1. Introduction

Liquid-liquid extraction is an important purification enrichment separation method used in the chemical, biochemical, petrochemical, pharmaceutical and food industries. This mass transfer operation consists of separating one or several substances (solute) present in a liquid phase by contacting it with another liquid phase in which these substances are preferentially transferred. It carries out separation by contacting a liquid feed with another immiscible liquid [

1,

2,

3,

4,

5,

6,

7,

8].

In choosing between liquid extraction and other applicable processes as a means of separation, the cost of operation as a whole is of primary concern. Liquid-liquid extraction is also significant in the area of biofuel purification. It is commonly used to separate glycerol from biodiesel, butanol from fermentation broth, and aromatics from lube oils [

9,

10,

11].

Despite the increasingly extensive applications of liquid extraction, greater versatility, and the extensive amount of research that has been done, it is nevertheless a relatively immature unit operation. It is characteristic of such operations that equipment types change rapidly, new designs are being proposed frequently and last through a few applications, only to be quickly replaced by others [

3,

12,

13,

14,

15]. There are many problems associated with traditional liquid-liquid extraction equipment like phase separation, solvent loss, emulsion formation, loading and flooding in conventional column contactors and mixer settlers. Moreover, traditional units also have high power consumption and are maintenance intensive due to their interior moving parts. Improving the contacting and separation performance has always been a challenge for technologists involved in developing liquid-liquid extraction equipment [

16,

17,

18,

19].

A new inclined plates extractor-separator is developed for operation with immiscible liquids in which extraction and separation is achieved in one unit, contrary to traditional mixer settlers. It is well known that effective use of turbulence can increase reactant contact and decrease reaction times because of the increased ability to transport and mixing of chemical species, added momentum, and energy as opposed to molecular diffusion alone. This can reduce the cost of operation [

20,

21,

22]. A turbulent jet is a powerful tool for enhancing mass transfer at the interface between immiscible liquids due to high local rates of energy of dissipation [

23,

24,

25] and plate separators are effective apparatus for the separation of dispersed feed which allows the droplets to coalesce on the inclined plate [

26]. The inclined plates extractor-separator combines mass transfer through turbulent jets, which produce high relative velocities between the two phases, and separation by the inclined plate. In the current study, different operating parameters on this new proposed inclined plates extractor separator have been studied in batch mode operation. The results have also been compared with a traditional mixer settler, and a gullwing contactor which has been reported as an innovation in the literature [

19] in terms of degree of extraction and power consumption for the same liquid-liquid extraction (LLE) system [

12,

27,

28].

2. Development of the Experimental Setup and Methods

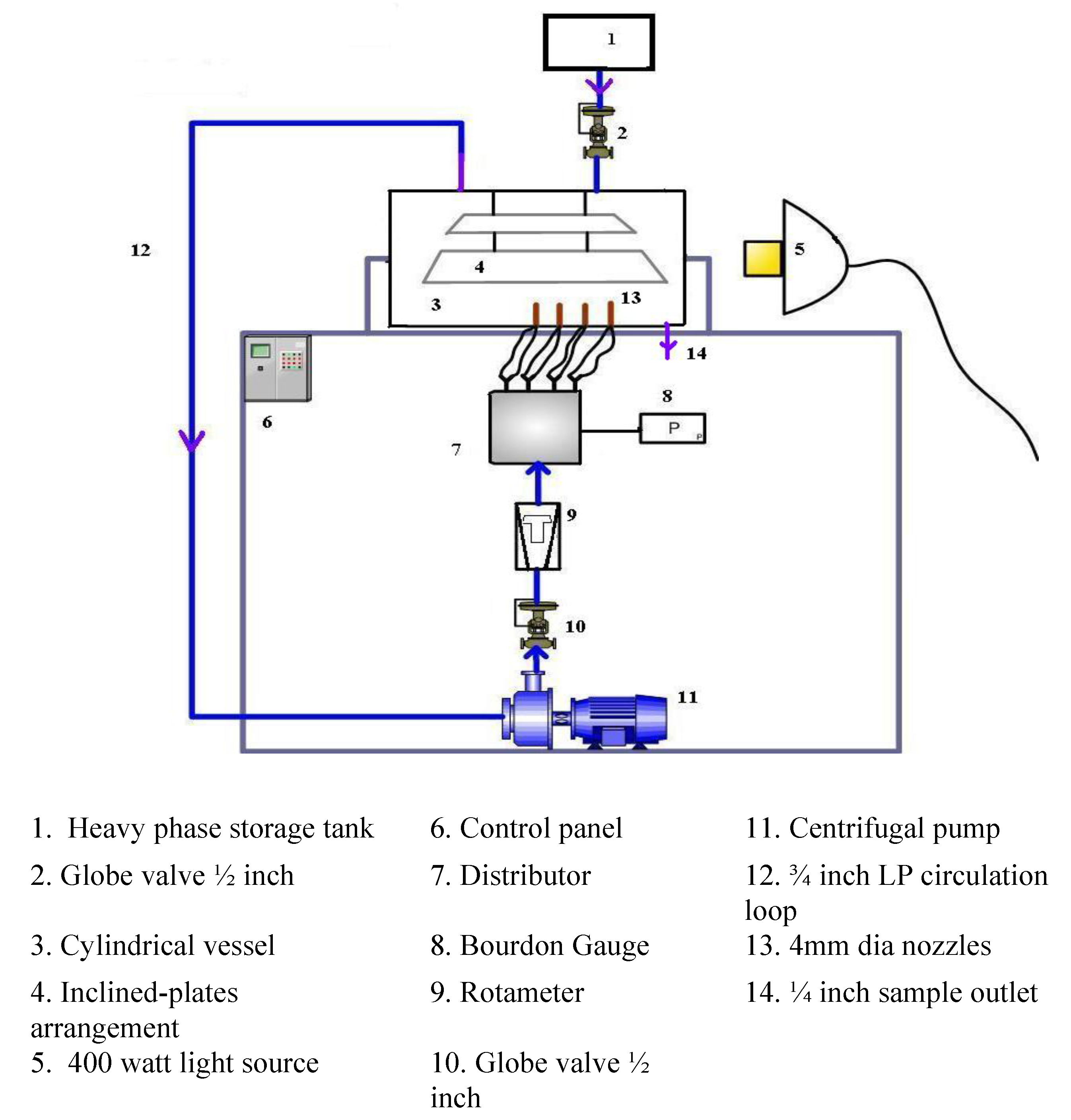

The main components of the experimental setup, shown in

Figure 1, consist of a cylindrical Perspex vessel of 0.457 m length and 0.3048 m diameter, corresponding to a volume of 33 litres. The remainder of the system includes a set of nozzles at the base of the vessel, a centrifugal pump, heavy phase storage tank, rotameter, valves for flow control, inclined plates, converging canopy, sample point, and a loop for light phase recirculation to the extractor-separator. The angle of inclination of the separating plate is one of the important parameters that influence the two phase flow characteristics [

29].

Figure 1.

Schematic diagram of the experimental rig.

Figure 1.

Schematic diagram of the experimental rig.

