Plugging Experiments for Ceramic Filling Layer with Different Grain Sizes Under Gas–Water Mixed Flow for Natural Gas Hydrate Development

Abstract

1. Introduction

2. Materials and Methods

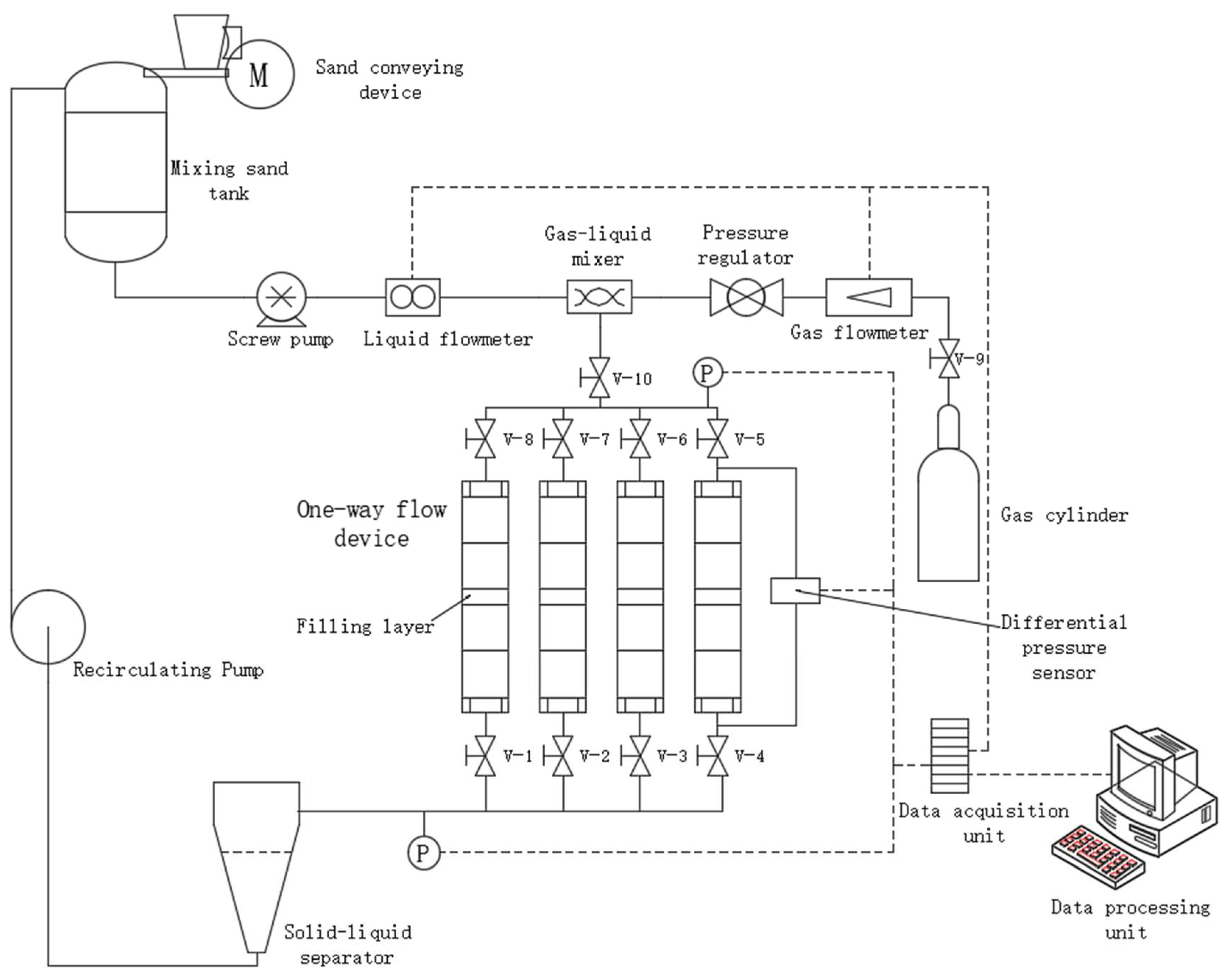

2.1. Experimental Principle and Experimental Apparatus

2.2. Experimental Methods and Experimental Materials

2.2.1. Experimental Methods

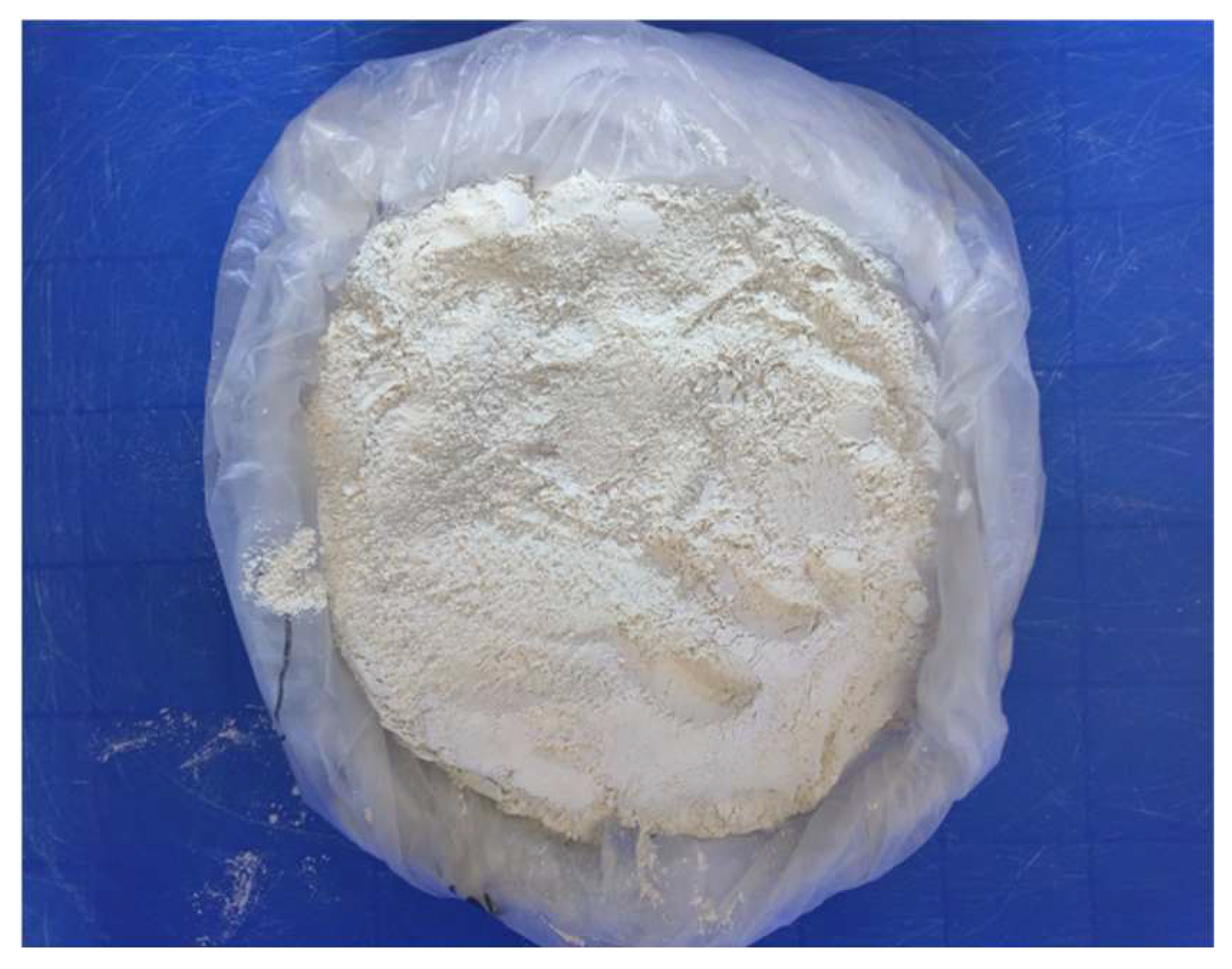

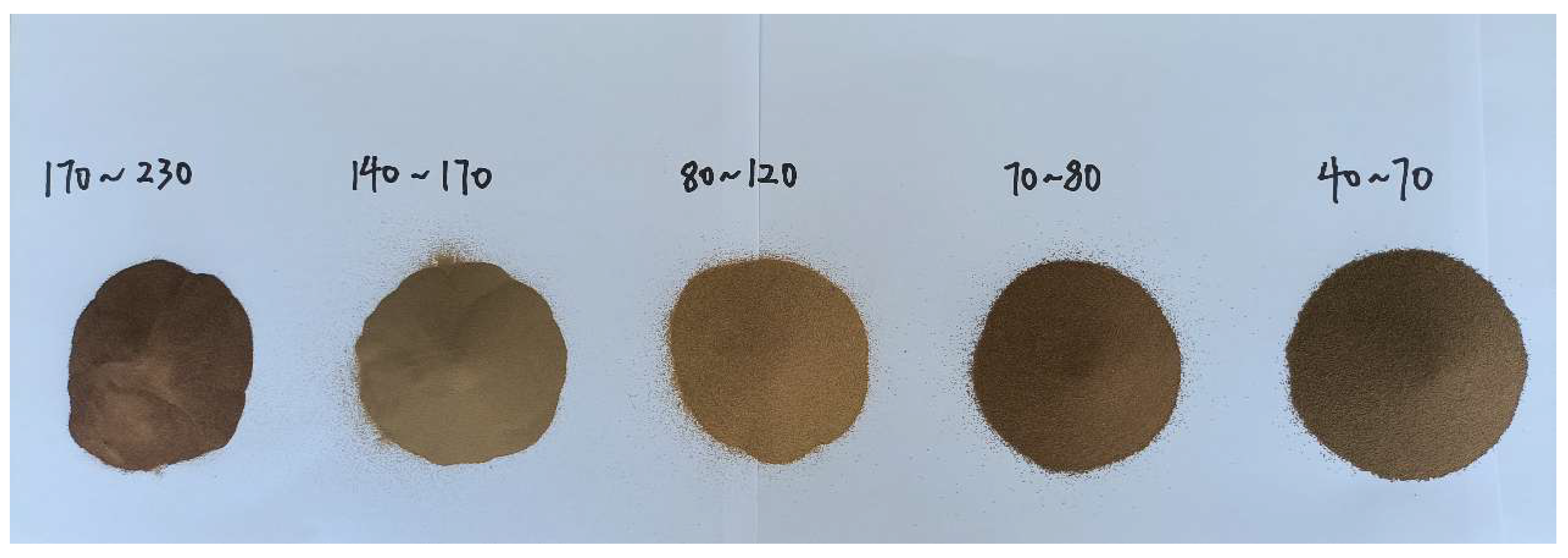

2.2.2. Experimental Materials

