1. Introduction

Climate change has become a central global issue, with the development of clean energy and the reduction of carbon emissions emerging as crucial strategies to combat global warming and the increasing frequency of extreme weather events. Around the world, countries are making significant strides in building green power generation infrastructure, such as wind, hydro, and nuclear energy, to address environmental, climate, and ecological challenges [

1,

2]. In this context, lithium-ion battery energy storage systems, as a cutting-edge clean energy solution, have become integral to the integration of renewable energy sources into the grid. With their notable advantages, such as their safety, high energy density, and long operational life, these systems are key to mitigating power fluctuations, balancing grid loads, smoothing peak–valley variations, and stabilizing both grid frequency and voltage [

3,

4,

5].

The SOH of a lithium-ion battery is how much usable power it has now compared to when it was new, which directly demonstrates its capabilities to smooth wind power variations. This smoothing capability ensures the stability of wind power grid integration. Improving the accuracy of lithium-ion battery health prediction can not only guarantee safety but also enhance energy efficiency and extend its lifespan [

6]. As a result, predicting the health of lithium-ion batteries has been a major focus of research. However, accurately estimating the health state of these batteries remains challenging due to their complex physical and chemical reactions. Currently, methods for predicting the health of lithium-ion batteries are typically classified into four categories [

7]: electrochemical model-based methods, experimental-based methods, physics-based methods, and data-driven methods.

Electrochemical model-based methods [

8,

9,

10] are highly accurate, as they rely on electrochemical reaction processes and aging mechanisms such as migration, diffusion, and chemical reaction kinetics. However, these models need a lot of different equations, which makes them expensive to run on computers, making them less commonly employed. Experimental-based methods [

11] predict health by deriving mathematical expressions for battery capacity degradation through fitting. While this approach is computationally efficient, the mathematical expressions may not always align with actual charging and discharging conditions, so their accuracy remains uncertain. Physics-based methods [

12,

13,

14] involve constructing equivalent circuit models, such as RC and PNGV models, and using the relationships between battery parameters (e.g., capacity and resistance) for capacity prediction, which is then used to estimate the state of health. However, these methods also have drawbacks, such as the need for complex matrix calculations and the complication of capacity degradation curves due to the regeneration of capacity in a stationary state [

8]. In data-driven methods, some researchers use existing battery data, such as the charge/discharge depth, temperature, and charge/discharge time, to predict battery health. These methods do not require a deep understanding of the design, material properties, or physical models of different electrochemical batteries, allowing researchers to use aging data, including current, voltage, temperature, discharge amount, and charge/discharge time [

15], to predict battery health. This approach does not require detailed knowledge of electrochemical battery designs or material properties. The most commonly used models in this approach are capacity loss models [

16] and resistance models [

17]. Furthermore, intelligent algorithms and machine learning techniques [

18], such as the Genetic Algorithm (GA), Support Vector Regression (SVR), and neural networks, have also been employed to predict the battery’s SOH. These data-driven methods are particularly appealing to many researchers due to their flexibility and the fact that they do not require replicating physical models. In the prediction of battery SOH, SVR has been widely adopted as an effective forecasting method due to its strong nonlinear mapping capability and excellent generalization performance in various prediction tasks. However, practical applications of SVR still face several challenges, particularly in parameter selection. Traditional SVR approaches typically rely on manual parameter tuning, which not only requires empirical expertise but may also lead to performance fluctuations and reduced prediction accuracy. To address these limitations, this paper proposes a GA-optimized SVR parameter selection method. By leveraging the GA to automatically search and optimize critical SVR parameters, this approach enhances prediction accuracy while minimizing manual intervention, thereby improving the overall reliability and precision of battery SOH predictions.

The goal of this study is to use data-driven methods to learn the causal relationship between various aging factors and the degradation of the state of health at each time interval through algorithms. The results show that the proposed GA-SVR method successfully predicts the SOH of the energy storage (ES) system. With strong applicability, this method can be further applied to SOH prediction in real-world operational scenarios.

The grid-connected power of a wind-storage system consists of both wind power and the charge/discharge power of the energy storage system. Given the current wind power, the charge/discharge power of the energy storage system can be calculated and determined by setting a target grid-connected power. In the use of energy storage to smooth wind power fluctuations, some scholars have adopted filtering algorithms, wavelet packet decomposition, and empirical mode decomposition (EMD) to calculate the target power for energy storage and grid-connected power [

19,

20,

21,

22,

23,

24]. For example, in the literature [

20], a wavelet packet decomposition algorithm is used to decompose photovoltaic (PV) power. To address the challenge of determining the parameters of wavelet packet decomposition, the author employed a filtering method to smooth out the fluctuations. However, this method also has issues with confirming the time constant and the presence of delays. In the literature [

21,

22], EMD and CEEMD, combined with other optimization algorithms, were used to process wind power, achieving good results. However, the drawback of their decomposition algorithms is modal aliasing, which was solved by the use of VMD [

23]. In the literature [

24], an adaptive variational mode decomposition algorithm was used to determine the pre-scheduling power of the wind-storage system with the goal of minimizing the overall cost. However, VMD has problems when it comes to choosing the number of modes and penalty coefficients by hand. If the mode number is set too high or too low, it can cause repeated data, adding noise or losing important information. The enhanced salp swarm algorithm (ISSA) assists in automatically determining the optimal number of layers and penalty coefficients for VMD, although it occasionally converges on a suboptimal solution.

MPC has some benefits compared to filtering control and other flexible control methods, especially when it comes to how quickly it responds and how accurate it is

[25]. It can assume future control needs and make improvements [

26,

27]. Additionally, it makes sure that the system works well and safely by putting limits on what inputs and outputs can be.

