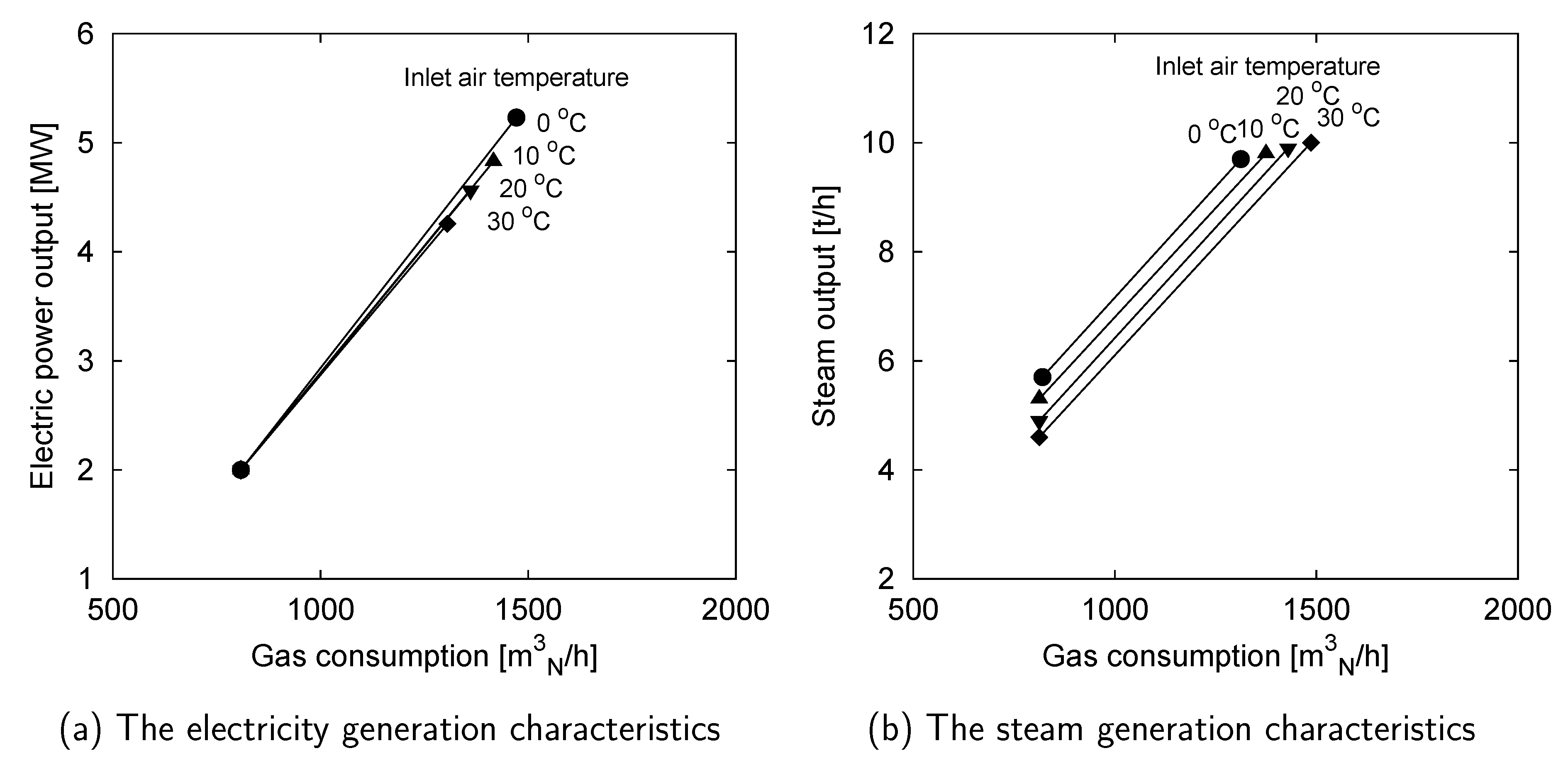

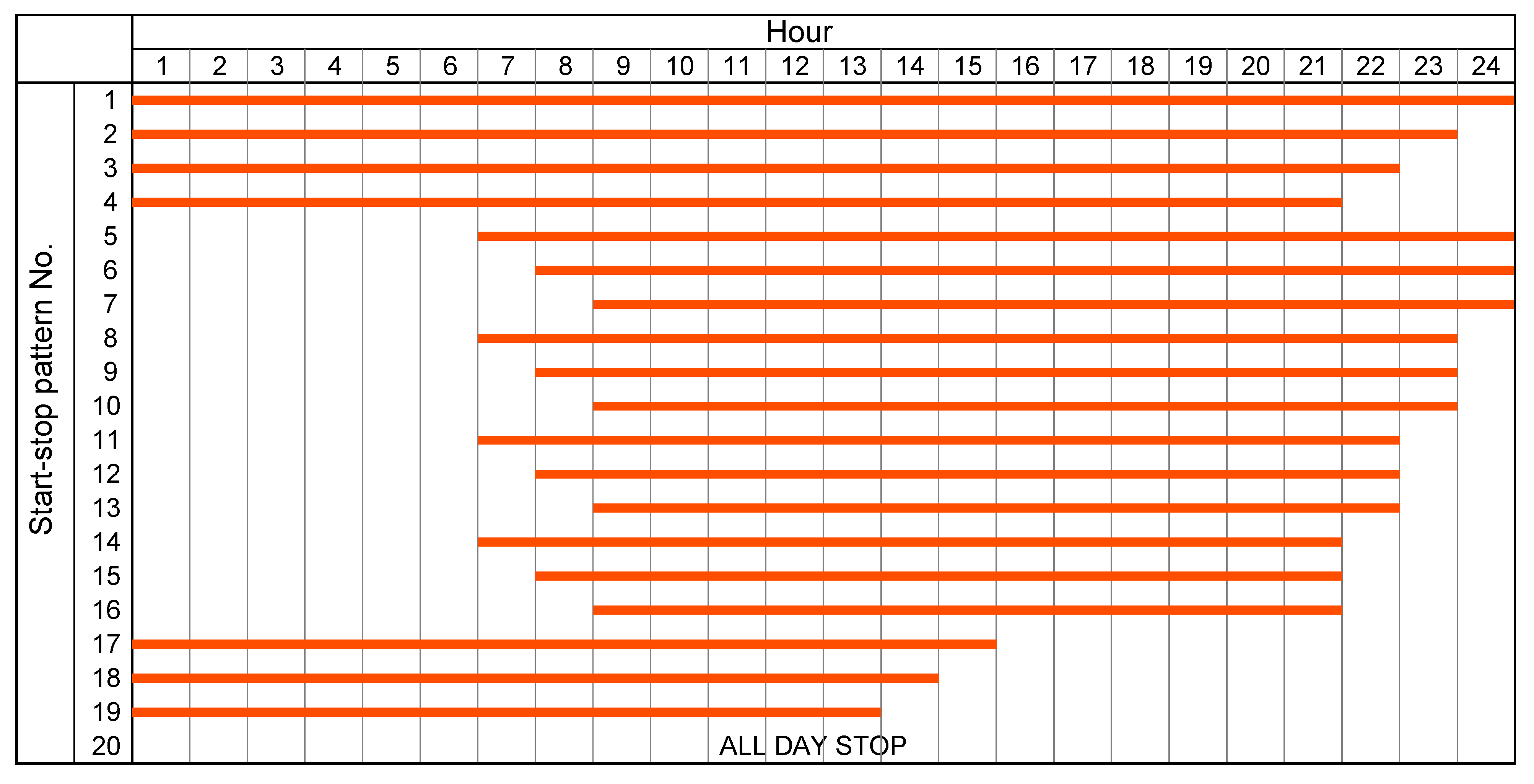

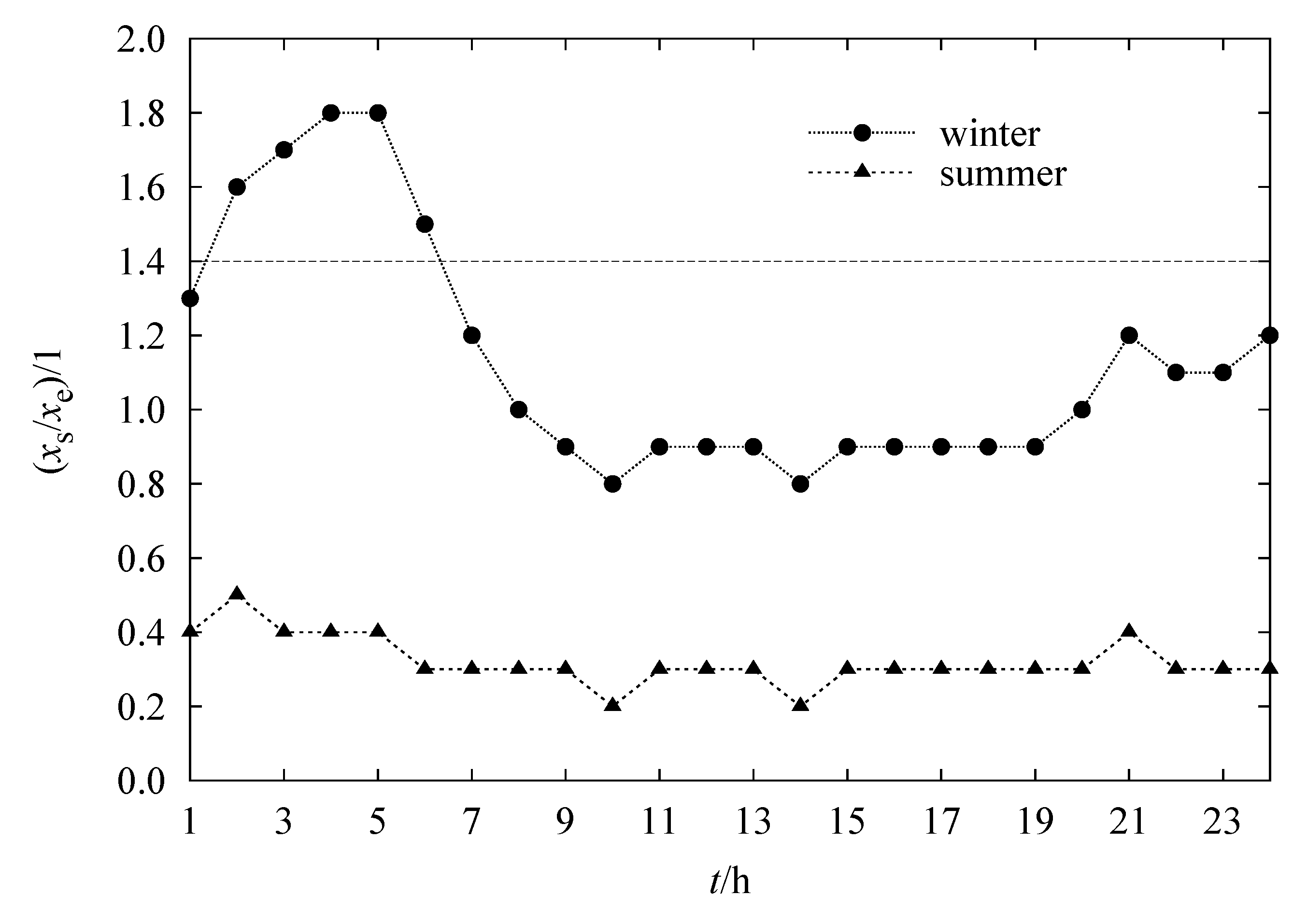

2.1. The Gas Turbine Cogeneration System Model

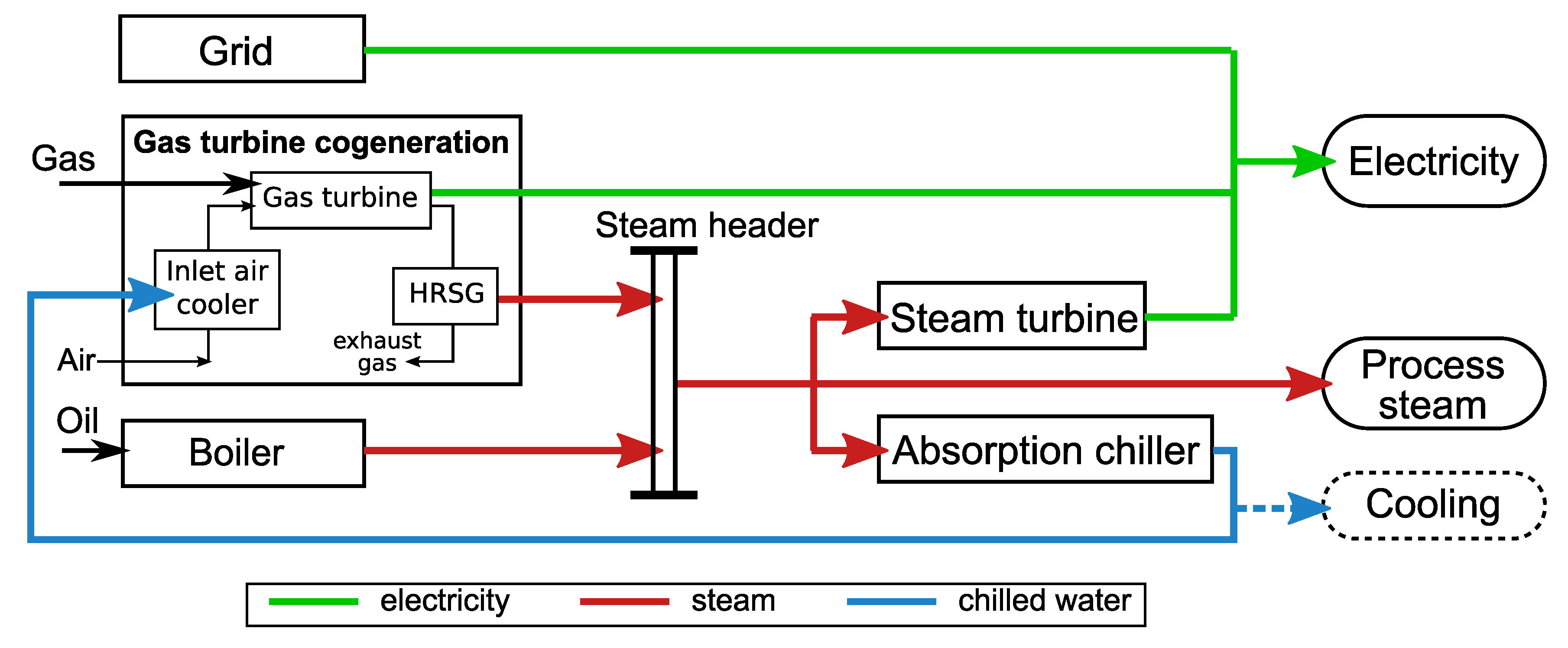

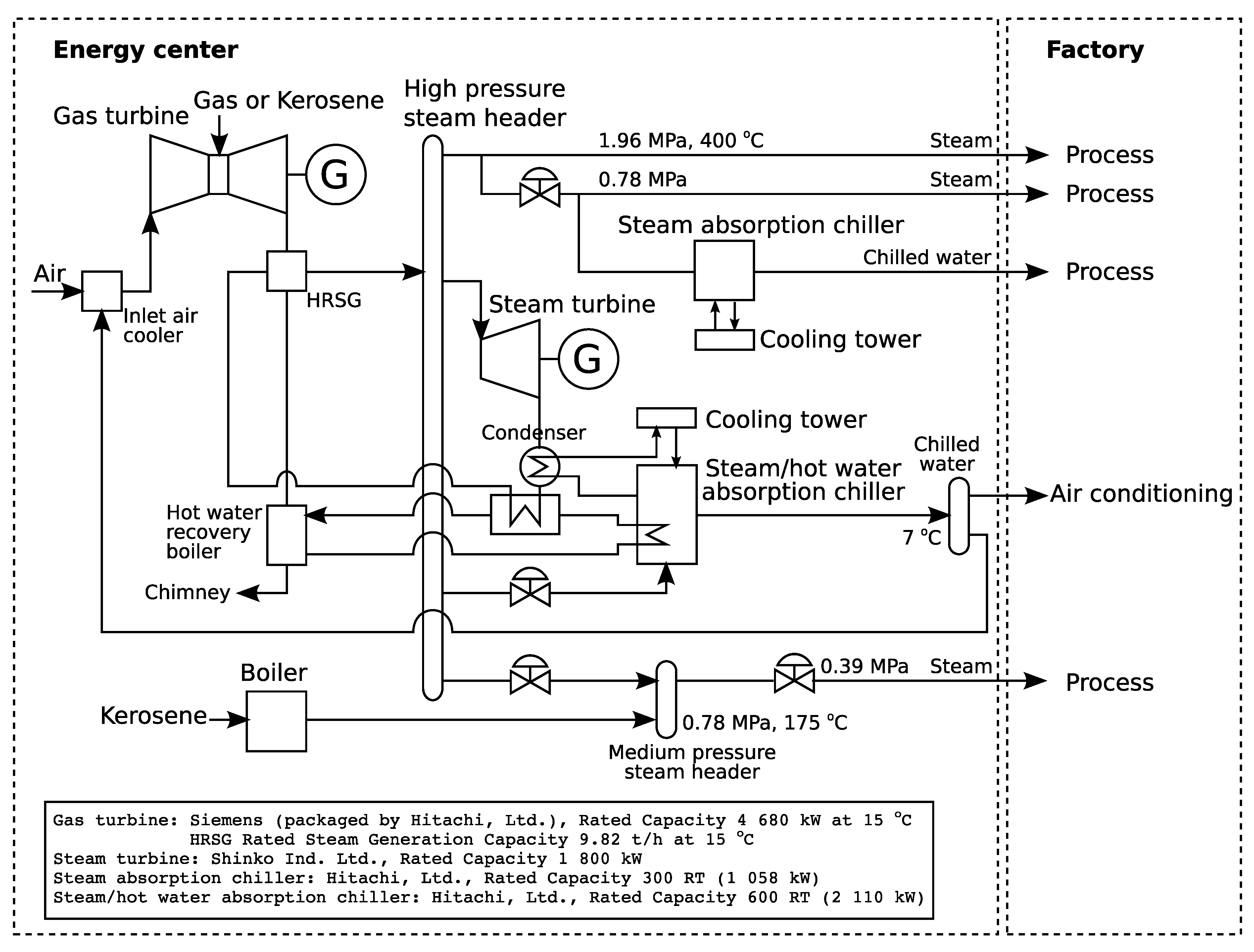

The gas turbine cogeneration system was expressed as a mathematical programming model. The system consisted of a gas turbine including an inlet air cooler and a heat recovery steam generator (HRSG), a steam turbine, an absorption chiller, a boiler and the electricity grid.

Figure 1 shows the energy flow of the system. Electricity, process steam, and cooling for process or for air-conditioning are typical demands in industry, and they can be provided by multiple suppliers. In the analysis, cooling demands other than for inlet air cooling were not taken into account, and therefore, the absorption chiller would work only to provide inlet air cooling of the gas turbine. The electricity was treated as the electric power in kilowatts, and the steam and the chilled water were treated as the heat flow rates in kilowatts so that the energy balance can be expressed in the same units.

Figure 1.

The energy flow of the simplified gas turbine cogeneration system with the turbine inlet air cooling.

Figure 1.

The energy flow of the simplified gas turbine cogeneration system with the turbine inlet air cooling.

The supplied electric power and heat flow rate of the steam should be greater than or equal to the demands, which can be expressed by Eqs. (

1-

2).

where,

and

represent the electric power demand and the heat flow rate of the steam demand. The electric power supply from the grid, the gas turbine and the steam turbine are denoted by

