Analysis of the Pelletability of Vegetable Crop Foliage Using a Commercial Flat Die Pellet Mill

Abstract

1. Introduction

2. Objectives

3. Material and Methods

3.1. Sample Preparation and Infeed Material Characterization

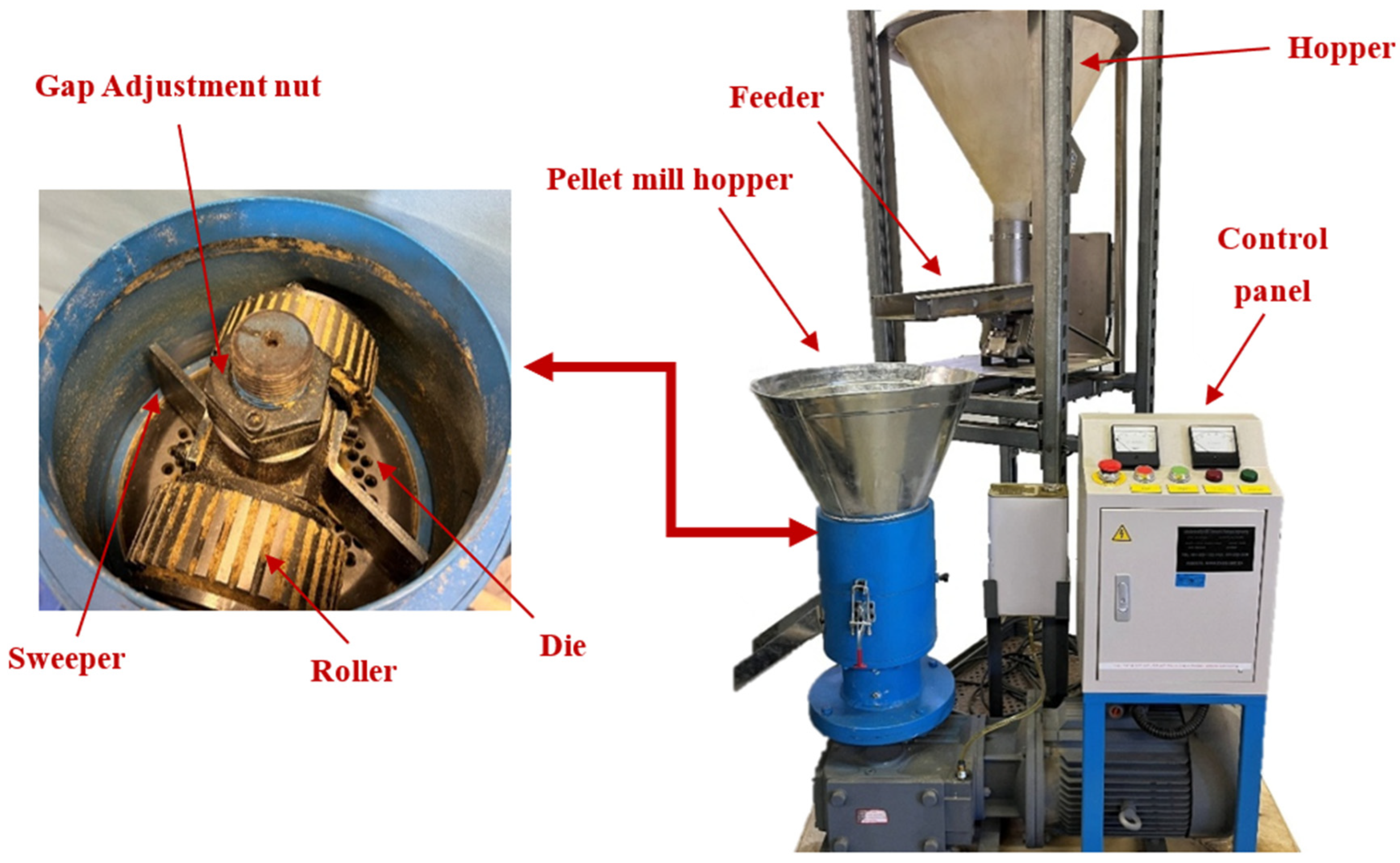

3.2. Pelletization

3.3. Pelletization Energy Consumption

3.4. Pellet Color Index

3.5. Bulk Density

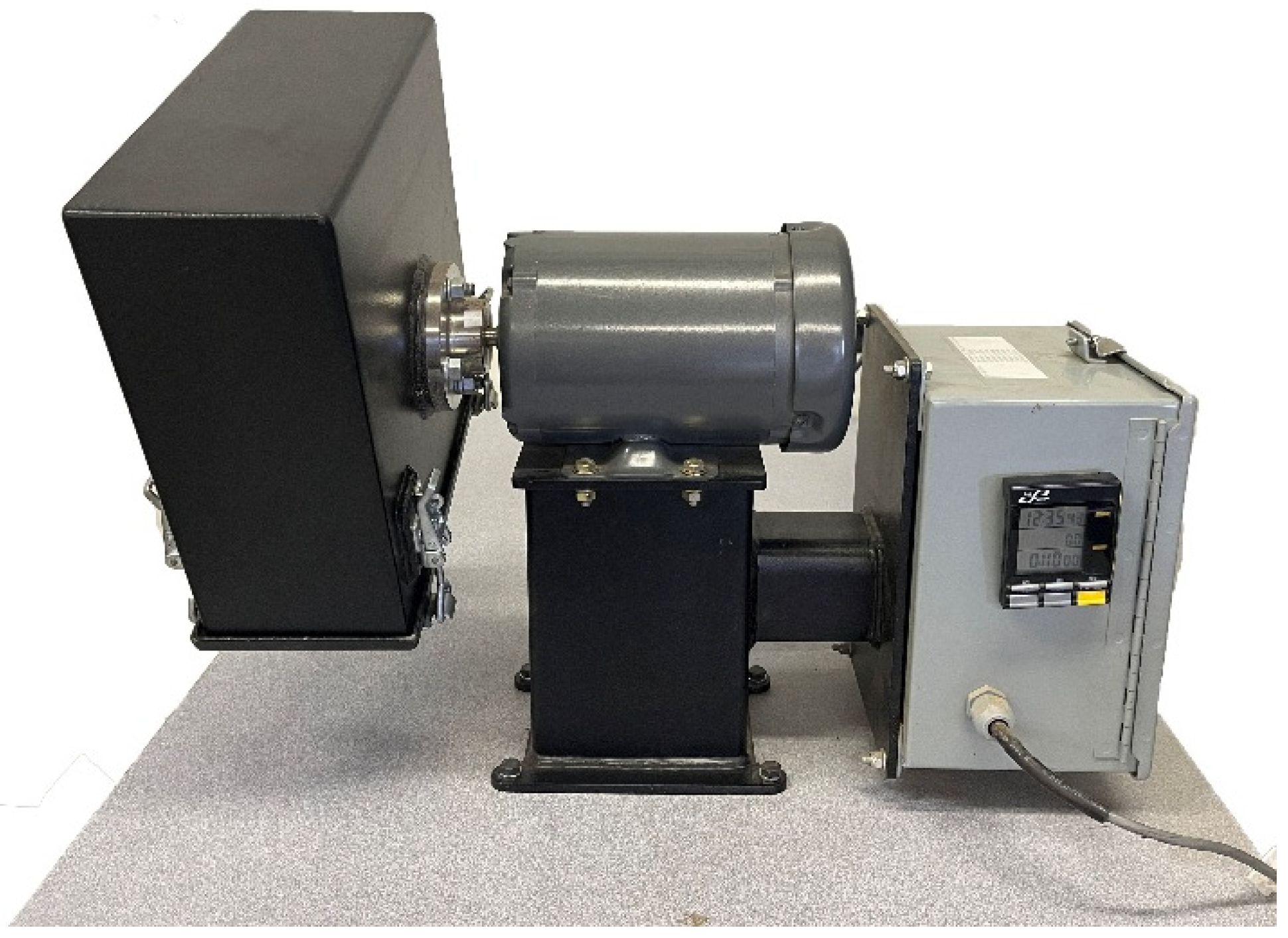

3.6. Bulk Durability Index

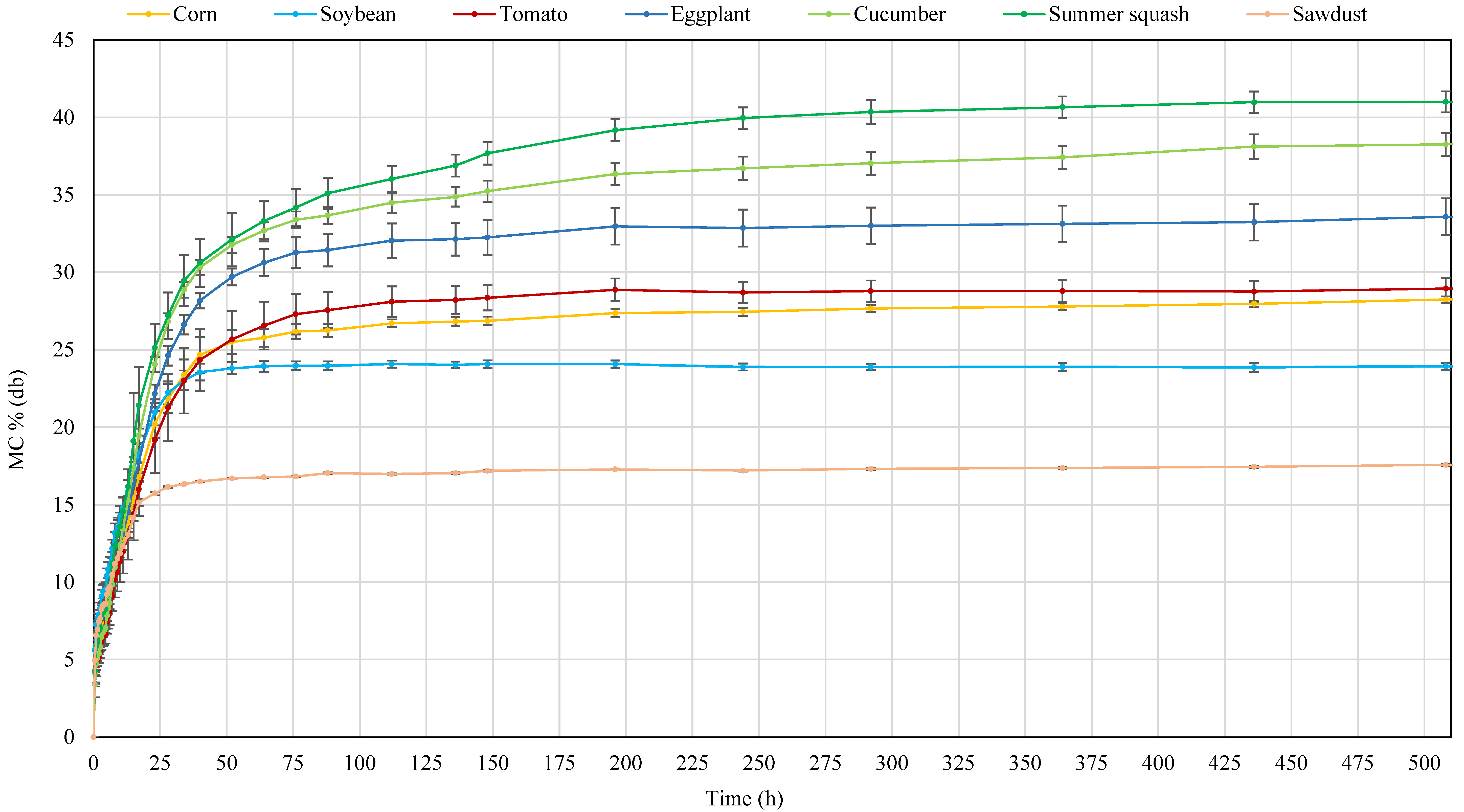

3.7. Pellet Moisture Uptake

4. Results and Discussion

4.1. Color Index Parameters

4.2. Pelletization Energy

4.3. Pellet Quality Analysis: Bulk Density and Bulk Durability

4.4. Pellet Moisture Uptake Analysis

4.5. Mathematical Modelling of Pellet Bulk Density and Bulk Durability

5. Conclusions

- Successful batch-scale pellet production was achieved for six types of biomasses, demonstrating the viability of greenhouse crop residues as a sustainable feedstock for bioenergy applications.

- Biomass composition significantly impacted pellet density, durability, color properties, and moisture uptake. Higher lignin content contributed to improved pellet cohesion, while ash content influenced moisture absorption and combustion properties.

- Net specific pelletization energy consumption (NSPEC) varied across feedstocks, with cucumber (21.8 kWh/t) and summer squash (18.7 kWh/t) exhibiting the lowest energy requirements, while soybean (49.6 kWh/t) and sawdust (47.3 kWh/t) required the most energy due to higher resistance to densification.