The Literature Summary Table is summarized as follows:

In the aspect of SOH prediction:

| Reference | Methodology | Advantages | Limitations |

| [8,9,10] | Electrochemical Model-Based Methods | High accuracy, considers electrochemical reactions | High computational cost, complex equations |

| [11] | Experimental-Based Methods | Computationally efficient, mathematical expression fitting | Accuracy depends on fitting equations, may not reflect real conditions |

| [12,13,14] | Physics-Based Methods (RC, PNGV models) | Uses real battery parameters for capacity prediction | Requires complex matrix calculations, capacity regeneration effect |

| [15] | Data-Driven Methods (Charge/Discharge data) | No need for deep electrochemical knowledge, flexible | Dependent on data quality, may not capture all degradation mechanisms |

| [16,17] | Capacity Loss and Resistance Models | Simple and widely used for SOH estimation | Limited accuracy in dynamic conditions |

| [18] | Machine Learning (GA, SVR, Neural Networks) | Strong generalization ability, flexible, automatic parameter tuning possible | Requires large dataset for training, sensitive to hyperparameters |

In the aspect of wind power fluctuation smoothing methods:

| Reference | Methodology | Advantages | Limitations |

| [19] | Filtering Algorithms | Simple implementation, effective in reducing high-frequency components | May cause delays, requires careful parameter tuning |

| [20] | Wavelet Packet Decomposition | Good for decomposing power fluctuations | Issues with selecting wavelet packet settings, potential time delays |

| [21,22] | Empirical Mode Decomposition (EMD, CEEMD) | Effective for wind power smoothing | Modal aliasing issue, requires optimization |

| [23] | Variational Mode Decomposition (VMD) | Addresses modal aliasing, improved signal decomposition | Manual selection of mode numbers and penalty coefficients |

| [24] | Adaptive Variational Mode Decomposition with ISSA | Optimized VMD parameter selection | May converge to suboptimal solutions |

This study aims to predict the SOH of energy storage and adjust the control strategy to smooth the power fluctuations of wind energy based on different SOH conditions. The main contributions of this paper are as follows:

