Abstract

Energy resources, particularly oil and natural gas, are vital for global development but have significant environmental impacts, including pollution and habitat destruction. Green management has become a critical concept in today’s global industries, mostly the petroleum industry. The petroleum industry is vital not only for the world but also for Türkiye’s energy needs and economic development. However, its operations significantly impact the environment through greenhouse gas emissions, water pollution, and habitat destruction. In response to both global and national environmental concerns and regulatory pressures, the Turkish petroleum industry should adopt green management practices. Despite the lack of prior studies regarding green management approaches and practices in Turkish petroleum industry, this study examines how Türkiye’s petroleum industry should integrate green management principles to minimize environmental impacts and promote sustainable development. To evaluate the environmental protection approaches and practices of petroleum enterprises based on their operational domains, a survey was conducted, and the collected data underwent statistical analysis. The survey questions were designed by the authors to determine the attitudes, approaches, and practices of managers in crude oil production and refining companies regarding green management. According to the results of the statistical data analysis, it has been determined that companies in the Turkish petroleum industry have adopted an approach known as green management or environmentally conscious entrepreneurship. The statistical analysis of the administered survey results indicates a positive relationship between firms’ operational performance scores and their green management practices scores (r = 0.247). The survey results demonstrate an increasing adoption of environmental consciousness and green management practices among managers in the Turkish petroleum sector, with 90.2% of participants providing a positive response. The survey results also indicate that green management practices have a positive impact on business operations. In this regard, 42.4% of participating managers believe that green management practices enhance corporate image, 38.0% state that they improve efficiency, 35.0% assert that they strengthen competitive advantage, and 31.5% indicate that they contribute positively to energy savings. The survey findings further indicate that 90.2% of participants recognize the contribution of green management practices to sustainable development in businesses, while an equal proportion asserts that these practices enhance clean and safe production. Moreover, 93.5% of respondents emphasize that production and processing activities carried out without environmental considerations pose a significant threat to the future of both the planet and humanity. In conclusion, based on the responses provided by the participants, it can be inferred that business managers have adopted the green management approach and recognize the significant role of green management practices in addressing environmental challenges. In line with the objectives of this study and the statistical findings obtained, a “green management model” has been proposed for enterprises in the Turkish petroleum industry, taking into consideration global practices and aligning with the principles of environmentally responsible green entrepreneurship. In this context, the study makes a significant contribution to the literature by proposing a green management model for the Turkish petroleum industry.

1. Introduction

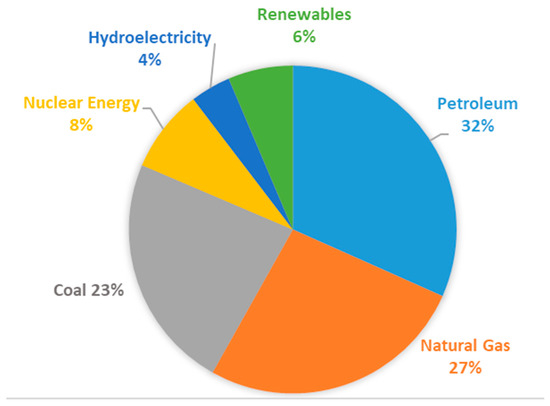

Since the second half of the 18th century, developments in nearly all aspects of social and economic life resulting from the Industrial Revolution have increased dependency on energy sources. Undoubtedly, energy production, provision, and utilization have become one of the foremost needs, particularly in both developed and developing countries. In contemporary society, hydrocarbons, specifically petroleum (oil) and natural gas, are among the most essential energy sources, fulfilling indispensable roles in various sectors, including industry, transportation, residential heating, and lighting. Moreover, the continuous development and supply of oil and natural gas resources are crucial for ensuring national energy stability and supporting the sustainable progress of society [1]. In particular, petroleum operations have played a crucial role in global industrial activities and world economy [2,3,4,5], serving as a primary source of energy for the world. According to 2023 data, petroleum, having the largest share in the primary energy requirement in the world, meets 32% of the world’s energy consumption and 27% of natural gas (Figure 1) [6]. However, the industry is now facing growing challenges posed by climate change, including the increasing frequency of extreme weather events, rising sea levels, and changing environmental conditions [7]. Economic growth naturally leads to higher energy demand and a rise in environmental pollution [8].

Figure 1.

World primary energy consumption rates in 2023.

The global petroleum industry represents an integrated sector that encompasses both national and multinational enterprises involved in exploration and production, transportation, refining, and marketing activities. This study conceptualizes activities related to crude oil production and refining within the framework of the “petroleum industry”.

The petroleum industry is distinguished from other sectors by the substantial scale of its production and processing. Greenhouse gas emissions, as well as the solid and liquid waste generated during production and refining processes, are significant, with their environmental impacts reaching critical levels [2,9,10,11,12,13,14]. Global greenhouse gas emissions have continued to rise, with the most substantial share and growth in total emissions stemming from the combustion of fossil fuels and industrial processes [15]. The environmental risks linked to the exploration and extraction of petroleum resources include acid rains, decrease in water quality, threats to the marine ecosystem, flooding, land subsidence, environmental degradation, and other harmful ecological impacts [16,17,18].

The consumption of fossil fuels and the energy derived from them in industrial activities, as well as their use in transportation and heating, lead to substantial emissions that are released into the atmosphere. These emissions consist of various gasses and compounds, including carbon dioxide (CO2), methane (CH4), nitrogen oxides (NOX), hydrofluorocarbons (HFCs), sulfur compounds, volatile organic compounds (VOCs), dust, and water vapor. These gasses and particulates impact the physical and chemical properties of the atmosphere and the energy balance, contributing to the increased retention of heat rays reflected from the Earth’s surface. Global warming, and consequently climate change, is primarily driven by the excessive accumulation of these gasses and particulates in the atmosphere that enhance the greenhouse effect beyond their natural levels [11,19,20]. The principal source of these emissions stems from the production and processing activities of fossil fuels. In this context, emissions derived from oil, coal, and natural gas are critical determinants of global warming [21,22,23].