- Cucumber and summer squash produced the most compact and durable pellets, with bulk density exceeding 665 kg/m3 and durability above 96%, making them ideal candidates for long-term storage and transportation.

- Sawdust exhibited the lowest moisture absorption (16–18% db) due to its high lignin content, while cucumber and summer squash had the highest moisture uptake (38–41% db), making them more susceptible to humidity related degradation.

- A predictive model was developed to relate single-pellet density and durability to bulk pellet properties, providing a scalable framework for optimizing industrial pellet production.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| MC | Moisture Content |

| GCV | Gross Calorific Value |

| AC | Ash Content |

| PSD | Particle Size Distribution |

| D50 | 50% of the particles have diameter less than the specific amount |

| W | Width |

| L | Length |

| A | Area |

| P | Perimeter |

| AR | Aspect Ratio |

| Deq | Equivalent Diameter |

| BDe | Pellet Bulk Density |

| BDu | Pellet Bulk Durability |

| TD | Biomass True Density |

| BD | Biomass Bulk Density |

| SPDe | Single Pellet Density |

| SPDu | Single Pellet Durability |

| TPEC | Total Pelletization Energy Consumption |

| PMEC | Pellet Mill Energy Consumption |

| NPEC | Net Pelletization Energy Consumption |

| NSPEC | Net Specific Pelletization Energy Consumption |

