A Novel Regularization Model for Inversion of the Fracture Geometric Parameters in Hydraulic-Fractured Shale Gas Wells

Abstract

1. Introduction

2. Basis of Fracture Modeling and Inversion

2.1. Related Works

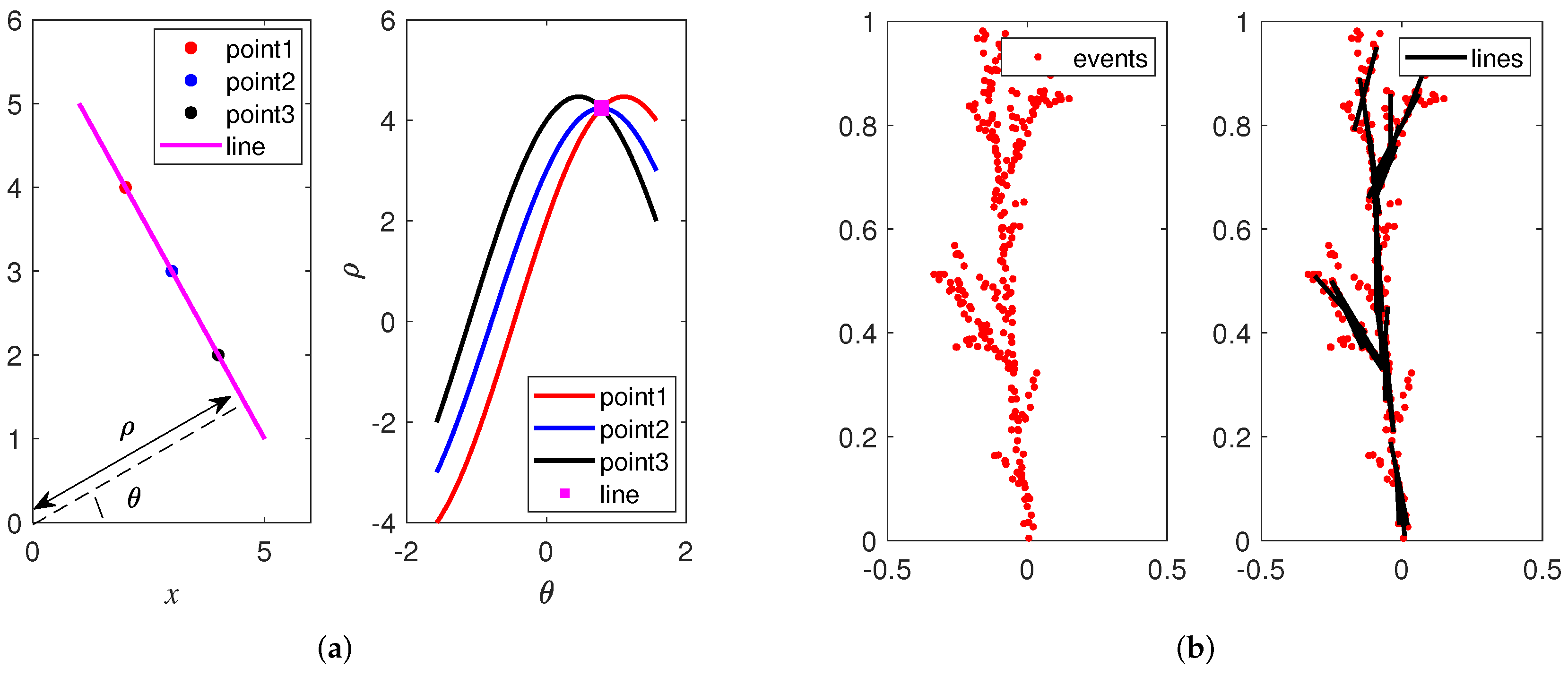

2.2. HF Transform

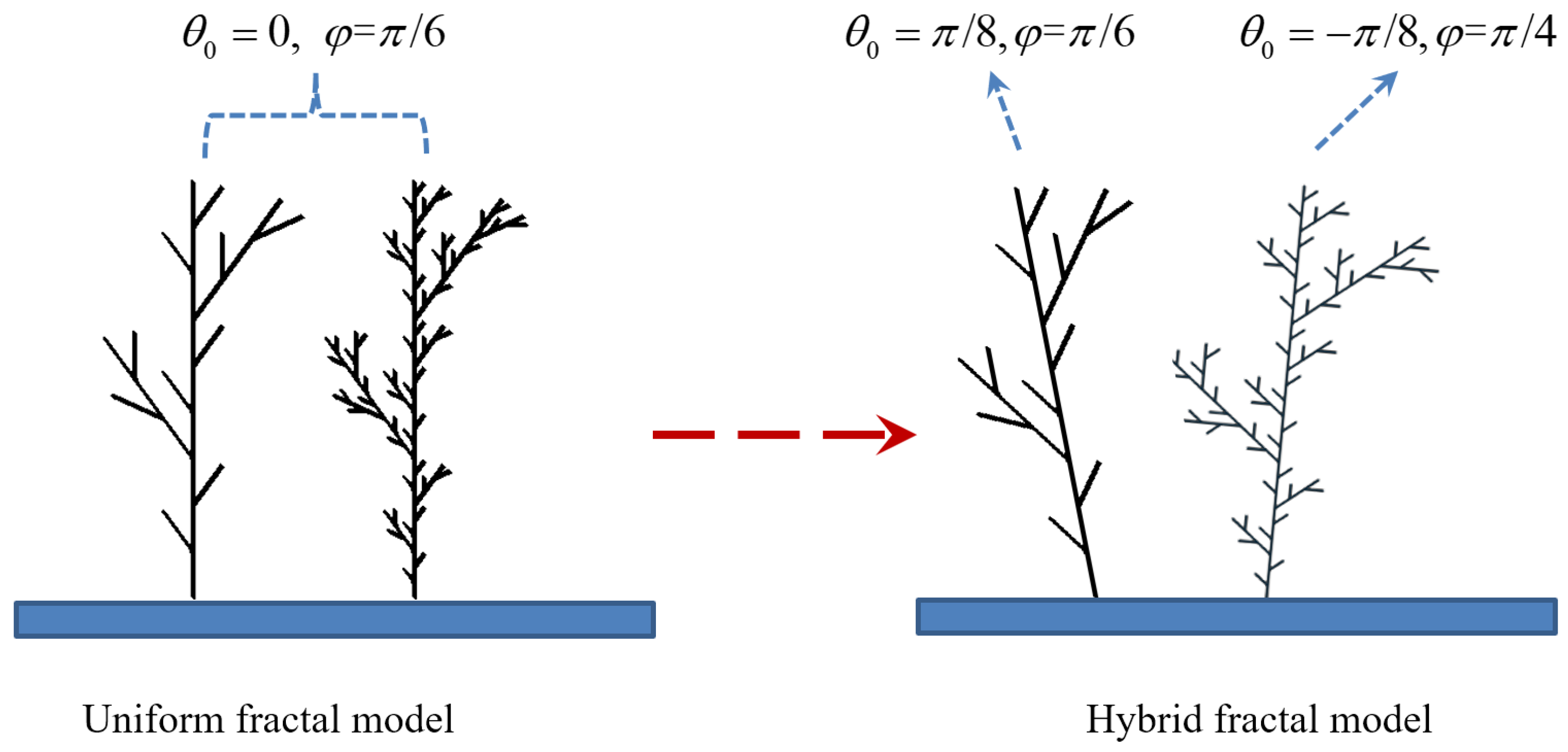

2.3. Fractal Tree

2.4. Inversion Problem and Regularization

3. Proposed Method

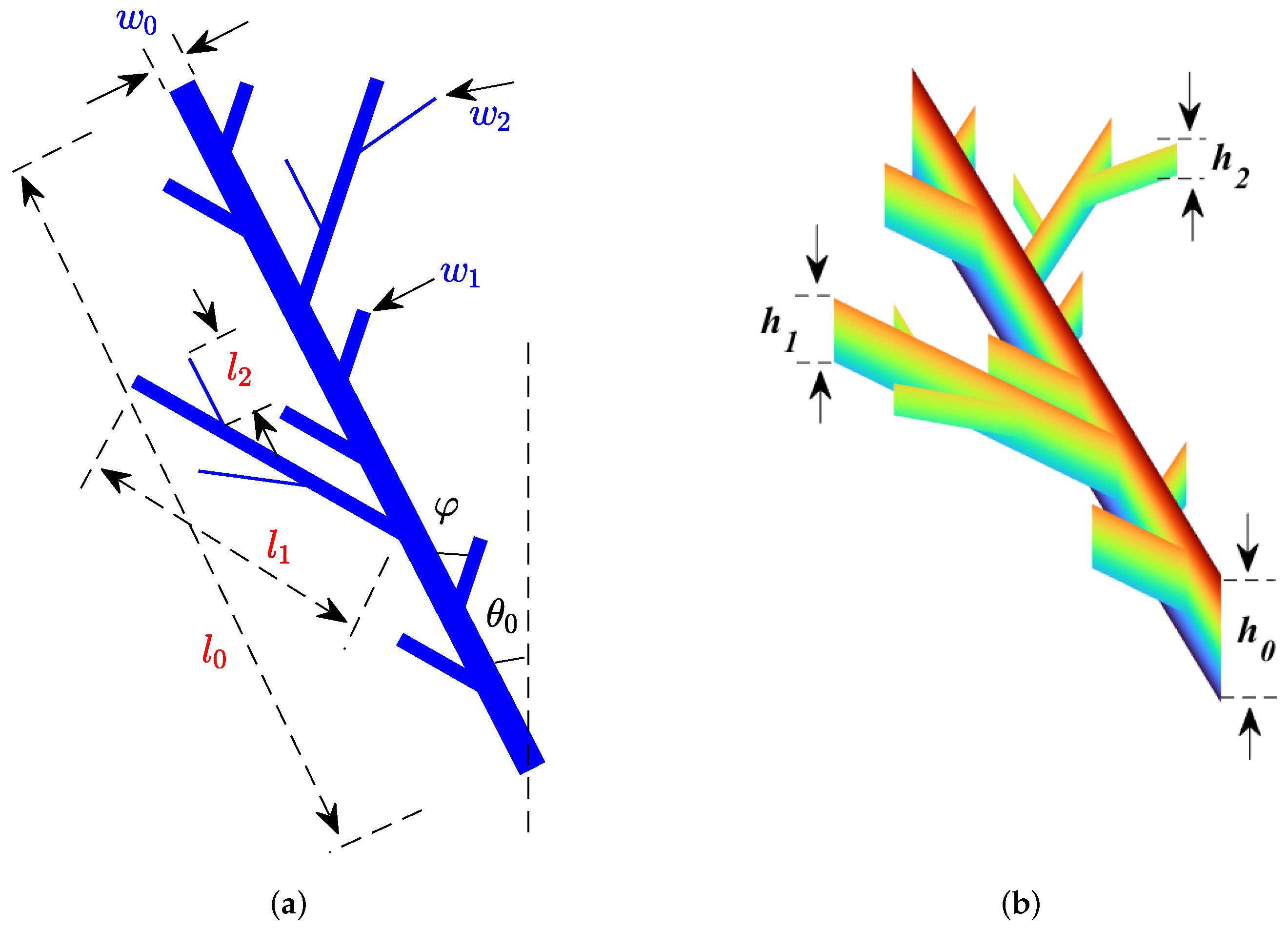

3.1. Hybrid Fractal Model with Multiple Parameters

- (1)

- Initial length , width , height mean , standard variance , and development direction ;

- (2)

- Change factors , and ;

- (3)

- Branching angle .