In the literature, different inclination angles for different LLE systems have been reported for two phase flow on inclined surfaces [

26,

29,

30]. As extraction and separation both are taking place in one unit, inclined plate position, angle of inclination, and jetting results are mutually dependent. It has been found by Munir that 30° is the optimum angle of inclination for both 4 mm and 5 mm diameter jets for the same system [

31] and inclined plate extractor-separator experiments were thus performed with this plate geometry. Water and tetrachloroethylene (TCE) have quite different densities of 1 gm/cm

3 and 1.62 gm/cm

3, respectively. For the evaluation of the efficiency of the contactor separator, water has been used as the jetted light phase to extract ethyl acetate (EA) from the heavy phase of a tetrachloroethylene mixture (TCE/EA 95:5 on a volume basis). Total inventories of 28–30 litres of water and 4.70–6.27 litres of TCE were used for 40 mm and 50 mm pool depth experiments, respectively. For the hydrodynamic study and jet linear velocity calculations validation a FASTCAM- Ultima, APX high speed camera was used. The dye selected was rhodamine red because of its complete solubility only in the light phase (water). Samples were taken from the heavy phase pool at measured time intervals and analyzed for ethyl acetate content using chromatography. The samples were analyzed until an equilibrium concentration was achieved in the vessel. Using the equilibrium concentration the extraction efficiencies were computed for various operating conditions.

The extraction performance of the batch jet fluidized extractor-separator was evaluated using the following equation [

27,

32,

33,

34]:

where:

DOE = degree of extraction (%)

Ci = initial concentration of ethyl acetate (%)

Ct = concentration of EA in TCE after elapse of time (t) (%)

Ceq = equilibrium concentration of EA in TCE (%)

During operation, the jet of the light phase strikes the stationary heavy phase at the bottom of the contactor and accelerates it to approximately its own velocity. During the course of this acceleration the stationary heavy phase is dispersed into droplets. Liquid-liquid dispersions play an important role in the extraction process. This is because the large interfacial area, due to dispersion, aids mass transfer [

35]. The heavy phase droplets are then propelled upwards by the jetted phase, producing high relative velocities between the phases, as shown in the velocity profile model (

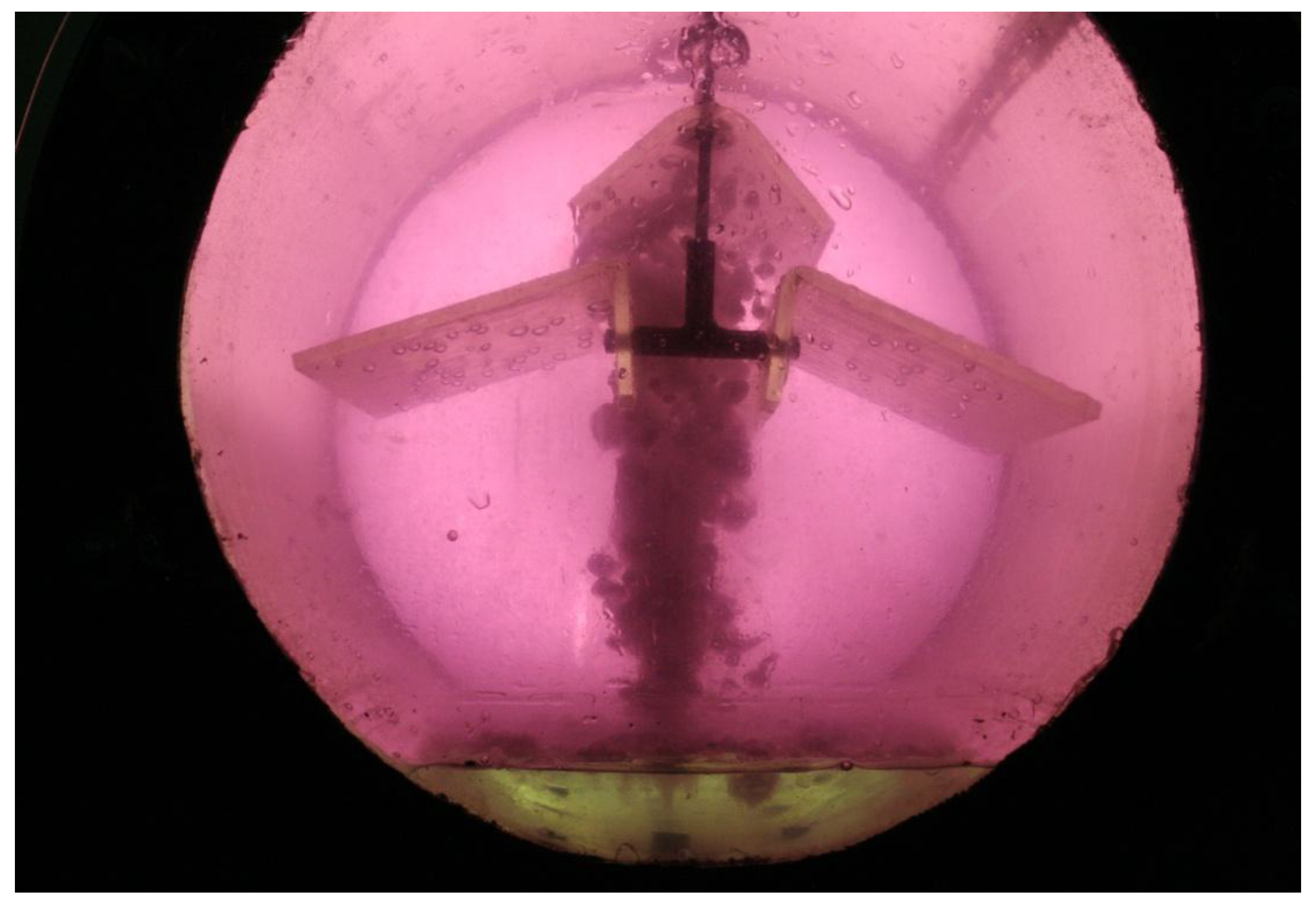

Figure 2).

The ratio of the buoyancy force on the attenuating jet to the internal viscous force λ

j is termed the buoyancy parameter. With a decrease in λ

j there will be an increase in the area of contact due to jet expansion and the force available at the jet exit will increase. This could lead to higher extraction efficiency [

33]. The values of λ

j under the conditions studied are given in

Table 1. The buoyancy parameter λ

j is evaluated via the following equation used by Kothari [

33]:

where:

This physical phenomenon of the entrainment of the heavy phase was also observed during flow visualization studies using the high speed camera system, as shown in

Figure 3.

Figure 3.

Development of growing jet with entrained heavy phase droplets.

Figure 3.

Development of growing jet with entrained heavy phase droplets.

