An Investigative Study on Mixed Waste Feedstock-Derived Biochar as Active Electrode Material for Supercapacitor Applications

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

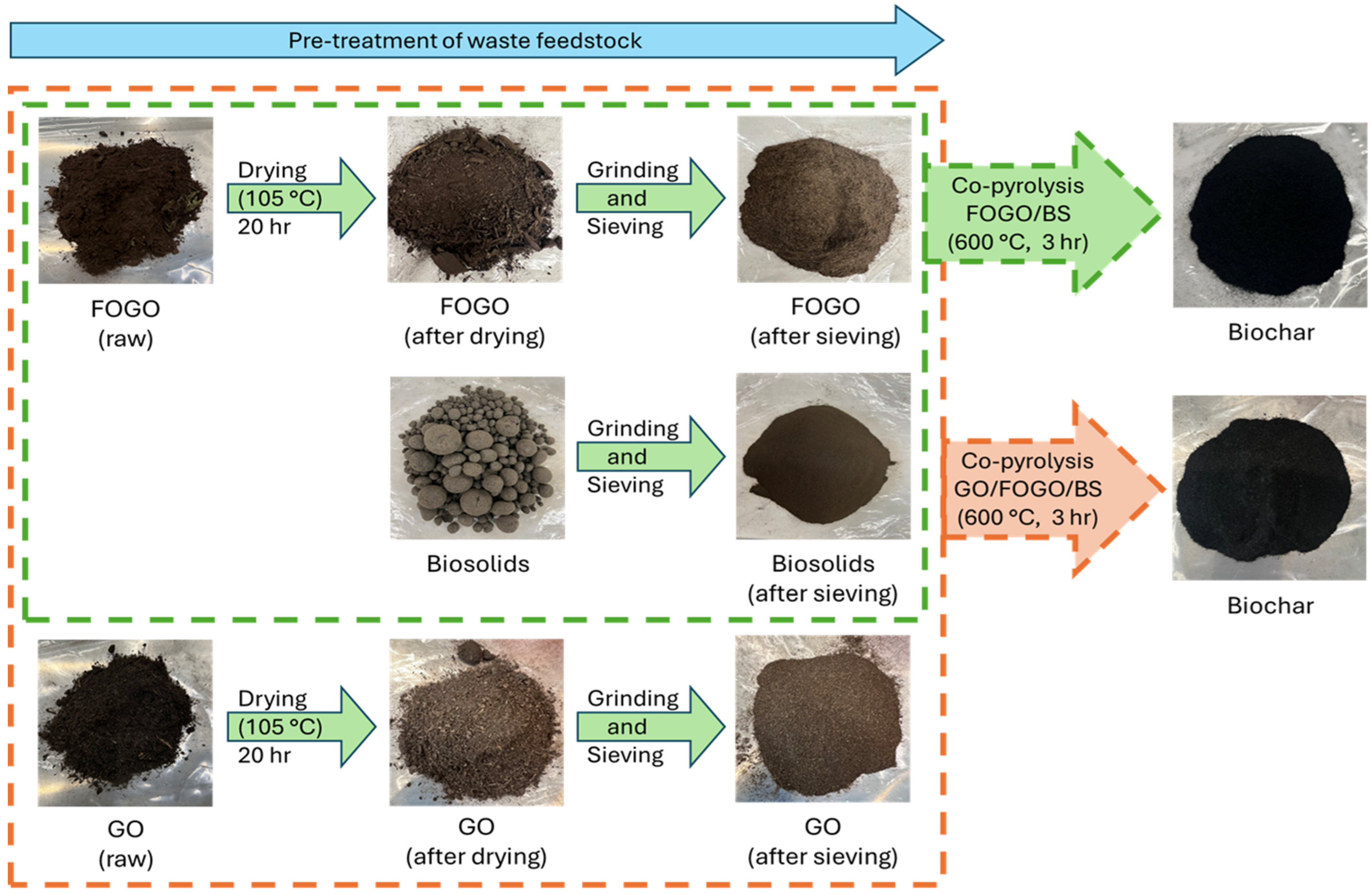

2.2. Biochar Production

2.3. Characterisation of Biochar

2.4. Supercapacitor Fabrication and Testing

3. Results and Discussion

3.1. Proximate and Ultimate Analysis of Feedstock and Biochar Samples

3.2. FTIR of Biochar Samples

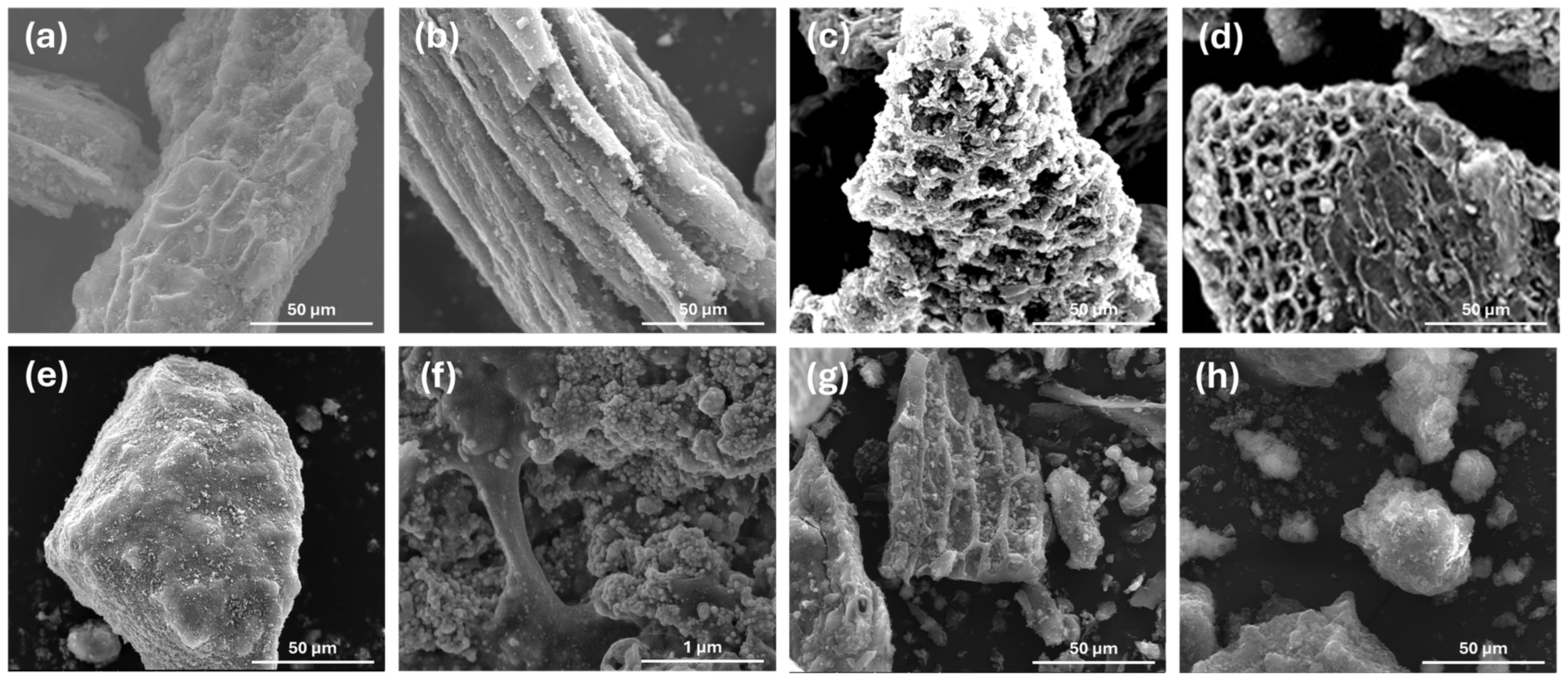

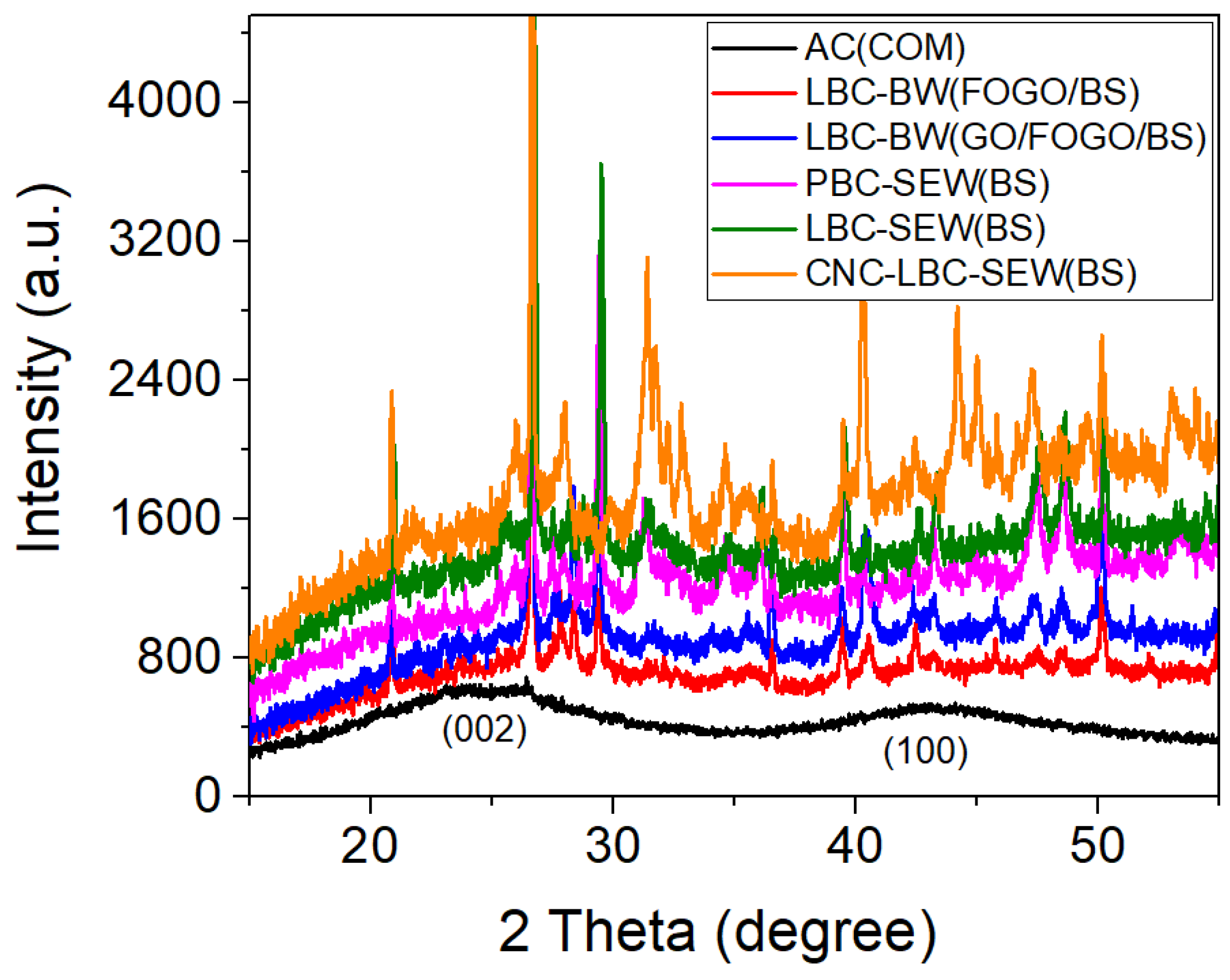

3.3. SEM and XRD Analysis of Biochar Samples

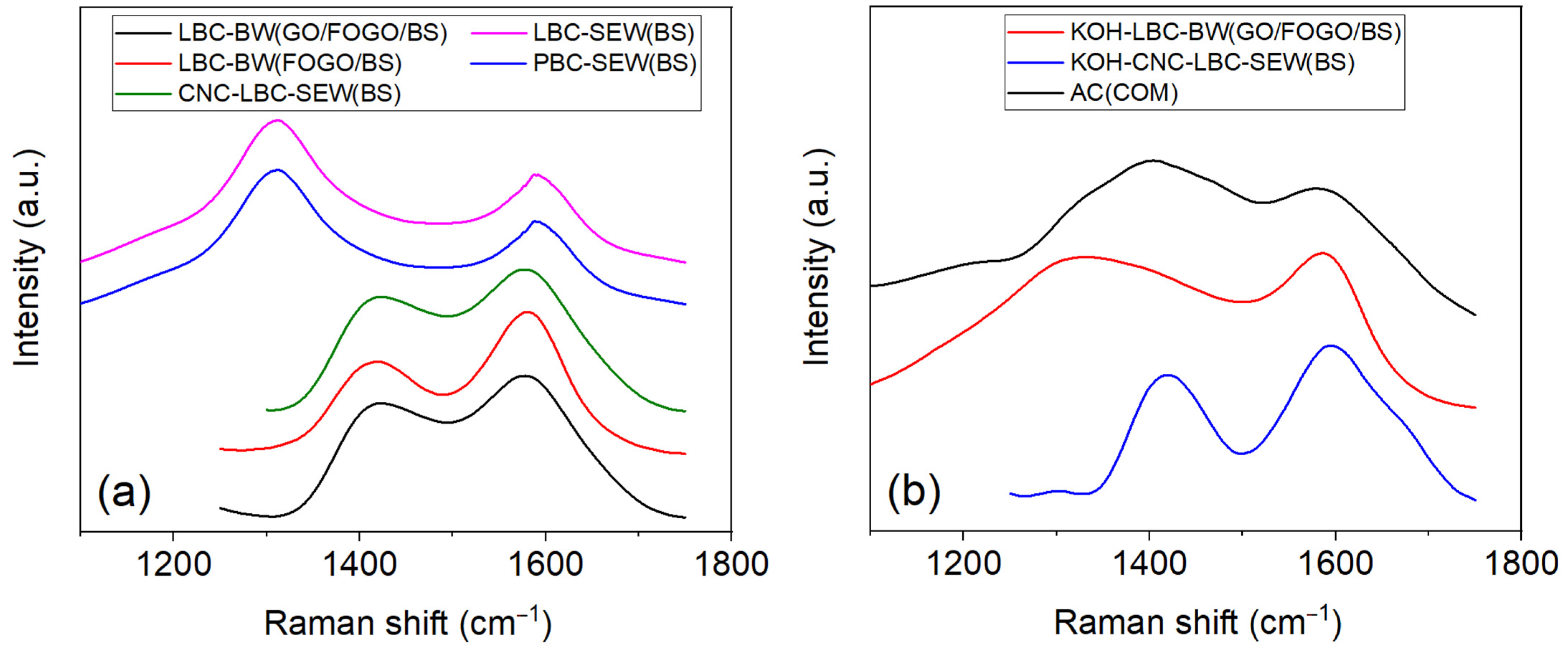

3.4. Raman and BET Analysis of Biochar Samples

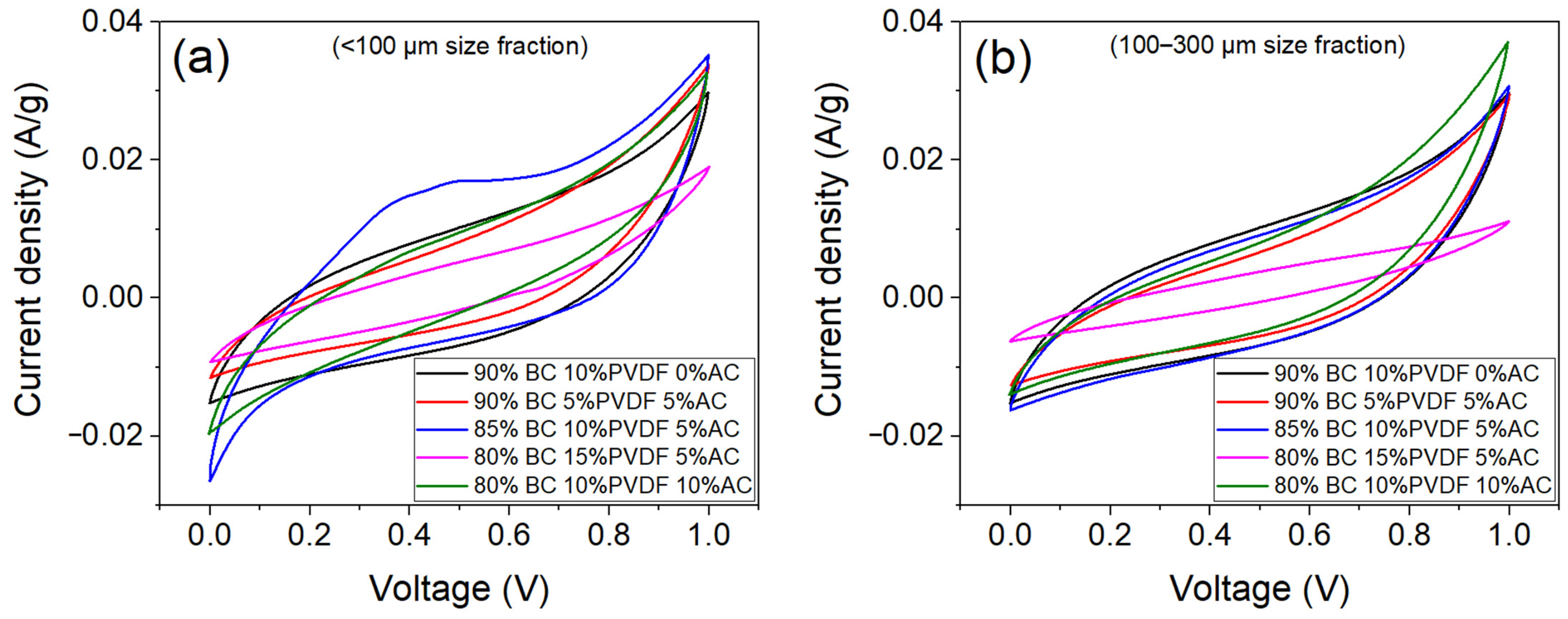

3.5. Optimisation of Biochar Ink and Electrode Composition

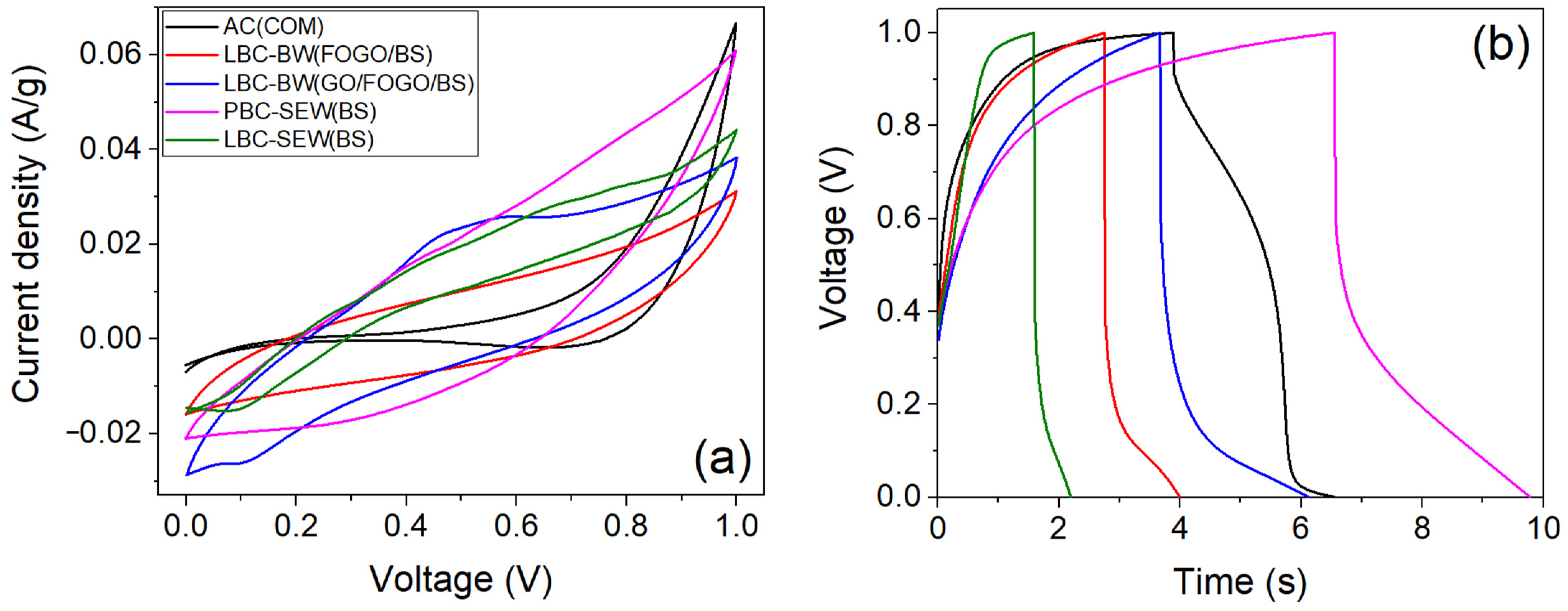

3.6. Supercapacitor Performance of As-Prepared Biochars

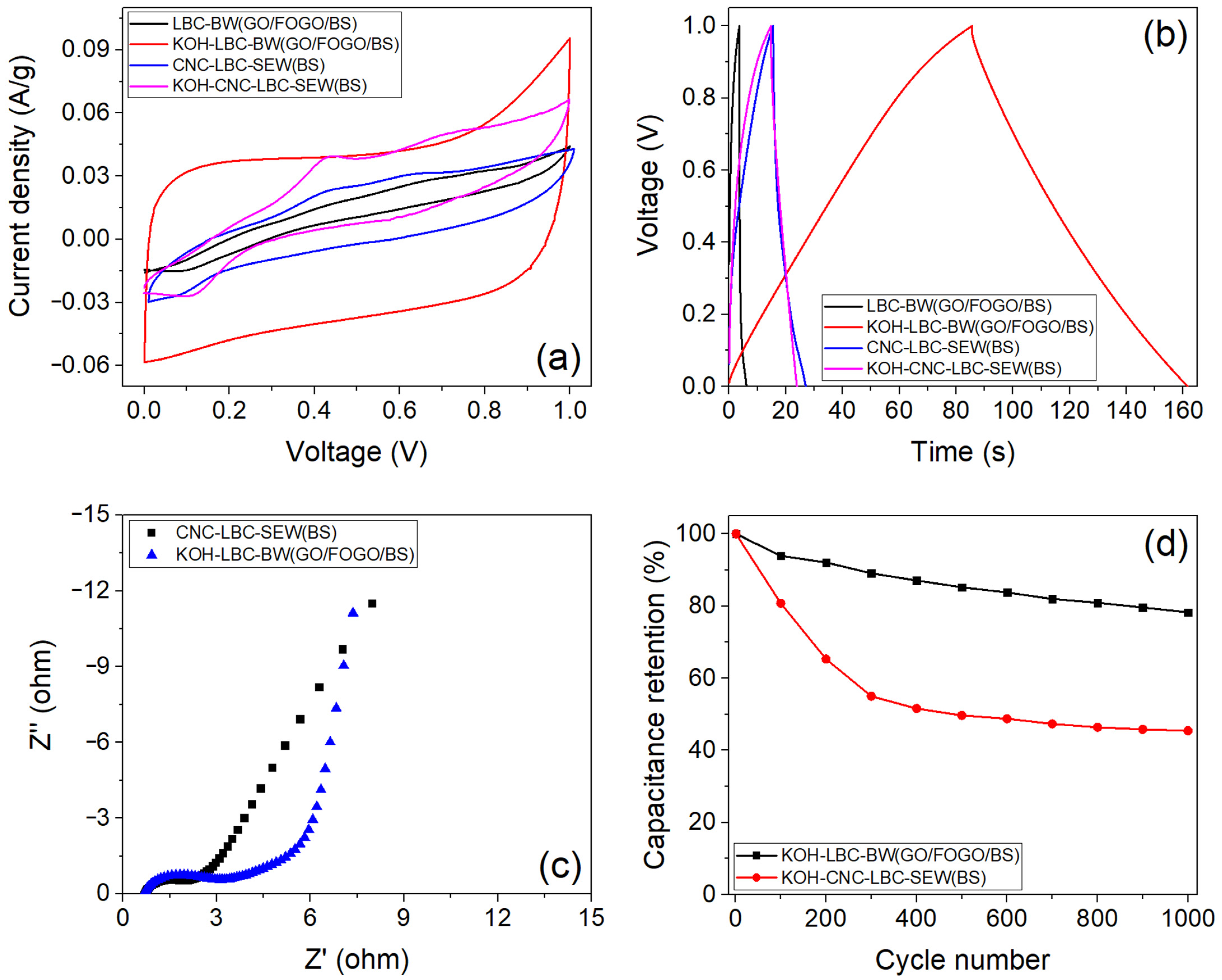