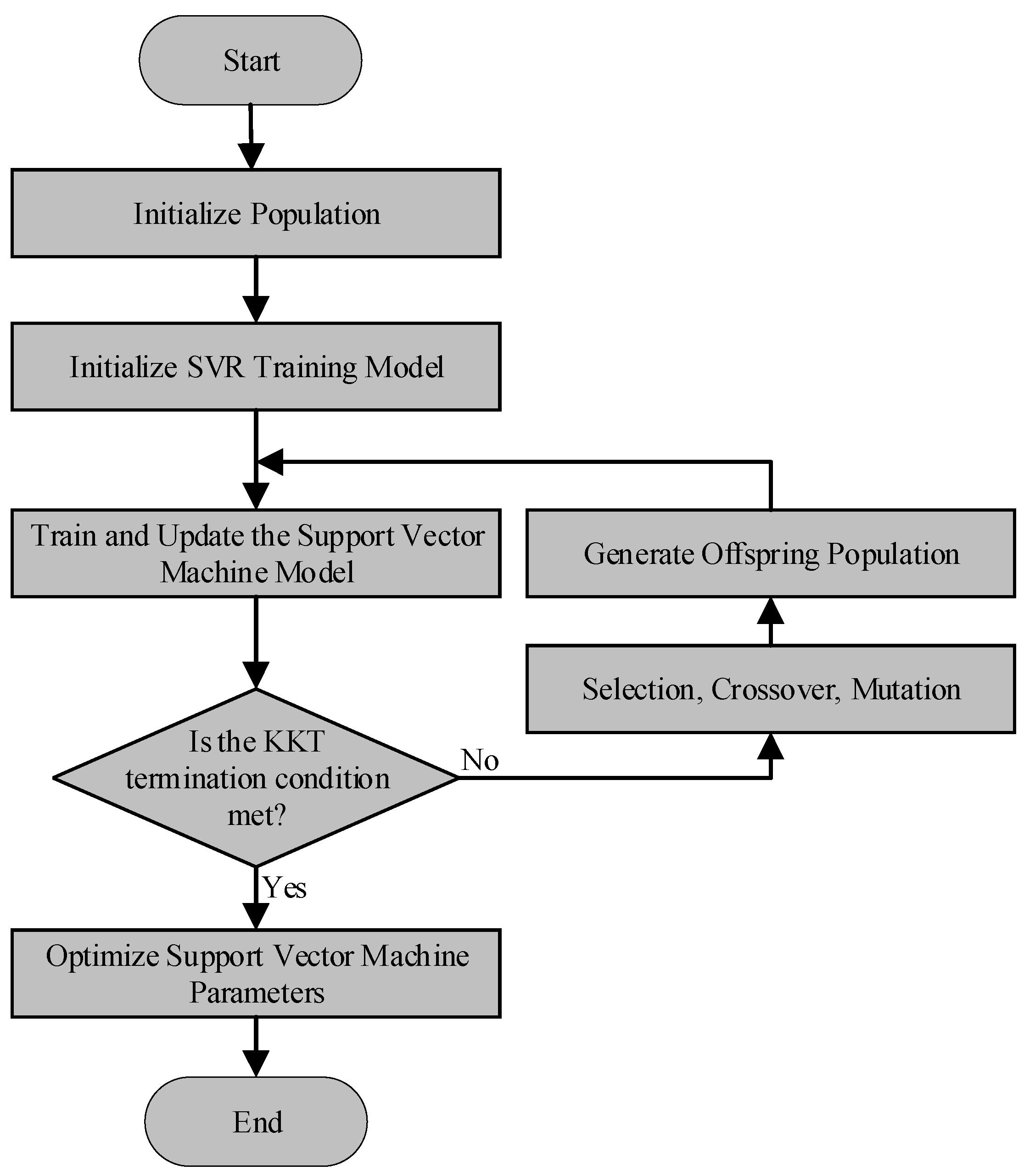

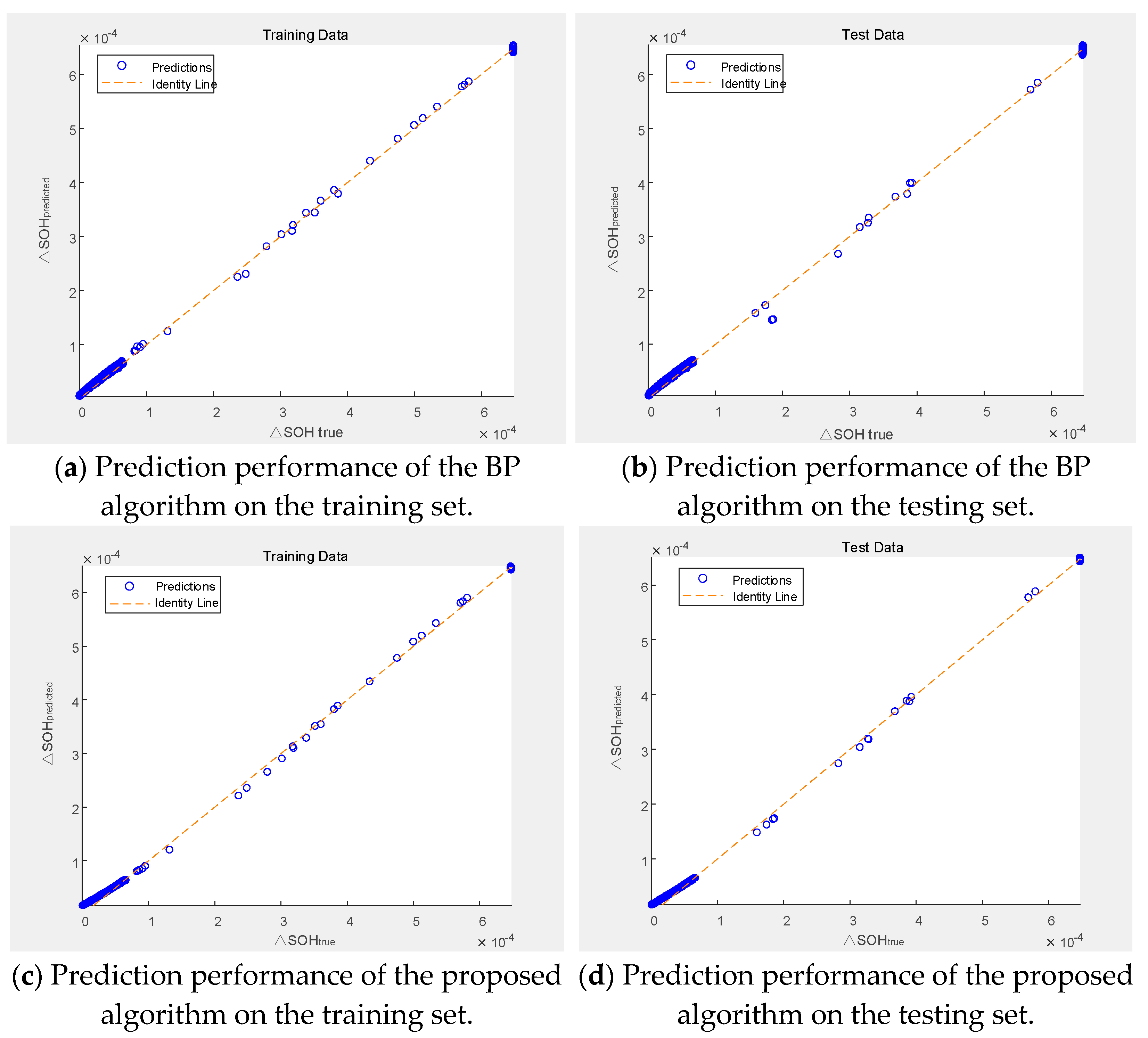

A GA-optimized SVR algorithm is proposed to predict the SOH of the energy storage system. The proposed algorithm improves the accuracy of the energy storage health prediction results.

A new method using MPC is suggested to manage how energy is charged and discharged in an energy storage system. This method ensures that the energy output from the storage system is reduced while still meeting the needs of the power grid, which helps to extend the life of the energy storage system.

Additionally, a fuzzy control strategy is added to enhance the MPC. This new strategy considers the SOH of the energy storage system and the changes in wind power as its inputs. It gives a weight to the objective function in the MPC, helping to adjust the control settings. This allows for balancing between smoothing out wind power changes and the output from the energy storage system. The goal is to meet the power fluctuations required by the grid while optimizing performance: when fluctuations are high, smoothing out the changes is more important; when the fluctuation is low, the energy storage output reduction is prioritized to minimize lifespan degradation. On the other hand, as a deterioration in energy storage health reduces the charge/discharge capabilities, the proposed fuzzy control strategy adaptively adjusts the parameters of the MPC objective function based on the energy storage SOH, thus controlling the energy storage output.

The rest of the paper is organized as follows:

Section 2 explains the SOH prediction methods. This explanation, includes factors influencing energy storage lifespan, as well as machine learning regression models, and their application in predicting energy storage health.

Section 3 introduces the MPC-based energy storage control strategy and the fuzzy control improvement applied to the MPC. This improvement adjusts the weight coefficients of the objective function based on energy storage SOH predictions and wind power fluctuation amplitude.

Section 4 provides a simulation analysis of the wind power smoothing effect and the adjustment of energy storage output under different SOH conditions using the proposed control strategy. The paper is concluded in

Section 5.