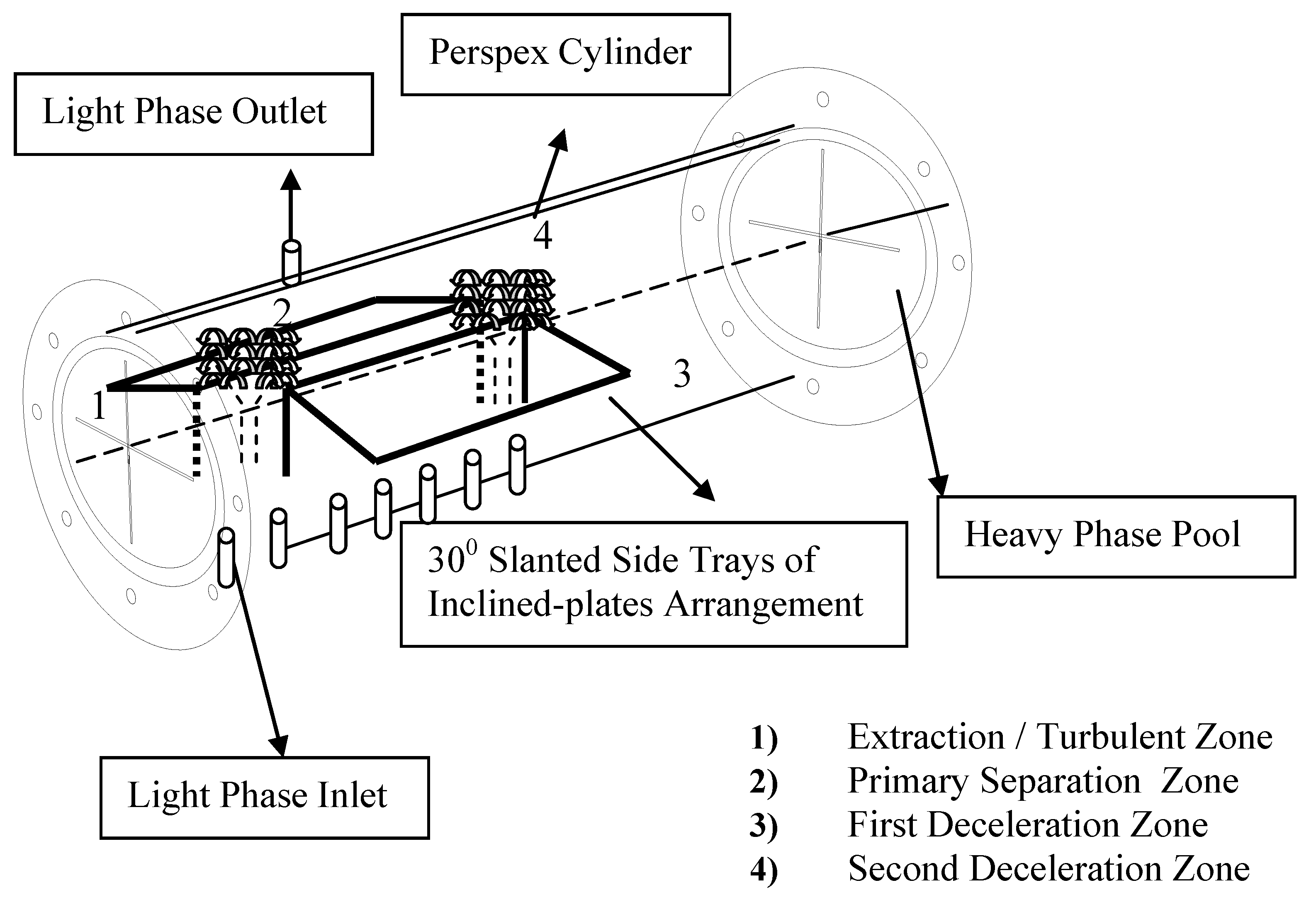

The turbulent extraction zone shown in

Figure 4 is intended to produce high relative velocities between in the two liquid phases so as to accelerate the diffusion controlled extraction process. It has been observed that the entrained droplets of the heavy phase are propelled upwards by the jetted light phase towards the canopy (

Figure 3), which diverges them to flow over the inclined-plates arrangement making maximum use of the available reactor volume. Here, the upward vertical motion is converted into downward inclined motion and over each half of the inclined-plates both the heavy and light phases are separated because of their density difference (primary extraction zone

