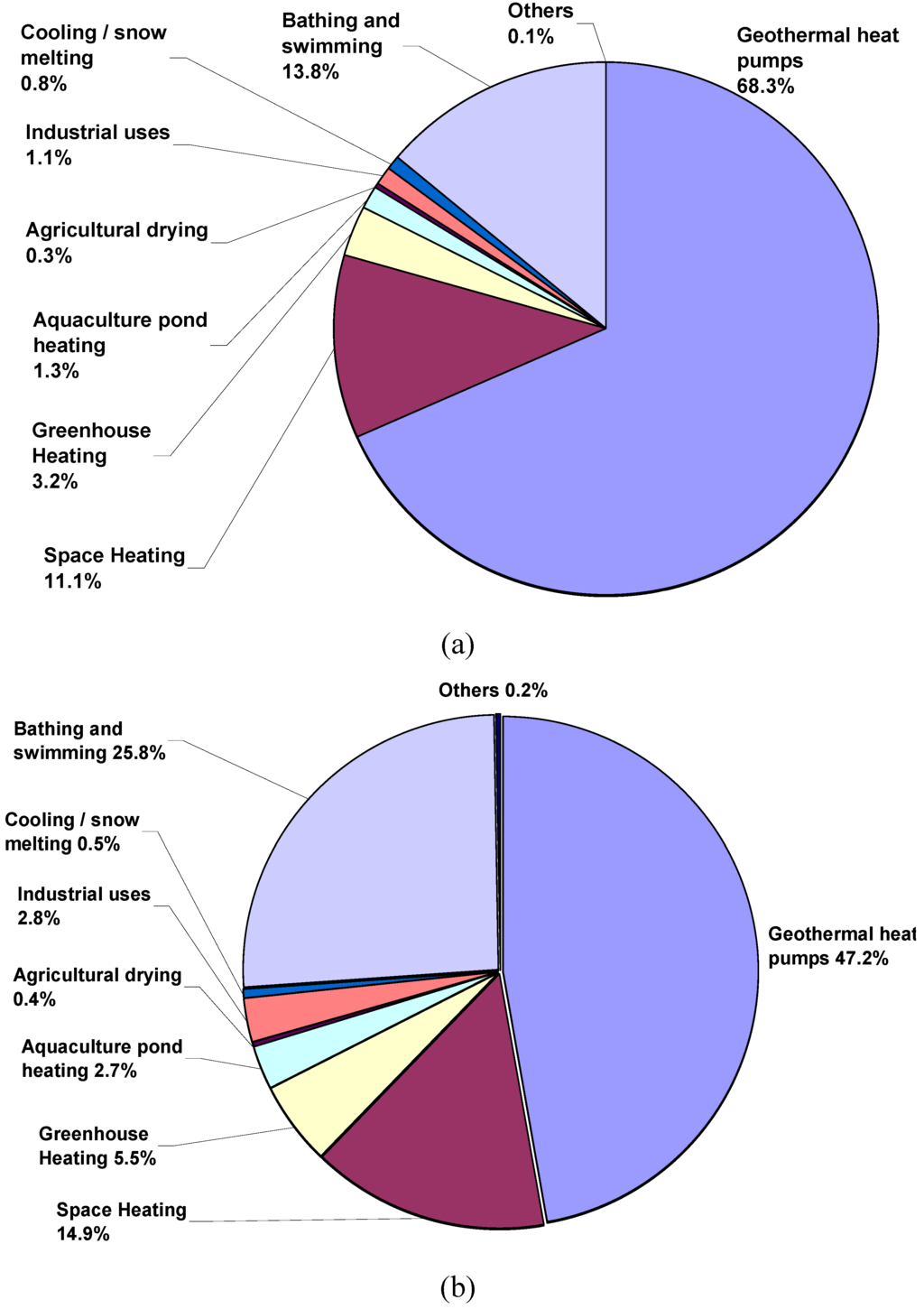

In Table 2 the 1995, 2000, 2005 and 2010 data are divided among the various uses in terms of capacity, energy utilization and capacity factor. This distribution can also be viewed as bar charts in Figure 2. Figure 3 presents the 2010 data in pie-chart form in percentages. An attempt was made to distinguish individual space heating from district heating, but this was often difficult, as the individual country reports did not always make this distinction. Our best estimate is that district heating represents 86% of the installed capacity and 85% of the annual energy use, similar to WGC2005. Snow melting represents the majority of the snow melting/air-conditioning category. “Other” is a category that covers a variety of uses: frequently the data sources do not provides details; but include animal husbandry.

Figure 2.

Comparison of worldwide energy in TJ/yr for 1995, 2000, 2005 and 2010 [1].

Figure 3.

Geothermal direct applications worldwide in 2010, distributed by: (a) percentage of total installed capacity; and (b) percentage of total energy use [1].

3.1. Geothermal Heat Pumps

Geothermal (ground-source) heat pumps have the largest energy use and installed capacity, accounting for 68.3% and 47.2% of the worldwide capacity and use. The installed capacity is 33,134 MWt and the annual energy use of 200,149 TJ/yr, with a capacity factor of 0.19 (in the heating mode). Almost all of the installations occur in North American, Europe and China, increasing from 26 countries in 2000, to 33 countries in 2005, to the present 43 countries. The equivalent number of installed 12 kW units (typical of US and Western European homes) is approximately 2.76 million, over double the number of units report for 2005, and four times the number for 2000. The size of individual units; however, ranges from 5.5 kW for residential use to large units of over 150 kW for commercial and institutional installations.

Table 2.

Summary of the various categories of direct use worldwide, referred to the period 1995–2010 [1].

| 2010 | 2005 | 2000 | 1995 | |

|---|---|---|---|---|

| Capacity (MWt) | ||||

| Geothermal Heat Pumps | 33,134 | 15,384 | 5,275 | 1,854 |

| Space Heating | 5,391 | 4,366 | 3,263 | 2,579 |

| Greenhouse Heating | 1,544 | 1,404 | 1,246 | 1,085 |

| Aquaculture Pond Heating | 653 | 616 | 605 | 1,097 |

| Agricultural Drying | 125 | 157 | 74 | 67 |

| Industrial Uses | 533 | 484 | 474 | 544 |

| Bathing and Swimming | 6,700 | 5,401 | 3,957 | 1,085 |

| Cooling / Snow Melting | 368 | 371 | 114 | 115 |

| Others | 42 | 86 | 137 | 238 |

| Total | 48,493 | 28,269 | 15,145 | 8,664 |

| Utilization (TJ/yr) | ||||

| Geothermal Heat Pumps | 200,149 | 87,503 | 23,275 | 14,617 |

| Space Heating | 63,025 | 55,256 | 42,926 | 38,230 |

| Greenhouse Heating | 23,264 | 20,661 | 17,864 | 15,742 |

| Aquaculture Pond Heating | 11,521 | 10,976 | 11,733 | 13,493 |

| Agricultural Drying | 1,635 | 2,013 | 1,038 | 1,124 |

| Industrial Uses | 11,745 | 10,868 | 10,220 | 10,120 |

| Bathing and Swimming | 109,410 | 83,018 | 79,546 | 15,742 |

| Cooling/Snow Melting | 2,126 | 2,032 | 1,063 | 1,124 |

| Others | 955 | 1,045 | 3,034 | 2,249 |

| Total | 423,830 | 273,372 | 190,699 | 112,441 |

| Capacity Factor | ||||

| Geothermal Heat Pumps | 0.19 | 0.18 | 0.14 | 0.25 |

| Space Heating | 0.37 | 0.40 | 0.42 | 0.47 |

| Greenhouse Heating | 0.48 | 0.47 | 0.45 | 0.46 |

| Aquaculture Pond Heating | 0.56 | 0.57 | 0.61 | 0.39 |

| Agricultural Drying | 0.41 | 0.41 | 0.44 | 0.53 |

| Industrial Uses | 0.70 | 0.71 | 0.68 | 0.59 |

| Bathing and Swimming | 0.52 | 0.49 | 0.64 | 0.46 |

| Cooling/Snow Melting | 0.18 | 0.18 | 0.30 | 0.31 |

| Others | 0.72 | 0.39 | 0.70 | 0.30 |

| Total | 0.28 | 0.31 | 0.40 | 0.41 |

In the United States, most units are sized for peak cooling load and are oversized for heating, except in the northern states; thus, they are estimated to average only 2,000 full-load hours per year (capacity factor of 0.23). In Europe, most units are sized for the heating load and are often designed to provide the base load with peaking by fossil fuel. As a result, these units may be in operation up to 6,000 full-load hours per year (capacity factor of 0.68), such as in Nordic countries. Unless the actual number of full-load hours was reported, a value of 2,200 hours was used for energy output (TJ/yr) calculations, and higher for some of the northern countries, based on reports by Curtis et al. [7].

The energy use reported for the heat pumps was deduced from the installed capacity (if it was not reported), based on an average coefficient of performance (COP) of 3.5, which allows for one unit of energy input (usually electricity) to 2.5 units of energy output, for a geothermal component of 71% of the rated capacity [i.e. (COP-1)/COP = 0.71]. The cooling load was not considered as geothermal, as in this case, heat is discharged into the ground or groundwater. Cooling, however, has a role in the substitution for fossil fuels and reduction of greenhouse gas emissions and is included as discussed in Section 8.

The leaders in installed units are the United States, China, Sweden, Norway and Germany.

3.2. Space Heating

Space conditioning includes both heating and cooling. Space heating with geothermal energy has widespread application, especially on an individual basis. Buildings heated from individual wells are popular in Klamath Falls, Oregon; Reno, Nevada, USA, and Taupo and Rotorua, New Zealand. Absorption space cooling with geothermal energy has not been popular because of the high temperature requirements and low efficiency. However, newer units recently placed on the market report to use temperatures below 100 °C efficiently. Geothermal heat pumps (groundwater and ground-coupled) have become popular in the U.S., Canada and Europe, used for both heating and cooling.