References

- Raza, M.H.; Abid, M.; Faisal, M.; Yan, T.; Akhtar, S.; Mehedi Adnan, K.M. Environmental and Health Impacts of Crop Residue Burning: Scope of Sustainable Crop Residue Management Practices. Int. J. Environ. Res. Public Health 2022, 19, 4753. [Google Scholar] [CrossRef] [PubMed]

- Choudhary, R.; Lenka, S.; Yadav, D.K.; Lenka, N.K.; Kanwar, R.S.; Sarkar, A.; Saha, M.; Singh, D.; Adhikari, T. Impact of Crop Residue, Nutrients, and Soil Moisture on Methane Emissions from Soil under Long-Term Conservation Tillage. Soil Syst. 2024, 8, 88. [Google Scholar] [CrossRef]

- Vincevica-Gaile, Z.; Zhylina, M.; Shishkin, A.; Ansone-Bertina, L.; Klavins, L.; Arbidans, L.; Dobkevica, L.; Zekker, I.; Klavins, M. Selected Residual Biomass Valorization into Pellets as a Circular Economy-Supported End-of-Waste. Clean. Mater. 2025, 15, 100295. [Google Scholar] [CrossRef]

- Civitarese, V.; Del Giudice, A.; Acampora, A.; Fischetti, E.; Gasperini, T.; De Francesco, C.; Toscano, G.; Scarfone, A. Combustion of Pelletized Coffee Residues for Bioenergy Valorization Within a Circular Economy Vision. Energies 2024, 17, 5875. [Google Scholar] [CrossRef]

- Ufitikirezi, J.D.D.M.; Filip, M.; Ghorbani, M.; Zoubek, T.; Olšan, P.; Bumbálek, R.; Strob, M.; Bartoš, P.; Umurungi, S.N.; Murindangabo, Y.T.; et al. Agricultural Waste Valorization: Exploring Environmentally Friendly Approaches to Bioenergy Conversion. Sustainability 2024, 16, 3617. [Google Scholar] [CrossRef]

