Abstract

The evaporative cooling system (ECS) is an energy-efficient and eco-friendly air-cooling technology that is very effective in dry climates, and the conventional method with cellulosic pads is widely used. However, because of the accumulation of dust and salts, these pads have a tendency to degrade quickly. This study aimed to examine the viability of using volcanic stone (Scoria) as an innovative material for evaporative cooling pads. The experiments were conducted in a wind tunnel (0.4 m × 0.6 m) with different pad thicknesses (d = 10 cm and 15 cm), water addition rates (mw =1.6, 2.4, and 4 kg.min−1.m−1), and air speeds (v = 0.75, 1.25, and 1.75 m·s−1). The results showed that the 10 cm thick pad consistently performed better than the 15 cm thick pad across all air speeds and water addition rates. The 10 cm thick pad achieved the highest cooling efficiency of 82% at a water addition rate of 2.4 L.min−1.m−1 and an air speed of 1.75 m·s−1. In contrast, the cooling efficiency for the 15cm-t hick pad was 64% under the same conditions. The 10 cm thick pad consumed more water (1.8 to 2.8 kg·h−1 compared to 1.0 and 2.4 kg·h−1 for the 15 cm pad), as the ECS performance was directly associated with the amount of water used. Higher air speed led to a drop in pressure, which impacted fan performance. The pressure drops across the pads were between 10 and 13 Pa for an air speed of 1.75 m·s−1. These results suggest that volcanic stone (Scoria) pads can provide effective cooling performance similar to that of commercial cellulosic pads but have added benefits of durability, less maintenance, and biological degradation resistance. The non-evaporative medium, especially the 10 cm thick Scoria pad, could be a more viable medium for evaporative cooling applications in arid areas.

1. Introduction

The limited water resources and unsuitable environmental conditions such as high temperature and low relative humidity, especially in the summer, are among the major challenges facing the agricultural sector in Saudi Arabia. According to Malhi [1], a temperature rises of 1.4 to 5.8 °C is expected by the end of this century. The temperatures in the Riyadh region reach more than 45 °C and the relative humidity is less than 10% in winter [2]. In hot climates during the summer months, the temperature of the air inside agricultural buildings can easily exceed 40 °C [3]. In general, a 4 to 24 °C drop, depending on the existing dry bulb temperature and humidity, is achievable [4]. Evaporative cooling systems (ECSs) adiabatically exchange sensible heat to latent heat [5]. This involves a thermodynamic process in which hot and humid air passes over a wet surface [6], resulting in a reduction in the dry bulb temperature of the air and a corresponding increase in the relative humidity. Single-stage ECSs are widely used in domestic applications, particularly in hot and dry areas for various domestic and industrial applications, such as the short- and long-term preservation of vegetables, fruits, etc., that do not require very low temperatures [7,8]. ECSs are relatively simple, efficient, and cost-effective, making them attractive alternatives to conventional cooling systems [7,9]. Thus, evaporative cooling is generally more efficient in areas where air temperature is high and relative humidity is low [5,10] and is considered one of the best ways to cool the air inside greenhouses because it maintains an appropriate moisture content around the plants and reduces electricity energy consumption [11]. It is considered a sustainable cooling system [7]; its use has spread due to its lower cost [12] compared to mechanical cooling systems (such as freon). Although ECSs are highly efficient in cooling and humidifying the air, they are still not able to control temperature and humidity accurately because their cooling capacity depends on the outside condition of the air [6], and the temperature of the air cannot be reduced below the wet bulb temperature of the air [7]. The cooling efficiency of an ECS depends on the pad material used, and attempts were made to obtain the highest saturation efficiency by changing the pad material [9]. The traditional ECS with a cellulosic cardboard pad is the most widely used method for controlling environmental conditions inside greenhouses. However, they quickly deteriorate as a result of the accumulation of salts and dust on them, which leads to a loss of much of their efficiency after the first year of use, a decrease in their lifespan, and an increase in their replacement and maintenance costs [13,14,15]. Many researchers are trying to search for or develop new, efficient, and sustainable pad materials, which are very much required for further enhancing the cooling potential of evaporative cooling devices [16]. Therefore, it is important to search for other materials with a long operating life and high efficiency that could be used as pads for ECSs. The ideal requirements for evaporative cooling pads are higher wetted water-to-air contact surfaces, minimum pressure drop, as well as being easy to clean, assemble, dismantle, and maintain [17]. Pozzolan bricks proved to be as effective as cellulose pads in cooling efficiency and exhibited remarkable durability in saline water and harsh conditions, eliminating the need for replacement [18]. The possibility of using volcanic stone (Scoria) in making evaporative cooling pads was studied. Scoria rocks are porous, spongy in appearance, and black, gray, brown, red, or white in color; the proportion of bubbles exceeds 50% of the total volume of the rock. As for its chemical composition, it is similar to that of basalt rocks. Black scoria granules retained 46% water, while red scoria granules retained 35% [19]. The use of these rocks as cooling pads may lead to an increase in the efficiency of ECSs, which could lead to reducing the stresses on plants in greenhouses and poultry in barns, especially during very hot times in the summer season, and thus contribute to increasing production and quality. Based on the above, there is an urgent need to search for practical materials that could be used as alternatives to the current cooling pads to overcome the problems experienced with traditional pads. Among these materials are pads made of scoria rocks, which are characterized by their high porosity, light weight, and availability in large areas in the Arabian Peninsula [20,21]. Therefore, the current study aimed to assess the effectiveness of ECSs utilizing volcanic stone (Scoria) cooling pads by analyzing the impact of pad thickness, air velocity, and water addition rate on cooling efficiency, water consumption, and pressure drop across the pads.

