Evaluation and Design of Supply Chains for Bioenergy Production

Abstract

1. Introduction

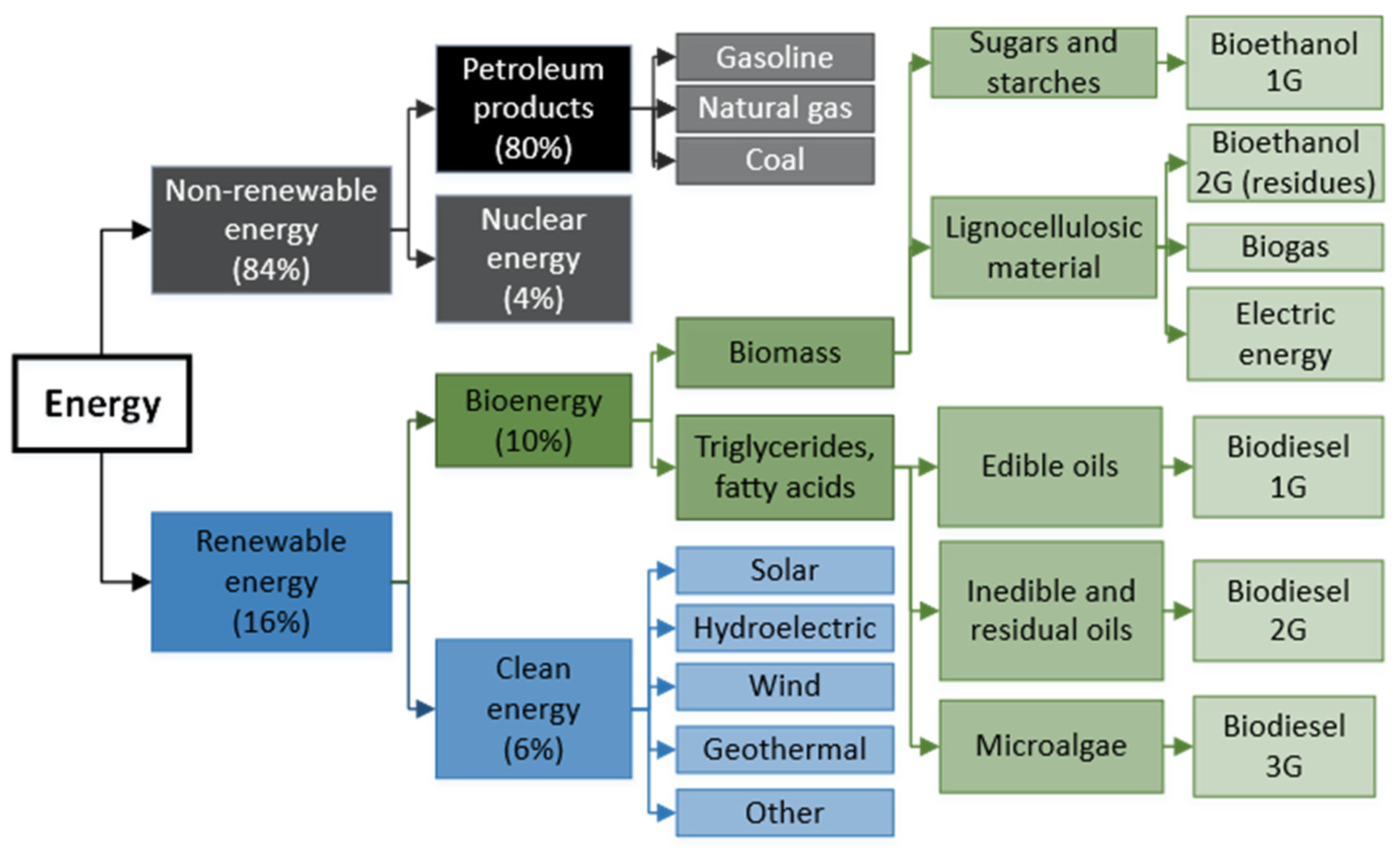

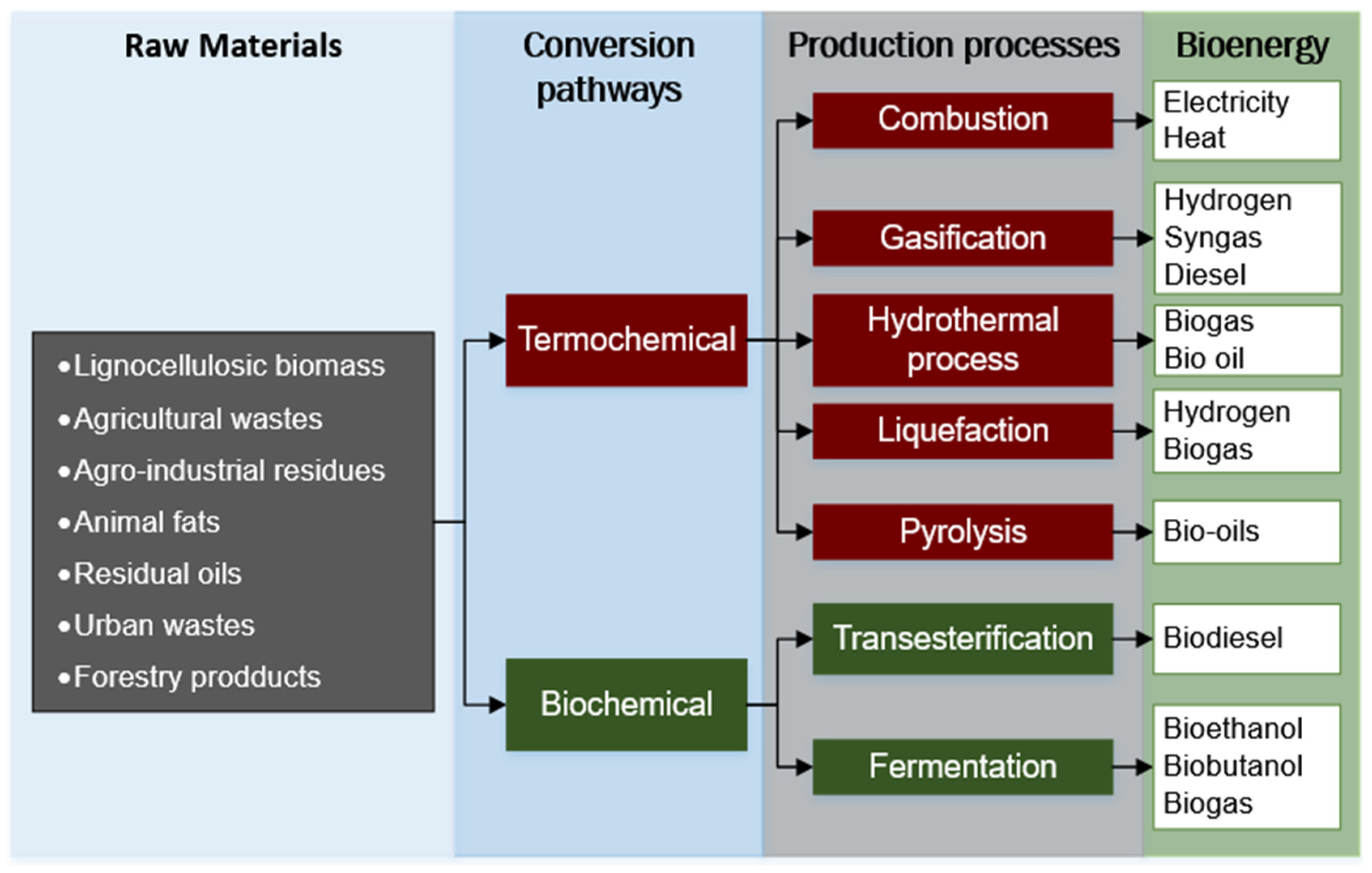

2. Bioenergy

2.1. Generalities

2.2. Liquid Biofuels

2.2.1. Biodiesel

2.2.2. Bioethanol

2.2.3. Drop-In Biofuels

2.3. Solids Biofuels

2.4. Gaseousus Biofuels

2.4.1. Biogas

2.4.2. Biohydrogen

2.4.3. Syngas

2.5. Regulations Associated with the Use of Bioenergy Products

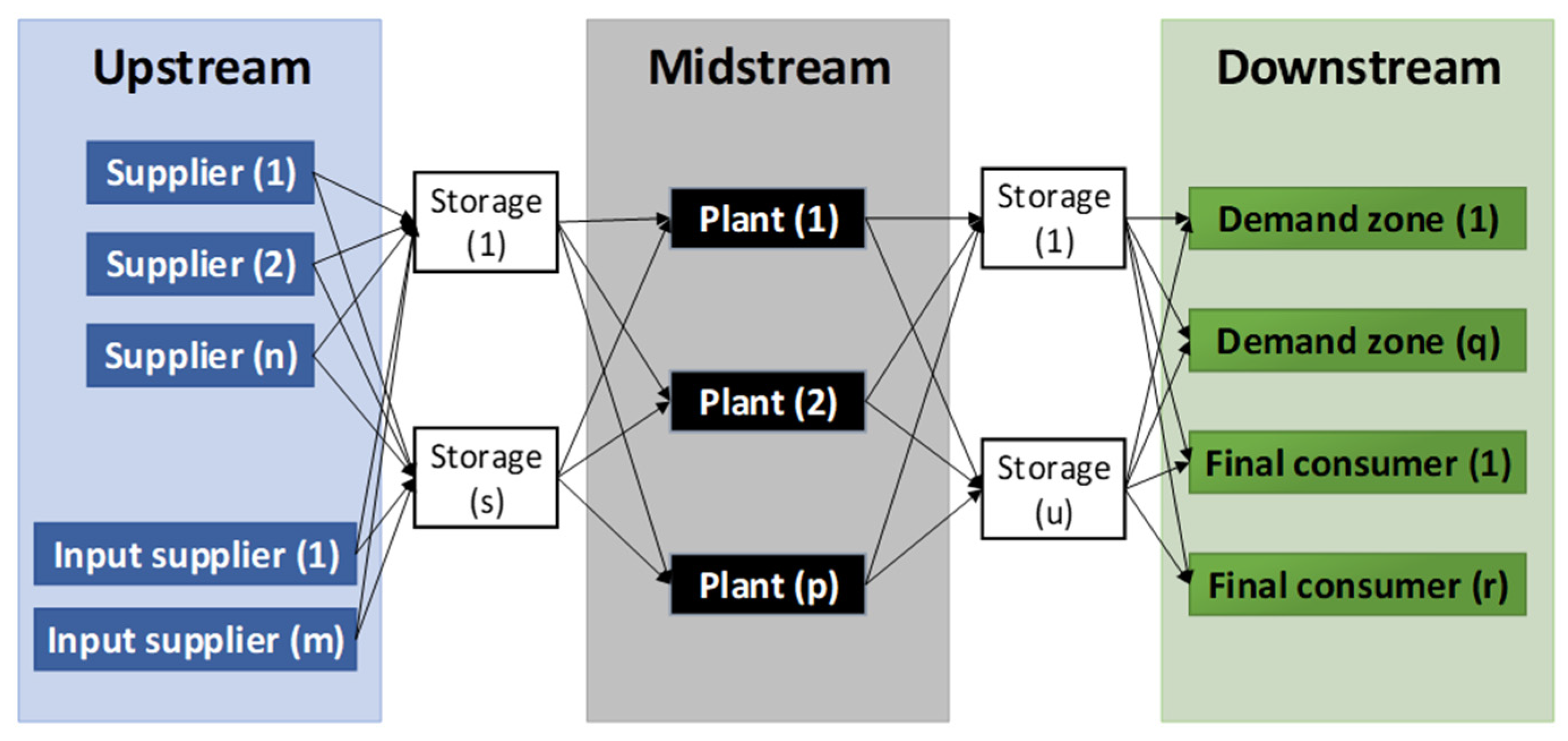

3. Supply Chain (SC)

3.1. Overview of SC

3.2. Bioenergy SC

4. Systematic Search Methodology

