An Experimental Study on Wave Force and Run-Up of Wind Turbine Foundation on Breakwater Under Wave Action

Abstract

:1. Introduction

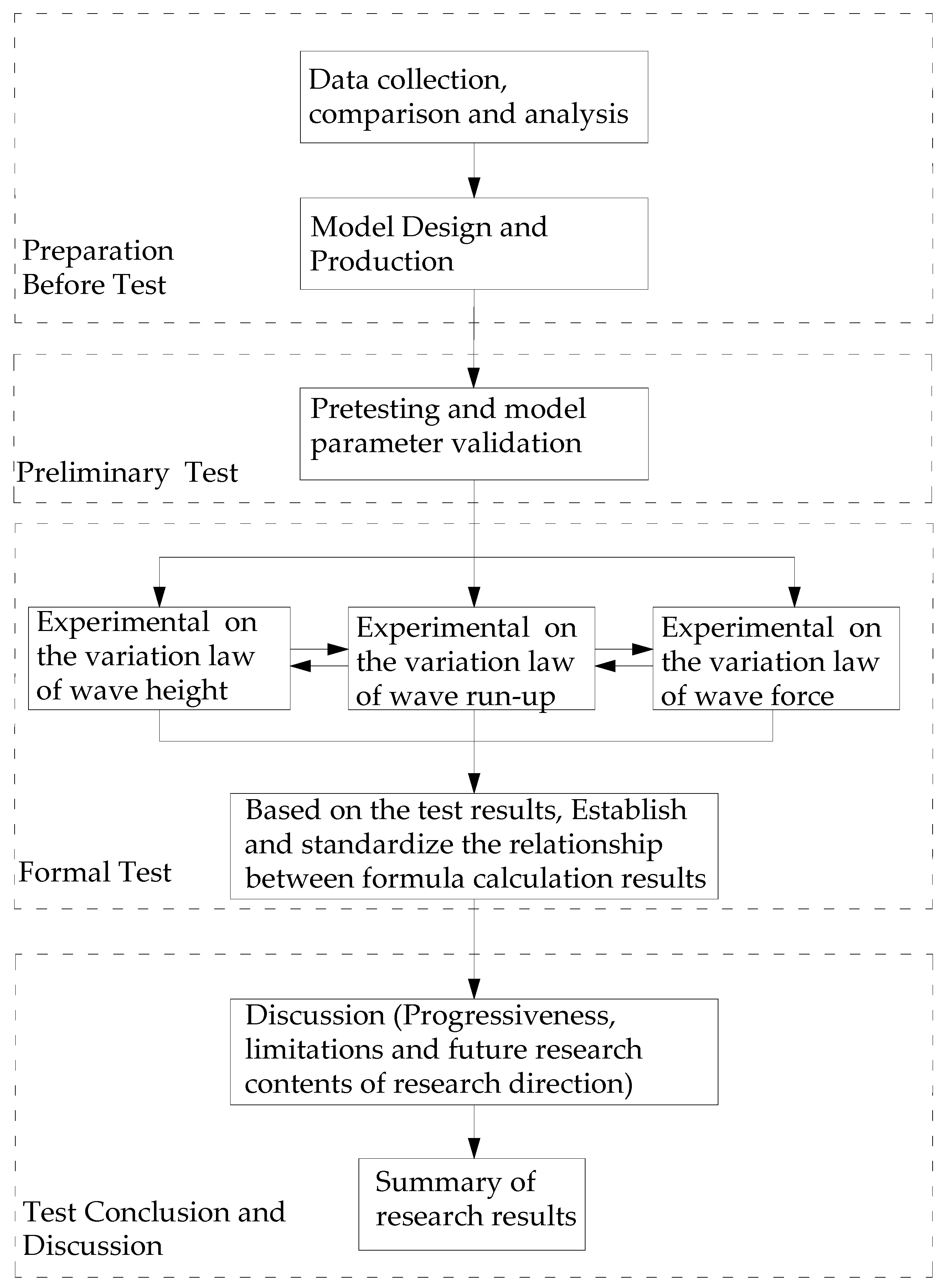