3.2. A Joint Regularization Model for Inverse Fracture Parameters

| Algorithm 1 Alternative Iterative Inversion Algorithm |

|

4. Experiments and Results

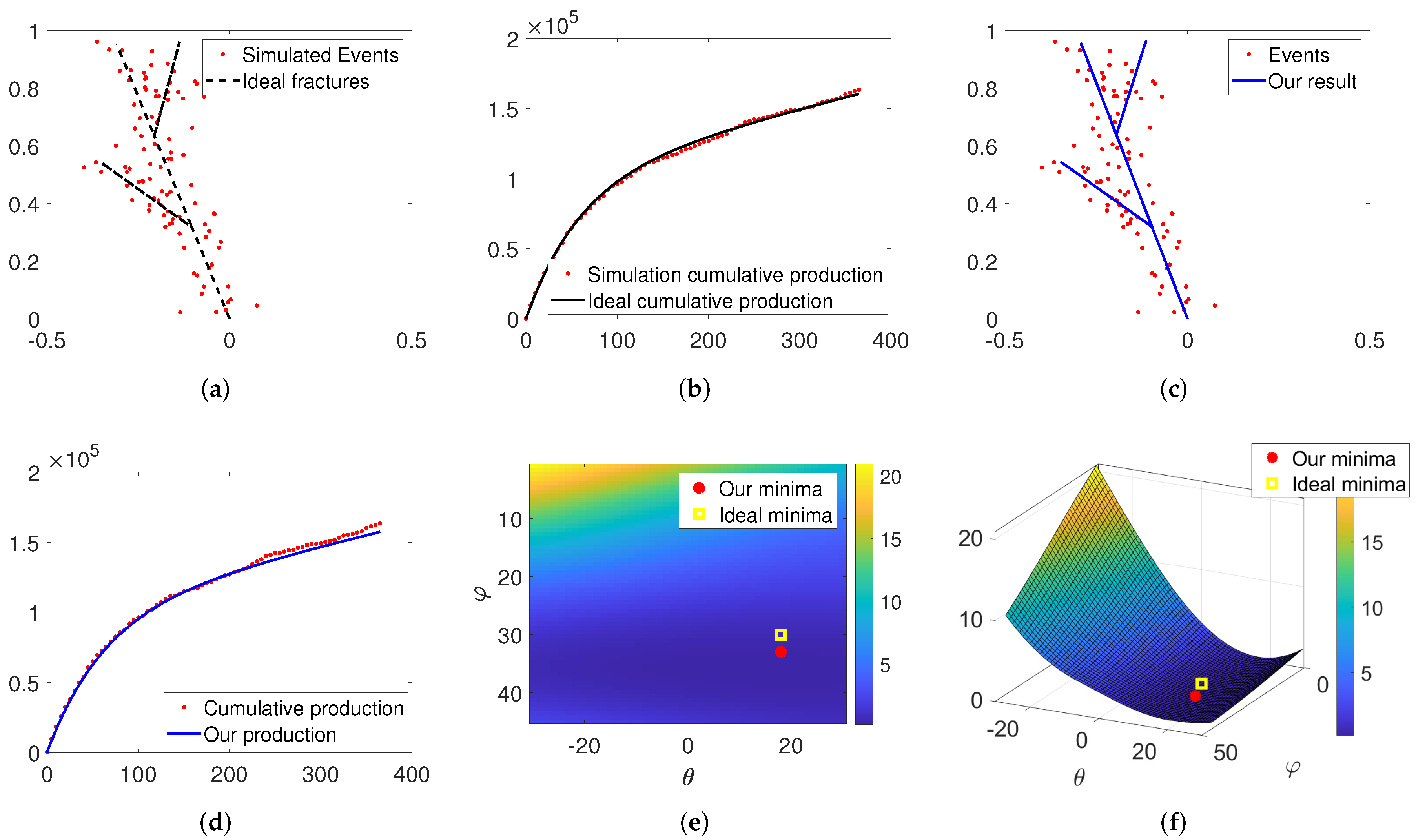

4.1. Synthetic Test 1

4.2. Synthetic Test 2

4.3. Test on Real Data

5. Discussion and Conclusions

5.1. Limitations

5.2. Future Work

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Bowker, K.A. Barnett Shale gas production, Fort Worth Basin: Issues and discussion. AAPG Bull. 2007, 91, 523–533. [Google Scholar] [CrossRef]

- Zou, C.; Zhao, Q.; Dong, D.; Yang, Z.; Qiu, Z.; Liang, F.; Wang, N.; Huang, Y.; Duan, A.; Zhang, Q.; et al. Geological characteristics, main challenges and future prospect of shale gas. J. Nat. Gas Geosci. 2017, 2, 273–288. [Google Scholar]