- Peng, J.H.; Bi, H.T.; Lim, C.J.; Sokhansanj, S. Study on Density, Hardness, and Moisture Uptake of Torrefied Wood Pellets. Energy Fuels 2013, 27, 967–974. [Google Scholar] [CrossRef]

- Ray, A.; Li, C.; Thompson, V.; Daubaras, D.; Nagle, N. Biomass Blending and Densification: Impacts on Feedstock Supply and Biochemical Conversion Performance; IntechOpen: London, UK, 2017. [Google Scholar]

- Tumuluru, J.S.; Wright, C.T.; Hess, J.R.; Kenney, K.L. A Review on Biomass Densification Technologie for Energy Application; Idaho National Laboratory: Idaho Falls, ID, USA, 2010. [CrossRef]

- Siyal, A.A.; Liu, Y.; Mao, X.; Ali, B.; Husaain, S.; Dai, J.; Zhang, T.; Fu, J.; Liu, G. Characterization and Quality Analysis of Wood Pellets: Effect of Pelletization and Torrefaction Process Variables on Quality of Pellets. Biomass Convers. Biorefin. 2021, 11, 2201–2217. [Google Scholar] [CrossRef]

- Mostafa, M.E.; Hu, S.; Wang, Y.; Su, S.; Hu, X.; Elsayed, S.A.; Xiang, J. The Significance of Pelletization Operating Conditions: An Analysis of Physical and Mechanical Characteristics as Well as Energy Consumption of Biomass Pellets. Renew. Sustain. Energy Rev. 2019, 105, 332–348. [Google Scholar] [CrossRef]

- Stelte, W.; Holm, J.K.; Sanadi, A.R.; Barsberg, S.; Ahrenfeldt, J.; Henriksen, U.B. Fuel Pellets from Biomass: The Importance of the Pelletizing Pressure and Its Dependency on the Processing Conditions. Fuel 2011, 90, 3285–3290. [Google Scholar] [CrossRef]

- Stahl, M.; Berghel, J.; Frodeson, S. Research Experience from the Use of Different Additives in Wood-Fuel Pellet Production. Int. J. Energy Prod. Manag. 2017, 2, 288–293. [Google Scholar] [CrossRef]

- Frodeson, S.; Anukam, A.I.; Berghel, J.; Ståhl, M.; Lasanthi, R.; Nilsson, K.; Henriksson, G.; Aladejana, E.B.; Se, S.F. Densification of Wood—Influence on Mechanical and Chemical Properties When 11 Naturally Occurring Substances in Wood Are Mixed with Beech and Pine. Energies 2021, 14, 5895. [Google Scholar] [CrossRef]

- Stahl, M.; Berghel, J.; Frodeson, S.; Granstrom, K.; Renstrom, R. Effects on Pellet Properties and Energy Use When Starch Is Added in the Wood-Fuel Pelletizing Process. ACS Publ. 2012, 26, 1937–1945. [Google Scholar] [CrossRef]

- Wilson, T.O. Factors Affecting Wood Pellet Durability. Master’s Thesis, The Pennsylvania State University, University Park, PA, USA, 2010. [Google Scholar]

- Adapa, P.K.; Tabil, L.G.; Schoenau, G.J. Factors Affecting the Quality of Biomass Pellet for Biofuel and Energy Analysis of Pelleting Process. Int. J. Agric. Biol. Eng. 2013, 6, 1–12. [Google Scholar]

- Scott, C.; Desamsetty, T.M.; Rahmanian, N. Unlocking Power: Impact of Physical and Mechanical Properties of Biomass Wood Pellets on Energy Release and Carbon Emissions in Power Sector. Waste Biomass Valorization 2024, 16, 441–458. [Google Scholar] [CrossRef]

- Nielsen, S.K.; Mandø, M.; Rosenørn, A.B. Review of Die Design and Process Parameters in the Biomass Pelleting Process. Powder Technol. 2020, 364, 971–985. [Google Scholar] [CrossRef]

- Nunes, L.J.; Loureiro, L.M.; Sá, L.C.; Matias, J.C.; Ferraz, A.I.; Rodrigues, A.C. Energy Recovery of Agricultural Residues: Incorporation of Vine Pruning in the Production of Biomass Pellets with ENplus® Certification. Recycling 2021, 6, 28. [Google Scholar] [CrossRef]

- Sun, P.; Wang, C.; Zhang, M.; Cui, L.; Dong, Y. Ash Problems and Prevention Measures in Power Plants Burning High Alkali Fuel: Brief Review and Future Perspectives. Sci. Total Environ. 2023, 901, 165985. [Google Scholar] [CrossRef]

- Harun, N.Y.; Afzal, M.T. Effect of Particle Size on Mechanical Properties of Pellets Made from Biomass Blends. Procedia Eng. 2016, 148, 93–99. [Google Scholar] [CrossRef]

- Lisowski, A.; Matkowski, P.; Dąbrowska, M.; Piątek, M.; Świętochowski, A.; Klonowski, J.; Mieszkalski, L.; Reshetiuk, V. Particle Size Distribution and Physicochemical Properties of Pellets Made of Straw, Hay, and Their Blends. Waste Biomass Valorization 2020, 11, 63–75. [Google Scholar] [CrossRef]