Consequently, the implementation of environmentally responsible green management practices has become increasingly vital within the petroleum industry to mitigate the adverse effects of waste generated by these processes and to foster a healthier environment [24]. Green management practices in the petroleum industry involve a range of strategies aimed at minimizing environmental impact while maintaining operational efficiency. These practices include energy conservation measures, such as optimizing energy use in drilling, extraction, and transportation, as well as integrating renewable energy sources to reduce dependency on traditional fossil fuels [25]. Waste management practices, including safe disposal, waste reduction, reuse, and recycling, are critical for minimizing the environmental footprint of petroleum operations [26]. As environmental regulations and restrictions grow increasingly stringent, effective waste management in the oil sector becomes even more critical. This necessitates continuous advancements in waste treatment technologies and management strategies to ensure compliance and sustainability [27]. Emission control technologies are also employed to limit the release of harmful pollutants, particularly greenhouse gasses, to meet both regulatory standards and sustainability targets. Furthermore, companies conduct comprehensive environmental and social risk assessments to evaluate and mitigate potential impacts on local ecosystems and communities [28]. By implementing these green management practices, the petroleum industry aims to comply with national environmental regulations and contribute to global sustainability efforts.

In order to raise awareness and seek solutions for the challenges posed by climate change globally, significant conferences were held in Rio in 1992 and in Kyoto in 1997 [29]. These gatherings aimed to reduce emissions in order to maintain global warming below 2 °C. However, the increase in global emissions that caused this problem could not be stopped and the proposed measures have not been implemented effectively. In 2005 and 2006, the agenda once again highlighted the importance of limiting the global temperature rise to 2 °C. This target was formally agreed at the Copenhagen Summit in 2009, with the participation of 192 countries. The idea of reducing emissions was based on the idea that fossil energy reserves were to be kept underground and never used. Accordingly, one third of all oil reserves, half of natural gas reserves, and 80% of coal should not be extracted. Achieving these targets necessitated a strong political commitment [29,30,31,32,33,34]. Despite being signed with broad consensus at international meetings, no significant success has been achieved in the fight against climate change.

The Paris Agreement, considered a turning point in the global fight against climate change, came into force on 4 November 2016, as a result of at least 55 parties, accounting for 55% of global greenhouse gas emissions, ratifying the agreement on 5 October 2016. Regarding emissions reduction, the Paris Agreement encourages developed countries to maintain absolute emissions reduction targets, while urging developing countries to enhance their emissions reduction goals. This involves adopting new, more ambitious targets that encompass their entire economies over time, tailored to their respective national circumstances. The Paris Agreement was ratified by Türkiye on 7 October 2021, through a Presidential Decree. Under the Paris Agreement, Türkiye has established a target to reduce emissions by 41% from projected increases by 2030 [35].

The petroleum industry produces substantial emissions and waste due to its extensive production scale and complex processing operations, adversely impacting water, air, soil, and biodiversity, thereby resulting in significant global environmental challenges [36]. These emissions and wastes contribute significantly to environmental pollution and, consequently, global warming. In order to minimize the effects of the environmental problems caused during the production and refining stages of the petroleum industry, there are methods and practices to reduce pollution at the source, to recycle waste, and to control emissions and bring them down to acceptable levels [37,38,39]. In the context of implementing international agreements, standards, and regulations related to environmental protection and emissions reduction, petroleum companies have been compelled to take corrective actions. As a result, the recently enacted stringent environmental regulations (such as the Paris Agreement), evolving global sustainability targets, and growing demand for responsible corporate practices underscore the importance of the adaptation [40,41]. Thus, petroleum companies are increasingly recognizing the importance of enhancing their environmental responsibilities, prompting them to initiate various efforts.

The petroleum industry in Türkiye has a relatively young history compared to major oil-producing countries. Petroleum exploration, production, and refining activities in Türkiye began during the Republican Era. In 1954, Türkiye Petrolleri Anonim Ortaklığı (TPAO) was established as an integrated organization managing all aspects of the petroleum industry, including the exploration, production, transportation, refining, petrochemicals, and distribution. However, following economic transformations in Türkiye after 1980, TPAO’s affiliated companies were privatized, leading to changes in its integrated structure. TPAO maintains its leading position in the industry. As a state-owned entity, TPAO is responsible for the majority of exploration and production activities in Türkiye [39]. Unfortunately, domestic production meets only 7% of Türkiye’s crude oil consumption and just 1% of its natural gas consumption. Türkiye’s refining sector is also significant, with large refineries of TÜPRAŞ and Star playing key role in processing imported crude oil [42].

Despite several exploration efforts, Türkiye has not yet emerged as a significant oil producer on the global stage. The country’s oil reserves remain modest and domestic production meets only a small fraction of its consumption needs. In 2023, Türkiye produced an average of 82 thousand barrels per day (b/d) of crude oil, imported 630 thousand b/d of crude oil, and 354 thousand b/d of refined products. While the share of domestic crude oil production in total oil supply was 7% in 2022, this ratio increased to 7.7% in 2023. In other words, Türkiye’s dependency on oil imports in 2023 was 92.3% [43].

Turkish petroleum industry consists of eleven domestic and foreign crude oil production companies and the TÜPRAŞ refineries (four refineries) and the Star İzmir refinery. The data presented in Table 1 were gathered through individual interviews with human resources department managers of companies in the Turkish petroleum industry. TPAO, TÜPRAŞ, and Star’s employees together constitute approximately 90% of Turkish petroleum industry’s work force. Managerial positions comprise only 8% of work force in Turkish petroleum industry in 2023.

Table 1.

Turkish petroleum industry’s labor force status by managerial position in 2023.

Petroleum remains a crucial component of Türkiye’s energy mix, despite the country’s limited domestic production capacity. Türkiye’s strategic location, between major oil-producing regions and consumer markets, makes it an important player in global energy transit. However, the country faces a series of challenges, including a high dependency on imported oil, fluctuating geopolitical tensions, increasing pressure to transition towards renewable energy sources, and growing environmental concerns. The petroleum industry is a cornerstone of Türkiye’s energy infrastructure, significantly contributing to the national economy. However, the environmental implications of oil exploration, production, and consumption have necessitated a shift towards more sustainable practices. Petroleum industry operations significantly impact the environment through greenhouse gas emissions, water pollution, and habitat destruction. In response to global environmental concerns and regulatory pressures, the industry has increasingly adopted green management practices. These include energy efficiency, waste reduction, and renewable energy integration to ensure sustainability without compromising productivity [44,45,46]. Green management is no longer an option but a necessity for Türkiye’s petroleum industry. The Turkish petroleum industry has increasingly integrated green management practices as part of its commitment to sustainability and environmental responsibility. In response to both regulatory demands and the global transition toward more sustainable energy systems, key companies, such as TPAO, have implemented several initiatives aimed at reducing their environmental footprint. Notable practices include energy efficiency improvements, waste reduction, and the adoption of advanced emission control technologies. Companies also introduced zero waste management strategies, promoting recycling, waste minimization, and compliance with national environmental standards. Furthermore, efforts to reduce greenhouse gas emissions are a priority, with the industry investing in cleaner technologies to mitigate its impact on climate change. While challenges remain, the commitment to sustainable practices will play a crucial role in the industry’s long-term success. Thus, the necessity of conducting a study to examine the perspective of petroleum companies in Türkiye towards the implementation of green management practices has emerged. Considering the absence of prior academic research on green management approaches in Turkish petroleum industry, the primary contribution of this study to the literature lies in the development of a survey instrument by the authors to examine the attitudes of managers on green management in the Turkish petroleum industry. Additionally, the study makes a significant contribution to the literature by proposing a green management model for the Turkish petroleum industry.

