Advancements in Integrated Thermoelectric Power Generation and Water Desalination Technologies: A Comprehensive Review

Abstract

1. Introduction

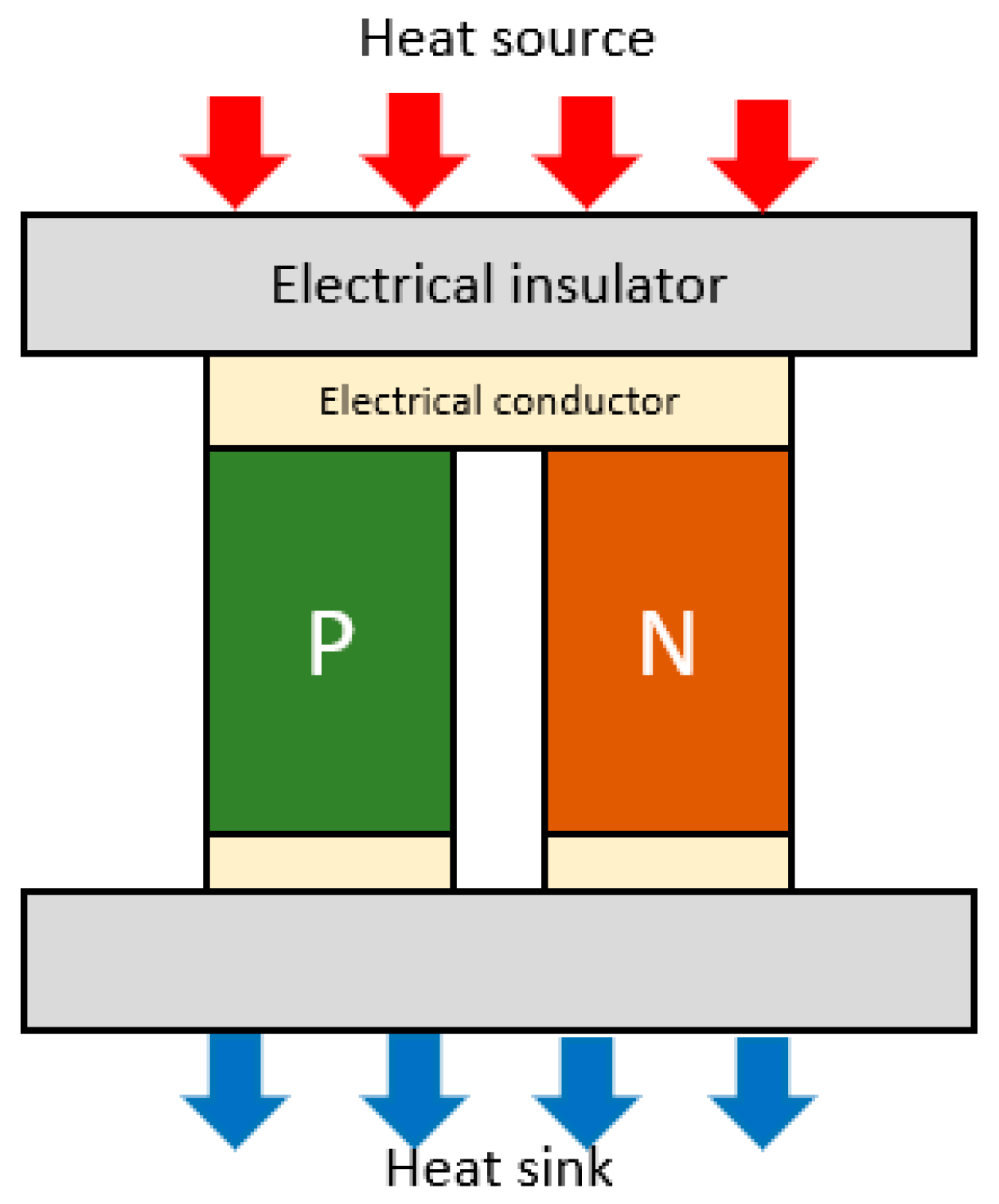

2. What Are Thermoelectric Generators (TEGs)?

Thermoelectric Materials

3. Membrane Distillation (MD)

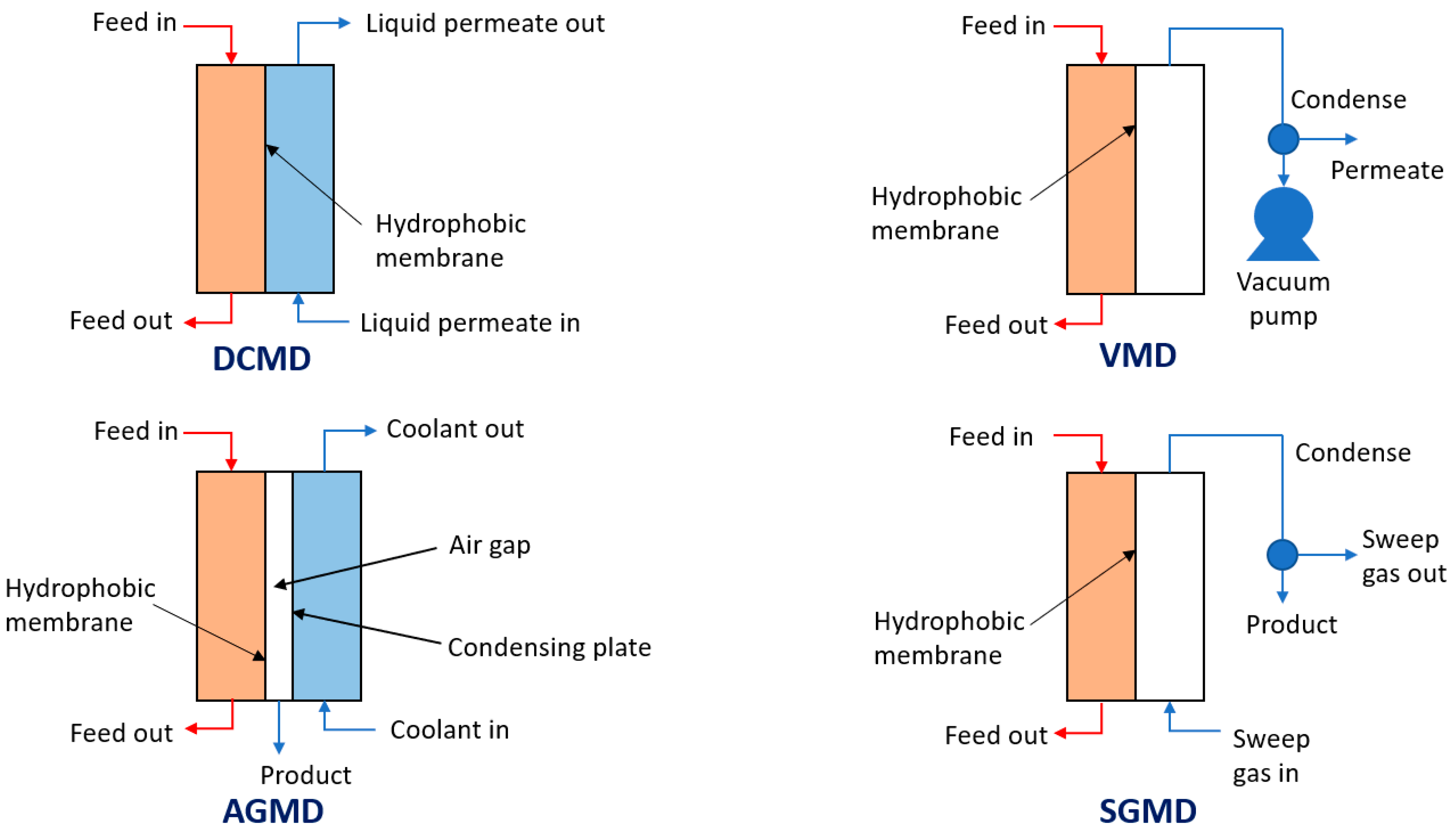

3.1. Membrane Distillation Configurations

3.1.1. Direct Contact Membrane Distillation (DCMD)

3.1.2. Air Gap Membrane Distillation (AGMD)

3.1.3. Vacuum Membrane Distillation (VMD)

3.1.4. Sweeping Gas Membrane Distillation (SGMD)

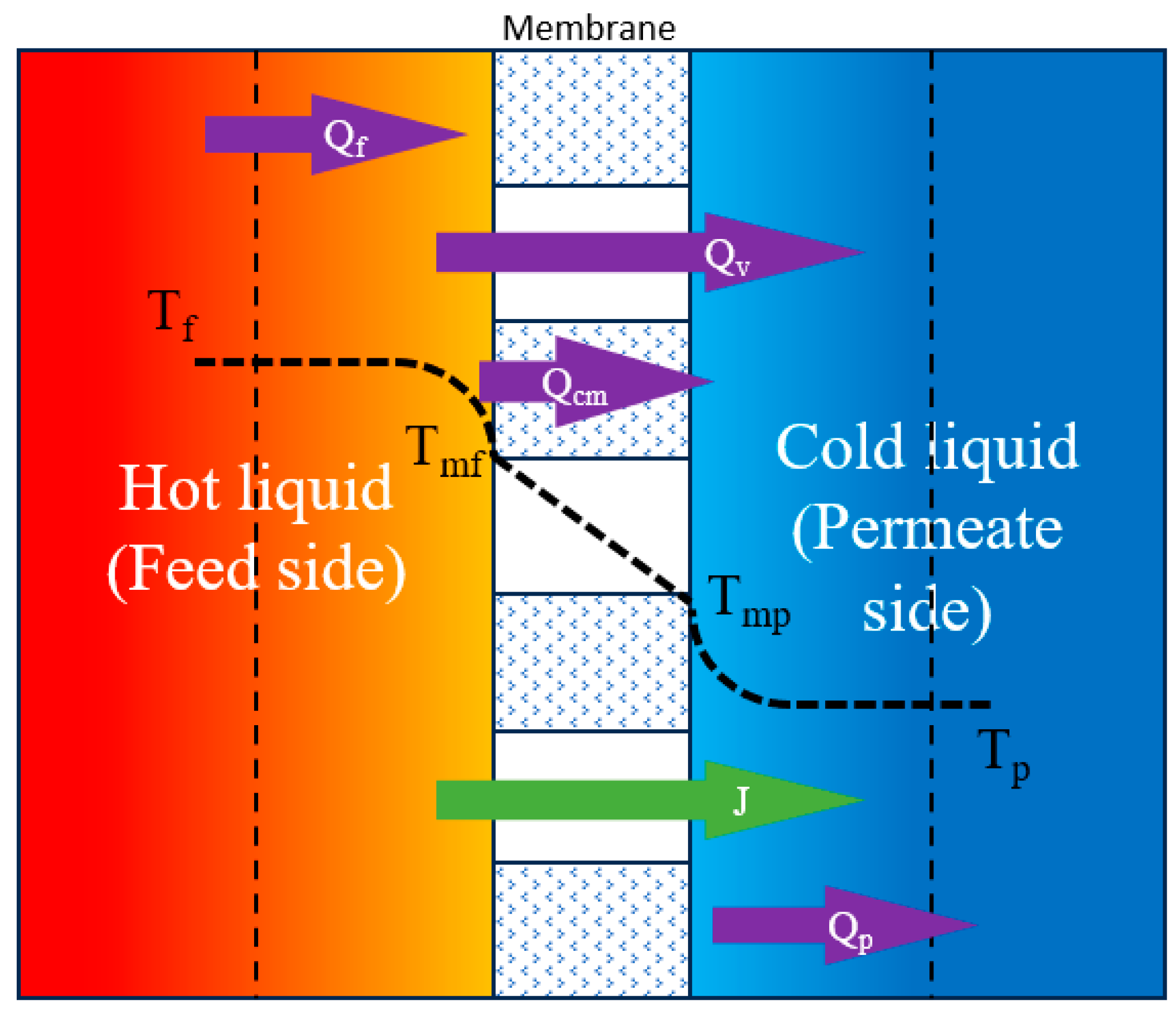

3.2. Heat and Mass Transfer in the MD Process

3.3. Membrane

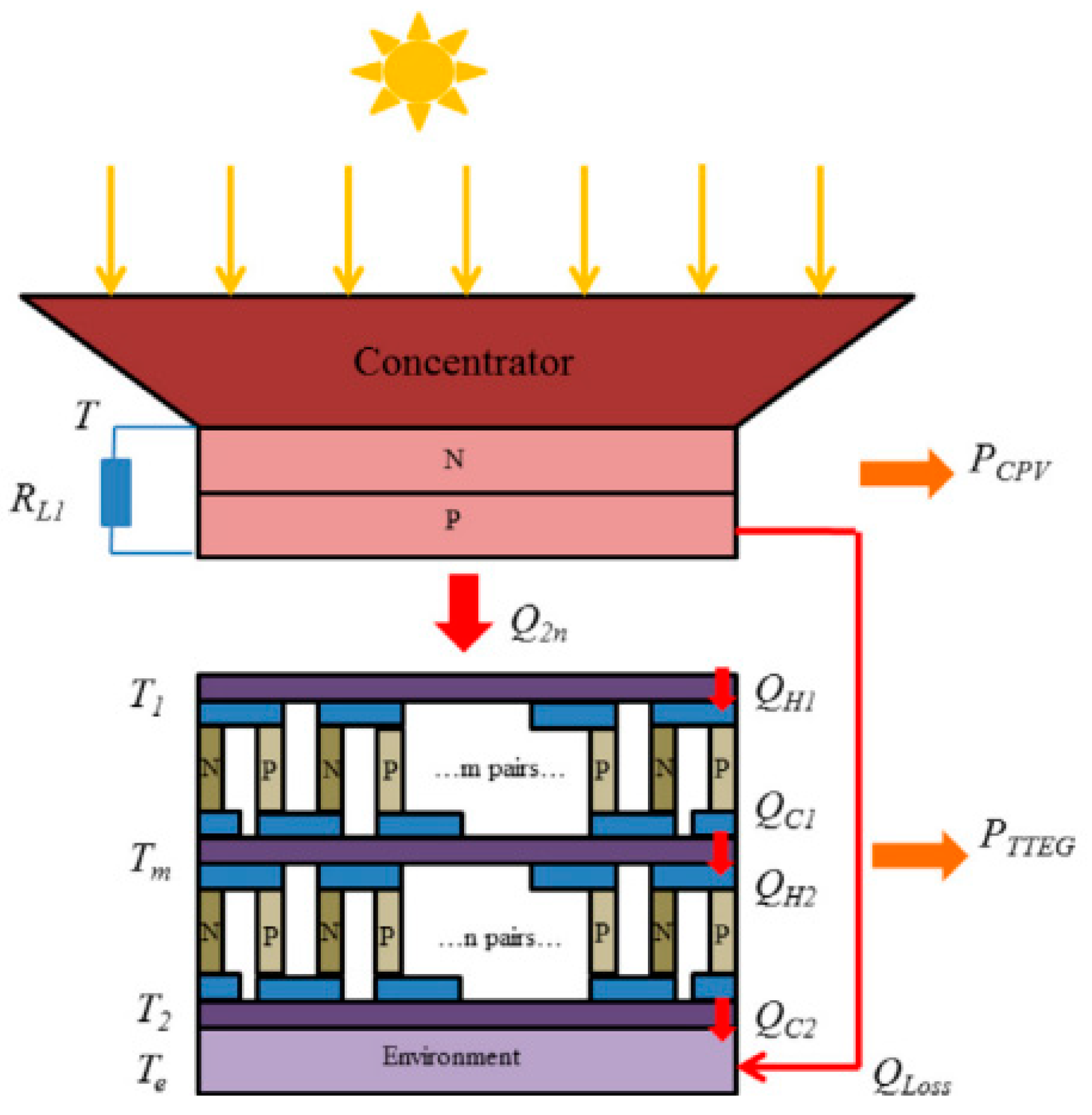

4. Combined Power Generation and Water Desalination Technology

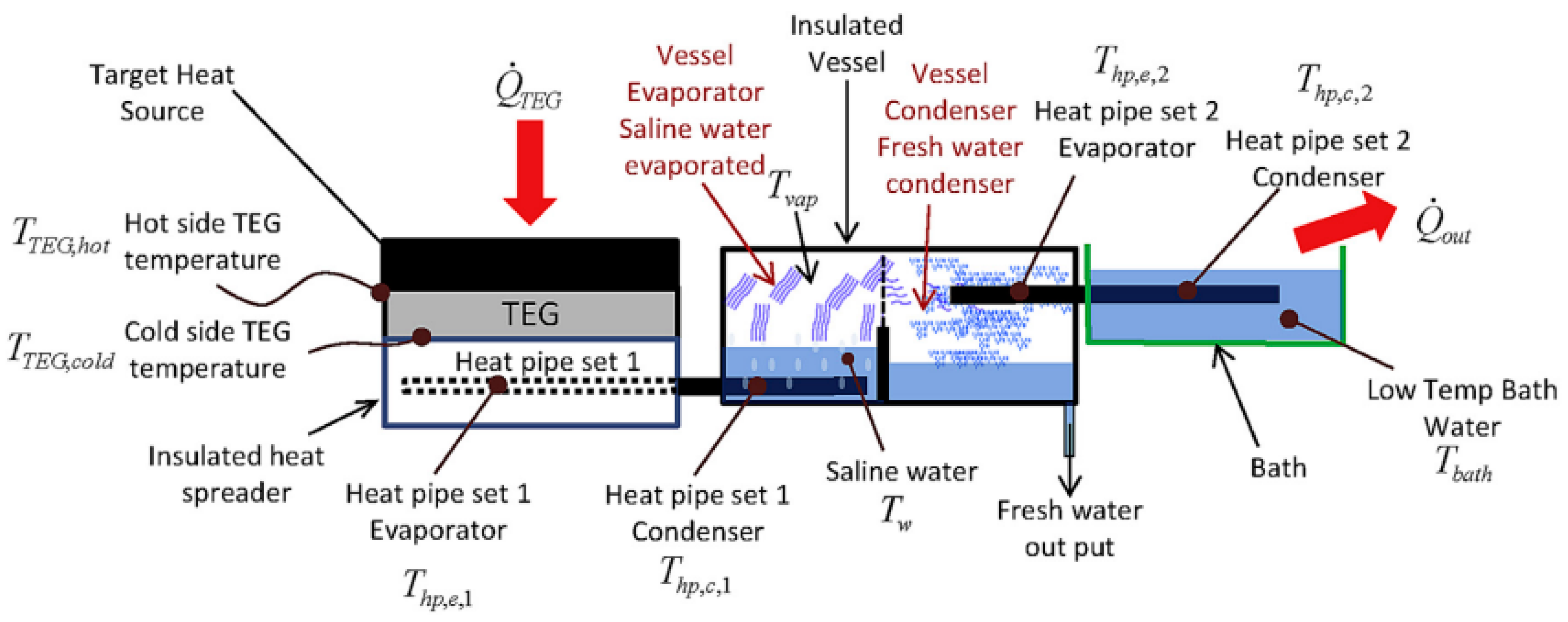

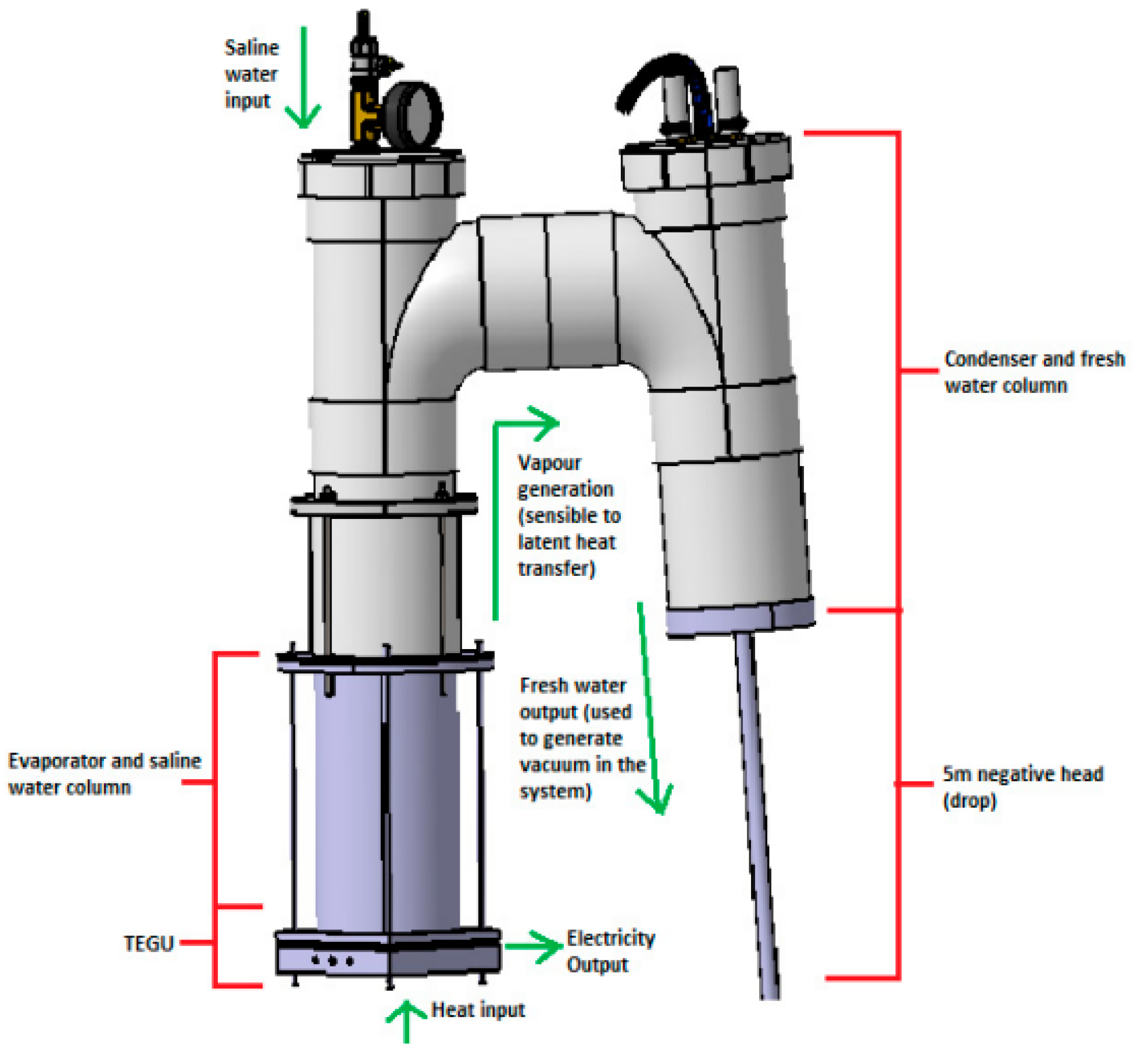

4.1. Experimental Studies and System Innovations

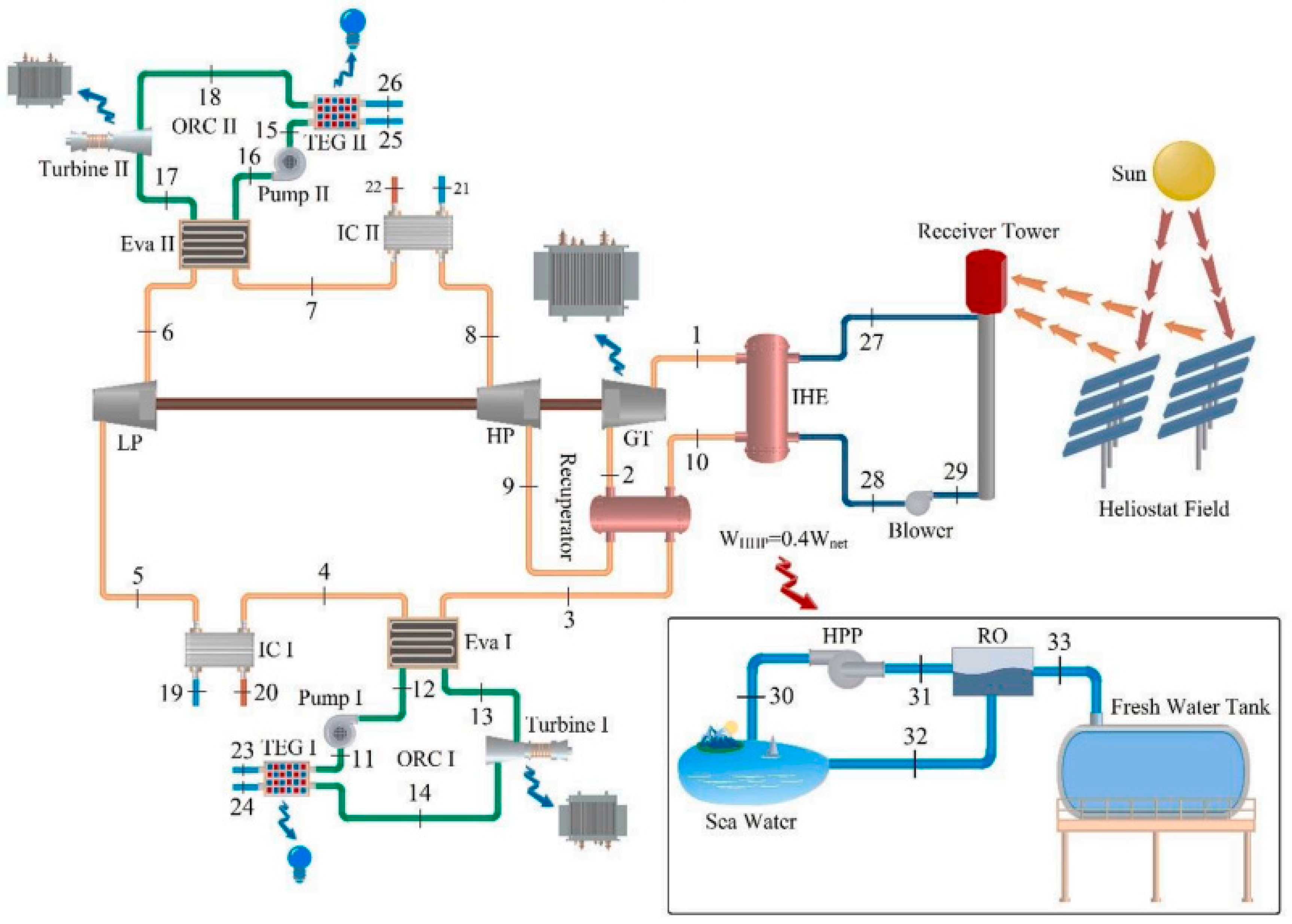

4.2. Multi-Generation Systems

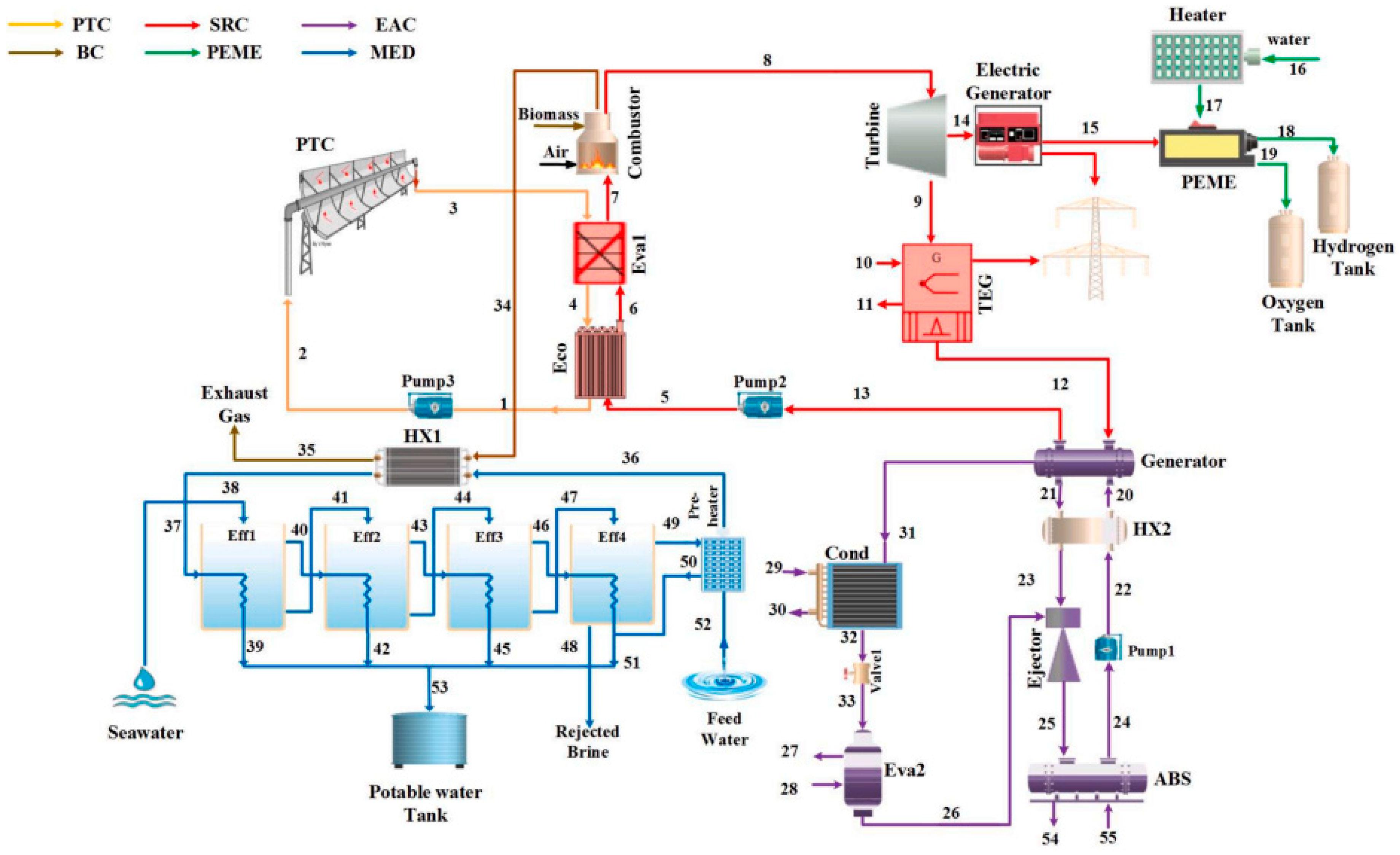

4.3. Biomass and Waste Heat Integration

4.4. Solar and Wind Energy Combined Systems

4.5. Economic Feasibility

5. Discussion

6. Conclusions

Funding

Conflicts of Interest

References

- United Nations Department of Economic and Social Affairs. World Population Prospects: The 2002 Revision. Comprehensive Tables; United Nations Publications: New York, NY, USA, 2003; Volume 1. [Google Scholar]

- Department of Climate Change, Energy, The Environment and Water, Australia Government. Australian Electricity Generation. 2023. Available online: https://www.energy.gov.au/sites/default/files/2024-08/australian_energy_update_2024.pdf (accessed on 8 December 2024).