- Mayerhofer, M.J.; Lolon, E.P.; Youngblood, J.E.; Heinze, J.R. Integration of microseismic fracture mapping results with numerical fracture network production modeling in the Barnett shale. In Proceedings of the SPE Annual Technical Conference and Exhibition, San Antonio, TX, USA, 24–27 September 2006; p. SPE-102103. [Google Scholar]

- Li, Q.; Li, Q.; Cao, H.; Wu, J.; Wang, F.; Wang, Y. The Crack Propagation Behaviour of CO2 Fracturing Fluid in Unconventional Low Permeability Reservoirs: Factor Analysis and Mechanism Revelation. Processes 2025, 13, 159. [Google Scholar] [CrossRef]

- Zang, C.; Jiang, H.; Shi, S.; Li, J.; Zou, Y.; Zhang, S.; Tian, G.; Yang, P. An analysis of the uniformity of multi-fracture initiation based on downhole video imaging technology: A case study of Mahu tight conglomerate in Junggar Basin, NW China. Pet. Explor. Dev. 2022, 49, 448–457. [Google Scholar] [CrossRef]

- Hou, B.; Chen, M.; Li, Z.; Wang, Y.; Diao, C. Propagation area evaluation of hydraulic fracture networks in shale gas reservoirs. Pet. Explor. Dev. 2014, 41, 833–838. [Google Scholar]

- Li, Y.; Liu, D.; Zhai, Y.; Shi, W.; Xian, Y. 3-D FEM azimuth forward modeling of hydraulic fractures based on electromagnetic theory. IEEE Geosci. Remote Sens. Lett. 2020, 18, 246–250. [Google Scholar]

- Chen, M.; Guo, T.; Xu, Y.; Qu, Z.; Zhang, S.; Zhou, T.; Wang, Y. Evolution mechanism of optical fiber strain induced by multi-fracture growth during fracturing in horizontal wells. Pet. Explor. Dev. 2022, 49, 211–222. [Google Scholar]

- Zhao, J.; Li, Y.; Wang, S.; Jiang, Y.; Zhang, L. Simulation of complex fracture networks influenced by natural fractures in shale gas reservoir. Nat. Gas Ind. B 2014, 1, 89–95. [Google Scholar]

- Doe, T.; Lacazette, A.; Dershowitz, W.; Knitter, C. Evaluating the effect of natural fractures on production from hydraulically fractured wells using discrete fracture network models. In Proceedings of the SPE/AAPG/SEG Unconventional Resources Technology Conference, URTEC, Denver, CO, USA, 12–14 August 2013; p. URTEC-1581931. [Google Scholar]

- Zhu, H.; Yang, X.; Liao, R.; Gao, D. Microseismic fracture interpretation and application based on parameters inversion. Geophys. Prospect. Pet. 2017, 56, 150–157. [Google Scholar]

- Rudzinski, L.; Debski, W. Extending the double difference location technique—Improving hypocenter depth determination. J. Seismol. 2013, 17, 83–94. [Google Scholar]

- Mi, L. Inversion method of discrete fracture network of shale gas based on gas production profile. Acta Pet. Sin. 2021, 42, 481. [Google Scholar]

- Clarkson, C.; Williams-Kovacs, J. A new method for modeling multi-phase flowback of multi-fractured horizontal tight oil wells to determine hydraulic fracture properties. In Proceedings of the SPE Annual Technical Conference and Exhibition? New Orleans, LA, USA, 30 September–2 October 2013; p. D031S041R007. [Google Scholar]

- Dai, C.; Liu, H.; Wang, Y.; Li, X.; Wang, W. A simulation approach for shale gas development in China with embedded discrete fracture modeling. Mar. Pet. Geol. 2019, 100, 519–529. [Google Scholar] [CrossRef]

- Zhang, K.; Ma, X.; Li, Y.; Wu, H.; Cui, C.; Zhang, X.; Zhang, H.; Yao, J. Parameter prediction of hydraulic fracture for tight reservoir based on micro-seismic and history matching. Fractals 2018, 26, 1840009. [Google Scholar] [CrossRef]