2. Materials and Methods

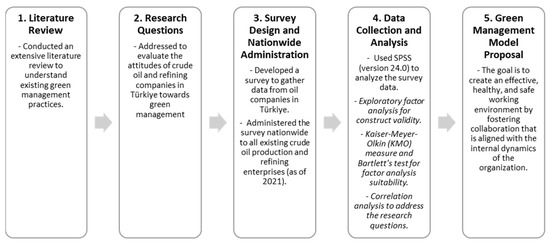

A multi-phase research approach was adopted, consisting of an extensive literature review, followed by a survey conducted nationwide. This survey targeted all existing crude oil exploration, production, and processing (refining) companies throughout the country (Table 1). The survey was conducted to include all existing crude oil production and refining (processing) enterprises in Türkiye as of 2021. While the relatively small number of companies operating in the petroleum industry in Türkiye may be considered a limitation, the study was able to reach the entire population of interest. Prior to the implementation of the survey, ethical approval was granted by the Ethics Committee of Ankara University, under decision number 237, dated 21 June 2021. It was assured that all information obtained from the research would be utilized exclusively for scientific purposes and that all personal data, including survey results, would be kept confidential. The data were collected through online questionnaires. The research questions were analyzed and verified based on an analysis of these data. The time span of data collection was from August to October 2021. In this study, 92 questionnaires were analyzed and evaluated. Additionally, the analysis of the questionnaire data was conducted using the SPSS (Statistical Package for Social Sciences) version 24.0 software to derive the results. The reason for using SPSS version 24.0 is that it offers a user-friendly interface and a wide range of statistical tools, making it ideal for data analysis in social sciences. Additionally, it provides features such as advanced data visualization, integration with other software, and enhanced statistical functions, ensuring reliable and efficient research outcomes. To determine the construct validity of the scales used in the research, exploratory factor analysis was conducted. To assess whether the scales were suitable for factor analysis, the Kaiser–Meyer–Olkin (KMO) measure and Bartlett’s test were performed. A correlation analysis was conducted to explain and test the research questions [39]. Based on the literature review, research, analyses and survey results, a proposed green management model has been designed for Türkiye’s petroleum industry. The technical roadmap of the study was developed as follows (Figure 2).

Figure 2.

Technical roadmap.

2.1. Research Questions

The attitudes of crude oil and refining companies operating in the petroleum industry in Türkiye towards environmental protection and compliance with international treaties and environmental legislation, as well as their sensitivity towards the environment, have been evaluated and tested within the framework of the following research questions [39]:

Research Question 1: Is there a dominant environmentally conscious green management approach in oil companies?

Research Question 2: Are there close relationships and collaborations among departments regarding green management practices in oil companies?

Research Question 3: Are production and other activities in oil companies conducted in accordance with the understanding of green management?

Research Question 4: Does the understanding of green management positively affect the activities of oil companies in Türkiye?

Research Question 5: Is there a high level of understanding of green management among managers in oil companies?

Research Question 6: Has the green management approach been integrated into the business culture of oil companies within the context of social responsibility?

The perspectives of business managers who responded to the questionnaire regarding their environmental sensitivity were evaluated in conjunction with the findings obtained from the analysis of the surveys. Consequently, an effort was undertaken to assess the environmental management practices and environmental sensitivity of firms within the Turkish petroleum industry.

2.2. Preparation of the Questionnaire and Data Collection

The attitudes and decisions of business managers are crucial for addressing the environmental impacts and issues arising from the activities of the petroleum industry through a green management approach. In this context, it is anticipated that the positive attitudes and approaches of business managers towards environmental issues will effectively enhance the environmental behaviors of all employees. During the preparation phase of the questionnaire used in this study, a literature review was conducted and developments related to green management practices in oil companies were examined.

The aim was to collect primary data through a survey applied to senior managers and department heads of oil production companies operating in various regions of Türkiye, as well as to refineries processing crude oil in Türkiye. As of 2021, a total of thirteen companies were identified, including eleven companies engaged in crude oil production and two refineries processing crude oil. The online questionnaire link was sent via email to the managers of TPAO (Ankara, Türkiye), domestic and foreign companies involved in crude oil production, as well as the four refineries under TÜPRAŞ (Istanbul, Türkiye) and the Star refinery under SOCAR (Istanbul, Türkiye). An official letter from the Ethics Committee of Ankara University was also shared with the managers of the companies from which data collection was planned, along with the questionnaire. A total of 92 respondents completed their questionnaires. It is assumed that this sample size represents all business managers in the sector. Therefore, the population size and target group for the purpose of the study comprise the managers of oil production companies and refineries operating in Türkiye.

The questionnaire used in this study, which includes questions about the environmental management strategies of businesses operating in the petroleum industry in Türkiye and the attitudes and thoughts of managers regarding this issue, consists of five sections. The first section addresses the general and demographic characteristics of the business, the second section pertains to the company’s environmental strategy, the third section focuses on managers’ attitudes and approaches towards the environment in light of the activities within the company, the fourth section examines the impact of environmental protection and green management practices on business success, and the fifth section addresses the extent to which managers agree with the changes and advantages provided by green management practices in the business. Additionally, demographic information regarding the respondent’s age, gender, education level, and position within the company are also provided [39].

3. Statistical Analysis of the Data and Results

To determine the construct validity of the scales used in the research, exploratory factor analysis was conducted. To assess whether the scales were suitable for factor analysis, the Kaiser–Meyer–Olkin (KMO) measure and Bartlett’s test were performed. The KMO coefficient is calculated to test the adequacy of the sample size, while the normality condition is examined through Bartlett’s test. In this context, the KMO test should yield a measurement result of 0.50 or higher, and the result of Bartlett’s test should be statistically significant [47]. During the factor analysis process, the factor loadings were examined to determine the assignment or removal of scale items to/from the factors.