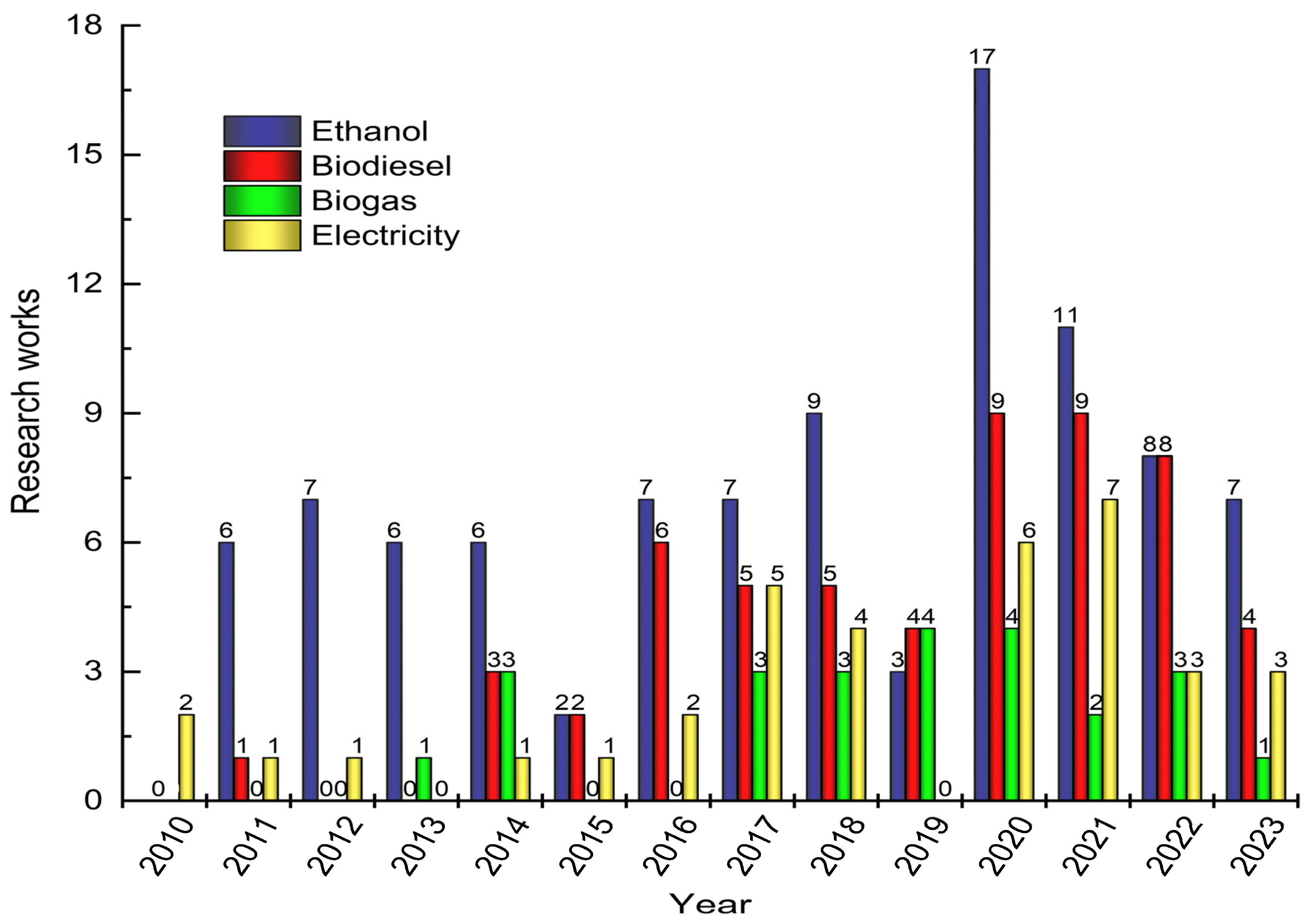

5. SC Designs of Bioenergy Production

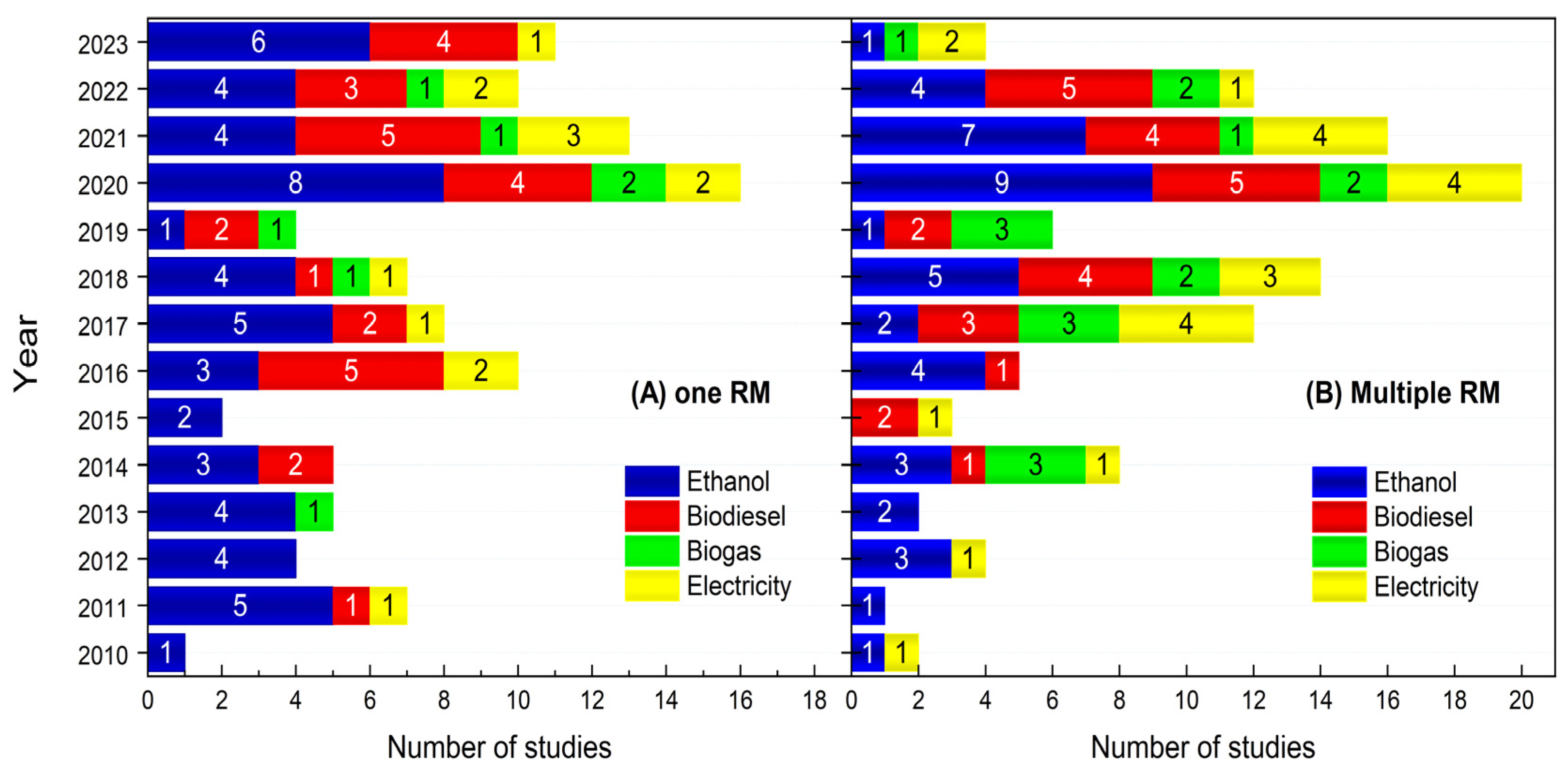

5.1. Products Used in the Design of Bioenergy SC

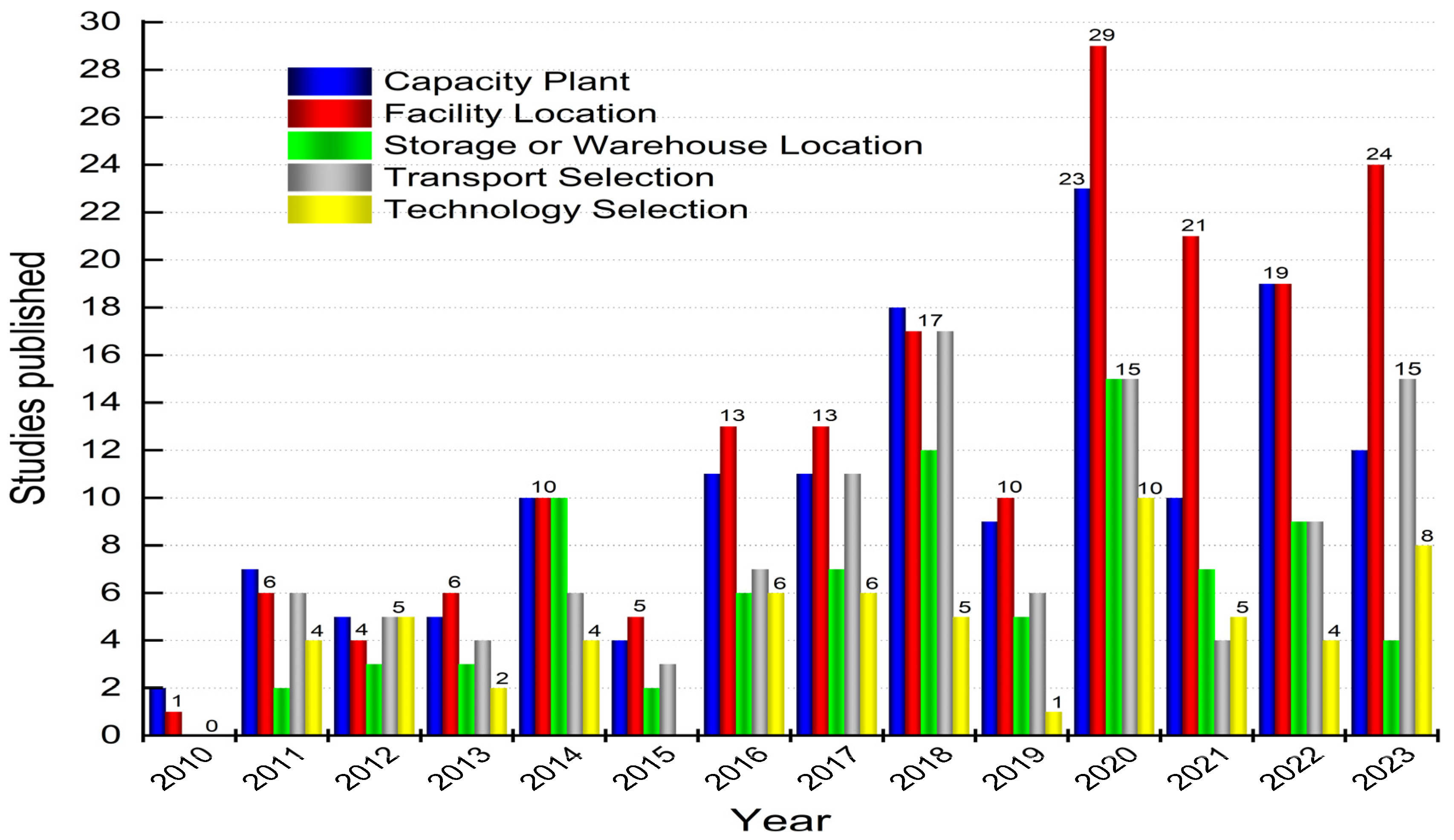

5.2. Decision-Making Addressed in the Bioenergy SC Design

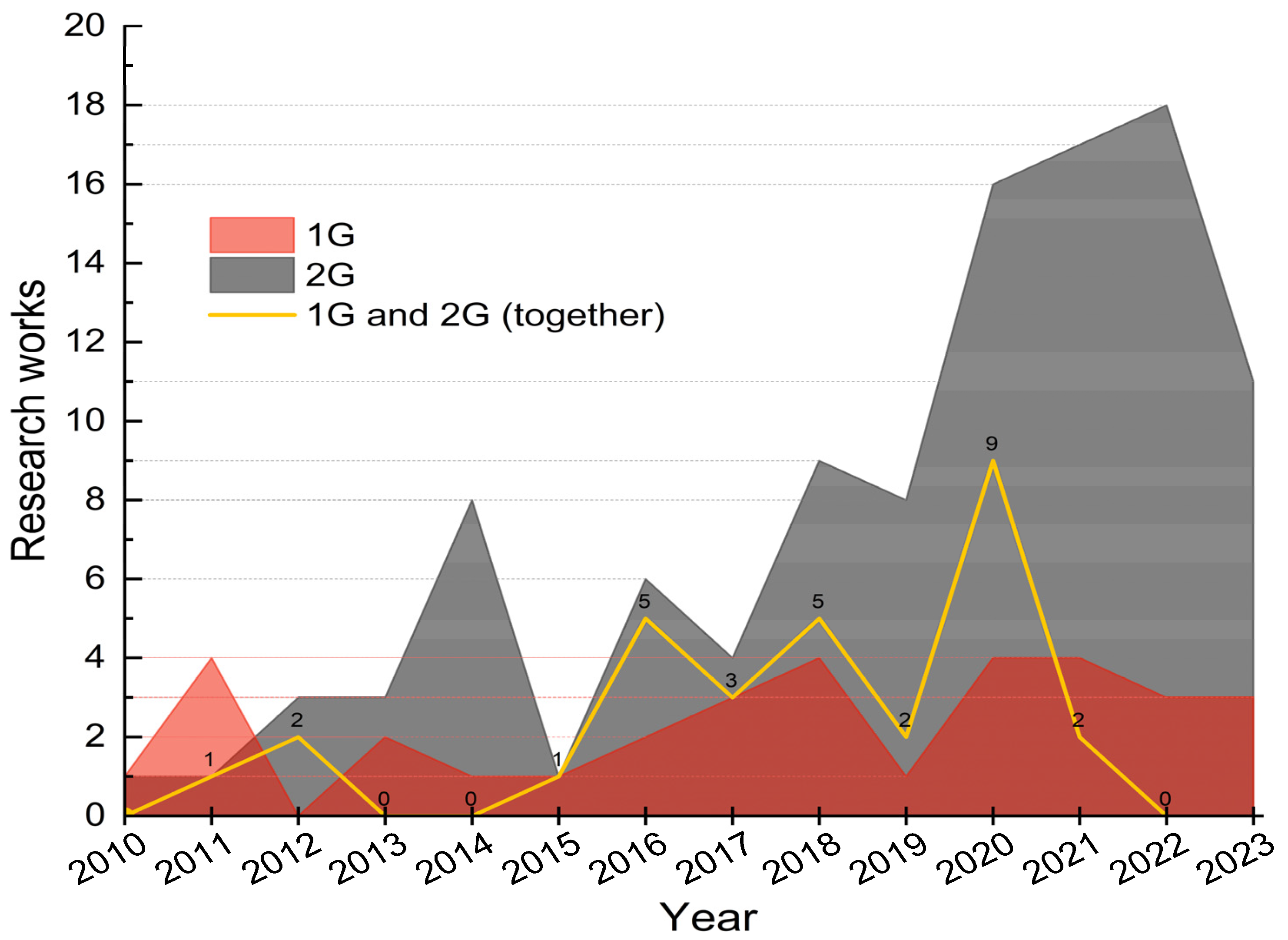

5.3. Raw Materials Considered in Bioenergy SC

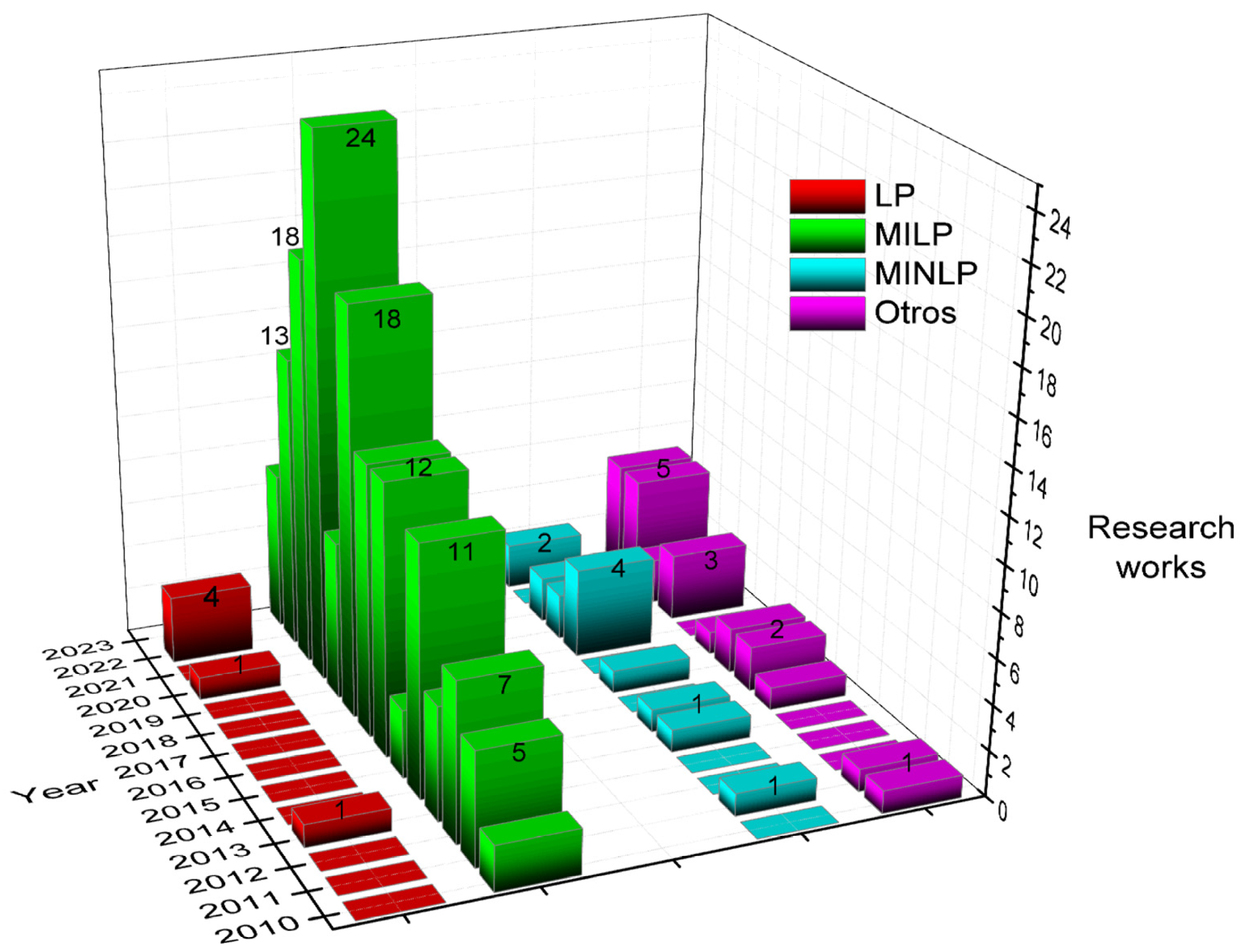

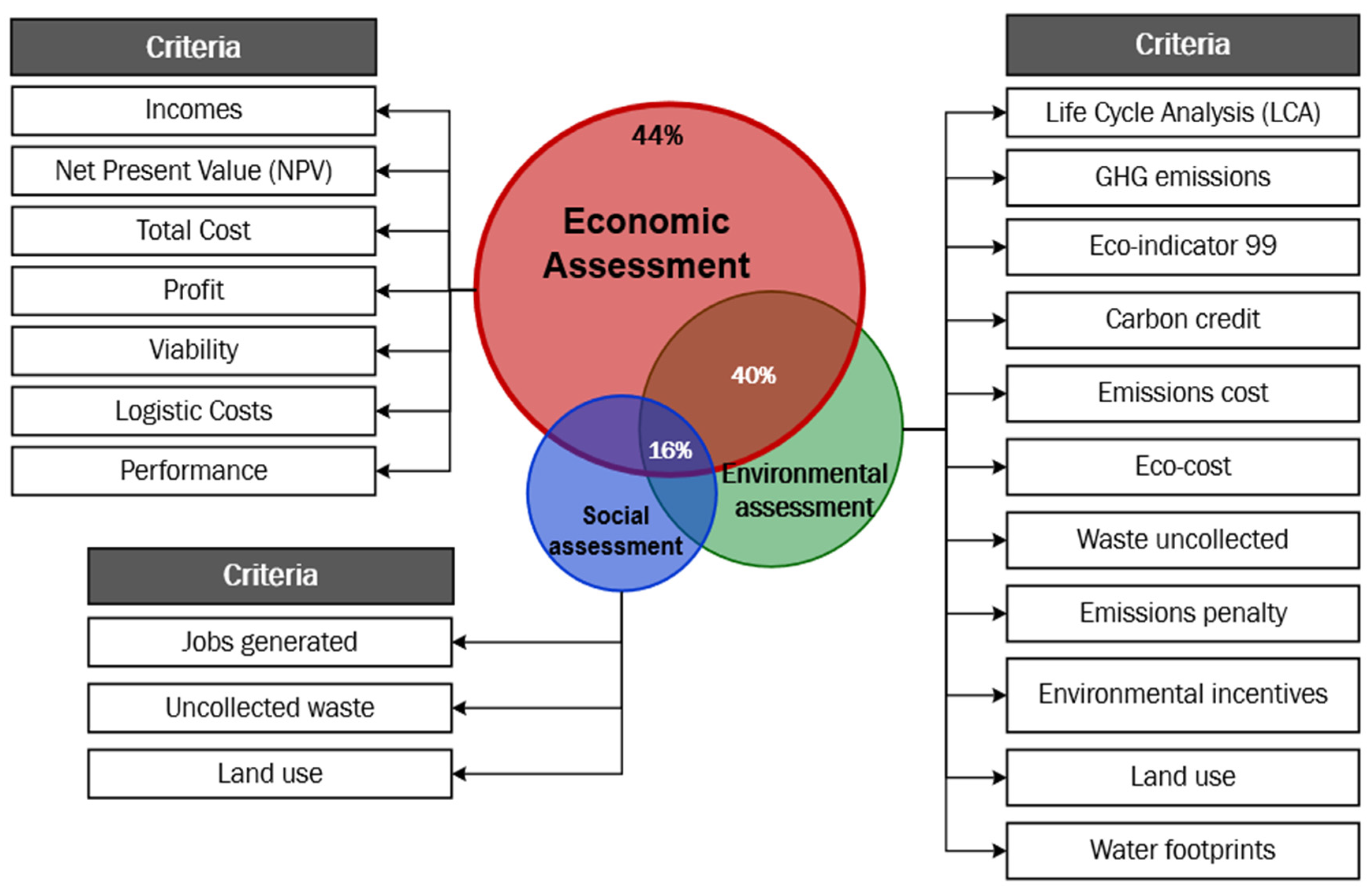

5.4. Model Types and Assessment Criteria Applied to Bioenergy SC

| Raw Material | MP Source | Criteria | Model Type | Scope | Country | Ref. | |||

