Piezoelectric Energy Harvesting System to Charge Batteries with the Use of a Portable Musical Organ

Abstract

1. Introduction

2. Materials and Methods

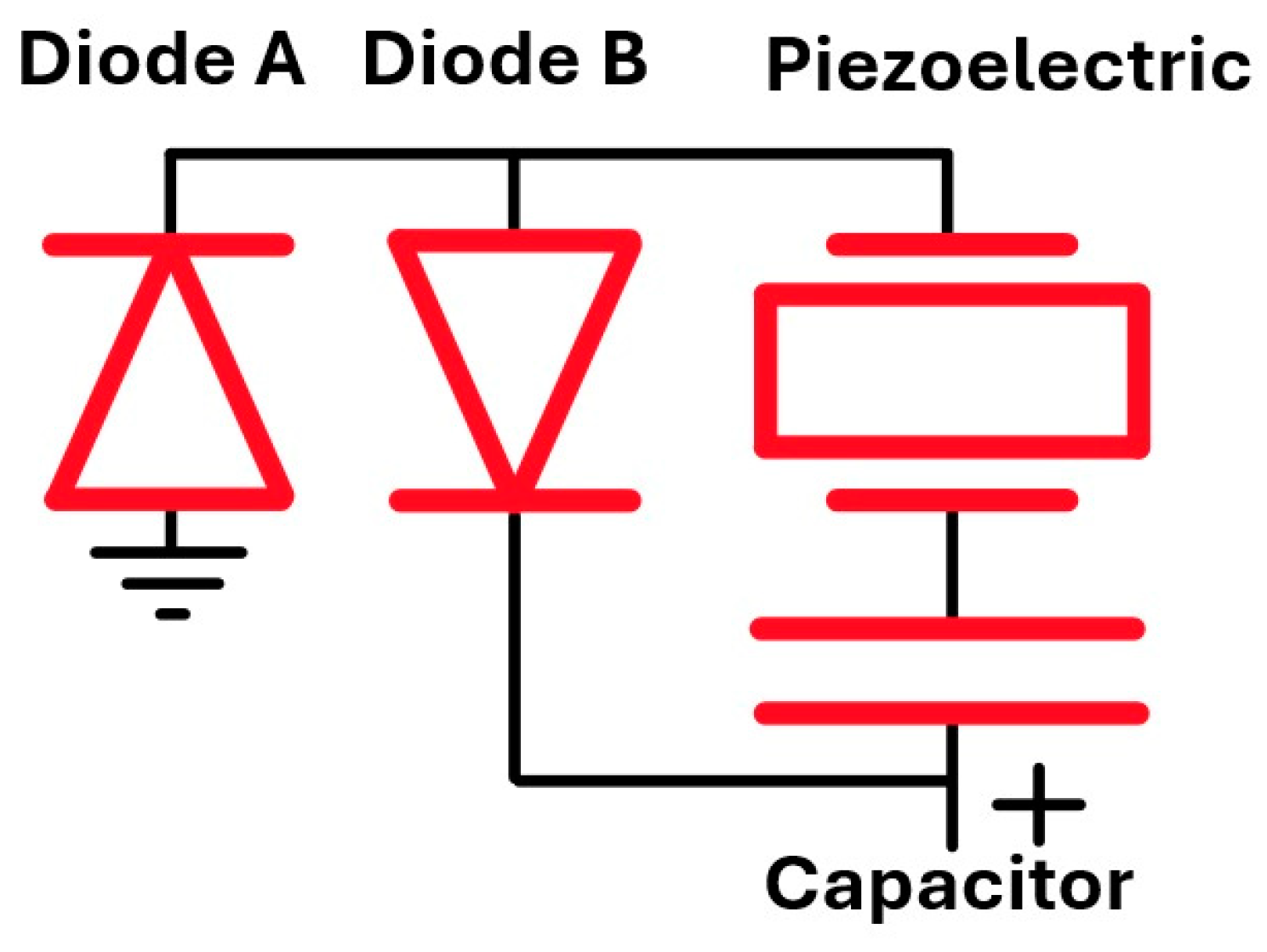

Proposed Electronic Structure

3. Mathematical Model

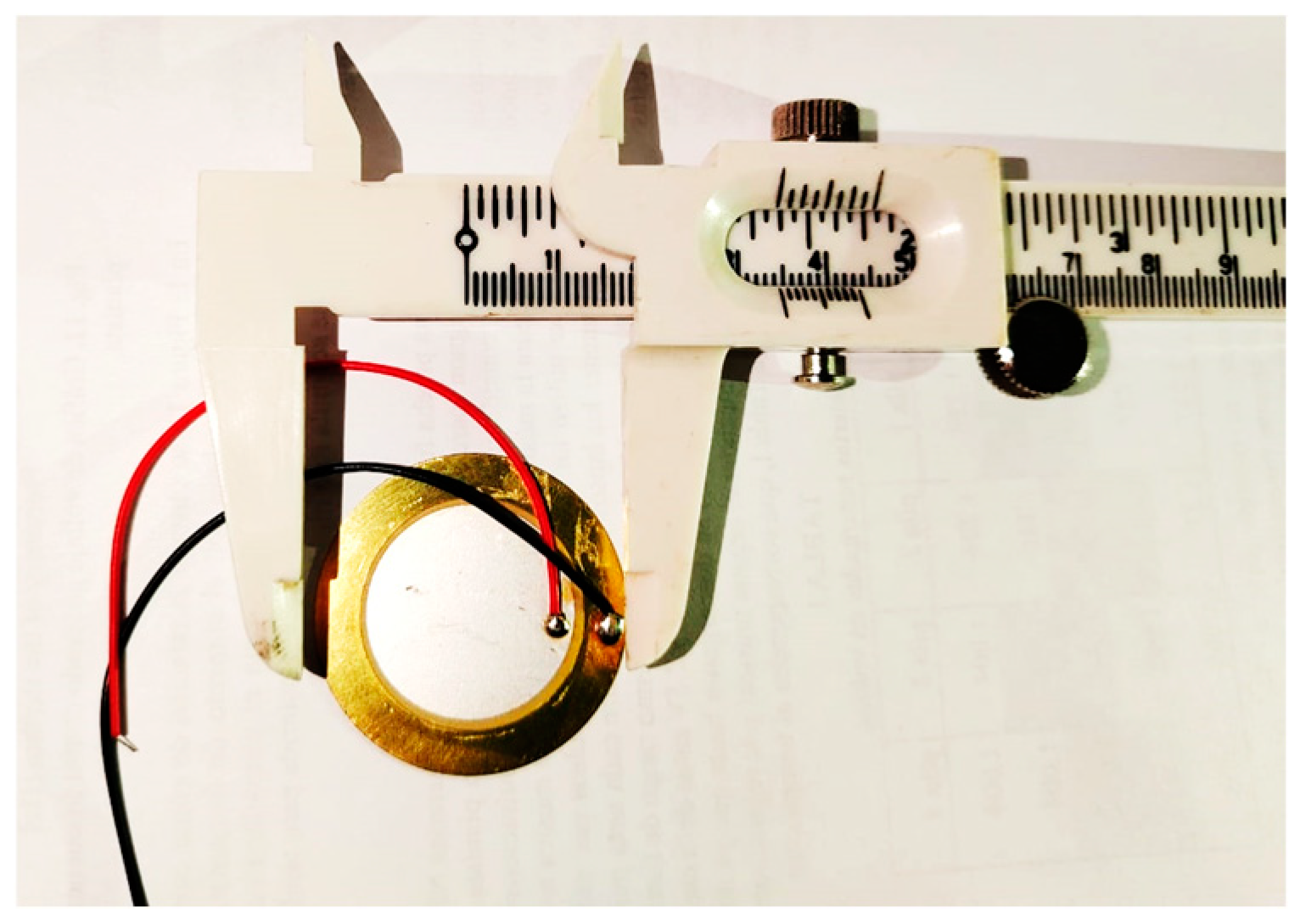

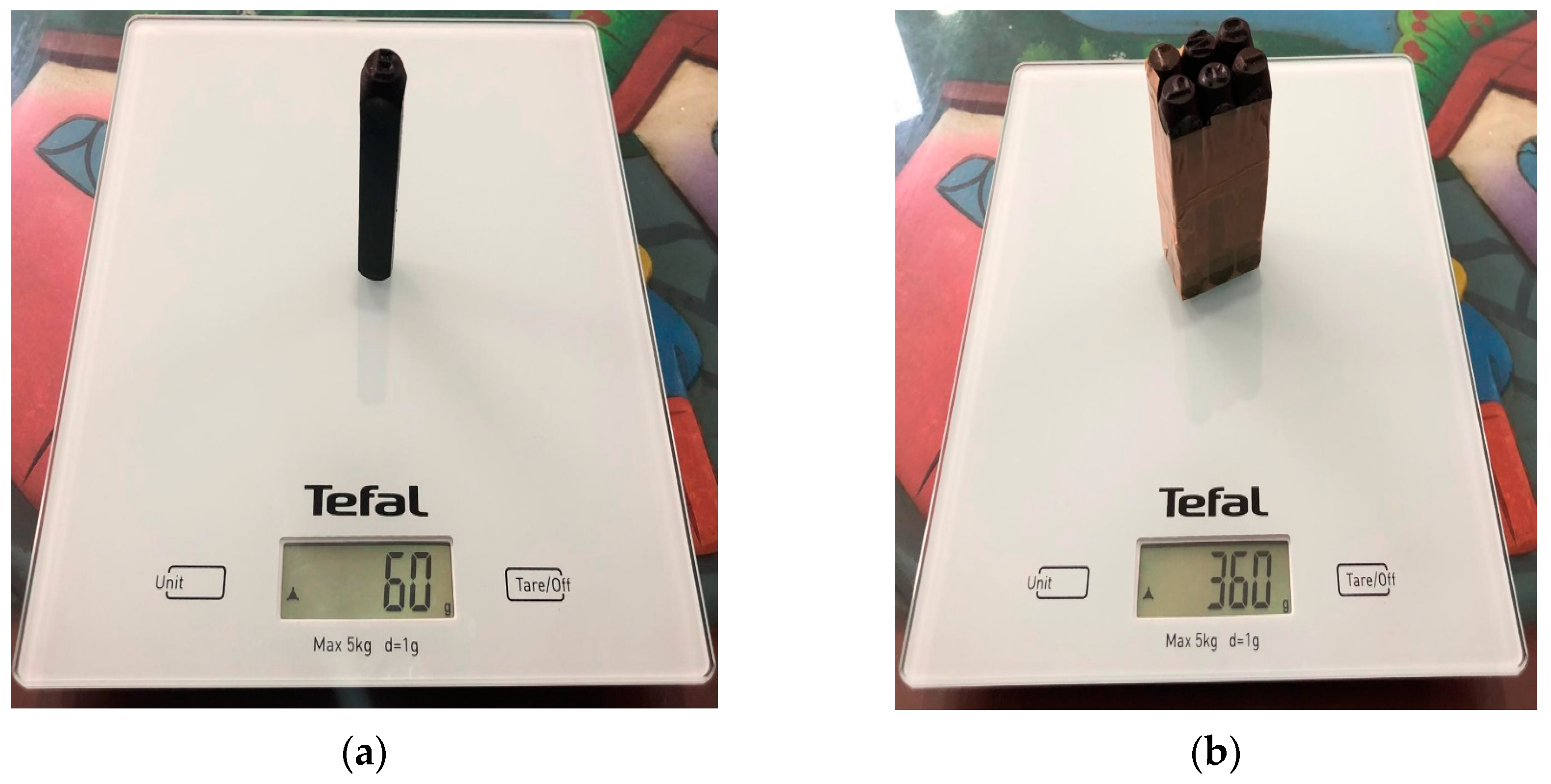

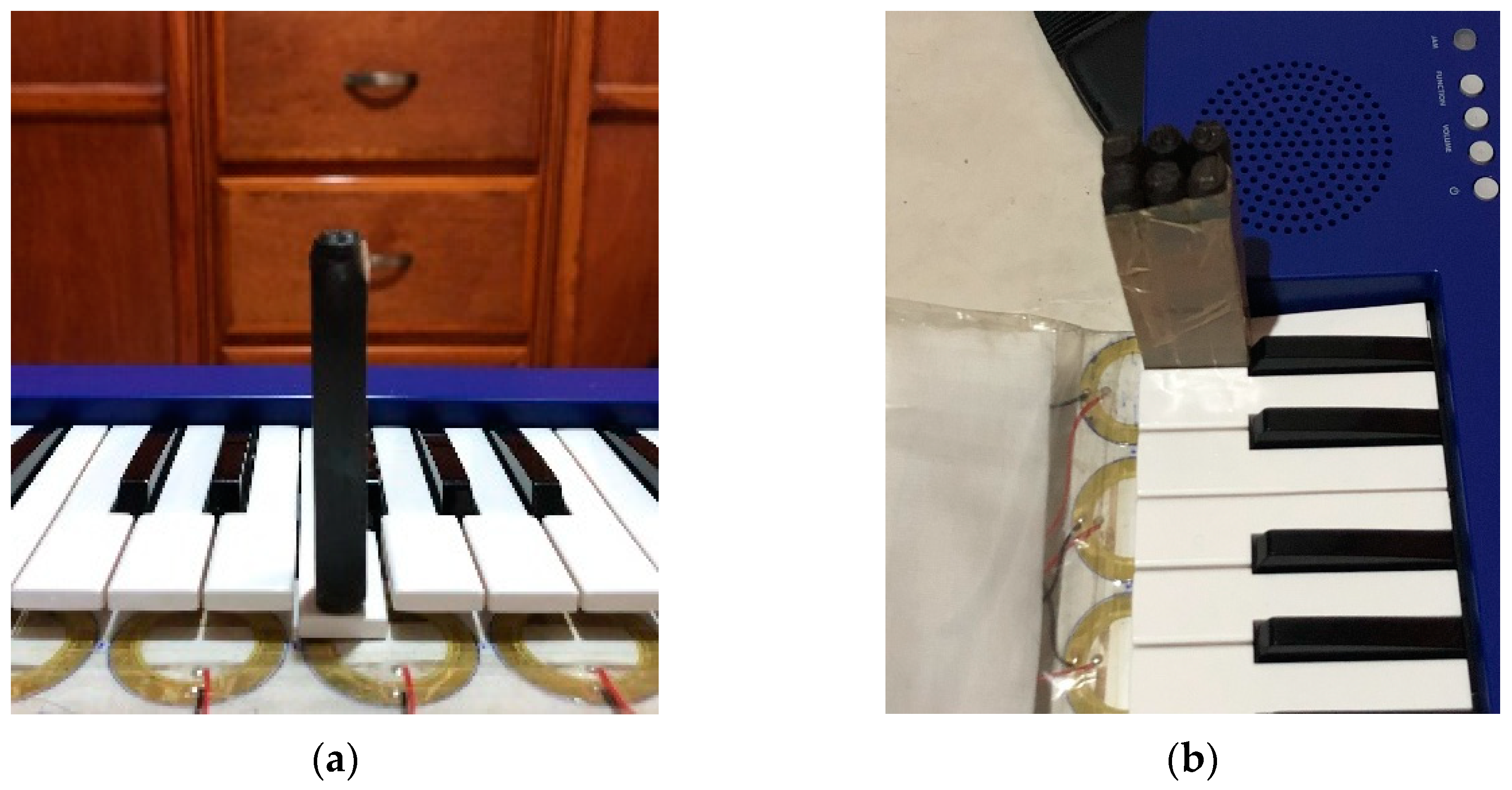

4. Design and Development

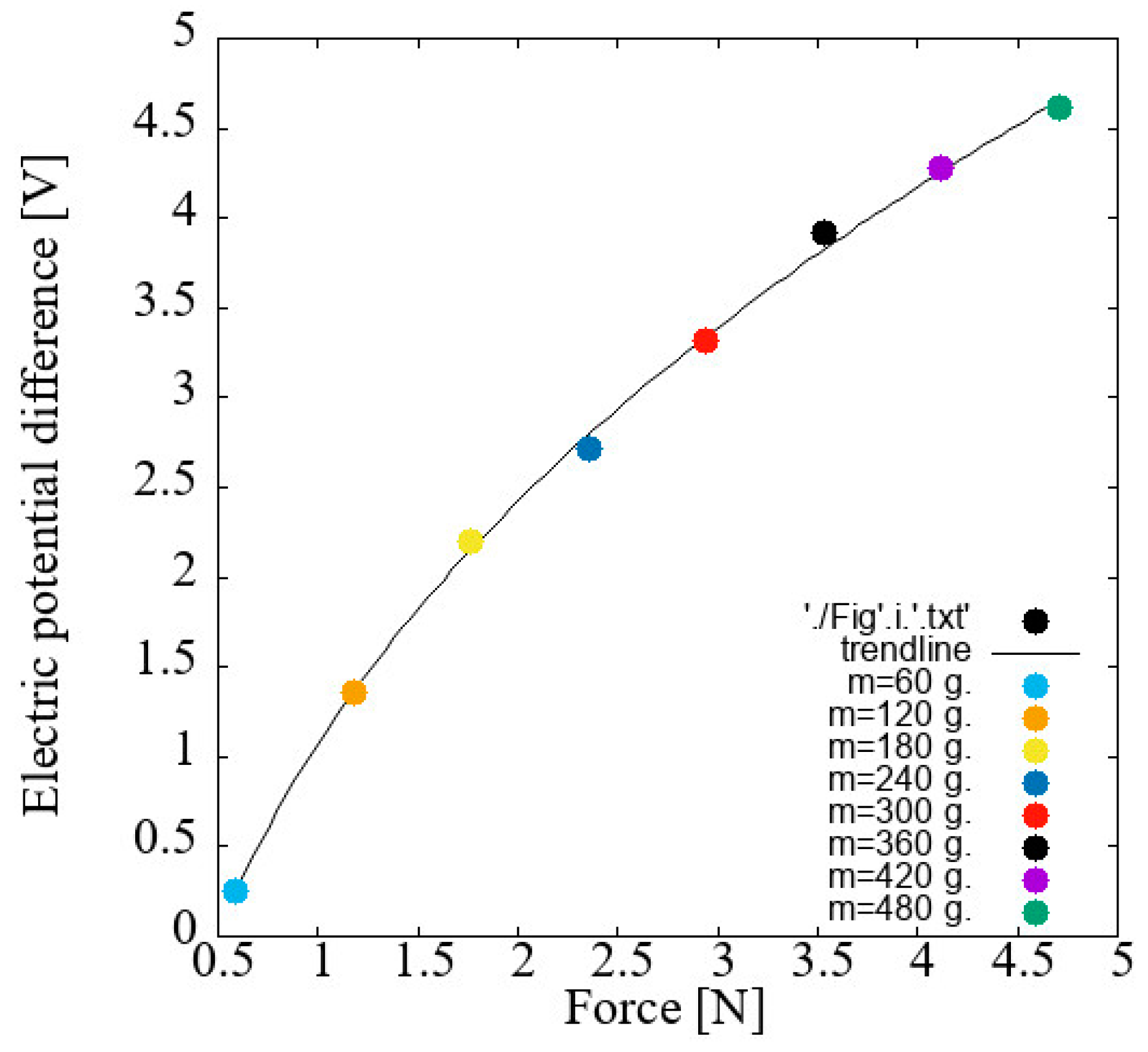

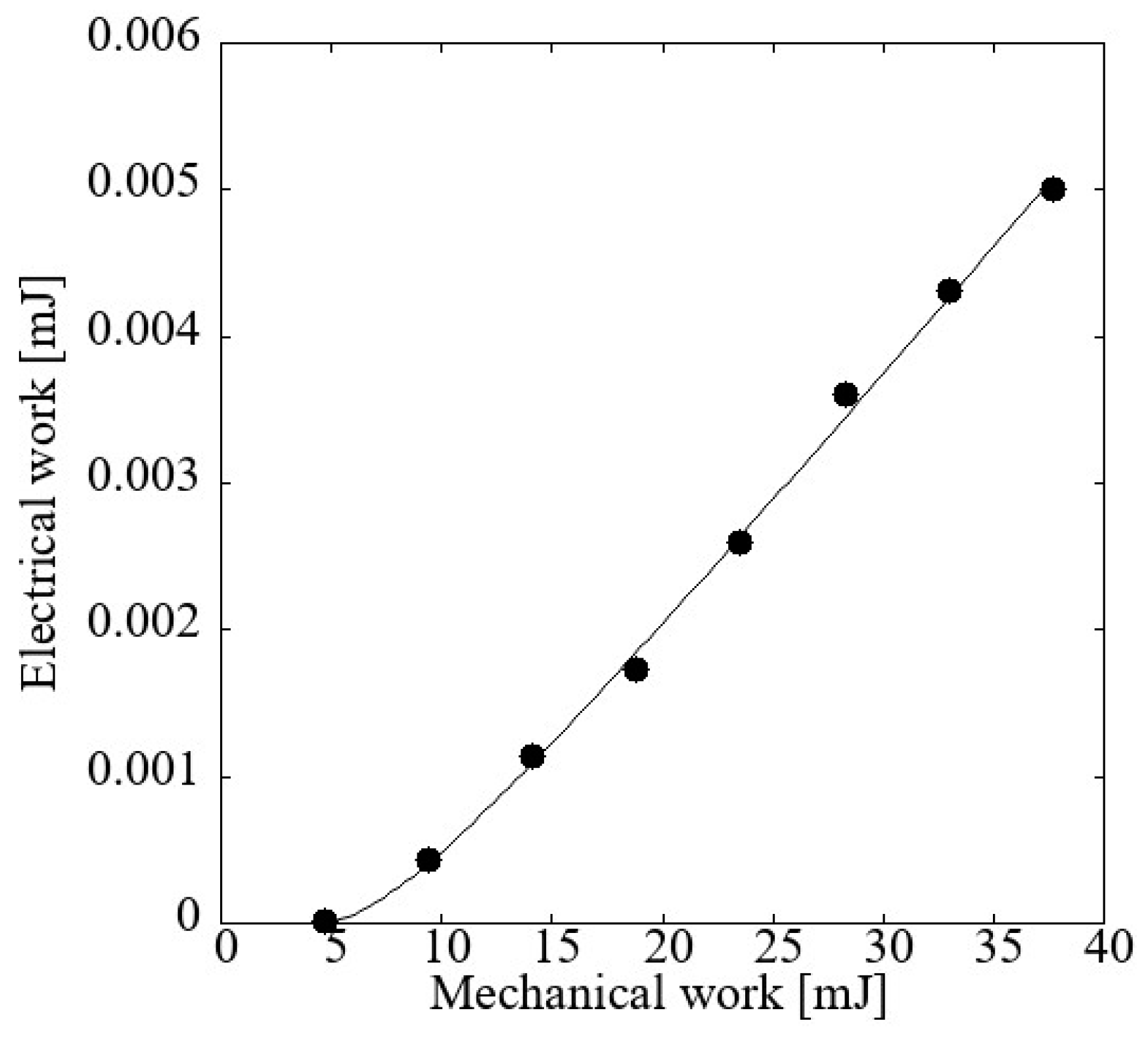

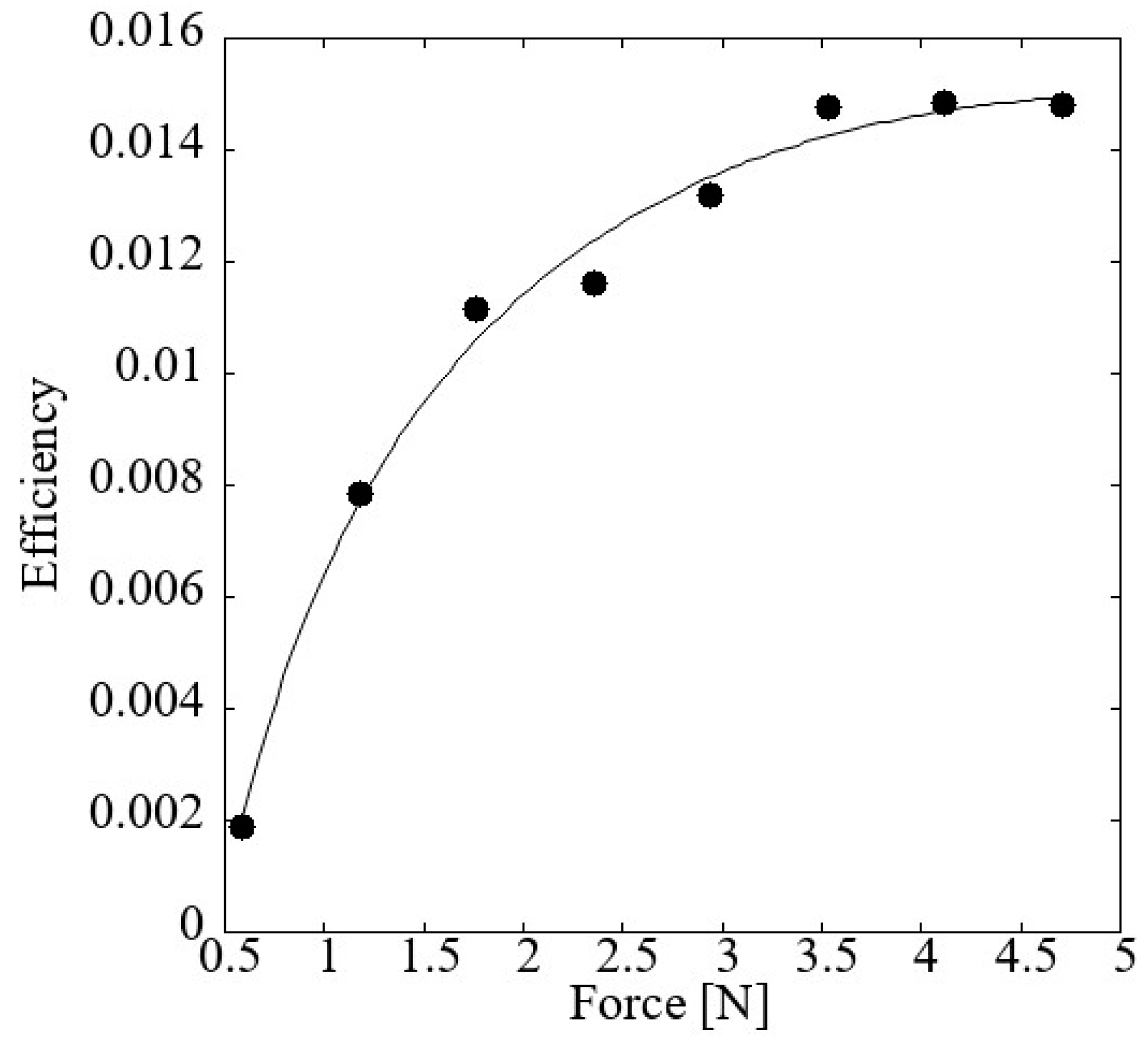

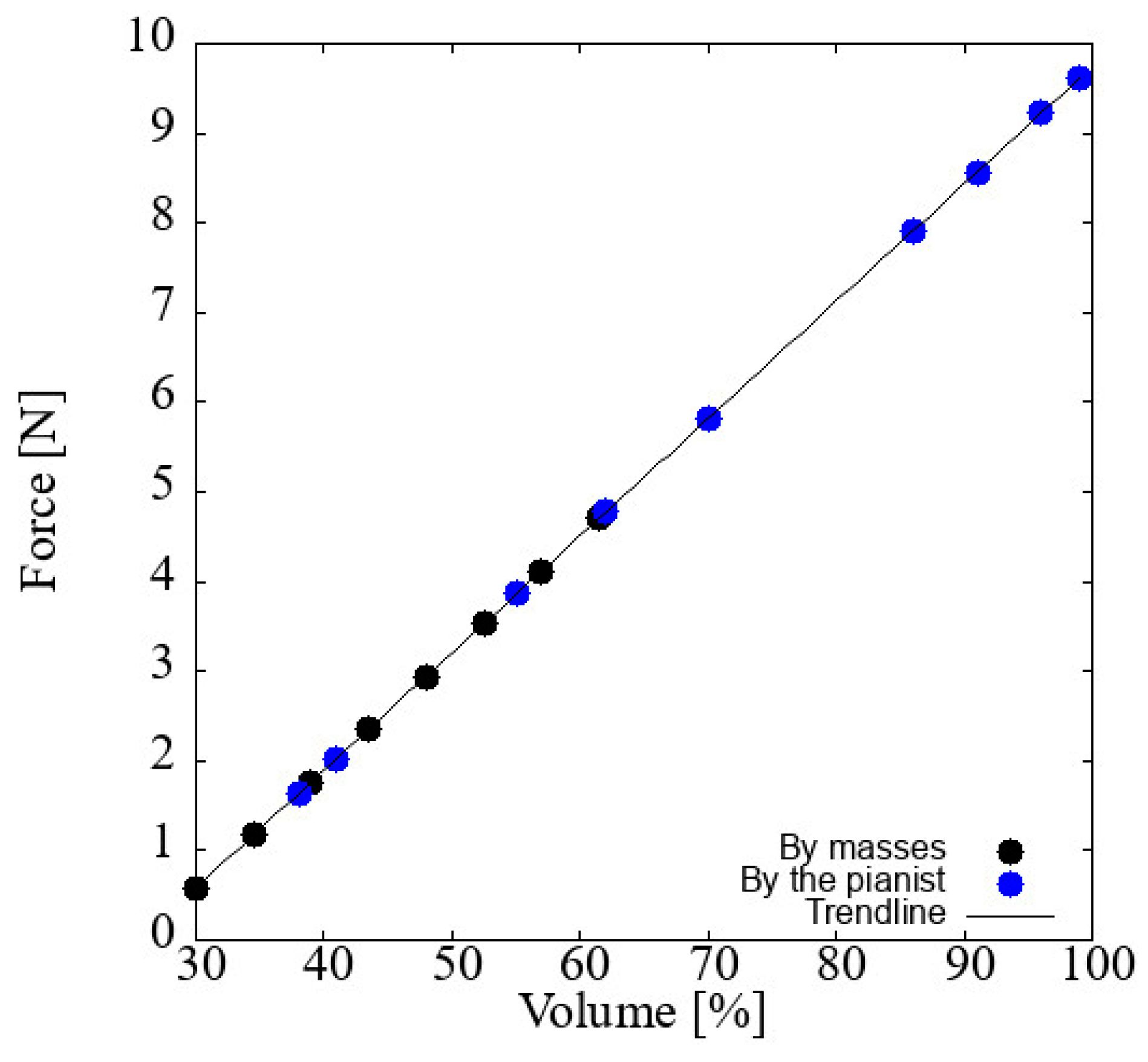

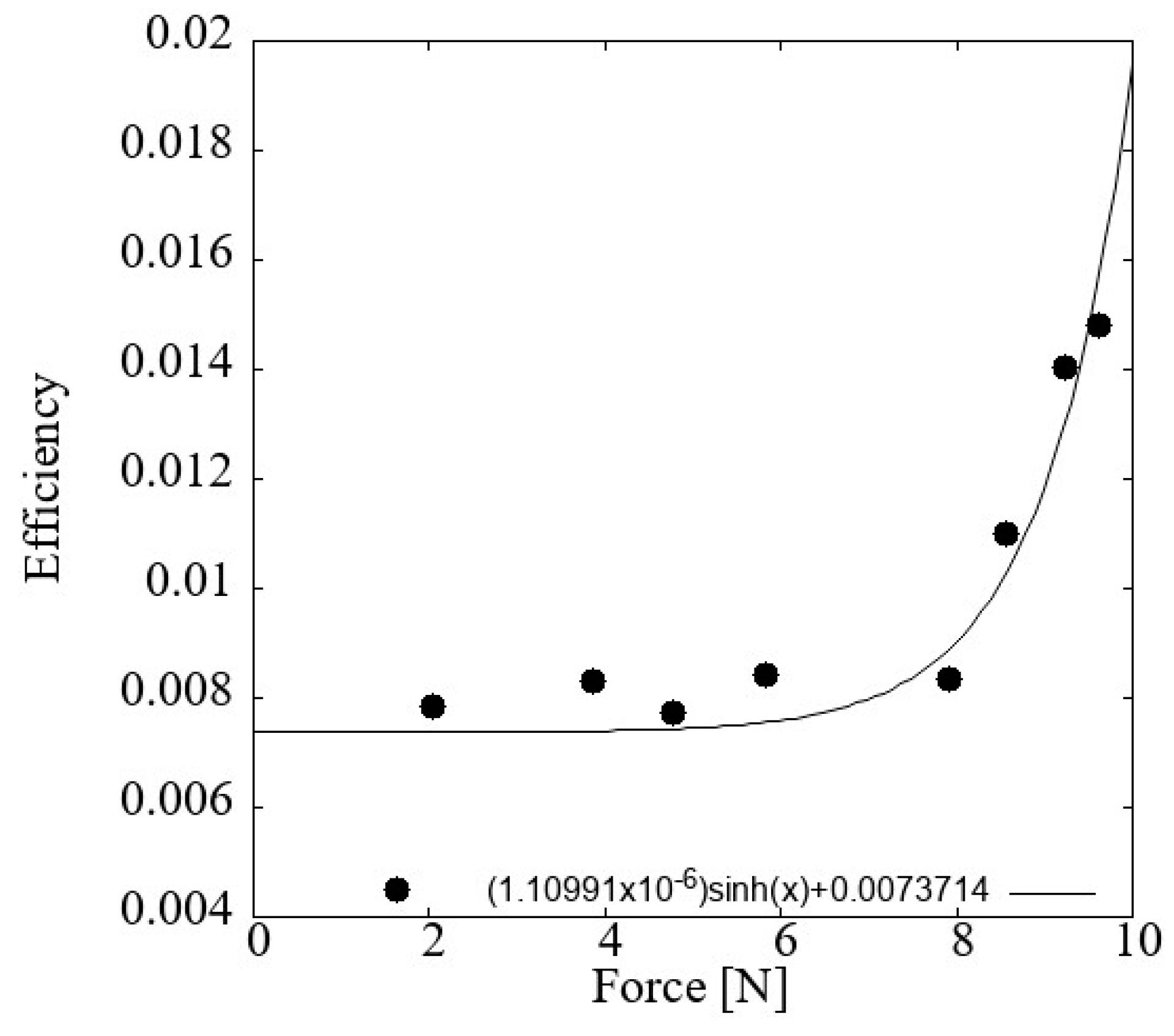

4.1. System Efficiency

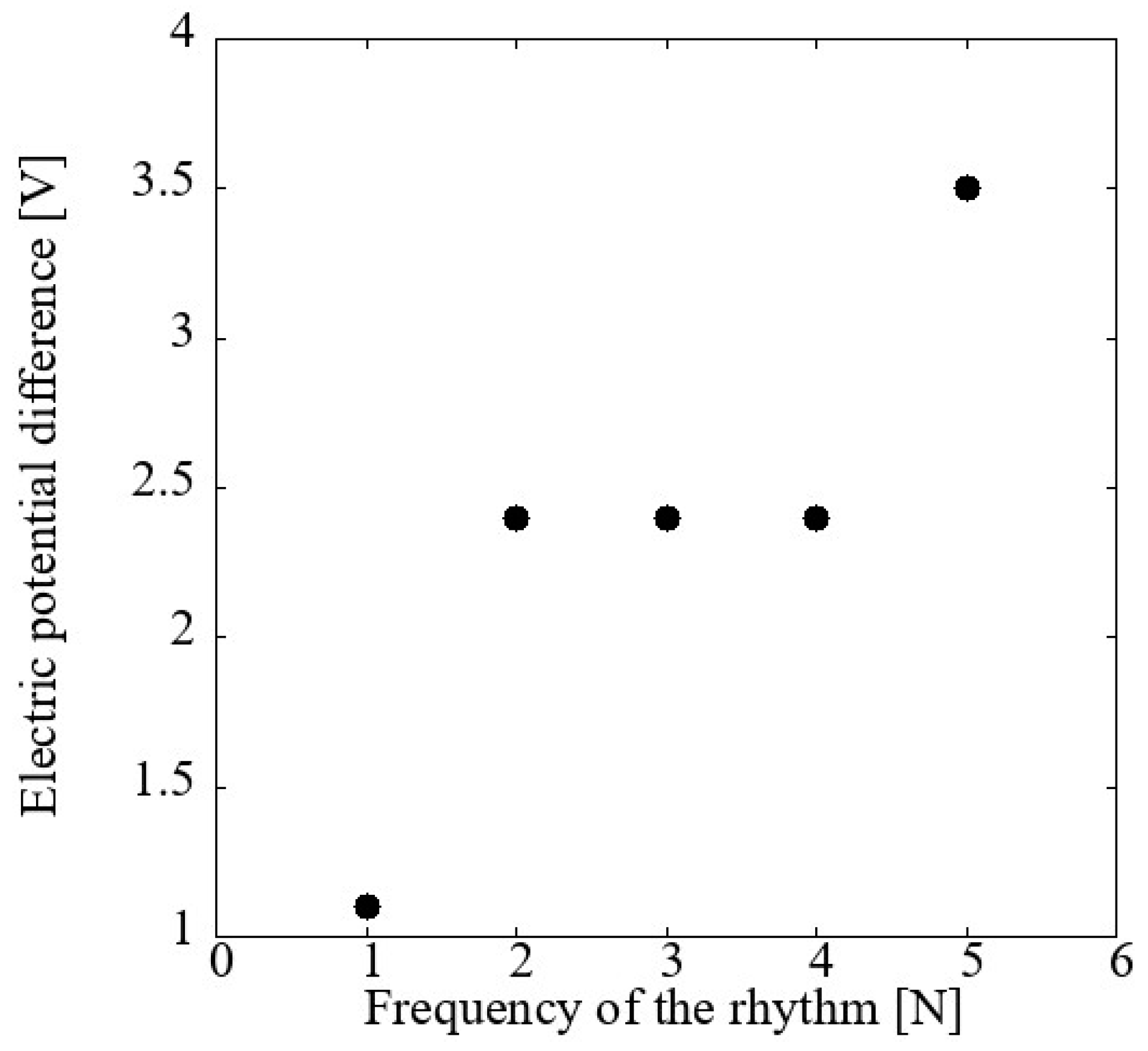