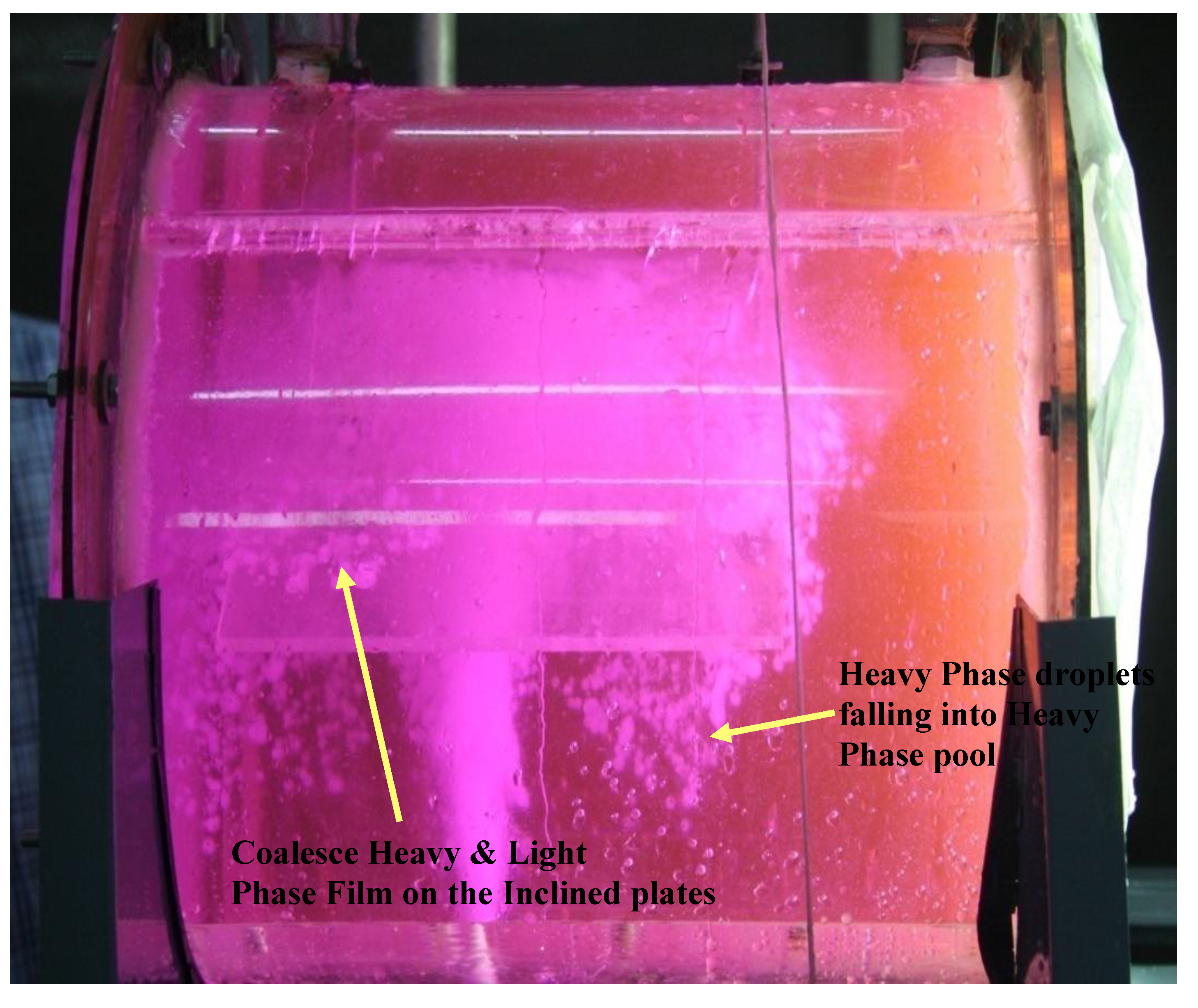

Figure 4). The purpose of installation of the inclined-plates arrangement is to separate the heavy phase from the light phase after extraction of the more valuable component from the heavy phase. During the upward motion through the nozzles, the light phase jet contacts the heavy phase and extracts the more valuable component depending upon its relative affinity with the light phase. In the later stage when droplets of both phases are brought to flow over the inclined-plates, the extraction process is simultaneously supported by separation phenomena. It has also been observed that the droplets of the heavy phase and light phase are coalesced into two films, respectively, under the influence of the shearing forces offered by the inclined-plates, the force of gravity and the component of the force of the upcoming jet. The motion of the coalesced films brings the heavy phase liquid film back to the bottom of the vessel for further contact and re-entrainment by the jetted light phase, as shown in

Figure 5. Water and tetrachloroethylene have widely differing specific gravities (1.0 and 1.62 respectively), allowing fast and effective separation. The force of gravity acting on the films because of their relative density difference and the high linear velocity of the jets generates a spinning motion (

Figure 2) of the heavy phase in its axial direction towards the inclined-plates arrangement so as to lead the coalesced films of both the light and heavy phases back into the turbulent zone. In the turbulent zone, further re-entrainment of the remaining more valuable component out of the heavy phase laminar pool takes place. The fresh upcoming light phase jet’s velocity component along the length of the vessel propagates the light phase film towards the first deceleration zone (

Figure 4). This zone is formed by the space resulting from the gap between the Inclined-plates arrangement and the rear end of the vessel, thus providing a reduction in the axial velocity of the light phase. This supports coalescence, and allows any remaining heavy phase droplets to coalesce and descend under the influence of gravity into the heavy phase pool. The samples were taken from the heavy phase bottom of this zone after measured intervals for ethyl acetate content examination using chromatography.

Figure 4.

Three dimensional view of the contactor/separator.

Figure 4.

Three dimensional view of the contactor/separator.

Figure 5.

Motion of the coalesced films on the inclined plates while heavy phase falling back to the bottom of the vessel for further contact and re-entrainment by the jetted light phase.

Figure 5.

Motion of the coalesced films on the inclined plates while heavy phase falling back to the bottom of the vessel for further contact and re-entrainment by the jetted light phase.

It has been found by Daood that 12.5 cm from the top cylindrical wall of the vessel is the optimum inclined plate position for both 4 mm and 5 mm diameter jets for the same system [

36].

3. Results and Discussions

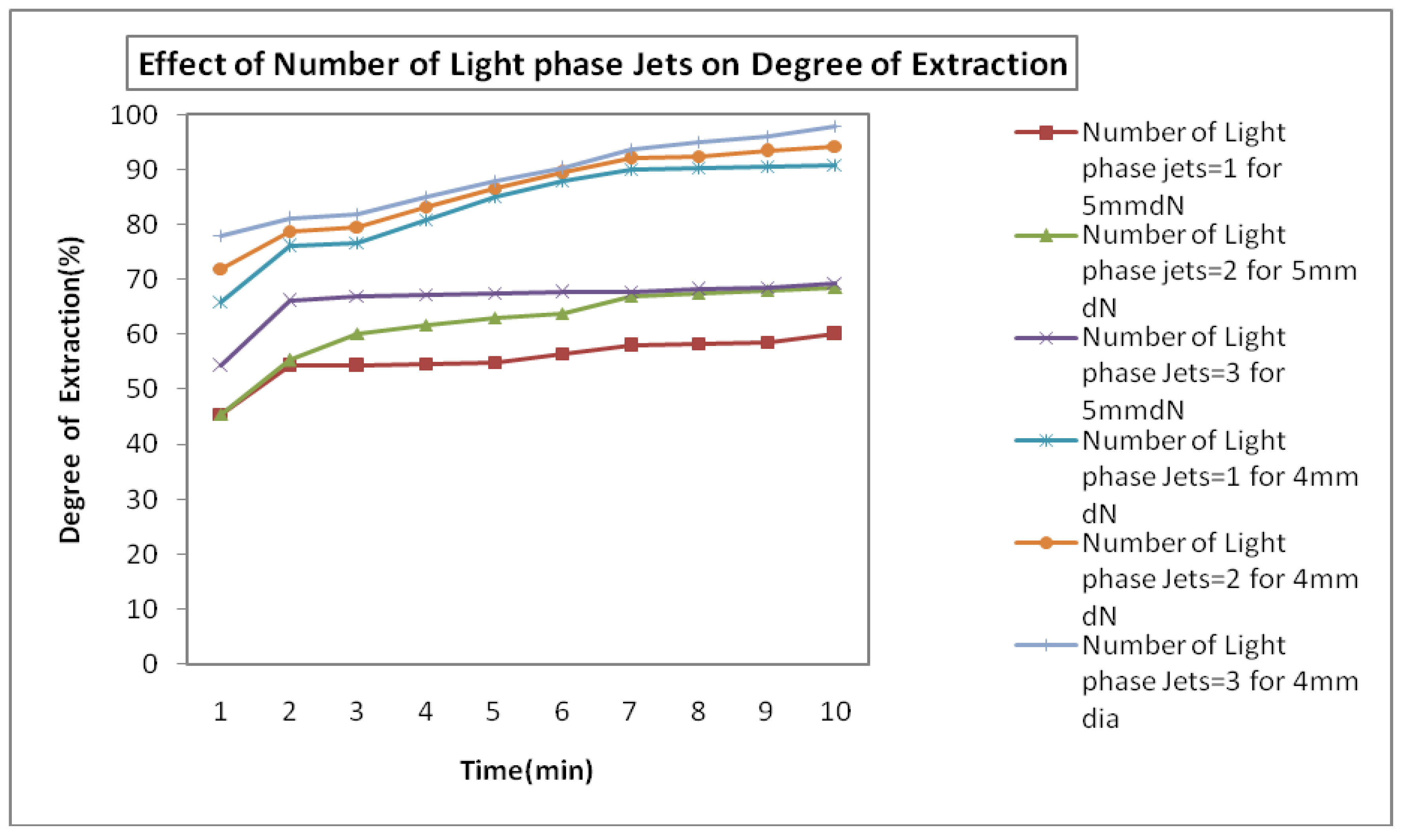

Degrees

Figure 6. It can be seen that in the case of the 4 mm nozzle diameter at 50 mm pool depth with a single light phase jet, the degree of extraction is 62% after one minute of operation and this increases slightly. Ultimately, a degree of extraction of 87.9% is achieved after an operating time of 10 minutes. In the case of two and three light phase jets, the degrees of extraction after one minute are 64.3% and 65.7%, respectively. After ten minutes, the degrees of extraction are 89.6% and 90.2%, respectively. This shows that the increase in the number of light phase jet injections does not significantly increase the extraction efficiency of the system in terms of degree of extraction. The reason for this was investigated through a hydrodynamics study and it was found that in the case of 50 mm pool depth, the jet with 4 mm nozzle diameter is not so forceful (U

N = 2m/s, λ

j = 49, N

Re = 8,000, N

Fr = 102) (

Table 1). Although it aided the attenuating jet to expand, while growing which increased the contact area (

Figure 7), due to decreased velocity, the outer portion of the jet having heavy phase droplets spreads and a part of the fluid in it reaches its terminal velocity prior to striking the curvature of the canopy and falls down in the heavy phase pool, as shown in

Figure 7, without completing the extraction process.