3.7. Effect of Different Treatment Methods on Biochar Supercapacitor Performance

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Rawat, S.; Boobalan, T.; Krishna, B.B.; Sathish, M.; Hotha, S.; Bhaskar, T. Biochar for Supercapacitor Application: A Comparative Study. Chem. Asian J. 2022, 17, e202200982. [Google Scholar] [CrossRef] [PubMed]

- Dunn, B.; Kamath, H.; Tarascon, J.-M. Electrical Energy Storage for the Grid: A Battery of Choices. Science 2011, 334, 928–935. [Google Scholar] [CrossRef]

- Baruch-Mordo, S.; Kiesecker, J.M.; Kennedy, C.M.; Oakleaf, J.R.; Opperman, J.J. From Paris to practice: Sustainable implementation of renewable energy goals. Environ. Res. Lett. 2019, 14, 024013. [Google Scholar] [CrossRef]

- Rawat, S.; Wang, C.-T.; Lay, C.-H.; Hotha, S.; Bhaskar, T. Sustainable biochar for advanced electrochemical/energy storage applications. J. Energy Storage 2023, 63, 107115. [Google Scholar] [CrossRef]

- Yaseen, M.; Khattak, M.A.; Humayun, M.; Usman, M.; Shah, S.S.; Bibi, S.; Hasnain, B.S.; Ahmad, S.M.; Khan, A.; Shah, N.; et al. A Review of Supercapacitors: Materials Design, Modification, and Applications. Energies 2021, 14, 7779. [Google Scholar] [CrossRef]

- Elmorshedy, M.F.; Elkadeem, M.; Kotb, K.M.; Taha, I.B.; Mazzeo, D. Optimal design and energy management of an isolated fully renewable energy system integrating batteries and supercapacitors. Energy Convers. Manag. 2021, 245, 114584. [Google Scholar] [CrossRef]

- Hsiao, C.-H.; Gupta, S.; Lee, C.-Y.; Tai, N.-H. Effects of physical and chemical activations on the performance of biochar applied in supercapacitors. Appl. Surf. Sci. 2023, 610, 155560. [Google Scholar] [CrossRef]

- Hsieh, C.-E.; Chang, C.; Gupta, S.; Hsiao, C.-H.; Lee, C.-Y.; Tai, N.-H. Binder-free CoMn2O4/carbon nanotubes composite electrodes for high-performance asymmetric supercapacitor. J. Alloys Compd. 2022, 897, 163231. [Google Scholar] [CrossRef]