|---|---|---|---|---|---|---|---|---|---|

| 1G | 2G | Ec. | Env. | Soc. | |||||

| Algae | X | MILP | Country | Korea | [217] | ||||

| Jatropha curcas | X | X | X | MILP | Country | Iran | [218] | ||

| Wastewater sludge | X | X | X | MILP | Region | USA (Mississippi) | [137] | ||

| Waste cooking oil | X | X | X | X | MILP | City | Suzhou (China) | [219] | |

| Soybean | X | X | MILP | Country | Iran | [220] | |||

| Microalgae | X | X | MILP | Country | Iran | [159] | |||

| Forestry wastes | X | X | X | MILP | Region | Canada | [221] | ||

| Wastewater sludge | X | X | X | MILP | Region | USA (Mississippi) | [145] | ||

| Vegetable oil | X | X | MILP | Country | Brazil | [222] | |||

| Oil palm | X | X | X | MILP | Country | Colombia | [223] | ||

| Waste cooking oil | X | X | X | X | MILP | Region | China (Jiangsu) | [219] | |

| Oil palm | X | X | X | X | MILP | Country | Colombia | [224] | |

| Sunflower and rapeseed | X | X | X | MILP | Country | Bulgaria | [225] | ||

| Waste cooking oil and Jatropha | X | X | MILP | Country | Iran | [226] | |||

| Jatropha y Waste Cooking oil | X | X | X | MPRO | Country | Iran | [226] | ||

| Jatropha | X | X | X | MILP | Country | Iran | [227] | ||

| Jatropha seeds and Waste cooking oil | X | X | MILP | Country | Iran | [228] | |||

| Wastewater sludge | X | X | MILP | Country | Iran | [229] | |||

| Camellia pleifera | X | X | MILP | Region | USA (Montana) | [230] | |||

| Jatropha and Waste Cooking oil | X | X | X | MILP | Region | Iran | [231] | ||

| Not specified | X | X | X | LNRM | Country | Iran | [232] | ||

| Kitchen waste | X | X | MILP | Region | China | [233] | |||

| Waste cooking oil | X | X | X | Other | Region | China | [234] | ||

| Chicken fat, mutton fat, and beef fat | X | X | X | MILP | Country | Pakistan | [235] | ||

| Chicken fat, beef and Mutton tallow | X | X | X | X | MILP | Country | Pakistan | [236] | |

| Algae | X | X | MINLP | Country | USA | [237] | |||

| Fat residue | X | X | X | X | X | MILP | Country | Bulgaria | [238] |

| Jatropha | X | X | X | MILP | Inter. | Iran | [239] | ||

| Moringa | X | X | X | MILP | Country | Iran | [240] | ||

| Forest and residues | X | X | X | X | MILP | Region | Iran | [241] | |

| Jatropha | X | X | X | X | MILP | Country | Iran | [242] | |

| Microalgae | X | X | MILP | Country | Korea | [243] | |||

| Castor bean seeds | X | X | MILP | Region | Brazil | [244] | |||

| Soybean, rapeseed, and sunflower | X | X | X | MINLP | Not specified | [245] | |||

| Product | Raw Material | RM Source | Criteria | Model Type | Scope | Country | Ref. | |||

|---|---|---|---|---|---|---|---|---|---|---|

| 1G | 2G | Ec. | Env. | Soc. | ||||||

| EE | Woody biomass | X | X | MILP | Region | USA (Tennessee) | [246] | |||

| Biogas | Animal manure | X | X | MILP | City | Turkey (Izmir) | [247] | |||

| Biogas | Agricultural wastes | X | X | X | MILP | Region | Italy | [248] | ||

| EE | Grass straw | X | X | X | X | MILP | Country | Iran | [249] | |

| EE | Forestry wastes | X | X | MILP | Country | Portugal | [146] | |||

| EE | Forestry wastes | X | X | MILP | Region | Canada (British Columbia) | [216] | |||

| Biogas | Animal manure | X | X | X | MILP | Region | USA (North Dakota) | [250] | ||

| Biogas | Artichoke by-products | X | X | X | MGLP | Region | Italy (Sardina) | [251] | ||

| Biogas | Livestock manure, | X | X | X | MILP | Region | Mexico | [252] | ||

| Biogas | Agricultural wastes and manure | X | X | MINLP | Region | Iran | [253] | |||

| Biogas | Crop, pasture, and livestock, and wood residues | X | X | X | MINLP | Region | USA | [152] | ||

| Biogas | Manure, Sewage Sludge | X | X | X | MILP | Region | USA (Wisconsin) | [254] | ||

| Biogas | Corn silage and livestock manure | X | X | MILP | Region | Italy (North) | [255] | |||

| Biogas | Residual crops | X | X | X | NLP | [256] | ||||

| Biogas | Chicken manure | X | X | MILP | Region | Turkey | [257] | |||

| Biogas | Manure, organic waste, and wastewater | X | X | X | MINLP | Region | Mexico | [258] | ||

| EE | Crop residue | X | MILP | Country | Pakistan | [259] | ||||

| EE | Wood pellets | X | X | MINLP | Region | Canada | [260] | |||

| EE | Woody biomass | X | X | MILP | Region | USA | [261] | |||

| EE | Agricultural wastes | X | X | X | MILP | Inter. | European Union | [262] | ||

| EE | Agricultural wastes | X | X | MILP | Country | Egypt | [263] | |||

| Raw Material | MP Source | Criteria | Model Type | Scope | Country | Ref. | |||

|---|---|---|---|---|---|---|---|---|---|

| 1G | 2G | Ec. | Env. | Soc. | |||||

| Corn | X | X | X | MILP | Region | Italy (North) | [133] | ||

| Corn and straw | X | X | X | X | MILP | Region | Italy (north) | [131] | |

| Coffee waste | X | X | X | X | MILP | Country | Colombia | [140] | |

| Corn, straw | X | X | X | X | MILP | Country | Italy (north) | [144] | |

| Straw, manure, and sugar beet | X | X | MILP | Country | Denmark (northwest) | [267] | |||

| Corn manure and silage | X | X | MILP | Region | Turkey (Izmir) | [268] | |||

| Agricultural residues | X | X | X | MILP | Region | Slovenia | [269] | ||

| Forestry residues | X | X | X | MILP | Country | Canada | [143] | ||

| Agricultural, forestry, and energy crop wastes | X | X | X | MILP | Region | Korea (Jeju Island) | [270] | ||

| Rice, wheat, barley, and corn straw | X | X | X | MILP | Country | Iran | [136] | ||

| Agricultural wastes | X | X | MILP | Country | Iran | [265] | |||

| Corn and oil | X | X | Country | USA | [271] | ||||

| Biomass and manure | X | X | MILP | Country | Slovenia | [266] | |||

| Animal and agricultural wastes | X | X | X | MILP | Region | Iran | [272] | ||

| Azadirachta indica and Eruca sativa | X | X | X | Other | Country | Iran | [273] | ||

| Food waste | X | X | MILP | Local | China | [274] | |||

| Agricultural wastes | X | X | X | MILP | Country | Ethiopia | [275] | ||

| Sugarcane | X | X | X | MILP | Country | Iraq | [276] | ||

| Biomass | X | X | Other | [132] | |||||

| Forest residues and Agricultural wastes | X | X | MILP | Country | Iran | [277] | |||

| Cereal straw | X | X | X | MILP | Country | Germany | [278] | ||

| Jatropha | X | X | X | MILP | Country | Iran | [279] | ||

| Agricultural wastes | X | X | MILP | Region | California | [181] | |||

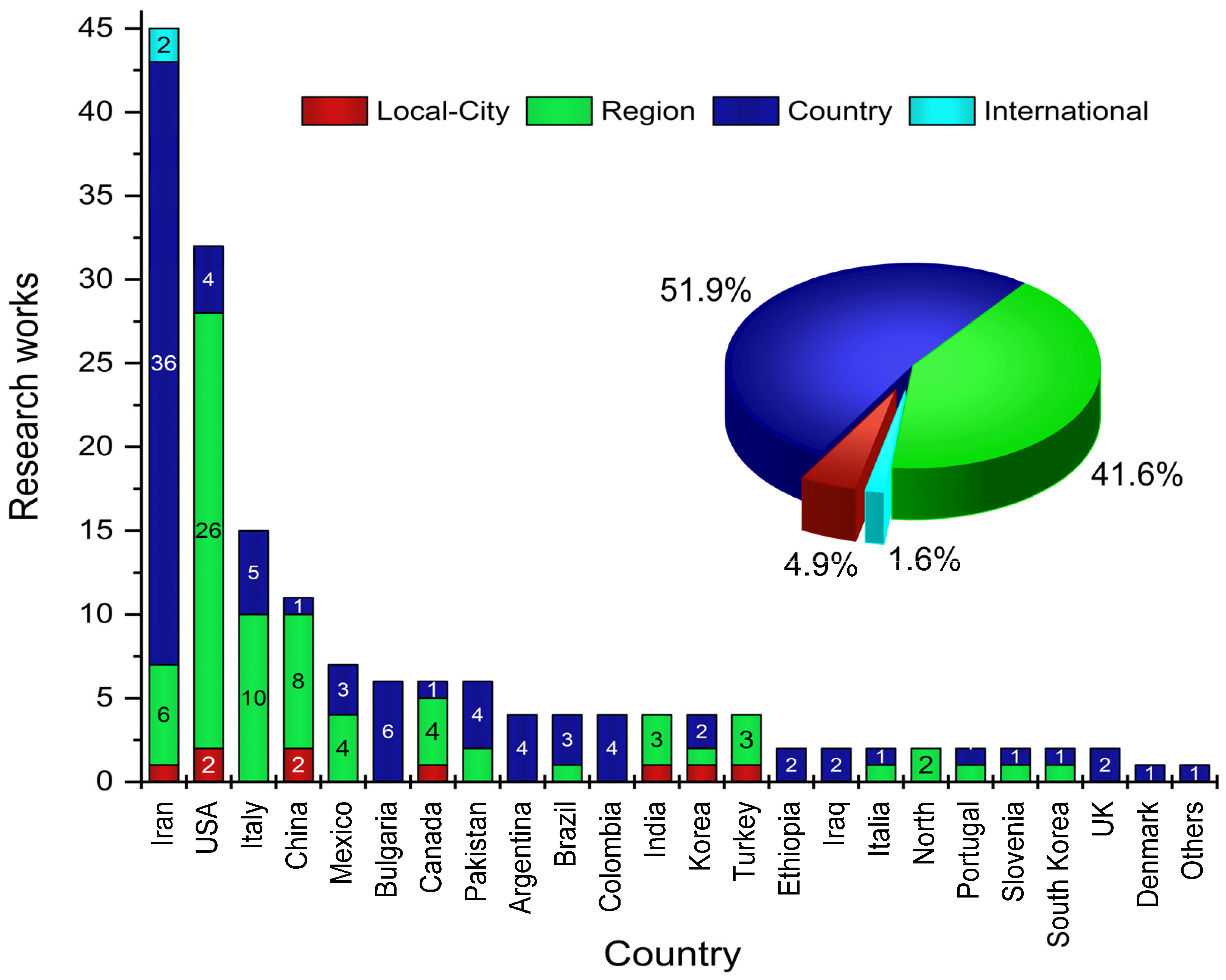

5.5. Bioenergy SC Application Context Scale

5.6. Uncertinity in Bioenergy SC Design

| Uncertainty Type | Parameter with Uncertainty | Strategy of Solution | Solver | Reference |

|---|---|---|---|---|

| Deterministic | Biomass purchase cost, Transportation cost, Fertilizer sales prices | Sensitivity analysis | LINGO | [284] |

| Epistemic | Costs and single setup multiple delivery, carbon emissions | Sensitivity analysis and Fuzzy parameters | Methauristic method | [285] |

| Deterministic | RM supply and Biodiesel demand | Sensitivity analysis and AEC method | Unspecified | [286] |

| Epistemic | Biodiesel demand, RM availability, biofuel prices | Sensitivity analysis | LINGO 18 | [163] |

| Random | Biodiesel demand, Jatropha yields | Scenarios analysis | GAMS | [227] |

| Random | RM availability, Biodiesel demand | Chance constrained | Unspecified | [287] |

| Epistemic | Size of leased land, Target to be achieved | Fuzzy objective and constraints | IBM ILOG (CPLEX) | [247] |

| Random | Biomass supply, Technology | Two-stage stochastic programming | GAMS (CPLEX) | [145] |

| Random | Biomass price, Biomass crop emissions | Scenarios analysis | GAMS (CPLEX) | [128] |

| Deterministic, Random | Technology (yields) | Sensitivity analysis | Gurobi | [254] |

| Random | Biomass purchase prices, Bioethanol demand, Ethanol purchase prices | Scenarios analysis | GAMS | [157] |

| Deterministic | Biofuel Demand, RM crop yields, Transportation capacities | Scenarios analysis | LINGO 11.0 | [176] |

| Random | RM supply, Bioethanol Demand | Two-stage stochastic programming | AMLP (CPLEX) | [172] |

| Deterministic, Random | RM crop yields | Scenarios analysis | Unspecified | [169] |

| Deterministic, Random | RM crop yields, Purchase prices, Bioethanol demand | Two-stage stochastic programming | GAMS | [177] |

| Random | Biodiesel demand, RM supply | Scenarios analysis | CPLEX | [219] |

| Random | RM availability | Two-stage stochastic programming | AMPL-CPLEX | [288] |

| Random | Biomass availability, transportation costs, Fixed and variable costs | Scenarios analysis | GAMS (CPLEX) | [146] |

| Epistemic | Bioethanol demand, RM and Bioethanol sales price, Environmental impact factor | Robust possibilistic programming | GAMS (CPLEX) | [173] |

| Deterministic | Bioethanol demand | Two-stage stochastic programming | GAMS (CPLEX) | [179] |

| Random | Environmental factor | multistage stochastic | AIMMS (CPLEX) | [244] |

| Epistemic | Risk coefficient | E-constraint | GAMS (CPLEX) | [218] |

| Deterministic, Random | Supply sources, Critical technical factors, Biodiesel demand | Two-stage stochastic programming | GAMS (GAMS) | [159] |

| Random | Biomass demand, Biomass availability, Biomass price | Chance constrained | Hybrid framework of Montecarlo | [253] |

| Epistemic | RM availability, Bioethanol demand | Robust possibilistic programming | GAMS (CPLEX) | [289] |

| Epistemic | Bioethanol export prices, Domestic bioethanol demand, External bioethanol demand | Robust possibilistic programming | GAMS (CPLEX) | [197] |

| Epistemic | Biodiesel demand | Scenarios analysis | Interior-point algoritm—CPLEX | [229] |