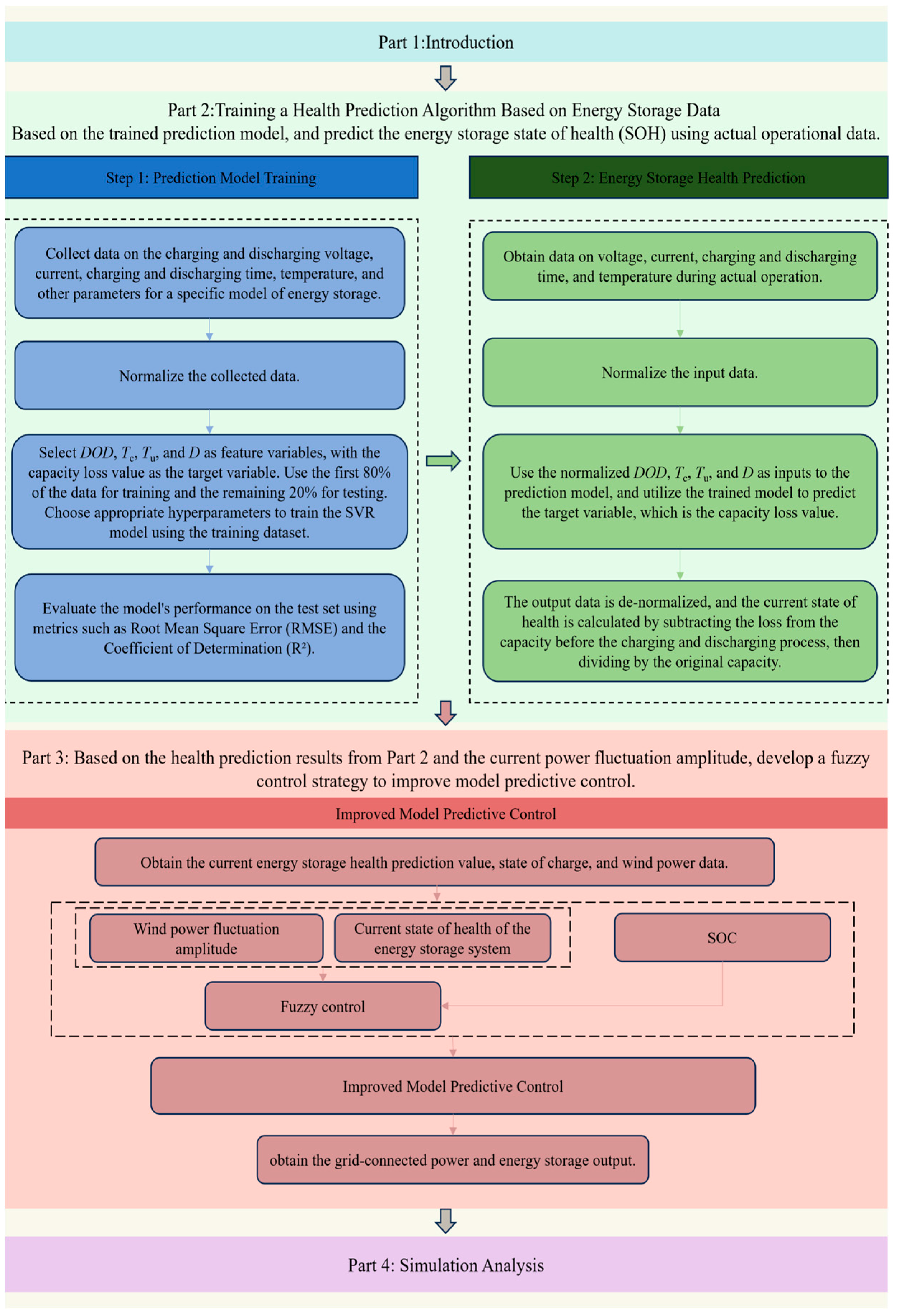

Figure 1 shows the organization of this paper.

3. Improved MPC Algorithm-Based Wind Power Grid-Connected Power Fluctuation Smoothing Strategy

In

Section 2, the SOH of the energy storage system is predicted. Using the expected SOH results and fuzzy control rules, an improved MPC is used to manage the energy output and reduce changes in the grid-connected power of wind power.

