A Cost-Driven Analysis of Thermal Performance in Power Modules †

Abstract

1. Introduction

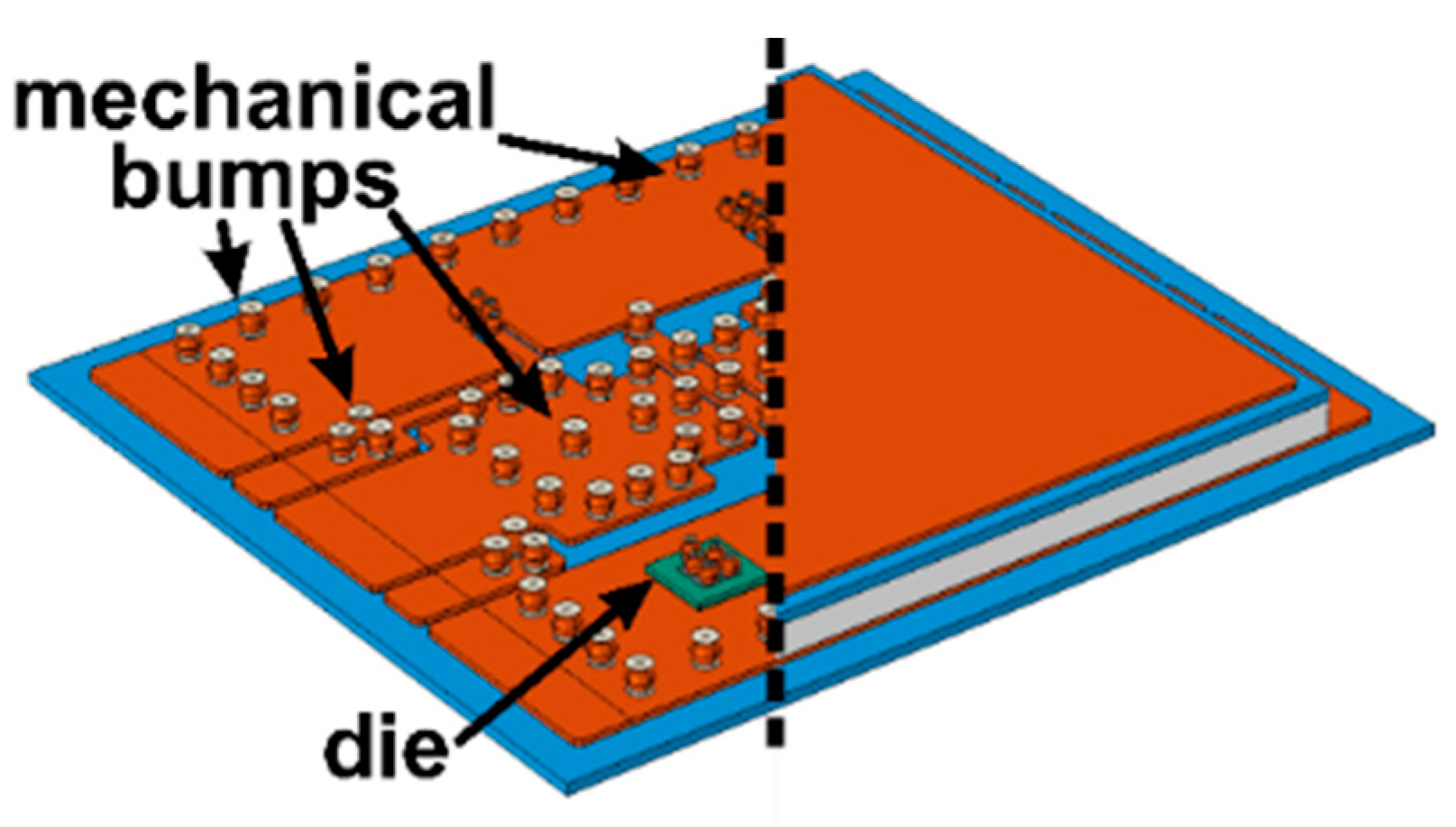

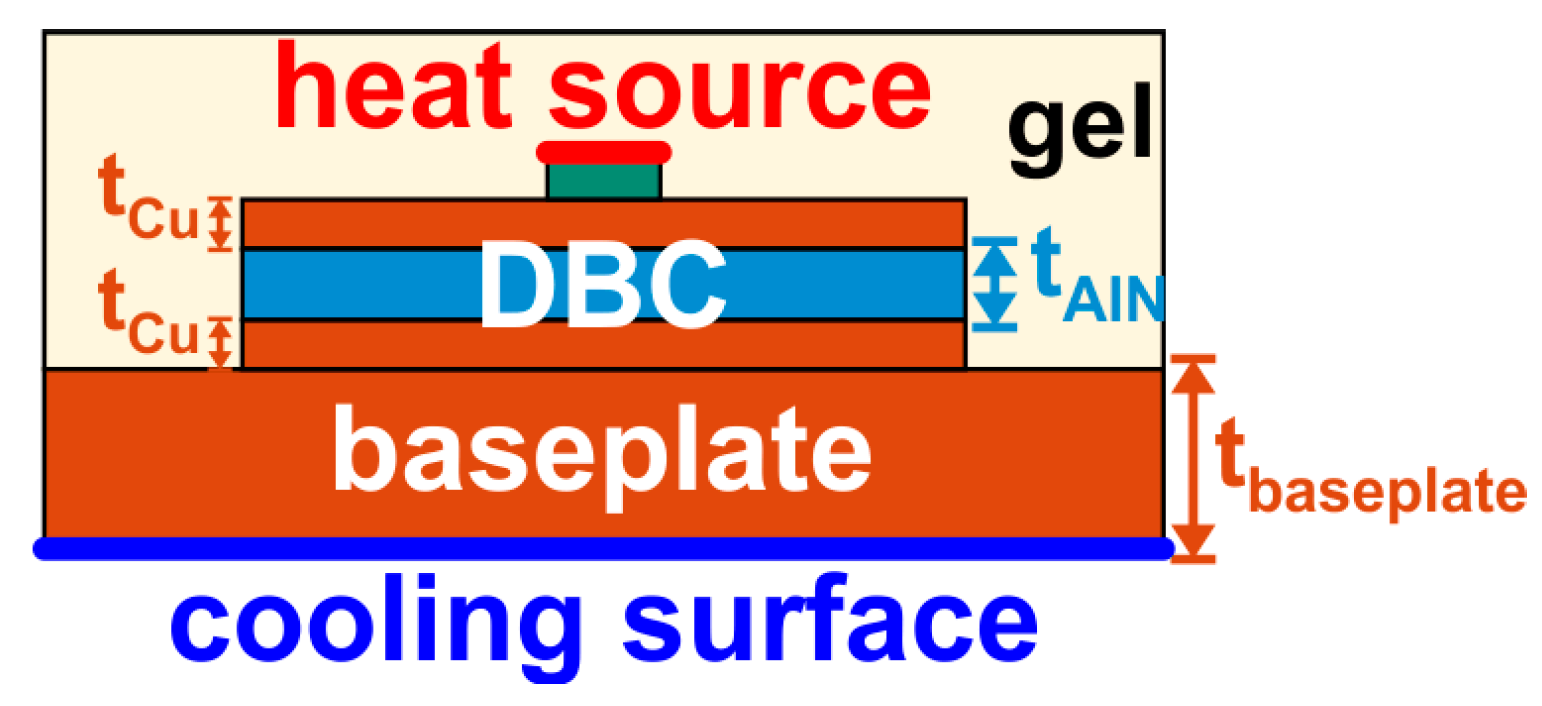