,

and

, respectively.

denotes the heat flow rate of steam from the boiler, and

denotes the heat flow rate of chilled water from the absorption chiller. The ratio of the heat flow rate of steam from the HRSG to the electric power from the gas turbine is denominated the steam to electricity ratio, and denoted by

. Then,

represents the heat flow rate of steam from the gas turbine cogeneration. The steam consumption ratios of the steam turbine and the absorption chiller are given as

and

, respectively. The former is equivalent to the inverse of the efficiency based on the steam input, and the latter is equivalent to the inverse of the coefficient of performance.

The inlet air cooling of the gas turbine enhances the maximum output from the gas turbine. By introducing the capacity of the gas turbine,

, the effect of the inlet air cooling was expressed by Eq. (

3).

It was assumed that the increment of the gas turbine capacity was proportional to the heat flow rate of chilled water supplied to the gas turbine. The proportional constant is denoted by .

In addition to the enhancement of the gas turbine capacity, the inlet air cooling improves the electric efficiency of the gas turbine. Provided that the improvement is proportional to the heat flow rate of chilled water to the gas turbine, the fuel consumption of the gas turbine can be expressed as , where is the fuel consumption ratio without the inlet air cooling and is the improvement factor of the fuel consumption by the inlet air cooling.

As the objective of the optimization is the minimization of the energy cost during a certain time period,

, the energy cost should be expressed as a function of