| Random | Biomass supply | Multistage stochastic | AIMMS (CPLEX) | [290] |

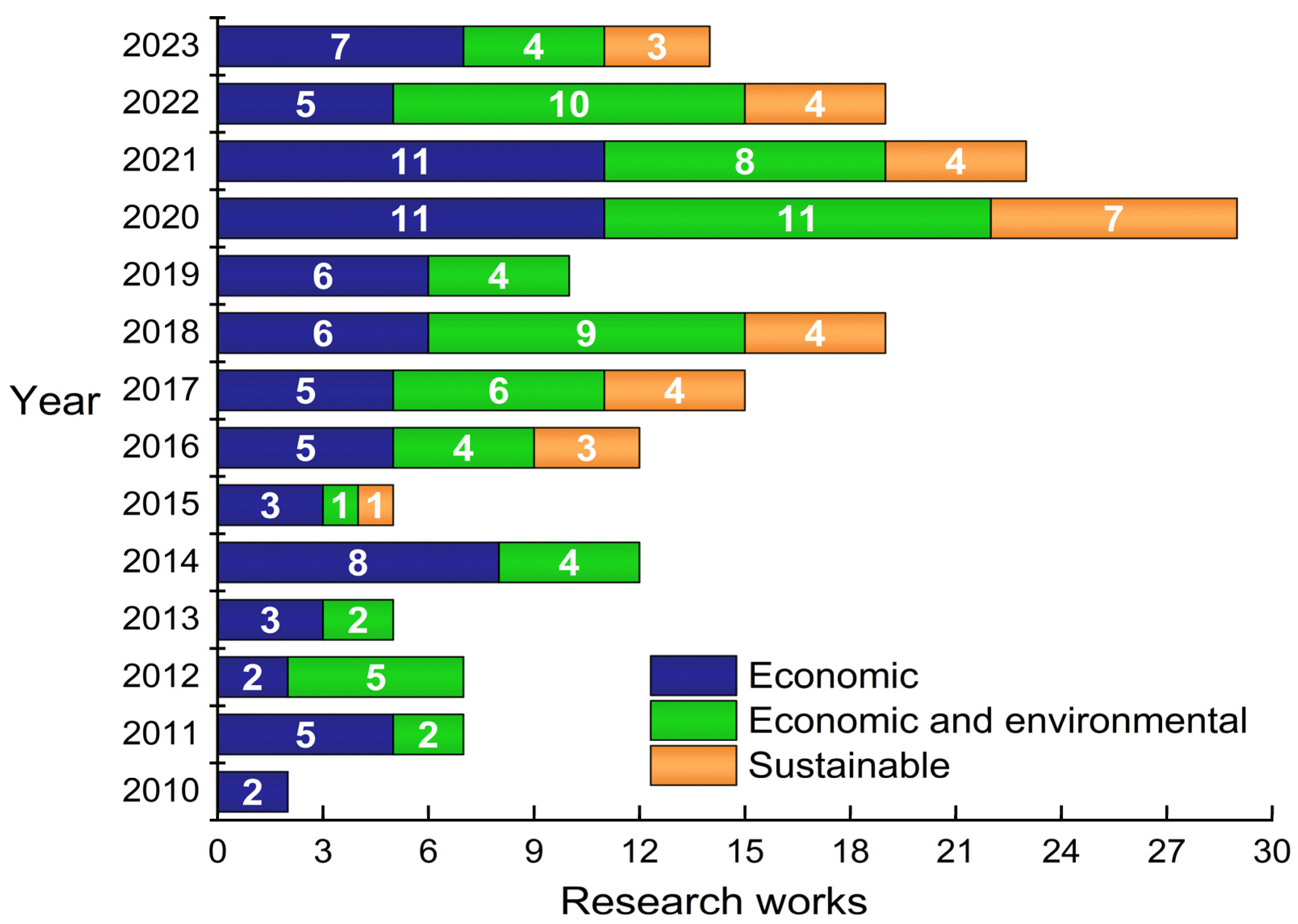

6. Research and Development Trends in Bioenergy SC Design

7. Conclusions

Funding

Acknowledgments

Conflicts of Interest

References

- IEA. Supply and Demand—Oil Information: Overview—Analysis; IEA: Paris, France, 2020. [Google Scholar]

- Energy Institute. Statistical Review of World Energy 2023; Energy Institute: London, UK, 2023. [Google Scholar]

- Prest, B.C. Explanations for the 2014 oil price decline: Supply or demand? Energy Econ. 2018, 74, 63–75. [Google Scholar] [CrossRef]

- OPEC. Nual Statistical Bulletin, 58th ed.; Organization of the Petroleum Exporting Countries: Vienna, Austria, 2023.

- Al-Khori, K.; Bicer, Y.; Koç, M. Integration of Solid Oxide Fuel Cells into oil and gas operations: Needs, opportunities, and challenges. J. Clean. Prod. 2020, 245, 118924. [Google Scholar] [CrossRef]

- IEA. World Energy Outlook 2023—Analysis—IEA; IEA: Paris, France, 2023. [Google Scholar]

- Qin, Z.; Zhuang, Q.; Cai, X.; He, Y.; Huang, Y.; Jiang, D.; Lin, E.; Liu, Y.; Tang, Y.; Wang, M.Q. Biomass and biofuels in China: Toward bioenergy resource potentials and their impacts on the environment. Renew. Sustain. Energy Rev. 2018, 82, 2387–2400. [Google Scholar] [CrossRef]

- Slade, R.; Bauen, A.; Gross, R. Global bioenergy resources. Nat. Clim. Change 2014, 4, 99–105. [Google Scholar] [CrossRef]

- Melin, K.; Kohl, T.; Koskinen, J.; Hurme, M. Performance of biofuel processes utilising separate lignin and carbohydrate processing. Bioresour. Technol. 2015, 192, 397–409. [Google Scholar] [CrossRef]

- Karlsson, H.; Ahlgren, S.; Sandgren, M.; Passoth, V.; Wallberg, O.; Hansson, P.-A. A systems analysis of biodiesel production from wheat straw using oleaginous yeast: Process design, mass and energy balances. Biotechnol. Biofuels 2016, 9, 229. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.; Park, C.; Kim, S. Process design and evaluation of production of bioethanol and β-lactam antibiotic from lignocellulosic biomass. Bioresour. Technol. 2014, 172, 194–200. [Google Scholar] [CrossRef]

- Sanchez, A.; Magaña, G.; Gomez, D.; Solís, M.; Banares-Alcantara, R. Bidimensional sustainability analysis of lignocellulosic ethanol production processes. Method and case study. Biofuels Bioprod. Biorefining 2014, 8, 670–685. [Google Scholar] [CrossRef]

- Celebi, A.D.; Ensinas, A.V.; Sharma, S.; Maréchal, F. Early-stage decision making approach for the selection of optimally integrated biorefinery processes. Energy 2017, 137, 908–916. [Google Scholar] [CrossRef]

- Belletante, S.; Montastruc, L.; Negny, S.; Domenech, S. Optimal design of an efficient, profitable and sustainable biorefinery producing acetone, butanol and ethanol: Influence of the in-situ separation on the purification structure. Biochem. Eng. J. 2016, 116, 195–209. [Google Scholar] [CrossRef]

- Hagman, L.; Blumenthal, A.; Eklund, M.; Svensson, N. The role of biogas solutions in sustainable biorefineries. J. Clean. Prod. 2018, 172, 3982–3989. [Google Scholar] [CrossRef]

- Shabani, N.; Akhtari, S.; Sowlati, T. Value chain optimization of forest biomass for bioenergy production: A review. Renew. Sustain. Energy Rev. 2013, 23, 299–311. [Google Scholar] [CrossRef]

- Iakovou, E.; Karagiannidis, A.; Vlachos, D.; Toka, A.; Malamakis, A. Waste biomass-to-energy supply chain management: A critical synthesis. Waste Manag. 2010, 30, 1860–1870. [Google Scholar] [CrossRef]

- Mafakheri, F.; Nasiri, F. Modeling of biomass-to-energy supply chain operations: Applications, challenges and research directions. Energy Policy 2014, 67, 116–126. [Google Scholar] [CrossRef]

- Kristianto, Y.; Zhu, L. Techno-economic optimization of ethanol synthesis from rice-straw supply chains. Energy 2017, 141, 2164–2176. [Google Scholar] [CrossRef]

- Knoope, M.M.J.; Balzer, C.H.; Worrell, E. Analysing the water and greenhouse gas effects of soya bean-based biodiesel in five different regions. GCB Bioenergy 2019, 11, 381–399. [Google Scholar] [CrossRef]

- Rodrigues Gurgel da Silva, A.; Giuliano, A.; Errico, M.; Rong, B.-G.; Barletta, D. Economic value and environmental impact analysis of lignocellulosic ethanol production: Assessment of different pretreatment processes. Clean. Technol. Environ. Policy 2019, 21, 637–654. [Google Scholar] [CrossRef]

- Dessbesell, L.; Xu, C.C.; Pulkki, R.; Leitch, M.; Mahmood, N. Forest biomass supply chain optimization for a biorefinery aiming to produce high-value bio-based materials and chemicals from lignin and forestry residues: A review of literature. Can. J. For. Res. 2017, 47, 277–288. [Google Scholar] [CrossRef]

- Ghaderi, H.; Pishvaee, M.S.; Moini, A. Biomass supply chain network design: An optimization-oriented review and analysis. Ind. Crops Prod. 2016, 94, 972–1000. [Google Scholar] [CrossRef]

- Mirkouei, A.; Haapala, K.R.; Sessions, J.; Murthy, G.S. A review and future directions in techno-economic modeling and optimization of upstream forest biomass to bio-oil supply chains. Renew. Sustain. Energy Rev. 2017, 67, 15–35. [Google Scholar] [CrossRef]

- Singhvi, M.S.; Gokhale, D.V. Lignocellulosic biomass: Hurdles and challenges in its valorization. Appl. Microbiol. Biotechnol. 2019, 103, 9305–9320. [Google Scholar] [CrossRef]

- Lo, S.L.Y.; How, B.S.; Leong, W.D.; Teng, S.Y.; Rhamdhani, M.A.; Sunarso, J. Techno-economic analysis for biomass supply chain: A state-of-the-art review. Renew. Sustain. Energy Rev. 2021, 135, 110164. [Google Scholar] [CrossRef]

- Azad, A.K.; Ameer Uddin, S.M. Performance study of a diesel engine by first generation bio-fuel blends with fossil fuel: An experimental study. J. Renew. Sustain. Energy 2013, 5, 13118. [Google Scholar] [CrossRef]

- Da Silva, E.; Serra, L. 2BSvs a major actor ensuring sustainability as an essential condition for biofuels’ long-term viability. OCL 2015, 22, D105. [Google Scholar] [CrossRef][Green Version]

- White, W. Chapter 6—Economic and Social Barriers Affecting Forest Bioenergy Mobilisation: A Review of the Literature. In Mobilisation of Forest Bioenergy in the Boreal and Temperate Biomes; Thiffault, E., Berndes, G., Junginger, M., Saddler, J.N., Smith, C.T., Eds.; Academic Press: Cambridge, MA, USA, 2016; pp. 84–101. [Google Scholar] [CrossRef]

- Oladosu, G.; Msangi, S. Biofuel-Food Market Interactions: A Review of Modeling Approaches and Findings. Agriculture 2013, 3, 53. [Google Scholar] [CrossRef]

- Rutz, D.; Janssen, R. Socio-Economic Impacts of Biofuels on Land Use Change. In Socio-Economic Impacts Bioenergy Production; Rutz, D., Janssen, R., Eds.; Springer International Publishing: Cham, Switzerland, 2014; pp. 81–93. [Google Scholar] [CrossRef]

- Moravvej, Z.; Makarem, M.A.; Rahimpour, M.R. Chapter 20—The fourth generation of biofuel. In Second and Third Generation of Feedstocks; Basile, A., Dalena, F., Eds.; Elsevier: Amsterdam, The Netherlands, 2019; pp. 557–597. [Google Scholar] [CrossRef]

- Ghosh, S.; Chowdhury, R.; Bhattacharya, P. Sustainability of cereal straws for the fermentative production of second generation biofuels: A review of the efficiency and economics of biochemical pretreatment processes. Appl. Energy 2017, 198, 284–298. [Google Scholar] [CrossRef]

- Kabir, G.; Hameed, B.H. Recent progress on catalytic pyrolysis of lignocellulosic biomass to high-grade bio-oil and bio-chemicals. Renew. Sustain. Energy Rev. 2017, 70, 945–967. [Google Scholar] [CrossRef]

- Mettler, M.S.; Vlachos, D.G.; Dauenhauer, P.J. Top ten fundamental challenges of biomass pyrolysis for biofuels. Energy Environ. Sci. 2012, 5, 7797–7809. [Google Scholar] [CrossRef]

- Chovau, S.; Degrauwe, D.; Van der Bruggen, B. Critical analysis of techno-economic estimates for the production cost of lignocellulosic bio-ethanol. Renew. Sustain. Energy Rev. 2013, 26, 307–321. [Google Scholar] [CrossRef]

- Tao, L.; Tan, E.C.D.; McCormick, R.; Zhang, M.; Aden, A.; He, X.; Zigler, B.T. Techno-economic analysis and life-cycle assessment of cellulosic isobutanol and comparison with cellulosic ethanol and n-butanol. Biofuels Bioprod. Biorefining 2014, 8, 30–48. [Google Scholar] [CrossRef]

- Luque, L.; Westerhof, R.; Rossum GVan Oudenhoven, S.; Kersten, S.; Berruti, F.; Rehmann, L. Pyrolysis based bio-refinery for the production of bioethanol from demineralized ligno-cellulosic biomass. Bioresour. Technol. 2014, 161, 20–28. [Google Scholar] [CrossRef] [PubMed]

- Guo, M.; Song, W.; Buhain, J. Bioenergy and biofuels: History, status, and perspective. Renew. Sustain. Energy Rev. 2015, 42, 712–725. [Google Scholar] [CrossRef]

- Stichnothe, H.; Storz, H.; Meier, D.; de Bari, I.; Thomas, S. Chapter 2—Development of Second-Generation Biorefineries. In Developing the Global Bioeconomy; Lamers, P., Searcy, E., Hess, J.R., Stichnothe, H., Eds.; Academic Press: Cambridge, MA, USA, 2016; pp. 11–40. [Google Scholar] [CrossRef]

- Alpanda, S.; Peralta-Alva, A. Oil crisis, energy-saving technological change and the stock market crash of 1973–74. Rev. Econ. Dyn. 2010, 13, 824–842. [Google Scholar] [CrossRef]

- Baumeister, C.; Kilian, L. Forecasting the Real Price of Oil in a Changing World: A Forecast Combination Approach. J. Bus. Econ. Stat. 2015, 33, 338–351. [Google Scholar] [CrossRef]

- Mat, S.C.; Idroas, M.Y.; Hamid, M.F.; Zainal, Z.A. Performance and emissions of straight vegetable oils and its blends as a fuel in diesel engine: A review. Renew. Sustain. Energy Rev. 2018, 82, 808–823. [Google Scholar] [CrossRef]

- OECD-FAO. OECD-FAO Agricultural Outlook 2023–2032; OECD: Paris, France, 2023. [CrossRef]

- Ambat, I.; Srivastava, V.; Sillanpää, M. Recent advancement in biodiesel production methodologies using various feedstock: A review. Renew. Sustain. Energy Rev. 2018, 90, 356–369. [Google Scholar] [CrossRef]

- Kumar, N.; Sonthalia, A.; Pali, H.S.; Sidharth. Next-Generation Biofuels—Opportunities and Challenges. In Innovations in Sustainable Energy and Cleaner Environment; Gupta, A.K., De, A., Aggarwal, S.K., Kushari, A., Runchal, A., Eds.; Springer: Singapore, 2020; pp. 171–191. [Google Scholar] [CrossRef]

- Sun, J.; Xiong, X.; Wang, M.; Du, H.; Li, J.; Zhou, D.; Zuo, J. Microalgae biodiesel production in China: A preliminary economic analysis. Renew. Sustain. Energy Rev. 2019, 104, 296–306. [Google Scholar] [CrossRef]

- Sakdasri, W.; Sawangkeaw, R.; Ngamprasertsith, S. Techno-economic analysis of biodiesel production from palm oil with supercritical methanol at a low molar ratio. Energy 2018, 152, 144–153. [Google Scholar] [CrossRef]

- Aboelazayem, O.; Gadalla, M.; Saha, B. Design and simulation of an integrated process for biodiesel production from waste cooking oil using supercritical methanolysis. Energy 2018, 161, 299–307. [Google Scholar] [CrossRef]

- Glisic, S.B.; Pajnik, J.M.; Orlović, A.M. Process and techno-economic analysis of green diesel production from waste vegetable oil and the comparison with ester type biodiesel production. Appl. Energy 2016, 170, 176–185. [Google Scholar] [CrossRef]

- Renewable Fuels Association (RFA). Ethanol Industry Outlook—Powered by Partnerships. 2024. Available online: https://ethanolrfa.org/resources/annual-industry-outlook (accessed on 1 January 2025).