- Labbé, R.; Paczkowski, S.; Knappe, V.; Russ, M.; Wöhler, M.; Pelz, S. Effect of Feedstock Particle Size Distribution and Feedstock Moisture Content on Pellet Production Efficiency, Pellet Quality, Transport and Combustion Emissions. Fuel 2020, 263, 116662. [Google Scholar] [CrossRef]

- Tumuluru, J.; Conner, C.; Hoover, A. Method to Produce Durable Pellets at Lower Energy Consumption Using High Moisture Corn Stover and a Corn Starch Binder in a Flat Die Pellet Mill. J. Vis. Exp. JoVE 2016, 15, 54092. [Google Scholar]

- Andersen, S.P.; Allen, B.; Domingo, G.C.; Andersen, S.P. Biomass in the EU Green Deal; Institute for European Environmental Policy (IEEP): Brussels, Belgium, 2021. [Google Scholar]

- Antar, M.; Lyu, D.; Nazari, M.; Shah, A.; Zhou, X.; Smith, D.L. Biomass for a Sustainable Bioeconomy: An Overview of World Biomass Production and Utilization. Renew. Sustain. Energy Rev. 2021, 139, 110691. [Google Scholar] [CrossRef]

- Duque-Acevedo, M.; Belmonte-Ureña, L.J.; Cortés-García, F.J.; Camacho-Ferre, F. Recovery of Agricultural Waste Biomass: A Sustainability Strategy for Moving Towards a Circular Bioeconomy; Springer: Berlin/Heidelberg, Germany, 2020. [Google Scholar]

- Statistics Canada Production and Value of Greenhouse Fruits and Vegetables. Available online: https://www150.statcan.gc.ca/t1/tbl1/en/tv.action?pid=3210045601 (accessed on 13 April 2025).

- Grygorczyk, A.; Blake, A. Underutilized By-Product Streams from the Canadian Horticulture Value Chain; Vineland Research and Innovation Centre: Vineland Station, ON, Canada, 2022. [Google Scholar]

- Jadischke, R.; Lubitz, W.D. Current State of Greenhouse Waste Biomass Disposal Methods, with a Focus on Essex County Ontario. Sustainability 2025, 17, 1476. [Google Scholar] [CrossRef]

- Faidallah, R.S.A.; Morad, M.M.; Wasfy, K.I.; El-Sharnouby, M.; Kesba, H.; El-Tahan, A.M.; El-Saadony, M.T.; Awny, A. Utilizing Biomass Energy for Improving Summer Squash Greenhouse Productivity during the Winter Season. Saudi J. Biol. Sci. 2022, 29, 822–830. [Google Scholar] [CrossRef]

- Huang, T.; Li, H.; Zhang, G.; Xu, F. Experimental Study on Biomass Heating System in the Greenhouse: A Case Study in Xiangtan, China. Sustainability 2020, 12, 5673. [Google Scholar] [CrossRef]

- Perron, M. Heating of Greenhouses from Biomass Polygeneration Systems. Master’s Thesis, Polytechnique Montreal, Montreal, QC, Canada, 2023. [Google Scholar]

- Reinoso Moreno, J.V.; Pinna-Hernández, G.; Fernández Fernández, M.D.; Sánchez Molina, J.A.; Rodríguez Díaz, F.; López Hernández, J.C.; Acién Fernández, F.G. Optimal Processing of Greenhouse Crop Residues to Use as Energy and CO2 Sources. Ind. Crops Prod. 2019, 137, 662–671. [Google Scholar] [CrossRef]

- Gholami B, O.; Sokhansanj, S.; Lau, A.; Arunachalam, S.; Smith, D. The Physiochemical Properties of Pellets Made from the Foliage of Vegetable Crops. Energies 2025, 18, 1969. [Google Scholar] [CrossRef]

- Sluiter, A.; Hames, B.; Ruiz, R.; Scarlata, C.; Sluiter, J.; Templeton, D. Determination of Ash in Biomass: Laboratory Analytical Procedure (LAP); Technical Report NREL/TP-510-42622; National Renewable Energy Laboratory: Golden, CO, USA, 2008.

- Sluiter, A.; Ruiz, R.; Scarlata, C.; Sluiter, J.; Templeton, D. Determination of Extractives in Biomass: Laboratory Analytical Procedure (LAP); Technical Report NREL/TP-510-42619; National Renewable Energy Laboratory: Golden, CO, USA, 2008. [Google Scholar]

- Sluiter, A.; Hames, B.; Ruiz, R.; Scarlata, C.; Sluiter, J.; Templeton, D.; Crocker, D. Determination of Structural Carbohydrates and Lignin in Biomass Laboratory Analytical Procedure (LAP); Technical Report NREL/TP-510-42618; National Renewable Energy Laboratory: Golden, CO, USA, 2008.

