1. Introduction

HGM/ER composite foam materials are multicomponent materials that incorporate hollow glass microspheres (HGM) as fillers and epoxy resin (ER) as the matrix. They are characterized by light weight, high strength, and excellent thermal insulation properties [

1,

2,

3]. Their comprehensive performance makes them widely used in various thermal insulation applications, such as marine oil pipelines [

4,

5,

6]. However, due to the influence of processing techniques and material properties, some gas is inevitably trapped during the composite process, forming void structures inside the material [

7]. Moreover, physical variables such as void size and filler ratio significantly influence the overall thermal conductivity of the composite material [

8,

9].

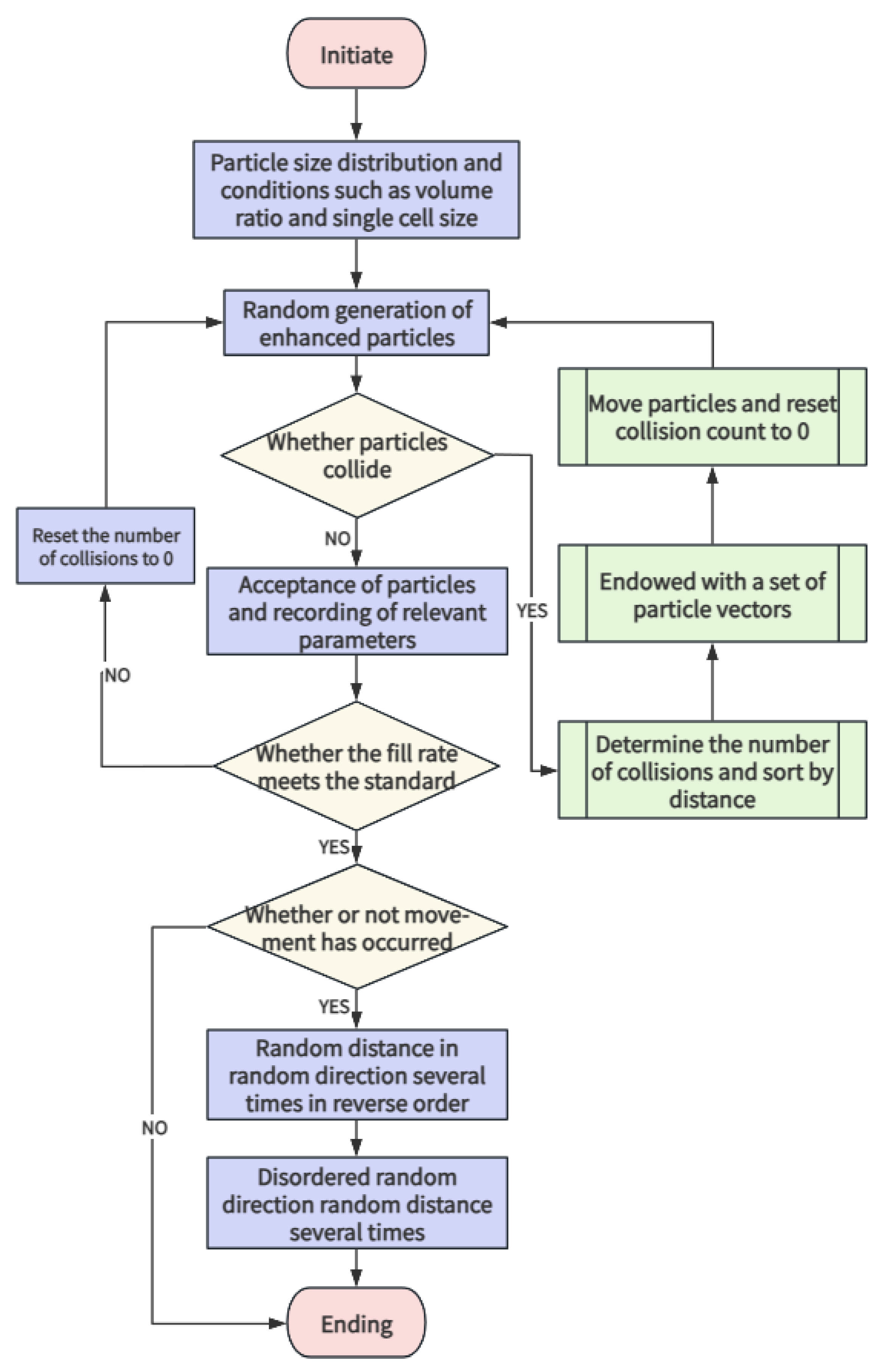

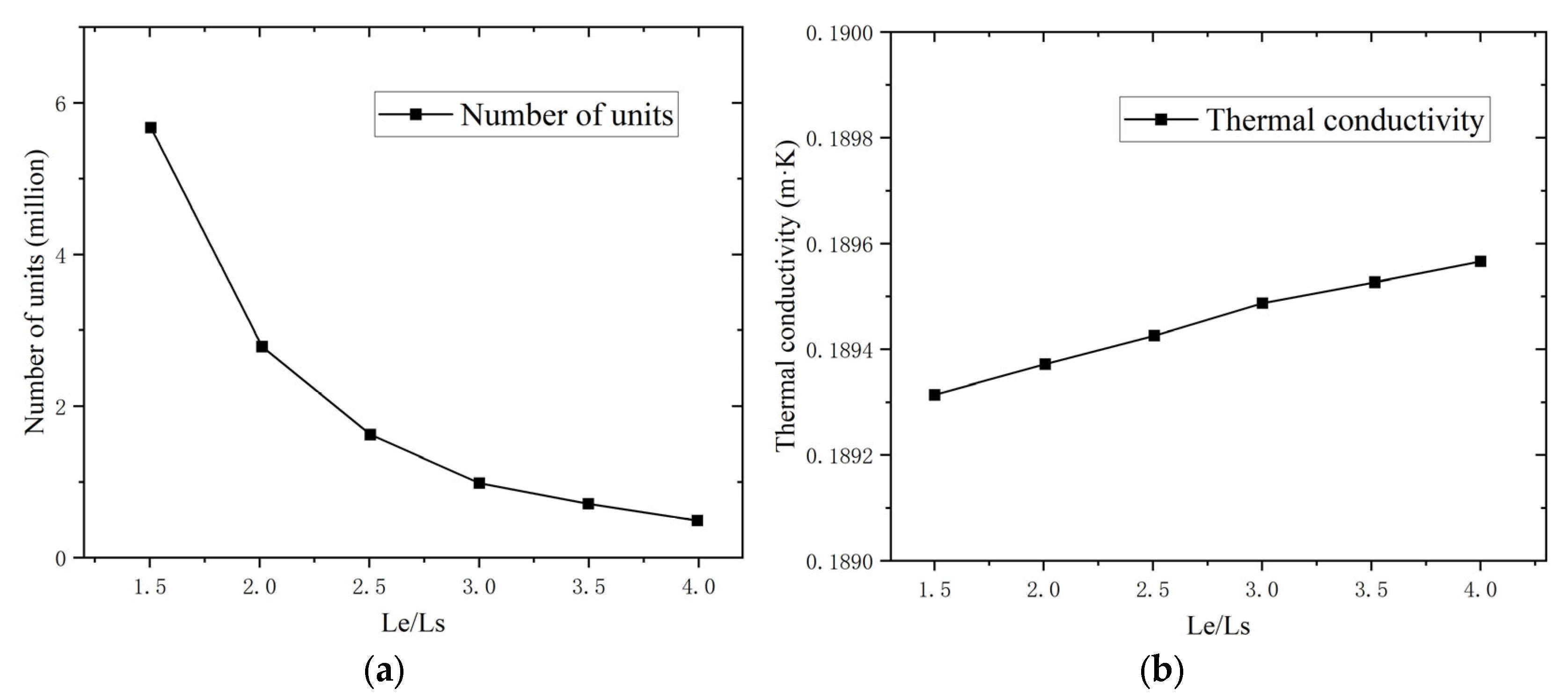

Most of the related scholars have macroscopically explored the influencing factors of the thermal properties of composites from the perspective of overall experiments [

10,

11], but due to the high complexity of RVE modeling of metamaterials [

12,

13] and the difficulty of numerical simulation, there is a lack of microscopic research on the internal thermal conductivity mechanism of composite materials. Therefore, the RSA algorithm was proposed, which is the most commonly used method for generating RVEs. However, the logic of RSA to generate particles one by one makes the first generated particles limit the space for the generation of subsequent particles, making it difficult for this algorithm to generate models with a high filling rate [

14]. Kari et al. [

15] introduced the RSA algorithm to generate spherical particles of the same dimensions, with a maximum filling rate of only 30%. Therefore, the improved RSA algorithm has been proposed a lot. Tian et al. [

16] improved the RSA algorithm based on molecular dynamics and collision detection, etc., which can achieve a filling rate of more than 50%. However, the problem with the improved algorithm is that the generated particles can cross the RVE boundaries, which will cut and remove the part that crosses the boundaries, which is unfavorable for materials such as hollow glass beads.

Once the RSA algorithm was proposed, it was widely used in numerical simulation. Luo Wen et al. [

17] developed secondary programming of the APDL language in ANSYS 15.0 and introduced the RSA algorithm to simulate the random distribution of microbeads in the resin matrix. Qi et al. [

18] improved the RSA algorithm, introduced periodic boundaries, and used Abaqus to obtain the average stress and strain of RVE. Zhu et al. [

19] constructed a randomly generated RVE model of carbon-brazed dimensional reinforced polyether ether ketone (PEEK) composite and investigated its mechanical properties.