2. Model Experiments

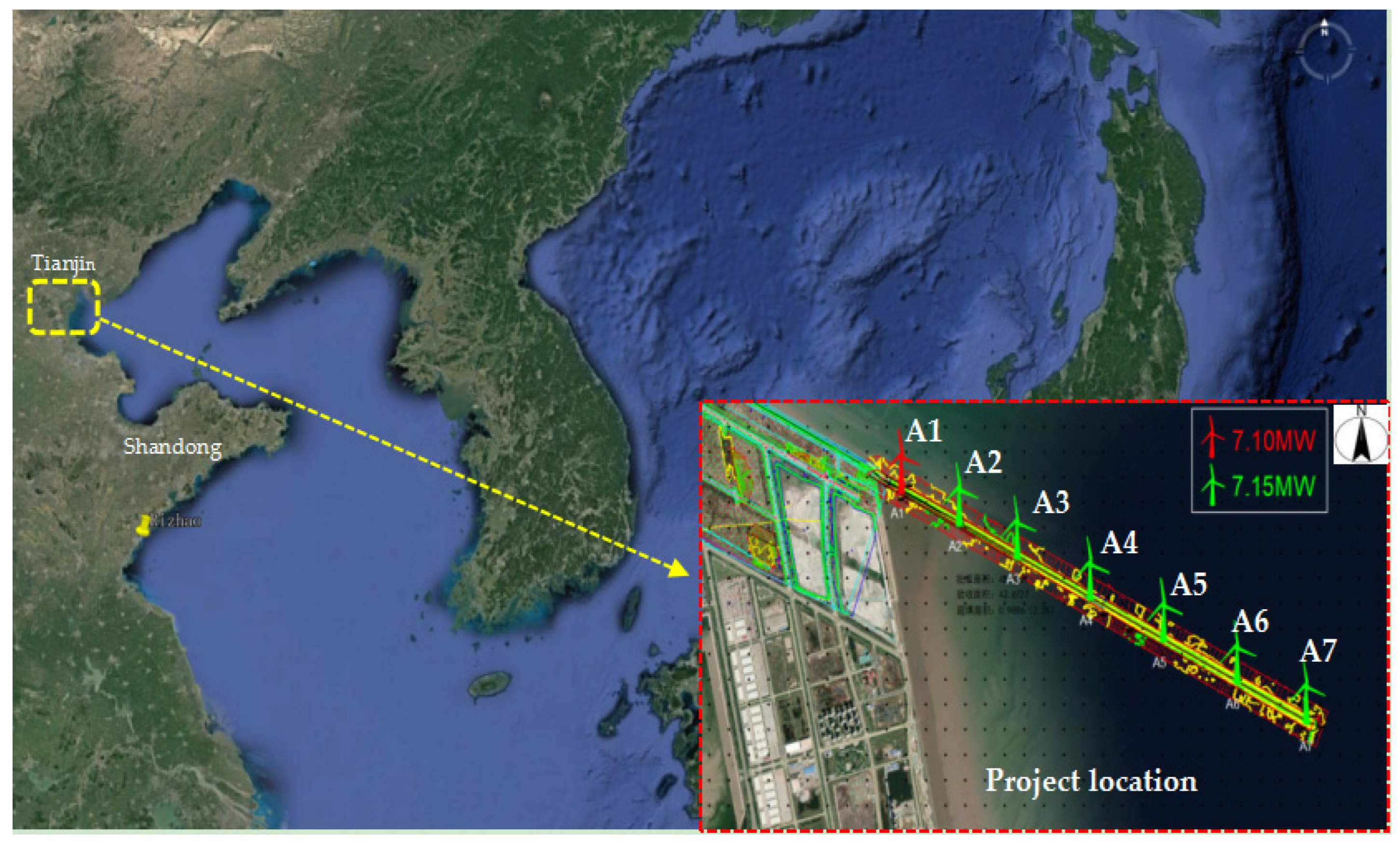

2.1. Engineering Background

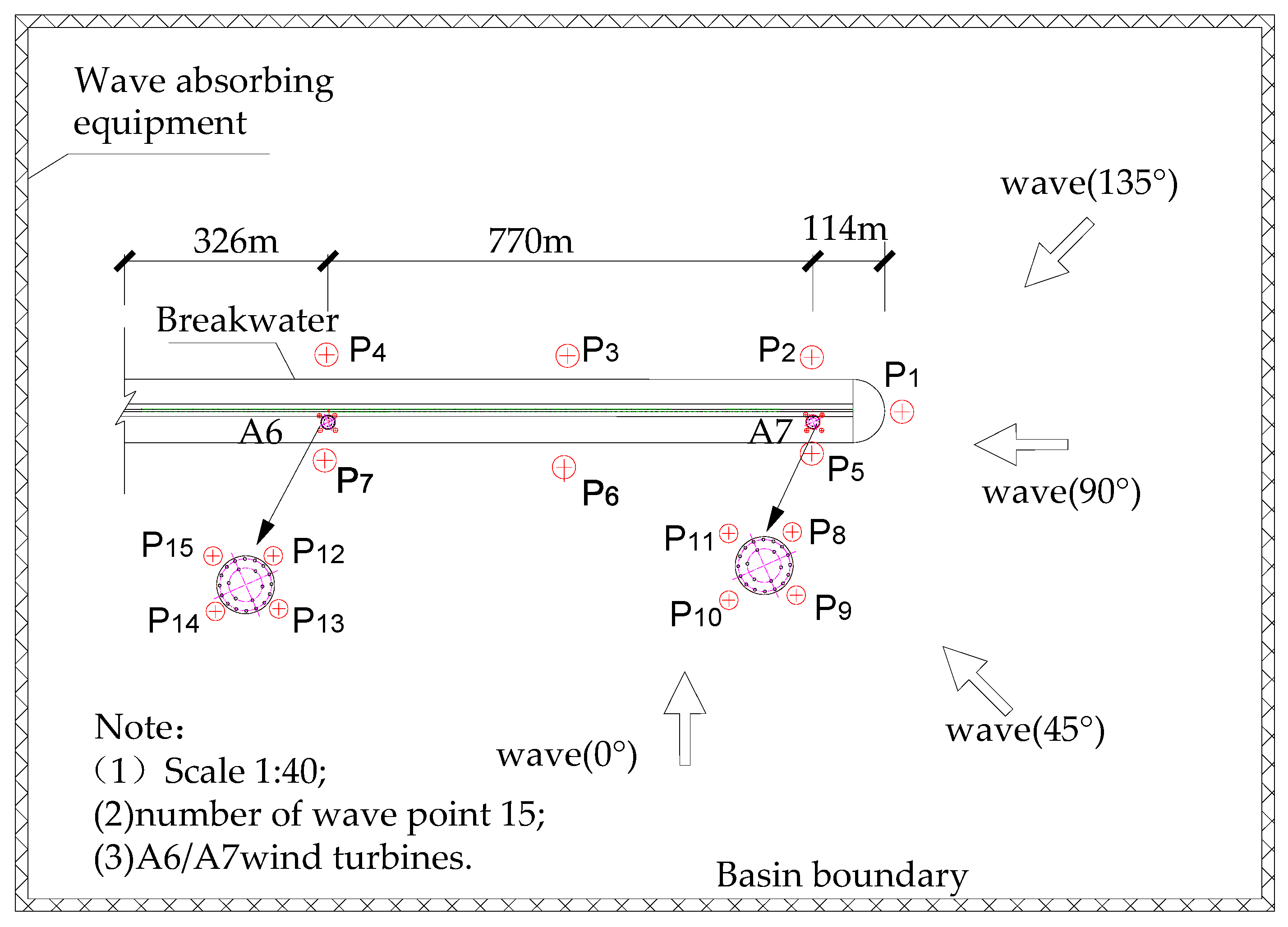

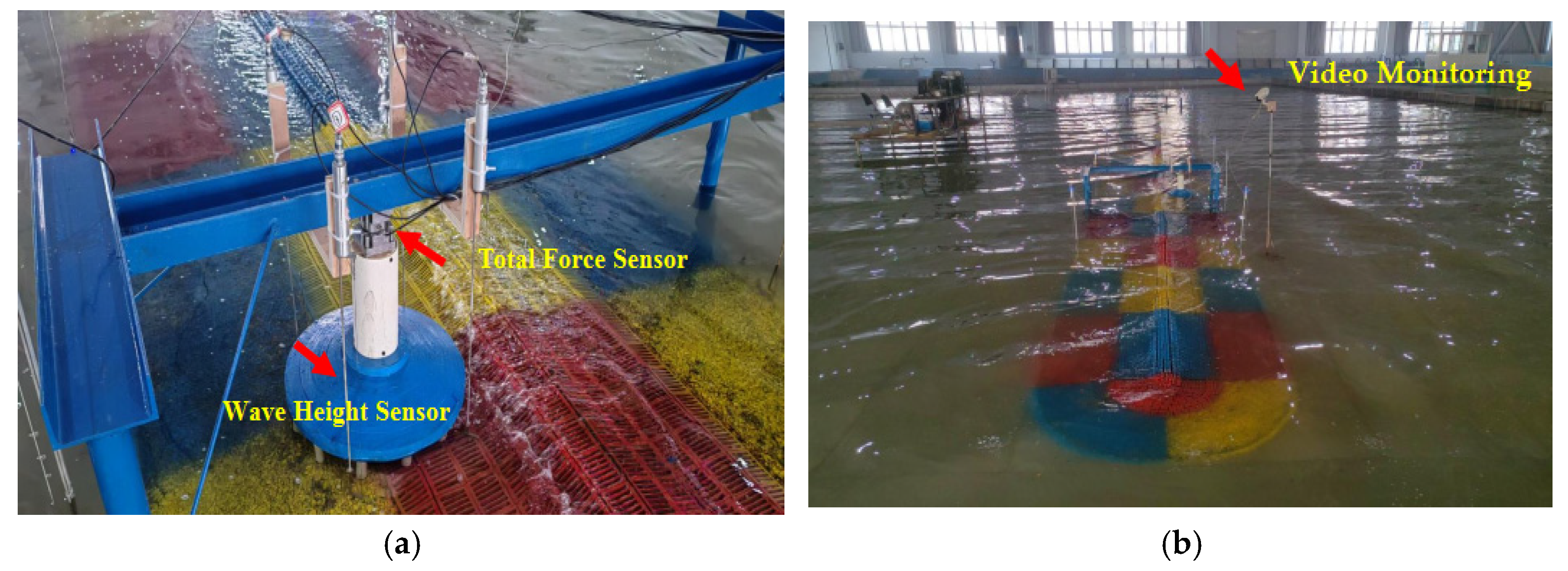