Downhole heat exchangers have been used for heating individual buildings using a closed loop of pipe in a well extracting only heat in Klamath Falls, Oregon, Reno, Nevada, Rotorua, New Zealand and Ismir, Turkey (see the Heat Exchanger section for more details). An example of space heating and cooling with low-to-moderate temperature geothermal energy is the Oregon Institute of Technology in Klamath Falls, Oregon. Here, twelve buildings (approximately 70,000 sq. m of floor space) are heated with water from three wells at 89 °C. Up to 62 L/s of fluid can be provided to the campus, with the average heat utilization rate over 0.53 MWt and the peak at 5.6 MWt. In addition, a 541 kW (154 tons) chiller requiring up to 38 L/s of geothermal fluid produces 23 L/s of chilled fluid at 7oC to meet the campus cooling base load (recently decommissioned) [8,9].

District heating involves the distribution of heat (hot water or steam) from a central location, through a network of pipes to individual houses or blocks of buildings. The distinction between a district heating and space heating system is that space heating usually involves one geothermal well per structure. The heat is used for space heating and cooling, domestic water heating and industrial process heat. A geothermal well field is the primary source of heat; however, depending on the temperature, the district may be a hybrid system, which would include fossil fuel and/or heat pump peaking. An important consideration in district heating projects is the thermal load density, or the heat demand divided by the ground area of the district. A high heat density, generally above 1.2 GJ/hr/ha (33.3 W/m2) or a favorability ratio of 2.5 GJ/ha/yr (0.0079 W/m2) is recommended. Often fossil fuel peaking is used to meet the coldest period, rather than drilling additional wells or pumping more fluids, as geothermal can usually meet 50% of the load 80 to 90% of the time, thus improving the efficiency and economics of the system [10]. Geothermal district heating systems are capital intensive. The principal costs are initial investment costs for production and injection wells, downhole and circulation pumps, heat exchangers, pipelines and distribution network, flow meters, valves and control equipment, and building retrofit. The distribution network may be the largest single capital expense, at approximately 35 to 75% of the entire project cost. Operating expenses, however, are in comparison lower and consists of pumping power, system maintenance, control and management. The typical savings to consumers range from approximately 30 to 50% per year of the cost of natural gas.

Space heat has increased 24% in installed capacity and 14% in annual energy use over WGC2005. The installed capacity now totals 5,394 MWt and the annual energy use is 63,025 TJ/year. As stated previously about 86% of the installed capacity and 85% of the annual energy use is in district heating (24 countries). The leaders in district heating annual energy use are Iceland, China, Turkey, France and Russia, whereas, Turkey, Italy, United States, Japan and Georgia are the major users in the individual space heating sector (a total of 27 countries).

3.3. Agribusiness Applications

Agribusiness applications (agriculture and aquaculture) are particularly attractive because they require heating at the lower end of the temperature range where there is an abundance of geothermal resources. Use of waste heat or the cascading of geothermal energy also has excellent possibilities. A number of agribusiness applications can be considered: greenhouse heating, aquaculture and animal husbandry facilities heating, soil warming and irrigation, mushroom culture heating and cooling, and bio-gas generation.

Numerous commercially marketable crops have been raised in geothermally heated greenhouses in Hungary, Russia, New Zealand, Japan, Iceland, China, Tunisia, and the U.S. These include vegetables, such as cucumbers, peppers, and tomatoes, flowers (both potted and bedded), house plants, tree seedlings, and cacti. Using geothermal energy for heating reduces operating costs (which can account for up to 35% of the product cost) and allows operation in colder climates where commercial greenhouses would not normally be economical.

The use of geothermal energy for raising catfish, shrimp, tilapia, eels, and tropical fish has produced crops faster than by conventional solar heating. Using geothermal heat allows better control of pond temperatures, thus optimizing growth. Fish breeding has been successful in Japan, China and the U.S. A very successful prawn raising operation, producing 400 tonnes of Giant Malaysian Freshwater Prawns per year at US$ 17 to 27/kg has been developed near the Wairakei geothermal field in New Zealand [11]. The most important factors to consider are the quality of the water and disease. If geothermal water is used directly, concentrations of dissolved heavy metals, fluorides, chlorides, arsenic, and boron must be identified and, if necessary, isolated.

Livestock raising facilities can encourage the growth of domestic animals by a controlled heating and cooling environment. An indoor facility can lower mortality rate of newborn, enhance growth rates, control diseases, increase litter size, make waste management and collection easier, and in most cases improved the quality of the product. Geothermal fluids can also be used for cleaning, sanitizing and drying of animal shelters and waste, as well as assisting in the production of bio-gas from the waste.

3.3.1. Greenhouse and Covered Ground Heating

Worldwide use of geothermal energy used for greenhouse heating increased by 10% in installed capacity and 13% in annual energy use. The installed capacity is 1,544 MWt and 23,264 TJ/yr in energy use. A total of 34 countries report geothermal greenhouse heating (compared to 30 for WGC2005), the leading countries being: Turkey, Hungary, Russia, China and Italy. Most countries did not distinguish between covered greenhouses versus uncovered ground heating, and only a few reported the actual area heated. The main crops grown in greenhouses are vegetables and flowers; however, tree seedlings (USA) and fruit such as bananas (Iceland) are also grown. Developed countries are experiencing competition from developing countries due to labor costs being lower—one of the main costs of operating these facilities. Using an average energy requirement, determined from WGC2000 data of 20 TJ/year/ha for greenhouse heating, the 23,264 TJ/yr corresponds to about 1,163 ha of greenhouses heated worldwide—a 16.3% increase over 2005.

3.3.2. Aquaculture Pond and Raceway Heating

Aquaculture use of geothermal energy has increased slightly over WC2005, reversing a downward trend from WGC1995; however, it is still down when compared to WGC1995. The increase over the past five years has been 6% for the installed capacity and 5% for annual energy use. The installed capacity is 653 MWt and the annual energy use is 11,521 TJ/yr. Twenty-two countries report this type of use, the main ones being China, USA, Italy, Iceland, and Israel. These facilities are labor intensive and require well-trained personnel, which are often hard to justified economically, thus the reason why the growth is slow. Tilapia, salmon and trout seem to be the most common species, but tropical fish, lobsters, shrimp, and prawns, as well as alligators also being farmed. Based on work in the United States, we calculate that 0.242 TJ/yr/tonne (7.75 W/kg) of fish (bass and tilapia) are required, using geothermal waters in uncovered ponds. Using the reported energy use of 11,521 TJ/yr, an equivalent 47,600 tonnes of annual production is estimated a 5.8% increase over 2005.

3.4. Industrial Applications & Agricultural Drying

The oldest industrial use is at Larderello, Italy, where boric acid and other borate compounds have been extracted from geothermal brines since 1790. Today, the two largest industrial uses are the diatomaceous earth drying plant in northern Iceland [6], and a pulp, paper and wood processing plant at Kawerau, New Zealand [12]. Notable U.S. examples are two onion dehydration plants in northern Nevada [13], and a sewage digestion facility in San Bernardino, California. Alcohol fuel production has been attempted in the U.S.; however, the economics were marginal and thus this industry has not been successful. With the recent increase in fossil fuel prices, there has been renewed interest in producing ethanol and bio-diesel using geothermal energy [14].

A recent development in the use of geothermal fluids is the enhanced heap leaching of precious metals in Nevada by applying heat to the cyanide process [15]. Using geothermal energy increases the efficiency of the process and extends the production into the winter months.

Drying and dehydration are important moderate-temperature uses of geothermal energy. Various vegetable and fruit products are feasible with continuous belt conveyors or batch (truck) dryers with air temperatures from 40 to 100 °C [16]. Geothermally drying alfalfa, onions, garlic, pears, apples and seaweed are examples of this type of direct-use.

An example of a small-scale food dehydrator is one located in northeastern Greece where four tonnes of tomatoes are dried daily, using 59oC geothermal water to dry 14 kg/hour on racks placed in a long tunnel drier resulting in 400 kg of dried product daily. The tomatoes are then placed in olive oil for shipment and sale. The plant is only operated by three employees [17]. At the other end of the spectrum is the large scale onion and garlic drying facilities located in western Nevada, USA employing 75 workers [18]. These continuous belt drier are fed 3,000 to 4,300 kg/hr of onions at a moisture content of around 85% and after 24 hours produce 500 to 700 kg/hr of dried onions at moisture contents around 4%. These large belt driers are approximately 3.8 m wide and 60 m long.

Industrial applications mostly need the higher temperature as compared to space heating, greenhouses and aquaculture projects. Examples of industrial operations that use geothermal energy are: heap leaching operations to extract precious metals in the USA (110 °C), dehydration of vegetables in the USA (130 °C), diatomaceous earth drying in Iceland (180 °C), and pulp and paper processing in New Zealand (205 °C). Drying and dehydration may be the two most important process uses of geothermal energy. A variety of vegetable and fruit products can be considered for dehydration at geothermal temperatures, such as onions, garlic, carrots, pears, apples and dates. Industrial processes also make more efficient use of the geothermal resources as they tend to have high capacity factors in the range of 0.4 to 0.7.

3.4.1 Agricultural Crop Drying

Fourteen countries report the use of geothermal energy for drying various grains, vegetables and fruit crops compared to 15 for WGC2005. Examples include: seaweed (Iceland), onion (USA), wheat and other cereals (Serbia), fruit (El Salvador, Guatemala and Mexico), Lucerne or alfalfa (New Zealand), coconut meat (Philippines), and timber (Mexico, New Zealand and Romania). A total of 125 MWt and 1,635 TJ/yr are being utilized, a decrease from WGC2005, mainly due to the shutting down of an onion and garlic dehydration plant in Nevada, USA.