2.3. Experimental Conditions [32]

3. Results and Discussion

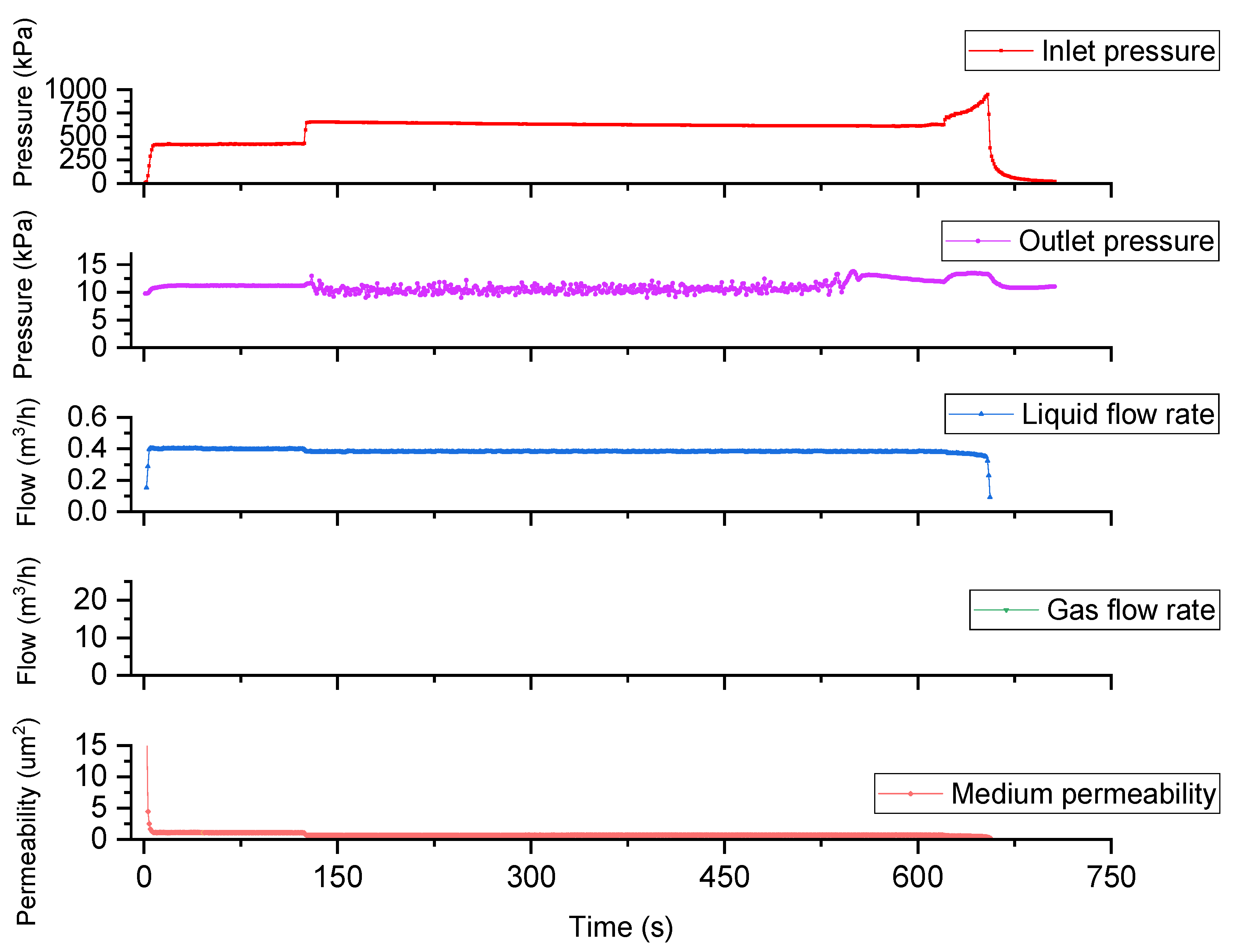

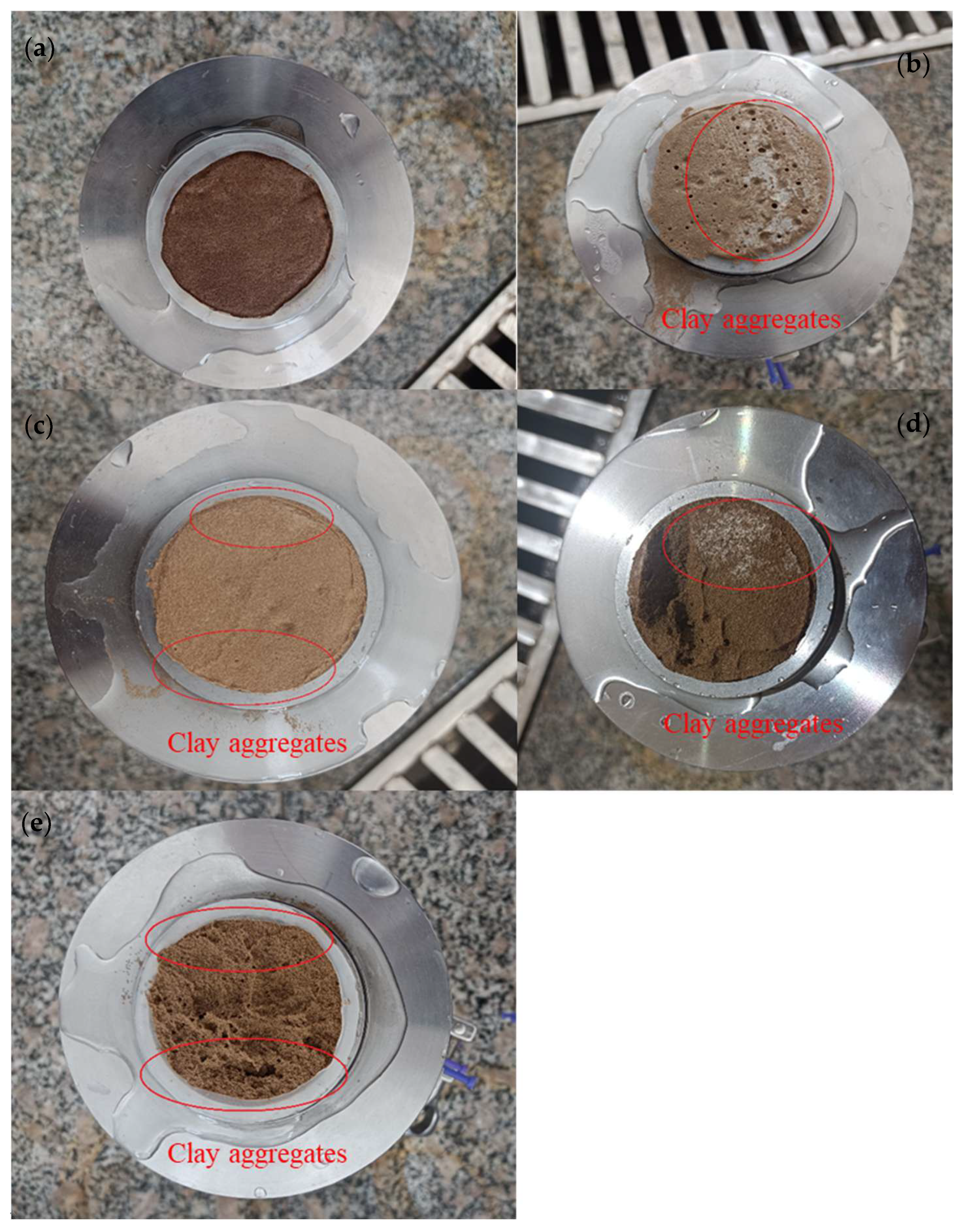

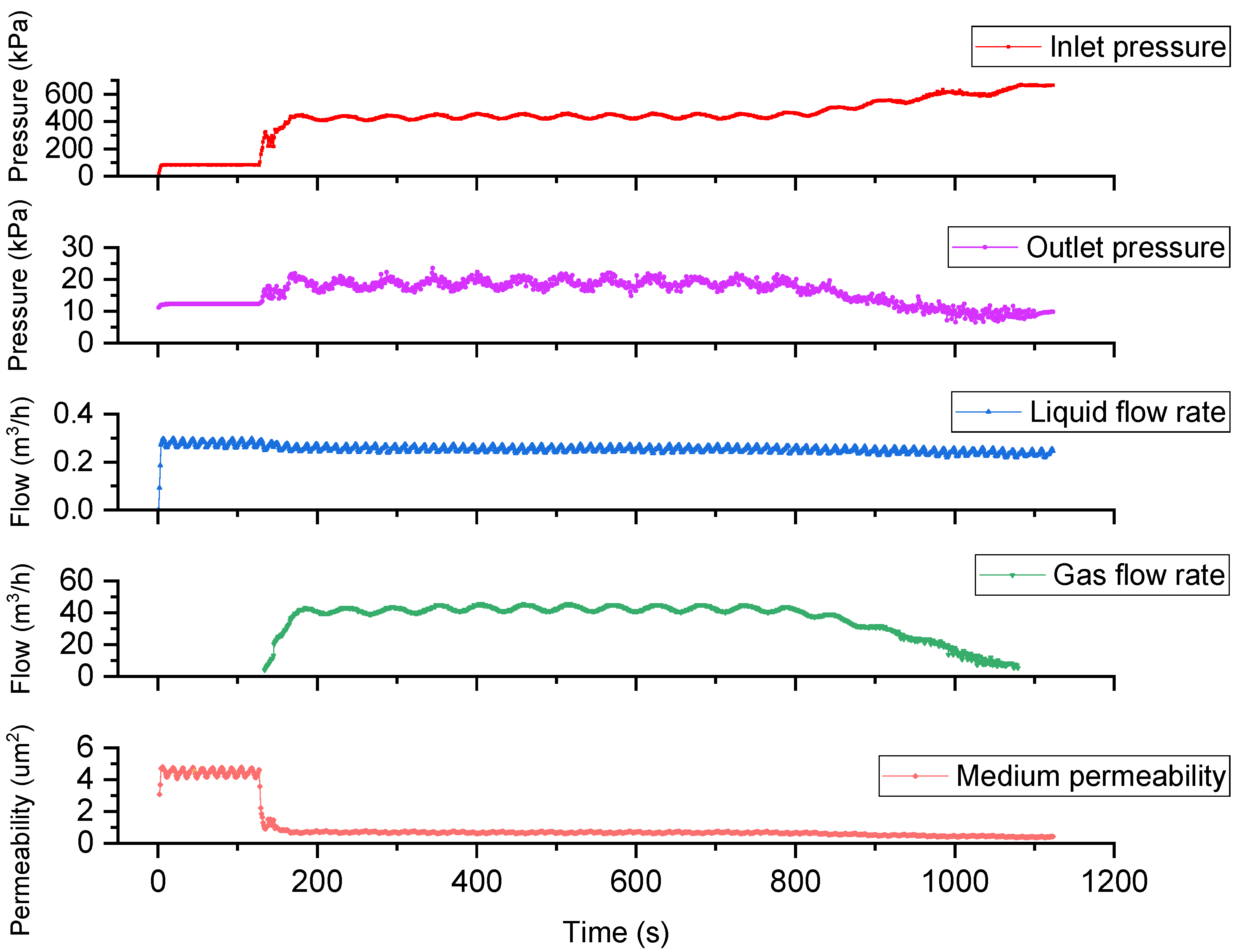

3.1. Fine-Grained Ceramic Layer (170–230 Mesh) Plugging Dynamics

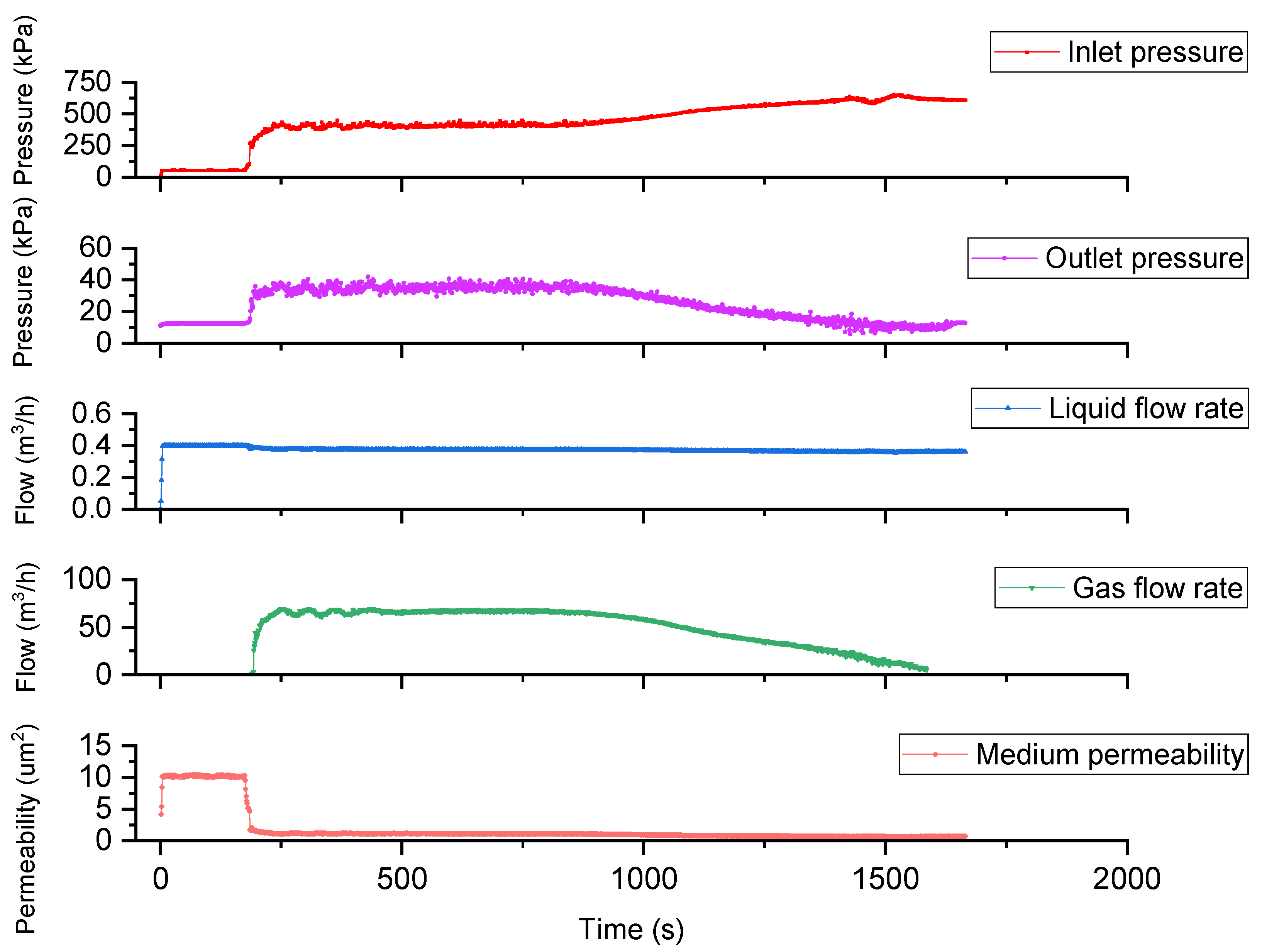

3.2. Medium-to-Coarse Ceramic Layers (140–170, 80–120, and 70–80 Mesh) and Three-Phase Plugging Behavior

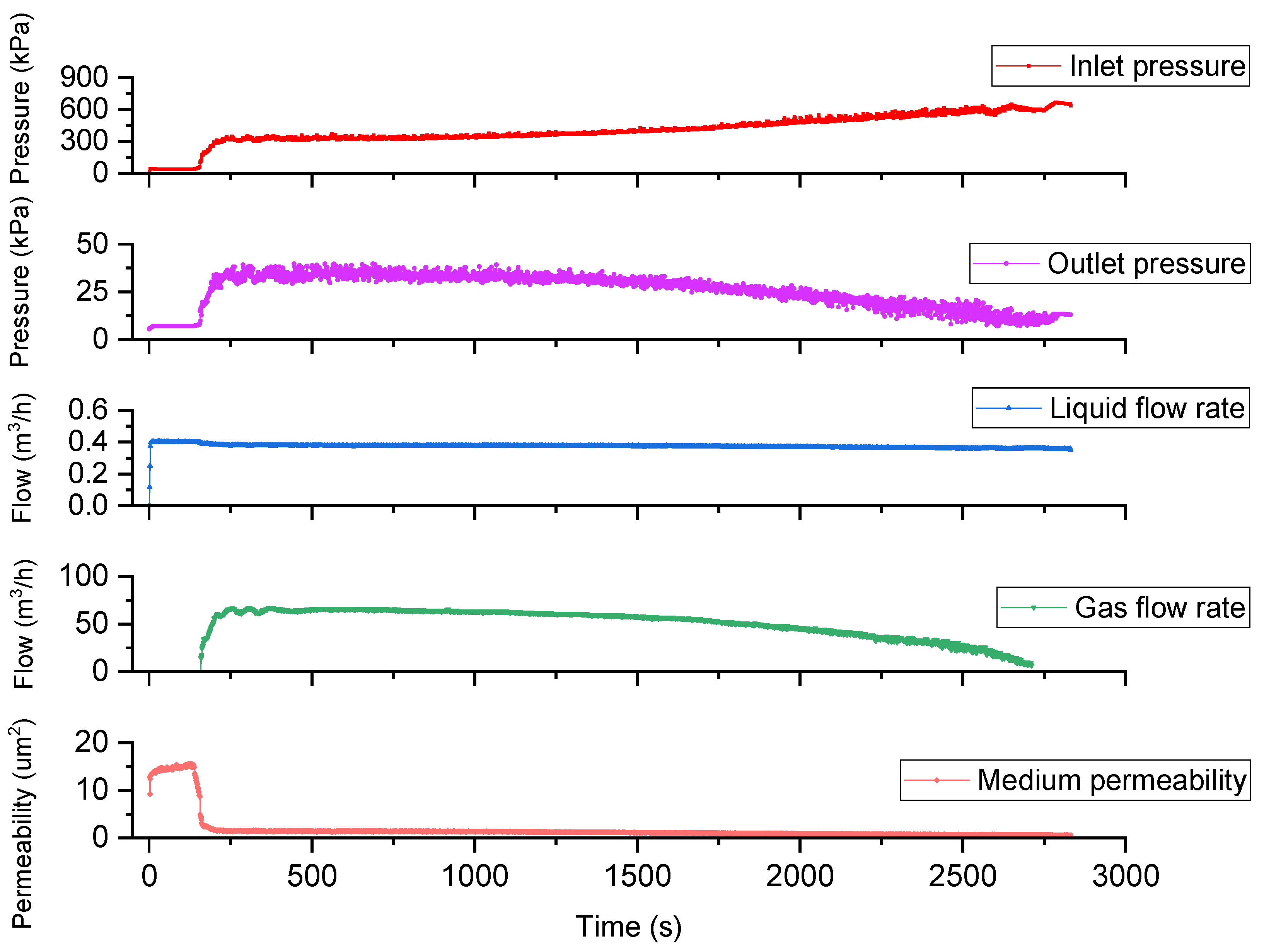

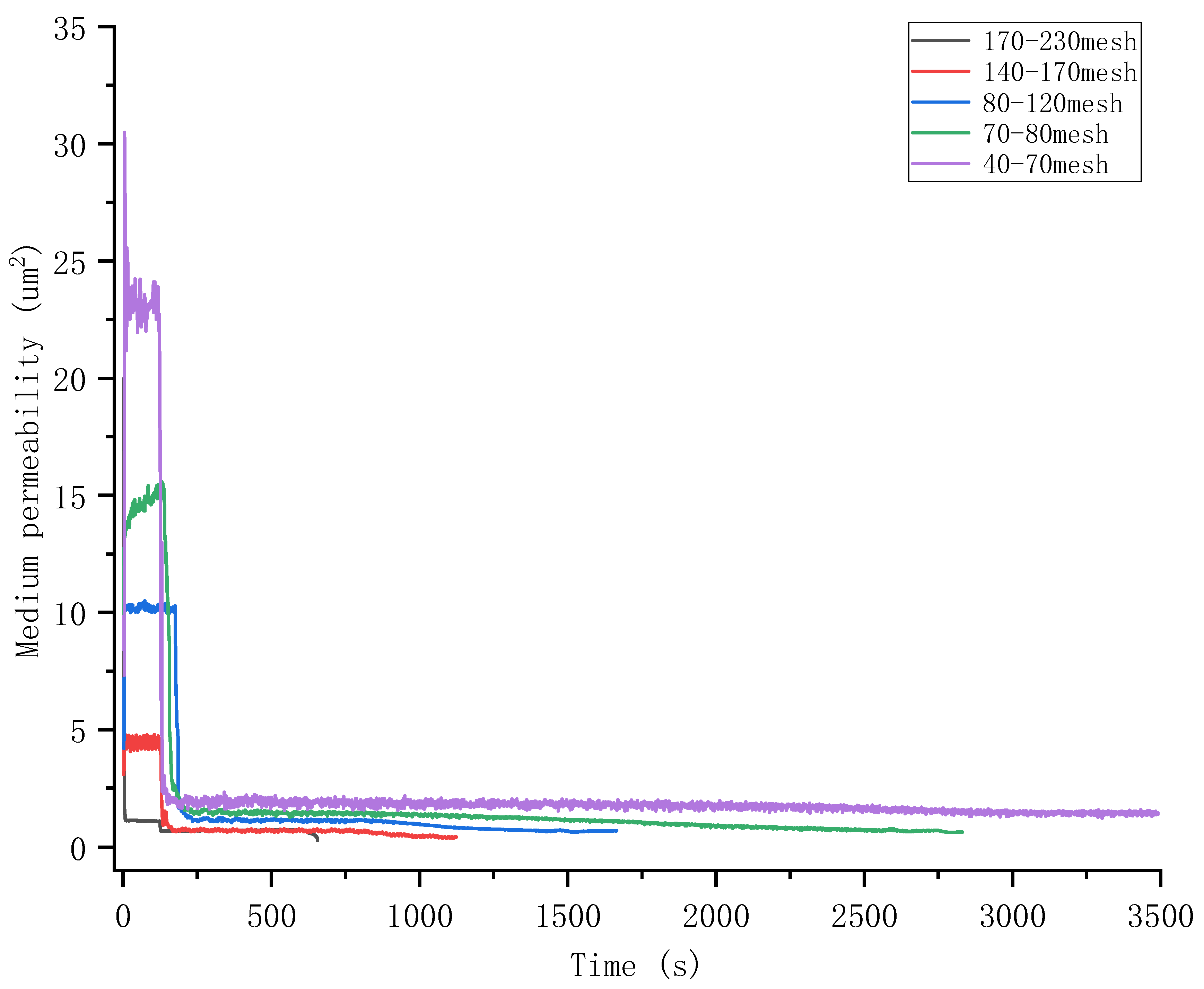

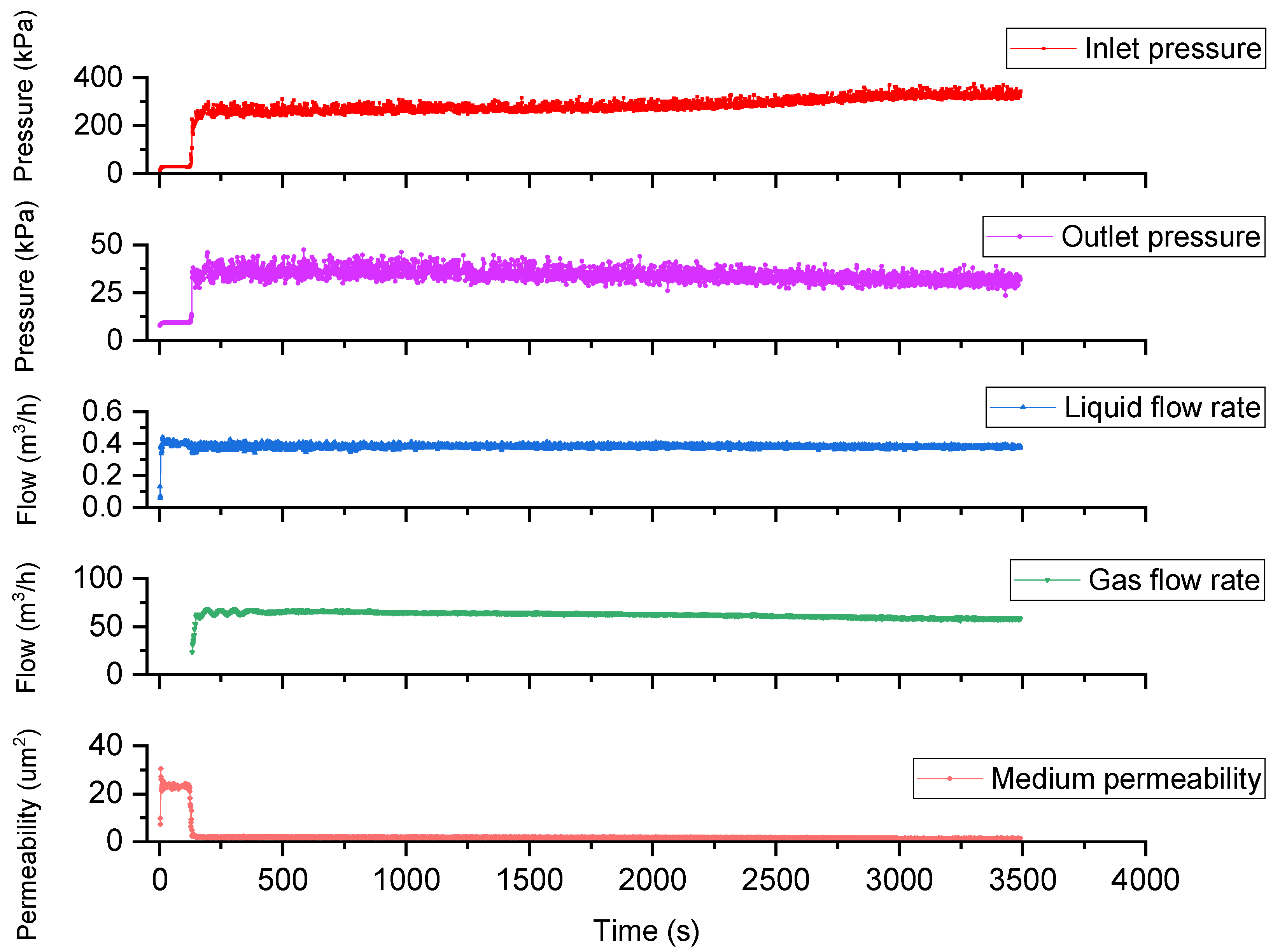

