Research on the Characteristics of a Range-Extended Hydraulic–Electric Hybrid Drive System for Tractor Traveling Systems

Abstract

1. Introduction

2. Materials and Methods

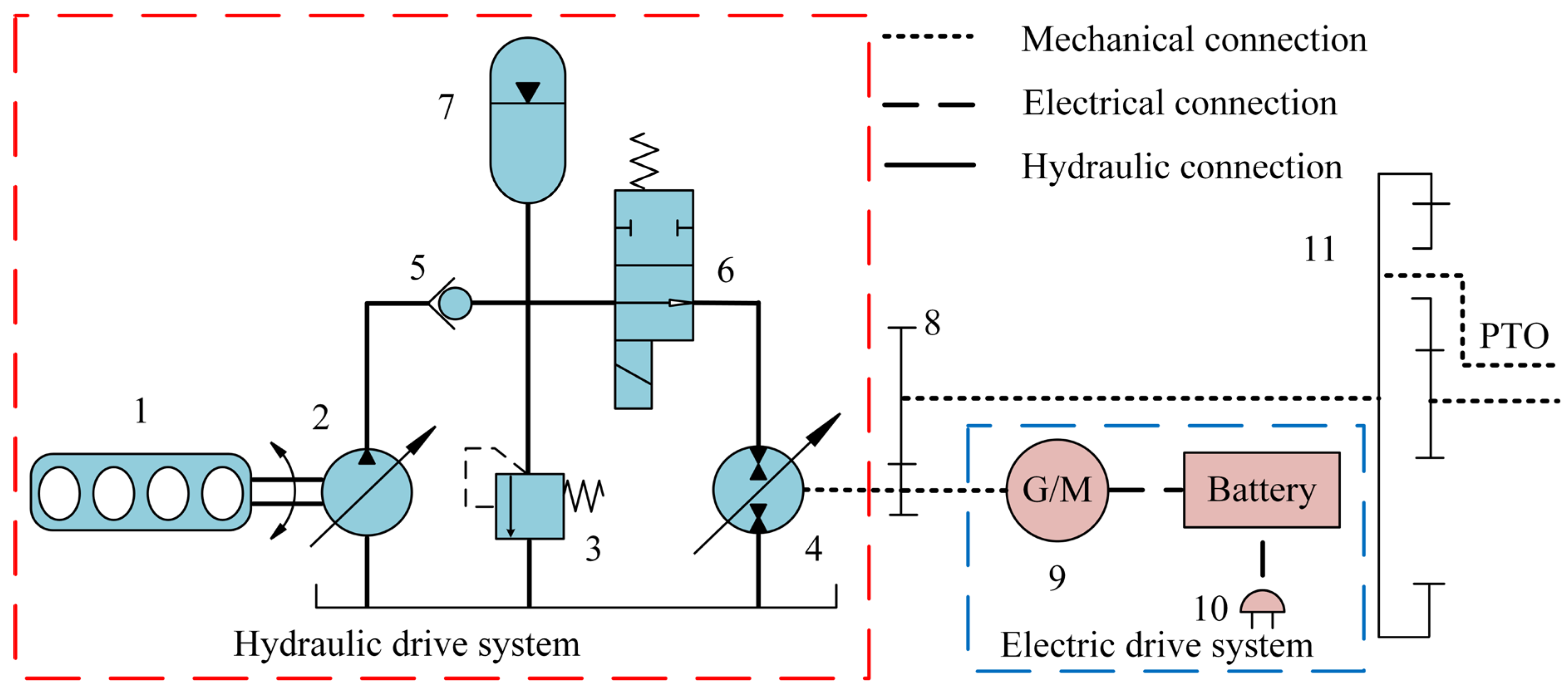

3. System Composition of Hybrid Tractor

3.1. Hybrid System Composition

3.2. Hydraulic–Electric Hybrid Drive System for Tractor Traveling Systems

4. Model of Hybrid Tractor Traveling Systems

4.1. Driver Model

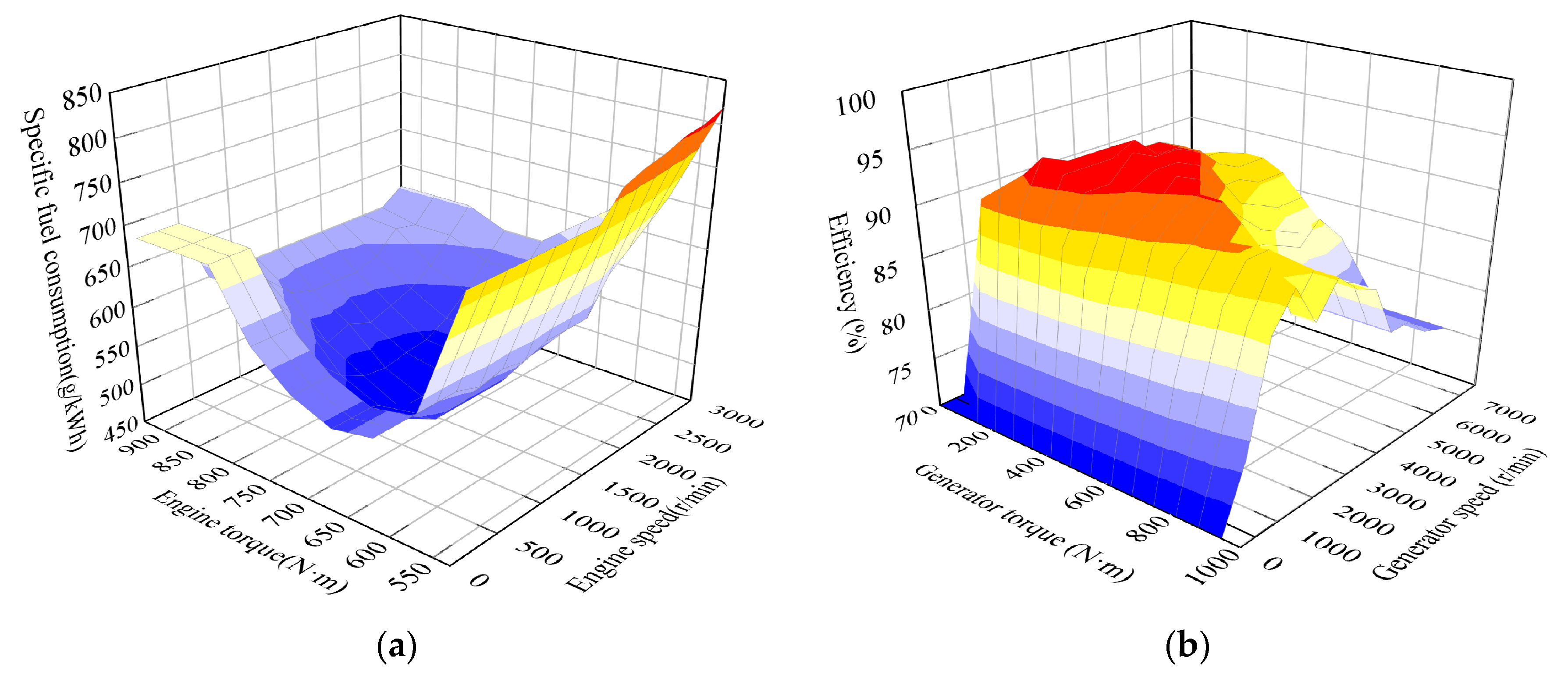