3.4.2. Industrial Process Heat

This is a category that has applications in 14 countries, down from 15 in 2005 and from 19 in 2000. These operations tend to be large and of high-energy consumptions. Examples include: concrete curing (Guatemala and Slovenia), bottling of water and carbonated drinks (Bulgaria, Serbia and the United States), milk pasteurization (Romania), leather industry (Serbia and Slovenia), chemical extraction (Bulgaria, Poland and Russia), CO2 extraction (Iceland and Turkey), pulp and paper processing (New Zealand), iodine and salt extraction (Vietnam), and borate and boric acid production (Italy). The installed capacity is 533 MWt and the annual energy use 11,745 TJ/yr, a 10% and 8% increase over 2005 respectively. This application has the highest capacity factor of all direct uses (0.70), as is to be expected because of its almost year-around operation.

3.5. Snow Melting and Space Cooling

There are very limited applications in this area, with pavement snow melting project in Argentina, Iceland, Japan, Switzerland and the United States. A total of about two million square meters of pavement are heated worldwide, the majority of which is in Iceland. A project in Argentina uses geothermal steam for highway snow melting in the Andes to keep a resort community open during winters, and in the United States, with most of the pavement snow melting on the Oregon Institute of Technology campus and in the City of Klamath Falls, Oregon [19]. The power required varies from 130 to 180 W/m2 (United States and Iceland). The installed capacity is 312 MWt and the annual energy use is 1,845 TJ/yr, an increase over 2005. Space cooling is reported in five countries, amounting to 56 MWt and 281 TJ/yr. Heat pumps in the cooling mode are not included as they return heat to the subsurface, and thus do not use geothermal energy.

3.6. Bathing and Swimming

People have used geothermal water and mineral waters for bathing and their health for many thousands of years. Balneology, the practice of using natural mineral water for the treatment and cure of disease, also has a long history. A spa originates at a location mainly due to the water from a spring or well. The water, with certain mineral constituents and often warm, give the spa certain unique characteristics that will attract customers. Associated with most spas is the use of muds (peoloids) which either is found at the site or is imported from special locations. Drinking and bathing in the water, and using the muds are thought to give certain health benefits to the user. Swimming pools have desirable temperature at 27 °C, however, this will vary from culture to culture by as much as 5oC. If the geothermal water is higher in temperature, then some sort of mixing or cooling by aeration or in a holding pond is required to lower the temperature, or it can first be used for space heating, and then cascaded into the pool. If the geothermal water is used directly in the pool, then a flow through process is necessary to replace the “used” water on a regular basis. In many cases, the pool water must be treated with chlorine, thus, it is more economical to use a closed loop for the treated water and have the geothermal water provide heat through a heat exchanger [20].

Romans, Chinese, Ottomans, Japanese and central Europeans have bathed in geothermal waters for centuries. Today, more than 2,200 hot springs resorts in Japan draw 100 million guests every year, and the “return-to-nature” movement in the U.S. has revitalized many hot spring resorts.

The geothermal water at Xiaotangshan Sanitarium, northwest of Beijing, China, has been used for medical purposes for over 500 years. Today, the 50 °C water is used to treat high blood pressure, rheumatism, skin disease, diseases of the nervous system, ulcers and generally for recuperation after surgery. In Rotorua, New Zealand at the center of the Taupo Volcanic Zone of North Island, the Queen Elizabeth Hospital was built during World War II for U.S. servicemen and later became the national hospital for the treatment of rheumatic disease. The hospital has 200 beds, and outpatient service, and a cerebral palsy unit. Both acidic and basic heated mud baths treat rheumatic diseases.

In Beppu on the southern island of Kyushu, Japan, the hot water and steam meet many needs: heating, bathing, cooking, industrial operations, agriculture research, physical therapy, recreational bathing, and even a small zoo [21]. The waters are promoted for “digestive system troubles, nervous troubles, and skin troubles.” Many sick and crippled people come to Beppu for rehabilitation and physical therapy. There are also eight Jigokus (“burning hells”) in town showing various geothermal phenomena, used as tourist attractions.

In the former Czechoslovakia, the use of thermal waters has been traced back before the occupation of the Romans and has had a recorded use of almost 1,000 years. Today, there are 60 spa resorts located mainly in Slovakia, visited by 460,000 patients usually for an average of three weeks each. These spas have old and well-established therapeutic traditions. Depending on the chemical composition of the mineral waters and spring gas, availability of peat and sulphurous mud, and climatic conditions, each sanatorium is designated for the treatment of specific diseases. The therapeutic successes of these spas are based on centuries of healing tradition (balneology), systematically supplemented by the latest discoveries of modern medical science [22].

Bathing and therapeutic sites in the U.S. included: Saratoga Springs, New York; Warm Springs, Georgia; Hot Springs, Virginia; White Sulfur Springs, West Virginia; Hot Spring, Arkansas; Thermopolis, Wyoming; and Calistoga, California. The original use of these sites was by Indians, where they bathed and recuperated from battle. There are over 115 major geothermal spas in the U.S. with an annual energy use of 1,500 TJ [20].

Capacity and annual use figures for this application are the most difficult to collect and quantify. Almost every country has spas and resorts that have swimming pools heated with geothermal water (including balneology), but many allow the water to flow continuously, regardless of use. As a result, the actual usage and capacity figures may be artificially high. In some cases where use was reported, no flows or temperature drops (∆T) were known; in these cases 0.35 MWt and 7.0 TJ/yr were applied to estimate the capacity and energy use for typical installations. In other cases, 5 L/s and a 10 °C temperature change were used (0.21 MWt) for the installed capacity and 3 L/s and 10 °C temperature change (4.0 TJ/yr) were used for the annual use. Undeveloped natural hot springs are not included.

In addition to the 67 counties (up from 60 in 2005) that reported bathing and swimming pool use, the author was also aware of developments in Malaysia, Mozambique, Singapore and Zambia, although no information was available. The installed capacity is 6,700 MWt and the annual energy use is 109,410 TJ/yr, up 24% and 32% respectively over 2005. We have also included the Japanese-style inns that utilize hot spring water for bathing, as we included these figures in 2000 and 2005 [23,24]. The largest reported uses are from China, Japan, Turkey, Brazil and Mexico.

3.7. Other Uses

Other uses, 42 MWt and 955 TJ/yr, are down compared to 2005. These were reported by seven countries, and include animal farming, spirulina cultivations, desalinations and sterilization of bottles.

4. Capacity Factors

Average capacity factors were determined for each country (Table 1) and for each category of use (Table 2). They vary from 0.09 to 1.00 (though, 1.00 or 100% annual use is suspect) for the countries and from 0.18 to 0.72 for the categories of use. The lower values refer to countries in which geothermal heat pumps usage predominates, as indicated by the 0.19 in Table 2, whereas the higher numbers are for countries with high industrial use (New Zealand) or continuous operation of pools for swimming and bathing (Iran).

The worldwide capacity factor has dropped from 0.40 in 2000 to 0.31 in 2005 to the current 0.28 over the past five years, again as a result in the increase in geothermal heat pump usage. Capacity factors for the various categories of use remained approximately constant, as compared to 2005.

The capacity factor is calculated as follows: (annual energy use in TJ/yr)/(installed capacity in MWt) x 0.1317. This number reflects the equivalent percentage of full load operating hours per year (i.e. CF = 0.70 is 70% full load hours or 6,132 equivalent hours/yr).