- U.S. Energy Information Administration. Electricity in the United States is Produced (Generated) with Diverse Energy Sources and Technologies. Available online: https://www.eia.gov/energyexplained/electricity/electricity-in-the-us.php (accessed on 8 December 2024).

- Ellerbeck, S. Explainer: What Exactly is Freshwater and Is There Enough of It? 2022. Available online: https://www.weforum.org/agenda/2022/10/water-freshwater-scarcity-uplink/ (accessed on 8 December 2024).

- Thomas, R.; Davies, J.; King, C.; Kruse, J.; Schauer, M.; Bisom, N.; Tsegai, D.; Madani, K. Economics of Drought Investing in Nature-Based Solutions for Drought Resilience—Proaction Pays; UNCCD Publication: Washington, DC, USA, 2024. [Google Scholar]

- Sahin, O.; Stewart, R.A.; Porter, M.G. Water security through scarcity pricing and reverse osmosis: A system dynamics approach. J. Clean. Prod. 2015, 88, 160–171. [Google Scholar] [CrossRef]

- IEA. Water-Energy Nexus; International Energy Agency: Paris, France, 2017; Available online: https://iea.blob.core.windows.net/assets/e4a7e1a5-b6ed-4f36-911f-b0111e49aab9/WorldEnergyOutlook2016ExcerptWaterEnergyNexus.pdf (accessed on 20 November 2024).

- Elimelech, M.; Phillip, W.A. The Future of Seawater Desalination: Energy, Technology, and the Environment. Sci. (Am. Assoc. Adv. Sci.) 2011, 333, 712–717. [Google Scholar] [CrossRef] [PubMed]

- Shalaby, S.M. Reverse osmosis desalination powered by photovoltaic and solar Rankine cycle power systems: A review. Renew. Sustain. Energy Rev. 2017, 73, 789–797. [Google Scholar] [CrossRef]