2.2. Experimental Design

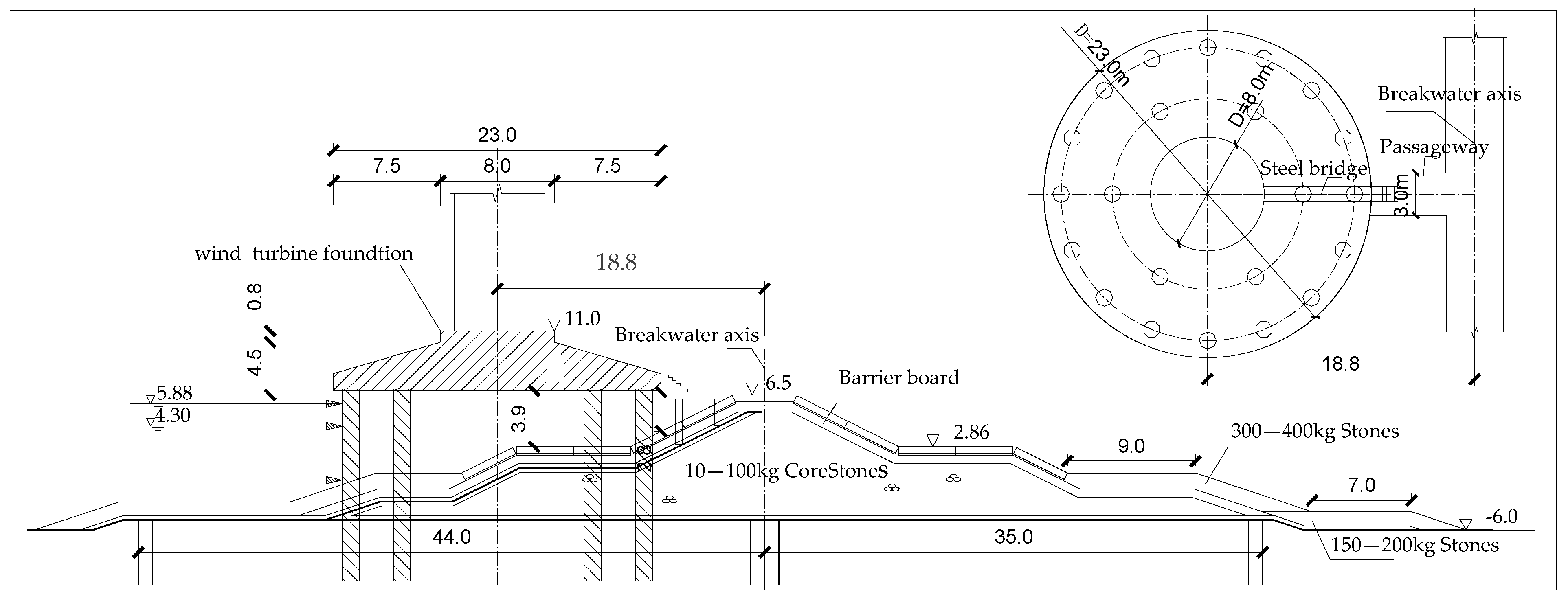

2.2.1. Infrastructure Scheme

2.2.2. Working Condition Design and Boundary Simulation

- Experimental condition design

- 2.