3.3. Coarse Ceramic Layer (40–70 Mesh) and Saucier Criterion Reassessment

3.4. Limitations and Field Implications

4. Conclusions

- (1)

- Limitations of Conventional Criteria in Mud-Rich Hydrate Systems: The Saucier criterion (median grain size ratio = 5–6), widely adopted in unconsolidated sandstones, proves inadequate for hydrate reservoirs with high shale content (e.g., 39% clay in South China Sea analogs). Our experiments reveal that even at a median grain size ratio of 24 (70–80 mesh ceramics), rapid plugging occurs due to mud-cake formation under gas–water mixed flow (Figure 5). This challenges the universality of traditional sand control design and necessitates a revised threshold (median grain size ratio ≥ 30) for hydrate-specific conditions, where clay migration dominates permeability loss over mechanical sand retention.

- (2)

- Optimized Ceramic Grading Strategy for Productivity Preservation: The median grain size ratio, gradientally distributed between 24–31, emerges as the critical balance point, achieving 54% retained permeability (initial k = 15.3 μm2, final k = 8.3 μm2) while blocking > 95% of formation sand (>20 μm). To address the transient fines invasion observed in “three-stage plugging” (Section 3.2), we propose a dual-layer graded packing. Primary layer: ceramics with a 40–70 mesh size (critical median grain size ratio of 27 ± 2) used for coarse sand retention through mechanical sieving and pore size optimization. Secondary layer: ceramics with a median grain size ratio in the 24–31 range to mitigate clay migration via gradient pore blocking and electrostatic stabilization. This configuration leverages the self-sealing behavior of mud cakes while minimizing the skin factor, offering a 23% productivity improvement over single-layer designs (vs. Ref. [25]). By selecting an optimal median grain size ratio within the range of 24 to 31 for the secondary layer, both sand control efficiency and permeability retention can be further optimized.