The above study shows that it is completely feasible to use the improved RSA algorithm for the thermal simulation of microbead-type composites, but the problems that need to be overcome are that the upper limit of the filling rate of the microbeads in the current algorithm does not consider the microbeads crossing the RVE boundary, the microbead filling rate is low, and the distribution is relatively inhomogeneous, so it is not able to predict the thermal performance of composite foams with a high filling rate [

20]. On the other hand, with the rise in the filling rate of the microbeads, the material void ratio can reach more than 8% [

21], which will make a difficult to ignore the impact on the thermal performance of composites. Current research on the relevant thermal performance is mostly focused on the parameters and properties of microbeads and resins, and seldom considers the influence of the void structure on the thermal performance of composites [

22] or the division of void types. Therefore, the current understanding of the internal thermal conductivity mechanism of void-containing composites is not clear enough, and the prediction of thermal conductivity has a large deviation, which needs to be measured with the help of professional equipment [

23].

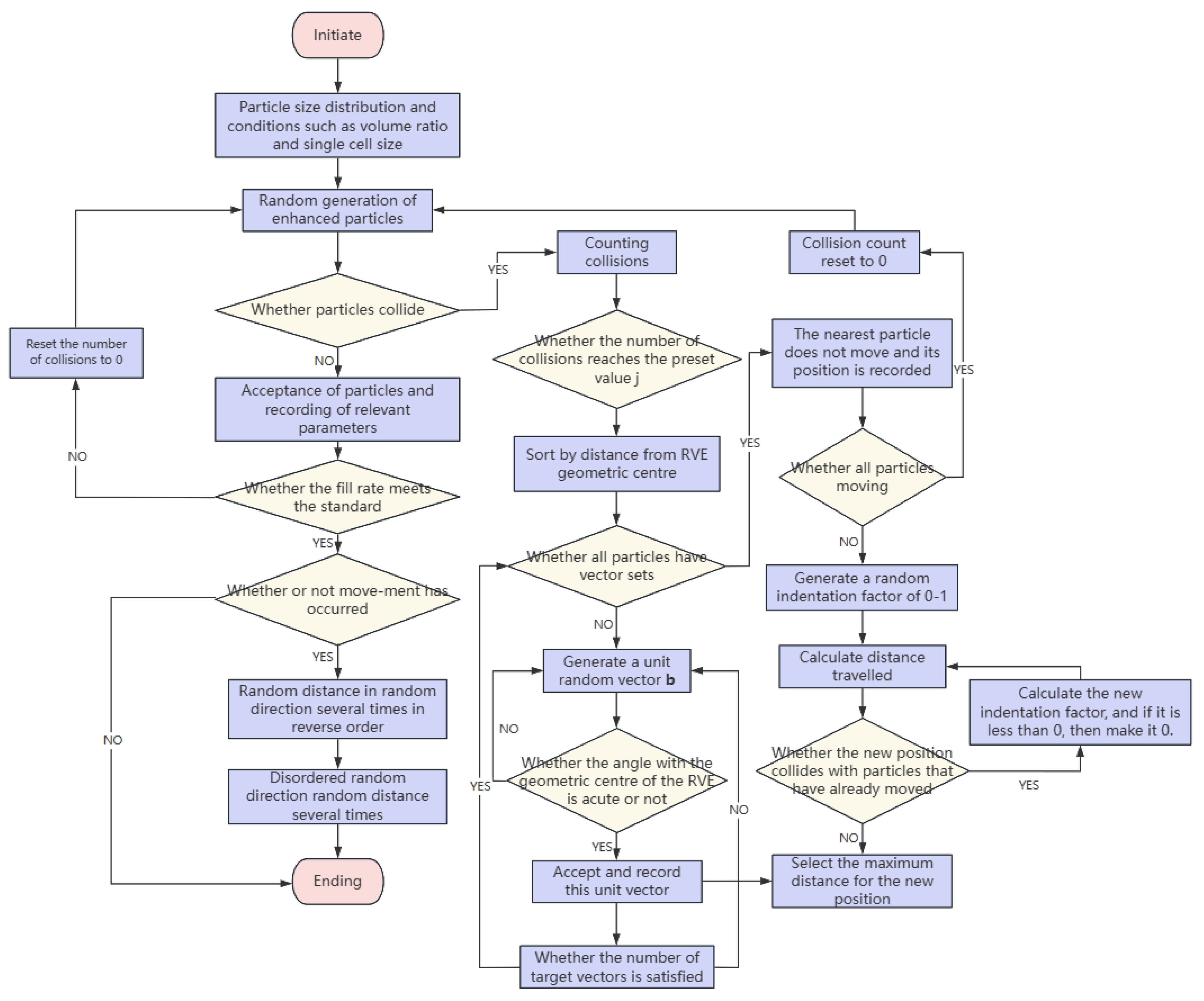

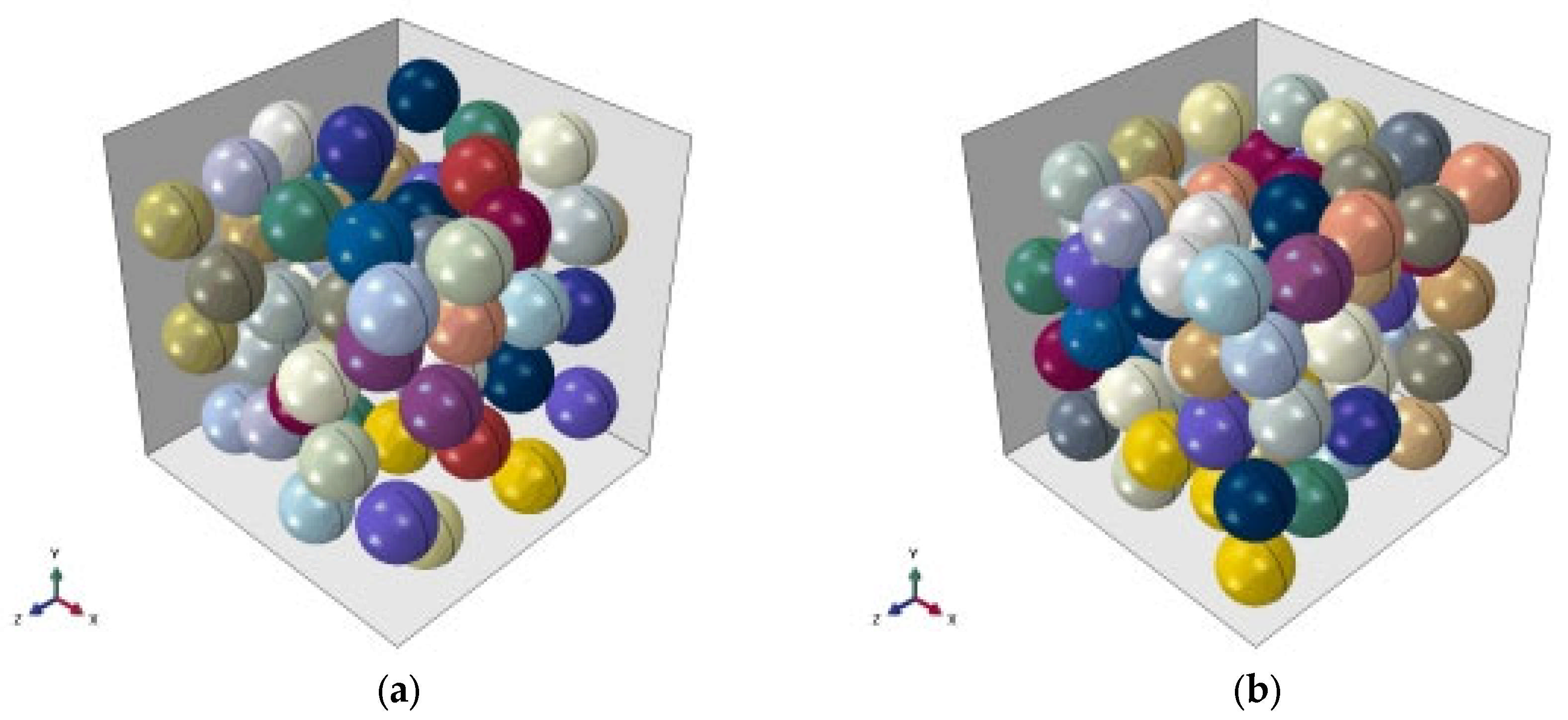

To overcome the above problems and generate RVE with a high filling rate without cutting the microbead particles, an improved RSA algorithm is proposed in this paper, which achieves high filling and uniform distribution of microbeads in RVE by formulating the particle movement strategy. In addition, this paper delineates the type of void structure within the HGM/ER composites and adopts the equivalent microbead thermal conductivity model to investigate its microscopic mechanism by thermal simulation using the Abaqus 2022 finite element software, which can provide a basis for the prediction of thermal conductivity of composites under different void ratios.