- Model Design and Production

- 3.

- Environmental simulation and methods

2.2.3. Layout and Methods of Measuring Points

3. Results

3.1. Variation Law of Wave Height at the Junction of Breakwater and Foundation

- (1)

- Comparing the four wave angles of 0°, 45°, 90°, and 135°, the wave height is highest at 0°, the maximum height of the breakwater is Hs = 3.43 m on the upstream side of the wave, and the maximum height of the wind turbine foundation is Hs = 3.82 m at position A7. The minimum wave direction angle is 135°;

- (2)

- Comparing the wave heights of 5.88 m and 4.30 m, the former is greater than the latter. Comparing the wave height results around the foundations of A6 and A7 wind turbines, the closer they are to the embankment, the greater the wave action they are subjected to;

- (3)

- For all measurement points, the area affected by the dual structure of the wind turbine foundation and breakwater has the highest wave height results. Comparing the wave height results of the four measuring points around the wind turbine foundation, it is found that far away from the breakwater, the maximum wave height is P9, which is greater than P8. However, when subjected to 135° wave action, the pattern is exactly the opposite, with P8 being greater than P9;

- (4)

- Comparing the wave height of the breakwater with and without the wind turbine foundation, it was found that the wave height increased by about 10% due to the influence of the foundation, indicating that the high pile wind turbine foundation had little impact.