2. Materials and Methods

2.1. Evaporative Cooling System and Study Area

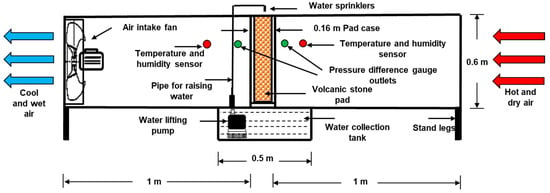

An evaporative cooling system with cooling pads was tested in a shaded area outside the General Department of Parks’ North Landscaping Unit building in the Riyadh Municipality during the months of July and August of 2022. The ECS used in the experiments (Figure 1) was made up of a rectangular aluminum frame that was 0.6 m high and 0.4 m wide. To draw in outside air across the pad, a variable-speed fan (220 V to 140 W) was installed at the front opening. The ECS was designed for easy insertion and removal of the replacement pad for each experiment. The system had a pipe at the top of the pad that distributed the water by spraying. The water flowed downward through the pad and was collected in a water tank. An electric pump (220 V–25 W), submerged in the reservoir, pumped the water back through the pipes. To minimize heat gain, the body of the channel was insulated with a layer of 25 mm thick insulation glass wool.

Figure 1.

Schematic diagram of the evaporative cooling system.

2.2. Volcanic Stone Cooling Pads

The cooling pad consisted of an aluminum frame filled with volcanic stones (1.6 to 2.5 cm diameter, with average bulk density of 2.6 g.cm−3). Volcanic stone is a type of igneous rock that condenses after a volcanic eruption when magma reaches the surface. It is porous, contains natural holes, is lightweight, highly resistant to erosion, and has a long lifespan. Its surface is uneven or cracked, with a conch-like shape, and lacks any regular internal atomic structure or regular external shape. The volcanic stones were held in place by galvanized metal mesh racks within the frame (porosity mesh was 4500 holes per square meter), which also acted as barriers and shelves. The aluminum frame was securely locked with tight galvanized metal wire to prevent the stones from escaping (Figure 2).

Figure 2.

Volcanic stone cooling pads within the aluminum frame.

2.3. Experiment Planning

The performance of the volcanic stone pad was evaluated by operating the evaporative cooling system (ECS) under three water addition rates (1.6, 2.4, and 4 L·min−1·m−1) and three air speeds (0.75, 1.25, and 1.75 m·s−1). Two pad thicknesses (10 cm and 15 cm) were tested to determine the optimal thickness for maximizing cooling efficiency.

Each experiment lasted one hour and was replicated three times (experimental factors were 3 × 3 × 2 × 3, and the average readings were taken). The air temperature (T1), and relative humidity (RH1) were measured before entering the pad, and the air temperature (T2) and relative humidity (RH2), were measured after leaving the pad. The pressure drops before and after the pad and as well as the amount of water consumed by the system were also recorded. Air temperature and relative humidity were logged every 30 s using a portable combined sensor data logger (OM-EL-ESB-2-LSD, Omega Inc., Norwalk, CT, USA). Air speed through the pad (m·s−1) was measured using a vane anemometer (Model: 850021, Taiwan). The pressure drop across the cooling pad was determined using a Testo 510-Digital manometer (differential pressure to 40 in. H2O, Testo, Titisee-Neustadt, Germany). Wet bulb effectiveness (η) representing the cooling efficiency of pad (%), was calculated based on the average temperatures and relative humidity values measured before and after the pad using the following equation [22]:

where: T1 is the air temperature before entering the pad, T2 is the air temperature after leaving the pad, and Twb is the wet bulb temperature of the air before it enters the cooler (°C).

The water addition rates were adjusted using a glass beaker marked with a scale (mm) to determine the amount of water added so that the amounts of 1.6, 2.4, and 4 L were added to the cooling pads every one minute, and, accordingly, the water opening stopcock was calibrated with this method. All devices used were calibrated before conducting the experiments.

2.4. Statistical Analysis

The statistical analysis of the results (based on analysis of variance (ANOVA), Dunkin’s mean test was applied at , using SAS ver. 9.0, SAS Institute, Cary, NC, USA) [23], showed that pad thickness had a significant effect on the cooling efficiency, with the 10 cm thick pad performing significantly better than the 15 cm thick pad (p < 0.05).

3. Results and Discussion

3.1. Effect of Pad Thickness on Cooling Efficiency

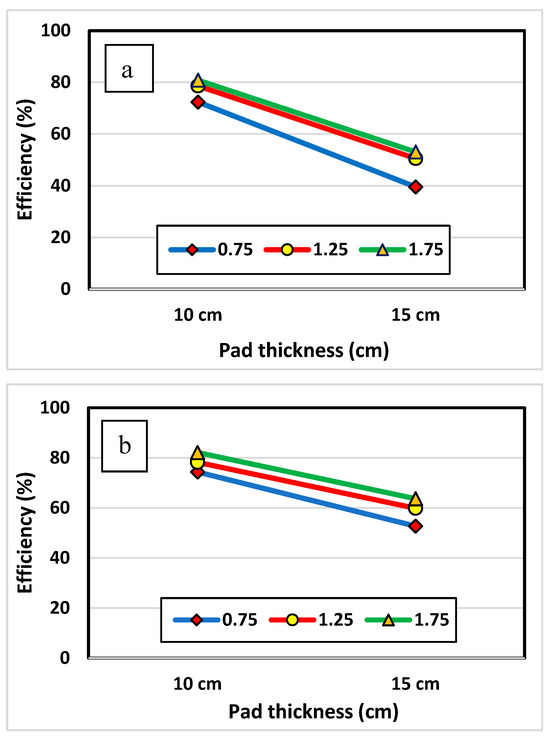

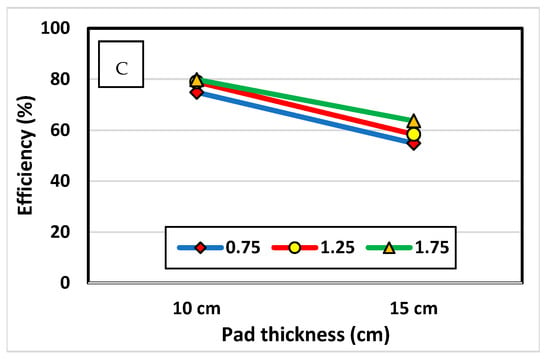

Figure 3a–c show that under at all tested conditions (air speeds of 0.75, 1.25, and 1.75 m·s−1 and water addition rates of 1.6, 2.4, and 4 L·min−1·m−1), the 10 cm thick pad had higher cooling efficiency, 82%, at an air speed of 1.75 m·s−1 and a water addition rate of 2.4 L·min−1·m−1, than the 15 cm thick pad, which was 64% for the same air speed and water addition rate. The low cooling efficiency of the 15 cm thick pad could be explained by the lack of pores between the stones, which restricted the flow of air and caused water droplets to pass through without sufficient evaporation [24].

