Impact of Agriculture on Greenhouse Gas Emissions—A Review

Abstract

:1. Introduction

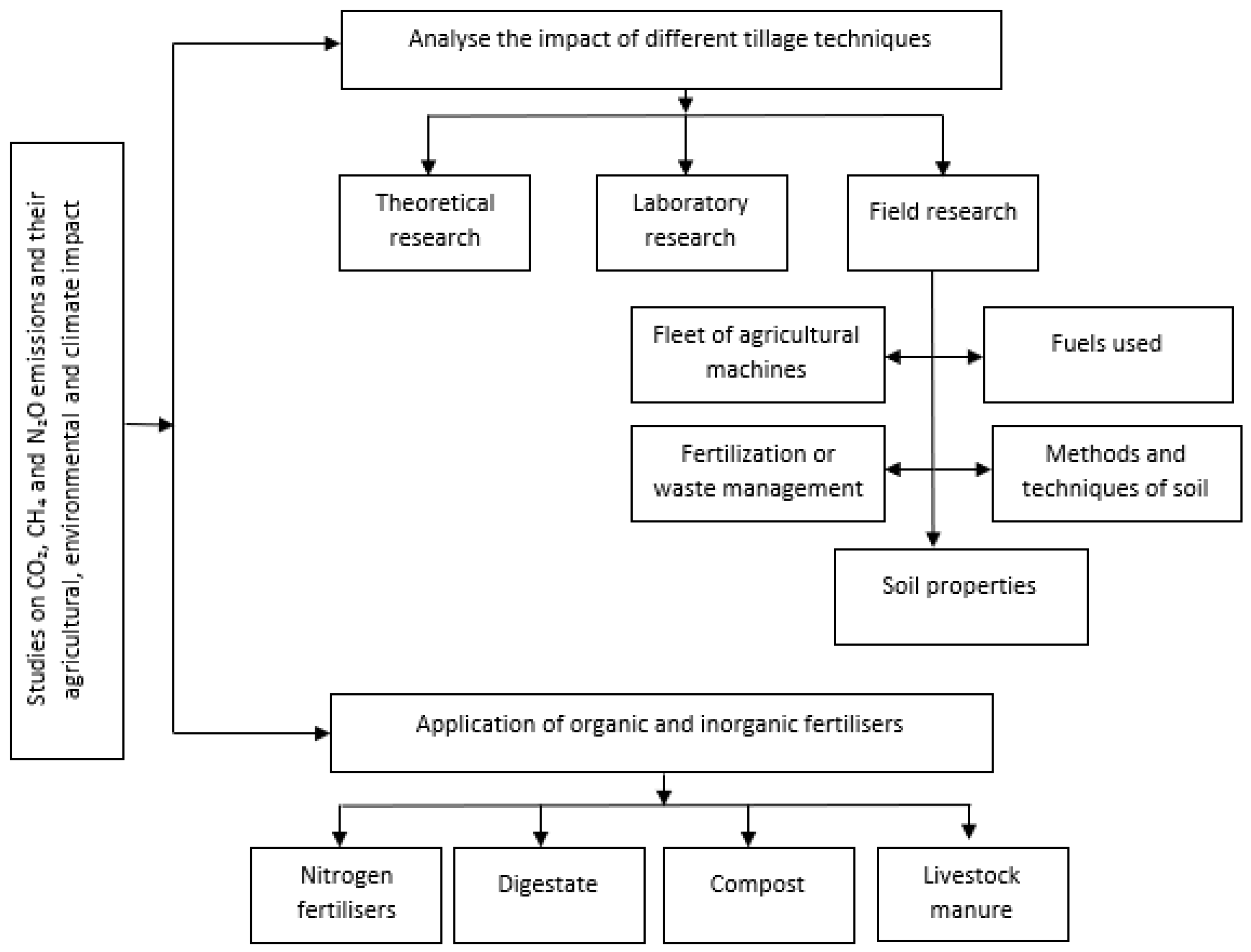

2. Methodology

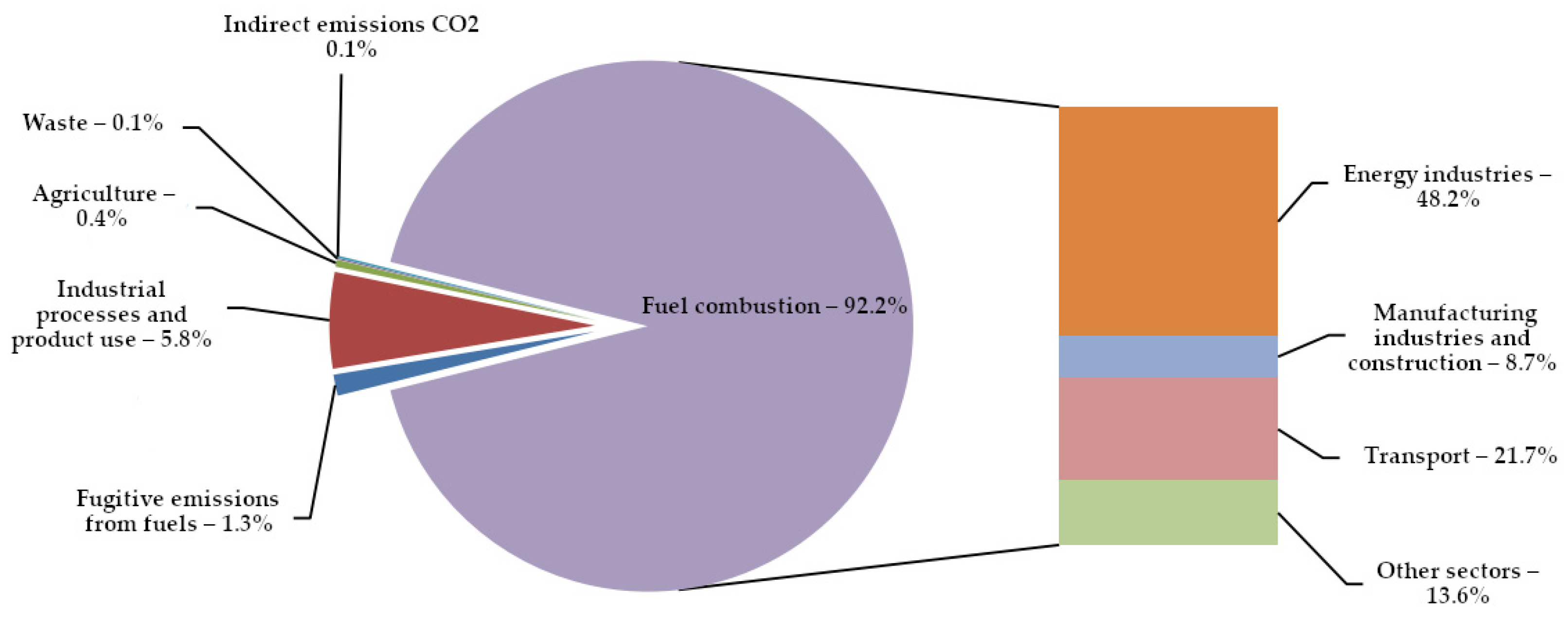

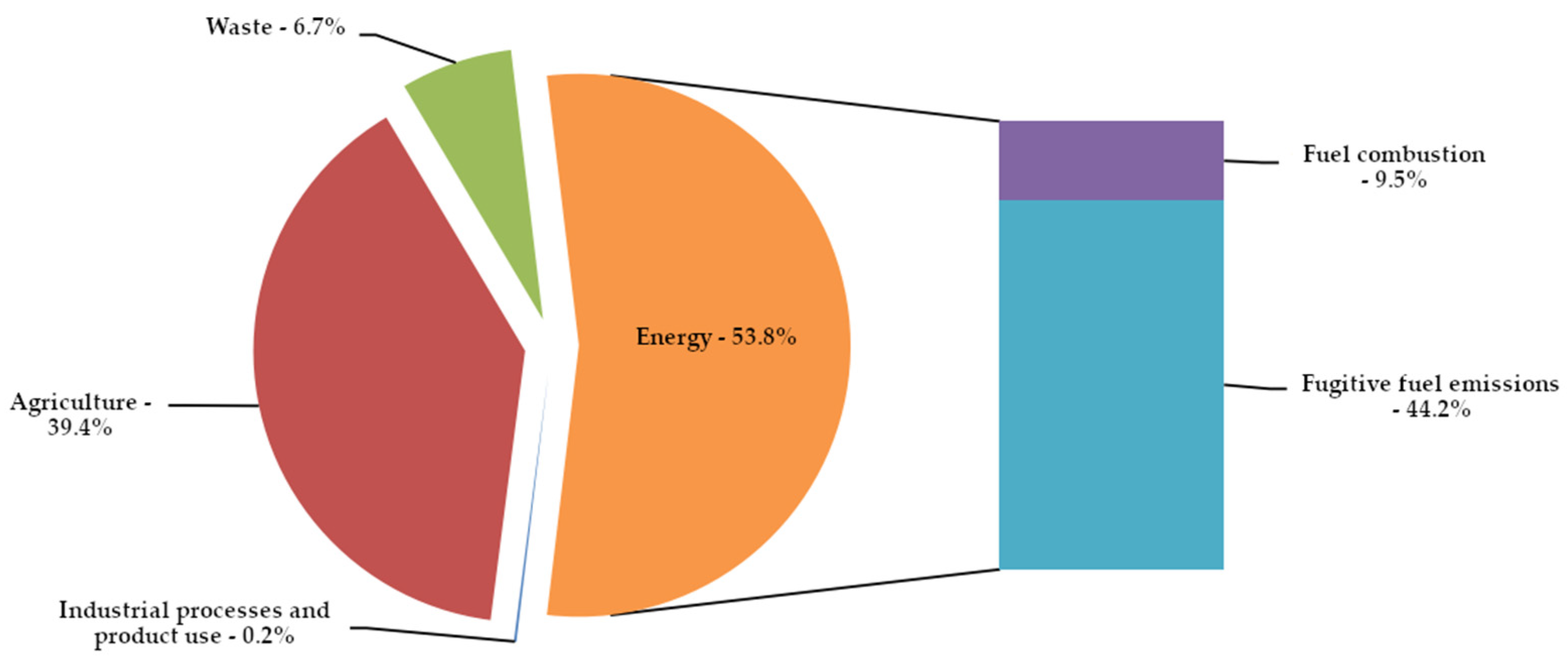

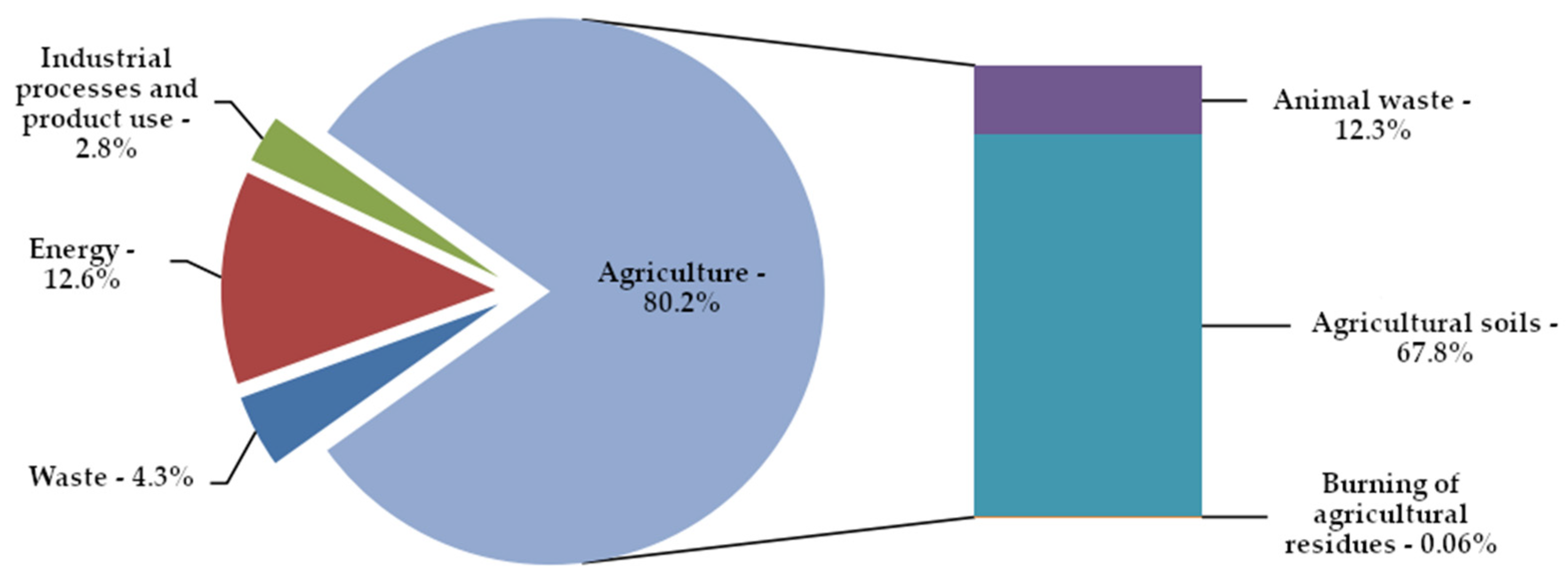

3. Greenhouse Gas Emission Sources

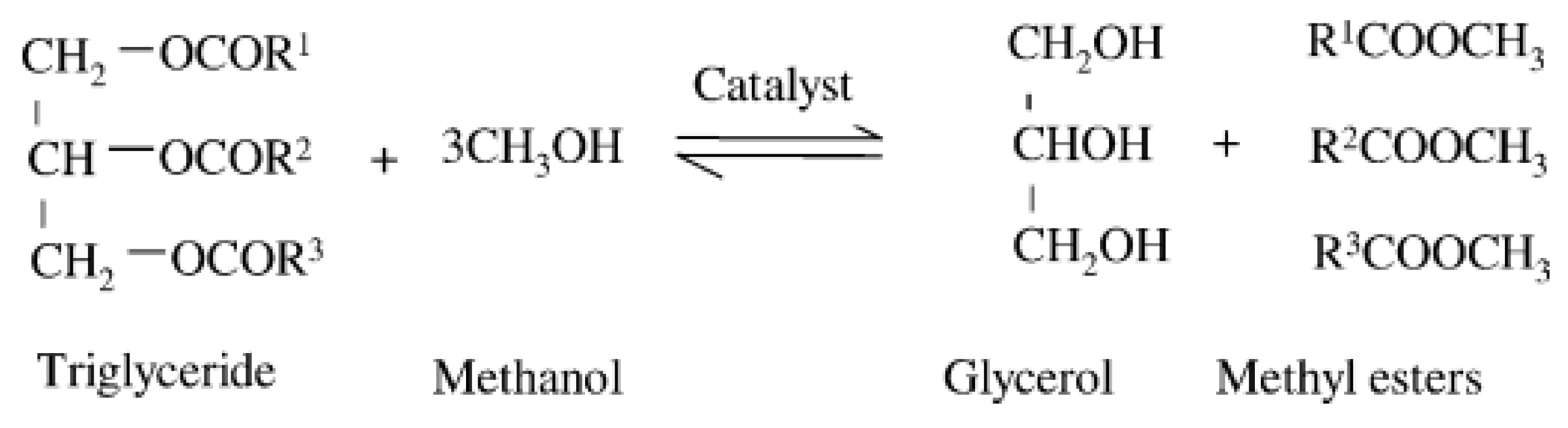

Alternative Fuels

4. Agricultural Machinery Fleet Compositions and Greenhouse Gas Emissions

5. Soil Properties and Crop Cultivation Techniques vs. Gas Emissions

5.1. Environmental Factors

5.2. Fertilisation

5.3. Agricultural Practices

Cultivation Technologies

6. Organic and Inorganic Fertilisers

6.1. Nitrogen Fertiliser

6.2. Compost

6.3. Livestock Manure

6.4. Digestate

7. Summary

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| AD | Anaerobic digestion |

| GHG | Greenhouse gas |

| SCR | Selective catalytic reduction |

| EGR | Exhaust gas recirculation |

| NOX | Nitrous oxides (g ha−1) |

| CO | Carbon monoxide (g ha−1) |

| CO2 | Carbon dioxide (kg ha−1) |

| PM | Particulate matter (g ha−1) |

| P2O5 | Diphosphorus pentoxide |

| K2O | Potassium oxide |

| LCA | Life cycle assessment |

| WFPS | Water-filled pore space |

| SCS | Soil carbon sequestration |

| SOC | Soil organic carbon |

| SIC | Soil inorganic carbon |

| CT | Conventional tillage |

| NT | No-tillage |

| RT | Reduced tillage |

| MT | Minimum tillage |

| RiT | Ridge tillage |

| ST | Strip tillage |

| STR | Strategic tillage |

| DT | Deep tillage |

| EBA | European Biogas Association |

| DM | Dry matter |

| MBP | Mechanical–biological waste processing |

| PAH | Polycyclic aromatic hydrocarbons |

| ILUC | Indirect land use change |

| EF | Emission factor |

| CCU | Carbon capture and utilisation |

| SMR | Steam methane reforming |

| FAME | Fatty acid methyl esters |

| EENF | Enhanced-efficiency nitrogen fertiliser |

| DCD | Dicyandiamide |

References

- Lee, H.; Romero, J. Climate Change 2023: Synthesis Report, 1st ed.; IPCC: Geneva, Switzerland, 2023; pp. 35–115. [Google Scholar]

- Lynch, J.; Cain, M.; Frame, D.; Pierrehumbert, R. Agriculture’s Contribution to Climate Change and Role in Mitigation Is Distinct from Predominantly Fossil CO2-Emitting Sectors. Front. Sustain. Food Syst. 2021, 4, 518039. [Google Scholar] [CrossRef] [PubMed]

- Mbow, C.; Rosenzweig, C.; Barioni, L.G.; Benton, T.G.; Herrero, M.; Krishnapillai, M.; Liwenga, E.; Pradhan, P.; Rivera-Ferre, M.G.; Sapkota, T.; et al. Food Security. In Climate Change and Land: An IPCC Special Report on Climate Change, Desertification, Land Degradation, Sustainable Land Management, Food Security, and Greenhouse Gas Fluxes in Terrestrial Ecosystems; Shukla, P.R., Skea, J., Calvo Buendia, E., Masson-Delmotte, V., Pörtner, H.-O., Roberts, D.C., Eds.; Intergovernmental Panel on Climate Change (IPCC): Geneva, Switzerland, 2019; in press. [Google Scholar]