- Brückner, S.; Liu, S.; Miró, L.; Radspieler, M.; Cabeza, L.F.; Lävemann, E. Industrial waste heat recovery technologies: An economic analysis of heat transformation technologies. Appl. Energy 2015, 151, 157–167. [Google Scholar] [CrossRef]

- Kumar, P.; Singh, O. Thermodynamic analysis of solid oxide fuel cell-gas turbine-organic Rankine cycle combined system. Int. J. Mater. Sci. Mech. Eng. (JMSME) 2019, 6, 98–102. [Google Scholar]

- Forman, C.; Muritala, I.K.; Pardemann, R.; Meyer, B. Estimating the global waste heat potential. Renew. Sustain. Energy Rev. 2016, 57, 1568–1579. [Google Scholar] [CrossRef]

- Papapetrou, M.; Kosmadakis, G.; Cipollina, A.; La Commare, U.; Micale, G. Industrial waste heat: Estimation of the technically available resource in the EU per industrial sector, temperature level and country. Appl. Therm. Eng. 2018, 138, 207–216. [Google Scholar] [CrossRef]

- Bianchi, G.; Panayiotou, G.P.; Aresti, L.; Kalogirou, S.A.; Florides, G.A.; Tsamos, K.; Tassou, S.A.; Christodoulides, P. Estimating the waste heat recovery in the European Union Industry. Energy Ecol. Environ. 2019, 4, 211–221. [Google Scholar] [CrossRef]

- Wang, X.; Christ, A.; Regenauer-Lieb, K.; Hooman, K.; Chua, H.T. Low grade heat driven multi-effect distillation technology. Int. J. Heat Mass Transf. 2011, 54, 5497–5503. [Google Scholar] [CrossRef]

- Elsaid, K.; Taha Sayed, E.; Yousef, B.A.A.; Kamal Hussien Rabaia, M.; Ali Abdelkareem, M.; Olabi, A.G. Recent progress on the utilization of waste heat for desalination: A review. Energy Convers. Manag. 2020, 221, 113105. [Google Scholar] [CrossRef]