4.2. System Operation for Different Frequency Values

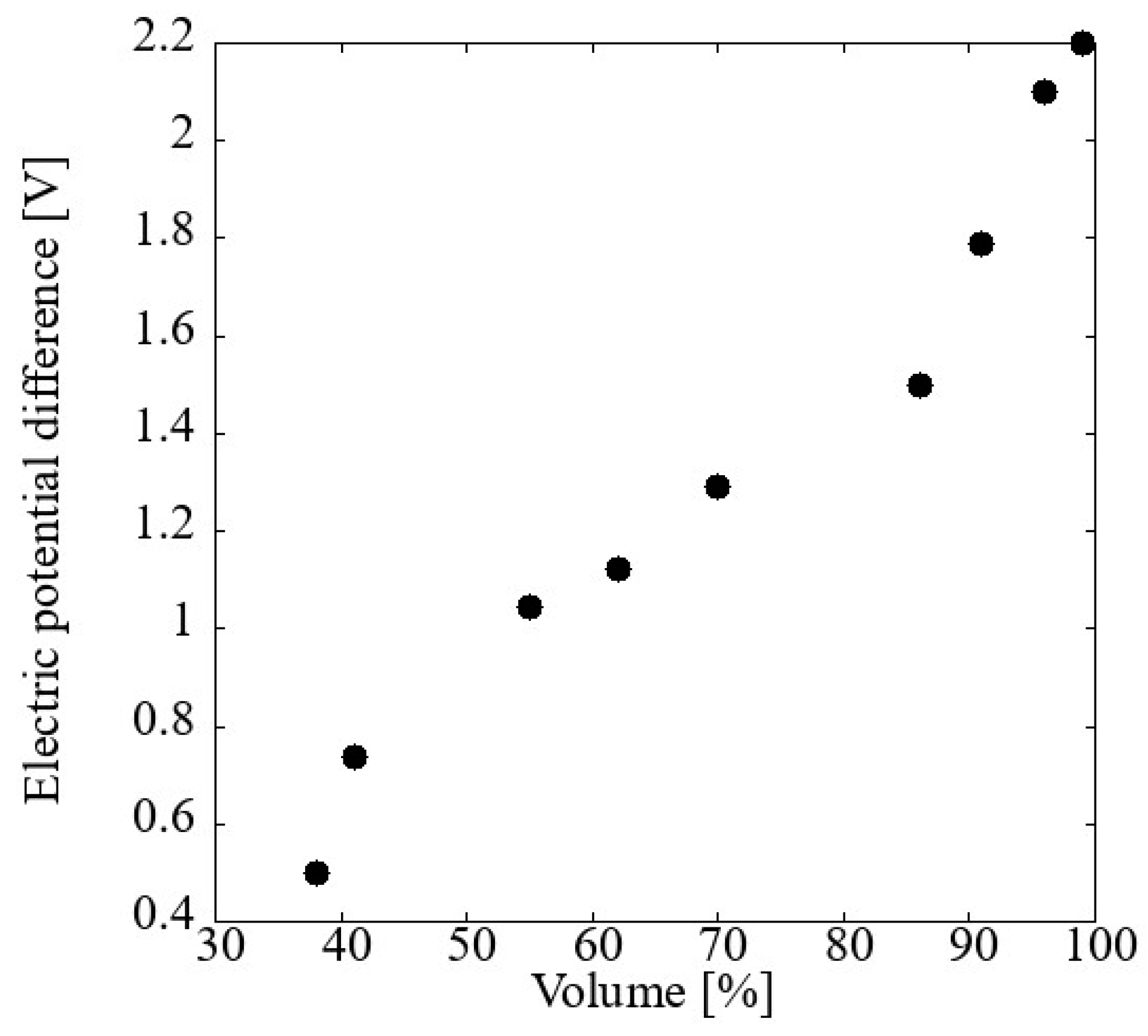

4.3. Battery Charge

5. Discussion

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| RB | Rechargeable battery |

| LMMS | Linux multimedia studio |

| PVDF | Polyvinylidene fluoride or polyvinylidene difluoride |

| MIDI | Musical Instrument Digital Interface |

References

- Ruda, M.; Bubela, T.; Kiselychnyk, M.; Boyko, O.; Trishch, R.; Kolach, T. Study of the life cycle of the elemental composition of batteries. In Proceedings of the 2022 IEEE 16th International Conference on Advanced Trends in Radioelectronics, Telecommunications and Computer Engineering (TCSET), Lviv-Slavske, Ukraine, 22–26 February 2022; IEEE: Piscataway, NJ, USA, 2022. [Google Scholar] [CrossRef]

