Artificial Intelligence in Wind Turbine Fault Detection and Diagnosis: Advances and Perspectives

Abstract

1. Introduction

- Inclusions

- -

- The searched terms mentioned above should be in the title or abstract.

- -

- The article must be published.

- -

- The paper uses either a data-driven approach or model-based approach for fault diagnosis.

- Exclusions

- -

- Articles that do not mention the source of data being used.

- -

- Articles that are not written in English.

- -

- Articles lacking experimental validation.

- Provide a comprehensive assessment of fault diagnosis techniques for wind turbines, focusing on both traditional and AI-driven approaches.

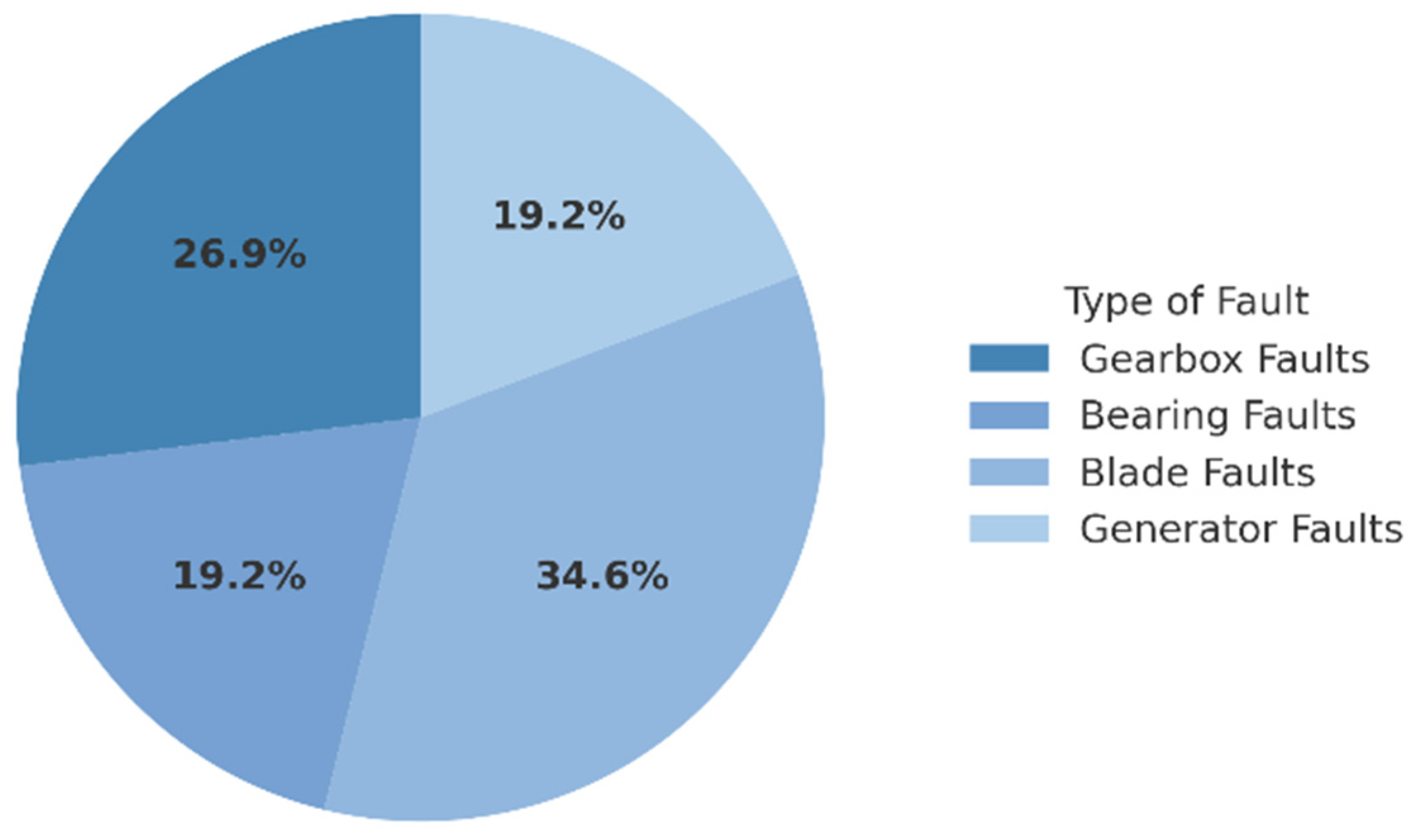

- Examine the role of machine learning (ML) and artificial intelligence (AI) in diagnosing faults across key wind turbine components, including bearings, blades, gearboxes, and generators.

- Identify and compare the strengths and limitations of data-driven and model-based fault diagnosis methods.