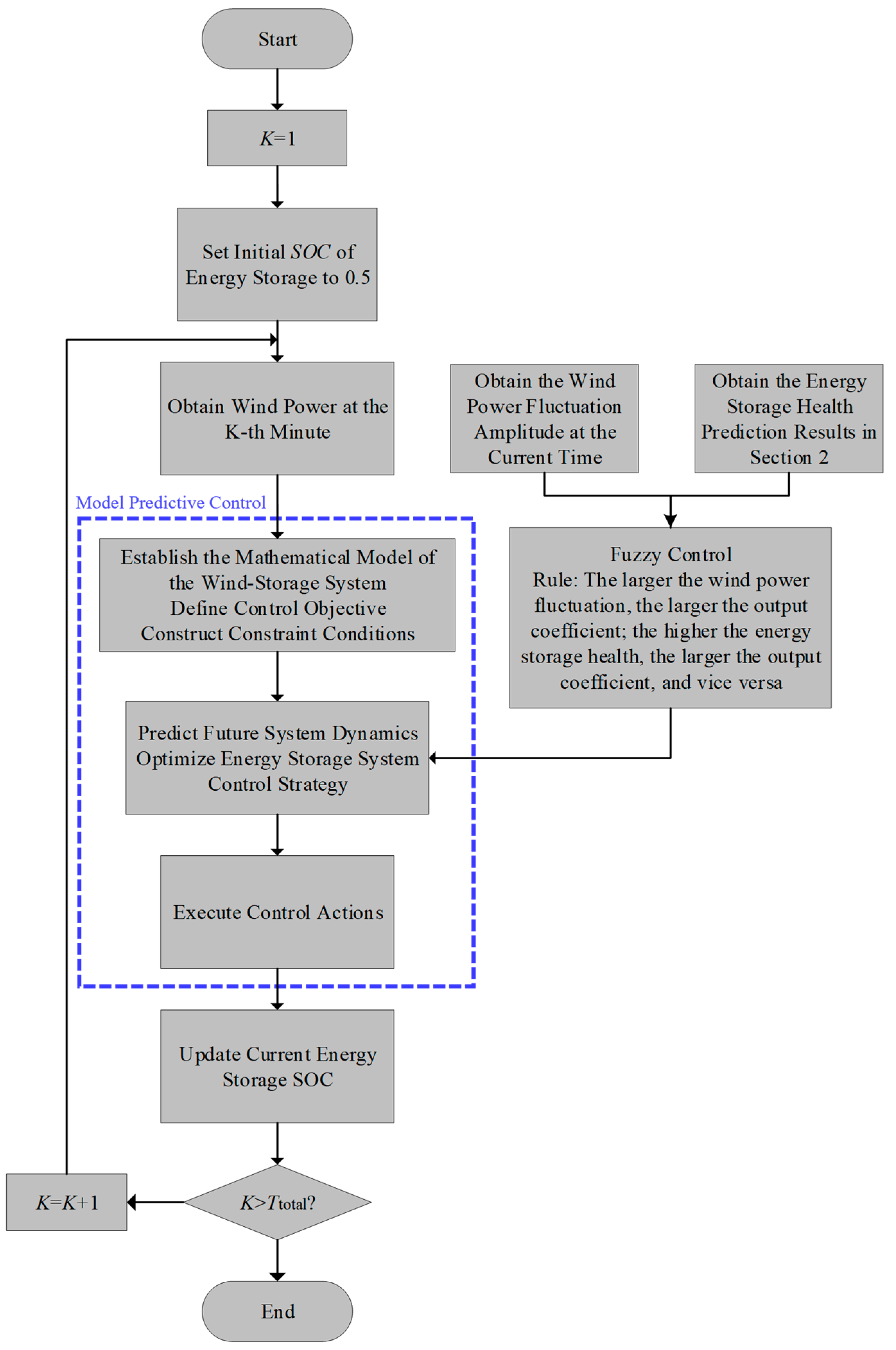

Figure 3 depicts the control flowchart, where the energy storage SOH is referenced in

Section 2.2.

Figure 3 illustrates the step-by-step process of the better control model that uses energy storage health predictions and fuzzy control rules. As seen in

Figure 3, the process will keep repeating, slowly making predictions and improvements until it reaches a total time of 600 min.

As seen in

Figure 3, the process will keep repeating, slowly making predictions and improvements until it reaches a total time of 600 min. In applying MPC, assume that the current control time node is

K (in minutes), and the total optimization control duration

T = 600 min. The optimization process can be described as follows:

Step 1: Initialization. Set the starting time node K = 1.

Step 2: At every moment K, by assessing the present circumstances, the state of the system in the future is anticipated and the control input is optimized to minimize the objective function.

Step 3: Control input update. The obtained control input is applied at the time node K based on the optimization results.

Step 4: Time node update. After the application of the control input, the time node is updated as K = K + 1.

Loop: Repeat steps 2–4 until the time node K reaches the total duration Ttotal = 600 min.