4.2. Range Extender Model

4.3. Battery Model

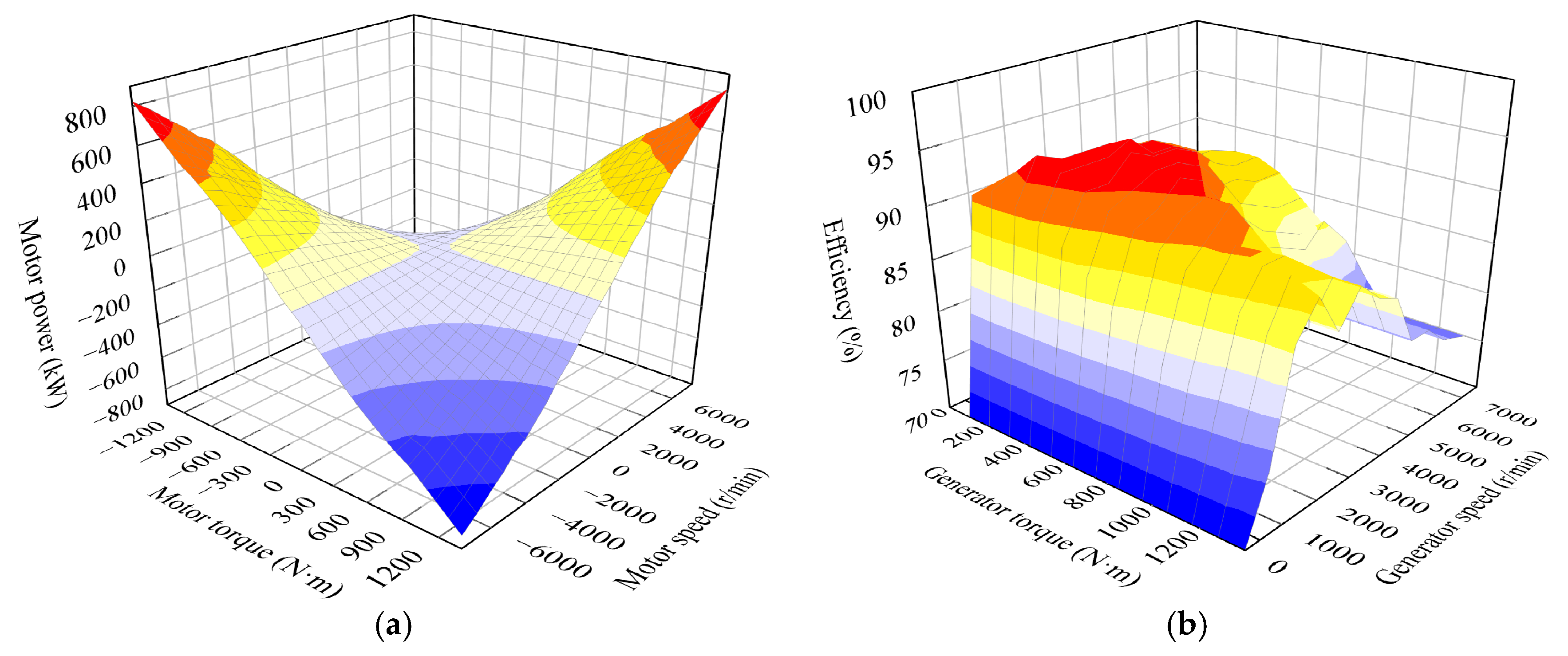

4.4. Drive Motor Model

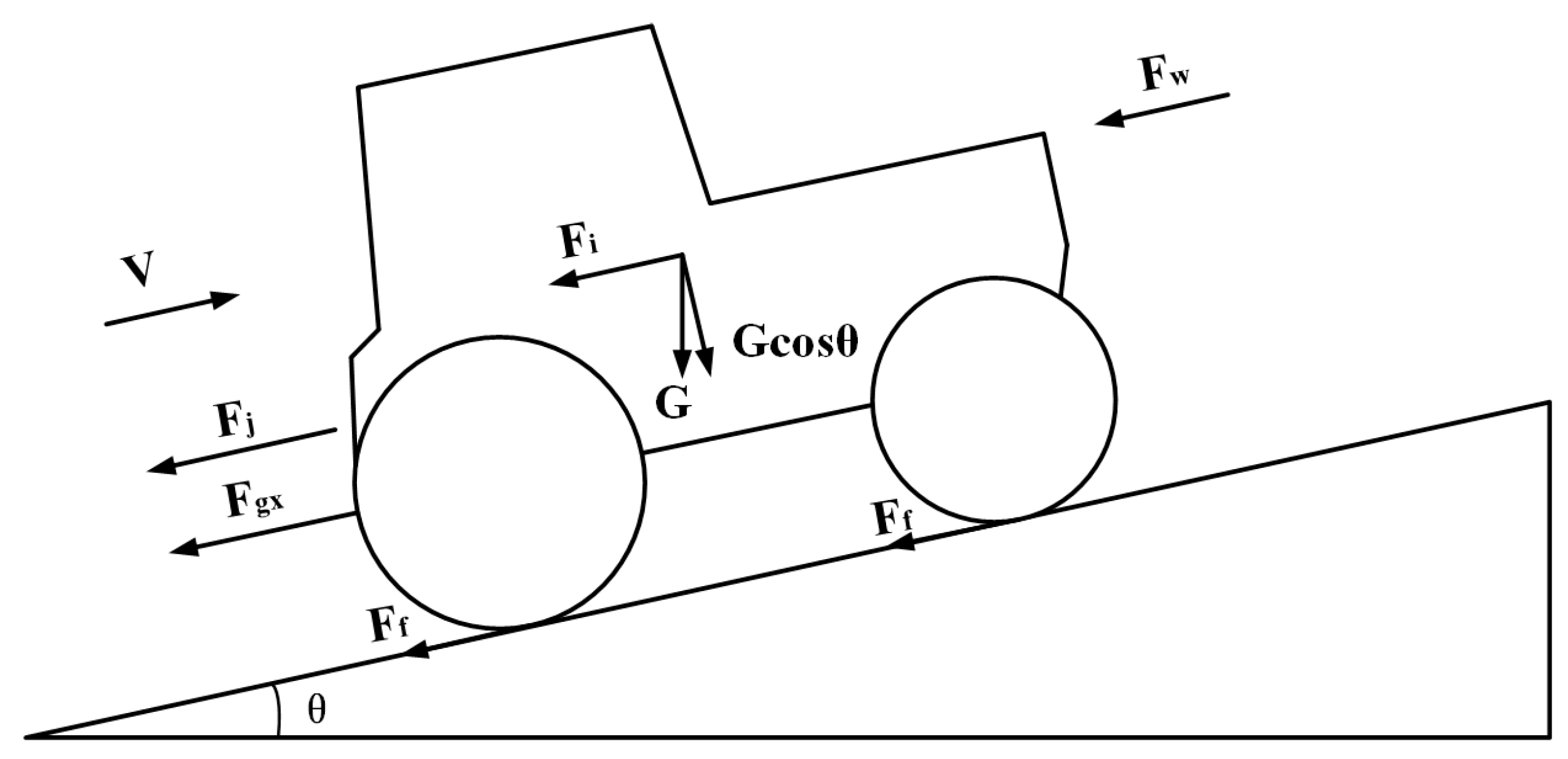

4.5. Longitudinal Dynamics Model of the Tractor

4.5.1. Dynamics Model of Tractor Plowing Operations

4.5.2. Dynamics Model of Tractor Transportation Operations

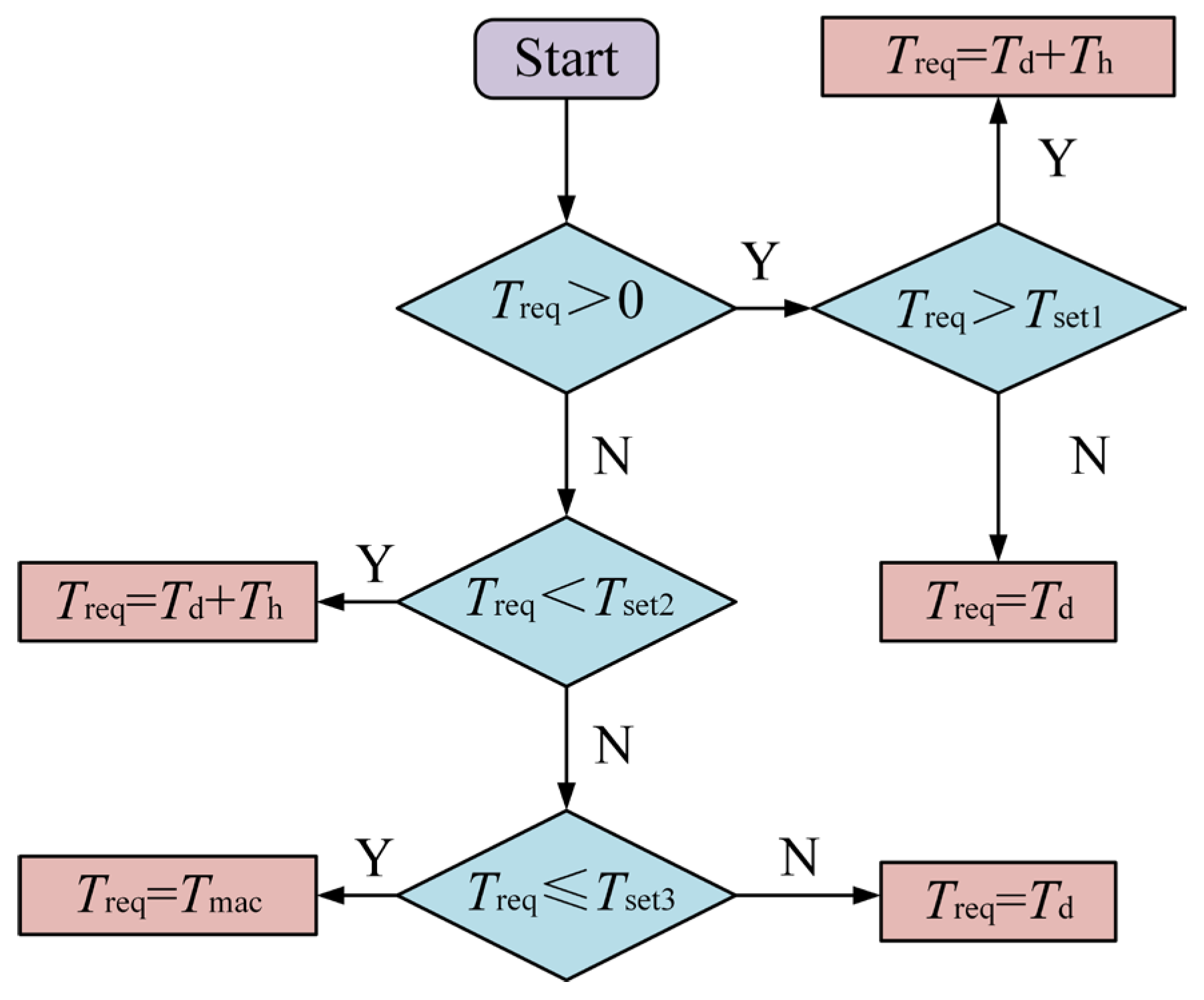

5. Establishment of Control Strategy and Co-Simulation Model

5.1. Control Strategy

- If Treq > Tset1 (threshold torque), the hydraulic pump/motor and electric motor jointly drive the wheels.

- If Treq is relatively low, the electric motor operates independently.

- During emergency braking, the mechanical brake provides the braking torque Tmac to ensure safety.

- If Treq is low, the electric motor alone generates the braking torque Td.

- If Treq falls within a predefined range, hydraulic regenerative braking is activated, where the hydraulic pump/motor recovers kinetic energy to provide the braking torque Th.