- Lai, Y.-H.; Gupta, S.; Hsiao, C.-H.; Lee, C.-Y.; Tai, N.-H. Multilayered nickel oxide/carbon nanotube composite paper electrodes for asymmetric supercapacitors. Electrochim. Acta 2020, 354, 136744. [Google Scholar]

- Chen, Y.; Li, S.; Chen, J.; Gao, L.; Guo, P.; Wei, C.; Fu, J.; Xu, Q. Sulfur-bridged bonds enabled structure modulation and space confinement of MnS for superior sodium-ion capacitors. J. Colloid Interface Sci. 2024, 664, 360–370. [Google Scholar] [CrossRef]

- Ma, J.; Qin, J.; Zheng, S.; Fu, Y.; Chi, L.; Li, Y.; Dong, C.; Li, B.; Xing, F.; Shi, H.; et al. Hierarchically Structured Nb2O5 Microflowers with Enhanced Capacity and Fast-Charging Capability for Flexible Planar Sodium Ion Micro-Supercapacitors. Nano-Micro Lett. 2024, 16, 67. [Google Scholar] [CrossRef]

- Tan, K.M.; Babu, T.S.; Ramachandaramurthy, V.K.; Kasinathan, P.; Solanki, S.G.; Raveendran, S.K. Empowering smart grid: A comprehensive review of energy storage technology and application with renewable energy integration. J. Energy Storage 2021, 39, 102591. [Google Scholar] [CrossRef]

- Senthil, C.; Lee, C.W. Biomass-derived biochar materials as sustainable energy sources for electrochemical energy storage devices. Renew. Sustain. Energy Rev. 2021, 137, 110464. [Google Scholar] [CrossRef]

- Yaashikaa, P.R.; Kumar, P.S.; Varjani, S.; Saravanan, A. A critical review on the biochar production techniques, characterization, stability and applications for circular bioeconomy. Biotechnol. Rep. 2020, 28, e00570. [Google Scholar] [CrossRef]

- Vuppaladadiyam, A.K.; Vuppaladadiyam, V.S.S.; Antunes, E.; Baig, Z.; Rehman, S.; Murugavelh, S.; Leu, S.Y.; Sarmah, A.K. Pyrolysis of anaerobic digested residues in the presence of catalyst-sorbent bifunctional material: Pyrolysis characteristics, kinetics and evolved gas analysis. Bioresour. Technol. 2022, 351, 127022. [Google Scholar] [CrossRef]