3.1. Model Predictive Control Algorithm for Energy Storage Power Optimization

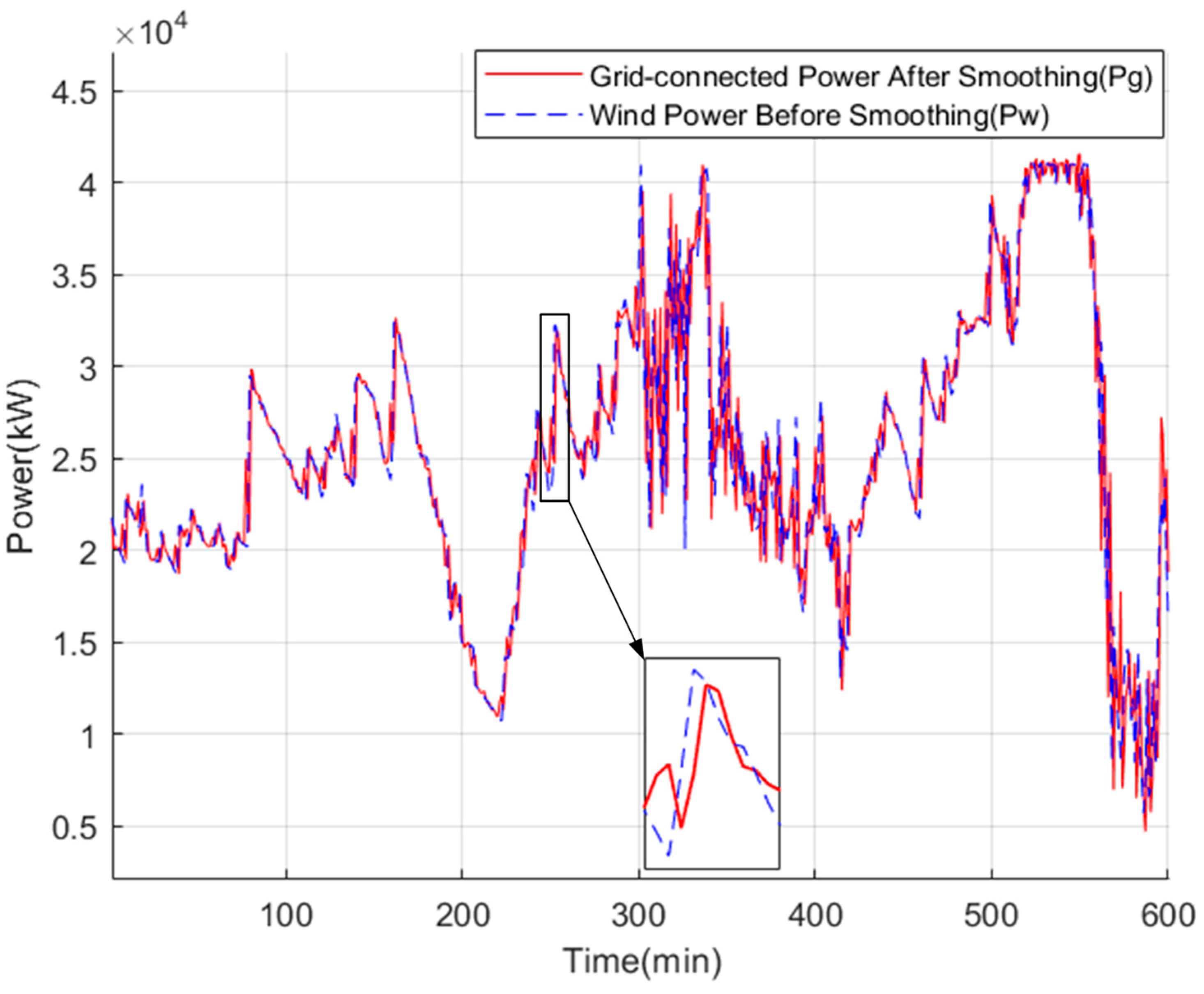

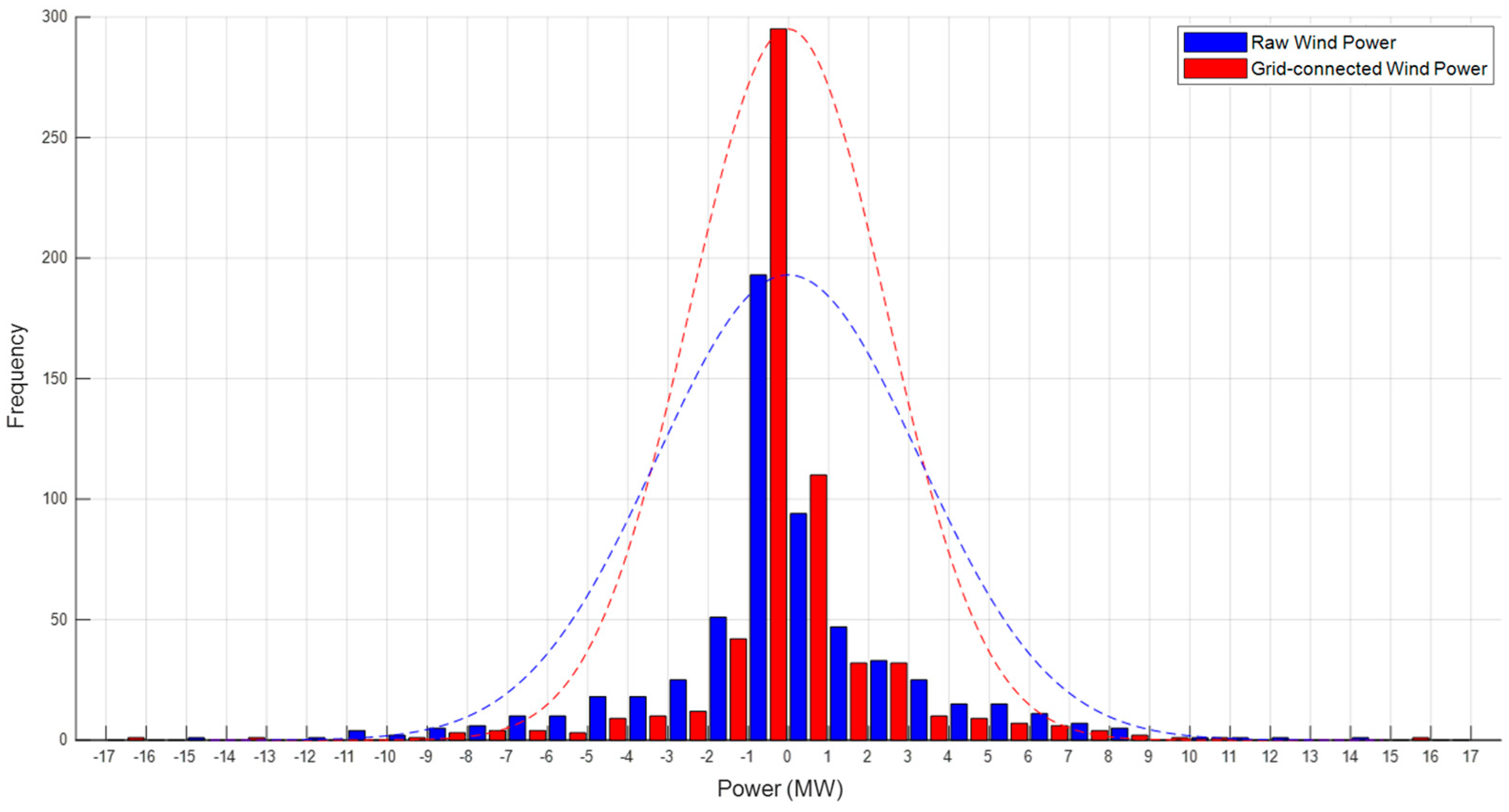

The wind power fluctuation needs to meet certain requirements for grid connection. The wind power grid connection conditions for the 50 MW wind farm studied in this paper are that the power fluctuation within 1 min should not exceed 1/10th of the installed capacity, and the power fluctuation within 10 min should not exceed 1/3rd of the installed capacity. On the other hand, the overall SOC constraints of the energy storage system must be considered. The goal of the control system is to reduce changes in power from the grid while keeping the SOC from becoming too high or too low. It also aims to avoid how often the battery needs to charge and discharge. The optimization model for the MPC algorithm is as follows:

In Equation (6), k represents the control time node, Pg is the wind power grid connection power in kilowatts, and Pb is the total energy storage power in kilowatts, where positive and negative Pb values indicate energy storage discharge power and energy storage absorption power, respectively. Furthermore, SOC represents the overall state of charge of the energy storage system, Eb is the rated capacity of the energy storage in kilowatt-hours, and Ts is the control period in minutes.

- (2)

Rolling Optimization Objective

Given the interdependence between wind power and energy storage, when the energy storage system has an adequate smoothing capacity, it should be utilized to minimize wind power fluctuations to the fullest extent. However, when the suppression capacity of energy storage is limited, the grid-connected fluctuations can be appropriately increased, or the energy storage output can be reduced, to restore the suppression capacity. Thus, considering the mutual constraints between the wind power fluctuation smoothing effect and the overall SOC of the energy storage, the overall target power of the hybrid energy storage system is optimized through a rolling process.