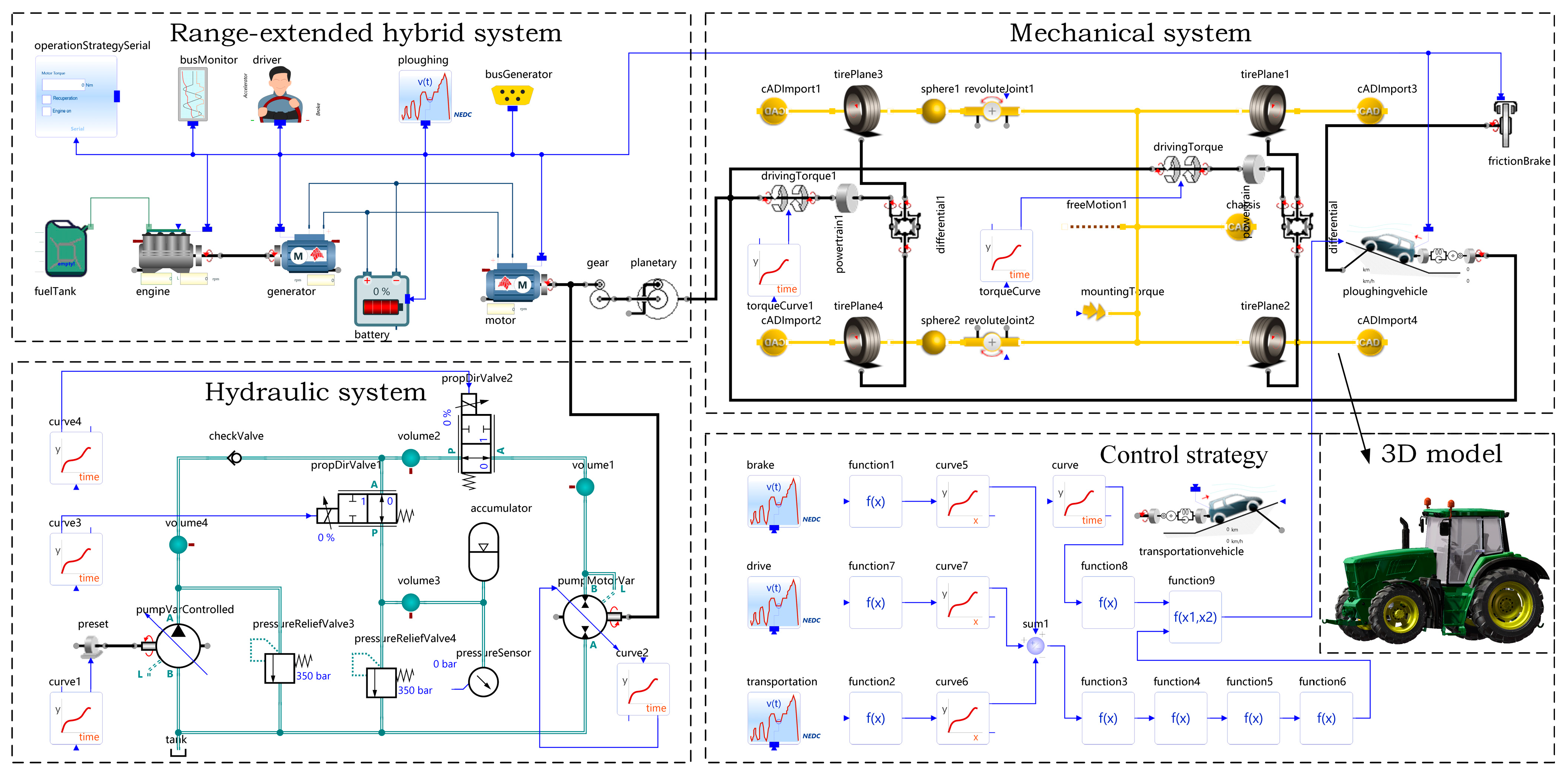

5.2. Multidisciplinary Co-Simulation Model

6. Simulation Analysis

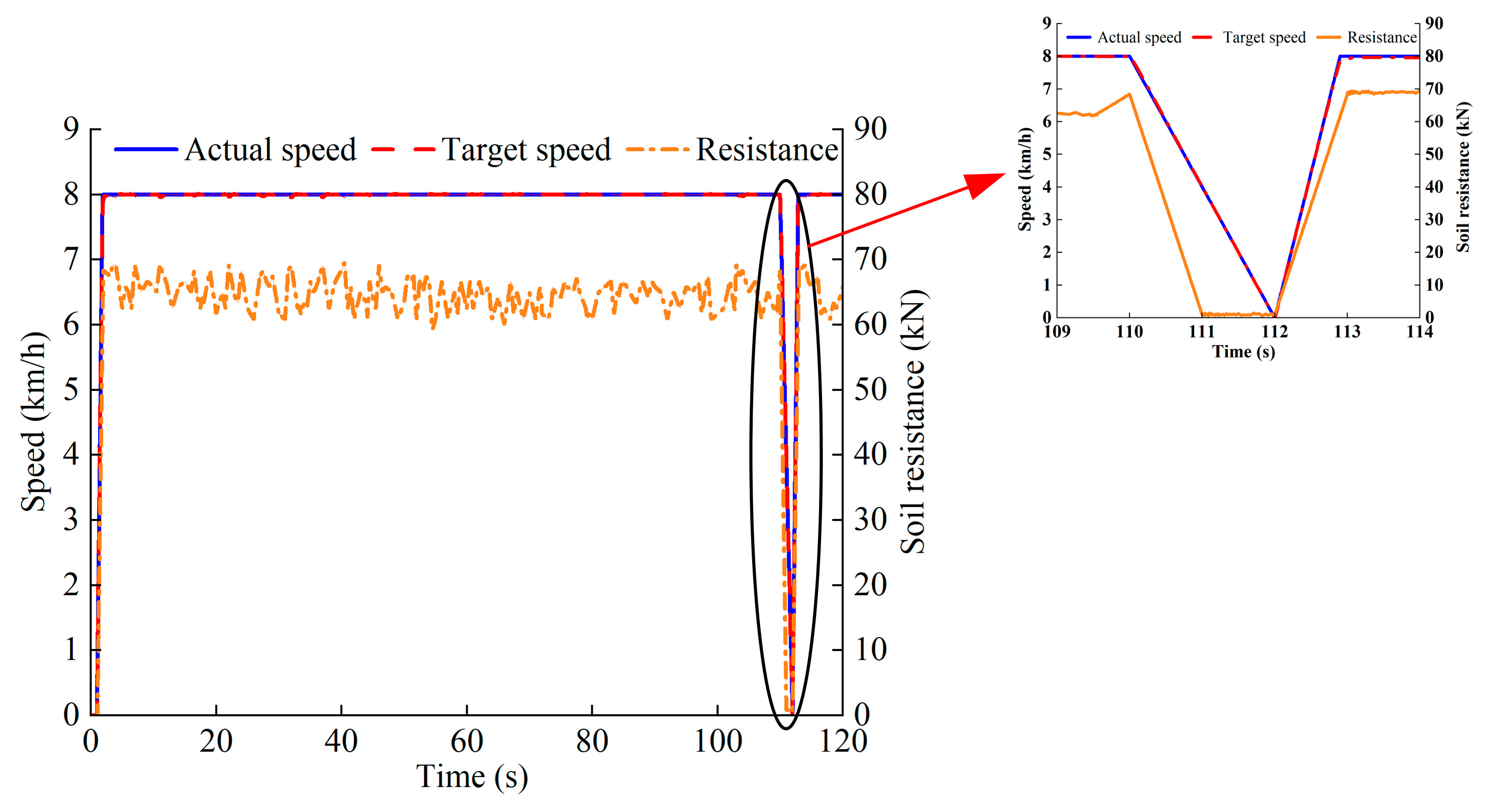

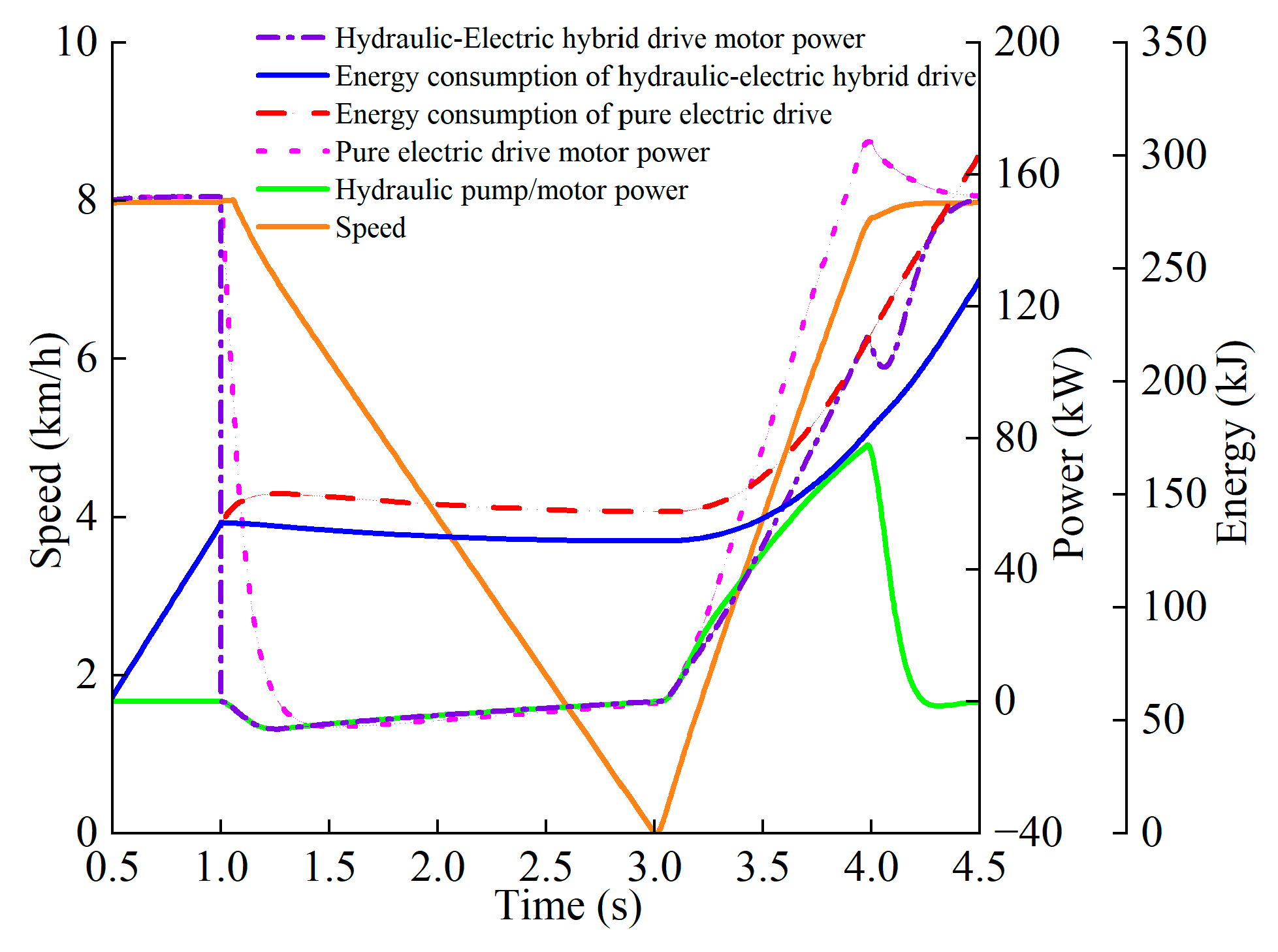

6.1. Plowing Operations

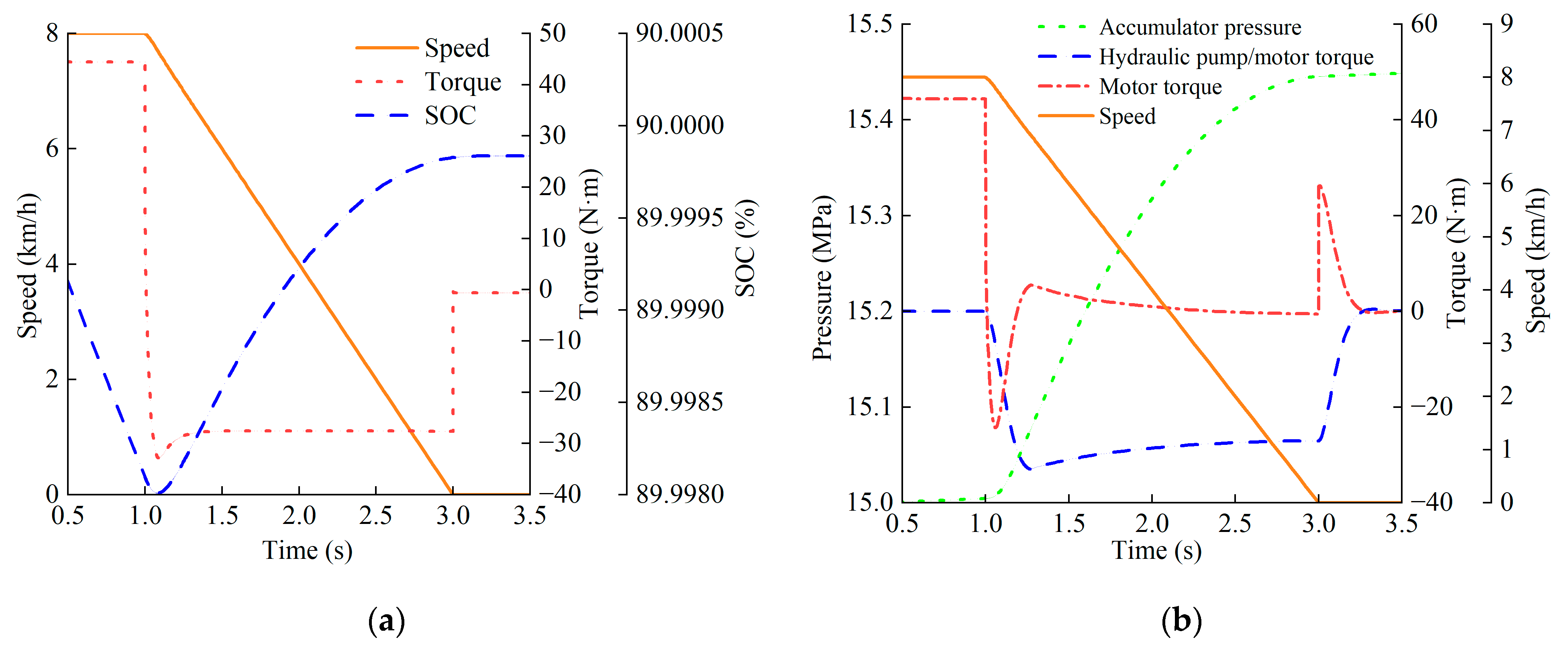

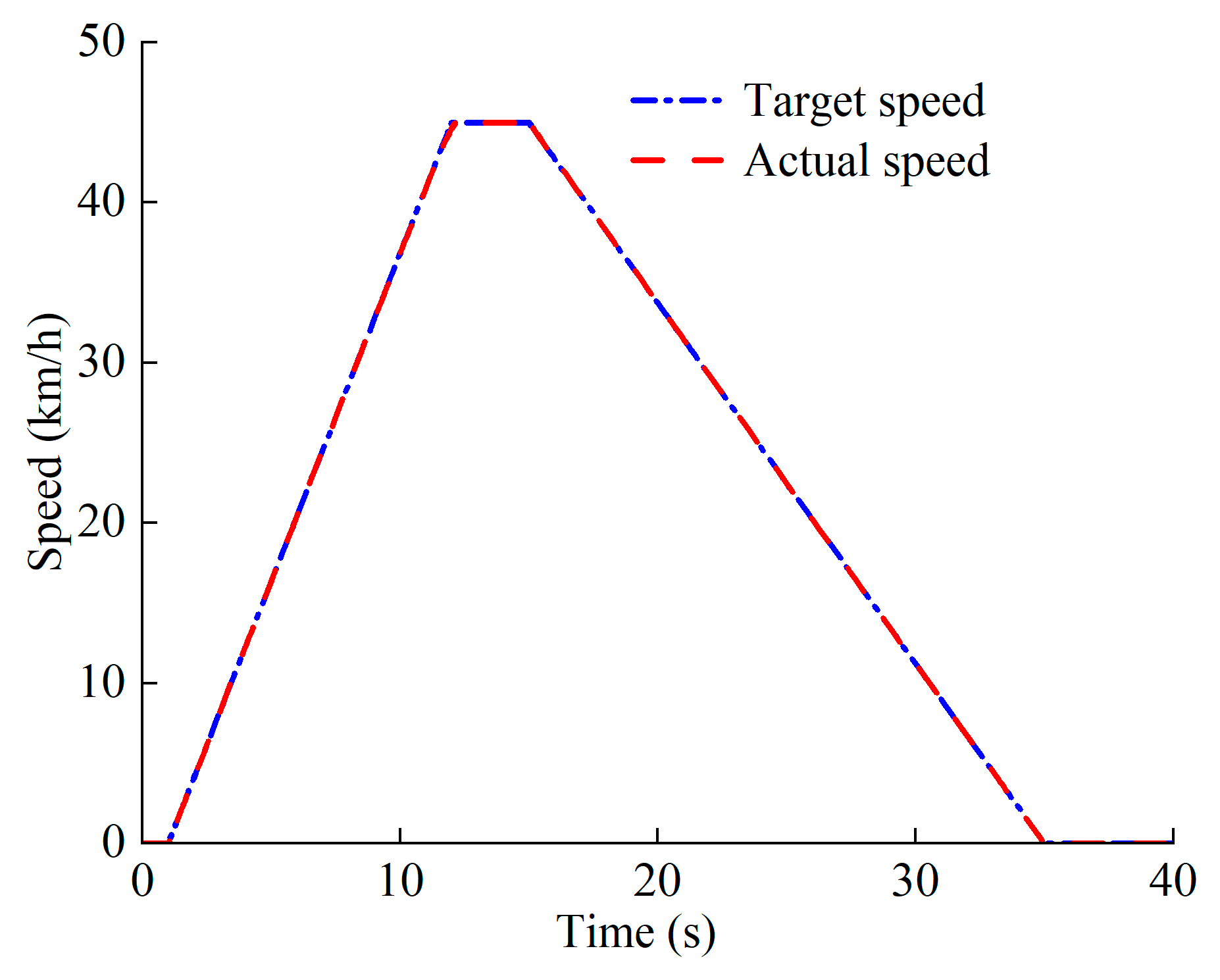

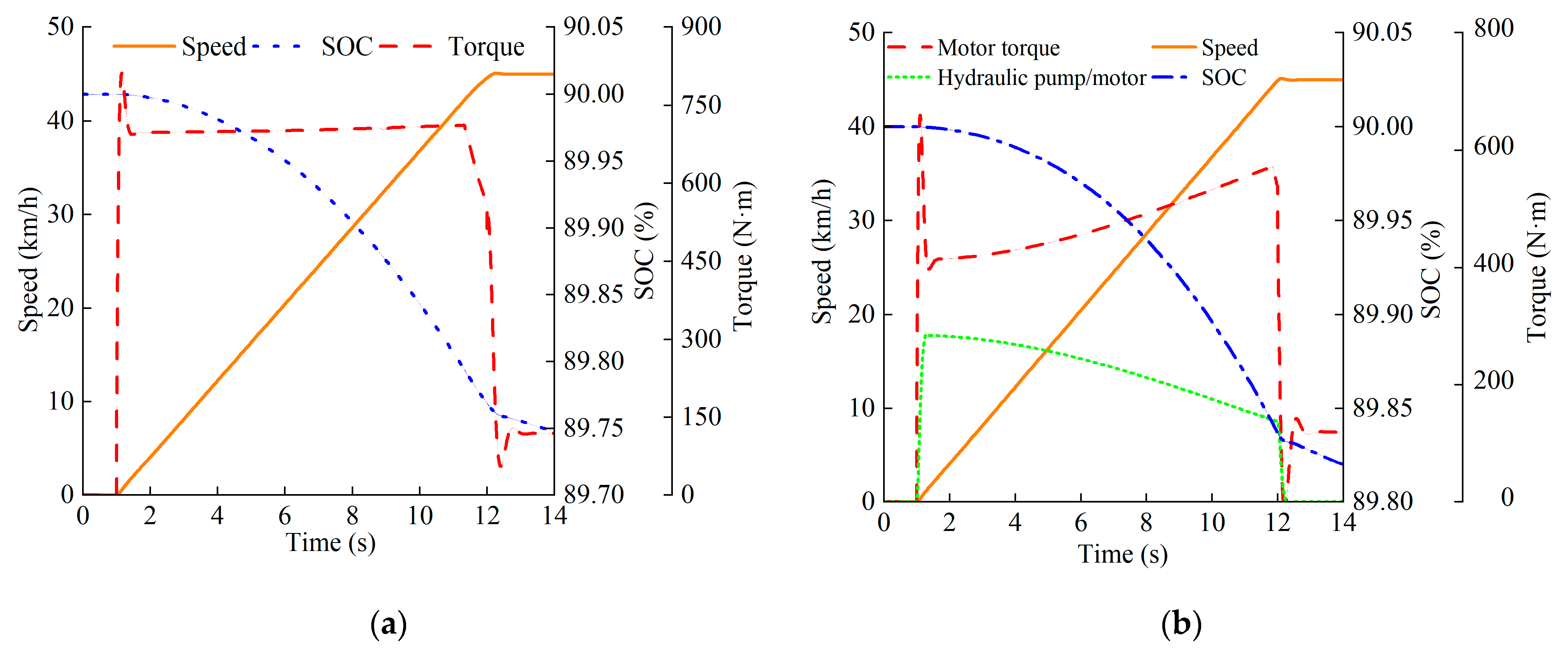

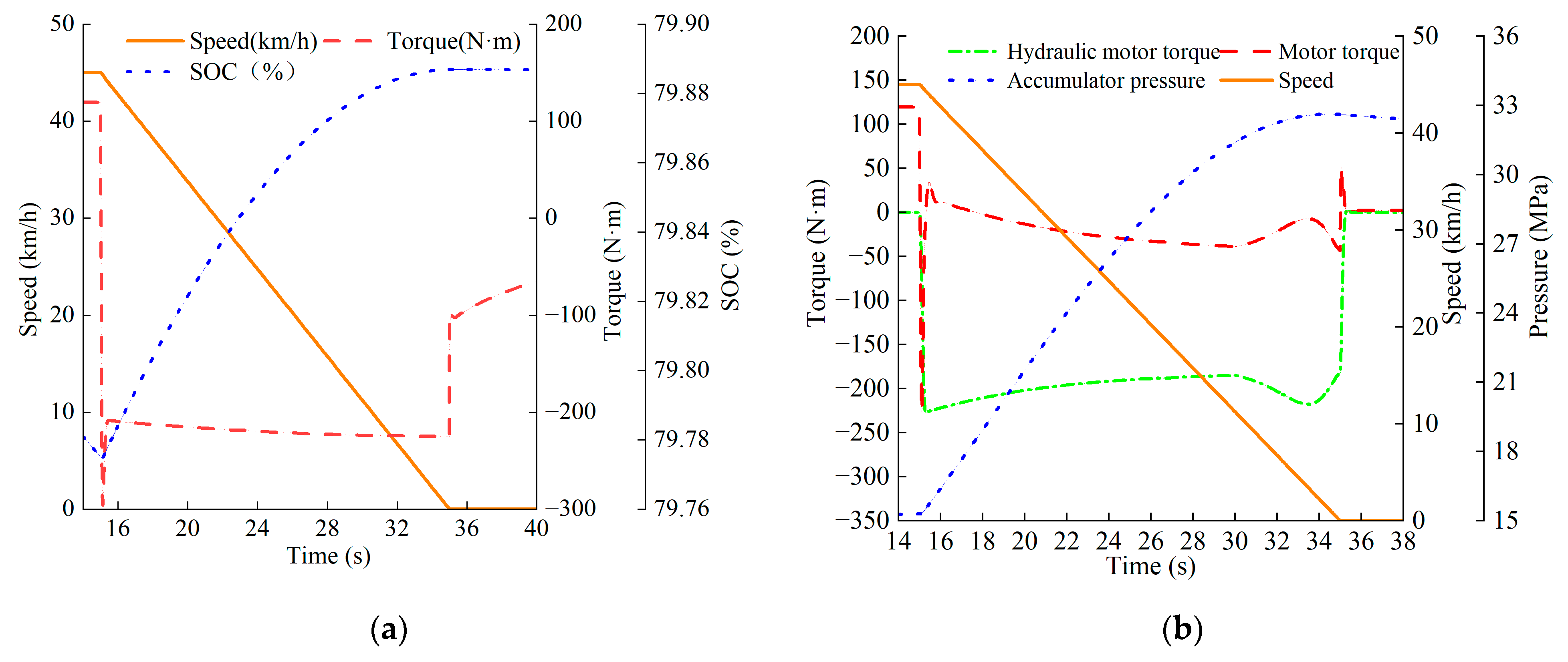

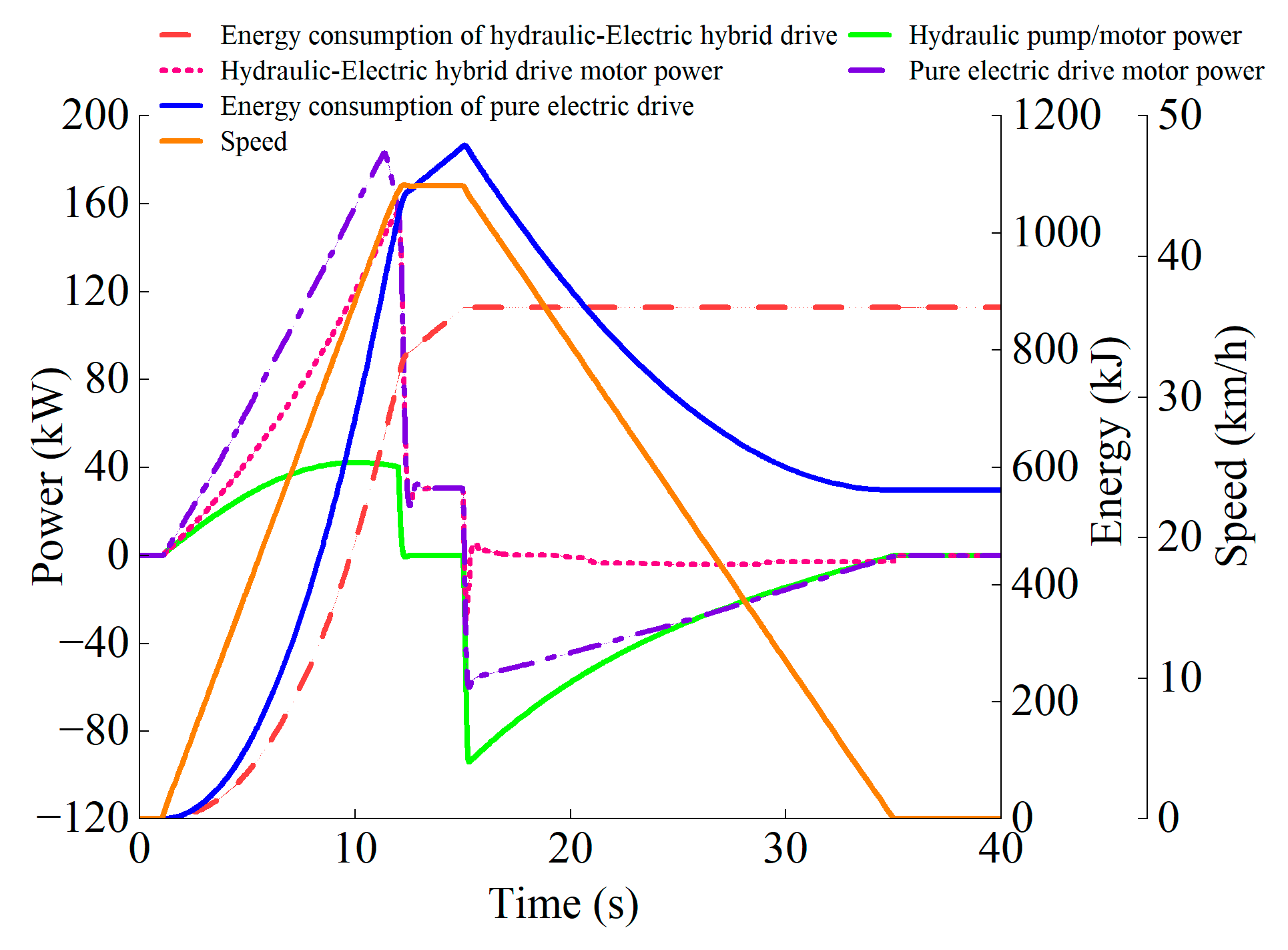

6.2. Transport Operations

7. Discussion

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tian, Y.; Zhao, Y.; Wang, Z.; Zhang, Y.; Miao, Y.; Zhang, L.; Wen, G.; Zhang, N. Non-dominated sorting artificial rabbit multi-objective sizing optimization for a conceptual powertrain of a 6 × 4 battery electric tractor truck. Energy 2024, 304, 132009. [Google Scholar] [CrossRef]