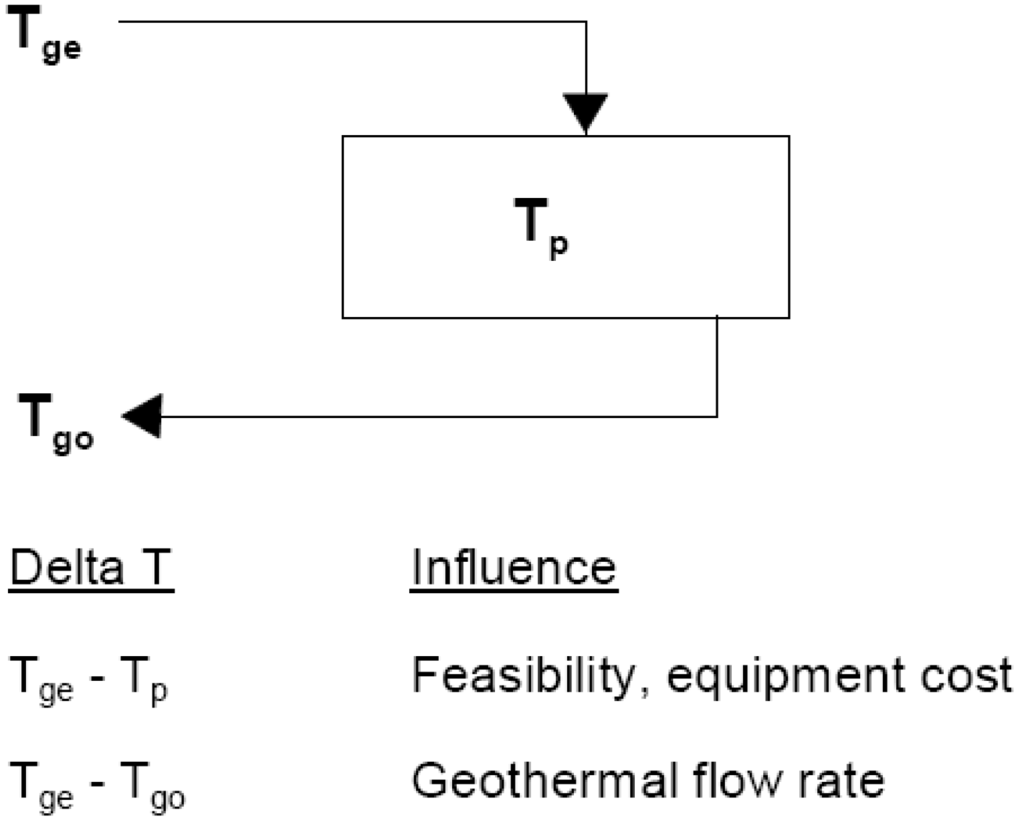

5. Direct-Use Temperature Requirements

The design of mechanical systems involving heat transfer, such as direct-use geothermal systems, is heavily influenced by temperature. Temperature difference (delta T or ΔT) is particularly important as it frequently governs feasibility, equipment selection and flow requirements for the system. Rafferty [25] addresses these issues with several “rules of thumb” that are described below. He introduces the material with the following discussion: Two primary temperature differences govern feasibility, flow requirements and design of direct-use equipment. These are illustrated in a simplified way in Figure 4. The first is the difference between the geothermal temperature entering the system (Tge) and the process temperature (Tp). This difference determines whether of not the application will be feasible. For a direct-use project, the temperature of the geothermal entering the system must be above the temperature of the process in order to transfer heat out of the geothermal water and into the process (aquaculture pond, building, greenhouse, etc.). Beyond that, it must be sufficiently above the process to allow the system to be constructed with reasonably sized heat transfer equipment. The greater the temperature difference between the geothermal resource and the process, the lower the cost of heat exchange equipment. The key question is how much above the process temperature does the geothermal need to be for a given application.

Figure 4.

Fundamental direct-use temperature differences [25].

The second temperature difference is the one between the geothermal entering the system and leaving the system (Tgo in Figure 4). This determines the geothermal flow rate necessary to meet the heat input requirement of the application. The greater the temperature difference between the entering and leaving temperatures, the lower the geothermal flow required. Obviously, the resource temperature is fixed. The process temperature plays a role as well since the leaving geothermal temperature cannot be lower than the process temperature to which it is providing heat. In addition, the specifics of the application and the heat transfer equipment associated with it also influence the temperature required. There are two broad groups of applications with similar characteristics in terms of heat transfer–aquaculture and pools, greenhouses and building space heating.

5.1. Pool and Aquaculture Pond Heating

Pond and pool heating is one of the simplest geothermal applications, as it usually uses the geothermal water directly in the pond/pool to provide the required heat demand [25], where 50 °C geothermal water is supplied to heat the pool water to 30 °C. Thus, the ΔT is 20 °C, and using a flow rate of 10 L/s, the energy supplied would be 837 kW (3.0 GJ/hr) (kW = L/s × ΔT × 4,184). If the supply temperature were instead 40 °C the flow rate would have to be doubled to provide the same amount of energy, and four times at 35 °C, and eight times at 32.5 °C.

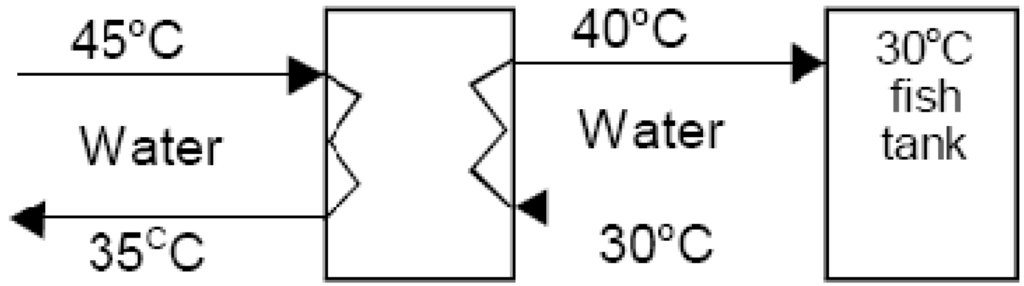

If the geothermal water cannot be used directly, due to health restrictions, then a heat exchanger is necessary to heat treated water for the pond or pool. Following the “rule of thumb” that the heated water to the pool should be 10 °C above the pool temperature, then according to the previous example 40 °C secondary water would have to be provided to the pool. Using a heat exchanger between the geothermal water and the secondary water an additional ΔT of 5 °C is required to accommodate the heat transfer between the geothermal water and the secondary water. Thus 45 °C geothermal water would be required, and on the return side of the heat exchanger the geothermal reject fluid should be 5 °C above the return temperature of the secondary water. Thus, the rule of thumb is “10/5/5” (Figure 5).

Figure 5.

Pond/pool heating with heat exchanger (modified from Rafferty [25]). Minimum acceptable supply water temperature = process temp. + 10 °C; Maximum available supply water temperature = resource temp. – 5 °C; Minimum achievable geo. leaving temperature = process temp. + 5 °C.

5.2. Greenhouse and Building Space Heating

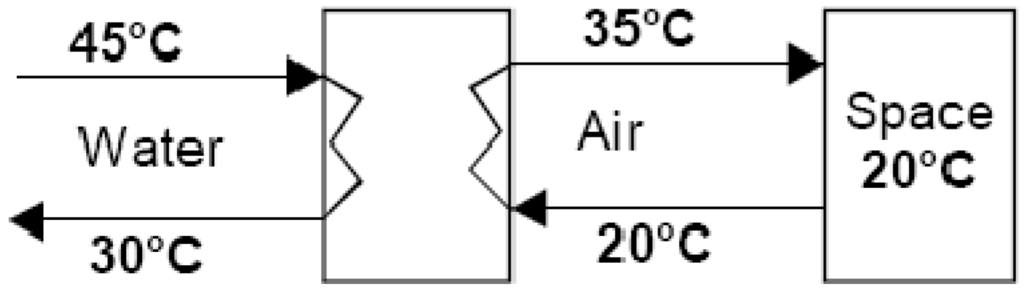

Heating of greenhouses and building often involves the transfer of heat to the air in the structure using a water-to-air heat exchanger called a coil, usually consisting of finned copper tubes [25]. In order to heat the space, heated air should be delivered at least 15 °C above the space temperature, 20 °C shown in Figure 6. Thus, the air should be delivered at 35 °C or above from the water to the coil. The reason for the large difference, 15 °C, is to limit the required quantity of air circulated to meet the heating requirements at reasonable levels. Also, as the difference becomes less, the fan and duct sizes become large and the fan power consumption can be excessive. In addition, occupant comfort is important, as when the air supply drops below the 15 °C difference, the temperature of the air approaches human skin temperature, which results in a “drafty” sensation to the occupants, even at the desired air temperature. In addition, the geothermal water delivered to the water-to-air heat exchangers should be at least 10 °C above the require air temperature to limited the size and cost of this heat exchanger—usually a coil type. The same ΔT is required between the leaving geothermal water and the return air temperature. Thus, to supply 20 °C heat to the room, a geothermal resource temperature would have to be at least 45 °C. The “rule of thumb” for this condition is then “15/10/10”.

Figure 6.

Space heating without isolation heat exchanger (modified from Rafferty [25]). Minimum acceptable supply water temperature = space temp. + 15 °C; Maximum available supply water temperature = geo. water temp. − 10 °C; Minimum achievable geo. leaving temperature = return air temp. + 10 °C.

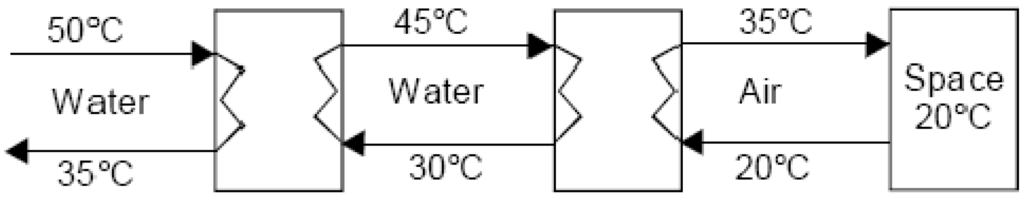

The example above assumes that the geothermal water is suitable to flow directly through the water-to-air heat exchanger (coil); however, if hydrogen sulfide is present, then this gas will attack copper and solder in the coil and cause leakage and failure to the unit. Thus, in the case where the geothermal must be isolated from the heating system equipment, a plate heat exchanger is normally placed between the two circuits to protect the heating equipment [25]. A plate heat exchanger is then added to the water-to-water side of the equipment (Figure 7). All the previous temperatures are still valid; the difference is that the plate heat exchangers will require additional temperature input to maintain the space (home) temperature of 20 °C. As in the previous example a ΔT of 5 °C is required between the geothermal supply and the output from the secondary water. Thus, the new geothermal temperature required to meet the needs of the system is 50 °C. The return geothermal water can only be cooled to 35 °C as a result of the intermediate water loop return temperature of 30 °C and the required 5 °C ΔT. This then provides of rule of thumb of “15/10/5”.

Figure 7.

Space heating 15/10/5 rule with geothermal isolation plate heat exchanger (modified from Rafferty [25]). Supply air to space air = 15 °C; Water/air heat exchanger = supply water to supply air of 10 °C; Water/water heat exchanger = supply water to supply water of 5 °C.

In summary, the following is provided by Rafferty [25]:

“All of the rules of thumb discussed here are exactly that. It is possible in all cases to “bend the rules,” and design systems and equipment for temperatures closer than the guidelines provided above. The values provided here are intended for initial evaluation of applications by those not in the practice of designing heating systems on a regular basis. The guidelines cited apply to new systems using commercially manufactured equipment. Homemade heat exchangers or existing equipment selected for water temperatures well above available geothermal temperature would require additional analysis.