- Pascuzzi, S.; Łyp-Wrońska, K.; Gdowska, K.; Paciolla, F. Sustainability Evaluation of Hybrid Agriculture-Tractor Powertrains. Sustainability 2024, 16, 1184. [Google Scholar] [CrossRef]

- Agriculture in 2021—Statistical Analyses. Central Statistical Office: Warsaw, Poland. Available online: https://stat.gov.pl/files/gfx/portalinformacyjny/pl/defaultaktualnosci/5507/3/18/1/rolnictwo_w_2021_r.pdf (accessed on 11 March 2024).

- Laborde, D.; Mamun, A.; Martin, W.; Piñeiro, V.; Vos, R. Agricultural subsidies and global greenhouse gas emissions. Nat. Commun. 2021, 12, 2601. [Google Scholar] [CrossRef] [PubMed]

- Linquist, B.; Van Groenigen, K.J.; Adviento-Borbe, M.A.; Pittelkow, C.; Van Kessel, C. An agronomic assessment of greenhouse gas emissions from major cereal crops. Glob. Change Biol. 2012, 18, 194–209. [Google Scholar] [CrossRef]

- Shibata, M.; Koeda, S.; Noji, T.; Kawakami, K.; Ido, Y.; Amano, Y.; Umezawa, N.; Higuchi, T.; Dewa, T.; Itoh, S.; et al. Design of new extraction surfactants for membrane proteins from peptide gemini surfactants. Bioconjug. Chem. 2016, 27, 2469–2479. [Google Scholar] [CrossRef]

- Verge, X.P.C.; De Kimpe, C.; Desjardins, R.L. Agricultural production, greenhouse gas emissions and mitigation potential. Agric. Meteorol. 2007, 142, 255–269. [Google Scholar] [CrossRef]

- European Commission. Commission Directive 2010/26/EU of 31 March 2010 amending Directive 97/68/EC of the European Parliament and of the Council on the approximation of the laws of the Member States relating to measures against the emission of gaseous and particulate pollutants from internal combustion engines to be installed in non-road mobile machinery. Dz. Urz. UE L 2010, 86, 29. [Google Scholar]

- European Commission. Commission Directive 2010/22/EU of 15 March 2010 amending for the purposes of adapting to technical progress Council Directives 80/720/EEC, 86/298/EEC, 86/415/EEC and 87/402/EEC and Directives 2000/25/EC and 2003/37/EC of the European Parliament and of the Council relating to the type-approval of agricultural or forestry tractors. Dz. Urz. UE L 2010, 91, 1. [Google Scholar]

- European Parliament. CO2 Emissions from Cars: Facts and Figures (Infographics). Available online: https://www.europarl.europa.eu/topics/en/article/20190313STO31218/co2-emissions-from-cars-facts-and-figures-infographics (accessed on 3 February 2025).