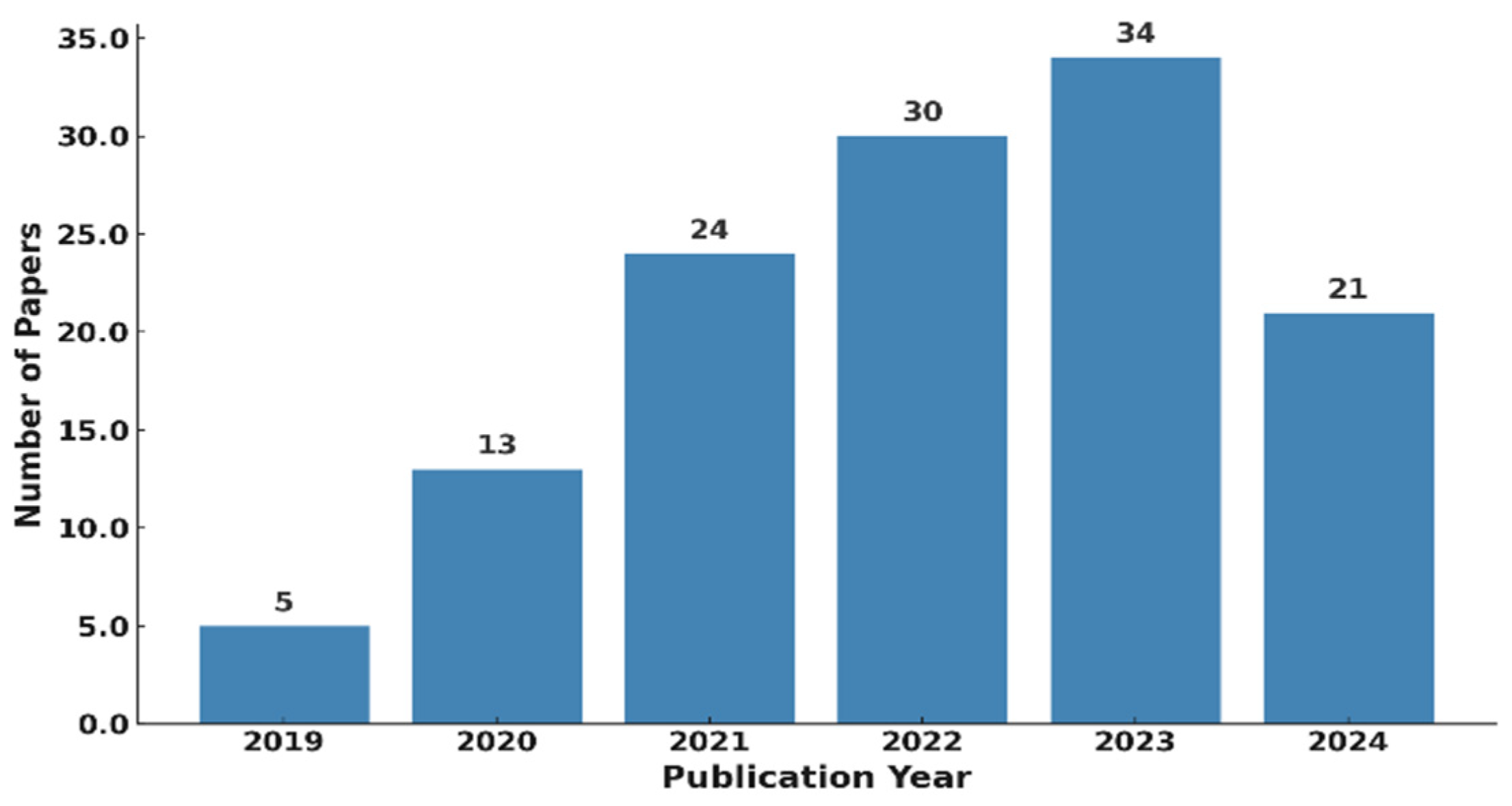

- Analyze recent advancements from 2019 to 2024, highlighting emerging trends and challenges in the field.

- Explore the potential of hybrid AI models and Digital Twin technology in improving real-world fault diagnosis, an area with limited existing research.

- It conducts a systematic review of fault diagnosis methodologies, integrating both model-based and data-driven approaches.

- It provides a comparative analysis of AI techniques used in wind turbine fault diagnosis.

- It identifies gaps and challenges in existing research, particularly in real-world validation and data availability.

- It discusses the potential role of Digital Twin technology for real-time fault monitoring, emphasizing its underexplored potential in wind turbine fault diagnosis.

- It presents recommendations for future advancements, including strategies for enhancing real-world implementation and the integration of hybrid AI models.