- Yousuf, A.; Pirozzi, D.; Sannino, F. Fundamentals of lignocellulosic biomass. In Lignocellulosic Biomass to Liquid Biofuels; Academic Press: Cambridge, MA, USA, 2020; pp. 1–15. [Google Scholar] [CrossRef]

- Bernier-Oviedo, D.J.; Rincón-Moreno, J.A.; Solanilla-Duqué, J.F.; Muñoz-Hernández, J.A.; Váquiro-Herrera, H.A. Comparison of two pretreatments methods to produce second-generation bioethanol resulting from sugarcane bagasse. Ind. Crops Prod. 2018, 122, 414–421. [Google Scholar] [CrossRef]

- Zabed, H.; Sahu, J.N.; Suely, A.; Boyce, A.N.; Faruq, G. Bioethanol production from renewable sources: Current perspectives and technological progress. Renew. Sustain. Energy Rev. 2017, 71, 475–501. [Google Scholar] [CrossRef]

- Mendes, F.M.; Vasconcelos, M.H.; Dias, M.O.S.; Ferraz, A.; Milagres, A.M.F.; Santos, J.C.; Jesus, C.D.F.; Watanabe, M.D.B.; Junqueira, T.L.; Bonomi, A. Alkaline sulfite pretreatment for integrated first and second generation ethanol production: A techno-economic assessment of sugarcane hybrids. Biomass Bioenergy 2018, 119, 314–321. [Google Scholar] [CrossRef]

- Hasanly, A.; Khajeh Talkhoncheh, M.; Karimi Alavijeh, M. Techno-economic assessment of bioethanol production from wheat straw: A case study of Iran. Clean. Technol. Environ. Policy 2018, 20, 357–377. [Google Scholar] [CrossRef]

- Gamliel, D.P.; Bollas, G.M.; Valla, J.A. Two-stage catalytic fast hydropyrolysis of biomass for the production of drop-in biofuel. Fuel 2018, 216, 160–170. [Google Scholar] [CrossRef]

- Zhang, X.; Brown, R.C. Introduction to Thermochemical Processing of Biomass into Fuels, Chemicals, and Power. In Thermochemical Processing of Biomass: Conversion into Fuels, Chemicals and Power, 2nd ed.; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2019; pp. 1–16. [Google Scholar] [CrossRef]

- Karatzos, S.; McMillan, J.D.; Saddler, J.N. The Potential and Challenges of Drop-in Biofuels, 1st ed.; IEA Bioenergy: Paris, France, 2014; Volume 39. [Google Scholar]

- Kargbo, H.; Harris, J.S.; Phan, A.N. “Drop-in” fuel production from biomass: Critical review on techno-economic feasibility and sustainability. Renew. Sustain. Energy Rev. 2021, 135, 110168. [Google Scholar] [CrossRef]

- Zargar, A.; Bailey, C.B.; Haushalter, R.W.; Eiben, C.B.; Katz, L.; Keasling, J.D. Leveraging microbial biosynthetic pathways for the generation of ‘drop-in’ biofuels. Curr. Opin. Biotechnol. 2017, 45, 156–163. [Google Scholar] [CrossRef]

- Karatzos, S.; van Dyk, J.S.; McMillan, J.D.; Saddler, J. Drop-in biofuel production via conventional (lipid/fatty acid) and advanced (biomass) routes. Part I. Biofuels Bioprod. Biorefining 2017, 11, 344–362. [Google Scholar] [CrossRef]

- Okeke, I.J.; Mani, S. Techno-economic assessment of biogas to liquid fuels conversion technology via Fischer-Tropsch synthesis. Biofuels Bioprod. Biorefining 2017, 11, 472–487. [Google Scholar] [CrossRef]

- Thilakaratne, R.; Wright, M.M.; Brown, R.C. A techno-economic analysis of microalgae remnant catalytic pyrolysis and upgrading to fuels. Fuel 2014, 128, 104–112. [Google Scholar] [CrossRef]

- de Jong, S.; Antonissen, K.; Hoefnagels, R.; Lonza, L.; Wang, M.; Faaij, A.; Junginger, M. Life-cycle analysis of greenhouse gas emissions from renewable jet fuel production. Biotechnol. Biofuels 2017, 10, 64. [Google Scholar] [CrossRef] [PubMed]

- Azadi, P.; Brownbridge, G.; Mosbach, S.; Inderwildi, O.; Kraft, M. Simulation and life cycle assessment of algae gasification process in dual fluidized bed gasifiers. Green. Chem. 2015, 17, 1793–1801. [Google Scholar] [CrossRef]

- Sebastião, D.; Gonçalves, M.S.; Marques, S.; Fonseca, C.; Gírio, F.; Oliveira, A.C.; Matos, C.T. Life cycle assessment of advanced bioethanol production from pulp and paper sludge. Bioresour. Technol. 2016, 208, 100–109. [Google Scholar] [CrossRef]

- van Dyk, S.; Su, J.; Mcmillan, J.D.; Saddler, J. Potential synergies of drop-in biofuel production with further co-processing at oil refineries. Biofuels Bioprod. Biorefining 2019, 13, 760–775. [Google Scholar] [CrossRef]

- Malik, A.S.; Mohapatra, S. Biomass based gasifiers for internal combustion (IC) engines: A review. Sadhana 2013, 38, 461–476. [Google Scholar] [CrossRef]

- Miranda, T.; Arranz, J.I.; Montero, I.; Román, S.; Rojas, C.V.; Nogales, S. Characterization and combustion of olive pomace and forest residue pellets. Fuel Process Technol. 2012, 103, 91–96. [Google Scholar] [CrossRef]

- Cardozo, E.; Erlich, C.; Alejo, L.; Fransson, T.H. Combustion of agricultural residues: An experimental study for small-scale applications. Fuel 2014, 115, 778–787. [Google Scholar] [CrossRef]

- Elmay, Y.; Trouvé, G.; Jeguirim, M.; Said, R. Energy recovery of date palm residues in a domestic pellet boiler. Fuel Process Technol. 2013, 112, 12–18. [Google Scholar] [CrossRef]

- Bridgwater, A.V. Renewable fuels and chemicals by thermal processing of biomass. Chem. Eng. J. 2003, 91, 87–102. [Google Scholar] [CrossRef]

- Mu, L.; Zhang, L.; Zhu, K.; Ma, J.; Ifran, M.; Li, A. Anaerobic co-digestion of sewage sludge, food waste and yard waste: Synergistic enhancement on process stability and biogas production. Sci. Total Environ. 2020, 704, 135429. [Google Scholar] [CrossRef]

- Paritosh, K.; Yadav, M.; Chawade, A.; Sahoo, D.; Kesharwani, N.; Pareek, N.; Vivekanand, V. Additives as a Support Structure for Specific Biochemical Activity Boosts in Anaerobic Digestion: A Review. Front. Energy Res. 2020, 8, 88. [Google Scholar] [CrossRef]

- Khounani, Z.; Nazemi, F.; Shafiei, M.; Aghbashlo, M.; Tabatabaei, M. Techno-economic aspects of a safflower-based biorefinery plant co-producing bioethanol and biodiesel. Energy Convers. Manag. 2019, 201, 112184. [Google Scholar] [CrossRef]

- Frankó, B.; Galbe, M.; Wallberg, O. Bioethanol production from forestry residues: A comparative techno-economic analysis. Appl. Energy 2016, 184, 727–736. [Google Scholar] [CrossRef]

- Wu, N.; Moreira, C.M.; Zhang, Y.; Doan, N.; Yang, S.; Phlips, E.J.; Svoronos, S.A.; Pullammanappallil, P.C. Techno-Economic Analysis of Biogas Production from Microalgae through Anaerobic Digestion. In Anaerobic Digestion; IntechOpen: Rijeka, Croatia, 2019. [Google Scholar] [CrossRef]

- Al-Wahaibi, A.; Osman, A.I.; Al-Muhtaseb, A.H.; Alqaisi, O.; Baawain, M.; Fawzy, S.; Rooney, D.W. Techno-economic evaluation of biogas production from food waste via anaerobic digestion. Sci. Rep. 2020, 10, 15719. [Google Scholar] [CrossRef]

- Aui, A.; Li, W.; Wright, M.M. Techno-economic and life cycle analysis of a farm-scale anaerobic digestion plant in Iowa. Waste Manag. 2019, 89, 154–164. [Google Scholar] [CrossRef]

- Gómez, X.; Fernández, C.; Fierro, J.; Sánchez, M.E.; Escapa, A.; Morán, A. Hydrogen production: Two stage processes for waste degradation. Bioresour. Technol. 2011, 102, 8621–8627. [Google Scholar] [CrossRef] [PubMed]

- Singh, A.; Kuila, A.; Adak, S.; Bishai, M.; Banerjee, R. Utilization of Vegetable Wastes for Bioenergy Generation. Agric. Res. 2012, 1, 213–222. [Google Scholar] [CrossRef]

- Sivagurunathan, P.; Kumar, G.; Mudhoo, A.; Rene, E.R.; Saratale, G.D.; Kobayashi, T.; Xu, K.; Kim, S.-H.; Kim, D.-H. Fermentative hydrogen production using lignocellulose biomass: An overview of pre-treatment methods, inhibitor effects and detoxification experiences. Renew. Sustain. Energy Rev. 2017, 77, 28–42. [Google Scholar] [CrossRef]

- Hu, B.-B.; Li, M.-Y.; Wang, Y.-T.; Zhu, M.-J. Enhanced biohydrogen production from dilute acid pretreated sugarcane bagasse by detoxification and fermentation strategy. Int. J. Hydrogen Energy 2018, 43, 19366–19374. [Google Scholar] [CrossRef]

- Eker, S.; Sarp, M. Hydrogen gas production from waste paper by dark fermentation: Effects of initial substrate and biomass concentrations. Int. J. Hydrogen Energy 2017, 42, 2562–2568. [Google Scholar] [CrossRef]

- Rolly Gonzales, R.; Hong, Y.; Park, J.-H.; Kumar, G.; Kim, S.-H. Kinetics and equilibria of 5-hydroxymethylfurfural (5-HMF) sequestration from algal hydrolyzate using granular activated carbon. J. Chem. Technol. Biotechnol. 2016, 91, 1157–1163. [Google Scholar] [CrossRef]

- Nagarajan, D.; Lee, D.-J.; Kondo, A.; Chang, J.-S. Recent insights into biohydrogen production by microalgae—From biophotolysis to dark fermentation. Bioresour. Technol. 2017, 227, 373–387. [Google Scholar] [CrossRef]

- Hosseini, S.E.; Abdul Wahid, M.; Jamil, M.M.; Azli, A.A.M.; Misbah, M.F. A review on biomass-based hydrogen production for renewable energy supply. Int. J. Energy Res. 2015, 39, 1597–1615. [Google Scholar] [CrossRef]

- Liu, B.; Christiansen, K.; Parnas, R.; Xu, Z.; Li, B. Optimizing the production of hydrogen and 1,3-propanediol in anaerobic fermentation of biodiesel glycerol. Int. J. Hydrogen Energy 2013, 38, 3196–3205. [Google Scholar] [CrossRef]

- Wang, M.; Han, L.; Liu, S.; Zhao, X.; Yang, J.; Loh, S.K.; Sun, X.; Zhang, C.; Fang, X. A Weibull statistics-based lignocellulose saccharification model and a built-in parameter accurately predict lignocellulose hydrolysis performance. Biotechnol. J. 2015, 10, 1424–1433. [Google Scholar] [CrossRef]

- Massanet-Nicolau, J.; Jones, R.J.; Guwy, A.; Dinsdale, R.; Premier, G.; Mulder, M.J.J. Maximising biohydrogen yields via continuous electrochemical hydrogen removal and carbon dioxide scrubbing. Bioresour. Technol. 2016, 218, 512–517. [Google Scholar] [CrossRef] [PubMed]

- Moreira, R.; Bimbela, F.; Gil-Lalaguna, N.; Sánchez, J.L.; Portugal, A. Clean syngas production by gasification of lignocellulosic char: State of the art and future prospects. J. Ind. Eng. Chem. 2021, 101, 1–20. [Google Scholar] [CrossRef]

- Sun, X.; Atiyeh, H.K.; Huhnke, R.L.; Tanner, R.S. Syngas fermentation process development for production of biofuels and chemicals: A review. Bioresour. Technol. Rep. 2019, 7, 100279. [Google Scholar] [CrossRef]

- Schmid, M.; Beirow, M.; Schweitzer, D.; Waizmann, G.; Spörl, R.; Scheffknecht, G. Product gas composition for steam-oxygen fluidized bed gasification of dried sewage sludge, straw pellets and wood pellets and the influence of limestone as bed material. Biomass Bioenergy 2018, 117, 71–77. [Google Scholar] [CrossRef]

- Held, J. SNG from wood—The gobigas project. In Synthetic Natural Gas from Coal, Dry Biomass, and Power-to-Gas Applications; Wiley Blackwell: Hoboken, NJ, USA, 2016; pp. 181–190. [Google Scholar] [CrossRef]

- Alamia, A.; Larsson, A.; Breitholtz, C.; Thunman, H. Performance of large-scale biomass gasifiers in a biorefinery, a state-of-the-art reference. Int. J. Energy Res. 2017, 41, 2001–2019. [Google Scholar] [CrossRef]

- Thunman, H.; Gustavsson, C.; Larsson, A.; Gunnarsson, I.; Tengberg, F. Economic assessment of advanced biofuel production via gasification using cost data from the GoBiGas plant. Energy Sci. Eng. 2019, 7, 217–229. [Google Scholar] [CrossRef]

- Menin, L.; Vakalis, S.; Benedetti, V.; Patuzzi, F.; Baratieri, M. Techno-economic assessment of an integrated biomass gasification, electrolysis, and syngas biomethanation process. Biomass Convers. Biorefinery 2021, 11, 445–459. [Google Scholar] [CrossRef]

- Akhtar, A.; Krepl, V.; Ivanova, T. A Combined Overview of Combustion, Pyrolysis, and Gasification of Biomass; American Chemical Society: Washington, DC, USA, 2018; Volume 32. [Google Scholar] [CrossRef]

- Philipps, G.; de Vries, S.; Jennewein, S. Development of a metabolic pathway transfer and genomic integration system for the syngas-fermenting bacterium Clostridium ljungdahlii. Biotechnol. Biofuels 2019, 12, 112. [Google Scholar] [CrossRef]

- Yasin, M.; Jang, N.; Lee, M.; Kang, H.; Aslam, M.; Bazmi, A.A.; Chang, I.S. Bioreactors, gas delivery systems and supporting technologies for microbial synthesis gas conversion process. Bioresour. Technol. Rep. 2019, 7, 100207. [Google Scholar] [CrossRef]

- IEA. Renewables 2023—Analysis an Forecast to 2028; IEA: Paris, France, 2024. [Google Scholar]

- IEA. Global Energy Review 2020; IEA: Paris, France, 2020. [Google Scholar]

- Ministerio de Minas y Energía Colombia. Decreto 2629 de 2007. D of No 46685 2007. Available online: https://www.funcionpublica.gov.co/eva/gestornormativo/norma.php?i=25667 (accessed on 1 January 2025).