The Cronbach’s alpha coefficient indicates the reliability level of the scale. This coefficient ranges from 0 to 1. The reliability of the scale is interpreted according to the following thresholds based on the alpha (α) coefficient [48]:

- 0.00 ≤ α < 0.40 indicates that the scale is not reliable,

- 0.40 ≤ α < 0.60 suggests that the reliability of the scale is low,

- 0.60 ≤ α < 0.80 indicates that the scale is reasonably reliable,

- 0.80 ≤ α < 1.00 signifies that the scale is highly reliable.

3.1. Results of the Factor Analysis for the Organizational Activities Scale

In the factor analysis conducted for the scale, the KMO value was calculated to be 0.759. This indicates that the sample size is appropriate for factor analysis (KMO > 0.500). Under Bartlett’s test, the chi-square (X2) value was computed as 633.531, which was found to be statistically significant (p < 0.05). Thus, the condition of normality was satisfied. Based on the results of the KMO and Bartlett tests, it was concluded that the data are suitable for factor analysis (Table 2).

Table 2.

KMO and Bartlett’s test values for the Organizational Activities Scale.

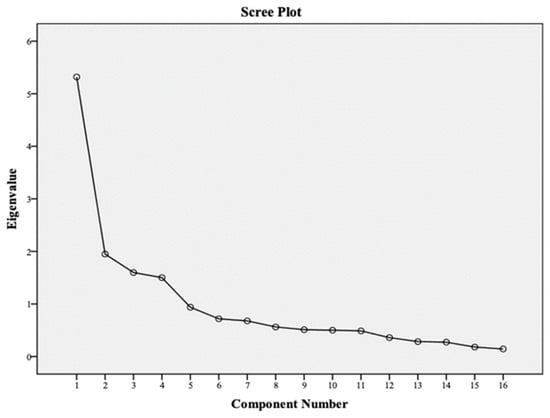

To determine the factor structure of the scale, a scree plot graph, which illustrates the dispersion of eigenvalues, was created (Figure 3).

Figure 3.

Scree plot of the organizational activities scale.

It has been determined that the scale demonstrates a unidimensional structure. To establish the distribution of the questions within the single factor, an analysis was conducted, and the distribution of the questions along with their factor loadings is presented in the table. According to the analysis results, the sixth question was removed from the scale, and it was concluded that the scale consists of 15 questions and a single factor.

The scale comprises a factor consisting of 15 items, with factor loadings shown in Table 3, listed in descending order from the highest (0.671) to the lowest (0.471). The total variance explained by the factor is 35.44%, and Cronbach’s alpha coefficient is 0.858 (Table 3).

Table 3.

Analysis results relating to the factors of the organizational activities scale.

3.2. Results of the Factor Analysis for the Green Management Strategies Scale

In the factor analysis conducted for the scale, the KMO value was calculated to be 0.893. Accordingly, the sample size is suitable for factor analysis (KMO > 0.500). The X2 value was calculated as 1005.797 in the Bartlett test and was found to be statistically significant (p < 0.05). Therefore, the condition for normal distribution is met. Based on the results of the KMO and Bartlett tests, it was concluded that the data are suitable for factor analysis (Table 4).

Table 4.

KMO and Bartlett’s test values.

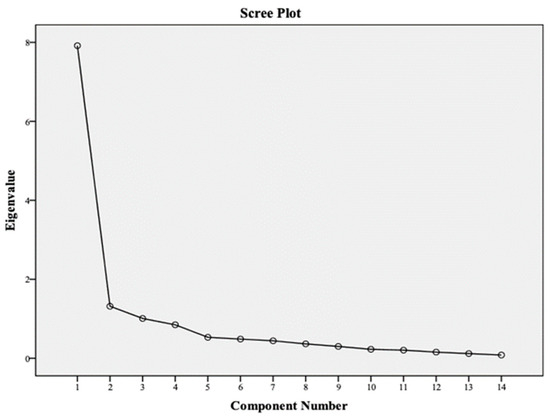

To determine the factor structure of the scale, the scree plot graph showing the distribution of eigenvalues was examined (Figure 4).

Figure 4.

Scree plot of the green management strategies scale.

It has been determined that the scale demonstrates a unidimensional structure. An analysis was conducted to ascertain the distribution of the items across the factors, and the distribution of the items along with their factor loadings is presented in the table. According to the analysis results, two items were removed from the scale, resulting in a final scale consisting of thirteen items and a single factor.

The first factor of the scale consists of 13 items with factor loadings shown in Table 5, listed in descending order from the highest (0.868) to the lowest (0.667). The total variance explained by the factor is 60.46%, and the Cronbach’s alpha coefficient is calculated to be 0.943 (Table 5).

Table 5.

Analysis results related to the factors of the green management strategies scale.

In this study, 92 questionnaires were analyzed and evaluated. Additionally, the analysis of the questionnaire data was conducted using the SPSS (Statistical Package for Social Sciences) version 24.0 software to obtain the results.

The scale scores were calculated, and the skewness and kurtosis coefficients were examined to determine the suitability of the scores for a normal distribution. It is considered sufficient for normal distribution that the kurtosis and skewness values obtained from the scales fall between +3 and −3 [49,50,51,52].

Upon examining the values in Table 6, it is observed that the kurtosis and skewness coefficients for each score fall between −3 and +3. Based on this finding, it can be concluded that the scores exhibit a normal distribution. Due to the normal distribution of the scores, parametric test techniques were employed in the study. The t-test and ANOVA were used to analyze whether the scale scores differed based on demographic characteristics. The t-test was utilized for the analysis of demographic variables with two groups, while the ANOVA test was used for the analysis of variables with k groups (k > 2).

Table 6.

Kurtosis and skewness values along with reliability coefficient.

According to the results derived from Table 7:

Table 7.

Differences in organizational activities scores based on relevant characteristics.

- The score for business activities shows a statistically significant difference regarding the presence of supported environmental social responsibility projects within the organization (p < 0.05). According to the average scores, businesses that support projects have higher scores than those without social responsibility projects.

- The presence of a unit responsible for environmental protection and green management practices in businesses shows a statistically significant difference (p < 0.05). Based on average scores, businesses with a green management unit have higher scores than those without.

- There is a statistically significant difference in the continuous implementation of processes related to environmental protection and green management practices among existing departments and managers in businesses (p < 0.05). The average scores of businesses with continuous green management practices are higher than those without.

- The regular reporting of performance regarding environmental protection and green management practices shows a statistically significant difference in implementation (p < 0.05). According to average scores, those who approve of reporting performance related to green management practices have higher scores than those who do not have an opinion on this matter.

- The widespread sharing of business performance results regarding green management among departments shows a statistically significant difference (p < 0.05). Based on average scores, those who approve of the widespread sharing of green management performance have higher scores than those who do not have an opinion.