6. Equipment

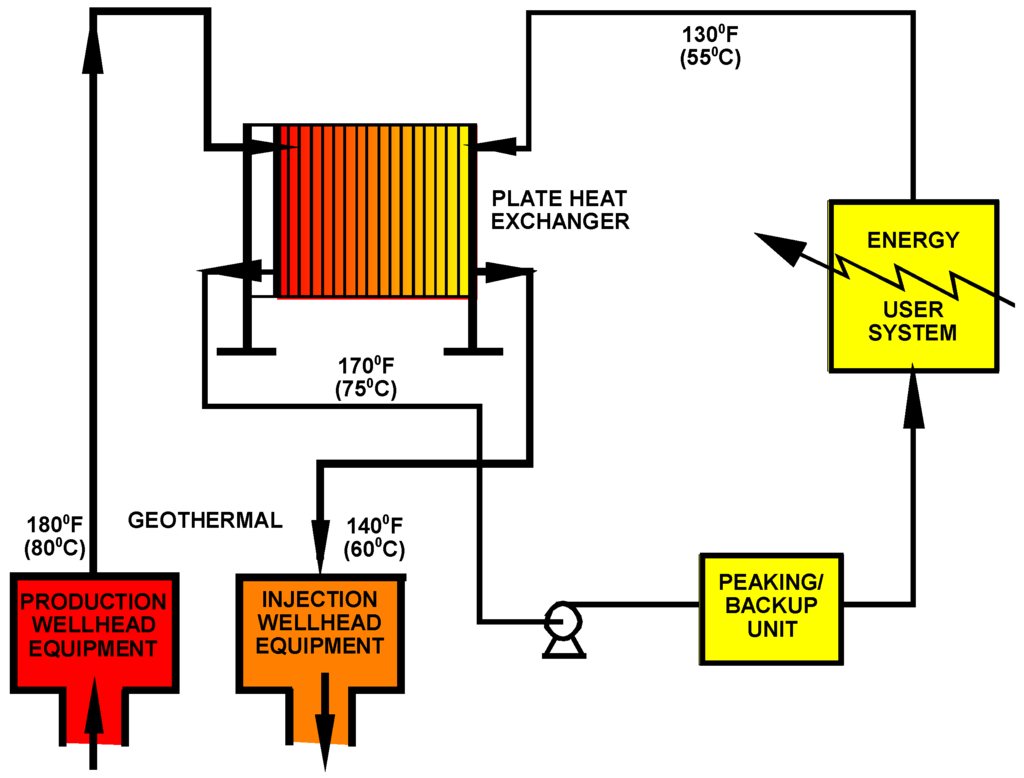

Standard equipment is used in most direct-use projects, provided allowances are made for the nature of geothermal water and steam. Temperature is an important consideration, so is water quality. Corrosion and scaling caused by the sometimes unique chemistry of geothermal fluids, may lead to operating problems with equipment components exposed to flowing water and steam. In many instances, fluid problems can be designed out of the system. One such example concerns dissolved oxygen, which is absent in most geothermal waters, except perhaps the lowest temperature waters. Care should be taken to prevent atmospheric oxygen from entering district heating waters; for example, by proper design of storage tanks. The isolation of geothermal water by installing a heat exchanger may also solve this and similar water quality derived problems. In this case, a clean secondary fluid is then circulated through the user side of the system as shown in Figure 8.

The primary components of most low-temperature direct-use systems are downhole and circulation pumps, transmission and distribution pipelines, peaking or back-up plants, and various forms of heat extraction equipment (Figure 8). Fluid disposal is either surface or subsurface (injection). A peaking system may be necessary to meet maximum load. This can be done by increasing the water temperature or by providing tank storage (such as done in most of the Icelandic district heating systems). Both options mean that fewer wells need to be drilled. When the geothermal water temperature is warm (below 50 °C), heat pumps are often used. The equipment used in direct-use projects represents several units of operations. The major units will now be described in the same order as seen by geothermal waters produced for district heating. Detailed discussion of equipment design and use can be found in Lund et al. [26].

Figure 8.

Geothermal direct-utilization system using a heat exchanger.

6.1. Downhole Pumps

Unless the well is artesian, downhole pumps are needed, especially in large-scale direct utilization system. Downhole pumps may be installed not only to lift fluid to the surface, but also to prevent the release of gas and the resultant scale formation. The two most common types are: lineshaft pump systems and submersible pump systems.

The lineshaft pump system consists of a multi-stage downhole centrifugal pump, a surface mounted motor and a long driveshaft assembly extending from the motor to the pump bowls. Most are enclosed, with the shaft rotating within a lubrication column which is centered in the production tubing. This assembly allow the bearings to be lubricated by oil, as hot water may not provide adequate lubrication. A variable-speed drive set just below the motor on the surface, can be used to regulate flow instead of just turning the pump on and off.

The electric submersible pump system consists of a multi-stage downhole centrifugal pump, a downhole motor, a seal section (also called a protector) between the pump and motor, and electric cable extending from the motor to the surface electricity supply.

Both types of downhole pumps have been used for many years for cold water pumping and more recently in geothermal wells (lineshafts have been used on the Oregon Institute of Technology campus in 89 °C water for almost 60 years). If a lineshaft pump is used, special allowances must be made for the thermal expansion of various components and for oil lubrication of the bearings [27]. The lineshaft pumps are preferred over the submersible pump in conventional geothermal applications for two main reasons: the lineshaft pump cost less, and it has a proven track record. However, for setting depths exceeding about 250 m, a submersible pump is required.

6.2. Piping

The fluid state in transmission lines of direct-use projects can be liquid water, steam vapor or a two-phase mixture. These pipelines carry fluids from the wellhead to either a site of application, or a steam-water separator. Thermal expansion of metallic pipelines heated rapidly from ambient to geothermal fluid temperatures (which could vary from 50 to 200 °C) causes stress that must be accommodated by careful engineering design.

The cost of transmission lines and the distribution networks in direct-use projects is significant. This is especially true when the geothermal resource is located at great distance from the main load center; however, transmission distances of up to 60 km have proven economical for hot water (i.e., the Akranes project in Iceland [28]), where asbestos cement covered with earth has been successful.

Carbon steel is now the most widely used material for geothermal transmission lines and distribution networks; especially if the fluid temperature is over 100 °C. Other common types of piping material are fiberglass reinforced plastic (FRP) and asbestos cement (AC). The latter material, used widely in the past, cannot be used in many systems today due to environmental concerns; thus, it is no longer available in many locations. Polyvinyl chloride (PVC) piping is often used for the distribution network, and for uninsulated waste disposal lines where temperatures of the fluid is around 60 °C or lower.

Cross-linked polyethylene pipe (PEX) have become popular in recent years as they can tolerate temperatures up to 100 °C and still take pressures up to 550 kPa. However, PEX pipe is currently only available in sizes less than 5 cm in diameter. Conventional steel piping requires expansion provisions, either bellows arrangements or by loops. A typical piping installation would have fixed points and expansion points about every 100 m. In addition, the piping would have to be placed on rollers or slip plates between points. When hot water metallic pipelines are buried, they can be subjected to external corrosion from groundwater and electrolysis. They must be protected by coatings and wrappings. Concrete tunnels or trenches have been used to protect pipes in many geothermal district heating systems. Although expensive (generally over U.S.$300 per meter of length), tunnels and trenches have the advantage of easing future expansion, providing access for maintenance and a corridor for other utilities such as domestic water, waste water, electrical cables, phone lines, etc.

Supply and distribution systems can consist of either a single-pipe or a two-pipe system. The single-pipe is a once-through system where the fluid is disposed of after use. This distribution system is generally preferred when the geothermal energy is abundant and the water is pure enough to be circulated through the distribution system. In a two-pipe system, the fluid is recirculated so the fluid and residual heat are conserved. A two-pipe system must be used when mixing of spent fluids is called for, and when the spent cold fluids need to be injected into the reservoir. Two-pipe distribution systems cost typically 20 to 30 percent more than single-piped systems.

The quantity of thermal insulation of transmission lines and distribution networks will depend on many factors. In addition to minimize the heat loss of the fluid, the insulation must be waterproof and water tight. Moisture can destroy the value of any thermal insulation, and cause rapid external corrosion. Above ground and overhead pipeline installations can be considered in special cases. Considerable insulation is achieved by burying hot water pipelines. For example, burying bare steel pipe results in a reduction in heat loss of about one-third as compared to aboveground in still air. If the soil around the buried pipe can be kept dry, then the insulation value can be retained. Carbon steel piping can be insulated with polyurethane foam, rock wool or fiberglass. Below ground, such pipes should be protected with a polyvinyl chloride (PVC) jacket; aboveground, aluminium can be used. Generally, 2.5 to 10 cm of insulation is adequate. In two-pipe systems, the supply and return lines are usually insulated; whereas, in single-pipe systems, only the supply line is insulated.