Figure 6.

Effect of number of light phase jets on DOE using 4 mm and 5 mm nozzles at 50 mm pool depth, 12.5 cm IPP.

Figure 6.

Effect of number of light phase jets on DOE using 4 mm and 5 mm nozzles at 50 mm pool depth, 12.5 cm IPP.

That is why the increase in degree of extraction with total operating time is not appreciable as the number of light phase jets increases. The degrees of extraction found were 87.9%, 89.6% and 90.2% for one, two and three light phase jets respectively. The force of the jet is decreased due to the static pressure applied by the pool of the heavy phase.

Figure 7.

Hydrodynamics of dN = 4 mm, pool depth 50 mm, IPP = 12.5 cm.

Figure 7.

Hydrodynamics of dN = 4 mm, pool depth 50 mm, IPP = 12.5 cm.

Table 1.

The effect of jet linear velocity on jet Reynolds number, jet Froude number and jet Buoyancy parameter.

Table 1.

The effect of jet linear velocity on jet Reynolds number, jet Froude number and jet Buoyancy parameter.

| Jet linear Velocity m/s | Jet Reynolds Number NRe | Jet Froude Number NFr | |

|---|

| dN = 5 mm | dN = 4 mm | dN = 5 mm | dN = 4 mm | dN = 5 mm | dN = 4 mm |

|---|

| 2.0 | 10,000 | 8,000 | 81.63 | 102 | 76 | 49 |

| 2.75 | 13,750 | 11,000 | 154.3 | 193 | 55 | 35 |

| 3.90 | 19,500 | 15,600 | 310 | 388 | 39 | 25 |

| 4.80 | 24,000 | 19,200 | 470 | 588 | 32 | 20 |

| 5.60 | 28,000 | 22,400 | 640 | 800 | 27 | 17 |

It is quite evident from the results plotted in

Figure 6 that in the case of a 5 mm nozzle diameter at a 50 mm pool depth with a single light phase jet, the degree of extraction reaches 83 percent within one minute, and gradually increases as the operation proceeds. It reaches to 96.3 percent after a time lapse of ten minutes. With two light phase jets, a degree of extraction of 88 percent is achieved just within one minute, and it gradually increases to 98.7 percent within 10 minutes. With three light phase jets, a degree of extraction of 93 percent is achieved just within a one minute time interval and it reaches 100 percent after only eight minutes of time. Samples from the light phase were analysed after the run, and carry-over was found to be below the detectable limit of 3 ppm. The reason is investigated through a hydrodynamic study and it is observed that the jet grows in the heavy phase as well as in the light phase until it strikes the inner curvature of the canopy. Then it is completely diverged on the inclined plate. The whole process occurs comprehensively and, optimum extraction takes place in the turbulent zone leading to higher mass transfer of ethyl acetate from tetrachloroethylene in to water (light phase). The jet velocity was 3.90 m/s, N

Re = 19,500, N

Fr = 310 and λ

j = 39. By decreasing the buoyancy parameter, the light phase jet expansion in the heavy phase as well as in the light phase was achieved, causing an increase in the area of contact between the phases. This results in enhanced extraction efficiency. The volumetric mass transfer KL

A is proportional to the square of jet velocity U

2N jet velocity [

32]. This means that at this velocity, the kinetic energy available at the nozzle exit creates the optimum turbulent contact (N

Re) and interfacial area for optimum mass transfer. Further to this, entrained heavy phase droplets are fully converged on the inclined plates, forming coalesced films for separation as shown in

Figure 8. The phenomenon mentioned is magnified using three light phase jets. So, when the numbers of light phase jets are increased, the same process takes place at a larger scale. An increase in number of light phase jets increases the light phase recirculation flow rate. Thus, the contacting area increases, the volume of heavy phase droplets entrained increases, which results in greater mass transfer. That is why a higher degree of extraction is achieved within very short time.

Figure 8.

Hydrodynamics of dN = 5 mm, pool depth 50 mm and IPP = 12.5 cm showing full convergence of heavy phase droplets on the inclined plates.

Figure 8.

Hydrodynamics of dN = 5 mm, pool depth 50 mm and IPP = 12.5 cm showing full convergence of heavy phase droplets on the inclined plates.