,

,

,

and

. By defining the unit energy prices of the electricity, gas and oil as

,

and

, respectively, the energy cost,

C, can be given as:

where, is the fuel consumption ratio of the boiler, which is equivalent to the inverse of the thermal efficiency.

All the parameters that represent the characteristics of equipment, such as , , , , , and , were assumed to be constant so that the system could be modeled by the linear programming. Therefore, the part load characteristics of equipment were linearly approximated.

2.2. The Mathematical Formulation and the Optimal Solution

From Eqs. (

1–

4), the optimization problem is formed as follows:

where,

. Using the Lagrange multipliers,

, the objective function can be expressed by the Lagrangian,

.

According to the Kuhn-Tucker conditions,

x and

λ satisfy the following conditions at the optimal solution.

The following inequalities are derived from Eq. (

10).

Equation (

11) means that

if the derived expression concerning the supplier

i satisfies the equality, otherwise,

. For example,

has a positive value if

equals

. If

is less than

, then

equals zero.

With regard to the constraint

, it is possible to classify the gas turbine operation into two conditions. The first one is the case where the electric power from the gas turbine is less than the capacity, which means

. The second one is the case where the electric power from the gas turbine is at the maximum, which means

. We denominate the former and the latter conditions the operational conditions I and II, respectively. Due to Eq. (

12) of the Kuhn-Tucker condition,

on the operational condition I, and

on the operational condition II.