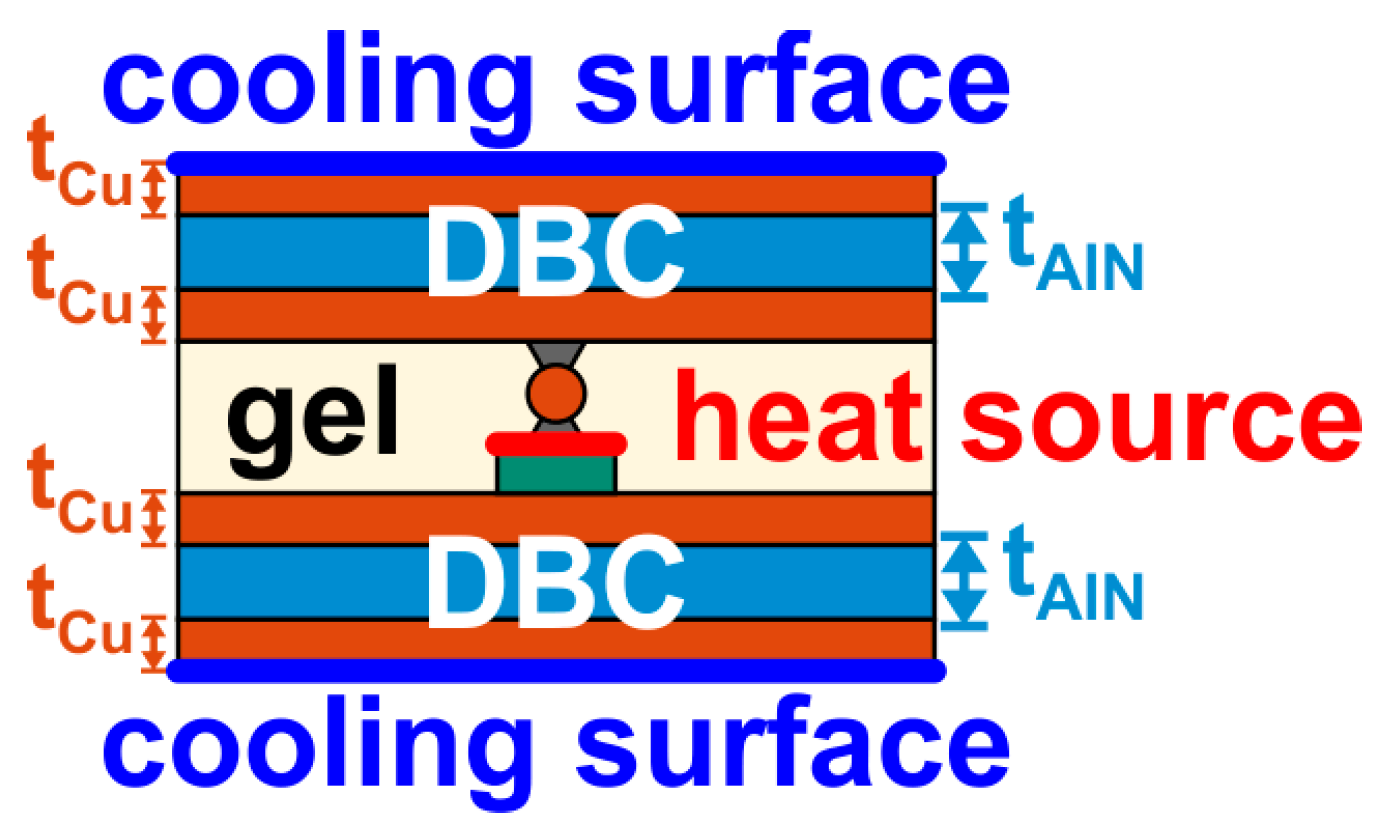

2. Power Modules Under Investigation

3. Methodology

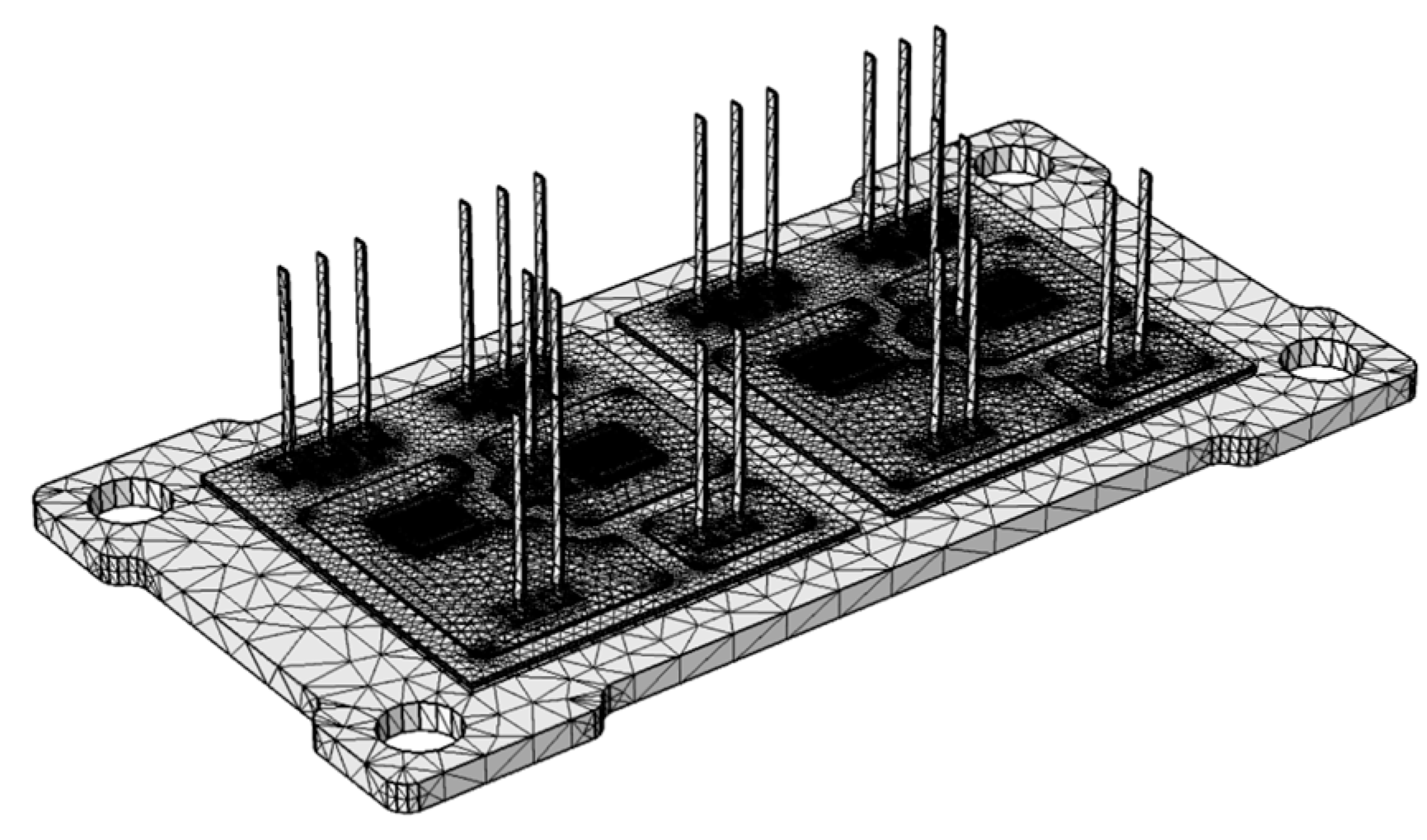

3.1. Methods

- (i)