- Meng, F.; Wang, D.; Zhang, M. Effects of different pretreatment methods on biochar properties from pyrolysis of corn stover. J. Energy Inst. 2021, 98, 294–302. [Google Scholar] [CrossRef]

- Prabakar, P.; Mustafa Mert, K.; Muruganandam, L.; Sivagami, K. A comprehensive review on biochar for electrochemical energy storage applications: An emerging sustainable technology. Front. Energy Res. 2024, 12, 1448520. [Google Scholar]

- Gao, Y.; Sun, R.; Li, A.; Ji, G. In-situ self-activation strategy toward highly porous biochar for supercapacitors: Direct carbonization of marine algae. J. Electroanal. Chem. 2021, 882, 114986. [Google Scholar]

- Makinde, W.O.; Hassan, M.A.; Pan, Y.; Guan, G.; López-Salas, N.; Khalil, A.S. Sulfur and nitrogen co-doping of peanut shell-derived biochar for sustainable supercapacitor applications. J. Alloys Compd. 2024, 991, 174452. [Google Scholar]

- Xiaorui, L.; Haiping, Y. A state-of-the-art review of N self-doped biochar development in supercapacitor applications. Front. Energy Res. 2023, 11, 1135093. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, Y.; Pei, L.; Ying, D.; Xu, X.; Zhao, L.; Jia, J.; Cao, X. Converting Ni-loaded biochars into supercapacitors: Implication on the reuse of exhausted carbonaceous sorbents. Sci. Rep. 2017, 7, 41523. [Google Scholar] [CrossRef]

- Zhang, J.-J.; Fan, H.-X.; Dai, X.-H.; Yuan, S.-J. Digested sludge-derived three-dimensional hierarchical porous carbon for high-performance supercapacitor electrode. R. Soc. Open Sci. 2018, 5, 172456. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.R.; Lee, D.Y.; Lee, J.H.; Lee, S.K.; Chun, Y.; Yoo, H.Y.; Lee, H.U.; Kwak, H.S.; Park, C.; Lee, J.H.; et al. High potential of microalgal sludge biochar for a flexible all-solid-state microsupercapacitor. J. Energy Storage 2021, 44, 103458. [Google Scholar] [CrossRef]

- Piwek, J.; Slesinski, A.; Fic, K.; Aina, S.; Vizintin, A.; Tratnik, B.; Tchernychova, E.; Lobera, M.P.; Bernechea, M.; Dominko, R. High frequency response of adenine-derived carbon in aqueous electrochemical capacitor. Electrochim. Acta 2022, 424, 140649. [Google Scholar]

- Li, X.; Hao, T.; Tang, Y.; Chen, G. A “Seawater-in-Sludge” approach for capacitive biochar production via the alkaline and alkaline earth metals activation. Front. Environ. Sci. Eng. 2020, 15, 3. [Google Scholar] [CrossRef]

- Zhang, D.; Hou, R.; Wang, W.; Zhao, H. Recovery and reuse of floc sludge for high-performance capacitors. Front. Environ. Sci. Eng. 2021, 16, 78. [Google Scholar] [CrossRef]

- Ismail, I.S.; Othman, M.F.H.; Rashidi, N.A.; Yusup, S. Recent progress on production technologies of food waste–based biochar and its fabrication method as electrode materials in energy storage application. Biomass Convers. Biorefinery 2023, 13, 14341–14357. [Google Scholar] [CrossRef]

- Khedulkar, A.P.; Pandit, B.; Dang, V.D.; Doong, R.-A. Agricultural waste to real worth biochar as a sustainable material for supercapacitor. Sci. Total Environ. 2023, 869, 161441. [Google Scholar] [CrossRef]

- Kwarciany, R.; Fiedur, M.; Saletnik, B. Opportunities and Threats for Supercapacitor Technology Based on Biochar—A Review. Energies 2024, 17, 4617. [Google Scholar] [CrossRef]

- Shah, K. A Pyrolysis Reaction System and Method of Pyrolysing an Organic Feed. Australia. 2019. Available online: https://patentscope.wipo.int/search/en/WO2019227162 (accessed on 15 January 2025).

- Kim, T.; Jung, G.; Yoo, S.; Suh, K.S.; Ruoff, R.S. Activated Graphene-Based Carbons as Supercapacitor Electrodes with Macro- and Mesopores. ACS Nano 2013, 7, 6899–6905. [Google Scholar] [CrossRef]

- Husain, Z.; Shakeelur Raheman, A.R.; Ansari, K.B.; Pandit, A.B.; Khan, M.S.; Qyyum, M.A.; Lam, S.S. Nano-sized mesoporous biochar derived from biomass pyrolysis as electrochemical energy storage supercapacitor. Mater. Sci. Energy Technol. 2022, 5, 99–109. [Google Scholar] [CrossRef]

- Tsai, W.-T.; Liu, S.-C.; Chen, H.-R.; Chang, Y.-M.; Tsai, Y.-L. Textural and chemical properties of swine-manure-derived biochar pertinent to its potential use as a soil amendment. Chemosphere 2012, 89, 198–203. [Google Scholar] [CrossRef]

- Mujtaba, G.; Hayat, R.; Hussain, Q.; Ahmed, M. Physio-Chemical Characterization of Biochar, Compost and Co-Composted Biochar Derived from Green Waste. Sustainability 2021, 13, 4628. [Google Scholar] [CrossRef]

- Boakye, P.; Nuagah, M.B.; Oduro-Kwarteng, S.; Appiah-Effah, E.; Kanjua, J.; Antwi, A.B.; Darkwah, L.; Sarkodie, K.; Sokama-Neuyam, Y.A. Pyrolysis of municipal food waste: A sustainable potential approach for solid food waste management and organic crop fertilizer production. Sustain. Environ. 2023, 9, 2260057. [Google Scholar] [CrossRef]