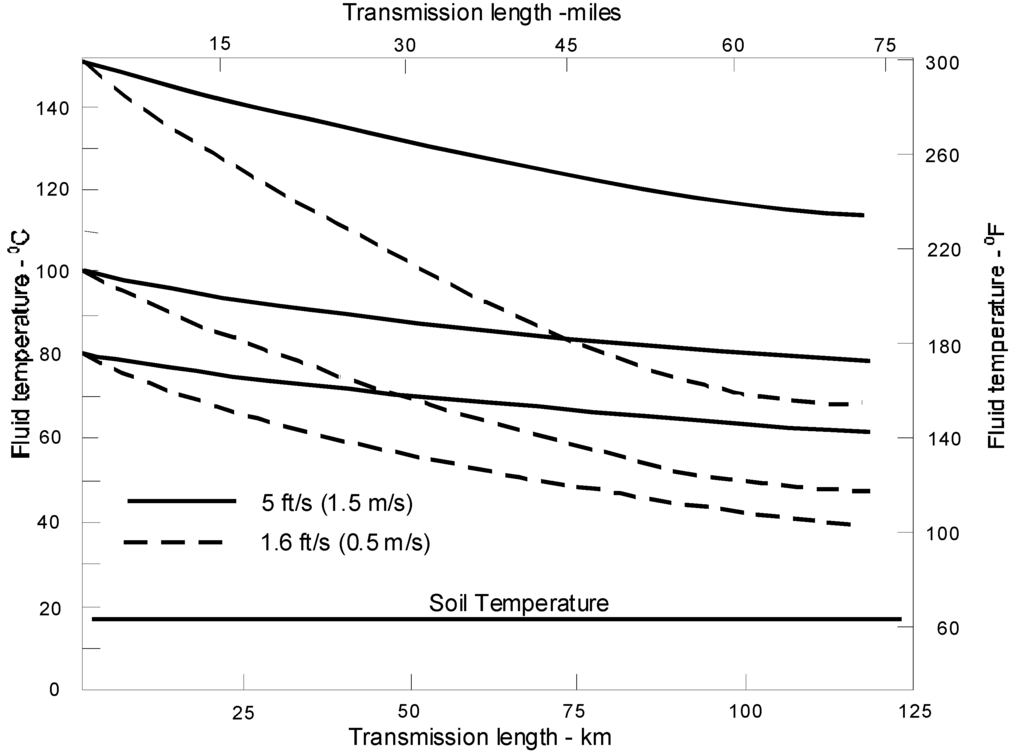

At flowing conditions, the temperature loss in insulated pipelines is in the range of 0.1 to 1.0 °C/km, and in uninsulated lines, the loss is 2 to 5 °C/km (in the approximate range of 5 to 15 L/s flow for 15-cm diameter pipe) [5]. It is less for larger diameter pipes. For example, less than 2 °C loss is experienced in the new above ground 29 km long and 80 and 90 cm diameter line (with 10 cm of rock wool insulation) from Nesjavellir to Reykjavik in Iceland [29]. The flow rate is around 560 L/s and takes seven hours to cover the distance. Uninsulated pipe costs about half of insulated pipe, and thus, is used where temperature loss is not critical. Pipe material does not have a significant effect on heat loss; however, the flow rate does. At low flow rates (off peak), the heat loss is higher than as greater flows. Figure 9 shows fluid temperatures, as a function of distance, in a 45-cm diameter pipeline, insulated with 50 cm of urethane foam [5].

There are several types of aboveground and buried pipeline installations. Steel piping is used if the temperature of the fluid is above 100 °C, whereas FRP or PVC can be used in low-temperature applications. Aboveground pipelines have been used extensively in Iceland, where excavation in lava rock is expensive and difficult; however, in the USA, below ground installations, either direct buried or in utilidors are used to protect the line from vandalism and to eliminate traffic barriers. A detailed discussion of these various installations can be found in Gudmundsson and Lund [4] and in Lund [5].

6.3. Heat Exchangers

The principal heat exchangers used in geothermal systems are the plate, shell-and-tube, and downhole types. The plate heat exchanger consists of a series of plates with gaskets held in a frame by clamping rods. The counter-current flow and high turbulence achieved in plate heat exchangers, provide for efficient thermal exchange in a small volume. In addition, they have the advantage when compared to shell-and-tube exchangers, of occupying less space, can easily be expanded when addition load is added, and cost 40% less. The plates are usually made of stainless steel; although, titanium is used when the fluids are especially corrosive. Plate heat exchangers are commonly used in geothermal heating situations worldwide.

Figure 9.

Temperature drop in hot water transmission lines [5].

Shell-and-tube heat exchangers may be used for geothermal applications, but are less popular due to problems with fouling, greater approach temperature (difference between incoming and outgoing fluid temperature), and the larger size.

Downhole heat exchangers installed directly in a well eliminate the problem of disposal of geothermal fluid, since only heat is removed from the well water. However, their use is limited to small heating loads such as the heating of individual homes, a small apartment house or business. The exchanger consists of a system of pipes or tubes suspended in the well through which secondary water is pumped or allowed to circulate by natural convection. In order to obtain maximum output, the well must be designed to have an open annulus between the wellbore and casing, and perforations above and below the heat exchanger surface. Natural convection circulates the water down inside the casing, through the lower perforations, up in the annulus and back inside the casing through the upper perforations [30,31]. The use of a separate pipe or promoter, has proven successful in older wells in New Zealand to increase the vertical circulation [32].

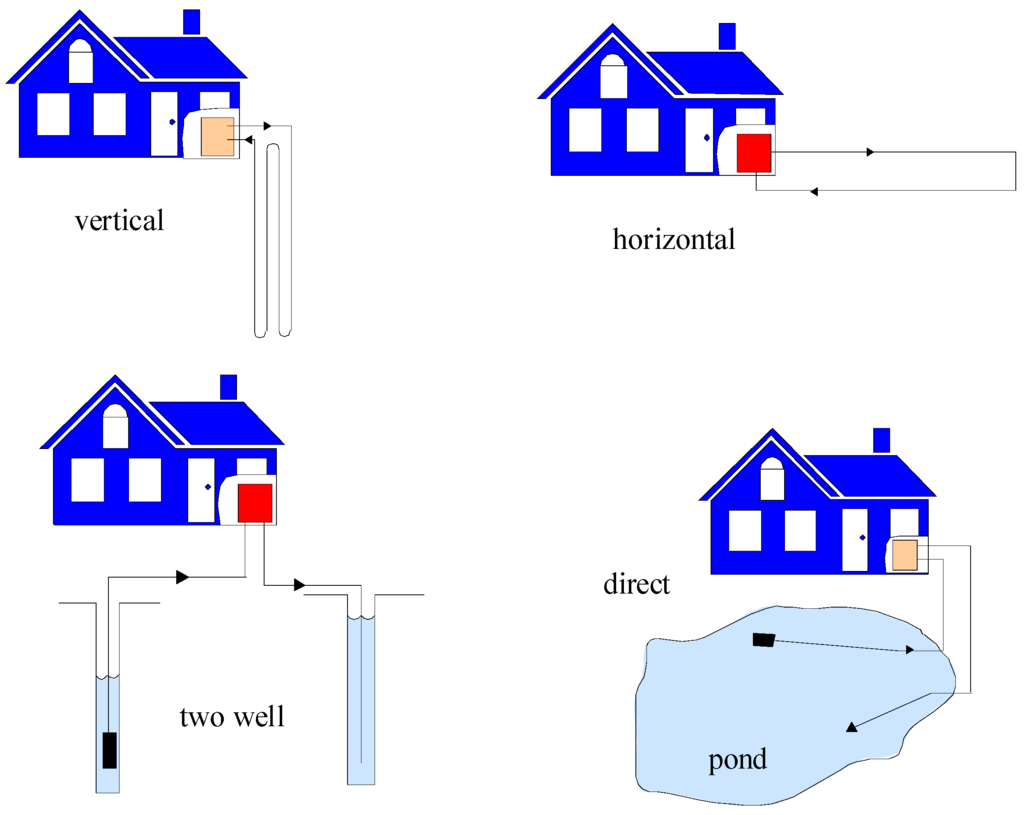

6.4. Heat Pumps

At the present time, ground-coupled and groundwater (often called ground-source or geothermal) heat pump systems are being installed in great numbers in the United States, Canada, Switzerland, Sweden, Austria and Germany [1,7]. Groundwater aquifers and soil temperatures in the range of 5 to 30 °C are being used in these systems. Geothermal heat pumps (GHP) utilize groundwater in wells (open loop) or by direct ground coupling (closed loop) with vertical or horizontal heat exchangers. Just about every state in the USA, especially in the mid-western and eastern states are utilizing these systems in part subsidized by public and private utilities. In some cases, the water in abandoned mines has been used to heat surface facilities [33,34]. It is estimated that almost 2.8 million units (12 kW) are installed in 43 countries worldwide, with most in Europe, China, Canada and the United States. Annual energy utilization growth rates are around 18%, the fastest of all the direct-use applications.

Like refrigerators, heat pumps operate on the basic principle that fluid absorbs heat when it evaporates into a gas, and likewise gives off heat when it condenses back into a liquid. A geothermal heat pump system can be used for both heating and cooling. The types of heat pumps that are adaptable to geothermal energy are the water-to-air and the water-to-water. Heat pumps are available with heating capacities of less than 3 kW to over 1,500 kW [35,36].

GHPs use the relatively constant temperature of the earth to provide heating, cooling and domestic hot water for homes, schools, government and commercial buildings. A small amount of electricity input is required to run a compressor, however, the energy output is in the order of three to four times this input. These “machines” cause heat to flow “uphill” from a lower to higher temperature location—really nothing more than a refrigeration unit that can be reversed. “Pump” is used to described the work done, and the temperature difference called the “lift”—the greater the lift, the greater the energy input. The technology isn’t new, as Lord Kelvin developed the concept in 1852, which was then modified as a GHP by Robert Webber in the 1940's. They gained commercial popularity in the 1960s and 1970s. Figure 10 shows diagrams of typical closed and open loop GHP installations.

Figure 10.

Typical closed and open loop geothermal heat pump installations.

GHPs come in two basic configurations: ground-coupled (closed loop) which are installed horizontally or vertically and groundwater (open loop) systems, which are installed in wells and lakes. The type chosen depends upon the soil and rock type at the installation, the land available and/or if a water well can be drilled economically or is already on site. A desuperheater can be provided to use reject heat in the summer and some input heat in the winter for the domestic hot water heating.