- Yadav, A.; Labhasetwar, P.K.; Shahi, V.K. Membrane distillation using low-grade energy for desalination: A review. J. Environ. Chem. Eng. 2021, 9, 105818. [Google Scholar] [CrossRef]

- Ahmad, Z.S.; Shukla, A.K.; Singh, V.; Sharma, M.; Kumar, P. Thermodynamic analysis of solar powered trigeneration arrangement for cooling, power and drinking water generation. Songklanakarin J. Sci. Technol. 2022, 44, 1419–1426. [Google Scholar]

- Loni, R.; Najafi, G.; Bellos, E.; Rajaee, F.; Said, Z.; Mazlan, M. A review of industrial waste heat recovery system for power generation with Organic Rankine Cycle: Recent challenges and future outlook. J. Clean. Prod. 2021, 287, 125070. [Google Scholar] [CrossRef]

- Varma, G.V.P.; Srinivas, T. Power generation from low temperature heat recovery. Renew. Sustain. Energy Rev. 2017, 75, 402–414. [Google Scholar] [CrossRef]

- Kim, K.H.; Chul Ho, H.; Hyung Jong, K. Comparative Thermodynamic Analysis of Kalina and Kalina Flash Cycles for Utilizing Low-Grade Heat Sources. Energies 2018, 11, 3311. [Google Scholar] [CrossRef]

- Kim, K.H. Thermodynamic Performance and Optimization Analysis of a Modified Organic Flash Cycle for the Recovery of Low-Grade Heat. Energies 2019, 12, 442. [Google Scholar] [CrossRef]

- Ji, D.; Cai, H.; Ye, Z.; Luo, D.; Wu, G.; Romagnoli, A. Comparison between thermoelectric generator and organic Rankine cycle for low to medium temperature heat source: A Techno-economic analysis. Sustain. Energy Technol. Assess. 2023, 55, 102914. [Google Scholar] [CrossRef]