- Ali, D.; de Castro, R.; Ehsani, R.; Vougioukas, S.; Wei, P. Unlocking the potential of electric and hybrid tractors via sensitivity and techno-economic analysis. Appl. Energy 2025, 377, 124545. [Google Scholar] [CrossRef]

- Lei, S.; Li, Y.; Liu, M.; Li, W.; Zhao, T.; Hou, S.; Xu, L. Hierarchical Energy Management and Energy Saving Potential Analysis for Fuel Cell Hybrid Electric Tractors. Energies 2025, 18, 247. [Google Scholar] [CrossRef]

- Liu, H.; Shen, C.; HU, L.; Chang, C.; Cao, G. Research progress and development trend of electric agricultural equipment. Trans. Chin. Soc. Agric. Eng. 2024, 40, 39–51. [Google Scholar]

- Sun, H.; Wang, J.; Wu, J. Current Status and Trends in Energy Management Strategies for Hybrid Electric Vehicles. Automob. Appl. Technol. 2024, 24, 118–121. [Google Scholar]

- Pan, M.; Cao, S.; Zhang, Z.; Ye, N.; Qin, H.; Li, L.; Guan, W. Recent progress on energy management strategies for hybrid electric vehicles. J. Energy Storage 2025, 116, 115936. [Google Scholar] [CrossRef]

- Zhu, Z.; Zeng, L.; Chen, L.; Zou, R.; Cai, Y. Fuzzy Adaptive Energy Management Strategy for a Hybrid Agricultural Tractor Equipped with HMCVT. Agricultural 2022, 12, 1986. [Google Scholar] [CrossRef]

- He, X.; Yu, Q.; Jiang, Z.; Tan, Y.; Chen, Y.; Xie, B.; Wen, C. Dual-layer adaptive power management strategy for E-tractor incorporating operating information and deep reinforcement learning. Energy 2025, 319, 134942. [Google Scholar] [CrossRef]

- Francesco, M.; Aurelio, S. Analysis of a Parallel Hybrid Electric Tractor for Agricultural Applications. Energies 2020, 13, 3055. [Google Scholar] [CrossRef]

- Zhang, J.; Feng, G.; Liu, M.; Yan, X.; Xu, L.; Shang, C. Research on Global Optimal Energy Management Strategy of Agricultural Hybrid Tractor Equipped with CVT. World Electr. Vehic. J. 2023, 14, 127. [Google Scholar] [CrossRef]

- Wang, S.; Wu, X.; Zhao, X.; Wang, S.; Xie, B.; Song, Z.; Wang, D. Co-optimization energy management strategy for a novel dual-motor drive system of electric tractor considering efficiency and stability. Energy 2023, 281, 128074. [Google Scholar] [CrossRef]

- Li, Z.; Xiao, P.; Pan, J.; Pei, W.; Lv, A. Energy management strategy for methanol hybrid commercial vehicles based on improved dung beetle algorithm optimization. PLoS ONE 2025, 20, e0313303. [Google Scholar] [CrossRef]