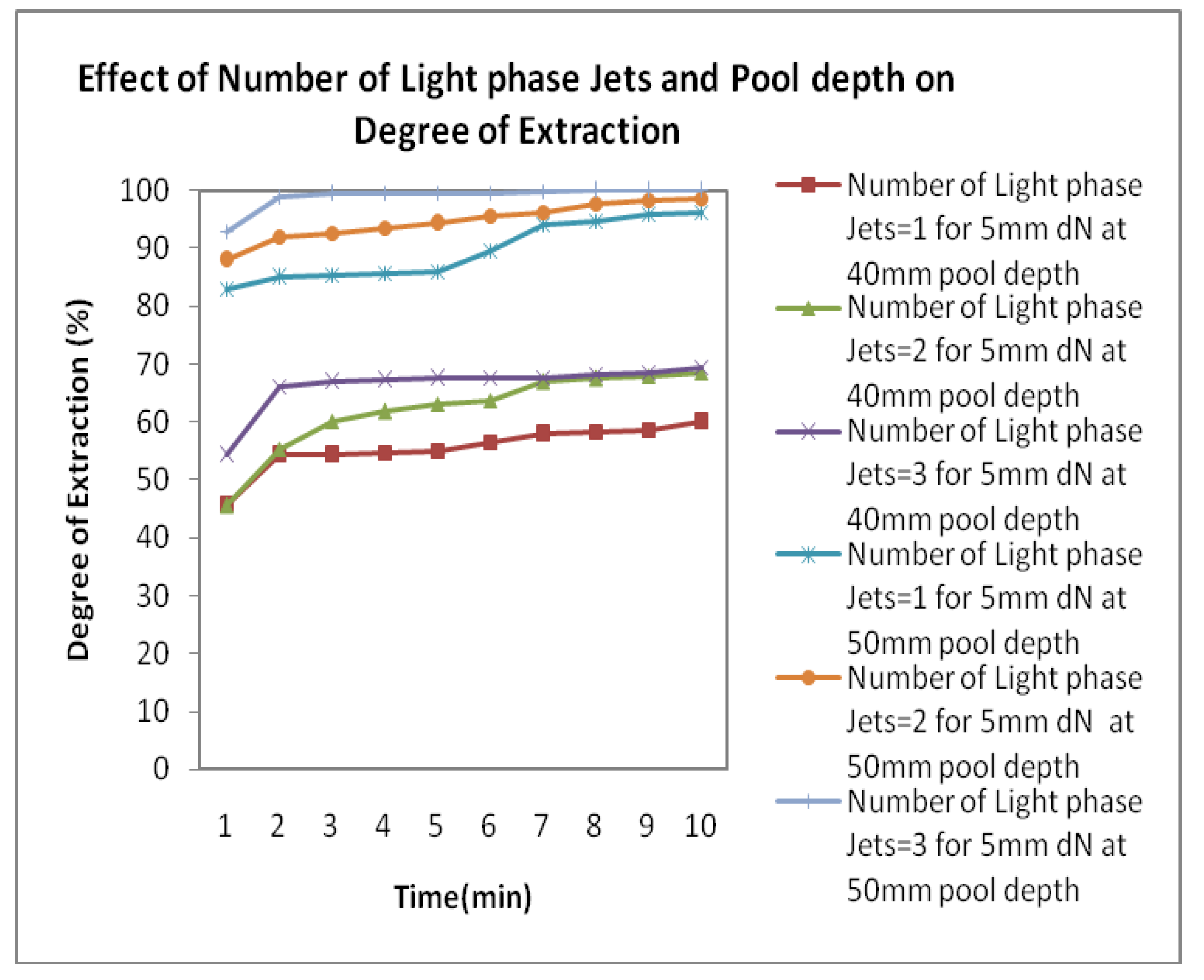

The results obtained by changing the phase ratio (by decreasing the pool depth to 40 mm of heavy phase with another set of operating parameters) are given in the graph shown in

Figure 9.

Figure 9.

Effect of number of light phase jets on DOE using 4 mm and 5 mm nozzle diameter at 40 mm pool depth with 12.5 cm IPP.

Figure 9.

Effect of number of light phase jets on DOE using 4 mm and 5 mm nozzle diameter at 40 mm pool depth with 12.5 cm IPP.

In the case of the 5 mm nozzle diameter with 40 mm pool depth, it is quite clear from

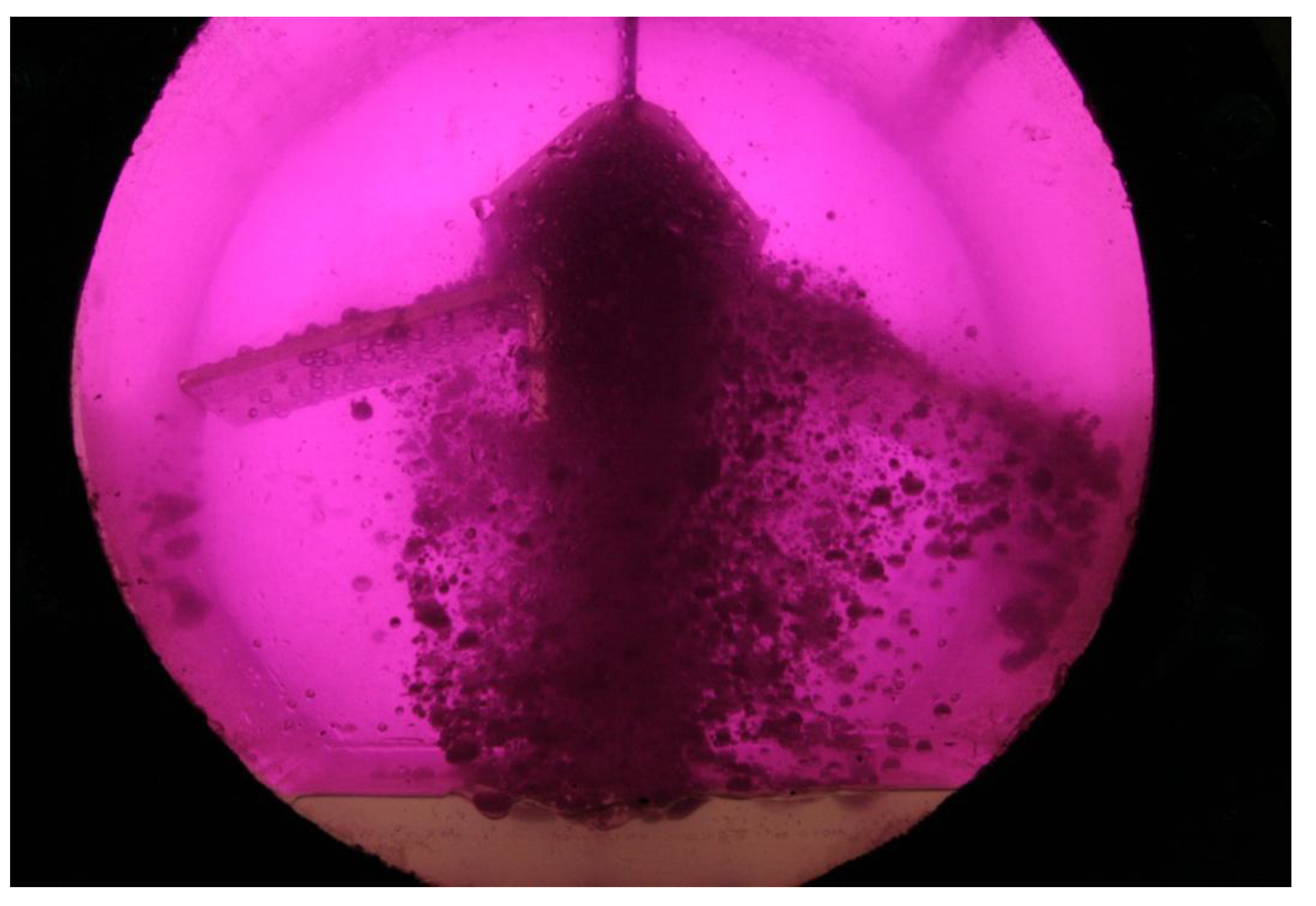

Figure 9 that the degree of extraction ranges from 45.5% to 60% with a single light phase jet. For two light phase jets the degree of extraction remains between 45.5% to 68.5% for the same time lapse of 10 minutes. Similarly, for three light phase jets with d

N = 5 mm, the degree of extraction remains between 54.3% to 69.4% for the same time lapse. This revealed that the degree of extraction does not increase as the number of light phase jets is increased from two to three. The reason, investigated through a flow visualization technique, showed the violent behaviour of the growing jet in the case of 5 mm d

N and 40mm pool depth as shown in

Figure 10.

Figure 10.

Violent behavior of jet when dN = 5 mm, pool depth 40 mm and IPP = 12.5 cm.

Figure 10.

Violent behavior of jet when dN = 5 mm, pool depth 40 mm and IPP = 12.5 cm.