- A 2D footprint of each layer composing the assemblies was imported into COMSOL and extruded into the 3rd dimension;

- (ii)

- (iii)

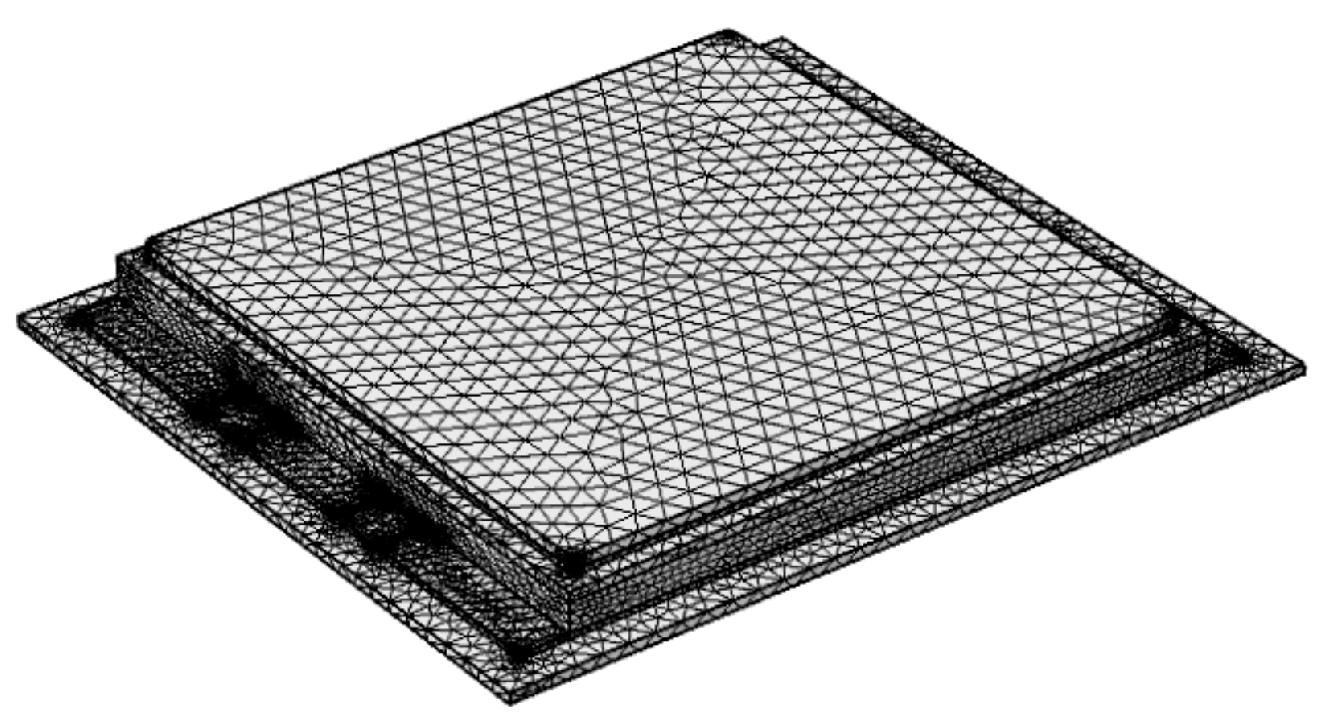

- The domains were discretized into a tetrahedral mesh;

- (iv)

- Boundary conditions (BCs) were assigned to the bottom surface, and to the top and bottom surfaces, in SSC and DSC PMs, respectively;

- (v)

- A dissipated power step was set on the HS, and the initial temperature of the domains was set to the ambient temperature, Tamb [K];

- (vi)

- A thermal-only dynamic simulation was conducted.