Building on the two points mentioned above, the optimization objective at time step

k for the

N prediction steps is as follows:

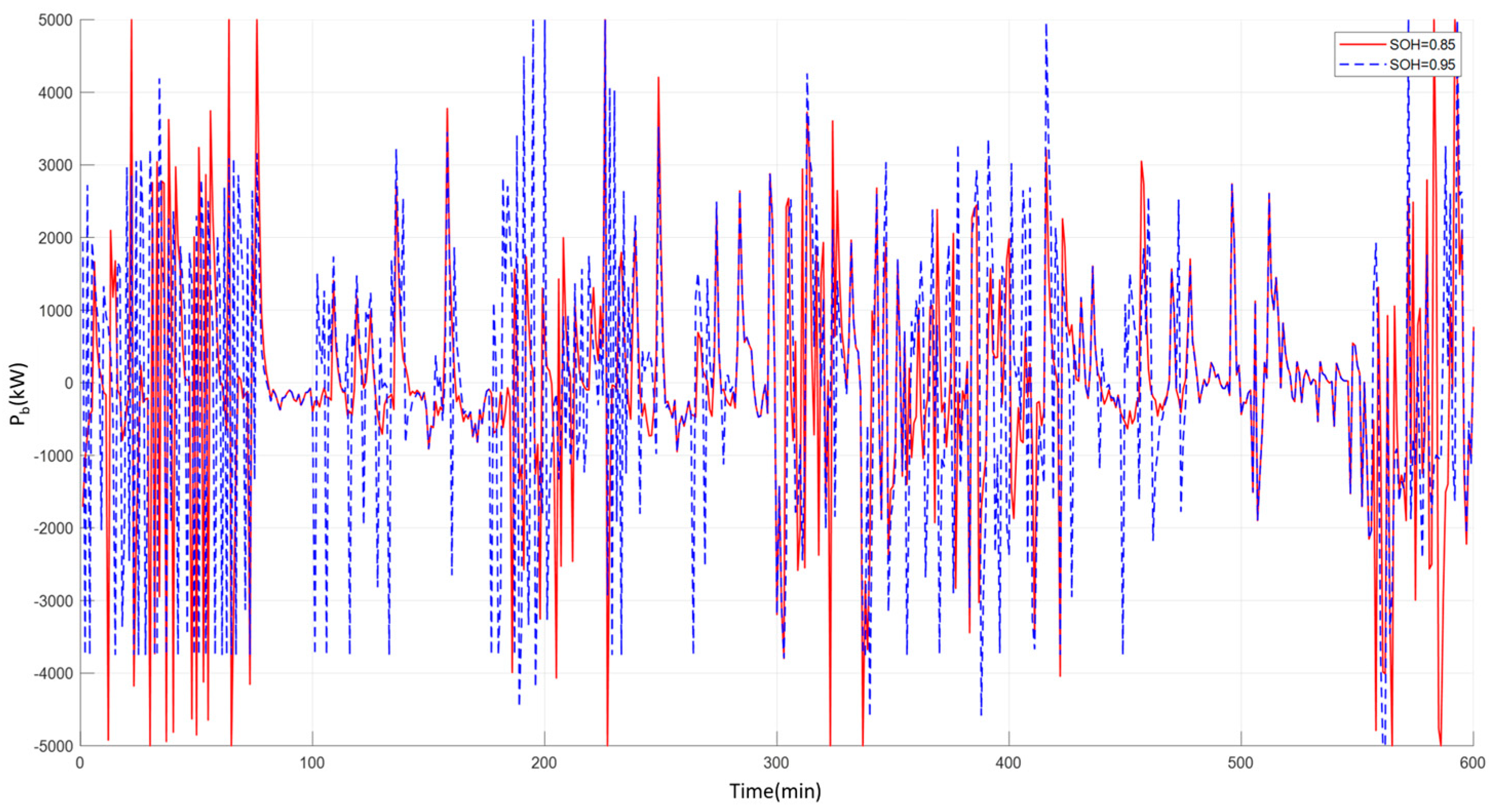

In Equation (7), ω(k) represents the charge and discharge capability index at time k, calculated based on the SOC and SOH of the hybrid energy storage system. A smaller value of ω(k) indicates reduced fluctuation in the grid-connected wind power relative to the wind farm’s generation power, and corresponds to a higher energy storage output. As the SOH of the energy storage declines, the dischargeable energy decreases as the SOC approaches its minimum value, resulting in a reduced discharge capability. The discharge depth required to release the same amount of energy will increase. The discharge depth is an important factor affecting energy storage health. Therefore, under different health conditions, the parameter ω can be adjusted to appropriately increase the wind power fluctuation under the condition of satisfying the grid-connected power fluctuation. This adjustment reduces the energy storage output, and prevents the situation where the energy storage’s health deteriorates more rapidly with the progression of usage time.

- (3)

Constraints

The MPC must also satisfy the following constraints, including energy storage power constraints, SOC constraints, and wind power fluctuation constraints:

In Equation (8), and are the minimum and maximum limits of the energy storage SOC, which are 0.1 and 0.9, respectively, is the fluctuation limit per unit time, set to 10% in this study, and Pmax is the maximum power constraint for the energy storage, which is equal to 8000 kW.

- (4)

Solution Process

The MPC mathematical model can be obtained as follows by rewriting the state-space Equation (6) in the following form:

where the system’s state variables

x(

k) include the grid-connected power and the SOC of the energy storage, and are represented as:

The system’s control variable

u(k) is the total power of the storage, given as:

The system’s measurable disturbance input

r(

k) is the wind power, defined as follows:

Therefore, based on the relationships between the variables in Equation (6), the coefficient matrices in Equation (9) can be written as

At time

k,

x(

k) is the known actual state value, and Equation (9) can be derived for time

k + 1 as

Let the state variable sequence, control variable, and disturbance sequence be

By analogy, the expression for the state variable at each time step can be obtained. Let

x(

k) =

x0, then Equation (9) can be extended as follows:

The extended coefficient matrix is

Using this matrix operation, all state variables in the optimization objective can be represented by the control variables. The constant terms that do not participate in the optimization, are omitted. Subsequently, the objective function can be converted into a standard quadratic programming form as follows:

In Equation (18), H and f denote the quadratic and linear coefficient matrices, respectively, corresponding to the control variables to be determined.

3.2. Fuzzy Control-Based Adaptive Adjustment of MPC Parameters

In the previous section, the power smoothing strategy based on the MPC algorithm considered the impact of the energy storage system’s SOC and wind power fluctuations on the minimum output of the energy storage system. However, the output capability of the energy storage system will gradually weaken as its health declines. In this case, it is necessary to appropriately reduce the energy storage output within the acceptable range of grid-connected power fluctuations. On the other hand, the energy storage output needs to be increased when wind power experiences severe fluctuations.