Figure 3.

Effect of pad thickness on cooling efficiency of the system at a water addition rate of (a) 1.6, (b) 2.4, and (c) 4 L.min−1 m−1.

Figure 3a–c clearly shows that increasing the air speed from 0.75 m·s−1 to 1.75 m·s−1 improved the cooling efficiency for both pad thicknesses. Yet, the 15 cm pad displayed no significant improvement, maintaining low efficiencies compared to the 10 cm pad at the same air speeds.

The high performance of the 10 cm thick pad in all cases could be due to its lower resistance to air flow. At suitable air speeds, adequate contact occurs between the air and water droplets, promoting effective heat exchange and evaporation without extreme drift. This results in a higher cooling efficiency [25]. However, the rate of efficiency increase was lower when the air speed increased from 1.25 to 1.75 m·s−1, which was likely due to air speeds exceeding 1.5 m·s−1, which caused the free water droplets to be carried away without evaporating [24]. Moreover, low pressure on both sides of the pad may further decrease the cooling efficiency [26]. The results obtained may depend on the specific conditions of this study, and the different granulometric conditions of the stone could lead to different responses to pad thickness.

3.2. Effect of Water Addition Rate on Cooling Efficiency

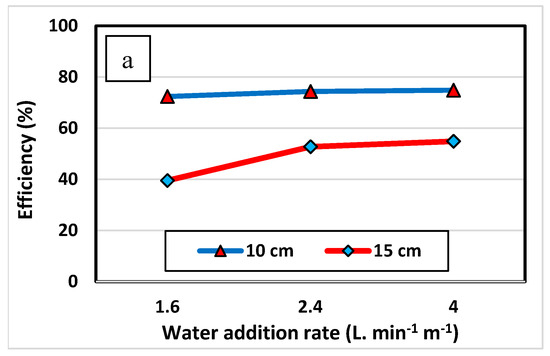

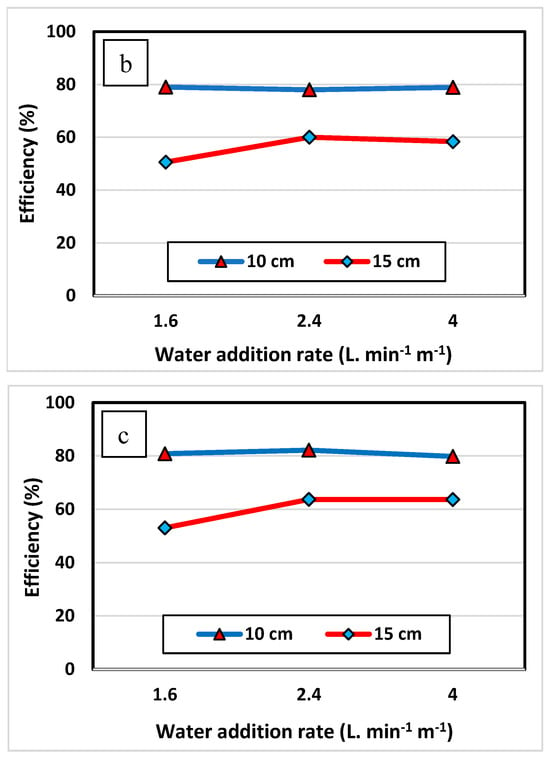

The water addition rate significantly (p < 0.05) affected the cooling efficiency, with the highest efficiency (82%) detected using the 10 cm pad at a water addition rate of 2.4 L. min−1 m−1 and a 1.75 m·s−1 air speed (Figure 4c).

Figure 4.

Effect of water addition rate on cooling efficiency of the system at an air speed of (a) 0.75, (b) 1.25, (c) 1.75 m·s−1.

The results in Figure 4a–c illustrate that increasing the water addition rate enhanced the cooling efficiency for both pad thicknesses. However, increasing the water addition rate to 4 L. min−1·m−1 did not considerably change the efficiency. The 15 cm pad showed no significant improvement, sustaining low cooling efficiencies compared to the 10 cm pad at all water addition rates.

The relationship between water addition and the efficiency was direct at low water addition rates. At higher rates, the efficiency increases were limited by pad saturation. Low water/air mass flow causes high evaporation rates and incomplete pad wetting. The required water addition for complete wetting depends on the pad material, thickness, and dimensions. These findings agree with those of previous studies by He [26], Jawad [27], Gunhan [28], and Al-Badri and Al-Waaly [29]. He [26] suggested determining the minimum water to keep the pad wet. Ghoname [30] recommended operating at a maximum water flow to reduce blockages. Yan [31] conducted tests on the water addition rates recommended by manufacturers and found that a recommended water flow rate 10 to 30 times the evaporation rate achieved total wetting and removed sediment from the pads.