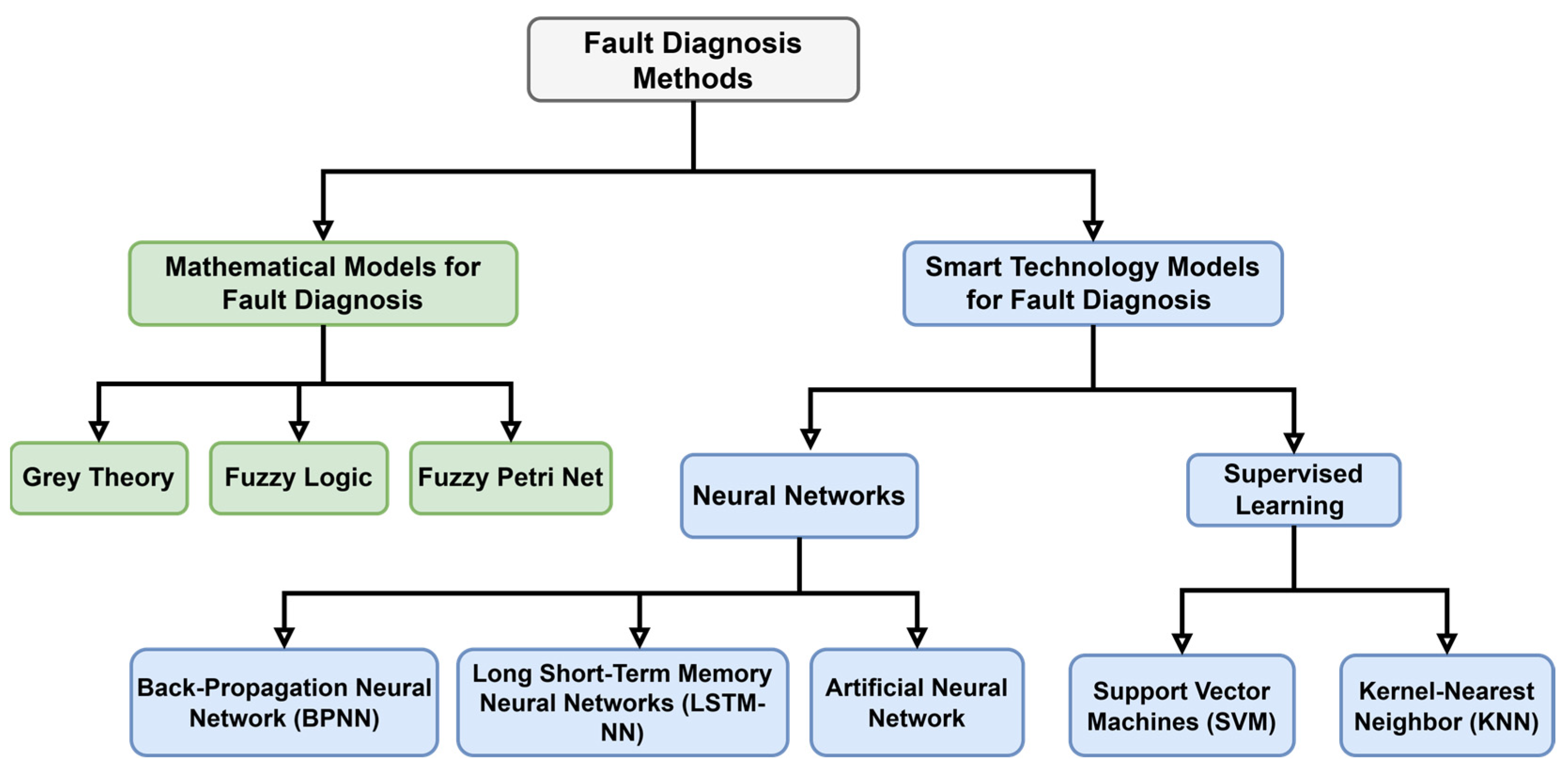

2. Overview of Fault Diagnosis

2.1. Traditional Fault Diagnosis Methods

2.2. AI-Driven Fault Diagnosis

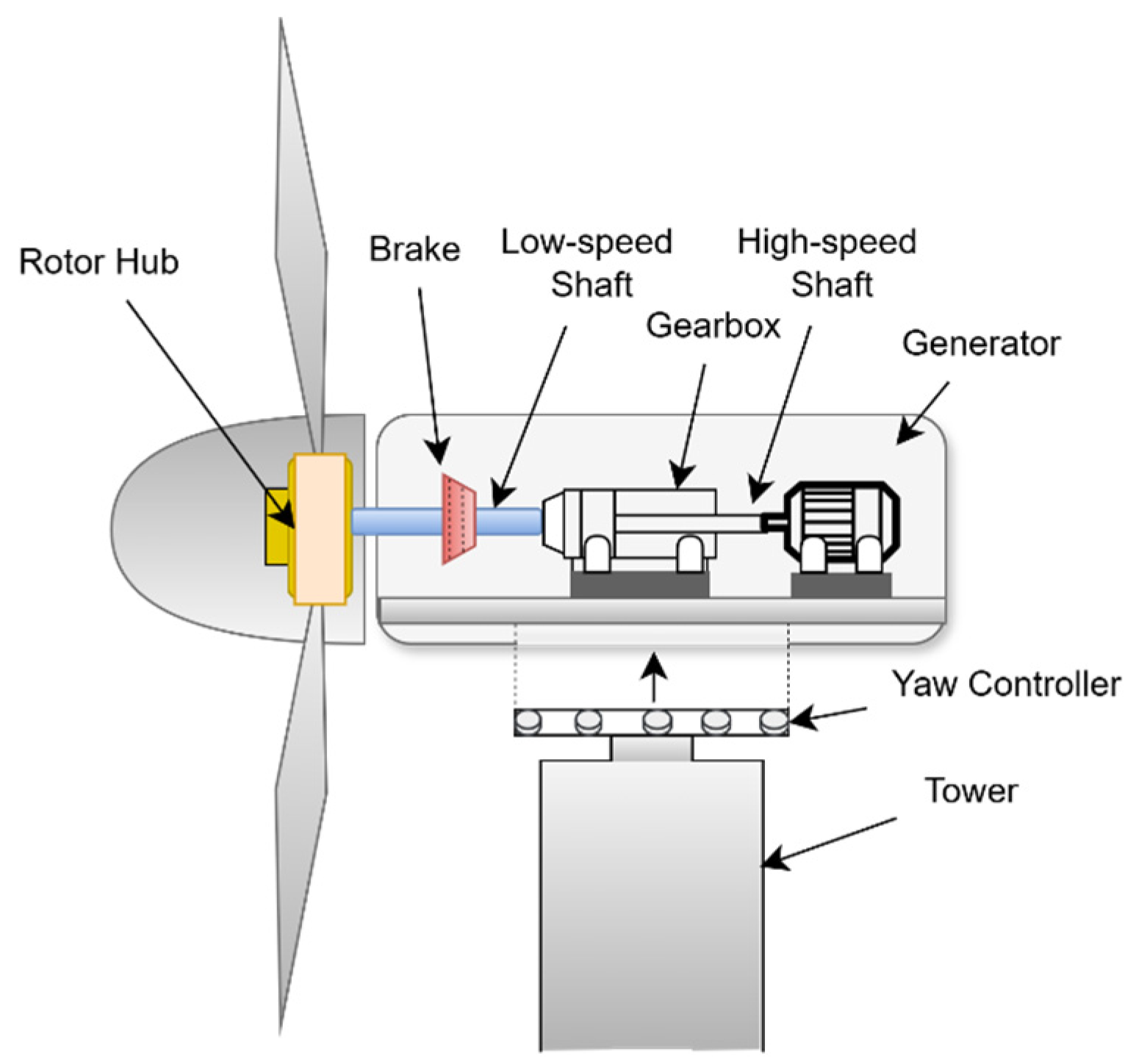

3. Wind Turbine Faults

3.1. Bearing Faults

3.2. Blade Faults

3.3. Gearbox Faults

3.4. Generator Faults

3.5. Multi-Faults

4. Analysis and Recommendations

4.1. Analysis of Fault Diagnosis Methods

4.2. Recommendations

- Integration of Hybrid AI Models: While various AI techniques such as ANNs, LSTM networks, and CNN have demonstrated their strengths, integrating hybrid models that combine the benefits of multiple techniques could improve fault detection accuracy. For example, merging LSTM with CNN could address both temporal and spatial complexities in fault diagnosis, especially for components such as the gearbox and blades.

- Use of Real-World Data for Model Training: Many of the reviewed studies rely heavily on simulated datasets. While these are useful for controlled testing, they often do not fully capture the complexities of real-world turbine operation. To ensure the generalization of fault diagnosis models beyond simulation environments, real-world validation is essential. One approach is integrating SCADA data, which provides real-time operational parameters such as temperature, vibration, and power output for model assessment. Additionally, field data collection through collaborations with industry partners can offer real-world sensor readings for comparison with simulated results. Transfer learning can further enhance model adaptability by fine-tuning pretrained models with real-world datasets. Moreover, utilizing publicly available wind turbine datasets enables cross-validation under diverse operating conditions. Digital twin can also be a very powerful tool for extracting real-world and real-time data, yet there are limited studies focusing on its application in wind turbine fault diagnosis. Incorporating these strategies can significantly improve the reliability and practical applicability of AI-based fault diagnosis methods.

- Development of Advanced Signal Processing Techniques: Current diagnostic techniques that rely on vibration signals often struggle with nonlinear and non-stationary patterns. It is recommended that more advanced signal processing methods, such as Empirical Mode Decomposition (EMD) or Wavelet Transform, be combined with AI techniques to enhance feature extraction and classification.

- Direct Data Input vs. Signal Processing with AI: An important area for further investigation is whether AI models perform better when fed directly with raw data or when used in combination with signal processing techniques. While AI has the capacity to learn features directly from raw data [103], applying signal processing first may help extract critical features that improve model accuracy [104]. Comparing these two approaches across different wind turbine components and fault types could provide valuable insights into optimizing fault diagnosis techniques.

- Noisy Signal Management: SCADA data are often noisy, which can affect the performance of diagnostic models. Implementing advanced noise filtering techniques, such as adaptive noise cancelation, will improve the quality of the input data and subsequently enhance the accuracy of the fault diagnosis.

- Adaptation to Diverse Operating Conditions: The variability in wind turbine operating conditions adds complexity to fault diagnosis. Future research should focus on developing models that can adapt to a wide range of operating conditions, normalizing the effects of seasonality and fluctuating wind speeds, so that diagnostic systems are more robust.