- IATA. Examples of Ground Transport Biofuel Mandates Around the World; IATA: Montreal, QC, Canada, 2019. [Google Scholar]

- Cooper, M.C.; Lambert, D.M.; Pagh, L.D. Supply chain management: More than a new name for logistics. Int. J. Logist. Manag. 1997, 8, 14. [Google Scholar] [CrossRef]

- Rollins, M.; Pekkarinen, S.; Mehtälä, M. Inter-firm customer knowledge sharing in logistics services: An empirical study. Int. J. Phys. Distrib. Logist. Manag. 2011, 41, 15. [Google Scholar] [CrossRef]

- Waters, D. Logistics: An Introduction to Supply Chain Management; Red Globe Press: New York, NY, USA, 2003. [Google Scholar]

- Stock, J.R.; Boyer, S.L. Developing a consensus definition of supply chain management: A qualitative study. Int. J. Phys. Distrib. Logist. Manag. 2009, 39, 690–711. [Google Scholar] [CrossRef]

- Cerchione, R.; Esposito, E. A systematic review of supply chain knowledge management research: State of the art and research opportunities. Int. J. Prod. Econ. 2016, 182, 276–292. [Google Scholar] [CrossRef]

- WCEDSWS. World commission on environment and development. Our Common. Futur. 1987, 17, 1–91. [Google Scholar]

- Al-Refaie, A.; Momani, D. ISM approach for modelling drivers to practices of green supply chain management in Jordanian industrial firms. Int. J. Bus. Perform. Supply Chain. Model. 2018, 10, 91–106. [Google Scholar] [CrossRef]

- Rajeev, A.; Pati, R.K.; Padhi, S.S.; Govindan, K. Evolution of sustainability in supply chain management: A literature review. J. Clean. Prod. 2017, 162, 299–314. [Google Scholar] [CrossRef]

- Mardani, A.; Kannan, D.; Hooker, R.E.; Ozkul, S.; Alrasheedi, M.; Tirkolaee, E.B. Evaluation of green and sustainable supply chain management using structural equation modelling: A systematic review of the state of the art literature and recommendations for future research. J. Clean. Prod. 2020, 249, 119383. [Google Scholar] [CrossRef]

- Paulraj, A.; Chen, I.J.; Blome, C. Motives and Performance Outcomes of Sustainable Supply Chain Management Practices: A Multi-theoretical Perspective. J. Bus. Ethics 2017, 145, 239–258. [Google Scholar] [CrossRef]

- Nakamba, C.C.; Chan, P.W.; Sharmina, M. How does social sustainability feature in studies of supply chain management? A review and research agenda. Supply Chain. Manag. An. Int. J. 2017, 22, 522–541. [Google Scholar] [CrossRef]

- Govindan, K.; Soleimani, H. A review of reverse logistics and closed-loop supply chains: A Journal of Cleaner Production focus. J. Clean. Prod. 2017, 142, 371–384. [Google Scholar] [CrossRef]

- Mani, V.; Gunasekaran, A.; Delgado, C. Enhancing supply chain performance through supplier social sustainability: An emerging economy perspective. Int. J. Prod. Econ. 2018, 195, 259–272. [Google Scholar] [CrossRef]

- Depping, V.; Grunow, M.; Middelaar, C.; van Dumpler, J. Integrating environmental impact assessment into new product development and processing-technology selection: Milk concentrates as substitutes for milk powders. J. Clean. Prod. 2017, 149, 1–10. [Google Scholar] [CrossRef]

- Xu, X.; Gursoy, D. Influence of sustainable hospitality supply chain management on customers’ attitudes and behaviors. Int. J. Hosp. Manag. 2015, 49, 105–116. [Google Scholar] [CrossRef]

- Kesharwani, R.; Sun, Z.; Dagli, C.; Xiong, H. Moving second generation biofuel manufacturing forward: Investigating economic viability and environmental sustainability considering two strategies for supply chain restructuring. Appl. Energy 2019, 242, 1467–1496. [Google Scholar] [CrossRef]

- Ahmed, W.; Sarkar, B. Impact of carbon emissions in a sustainable supply chain management for a second generation biofuel. J. Clean. Prod. 2018, 186, 807–820. [Google Scholar] [CrossRef]

- Garofalo, P.; Campi, P.; Vonella, A.V.; Mastrorilli, M. Application of multi-metric analysis for the evaluation of energy performance and energy use efficiency of sweet sorghum in the bioethanol supply-chain: A fuzzy-based expert system approach. Appl. Energy 2018, 220, 313–324. [Google Scholar] [CrossRef]

- Ebinger, J.; Vergara, W. Climate Impacts on Energy Systems: Key Issues for Energy Sector Adaptation; The World Bank: Washington, DC, USA, 2011. [Google Scholar]

- Yalew, S.G.; van Vliet, M.T.H.; Gernaat, D.E.H.J.; Ludwig, F.; Miara, A.; Park, C.; Byers, E.; De Cian, E.; Piontek, F.; Iyer, G.; et al. Impacts of climate change on energy systems in global and regional scenarios. Nat. Energy 2020, 5, 794–802. [Google Scholar] [CrossRef]

- Marchi, B.; Zanoni, S. Supply Chain Management for Improved Energy Efficiency: Review and Opportunities. Energies 2017, 10, 1618. [Google Scholar] [CrossRef]

- Hong, B.H.; How, B.S.; Lam, H.L. Overview of sustainable biomass supply chain: From concept to modelling. Clean. Technol. Environ. Policy 2016, 18, 2173–2194. [Google Scholar] [CrossRef]

- Ascenso, L.; D’Amore, F.; Carvalho, A.; Bezzo, F. Assessing multiple biomass-feedstock in the optimization of power and fuel supply chains for sustainable mobility. Chem. Eng. Res. Des. 2018, 131, 127–143. [Google Scholar] [CrossRef]

- He-Lambert, L.; English, B.C.; Lambert, D.M.; Shylo, O.; Larson, J.A.; Yu, T.E.; Wilson, B. Determining a geographic high resolution supply chain network for a large scale biofuel industry. Appl. Energy 2018, 218, 266–281. [Google Scholar] [CrossRef]

- Zhu, T.; Curtis, J.; Clancy, M. Promoting agricultural biogas and biomethane production: Lessons from cross-country studies. Renew. Sustain. Energy Rev. 2019, 114, 109332. [Google Scholar] [CrossRef]

- d’Amore, F.; Bezzo, F. Strategic optimisation of biomass-based energy supply chains for sustainable mobility. Comput. Chem. Eng. 2016, 87, 68–81. [Google Scholar] [CrossRef]

- Gan, J.; Smith, C.T. Optimal plant size and feedstock supply radius: A modeling approach to minimize bioenergy production costs. Biomass Bioenergy 2011, 35, 3350–3359. [Google Scholar] [CrossRef]

- Ortiz-Gutiérrez, R.A.; Giarola, S.; Bezzo, F. Optimal design of ethanol supply chains considering carbon trading effects and multiple technologies for side-product exploitation. Environ. Technol. 2013, 34, 2189–2199. [Google Scholar] [CrossRef]

- De Meyer, A.; Cattrysse, D.; Rasinmäki, J.; Van Orshoven, J. Methods to optimise the design and management of biomass-for-bioenergy supply chains: A review. Renew. Sustain. Energy Rev. 2014, 31, 657–670. [Google Scholar] [CrossRef]

- Sharma, B.; Ingalls, R.G.; Jones, C.L.; Khanchi, A. Biomass supply chain design and analysis: Basis, overview, modeling, challenges, and future. Renew. Sustain. Energy Rev. 2013, 24, 608–627. [Google Scholar] [CrossRef]

- Mousavi Ahranjani, P.; Ghaderi, S.F.; Azadeh, A.; Babazadeh, R. Robust design of a sustainable and resilient bioethanol supply chain under operational and disruption risks. Clean. Technol. Environ. Policy 2020, 22, 119–151. [Google Scholar] [CrossRef]

- Marufuzzaman, M.; Eksioglu, S.D.; Hernandez, R. Environmentally friendly supply chain planning and design for biodiesel production via wastewater sludge. Transp. Sci. 2014, 48, 555–574. [Google Scholar] [CrossRef]

- Rahemi, H.; Torabi, S.A.; Avami, A.; Jolai, F. Bioethanol supply chain network design considering land characteristics. Renew. Sustain. Energy Rev. 2020, 119, 109517. [Google Scholar] [CrossRef]

- Esmaeili, S.A.H.; Szmerekovsky, J.; Sobhani, A.; Dybing, A.; Peterson, T.O. Sustainable biomass supply chain network design with biomass switching incentives for first-generation bioethanol producers. Energy Policy 2020, 138, 111222. [Google Scholar] [CrossRef]

- Duarte, A.; Sarache, W.; Costa, Y. Biofuel supply chain design from Coffee Cut Stem under environmental analysis. Energy 2016, 100, 321–331. [Google Scholar] [CrossRef]

- Gao, C. Incorporating social benefits in optimal design of bioethanol supply chains: A case study in China. Prod. Manuf. Res. 2022, 10, 176–197. [Google Scholar] [CrossRef]

- Abbasi, G.; Khoshalhan, F.; Javad Hosseininezhad, S. Municipal solid waste management and energy production: A multi-objective optimization approach to incineration and biogas waste-to-energy supply chain. Sustain. Energy Technol. Assess. 2022, 54, 102809. [Google Scholar] [CrossRef]

- Liu, W.-Y.; Lin, C.-C.; Yeh, T.-L. Supply chain optimization of forest biomass electricity and bioethanol coproduction. Energy 2017, 139, 630–645. [Google Scholar] [CrossRef]

- d’Amore, F.; Bezzo, F. Managing technology performance risk in the strategic design of biomass-based supply chains for energy in the transport sector. Energy 2017, 138, 563–574. [Google Scholar] [CrossRef]

- Marufuzzaman, M.; Eksioglu, S.D.; Huang, Y. Two-stage stochastic programming supply chain model for biodiesel production via wastewater treatment. Comput. Oper. Res. 2014, 49, 1–17. [Google Scholar] [CrossRef]

- Paulo, H.; Azcue, X.; Barbosa-Póvoa, A.P.; Relvas, S. Supply chain optimization of residual forestry biomass for bioenergy production: The case study of Portugal. Biomass Bioenergy 2015, 83, 245–256. [Google Scholar] [CrossRef]

- Park, Y.S.; Szmerekovsky, J.; Osmani, A.; Aslaam, N.M. Integrated multimodal transportation model for a switchgrass-based bioethanol supply chain: Case study in North Dakota. Transp. Res. Rec. 2017, 2628, 32–41. [Google Scholar] [CrossRef]

- Rabbani, M.; Momen, S.; Akbarian-Saravi, N.; Farrokhi-Asl, H.; Ghelichi, Z. Optimal design for sustainable bioethanol supply chain considering the bioethanol production strategies: A case study. Comput. Chem. Eng. 2020, 134, 106720. [Google Scholar] [CrossRef]

- Kostin, A.; Macowski, D.H.; Pietrobelli, J.M.T.A.; Guillén-Gosálbez, G.; Jiménez, L.; Ravagnani, M.A.S.S. Optimization-based approach for maximizing profitability of bioethanol supply chain in Brazil. Comput. Chem. Eng. 2018, 115, 121–132. [Google Scholar] [CrossRef]

- Mohamed Abdul Ghani, N.M.A.; Szmerekovsky, J.G.; Vogiatzis, C. Plant capacity level and location as a mechanism for sustainability in biomass supply chain. Energy Syst. 2020, 11, 1075–1109. [Google Scholar] [CrossRef]

- Li, Y.; Kesharwani, R.; Sun, Z.; Qin, R.; Dagli, C.; Zhang, M.; Wang, D. Economic viability and environmental impact investigation for the biofuel supply chain using co-fermentation technology. Appl. Energy 2020, 259, 114235. [Google Scholar] [CrossRef]

- Sarker, B.R.; Wu, B.; Paudel, K.P. Modeling and optimization of a supply chain of renewable biomass and biogas: Processing plant location. Appl. Energy 2019, 239, 343–355. [Google Scholar] [CrossRef]

- Ghosh, P.; Westhoff, P.; Debnath, D. Biofuels, food security, and sustainability. In Biofuels, Bioenergy and Food Security; Academic Press: Cambridge, MA, USA, 2019; pp. 211–229. [Google Scholar] [CrossRef]

- Wheeler, J.; Galán-Martín, Á.; Mele, F.D.; Guillén-Gosálbez, G. Designing biomass supply chains within planetary boundaries. AIChE J. 2021, 67, e17131. [Google Scholar] [CrossRef]

- Shavazipour, B.; Stray, J.; Stewart, T.J. Sustainable planning in sugar-bioethanol supply chain under deep uncertainty: A case study of South African sugarcane industry. Comput. Chem. Eng. 2020, 143, 107091. [Google Scholar] [CrossRef]

- Kheybari, S.; Davoodi Monfared, M.; Salamirad, A.; Rezaei, J. Bioethanol sustainable supply chain design: A multi-attribute bi-objective structure. Comput. Ind. Eng. 2023, 180, 109258. [Google Scholar] [CrossRef]

- Osmani, A.; Zhang, J. Economic and environmental optimization of a large scale sustainable dual feedstock lignocellulosic-based bioethanol supply chain in a stochastic environment. Appl. Energy 2014, 114, 572–587. [Google Scholar] [CrossRef]

- Zhang, F.; Wang, J.; Liu, S.; Zhang, S.; Sutherland, J.W. Integrating GIS with optimization method for a biofuel feedstock supply chain. Biomass Bioenergy 2017, 98, 194–205. [Google Scholar] [CrossRef]

- Mohseni, S.; Pishvaee, M.S.; Sahebi, H. Robust design and planning of microalgae biomass-to-biodiesel supply chain: A case study in Iran. Energy 2016, 111, 736–755. [Google Scholar] [CrossRef]

- Memişoğlu, G.; Üster, H. Integrated bioenergy supply chain network planning problem. Transp. Sci. 2016, 50, 35–56. [Google Scholar] [CrossRef]

- Yue, D.; Pandya, S.; You, F. Integrating Hybrid Life Cycle Assessment with Multiobjective Optimization: A Modeling Framework. Environ. Sci. Technol. 2016, 50, 1501–1509. [Google Scholar] [CrossRef]

- Winston, W.L.; Goldberg, J.B. Operations Research: Applications and Algorithms; Duxbury Press: Boston, MA, USA, 2004; Volume 3. [Google Scholar]

- Munir, M.A.; Imran, S.; Farooq, M.; Latif, H.; Hussain, A.; Rehman, A.U.; Sultan, M.; Ali, Q.; Krzywanski, J. Development of a supply chain model for the production of biodiesel from waste cooking oil for sustainable development. Front. Energy Res. 2023, 11, 1222787. [Google Scholar] [CrossRef]

- Aboytes-Ojeda, M.; Castillo-Villar, K.K.; Cardona-Valdés, Y. Bi-objective stochastic model for the design of biofuel supply chains incorporating risk. Expert. Syst. Appl. 2022, 202, 117285. [Google Scholar] [CrossRef]

- Mutenure, M.; Čuček, L.; Egieya, J.; Isafiade, A.J.; Kravanja, Z. Optimization of bioethanol and sugar supply chain network: A South African case study. Clean. Technol. Environ. Policy 2018, 20, 925–948. [Google Scholar] [CrossRef]

- Corsano, G.; Fumero, Y.; Montagna, J.M. Integrated decision making for the optimal bioethanol supply chain. Energy Convers. Manag. 2014, 88, 1127–1142. [Google Scholar] [CrossRef]

- Bai, Y.; Li, X.; Peng, F.; Wang, X.; Ouyang, Y. Effects of disruption risks on biorefinery location design. Energies 2015, 8, 1468–1486. [Google Scholar] [CrossRef]

- Yue, D.; You, F. Fair profit allocation in supply chain optimization with transfer price and revenue sharing: MINLP model and algorithm for cellulosic biofuel supply chains. AIChE J. 2014, 60, 3211–3229. [Google Scholar] [CrossRef]

- Ye, F.; Li, Y.; Lin, Q.; Zhan, Y. Modeling of China’s cassava-based bioethanol supply chain operation and coordination. Energy 2017, 120, 217–228. [Google Scholar] [CrossRef]

- Akgul, O.; Zamboni, A.; Bezzo, F.; Shah, N.; Papageorgiou, L.G. Optimization-Based Approaches for Bioethanol Supply Chains. Ind. Eng. Chem. Res. 2011, 50, 4927–4938. [Google Scholar] [CrossRef]

- Zhang, J.; Osmani, A.; Awudu, I.; Gonela, V. An integrated optimization model for switchgrass-based bioethanol supply chain. Appl. Energy 2013, 102, 1205–1217. [Google Scholar] [CrossRef]

- Chen, C.-W.; Fan, Y. Bioethanol supply chain system planning under supply and demand uncertainties. Transp. Res. Part E Logist. Transp. Rev. 2012, 48, 150–164. [Google Scholar] [CrossRef]

- Bairamzadeh, S.; Pishvaee, M.S.; Saidi-Mehrabad, M. Multiobjective Robust Possibilistic Programming Approach to Sustainable Bioethanol Supply Chain Design under Multiple Uncertainties. Ind. Eng. Chem. Res. 2016, 55, 237–256. [Google Scholar] [CrossRef]

- Mazzetto, F.; Ortiz-Gutiérrez, R.A.; Manca, D.; Bezzo, F. Strategic design of bioethanol supply chains including commodity market dynamics. Ind. Eng. Chem. Res. 2013, 52, 10305–10316. [Google Scholar] [CrossRef]

- Murillo-Alvarado, P.E.; Santibañez-Aguilar, J.E.; Ponce-Ortega, J.M.; Castro-Montoya, A.J.; Serna-González, M.; El-Halwagi, M.M. Optimization of the supply chain associated to the production of bioethanol from residues of agave from the tequila process in mexico. Ind. Eng. Chem. Res. 2014, 53, 5524–5538. [Google Scholar] [CrossRef]

- Ren, J.; An, D.; Liang, H.; Dong, L.; Gao, Z.; Geng, Y.; Zhu, Q.; Song, S.; Zhao, W. Life cycle energy and CO2 emission optimization for biofuel supply chain planning under uncertainties. Energy 2016, 103, 151–166. [Google Scholar] [CrossRef]