- Rana, S.; Orr, B.; Iqbal, A.; Ding, L.C.; Akbarzadeh, A.; Date, A. Modelling and Optimization of Low-temperature Waste Heat Thermoelectric Generator System. Energy Procedia 2017, 110, 196–201. [Google Scholar] [CrossRef]

- Rana, M.S. Analysis and Optimisation of Power Generation from Low-Grade Waste Heat Using Thermoelectric Generators. Ph.D. Thesis, RMIT University, Melbourne, Australia, 2019. [Google Scholar]

- Champier, D. Thermoelectric generators: A review of applications. Energy Convers. Manag. 2017, 140, 167–181. [Google Scholar] [CrossRef]

- Mamur, H.; Bhuiyan, M.R.A.; Korkmaz, F.; Nil, M. A review on bismuth telluride (Bi2Te3) nanostructure for thermoelectric applications. Renew. Sustain. Energy Rev. 2018, 82, 4159–4169. [Google Scholar] [CrossRef]

- Sharma, P.K.; Senguttuvan, T.D.; Sharma, V.K.; Chaudhary, S. Revisiting the thermoelectric properties of lead telluride. Mater. Today Energy 2021, 21, 100713. [Google Scholar] [CrossRef]

- Cook, B. Silicon–Germanium: The Legacy Lives On. Energies 2022, 15, 2957. [Google Scholar] [CrossRef]

- Rogl, G.; Grytsiv, A.; Rogl, P.; Bauer, E.; Hochenhofer, M.; Anbalagan, R.; Mallik, R.C.; Schafler, E. Nanostructuring of p- and n-type skutterudites reaching figures of merit of approximately 1.3 and 1.6, respectively. Acta Mater. 2014, 76, 434–448. [Google Scholar] [CrossRef]

- Zhao, L.-D.; Lo, S.-H.; Zhang, Y.; Sun, H.; Tan, G.; Uher, C.; Wolverton, C.; Dravid, V.P.; Kanatzidis, M.G. Ultralow thermal conductivity and high thermoelectric figure of merit in SnSe crystals. Nature 2014, 508, 373–377. [Google Scholar] [CrossRef]

- Inoue, R.; Nakano, J.; Nakamura, T.; Ube, T.; Iida, T.; Kogo, Y. Mechanical and thermoelectric properties of intragranular SiC- Nanoparticle/Mg2Si composites. J. Alloys Compd. 2019, 775, 657–666. [Google Scholar] [CrossRef]

- Shi, W.; Gao, M.; Wei, J.; Gao, J.; Fan, C.; Ashalley, E.; Li, H.; Wang, Z. Tin Selenide (SnSe): Growth, Properties, and Applications. Adv. Sci. 2018, 5, 1700602. [Google Scholar] [CrossRef]

- Zhao, H.; Wang, D.; Wang, B.; Song, A.; Chen, C.; Hu, W.; Yu, D.; Xu, B.; Tian, Y. Enhanced thermoelectric properties of Mg2Si0.3Sn0.7 via Bi-doping under high pressure. J. Alloys Compd. 2024, 987, 174215. [Google Scholar] [CrossRef]

- Cataldo, R.L.; Bennett, G.L. US space radioisotope power systems and applications: Past, present and future. In Radioisotopes-Applications in Physical Sciences; Intech Open: London, UK, 2011; pp. 473–496. [Google Scholar]

- Chen, L.; Lee, J. Effect of pulsed heat power on the thermal and electrical performances of a thermoelectric generator. Appl. Energy 2015, 150, 138–149. [Google Scholar] [CrossRef]

- Karana, D.R.; Sahoo, R.R. Performance assessment of the automotive heat exchanger with twisted tape for thermoelectric based waste heat recovery. J. Clean. Prod. 2021, 283, 124631. [Google Scholar] [CrossRef]

- Fernández-Yáñez, P.; Romero, V.; Armas, O.; Cerretti, G. Thermal management of thermoelectric generators for waste energy recovery. Appl. Therm. Eng. 2021, 196, 117291. [Google Scholar] [CrossRef]

- Casi, Á.; Araiz, M.; Catalán, L.; Astrain, D. Thermoelectric heat recovery in a real industry: From laboratory optimization to reality. Appl. Therm. Eng. 2021, 184, 116275. [Google Scholar] [CrossRef]

- Kumar, P.; Singh, O. Fuel Cell and Hydrogen-based Hybrid Energy Conversion Technologies. In Prospects of Hydrogen Fueled Power Generation; River Publishers: Aalborg, Denmark, 2024. [Google Scholar]

- Byon, Y.-S.; Jeong, J.-W. Phase change material-integrated thermoelectric energy harvesting block as an independent power source for sensors in buildings. Renew. Sustain. Energy Rev. 2020, 128, 109921. [Google Scholar] [CrossRef]

- Wang, W.; Cionca, V.; Wang, N.; Hayes, M.; O’Flynn, B.; O’Mathuna, C. Thermoelectric energy harvesting for building energy management wireless sensor networks. Int. J. Distrib. Sens. Netw. 2013, 9, 232438. [Google Scholar] [CrossRef]

- Dias, P.C.; Cadavid, D.; Ortega, S.; Ruiz, A.; França, M.B.M.; Morais, F.J.O.; Ferreira, E.C.; Cabot, A. Autonomous soil moisture sensor based on nanostructured thermosensitive resistors powered by an integrated thermoelectric generator. Sens. Actuators A Phys. 2016, 239, 1–7. [Google Scholar] [CrossRef]

- Paterova, T.; Prauzek, M.; Konecny, J.; Ozana, S.; Zmij, P.; Stankus, M.; Weise, D.; Pierer, A. Environment-Monitoring IoT Devices Powered by a TEG Which Converts Thermal Flux between Air and Near-Surface Soil into Electrical Energy. Sensors 2021, 21, 8098. [Google Scholar] [CrossRef] [PubMed]

- Ma, L.; Zhao, Q.; Zhang, H. Performance analysis of a new hybrid system composed of a concentrated photovoltaic cell and a two-stage thermoelectric generator. Sustain. Energy Grids Netw. 2021, 27, 100481. [Google Scholar] [CrossRef]

- Chen, Y.-W.; Wu, C.-C.; Hsu, C.-C.; Dai, C.-L. Fabrication and Testing of Thermoelectric CMOS-MEMS Microgenerators with CNCs Film. Appl. Sci. 2018, 8, 1047. [Google Scholar] [CrossRef]

- Elmoughni, H.M.; Menon, A.K.; Wolfe, R.M.W.; Yee, S.K. A Textile-Integrated Polymer Thermoelectric Generator for Body Heat Harvesting. Adv. Mater. Technol. 2019, 4, 1800708. [Google Scholar] [CrossRef]

- Dughaish, Z.H. Lead telluride as a thermoelectric material for thermoelectric power generation. Phys. B Condens. Matter 2002, 322, 205–223. [Google Scholar] [CrossRef]

- Drioli, E.; Ali, A.; Macedonio, F. Membrane distillation: Recent developments and perspectives. Desalination 2015, 356, 56–84. [Google Scholar] [CrossRef]

- Ve, Q.L. Effect of Configuration and Spacer Materials on Yield of Direct Contact Membrane Distillation. Ph.D. Thesis, RMIT University, Melbourne, Australia, 2021. [Google Scholar]

- Kalla, S.; Piash, K.S.; Sanyal, O. Anti-fouling and anti-wetting membranes for membrane distillation. J. Water Process Eng. 2022, 46, 102634. [Google Scholar] [CrossRef]

- Elmarghany, M.R.; El-Shazly, A.H.; Salem, M.S.; Sabry, M.N.; Nady, N. Thermal analysis evaluation of direct contact membrane distillation system. Case Stud. Therm. Eng. 2019, 13, 100377. [Google Scholar] [CrossRef]

- Alkhudhiri, A.; Darwish, N.; Hilal, N. Membrane distillation: A comprehensive review. Desalination 2012, 287, 2–18. [Google Scholar] [CrossRef]

- Duyen, P.M.; Jacob, P.; Rattanaoudom, R.; Visvanathan, C. Feasibility of sweeping gas membrane distillation on concentrating triethylene glycol from waste streams. Chem. Eng. Process. Process Intensif. 2016, 110, 225–234. [Google Scholar] [CrossRef]

- Criscuoli, A.; Carnevale, M.C.; Drioli, E. Evaluation of energy requirements in membrane distillation. Chem. Eng. Process. Process Intensif. 2008, 47, 1098–1105. [Google Scholar] [CrossRef]

- Dow, N.; Gray, S.; Li, J.-d.; Zhang, J.; Ostarcevic, E.; Liubinas, A.; Atherton, P.; Roeszler, G.; Gibbs, A.; Duke, M. Pilot trial of membrane distillation driven by low grade waste heat: Membrane fouling and energy assessment. Desalination 2016, 391, 30–42. [Google Scholar] [CrossRef]

- Choi, Y.-J.; Lee, S.; Koo, J.; Kim, S.-H. Evaluation of economic feasibility of reverse osmosis and membrane distillation hybrid system for desalination. Desalination Water Treat. 2016, 57, 24662–24673. [Google Scholar] [CrossRef]