2. Theoretical Basis

2.1. Heat Transfer Theory

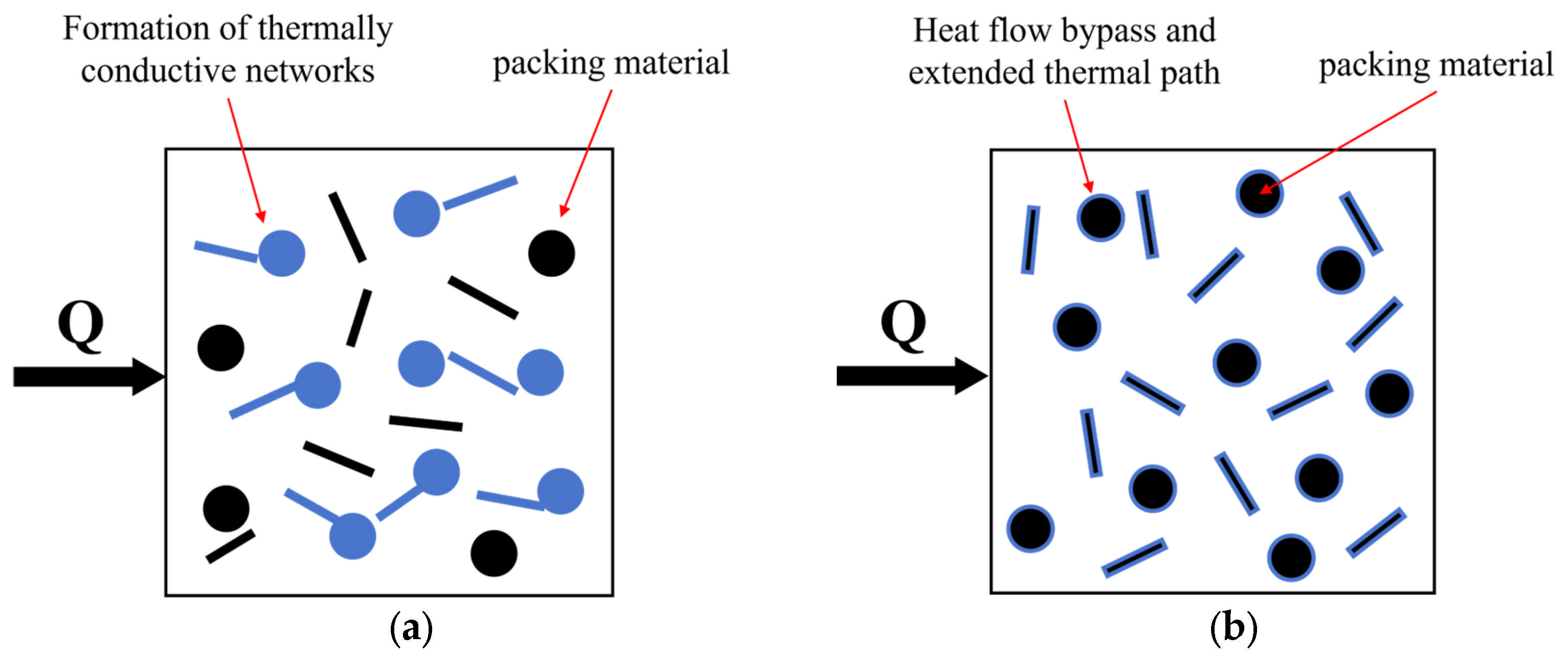

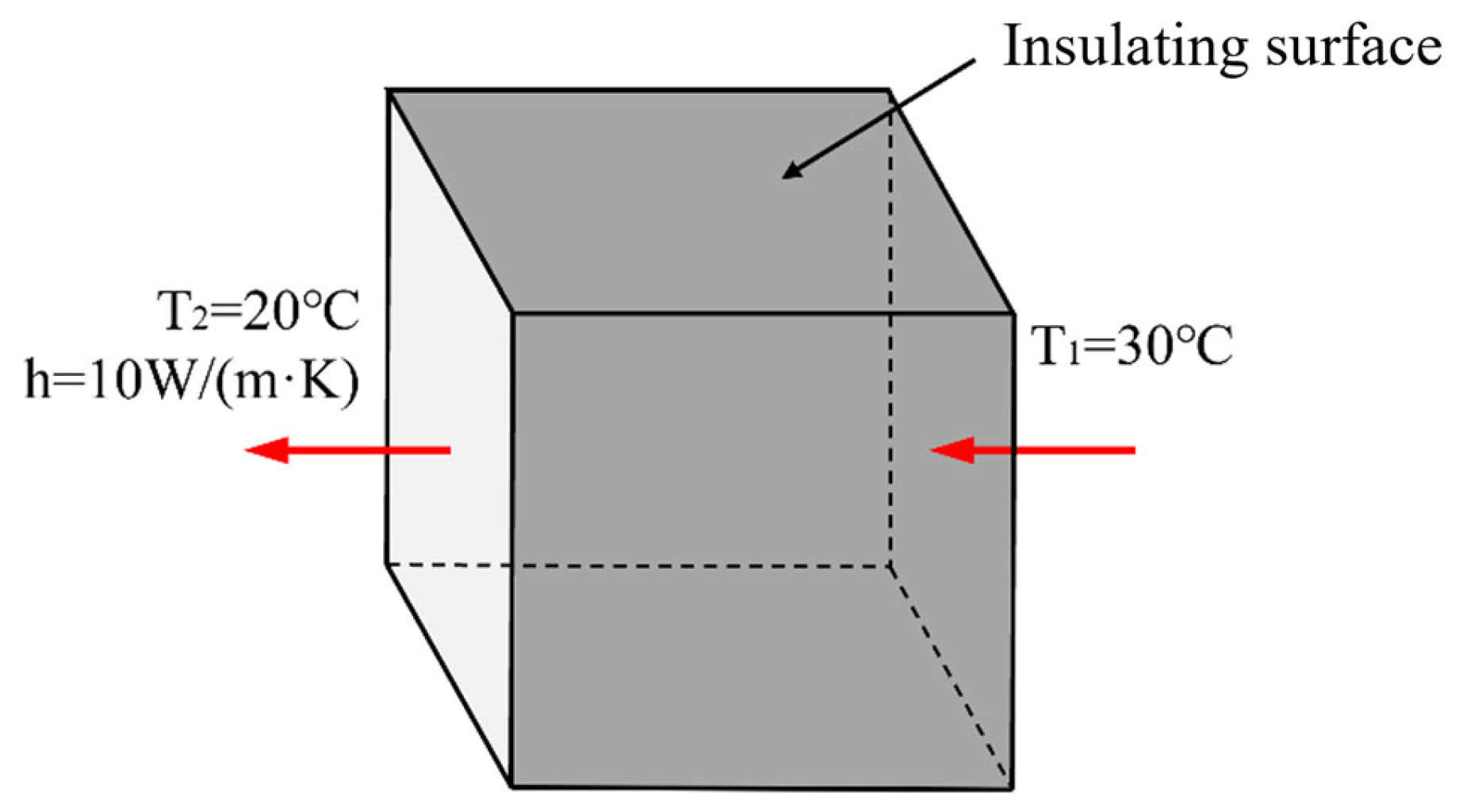

The thermal conduction path theory is one of the primary directions in the study of thermal conductivity mechanisms in polymer materials such as HGM/ER. Specifically, it can be described as follows. Thermally conductive fillers may form conductive networks within the polymer, leading to an increase in the overall thermal conductivity of the composite material. Thermal insulating fillers, on the other hand, increase the thermal conduction path length within the matrix, resulting in a decrease in the overall thermal conductivity of the composite material, as illustrated in

Figure 1. The outer wall thickness of HGM is much smaller than its diameter, and thus the microspheres and void structures can be considered predominantly composed of air cavities, making them typical thermal insulating fillers compared to the matrix.

Heat transfer within a material occurs via three primary mechanisms: convective heat, radiative heat, and conductive heat. In the study of heat transfer mechanisms within HGM/ER composites, the heat transfer via convection [

24] and radiation [

25] can be neglected due to the extremely small diameter of the voids and the very thin walls of the microspheres. The primary focus is on the effect of conductive heat transfer. Heat conduction depends on the motion of microscopic energy carriers in a material. For HGM/ER composites, the heat conduction within the voids arises from collisions between gas molecules, following the kinetic theory model (Equation (1)) [

26]. In contrast, the heat conduction of the solid outside the voids mainly depends on lattice vibrations of the solid molecules around their equilibrium positions and follows the dynamic model (Equation (2)) [

27]:

In the formula,

is the gas thermal conductivity coefficient;

is the gas-specific heat capacity at constant volume;

is the root mean square velocity of the gas molecules;

is the mean free path of the gas molecules;

ε is the correction factor that describes the influence of viscosity on the thermal conductivity coefficient.

In the formula, represents the thermal conductivity coefficient of the solid; represents the specific heat capacity at constant volume of the solid; represents the root mean square velocity of the solid; represents the mean free path of the phonons in the solid.

This study investigates the steady-state temperature field, where the temperature distribution at each point in the material is independent of time. Heat transfer at each node within the filled system follows Fourier’s law [

28]. In three-dimensional numerical simulations, considering Fourier’s law in a Cartesian coordinate system, the formula is as follows:

In the formula, q represents the heat flux density, in units of W/m2; λ represents the thermal conductivity coefficient, which indicates the material’s ability to conduct heat, in units of W/(m·K); gradt represents the temperature gradient. The negative sign in the formula indicates that the direction of the heat flux density vector is opposite the direction of the temperature gradient vector, meaning that in heat conduction, heat always spontaneously flows from regions of higher temperature to regions of lower temperature.