- dos Santos, K.O.; Guimarães Aniceto Silva, N.; Henrique Gonçalves Reis, O.; de Paula Almeida, J.V.; Galindo de Oliveira, G. Management of toxic waste released by incorrectly discarded batteries in Brazil. Chem. Teach. Int. 2024, 6, 121–125. [Google Scholar] [CrossRef]

- Hamade, R.; Ayache, R.A.; Ghanem, M.B.; Masri, S.E.; Ammouri, A. Life cycle analysis of AA alkaline batteries. Procedia Manuf. 2020, 43, 415–422. [Google Scholar] [CrossRef]

- Covaci, C.; Gontean, A. Piezoelectric energy harvesting solutions: A review. Sensors 2020, 20, 3512. [Google Scholar] [CrossRef]

- Harb, A. Energy harvesting: State-of-the-art. Renew. Energy 2011, 36, 2641–2654. [Google Scholar] [CrossRef]

- Liu, Y.; Khanbareh, H.; Halim, M.A.; Feeney, A.; Zhang, X.; Heidari, H.; Ghannam, R. Piezoelectric energy harvesting for self-powered wearable upper limb applications. Nano Sel. 2021, 2, 1459–1479. [Google Scholar] [CrossRef]

- Chou, X.; Zhu, J.; Qian, S.; Niu, X.; Qian, J.; Hou, X.; Mu, J.; Geng, W.; Cho, J.; He, J.; et al. All-in-one filler-elastomer-based high-performance stretchable piezoelectric nanogenerator for kinetic energy harvesting and self-powered motion monitoring. Nano Energy 2018, 53, 550–558. [Google Scholar] [CrossRef]