3.2. Wave Run-Up Results on the Foundation of the Bearing Platform

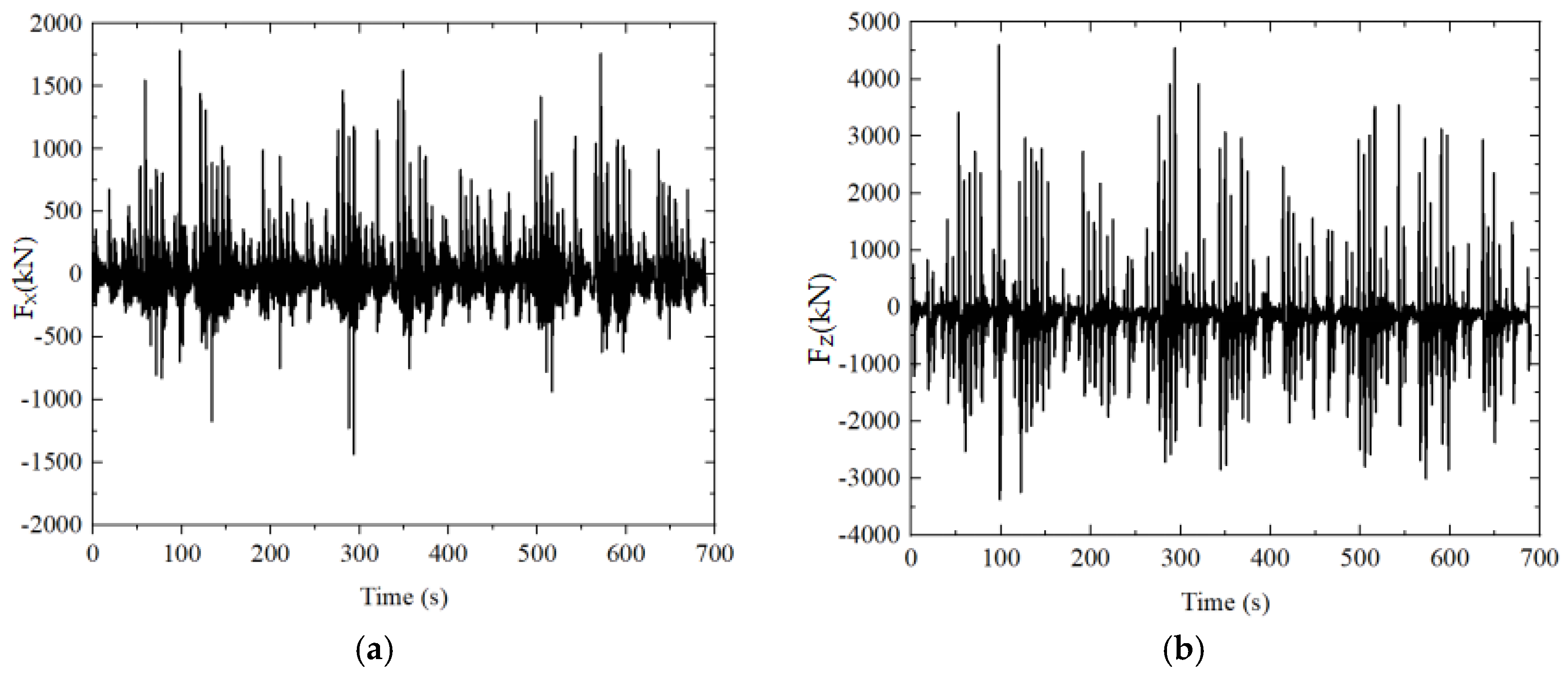

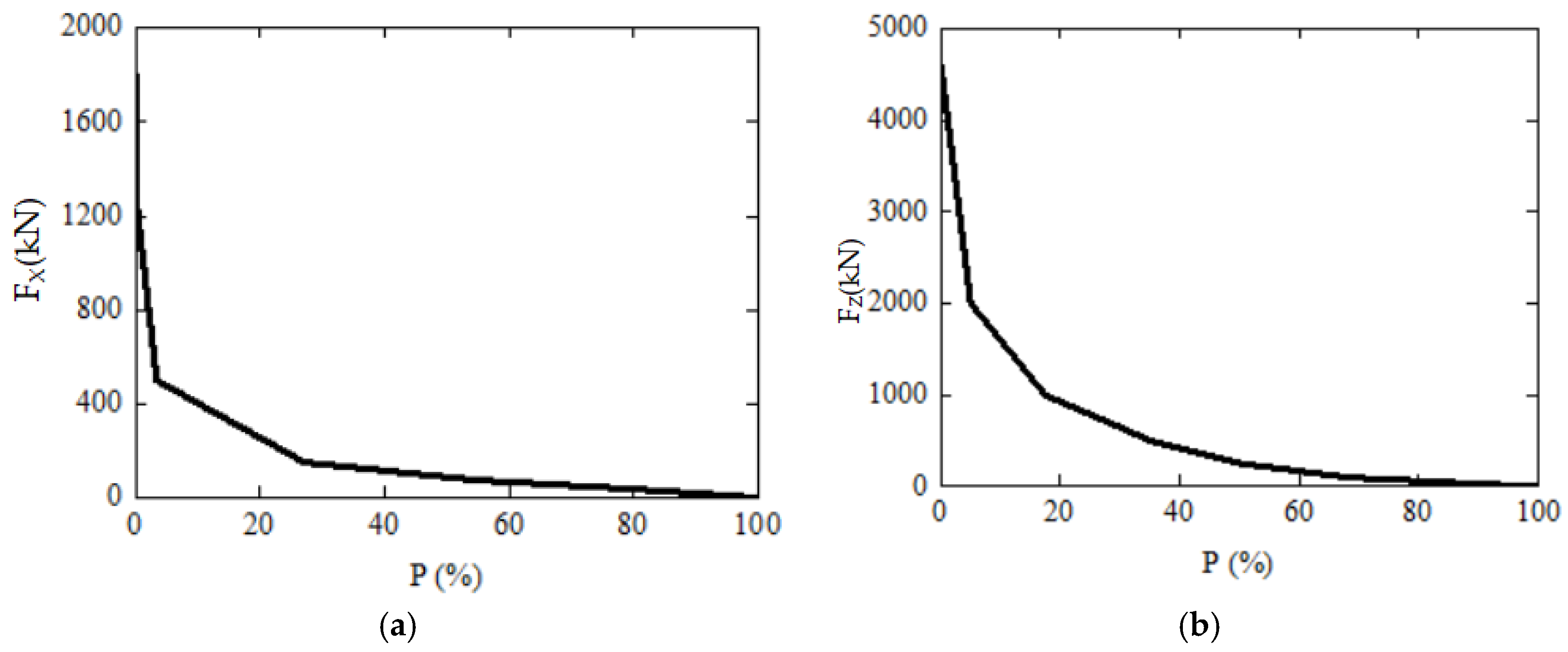

3.3. Results of Wave Force on the Foundation

- (1)

- Comparing the four wave angles of 0°, 45°, 90°, and 135°, the maximum wave force occurs at 0°, and there is a vertical force greater than the horizontal force. A6 and A7 have a maximum force of 1213.5 kN and 4869.4 kN, respectively. The foundation force of A7 is approximately four times that of A6, so differentiated design should be considered when designing wind turbine foundation structures at different positions along the axis of the breakwater;

- (2)

- Comparing the wave heights of 5.88 m and 4.30 m, the former is greater than the latter;

- (3)

- Comparing the force results of the foundation at two different elevations after design and adjustment, it was found that as the elevation increases, the force decreases significantly. For A7, when the elevation increases by 1.5 m, the wave force can be reduced by 50%.

3.4. Impact of Foundation on the Stability of the Existing Breakwater Armor Structure

3.5. Comparative Analysis of Calculation Results with Standard Formulas

- Comparative analysis of wave forces

- 2.

- Comparative analysis of wave forces

4. Discussion

- (1)

- The significance of model testing. The research on wind turbine foundation in this model experiment is different from previous deepwater projects in the ocean, manifested as nearshore engineering. At the same time, the project is built on an existing breakwater, so the structure not only needs to withstand the direct action of waves but also consider the changes in local current and wave shape caused by the existing structure. Based on this complex hydrodynamic environment, the calculation values for structural safety design are greatly challenged, especially the determination of coefficients in previous calculation formulas and the accuracy of calculations. Especially for the determination of the foundation design elevation that directly affects the safety of power supply equipment, the results of this experiment also prove that there is a deviation of 20–50% between the two. Therefore, for major projects, it is necessary to use model experiments for verification;

- (2)

- Future research work. Although the project belongs to nearshore engineering, the impact of wind and current loads on wind turbine foundations is much smaller than that of open sea areas. However, for offshore wind turbine engineering, a large number of scholars have studied wind loads [35,36] and current loads [37,38], and the results show that these two loads are also important factors affecting foundation safety design. Currently, the experimental results only provide results under wave loads. Therefore, further improvement will be made on the degree of influence of wind and current loads on the wind turbine foundation of breakwaters to further ensure structural safety;

- (3)

- The trend of constructing wind turbine projects on breakwaters. For the wind turbine foundation of the breakwater, research has shown that the implementation of wind turbine engineering only increases the wave height of the breakwater by 10% and has little impact on stability. In addition, compared to other seabed wind turbine foundations, which are protected by breakwaters, there is no need to pay attention to erosion protection and foundation treatment at this time. At the same time, due to the shallow water depth near the shore, it is also convenient for foundation construction, further saving engineering investment. These conditions will be conducive to the promotion and application of wind power projects built on breakwaters. Therefore, in the future development and construction of offshore wind turbine projects, building wind turbine projects on breakwaters will be the main trend for nearshore wind turbine projects in the face of complex ocean environments.