- (3)

- Roadmap for Field Application and Knowledge Gaps: Key barriers to scaling laboratory findings include (a) temperature sensitivity: depressurization-induced cooling (ΔT ≈ −2 °C [4]) may alter clay swelling dynamics, unaccounted for in current isothermal experiments; (b) long-term stability: ceramic abrasion and chemical interactions (e.g., hydrate reformation in pores) require >1000-h cyclic flow tests; and (c) radial flow bias: unidirectional experiments underestimate screen erosion in the radial wells (3× higher plugging rates observed in Ref. [25]). To bridge these gaps, future work should prioritize (a) multi-physics modeling: integrate thermal-hydraulic-mechanical (THM) coupling with DEM to predict mud-cake evolution; (b) material engineering: develop hydrophobic ceramic coatings (e.g., silane grafting [22]) to inhibit clay adhesion; and (c) field pilots: validate graded packing in offshore hydrate trials with real-time P/T/sand monitoring (e.g., China’s Shenhu Area).

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhang, X.; Lu, X.; Liu, L. Advances in natural gas hydrate recovery methods. Prog. Geophys. 2014, 29, 858–869. (In Chinese) [Google Scholar] [CrossRef]

- Jia, R.; Xu, J.; Hao, D.; Li, Q.; Yang, G. The influence of reservoir and exploitation parameters on production capacity of gas hydrate. Mar. Geol. Quat. Geol. 2023, 43, 202–216. (In Chinese) [Google Scholar] [CrossRef]

- Li, S.; Guo, S.; Chen, Y.; Zhang, N.; Wu, D. Advances and recommendations for multi-field characteristics and coupling seepage in natural gas hydrate development. Chin. J. Theor. Appl. Mech. 2020, 52, 828–842. (In Chinese) [Google Scholar] [CrossRef]

- Rutqvist, J.; Moridis, G.J.; Grover, T.; Collett, T. Geomechanical response of permafrost-associated hydrate deposits to depressurization-induced gas production. J. Pet. Sci. Eng. 2009, 67, 1–12. [Google Scholar] [CrossRef]

- Akaki, T.; Kimoto, S. Numerical modelling of internal erosion during hydrate dissociation based on multiphase mixture theory. Int. J. Numer. Anal. Methods Geomech. 2020, 44, 327–350. [Google Scholar] [CrossRef]

- Rutqvist, J.; Moridis, G.; Grover, T.; Silpngarmlert, S.; Collett, T.; Holdich, S. Coupled multiphase fluid flow and wellbore stability analysis associated with gas production from oceanic hydrate-bearing sediments. J. Pet. Sci. Eng. 2012, 92, 65–81. [Google Scholar] [CrossRef]

- Yan, C.; Dong, L.; Ren, X.; Cheng, Y. Stability of submarine slopes during replacement of methane in natural gas hydrates with carbon dioxide. J. Clean. Prod. 2023, 383, 135440. [Google Scholar] [CrossRef]

- He, Y.; Song, B.; Li, Q. Coupling Submarine Slope Stability and Wellbore Stability Analysis with Natural Gas Hydrate Drilling and Production in Submarine Slope Strata in the South China Sea. J. Mar. Sci. Eng. 2023, 11, 2069. [Google Scholar] [CrossRef]

- Jia, R.; Xu, J.; Li, Q.; Yang, G. Analysis of the influence of depressurization amplitude and sand blockage on gas hydrate production capacity. Sci. Technol. Eng. 2023, 23, 6434–6447. (In Chinese) [Google Scholar] [CrossRef]

- Guo, W.; Zhang, P.; Zhong, X.; Wang, X.; Jia, R.; Chen, C.; Wang, Y. Retrospect, Exploration, andInnovation: A ReviewontheTenthInternational Conference on Gas Hydrates. J. Jilin Univ. (Earth Sci. Ed.) 2023, 53, 1760–1772. (In Chinese) [Google Scholar] [CrossRef]

- Wang, Z.; Gong, J.; Wu, J.; Yin, H.; Shi, S.; Yan, J.; Li, X. Research progress on key technologies for drilling and completion of offshore gas hydrate. Sci. Technol. Rev. 2023, 41, 71–78. (In Chinese) [Google Scholar] [CrossRef]

- Shao, M.; Wang, P.; Wu, L.; Zhang, W.; Tian, Q. A comparative analysis of offshore gas hydrates production test in Japan. Mar. Geol. Front. 2022, 38, 8–15. (In Chinese) [Google Scholar] [CrossRef]

- Lu, J.; Lin, D.; Li, D.; Liang, D.; Zhang, Y.; Wu, S.; He, Y.; Shi, L. Research Status on Water Controlling and Sand Controlling in Horizontal Well Completion during Gas Hydrate Exploitation. Adv. New Renew. Energy 2022, 10, 447–455. (In Chinese) [Google Scholar] [CrossRef]

- Wang, H.; Wang, J.; Yu, C.; Liu, Y. Key Technologies for Natural Gas Hydrate Mining. Drill. Prod. Technol. 2022, 45, 51–56. (In Chinese) [Google Scholar] [CrossRef]

- Liu, C.; Ye, Y.; Meng, Q.; Lu, Z.; Zhu, Y.; Liu, J.; Yang, S. Raman Spectroscopic Characteristics of Natural Gas Hydrate Recovered from Shenhu Area in South China Sea and Qilian Mountain Permafrost. Acta Chim. Sin. 2010, 68, 1881–1886. (In Chinese) [Google Scholar]

- Oyama, H.; Nagao, J.; Suzuki, K.; Narita, H. Experimental analysis of sand production from methane hydrate bearing sediments applying depressurization method. J. MMIJ 2010, 126, 497–502. [Google Scholar] [CrossRef]

- Oyama, H.; Konno, Y.; Masuda, Y.; Narita, H. Dependence of depressurization-induced dissociation of methane hydrate bearing laboratory cores on heat transfer. Energy Fuels 2009, 23, 4995–5002. [Google Scholar] [CrossRef]

- Jung, J.; Kang, H.; Cao, S.C.; Al-Raoush, R.I.; Alshibli, K.; Lee, J.Y. Effects of fine-grained particles’ migration and clogging in porous media on gas production from hydrate-bearing sediments. Geofluids 2019, 2019, 1–11. [Google Scholar] [CrossRef]

- Cao, S.C.; Jang, J.; Jung, J.; Waite, W.F.; Collett, T.S.; Kumar, P. 2D micromodel study of clogging behavior of fine-grained particles associated with gas hydrate production in NGHP-02 gas hydrate reservoir sediments. Mar. Pet. Geol. 2019, 108, 714–730. [Google Scholar] [CrossRef]