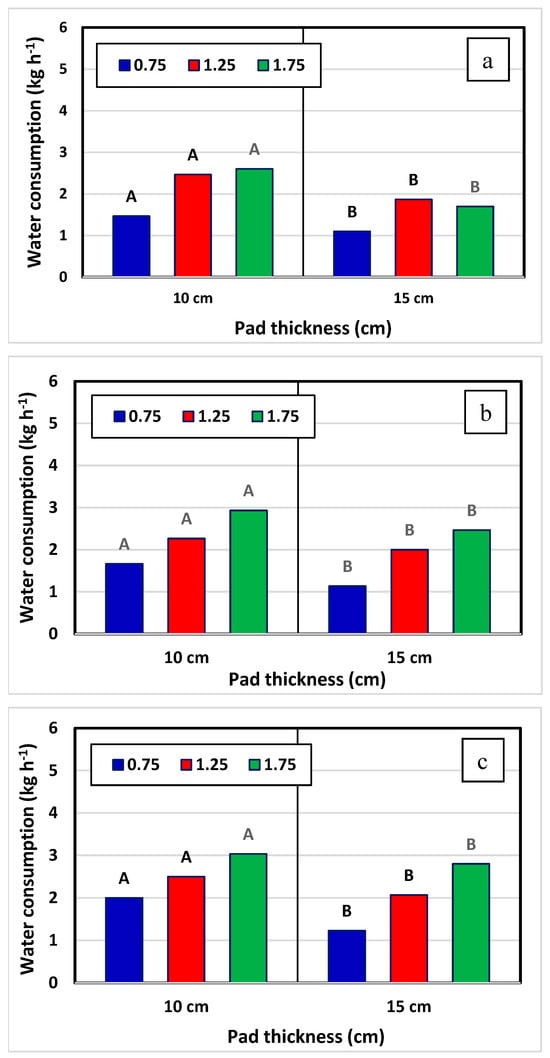

3.3. Effect of Pad Thickness on Water Consumption

The results in Figure 5a–c show that the pad thickness significantly (p < 0.05) influenced the water consumption rate, as the thinner pads allowed more air flow, leading to higher evaporation and water consumption. The 10 cm pad used more water than the 15 cm pad, with water consumption decreasing as pad thickness increased. The highest amount of water consumption recorded (2.8 kg h−1) was for the 10 cm thick pad at an air speed of 1.75 m·s−1 and a water addition rate of 4 L. min−1 m−1. In contrast, the amount of water consumed by the 15 cm thick pad was 2.4 kg h−1 at the same air speed and water addition rate.

Figure 5.

Effect of pad thickness on water consumption at an addition rate of (a) 1.6, (b) 2.4, (c) 4 kg min−1 m−1.

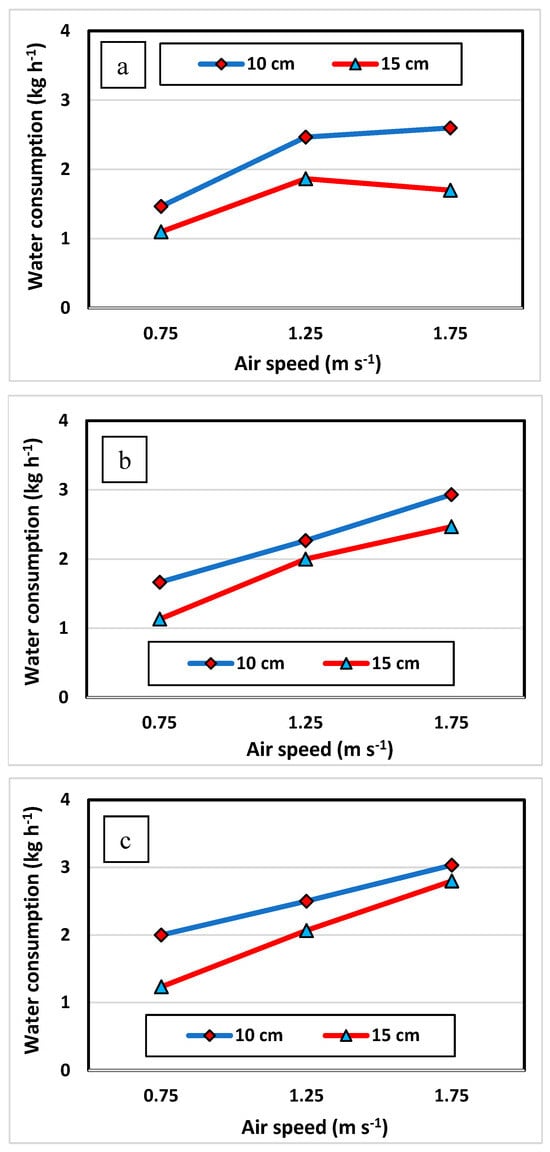

3.4. Effect of Air Speed on Water Consumption

The statistical analysis showed that the air speed had a significant (p < 0.05) effect on the water consumption rate. The results in Figure 6a–c show that there was a direct relationship between the peed of air and water consumption, where the higher the air speed passing through the pad, the greater the amount of water consumed. The highest amount of water consumed (3.1 kg h−1) was detected using the 10 cm pad at an air speed of 1.75 m·s−1 and a water addition rate of 4 L. min−1 m−1 (Figure 6c). In contrast, the 15 cm pad consumed less water (2.8 kg h−1) under the same conditions. This is in line with a study carried out by Al-Helal and Al-Tuwaijri [32], in which they indicated that there was a direct relationship between the increase in water consumption and the increase in the speed of the air passing through the cooling process, as a result of the increase in the contact area between the air and the water passing through the cooling pads.

Figure 6.

Effect of air speed passing through the pad on water consumption at a water addition rate of: (a) 1.6, (b) 2.4, (c) 4 L. min−1 m−1.