In the ground-coupled system, a closed loop of pipe, placed either horizontally (1 to 2 m deep) or vertically (50 to 100 m deep) is placed in the ground and a water-antifreeze solution is circulated through the plastic pipes (high density polyethylene) to either collect heat from the ground in the winter or reject heat to the ground in the summer [37]. The open loop system uses ground water or lake water directly in the heat exchanger and then discharges it into another well, into a stream or lake, or on the ground (say for irrigation), depending upon local laws.

The efficiency of GHP units are described by the Coefficient of Performance (COP) in the heating mode and the Energy Efficiency Ratio (EER) in the cooling mode (COPh and COPc, respectively in Europe) which is the ratio of the output energy divided by the input energy (electricity for the compressor) and varies from 3 to 6 with present equipment (the higher the number the better the efficiency). Thus a COP of 4 would indicate that the unit produced four units of heating energy for every unit of electrical energy input. In comparison, an air-source heat pump has a COP of around 2 and is dependent upon backup electrical energy to meet peak heating and cooling requirements. In Europe, this ratio is sometimes referred to as the “Seasonal Performance Factor” (“Jahresarbeitszahl” in German) and in the United States as the “Seasonal Energy Efficiency Ratio” (SEER), which is the average COP over the heating and cooling season, respectively, and takes into account system properties.

6.5. Convectors

Heating of individual rooms and buildings is achieved by passing geothermal water (or a heated secondary fluid) through heat convectors (or emitters) located in each room. The method is similar to that used in conventional space heating systems. Three major types of heat convectors are used for space heating: (1) forced air, (2) natural air flow using hot water or finned tube radiators, and (3) radiant panels. All these can be adapted directly to geothermal energy or converted by retrofitting existing systems.

6.6. Refrigeration

Cooling can be accomplished from geothermal energy using lithium bromide and ammonia absorption refrigeration systems [26,38]. The lithium bromide system is the most common because if uses water as the refrigerant. However, it is limited to cooling above the freezing point of water. The major application of lithium bromide units is for the supply of chilled water for space and process cooling. They may be either one- or two-stage units. The two-stage units require higher temperatures (about 160 °C); but, they also have high efficiency. The single-stage units can be driven with hot water at temperatures as low as 77 °C. The lower the temperature of the geothermal water, the higher the flow rate required and the lower the efficiency. Generally, a condensing (cooling) tower is required, which will add to the cost and space requirements.

For geothermally-driven refrigeration below the freezing point of water, the ammonia absorption system must be considered. However, these systems are normally applied in very large capacities and have seen limited use. For the lower temperature refrigeration, the driving temperature must be at or above about 120 °C for a reasonable performance.

7. Economic Considerations

Geothermal projects require a relatively large initial capital investment, with small annual operating costs thereafter. Thus, a district heating project, including production wells, pipelines, heat exchangers, and injection wells, may cost several million dollars. By contrast, the initial investment in a fossil fuel system includes only the cost of a central boiler and distribution lines. The annual operation and maintenance costs for the two systems are similar, except that the fossil fuel system may continue to pay for fuel at an every-increasing rate; while, the cost of the geothermal fuel is stable. The two systems, one with a high initial capital cost and the other with high annual costs, must be compared. Table 3 is an attempt to quantify the cost of various direct use types based on experiences in the United States.

Table 3.

Average costs of direct-use systems in the United States for 2005.

| Application | Capital Cost | O&M | Total | |

|---|---|---|---|---|

| $/kW | $/kWyr | $/kWyr | $/kWyr | |

| Residential Space Heat* | 800 | 71.1 | 7.1 | 78.2 |

| Comm/Inst. Space Heat* | 500 | 44.4 | 4.4 | 48.4 |

| District Heating | 650 | 57.7 | 5.8 | 63.5 |

| Greenhouse Heating | 250 | 22.2 | 2.2 | 24.4 |

| Aquaculture Pond Heat | 200 | 17.8 | 1.8 | 19.6 |

| Geothermal HP** | 850 | 75.5 | 7.6 | 83.1 |

Note: Based on 30 year life at 8.0% interest and O&M at 10% of capital cost. The above costs includes a shallow well (<300 m) and no retrofit costs; however cost can vary by as much as 100% depending on the local geology, hydrology, building construction and infrastructure.* Assumes one production and one injection well for a single building.** Heat pump figures are considered only for the heating mode.

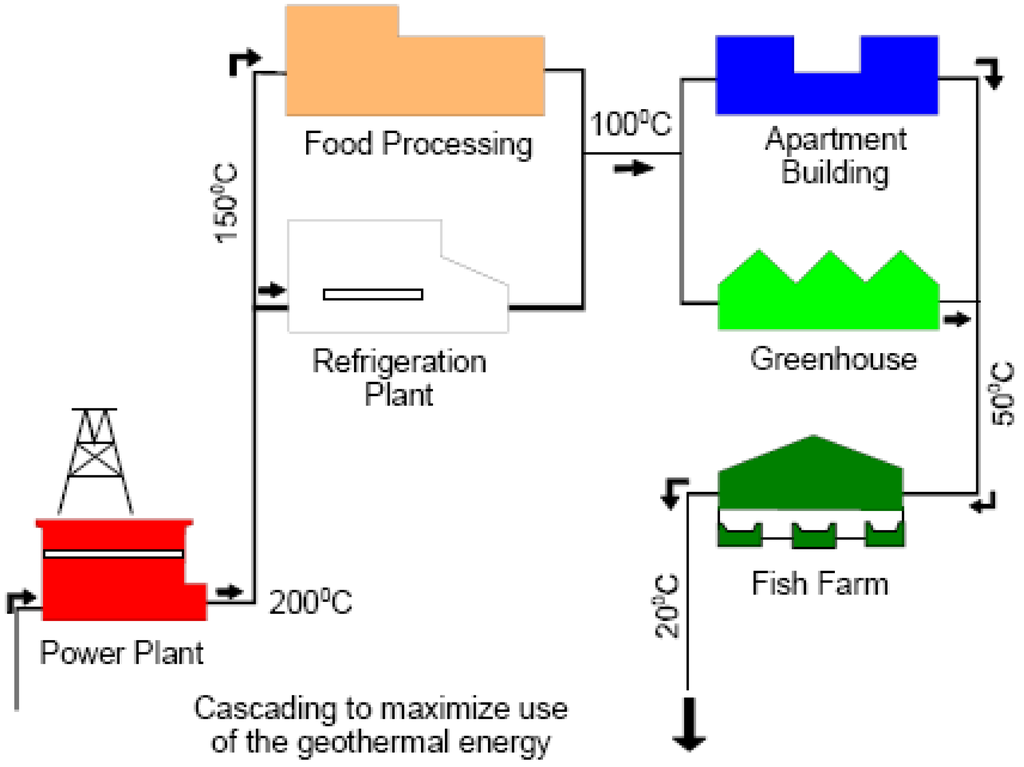

Geothermal resources fill many needs: power generation, space heating, greenhouse heating, industrial processing, and bathing to name a few. Considered individually, however, some of the uses may not promise an attractive return on investment because of the high initial capital cost. Thus, we may have to consider using a geothermal fluid several times to maximize benefits. This multistage utilization, where lower and lower water temperatures are used in successive steps, is called cascading or waste heat utilization. A simple form of cascading employs waste heat from a power plant for direct use projects referred to as a combined heat and power application [39].

Geothermal cascading has been proposed and successfully attempted on a limited scale throughout the world. A generalized example is shown in Figure 11. In Rotorua, New Zealand, for example, after geothermal water and steam heat a home, the owner will often use the waste heat for a backyard swimming pool and steam cooker. At the Otake geothermal power plant in Japan, about 165 tonnes per hour of hot water flows to downstream communities for space heating, greenhouses, baths and cooking. In Sapporo, Hokkaido, Japan, the waste water from the pavement snow melting system is retained at 65 °C and reused for bathing. An examples of combined heat and power installation using geothermal waters down to 100 °C are installed in Germany and Austria. At Neustadt Glewe in northern Germany 98 °C water from a 2,300 m-deep well at 1,700 l/s provides 11 MW (thermal) for a district heating network and 210 kW (electric) from a binary power plant meeting the electricity demands for 500 households.

Figure 11.

An example of geothermal cascading (combined heat and power).

8. Energy Savings

Geothermal, a domestic source of sustainable and renewable energy, replaces other forms of energy use, especially fossil fuels. For many countries, geothermal energy leads to a reduction in their dependence on imported fuel, and for all countries, it means the elimination of pollutants such as particulates and greenhouse gases. An attempt is made here to quantify the fossil fuel savings, using a 0.35 efficiency factor if the competing energy is used to generate electricity and 0.70 if it is used directly to produce heat, such as in a furnace.

Using the 423,830 TJ/year of energy consumed in direct geothermal applications in 2009 (see Table 1), and estimating that a barrel of fuel oil contains 6.06 × 109 J, and that the fuel is used to produce replacement electricity, the savings would be 200.0 million barrels of oil or 30.0 million tonnes of oil annually. If the oil were used directly to produce energy by burning for heating, then these savings would be 100.0 million barrels and 15.0 million tonnes respectively. The actual savings are most likely somewhere in between these two values. Note that 200.0 million barrels is almost three days of worldwide oil consumption.