- Li, R.; Yu, Y.; Zhou, B.; Guo, Q.; Li, M.; Pei, J. Harvesting energy from pavement based on piezoelectric effects: Fabrication and electric properties of piezoelectric vibrator. J. Renew. Sustain. Energy 2018, 10, 054701. [Google Scholar] [CrossRef]

- Moure, A.; Rodríguez, M.I.; Rueda, S.H.; Gonzalo, A.; Rubio-Marcos, F.; Cuadros, D.U.; Pérez-Lepe, A.; Fernández, J.F. Feasible integration in asphalt of piezoelectric cymbals for vibration energy harvesting. Energy Convers. Manag. 2016, 112, 246–253. [Google Scholar] [CrossRef]

- Karimi, M.; Karimi, A.H.; Tikani, R.; Ziaei-Rad, S. Experimental and theoretical investigations on piezoelectric-based energy harvesting from bridge vibrations under travelling vehicles. Int. J. Mech. Sci. 2016, 119, 1–11. [Google Scholar] [CrossRef]

- del Castillo-García, G.; Blanco-Fernandez, E.; Pascual-Muñoz, P.; Castro-Fresno, D. Energy harvesting from vehicular traffic over speed bumps: A review. Proc. Inst. Civ. Eng.-Energy 2018, 171, 58–69. [Google Scholar] [CrossRef]

- Sezer, N.; Koç, M. A comprehensive review on the state-of-the-art of piezoelectric energy harvesting. Nano Energy 2021, 80, 105567. [Google Scholar] [CrossRef]

- Lund, A.; Rundqvist, K.; Nilsson, E.; Yu, L.; Hagström, B.; Müller, C. Energy harvesting textiles for a rainy day: Woven piezoelectrics based on melt-spun PVDF microfibres with a conducting core. NPJ Flex. Electron. 2018, 2, 9. [Google Scholar] [CrossRef]