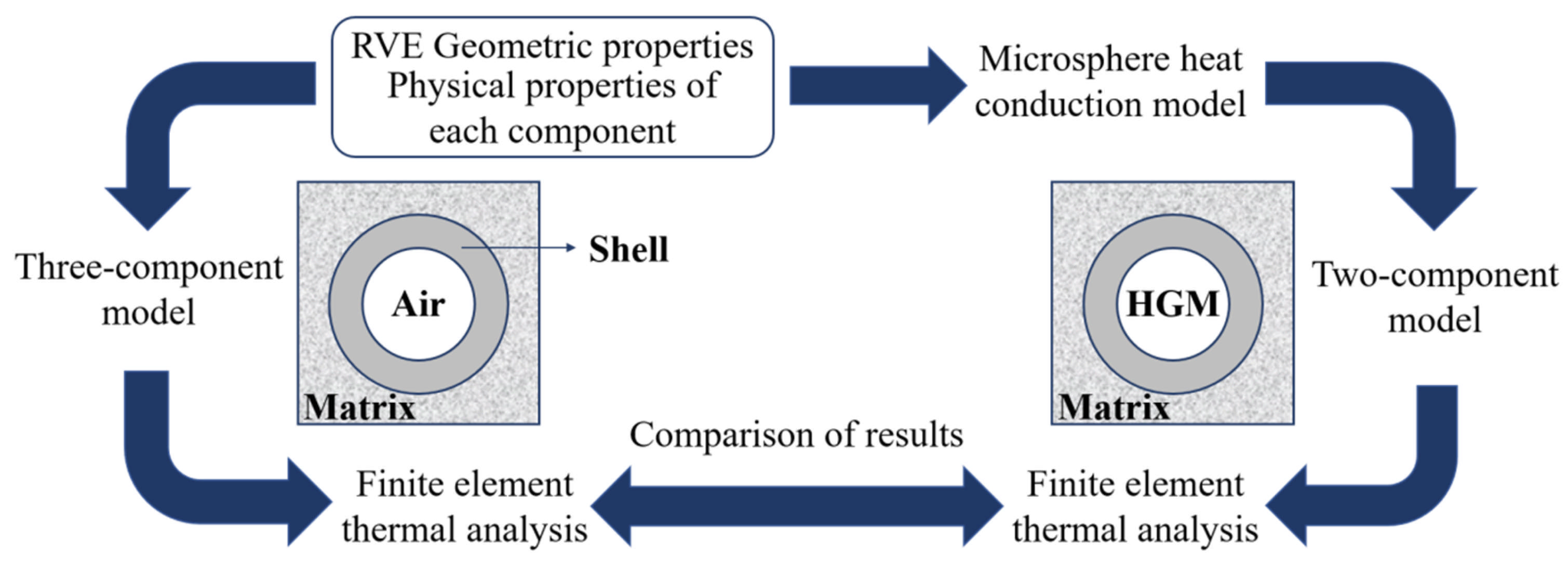

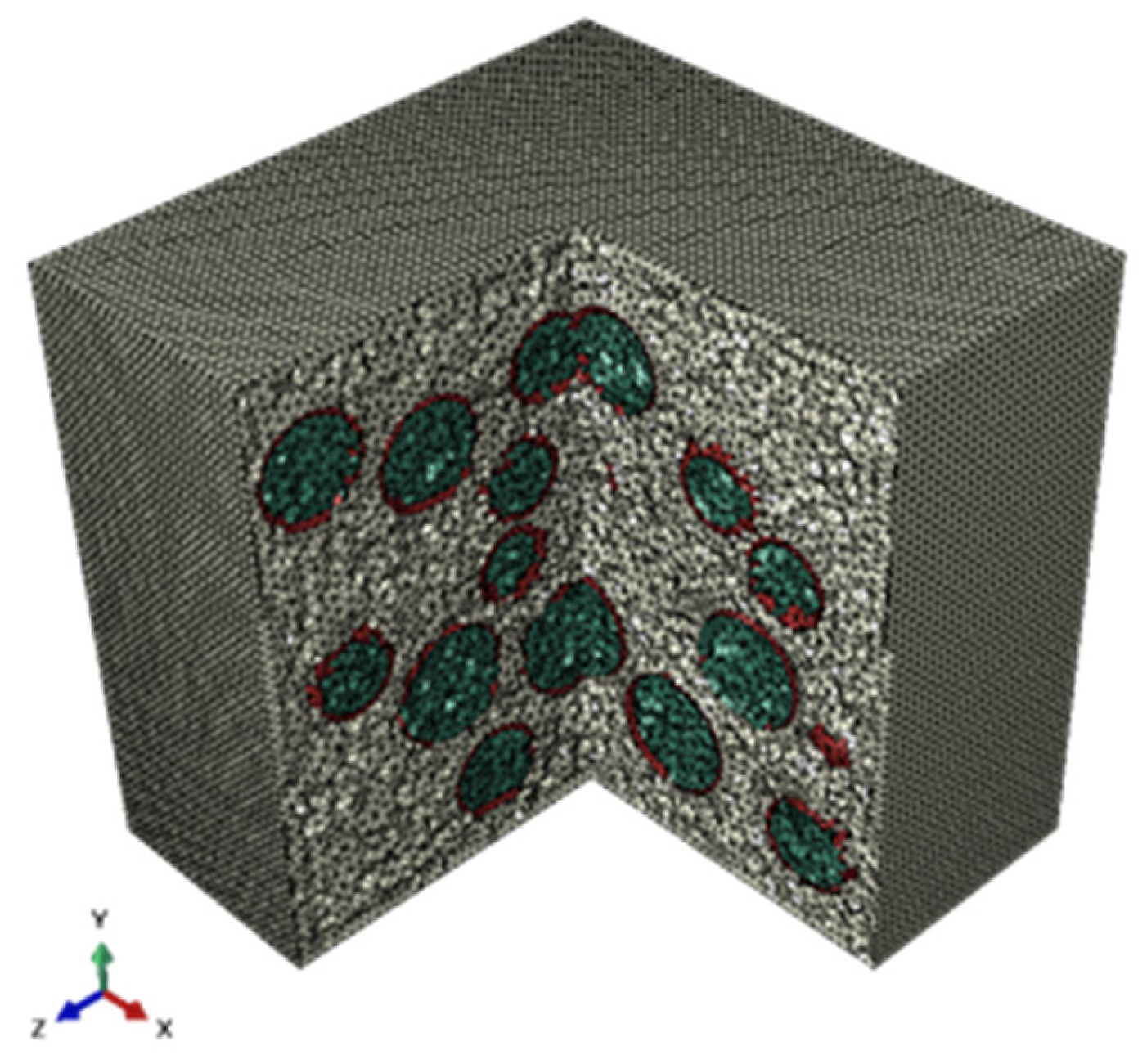

2.2. Microbead Thermal Conductivity Model

For HGM/ER composites with a void structure, the model is highly complex, comprising four components: the resin matrix, voids, the outer layer of microsphere glass, and the internal gas of the microspheres. The computational load for thermal simulations is significant, necessitating model simplifications. On the other hand, if the equivalent thermal conductivity of the microspheres is known, simplifying the two-component model into a single-component model allows for the exclusion of variables within the microspheres, thus enabling a more focused analysis of the influence of the void structure outside the microspheres on the thermal performance of the composite material. Therefore, in the subsequent analysis, this study considers an equivalent microsphere thermal conductivity model for heat transfer simulations, as shown in

Figure 2.

In the simplification of the thermal conductivity model for hollow glass microspheres, numerous two-component models have been proposed by leading scholars, such as the Park model based on the heat conduction equation [

29], the Liu model based on the generalized self-consistent theory [

30], and the Benveniste model based on microthermal conduction theory [

31], as shown in

Table 1 below.

In the formulas in the table, to unify the variables, the same variables are represented by the same symbols. Here, is the thermal conductivity coefficient of the hollow glass microspheres, in units of W/(m·K); is the thermal conductivity coefficient of the glass shell layer of the hollow glass microspheres, in units of W/(m·K); is the thermal conductivity coefficient of the air layer inside the hollow glass microspheres, in units of W/(m·K); f is the volume fraction of air inside the microspheres.

Since the simulation results of the 3D model are closer to the experimental data than those of the 2D model [

22], this paper compares and analyzes the thermal conductivity differences of the above three types of microsphere two-component and three-component models at different particle size ratios, while ensuring that the geometric and physical properties, such as microsphere particle size and filling ratio, are consistent across the models.