5. Conclusions

- (1)

- Comparing the wave heights at four wave angles of 0°, 45°, 90°, and 135°, the maximum wave height at 0° wave direction was Hs = 3.82 m, and at position A7. After the construction, the wave height at the breakwater location increased by 10%. Based on the stability results, it is believed that the overall impact is not significant;

- (2)

- Wave run-up under the action of waves at a high water level of 5.88 m, except for 135° wave direction, does not meet the requirements. When the elevations of A6 and A7 are adjusted to 12.0 m and 12.5 m, it is feasible;

- (3)

- At 0° wave direction, the foundation is subjected to the maximum wave force due to wave action, and the vertical force is greater than the horizontal force. The maximum wave forces of A6 and A7 are 1213.5 kN and 4869.4 kN, respectively, with a difference of about 4 times. After raising the elevation, the force decreases by 50%. The design needs to consider differentiated design according to different location types;

- (4)

- The comparison between the test results and the calculation results of the standard formula is basically 1.2–1.5 times, which can enrich the current standard calculation basis. This study not only solves practical problems in engineering but also provides valuable experimental data and reference for the construction of wind power projects on breakwaters in the future.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chi, C.G. Current status of basic research on offshore wind power. Shanxi Archit. 2018, 44, 47–48. [Google Scholar] [CrossRef]

- Yu, T.; Zhao, Z.; Shi, Z. Experimental Investigation of Wave Load and Run-up on the Composite Bucket Foundation Influenced by Regular Waves. J. Ocean. Univ. China 2021, 20, 271–284. [Google Scholar] [CrossRef]

- Huang, W.P.; Shang, J.H.; Wang, J.F. Current Status of Offshore Wind Turbine Foundation Structures Abroad. In Proceedings of the Inaugural Meeting and First Academic Symposium of the Ocean Energy Professional Committee of the China Renewable Energy Society, Hangzhou, China, 27–28 March 2008; Volume 6, pp. 51–58. [Google Scholar]

- Zhang, Q.; Tang, G.; Lu, L. Scour protections of collar around a monopile foundation in steady current. Appl. Ocean. Res. 2021, 112, 102718. [Google Scholar] [CrossRef]

- Jia, X.L.; Sun, Z.Z.; Deng, Z.C. Analysis of bearing capacity and structural strength of multi pile underwater foundation. China Ocean. Platf. 2020, 35, 74–79. [Google Scholar]

- Shuiitu, A.A.; Mehmanparast, A.; Hart, P. Comparative study between S-N and fracture mechanics approach on reliability assessment of offshore wind turbine jacket foundations. Reliab. Eng. Syst. Saf. 2015, 215, 107838. [Google Scholar] [CrossRef]

- Yu, T.S. Research on the Dynamic Response and Flushing Characteristics of Composite Cylinder-Type Foundation; Tianjin University: Tianjin, China, 2014. [Google Scholar]

- Li, X.; Zhang, M.M.; Yang, H.L. Research on the Intelligent Control of Fatigue Loads for Tension-leg Floating Wind Motor Units. J. Sol. Energy 2020, 41, 278–286. [Google Scholar]

- Chen, W.Y.; Gao, Y.Y.; Wang, B. Numerical simulation study on wave climbing of offshore wind power foundation based on mass source term wave generation. In Proceedings of the 19th China Ocean (Shore) Engineering Academic Symposium (Part 1), Zhoushan, China, 1 September 2019; Volume 8, pp. 266–272. [Google Scholar]

- Shan, T.B. Exploration of the Mechanism of Wave Climbing and Key Characteristics of Air Gap Response in Semi submersible Platforms; Shanghai Jiao Tong University: Shanghai, China, 2013. [Google Scholar]

- Ramirez, J.; Frigaard, P.; Andersen, T.L. Large scale model test investigation on wave run-up in irregular waves at slender piles. Coast. Eng. 2013, 72, 69–79. [Google Scholar] [CrossRef]

- Chen, L.L.; Jiang, J.N.; Liu, C.G. Effect of wave load on vibration response of offshore wind turbine-type infrastructure. Renew. Energy Resour. 2024, 42, 774–780. [Google Scholar] [CrossRef]

- Wang, T.; Zhang, Q.; Ye, G.L. The influence law of wave loads and soil characteristics on the horizontal deformation of wind power single pile foundations. Mar. Eng. 2022, 40, 93–103. [Google Scholar] [CrossRef]

- Liu, R.; Sun, G.D.; Yuan, Y. Research on the cumulative inclination of offshore wind and torch type foundation under asymmetric wind-wave loads. J. Tianjin Univ. 2023, 56, 613–622. [Google Scholar] [CrossRef]

- Kong, D.S.; Zhang, J.; Gong, Y. Analysis of factors influencing stress deformation characteristics of offshore wind power single pile foundation under wave loads. Mar. Sci. Bull. 2020, 39, 632–640. [Google Scholar] [CrossRef]

- Jiang, T.; He, T.L.; Wang, X.A. Research on the hysteresis effect and horizontal bearing capacity change characteristics of offshore wind turbine pile foundation under wave loads. J. Sol. Energy 2024, 45, 546–553. [Google Scholar] [CrossRef]

- Yan, B.W.; Zhu, H.L.; Huang, X. Study on the Influence of Typhoon Non stationarity on the Dynamic Response of Steel Grid Floating Foundation Offshore Wind Turbine. Eng. Mech. 2022, 39, 237–246. [Google Scholar] [CrossRef]

- Luo, L.B.; Wang, Y.A.; Huang, J.Q. Research on the influence of ocean cyclic load on the basic horizontal bearing capacity of suction barrels. J. Sol. Energy 2021, 42, 142–147. [Google Scholar] [CrossRef]

- He, B.; Song, M.X.; Wei, M.X. Research on Wave Load Characteristics of Large Diameter Single Pile Foundations for Offshore Wind Power. J. Sol. Energy 2024, 45, 324–330. [Google Scholar] [CrossRef]

- Qin, T.Q.; Yuan, C.F.; Yuan, M.H. Basic dynamic load bearing characteristics of offshore wind power suction barrels based on the East China Sea wind and wave statistics from 2010 to 2020. Mar. Eng. 2023, 41, 169–178. [Google Scholar] [CrossRef]