- Taylor, G.W.; Burns, J.R.; Kammann, S.A.; Powers, W.B.; Welsh, T.R. The Energy Harvesting Eel: A small subsurface ocean/river power generator. IEEE J. Ocean. Eng. 2001, 26, 539–547. [Google Scholar] [CrossRef]

- Orrego, S.; Shoele, K.; Ruas, A.; Doran, K.; Caggiano, B.; Mittal, R.; Kang, S.H. Harvesting ambient wind energy with an inverted piezoelectric flag. Appl. Energy 2017, 194, 212–222. [Google Scholar] [CrossRef]

- Puscasu, O.; Counsell, N.; Herfatmanesh, M.R.; Peace, R.; Patsavellas, J.; Day, R. Powering lights with piezoelectric energy-harvesting floors. Energy Technol. 2018, 6, 906–916. [Google Scholar] [CrossRef]

- Riaz, A.; Sarker, M.R.; Saad, M.H.M.; Mohamed, R. Review on comparison of different energy storage technologies used in micro-energy harvesting, wsns, low-cost microelectronic devices: Challenges and recommendations. Sensors 2021, 21, 5041. [Google Scholar] [CrossRef]

- Khaliq, A.; Sheeraz, M.; Ullah, A.; Seog, H.J.; Ahn, C.W.; Kim, T.H.; Cho, S.; Kim, I.W. Ferroelectric seeds-induced phase evolution and large electrostrain under reduced poling field in bismuth-based composites. Ceram. Int. 2018, 44, 13278–13285. [Google Scholar] [CrossRef]

- Surmenev, R.A.; Orlova, T.; Chernozem, R.V.; Ivanova, A.A.; Bartasyte, A.; Mathur, S.; Surmeneva, M.A. Hybrid lead-free polymer-based nanocomposites with improved piezoelectric response for biomedical energy-harvesting applications: A review. Nano Energy 2019, 62, 475–506, Accedido el 25 de marzo de 2025. [En línea]. [Google Scholar] [CrossRef]

- Zheng, Q.; Shi, B.; Li, Z.; Wang, Z.L. Recent progress on piezoelectric and triboelectric energy harvesters in biomedical systems. Adv. Sci. 2017, 4, 1700029. [Google Scholar] [CrossRef]

- Heidenreich, P.A.; Trogdon, J.G.; Khavjou, O.A.; Butler, J.; Dracup, K.; Ezekowitz, M.D.; Finkelstein, E.A.; Hong, Y.; Johnston, S.C.; Khera, A.; et al. Forecasting the future of cardiovascular disease in the united states. Circulation 2011, 123, 933–944. [Google Scholar] [CrossRef]

- Meng, K.; Chen, J.; Li, X.; Wu, Y.; Fan, W.; Zhou, Z.; He, Q.; Wang, X.; Fan, X.; Zhang, Y.; et al. Flexible weaving constructed self-powered pressure sensor enabling continuous diagnosis of cardiovascular disease and measurement of cuffless blood pressure. Adv. Funct. Mater. 2018, 29, 1806388. [Google Scholar] [CrossRef]

- He, Z.; Gao, B.; Li, T.; Liao, J.; Liu, B.; Liu, X.; Wang, C.; Feng, Z.; Gu, Z. Piezoelectric-Driven self-powered patterned electrochromic supercapacitor for human motion energy harvesting. ACS Sustain. Chem. Eng. 2018, 7, 1745–1752. [Google Scholar] [CrossRef]

- Ben Ammar, M.B.; Sahnoun, S.; Fakhfakh, A.; Viehweger, C.; Kanoun, O. Self-Powered synchronized switching interface circuit for piezoelectric footstep energy harvesting. Sensors 2023, 23, 1830. [Google Scholar] [CrossRef]

- Maria Joseph Raj, N.P.; Alluri, N.R.; Vivekananthan, V.; Chandrasekhar, A.; Khandelwal, G.; Kim, S.-J. Sustainable yarn type-piezoelectric energy harvester as an eco-friendly, cost-effective battery-free breath sensor. Appl. Energy 2018, 228, 1767–1776. [Google Scholar] [CrossRef]

- Chinachatchawarat, T.; Pattarapongsakorn, T.; Ploypray, P.; Jintanawan, T.; Phanomchoeng, G. Optimizing piezoelectric bimorphs for energy harvesting from body motion: Finger movement in computer mouse clicking. Energies 2024, 17, 4121. [Google Scholar] [CrossRef]

- Tang, W.; Tian, J.; Zheng, Q.; Yan, L.; Wang, J.; Li, Z.; Wang, Z.L. Implantable Self-Powered Low-Level Laser Cure System for Mouse Embryonic Osteoblasts’ Proliferation and Differentiation. ACS Nano 2015, 9, 7867–7873. [Google Scholar] [CrossRef]

- Zheng, Q.; Shi, B.; Fan, F.; Wang, X.; Yan, L.; Yuan, W.; Wang, S.; Liu, H.; Li, Z.; Wang, Z.L. In Vivo Powering of Pacemaker by Breathing-Driven Implanted Triboelectric Nanogenerator. Adv. Mater. 2014, 26, 5851–5856. [Google Scholar] [CrossRef]

- Lai, Z.; Wang, S.; Zhu, L.; Zhang, G.; Wang, J.; Yang, K.; Yurchenko, D. A hybrid piezo-dielectric wind energy harvester for high-performance vortex-induced vibration energy harvesting. Mech. Syst. Signal Process. 2021, 150, 107212. [Google Scholar] [CrossRef]

- Lallart, M.; Cottinet, P.J.; Lebrun, L.; Guiffard, B.; Guyomar, D. Evaluation of energy harvesting performance of electrostrictive polymer and carbon-filled terpolymer composites. J. Appl. Phys. 2010, 108, 034901. [Google Scholar] [CrossRef]

- Wang, J.; Ma, L.; He, J.; Yao, Y.; Zhu, X.; Peng, L.; Yang, J.; Li, K.; Qu, M. Superwettable hybrid dielectric based multimodal triboelectric nanogenerator with superior durability and efficiency for biomechanical energy and hydropower harvesting. Chem. Eng. J. 2022, 431, 134002. [Google Scholar] [CrossRef]

- George, A.; Varghese, H.; Chandran, A.; Surendran, K.P.; Gowd, B. Directional freezing-induced self-poled piezoelectric nylon 11 aerogels as high-performance mechanical energy harvesters. J. Mater. Chem. A 2023, 12, 911–922. [Google Scholar] [CrossRef]

- Xu, T.-B.; Siochi, E.J.; Kang, J.H.; Zuo, L.; Zhou, W.; Tang, X.; Jiang, X. A piezoelectric PZT ceramic multilayer stack for energy harvesting under dynamic forces. In Proceedings of the ASME 2011 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, ASMEDC, Washington, DC, USA, 28–31 August 2011. [Google Scholar] [CrossRef]

- Yang, W.; Yao, F.; Zhou, Y. Voltage ripple suppression methods for the capacitor in modular multilevel converter submodules employing a reversed pulse width modulation-switching channel. Electronics 2022, 11, 2193. [Google Scholar] [CrossRef]

- Yaqoob, U.; Habibur, R.M.; Sheeraz, M.; Kim, H.C. Realization of self-poled, high performance, flexible piezoelectric energy harvester by employing PDMS-rGO as sandwich layer between P(VDF-TrFE)-PMN-PT composite sheets. Compos. Part B Eng. 2019, 159, 259–268. [Google Scholar] [CrossRef]

- Pîrvu, C.I.; Sover, A.; Abrudeanu, M. Participation of polymer materials in the structure of piezoelectric composites. Polymers 2024, 16, 3603. [Google Scholar] [CrossRef]