- Nayar, K.G.; Sharqawy, M.H.; Banchik, L.D.; Lienhard, V.J.H. Thermophysical properties of seawater: A review and new correlations that include pressure dependence. Desalination 2016, 390, 1–24. [Google Scholar] [CrossRef]

- Phattaranawik, J.; Jiraratananon, R.; Fane, A.G. Effect of pore size distribution and air flux on mass transport in direct contact membrane distillation. J. Membr. Sci. 2003, 215, 75–85. [Google Scholar] [CrossRef]

- Anvari, A.; Azimi Yancheshme, A.; Kekre, K.M.; Ronen, A. State-of-the-art methods for overcoming temperature polarization in membrane distillation process: A review. J. Membr. Sci. 2020, 616, 118413. [Google Scholar] [CrossRef]

- Cheng, L.-H.; Wu, P.-C.; Chen, J. Numerical Simulation and Optimal Design of AGMD-Based Hollow Fiber Modules for Desalination. Ind. Eng. Chem. Res. 2009, 48, 4948–4959. [Google Scholar] [CrossRef]

- Hitsov, I.; De Sitter, K.; Dotremont, C.; Cauwenberg, P.; Nopens, I. Full-scale validated Air Gap Membrane Distillation (AGMD) model without calibration parameters. J. Membr. Sci. 2017, 533, 309–320. [Google Scholar] [CrossRef]

- Li, K.; Hou, D.; Fu, C.; Wang, K.; Wang, J. Fabrication of PVDF nanofibrous hydrophobic composite membranes reinforced with fabric substrates via electrospinning for membrane distillation desalination. J. Environ. Sci. 2019, 75, 277–288. [Google Scholar] [CrossRef] [PubMed]

- Essalhi, M.; Khayet, M. Self-sustained webs of polyvinylidene fluoride electrospun nanofibers at different electrospinning times: 1. Desalination by direct contact membrane distillation. J. Membr. Sci. 2013, 433, 167–179. [Google Scholar] [CrossRef]

- Drioli, E.; Ali, A.; Simone, S.; Macedonio, F.; Al-Jlil, S.A.; Al Shabonah, F.S.; Al-Romaih, H.S.; Al-Harbi, O.; Figoli, A.; Criscuoli, A. Novel PVDF hollow fiber membranes for vacuum and direct contact membrane distillation applications. Sep. Purif. Technol. 2013, 115, 27–38. [Google Scholar] [CrossRef]

- Hou, D.; Wang, J.; Sun, X.; Ji, Z.; Luan, Z. Preparation and properties of PVDF composite hollow fiber membranes for desalination through direct contact membrane distillation. J. Membr. Sci. 2012, 405-406, 185–200. [Google Scholar] [CrossRef]

- Duong, H.C.; Chivas, A.R.; Nelemans, B.; Duke, M.; Gray, S.; Cath, T.Y.; Nghiem, L.D. Treatment of RO brine from CSG produced water by spiral-wound air gap membrane distillation—A pilot study. Desalination 2015, 366, 121–129. [Google Scholar] [CrossRef]

- Duong, H.C.; Cooper, P.; Nelemans, B.; Cath, T.Y.; Nghiem, L.D. Evaluating energy consumption of air gap membrane distillation for seawater desalination at pilot scale level. Sep. Purif. Technol. 2016, 166, 55–62. [Google Scholar] [CrossRef]

- Chen, X.; Gao, X.; Fu, K.; Qiu, M.; Xiong, F.; Ding, D.; Cui, Z.; Wang, Z.; Fan, Y.; Drioli, E. Tubular hydrophobic ceramic membrane with asymmetric structure for water desalination via vacuum membrane distillation process. Desalination 2018, 443, 212–220. [Google Scholar] [CrossRef]

- Pagliero, M.; Bottino, A.; Comite, A.; Costa, C. Silanization of tubular ceramic membranes for application in membrane distillation. J. Membr. Sci. 2020, 601, 117911. [Google Scholar] [CrossRef]

- Essalhi, M.; Khayet, M. Self-sustained webs of polyvinylidene fluoride electrospun nano-fibers: Effects of polymer concentration and desalination by direct contact membrane distillation. J. Membr. Sci. 2014, 454, 133–143. [Google Scholar] [CrossRef]

- Tian, M.; Yuan, S.; Decaesstecker, F.; Zhu, J.; Volodine, A.; Van der Bruggen, B. One-step fabrication of isotropic poly(vinylidene fluoride) membranes for direct contact membrane distillation (DCMD). Desalination 2020, 477, 114265. [Google Scholar] [CrossRef]

- Li, Y.; Jin, C.; Peng, Y.; An, Q.; Chen, Z.; Zhang, J.; Ge, L.; Wang, S. Fabrication of PVDF hollow fiber membranes via integrated phase separation for membrane distillation. J. Taiwan Inst. Chem. Eng. 2019, 95, 487–494. [Google Scholar] [CrossRef]

- Zou, L.; Zhang, X.; Gusnawan, P.; Zhang, G.; Yu, J. Crosslinked PVDF based hydrophilic-hydrophobic dual-layer hollow fiber membranes for direct contact membrane distillation desalination: From the seawater to oilfield produced water. J. Membr. Sci. 2021, 619, 118802. [Google Scholar] [CrossRef]

- Zhu, J.; Jiang, L.; Matsuura, T. New insights into fabrication of hydrophobic/hydrophilic composite hollow fibers for direct contact membrane distillation. Chem. Eng. Sci. 2015, 137, 79–90. [Google Scholar] [CrossRef]

- Feng, X.; Jiang, L.Y.; Matsuura, T.; Wu, P. Fabrication of hydrophobic/hydrophilic composite hollow fibers for DCMD: Influence of dope formulation and external coagulant. Desalination 2017, 401, 53–63. [Google Scholar] [CrossRef]

- Hagedorn, A.; Fieg, G.; Winter, D.; Koschikowski, J.; Mann, T. Methodical design and operation of membrane distillation plants for desalination. Chem. Eng. Res. Des. 2017, 125, 265–281. [Google Scholar] [CrossRef]

- Eykens, L.; Hitsov, I.; De Sitter, K.; Dotremont, C.; Pinoy, L.; Van der Bruggen, B. Direct contact and air gap membrane distillation: Differences and similarities between lab and pilot scale. Desalination 2017, 422, 91–100. [Google Scholar] [CrossRef]

- Larbot, A.; Gazagnes, L.; Krajewski, S.; Bukowska, M.; Kujawski, W. Water desalination using ceramic membrane distillation. Desalination 2004, 168, 367–372. [Google Scholar] [CrossRef]

- Kujawa, J.; Cerneaux, S.; Kujawski, W.; Knozowska, K. Hydrophobic Ceramic Membranes for Water Desalination. Appl. Sci. 2017, 7, 402. [Google Scholar] [CrossRef]

- Kujawa, J.; Cerneaux, S.; Koter, S.; Kujawski, W. Highly Efficient Hydrophobic Titania Ceramic Membranes for Water Desalination. ACS Appl. Mater. Interfaces 2014, 6, 14223–14230. [Google Scholar] [CrossRef] [PubMed]

- Shoeibi, S.; Saemian, M.; Parsa, S.M.; Khiadani, M.; Mirjalily, S.A.A.; Kargarsharifabad, H. A novel solar desalination system equipped with thermoelectric generator, reflectors and low-cost sensible energy-storage for co-production of power and drinking water. Desalination 2023, 567, 116955. [Google Scholar] [CrossRef]

- Date, A.; Gauci, L.; Chan, R.; Date, A. Performance review of a novel combined thermoelectric power generation and water desalination system. Renew. Energy 2015, 83, 256–269. [Google Scholar] [CrossRef]

- Demir, M.E.; Dincer, I. Development of an integrated hybrid solar thermal power system with thermoelectric generator for desalination and power production. Desalination 2017, 404, 59–71. [Google Scholar] [CrossRef]

- Alzahmi, A.; Alswat, M.; El-Askary, W.A.; Ramzy, K. Harvesting waste-heat energy of shell and tube heat exchanger used for desalination purposes using thermoelectric power generation modules: Numerical studies. Int. Commun. Heat Mass Transf. 2024, 156, 107569. [Google Scholar] [CrossRef]

- Myneni, N.; Date, A.; Ward, M.; Gokhale, P.; Gay, M. Combined Thermoelectric Power Generation and Passive Vacuum Desalination. Energy Procedia 2017, 110, 262–267. [Google Scholar] [CrossRef]

- Khanmohammadi, S.; Chaghakaboodi, H.A.; Musharavati, F. A new design of solar tower system amplified with a thermoelectric unit to produce distilled water and power. Appl. Therm. Eng. 2021, 197, 117406. [Google Scholar] [CrossRef]

- Assareh, E.; Alirahmi, S.M.; Ahmadi, P. A Sustainable model for the integration of solar and geothermal energy boosted with thermoelectric generators (TEGs) for electricity, cooling and desalination purpose. Geothermics 2021, 92, 102042. [Google Scholar] [CrossRef]

- Hashemian, N.; Noorpoor, A. Optimization and multi-aspect evaluation of a solar/biomass-powered multi-generation plant with an integrated thermoelectric generator unit. Sustain. Energy Technol. Assess. 2023, 56, 102998. [Google Scholar] [CrossRef]