- Focus on Early Fault Detection: As demonstrated by the success of non-singleton fuzzy logic and ML models like LSTM, early detection is critical to preventing major failures. Future development should focus on improving the sensitivity of these models, particularly in detecting subtle, evolving faults before they escalate into critical issues.

- Improved Computational Efficiency: Some AI-driven models, while highly accurate, are computationally intensive [105]. Research should focus on optimizing these models to balance between accuracy and computational efficiency, making them suitable for real-time fault diagnosis applications in operational wind farms.

- Computational Challenges in Real-Time Deployment: An important area for future exploration is the computational challenges associated with deploying AI-based fault diagnosis models in real-time industrial settings. High computational costs can be a limiting factor, as deep learning models often require significant processing power, making on-site deployment challenging. Additionally, real-time processing constraints must be addressed to ensure low-latency fault detection while handling large streaming datasets efficiently. Another critical aspect is model interpretability, as black-box AI models may not be easily trusted in industrial environments. Furthermore, seamless integration with existing industrial systems remains a challenge, particularly when dealing with legacy infrastructure. Investigating optimization techniques, lightweight model architectures, and hybrid edge-cloud solutions can enhance the feasibility of real-time fault detection and should be considered in future research.

- Implementation of Hybrid Models: Future research can explore the integration of hybrid models, such as CNN-RNN architectures, to leverage both spatial and temporal dependencies for improved fault detection in wind turbines. Additionally, transformer-based models with self-attention mechanisms present a promising approach for analyzing time-series sensor data, offering enhanced feature extraction and long-range dependency modeling compared to traditional RNNs. Applying transformers to fault diagnosis could improve predictive accuracy and robustness, particularly in handling noisy or incomplete data. Further studies should also focus on optimizing computational efficiency through techniques such as pruning, quantization, and edge computing, enabling real-time fault detection with reduced computational costs for industrial applications.

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Li, L.; Lin, J.; Wu, N.; Xie, S.; Meng, C.; Zheng, Y.; Wang, X.; Zhao, Y. Review and outlook on the international renewable energy development. Energy Built Environ. 2022, 3, 139–157. [Google Scholar] [CrossRef]

- García Márquez, F.P.; Karyotakis, A.; Papaelias, M. (Eds.) Renewable Energies; Springer Nature: Cham, Switzerland, 2018. [Google Scholar] [CrossRef]

- Gielen, D.; Boshell, F.; Saygin, D.; Bazilian, M.D.; Wagner, N.; Gorini, R. The role of renewable energy in the global energy transformation. Energy Strategy Rev. 2019, 24, 38–50. [Google Scholar] [CrossRef]

- Keleş, S.; Bilgen, S. Renewable energy sources in Turkey for climate change mitigation and energy sustainability. Renew. Sustain. Energy Rev. 2012, 16, 5199–5206. [Google Scholar] [CrossRef]

- Breeze, P. Wind Power. In Power Generation Technologies; Elsevier: Amsterdam, The Netherlands, 2014; pp. 223–242. [Google Scholar] [CrossRef]

- Herbert, G.J.; Iniyan, S.; Sreevalsan, E.; Rajapandian, S. A review of wind energy technologies. Renew. Sustain. Energy Rev. 2007, 11, 1117–1145. [Google Scholar] [CrossRef]

- Hamdaoui, Y.; Maach, A. Dynamic balancing of powers in islanded microgrid using distributed energy resources and prosumers for efficient energy management. In Proceedings of the 2017 IEEE International Conference on Smart Energy Grid Engineering (SEGE), Oshawa, ON, Canada, 14–17 August 2017; pp. 155–161. [Google Scholar] [CrossRef]

- Díaz, H.; Soares, C.G. Review of the current status, technology and future trends of offshore wind farms. Ocean Eng. 2020, 209, 107381. [Google Scholar] [CrossRef]

- Bilgili, M.; Alphan, H. Global growth in offshore wind turbine technology. Clean Technol. Environ. Policy 2022, 24, 2215–2227. [Google Scholar] [CrossRef]

- Explainer: What Is Offshore Wind and What Does Its Future Look Like? World Economic Forum. Available online: https://www.weforum.org/agenda/2022/11/offshore-wind-farms-future-renewables/ (accessed on 9 December 2023).

- Pryor, S.C.; Barthelmie, R.J.; Shepherd, T.J. Wind power production from very large offshore wind farms. Joule 2021, 5, 2663–2686. [Google Scholar] [CrossRef]

- Jung, C.; Schindler, D. The properties of the global offshore wind turbine fleet. Renew. Sustain. Energy Rev. 2023, 186, 113667. [Google Scholar] [CrossRef]

- Machado, J.T.M.; de Andrés, M. Implications of offshore wind energy developments in coastal and maritime tourism and recreation areas: An analytical overview. Environ. Impact Assess. Rev. 2023, 99, 106999. [Google Scholar] [CrossRef]

- Guo, Q.; Yang, Z.R.; Liu, C.; Xu, Y.; Xie, L.Y. Anti-typhoon yaw control technology for offshore wind farms. In Proceedings of the 2020 5th International Conference on Mechanical, Control and Computer Engineering (ICMCCE), Harbin, China, 25–27 December 2020. [Google Scholar]

- Faulstich, S.; Hahn, B.; Tavner, P.J. Wind turbine downtime and its importance for offshore deployment. Wind Energy 2011, 14, 327–337. [Google Scholar] [CrossRef]

- Yang, W.; Tavner, P.J.; Crabtree, C.J.; Feng, Y.; Qiu, Y. Wind turbine condition monitoring: Technical and commercial challenges. Wind Energy 2014, 17, 673–693. [Google Scholar] [CrossRef]

- Qiao, W.; Lu, D. A Survey on Wind Turbine Condition Monitoring and Fault Diagnosis—Part I: Components and Subsystems. IEEE Trans. Ind. Electron. 2015, 62, 6536–6545. [Google Scholar] [CrossRef]

- Lundgren, A.; Jung, D. Data-driven fault diagnosis analysis and open-set classification of time-series data. Control Eng. Pract. 2022, 121, 105006. [Google Scholar] [CrossRef]

- Gawde, S.; Patil, S.; Kumar, S.; Kamat, P.; Kotecha, K.; Abraham, A. Multi-fault diagnosis of Industrial Rotating Machines using Data-driven approach: A review of two decades of research. Eng. Appl. Artif. Intell. 2023, 123, 106139. [Google Scholar] [CrossRef]

- Jaros, R.; Byrtus, R.; Dohnal, J.; Danys, L.; Baros, J.; Koziorek, J.; Zmij, P.; Martinek, R. Advanced Signal Processing Methods for Condition Monitoring. Arch. Comput. Methods Eng. 2023, 30, 1553–1577. [Google Scholar] [CrossRef]

- Ning, K. Data Driven Artificial Intelligence Techniques in Renewable Energy System. Ph.D. Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 2021. Available online: https://dspace.mit.edu/handle/1721.1/132891 (accessed on 4 October 2024).