- Lovarelli, D.; Bacenetti, J. Exhaust Gases Emissions from Agricultural Tractors: State of the Art and Future Perspectives for Machinery Operators. Biosyst. Eng. 2019, 186, 204–213. [Google Scholar] [CrossRef]

- Bacenetti, J.; Lovarelli, D.; Facchinetti, D.; Pessina, D. An Environmental Comparison of Techniques to Reduce Pollutants Emissions Related to Agricultural Tractors. Biosyst. Eng. 2018, 171, 30–40. [Google Scholar] [CrossRef]

- Martini, V.; Mocera, F.; Somà, A. Numerical Investigation of a Fuel Cell-Powered Agricultural Tractor. Energies 2022, 15, 8818. [Google Scholar] [CrossRef]

- Renius, K.T. Fundamentals of Tractor Design; Springer: Cham, Switzerland, 2020; p. 287. [Google Scholar] [CrossRef]

- Janulevičius, A.; Juostas, A.; Cipliene, A. Nitrogen-oxide emissions from diesel-engine farm tractors during real-life cycles and their correlation with the not-to-exceed operating zones. Biosyst. Eng. 2017, 161, 93–105. [Google Scholar] [CrossRef]

- Perozzi, D.; Mattetti, M.; Molari, G.; Sereni, E. Methodology to analyse farm tractor idling time. Biosyst. Eng. 2016, 148, 81–89. [Google Scholar] [CrossRef]

- Gu, Y.; Yim, S.H.L. The Air Quality and Health Impacts of Domestic Trans-Boundary Pollution in Various Regions of China. Environ. Int. 2016, 97, 117–124. [Google Scholar] [CrossRef]

- Zhang, Q.; Jiang, X.; Tong, D.; Davis, S.J.; Zhao, H.; Geng, G.; Feng, T.; Zheng, B.; Lu, Z.; Streets, D.G.; et al. Transboundary Health Impacts of Transported Global Air Pollution and International Trade. Nature 2017, 543, 705–709. [Google Scholar] [CrossRef]

- Volvo SCR and Fuel Efficiency. Technical Report. 2010. Available online: https://www.volvogroup.com/en/news-and-media/news/2011/jan/news-94807.html (accessed on 2 January 2025).

- Sendzikiene, E.; Makareviciene, V.; Kalenska, S. Exhaust emissions from the engine running on multi-component fuel. Transport 2012, 27, 111–117. [Google Scholar] [CrossRef]

- Labeckas, G.; Slavinskas, S. Performance and emission characteristics of a direct injection diesel engine operating on KDV synthetic diesel fuel. Energy Convers. Manag. 2013, 66, 173–188. [Google Scholar] [CrossRef]

- Tomic, M.; Savin, L.; Micic, R.; Simikić, M.; Furman, T. Effects of fossil diesel and biodiesel blends on the performances and emissions of agricultural tractor engines. Therm. Sci. 2013, 17, 263–278. [Google Scholar] [CrossRef]

- Guo, X.; Wu, H.; Chen, D.; Ye, Z.; Shen, Y.; Liu, J.; Cheng, S. Estimation and prediction of pollutant emissions from agricultural and construction diesel machinery in the Beijing-Tianjin-Hebei (BTH) region, China. Environ. Pollut. 2020, 260, 113973. [Google Scholar] [CrossRef]

- Hansson, P.A.; Lindgren, M.; Noren, O. A Comparison Between Different Methods of Calculating Average Engine Emissions for Agricultural Tractors. J. Agric. Engng Res. 2001, 80, 37–43. [Google Scholar] [CrossRef]

- Dyer, J.A.; Desjardin, R.L. Simulated Farm Fieldwork, Energy Consumption and Related Greenhouse Gas Emissions in Canada. Biosyst. Eng. 2003, 85, 503–513. [Google Scholar] [CrossRef]

- Nelson, P.F.; Tibbett, A.R.; Day, S.J. Effects of vehicle type and fuel quality on real world toxic emissions from diesel vehicles. Atmos. Environ. 2008, 42, 5291–5303. [Google Scholar] [CrossRef]

- Li, Y.X.; McLaughlin, N.B.; Patterson, B.S.; Burtt, S.D. Fuel efficiency and exhaust emissions for biodiesel blends in an agricultural tractor. Can. Biosyst. Eng. 2006, 48, 15–22. [Google Scholar]

- Lindgren, M.; Larsson, G.; Hansson, P.A. Evaluation of factors influencing emissions from tractors and construction equipment during realistic work operations using diesel fuel and bio-fuels as substitutes. Biosyst. Eng. 2010, 107, 123–130. [Google Scholar] [CrossRef]

- Janulevičius, A.; Juostas, A.; Pupinis, G. Tractor’s engine performance and emission characteristics in the process of ploughing. Energy Convers. Manag. 2013, 75, 498–508. [Google Scholar] [CrossRef]

- Inventory of Greenhouse Gas Emissions and Removals in Poland for the Years 1988–2022; National Inventory Report 2024; National Center for Emission Balancing and Management: Warsaw, Poland, 2024; Available online: https://www.kobize.pl/uploads/materialy/materialy_do_pobrania/krajowa_inwentaryzacja_emisji/NIR_2024_raport_syntetyczny_PL.pdf (accessed on 3 February 2025).

- Wirkowski, P.; Markowski, J.; Kniaziewicz, T. Possibilities of Testing Emissions of Harmful Compounds in The Exhaust From A Marine Turbine Combustion Engine In Operating Conditions. Eksplotacja i Testy 2017, 12, 1410–1414. [Google Scholar]

- Wasilewski, J.; Krzaczek, P.; Szyszlak-Bargłowicz, J.; Zając, G.; Koniuszy, A.; Hawrot-Paw, M.; Marcinkowska, W. Evaluation of Nitrogen Oxide (NO) and Particulate Matter (PM) Emissions from Waste Biodiesel Combustion. Energies 2024, 17, 328. [Google Scholar] [CrossRef]

- Engine Exhaust Gases—What They Contain and How It Affects Humans. Available online: https://autokult.pl/spaliny-silnikow-co-zawieraja-i-jak-to-wplywa-na-czlowieka-2,6808774652958337a (accessed on 11 March 2024).

- Toxic Compounds in Car Exhaust Gases and Their Impact on Health. Available online: https://klimawent.com.pl/jakie-szkodliwe-substancje-znajduja-sie-w-spalinach-samochodowych/ (accessed on 11 March 2024).

- Scott, D.; Hall, C.M.; Rushton, B.; Gössling, S. A review of the IPCC Sixth Assessment and implications for tourism development and sectoral climate action. J. Sustain. Tour. 2023, 32, 1725–1742. [Google Scholar] [CrossRef]

- Golka, W.; Ptaszyński, S. Expenditures for soil cultivation in conservative and conventional technology. Problemy Inż. Roln. 2014, 3, 31–47. [Google Scholar]

- Parton, W.J.; Del Grosso, S.J.; Marx, E.; Swan, A.L. Agriculture’s Role in Cutting Greenhouse Gas Emissions. Issues Sci. Technol. 2011, 27, 29–32. [Google Scholar]

- Solmaz, H. Combustion, performance, and emission characteristics of fusel oil in a spark ignition engine. Fuel Process. Technol. 2015, 133, 20–28. [Google Scholar] [CrossRef]

- European Biodiesel Board—Statistical Report 2023. Available online: https://ebb-eu.org/wp-content/uploads/2024/03/EBB_Statistical_Report2023-Final.pdf (accessed on 29 September 2024).

- OECD FAO Agricultural Outlook 2021–2030. Available online: https://openknowledge.fao.org/server/api/core/bitstreams/313b0161-6176-4a76-b505-6f6d3836b9c7/content (accessed on 5 November 2024).

- McCormick, R.L.; Williams, A.; Ireland, J.; Brimhall, M.; Hayes, R.R. Effects of Biodiesel Blends on Vehicle Emissions: Fiscal Year 2006 Annual Operating Plan Milestone 10.4. Biodiesel Fuels Reexamined 2011, 71, 71–124. [Google Scholar] [CrossRef]

- Canakci, M. Combustion Characteristics of a Turbocharged DI Compression Ignition Engine Fueled with Petroleum Diesel Fuels and Biodiesel. Bioresour. Technol. 2007, 98, 1167–1175. [Google Scholar] [CrossRef] [PubMed]

- Bajaj, A.; Lohan, P.; Prabhat, N.; Jha, P.N.; Mehrotra, R. Biodiesel Production through Lipase Catalyzed Transesterification: An Overview. J. Mol. Catal. B Enzym. 2010, 62, 9–14. [Google Scholar] [CrossRef]

- Ma, F.; Hanna, M.A. Biodiesel Production: A Review. Bioresour. Technol. 1999, 70, 1–15. [Google Scholar] [CrossRef]

- Meher, L.C.; Vidya Sagar, D.; Naik, S.N. Technical Aspects of Biodiesel Production by Transesterification—A Review. Renew. Sustain. Energy Rev. 2006, 10, 248–268. [Google Scholar] [CrossRef]

- Mota, G.F.; de Sousa, I.G.; de Oliveira, A.L.B.; Cavalcante, A.L.G.; da Silva, M.K.; Cavalcante, F.T.T.; da Silva Souza, J.E.; de Aguiar Falcão, Í.R.; Rocha, T.G.; Valério, R.B.R.; et al. Biodiesel Production from Microalgae Using Lipase-Based Catalysts: Current Challenges and Prospects. Algal Res. 2022, 62, 102616. [Google Scholar] [CrossRef]

- Vicente, G.; Martínez, M.; Aracil, J. Integrated Biodiesel Production: A Comparison of Different Homogeneous Catalysts Systems. Bioresour. Technol. 2004, 92, 297–305. [Google Scholar] [CrossRef]

- Ullah, K.; Ahmad, M.; Sharma, V.K.; Lu, P.; Harvey, A.; Zafar, M.; Sultana, S. Assessing the Potential of Algal Biomass Opportunities for Bioenergy Industry: A Review. Fuel 2015, 143, 414–423. [Google Scholar] [CrossRef]