- Qin, M.F. Research on the Response of Large Offshore Wind Power Infrastructure During the Typhoon; Dalian University of Technology: Dalian, China, 2023. [Google Scholar]

- Liu, H.Y. Research on the Coupling Bearing Characteristics of Large-Diameter Steel Pipe Pile Foundations of Offshore Fan Under Combined Loads; Jiangsu University of Science and Technology: Jiangsu, China, 2023. [Google Scholar]

- Bredmose, H.; Skourup, J.; Hansen, E.A. Numerical reproduction of extreme wave loads on a gravity wind turbine foundation. In Proceedings of the 25th International Conference on Offshore Mechanics and Arctic Engineering, Hamburg, Germany, 4–9 June 2006; American Society of Mechanical Engineers: Santa Clara, CA, USA, 2006; Volume 8, pp. 279–287. [Google Scholar]

- Marcus, D.; Hojjat, M.; Wuchner, R. A numerical wave channel for the design of offshore structures with consideration of wave—Current interaction. In Proceedings of the Paper presented at the The Twenty-second International Offshore and Polar Engineering Conference, Rhodes, Greece, Vladivostok, Russia, 17–22 June 2012; Volume 1, pp. 695–702. [Google Scholar]

- Guan, N. Study on Wave Load of Offshore Wind Turbine Foundation Structure; Tianjin University: Tianjin, China, 2013. [Google Scholar]

- Mccamy, Y.; Fuchs, R. Wave Forces on Piles: Diffraction Theory; Corps of Engineers Washington DC Beach Erosion Board: Washington, DC, USA, 1954. [Google Scholar]

- Kriebel, D.L. Nonlinear wave interaction with a vertical circular cylinder. Part I: Diffraction theory. Ocean. Eng. 1990, 17, 345–377. [Google Scholar]

- Kriebel, D.L. Nonlinear wave interaction with a vertical circular cylinder. Part II: Wave run-up. Ocean. Eng. 1992, 19, 75–99. [Google Scholar] [CrossRef]

- Martin, J.A.; Easson, W.J.; Bruce, T. Run-up on columns in steep, deep water regular waves. J. Waterw. Port Coast. Ocean. Eng. 2001, 127, 26–32. [Google Scholar] [CrossRef]

- Hallermeier, R.J. Nonlinear flow of wave crests past a thin pile. J. Waterw. Port. Coast. Ocean. Eng. 1976, 102, 365–377. [Google Scholar]

- Vos, L.D.D.; Frigaard, P.; Rouck, M.D. Wave run-up on cylindrical and cone shaped foundations for offshore wind turbines. Coast. Eng. 2007, 54, 17–29. [Google Scholar] [CrossRef]

- Kazeminezhad, M.H.; Etemad-Shahidi, A.A. New method for the prediction of wave run-up on vertical piles. Coast. Eng. 2015, 98, 55–64. [Google Scholar] [CrossRef]

- JTJ/T231-2021; Technical Specification for Simulation Test of Water Transport Engineering. People’s Communications Press: Beijing, China, 2021.

- JTS 145-2015; Code of Hydrology for Harbor and Waterway. People’s Communications Publishing House Co., Ltd.: Beijing, China, 2015.

- Lu, Z.Y.; Ma, H.W.; Li, Y.H. Experimental Study on the Influence of Typhoons on the Cumulative Deformation of Monopile Foundations for Offshore Wind Turbines. J. Mar. Technol. 2019, 38, 75–82. [Google Scholar] [CrossRef]

- Li, Y.Z. Research on the Dynamic Bearing Characteristics of Offshore Wind Power Single Pile Foundation Under Wind-Wave-Gravity Load; Shandong University of Science and Technology: Qingdao, China, 2020. [Google Scholar]

- Yu, H.K. Research on the Dynamic Response of Offshore Fan-Plunger Wing Pile Foundation Under Wave Current Load; Hebei University: Beijing, China, 2023. [Google Scholar]

- Li, T.; Wang, S.Y.; Li, B. Experimental study on local scour of large-diameter wing single pile foundation for offshore wind turbines under wave and current effects. Ocean. Eng. 2024, 42, 60–70. [Google Scholar] [CrossRef]

| Wave Directions | Water Level | Wave Condition | ||

|---|---|---|---|---|

| H1% (m) | Hs (m) | Tp (s) | ||

| 0°/45° | 5.88 m | 4.30 | 3.15 | 7.0 |

| 4.30 m | 3.96 | 2.94 | 7.0 | |

| 90° | 5.88 m | 5.14 | 3.86 | 9.2 |

| 4.30 m | 4.45 | 3.41 | 9.2 | |

| 135° | 5.88 m | 4.49 | 3.30 | 9.8 |

| 4.30 m | 4.07 | 3.03 | 9.8 | |

| Location | Point | 5.88 m | 4.30 m | ||||||

|---|---|---|---|---|---|---|---|---|---|

| 0° | 45° | 90° | 135° | 0° | 45° | 90° | 135° | ||

| Along the breakwater | P1 | 2.98 | 3.20 | 3.44 | 2.79 | 2.60 | 2.79 | 3.14 | 2.25 |

| P2 | 1.46 | 2.21 | 3.65 | 1.99 | 1.08 | 1.82 | 3.26 | 1.70 | |

| P3 | 0.23 | 1.38 | 3.03 | 2.21 | 0.15 | 1.04 | 2.52 | 1.79 | |

| P4 | 0.12 | 1.23 | 2.66 | 1.80 | 0.10 | 0.78 | 2.26 | 1.38 | |

| P5 | 3.24 | 2.68 | 2.38 | 0.73 | 2.76 | 2.28 | 1.75 | 0.62 | |

| P6 | 3.43 | 2.74 | 1.29 | 0.81 | 2.79 | 2.23 | 1.32 | 0.48 | |

| P7 | 3.06 | 2.49 | 1.69 | 0.70 | 2.80 | 2.28 | 1.55 | 0.35 | |

| A7 wind turbine foundation | P8 | 3.54 | 2.88 | 2.76 | 1.24 | 2.89 | 2.18 | 1.95 | 0.79 |