- Zhang, L.; He, X.; Li, X.; Li, K.; He, J.; Zhang, Z.; Guo, J.; Chen, Y.; Liu, W. Shale gas exploration and development in the Sichuan Basin: Progress, challenge and countermeasures. Nat. Gas Ind. B 2022, 9, 176–186. [Google Scholar] [CrossRef]

- Fisher, M.; Heinze, J.; Harris, C.; Davidson, B.; Wright, C.; Dunn, K. Optimizing horizontal completion techniques in the Barnett shale using microseismic fracture mapping. In Proceedings of the SPE Annual Technical Conference and Exhibition, Houston, TX, USA, 26–29 September 2004; p. SPE-90051. [Google Scholar]

- Bian, H.L.; Guan, J.; Mao, Z.Q.; Ju, X.D.; Han, G.Q. Pore structure effect on reservoir electrical properties and well logging evaluation. Appl. Geophys. 2014, 11, 374–383. [Google Scholar] [CrossRef]

- Sun, Z.; Yang, S.; Zhang, F.; Lu, J.; Wang, R.; Ou, X.; Lei, A.; Han, F.; Cen, W.; Wei, D.; et al. A reconstructed method of acoustic logging data and its application in seismic lithological inversion for uranium reservoir. Remote Sens. 2023, 15, 1260. [Google Scholar] [CrossRef]

- Liu, R.; Jiang, Y.; Li, B.; Wang, X. A fractal model for characterizing fluid flow in fractured rock masses based on randomly distributed rock fracture networks. Comput. Geotech. 2015, 65, 45–55. [Google Scholar] [CrossRef]

- Wan, T.; Sheng, J.; Soliman, M.; Zhang, Y. Effect of fracture characteristics on behavior of fractured shale-oil reservoirs by cyclic gas injection. SPE Reserv. Eval. Eng. 2016, 19, 350–355. [Google Scholar] [CrossRef]

- Li, Q.; Li, Q.; Wu, J.; Li, X.; Li, H.; Cheng, Y. Wellhead stability during development process of hydrate reservoir in the Northern South China Sea: Evolution and mechanism. Processes 2024, 13, 40. [Google Scholar] [CrossRef]

- Hough, P.V. Method and Means for Recognizing Complex Patterns. U.S. Patent 3,069,654, 18 December 1962. [Google Scholar]

- Duda, R.O.; Hart, P.E. Use of the Hough transformation to detect lines and curves in pictures. Commun. ACM 1972, 15, 11–15. [Google Scholar] [CrossRef]

- Bhattacharya, P.; Rosenfeld, A.; Weiss, I. Point-to-line mappings as Hough transforms. Pattern Recognit. Lett. 2002, 23, 1705–1710. [Google Scholar]

- Lu, L.; Zhang, D. Assisted history matching for fractured reservoirs by use of hough-transform-based parameterization. SPE J. 2015, 20, 942–961. [Google Scholar]

- Yu, X.; Rutledge, J.; Leaney, S.; Maxwell, S. Discrete-fracture-network generation from microseismic data by use of moment-tensor-and event-location-constrained hough transforms. SPE J. 2016, 21, 221–232. [Google Scholar]

- Barton, C.C.; La Pointe, P.R. Fractals in Petroleum Geology and Earth Processes; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2012. [Google Scholar]

- Zhao, Y.; Wang, C.; Ning, L.; Zhao, H.; Bi, J. Pore and fracture development in coal under stress conditions based on nuclear magnetic resonance and fractal theory. Fuel 2022, 309, 122112. [Google Scholar]

- Liu, R.; Li, B.; Jiang, Y. A fractal model based on a new governing equation of fluid flow in fractures for characterizing hydraulic properties of rock fracture networks. Comput. Geotech. 2016, 75, 57–68. [Google Scholar] [CrossRef]

- Miao, T.; Yu, B.; Duan, Y.; Fang, Q. A fractal analysis of permeability for fractured rocks. Int. J. Heat Mass Transf. 2015, 81, 75–80. [Google Scholar] [CrossRef]

- Kummerow, J. Using the value of the crosscorrelation coefficient to locate microseismic events. Geophysics 2010, 75, MA47–MA52. [Google Scholar]

- Rudin, L.I.; Osher, S.; Fatemi, E. Nonlinear total variation based noise removal algorithms. Phys. D Nonlinear Phenom. 1992, 60, 259–268. [Google Scholar]