- Kuan, I.-C.; Kao, W.-C.; Chen, C.-L.; Yu, C.-Y. Microbial Biodiesel Production by Direct Transesterification of Rhodotorula glutinis Biomass. Energies 2018, 11, 1036. [Google Scholar] [CrossRef]

- Martani, F.; Maestroni, L.; Torchio, M.; Ami, D.; Natalello, A.; Lotti, M.; Porro, D.; Branduardi, P. Conversion of Sugar Beet Residues into Lipids by Lipomyces starkeyi for Biodiesel Production. Microb. Cell Fact. 2020, 19, 204. [Google Scholar] [CrossRef] [PubMed]

- Lovarelli, D.; Bacenetti, J. Bridging the Gap between Reliable Data Collection and the Environmental Impact for Mechanised Field Operations. Biosyst. Eng. 2017, 160, 109–123. [Google Scholar] [CrossRef]

- Seyyedhasani, H.; Dvorak, J.S. Reducing Field Work Time Using Fleet Routing Optimization. Biosyst. Eng. 2018, 169, 1–10. [Google Scholar] [CrossRef]

- Battiato, A.; Diserens, E. Tractor Traction Performance Simulation on Differently Textured Soils and Validation: A Basic Study to Make Traction and Energy Requirements Accessible to the Practice. Soil Tillage Res. 2017, 166, 18–32. [Google Scholar] [CrossRef]

- Lyasko, M. How to Calculate the Effect of Soil Conditions on Tractive Performance. J. Terramech. 2010, 47, 423–445. [Google Scholar] [CrossRef]

- Peça, J.O.; Serrano, J.M.; Pinheiro, A.; Carvalho, M.; Nunes, M.; Ribeiro, L.; Santos, F. Speed Advice for Power Efficient Drawbar Work. J. Terramech. 2010, 47, 55–61. [Google Scholar] [CrossRef]

- Janulevičius, A.; Juostas, A.; Čiplienė, A. Estimation of Carbon-Oxide Emissions of Tractors during Operation and Correlation with the Not-to-Exceed Zone. Biosyst. Eng. 2016, 147, 117–129. [Google Scholar] [CrossRef]

- Zaman, M.; Kleineidam, K.; Bakken, L.; Berendt, J.; Bracken, C.; Cai, Z.; Chang, S.X.; Clough, T.; Dawar, K.; Ding, W.X.; et al. Measuring Emission of Agricultural Greenhouse Gases and Developing Mitigation Options using Nuclear and Related Techniques, 1st ed.; Springer: Cham, Switzerland, 2021; 337p. [Google Scholar] [CrossRef]

- Qafoku, N.P. Climate-Change Effects on Soils: Accelerated Weathering, Soil Carbon, and Elemental Cycling. Adv. Agron. 2015, 131, 111–172. [Google Scholar] [CrossRef]

- Tamocai, C.; Canadell, J.G.; Schuur, E.A.G.; Kuhry, P.; Mazhitova, G.; Zimov, S. Soil Organic Carbon Pools in the Northern Circumpolar Permafrost Region. Glob. Biogeochem. Cycles 2009, 23, GB2023. [Google Scholar] [CrossRef]

- Raich, J.W.; Potter, C.S. Global Patterns of Carbon Dioxide Emissions from Soils. Glob. Biogeochem. Cycles 1995, 9, 23–36. [Google Scholar] [CrossRef]

- Birch, E.L. A Review of “Climate Change 2014: Impacts, Adaptation, and Vulnerability” and “Climate Change 2014: Mitigation of Climate Change”. J. Am. Plan. Assoc. 2014, 80, 184–185. [Google Scholar] [CrossRef]

- Ray, R.L.; Griffin, R.W.; Fares, A.; Elhassan, A.; Awal, R.; Woldesenbet, S.; Risch, E. Soil CO2 Emission in Response to Organic Amendments, Temperature, and Rainfall. Sci. Rep. 2020, 10, 584. [Google Scholar] [CrossRef] [PubMed]

- Chapuis-Lardy, L.; Wrage, N.; Metay, A.; Chotte, J.L.; Bernoux, M. Soils, a Sink for N2O? A Review. Glob. Change Biol. 2007, 13, 1–17. [Google Scholar] [CrossRef]

- Ludwig, J.; Meixner, F.X.; Vogel, B.; Förstner, J. Soil-Air Exchange of Nitric Oxide: An Overview of Processes, Environmental Factors, and Modeling Studies. Biogeochemistry 2001, 52, 225–257. [Google Scholar] [CrossRef]

- Schindlbacher, A.; Zechmeister-Boltenstern, S.; Butterbach-Bahl, K. Effects of Soil Moisture and Temperature on NO, NO2, and N2O Emissions from European Forest Soils. J. Geophys. Res. Atmos. 2004, 109, 17302. [Google Scholar] [CrossRef]

- Fang, C.; Moncrieff, J.B. The Dependence of Soil CO2 Efflux on Temperature. Soil Biol. Biochem. 2001, 33, 155–165. [Google Scholar] [CrossRef]

- Holst, J.; Liu, C.; Yao, Z.; Brüggemann, N.; Zheng, X.; Giese, M.; Butterbach-Bahl, K. Fluxes of Nitrous Oxide, Methane, and Carbon Dioxide during Freezing–Thawing Cycles in an Inner Mongolian Steppe. Plant Soil 2008, 308, 105–117. [Google Scholar] [CrossRef]

- Groffman, P.M.; Hardy, J.P.; Driscoll, C.T.; Fahey, T.J. Snow Depth, Soil Freezing, and Fluxes of Carbon Dioxide, Nitrous Oxide, and Methane in a Northern Hardwood Forest. Glob. Change Biol. 2006, 12, 1748–1760. [Google Scholar] [CrossRef]

- Dutaur, L.; Verchot, L.V. A Global Inventory of the Soil CH4 Sink. Global Biogeochem. Cycles 2007, 21, 4013. [Google Scholar] [CrossRef]

- Cuhel, J.; Simek, M.; Laughlin, R.J.; Bru, D.; Chèneby, D.; Watson, C.J.; Philippot, L. Insights into the Effect of Soil pH on N2O and N2 Emissions and Denitrifier Community Size and Activity. Appl. Environ. Microbiol. 2010, 76, 1870–1878. [Google Scholar] [CrossRef]

- Pilegaard, K.; Skiba, U.; Ambus, P.; Beier, C.; Brüggemann, N.; Butterbach-Bahl, K.; Dick, J.; Dorsey, J.; Duyzer, J.; Gallagher, M.; et al. Factors Controlling Regional Differences in Forest Soil Emission of Nitrogen Oxides (NO and N2O). Biogeosciences 2006, 3, 651–661. [Google Scholar] [CrossRef]

- Zhang, A.; Cui, L.; Pan, G.; Li, L.; Hussain, Q.; Zhang, X.; Zheng, J.; Crowley, D. Effect of Biochar Amendment on Yield and Methane and Nitrous Oxide Emissions from a Rice Paddy in the Tai Lake Plain, China. Agric. Ecosyst. Environ. 2010, 139, 469–475. [Google Scholar] [CrossRef]

- Sanz-Cobena, A.; García-Marco, S.; Quemada, M.; Gabriel, J.L.; Almendros, P.; Vallejo, A. Do Cover Crops Enhance N2O, CO2, or CH4 Emissions from Soil in Mediterranean Arable Systems? Sci. Total Environ. 2014, 466–467, 164–174. [Google Scholar] [CrossRef] [PubMed]

- Jungkunst, H.F.; Fiedler, S. Latitudinally Differentiated Water Table Control of Carbon Dioxide, Methane, and Nitrous Oxide Fluxes from Hydromorphic Soils: Feedbacks to Climate Change. Glob. Change Biol. 2007, 13, 2668–2683. [Google Scholar] [CrossRef]

- Paustian, K.; Six, J.; Elliot, E.T.; Hunt, H.W. Management Options for Reducing CO2 Emissions from Agricultural Soils. Biogeochemistry 2000, 48, 147–163. [Google Scholar] [CrossRef]

- Ingram, J.; Maye, D. What Are the Implications of Digitalisation for Agricultural Knowledge? Front. Sustain. Food Syst. 2020, 4, 66. [Google Scholar] [CrossRef]

- Saiz-Rubio, V.; Rovira-Más, F. From Smart Farming Towards Agriculture 5.0: A Review on Crop Data Management. Agronomy 2020, 10, 207. [Google Scholar] [CrossRef]

- Garnier, P.; Makowski, D.; Hedde, M.; Bertrand, M. Changes in Soil Carbon Mineralization Related to Earthworm Activity Depend on the Time Since Inoculation and Their Density in Soil. Sci. Rep. 2022, 12, 13616. [Google Scholar] [CrossRef]

- Porwollik, V.; Rolinski, S.; Heinke, J.; Müller, C. Generating a Rule-Based Global Gridded Tillage Dataset. Earth Syst. Sci. Data 2019, 11, 823–843. [Google Scholar] [CrossRef]

- Robinson, S. Climate Change Adaptation in SIDS: A Systematic Review of the Literature Pre and Post the IPCC Fifth Assessment Report. Wiley Interdiscip. Rev. Clim. Change 2020, 11, e653. [Google Scholar] [CrossRef]

- Bayer, C.; Gomes, J.; Vieira, F.C.B.; Zanatta, J.A.; de Cássia Piccolo, M.; Dieckow, J. Methane Emission from Soil under Long-Term No-Till Cropping Systems. Soil Tillage Res. 2012, 124, 1–7. [Google Scholar] [CrossRef]

- Yadav, D.; Wang, J. Modelling Carbon Dioxide Emissions from Agricultural Soils in Canada. Environ. Pollut. 2017, 230, 1040–1049. [Google Scholar] [CrossRef] [PubMed]

- Vellinga, T.V.; van den Pol-van Dasselaar, A.; Kuikman, P.J. The Impact of Grassland Ploughing on CO2 and N2O Emissions in the Netherlands. Nutr. Cycl. Agroecosyst. 2004, 70, 33–45. [Google Scholar] [CrossRef]

- Petersen, B.M.; Knudsen, M.T.; Hermansen, J.E.; Halberg, N. An Approach to Include Soil Carbon Changes in the Life Cycle Assessments. J. Clean. Prod. 2013, 52, 217–224. [Google Scholar] [CrossRef]

- Golka, W. Soil Cultivation Techniques That Reduce Greenhouse Gas Emissions. Probl. Inżynierii Rol. 2011, 19, 51–60. [Google Scholar]

- Tukker, A.; Jansen, B. Environmental Impacts of Products: A Detailed Review of Studies. J. Ind. Ecol. 2006, 10, 159–182. [Google Scholar] [CrossRef]

- Chataut, G.; Bhatta, B.; Joshi, D.; Subedi, K.; Kafle, K. Greenhouse Gases Emission from Agricultural Soil: A Review. J. Agric. Food Res. 2023, 11, 100533. [Google Scholar] [CrossRef]

- Zhao, R.F.; Chen, X.P.; Zhang, F.S.; Zhang, H.; Schröder, J.; Römheld, V. Fertilization and Nitrogen Balance in a Wheat–Maize Rotation System in North China. Agron. J. 2006, 98, 938–945. [Google Scholar] [CrossRef]

- Greenhouse Gas Emissions from Agriculture—Agricultural Practices Reducing Greenhouse Gas Emissions. Available online: https://www.kpodr.pl/wp-content/uploads/2020/11/4-_J%C4%99drejek_Anna-Emisja-gaz%C3%B3w-cieplarnianych-z-rolnictwa.pdf (accessed on 2 August 2024).