- Cao, Y.; Dhahad, H.A.; Togun, H.; Hussen, H.M.; Anqi, A.E.; Farouk, N.; Issakhov, A.; Parikhani, T. Effect of working fluids in a novel geothermal-based integration of organic-flash and power/cooling generation cycles with hydrogen and freshwater production units. Int. J. Hydrogen Energy 2021, 46, 28370–28386. [Google Scholar] [CrossRef]

- Bouzayani, N.; Galanis, N.; Orfi, J. Thermodynamic analysis of combined electric power generation and water desalination plants. Appl. Therm. Eng. 2009, 29, 624–633. [Google Scholar] [CrossRef]

- Chitgar, N.; Moghimi, M. Design and evaluation of a novel multi-generation system based on SOFC-GT for electricity, fresh water and hydrogen production. Energy 2020, 197, 117162. [Google Scholar] [CrossRef]

- Safari, F.; Dincer, I. Development and analysis of a novel biomass-based integrated system for multigeneration with hydrogen production. Int. J. Hydrogen Energy 2019, 44, 3511–3526. [Google Scholar] [CrossRef]

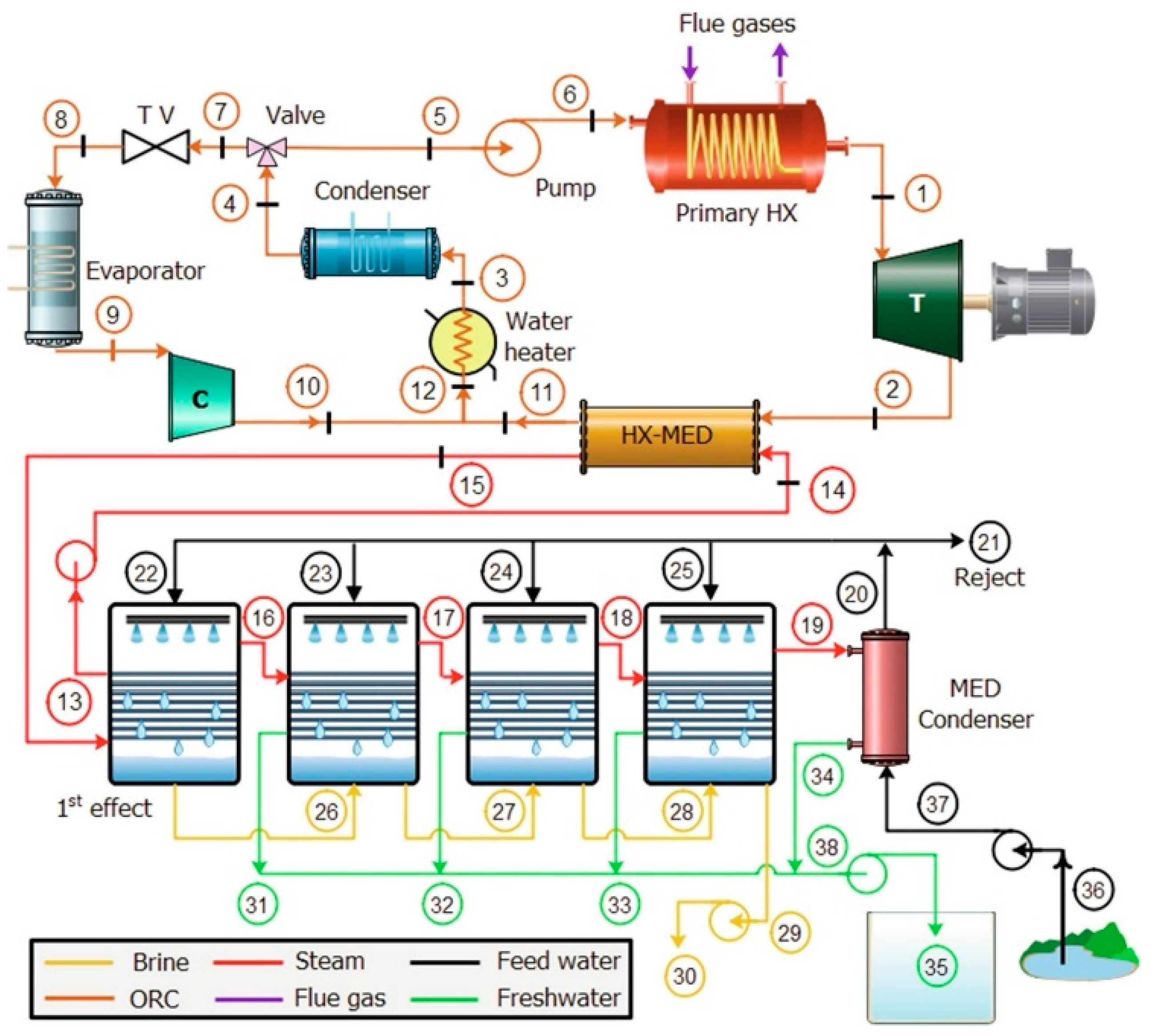

- Mohammed, R.H.; Ibrahim, M.M.; Abu-Heiba, A. Exergoeconomic and multi-objective optimization analyses of an organic Rankine cycle integrated with multi-effect desalination for electricity, cooling, heating power, and freshwater production. Energy Convers. Manag. 2021, 231, 113826. [Google Scholar] [CrossRef]

- Demir, M.E.; Çıtakoğlu, F. Design and modeling of a multigeneration system driven by waste heat of a marine diesel engine. Int. J. Hydrogen Energy 2022, 47, 40513–40530. [Google Scholar] [CrossRef]

- Hamrang, F.; Shokri, A.; Mahmoudi, S.M.S.; Ehghaghi, B.; Rosen, M.A. Performance Analysis of a New Electricity and Freshwater Production System Based on an Integrated Gasification Combined Cycle and Multi-Effect Desalination. Sustainability 2020, 12, 7996. [Google Scholar] [CrossRef]

- Zhu, C.; Wang, M.; Guo, M.; Deng, J.; Du, Q.; Wei, W.; Zhang, Y.; Ashraf Talesh, S.S. Optimizing solar-driven multi-generation systems: A cascade heat recovery approach for power, cooling, and freshwater production. Appl. Therm. Eng. 2024, 240, 122214. [Google Scholar] [CrossRef]

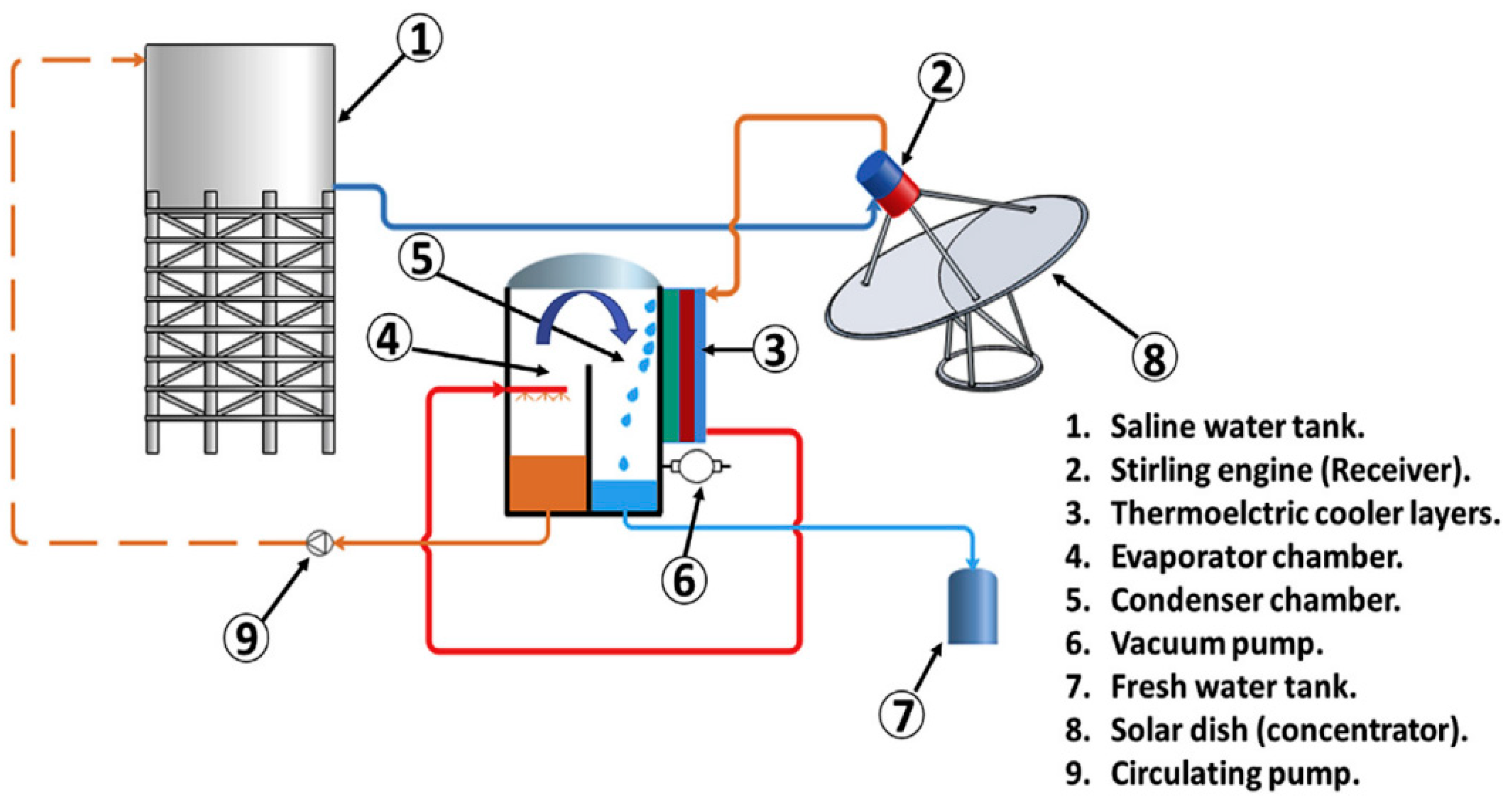

- Al-Nimr, M.d.A.; Al-Ammari, W.A. A novel hybrid and interactive solar system consists of Stirling engine/vacuum evaporator/thermoelectric cooler for electricity generation and water distillation. Renew. Energy 2020, 153, 1053–1066. [Google Scholar] [CrossRef]