3.2. Mesh- and Grid-Independence Analysis

3.3. Materials

4. Results

4.1. Parametric Analysis for SSC Baseplate

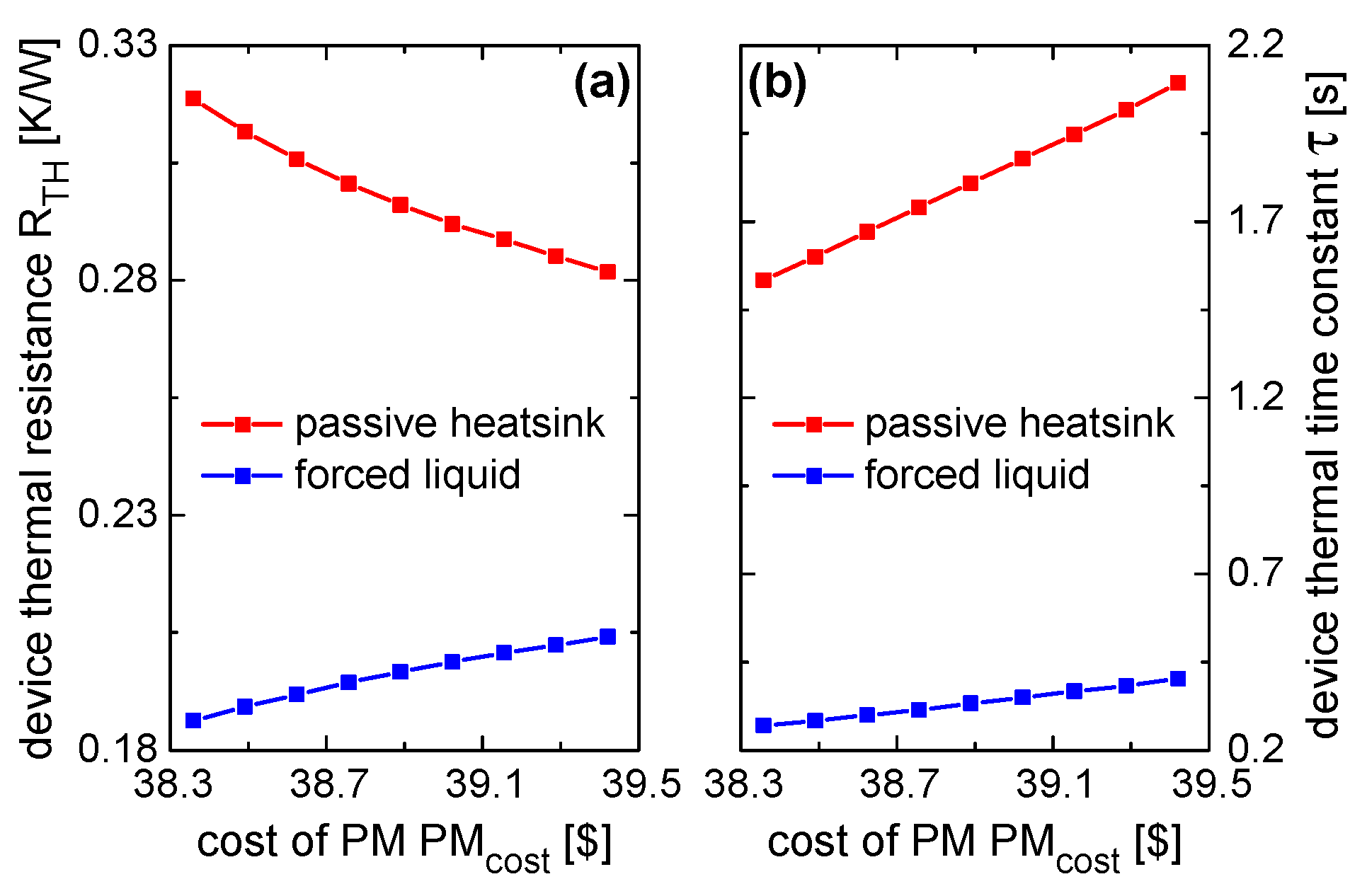

- In the case of passive heatsink, increasing the baseplate thickness has a beneficial influence on the device’s static thermal behavior. Thicker baseplates promote heat spreading, which takes place to reduce the conductive (by virtue of the larger average cross-section of the heat flux) and the convective (thanks to the wider effective area of heat exchange on the baseplate’s bottom surface) contributions to RTH. As a result, an RTH decrease of ~11.5% was quantified.

- Conversely, with the more efficient forced liquid cooling, the RTH increases with tbaseplate by approximately 9.6%, leading to opposite behaviors to those seen with passive heatsink cooling. This can be explained as follows: if high-performing cooling systems are employed, the CSs become more and more efficient in terms of heat exchange. This means that the heat is not encouraged to spread as much as in the case of passive heatsinks (the heat spreading becomes less necessary). Therefore, in this case, a thinner baseplate is preferred, as it minimizes the distance between the HS and the CS.

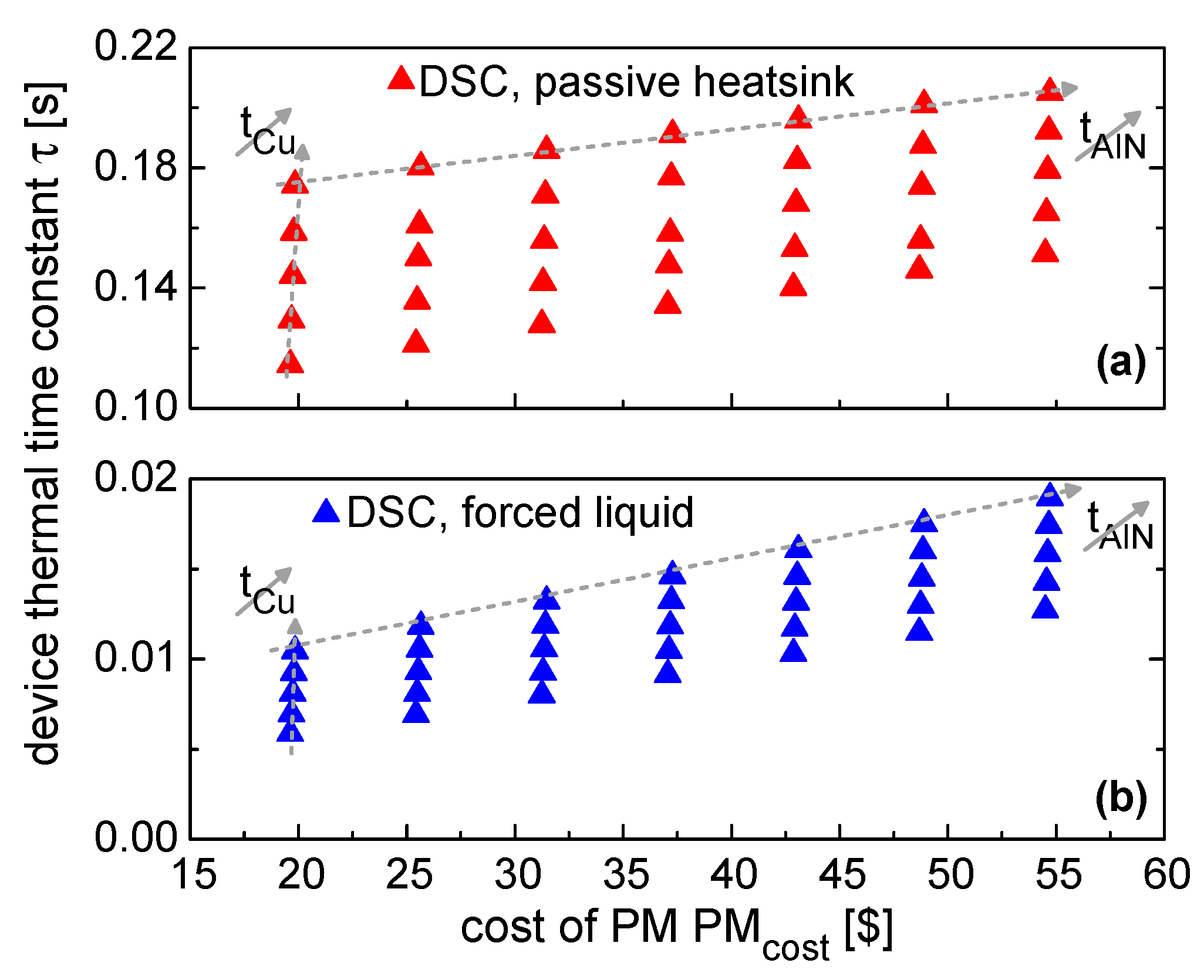

- Moving from a passive heatsink to liquid cooling has a significant impact on τ values, that is, they decrease by a higher order of magnitude; in addition, the τ vs. PMcost slope is much higher in the passive heatsink case, where heat spreading mechanisms are incentivized by thicker baseplates and, hence, the equivalent thermal capacity associated with the assembly increases.