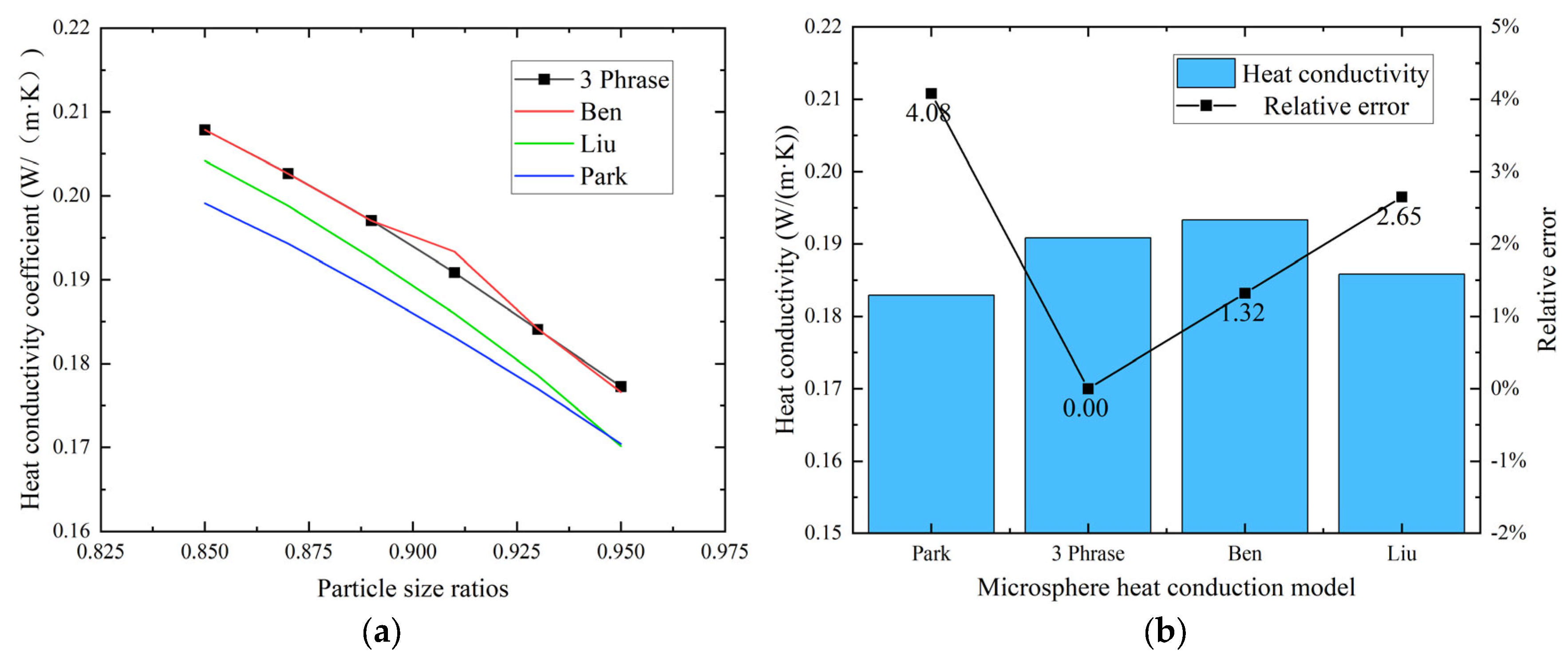

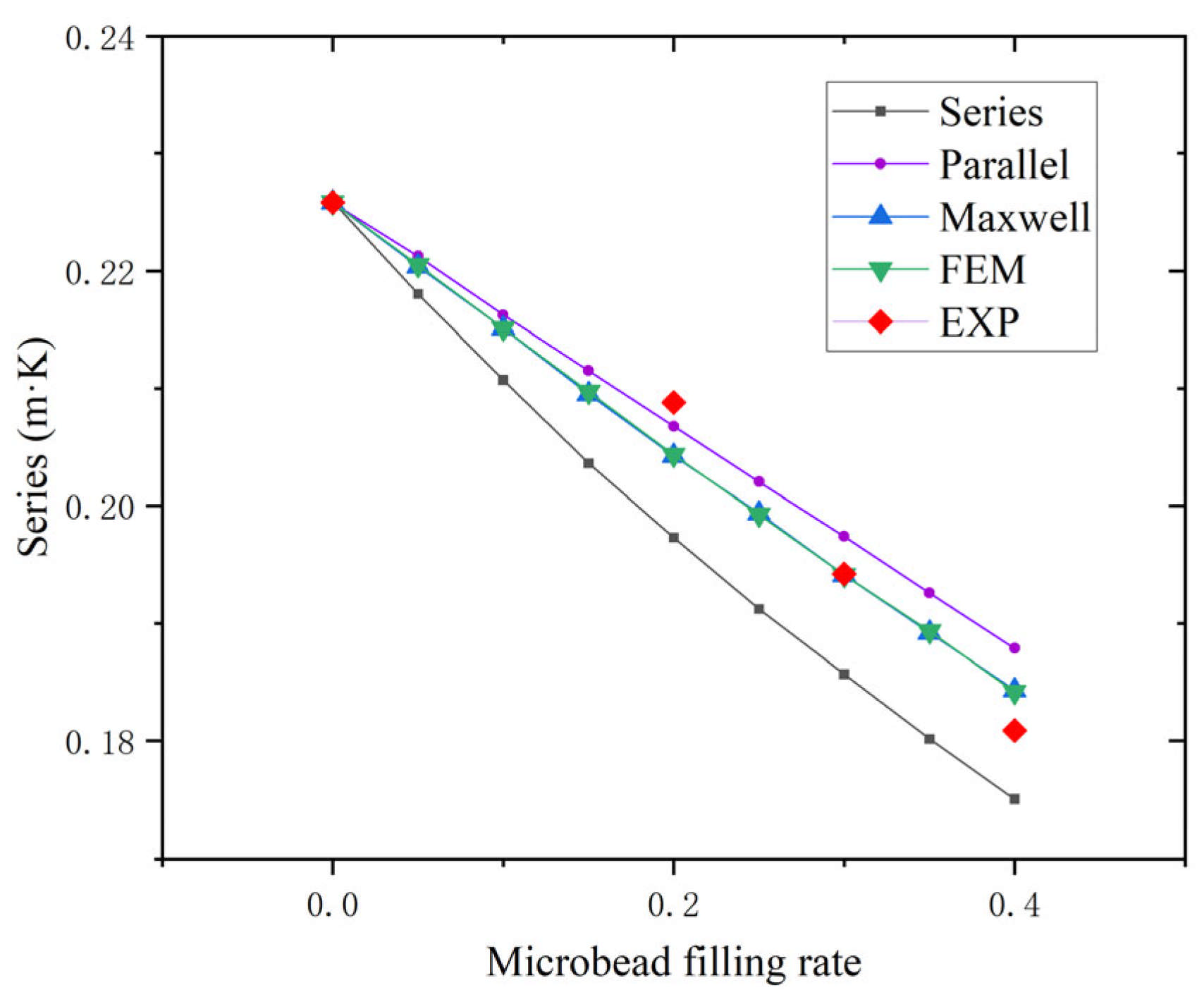

As shown in

Figure 3, with the increase in particle size ratio, the thermal conductivity of the microspheres decreases. The thermal conductivity of the microspheres calculated using the Benveniste model is in good agreement with that of the ternary model, and even when the particle size ratio is 0.91, where the error is largest, the relative error is only 1.32%, which is still smaller than that of the Park and Liu models. Therefore, in subsequent simulations, the Benveniste model will be used to calculate the thermal conductivity of hollow glass microspheres and the binary microspheres will be simplified to a single component.