- Li, W.; Li, H.; Gu, S.; Chen, T. Process fault diagnosis with model- and knowledge-based approaches: Advances and opportunities. Control Eng. Pract. 2020, 105, 104637. [Google Scholar] [CrossRef]

- Yang, W.; Pelegri, A.A. Strain Rate Effect on the Stiffness of Random Fiber Composites due to Matrix Cracking and Interfacial Debonding. In Proceedings of the ASME 2012 International Mechanical Engineering Congress and Exposition, Houston, TX, USA, 9–15 November 2012; pp. 673–680. [Google Scholar] [CrossRef]

- Igba, J.; Alemzadeh, K.; Durugbo, C.; Henningsen, K. Through-life Engineering Services: A Wind Turbine Perspective. Procedia CIRP 2014, 22, 213–218. [Google Scholar] [CrossRef]

- Feng, Y.; Qiu, Y.; Crabtree, C.J.; Long, H.; Tavner, P.J. Monitoring wind turbine gearboxes. Wind. Energy 2013, 16, 728–740. [Google Scholar] [CrossRef]

- Sheldon, J.; Mott, G.; Lee, H.; Watson, M. Robust wind turbine gearbox fault detection. Wind. Energy 2014, 17, 745–755. [Google Scholar] [CrossRef]

- Wang, J.; Gao, R.X.; Yan, R. Integration of EEMD and ICA for wind turbine gearbox diagnosis. Wind Energy 2014, 17, 757–773. [Google Scholar] [CrossRef]

- Wang, J.; Gao, R.; Yan, R.; Wang, L. An Integrative Computational Method for Gearbox Diagnosis. Procedia CIRP 2013, 12, 133–138. [Google Scholar] [CrossRef]

- Tang, B.; Song, T.; Li, F.; Deng, L. Fault diagnosis for a wind turbine transmission system based on manifold learning and Shannon wavelet support vector machine. Renew. Energy 2014, 62, 1–9. [Google Scholar] [CrossRef]

- Wilkinson, M.R.; Tavner, P.J. Extracting condition monitoring information from a wind turbine drive train. In Proceedings of the 39th International Universities Power Engineering Conference, UPEC 2004, Bristol, UK, 6–8 September 2004; pp. 591–594. Available online: https://ieeexplore.ieee.org/abstract/document/1492088 (accessed on 6 September 2024).

- Hameed, Z.; Hong, Y.; Cho, Y.; Ahn, S.; Song, C. Condition monitoring and fault detection of wind turbines and related algorithms: A review. Renew. Sustain. Energy Rev. 2009, 13, 1–39. [Google Scholar] [CrossRef]

- Chen, X.; Yang, Y.; Cui, Z.; Shen, J. Vibration fault diagnosis of wind turbines based on variational mode decomposition and energy entropy. Energy 2019, 174, 1100–1109. [Google Scholar] [CrossRef]

- Yang, W.; Court, R.; Jiang, J. Wind turbine condition monitoring by the approach of SCADA data analysis. Renew. Energy 2013, 53, 365–376. [Google Scholar] [CrossRef]

- Wei, L.; Qian, Z.; Pei, Y.; Wang, J. Wind Turbine Fault Diagnosis by the Approach of SCADA Alarms Analysis. Appl. Sci. 2021, 12, 69. [Google Scholar] [CrossRef]

- Qiu, Y.; Feng, Y.; Infield, D. Fault diagnosis of wind turbine with SCADA alarms based multidimensional information processing method. Renew. Energy 2020, 145, 1923–1931. [Google Scholar] [CrossRef]

- Liu, Y.; Wu, Z.; Wang, X. Research on Fault Diagnosis of Wind Turbine Based on SCADA Data. IEEE Access 2020, 8, 185557–185569. [Google Scholar] [CrossRef]

- Dao, P.B. Condition monitoring and fault diagnosis of wind turbines based on structural break detection in SCADA data. Renew. Energy 2022, 185, 641–654. [Google Scholar] [CrossRef]

- Shi, Y.; Liu, Y.; Gao, X. Study of Wind Turbine Fault Diagnosis and Early Warning Based on SCADA Data. IEEE Access 2021, 9, 124600–124615. [Google Scholar] [CrossRef]

- Marti-Puig, P.; Blanco, M.A.; Serra-Serra, M.; Solé-Casals, J. Wind Turbine Prognosis Models Based on SCADA Data and Extreme Learning Machines. Appl. Sci. 2021, 11, 590. [Google Scholar] [CrossRef]

- Vatanchi, S.M.; Etemadfard, H.; Maghrebi, M.F.; Shad, R. A Comparative Study on Forecasting of Long-term Daily Streamflow using ANN, ANFIS, BiLSTM and CNN-GRU-LSTM. Water Resour. Manag. 2023, 37, 4769–4785. [Google Scholar] [CrossRef]

- Hanifi, S.; Zare-Behtash, H.; Cammarano, A.; Lotfian, S. Offshore wind power forecasting based on WPD and optimised deep learning methods. Renew. Energy 2023, 218, 119241. [Google Scholar] [CrossRef]

- Zhang, W.; Teng, F.; Li, J.; Zhang, Z.; Niu, L.; Zhang, D.; Song, Q.; Zhang, Z. Denoising method based on CNN-LSTM and CEEMD for LDV signals from accelerometer shock testing. Measurement 2023, 216, 112951. [Google Scholar] [CrossRef]

- Kerboua, A.; Kelaiaia, R. Fault Diagnosis in an Asynchronous Motor Using Three-Dimensional Convolutional Neural Network. Arab. J. Sci. Eng. 2024, 49, 3467–3485. [Google Scholar] [CrossRef]

- Adlen, K.; Ridha, K. Recurrent neural network optimization for wind turbine condition prognosis. Diagnostyka 2022, 23, 1–11. [Google Scholar] [CrossRef]

- Wen, X.; Li, W. Time Series Prediction Based on LSTM-Attention-LSTM Model. IEEE Access 2023, 11, 48322–48331. [Google Scholar] [CrossRef]

- Hameed, B.S.; Krishnan, U.M. Artificial Intelligence-Driven Diagnosis of Pancreatic Cancer. Cancers 2022, 14, 5382. [Google Scholar] [CrossRef]

- Qu, F.; Liu, J.; Zhu, H.; Zhou, B. Wind turbine fault detection based on expanded linguistic terms and rules using non-singleton fuzzy logic. Appl. Energy 2020, 262, 114469. [Google Scholar] [CrossRef]