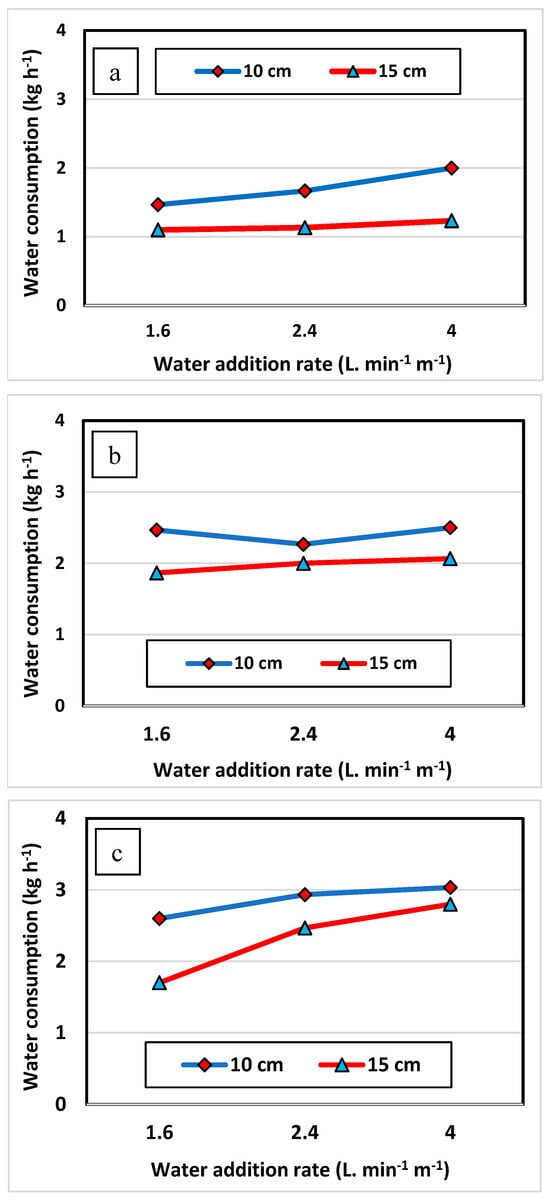

3.5. Effect of Water Addition Rate on Water Consumption

The results in Figure 7a–c show that the 10 cm thick pad consumed more water (3 kg h−1) at a 4 L. min−1 m−1 water addition rate and 1.75 m·s−1 air speed compared to the 15 cm thick pad under the same conditions. This may have been due to the 10 cm pad having lower resistance to the flow of air and allowing more evaporation, especially at high air speeds and a 4 L. min−1·m−1 water addition rate, where excess water drained without evaporating, leading to increased water consumption. In contrast, the 15 cm pad showed higher air flow resistance and lower evaporation rates due to its increased surface area. So, it used less water than the 10 cm pad.

Figure 7.

Effect of water addition rate on the water consumption at an air speed of (a) 0.75, (b) 1.25, (c) 1.75 m·s−1.

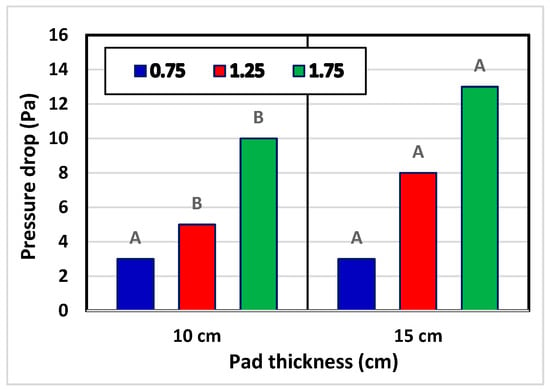

3.6. Effect of Pad Thickness on the Pressure Drop on Both Sides of the Pad

Data analysis indicated that there was no significant effect of the pad thickness on the pressure drop on either side of the pad. At a low air speed (0.75 m·s−1), the pressure drop on both sides of the pad was not affected by the pad thickness (constant value of −3 Pa), while at medium air speed (1.25 m·s−1), the pressure drop decreased to −5 Pa for the 10 cm thick pad, and it decreased to −8 Pa for the 15 cm thick pad. Also, at high speed (1.75 m·s−1), the pressure drop decreased from −5 to −10 Pa for the 10 cm thick pad, and it decreased to −13 Pa for the 15 cm thick pad (Figure 8). Thus, it can be said that the greater the thickness of the cooling pad, the greater the resistance to air flow through it, as the duration of contact with the air passing through the pad increases. This results in a decrease in the rate of water evaporation and thus a decrease in the cooling efficiency of the system [24,25]. It was also noted that the pressure drop values for the pad with a thickness of 10 cm were closer to each other with increasing air speed compared to the pad with a thickness of 15 cm. This result is very similar to the results obtained by Liao and Chiu [14].

Figure 8.

Effect of pad thickness on the pressure drop on both sides of the pad.

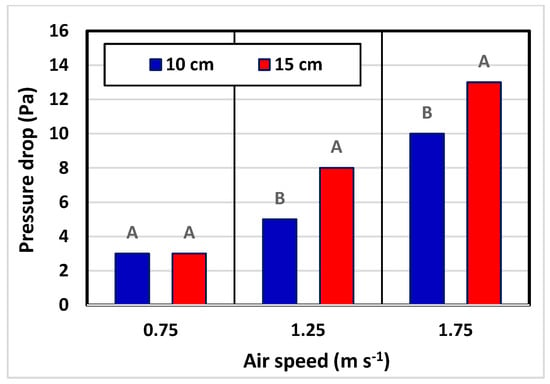

3.7. Effect of Air Speed on the Pressure Drop on Both Sides of the Pad

In Figure 9, there is an inverse relationship between air speed and pressure drop on both sides of the pad: the increase in air speed decreases the pressure drop on both sides of the pad. For the 10 cm thick pad, by increasing the air speed from 0.75 to 1.75 m·s−1, the pressure drop decreased from −3 to−10 Pa. This result is very similar to the results obtained by Liao and Chiu [14], who found a decrease in static pressure on both sides of the pad with increasing air flow whether the pad was made of volcanic rocks or coarse or fine pumice stones. This is also in agreement with Gunhan [28], whose results indicated that the evaporative efficiency of the pads decreased slightly with the increase in air speed from 0.6 to 1.6 m·s−1 for lava stone pads, cellulosic pads, and masonry pads. The same happened with the 15 cm thick pad; it was noticeable that the decrease occurred sharply from the beginning of the air speed increase from 0.75 to 1.25 m·s−1 as the pressure decreased further from −3 to −8 Pa. By increasing the air speed from 1.25 to 1.75 m·s−1, the pressure dropped dramatically again from −8 to −13 Pa. This severe decrease in pressure resulting from an increase in the air fan speed caused a decrease in the efficiency of the system because an increase in the fan speed to a value higher than 1.5 m·s−1 led to the withdrawal of free water droplets from the airway without evaporation, which led to a decrease in efficiency [24].