- The existence of close relationships and collaborative practices among departments regarding green management practices in businesses shows a statistically significant difference (p < 0.05). According to average scores, those who approve of close relationships and collaboration among departments have higher scores than those who do not.

- The provision of training to employees regarding green management practices shows a statistically significant difference in implementation (p < 0.05). According to average scores, businesses that provide training have higher scores than those that do not.

- The presence of an advanced database for monitoring green management practices in businesses shows a statistically significant difference (p < 0.05) and has higher average scores compared to those without a database.

- The use of environmentally friendly new technologies instead of outdated technologies that harm the environment shows a statistically significant difference (p < 0.05). According to average scores, those who approve of using environmentally friendly new technologies have higher scores than those who do not have an opinion on the matter (Table 7).

According to the results derived from Table 8:

Table 8.

Differences in green management strategies and practices based on relevant characteristics.

- The score for green management strategies and practices shows a statistically significant difference regarding the presence of a unit responsible for environmental protection and green management practices in businesses (p < 0.05). According to the average scores, businesses with a green management unit have higher scores than those without.

- There is a statistically significant difference in the continuous application of processes related to green management principles among existing departments and managers in businesses (p < 0.05). Based on average scores, the presence of continuous applications related to green management principles has higher scores than those without continuous applications.

- In the same context, the regular preparation of reports regarding the results of green management practices in businesses shows a statistically significant difference (p < 0.05). According to average scores, the score for preparing reports related to green management practices is higher than the score for not preparing such reports.

- The widespread sharing of performance results related to green management among departments in businesses shows a statistically significant difference (p < 0.05). According to average scores, the score for sharing performance results related to green management among departments is higher than the score for not sharing them.

- The existence of close relationships and collaboration between the responsible unit and managers and departments regarding green management practices in businesses shows a statistically significant difference (p < 0.05). Based on average scores, the score for having close relationships and collaboration between the responsible unit and managers and departments is higher than the score for not having such relationships and collaboration (Table 8).

3.3. Findings Related to the Research Questions

A “correlation analysis” was conducted to explain and test the research questions. The correlation analysis examined whether business activities are related to environmental protection and green management practices. It was concluded that there is a positive relationship between the organizational activity score and the score for green management strategies (r = 0.247) (Table 9).

Table 9.

Correlation analysis.

In this study, green management practices were considered a new understanding and approach in environmental management. Managers are responsible for the environmental activities and implementation of strategies in oil companies. Therefore, in the conducted survey, business managers were considered the target audience. The sensitivity of the responding business managers regarding environmental issues, their awareness levels, and their thoughts on green management practices were evaluated within the context of the research questions.

Research Question 1: The understanding of environmentally conscious green management in oil companies in Türkiye has increased, with participants providing a positive response rate of 90.2% in this regard.

Research Question 2: There are close relationships and collaborations among the green management unit heads, managers, and departments regarding green management practices in oil companies. According to average scores, those who confirm the existence of close relationships and collaboration among departments scored (4.10), while those who did not confirm scored (2.74).

Research Question 3: Production and other activities (refining) in oil companies are conducted in accordance with the understanding of green management. The percentage of those who approve of the continuous application of practices related to green management principles in businesses is 64.1%, while the percentage of those responding “No” or “No Opinion” is 35.9%.

Research Question 4: It has been determined that the understanding of green management positively affects the activities of oil companies. According to the participants’ views, green management practices have led to a 42.4% increase in the companies’ image, improved efficiency by 38.0%, increased competitiveness by 35.0%, and resulted in a 31.5% rise in energy savings.

Research Question 5: It is understood that managers in oil companies have a high level of understanding regarding green management, based on their approaches to green management strategies and practices. Indeed, the business managers indicated that they agreed by 91.4% that green management practices positively affect environmental ecology and expressed that it is possible to reduce environmental pollution and greenhouse gas emissions through green management practices.

Research Question 6: The green management approach has been integrated into the business culture in oil companies within the context of social responsibility. According to the responses from participants, it is accepted by 90.2% that green management approaches and practices significantly contribute to achieving sustainable development, that green management increases clean and safe production by 90.2%, and that production and processing activities carried out without considering the environment threaten the future of the world and humanity, as expressed by 93.5%.

As a result, based on the statistical results obtained from the conducted survey, the activities and green management practices related to environmental management and protection in oil companies in Türkiye are the responsibility of the managers. Therefore, business managers were taken as the target audience in the study. It was determined that the majority of the managers hold positions as managers and chiefs, while others are directors, department heads, and assistant department heads. All participant managers completed undergraduate and postgraduate education. As responsible individuals in managerial positions, they play an effective role in the green management approach and practices related to the environment.

In terms of environmental activities in oil companies in Türkiye, it has been concluded that environmental impacts are highly evaluated in production and processing processes, that resources are allocated from the annual budget for taking environmental measures, and that “Environmental Teams” or an “Environmental Unit” are established within businesses. Responsible managers in oil companies provided positive responses to the survey questions regarding green management strategies and practices. The 92 participating managers who answered the survey accepted the idea that green management practices would be effective in achieving sustainable development and that oil production and processing activities conducted without considering the environment would adversely affect the world and humanity, and they acknowledged the importance of establishing a unit related to green management practices.

4. A Proposed Green Management Model for the Turkish Petroleum Industry

The petroleum industry encompasses highly complex production, processing, and refining processes and these activities generate a large volume of emissions and waste. The increase in greenhouse gas emissions in the atmosphere has led to global warming and, consequently, climate change, elevating environmental issues to a global scale. Therefore, it is becoming increasingly important for companies in the petroleum industry to conduct their operations in a way that minimizes adverse environmental effects. Implementing green management practices that protect the environment and natural resources across all stages of the petroleum industry represents the most rational course of action. Green management embodies an environmentally conscious management philosophy framed within specific goals and principles. The primary goal of green management practices is to minimize all forms of environmental impact in alignment with the organization’s strategic management framework, facilitate production and refining processes using environmentally sustainable technologies, enhance waste management strategies, ensure effective coordination among different organizational divisions, and foster a green business environment.

Given the substantial quantities of raw materials (i.e., oil and natural gas), heavy machinery, and diverse chemicals utilized throughout the exploration, production, and refining processes, the sector is inherently linked to emissions of gasses and particulates, as well as the generation of waste. In this context, the green management approach and its associated practices serve as a guiding framework for environmental preservation, energy management, and the effective management of clean water and waste. The proposed green management model for Türkiye’s petroleum industry has been designed with the following foundational elements [39].

- Objective: To foster sustainable development within the overarching policies of petroleum enterprises, ensuring the rational and efficient utilization of all resources, the maintenance of environmental quality, and a proactive approach to environmental issues.