- Xia, Y.; Deng, Y.; Wei, S.; Jin, Y. Numerical simulation of multi-scale coupled flow in after-fracturing shale gas reservoirs. Chin. J. Theor. Appl. Mech. 2023, 55, 616–629. [Google Scholar]

- Rees, T.; Dollar, H.S.; Wathen, A.J. Optimal solvers for PDE-constrained optimization. SIAM J. Sci. Comput. 2010, 32, 271–298. [Google Scholar]

- van Leeuwen, T.; Herrmann, F.J. A penalty method for PDE-constrained optimization in inverse problems. Inverse Probl. 2015, 32, 015007. [Google Scholar] [CrossRef]

- Peng, Y.; Zhou, B.; Qi, F. PDE-Constrained Scale Optimization Selection for Feature Detection in Remote Sensing Image Matching. Mathematics 2024, 12, 1882. [Google Scholar] [CrossRef]

| Symbol | Meaning | Value | Symbol | Meaning | Value |

|---|---|---|---|---|---|

| Matrix porosity | 0.02 | Fracture porosity | 0.2 | ||

| Original matrix permeability | 100 nD | Knudsen coefficient | |||

| Adsorbed gas coefficient | M | Molar mass of gas | 16.043 g/mol | ||

| R | Pore radius | 40 nm | Original Reservoir pressure | 20 Mpa | |

| T | Reservoir Temperature | 300 K | Fracture initial width | 5 mm |

| Stage | Number of Events | Length | Width | Height | Orientation |

|---|---|---|---|---|---|

| Stage 1 | 68 | 350 | 85 | 65 | 85 |

| Stage 2 | 114 | 200 | 50 | 40 | 90 |

| Stage 3 | 69 | 330 | 90 | 90 | 75 |

| Stage 4 | 72 | 180 | 100 | 80 | 85 |

| Stage 5 | 116 | 180 | 100 | 75 | 90 |

| … | … | … | … | … | … |

| Stage 29 | 50 | 145 | 108 | 38 | 114 |

| Stage 30 | 39 | 180 | 89 | 67 | 91 |

| Well | Day Index | Date | Production Hours | Daily Gas | Cumulative Gas |

|---|---|---|---|---|---|

| Well X | 1 | 16 November 2018 | 24 | 6.4994 | 6.50 |

| Well X | 2 | 17 November 2018 | 24 | 10.7639 | 17.26 |

| Well X | 3 | 18 November 2018 | 24 | 14.1072 | 31.37 |

| Well X | 4 | 19 November 2018 | 24 | 21.0404 | 52.41 |

| … | … | … | … | … | … |

| Well X | 344 | 25 October 2019 | 24 | 8.2233 | 6193.89 |

| Well X | 345 | 26 October 2019 | 24 | 2.2443 | 6196.13 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, H.; Zhang, L.; Li, L.; Zhou, B.; Zhang, Y.; Fu, Y. A Novel Regularization Model for Inversion of the Fracture Geometric Parameters in Hydraulic-Fractured Shale Gas Wells. Energies 2025, 18, 1723. https://doi.org/10.3390/en18071723

Li H, Zhang L, Li L, Zhou B, Zhang Y, Fu Y. A Novel Regularization Model for Inversion of the Fracture Geometric Parameters in Hydraulic-Fractured Shale Gas Wells. Energies. 2025; 18(7):1723. https://doi.org/10.3390/en18071723

Chicago/Turabian StyleLi, Hongxi, Li Zhang, Lu Li, Bin Zhou, Yunjun Zhang, and Yu Fu. 2025. "A Novel Regularization Model for Inversion of the Fracture Geometric Parameters in Hydraulic-Fractured Shale Gas Wells" Energies 18, no. 7: 1723. https://doi.org/10.3390/en18071723

APA StyleLi, H., Zhang, L., Li, L., Zhou, B., Zhang, Y., & Fu, Y. (2025). A Novel Regularization Model for Inversion of the Fracture Geometric Parameters in Hydraulic-Fractured Shale Gas Wells. Energies, 18(7), 1723. https://doi.org/10.3390/en18071723