- Li, L.; Gao, Z.; Nie, J. Load-adaptive Energy Management Strategy for Electric Tractor Based on Hybrid Power Source. Trans. Chin. Soc. Agric. Mach. 2024, 55, 459–469. [Google Scholar]

- Zhao, Y.; Xu, L.; Zhao, C.; Xu, H.; Yan, X. Research on Energy Management Strategy for Hybrid Tractors Based on DP-MPC. Energies 2024, 17, 3924. [Google Scholar] [CrossRef]

- Zhao, S.; Gao, Z.; Li, X.; Li, Y.; Xu, Y. Research on Energy Management Stractegy of Fuel Cell Tractor Hybrid Power System. World Electr. Vehic. J. 2024, 15, 61. [Google Scholar] [CrossRef]

- Zhao, X.; Zhang, G.; Wang, J.; Xue, Z.; Liu, M.; Liu, Y. Study and Verification of a Fuzzy-Following Energy Management Strategy for Hybrid Tractors. World Electr. Vehic. J. 2024, 16, 18. [Google Scholar] [CrossRef]

- Ahtisham, U.; Ali, N. Review of intelligent energy management techniques for hybrid electric vehicles. J. Energy Storage 2024, 92, 112132. [Google Scholar]

- Manuel, A.P.E.; Joaquim, M.F.; Joaquim, A.L.; Luigi, A.; Massimiliano, R. Optimal design of aseries hybrid powertrain for an agricultural tractor. Energy Convers. Manag. 2024, 24, 100789. [Google Scholar]

- Li, T.; Xie, B.; Li, Z.; Li, J. Design and Optimization of a Dual-Input Coupling Powertrain System: A Case Study for Electric Tractors. Appl. Sci. 2020, 10, 1608. [Google Scholar] [CrossRef]

- Park, Y.J.; Kim, J.G.; Lee, G.H. Characteristic Analysis of Planetary Gear Set of Hydromechanical Transmission System of Agricultural Tractors. J. Biosyst. Eng. 2016, 41, 145–152. [Google Scholar] [CrossRef]

- Claudio, R.; Davide, P.; Carlo, F.; Marco, B.; Riccardo, M. A Hybrid–Electric Driveline for Agricultural Tractors Based on an e-CVT Power-Split Transmission. Energies 2021, 14, 6912. [Google Scholar] [CrossRef]

- Quan, L.; Yan, Z.; Zhang, S.; Yang, Y.; Ge, L.; Li, Z. New Progress in Energy-efficient Electrical Drive and Hydraulic Transmission Technologies for Non-road Mobile Equipment. J. Mech. Eng. 2023, 59, 385–400. [Google Scholar]

- Cui, J.; Quan, L.; Liu, Z.; Ge, L.; Huang, W. Characteristics and Energy Efficiency Analysis of Electro-hydraulic Hybrid Drive Large Inertia Swing System. Trans. Chin. Soc. Agric. Manchinery 2023, 54, 450–458. [Google Scholar]

- Li, Z.; Wang, C.; Quan, L.; Hao, Y.; Ge, L.; Xia, L. Study on energy efficiency characteristics of the heavy-duty manipulator driven by electro-hydraulic hybrid active-passive system. Automat. Constr. 2021, 125, 103646. [Google Scholar] [CrossRef]

- Lin, L.; Zhang, T.; Lu, L.; Zhang, H.; Yang, J.; Zhang, Z. An energy active regulation management strategy based on driving mode recognition for electro-hydraulic hybrid vehicles. Energy 2023, 285, 129548. [Google Scholar]

- Mu, H.; Cheng, H.; Tang, X.; Ding, Q.; Ma, W. A hybrid distributed-centralized load sensing system for efficiency improvement of electrified construction machinery. Energy 2025, 314, 134123. [Google Scholar] [CrossRef]

- ISO 15550:2016; Internal Combustion Engines—Determination and Method for the Measurement of Engine Power—General Requirements. ISO: Geneva, Switzerland, 2016.

- IEC 62660-1:2018; Secondary Lithium-Ion Cells for the Propulsion of Electric Road Vehicles—Part 1: Performance Testing. IEC: Geneva, Switzerland, 2018.

- ISO 8854:2012; Road Vehicles—Alternators with Regulators—Test Methods and General Requirements. ISO: Geneva, Switzerland, 2012.

- ISO 8426-2:2024; Hydraulic Fluid Power—Determination of Derived Displacement of Positive Displacement Pumps and Motors—Part 2: Zero-Pressure Intercept Method. ISO: London, UK, 2024.

| Components | Parameters | Value | Standards | Response Time |

|---|---|---|---|---|

| Tractor | Mass | 8500 kg | - | - |

| Drive wheel radius | 0.725 m | |||

| Range extender | Engine rated power | 200 kW (≤±5%) | ISO 15550 [27] | 3 s |

| Engine rated speed | 2500 r/min (≤±3%) | |||

| Minimum fuel consumption rate | 470 g/(kWh) (≤±0.8%) | |||

| Battery | Rated capacity | 150 kWh (≤±2%) | IEC 62660-1 [28] | 50 ms |

| Rated voltage | 380 V (≤±0.02%) | |||

| SOC | 20–80% (≤±3%) | |||

| Drive motor | Rated power | 165 kW (≤±3%) | ISO 8854:2012 [29] | 7 ms |

| Rated speed | 2800 r/min (≤±3%) | |||

| Rated torque | 560 N·m (≤±0.3%) | |||

| Hydraulic pump/motor | Rated power | 220 kW (≤±5%) | ISO 8426 [30] | 25 ms |

| Rated torque | 401 N·m (≤±0.3%) | |||

| Maximum displacement | 63 mL/r (≤±0.5%) |

| Working Mode | Range Extender | Drive Motor | Hydraulic Pump/Motor |

|---|---|---|---|

| Parking | Shut down | Shut down | Shut down |

| Hydraulic–Electric Hybrid Drive | Shut down | Start (motor) | Start (motor) |

| Braking Energy Recovery | Shut down | Start (generator) | Start (pump) |

| Pure Electric Drive | Shut down | Start (motor) | Shut down |

| Range-Extended Mode | Start | Start (motor) | Shut down |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, H.; Quan, L.; Hao, Y.; Pan, Z.; Xie, S. Research on the Characteristics of a Range-Extended Hydraulic–Electric Hybrid Drive System for Tractor Traveling Systems. Energies 2025, 18, 2075. https://doi.org/10.3390/en18082075

Wu H, Quan L, Hao Y, Pan Z, Xie S. Research on the Characteristics of a Range-Extended Hydraulic–Electric Hybrid Drive System for Tractor Traveling Systems. Energies. 2025; 18(8):2075. https://doi.org/10.3390/en18082075

Chicago/Turabian StyleWu, Hanwen, Long Quan, Yunxiao Hao, Zhijie Pan, and Songtao Xie. 2025. "Research on the Characteristics of a Range-Extended Hydraulic–Electric Hybrid Drive System for Tractor Traveling Systems" Energies 18, no. 8: 2075. https://doi.org/10.3390/en18082075

APA StyleWu, H., Quan, L., Hao, Y., Pan, Z., & Xie, S. (2025). Research on the Characteristics of a Range-Extended Hydraulic–Electric Hybrid Drive System for Tractor Traveling Systems. Energies, 18(8), 2075. https://doi.org/10.3390/en18082075