Optimized Design and Testing of Enhanced Heat Transfer Secondary Micro-Channels on the Surface of Fuel Cell Bipolar Plate Flow Channels

Abstract

1. Introduction

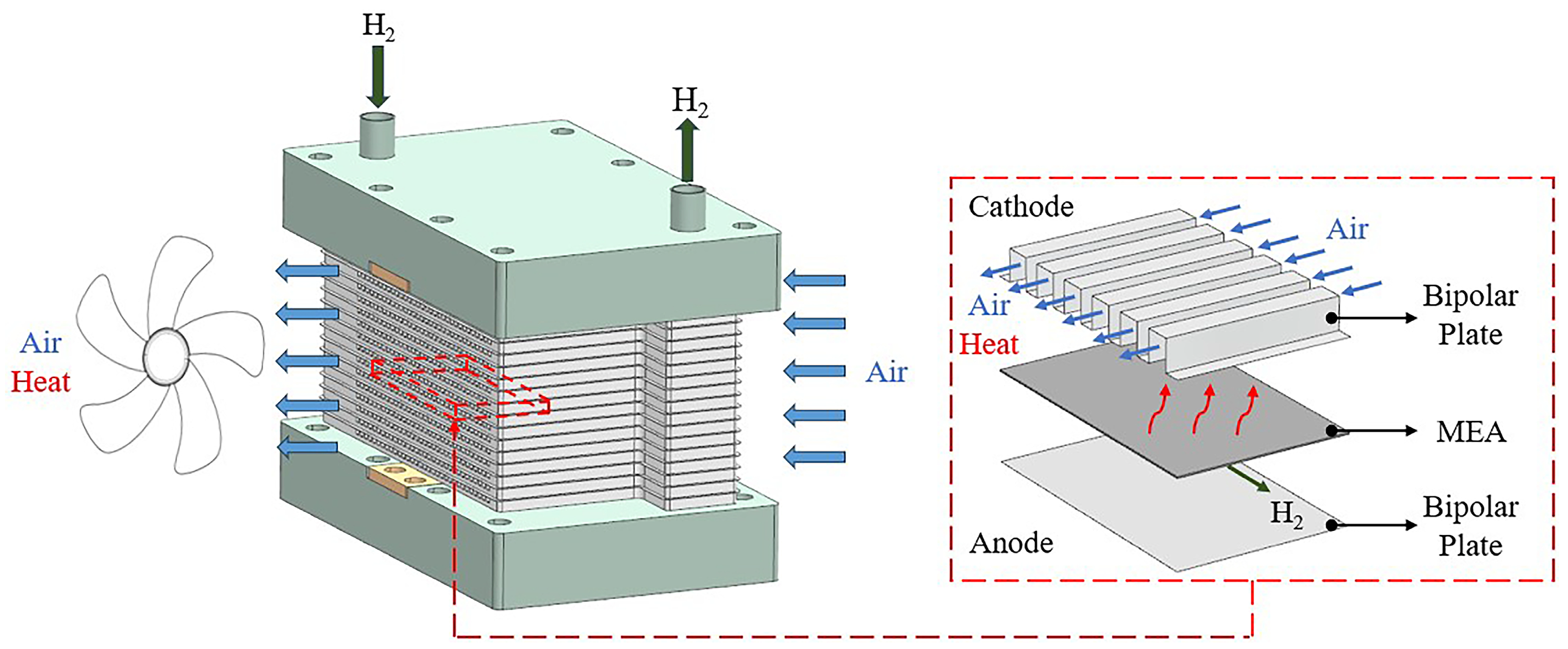

2. Principle and Structure Design

3. Comparison of Heat Transfer in Secondary Micro-Channels Flow Field Structure

3.1. Heat Transfer Simulation Model and Boundary Conditions

3.2. Mesh Scheme and Independence Verification

3.3. Simulation Results Analysis

3.4. Optimization of Secondary Micro-Channel Structural Parameters

3.5. Experimental Validation of Channel Heat Transfer

4. Air-Cooled PEMFC Testing

4.1. Experimental Conditions and Methods

4.2. Results and Discussion

5. Conclusions

6. Outlook and Future Work

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, X.; Ye, T.; Meng, X.; He, D.; Li, L.; Song, K.; Jiang, J.; Sun, C. Advances in the Application of Sulfonated Poly (Ether Ether Ketone) (SPEEK) and Its Organic Composite Membranes for Proton Exchange Membrane Fuel Cells (PEMFCs). Polymers 2024, 16, 2840. [Google Scholar] [CrossRef] [PubMed]