- No-Till Cultivation and Climate. Available online: https://www.farmer.pl/bez-pluga/uprawa-bezorkowa-a-klimat,117580.html (accessed on 2 August 2024).

- Environmental Benefits of Conservation Tillage—Glyphosate Renewal Group. Available online: https://www.glyphosate.eu/pl/przydatne-informacje/rolnictwo-zrownowazone/srodowiskowe-korzysci-stosowania-uprawy-konserwujacej/ (accessed on 2 August 2024).

- What are the Benefits of Soil Conservation Tillage? Świętokrzyski Agricultural Advisory Centre in Modliszewice. Available online: https://www.sodr.pl/informacje-branzowe/index/Jakie-korzysci-z-uprawy-konserwujacej-gleby/idn:2660 (accessed on 2 August 2024).

- Johnson, J.M.F.; Franzluebbers, A.J.; Weyers, S.L.; Reicosky, D.C. Agricultural Opportunities to Mitigate Greenhouse Gas Emissions. Environ. Pollut. 2007, 150, 107–124. [Google Scholar] [CrossRef]

- Yue, K.; Fornara, D.A.; Heděnec, P.; Wu, Q.; Peng, Y.; Peng, X.; Ni, X.; Wu, F.; Peñuelas, J. No Tillage Decreases GHG Emissions with No Crop Yield Tradeoff at the Global Scale. Soil Tillage Res. 2023, 228, 105643. [Google Scholar] [CrossRef]

- Plaza-Bonilla, D.; Álvaro-Fuentes, J.; Arrúe, J.L.; Cantero-Martínez, C. Tillage and Nitrogen Fertilization Effects on Nitrous Oxide Yield-Scaled Emissions in a Rainfed Mediterranean Area. Agric. Ecosyst. Environ. 2014, 189, 43–52. [Google Scholar] [CrossRef]

- Manni, M.; Di Giuseppe, A.; Nicolini, A.; Sciurpi, F.; Cotana, F. Influences of a Highly Reflective Mulching Membrane on Heat Propagation throughout the Soil. Sustainability 2021, 13, 9737. [Google Scholar] [CrossRef]

- Di Giuseppe, A.; Pazzaglia, A.; Fabbrizi, G.; Castellani, B.; Nicolini, A.; Rossi, F.; Cotana, F. Effects of a High-Reflective Mulching Membrane on Environmental Parameters and Food Crops Cultivation: Results from a Summer Season Campaign. J. Phys. Conf. Ser. 2023, 2648, 012087. [Google Scholar] [CrossRef]

- Zhang, G.X.; Zhao, D.; Liu, S.; Liao, Y.; Han, J. Can Controlled-Release Urea Replace the Split Application of Normal Urea in China? A Meta-Analysis Based on Crop Grain Yield and Nitrogen Use Efficiency. Field Crops Res. 2022, 275, 108343. [Google Scholar] [CrossRef]

- Wood, S.; Cowie, A. A Review of Greenhouse Gas Emission Factors for Fertiliser Production. IEA Bioenergy Task 2004, 38, 20. [Google Scholar]

- Erisman, J.W.; Sutton, M.A.; Galloway, J.; Klimont, Z.; Winiwarter, W. How a Century of Ammonia Synthesis Changed the World. Nat. Geosci. 2008, 1, 636–639. [Google Scholar] [CrossRef]

- AR5 Synthesis Report: Climate Change 2014. Available online: https://www.ipcc.ch/site/assets/uploads/2018/05/SYR_AR5_FINAL_full_wcover.pdf (accessed on 6 January 2025).

- Kongshaug, G. Energy Consumption and Greenhouse Gas Emission in Fertilizer Production. Available online: https://www.fertilizer.org/wp-content/uploads/2023/01/1998_ifa_marrakech_kongshaug.pdf (accessed on 6 November 2024).

- Sutton, M.A.; Howard, C.M.; Bleeker, A.; Datta, A. The Global Nutrient Challenge: From Science to Public Engagement. Environ. Dev. 2013, 6, 80–85. [Google Scholar] [CrossRef]

- International Federation for Information Processing. Available online: https://www.ifip.org/ (accessed on 6 November 2024).

- The Royal Society. “Ammonia: Zero-Carbon Fertiliser, Fuel, and Energy Store”. Available online: https://www.royalsociety.org/ (accessed on 6 November 2024).

- From Farm to Fork Strategy. Available online: https://food.ec.europa.eu/horizontal-topics/farm-fork-strategy_en (accessed on 6 November 2024).

- Regulation (EC) No 1107/2009 of the European Parliament and of the Council of 21 October 2009. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32009R1107 (accessed on 15 January 2025).

- Bellarby, J.; Foereid, B.; Hastings, A.F.S.J. Cool Farming: Climate Impacts of Agriculture and Mitigation Potential; Greenpeace International: Amsterdam, The Netherlands, 2008; p. 44. [Google Scholar]

- Gaidajis, G.; Kakanis, I. Life Cycle Assessment of Nitrate and Compound Fertilizers Production—A Case Study. Sustainability 2020, 13, 148. [Google Scholar] [CrossRef]

- Torrellas, M.; Antón, A.; López, J.C.; Baeza, E.J.; Parra, J.P.; Muñoz, P.; Montero, J.I. LCA of a Tomato Crop in a Multi-Tunnel Greenhouse in Almeria. Int. J. Life Cycle Assess. 2012, 17, 863–875. [Google Scholar] [CrossRef]

- Sobolewska, A.; Bukowski, M. Consumption of Nitrogen Fertilizers in the EU—External Costs of Their Production by Country of Application. Agriculture 2025, 15, 224. [Google Scholar] [CrossRef]

- Mauromicale, G.; Longo, A.M.G.; Monaco, A.L. The Effect of Organic Supplementation of Solarized Soil on the Quality of Tomato Fruit. Sci. Hortic. 2011, 129, 189–196. [Google Scholar] [CrossRef]

- Fan, X.; Li, F.; Liu, F.; Kumar, D. Fertilization with a New Type of Coated Urea: Evaluation for Nitrogen Efficiency and Yield in Winter Wheat. J. Plant Nutr. 2004, 27, 853–865. [Google Scholar] [CrossRef]

- Institute of Agricultural and Food Economics—Economic Burden of Fertilization in Agriculture. Available online: https://dpr.iung.pl/wp-content/uploads/ekonomiczne_uwarunkowania_nawozenia3.pdf (accessed on 6 November 2024).

- Walling, E.; Vaneeckhaute, C. Greenhouse Gas Emissions from Inorganic and Organic Fertilizer Production and Use: A Review of Emission Factors and Their Variability. J. Environ. Manag. 2020, 276, 111211. [Google Scholar] [CrossRef]

- Fertilizers Europe. Available online: https://www.fertilizerseurope.com/news/fertilizers-europe-joins-the-european-board-on-agriculture-and-food-ebaf/ (accessed on 6 November 2024).

- Koop, S.H.A.; Leeuwen, C.J. The Challenges of Water, Waste and Climate Change in Cities. Environ. Dev. Sustain. 2017, 19, 385–418. [Google Scholar] [CrossRef]

- Kaab, A.; Sharifi, M.; Mobli, H.; Nabavi-Pelesaraei, A.; Kwok-Wing, C. Combined Lifecycle Assessment and Artificial Intelligence for Prediction of Output Energy and Environmental Impacts of Sugarcane Production. Sci. Total Environ. 2019, 664, 1005–1019. [Google Scholar] [CrossRef]

- Sutton, M.A.; Howard, C.; Erisman, J.W.; Billen, G.; Bleeker, A.; Grenfelt, P.; van Grinsven, H.; Grizzetti, B. The European Nitrogen Assessment: Sources, Effects and Policy Perspectives; Cambridge University Press: Cambridge, UK, 2011; pp. I–VI. [Google Scholar] [CrossRef]

- Shakoor, A.; Shahbaz, M.; Farooq, T.H.; Sahar, N.E.; Shahzad, S.M.; Altaf, M.M.; Ashraf, M. A Global Meta-Analysis of Greenhouse Gases Emission and Crop Yield under No-Tillage as Compared to Conventional Tillage. Sci. Total Environ. 2021, 750, 142299. [Google Scholar] [CrossRef]

- Chen, Y.T.; Peng, J.; Wang, J.; Fu, P.; Yu, H.Y.; Zhang, C.; Fahad, S.; Peng, S.; Cui, K.; Nie, L.; et al. Crop Management Based on Multi-Split Topdressing Enhances Grain Yield and Nitrogen Use Efficiency in Irrigated Rice in China. Field Crops Res. 2015, 184, 50–57. [Google Scholar] [CrossRef]

- Wu, W.; Ma, B.L.; Fan, J.-J.; Sun, M.; Yuan, Y.Y.; Guo, W.-S.; Voldeng, H.D. Management of Nitrogen Fertilization to Balance Reducing Lodging Risk and Increasing Yield and Protein Content in Spring Wheat. Field Crops Res. 2019, 241, 107584. [Google Scholar] [CrossRef]

- Du, X.B.; Zhang, X.; Xi, M.; Kong, L. Split Application Enhances Sweet Potato Starch Production by Regulating the Conversion of Sucrose to Starch under Reduced Nitrogen Supply. Plant Physiol. Biochem. 2020, 151, 743–750. [Google Scholar] [CrossRef]