The jet strikes the inner curvature of the canopy with a high linear velocity of Un = 4.80 m/s, N

Re = 24,000, N

Fr = 470, λ

j = 32 and half of it travels towards the front and rear end flanged flat circular plate of the cylindrical vessel, instead of getting diverged on the surface of the inclined plates as shown in

Figure 10. When two or three jets with d

N = 5 mm at a pool depth of 40 mm are introduced, the same phenomenon takes place for three vibrant jets and haze formation occurs, as shown in

Figure 11. For effective mass transfer, a large interfacial area must be generated between the two phases (many well dispersed small droplets); that is exactly the opposite of what is required for rapid coalescence and separation of two phases [

12]. The heavy phase droplets do not coalesce to form a film on the surface of the Inclined-plate but rather act like solid spheres and no mass transfer occurs [

37,

38]. That is why an increase in the light phase injections has no impact on the ultimate degree of extraction. Contrary to the results with 5 mm nozzle diameter with 40 mm pool depth, it can be seen in

Figure 9 that with a 4 mm nozzle diameter at 40 mm pool depth and 12.5 cm inclined-plates position, the degree of extraction is between 66 to 90.8 percent with a single light phase jet, while with two and three light phase injections the degrees of extraction are between 72 to 94.3 and 78 to 98 percent, respectively, for a time period of 1 to 10 minutes. Here it can be seen that maximum D.O.E with single light phase injection is 90.8%, with two injections it is 94.3% and with three injections it becomes 98 percent for a time lapse of ten minutes. During the experimental runs on the rig, it is observed that for 40 mm pool depth with nozzle diameter of 4 mm, and for 50 mm pool depth with 5 mm nozzle diameter, the process of contacting and separation is almost complete, as shown in

Figure 9 and

Figure 12.

Figure 11.

Haze formation at 40 mm pool depth, number of light phase jets = 3, dN = 5 mm.

Figure 11.

Haze formation at 40 mm pool depth, number of light phase jets = 3, dN = 5 mm.

Figure 12.

Effect of number of light phase jets on DOE using 5 mm nozzle diameter and 50 mm pool depths.

Figure 12.

Effect of number of light phase jets on DOE using 5 mm nozzle diameter and 50 mm pool depths.

A more explanatory comparison exhibiting the effect of number of light phase jets on the degree of extraction using 5 mm diameter nozzle at 12.5 cm inclined-plate position with pool depth of 40 mm and 50 mm is given in

Figure 13 and

Figure 14, which depict that an increase in the number of light phase injections with d

N = 5 mm, increases the degree of extraction at 12.5 cm inclined-plate position, provided the pool depth is kept at 50 mm (or a phase ratio of 19:81). Otherwise, an increase in the number of light phase injections with d

N = 5 mm does not have a significant effect on the degree of extraction at the same inclined-plate position with the pool depth of 40 mm or at a phase ratio of 14:86. The light phase proportion includes the volume of light phase in the recirculation loop, pump and distribution box.

Figure 13.

Effect of number of light phase jets and pool depths on degree of extraction using 5 mm nozzle diameter at 40 mm and 50 mm pool depths, 12.5 cm IPP. Total operating time = 10 min.

Figure 13.

Effect of number of light phase jets and pool depths on degree of extraction using 5 mm nozzle diameter at 40 mm and 50 mm pool depths, 12.5 cm IPP. Total operating time = 10 min.