- Veziroğlu, T.N.; Şahi, S. 21st Century’s Energy: Hydrogen Energy System. Energy Convers. Manag. 2008, 49, 1820–1831. [Google Scholar] [CrossRef]

- Luo, X.; Wang, J.; Dooner, M.; Clarke, J. Overview of Current Development in Electrical Energy Storage Technologies and the Application Potential in Power System Operation. Appl. Energy 2015, 137, 511–536. [Google Scholar] [CrossRef]

- Sharaf, O.Z.; Orhan, M.F. An Overview of Fuel Cell Technology: Fundamentals and Applications. Renew. Sustain. Energy Rev. 2014, 7, 810–853. [Google Scholar] [CrossRef]

- Xie, F.; Shao, Z.; Hou, M.; Yu, H.; Song, W.; Sun, S.; Zhou, L.; Yi, B. Recent Progresses in H2-PEMFC at DICP. J. Energy Chem. 2019, 36, 129–140. [Google Scholar] [CrossRef]

- Zhou, S.; Fan, L.; Zhang, G.; Gao, J.; Lu, Y.; Zhao, P.; Wen, C.; Shi, L.; Hu, Z. A Review on Proton Exchange Membrane Multi-Stack Fuel Cell Systems: Architecture, Performance, and Power Management. Appl. Energy 2022, 310, 118555. [Google Scholar] [CrossRef]

- Ramezanizadeh, M.; Nazari, M.A.; Ahmadi, M.H.; Chen, L. A Review on the Approaches Applied for Cooling Fuel Cells. Int. J. Heat Mass Transf. 2019, 139, 517–525. [Google Scholar] [CrossRef]

- Soupremanien, U.; Le Person, S.; Favre-Marinet, M.; Bultel, Y. Tools for Designing the Cooling System of a Proton Exchange Membrane Fuel Cell. Appl. Therm. Eng. 2012, 40, 161–173. [Google Scholar] [CrossRef]

- Kurnia, J.C.; Sasmito, A.P.; Shamim, T. Performance Evaluation of a PEM Fuel Cell Stack with Variable Inlet Flows under Simulated Driving Cycle Conditions. Appl. Energy 2017, 206, 751–764. [Google Scholar] [CrossRef]

- Meng, X.; Sun, C.; Mei, J.; Tang, X.; Hasanien, H.M.; Jiang, J.; Fan, F.; Song, K. Fuel Cell Life Prediction Considering the Recovery Phenomenon of Reversible Voltage Loss. J. Power Sources 2025, 625, 235634. [Google Scholar] [CrossRef]

- Zhang, J.; Xie, Z.; Zhang, J.; Tang, Y.; Song, C.; Navessin, T.; Shi, Z.; Song, D.; Wang, H.; Wilkinson, D.P.; et al. High Temperature PEM Fuel Cells. J. Power Sources 2006, 160, 872–891. [Google Scholar] [CrossRef]

- Zhang, J.; Xu, J.; Han, H.; Lei, L.; Xin, G. Single-Phase and Flow Boiling Heat Transfer Characteristics in Staggered Finned Manifold Microchannel Heat Sink. Case Stud. Therm. Eng. 2024, 60, 104669. [Google Scholar]

- Wang, Q.; Tao, J.; Cui, Z.; Zhang, T.; Chen, G. Numerical Simulation of Fluid and Heat Transfer Characteristics of Microchannel Heat Sink with Fan-Shaped Grooves and Triangular Truncated Ribs. Int. Commun. Heat Mass Transf. 2024, 155, 107580. [Google Scholar] [CrossRef]

- Zhang, F.; Wu, B.; Du, B. Heat Transfer Optimization Based on Finned Microchannel Heat Sink. Int. J. Therm. Sci. 2022, 172, 107357. [Google Scholar] [CrossRef]

- Nie, X.; Zhu, C.; Fu, T.; Ma, Y. Mass Transfer Intensification and Mechanism Analysis of Gas–Liquid Two-Phase Flow in the Microchannel Embedding Triangular Obstacles. Chin. J. Chem. Eng. 2022, 51, 100–108. [Google Scholar] [CrossRef]