4.2. Parametric Analysis for DBC Substrate in SSC and DSC PMs

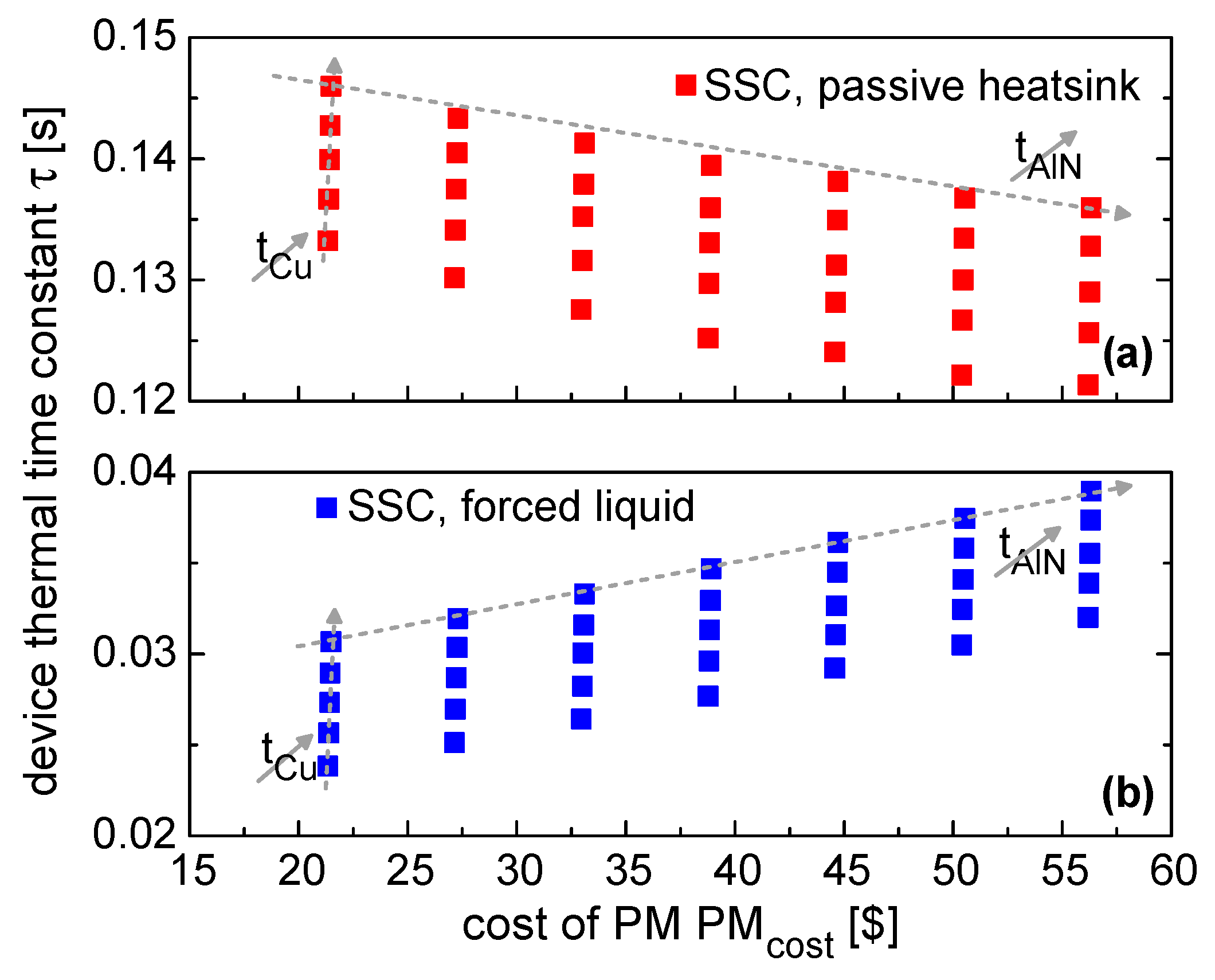

- PMcost increases with both tCu and tAlN; however, due to the high cost of ceramic, it is always less expensive to employ thicker Cu layers rather than AlN ones.

- The beneficial effect of using forced liquid cooling was quantified, resulting in an average decrease of ~33% in the RTH of devices embedded in SSC PMs; such a decrease is mainly due to the convective contribution of the junction-to-ambient RTH, which steeply decreases at high h values.

- Differently from SSC PMs, DBC substrates are responsible for the heat spreading action in DSC assemblies, since there is no thick baseplate serving this specific purpose. This is evident when considering the large spread in RTH values obtained in the case of passive heatsink cooling, where heat spreading mechanisms are incentivized. Here, increasing tCu and tAlN has a significant and beneficial impact on the overall RTH.

- On the contrary, when forced liquid cooling is employed, RTH is dominated by its conductive contribution [31], and thicker layers have a detrimental effect. As a general rule, as long as the BCs are not restricting the outgoing heat flux (that is, at high h values), the conductive contribution given by thermally resistive layers becomes the limiting factor in reducing the overall RTH.