- Jung, J.W.; Jang, J.; Santamarina, J.C.; Tsouris, C.; Phelps, T.J.; Rawn, C.J. Gas production from hydrate-bearing sediments: The role of fine particles. Energy Fuels 2012, 26, 480–487. [Google Scholar] [CrossRef]

- Lu, J.; Li, D.; He, Y.; Shi, L.; Liang, D.; Xiong, Y. Study on Productivity and Sand Production of Marine Natural Gas Hydrate Development. Adv. New Renew. Energy 2020, 8, 227–233. (In Chinese) [Google Scholar] [CrossRef]

- Qiang, S.; Sun, Y.; Zhang, G.; Shen, Y.; Sun, Y.; Li, B. The influence of shape memory on the performance of polymers used for sand control in hydrate production wells. Drill. Eng. 2023, 50, 1–10. (In Chinese) [Google Scholar] [CrossRef]

- Dong, C.; Zhong, Y.; Wu, Y.; Zou, Y. Experimental study on sand retention mechanisms and feasibility evaluation of sand control for gas hydrate reservoirs with highly clayey fine sands. J. China Univ. Pet. 2018, 42, 79–87. (In Chinese) [Google Scholar] [CrossRef]

- Dong, C.; Zhou, B.; Song, Y.; Liu, C.; Deng, J. Sand-retaining simulation experiment of screen media for formation sand in natural gas hydrate reservoirs and evaluation method. J. China Univ. Pet. 2020, 44, 79–88. (In Chinese) [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, W.; Zhang, P.; Li, G.; Tian, S.; Lu, J.; Zhang, B. A solution to sand production from natural gas hydrate deposits with radial wells: Combined gravel packing and sand screen. J. Mar. Sci. Eng. 2022, 10, 71. [Google Scholar] [CrossRef]

- Ding, J.; Cheng, Y.; Yan, C.; Song, B.; Sun, H.; Teng, F. Experimental study of sand control in a natural gas hydrate reservoir in the South China sea. Int. J. Hydrogen Energy 2019, 44, 23639–23648. [Google Scholar] [CrossRef]

- Ding, J.; Cheng, Y.; Yan, C. Research on sand control effect and micro-plugging mechanism of sand control medium in the development of natural gas hydrate reservoir. J. Pet. Sci. Eng. 2022, 215, 110703. [Google Scholar] [CrossRef]

- Li, X.; Hu, H.; Wang, Y. Experimental study of gas-liquid-sand production behaviors during gas hydrates dissociation with sand control screen. Energy 2022, 254, 124414. [Google Scholar] [CrossRef]

- Yoneda, J.; Masui, A.; Konno, Y.; Jin, Y.; Egawa, K.; Kida, M.; Ito, T.; Nagao, J.; Tenma, N. Mechanical properties of hydrate-bearing turbidite reservoir in the first gas production test site of the Eastern Nankai Trough. Mar. Pet. Geol. 2015, 66, 471–486. [Google Scholar] [CrossRef]

- Ye, J.; Qin, X.; Xie, W.; Lu, H.; Ma, J.; Qiu, H.; Liang, J.; Lu, J.; Kuang, Z.; Lu, C.; et al. Main progress of the second gas hydrate trial production in the South China Sea. Geol. China 2020, 47, 557–568. (In Chinese) [Google Scholar] [CrossRef]

- Chen, F.; Zhou, Y.; Su, X.; Liu, G.; Lu, H.; Wang, J. Gas hydrate saturation and its relation with grain size of the hydrate-bearing sediments in the shenhu area of northern south china sea. Mar. Geol. Quat. Geol. 2011, 31, 95–100. (In Chinese) [Google Scholar] [CrossRef]

- Zhao, X. Plugging Experiments on Different Packing Schemes during Hydrate Exploitation by Depressurization. Processes 2023, 11, 2075. [Google Scholar] [CrossRef]

- Teng, F. Experimental Study on Sand Production of Natural Gas Hydrate Reservoir. Master’s Thesis, China University of Petroleum, Beijing, China, 2018. [Google Scholar] [CrossRef]

- Dullien, F.A.L. Porous Media: Fluid Transport and Pore Structure; Academic Press: Cambridge, MA, USA, 1992. [Google Scholar]

- Xiao, B.; Zhu, H.; Chen, F.; Long, G.; Li, Y. A fractal analytical model for Kozeny-Carman constant and permeability of roughened porous media composed of particles and converging-diverging capillaries. Powder Technol. 2023, 420, 118256. [Google Scholar] [CrossRef]

| Sample Types | Median Grain Size (d50) /μm | Particle Size Interval /μm | Median Grain Size Ratio | Note |

|---|---|---|---|---|

| 170–230 mesh | 82.075 | 17.125~251.105 | 8 | Custom |

| 140–170 mesh | 128.12 | 58.041~283.704 | 12 | Custom |

| 80–120 mesh | 183.358 | 83.707~409.163 | 17 | Custom |

| 70–80 mesh | 248.57 | 106.852~22.296 | 24 | Custom |

| 40–70 mesh | 330.396 | 196.714~51.056 | 31 | Existing |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, X.; Zhao, Y.; Mu, M.; Zhou, A.; Zhao, H.; Xie, F. Plugging Experiments for Ceramic Filling Layer with Different Grain Sizes Under Gas–Water Mixed Flow for Natural Gas Hydrate Development. Energies 2025, 18, 1761. https://doi.org/10.3390/en18071761

Zhao X, Zhao Y, Mu M, Zhou A, Zhao H, Xie F. Plugging Experiments for Ceramic Filling Layer with Different Grain Sizes Under Gas–Water Mixed Flow for Natural Gas Hydrate Development. Energies. 2025; 18(7):1761. https://doi.org/10.3390/en18071761

Chicago/Turabian StyleZhao, Xiaolong, Yizhong Zhao, Meng Mu, Aiyong Zhou, Haifeng Zhao, and Fei Xie. 2025. "Plugging Experiments for Ceramic Filling Layer with Different Grain Sizes Under Gas–Water Mixed Flow for Natural Gas Hydrate Development" Energies 18, no. 7: 1761. https://doi.org/10.3390/en18071761

APA StyleZhao, X., Zhao, Y., Mu, M., Zhou, A., Zhao, H., & Xie, F. (2025). Plugging Experiments for Ceramic Filling Layer with Different Grain Sizes Under Gas–Water Mixed Flow for Natural Gas Hydrate Development. Energies, 18(7), 1761. https://doi.org/10.3390/en18071761