Figure 9.

Effect of air speed on the pressure drop on both sides of the pad.

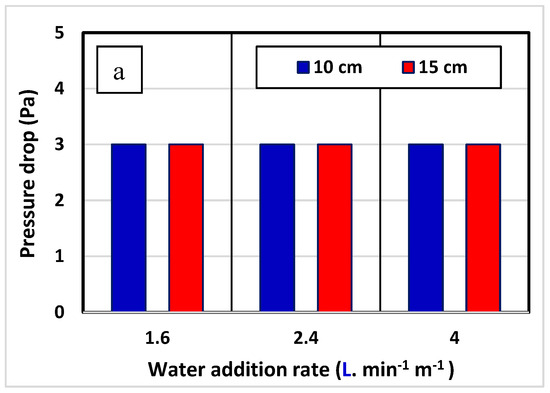

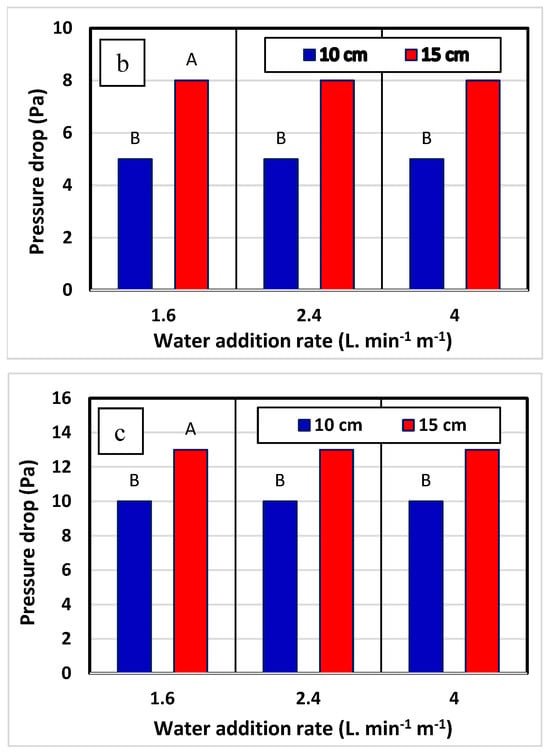

3.8. Effect of Water Adding Rate on the Pressure Drop on Both Sides of the Pad

There was no clear relationship between the water addition rate and the pressure drop on both sides of the pad, according to Figure 10a–c, as the pressure drop was not affected by the increase in the water addition rate at different air speeds. For the pad with a thickness of 10 cm, it was found that the pressure drops on both sides was constant at −3 Pa and was not affected by the increase in the water addition rate at a speed of 0.75 m·s−1, decreased to −5 Pa with an increase in the speed to 1.25 m·s−1, and then decreased to (−10 Pa) by increasing the speed to 1.75 m·s−1. As for the 15 cm thick pad, it was found that the pressure drops on both sides was also constant (−3 Pa) at a speed of 0.75 m·s−1 (Figure 10a), decreased to −8 Pa with an increase in the speed to 1.25 m·s−1 (Figure 10b), and then decreased to −13 Pa by increasing the speed to 1.75 m·s−1 (Figure 10c). At the low air speed (0.75 m·s−1), the pressure drops on both sides of the pad were equal for each of the two pad thickness of 10 and 15 cm. Increasing the water addition rate to the pad did not affect the pressure drop on either side of the pad for either type, as the pressure drop was constant when the water addition rate was increased from 1.6 to 2.4 kg min−1 m−1 and from 2.4 to 4 kg min−1 m−1. This result is fully consistent with what was found by Tejero-Gonzalez and Franco-Salas [17]: the water addition rate has a very small effect on the pressure drop when compared to the effects of the air speed and the thickness of the pad.

Figure 10.

The effect of water addition rate on the pressure drop at an air speed of (a) 0.75, (b) 1.25, (c) 1.75 m s−1.

3.9. Comparison Between Cooling Efficiency of Volcanic Stone Pads and Commercial Cellulosic Pads

Table 1 shows the cooling efficiency of volcanic stone pads compared to the cooling efficiency of cellulosic paper pads, as studied by a number of other researchers, which are the most commonly used in agricultural establishments. This study showed that the cooling efficiency of the volcanic cooling pad (82%) was very close to the cooling efficiency of the commercial pad, which ranged between 64.38% and 91% (increasing by 5% or more), and even superior to it in terms of long operating life and not being subject to mold or damage as well as having low maintenance requirements.

Table 1.

Comparison of the highest cooling efficiency obtained from the current pad with that of a commercial cellulosic paper pad in a number of studies.

4. Conclusions

In conclusion, it was clear that the 10 cm thick pad showed much better cooling performance than the 15 cm thick pad, with an average cooling efficiency of 78% compared to 55%.

Cooling efficiency was greatly affected by the air speed. For the 10 cm thick pad, the greatest efficiency (81%) was noted at a 1.75 m·s−1 air speed, with a 54% maximum (at a corresponding air speed) for the 15 cm thick pad.