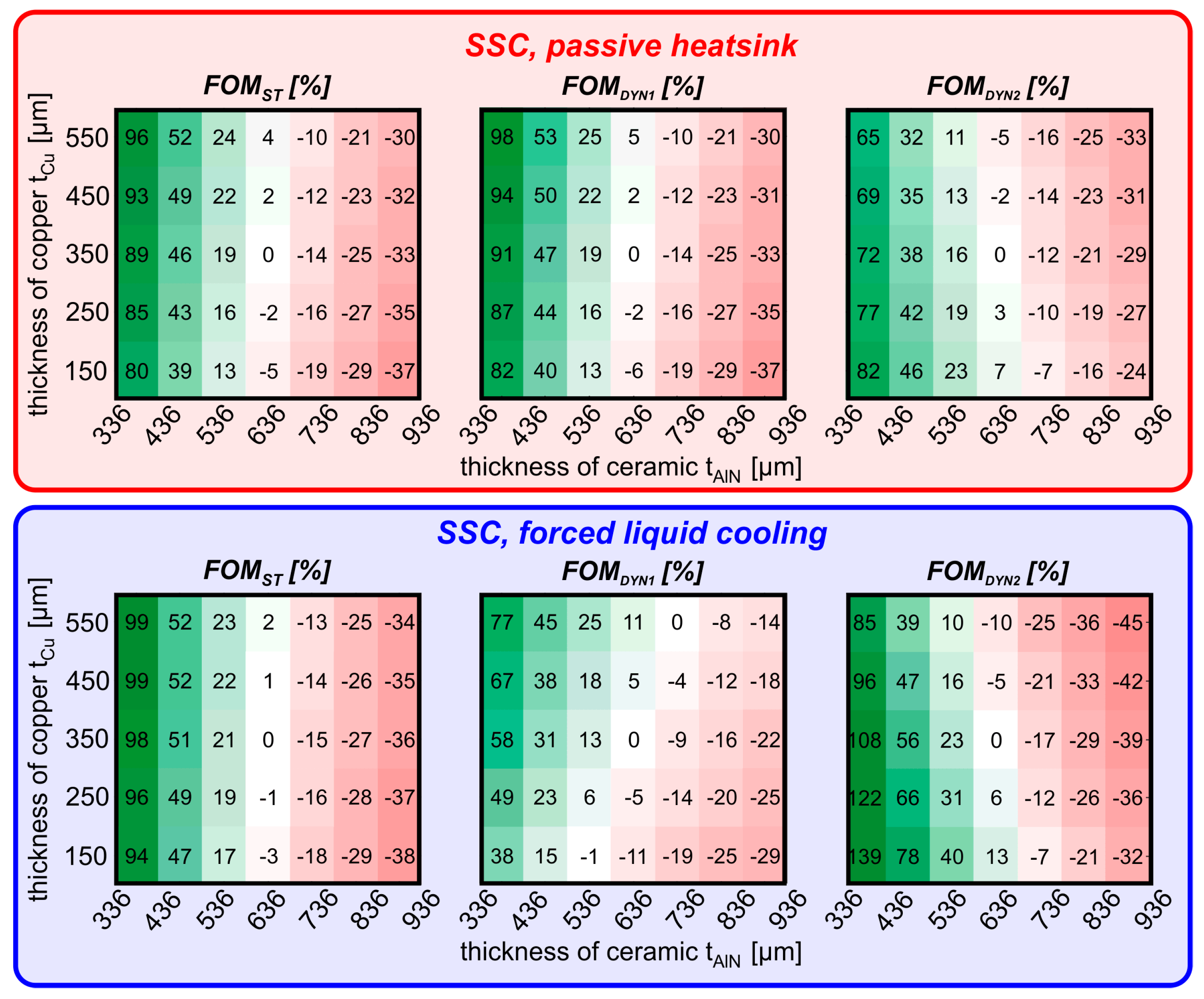

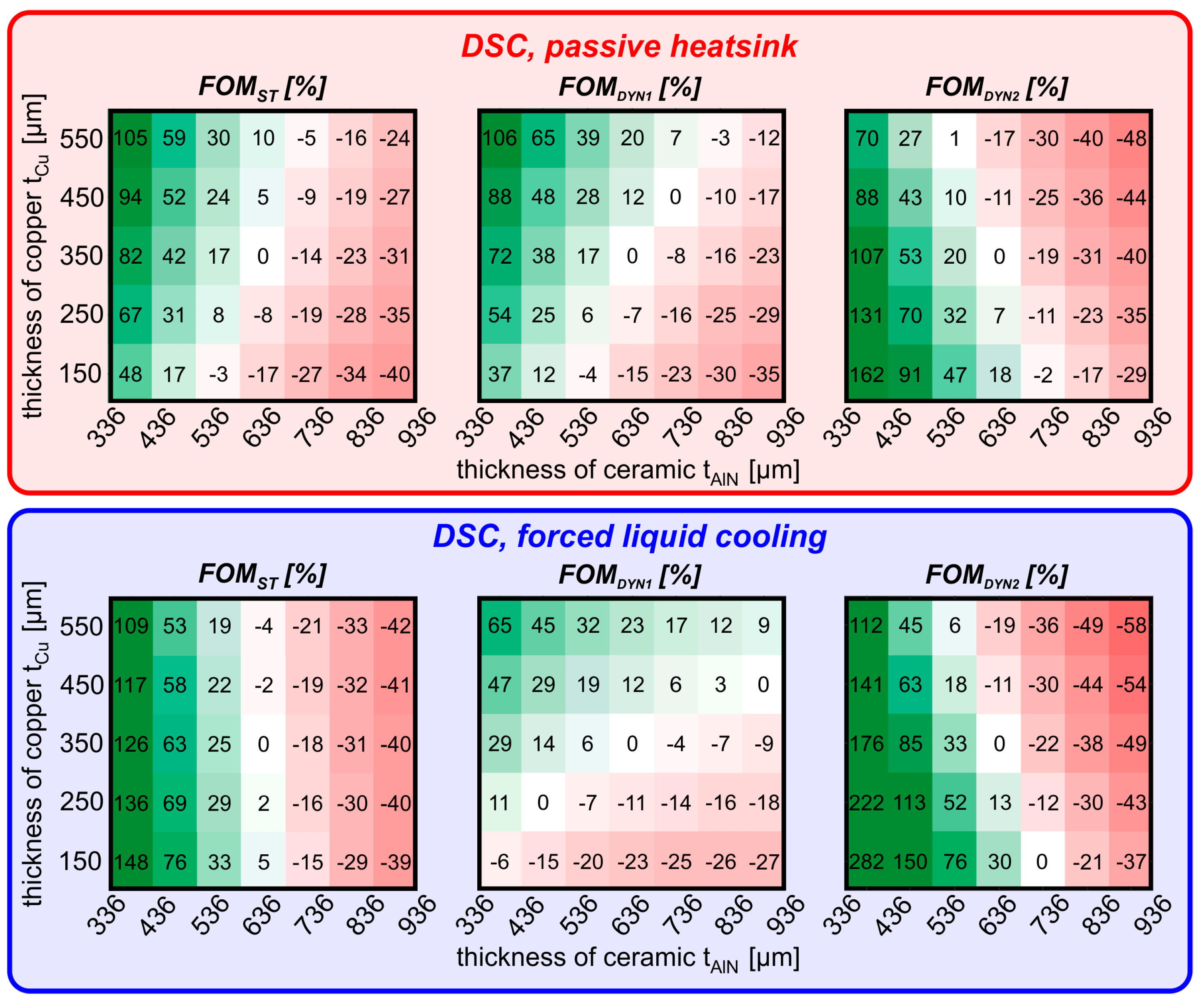

4.3. Static and Dynamic Cost-Impacted Thermal FOMs

- FOMST [W/K$] is defined as

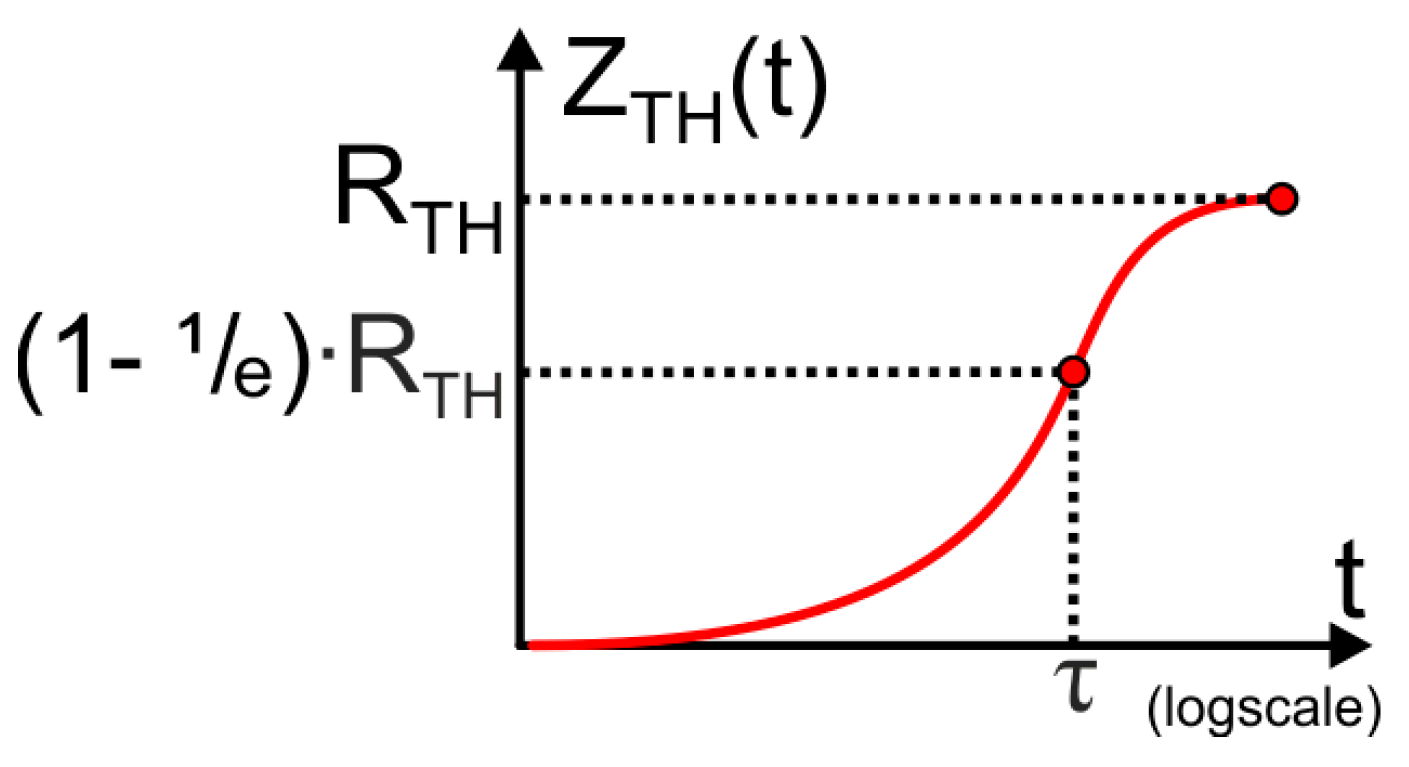

- FOMDYN1 [s/$] and FOMDYN2 [1/s$] are defined to assess and quantify the thermal behavior of devices in terms of dynamic performance and cost:where τ and PMcost are a function of tCu and tAlN. The choice between FOMDYN1 and FOMDYN2 largely depends on the designer’s goal and on the application environment of the specific assembly. FOMDYN1 promotes high τ values, which is the ideal choice if designers are aiming to improve device ruggedness against failure events such as short-circuit, clamped, and unclamped inductive switching events [32,33]. Under these circumstances, devices undertake a large amount of dissipated power, and they fail due to their temperature rapidly rising: the higher the τ value, the slower the rate at which the device approaches its failure. On the other hand, designers should rely on FOMDYN2 if the reliability of the application is not their main concern. Since the design of power circuits is typically aimed at optimizing the electrothermal periodic steady state (or limit cycle), reaching this regime sooner is preferable, meaning that lower τ values are favored.

- It is always convenient to design PMs in the low-tAlN corner, since AlN is the most expensive material, and it negatively (and significantly) impacts on all three FOMsT; indeed, the worst design choice is represented by PMs with thick AlN sheets, regardless of tCu. It must be noted that the ceramic thickness must ensure compliance with electrical ruggedness specifications, where a thicker ceramic layer is generally preferable [34]. Therefore, designers should choose the minimum thickness within the range that meets this requirement.

- Focusing on the FOMST, designs with tAlN = 0.336 mm can still be improved with appropriate tCu choices. More specifically, the low Cu cost makes thicker Cu sheets almost always convenient, except for in the case of forced liquid cooled DSC PMs. In this latter case, there is no need for heat spreading, and the thinner the assembly, the better.

- Regarding dynamic FOMs, it is confirmed that designs with the lowest tAlN value perform better. However, two different corners are preferred, depending on the FOM: a design based on FOMDYN1 (FOMDYN2) should make use of thicker (thinner) Cu layers, that is, the PM should belong to the upper-left (bottom-left) corner of the colormaps shown in Figure 15 and Figure 16.

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chen, Z.; Huang, A.Q. High Performance SiC Power Module Based on Repackaging of Discrete SiC Devices. IEEE Trans. Power Electron. 2023, 38, 9306–9310. [Google Scholar] [CrossRef]

- Lee, H.; Smet, V.; Tummala, R. A Review of SiC Power Module Packaging Technologies: Challenges, Advances, and Emerging Issues. IEEE J. Emerg. Sel. Top. Power Electron. 2020, 8, 239–255. [Google Scholar] [CrossRef]

- Yang, Y.; Dorn-Gomba, L.; Rodriguez, R.; Mak, C.; Emadi, A. Automotive Power Module Packaging: Current Status and Future Trends. IEEE Access 2020, 8, 160126–160144. [Google Scholar] [CrossRef]