- Ulusoy, U.; Yekeler, M.; Hiçyilmaz, C. Determination of the Shape, Morphological and Wettability Properties of Quartz and Their Correlations. Miner. Eng. 2003, 16, 951–964. [Google Scholar] [CrossRef]

- Rezaei, H.; Lim, C.J.; Lau, A.; Sokhansanj, S. Size, Shape and Flow Characterization of Ground Wood Chip and Ground Wood Pellet Particles. Powder Technol. 2016, 301, 737–746. [Google Scholar] [CrossRef]

- Behnke, K.C.; Fahrenholz, A.; Stark, C.; Jones, C. Factors Affecting Pellet Quality; University of Maryland: College Park, MD, USA, 2015. [Google Scholar]

- Robertson, A.R. The CIE 1976 Color-Difference Formulae. Color Res. Appl. 1977, 2, 7–11. [Google Scholar] [CrossRef]

- Schilling, C.; Wöhler, M.; Yazdanpanah, F.; Bi, X.; Lau, A.; Lim, J.; Sokhansanj, S.; Pelz, S. Development of a Novel Wood Pellet Durability Tester for Small Samples. In Proceedings of the World Sustainable Energy Days, Wels, Austria, 26–27 February 2015. [Google Scholar]

- Andlar, M.; Rezić, T.; Marđetko, N.; Kracher, D.; Ludwig, R.; Šantek, B. Lignocellulose Degradation: An Overview of Fungi and Fungal Enzymes Involved in Lignocellulose Degradation. Eng. Life Sci. 2018, 18, 768–778. [Google Scholar] [CrossRef] [PubMed]

- Yang, H.; Yan, R.; Chen, H.; Lee, D.; Fuel, C.Z. Characteristics of Hemicellulose, Cellulose and Lignin Pyrolysis. Fuel 2007, 86, 1781–1788. [Google Scholar] [CrossRef]

- Sgarbossa, A.; Costa, C.; Menesatti, P.; Antonucci, F.; Pallottino, F.; Zanetti, M.; Grigolato, S.; Cavalli, R. Colorimetric Patterns of Wood Pellets and Their Relations with Quality and Energy Parameters. Fuel 2014, 137, 70–76. [Google Scholar] [CrossRef]

- Meier, S.; Rector, L.R.; Allen, G.; Hopke, P.K.; Chandrasekaran, S.R.; Lin, L. Elemental Analysis of Wood Fuels. Available online: https://www.nyserda.ny.gov/-/media/Project/Nyserda/Files/Publications/Research/Biomass-Solar-Wind/elemental-analysis-wood-fuel.pdf (accessed on 26 February 2025).

- Noman, H.M.; Rana, D.S.; Rana, K.S. Influence of Sulphur and Zinc Levels and Zinc Solubilizer on Productivity, Economics and Nutrient Uptake in Groundnut (Arachis Hypogaea). Indian J. Agron. 2015, 60, 301–306. [Google Scholar] [CrossRef]

- Banadkoki, O.G.; Sokhansanj, S.; Lau, A.; Lee, J.S.; Arunachalam, S.; Smith, D. The Study of Post-Harvest Processing and Handling of Residues from Plants Grown Primarily for Agronomics: Soybean Stalk, Corn Stover, Tomato Vine, Cucumber, Eggplant, and Summer Squash. Eur. J. Agric. Food Sci. 2024, 6, 44–53. [Google Scholar] [CrossRef]

- Ghadernejad, K.; Kianmehr, M.; Arabhosseini, A. Effect of Moisture Content and Particle Size on Energy Consumption for Dairy Cattle Manure Pellets. Agric. Eng. Int. CIGR J. 2012, 14, 125–130. [Google Scholar]

- Ahmed, I.; Ali, A.; Ali, B.; Hassan, M.; Hashmi, H.; Ali, Z. Pelletization of Biomass Feedstocks: Effect of Moisture Content, Particle Size and a Binder on Characteristics of Biomass Pellets. Res. Square 2021. [Google Scholar] [CrossRef]

- Tumuluru, J.S.; Wright, C.T.; Hess, J.R.; Kenney, K.L. A Review of Biomass Densification Systems to Develop Uniform Feedstock Commodities for Bioenergy Application. Biofuels Bioprod. Biorefin. 2011, 5, 683–707. [Google Scholar] [CrossRef]

- Berghel, J.; Ståhl, M.; Frodeson, S.; Pichler, W.; Weigl-Kuska, M. A Comparison of Relevant Data and Results from Single Pellet Press Research Is Mission Impossible: A Review; Elsevier: Amsterdam, The Netherlands, 2022. [Google Scholar]

- Zhang, X.; Guo, Q.; Xu, Y.; Li, P.; Chen, C.; Wu, S. Mechanical Testing of Tomato Plant Stem in Relation to Structural Composition. Agric. Res. 2016, 5, 236–245. [Google Scholar] [CrossRef]

- Hou, J. Related Study on Mechanical Characteristic and Physicochemical Property of Corn Stra. Master’s Thesis, Northeast Agricultural University, Harbin, China, 2013. [Google Scholar]

- Liu, Y.; Wang, Y.; Wang, B.; Shi, Q.; Biology, H.M.-B.P. Preliminary Study on the Diagnosis of NK Stress Based on the Puncture Mechanical Characteristics of Cucumber Stem. BMC Plant Biol. 2024, 24, 26. [Google Scholar] [CrossRef] [PubMed]

- Xiliang, Z.; Xiaojia, S.; Yunfeng, X.; Li, P.; Guo, Q. Mechanical Characteristics and Microstructure of Cucumber Vine Straw. J. Agric. Mech. Res. 2014, 36, 156–159. [Google Scholar] [CrossRef]

- Styks, J.; Knapczyk, A.; Łapczyńska-Kordon, B. Effect of Compaction Pressure and Moisture Content on Post-Agglomeration Elastic Springback of Pellets. Materials 2021, 14, 879. [Google Scholar] [CrossRef] [PubMed]