- Rahimi-Esbo, M.; Rahgoshay, S.; Hassani, M.; Firouzjaei, K.D. Novel Design and Numerical Evaluating of a Cooling Flow Field in PEMFC with Metallic Bipolar Plates. Int. J. Hydrogen Energy, 2020; in press. [Google Scholar] [CrossRef]

- Yu, X.; Tu, Z.; Chan, S.H. Thermal Management on an Air-Cooled PEMFC Stack with Concave-Convex Dual Flow Channel Bipolar Plates. Int. J. Hydrogen Energy 2024, 52, 1018–1032. [Google Scholar] [CrossRef]

- Zhang, X.; Huang, Y.; Ma, Z.; Gao, T. Study on Heat Transfer Enhancement Performance of Cooling Channel with Elliptical Dimples in a Proton Exchange Membrane Fuel Cell. Int. Commun. Heat Mass Transf. 2024, 153, 107343. [Google Scholar] [CrossRef]

- Zhang, Y.; He, S.; Jiang, X.; Xiong, M.; Ye, Y.; Yang, X. Three-Dimensional Multi-Phase Simulation of Different Flow Fields with Cooling Channel in Proton Exchange Membrane Fuel Cell. Int. J. Hydrogen Energy 2022, 47, 37929–37944. [Google Scholar] [CrossRef]

- Afshari, E.; Ziaei-Rad, M.; Dehkordi, M.M. Numerical Investigation on a Novel Zigzag-Shaped Flow Channel Design for Cooling Plates of PEM Fuel Cells. J. Energy Inst. 2017, 90, 752–763. [Google Scholar] [CrossRef]

- Peng, C.; Gu, H.; Zhang, G.; Luo, K.; Xu, P.; Lv, S.; Zhang, Q.; Chen, G. Numerical Study on Heat Transfer Enhancement of a Proton Exchange Membrane Fuel Cell with the Dimpled Cooling Channel. Int. J. Hydrogen Energy 2023, 48, 3122–3134. [Google Scholar] [CrossRef]

- Zhang, G.; Kandlikar, S.G. A Critical Review of Cooling Techniques in Proton Exchange Membrane Fuel Cell Stacks. Int. J. Hydrogen Energy 2012, 37, 2412–2429. [Google Scholar] [CrossRef]

- Sasmito, A.P.; Birgersson, E.; Mujumdar, A.S. Numerical Evaluation of Various Thermal Management Strategies for Polymer Electrolyte Fuel Cell Stacks. Int. J. Hydrogen Energy 2011, 36, 12991–13007. [Google Scholar] [CrossRef]

- Mohamed, W.A.N.W.; Abu Talib, S.F.; Zakaria, I.A.; Mamat, A.M.I.; Daud, W.R.W. Effect of Dynamic Load on the Temperature Profiles and Cooling Response Time of a Proton Exchange Membrane Fuel Cell. J. Energy Inst. 2018, 91, 349–357. [Google Scholar] [CrossRef]

- Bergman, T.L. Fundamentals of Heat and Mass Transfer; John Wiley & Sons: Hoboken, NJ, USA, 2011. [Google Scholar]

- Yan, S.; Yang, M.; Sun, C.; Xu, S. Liquid Water Characteristics in the Compressed Gradient Porosity Gas Diffusion Layer of Proton Exchange Membrane Fuel Cells Using the Lattice Boltzmann Method. Energies 2023, 16, 6010. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| (K) | 293.15 |