2.3. The Optimal Solution where the Electric Power from the Gas Turbine is less than the Capacity

On the operational condition I where

, Eqs. (

14–

18) can be drawn on the

-

plane because

equals zero. The region surrounded by the inequalities gives the feasible solutions, and the output of the supplier

i has a positive value, i.e.

, when the solution exists on the line which represents the supplier

i.

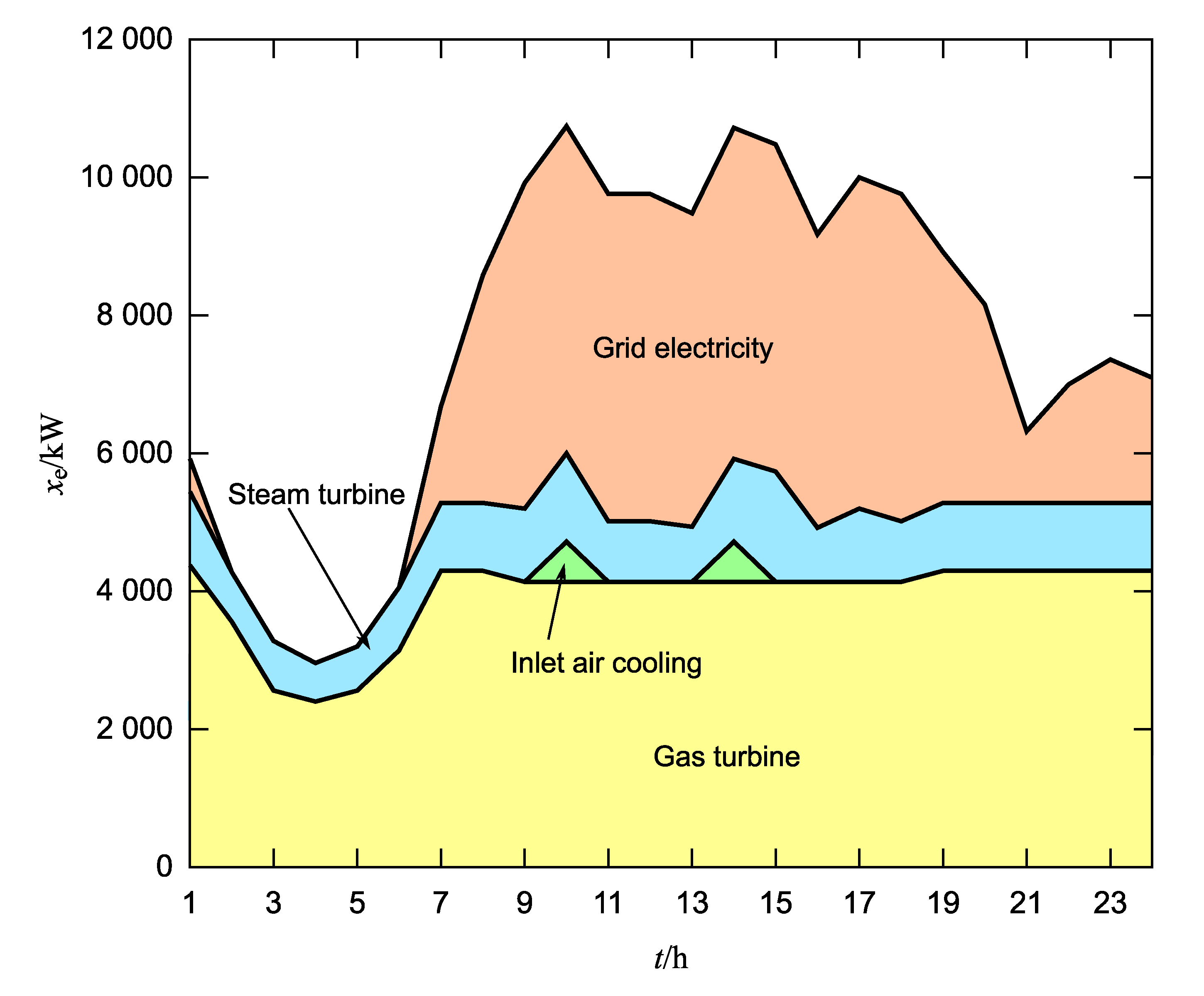

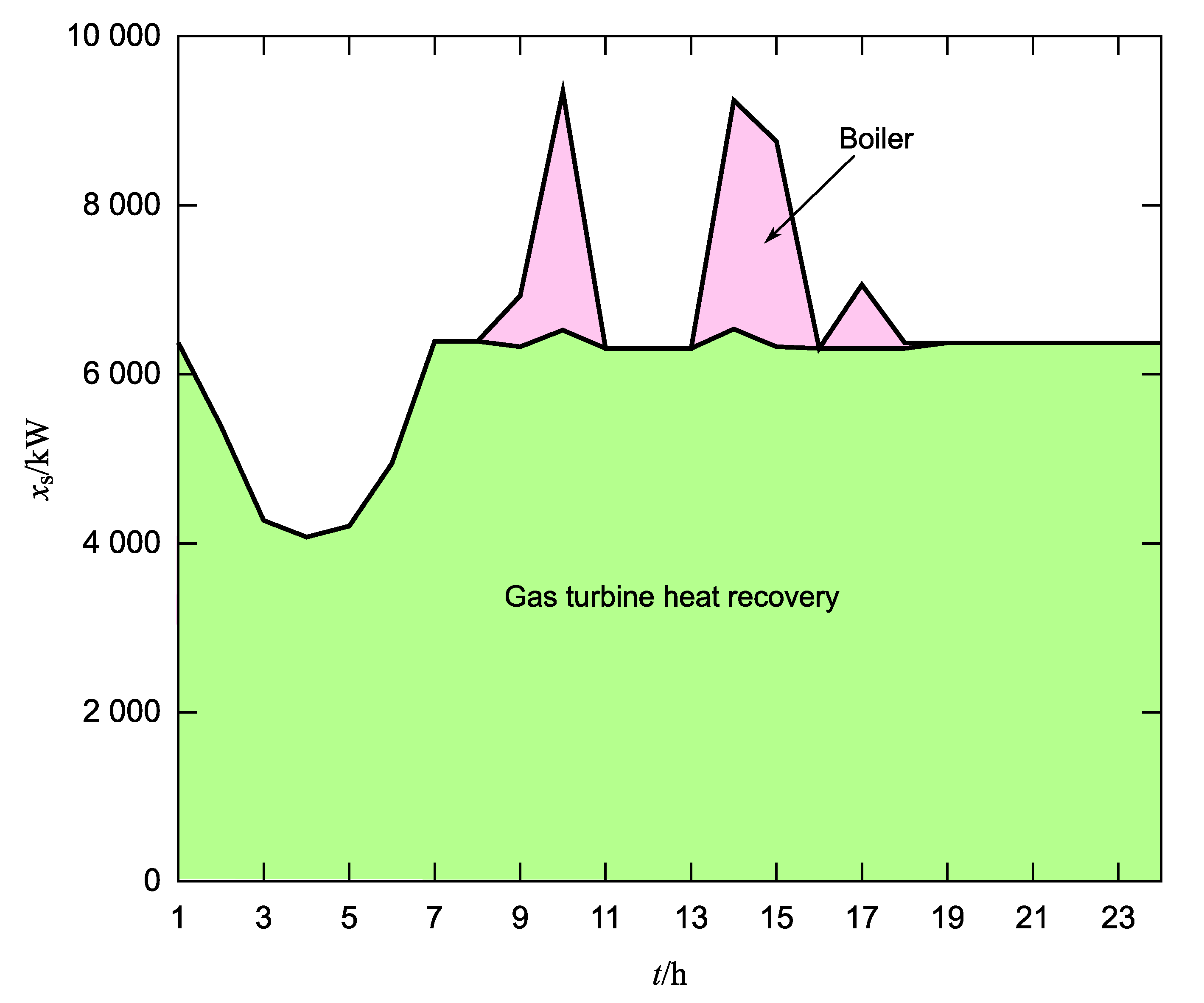

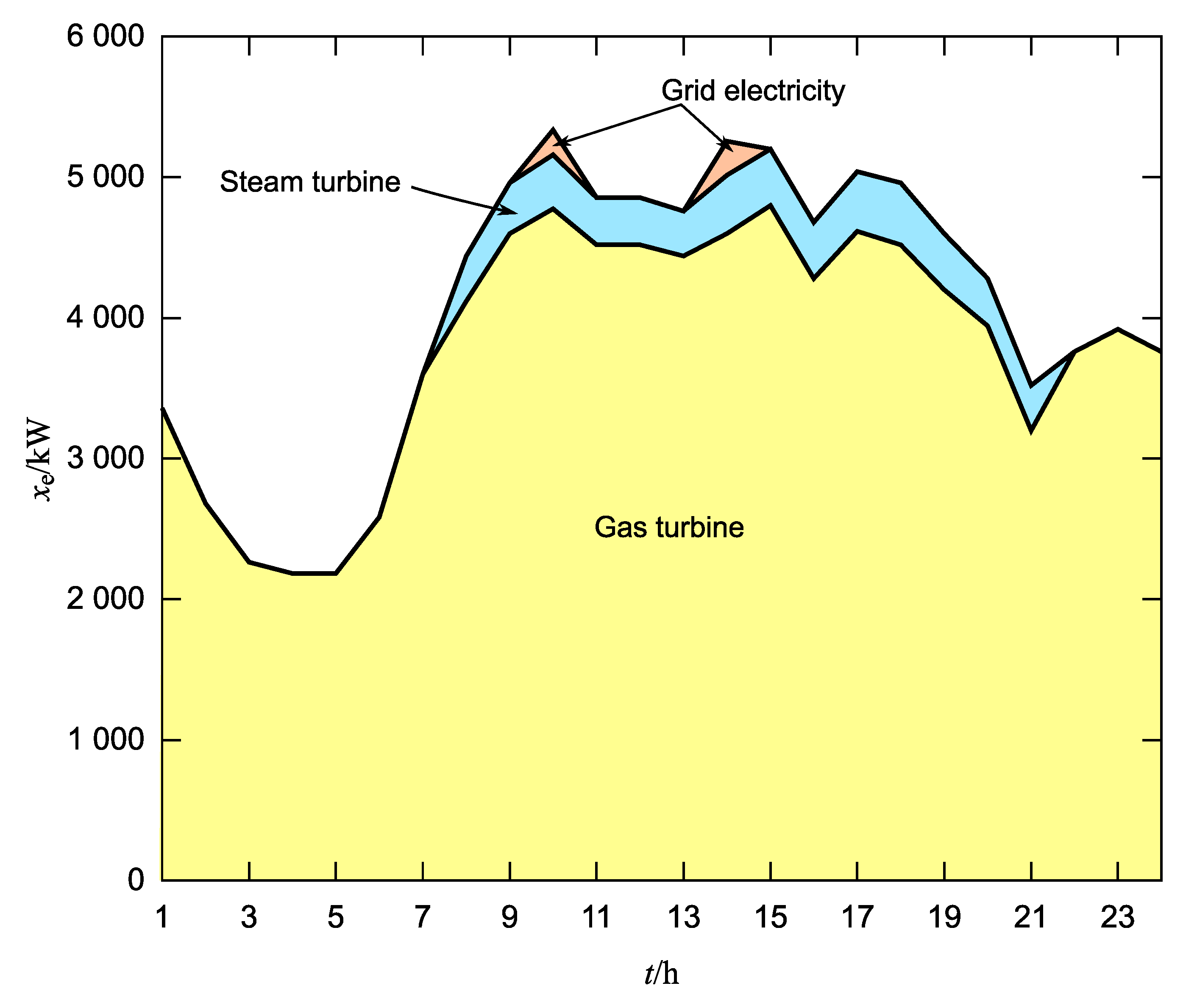

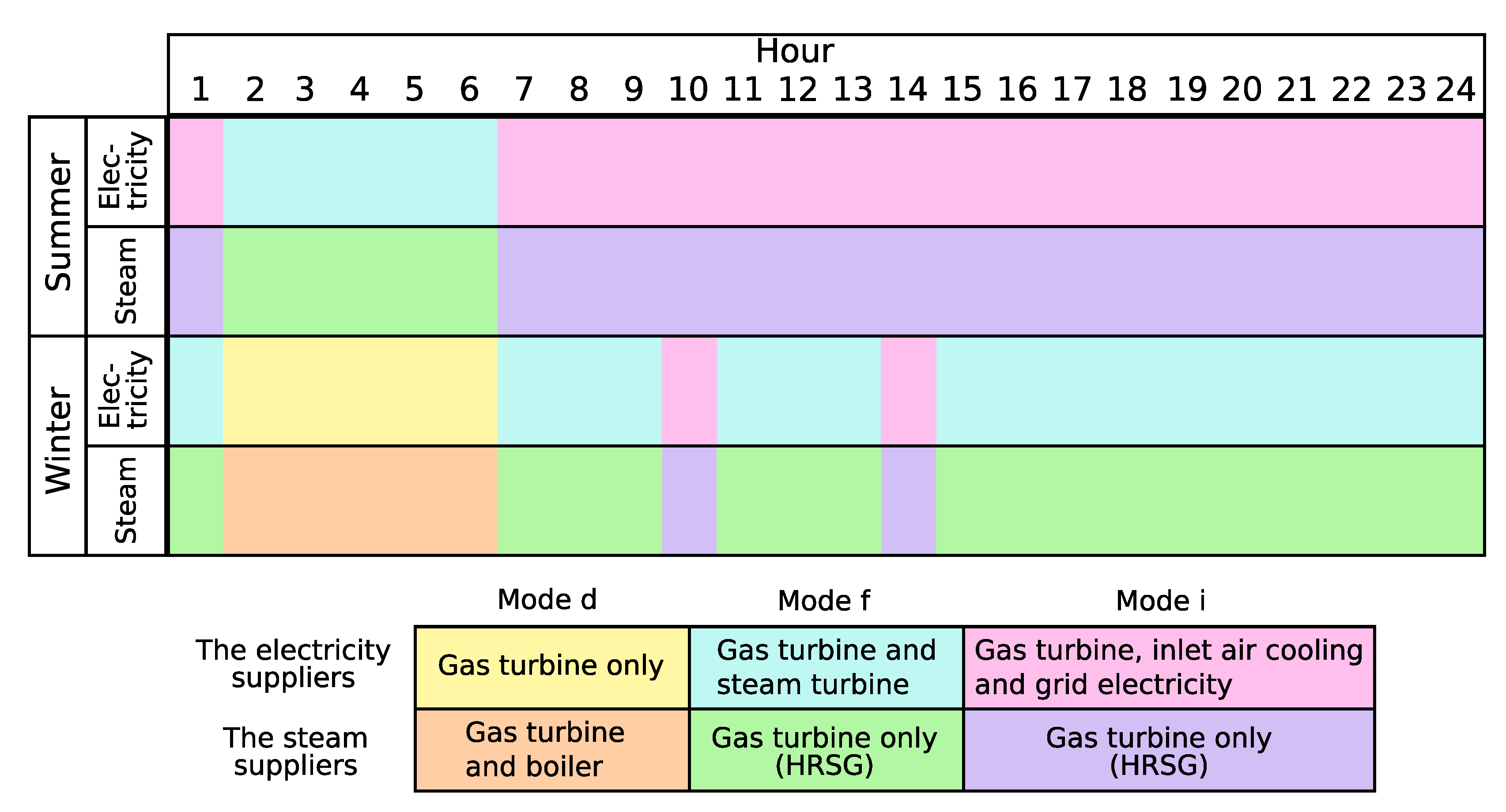

Figure 2 illustrates eight cases of the feasible solution region appeared on the

-

plane. The possible optimal solutions are marked as the operation modes “a" to “g". The mode a appears in the case A, where the grid electricity and the boiler are chosen at the optimal operation. In the mode b, the boiler and the steam turbine satisfy the electric power demand and the heat flow rate of the steam demand. After the case C, the electric power from the gas turbine is positive at the optimal operation. In the case C, the optimal operation is the gas turbine only (mode c), the combination of the gas turbine and the boiler (mode d) or the combination of the gas turbine and the grid electricity (mode e). In this case, the optimal operation will be chosen by the ratio of the heat flow rate of the steam demand to the electric power demand, which will be discussed later. When the line which represents the boiler does not cross the gas turbine line in the first quadrant, which is the case C’, only the modes c and e appear as the possible optimal solutions. The modes f and g appear in the cases D and E, respectively. The suppliers chosen at each mode are summarized in

Table 1.

Table 1.

The combination of suppliers at each mode.

Table 1.

The combination of suppliers at each mode.

| Mode | Grid | Boiler | Gas Turbine | Steam Turbine | Absorption Chiller |

|---|

| a | ⊠ | ⊠ | □ | □ | □ |

| b | □ | ⊠ | □ | ⊠ | □ |

| c | □ | □ | ⊠ | □ | □ |

| d | □ | ⊠ | ⊠ | □ | □ |

| e | ⊠ | □ | ⊠ | □ | □ |

| f | □ | □ | ⊠ | ⊠ | □ |

| g | □ | □ | ⊠ | □ | ⊠ |

| h | □ | ⊠ | ⊠ | □ | ⊠ |

| i | ⊠ | □ | ⊠ | □ | ⊠ |