4. Effect of Voids on the Thermal Properties of HGM/ER

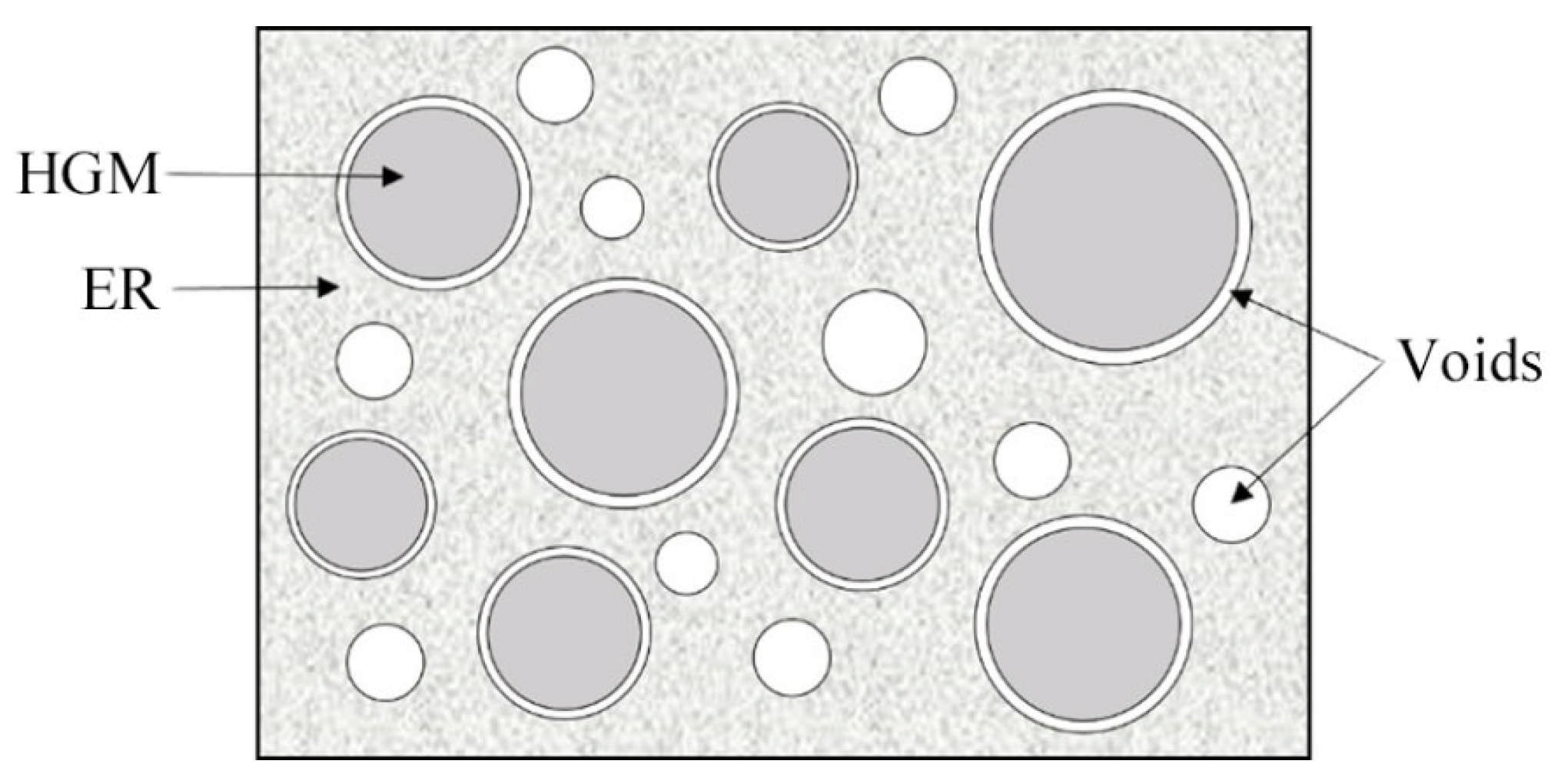

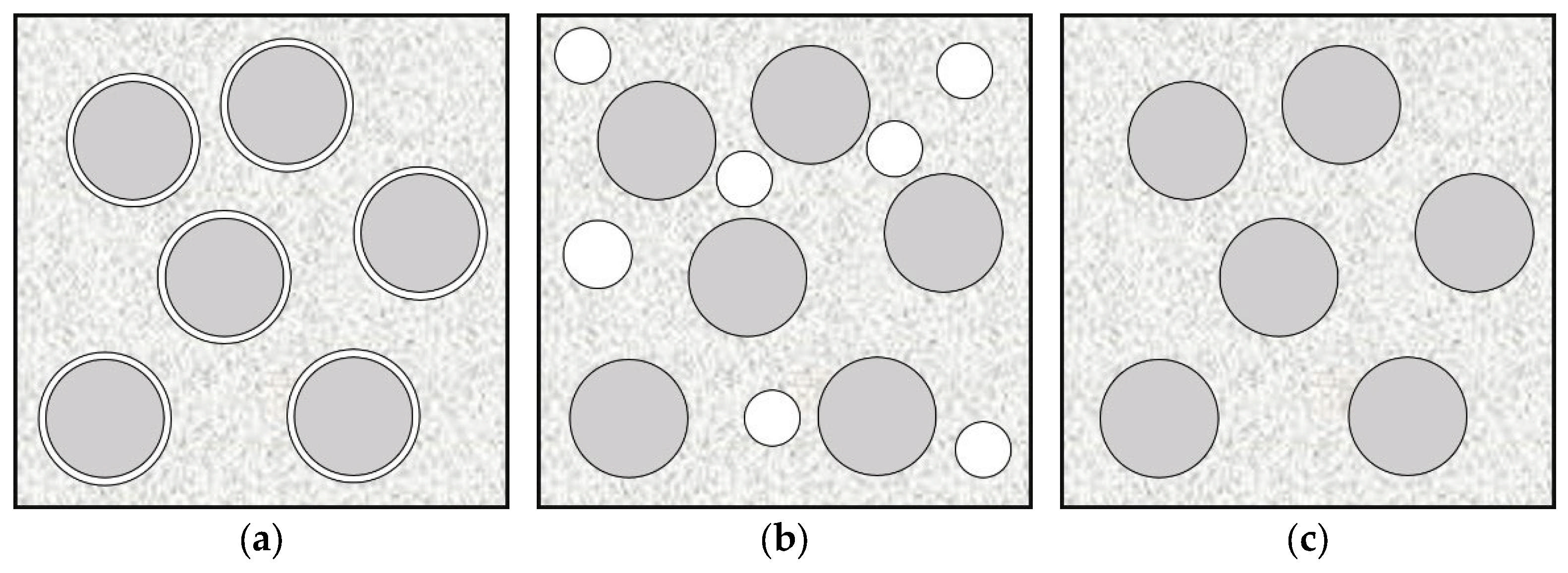

There are two main types of void structures outside the microspheres: one is bubbles, free within the resin, and the other exists as interfacial thermal resistance, embedded between the microsphere shell and the resin, as shown in

Figure 10. Both void morphologies occur randomly and indeterminately, which is closely related to the manufacturing process and the chemical reagents used. This study simplifies the voids free within the resin as spherical structures [

36], referred to as free voids, and simplifies the voids on the outer surface of microspheres as spherical shells, referred to as interfacial voids. It is assumed that the thermal conductivity of the interfacial voids is not affected by the Knudsen effect [

37]. In fact, due to the presence of interfacial effects, the microbead inorganic glass surface may appear difficult to bond with the organic epoxy resin, but this phenomenon is not global, so the assumptions made in this paper about the shape of the interfacial voids may bias the low results of the thermal conductivity prediction.

The increase in the particle size of the beads and the increase in the volume fraction may cause an increase in the void ratio inside the HGM/ER materials [

38], and the mixing time and the degree of homogeneity also affect the void ratio of the composites, which is inherently stochastic. In this paper, the effect of void type on the thermal properties of the material will be investigated through a single void structure thermal simulation, as shown in

Figure 11. In establishing the RVE model of the void structure, the thickness of the interfacial void layer is the average thickness of the void ratio uniformly distributed over all the microbeads, and the size of the spherical voids is designed to be randomly distributed in the range of 15~25 μm.

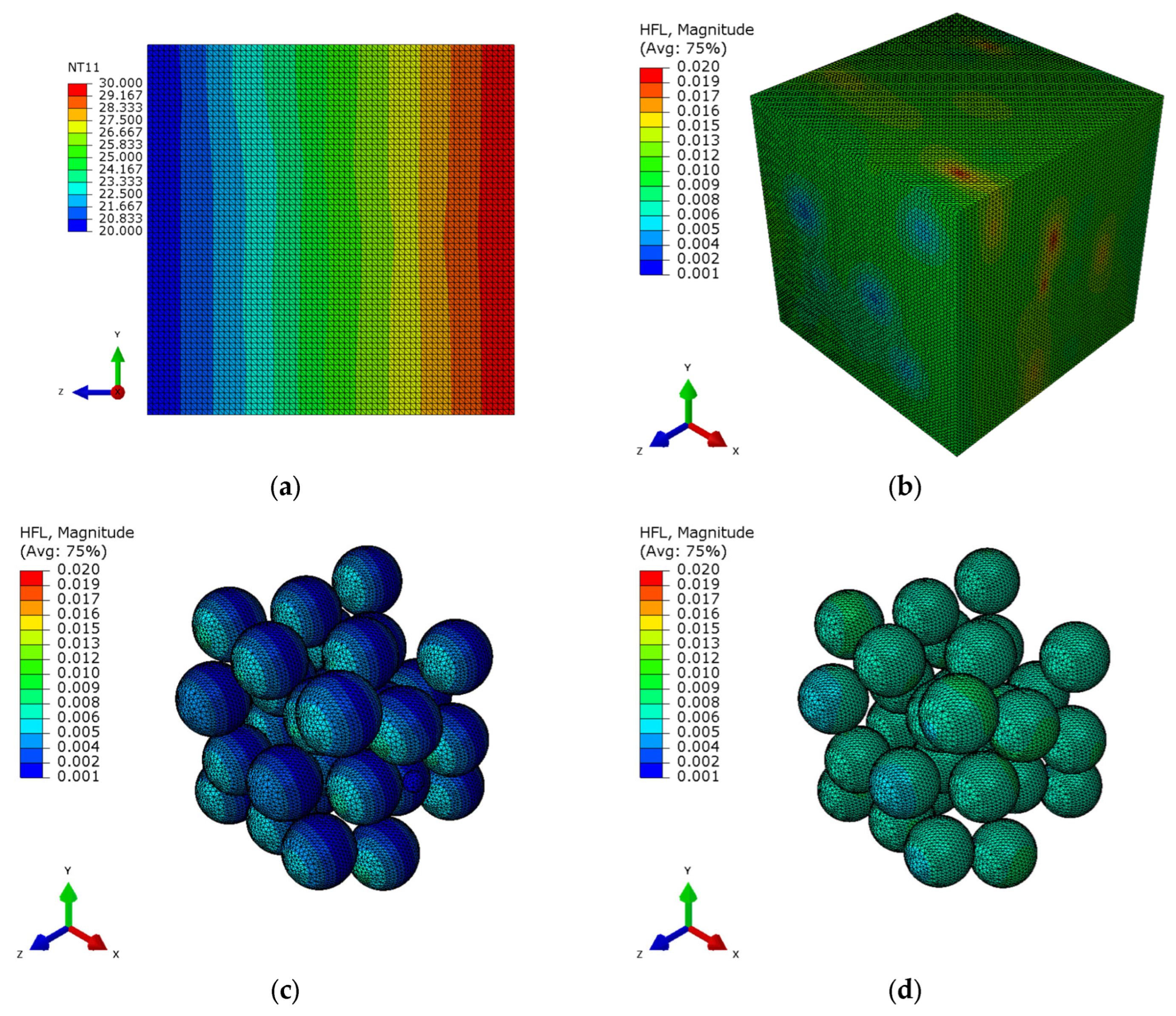

4.1. Effect of Interface Voids on the Thermal Properties of HGM/ER

The thermal conductivity of resin is set to 0.226 W/(m·K), and the thermal conductivity of air is set to 0.029 W/(m·K). The microsphere diameter is 50 μm, with a diameter ratio of 0.9 and a volume fraction of 25%. RVE models of HGM/ER composites with interface voids of 3%, 4%, 5%, and 6% are established. The effective thermal conductivity of the composites calculated is shown in the following

Table 2.

From the table, it can be seen that under the same microsphere diameter and volume fraction conditions, the effective thermal conductivity of the HGM/ER material is negatively correlated with the change in interface voids. When the interface voids increase from 3% to 6%, the material’s thermal conductivity decreases from 0.197 W/(m·K) to 0.185 W/(m·K), a reduction of 6%. Given that the voids of the HGM/ER material can reach more than 8% [

21], interface voids are an important factor affecting the thermal properties of the material under practical conditions. To further investigate the effect of interface voids on the material’s thermal performance, the thermal simulation contour for voids of 6% is shown below.

As shown in the temperature profile in

Figure 12a, the temperature contour lines on the side of the RVE are irregular, which is due to the random distribution of HGM and void structures that alter the natural convection and heat conduction within the resin matrix, resulting in an uneven temperature decrease as heat is transferred through different phases within the RVE.