- Popok, V.N.; Pedersen, K.B.; Kristensen, P.K.; Pedersen, K. Comprehensive Physical Analysis of Bond Wire Interfaces in Power Modules. Microelectron. Reliab. 2016, 58, 58–64. [Google Scholar] [CrossRef]

- Tsai, C.-C.; Liao, L.-L.; Su, Y.-F.; Hung, T.-Y.; Chiang, K.-N. Reliability Analysis of Copper Bump Interconnection in Double-Sided Power Module. In Proceedings of the 2015 16th International Conference on Thermal, Mechanical and Multi-Physics Simulation and Experiments in Microelectronics and Microsystems, Budapest, Hungary, 19–22 April 2015; pp. 1–4. [Google Scholar]

- Scognamillo, C.; Catalano, A.P.; Castellazzi, A.; d’Alessandro, V. Numerical Analysis of the Thermal Impact of Ceramic Materials in Double-Sided Cooled Power Modules. In Proceedings of the 2020 26th International Workshop on Thermal Investigations of ICs and Systems (THERMINIC), Berlin, Germany, 14 September–9 October 2020; pp. 1–5. [Google Scholar]

- COMSOL AB. COMSOL Multiphysics User’s Guide, Release 5.3A; COMSOL AB: Stockholm, Sweden, 2018. [Google Scholar]

- Li, X.; Li, D.; Qi, F.; Packwood, M.; Luo, H.; Wang, Y.; Dai, X.; Luo, H.; Liu, G. EM-Electrothermal Analysis of Semiconductor Power Modules. IEEE Trans. Compon. Packag. Manuf. Technol. 2019, 9, 1495–1503. [Google Scholar] [CrossRef]

- Yun, C.-S.; Malberti, P.; Ciappa, M.; Fichtner, W. Thermal Component Model for Electrothermal Analysis of IGBT Module Systems. IEEE Trans. Adv. Packag. 2001, 24, 401–406. [Google Scholar] [CrossRef]

- Ning, P.; Liang, Z.; Wang, F. Power Module and Cooling System Thermal Performance Evaluation for HEV Application. IEEE J. Emerg. Sel. Top. Power Electron. 2014, 2, 487–495. [Google Scholar] [CrossRef]

- Calabretta, M.; Sitta, A.; Oliveri, S.M.; Sequenzia, G. Silicon Carbide Multi-Chip Power Module for Traction Inverter Applications: Thermal Characterization and Modeling. IEEE Access 2021, 9, 76307–76314. [Google Scholar] [CrossRef]

- Wang, L.; Malcolm, D.; Liu, W.; Liu, Y.-F. Thermal Analysis of a Magnetic Packaged Power Module. In Proceedings of the 2016 IEEE Applied Power Electronics Conference and Exposition (APEC), Long Beach, CA, USA, 20–24 March 2016; pp. 2095–2101. [Google Scholar]

- Tang, G.; Wai, L.C.; Boon Lim, S.; Lau, B.L.; Kazunori, Y.; Zhang, X.W. Thermal Analysis, Characterization and and Material Selection for SiC Device Based Intelligent Power Module (IPM). In Proceedings of the 2020 IEEE 70th Electronic Components and Technology Conference (ECTC), Orlando, FL, USA, 3–30 June 2020; pp. 2078–2085. [Google Scholar]

- Khatir, Z.; Lefebvre, S. Thermal Analysis of High Power IGBT Modules. In Proceedings of the 12th International Symposium on Power Semiconductor Devices & ICs. Proceedings (Cat. No.00CH37094), Toulouse, France, 22–25 May 2000; pp. 271–274. [Google Scholar]

- Shahjalal, M.; Shams, T.; Hossain, S.B.; Rishad Ahmed, M.; Ahsan, M.; Haider, J.; Goswami, R.; Alam, S.B.; Iqbal, A. Thermal Analysis of Si-IGBT Based Power Electronic Modules in 50kW Traction Inverter Application. e-Prime Adv. Electr. Eng. Electron. Energy 2023, 3, 100112. [Google Scholar] [CrossRef]