| j | □ | □ | ⊠ | ⊠ | ⊠ |

The cases A through E will occur depending on the performance parameters of the suppliers and the unit energy prices. The conditions of each case can be obtained from the graphical analysis. For example, the case A occurs if

at the intersection of G and B is smaller than that at the intersection of GT and B, and is smaller than that at the intersection of ST and B. In addition, the line B has to be located above the line AC so that the feasible solution region exists. Then, the following conditions can be derived.

Equation (

19) means that the gas cost to produce a certain quantity of electricity and steam with the gas turbine is higher than the total of the electricity and oil costs to purchase the same quantity of electricity from the grid and to produce the same quantity of steam with the boiler. Equation (

20) means that the electricity cost to purchase a certain quantity of electricity is cheaper than the oil cost to produce the same quantity of electricity using the boiler and the steam turbine. Equation (

21) indicates that the reduction of the gas cost by a certain quantity of the inlet air cooling should be smaller than the oil cost to provide the same quantity of cooling using the boiler and the absorption chiller. Otherwise, the optimal solution does not exist because the reduction of the gas cost is unlimited by the inlet air cooling using the absorption chiller driven by the boiler.

Figure 2.

The possible cases of the optimal solution on the operational condition I.

Figure 2.

The possible cases of the optimal solution on the operational condition I.

Similarly, the following conditions can be derived for the other cases. The condition given as Eq. (

21) has to be applied to all the cases below.

Equation (

22) compares the production cost of the electricity and the steam between the gas and the oil. The gas cost to produce a certain quantity of electricity and steam by the gas turbine is higher than the oil cost to produce the same quantity of electricity and steam by the combination of the boiler and the steam turbine. Equation (

23) is the opposite of Eq. (