- Lu, J.; Hu, T.; Zhang, B.; Wang, L.; Yang, S.; Fan, J.; Yan, S.; Zhang, F. Nitrogen Fertilizer Management Effects on Soil Nitrate Leaching, Grain Yield and Economic Benefit of Summer Maize in Northwest China. Agric. Water Manag. 2021, 247, 106739. [Google Scholar] [CrossRef]

- Yang, M.; Hou, Z.; Guo, N.; Yang, E.; Sun, D.; Fang, Y. Effects of Enhanced-Efficiency Nitrogen Fertilizers on CH4 and CO2 Emissions in a Global Perspective. Field Crops Res. 2022, 288, 108694. [Google Scholar] [CrossRef]

- Li, Y.; Shah, S.H.H.; Wang, J. Modelling of Nitrification Inhibitor and Its Effects on Emissions of Nitrous Oxide (N2O) in the UK. Sci. Total Environ. 2020, 709, 136156. [Google Scholar] [CrossRef] [PubMed]

- Qiao, D.; Liu, H.; Yu, L.; Bao, X.; Simon, G.P.; Petinakis, E.; Chen, L. Preparation and Characterization of Slow-Release Fertilizer Encapsulated by Starch-Based Superabsorbent Polymer. Carbohydr. Polym. 2016, 147, 146–154. [Google Scholar] [CrossRef] [PubMed]

- Vilarrasa-Nogué, M.; Teira-Esmatges, M.R.; Pascual, M.; Villar, J.M.; Rufat, J. Effect of N Dose, Fertilization Duration and Application of a Nitrification Inhibitor on GHG Emissions from a Peach Orchard. Sci. Total Environ. 2020, 699, 134042. [Google Scholar] [CrossRef]

- Lan, T.; Han, Y.; Roelcke, M.; Nieder, R.; Cai, Z. Effects of the Nitrification Inhibitor Dicyandiamide (DCD) on Gross N Transformation Rates and Mitigating N2O Emission in Paddy Soils. Soil Biol. Biochem. 2013, 67, 174–182. [Google Scholar] [CrossRef]

- Ministry of Agriculture and Rural Development; Greenhouse Gas (GHG) Emissions from Agriculture. Available online: https://www.gov.pl/web/rolnictwo/emisje-gazow-cieplarnianych-ghg-z-rolnictwa (accessed on 29 November 2024).

- Bai, M.; Impraim, R.; Coates, T.; Flesch, T.; Trouvé, R.; van Grinsven, H.; Cao, Y.; Hill, J.; Chen, D. Lignite Effects on NH3, N2O, CO2 and CH4 Emissions during Composting of Manure. J. Environ. Manag. 2020, 271, 110960. [Google Scholar] [CrossRef]

- Iqbal, A.; Liu, X.; Chen, G. Municipal Solid Waste: Review of Best Practices in Application of Life Cycle Assessment and Sustainable Management Techniques. Sci. Total Environ. 2020, 729, 138622. [Google Scholar] [CrossRef]

- Kaza, S.; Yao, L.C.; Bhada-Tata, P.; Van Woerden, F.; Martin, T.M.R.; Serrona, K.R.B.; Thakur, R.; Pop, F.; Hayashi, S.; Solorzano, G.; et al. What a Waste 2.0: A Global Snapshot of Solid Waste Management to 2050; Urban Development Series; World Bank Group: Washington, DC, USA, 2018. [Google Scholar]

- Ministerstwo Klimatu i Środowiska. Available online: https://www.gov.pl/web/srodowisko (accessed on 29 November 2024).

- Suthar, S.; Singh, S. Vermicomposting of Domestic Waste by Using Two Epigeic Earthworms. J. Environ. Sci. Technol. 2008, 5, 99–106. [Google Scholar] [CrossRef]

- Kaviraj; Sharma, S. Municipal Solid Waste Management through Vermicomposting Employing Exotic and Local Species of Earthworms. Bioresour. Technol. 2003, 90, 169–173. [Google Scholar] [CrossRef]

- Dumontet, S.; Dinel, H.; Baloda, S.B. Pathogen Reduction in Sewage Sludge by Composting and Other Biological Treatments: A Review. Biol. Agric. Hortic. 1999, 16, 409–430. [Google Scholar] [CrossRef]

- European Environment Agency (EEA). Bio-Waste in Europe—Turning Challenges into Opportunities. EEA Report 2020. Available online: https://www.eea.europa.eu/publications/bio-waste-in-europe (accessed on 29 November 2024).

- Hoornweg, D.; Bhada-Tata, P. What a Waste: A Global Review of Solid Waste Management; World Bank: Washington, DC, USA, 2012. [Google Scholar]

- ECN DATA REPORT 2022. Compost and Digest for a Circular Bioeconomy: Overview of Bio-Waste Collection, Treatment & Markets Across Europe. Available online: https://www.compostnetwork.info/wordpress/wp-content/uploads/ECN-rapport-2022.pdf (accessed on 5 December 2024).

- Yasmin, N.; Jamuda, M.; Panda, A.K.; Samal, K.; Nayak, J.K. Emission of greenhouse gases (GHGs) during composting and vermicomposting: Measurement, mitigation, and perspectives. Energy Nexus 2022, 7, 100092. [Google Scholar] [CrossRef]

- Ermolaev, E.; Sundberg, C.; Pell, M.; Jönsson, H. Greenhouse gas emissions from home composting in practice. Bioresour. Technol. 2014, 151, 174–182. [Google Scholar] [CrossRef] [PubMed]

- Li, H.H.; Zhang, T.; Sabry, M.; Shaheen, S.M.; Abdelrahman, H.; Ali, E.F.; Bolan, N.S.; Li, G.; Rinklebe, J. Microbial inoculants and struvite improved organic matter humification and stabilized phosphorus during swine manure composting: Multivariate and multiscale investigations. Bioresour. Technol. 2022, 351, 126976. [Google Scholar] [CrossRef] [PubMed]

- Tran, H.-T.; Bolan, N.S.; Lin, C.H.; Binh, Q.A.; Nguyen, M.-K.; Luu, T.A.; Le, V.G.; Pham, C.Q.; Hoang, H.G.; Vo, D.-V.N. Succession of biochar addition for soil amendment and contaminants remediation during co-composting: A state-of-the-art review. J. Environ. Manag. 2023, 342, 118191. [Google Scholar] [CrossRef]

- Nordahl, S.L.; Preble, C.V.; Kirchstetter, T.W.; Scown, C.D. Greenhouse gas and air pollutant emissions from composting. Environ. Sci. Technol. 2023, 57, 2235–2247. [Google Scholar] [CrossRef]

- Breitenbeck, G.A.; Schellinger, D. Calculating the reduction in material mass and volume during composting. Compost Sci. Util. 2004, 12, 365–371. [Google Scholar] [CrossRef]

- Guan, P.; Prasher, S.O.; Afzal, M.T.; George, S.; Ronholm, J.; Dhiman, J.; Patel, R.M. Removal of Escherichia coli from lake water in a biochar-amended biosand filtering system. Ecol. Eng. 2020, 150, 105819. [Google Scholar] [CrossRef]

- Ermolaev, E.; Jarvis, Å.; Sundberg, C.; Smårs, S.; Pell, M.; Jönsson, H. Nitrous oxide and methane emissions from food waste composting at different temperatures. Waste Manag. 2015, 46, 113–119. [Google Scholar] [CrossRef]

- Lores, M.; Gómez-Brandón, M.; Pérez-Díaz, D.; Domínguez, J. Using FAME profiles for the characterization of animal wastes and vermicomposts. Soil Biol. Biochem. 2006, 38, 2993–2996. [Google Scholar] [CrossRef]

- Chattopadhyay, G.N. Use of vermicomposting biotechnology for recycling organic wastes in agriculture. Int. J. Recycl. Org. Waste Agric. 2012, 1, 8. [Google Scholar] [CrossRef]

- Tognetti, C.; Laos, F.; Mazzarino, M.J.; Hernández, M.T. Composting vs. vermicomposting: A comparison of end product quality. Compos. Sci. Util. 2005, 13, 6–13. [Google Scholar] [CrossRef]

- Guo, L.; Wu, G.; Li, C.; Liu, W.; Yu, X.; Cheng, D.; Jiang, G. Vermicomposting with maize increases agricultural benefits by 304%. Agron. Sustain. Dev. 2015, 35, 1149–1155. [Google Scholar] [CrossRef]

- Lv, B.; Zhang, D.; Cui, Y.; Yin, F. Effects of C/N ratio and earthworms on greenhouse gas emissions during vermicomposting of sewage sludge. Bioresour. Technol. 2018, 268, 408–414. [Google Scholar] [CrossRef] [PubMed]

- Nigussie, A.; Kuyper, T.W.; Bruun, S.; de Neergaard, A. Vermicomposting as a technology for reducing nitrogen losses and greenhouse gas emissions from small-scale composting. J. Clean. Prod. 2016, 139, 429–439. [Google Scholar] [CrossRef]

- Samal, K.; Naushin, Y.; Priya, K. Challenges in the implementation of Phyto Fuel System (PFS) for wastewater treatment and harnessing bio-energy. J. Environ. Chem. Eng. 2020, 8, 104388. [Google Scholar] [CrossRef]

- Li, Y.; Kumar Awasthi, M.; Sindhu, R.; Binod, P.; Zhang, Z.; Taherzadeh, M.J. Biochar preparation and evaluation of its effect in composting mechanism: A review. Bioresour. Technol. 2023, 384, 129329. [Google Scholar] [CrossRef]

- Wang, Q.; Awasthi, M.K.; Ren, X.; Zhao, J.; Li, R.; Wang, Z.; Wang, M.; Chen, H.; Zhang, Z. Combining biochar, zeolite and wood vinegar for composting of pig manure: The effect on greenhouse gas emission and nitrogen conservation. Waste Manag. 2018, 74, 221–230. [Google Scholar] [CrossRef]

- Stocker, T.F.; Qin, D.; Plattner, G.-K.; Alexander, L.V.; Allen, S.K.; Bindoff, N.L.; Bréon, F.-M.; Church, J.A.; Cubasch, U.; Emori, S.; et al. Technical Summary. In Climate Change 2013: The Physical Science Basis; Contribution of Working Group I to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change; Cambridge University Press: Cambridge, UK, 2013; pp. 33–115. [Google Scholar]

- Jäckel, U.; Thummes, K.; Kämpfer, P. Thermophilic methane production and oxidation in compost. FEMS Microbiol. Ecol. 2005, 52, 175–184. [Google Scholar] [CrossRef]