- Kabat, S.R.; Panigrahi, C.K.; Ganthia, B.P. Fuzzy Logic Based Fault Current Prediction in Double Fed Induction Generator Based Wind Turbine System. Mater. Today Proc. 2023, 80, 2530–2538. [Google Scholar] [CrossRef]

- Simani, S.; Castaldi, P. Intelligent Fault Diagnosis Techniques Applied to an Offshore Wind Turbine System. Appl. Sci. 2019, 9, 783. [Google Scholar] [CrossRef]

- Li, H.; Hu, Y.; Yang, C.; Chen, Z.; Ji, H.; Zhao, B. An improved fuzzy synthetic condition assessment of a wind turbine generator system. Int. J. Electr. Power Energy Syst. 2013, 45, 468–476. [Google Scholar] [CrossRef]

- Sun, P.; Li, J.; Wang, C.; Lei, X. A generalized model for wind turbine anomaly identification based on SCADA data. Appl. Energy 2016, 168, 550–567. [Google Scholar] [CrossRef]

- Zhang, Z.-Y.; Wang, K.-S. Wind turbine fault detection based on SCADA data analysis using ANN. Adv. Manuf. 2014, 2, 70–78. [Google Scholar] [CrossRef]

- Chen, J.; Hu, W.; Cao, D.; Zhang, B.; Huang, Q.; Chen, Z.; Blaabjerg, F. An Imbalance Fault Detection Algorithm for Variable-Speed Wind Turbines: A Deep Learning Approach. Energies 2019, 12, 2764. [Google Scholar] [CrossRef]

- Yang, T.; Teng, J.; Li, C.; Feng, Y. Wind turbine fault detection and diagnosis using LSTM neural network. In Proceedings of the 2020 39th Chinese Control Conference (CCC), Shenyang, China, 27–29 July 2020; pp. 4042–4047. [Google Scholar] [CrossRef]

- Dehghanabandaki, S.; Zhao, Q. Fault Detection of Wind Turbine System Based on Deep Learning and System Identification. In Proceedings of the 2022 IEEE International Symposium on Advanced Control of Industrial Processes (AdCONIP), Vancouver, BC, Canada, 7–9 August 2022; pp. 42–47. [Google Scholar] [CrossRef]

- Yang, X.; Zhang, Y.; Lv, W.; Wang, D. Image recognition of wind turbine blade damage based on a deep learning model with transfer learning and an ensemble learning classifier. Renew. Energy 2021, 163, 386–397. [Google Scholar] [CrossRef]

- He, J.; Wu, P.; Gao, J.; Zhang, X.; Lou, S. Wind Turbine Gearbox Fault Detection based on Dilated Convolutional Neural Networks. In Proceedings of the 2020 7th International Conference on Information, Cybernetics, and Computational Social Systems (ICCSS), Guangzhou, China, 13–15 November 2020; pp. 517–521. [Google Scholar] [CrossRef]

- Wang, M.-H.; Lu, S.-D.; Hsieh, C.-C.; Hung, C.-C. Fault Detection of Wind Turbine Blades Using Multi-Channel CNN. Sustainability 2022, 14, 1781. [Google Scholar] [CrossRef]

- Yang, Y.; Fu, P.; He, Y. Bearing Fault Automatic Classification Based on Deep Learning. IEEE Access 2018, 6, 71540–71554. [Google Scholar] [CrossRef]

- Teng, W.; Cheng, H.; Ding, X.; Liu, Y.; Ma, Z.; Mu, H. DNN-based approach for fault detection in a direct drive wind turbine. IET Renew. Power Gener. 2018, 12, 1164–1171. [Google Scholar] [CrossRef]

- Vives, J. Incorporating Machine Learning into Vibration Detection for Wind Turbines. In Modelling and Simulation in Engineering; Wiley: Hoboken, NJ, USA, 2022; pp. 1–8. [Google Scholar] [CrossRef]

- Santos, P.; Villa, L.F.; Reñones, A.; Bustillo, A.; Maudes, J. An SVM-Based Solution for Fault Detection in Wind Turbines. Sensors 2015, 15, 5627–5648. [Google Scholar] [CrossRef]

- Cheng, F.; Wang, J.; Qu, L.; Qiao, W. Rotor-Current-Based Fault Diagnosis for DFIG Wind Turbine Drivetrain Gearboxes Using Frequency Analysis and a Deep Classifier. IEEE Trans. Ind. Appl. 2018, 54, 1062–1071. [Google Scholar] [CrossRef]

- Energyabcs. 7 Factors Affecting Wind Turbine Efficiency. Energyabcs.com. Available online: https://www.energyabcs.com/factors-affecting-wind-turbine-efficiency/ (accessed on 25 August 2024).

- Kosko, B.; Isaka, S. Fuzzy logic. Sci. Am. 1993, 269, 76–81. [Google Scholar]

- Cardoso, J.; Valette, R.; Dubois, D. Fuzzy Petri Nets: An Overview. IFAC Proc. Vol. 1996, 29, 4866–4871. [Google Scholar] [CrossRef]

- Guo, G.; Wang, H.; Bell, D.; Bi, Y.; Greer, K. KNN Model-Based Approach in Classification. In On the Move to Meaningful Internet Systems 2003: CoopIS, DOA, and ODBASE. OTM 2003; Meersman, R., Tari, Z., Schmidt, D.C., Eds.; Lecture Notes in Computer Science; Springer: Berlin/Heidelberg, Germany, 2003; Volume 2888. [Google Scholar]

- Suthaharan, S. Support Vector Machine. In Machine Learning Models and Algorithms for Big Data Classification; Integrated Series in Information Systems; Springer: Boston, MA, USA, 2016; Volume 36, pp. 207–235. [Google Scholar] [CrossRef]

- Zhang, J.; Zheng, Y.; Qi, D.; Li, R.; Yi, X. DNN-based prediction model for spatio-temporal data. In Proceedings of the 24th ACM SIGSPATIAL International Conference on Advances in Geographic Information Systems, Burlingame CA, USA, 31 October–3 November 2016; pp. 1–4. [Google Scholar] [CrossRef]

- Bearing Data Center|Case School of Engineering|Case Western Reserve University. Case School of Engineering. Available online: https://engineering.case.edu/bearingdatacenter (accessed on 11 October 2024).