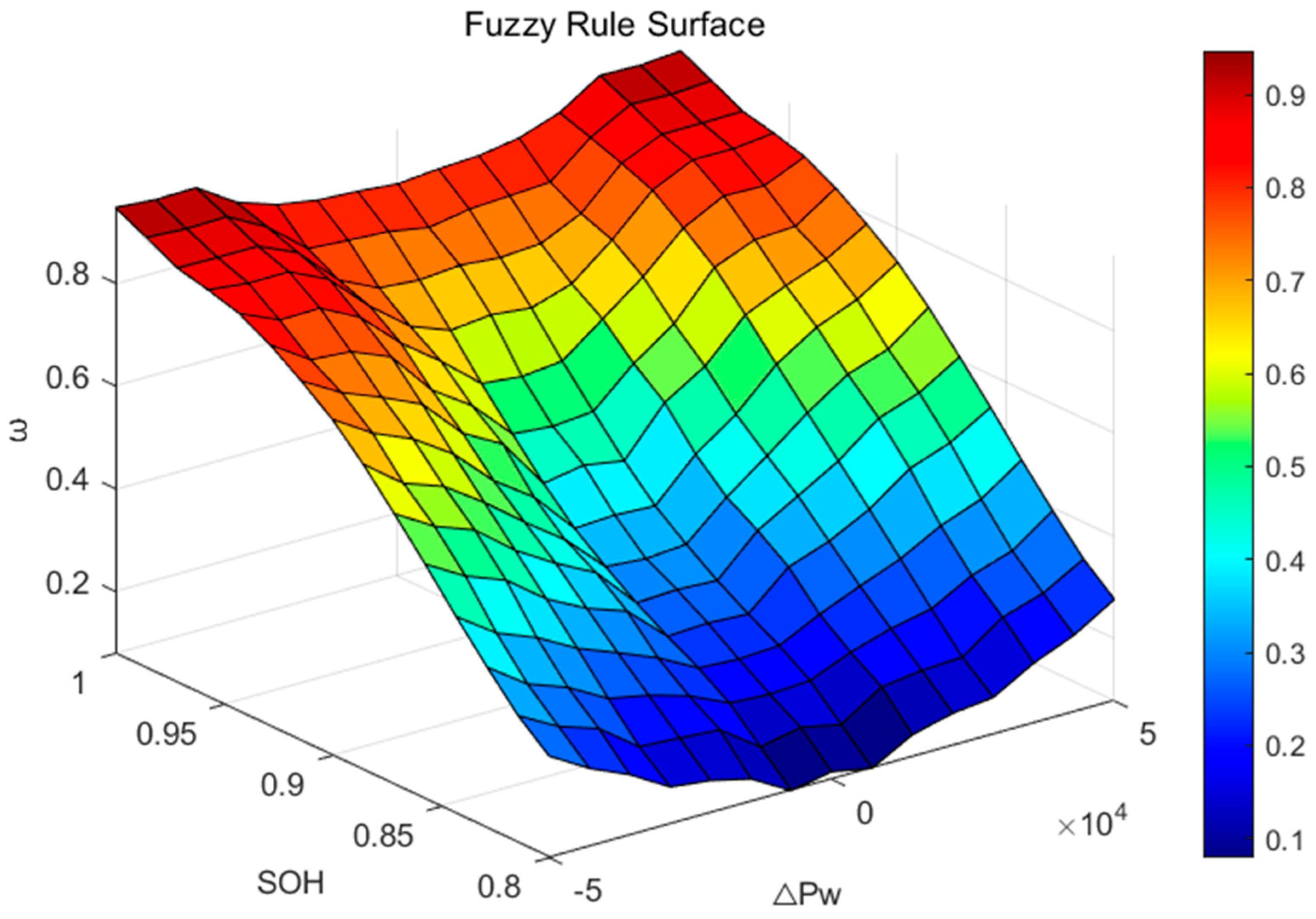

To optimize the control performance of the energy storage system, this study develops fuzzy control rules, using the SOH of the energy storage system and the active power variation relative to the previous minute as the input variables for the controller. The weight coefficient ω of the MPC is used as the control output to adaptively adjust the weight relationship between the energy storage battery’s output and the grid-connected power fluctuation suppression.

Specifically, under the same state of health of the energy storage battery, larger wind power fluctuations lead to greater energy storage output, while smaller wind fluctuations result in reduced output from the energy storage system. On the other hand, for the same wind power fluctuation, as the state of health of the energy storage battery decreases, its charging and discharging capacity is also reduced, which leads to a corresponding decrease in the energy storage output. Under the premise of meeting the grid connection requirements, this mechanism reduces the energy demand during the charging and discharging process, thus minimizing the negative impact on the battery’s health and balancing the trade-off between fluctuation suppression and battery lifespan.

This paper constructs the membership functions for the inputs and outputs using triangular shape functions, and designs the fuzzy linguistic values for each group as follows:

Input 1: This is the SOH value, with a continuous domain of [0.8, 1] and a fuzzy domain of {0.8, 0.85, 0.9, 0.95, 1}, corresponding to the fuzzy subsets {VS, S, M, L, VL}. These subsets represent the SOH values as {Very Small, Small, Medium, Large, Very Large}.

Input 2: At each moment, the change in active power of the wind farm relative to the previous minute has a continuous domain of [−20,000, 20,000], corresponding to a fuzzy domain of {−50,000, −30,000, −10,000, 10,000, 30,000, 50,000}, and the corresponding fuzzy subsets {NL, NM, NS, PS, PM, PL}. These subsets represent the current power fluctuation as {Negative Large, Negative Medium, Negative Small, Positive Small, Positive Medium, Positive Large}. When the discharge power signal is negative, it indicates a charging power signal.

Output: The continuous domain for the weight coefficient ω is [0, 1], with a fuzzy domain of {0, 0.0125, 0.0250, 0.0375, 0.0500, 0.0675, 0.0800, 0.0975, 1}, and the corresponding fuzzy subsets {ES, VS, S, MS, M, ML, L, VL, EL}. These subsets represent the weight coefficient values as {Extremely Small, Small, Medium Small, Medium, Medium Large, Large, Very Large, Extremely Large}.

Table 1 shows the specific fuzzy control rules.