- Yuan, J.; Chadwick, D.; Zhang, D.; Li, G.; Chen, S.; Luo, W.; Du, L.; He, S.; Peng, S. Effects of aeration rate on maturity and gaseous emissions during sewage sludge composting. Waste Manag. 2016, 56, 403–410. [Google Scholar] [CrossRef]

- Vergara, S.E.; Silver, W.L. Greenhouse Gas Emissions from Windrow Composting of Organic Wastes: Patterns and Emissions Factors. Environ. Res. Lett. 2019, 14, 124027. [Google Scholar] [CrossRef]

- Agyarko-Mintah, E.; Cowie, A.; Singh, B.P.; Joseph, S.; Van Zwieten, L.; Cowie, A.; Harden, S.; Smillie, R. Biochar increases nitrogen retention and lowers greenhouse gas emissions when added to composting poultry litter. Waste Manag. 2017, 61, 138–149. [Google Scholar] [CrossRef] [PubMed]

- Chen, W.; Liao, X.D.; Wu, Y.B.; Liang, J.B.; Mi, J.D.; Huang, J.J.; Zhang, H.; Wu, Y.; Qiao, Z.F.; Li, X.; et al. Effects of different types of biochar on methane and ammonia mitigation during layer manure composting. Waste Manag. 2017, 61, 506–515. [Google Scholar] [CrossRef] [PubMed]

- Pan, C.N.; Zhao, Y.; Zhao, L.; Wu, J.Q.; Zhang, X.; Xie, X.Y.; Kang, K.J.; Jia, L.M. Modified montmorillonite and illite adjusted the preference of biotic and abiotic pathways of humus formation during chicken manure composting. Bioresour. Technol. 2021, 319, 124121. [Google Scholar] [CrossRef] [PubMed]

- Geng, X.; Yang, H.; Gao, W.; Yue, D.; Mu, D.; Wei, Z. Greenhouse gas emission characteristics during kitchen waste composting with biochar and zeolite addition. Bioresource Technol. 2024, 399, 130575. [Google Scholar] [CrossRef]

- Samal, K.; Mahapatra, S.; Ali, M.H.; Samal, K. Pharmaceutical wastewater as emerging contaminants (EC): Treatment technologies, impact on environment and human health. Energy Nexus 2022, 6, 100076. [Google Scholar] [CrossRef]

- Wang, J.; Hu, Z.; Xu, X.; Jiang, X.; Zheng, B.; Liu, X.; Pan, X.; Kardol, P. Emissions of ammonia and greenhouse gases during combined pre-composting and vermicomposting of duck manure. Waste Manag. 2014, 34, 1546–1552. [Google Scholar] [CrossRef]

- Bernal, M.P.; Alburquerque, J.A.; Moral, R. Composting of animal manures and chemical criteria for compost maturity assessment: A review. Bioresour. Technol. 2009, 100, 5444–5453. [Google Scholar] [CrossRef]

- Thangarajan, R.; Bolan, N.S.; Tian, G.; Naidu, R.; Kunhikrishnan, A. Role of organic amendment application on greenhouse gas emission from soil. Sci. Total Environ. 2013, 465, 72–96. [Google Scholar] [CrossRef]

- Thakrar, S.K.; Goodkind, A.L.; Tessum, C.W.; Marshall, J.D.; Hill, J.D. Life cycle air quality impacts on human health from potential switchgrass production in the United States. Biomass Bioenergy 2018, 114, 73. [Google Scholar] [CrossRef]

- Xiao, Y.; Zeng, G.M.; Yang, Z.H.; Ma, Y.H.; Huang, C.; Xu, Z.Y.; Huang, J.; Fan, C.Z. Changes in the actinomycetal communities during continuous thermophilic composting as revealed by denaturing gradient gel electrophoresis and quantitative PCR. Bioresour. Technol. 2011, 102, 1383–1388. [Google Scholar] [CrossRef]

- Vac, S.C.; Popiţa, G.E.; Frunzeti, N.; Popovici, A. Evaluation of greenhouse gas emission from animal manure using the closed chamber method for gas fluxes. Not. Bot. Horti Agrobot. Cluj-Napoca 2013, 41, 576–581. [Google Scholar] [CrossRef]

- Pagliar, P.; Wilson, M.L.; He, Z. Animal manure production and utilization: Impact of modern concentrated animal feeding operations. Agric. Food Sci. Environ. Sci. 2020, 67, 1–14. [Google Scholar] [CrossRef]

- Nguyen, T.L.T.; Hermansen, J.E.; Mogensen, L. Environmental consequences of different beef production systems in the EU. J. Clean. Prod. 2010, 18, 756–766. [Google Scholar] [CrossRef]

- Kolasa-Więcek, A. Impact of increased livestock production on greenhouse gas emissions. Problematyka Rolno-Żywnościowa 2012, 1, 109–112. [Google Scholar]

- Lv, M.; Li, Z.; Che, Y.; Han, F.X.; Liu, M. Soil Organic C, Nutrients, Microbial Biomass, and Grain Yield of Rice (Oryza sativa L.) after 18 Years of Fertilizer Application to an Infertile Paddy Soil. Biol. Fertil. Soils 2011, 47, 777–783. [Google Scholar] [CrossRef]

- Zhou, M.; Zhu, B.; Wang, S.; Zhu, X.; Vereecken, H.; Brüggemann, N. Stimulation of N2O Emission by Manure Application to Agricultural Soils May Largely Offset Carbon Benefits: A Global Meta-Analysis. Glob. Change Biol. 2017, 23, 4068–4083. [Google Scholar] [CrossRef]

- Systemy Gromadzenia Biogazu i Zarządzanie Obornikiem, Xylem Polska. Available online: https://www.xylem.com/pl-pl/solutions/agriculture--irrigation/biogas/ (accessed on 7 August 2024).

- Verderame, G.M.; Ricci, P.; Del Gaudio, C.; De Risi, M.T. Experimental Tests on Masonry Infilled Gravity- and Seismic-Load Designed RC Frames. In Proceedings of the 16th International Brick and Block Masonry Conference, Padova, Italy, 26–30 June 2016; pp. 1349–1358. [Google Scholar]

- Zahoor, I.; Mushtaq, A. Water Pollution from Agricultural Activities: A Critical Global Review. IJCBS 2023, 23, 164–176. [Google Scholar]

- Chang, B.; Xu, Y.; Zhang, Z.; Wang, X.; Jin, Q.; Wang, Y. Purification Effect of Water Eutrophication Using the Mosaic System of Submerged–Emerged Plants and Growth Response. Plants 2024, 13, 560. [Google Scholar] [CrossRef]

- Różyło, K.; Bohacz, J. Microbial and Enzyme Analysis of Soil after the Agricultural Utilization of Biogas Digestate and Mineral Mining Waste. Int. J. Environ. Sci. Technol. 2020, 17, 1051–1062. [Google Scholar] [CrossRef]

- European Biogas Association. Exploring Digestate’s Contribution to Healthy Soils 2019. Available online: https://www.europeanbiogas.eu/exploring-digestates-contribution-to-healthy-soils-2/ (accessed on 7 August 2024).

- Wang, B.; Lerdau, M.; He, Y. Widespread Production of Nonmicrobial Greenhouse Gases in Soils. Glob. Change Biol. 2017, 23, 4472–4482. [Google Scholar] [CrossRef]

- Möller, K.; Müller, T. Effects of Anaerobic Digestion on Digestate Nutrient Availability and Crop Growth: A Review. Eng. Life Sci. 2012, 3, 242–257. [Google Scholar] [CrossRef]

- Losak, T.; Hlusek, J.; Zatloukalova, A.; Musilova, L.; Skarpa, P.; Zlamalova, T.; Fryc, J.; Vitez, T.; Marecek, J.; Martensson, A. Digestate from Biogas Plants Is an Attractive Alternative to Mineral Fertilisation of Kohlrabi. J. Sustain. Dev. Energy Water Environ. Syst. 2014, 2, 309–318. [Google Scholar] [CrossRef]

- Nkoa, R. Agricultural Benefits and Environmental Risks of Soil Fertilization with Anaerobic Digestates: A Review. Agron. Sustain. Dev. 2014, 34, 473–492. [Google Scholar] [CrossRef]

- Zhao, R.; Wang, H.H.; Gao, J.; Zhang, Y.J.; Li, X.; Zhou, J.J.; Liang, P.; Gao, X.W.; Gu, S.H. Plant Volatile Compound Methyl Benzoate Is Highly Effective Against Spodoptera frugiperda and Safe to Non-Target Organisms as an Eco-Friendly Botanical-Insecticide. Ecotoxicol. Environ. Saf. 2022, 245, 114101. [Google Scholar] [CrossRef]

| Feature/Characteristic | Results | Authors |

|---|---|---|

| Use of biodiesel as an alternative fuel | The use of alternative fuels, specifically biodiesel, resulted in savings ranging from 77 to 81% when compared to an official fossil fuel equivalent of 94 g CO2eq/MJ. Consequently, in 2021, biodiesel saved approximately 45 Mtonnes of CO2eq emissions. | European Biodiesel Board, 2023 [41] |

| Fuel consumption and tractor exhaust emissions | These are largely determined by the engine speed and load modes. The study showed that fuel consumption can be reduced by 5–25% by selecting an operating mode where the engine speed is 70–85% of the nominal value, and the tractor is loaded in a manner that allows the engine to develop 80% of its maximum power. | Peca et al., 2010 [57] |

| Agricultural gas emissions | The agricultural sector alone is responsible for over 80% of anthropogenic N2O emissions, 70% of anthropogenic NH3 emissions, and approximately 40% of anthropogenic CH4 emissions. The primary contributors to these emissions are the use of livestock manure and inorganic fertilisers. | Birch, E.L., 2014 [63] |

| N2O emissions from the soil | Under field conditions, the relationships between moisture and temperature overlap, which hampers the observation of clear relationships. Temperature alone regulates freezing and thawing events, forcing gas emissions from soils and accounting for up to 50% of total annual N2O emissions. | Fang and Moncrieff, 2001 [68]; Holst et al., 2008 [69] |

| Appropriate fertiliser dose | The fertiliser dose should be adjusted to the crops’ needs, as not all forms of nitrogen can be taken up by plants. Such an approach will significantly contribute to minimising N2O emissions. The nitrogen supplied to crops that is not taken up leads to increased N2O emissions. | Sanz-Cobena et al., 2014 [75] |