20), which means that the oil cost to produce a certain quantity of electricity by the boiler and the steam turbine is cheaper than the purchase price of electricity.

Equation (

24) is the opposite case of Eq. (

19). Equation (

25) compares the boiler and the gas turbine regarding the steam production, which is related to the mode d. In the case C, the oil cost for the boiler is cheaper than the gas cost for the gas turbine to produce a certain quantity of steam. If the gas cost is cheaper, mode d is not a candidate for the optimal solution, as illustrated in the case C’. Equations (

26) and (

27) evaluate the effectiveness of the steam turbine and the inlet air cooling by the absorption chiller, respectively. The grid electricity is superior to the steam turbine and to the inlet air cooling in this case.

Case D:

Similarly to the case C’, the case D’ occurs if the inequality sign of Eq. (

25) is reversed. Equation (

28) is the opposite case of Eq. (

22), which is the comparison of the electricity production between gas and oil. Equation (

29) is the opposite case of Eq. (

26), which is the comparison of the steam turbine and grid electricity. The gas cost to produce a certain quantity of electricity by the combination of the gas turbine and the steam turbine is cheaper than the purchase cost of the same quantity of electricity from the grid. Equation (

30) gives the condition where the steam turbine is more advantageous than the inlet air cooling by the absorption chiller. The left hand side of Eq. (

30) represents an additional steam required for a certain quantity of electricity production by the inlet air cooling. Therefore, Eq. (

30) insists that the steam required for a certain quantity of electricity production by the steam turbine is smaller than that required for the same quantity of electricity production by the inlet air cooling in this case, and it is independent of energy prices.

Case E:

The case E’ occurs if Eq. (

25) is reversed. Equations (

31) and (

32) are the opposite cases of Eqs. (

27) and (

30), which give the conditions where the inlet air cooling is more advantageous compared with the alternative technologies. In this case, Eq. (

28) is always satisfied because of Eqs. (

21) and (

32).