- Ozalas, M.T. The Impact of Electro-Thermal Coupling on HBT Power Amplifiers. In Proceedings of the 2014 IEEE Compound Semiconductor Integrated Circuit Symposium (CSICS), La Jolla, CA, USA, 19–22 October 2014; pp. 1–4. [Google Scholar]

- Scognamillo, C.; Catalano, A.P.; Codecasa, L.; Castellazzi, A.; d’Alessandro, V. Numerical Investigation on the Thermal Resistance and Assembly Cost in SSC and DSC Power Modules. In Proceedings of the 2024 30th International Workshop on Thermal Investigations of ICs and Systems (THERMINIC), Toulouse, France, 25–27 September 2024; pp. 1–4. [Google Scholar]

- Shammas, N.Y.A. Present Problems of Power Module Packaging Technology. Microelectron. Reliab. 2003, 43, 519–527. [Google Scholar] [CrossRef]

- Catalano, A.P.; Scognamillo, C.; d’Alessandro, V.; Castellazzi, A. Numerical Simulation and Analytical Modeling of the Thermal Behavior of Single- and Double-Sided Cooled Power Modules. IEEE Trans. Compon. Packag. Manuf. Technol. 2020, 10, 1446–1453. [Google Scholar] [CrossRef]

- Lebey, T.; Malec, D.; Dinculescu, S.; Costan, V.; Breit, F.; Dutarde, E. Partial Discharges Phenomenon in High Voltage Power Modules. IEEE Trans. Dielectr. Electr. Insul. 2006, 13, 810–819. [Google Scholar] [CrossRef]

- Palankovski, V.; Quay, R. Analysis and Simulation of Heterostructure Devices; Computational Microelectronics; Springer: Vienna, Austria, 2004; ISBN 978-3-7091-7193-6. [Google Scholar]

- Lienhard, J.H., IV; Lienhard, J.H., V. A Heat Transfer Textbook, 3rd ed.; Phlogiston Press: Cambridge, MA, USA, 2008. [Google Scholar]

- Yole Intelligence. Status of the Power Module Packaging Industry 2023 Report; Yole Intelligence: Lyon, France, 2023. [Google Scholar]

- Good-Fellow AlN Manufacturer Website. Available online: https://www.goodfellow.com/eu/aluminium-nitride-sheet-group (accessed on 1 February 2025).

- Sigma-Aldritch AlN Manufacturer Website. Available online: https://www.sigmaaldrich.com/US/en/product/aldrich/gf43729803 (accessed on 1 February 2025).

- Ortech-Ceramics AlN Manufacturer Website. Available online: https://www.ortechceramics.com/products/uncategorized/aluminum-nitride-substrate/ (accessed on 1 February 2025).

- McMaster AlN Manufacturer Website. Available online: https://www.mcmaster.com/products/aluminum-nitride (accessed on 1 February 2025).

- Stock Quotation of Cu. Available online: https://www.marketindex.com.au/copper (accessed on 1 February 2025).

- Ketchen, M.B.; Xiu, K.; Bhushan, M. Measurement of Thermal Time Constant in 65-Nm PD-SOI Technology with Sub-Ns Resolution. In Proceedings of the 2007 IEEE International SOI Conference, Indian Wells, CA, USA, 1–4 October 2007; pp. 53–54. [Google Scholar]

- Mukhopadhyay, S.; Kundu, A.; Lee, Y.W.; Hsieh, H.D.; Huang, D.S.; Horng, J.J.; Chen, T.H.; Lee, J.H.; Tsai, Y.S.; Lin, C.K.; et al. An Unique Methodology to Estimate The Thermal Time Constant and Dynamic Self Heating Impact for Accurate Reliability Evaluation in Advanced FinFET Technologies. In Proceedings of the 2018 IEEE International Electron Devices Meeting (IEDM), San Francisco, CA, USA, 1–5 December 2018; pp. 17.4.1–17.4.4. [Google Scholar]

- Catalano, A.P.; Scognamillo, C.; Castellazzi, A.; Codecasa, L.; d’Alessandro, V. Study of the Thermal Behavior of Double-Sided Cooled Power Modules. In Proceedings of the 2021 27th International Workshop on Thermal Investigations of ICs and Systems (THERMINIC), Berlin, Germany, 23 September 2021; pp. 1–5. [Google Scholar]

- Yao, K.; Yano, H.; Tadano, H.; Iwamuro, N. Investigations of SiC MOSFET Short-Circuit Failure Mechanisms Using Electrical, Thermal, and Mechanical Stress Analyses. IEEE Trans. Electron Devices 2020, 67, 4328–4334. [Google Scholar] [CrossRef]

- Ren, N.; Wang, K.L.; Wu, J.; Xu, H.; Sheng, K. Failure Mechanism Analysis of SiC MOSFETs in Unclamped Inductive Switching Conditions. In Proceedings of the 2019 31st International Symposium on Power Semiconductor Devices and ICs (ISPSD), Shanghai, China, 19–23 May 2019; pp. 183–186. [Google Scholar]

- Scognamillo, C.; Catalano, A.P.; Lasserre, P.; Duchesne, C.; d’Alessandro, V.; Castellazzi, A. Combined Experimental-FEM Investigation of Electrical Ruggedness in Double-Sided Cooled Power Modules. Microelectron. Reliab. 2020, 114, 113742. [Google Scholar] [CrossRef]

| Material | k(T0) [W/m∙K] | cp [J/kg∙K] | ρ [kg/m3] | α | β [W/m∙K2] |

|---|---|---|---|---|---|

| SiC | 370 | 690 | 3211 | 1.29 | - |

| AlN | 150 | 748 | 3230 | 1.84 | - |

| Al | 200 | 905 | 2707 | - | 2.1∙10−2 |

| Cu | 398 | 384 | 8954 | - | 5.2∙10−2 |

| SnAg (solder) | 57 | 220 | 7500 | - | 2.0∙10−2 |

| insulator | 0.29 | 1624 | 1024 | constant k | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Scognamillo, C.; Catalano, A.P.; Codecasa, L.; Castellazzi, A.; d’Alessandro, V. A Cost-Driven Analysis of Thermal Performance in Power Modules. Energies 2025, 18, 1665. https://doi.org/10.3390/en18071665

Scognamillo C, Catalano AP, Codecasa L, Castellazzi A, d’Alessandro V. A Cost-Driven Analysis of Thermal Performance in Power Modules. Energies. 2025; 18(7):1665. https://doi.org/10.3390/en18071665

Chicago/Turabian StyleScognamillo, Ciro, Antonio Pio Catalano, Lorenzo Codecasa, Alberto Castellazzi, and Vincenzo d’Alessandro. 2025. "A Cost-Driven Analysis of Thermal Performance in Power Modules" Energies 18, no. 7: 1665. https://doi.org/10.3390/en18071665

APA StyleScognamillo, C., Catalano, A. P., Codecasa, L., Castellazzi, A., & d’Alessandro, V. (2025). A Cost-Driven Analysis of Thermal Performance in Power Modules. Energies, 18(7), 1665. https://doi.org/10.3390/en18071665