When heat flow directly reaches the interface voids, it is divided into three parts. One part of the heat flow passes through interface voids into hollow glass microspheres; another part spreads along the interface voids layer, but due to the longer path and relatively higher thermal resistance, heat flow along this path is minimal; the third part is along the resin outside voids, where the resin has the lowest thermal resistance, so the heat flow is maximal. From the heat flow contour of the interface voids (

Figure 12c), it can be seen that along the z-direction of heat transfer, the middle part of the spherical void becomes darker as it approaches the center, indicating a decrease in the heat transfer and an increase in thermal resistance. This region of heat flow tends to accumulate more in the resin matrix outside interface voids, as shown by the red area in

Figure 12b. The color at both ends of the interface voids becomes lighter, indicating that part of the heat flow, after traveling along a certain path through the interface voids, enters the microsphere with relatively lower thermal resistance, as shown in

Figure 12d.

The first two heat transfer pathways involve varying degrees of flow through the porous regions. Therefore, compared to direct heat transfer through high thermal conductivity resins or glass microspheres, these two pathways exhibit higher thermal resistance. The third heat transfer pathway bypasses the porous layer and transfers heat through the resin matrix, resulting in the highest heat flux. However, as the pore size increases, the bypass path becomes longer, which in turn increases the thermal resistance to heat transfer. Therefore, the presence of voids at the outer interface of the microspheres increases the thermal resistance to heat transfer at different levels. On a macroscopic scale, this results in a reduction in the material’s thermal conductivity.

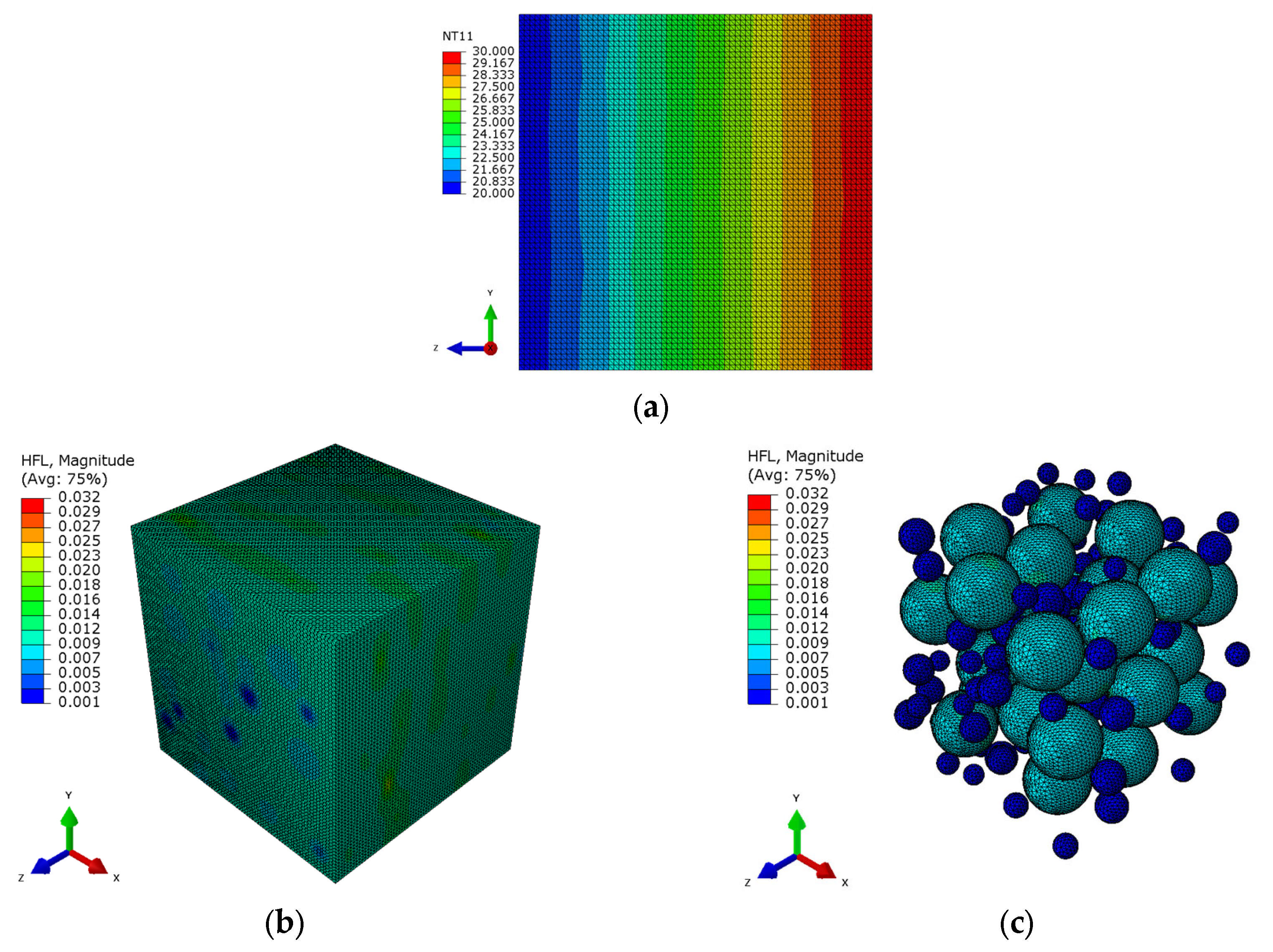

4.2. Effect of Free Voids on the Thermal Performance of HGM/ER

Under the same conditions as above, a thermal simulation was performed on the RVE model of the HGM/ER composite material, which only contains free voids. The effective thermal conductivity of the processed material is shown in the following

Table 3.

Similar to the pattern observed for interface voids, under the same conditions of glass microsphere particle size and filling ratio, the effective thermal conductivity of HGM/ER material linearly decreases with the increase in free voids. When the free voids increase from 3% to 6%, the material’s thermal conductivity decreases from 0.202 W/(m·K) to 0.194 W/(m·K), a reduction of 4%. Compared to interface voids, the change in thermal conductivity caused by free voids is relatively small. Taking the thermal simulation contour map of HGM/ER material with 6% voids as an example, the microscopic heat conduction mechanism inside the material is explained, as shown in

Figure 8.

According to Fourier’s law of heat conduction, heat flow tends to move towards areas with relatively low thermal resistance. In the RVE, heat flows through the microspheres and voids with high thermal resistance, leading to an uneven temperature distribution within the RVE model, as shown in

Figure 13a. This is consistent with the reason for the uneven temperature distribution caused by the interface voids.

Figure 13c shows the heat flow distribution map for the microspheres and voids. It can be observed that the heat flow passing through the voids is significantly smaller than that through the microspheres. This is due to two reasons: on one hand, the thermal resistance of the free voids is higher than that of the microspheres; on the other hand, the particle size of the free voids is smaller than that of the microspheres, resulting in a shorter path for the heat flow to bypass the voids. Therefore, when the heat flow directly moves toward the microspheres and voids, it bypasses the voids, and the proportion of heat flow diverted from the resin matrix is higher, as shown in

Figure 13b,c.

Compared to interface voids, the effect of free voids on the thermal performance of HGM/ER materials is simpler. Both the thermal resistance of the voids themselves and the bypassing of heat flow contribute to an increase in the overall thermal resistance, leading to a decrease in the material’s thermal conductivity as the free void fraction increases.