- Li, Z.; Deng, L.; Kinloch, I.A.; Young, R.J. Raman spectroscopy of carbon materials and their composites: Graphene, nanotubes and fibres. Prog. Mater. Sci. 2023, 135, 101089. [Google Scholar] [CrossRef]

- Maliutina, K.; Tahmasebi, A.; Yu, J. Effects of pressure on morphology and structure of bio-char from pressurized entrained-flow pyrolysis of microalgae. Data Brief 2018, 18, 422–431. [Google Scholar] [CrossRef]

- Yin, Y.; Yin, J.; Zhang, W.; Tian, H.; Hu, Z.; Ruan, M.; Song, Z.; Liu, L. Effect of Char Structure Evolution During Pyrolysis on Combustion Characteristics and Kinetics of Waste Biomass. J. Energy Resour. Technol. 2018, 140, 072203. [Google Scholar] [CrossRef]

- Pariyar, P.; Kumari, K.; Jain, M.K.; Jadhao, P.S. Evaluation of change in biochar properties derived from different feedstock and pyrolysis temperature for environmental and agricultural application. Sci. Total Environ. 2020, 713, 136433. [Google Scholar] [CrossRef]

- Daraghmeh, A.; Hussain, S.; Servera, L.; Xuriguera, E.; Cornet, A.; Cirera, A. Impact of binder concentration and pressure on performance of symmetric CNFs based supercapacitors. Electrochim. Acta 2017, 245, 531–538. [Google Scholar] [CrossRef]

- Jiang, J. High Temperature Monolithic Biochar Supercapacitor Using Ionic Liquid Electrolyte. J. Electrochem. Soc. 2017, 164, H5043. [Google Scholar] [CrossRef]

- Hussain, I.; Arifeen, W.U.; Khan, S.A.; Aftab, S.; Javed, M.S.; Hussain, S.; Ahmad, M.; Chen, X.; Zhao, J.; Rosaiah, P.; et al. M4X3 MXenes: Application in Energy Storage Devices. Nano-Micro Lett. 2024, 16, 215. [Google Scholar] [CrossRef]

- Tran, T.S.; Balu, R.; Mata, J.; Dutta, N.K.; Choudhury, N.R. 3D printed graphene aerogels using conductive nanofibrillar network formulation. Nano Trends 2023, 2, 100011. [Google Scholar] [CrossRef]

- Younis, A.; Chu, D.; Li, S. Ethanol-directed morphological evolution of hierarchical CeOx architectures as advanced electrochemical capacitors. J. Mater. Chem. A 2015, 3, 13970–13977. [Google Scholar] [CrossRef]

- Chen, N.; Younis, A.; Huang, S.; Chu, D.; Li, S. Advanced three-dimensional hierarchical Pr6O11@Ni-Co oxides-based core-shell electrodes for supercapacitance application. J. Alloys Compd. 2019, 783, 772–778. [Google Scholar] [CrossRef]

- Lü, F.; Lu, X.; Li, S.; Zhang, H.; Shao, L.; He, P. Dozens-fold improvement of biochar redox properties by KOH activation. Chem. Eng. J. 2022, 429, 132203. [Google Scholar] [CrossRef]

- Mei, B.-A.; Munteshari, O.; Lau, J.; Dunn, B.; Pilon, L. Physical Interpretations of Nyquist Plots for EDLC Electrodes and Devices. J. Phys. Chem. C 2018, 122, 194–206. [Google Scholar] [CrossRef]

- Chen, Z.; Zhang, Q.; Liang, Q. Carbon-Coatings Improve Performance of Li-Ion Battery. Nanomaterials 2022, 12, 1936. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Li, X.; Jin, B.; Tang, H.; Ma, L.; Zhang, R.; Ran, J.; Zhang, H. Optimizing porous structure of carbon electrodes for temperature-independent capacitance at sub-zero temperatures. Chem. Eng. J. 2022, 441, 136053. [Google Scholar] [CrossRef]

- Olawade, D.B.; Fapohunda, O.; Wada, O.Z.; Usman, S.O.; Ige, A.O.; Ajisafe, O.; Oladapo, B.I. Smart waste management: A paradigm shift enabled by artificial intelligence. Waste Manag. Bull. 2024, 2, 244–263. [Google Scholar] [CrossRef]

| Sample Code | Description |

|---|---|

| BSs-BW | Biosolids obtained from Barwon Water |

| BSs-SEW | Biosolids obtained from South East Water |

| FOGOs-BW | Food organics and garden organics obtained from Geelong City Council supplied by Barwon Water |

| GOs-BW | Garden organics obtained from Barwon Water |

| Sample Code | Description |

|---|---|

| LBC-BW(GOs/FOGOs/BSs) | Lab biochar: produced via pyrolysis of a waste mixture of 70% GOs, 20% FOGOs and 10% BSs obtained from Barwon Water. |

| LBC-BW(FOGOs/BSs) | Lab biochar: produced via pyrolysis of a waste mixture of 80% FOGOs and 20% BSs obtained from Barwon Water. |

| LBC-SEW(BSs) | Lab biochar: produced via pyrolysis of BS waste obtained from the South East Water. |

| PBC-SEW(BSs) | Pilot plant biochar: produced via pyrolysis of BS waste obtained from the South East Water. |

| CNC-LBC-SEW(BSs) | Carbon nanomaterial coated lab biochar: produced via pyrolysis of BS waste obtained from the South East Water. |

| KOH-LBC-BW(GOs/FOGOs/BSs) | KOH-activated lab biochar: produced via pyrolysis of LBC-BW(GOs/FOGOs/BSs) biochar and KOH mixture. |

| KOH-CNC-LBC-SEW(BSs) | KOH-activated lab biochar: produced via pyrolysis of CNC-LBC-SEW(BSs) biochar and KOH mixture. |