- Cédric, L.; Anis, K.; Sophie, B.; Frédéric, G. Piezoelectric polymer characterization setup for active energy harvesting. Polym. Adv. Technol. 2025, 36, e70056. [Google Scholar] [CrossRef]

- Lee, S.; Lim, Y. Generating Power Enhancement of Flexible PVDF Generator by Incorporation of CNTs and Surface Treatment of PEDOT:PSS Electrodes. Macromol. Mater. Eng. 2018, 303, 1700588. [Google Scholar] [CrossRef]

- Manna, S.; Nandi, A.K. Piezoelectric β Polymorph in Poly(vinylidene fluoride)-Functionalized Multiwalled Carbon Nanotube Nanocomposite Films. J. Phys. Chem. C 2007, 111, 14670–14680. [Google Scholar] [CrossRef]

- Thakur, P.; Kool, A.; Hoque, N.A.; Bagchi, B.; Khatun, F.; Biswas, P.; Brahma, D.; Roy, S.; Banerjee, S.; Das, S. Superior performances of in situ synthesized ZnO/PVDF thin film based self-poled piezoelectric nanogenerator and self-charged photo-power bank with high durability. Nano Energy 2018, 44, 456–467. [Google Scholar] [CrossRef]

- Dutta, B.; Kar, E.; Bose, N.; Mukherjee, S. NiO@SiO2/PVDF: A Flexible Polymer Nanocomposite for a High Performance Human Body Motion-Based Energy Harvester and Tactile e-Skin Mechanosensor. ACS Sustain. Chem. Eng. 2018, 6, 10505–10516. [Google Scholar] [CrossRef]

- Habibur, R.M.; Yaqoob, U.; Muhammad, S.; Uddin, A.I.; Kim, H.C. The effect of RGO on dielectric and energy harvesting properties of P(VDF-TrFE) matrix by optimizing electroactive β phase without traditional polling process. Mater. Chem. Phys. 2018, 215, 46–55. [Google Scholar] [CrossRef]

- Gino, M.E.; Selleri, G.; Cocchi, D.; Brugo, T.M.; Testoni, N.; De Marchi, L.; Zucchelli, A.; Fabiani, D.; Focarete, M.L. On the design of a piezoelectric self-sensing smart composite laminate. Mater. Des. 2022, 219, 110783. [Google Scholar] [CrossRef]

- Timmermans, S.; Dehez, B.; Fisette, P. Multibody-Based piano action: Validation of a haptic key. Machines 2020, 8, 76. [Google Scholar] [CrossRef]

- Samia, A.; Mohammed, E.-G.; Yoen, M.; Jean-Christophe, T.; Raynald, S. Mechanical characterization of a piezoelectric sensor for podiatrist applications. In Proceedings of the 2022 IEEE International Systems Conference (SysCon), Montreal, QC, Canada, 25–28 April 2022; pp. 1–5. [Google Scholar] [CrossRef]

- Harding, D.C.; Brandt, K.D.; Hillberry, B.M. Finger joint force minimization in pianists using optimization techniques. J. Biomech. 1993, 26, 1403–1412. [Google Scholar] [CrossRef]

- Turner, C.; Visentin, P.; Oye, D.; Rathwell, S.; Shan, G. Pursuing artful movement science in music performance: Single subject motor analysis with two elite pianists. Percept. Mot. Ski. 2021, 128, 1252–1274. [Google Scholar] [CrossRef]

- Gordon, E.E. An approach to the quantitative study of dynamics. J. Res. Music. Educ. 1960, 8, 23–30. [Google Scholar] [CrossRef]

- Tase, A.; Tase, A.; Dumitrache, M.; Calina, F.C.; Stanciulescu, L.; Stoiculescu, A. Could piano music therapy alleviate high sinus rhythm in subjects with controlled hypertension? Eur. Heart J. 2024, 45 (Supp. S1), ehae666-2953. [Google Scholar] [CrossRef]

- Bowling, D.L.; Purves, D.; Gill, K.Z. Vocal similarity predicts the relative attraction of musical chords. Proc. Natl. Acad. Sci. USA 2017, 115, 216–221. [Google Scholar] [CrossRef]

- Chaffin, R. Learning clair de lune: Retrieval practice and expert memorization. Music. Percept. 2007, 24, 377–393. [Google Scholar] [CrossRef]

- Chaffin, R.; Imreh, G.; Lemieux, A.F.; Chen, C. Seeing the big picture: Piano practice as expert problem solving. Music. Percept. 2003, 20, 465–490. [Google Scholar] [CrossRef]

| Matiz | Sound Volume (%) | Resultant Force (N) | Sensor (N) | Force Comparison (%) |

|---|---|---|---|---|

| Forte | 86 | 7.4229 | 0.7324 | 9.86% |

| Fortissimo | 91 | 8.0769 | 0.7845 | 9.71% |

| Fortississimo | 96 | 8.7309 | 0.8499 | 9.73% |

| Maximum | 99 | 9.1233 | 0.9152 | 10.03% |

| Minutes | RB 1 | RB 2 | RB 3 | RB 4 |

|---|---|---|---|---|

| 0 | 1.226 | 1.226 | 1.004 | 1.004 |

| 5 | 1.226 | 1.226 | 1.004 | 1.004 |

| 10 | 1.227 | 1.226 | 1.005 | 1.004 |

| 15 | 1.227 | 1.227 | 1.005 | 1.005 |

| 30 | 1.227 | 1.227 | 1.005 | 1.005 |

| Reference | Type of Movement | V | mW | Keyboard Implementation |

|---|---|---|---|---|

| This proposal | Swipe hand over keyboard | 14 | 0.04606 | Yes |

| This proposal | Press a key at 5 Hz with one finger | 3.5 | 0.01439 | Yes |

| [7] | Stretch | 20 | 0.011 | No |

| [23] | Impacts on the palm | 2 | 0.00018 | No |

| [24] | Footsteps | 7.2 | 3.6 | No |

| [26] | Press with finger | 5.5 | 0.34 | No |

| [13] | Climbing stairs with a backpack | 4 | 0.004 | No |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vega-Ávila, J.E.; Anaya-Ruiz, G.A.; Román-Godínez, J.J.; Esquivel-Barajas, G.G.; Ortiz-Marín, J.; Gudiño-Valdez, R.; Aguilar-Rodríguez, H. Piezoelectric Energy Harvesting System to Charge Batteries with the Use of a Portable Musical Organ. Energies 2025, 18, 1850. https://doi.org/10.3390/en18071850

Vega-Ávila JE, Anaya-Ruiz GA, Román-Godínez JJ, Esquivel-Barajas GG, Ortiz-Marín J, Gudiño-Valdez R, Aguilar-Rodríguez H. Piezoelectric Energy Harvesting System to Charge Batteries with the Use of a Portable Musical Organ. Energies. 2025; 18(7):1850. https://doi.org/10.3390/en18071850

Chicago/Turabian StyleVega-Ávila, Josué Esaú, Guillermo Adolfo Anaya-Ruiz, José Joel Román-Godínez, Gabriela Guadalupe Esquivel-Barajas, Jorge Ortiz-Marín, Rogelio Gudiño-Valdez, and Hilda Aguilar-Rodríguez. 2025. "Piezoelectric Energy Harvesting System to Charge Batteries with the Use of a Portable Musical Organ" Energies 18, no. 7: 1850. https://doi.org/10.3390/en18071850

APA StyleVega-Ávila, J. E., Anaya-Ruiz, G. A., Román-Godínez, J. J., Esquivel-Barajas, G. G., Ortiz-Marín, J., Gudiño-Valdez, R., & Aguilar-Rodríguez, H. (2025). Piezoelectric Energy Harvesting System to Charge Batteries with the Use of a Portable Musical Organ. Energies, 18(7), 1850. https://doi.org/10.3390/en18071850