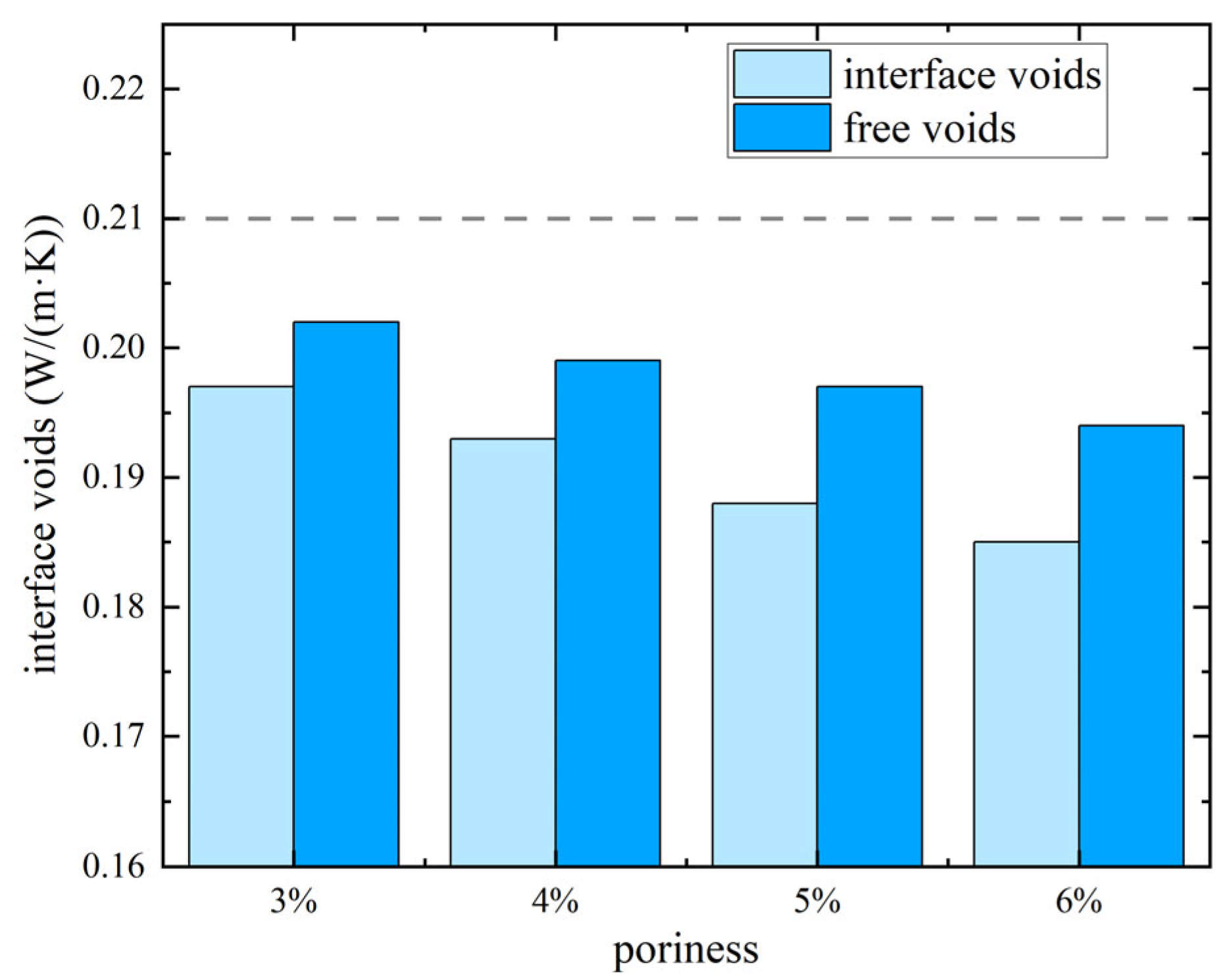

5. Effect of Void Morphology on the Thermal Performance of HGM/ER

In the previous sections, the voids around the microspheres were classified into interface voids and free voids, both of which influence the heat transfer within the material at the microscopic level. Under the same voids, the impact of free voids on the thermal performance of HGM/ER materials is smaller than that of interface voids. Based on the simulation data discussed earlier, the following section will provide a detailed comparative analysis to explore the reasons for the differences in the impact of these two types of voids on the material’s thermal conductivity.

Observing

Figure 14, where the dashed line represents the control group with no voids, it is evident that under the same voids, the difference in the reduction in thermal conductivity caused by interface voids and free voids is significant. Taking 3% voids as an example, free voids cause the material’s thermal conductivity to decrease from 0.210 W/(m·K) to 0.202 W/(m·K), whereas the reduction in thermal conductivity caused by interface voids is 65.5% greater than that caused by free voids. Additionally, under conditions of 3% interface voids and 5% free voids, the thermal conductivity is both 0.197 W/(m·K), which means that for the same thermal conductivity, the volume fraction of interface voids in the material is 60% smaller than that of free voids. The specific reasons for this can be further analyzed through the heat profile inside the material.

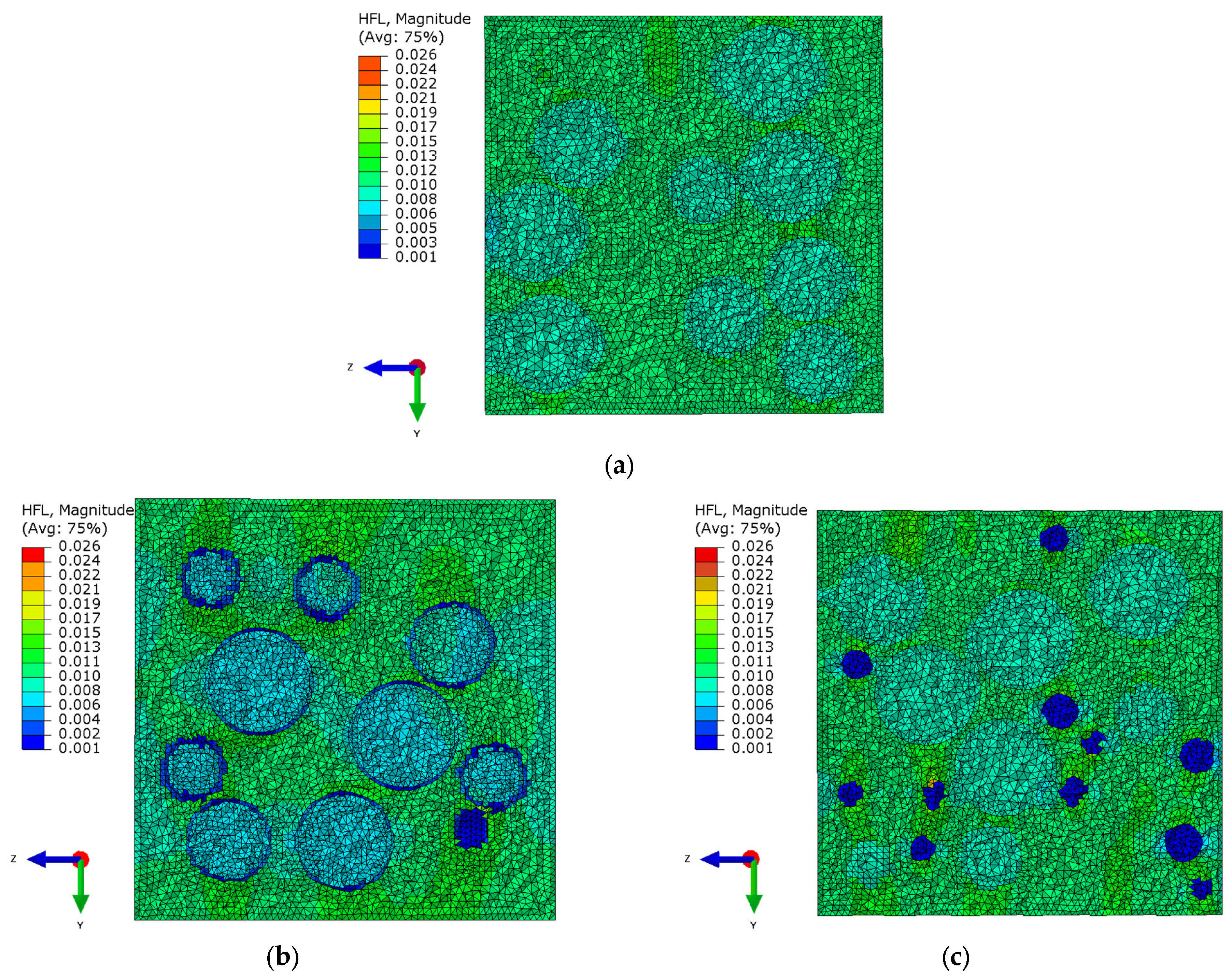

The dark blue regions in

Figure 15b,c represent void structures with different morphologies. Compared to

Figure 15a, the presence of voids increases the areas of dark green in the corresponding heat flow distribution contour map. This reflects the phenomenon of heat flow by passing and converging in specific areas. Due to the influence of void morphology, the amount of heat flow passing through the microspheres varies. In the RVE model containing interface voids, the microspheres appear darker blue, indicating a smaller amount of heat flow passing through. The reason for this is that interface voids increase thermal resistance along the path to the microspheres, causing more heat flow to bypass the voids and propagate through the resin matrix.

However, notably, as the particle size of the microspheres and their interface voids increases, the path of heat flow becomes longer. At this point, the radial thermal resistance across the interface voids is smaller than the thermal resistance of heat flow passing through the resin matrix. As shown in

Figure 15b, with larger microspheres, more heat flow directly passes through the interface voids into the microspheres, which results in lighter colors at both ends of the interface voids along the heat flow’s z-direction. In contrast, for smaller particle sizes, the interface voids at both ends along the y-direction are colored blue, indicating lower bypass thermal resistance and less heat flow passing through the interface voids.

For free voids, as shown in

Figure 15c, the particle size also affects the heat flow path. It can be observed that the larger the particle size of the voids, the more saturated the blue areas in the heat profile, which approached the shape of the voids themselves. This is due to the bypassing phenomenon during thermal simulation, where very little heat flow passes radially through the voids. Additionally, since free voids are smaller in size compared to the microspheres, they do not directly affect the thermal conductivity of the microspheres, which occupy a larger volume. Therefore, the impact of free voids on the thermal conductivity of the composite material is smaller than that of interface voids. In other words, for the same void fraction, HGM/ER materials containing only interface voids have better thermal insulation performance.

6. Conclusions

This study validates the accuracy and reliability of the Benveniste equivalent microbead thermal conductivity model in calculating the thermal conductivity of HGM. The RSA algorithm is improved and optimized to achieve high particle packing and uniform distribution in the cell units. Additionally, a classification method for void types is proposed to explore the effects of void fraction and morphology on the thermal properties of HGM/ER materials, providing a detailed interpretation of the internal heat conduction mechanisms from a microscopic perspective. The main conclusions are as follows:

Among the equivalent microbead thermal conductivity models, the Benveniste model shows the best agreement with the three-component thermal conductivity model. The maximum relative error occurs at a particle size ratio of 0.91, but it is only 1.32%.

The improved and optimized RSA algorithm achieves a higher particle packing density, increasing the upper limit of packing by 25% compared to the traditional RSA algorithm, while also ensuring a more uniform particle distribution.

The void types can be classified as interface voids and free voids. The air within the voids causes heat flow bypassing, and the strength of this bypassing phenomenon is influenced by both the void type and particle size. Simplification of the interfacial voids may result in a low prediction of the thermal conductivity.

The void fraction is negatively correlated with the thermal conductivity. The effect of interface voids on reducing the thermal conductivity of the material is more significant, being nearly 60% higher compared to free voids of the same volume.

The thermal conductivity of the void-containing HGM/ER materials studied in this paper has an upper limit corresponding to that of materials containing only free voids and a lower limit corresponding to materials with only interface voids. This allows for an estimation of the thermal conductivity of materials with different void fractions, providing important references for the practical application of HGM/ER composites in insulation and thermal insulation fields.