| Use of fuels | The application of various crop cultivation and processing techniques is a major factor responsible for greenhouse gas emissions. In the agricultural sector, the consumption of fuels and energy in agriculture, including activities such as food processing, the use of inputs on a farm, and the use of land for agricultural purposes, contributes to intensification. | Robinson, S., 2020 [82] |

| No-tillage and reduced tillage | No-tillage has been demonstrated to contribute to reducing methane emissions compared with plough tillage and no-plough tillage. No-tillage, or reduced tillage, has a positive effect on the sustainable development of agriculture, increases the soil carbon content, reduces soil erosion, improves the physical conditions of the soil, and reduces greenhouse gas emissions without compromising crop yields. When comparing no-plough tillage to conventional tillage, the former reduces CH4. | Chataut, G. et al., 2023 [89] Zhao, R.F. et al., 2006 [90] |

| Ploughing | Ploughing is considered the most energy-intensive tillage operation. When fuel is combusted during machinery operation, the main component of the exhaust gas is carbon dioxide. It has been calculated that 1 litre of consumed diesel equals 3.15 kg of carbon dioxide generated. | https://www.farmer.pl/bez-pluga/uprawa-bezorkowa-a-klimat,117580.html (accessed on 2 August 2024) [92] |

| Ploughing, no-plough tillage, no-tillage | Conventional plough tillage emits 180.76 kg CO2/ha, no-plough tillage emits 89.36 kg CO2/ha, whereas no-tillage farming emits only 19.50 kg CO2/ha. | https://www.farmer.pl/bez-pluga/uprawa-bezorkowa-a-klimat,117580.html (accessed on 2 August 2024) [92] |

| Reduced tillage | Reduced tillage increases N2O and CH4 emissions by 31.0 and 24.7%, respectively, while reducing crop yields by 17.4%, without an effect on CO2 emissions, whereas no tillage reduces CO2, N2O, and CH4 emissions and the total global warming potential (GWP) by an average of 15.1, 7.5, 19.8, and 22.6, respectively. | Kai Yue et al., 2023 [96] |

| Fertiliser production | The production of fertilisers consumes approximately 1.2% of global energy and accounts for approximately 1.2% of total greenhouse gas emissions. | Kongshaug, 1998 [104] |

| Ammonia production | According to reports, the production of ammonia is already contributing to 1–2% of global carbon dioxide emissions. | International Federation for Information Processing, 2024 [106] |

| Nitrogen fertiliser | A study examining the entire life cycle of nitrogen fertilisers (from production to field use) reveals that the greatest environmental impact is caused by fertiliser production, as well as nitrogen dioxide emissions resulting from the use of fertilisers. | Torrellas et al., 2012 [112] |

| Fertiliser production in Poland | In 2021, Poland’s share in fertiliser production in the EU was 18.6%, comprising 20.4% for N, 24.4% for P2O5, and 10.6% for K2O, as reported by the Institute of Agricultural and Food Economics (IERiGŻ). | Institute of Agricultural and Food Economics [116] |

| Urea split method | This study showed that the split method produces excellent results in terms of reducing greenhouse gas emissions and nitrate leaching. However, one cannot ignore the fact that its application resulted in significant additional field work and increased labour input, compared with a single basic application of the whole N fertiliser, due to the lack of machinery to support the application of N fertiliser. | Lu et al., 2021 [126] |

| Poland’s agriculture and emissions | Poland’s agriculture is a primary source of nitrous oxide (N2O) emissions, accounting for 80.2% of the country’s total anthropogenic emissions of this gas. Regarding total nitrous oxide emissions from agriculture, 83.7% originated from land use (nitrogen fertilisation) and 15.24% from livestock manure management. | Ministry of Agriculture and Rural Development [132] |

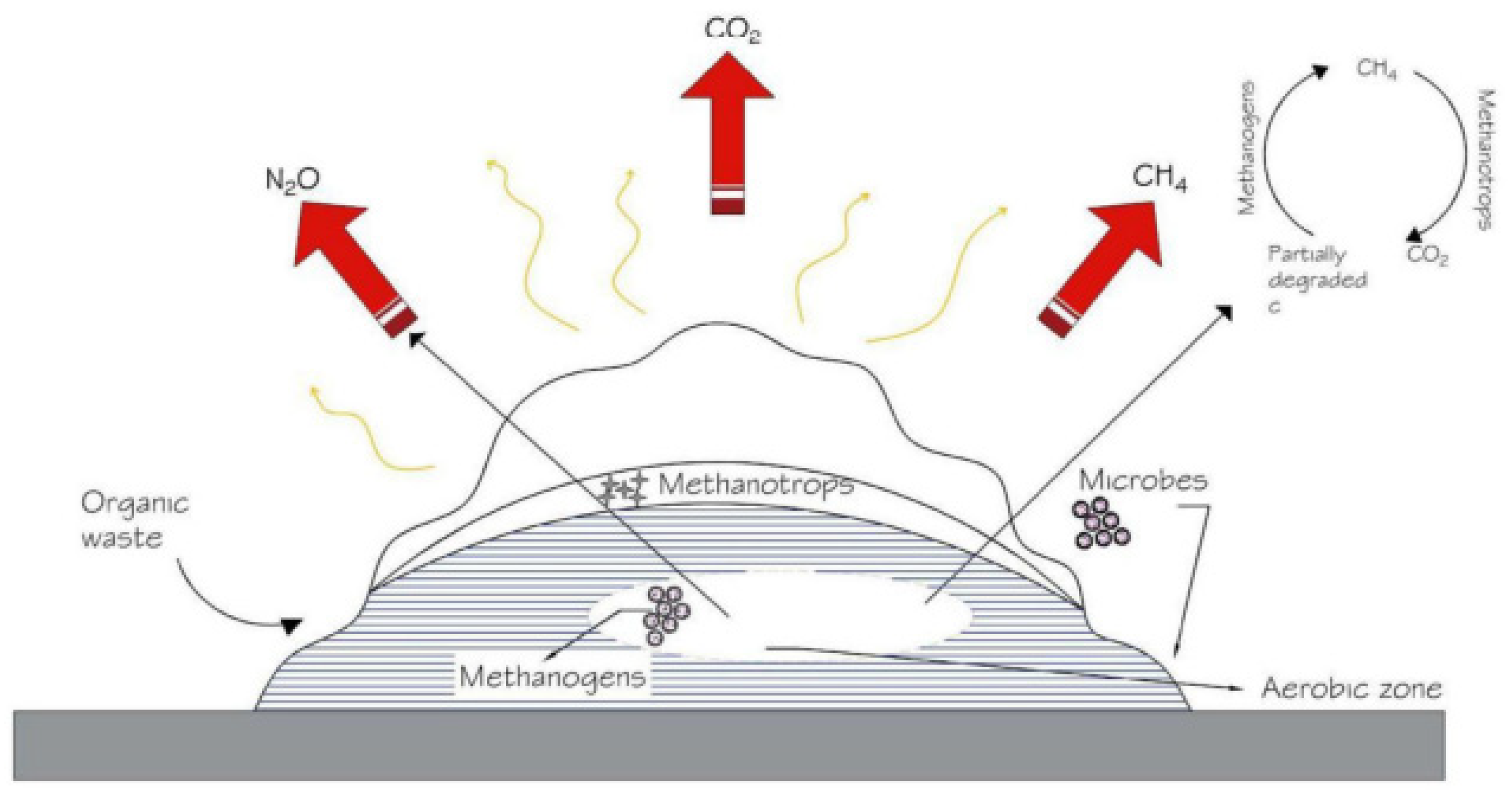

| Methane emissions | According to data acquired by Bai et al., it is estimated that landfills worldwide contribute approximately 12% of annual methane (CH4) emissions, i.e., 734 kg CO2-eq/tonne of treated wet waste. | Bai et al., 2020 [133] |

| Biowaste recycling | Every year, 118 to 138 million tonnes of biological waste are generated across the European Union, of which only approximately 40% (equivalent to 47.5 million tonnes per annum [M tpa]) is effectively recycled into high-quality compost and digestate. | ECN Data Report, 2022 [142] |

| Composting | This process is part of any strategy aimed at diverting organic waste and reducing methane (CH4) emissions from organised landfills. The amount of greenhouse gases generated by the composting process is largely determined by the waste type and composition. | Nordahl et al., 2023 [147] |

| Vermicomposting vs. composting | A study showed that the reduction in N2O and CH4 emissions during vermicomposting, compared with composting, was higher by 40 and 32%, respectively, when the moisture content in the raw material was higher, and the reduction in these greenhouse gases accounted for 23 and 16%, respectively, at a low moisture content of the mass under study. | Nigussie et al., 2016 [156] |

| Manure | According to a study, livestock manure contributes to 37% of global greenhouse gas emissions. | Vac et al., 2013 [174] |

| Livestock breeding sector | The livestock breeding sector is primarily responsible for the emissions of CH4 and N2O, i.e., compounds with a global warming potential (GWP) index value significantly higher than that of CO2. For CH4, it is 21-fold, and for N2O, 310-fold higher than that for CO2. | Kolasa-Więcek, 2012 [177] |

| Nitrous oxide emissions from manure | The use of this organic fertiliser increased N2O emissions by an average of 32.7% (95% confidence interval: 5.1–58.2%) compared with a synthetic nitrogen fertiliser. | Zhou, M. et al., 2017 [179] |

| Biomethane | Biomethane production alone would enable a 26 million tonne reduction in greenhouse gas emissions in Poland. It is worth mentioning that all of Poland’s agriculture sectors combined emit 33 million tonnes of greenhouse gases. Between January and November 2023, Poland’s electricity production totalled 148 TWh, representing a 7.2% decrease compared to the previous year. | Różyło, K.; Bohacz J., 2020 [184] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sokal, K.; Kachel, M. Impact of Agriculture on Greenhouse Gas Emissions—A Review. Energies 2025, 18, 2272. https://doi.org/10.3390/en18092272

Sokal K, Kachel M. Impact of Agriculture on Greenhouse Gas Emissions—A Review. Energies. 2025; 18(9):2272. https://doi.org/10.3390/en18092272

Chicago/Turabian StyleSokal, Karolina, and Magdalena Kachel. 2025. "Impact of Agriculture on Greenhouse Gas Emissions—A Review" Energies 18, no. 9: 2272. https://doi.org/10.3390/en18092272

APA StyleSokal, K., & Kachel, M. (2025). Impact of Agriculture on Greenhouse Gas Emissions—A Review. Energies, 18(9), 2272. https://doi.org/10.3390/en18092272