- Zadeh, L.A. Is there a need for fuzzy logic? Inf. Sci. 2008, 178, 2751–2779. [Google Scholar] [CrossRef]

- Suganthi, L.; Iniyan, S.; Samuel, A.A. Applications of fuzzy logic in renewable energy systems—A review. Renew. Sustain. Energy Rev. 2015, 48, 585–607. [Google Scholar] [CrossRef]

- Zheng, Y.; Liu, Q.; Chen, E.; Ge, Y.; Zhao, J.L. Time series classification using multi-channels deep convolutional neural networks. In Proceedings of the International Conference on Web-Age Information Management, Macau, China, 16–18 June 2014; Springer: Cham, Switzerland, 2014; pp. 298–310. [Google Scholar] [CrossRef]

- Kodosky, J. LabVIEW. In Proceedings of the ACM on Programming Languages; Association for Computing Machinery: New York, NY, USA, 2020; Volume 4, pp. 1–54. [Google Scholar]

- Jones, D.; Snider, C.; Nassehi, A.; Yon, J.; Hicks, B. Characterising the Digital Twin: A systematic literature review. CIRP J. Manuf. Sci. Technol. 2020, 29, 36–52. [Google Scholar] [CrossRef]

- Guo, H.; Jiang, Y.; Zhao, D. Wind Turbine Blade Fault Diagnosis Method Based on Digital Twin and Convolutional Neural Network. In Proceedings of the 2024 5th International Seminar on Artificial Intelligence, Networking and Information Technology (AINIT), Nanjing, China, 29–31 March 2024; pp. 1805–1809. [Google Scholar] [CrossRef]

- Liu, D.; Yu, J. Otsu Method and K-means. In Proceedings of the 2009 Ninth International Conference on Hybrid Intelligent Systems, Shenyang, China, 12–14 August 2009; pp. 344–349. [Google Scholar]

- Krizhevsky, A.; Sutskever, I.; Hinton, G.E. Imagenet classification with deep convolutional neural networks. Adv. Neural Inf. Process. Syst. 2012, 25. [Google Scholar] [CrossRef]

- Lu, S.; Lu, Z.; Zhang, Y.-D. Pathological brain detection based on AlexNet and transfer learning. J. Comput. Sci. 2019, 30, 41–47. [Google Scholar] [CrossRef]

- Bishop, C.M. Mixture Density Networks. 1994. Available online: https://research.aston.ac.uk/en/publications/mixture-density-networks (accessed on 23 December 2024).

- Peter, Ď.; Silvia, P. ARIMA vs. ARIMAX–which approach is better to analyze and forecast macroeconomic time series. In Proceedings of the 30th International Conference Mathematical Methods in Economics, Karviná, Czech Republic, 11–13 September 2012; pp. 136–140. [Google Scholar]

- Hu, X.; Yao, F. Dynamic principal component analysis in high dimensions. J. Am. Stat. Assoc. 2022, 119, 308–319. [Google Scholar] [CrossRef]

- Farrag, T.A.; Elattar, E.E. Optimized deep stacked long short-term memory network for long-term load forecasting. IEEE Access 2021, 9, 68511–68522. [Google Scholar] [CrossRef]

- Park, P.; Di Marco, P.; Shin, H.; Bang, J. Fault Detection and diagnosis using combined autoencoder and long short-term memory network. Sensors 2019, 19, 4612. [Google Scholar] [CrossRef] [PubMed]

- Wind Turbine Design Software|Bladed. Available online: https://www.dnv.com/services/wind-turbine-design-software-bladed-3775/ (accessed on 8 April 2024).

- Xue, T.; Zhong, M.; Li, L.; Ding, S.X. An Optimal Data-Driven Approach to Distribution Independent Fault Detection. IEEE Trans. Ind. Inform. 2020, 16, 6826–6836. [Google Scholar] [CrossRef]

- Youngworth, R.N.; Gallagher, B.B.; Stamper, B.L. An overview of power spectral density (PSD) calculations. In Proceedings of the Optics & Photonics 2005, San Diego, CA, USA, 31 July–4 August 2005; Stahl, H.P., Ed.; p. 58690U. [Google Scholar] [CrossRef]

- Bhuiyan, R.; Abdullah, J.; Hashim, N.; Al Farid, F.; Isa, W.N.M.; Uddin, J.; Abdullah, N. Deep Dilated Convolutional Neural Network for Crowd Density Image Classification with Dataset Augmentation for Hajj Pilgrimage. Sensors 2022, 22, 5102. [Google Scholar] [CrossRef]

- Popescu, M.-C.; Balas, V.E.; Perescu-Popescu, L.; Mastorakis, N. Multilayer perceptron and neural networks. WSEAS Trans. Circuits Syst. 2009, 8, 579–588. [Google Scholar]

- Huang, C.; Li, Y.; Zhang, T.; Hou, G.; Zhang, J. Fault diagnosis of wind turbine gearbox by diminishing step fruit fly algorithm optimized SVM. In Proceedings of the 2017 Chinese Automation Congress (CAC), Jinan, China, 20–22 October 2017; pp. 4431–4436. [Google Scholar]

- Ardjani, F.; Sadouni, K.; Benyettou, M. Optimization of SVM multiclass by particle swarm (PSO-SVM). In Proceedings of the 2010 2nd International Workshop on Database Technology and Applications, Wuhan, China, 27–28 November 2010; pp. 1–4. [Google Scholar]

- Wang, Y.; Sun, W.; Liu, L.; Wang, B.; Bao, S.; Jiang, R. Fault Diagnosis of Wind Turbine Planetary Gear Based on a Digital Twin. Appl. Sci. 2023, 13, 4776. [Google Scholar] [CrossRef]

- Cen, J.; Yang, Z.; Liu, X.; Xiong, J.; Chen, H. A Review of Data-Driven Machinery Fault Diagnosis Using Machine Learning Algorithms. J. Vib. Eng. Technol. 2022, 10, 2481–2507. [Google Scholar] [CrossRef]

- Zeiler, A.; Faltermeier, R.; Keck, I.R.; Tomé, A.M.; Puntonet, C.G.; Lang, E.W. Empirical mode decomposition—An introduction. In Proceedings of the the 2010 International Joint Conference on Neural Networks (IJCNN), Barcelona, Spain, 18–23 July 2010. [Google Scholar] [CrossRef]

- Yazdani, S.; Montazeri-Gh, M. A novel gas turbine fault detection and identification strategy based on hybrid dimensionality reduction and uncertain rule-based fuzzy logic. Comput. Ind. 2020, 115, 103131. [Google Scholar] [CrossRef]

- Hunter, J.S. The exponentially weighted moving average. J. Qual. Technol. 1986, 18, 203–210. [Google Scholar]

- Hecht-Nielsen, R. Theory of the backpropagation neural network. In Neural Networks for Perception; Elsevier: Amsterdam, The Netherlands, 1992; pp. 65–93. [Google Scholar]