| P9 | 3.75 | 3.10 | 2.91 | 0.97 | 3.01 | 2.64 | 1.77 | 0.69 | |

| P10 | 3.82 | 1.61 | 1.63 | 0.71 | 2.94 | 2.42 | 1.29 | 0.48 | |

| P11 | 3.61 | 1.77 | 2.09 | 1.21 | 2.78 | 1.82 | 1.54 | 0.62 | |

| A6 wind turbine foundation | P12 | 3.32 | 2.43 | 1.72 | 1.15 | 2.65 | 1.93 | 1.56 | 0.44 |

| P13 | 3.64 | 2.62 | 1.81 | 0.79 | 2.98 | 2.50 | 1.58 | 0.40 | |

| P14 | 3.58 | 2.12 | 1.23 | 0.86 | 2.91 | 2.34 | 1.02 | 0.36 | |

| P15 | 3.28 | 1.33 | 1.51 | 0.99 | 2.59 | 0.84 | 1.26 | 0.25 | |

| Water Level | Direction | A7 Wind Turbine Foundation | A6 Wind Turbine Foundation |

|---|---|---|---|

| 5.88 m | 0° | 12.33 | 11.80 |

| 45° | 11.72 | 11.06 | |

| 90° | 11.19 | 9.61 | |

| 135° | 8.07 | 7.16 | |

| 4.30 m | 0° | 8.06 | 8.03 |

| 45° | 7.60 | 7.43 | |

| 90° | 7.48 | 7.14 | |

| 135° | 5.18 | 5.05 |

| Water Level | Direction | A7 (kN) | A6 (kN) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| 11.0 m Elevation | 12.5 m Elevation | 11.0 m Elevation | 12.0 m Elevation | ||||||

| Fxmax | Fzmax | Fxmax | Fzmax | Fxmax | Fzmax | Fxmax | Fzmax | ||

| 5.88 m | 0° | 1745.2 | 4869.4 | 825.1 | 1925.6 | 425.6 | 1213.5 | 106.2 | 356.8 |

| 45° | 1360.0 | 3328.0 | 524.1 | 1612.5 | 162.0 | 388.0 | 52.0 | 143.0 | |

| 90° | 376.0 | 1095.0 | 236.4 | 654.2 | 116.0 | 274.0 | / | / | |

| 135° | 118.0 | 251.0 | / | / | 94.0 | 245.0 | / | / | |

| 4.30 m | 0° | 715.2 | 2089.6 | / | / | 245.6 | 621.3 | / | / |

| 45° | 234.0 | 715.0 | / | / | 122.0 | 260.0 | / | / | |

| 90° | 127.0 | 247.0 | / | / | 52.0 | 143.0 | / | / | |

| 135° | 21.0 | 38.0 | / | / | / | / | / | / | |

| Water Level | Direction | A7 (kN) | |||||

|---|---|---|---|---|---|---|---|

| Standard | Test | KF (Test/Standard) | |||||

| Fx | FZ | Fx | FZ | Fx | FZ | ||

| 5.88 m | 0° | 1466.6 | 3958.9 | 1745.2 | 4869.4 | 1.19 | 1.23 |

| 45° | 1079.4 | 2579.8 | 1360.0 | 3328.0 | 1.26 | 1.29 | |

| 90° | 293.8 | 835.9 | 376.0 | 1095.0 | 1.28 | 1.31 | |

| 135° | 89.4 | 185.9 | 118.0 | 251.0 | 1.32 | 1.35 | |

| 4.30 m | 0° | 572.2 | 1503.3 | 715.2 | 2089.6 | 1.25 | 1.39 |

| 45° | 172.1 | 507.1 | 234.0 | 715.0 | 1.36 | 1.41 | |

| 90° | 92.7 | 169.2 | 127.0 | 247.0 | 1.37 | 1.46 | |

| 135° | 14.9 | 25.0 | 21.0 | 38.0 | 1.41 | 1.52 | |

| Water Level | Direction | A7 (m) | ||

|---|---|---|---|---|

| Test | Standard | KR (Test/Standard) | ||

| 5.88 m | 0° | 12.33 | 10.63 | 1.16 |

| 45° | 11.72 | 9.85 | 1.19 | |

| 90° | 11.19 | 9.17 | 1.22 | |

| 135° | 8.07 | 6.21 | 1.30 | |

| 4.30 m | 0° | 8.06 | 6.66 | 1.21 |

| 45° | 7.60 | 5.94 | 1.28 | |

| 90° | 7.48 | 5.66 | 1.32 | |

| 135° | 5.18 | 3.67 | 1.41 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, J.; Ge, L.; Xu, Y.; Chen, S. An Experimental Study on Wave Force and Run-Up of Wind Turbine Foundation on Breakwater Under Wave Action. Energies 2025, 18, 1676. https://doi.org/10.3390/en18071676

Chen J, Ge L, Xu Y, Chen S. An Experimental Study on Wave Force and Run-Up of Wind Turbine Foundation on Breakwater Under Wave Action. Energies. 2025; 18(7):1676. https://doi.org/10.3390/en18071676

Chicago/Turabian StyleChen, Jiangnan, Longzai Ge, Yanan Xu, and Songgui Chen. 2025. "An Experimental Study on Wave Force and Run-Up of Wind Turbine Foundation on Breakwater Under Wave Action" Energies 18, no. 7: 1676. https://doi.org/10.3390/en18071676

APA StyleChen, J., Ge, L., Xu, Y., & Chen, S. (2025). An Experimental Study on Wave Force and Run-Up of Wind Turbine Foundation on Breakwater Under Wave Action. Energies, 18(7), 1676. https://doi.org/10.3390/en18071676