| AC(COM) | Activated carbon powder purchased from ChemSupply. |

| Proximate Analysis (wt. %) | Ultimate Analysis (wt.%) | |||||||

|---|---|---|---|---|---|---|---|---|

| Moisture | Ash | Volatile Matter | Fixed Carbon | C | H | N | S | |

| Feedstock | ||||||||

| FOGOs-BW | 3.8 | 27.3 | 53.0 | 12.6 | 39.0 | 4.4 | 1.3 | 0.1 |

| GOs-BW | 2.3 | 22.0 | 60.1 | 14.0 | 23.1 | 2.9 | 3.6 | 0.2 |

| BSs-SEW | 2.4 | 23.0 | 61.2 | 13.1 | 27.5 | 4.4 | 4.3 | 0.6 |

| BSs-BW | 2.9 | 21.3 | 62.8 | 12.2 | 41.5 | 6.2 | 7.1 | 0.2 |

| Biochar | ||||||||

| LBC-BW(GOs/ FOGOs/BSs) | 1.1 | 79.5 | 5.1 | 14.3 | 32.3 | 1.1 | 1.9 | 0.1 |

| LBC-BW(FOGOs/BSs) | 1.2 | 80.6 | 4.7 | 13.5 | 24.8 | 0.6 | 1.1 | 0.1 |

| PBC-SEW(BSs) | 1.2 | 72.6 | 4.7 | 21.5 | 19.3 | 0.5 | 1.6 | 0.9 |

| LBC-SEW(BSs) | 1.8 | 61.3 | 11.6 | 23.3 | 31.0 | 1.2 | 3.5 | 0.8 |

| CNC-LBC-SEW(BSs) | 1.2 | 72.6 | 4.7 | 21.5 | 36.7 | 0.45 | 1.3 | 0.6 |

| Sample Name | BET | Raman | ||

|---|---|---|---|---|

| Surface Area (m2/g) | Mesopore Volume (cm2/g) | Mesopore Size (nm) | ID/IG Ratio | |

| LBC-BW(GOs/FOGOs/BSs) | 116.2 | 0.039 | 2.32 | 0.81 |

| LBC-BW(FOGOs/BSs) | 67.8 | 0.034 | 3.1 | 0.65 |

| PBC-SEW(BSs) | 132.8 | 0.047 | 8.4 | 1.56 |

| LBC-SEW(BSs) | 4.7 | 0.054 | 45.3 | 1.61 |

| CNC-LBC-SEW(BSs) | 12.5 | 0.004 | 16.9 | 0.81 |

| KOH-LBC-BW(GOs/FOGOs/BSs) | 845.8 | 0.174 | 3.21 | 0.98 |

| KOH-CNC-LBC-SEW(BSs) | 261 | 0.484 | 7.42 | 0.81 |

| AC(COM) | - | - | - | 1.22 |

| Biochar (wt.%) | PVDF (wt.%) | AC(COM) (wt.%) | CS (F/g) | |

|---|---|---|---|---|

| <100 µm | 100–300 µm | |||

| 90 | - | 10 | - | 1.99 |

| - | 90 | 10 | - | 1.35 |

| 90 | - | 5 | 5 | 0.98 |

| - | 90 | 5 | 5 | 0.96 |

| 85 | - | 10 | 5 | 1.72 |

| - | 85 | 10 | 5 | 1.27 |

| 80 | - | 10 | 10 | 1.05 |

| - | 80 | 10 | 10 | 0.98 |

| 80 | - | 15 | 5 | 0.52 |

| - | 80 | 15 | 5 | 0.32 |

| Sample Name | CS (F/g) | E (Wh/kg) | RES (Ω) | P (W/kg) |

|---|---|---|---|---|

| LBC-BW(GOs/FOGOs/BSs) | 0.98 | 0.14 | 76.90 | 44.64 |

| LBC-BW(FOGOs/BSs) | 0.50 | 0.07 | 122.44 | 13.18 |

| PBC-SEW(BSs) | 1.29 | 0.18 | 88.57 | 44.54 |

| LBC-SEW(BSs) | 0.24 | 0.03 | 134.92 | 12.50 |

| CNC-LBC-SEW(BSs) | 4.60 | 0.64 | 18.62 | 591.17 |

| KOH-LBC-BW(GOs/FOGOs/BSs) | 30.33 | 4.21 | 5.18 | 2154.48 |

| KOH-CNC-LBC-SEW(BSs) | 3.64 | 0.51 | 21.27 | 649.62 |

| AC (COM) | 1.06 | 0.15 | 45.99 | 474.19 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pabba, S.; Balu, R.; Vuppaladadiyam, A.K.; Veluswamy, G.; Jena, M.K.; Hakeem, I.G.; Choudhury, N.R.; Sharma, A.; Thomas, M.; Surapaneni, A.; et al. An Investigative Study on Mixed Waste Feedstock-Derived Biochar as Active Electrode Material for Supercapacitor Applications. Energies 2025, 18, 1864. https://doi.org/10.3390/en18071864

Pabba S, Balu R, Vuppaladadiyam AK, Veluswamy G, Jena MK, Hakeem IG, Choudhury NR, Sharma A, Thomas M, Surapaneni A, et al. An Investigative Study on Mixed Waste Feedstock-Derived Biochar as Active Electrode Material for Supercapacitor Applications. Energies. 2025; 18(7):1864. https://doi.org/10.3390/en18071864

Chicago/Turabian StylePabba, Sudhakar, Rajkamal Balu, Arun Krishna Vuppaladadiyam, Ganesh Veluswamy, Manoj Kumar Jena, Ibrahim Gbolahan Hakeem, Namita Roy Choudhury, Abhishek Sharma, Michael Thomas, Aravind Surapaneni, and et al. 2025. "An Investigative Study on Mixed Waste Feedstock-Derived Biochar as Active Electrode Material for Supercapacitor Applications" Energies 18, no. 7: 1864. https://doi.org/10.3390/en18071864

APA StylePabba, S., Balu, R., Vuppaladadiyam, A. K., Veluswamy, G., Jena, M. K., Hakeem, I. G., Choudhury, N. R., Sharma, A., Thomas, M., Surapaneni, A., Patel, S., & Shah, K. (2025). An Investigative Study on Mixed Waste Feedstock-Derived Biochar as Active Electrode Material for Supercapacitor Applications. Energies, 18(7), 1864. https://doi.org/10.3390/en18071864