- Dinh, M.-C.; Ngo, M.-T.; Kim, C.; Lee, S.J.; Yu, I.-K.; Park, M. Implementation of Digital Twin-Assisted Condition Monitoring and Fault Diagnosis for Wind Turbines. In Proceedings of the 2023 12th International Conference on Renewable Energy Research and Applications (ICRERA), Oshawa, ON, Canada, 29 August–1 September 2023; pp. 146–150. [Google Scholar] [CrossRef]

- Boje, C.; Guerriero, A.; Kubicki, S.; Rezgui, Y. Towards a semantic Construction Digital Twin: Directions for future research. Autom. Constr. 2020, 114, 103179. [Google Scholar] [CrossRef]

- Souza, P.V.d.C. Fuzzy neural networks and neuro-fuzzy networks: A review the main techniques and applications used in the literature. Appl. Soft Comput. 2020, 92, 106275. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, Z.; Zhao, S. Short-term fault prediction of mechanical rotating parts on the basis of fuzzy-grey optimising method. Mech. Syst. Signal Process. 2007, 21, 856–865. [Google Scholar] [CrossRef]

- Wang, J.; Li, S.; Xin, Y.; An, Z. Gear Fault Intelligent Diagnosis Based on Frequency-Domain Feature Extraction. J. Vib. Eng. Technol. 2019, 7, 159–166. [Google Scholar] [CrossRef]

- Whang, S.E.; Roh, Y.; Song, H.; Lee, J.-G. Data collection and quality challenges in deep learning: A data-centric AI perspective. VLDB J. 2023, 32, 791–813. [Google Scholar] [CrossRef]

- Zhang, C.; Mousavi, A.A.; Masri, S.F.; Gholipour, G.; Yan, K.; Li, X. Vibration feature extraction using signal processing techniques for structural health monitoring: A review. Mech. Syst. Signal Process. 2022, 177, 109175. [Google Scholar] [CrossRef]

- Thompson, N.C.; Greenewald, K.; Lee, K.; Manso, G.F. The Computational Limits of Deep Learning. arXiv 2022, arXiv:2007.05558. Available online: http://arxiv.org/abs/2007.05558 (accessed on 6 October 2024).

| Study | Fault Detected | Data | Input Data Type | Method |

|---|---|---|---|---|

| [47] | Blade Angle Sensor | SCADA | N/A | Non-Singleton Fuzzy Logic |

| [48] | Faulty Phases and Short Circuit Fault in Double Fed Induction Generator (DFIG) | SCADA | Voltage and Current | Fuzzy Logic Controller |

| [49] | Pitch Faults, Torque Converter Faults, and Drivetrain Wear | Simulated Data | Blade Pitch Angle and Generator Torque | Fuzzy Logic and NN |

| [50] | Overall Condition of the Wind Turbine Generator System | SCADA | Wind Speed, Temperature of Components, Reactive Power, Voltage and Current | Fuzzy Synthetic Condition Assessment |

| [51] | General Anomalies in Wind Turbines | SCADA | Rotor Speed, Temperature of Components, and Output Power | BPNN |

| [52] | Main Shaft Rear Bearing | SCADA | Active Power Output, Anemometer-Measured Wind and Turbine Speed, Turbine Rear, and Front Vibration Signals | ANN |

| [53] | Blades | Simulated Data | Wind Speed, Rotor Speed, Electrical Power, Turbine Current, and Generator Torque | LSTM |

| [54] | Blade Angle, Generator, and Gearbox | Simulated data | Rotor speed and Pitch Angle | LSTM |

| [55] | Sensor and Actuator Faults (for Blade and Pitch) | Simulated data | Rotor Effective Wind Speed, Pitch Angle, and Rotor Speed | LSTM |

| [56] | Blade Faults | Dataset | Images | CNN |

| [57] | Gearbox | Real-time Data | Vibration Signals | DCNN |

| [58] | Blades (Blade Angle Anomaly, Blade Surface Damage, and Blade Breakage) | N/A | Vibration Signals | MCNN |

| [59] | Bearings | N/A | Vibrations Signals | DNN |

| [60] | Permanent Magnet of Generator | SCADA | Temperature, Vibration, Pressure, Wind speed, Current and Torque | DNN |

| [61] | Bearing Brake Failure | Simulated Data | Vibration signals | SVM and KNN |

| [62] | Blade Misalignment | Simulated Data | Vibration Signals, Current and Torque of Electric Drive | SVM |

| [90] | Fatigue Spalling and Cracks in Gearbox | Real-time Data | Vibrations Signals | SVM |

| [63] | Gearbox | Simulated Data | Rotor Current | SAE-Based Multiclass SVM |

| [76] | Blades | Digital twin | Vibration Signals | CNN |

| [98] | Generator and Gearbox | SCADA and Digital twin | Vibration Signals and Output Power | DNN, RNN, and LSTM |

| Model Type | Method | Advantages | Limitations |

|---|---|---|---|

| Mathematical Model | Fuzzy Logic |

|

|

| Non-Singleton Fuzzy Logic |

|

| |

| Grey Theory |

|

| |

| Fuzzy Petri Net |

|

| |

| Smart Technology Models | Back-Propagation Neural Network |

|

|

| Artificial Neural Network |

|

| |

| Long Short-Term Memory |

|

| |

| Convolutional Neural Network |

|

| |

| Deep Convolutional Neural Network |

|

| |

| Multiscale Convolutional Neural Network |

|

| |

| Deep Neural Network |

|

| |

| K-Nearest Neighbors |

|

| |

| Support Vector Machines |

|

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alagha, N.; Khairuddin, A.S.M.; Haitaamar, Z.N.; Al-Khatib, O.; Kanesan, J. Artificial Intelligence in Wind Turbine Fault Detection and Diagnosis: Advances and Perspectives. Energies 2025, 18, 1680. https://doi.org/10.3390/en18071680

Alagha N, Khairuddin ASM, Haitaamar ZN, Al-Khatib O, Kanesan J. Artificial Intelligence in Wind Turbine Fault Detection and Diagnosis: Advances and Perspectives. Energies. 2025; 18(7):1680. https://doi.org/10.3390/en18071680

Chicago/Turabian StyleAlagha, Nejad, Anis Salwa Mohd Khairuddin, Zineddine N. Haitaamar, Obada Al-Khatib, and Jeevan Kanesan. 2025. "Artificial Intelligence in Wind Turbine Fault Detection and Diagnosis: Advances and Perspectives" Energies 18, no. 7: 1680. https://doi.org/10.3390/en18071680

APA StyleAlagha, N., Khairuddin, A. S. M., Haitaamar, Z. N., Al-Khatib, O., & Kanesan, J. (2025). Artificial Intelligence in Wind Turbine Fault Detection and Diagnosis: Advances and Perspectives. Energies, 18(7), 1680. https://doi.org/10.3390/en18071680