The 10 cm thick pad achieved stable cooling efficiency between 77% and 78% at different water addition rates, indicating that the water addition rate had little effect on cooling efficiency. However, it should be noted that for the 15 cm thick pad, an improvement in efficiency was obtained at a water addition rate of 1.6 L. min−1·m−1 of 49% and an increase in water addition of 2.4 L. min−1·m−1 achieved from an efficiency of 56%. The addition of water was set to 4 L. min−1·m−1, which did not significantly affect efficiency, which remained in the range of 60%, indicating a saturation effect.

A higher air speed through the cooling pads produced a drop in pressure, which impacted fan performance. The pressure drops across the pads were between 10 and 13 Pa for an air speed of 1.75 m·s−1. Neither pad thickness, air speed, nor water addition rate showed a statistically significant interaction in terms of cooling efficiency or water consumption.

Overall, based on these results and a comparison with commercial cellulosic cooling pads, the volcanic stone (Scoria) pads showed similar cooling efficiency. Scoria pads are a practical substitute for conventional cooling pads, providing a myriad advantages: longer life span, no maintenance, and resistance to biological degradation such as rotting.

Author Contributions

M.A.R.: conceptualization, writing—original draft, investigation, supervision; I.M.A.-H.: conceptualization, reviewing, investigation, supervision; S.M.A.-K.: methodology, implementation of experiments, formal analysis, validation, investigation, data curation. F.N.A. and A.A.F.: review and editing, visualization; W.A.A.: methodology, investigation, data curation; M.A.R., F.A.A. and S.M.A.-K.: statistical analysis; M.N.I., R.B.F. and M.R.S.: assisting with conducting experiments and measurements. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

All data are available within this article.

Conflicts of Interest

The authors confirm that there are no relevant financial or non-financial competing interests to report.

References

- Malhi, G.S.; Kaur, M.; Kaushik, P. Impact of Climate Change on Agriculture and Its Mitigation Strategies: A Review. Sustainability 2021, 13, 1318. [Google Scholar] [CrossRef]

- Abdel-Ghany, A.M.; Al-Helal, I.M.; Alzahrani, S.M.; Alsadon, A.A.; Ali, I.M.; Elleithy, R.M. Covering materials incorporating radiation-preventing techniques to meet greenhouse-cooling challenges in arid regions: A review. Sci. World J. 2012, 2012, 906360. [Google Scholar] [CrossRef]

- Bucklin, R.A.; Leary, J.D.; McConnell, D.B.; Wilkerson, E.G. Fan and Pad Greenhouse Evaporative Cooling Systems; CIR1135; IFAS Extension, University of Florida: Homestead, FL, USA, 2004; pp. 1–7. [Google Scholar]

- Bhatia, B.E. Instructor, PDH online Course M231 (4 PDH). In Principles of Evaporative Cooling System; PDH Center: Fairfax, VA, USA, 2012; pp. 1–56. [Google Scholar]

- Dzivama, A.U.; Bindir UB Aboaba, F.O. Evaluation of pad materials in construction of active evaporative cooler for storage of fruits and vegetables in arid environments. Agric. Mech. Asia Afr. Lat. Am. AMA 1999, 30, 51–55. [Google Scholar]

- Chopra, M.K.; Kumar, R. Design of New Evaporative Cooler and Usage of Different Cooling Pad Materials for Improved Cooling Efficiency. Int. Res. J. Eng. Technol. IRJET 2017, 4, 503–511. [Google Scholar]

- Kapilan, N.; Isloor, A.M.; Karinka, S. A comprehensive review on evaporative cooling systems. Results Eng. 2023, 18, 101059. [Google Scholar] [CrossRef]

- Awafoa, E.A.; Nketsiah, S.; Alhassan, M.; Appiah, E. Design, construction, and performance evaluation of an evaporative cooling system for tomatoes storage. Agric. Eng. 2020, 24, 1–12. [Google Scholar]

- Akram, W.; Badholiya, S.K. Performance Analysis of Direct Evaporative Coolers Using Various Cooling Pad Materials: A Comparative Study. Int. J. Res. Publ. Rev. 2024, 5, 5947–5954. [Google Scholar]

- Watson, J.A.; Gomez, C.; Bucklin, R.A.; Leary, J.D.; McConnell, D.B. Fan and Pad Greenhouse Evaporative Cooling Systems. Available online: https://edis.ifas.ufl.edu/publication/AE069 (accessed on 3 April 2025).

- Ferdous, A.; Ahmad, S.; Asif, K.; Gowtam, M.; Nazmul, A.; Rahman, D. An Experimental Study on the Design, Performance and Suitability of Evaporative Cooling System using Different Indigenous Materials. AIP Conf. Proc. 2017, 1851, 020075. [Google Scholar] [CrossRef]

- Jain, J.K.; Hindoliya, D.A. Development and Testing of Regenerative Evaporative Cooler. Int. J. Eng. Trends Technol. 2012, 3, 694–697. [Google Scholar]

- Tinoco, I.D.; Figueiredo, J.L.; Santos, R.C.; da Silva, J.N.; Yanagi, T.; de Paula, M.O.; Corderio, M.B. Comparison of the cooling effect of different materials used in evaporative pads. J. Mod. Manuf. Syst. Technol. 2001, 1, 61–68. [Google Scholar] [CrossRef]

- Liao, C.M.; Chiu, K.H. Wind tunnel modeling the system performance of alternative evaporative cooling pads in Taiwan region. Build. Environ. 2002, 37, 177–187. [Google Scholar] [CrossRef]

- Al-Sulaiman, F. Evaluation of the performance of local fibers in evaporative cooling. Energy Convers. Manag. 2002, 43, 2267–2273. [Google Scholar] [CrossRef]

- Kapish, T.D.; Dharme, M.R.; Gawande, K.R. An Experimental Analysis of Direct Evaporative Cooler by Varying materials of Cooling Pad. Int. J. Mech. Prod. Eng. Res. Dev. IJMPERD 2017, 7, 585–590. [Google Scholar]

- Tejero-González, A.; Franco-Salas, A. Optimal operation of evaporative cooling pads: A review. Renew. Sustain. Energy Rev. 2021, 151, 111632. [Google Scholar] [CrossRef]