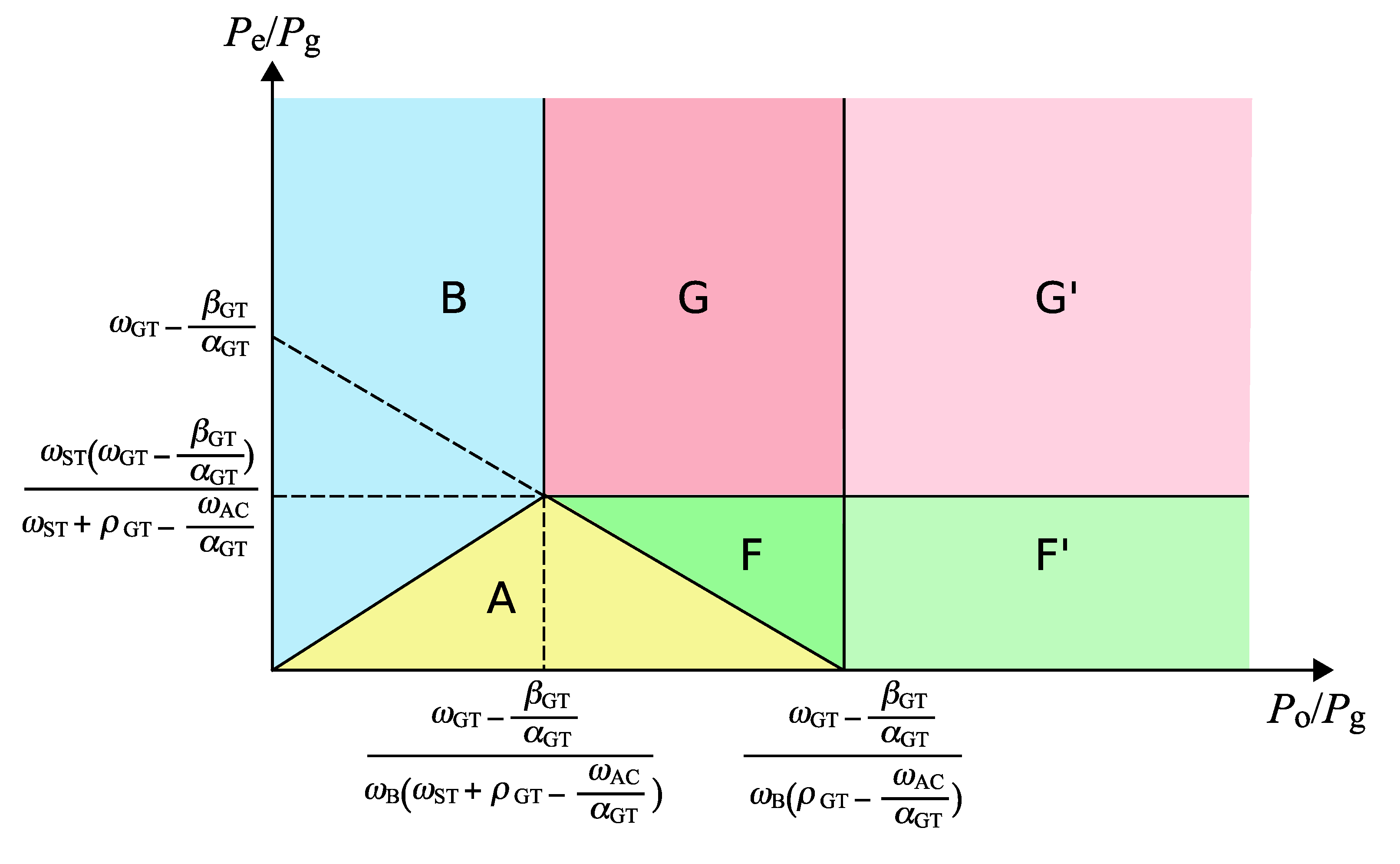

The conditions discussed above can be arranged using the relative electricity price,

and the relative oil price,

. The optimal cases to be chosen are graphically shown in

Figure 3 on the

-

plane. When Eq. (

30) is valid,

Figure 3 (a) should be applied. The inlet air cooling is not an optimal option in any case. When Eq. (

32) is valid, the cases E and E’ appear on the plane and the steam turbine is never chosen, as depicted in

Figure 3 (b). It is noteworthy that if the inlet air cooling cannot improve the gas turbine efficiency, i.e.

, the inlet air cooling is never the optimal solution.

As the cases C, D and E include three operation modes, another criterion for the selection of the optimal operation mode is necessary in those cases. The additional criterion is related with the steam to electricity ratio, and can be derived from the consideration below.

In the cases C, D and E,

and

have positive values. Therefore, two of the constraints given as Eqs. (

6) and (

7) take the equality conditions due to the Kuhn-Tucker condition Eq. (

12). Then, the two equations can be solved simultaneously for two variables which have positive values at each mode.

For the mode d, the simultaneous equations can be solved under

and

. Then, one can obtain

and

. Because

has a positive value, the following condition has to be satisfied for the mode d to be selected.

At the mode e, one can obtain

and

, and the following condition can be drawn out of the former expression because

is greater than zero at this mode.

Similar considerations can be applied to the cases D and E. Consequently, Eq. (

33) is the condition for the mode d to be selected, while Eq. (

34) is the condition for the modes e, f or g to be selected. Furthermore, it is obvious that the mode c has to be chosen if the steam to electricity ratio of the gas turbine is equal to the ratio of the heat flow rate of the steam demand to the electric power demand, i.e.

.

Equations (

33) and (

34) mean that when the steam to electricity ratio of the gas turbine is smaller than the ratio of the heat flow rate of the steam demand to the electric power demand, the gas turbine should be operated to meet the electric power demand. Then, the boiler should balance the heat flow rate of the steam supply with the demand. On the other hand, if the steam to electricity ratio of the gas turbine is larger than the ratio of the heat flow rate of the steam demand to the electric power demand, the gas turbine has to be operated to meet the heat flow rate of the steam demand. Then, the insufficient electric power supply from the gas turbine has to be compensated by either the grid (mode e), the steam turbine (mode f), or the inlet air cooling (mode g). There is no need of any auxiliary equipment to supply additional electric power or steam if the steam to electricity ratio of the gas turbine matches the demands.

Figure 3.

The optimal operation cases expressed on the relative oil price-relative electricity price plane (the operational condition I).

Figure 3.

The optimal operation cases expressed on the relative oil price-relative electricity price plane (the operational condition I).