- He, H.; Wang, Y.; Sun, W.; Sun, Y.; Wu, K. Effects of Different Biomass Feedstocks on the Pelleting Process and Pellet Qualities. Sustain. Energy Technol. Assess. 2024, 69, 103912. [Google Scholar] [CrossRef]

- Dao, C.N.; Salam, A.; Kim Oanh, N.T.; Tabil, L.G. Effects of Length-to-Diameter Ratio, Pinewood Sawdust, and Sodium Lignosulfonate on Quality of Rice Straw Pellets Produced via a Flat Die Pellet Mill. Renew. Energy 2022, 181, 1140–1154. [Google Scholar] [CrossRef]

- Lavergne, S.; Larsson, S.H.; Da Silva Perez, D.; Marchand, M.; Campargue, M.; Dupont, C. Effect of Process Parameters and Biomass Composition on Flat-Die Pellet Production from Underexploited Forest and Agricultural Biomass. Fuel 2021, 302, 121076. [Google Scholar] [CrossRef]

- Tumuluru, J.S. Effect of Pellet Die Diameter on Density and Durability of Pellets Made from High Moisture Woody and Herbaceous Biomass. Carbon Resour. Convers. 2018, 1, 44–54. [Google Scholar] [CrossRef]

- Ríos-Badrán, I.M.; Luzardo-Ocampo, I.; García-Trejo, J.F.; Santos-Cruz, J.; Gutiérrez-Antonio, C. Production and Characterization of Fuel Pellets from Rice Husk and Wheat Straw. Renew. Energy 2020, 145, 500–507. [Google Scholar] [CrossRef]

- Said, N.; Abdel Daiem, M.M.; García-Maraver, A.; Zamorano, M. Influence of Densification Parameters on Quality Properties of Rice Straw Pellets. Fuel Process. Technol. 2015, 138, 56–64. [Google Scholar] [CrossRef]

- Ciolkosz, D.; Hilton, R.; Swackhamer, C.; Yi, H.; Puri, V.M.; Swomley, D.; Roth, G. Farm-Scale Biomass Pelletizer Performance for Switchgrass Pellet Production. Appl. Eng. Agric. 2015, 31, 559–567. [Google Scholar] [CrossRef]

- Jacobson, R.; Sokhansanj, S.; Roeser, D.; Hansen, J.; Gopaluni, B.; Bi, X. A Cost Analysis of Mobile and Stationary Pellet Mills for Mitigating Wildfire Costs. J. Sustain. Bioenergy Syst. 2021, 11, 131–143. [Google Scholar] [CrossRef]

- Yang, Y.; Song, L.; Li, Y.; Shen, Y.; Yang, M.; Wang, Y.; Zheng, H.; Qi, W.; Lei, T. Effects of Different Biomass Types on Pellet Qualities and Processing Energy Consumption. Agriculture 2025, 15, 316. [Google Scholar] [CrossRef]

- Carroll, J.; Finnan, J. The Relationship between Bulk Density and Energy Input, in Biomass Pellet Production. Adv. Anim. Biosci. 2010, 1, 331. [Google Scholar] [CrossRef]

- Tumuluru, J. High Moisture Corn Stover Pelleting in a Flat Die Pellet Mill Fitted with a 6 Mm Die: Physical Properties and Specific Energy Consumption. Energy Sci. Eng. 2015, 3, 327–341. [Google Scholar] [CrossRef]

- Smołka-Danielowska, D.; Jabłońska, M. Chemical and Mineral Composition of Ashes from Wood Biomass Combustion in Domestic Wood-Fired Furnaces. Int. J. Environ. Sci. Technol. 2022, 19, 5359–5372. [Google Scholar] [CrossRef]

- Kalembkiewicz, J.; Galas, D.; Sitarz-Palczak, E. The Physicochemical Properties and Composition of Biomass Ash and Evaluating Directions of Its Applications. J. Environ. Stud. 2018, 27, 1–11. [Google Scholar] [CrossRef]

- Lisý, A.; Ház, A.; Nadányi, R.; Jablonský, M.; Šurina, I. About Hydrophobicity of Lignin: A Review of Selected Chemical Methods for Lignin Valorisation in Biopolymer Production. Energies 2022, 15, 6213. [Google Scholar] [CrossRef]

- Lee, J.S.; Sokhansanj, S.; Lau, A.K.; Lim, J.; Bi, X.T. Moisture Adsorption Rate and Durability of Commercial Softwood Pellets in a Humid Environment. Biosyst. Eng. 2021, 203, 1–8. [Google Scholar] [CrossRef]

- Qiu, C.; Jiang, L.; Gao, Y.; Sheng, L. Effects of Oxygen-Containing Functional Groups on Carbon Materials in Supercapacitors: A Review. Mater. Des. 2023, 230, 111952. [Google Scholar] [CrossRef]

| Pellets | Color Parameters (-) | |||

|---|---|---|---|---|

| L* | a* | b* | ||

| Corn | 49.0 c | 4.6 a | 17.5 b | 13.3 bc |

| Soybean | 52.5 b | 4.5 a | 17.6 b | 13.6 bc |

| Tomato | 43.0 d | 3.3 b | 15.9 c | 18.8 a |

| Eggplant | 41.8 de | 4.3 a | 16.9 bc | 12.6 c |

| Cucumber | 41.1 e | 3.3 b | 15.6 c | 19.8 a |

| Summer squash | 38.9 f | 2.5 b | 13.1 d | 14.8 b |

| Sawdust | 69.2 a | 4.6 a | 21.0 a | 5.8 d |

| Pr > F (Model) | <0.0001 | <0.0001 | <0.0001 | <0.0001 |

| Significant | Yes | Yes | Yes | Yes |

| Samples | MC (wb, %) | Infeed Material Mass (g) | Produced Pellet Mass (g) | Fine Particle (%) | Pelletization Performance (%) | Feeding Time (s) | Feed Rate (g/s) | NSPEC (kWh/t) |