- Environment: The management of emissions, pollution, and waste in all activities, in harmony with the environmental components of the operational area and its dimensions, alongside the continuous improvement of environmental impacts.

- Production and Products: The application of advanced technologies for environmentally sustainable production, eco-friendly refining processes, and the manufacturing of environmentally responsible green products.

- Communication and Organization: Integrated collaboration between the green management unit and the production and refining departments, facilitating participatory engagement at all hierarchical levels.

To establish a green management model within the operational processes of the petroleum industry, it is essential to first comprehend the underlying environmental issues. A dedicated unit (green management unit) should be constituted to collaborate with various departments and assume responsibility for environmental management within the context of the organization’s comprehensive strategic plan. This unit should function primarily as a green management implementation team, aligned with the environmental expectations articulated by both management and employees.

The members of the green management team, responsible for facilitating inter-departmental cooperation within the organization, should comprise individuals with specialized training in areas such as environmental protection, energy efficiency, emissions management, and waste management. Following the establishment of the green management team, a structured framework outlining operational methodologies should be developed, detailing the topics of focus, as well as the roles and responsibilities of team members. A visioning session should be convened involving senior management, departmental leaders, and consultants from organizations providing environmental management services to establish clear objectives and goals. For instance, information may be solicited from experts at consultancy firms regarding environmental management certification processes. This organizational structuring is crucial for laying the groundwork for effective green management and for developing strategic initiatives aimed at achieving environmental targets, thereby facilitating the systematic monitoring of the organization’s environmental protection and management activities over time. Ultimately, the endeavors of the green management team will serve to install a green identity within the organization.

To achieve results from green management practices, it is essential to understand the environmental and social connections of the enterprise. The following considerations should be taken into account:

- Environmental issues directly influenced by the enterprise;

- The relationship between environmental issues supported by the enterprise and its operational activities;

- The value added or to be added by green management practices to the enterprise;

- The support of the organizational culture for green management practices, as well as relationships with NGOs and local media.

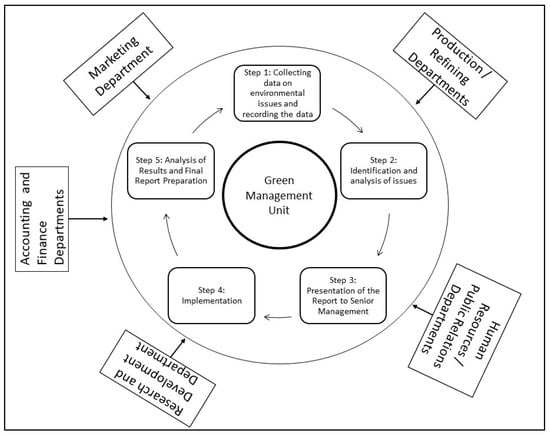

Once these factors are identified, applications that support the objectives of the proposed green management model can be developed. The following five fundamental steps should be followed for environmental practices aligned with the green management model (Figure 5) [39].

Figure 5.

Schematic representation of the green management implementation model in the petroleum sector.

- Step 1: Data Collection and the Documentation of Environmental Issues

In this phase, the green management implementation team identifies the environmental elements affected by the enterprise and investigates the relevance of the resulting impacts to the operational activities. The causes of environmental issues, the specific environmental elements most impacted, and the degree and stages of these impacts are examined. Once environmental problems are meticulously identified, the collected data are documented for analysis in light of the green management vision.

- Step 2: Identification and Analysis of Issues

During this phase, the collected data are analyzed to assess the scale of environmental and local social impacts and to determine the actions to be taken for the improvement of environmental issues. After identifying the environmental problems based on the data analysis, the findings are prepared in report form for presentation to senior management.

- Step 3: Presentation of the Report to Senior Management

The involvement of senior management is crucial in green management practices. In this phase, the report detailing the identified environmental issues, along with proposed solutions and associated costs, is submitted to senior management for review. This report informs management of the environmental challenges facing the enterprise and the proposed strategies to overcome them. Additionally, the report outlines the implementation plan, timeline, and financial implications, pending the approval of senior management.

- Step 4: Implementation

This phase marks the transformation of the green management concept into action and assesses the potential outcomes of the initiatives. Continuous monitoring, measurement, and evaluation throughout the process are essential for achieving positive results. The expertise and contributions of ISO 14001 specialists are utilized during implementation. The activities conducted are monitored, measurements are taken, and compliance with environmental regulations is ensured, leading to corrective actions where necessary.

- Step 5: Analysis of Results and Final Report Preparation

In this final phase, a final report is presented to senior management detailing the positive outcomes achieved, unresolved issues, and any outstanding matters that require attention following the implementation. If deemed necessary, a joint meeting can be convened with senior management, ISO 14001 consulting experts, the green management team, departmental managers, and representatives from NGOs to discuss and clarify the results obtained from the initiatives. Such collaboration fosters opportunities for partnership, facilitates learning and information sharing, and enhances community support and satisfaction. Consequently, this phase evaluates the adequacy and effectiveness of the implementation.

The objective of the green management model is to develop an effective, healthy, and safe working vision through collaboration integrated with the internal dynamics of the enterprise. In green management practices, in addition to having advanced technologies, interdepartmental communication and collaboration, employee participation, and the adoption of initiatives are of great importance.

5. Conclusions

The adoption of green management in Türkiye’s petroleum industry has progressed significantly over the years, from basic environmental policies to advanced sustainable practices. Despite significant progress, challenges persist, including the high costs associated with green technologies, regulatory compliance complexities, and the need for continuous innovation. Future prospects hinge on policy enhancements, increased investment in sustainable technologies, and the fostering of a corporate culture that prioritizes environmental stewardship. Given the absence of prior research on green management approaches in the Turkish petroleum industry, the one of most significant contributions of this study to the literature is the development of a survey instrument by the authors to examine the perspectives of managers on green management in the Turkish petroleum industry. It is understood that managers in oil companies have a high level of understanding regarding green management, based on the statistical results obtained from the conducted survey.

Although Türkiye’s petroleum industry has demonstrated an increasing commitment to environmental responsibility, there should be a more professional and sustainable mechanism to support this commitment. In this context, the study makes a significant contribution to the literature by proposing a green management model for the Turkish petroleum industry. Furthermore, a critical aspect that distinguishes this study is its pioneering contribution to the field, given the absence of prior academic research on green management models in the Turkish petroleum industry. The green management model proposed in this study enables organizations to establish an effective, healthy and safe working environment through integrated collaboration and communication, thereby ensuring the sustainability of green management practices.