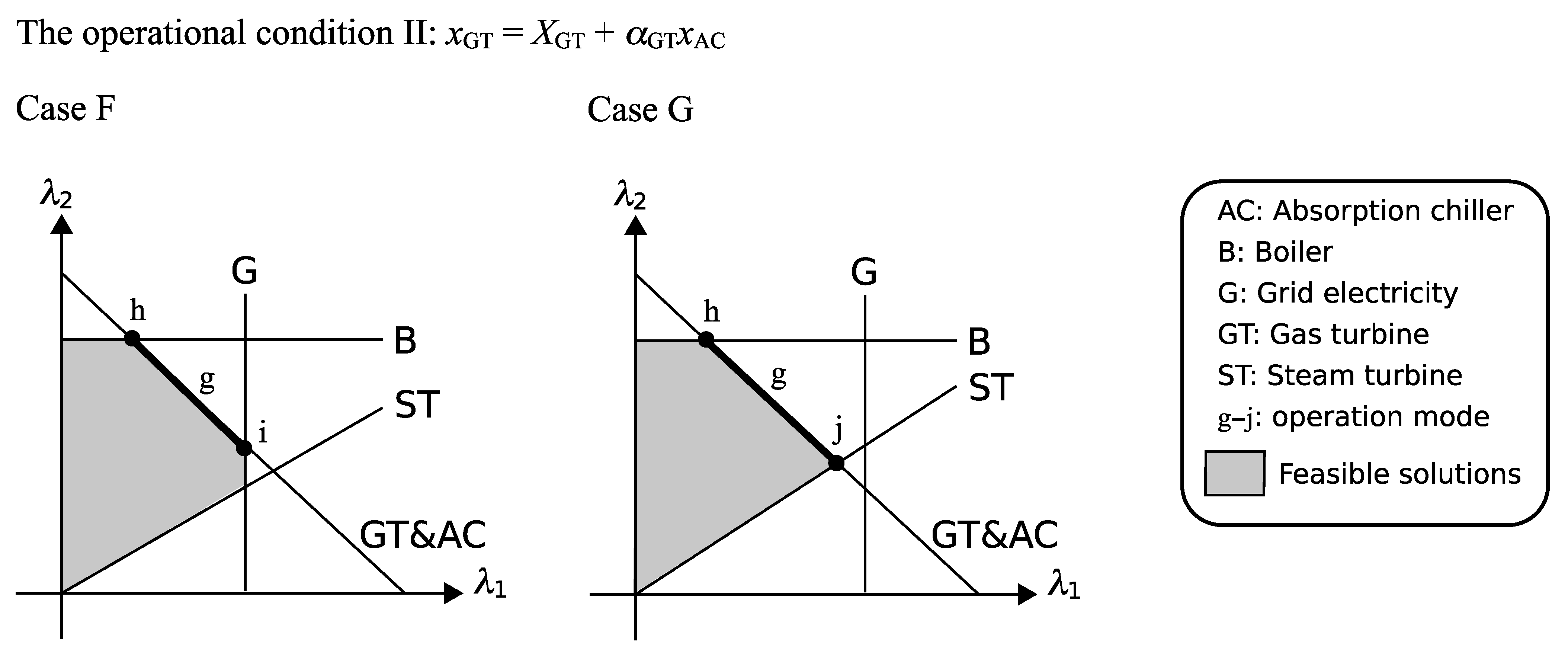

2.4. The Optimal Solution where the Electric Power from the Gas Turbine is at the Maximum

In the operational condition II, the third constraint, Eq. (

8), takes the equality condition and

would have a positive value. Then, Eqs. (

15) and (

18) yields:

It is reasonable to assume that

and

in the case of gas turbine cogeneration systems because of relatively low electric efficiency (≈ 25 %) and a high heat to electricity ratio (

). Then, the optimal solution cases can be defined by a similar consideration to the operational condition I, and the newly appeared cases are illustrated in

Figure 4. The cases F and G can occur in the operational condition II in addition to the cases A and B of the operational condition I. Similarly to the cases C’ and D’ of the operational condition I, the cases F’ and G’ can be defined where the mode h is excluded from the cases F and G, respectively.

Figure 4.

The optimal solution cases on the operational condition II.

Figure 4.

The optimal solution cases on the operational condition II.

In the operational condition II, the conditions of the cases A and B are slightly different from those in the operational condition I, as given below.

The conditions for the cases F and G are obtained as follows.

Case G:

The cases F’ and G’ occur when the inequality sign of Eq. (

41) is reversed. Equations (

36), (

38), (

40), (

41), (

42), (

43) and (

44) correspond to Eqs. (

19), (

22), (

24), (

25), (

26), (

28) and (

29), respectively. In these equations,

is substituted for

, and

is substituted for

.

The optimal cases of the operational condition II are illustrated on the

-

plane as shown in

Figure 5. Unlike the operational condition I, there is no lower limit of the relative oil price for the optimal solution to exist. The line separating the cases F and G is determined by the multiple parameters. Basically, a larger

or a smaller

lowers the line, which causes a higher possibility for the case G to be selected.

Figure 5.

The optimal operation cases expressed on the relative oil price-relative electricity price plane (the operational condition II).

Figure 5.

The optimal operation cases expressed on the relative oil price-relative electricity price plane (the operational condition II).

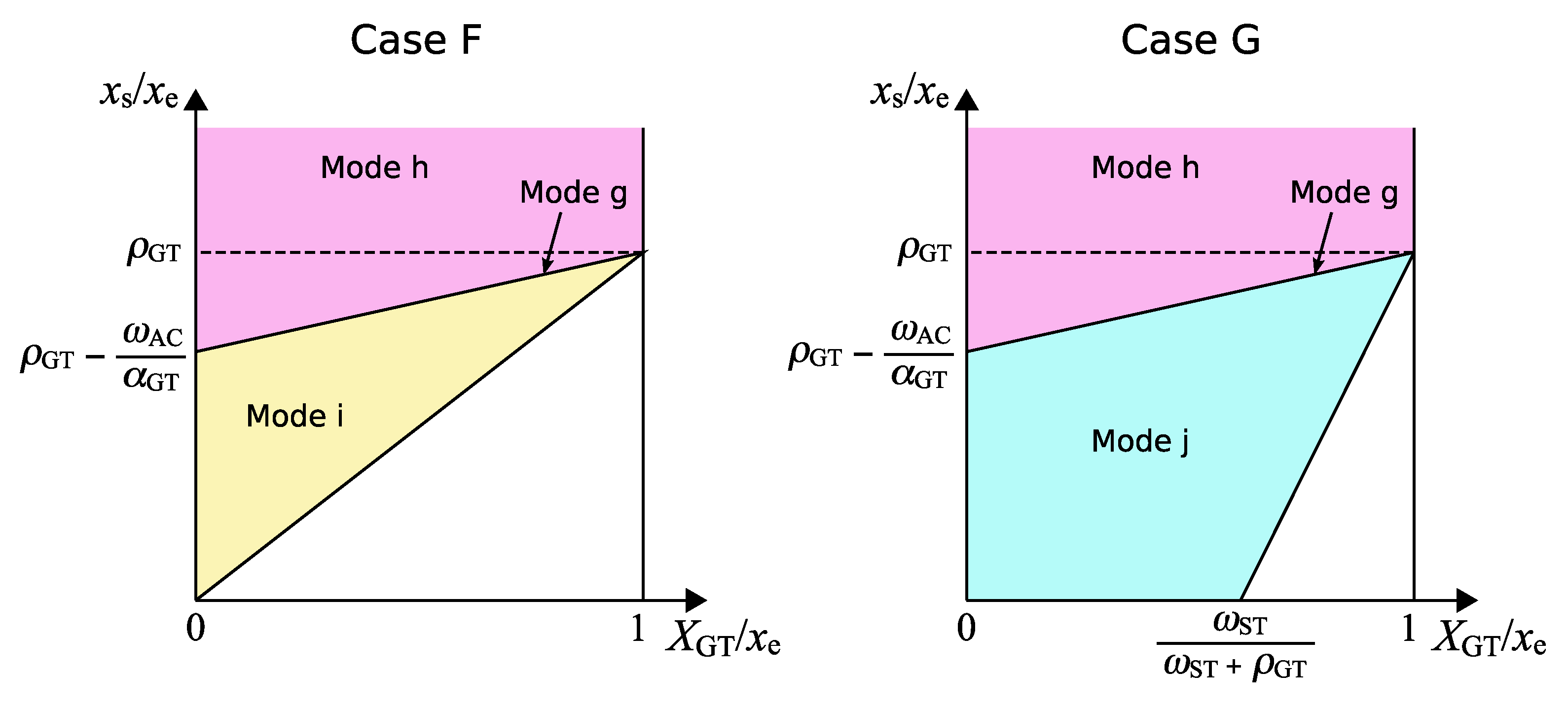

To find the optimal mode out of three operation modes included in the cases F or G, another strategy is necessary. The additional conditions can be found by a similar examination on the variables to that done for the cases C, D and E. In the operational condition II, three variables can be analytically solved by the constraints given as Eqs. (

6), (

7) and (

8) taking equality conditions.

In the mode g, only two variables,

and

, are positive and the other variables are equal to zero. Therefore, the analytical solutions of those in the operational condition II can be obtained from equations derived from Eqs. (

6) and (

7) as

and

. Then the third constraint gives the equality condition concerning

and

as follows:

where,

represents the ratio of the gas turbine capacity to the electricity demand, and

.

For mode h, the condition where this mode should be selected is derived from the analytical solution of

with

as follows:

For the mode i,

and

give the following two conditions.

For the mode j,

and

give the following conditions.

The conditions given as Eqs. (

45–

50) are graphically shown in

Figure 6. In the cases F and G, the operational condition II cannot be applied to the region of

and

, respectively, because

becomes negative in this region. The optimal operation should be found under the operational condition I in this region.