|---|---|---|---|---|---|---|---|---|

| Corn | 12.10 | 2058.3 | 2011.5 | 2.3 | 95.5 | 157 | 13.1 | 33.0 |

| Soybean | 11.80 | 2041.5 | 1961.9 | 5.9 | 90.4 | 150 | 13.6 | 49.6 |

| Tomato | 12.00 | 2150.0 | 2017.5 | 4.1 | 90.0 | 119 | 18.1 | 28.2 |

| Eggplant | 12.05 | 2085.0 | 1913.4 | 1.6 | 90.3 | 152 | 13.7 | 32.4 |

| Cucumber | 12.10 | 2152.8 | 2088.7 | 1.7 | 95.4 | 127 | 16.9 | 21.8 |

| Summer squash | 12.05 | 1987.8 | 1945.9 | 1.9 | 96.0 | 121 | 16.4 | 18.7 |

| Sawdust | 11.90 | 2167.6 | 2038.5 | 3.3 | 91.0 | 110 | 19.7 | 47.3 |

| Properties | Ground Foliage Samples | Correlations with | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Corn | Soybean | Tomato | Eggplant | Cucumber | Summer Squash | Sawdust | Pellet BDe (kg/m3) | Pellet BDu (%) | NSPEC (kWh/t) | |

| Pellet BDe (kg/m3) | 629.4 c | 586.8 e | 663.3 b | 630.1 c | 691.2 a | 665.5 b | 612.5 d | 1 | 0.729 | −0.913 |

| Pellet BDu (%) | 97.6 b | 92.3 e | 96.9 c | 96.6 d | 97.9 a | 96.6 d | 96.6 d | 0.729 | 1 | −0.663 |

| NSPEC (kWh/t) | 33.0 c | 49.6 a | 28.2 d | 32.4 c | 21.8 e | 18.7 f | 47.3 b | −0.913 | −0.663 | 1 |

| Extractive (%, db) | 5.7 a | 1.5 d | 4.8 b | 4.4 b | 1.8 cd | 1.7 cd | 2.2 c | 0.018 | 0.410 | −0.111 |

| Lignin (%, db) | 18.5 b | 15.4 d | 16.2 c | 12.4 e | 9.4 f | 5.6 g | 29.2 a | −0.566 | −0.065 | 0.754 |

| GCV (MJ/kg, db) | 17.2 bc | 17.5 b | 14.8 d | 16.7 c | 14.3 d | 13.6 e | 21.0 a | −0.758 | −0.261 | 0.861 |

| Ash (%) | 5.5 f | 6.8 e | 18.3 c | 14.5 d | 25.3 b | 33.6 a | 0.3 g | 0.795 | 0.304 | −0.890 |

| C/O ratio (-) | 0.953 b | 0.964 b | 0.795 d | 0.836 c | 0.640 e | 0.455 f | 1.158 a | −0.750 | −0.280 | 0.889 |

| TD (g/cm3) | 1.239 e | 1.398 d | 1.424 b | 1.242 e | 1.412 c | 1.489 a | 1.395 d | 0.337 | −0.178 | −0.226 |

| BD (kg/m3) | 107.7 f | 200.2 c | 259.9 b | 196.4 d | 259.5 b | 289.0 a | 186.9 e | 0.615 | 0.038 | −0.558 |

| D50 (mm) | 0.71 b | 0.67 c | 0.61 d | 0.69 b | 0.65 c | 0.59 e | 0.85 a | −0.510 | 0.031 | 0.670 |

| AR (-) | 0.32 a | 0.37 a | 0.40 a | 0.45 a | 0.32 a | 0.40 a | 0.33 a | −0.024 | −0.022 | −0.051 |

| Deq (mm) | 1.9 ab | 1.9 ab | 1.3 b | 2.2 a | 1.9 ab | 2.1 ab | 2.6 a | −0.211 | 0.019 | 0.169 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gholami Banadkoki, O.; Sokhansanj, S.; Lau, A. Analysis of the Pelletability of Vegetable Crop Foliage Using a Commercial Flat Die Pellet Mill. Energies 2025, 18, 2284. https://doi.org/10.3390/en18092284

Gholami Banadkoki O, Sokhansanj S, Lau A. Analysis of the Pelletability of Vegetable Crop Foliage Using a Commercial Flat Die Pellet Mill. Energies. 2025; 18(9):2284. https://doi.org/10.3390/en18092284

Chicago/Turabian StyleGholami Banadkoki, Omid, Shahab Sokhansanj, and Anthony Lau. 2025. "Analysis of the Pelletability of Vegetable Crop Foliage Using a Commercial Flat Die Pellet Mill" Energies 18, no. 9: 2284. https://doi.org/10.3390/en18092284

APA StyleGholami Banadkoki, O., Sokhansanj, S., & Lau, A. (2025). Analysis of the Pelletability of Vegetable Crop Foliage Using a Commercial Flat Die Pellet Mill. Energies, 18(9), 2284. https://doi.org/10.3390/en18092284