- Osmani, A.; Zhang, J. Stochastic optimization of a multi-feedstock lignocellulosic-based bioethanol supply chain under multiple uncertainties. Energy 2013, 59, 157–172. [Google Scholar] [CrossRef]

- Giarola, S.; Zamboni, A.; Bezzo, F. Spatially explicit multi-objective optimisation for design and planning of hybrid first and second generation biorefineries. Comput. Chem. Eng. 2011, 35, 1782–1797. [Google Scholar] [CrossRef]

- Kostin, A.M.; Guillén-Gosálbez, G.; Mele, F.D.; Bagajewicz, M.J.; Jiménez, L. Design and planning of infrastructures for bioethanol and sugar production under demand uncertainty. Chem. Eng. Res. Des. 2012, 90, 359–376. [Google Scholar] [CrossRef]

- Bairamzadeh, S.; Saidi-Mehrabad, M.; Pishvaee, M.S. Modelling different types of uncertainty in biofuel supply network design and planning: A robust optimization approach. Renew. Energy 2018, 116, 500–517. [Google Scholar] [CrossRef]

- Huang, Y.; Chen, C.-W.; Fan, Y. Multistage optimization of the supply chains of biofuels. Transp. Res. Part. E Logist. Transp. Rev. 2010, 46, 820–830. [Google Scholar] [CrossRef]

- Miret, C.; Chazara, P.; Montastruc, L.; Negny, S.; Domenech, S. Design of bioethanol green supply chain: Comparison between first and second generation biomass concerning economic, environmental and social criteria. Comput. Chem. Eng. 2016, 85, 16–35. [Google Scholar] [CrossRef]

- Gonela, V.; Zhang, J.; Osmani, A.; Onyeaghala, R. Stochastic optimization of sustainable hybrid generation bioethanol supply chains. Transp. Res. Part E Logist. Transp. Rev. 2015, 77, 1–28. [Google Scholar] [CrossRef]

- Bernardi, A.; Giarola, S.; Bezzo, F. Optimizing the economics and the carbon and water footprints of bioethanol supply chains. Biofuels Bioprod. Biorefining 2012, 6, 656–672. [Google Scholar] [CrossRef]

- Kostin, A.; Guillén-Gosálbez, G.; Mele, F.D.; Jiménez, L. Identifying key life cycle assessment metrics in the multiobjective design of bioethanol supply chains using a rigorous mixed-integer linear programming approach. Ind. Eng. Chem. Res. 2012, 51, 5282–5291. [Google Scholar] [CrossRef]

- Bernardi, A.; Giarola, S.; Bezzo, F. Spatially Explicit Multiobjective Optimization for the Strategic Design of First and Second Generation Biorefineries Including Carbon and Water Footprints. Ind. Eng. Chem. Res. 2013, 52, 7170–7180. [Google Scholar] [CrossRef]

- Ebadian, M.; Sowlati, T.; Sokhansanj, S.; Smith, L.T.; Stumborg, M. Development of an integrated tactical and operational planning model forsupply of feedstock to a commercial-scale bioethanol plant. Biofuels Bioprod. Biorefining 2014, 8, 171–188. [Google Scholar] [CrossRef]

- Zamboni, A.; Murphy, R.J.; Woods, J.; Bezzo, F.; Shah, N. Biofuels carbon footprints: Whole-systems optimisation for GHG emissions reduction. Bioresour. Technol. 2011, 102, 7457–7465. [Google Scholar] [CrossRef]

- Zamboni, A.; Bezzo, F.; Shah, N. Spatially Explicit Static Model for the Strategic Design of Future Bioethanol Production Systems. 2. Multi-Objective Environmental Optimization. Energy Fuels 2009, 23, 5134–5143. [Google Scholar] [CrossRef]

- Kostin, A.M.; Guillén-Gosálbez, G.; Mele, F.D.; Bagajewicz, M.J.; Jiménez, L. A novel rolling horizon strategy for the strategic planning of supply chains. Application to the sugar cane industry of Argentina. Comput. Chem. Eng. 2011, 35, 2540–2563. [Google Scholar] [CrossRef]

- Saadati, M.; Hosseininezhad, S.J. Designing a hub location model in a bagasse-based bioethanol supply chain network in Iran (case study: Iran sugar industry). Biomass Bioenergy 2019, 122, 238–256. [Google Scholar] [CrossRef]

- Ivanov, B.B.; Dzhelil, Y.R.; Ganev, E.I.; Dobruzhaliev, D.G. Multi-period model of sustainable integrated hybrid first and second generation bioethanol supply chains. Chem. Eng. Trans. 2018, 70, 289–294. [Google Scholar]

- Gao, C.; Qu, D.; Yang, Y. Optimal Design of Bioenergy Supply Chains Considering Social Benefits: A Case Study in Northeast China. Processes 2019, 7, 437. [Google Scholar] [CrossRef]

- Akbarian-Saravi, N.; Mobini, M.; Rabbani, M. Development of a comprehensive decision support tool for strategic and tactical planning of a sustainable bioethanol supply chain: Real case study, discussions and policy implications. J. Clean. Prod. 2020, 244, 118871. [Google Scholar] [CrossRef]

- Ghaderi, H.; Moini, A.; Pishvaee, M.S. A multi-objective robust possibilistic programming approach to sustainable switchgrass-based bioethanol supply chain network design. J. Clean. Prod. 2018, 179, 368–406. [Google Scholar] [CrossRef]

- Ivanov, B. Multi-period deterministic model of sustainable integrated of hybrid first and second generation bioethanol supply chains for synthesis and renovation. Bulg. Chem. Commun. 2018, 50, 24–35. [Google Scholar]

- Gilani, H.; Sahebi, H. A multi-objective robust optimization model to design sustainable sugarcane-to-biofuel supply network: The case of study. Biomass Convers. Biorefinery 2020, 11, 2521–2542. [Google Scholar] [CrossRef]

- Zhong, J.; Yu, T.E.; Clark, C.D.; English, B.C.; Larson, J.A.; Cheng, C.-L. Effect of land use change for bioenergy production on feedstock cost and water quality. Appl. Energy 2018, 210, 580–590. [Google Scholar] [CrossRef]

- León-Olivares, E.; Minor-Popocatl, H.; Aguilar-Mejía, O.; Sánchez-Partida, D. Optimization of the Supply Chain in the Production of Ethanol from Agricultural Biomass Using Mixed-Integer Linear Programming (MILP): A Case Study. Math. Probl. Eng. 2020, 2020, 1–25. [Google Scholar] [CrossRef]

- Akgul, O.; Shah, N.; Papageorgiou, L.G. An optimisation framework for a hybrid first/second generation bioethanol supply chain. Comput. Chem. Eng. 2012, 42, 101–114. [Google Scholar] [CrossRef]

- Allameh, G.; Saidi-Mehrabad, M. Pricing decisions in a decentralized biofuel supply chain with RIN mechanism considering environmental impacts. Biomass Bioenergy 2021, 150, 106090. [Google Scholar] [CrossRef]

- Giarola, S.; Shah, N.; Bezzo, F. A comprehensive approach to the design of ethanol supply chains including carbon trading effects. Bioresour. Technol. 2012, 107, 175–185. [Google Scholar] [CrossRef]

- Galanopoulos, C.; Barletta, D.; Zondervan, E. A decision support platform for a bio-based supply chain: Application to the region of Lower Saxony and Bremen (Germany). Comput. Chem. Eng. 2018, 115, 233–242. [Google Scholar] [CrossRef]

- Haj Hasan, A.; Avami, A. Comparative assessment of bioethanol supply chain: Insights from Iran. Biofuels 2021, 12, 475–483. [Google Scholar] [CrossRef]

- Gilani, H.; Sahebi, H.; Oliveira, F. Sustainable sugarcane-to-bioethanol supply chain network design: A robust possibilistic programming model. Appl. Energy 2020, 278, 115653. [Google Scholar] [CrossRef]

- Haji Esmaeili, S.A.; Sobhani, A.; Szmerekovsky, J.; Dybing, A.; Pourhashem, G. First-generation vs. second-generation: A market incentives analysis for bioethanol supply chains with carbon policies. Appl. Energy 2020, 277, 115606. [Google Scholar] [CrossRef]

- You, C.; Han, S.; Kim, J. Integrative design of the optimal biorefinery and bioethanol supply chain under the water-energy-food-land (WEFL) nexus framework. Energy 2021, 228, 120574. [Google Scholar] [CrossRef]

- Kwon, O.; Han, J. Waste-to-bioethanol supply chain network: A deterministic model. Appl. Energy 2021, 300, 117381. [Google Scholar] [CrossRef]

- Saif, Y.; Almansoori, A.; Bilici, I.; Elkamel, A. Sustainable management and design of the energy-water-food nexus using a mathematical programming approach. Can. J. Chem. Eng. 2020, 98, 2056–2078. [Google Scholar] [CrossRef]

- Macowski, D.H.; Bonfim-Rocha, L.; Orgeda, R.; Camilo, R.; Ravagnani, M.A.S.S. Multi-objective optimization of the Brazilian industrial sugarcane scenario: A profitable and ecological approach. Clean. Technol. Environ. Policy 2020, 22, 591–611. [Google Scholar] [CrossRef]

- Espinoza-Vázquez, Y.M.; Gómez-Castro, F.I.; Ponce-Ortega, J.M. Optimization of the supply chain for the production of biomass-based fuels and high-added value products in Mexico. Comput. Chem. Eng. 2021, 145, 107181. [Google Scholar] [CrossRef]

- Gutierrez-Franco, E.; Polo, A.; Clavijo-Buritica, N.; Rabelo, L. Multi-objective optimization to support the design of a sustainable supply chain for the generation of biofuels from forest waste. Sustainability 2021, 13, 7774. [Google Scholar] [CrossRef]

- Ge, Y.; Li, L.; Yun, L. Modeling and economic optimization of cellulosic biofuel supply chain considering multiple conversion pathways. Appl. Energy 2021, 281, 116059. [Google Scholar] [CrossRef]

- Ren, J.; Manzardo, A.; Toniolo, S.; Scipioni, A.; Tan, S.; Dong, L.; Gao, S. Design and modeling of sustainable bioethanol supply chain by minimizing the total ecological footprint in life cycle perspective. Bioresour. Technol. 2013, 146, 771–774. [Google Scholar] [CrossRef]

- Sam, M.L.; Saptari, A.; Bin Salleh, M.R.; Mohamad, E. Comparison between linear programming and integer linear programming: A review. Int. J. Math. Oper. Res. 2018, 13, 91–106. [Google Scholar] [CrossRef]

- Cambero, C.; Sowlati, T.; Marinescu, M.; Röser, D. Strategic optimization of forest residues to bioenergy and biofuel supply chain. Int. J. Energy Res. 2015, 39, 439–452. [Google Scholar] [CrossRef]

- Ahn, Y.-C.; Lee, I.-B.; Lee, K.-H.; Han, J.-H. Strategic planning design of microalgae biomass-to-biodiesel supply chain network: Multi-period deterministic model. Appl. Energy 2015, 154, 528–542. [Google Scholar] [CrossRef]

- Babazadeh, R.; Razmi, J.; Pishvaee, M.S.; Rabbani, M. A sustainable second-generation biodiesel supply chain network design problem under risk. Omega 2017, 66, 258–277. [Google Scholar] [CrossRef]

- Zhang, Y.; Jiang, Y. Robust optimization on sustainable biodiesel supply chain produced from waste cooking oil under price uncertainty. Waste Manag. 2017, 60, 329–339. [Google Scholar] [CrossRef] [PubMed]

- Azadeh, A.; Vafa Arani, H. Biodiesel supply chain optimization via a hybrid system dynamics-mathematical programming approach. Renew. Energy 2016, 93, 383–403. [Google Scholar] [CrossRef]

- Cambero, C.; Sowlati, T.; Pavel, M. Economic and life cycle environmental optimization of forest-based biorefinery supply chains for bioenergy and biofuel production. Chem. Eng. Res. Des. 2016, 107, 218–235. [Google Scholar] [CrossRef]

- Leão, R.R.D.C.C.; Hamacher, S.; Oliveira, F. Optimization of biodiesel supply chains based on small farmers: A case study in Brazil. Bioresour. Technol. 2011, 102, 8958–8963. [Google Scholar] [CrossRef]

- García Cáceres, R.G. Strategic planning of the biodiesel supply chain Planeación estratégica de la cadena de abastecimiento del biodiesel. Eng. Univ. 2018, 22, 1–29. [Google Scholar] [CrossRef]

- Costa, Y.; Duarte, A.; Sarache, W. A decisional simulation-optimization framework for sustainable facility location of a biodiesel plant in Colombia. J. Clean. Prod. 2017, 167, 174–191. [Google Scholar] [CrossRef]

- Ivanov, B.; Dimitrova, B.; Dobrudzhaliev, D. Optimal design and planning of biodiesel supply chain considering crop rotation model. Part 2. Location of biodiesel production plants on the Bulgarian scale. Bulg. Chem. Commun. 2014, 46, 306–319. [Google Scholar]

- Rezaei, M.; Chaharsooghi, S.K.; Husseinzadeh Kashan, A.; Babazadeh, R. Optimal design and planning of biodiesel supply chain network: A scenario-based robust optimization approach. Int. J. Energy Environ. Eng. 2020, 11, 111–128. [Google Scholar] [CrossRef]

- Ghelichi, Z.; Saidi-Mehrabad, M.; Pishvaee, M.S. A stochastic programming approach toward optimal design and planning of an integrated green biodiesel supply chain network under uncertainty: A case study. Energy 2018, 156, 661–687. [Google Scholar] [CrossRef]

- Babazadeh, R. Optimal design and planning of biodiesel supply chain considering non-edible feedstock. Renew. Sustain. Energy Rev. 2017, 75, 1089–1100. [Google Scholar] [CrossRef]

- Mohseni, S.; Pishvaee, M.S. Data-driven robust optimization for wastewater sludge-to-biodiesel supply chain design. Comput. Ind. Eng. 2020, 139, 105944. [Google Scholar] [CrossRef]

- Jeong, H.; Sieverding, H.L.; Stone, J.J. Biodiesel Supply Chain Optimization Modeled with Geographical Information System (GIS) and Mixed-Integer Linear Programming (MILP) for the Northern Great Plains Region. Bioenergy Res. 2019, 12, 229–240. [Google Scholar] [CrossRef]

- Babazadeh, R. Robust Optimization Method to Green Biomass-to-Bioenergy Systems under Deep Uncertainty. Ind. Eng. Chem. Res. 2018, 57, 7975–7986. [Google Scholar] [CrossRef]

- Babazadeh, R.; Razmi, J.; Rabbani, M.; Pishvaee, M.S. An integrated data envelopment analysis–mathematical programming approach to strategic biodiesel supply chain network design problem. J. Clean. Prod. 2017, 147, 694–707. [Google Scholar] [CrossRef]

- Geng, N.; Sun, Y. Multiobjective Optimization of Sustainable WCO for Biodiesel Supply Chain Network Design. Discret. Dyn. Nat. Soc. 2021, 2021, 1–16. [Google Scholar] [CrossRef]

- Geng, N.; Fu, Q.; Sun, Y. Stochastic Programming of Sustainable Waste Cooking Oil for Biodiesel Supply Chain under Uncertainty. J. Adv. Transp. 2021, 2021, 1. [Google Scholar] [CrossRef]

- Habib, M.S.; Asghar, O.; Hussain, A.; Imran, M.; Mughal, M.P.; Sarkar, B. A robust possibilistic programming approach toward animal fat-based biodiesel supply chain network design under uncertain environment. J. Clean. Prod. 2021, 278, 122403. [Google Scholar] [CrossRef]

- Habib, M.S.; Tayyab, M.; Zahoor, S.; Sarkar, B. Management of animal fat-based biodiesel supply chain under the paradigm of sustainability. Energy Convers. Manag. 2020, 225, 113345. [Google Scholar] [CrossRef]

- Yadala, S.; Smith, J.D.; Young, D.; Crunkleton, D.W.; Cremaschi, S. Optimization of the algal biomass to biodiesel supply chain: Case studies of the state of Oklahoma and the United States. Processes 2020, 8, 476. [Google Scholar] [CrossRef]

- Ganev, E.; Ivanov, B.; Vaklieva-Bancheva, N.; Kirilova, E.; Dzhelil, Y. A multi-objective approach toward optimal design of sustainable integrated biodiesel/diesel supply chain based on first-and second-generation feedstock with solid waste use. Energies 2021, 14, 2261. [Google Scholar] [CrossRef]

- Afkhami, P.; Zarrinpoor, N. Optimization design of a supply chain for jatropha-based biofuel from a sustainable development perspective considering international resources and demand: A case study. Ind. Eng. Chem. Res. 2021, 60, 6188–6207. [Google Scholar] [CrossRef]