Green management is no longer an option but a necessity for Türkiye’s petroleum industry. The global trend toward decarbonization offers an opportunity for Türkiye’s petroleum industry to reinvent itself. While challenges remain, the commitment to sustainable practices will play a crucial role in the industry’s long-term success. By leveraging international partnerships and funding mechanisms, the industry can enhance its green management capabilities. Moreover, increasing public and governmental support for sustainability initiatives can drive further investments in eco-friendly technologies.

Author Contributions

Conceptualization and methodology Ö.K. and Ö.A.; supervision Ö.A. and C.Z.; writing—original draft preparation, Ö.K.; writing—review and editing, Ö.K., Ö.A. and C.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

The study was conducted in accordance with the Declaration of Helsinki, and the protocol was approved by Ankara University Sub-Ethics Committee of the Social Sciences Institute (decision no. 11/237) on 21 June 2021 for studies involving humans.

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Li, Q.; Li, Q.; Wu, J.; Li, X.; Li, H.; Cheng, Y. Wellhead Stability During Development Process of Hydrate Reservoir in the Northern South China Sea: Evolution and Mechanism. Processes 2025, 13, 40. [Google Scholar] [CrossRef]

- Hasan, J.; Thomas, A.; Tomos, O. Sustainable Supply Chain Practices in the Oil and Gas Industry: A Case Study. Sustainability 2024, 16, 1720. [Google Scholar] [CrossRef]

- Florescu, M.S.; Ceptureanu, E.G.; Cruceru, A.F.; Ceptureanu, S.I. Sustainable Supply Chain Management Strategy Influence on Supply Chain Management Functions in the Oil and Gas Distribution Industry. Energies 2019, 12, 1632. [Google Scholar] [CrossRef]

- Ceptureanu, E.G.; Ceptureanu, S.I.; Olaru, M.; Bogdan, V.L. An exploratory study on coopetitive behavior in oil and gas distribution. Energies 2018, 11, 1234. [Google Scholar] [CrossRef]

- Ceptureanu, E.G.; Ceptureanu, S.I.; Radulescu, V.; Ionescu, S. What makes coopetition successful? An inter-organizational side analysis on Critical Success Factors in oil and gas distribution networks. Energies 2018, 11, 3447. [Google Scholar] [CrossRef]

- Energy Institute. Statistical Review of World Energy. Available online: https://www.energyinst.org/statistical-review (accessed on 9 October 2024).

- Ibn-Mohammed, T.; Mustapha, K.B.; Godsell, J.; Adamu, Z.; Babatunde, K.A.; Akintade, D.D.; Acquaye, A.; Fujii, H.; Ndiaye, M.M.; Yamoah, F.A.; et al. A critical analysis of the impacts of COVID-19 on the global economy and ecosystems and opportunities for circular economy strategies. Resour. Conserv. Recycl. 2021, 164, 105169. [Google Scholar] [CrossRef]

- Li, Q.; Li, Q.; Cao, H.; Wu, J.; Wang, F.; Wang, Y. The Crack Propagation Behaviour of CO2 Fracturing Fluid in Unconventional Low Permeability Reservoirs: Factor Analysis and Mechanism Revelation. Processes 2025, 13, 159. [Google Scholar] [CrossRef]

- Alshammari, K.H.; Alshammari, A.F. Green Innovation and Its Effects on Innovation Climate and Environmental Sustainability: The Moderating Influence of Green Abilities and Strategies. Sustainability 2023, 15, 15898. [Google Scholar] [CrossRef]

- Isallah, H. The Impact of the Petroleum Industry Act on Corporate Social Responsibility and Taxation in Nigeria’s Upstream Oil and Gas Sector: A Path towards Sustainable Development. Sustainability 2023, 15, 15538. [Google Scholar] [CrossRef]

- Mahmood, Y.; Afrin, T.; Huang, Y.; Yodo, N. Sustainable Development for Oil and Gas Infrastructure from Risk, Reliability, and Resilience Perspectives. Sustainability 2023, 15, 4953. [Google Scholar] [CrossRef]

- Czachorowski, K.V. Cleaning Up Our Act: Systems Engineering to Promote Business Model Innovation for the Offshore Exploration and Production Supply Chain Operations. Sustainability 2021, 13, 2113. [Google Scholar] [CrossRef]

- Elsayed, N.; Ammar, S. Sustainability governance and legitimisation processes: Gulf of Mexico oil spill. Sustain. Account. Manag. Policy J. 2020, 11, 253–278. [Google Scholar] [CrossRef]

- Jagoda, K.; Wojcik, P. Implementation of risk management and corporate sustainability in the Canadian oil and gas industry: An evolutionary perspective. Account. Res. J. 2019, 32, 381–398. [Google Scholar] [CrossRef]

- IPCC. Climate Change 2023: Synthesis Report, Summary for Policymakers. Available online: https://www.ipcc.ch/report/ar6/syr/downloads/report/IPCC_AR6_SYR_SPM.pdf (accessed on 23 December 2024).

- Ukhurebor, K.E.; Athar, H.; Adetunji, C.O.; Aigbe, U.O.; Onyancha, R.B.; Abifarin, O. Environmental implications of petroleum spillages in the Niger Delta region of Nigeria: A review. J. Environ. Manag. 2021, 293, 112872. [Google Scholar] [CrossRef] [PubMed]

- Akhmiyeva, R.B. Environmental consequences of pollution of the natural environment with oil products. In AIP Conference Proceedings; AIP Publishing: Melville, NY, USA, 2022; Volume 2657. [Google Scholar]

- Albeldawi, M. Environmental impacts and mitigation measures of offshore oil and gas activities. In Developments in Petroleum Science; Elsevier: Amsterdam, The Netherlands, 2023; Volume 78, pp. 313–352. [Google Scholar]

- Sukumaran, K. Impact of Human Activities Inducing and Triggering of Natural Disasters. In A System Engineering Approach to Disaster Resilience; Springer: Berlin/Heidelberg, Germany, 2022; pp. 17–31. [Google Scholar]

- Allen, D.T. Emissions from oil and gas operations in the United States and their air quality implications. J. Air Waste Manag. Assoc. 2016, 66, 549–575. [Google Scholar] [CrossRef]

- Altunok, A.E.; Altunok, E. AB İklim Değişikliği Politikaları. Denetişim Derg. 2016, 12, 45–55. [Google Scholar]

- Güner, E.D.; Turan, E.S. Yenilenebilir Enerji Kaynaklarının Küresel İklim Değişikliği Üzerine Etkisi. Doğal Afetler Çevre Derg. 2017, 3, 48–55. [Google Scholar] [CrossRef]