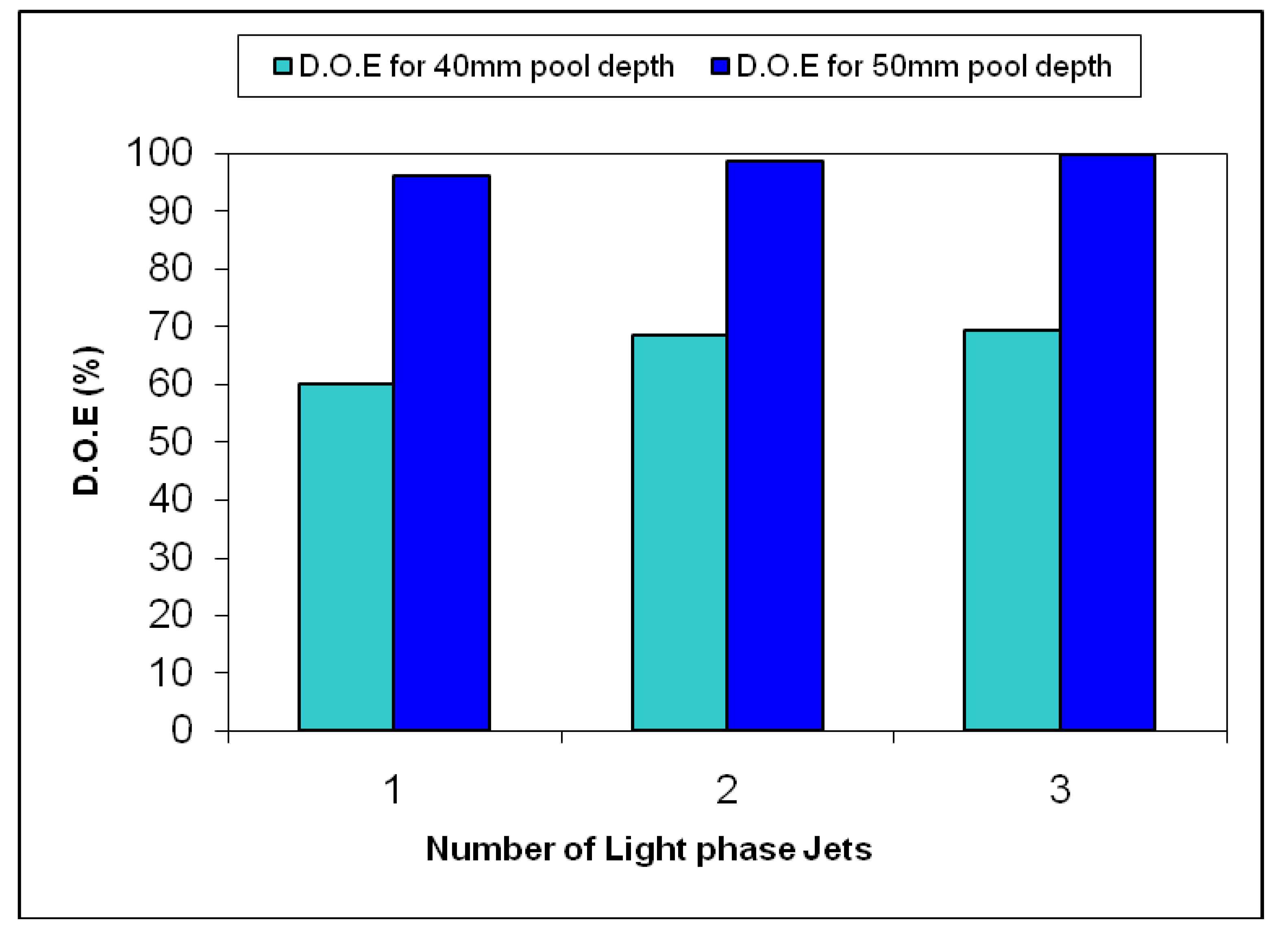

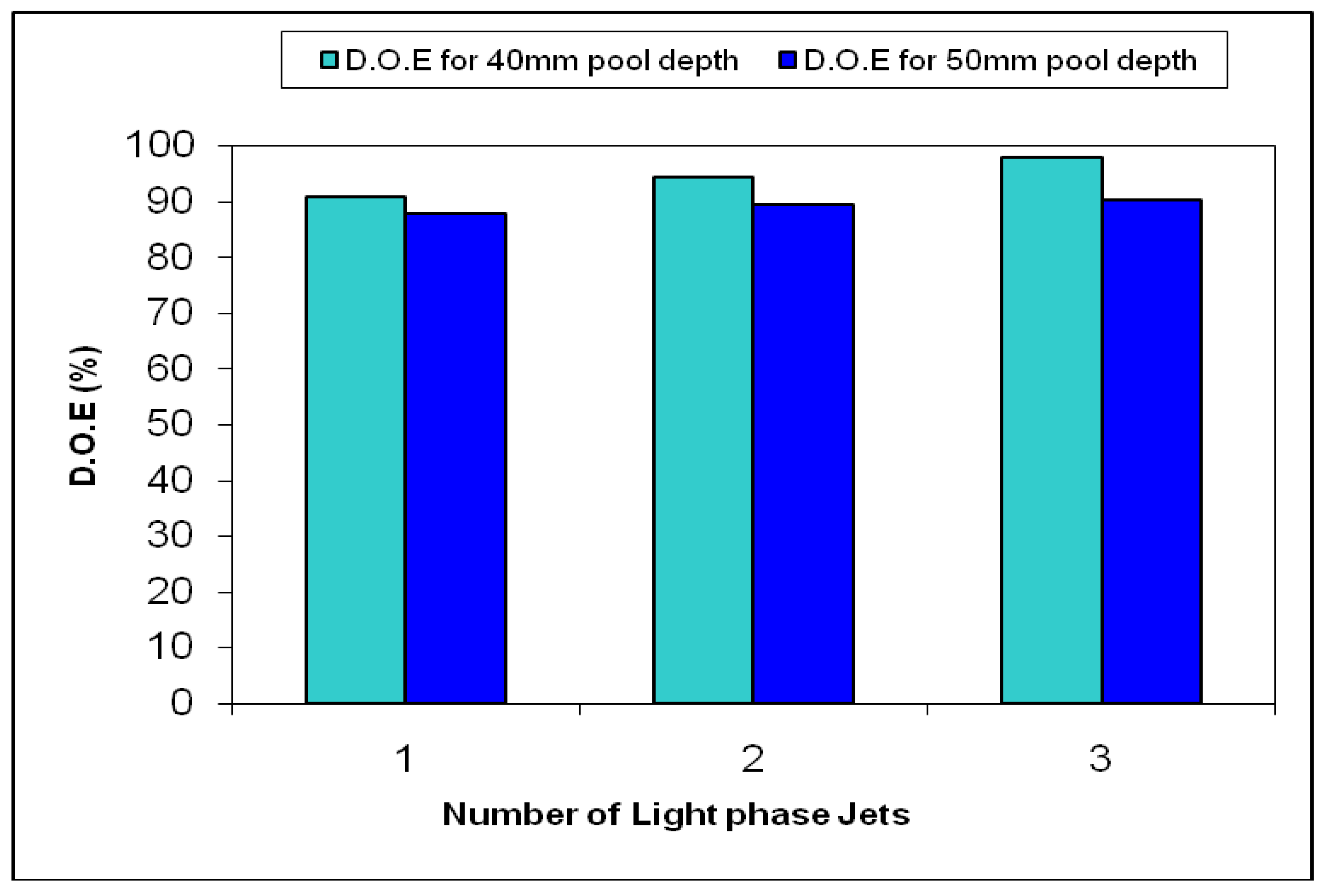

A more comprehensive comparison of the effect of number of light phase jets on the degree of extraction using 4 mm nozzle diameter at 40 mm and 50 mm pool depths with 12.5 cm inclined-plates position is shown in a bar chart given in

Figure 14. This explains that in the case of 50 mm pool depth and 4 mm nozzle diameter, the increase in the number of light phase jets does not have any significant effect on the degree of extraction. On the other hand, when the pool depth is kept at 40 mm, the degree of extraction increases with the addition of each light phase jet.

Figure 14.

Effect of number of light phase jets and pool depths on degree of extraction using 4 mm nozzle diameter at 40 mm and 50 mm pool depths, 12.5 cm IPP. Total operating time = 10 min.

Figure 14.

Effect of number of light phase jets and pool depths on degree of extraction using 4 mm nozzle diameter at 40 mm and 50 mm pool depths, 12.5 cm IPP. Total operating time = 10 min.

3.1. Hydraulic Power Consumption

The hydraulic power, which is the power input through the jet to attain a certain degree of extraction [

39] in the Inclined-plate contactor (h

IPES), can be computed using the following relation [

27,

32,

33,

40]:

The hydraulic power consumed per unit volume of extractor–separator can be calculated by using the following relation [

40]:

Table 2 given below illustrates the hydraulic power required while using optimum nozzle diameters corresponding to different pool depths.

Table 2.

Hydraulic power consumption for optimum conditions.

Table 2.

Hydraulic power consumption for optimum conditions.

| Nozzle diameter (mm) | Pool depth (mm) | DOE (%) | Number of Light Phase Jets | h/ IPES

kW/m3 |

|---|

| 4 | 40 | 98 | 3 | 0.059 |

| 5 | 50 | 100 | 3 | 0.12 |

From Equation 3, it is evident that the hydraulic power consumed is directly proportional to the product of volumetric flow rate to the distributor and the pressure reading at the distributor. On the other hand, in an agitator drive system the power consumed to achieve a certain degree of extraction is directly proportional to the third power of the RPM of the agitator [

41]. In a mixer settler, the whole of the contents of the mixing vessel are in motion, while in the case of the jet mixing system, only a small portion of the two phases near the jet is in motion. The conventional mixer settler operating at optimum conditions for the same EA-TCE-Water system, i.e., 400 rpm for 99% degree of extraction consumed 0.92 Kw/m

3 [

27]. The inclined plate extractor-separator reduced the whole operating time by 67% and achieved 100% extraction. The inclined plate extractor-separator consumes only 6.4% of the power and for 98 % (one percent less) degree of extraction in comparison to the 99% degree of extraction of the mixer-settler, whereas for a 100% degree of extraction (one percent above the mixer-settler’s optimum degree of extraction), the inclined plate extractor-separator utilizes only 13% of the power consumed by the mixer settler. Similarly, it was also found that the proposed inclined plates extractor-separator with 4 mm nozzle diameter, three light phase jets with 40 mm pool depth requires only 0.06 kW/m

3 hydraulic power in comparison to the 0.11 kW/m

3 used by the of a gullwing extractor-separator under optimum conditions (4 mm nozzle diameter, eight jets with 40 mm pool depth). The investigation showed that in the gullwing extractor-separator, two 65 mm diameter gull wings were nominated as optimum gull wings as far as the 99 % degree of extraction is concerned [

42], but the area of separation in this gullwing case was only 245.16 cm

2 in comparison to 464.52 cm

2 separation area of the inclined-plate, so the area of separation provided in the inclined plates extractor-separator is 89 percent larger than the area of the gullwing contactor on a per unit volume basis.