- Mirhashemi, M.S.; Mohseni, S.; Hasanzadeh, M.; Pishvaee, M.S. Moringa oleifera biomass-to-biodiesel supply chain design: An opportunity to combat desertification in Iran. J. Clean. Prod. 2018, 203, 313–327. [Google Scholar] [CrossRef]

- Jazi, E.M.; Sangroudi, H.A. Designing A Hybrid First/Second Generation Biofuel Supply Chain with Reliable Multimodal Transport: A Mathematical Model. Int. J. Ind. Eng. Prod. Res. 2020, 31, 101–113. [Google Scholar] [CrossRef]

- Mohtashami, Z.; Bozorgi-Amiri, A.; Tavakkoli-Moghaddam, R. A two-stage multi-objective second generation biodiesel supply chain design considering social sustainability: A case study. Energy 2021, 233, 121020. [Google Scholar] [CrossRef]

- Yu, J.; Lee, I.-B.; Han, J.; Ahn, Y. Stochastic approach to optimize the supply chain network of microalga-derived biodiesel under uncertain diesel demand. J. Chem. Eng. Japan 2020, 53, 24–35. [Google Scholar] [CrossRef]

- Senna, P.; Pinha, D.; Ahluwalia, R.; Guimarães, J.C.; Severo, E.; Reis, A. A three-stage stochastic optimization model for the Brazilian biodiesel supply chain. Producao 2016, 26, 501–515. [Google Scholar] [CrossRef][Green Version]

- Ren, J.; Tan, S.; Yang, L.; Goodsite, M.E.; Pang, C.; Dong, L. Optimization of emergy sustainability index for biodiesel supply network design. Energy Convers. Manag. 2015, 92, 312–321. [Google Scholar] [CrossRef]

- Castillo-Villar, K.K.; Minor-Popocatl, H.; Webb, E. Quantifying the impact of feedstock quality on the design of bioenergy supply chain networks. Energies 2016, 9, 203. [Google Scholar] [CrossRef]

- Balaman, Ş.Y.; Selim, H. A fuzzy multiobjective linear programming model for design and management of anaerobic digestion based bioenergy supply chains. Energy 2014, 74, 928–940. [Google Scholar] [CrossRef]

- Patrizio, P.; Leduc, S.; Chinese, D.; Kraxner, F. Internalizing the external costs of biogas supply chains in the Italian energy sector. Energy 2017, 125, 85–96. [Google Scholar] [CrossRef]

- Rabbani, M.; Saravi, N.A.; Farrokhi-Asl, H.; Lim, S.F.W.T.; Tahaei, Z. Developing a sustainable supply chain optimization model for switchgrass-based bioenergy production: A case study. J. Clean. Prod. 2018, 200, 827–843. [Google Scholar] [CrossRef]

- Park, Y.S.; Szmerekovsky, J.; Dybing, A. Optimal Location of Biogas Plants in Supply Chains under Carbon Effects: Insight from a Case Study on Animal Manure in North Dakota. J. Adv. Transp. 2019, 2019, 13. [Google Scholar] [CrossRef]

- De Menna, F.; Malagnino, R.A.; Vittuari, M.; Segrè, A.; Molari, G.; Deligios, P.A.; Solinas, S.; Ledda, L. Optimization of agricultural biogas supply chains using artichoke byproducts in existing plants. Agric. Syst. 2018, 165, 137–146. [Google Scholar] [CrossRef]

- Díaz-Trujillo, L.A.; Nápoles-Rivera, F. Optimization of biogas supply chain in Mexico considering economic and environmental aspects. Renew. Energy 2019, 139, 1227–1240. [Google Scholar] [CrossRef]

- Khishtandar, S. Simulation based evolutionary algorithms for fuzzy chance-constrained biogas supply chain design. Appl. Energy 2019, 236, 183–195. [Google Scholar] [CrossRef]

- Hu, Y.; Scarborough, M.; Aguirre-Villegas, H.; Larson, R.A.; Noguera, D.R.; Zavala, V.M. A Supply Chain Framework for the Analysis of the Recovery of Biogas and Fatty Acids from Organic Waste. ACS Sustain. Chem. Eng. 2018, 6, 6211–6222. [Google Scholar] [CrossRef]

- Chinese, D.; Patrizio, P.; Nardin, G. Effects of changes in Italian bioenergy promotion schemes for agricultural biogas projects: Insights from a regional optimization model. Energy Policy 2014, 75, 189–205. [Google Scholar] [CrossRef]

- Sarkar, B.; Mridha, B.; Pareek, S.; Sarkar, M.; Thangavelu, L. A flexible biofuel and bioenergy production system with transportation disruption under a sustainable supply chain network. J. Clean. Prod. 2021, 317, 128079. [Google Scholar] [CrossRef]

- Gital Durmaz, Y.; Bilgen, B. Multi-objective optimization of sustainable biomass supply chain network design. Appl. Energy 2020, 272, 115259. [Google Scholar] [CrossRef]

- Díaz-Trujillo, L.A.; Fuentes-Cortés, L.F.; Nápoles-Rivera, F. Economic and environmental optimization for a biogas supply Chain: A CVaR approach applied to uncertainty of biomass and biogas demand. Comput. Chem. Eng. 2020, 141, 107018. [Google Scholar] [CrossRef]

- Rafique, R.; Jat, M.; Hakeem-Ur-Rehman Chudhery, M.A.Z. Bioenergy supply chain optimization for addressing energy deficiency: A dynamic model for large-scale network designs. J. Clean. Prod. 2021, 318, 128495. [Google Scholar] [CrossRef]

- Mafakheri, F.; Adebanjo, D.; Genus, A. Coordinating biomass supply chains for remote communities: A comparative analysis of non-cooperative and cooperative scenarios. Int. J. Prod. Res. 2021, 59, 4615–4632. [Google Scholar] [CrossRef]

- Saghaei, M.; Ghaderi, H.; Soleimani, H. Design and optimization of biomass electricity supply chain with uncertainty in material quality, availability and market demand. Energy 2020, 197, 117165. [Google Scholar] [CrossRef]

- Negri, V.; Galán-Martín, Á.; Pozo, C.; Fajardy, M.; Reiner, D.M.; Mac Dowell, N.; Guillén-Gosálbez, G. Life cycle optimization of BECCS supply chains in the European Union. Appl. Energy 2021, 298, 117252. [Google Scholar] [CrossRef]

- Abdelhady, S.; Shalaby, M.A.; Shaban, A. Techno-economic analysis for the optimal design of a national network of agro-energy biomass power plants in Egypt. Energies 2021, 14, 3063. [Google Scholar] [CrossRef]

- Duarte, A.; Sarache, W.; Costa, Y. A facility-location model for biofuel plants: Applications in the Colombian context. Energy 2014, 72, 476–483. [Google Scholar] [CrossRef]

- Mahjoub, N.; Sahebi, H.; Mazdeh, M.; Teymouri, A. Optimal design of the second and third generation biofuel supply network by a multi-objective model. J. Clean. Prod. 2020, 256, 120355. [Google Scholar] [CrossRef]

- Egieya, J.M.; Čuček, L.; Zirngast, K.; Isafiade, A.J.; Pahor, B.; Kravanja, Z. Biogas supply chain optimization considering different multi-period scenarios. Chem. Eng. Trans. 2018, 70, 985–990. [Google Scholar] [CrossRef]

- Jensen, I.G.; Münster, M.; Pisinger, D. Optimizing the supply chain of biomass and biogas for a single plant considering mass and energy losses. Eur. J. Oper. Res. 2017, 262, 744–758. [Google Scholar] [CrossRef]

- Balaman, Ş.Y.; Selim, H. A network design model for biomass to energy supply chains with anaerobic digestion systems. Appl. Energy 2014, 130, 289–304. [Google Scholar] [CrossRef]

- Egieya, J.M.; Čuček, L.; Zirngast, K.; Isafiade, A.J.; Pahor, B.; Kravanja, Z. Synthesis of biogas supply networks using various biomass and manure types. Comput. Chem. Eng. 2019, 122, 129–151. [Google Scholar] [CrossRef]

- Lee, M.; Cho, S.; Kim, J. A comprehensive model for design and analysis of bioethanol production and supply strategies from lignocellulosic biomass. Renew. Energy 2017, 112, 247–259. [Google Scholar] [CrossRef]

- Ghaderi, H.; Gitinavard, H.; Pishvaee, M.S. A system dynamics approach to analysing bioethanol and biodiesel supply chains: Increasing bioethanol and biodiesel market shares in the USA. Int. J. Energy Technol. Policy 2020, 16, 57–84. [Google Scholar] [CrossRef]

- Bijarchiyan, M.; Sahebi, H.; Mirzamohammadi, S. A sustainable biomass network design model for bioenergy production by anaerobic digestion technology: Using agricultural residues and livestock manure. Energy Sustain. Soc. 2020, 10, 19. [Google Scholar] [CrossRef]

- Samani, M.R.G.; Hosseini-Motlagh, S.-M. A mixed uncertainty approach to design a bioenergy network considering sustainability and efficiency measures. Comput. Chem. Eng. 2021, 149, 107305. [Google Scholar] [CrossRef]

- Liu, Y.; Huang, T.; Peng, D.; Huang, J.; Maurer, C.; Kranert, M. Optimizing the co-digestion supply chain of sewage sludge and food waste by the demand oriented biogas supplying mechanism. Waste Manag. Res. 2021, 39, 302–313. [Google Scholar] [CrossRef]

- Tesfamichael, B.; Montastruc, L.; Negny, S.; Yimam, A. Designing and planning of Ethiopia’s biomass-to-biofuel supply chain through integrated strategic-tactical optimization model considering economic dimension. Comput. Chem. Eng. 2021, 153, 107425. [Google Scholar] [CrossRef]

- Abdali, H.; Sahebi, H.; Pishvaee, M. The water-energy-food-land nexus at the sugarcane-to-bioenergy supply chain: A sustainable network design model. Comput. Chem. Eng. 2021, 145, 107199. [Google Scholar] [CrossRef]

- Razm, S.; Dolgui, A.; Hammami, R.; Brahimi, N.; Nickel, S.; Sahebi, H. A two-phase sequential approach to design bioenergy supply chains under uncertainty and social concerns. Comput. Chem. Eng. 2021, 145, 107131. [Google Scholar] [CrossRef]

- Galanopoulos, C.; Giuliano, A.; Barletta, D.; Zondervan, E. An integrated methodology for the economic and environmental assessment of a biorefinery supply chain. Chem. Eng. Res. Des. 2020, 160, 199–215. [Google Scholar] [CrossRef]

- Rafie, S.M.; Sahebi, H. An integrated gas-oil and bio-diesel supply network model with strategic and tactical applications considering the environmental aspects. Oil Gas. Sci. Technol. 2021, 76, 47. [Google Scholar] [CrossRef]

- Kanan, M.; Habib, M.S.; Shahbaz, A.; Hussain, A.; Habib, T.; Raza, H.; Abusaq, Z.; Assaf, R. A Grey-Fuzzy Programming Approach towards Socio-Economic Optimization of Second-Generation Biodiesel Supply Chains. Sustainability 2022, 14, 10169. [Google Scholar] [CrossRef]

- Rezaei, E.E.; Ghazaryan, G.; Moradi, R.; Dubovyk, O.; Siebert, S. Crop harvested area, not yield, drives variability in crop production in Iran. Environ. Res. Lett. 2021, 16, 064058. [Google Scholar] [CrossRef]

- Kendall, A.; Gal, Y.; Cipolla, R. Multi-Task Learning Using Uncertainty to Weigh Losses for Scene Geometry and Semantics. In Proceedings of the 2018 IEEE/CVF Conference on Computer Vision and Pattern Recognition Workshops (CVPRW), Salt Lake City, UT, USA, 18–22 June 2018; pp. 7482–7491. [Google Scholar]

- Hallegatte, S.; Shah, A.; Brown, C.; Lempert, R.; Gill, S. Investment Decision Making Under Deep Uncertainty—Application to Climate Change; Policy Research Working Paper; World Bank: Washington, DC, USA, 2012. [Google Scholar]

- Senocak, A.A.; Guner Goren, H. Three-phase artificial intelligence-geographic information systems-based biomass network design approach: A case study in Denizli. Appl. Energy 2023, 343, 121214. [Google Scholar] [CrossRef]

- Umar, M.; Tayyab, M.; Chaudhry, H.R.; Su, C.-W. Navigating epistemic uncertainty in third-generation biodiesel supply chain management through robust optimization for economic and environmental performance. Ann. Oper. Res. 2023. [Google Scholar] [CrossRef]

- Rahmani, S.; Goli, A. Robust sustainable canola oil-based biodiesel supply chain network design under supply and demand uncertainty. Environ. Sci. Pollut. Res. 2023, 30, 86268–86299. [Google Scholar] [CrossRef]

- Rungphanich, K.; Siemanond, K. Chance constrained optimization of biodiesel supply chain. Chem. Eng. Trans. 2019, 76, 571–576. [Google Scholar] [CrossRef]

- Huang, Y.; Fan, Y.; Chen, C.-W. An Integrated Biofuel Supply Chain to Cope with Feedstock Seasonality and Uncertainty. Transp. Sci. 2014, 48, 540–554. [Google Scholar] [CrossRef]

- Babazadeh, R. Application of Fuzzy Optimization to Bioenergy-Supply-Chain Planning under Epistemic Uncertainty: A New Approach. Ind. Eng. Chem. Res. 2019, 58, 6519–6536. [Google Scholar] [CrossRef]

- Shabani, N.; Sowlati, T. A hybrid multi-stage stochastic programming-robust optimization model for maximizing the supply chain of a forest-based biomass power plant considering uncertainties. J. Clean. Prod. 2016, 112, 3285–3293. [Google Scholar] [CrossRef]

- Kanan, M.; Habib, M.S.; Habib, T.; Zahoor, S.; Gulzar, A.; Raza, H.; Abusaq, Z. A Flexible Robust Possibilistic Programming Approach for Sustainable Second-Generation Biogas Supply Chain Design under Multiple Uncertainties. Sustainability 2022, 14, 11597. [Google Scholar] [CrossRef]

- Dwivedi, Y.K.; Hughes, L.; Kar, A.K.; Baabdullah, A.M.; Grover, P.; Abbas, R.; Andreini, D.; Abumoghli, I.; Barlette, Y.; Bunker, D.; et al. Climate change and COP26: Are digital technologies and information management part of the problem or the solution? An editorial reflection and call to action. Int. J. Inf. Manag. 2022, 63, 102456. [Google Scholar] [CrossRef]

| Approach | Objectives | Assessment Tools | Reference |

|---|---|---|---|

| Process simulation |

|

| [9,10,11,12,13,14,15] |

| Supply chain management (SCM) |

|

| [16,17,18,19,20] |

| Country | Blending Proportion Implemented by Policy | Country | Blending Proportion Implemented by Policy |

|---|---|---|---|

| Angola | E10 | Malaysia | B10 |

| Germany | E5 and B5 | Mexico | E7 |

| Argentina | E25 and B10 | Nigeria | E10 |

| Australia | E7 and B4 | Norway | B10 |

| Austria | B10 | New Zealand | B5 |

| Belgium | E10 and B7 | Zimbabwe | E15 |

| Brazil | De E18 a E25 and B10 | Mozambique | E15 |

| Bolivia | E12 and B3 | Panama | E12 |

| Bulgaria | E12 | Paraguay | E24 and B1 |

| Canada | E7 and B2 | Peru | B10 and E7.8 |

| Chile | B5 | Poland | B12 |

| China | E12 and B10 | Portugal | E10 and B12 |

| Colombia | E10 and B10 | Netherlands | E10 and B7 |

| South Korea | E2 | Philippines | E12 and B2 |

| Costa Rica | E7 and E20 | Romania | E5 and B7 |

| Croatia | E10 and B10 | United Kingdom | E10 and B10 |

| Denmark | E7 | Czech Republic | B7 |

| Ecuador | B5 | Dominican Republic | E15 |

| Slovenia | B5 | South Africa | E10 and B5 |

| Spain | E5 and B5 | South Korea | B2.5 |

| Ethiopia | E10 | Sudan | E7 |

| France | E10 and B10 | Sweden | E10 and B10 |

| Finland | E18 | Thailand | E5 and B10 |

| Greece | E10 | Turkey | E7 |

| Guatemala | E5 | Hungary | E7 B10 |

| India | E5 | Ukraine | E7 |

| Indonesia | E3 and B20 | Uruguay | B5 and E7 para 2015 |

| Ireland | E12 and B10 | Vietnam | E5 |

| Italy | E10 and B7 | Zambia | E10 and B5 |