- Lefers, R.; Davies, P.A.; Almadhoun, N. Proof of Concept: Pozzolan Bricks for Saline Water Evaporative Cooling in Controlled Environment Agriculture. Appl. Eng. Agric. 2018, 34, 929–937. [Google Scholar] [CrossRef]

- Beyene, A.; Merka, H.; Tsige, D. Suitability analysis of vertically installed scoria gravel drains for enhancing consolidation performance of clayey ground. Results Eng. 2023, 17, 100975. [Google Scholar] [CrossRef]

- Fares, G.; Alhozaimy, A.; Al-Negheimish, A.; Alawad, O.A. Characterization of scoria rock from Arabian lava fields as natural pozzolan for use in concrete, European. J. Environ. Civ. Eng. 2022, 26, 39–57. [Google Scholar]

- Aldossari, M.S.; Fares, G.; Ghrefat, H.A. Estimation of pozzolanic activity of scoria rocks using ASTER remote sensing. J. Mater. Civ. Eng. 2019, 31, 04019100. [Google Scholar] [CrossRef]

- Arunkumar, H.S.; Madhwesh, N.; Shenoy, S.; Kumar, S. Performance evaluation of an indirect-direct evaporative cooler using biomass-based packing material. Int. J. Sustain. Eng. 2024, 17, 469–480. [Google Scholar] [CrossRef]

- Steel, R.G.D.; Torrie, J.H. Principles and Procedures of Statistics: A Biometrical Approach, 2nd ed.; McGraw Hill: New York, NY, USA, 1980. [Google Scholar]

- Wiersma, F.; Benham, D.S. Design Criteria for Evaporative Cooling; ASAE Paper No. 74-4527; ASAE: St. Joseph, MI, USA, 1974. [Google Scholar]

- Watt, J.R. Investigation Evaporative Cooling; Report U.S. Naval Civil Engineering Research and Evaluation Laboratory: Port Hueneme, CA, USA, 1953. [Google Scholar]

- He, S.; Guan, Z.; Gurgenci, H.; Hooman, K.; Alkhedhair, A.M. Experimental study of heat transfer coefficient and pressure drop of cellulose corrugated media. In Proceedings of the 19th Australasian Fluid Mechanics Conference, Melbourne, Australia, 8–11 December 2014; pp. 8–11. [Google Scholar]

- Jawad, S.K.; Muhammad, I.S. A study of the effect of changing some factors affecting the thermal performance of an evaporative air cooler. Iraqi J. Mech. Eng. Mater. 2009, 9, 249–264. [Google Scholar]

- Gunhan, T.; Demir, V.; Yagcioglu, A. Evaluation of the suitability of some local materials as cooling pads. Biosyst. Eng. 2007, 96, 369–377. [Google Scholar]

- Al-Badri, A.R.; Al-Waaly, A.A. The influence of chilled water on the performance of direct evaporative cooling. J. Energy Build. 2017, 155, 143–150. [Google Scholar]

- Ghoname, M.S. Effect of pad water flow rate on evaporative cooling system efficiency in laying hen housing. J. Agric. Eng. 2020, 1051, 209–219. [Google Scholar] [CrossRef]

- Yan, M.; He, S.; Li, N.; Huang, X.; Gao, M.; Xu, M. Experimental investigation on a novel arrangement of wet medium for evaporative cooling of air. Int. J. Refrig. 2020, 124, 64–74. [Google Scholar] [CrossRef]

- Al-Helal; Al-Tuwaijri. Evaporative Cooling Efficiency of Palm Leaf Pads and Paper Pads with Cross Grooves under Dry Climate Conditions. Egypt. J. Agric. Eng. 2001, 18, 469–483. [Google Scholar]

- Franco, A.; Valera, D.L.; Peña, A. Energy Efficiency in Greenhouse Evaporative Cooling Techniques: Cooling Boxes versus Cellulose Pads. Energies 2014, 7, 1427–1447. [Google Scholar] [CrossRef]

- Sattar, A.; Salem, S.; Al-Badri, S.B. Rationalization of water consumption for evaporative cooling pads. Iraqi J. Agric. Sci. 2012, 43, 78–82. [Google Scholar]

- Al-Helal, M. A Pilot-Scale Study for Evaluating the Performance of a Fan-Pad Cooling System under Different Climatic Conditions of Saudi Arabia. Misr J. Ag. Eng. 2009, 26, 514–533. [Google Scholar]

- Dağtekin, M.; Karaca, C.; Yıldız, Y.; Başçetinçelik, A.; Paydak, Ö. The effects of air velocity on the performance of pad evaporative cooling systems. Afr. J. Agric. Res. 2011, 6, 1813–1822. [Google Scholar]

- Franco, A.; Valera, D.L.; Madueno, A.; Peña, A. Influence of water and air flow on the performance of cellulose evaporative cooling pads used in Mediterranean greenhouses. Trans. ASABE 2010, 53, 565–576. [Google Scholar] [CrossRef]

- Dhamneya, A.K.; Rajput, S.P.S.; Singh, A. Experimental Performance Analysis of Alternative Cooling Pad Made by Agricultural Waste for Direct Evaporative Cooling System. Int. J. Mech. Eng. Technol. 2017, 8, 7. [Google Scholar]

- Laknizi, A.; Ben Abdellah, A.; Mahdaoui, M.; Anoune, K. Application of Taguchi and ANOVA methods in the optimization of a direct evaporative cooling pad. Int. J. Sustain. Eng. 2021, 14, 1218–1228. [Google Scholar] [CrossRef]

- Elmsaad, E.; Emam, A.; Omran, A. Effect of Utilization of Different Materials and Thicknesses Evaporative Cooling Pad on Cooling Efficiency in Greenhouses in Hot-Arid Regions. Egypt. J. Agron. 2023, 45, 171–187. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).