| (m/s) | 3–4.5 |

| 0 | |

| (W) | 0.5 |

| Item | Level Number | Parameter Name | ||

|---|---|---|---|---|

| w (mm) | h (mm) | s (mm) | ||

| Parameter Values | 1 | 0.1 | 0.2 | 0.4 |

| 2 | 0.2 | 0.3 | 0.5 | |

| 3 | 0.3 | 0.4 | 0.6 | |

| Number | w (mm) | h (mm) | s (mm) | (°C) |

|---|---|---|---|---|

| 1 | 0.1 | 0.2 | 0.4 | 70.52 |

| 2 | 0.1 | 0.3 | 0.5 | 69.32 |

| 3 | 0.1 | 0.4 | 0.6 | 68.39 |

| 4 | 0.2 | 0.2 | 0.5 | 68.5 |

| 5 | 0.2 | 0.3 | 0.6 | 66.58 |

| 6 | 0.2 | 0.4 | 0.4 | 65.43 |

| 7 | 0.3 | 0.2 | 0.6 | 66.38 |

| 8 | 0.3 | 0.3 | 0.4 | 64.22 |

| 9 | 0.3 | 0.4 | 0.5 | 62.22 |

| Objective Function | Analysis Factors | Experimental Factors | ||

|---|---|---|---|---|

| w | h | s | ||

| 69.41 | 68.47 | 66.72 | ||

| 66.84 | 66.71 | 66.68 | ||

| 64.27 | 65.35 | 67.12 | ||

| 5.173 | 3.12 | 0.44 | ||

| Primary factor order | w > h > s | |||

| Optimal combination | w3h3s2 | |||

| (°C) | (°C/W) | |

|---|---|---|

| Straight-flow channel | 72.23 | 99.78 |

| Optimized Secondary Micro-channel | 62.22 | 78.64 |

| Study | Method | Result |

|---|---|---|

| This Study | Secondary microchannel structure in bipolar plate | Heat transfer performance improved by 22.5%, temperature reduced by 14 °C, and stack output power increased by 27% |

| Zhang et al. [12] | Staggered fin manifold microchannel structure | Reduced maximum temperature by 5–10 K |

| Wang et al. [13] | Microchannel heat sink with fan-shaped grooves and triangular truncated ribs | Improved heat dissipation for high heat flux electronic devices |

| Zhang et al. [14] | Microchannel heat sink with internal fins | Reduced maximum and average temperatures by 6.67% and 6.75% |

| Nie et al. [15] | Microchannels with embedded triangular ribs on sidewalls | Maximum PEC of 2.35 (equilateral ribs) and 2.1 (isosceles ribs); pressure drop increased by only 0.41 kPa |

| Rahimi-Esbo et al. [16] | Metallic bipolar plate with baffles in cooling flow field | Improved fuel cell temperature uniformity and overall performance |

| Yu et al. [17] | Air-cooled PEMFC stack with concave–convex dual flow channels | At 0.4 A/cm2, increasing airflow from 1 m/s to 1.5 m/s reduced max temperature by 16.5% |

| Zhang et al. [18] | Elliptical dimple cooling (EDC) channel structure | Improved heat transfer efficiency by 10.6% over smooth channels |

| Zhang et al. [19] | Waveform interweaving cooling flow field | More uniform water distribution in MEA; enhanced heat dissipation despite increased pressure drop |

| Afshari et al. [20] | Sawtooth-shaped water-cooled fuel cell cooling channel | Reduced max surface temperature, temperature difference, and uniformity index by 5%, 23%, and 8% compared to straight channels |

| Peng et al. [21] | Cooling channels with circular dimples | Improved cooling performance by 10%; pressure loss reduced by 13% compared to wavy channels |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Liu, J.; Liu, Y.; Zhang, G. Optimized Design and Testing of Enhanced Heat Transfer Secondary Micro-Channels on the Surface of Fuel Cell Bipolar Plate Flow Channels. Energies 2025, 18, 1459. https://doi.org/10.3390/en18061459

Zhang X, Liu J, Liu Y, Zhang G. Optimized Design and Testing of Enhanced Heat Transfer Secondary Micro-Channels on the Surface of Fuel Cell Bipolar Plate Flow Channels. Energies. 2025; 18(6):1459. https://doi.org/10.3390/en18061459

Chicago/Turabian StyleZhang, Xiaofan, Jia Liu, Yan Liu, and Guoguan Zhang. 2025. "Optimized Design and Testing of Enhanced Heat Transfer Secondary Micro-Channels on the Surface of Fuel Cell Bipolar Plate Flow Channels" Energies 18, no. 6: 1459. https://doi.org/10.3390/en18061459

APA StyleZhang, X., Liu, J., Liu, Y., & Zhang, G. (2025). Optimized Design and Testing of Enhanced Heat Transfer Secondary Micro-Channels on the Surface of Fuel Cell Bipolar Plate Flow Channels. Energies, 18(6), 1459. https://doi.org/10.3390/en18061459