- Erinç, S. Klimatoloji ve Metodları; İstanbul Üniversitesi Yayınları: Istanbul, Turkey, 1984. [Google Scholar]

- Kocman, O.; Atay, O. A Comparative Study of the Petroleum Industry Environmentally-Responsible Green Management Implementations. J. Glob. Strateg. Manag. 2021, 15, 5–18. [Google Scholar] [CrossRef]

- Gunningham, N.; Sinclair, D. Environmental management in the oil and gas industry: Challenges and strategies. J. Pet. Environ. Manag. 2021, 8, 34–50. [Google Scholar]

- Daruwala, K. Waste Management in Oil and Gas Industry: A Comparative Study of India and Russia. PDEU J. Energy Manag. 2024, Issue X, 47–55. [Google Scholar]

- Shahbaz, M.; Rashid, N.; Saleem, J.; Mackey, H.; McKay, G.; Al-Ansari, T. A review of waste management approaches to maximise sustainable value of waste from the oil and gas industry and potential for the State of Qatar. Fuel 2023, 332, 126220. [Google Scholar] [CrossRef]

- Vora, M.; Sanni, S.; Flage, R. An environmental risk assessment framework for enhanced oil recovery solutions from offshore oil and gas industry. Environ. Impact Assess. Rev. 2021, 88, 106512. [Google Scholar] [CrossRef]

- Özçelik, S. The Analysis of Climate Change Negotiations Between 1995–2002. Uluslararası Kriz Siyaset Araştırmaları Derg. 2020, 4, 187–212. [Google Scholar]

- Kuban, B. İklim değişikliği ile mücadele ve Paris 2015. Cumhur. Bilim Teknol. Derg. 2015, 1456, 13. [Google Scholar]

- Kuban, B. İklim değişikliği: Finans kapitalin gözü mü açıldı? Cumhur. Bilim Teknol. Derg. 2015, 1486, 11. [Google Scholar]

- Oksay, R. İklim Değişikliği İle Mücadelede Çözüm Arayışları: Küresel Isınmanın Baş Sorumluları Şimdi Çözüm Peşinde. Cumhur. Bilim Teknol. Derg. 2015, 1499, 10–11. [Google Scholar]

- Oksay, R. Paris İklim Zirvesi’nden Antlaşma Çıktı: Küresel Isınmayı Durdurmak İçin Son Şans. Cumhur. Bilim Teknol. Derg. 2015, 1501, 10–11. [Google Scholar]

- Karakaya, E. Paris İklim Anlaşması: İçeriği ve Türkiye Üzerine Bir Değerlendirme. Adnan Menderes Üniversitesi Sos. Bilim. Enstitüsü Derg. 2016, 3, 1–12. [Google Scholar] [CrossRef]

- Republic of Türkiye Ministry of Foreign Affairs. Paris Agreement. Available online: https://www.mfa.gov.tr/paris-anlasmasi.tr.mfa (accessed on 4 November 2024).

- Abedin, B.; Gabor, M.R.; Susanu, I.O.; Jaber, Y.F. Exploring the Perspectives of Oil and Gas Industry Managers on the Adoption of Sustainable Practices: A Q Methodology Approach to Green Marketing Strategies. Sustainability 2024, 16, 5948. [Google Scholar] [CrossRef]

- O’Rourke, D.; Connolley, S. Just Oil? The Distribution of Oil Production and Comsumption. Annu. Rev. Environ. Resour. 2003, 28, 587–617. [Google Scholar] [CrossRef]

- Kadafa, A.A. Environmental Impacts of Oil Exploration and Explotation in the Niger Delta of Nigeria. Glob. J. Sci. Front. Resarch Environ. Earth Sci. 2012, 12, 18–28. [Google Scholar]

- Koçman, Ö. Dünyada ve Türkiye’de Petrol Sektöründe Yeşil Yönetim- Türkiye İçin Bir Model Önerisi. PhD Thesis, Ankara Üniversitesi Sosyal Bilimler Enstitüsü, Ankara, Turkey, 2022. [Google Scholar]

- D’Orazio, P. Navigating financial stability through the dual challenges of climate change and pandemics. Curr. Opin. Environ. Sustain. 2023, 65, 101386. [Google Scholar] [CrossRef]

- George, G.; Schillebeeckx, S.J. Digital transformation, sustainability, and purpose in the multinational enterprise. J. World Bus. 2022, 57, 101326. [Google Scholar] [CrossRef]

- Atay, Ö.; Koçman, Ö. The situation of women in Turkish petroleum industry. Uluslararası Sos. Bilim. Eğitim Derg. USBED 2024, 6, 426–438. [Google Scholar]

- TPAO. Petrol ve Doğal Gaz Sektör Raporu. 2023. Available online: https://www.tpao.gov.tr/file/2409/2023-sektor-raporu-218866f6cc2266839.pdf (accessed on 9 March 2025).

- TPAO Sustainability Report. 2022. Available online: https://www.tpao.gov.tr/file/2401/tpao-sr22-en-170465980df6d0c3f.pdf (accessed on 9 March 2025).

- TÜPRAŞ Integrated Annual Report. 2023. Available online: https://www.tupras.com.tr/assets/img/sustainability/tupras-2023-integrated-annual-report.pdf (accessed on 23 December 2024).

- SOCAR Türkiye Sustainability Report. 2022. Available online: https://socar.com.tr/uploads/raporlar/SOCAR_Turkey_Sustainability_Report_2022.pdf (accessed on 23 December 2024).

- Jeong, J. Analysis of the Factors and the Roles of Hrd in Organizational Learning Styles as Identified by Key Informants at Selected Corporations in the Republic of Korea. Ph.D. Thesis, Texas A&M University, College Station, TX, USA, 2004. [Google Scholar]

- Nunnally, J.C. Psychometic Theory, 1st ed.; McGraw-Hill, Inc.: New York, NY, USA, 1967; p. 248. [Google Scholar]

- Groeneveld, R.A.; Meeden, G. Measuring Skewness and Kurtosis. Statistician 1984, 33, 391–399. [Google Scholar] [CrossRef]

- Moors, J.J.A. The Meaning of Kurtosis: Darlington Reexamined. Am. Stat. 1986, 40, 283–284. [Google Scholar] [CrossRef]

- Hopkins, K.D.; Weeks, D.L. Tests for Normality and Measures of Skewness and Kurtosis: Their Place in Research Reporting. Educ. Psychol. Meas. 1990, 50, 717–729. [Google Scholar] [CrossRef]

- De Carlo, L.T. On the Meaning and Use of Kurtosis. Psychol. Methods 1997, 2, 292–307. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).