Using figures developed by Lawrence Livermore Laboratories for the U.S. Department of energy [40] and by private consultants Goddard and Goddard [41] the following savings would be realized for carbon, CO2, SOx and NOx. If electricity were produced then the carbon savings would be 14.65 tonnes/TJ from natural gas, 62.6 tonnes/TJ for oil or 72.7 tonnes/TJ from coal, which then produces a savings in carbon production of 6.22, 26.54 or 30.82 million tonnes, respectively. Similarly, using 193 kg/MWh (53.6 tonnes/TJ), 817 kg/MWh (227.0 tonnes/TJ), and 953 kg/MWh (264.7 tonnes/TJ) for carbon dioxide emissions when producing electricity from natural gas, oil and coal, respectively, the savings in CO2 emissions would be 22.72, 96.24, and 112.22 million tonnes, respectivey. The savings in SOx and NOx producing electricity from natural gas, oil and coal would be 0.0, 0.59 and 0.64 million tonnes, and 5.90, 17.67, and 17.67 thousand tonnes, respectively. If heat were produced by burning these fuels, the carbon, CO2 and SOx and NOx savings would be half of these values. Again, the actual savings would be somewhere in between these values since a mix of fossil fuels would be used for heating and electricity generation.

If savings in the cooling mode of geothermal heat pumps is considered, which is not geothermal, then this is equivalent to an additional annual savings of approximately 50.0 million barrels (7.5 million tonnes) of fuel oil, or 6.6 million tonnes of carbon pollution from burning fuel oil, assuming the annual energy used in cooling is approximately half that used in the heating mode (+25%). The above figures are summaried in Table 4.

Table 4.

Worldwide savings in energy, carbon and greenhouse gases using geothermal energy in terms of fuel oil (million of tonnes—TOE) including geothermal heat pump cooling [1].

| Fuel Oil | Carbon | CO2 | SOx | NOx | ||

| bbl | TOE | TOE | TOE | TOE | TOE | |

| As Electricity Electricity | 250.0 | 37.5 | 33.2 | 1o6.9 | 0.74 | 0.022 |

| As Direct Heat | 125.0 | 18.8 | 16.6 | 53.4 | 0.37 | 0.011 |

9. Concluding Remarks

As in 1995, 2000 and 2005, several countries stand out as major consumers of geothermal fluids for direct-uses; however, in most countries development has been slow. This is not surprising as fossil fuels are a major competitor, and development has been curtained due to the recent downturn in the world economy, and the initial high investment costs. Many countries have; however, been doing the necessary groundwork, conducting inventories and quantifying their resources in preparation for development with the economic situation is better and governments and private investors see the benefits of developing a domestic renewable energy source.

With the increased interest in geothermal heat pumps, geothermal energy can now be developed anywhere, for both heating and cooling. Low-to-moderate temperature geothermal resources are also being used in combined heat and power plants (CHP), where hot waters with temperatures below 100 °C are first run through a binary (Organic Rankine Cycle) power plant and then cascaded for space, swimming pool, greenhouse and aquaculture pond heating, before being injected back into the aquifer. CHP projects certainly maximize the use of the resources and improve the economics, as has been shown in Iceland, Austria and Germany.

Key data and explanations were frequently missing from the WGC2010 country update reports used in this worldwide summary. Some data also appeared to be in error or misreported. We have attempted to correct for these errors by contacting WGC2010 authors and by making estimates for the missing data, and have pointed this out in the relevant country summaries [1].

Despite these discrepancies and the effort required to correct them, work on this review has proved useful, as it has allowed us to demonstrate that using low-to-moderate temperature geothermal resources in the direct-heat applications, given the right conditions, is an economically feasible business, and can make a significant contribution to a country’s or region’s energy mix. As oil and gas supplies dwindle and increase in price, geothermal energy will become an even more economically viable alternative source of energy.

At the moment of writing this report (June, 2010), the cost of crude oil is at US$78/barrel and has been in the recent past over US$100/barrel, and natural gas prices are also on the rise. Thus, with geothermal energy becoming increasingly more competitive with fossil fuels and the environmental benefits associated with renewable energy resources better understood, development of this natural “heat from the earth” should accelerate in the future. An important task for all of us in the geothermal community is to spread the word on geothermal energy, its various applications, and the many environmental benefits that can accrue from its use.

References

- Lund, J.W.; Freeston, H.H.; Boyd, T.L. Direct Utilization of Geothermal Energy 2010 Worldwide Review. In Proceedings of World Geothermal Congress 2010, Bali, Indonesia, 26–30 April 2010. No. 0007.

- Dickson, M.H.; Fanelli, M. Geothermal Energy: Utilization and Technology; UNESCO Renewable Energy Series: Paris, France, 2003; p. 205. [Google Scholar]

- Cataldi, R.; Hodgson, S.F.; Lund, J.W. Stories from a Heated Earth–Our Geothermal Heritage; Geothermal Resources Council and International Geothermal Association: Davis, CA, USA, 1999; p. 569. [Google Scholar]

- Gudmundsson, J.S.; Lund, J.W. Direct Uses of Earth Heat. Int. J. Energy Res. 1985, 9, 345–375. [Google Scholar] [CrossRef]

- Lund, J.W. Geothermal Direct-Use Equipment Overview. In Geo-Heat Center Quarterly Bulletin; Geo-Heat Center, Oregon Institute of Technology: Klamath Falls, OR, USA, 1998; pp. 1–6. [Google Scholar]

- Ragnarsson, A. Geothermal Development in Iceland 2005-2009. In Proceedings of World Geothermal Congress 2010, Bali, Indonesia; 2010. No. 0124. [Google Scholar]

- Curtis, R.; Lund, J.; Sanner, B.; Rybach, L.; Hellström, G. Ground Source Heat Pumps—Geothermal Energy for Anyone, Anywhere: Current Worldwide Activity. In Proceedings of World Geothermal Congress 2005, Antalya, Turkey, 24–29 April 2005. No. 1437.

- Boyd, T.L. The Oregon Institute of Technology Geothermal Heating System—Then and Now. In Geo-Heat Center Quarterly Bulletin; Geo-Heat Center, Oregon Institute of Technology: Klamath Falls, OR, USA, 1999; pp. 10–13. [Google Scholar]

- Lund, J.W.; Boyd, T. Oregon Institute of Technology Geothermal Uses and Projects, Past, Present and Future. In Proceedings of Thirty-Fourth Workshop on Geothermal Reservoir Engineering, Stanford University, Stanford, CA, USA, 9–11 February 2009. (CD ROM).

- Bloomquist, R.G.; Nimmons, J.T.; Rafferty, K. District Heating Development Guide; Washington State Energy Office: Olympia, DC, USA, 1987; Volume 1. [Google Scholar]

- Lund, J.W.; Klein, R. Prawn Park—Taupo, New Zealand. In Geo-Heat Center Quarterly Bulletin; Geo-Heat Center, Oregon Institute of Technology: Klamath Falls, OR, USA, 1995; pp. 27–29. [Google Scholar]

- Bloomer, A. Kawerau Geothermal Development: A Case Study. In Geo-Heat Center Quarterly Bulletin; Geo-Heat Center, Oregon Institute of Technology: Klamath Falls, OR, USA, 1998; pp. 15–18. [Google Scholar]

- Lund, J.W. Onion Dehydration. In Transaction; Geothermal Resources Council: Davis, CA, USA, 1995; pp. 69–74. [Google Scholar]

- Chiasson, A. Geothermal Energy Utilization in Ethanol Production. In Geo-Heat Center Quarterly Bulletin; Geo-Heat Center, Oregon Institute of Technology: Klamath Falls, OR, USA, 2007; pp. 2–5. [Google Scholar]

- Trexler, D.T.; Flynn, T.; Hendrix, J.W. Heap Leaching. In Geo-Heat Center Quarterly Bulletin; Geo-Heat Center, Oregon Institute of Technology: Klamath Falls, OR, USA, 1990; pp. 1–4. [Google Scholar]

- Lund, J.W.; Rangel, M.A. Pilot Fruit Drier for the Los Azufres Geothermal Field, Mexico. In Processing of The World Geothermal Congress, Florence, Italy, 18–31 May 1995; 1995; pp. 2335–2338. [Google Scholar]

- Andritsos, N.; Dalampakis, P.; Kolios, N. Use of Geothermal Energy for Tomato Drying. In Geo-Heat Center Quarterly Bulletin; Geo-Heat Center, Oregon Institute of Technology: Klamath Falls, OR, USA, 2003; pp. 9–13. [Google Scholar]

- Lund, J.W.; Lienau, P.J. Onion Dehydration. In Geo-Heat Center Quarterly Bulletin; Geo-Heat Center, Oregon Institute of Technology: Klamath Falls, OR, USA, 1994; pp. 15–18. [Google Scholar]

- Lund, J.W.; Boyd, T. Geothermal Uses and Projects on the Oregon Institute of Technology Campus. In Geo-Heat Center Quarterly Bulletin; Geo-Heat Center, Oregon Institute of Technology: Klamath Falls, OR, USA, 2010; pp. 12–17. [Google Scholar]

- Lund, J.W. Balneological Use of Thermal and Mineral Waters in the USA. In Geothermics; Elsevier: Amsterdam, Netherlands, 1996; pp. 103–148. [Google Scholar]

- Taguchi, S.; Itoi, R.; Ysa, Y. Beppu Hot Springs. In Geo-Heat Center Quarterly Bulletin; Geo-Heat Center, Oregon Institute of Technology: Klamath Falls, OR, USA, 1996; pp. 1–6. [Google Scholar]

- Lund, J.W. Geothermal Spas in Czechoslovakia. In Geo-Heat Center Quarterly Bulletin; Geo-Heat Center, Oregon Institute of Technology: Klamath Falls, OR, USA, 1990; pp. 20–24. [Google Scholar]

- Lund, J.W.; Freeston, D.H. World-Wide Direct Uses of Geothermal Energy 2000. In Geothermic; Elsevier: London, UK, 2001; pp. 29–68. [Google Scholar]

- Lund, J.W.; Freeston, D.H.; Boyd, T.L. Direct Application of Geothermal Energy: 2005 Worldwide Review. In Geothermics; Elsevier: Amsterdam. Netherlands, 2005; pp. 691–727. [Google Scholar]