- Yari, M.; Mazareh, A.E.; Mehr, A.S. A novel cogeneration system for sustainable water and power production by integration of a solar still and PV module. Desalination 2016, 398, 1–11. [Google Scholar] [CrossRef]

- Zheng, S.; Abed, A.M.; Chaturvedi, R.; Nutakki, T.U.K.; Abdullaev, S.; Hu, J.; Fouad, Y.; Mahariq, I. Energetic/economic/scalability assessment of active solar energy and waste heat utilization in urban environments for H2/freshwater production: A CSP-centered multigeneration system with dual-loop power generation. Process Saf. Environ. Prot. 2024, 190, 495–511. [Google Scholar] [CrossRef]

- Demir, M.E.; Dincer, I. Development and analysis of a new integrated solar energy system with thermal storage for fresh water and power production. Int. J. Energy Res. 2018, 42, 2864–2874. [Google Scholar] [CrossRef]

- Demir, M.E.; Dincer, I. Development and assessment of a solar driven trigeneration system with storage for electricity, ammonia and fresh water production. Energy Convers. Manag. 2021, 245, 114585. [Google Scholar] [CrossRef]

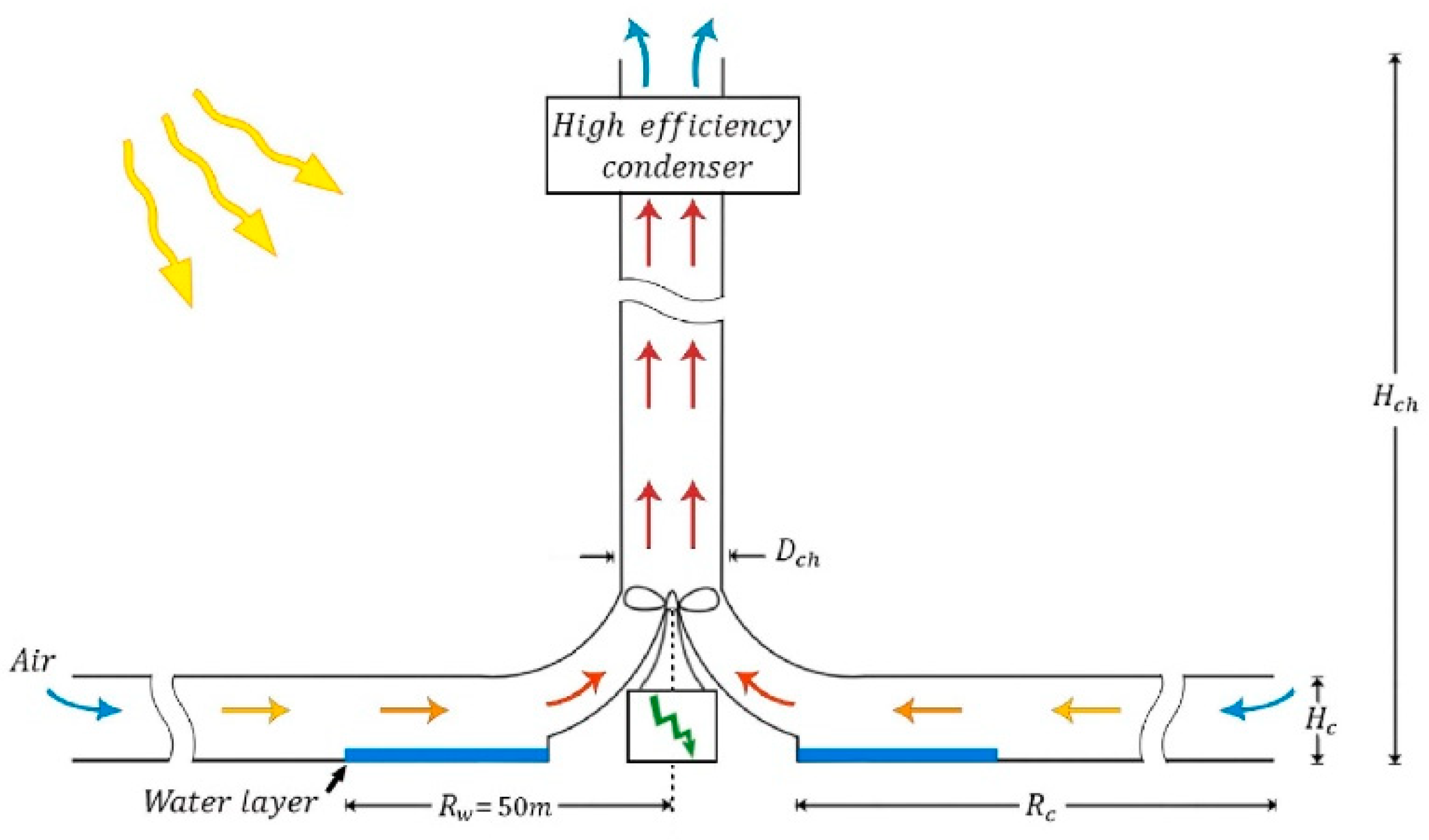

- Azad, A.; Aghaei, E.; Jalali, A.; Ahmadi, P. Multi-objective optimization of a solar chimney for power generation and water desalination using neural network. Energy Convers. Manag. 2021, 238, 114152. [Google Scholar] [CrossRef]

- Zuo, L.; Ding, L.; Chen, J.; Zhou, X.; Xu, B.; Liu, Z. Comprehensive study of wind supercharged solar chimney power plant combined with seawater desalination. Sol. Energy 2018, 166, 59–70. [Google Scholar] [CrossRef]

- Zuo, L.; Liu, Z.; Ding, L.; Qu, N.; Dai, P.; Xu, B.; Yuan, Y. Performance analysis of a wind supercharging solar chimney power plant combined with thermal plant for power and freshwater generation. Energy Convers. Manag. 2020, 204, 112282. [Google Scholar] [CrossRef]

- Chitsaz, A.; Khalilarya, S.; Mojaver, P. Supercritical CO2 utilization in a CO2 zero emission novel system for bio-synthetic natural gas, power and freshwater productions. J. CO2 Util. 2022, 59, 101947. [Google Scholar] [CrossRef]

- Li, Y.; Jiao, S.; Dai, Y.; Wang, J.; Li, J.; Kang, N.; Irfan, M.; Liu, X. Spontaneous and sustainable multifunctional transpiration generator for simultaneous harvesting of electricity, freshwater and salt. Appl. Energy 2023, 341, 121110. [Google Scholar] [CrossRef]

- Cao, Y.; Dhahad, H.A.; Parikhani, T.; Anqi, A.E.; Mohamed, A.M. Thermo-economic evaluation of a combined Kalina cycle and humidification-dehumidification (HDH) desalination system integrated with thermoelectric generator and solar pond. Int. J. Heat Mass Transf. 2021, 168, 120844. [Google Scholar] [CrossRef]

- Rostamzadeh, H.; Namin, A.S.; Nourani, P.; Amidpour, M.; Ghaebi, H. Feasibility investigation of a humidification-dehumidification (HDH) desalination system with thermoelectric generator operated by a salinity-gradient solar pond. Desalination 2019, 462, 1–18. [Google Scholar] [CrossRef]

- Ebadollahi, M.; Shahbazi, B.; Ghaebi, H. Efficiency and flexibility enhancement of nanofluid-based hybrid solar desalination system equipped with thermoelectric generator for eco-friendly freshwater and power cogeneration. Process Saf. Environ. Prot. 2024, 190, 108–122. [Google Scholar] [CrossRef]

- Abouzied, A.S.; Guo, X.; Abed, A.M.; Alghassab, M.A.; Alhomayani, F.M.; Khan, B.; Elmasry, Y.; Almadhor, A.; Alkhalaf, S.; Alrawashdeh, A.I. Unique thermal architecture integrating heliostat solar fields with a dual-loop power generation cycle employing thermoelectric; thermal/financial study and GA optimization. Case Stud. Therm. Eng. 2025, 65, 105563. [Google Scholar] [CrossRef]

- Shafii, M.B.; Shahmohamadi, M.; Faegh, M.; Sadrhosseini, H. Examination of a novel solar still equipped with evacuated tube collectors and thermoelectric modules. Desalination 2016, 382, 21–27. [Google Scholar] [CrossRef]

- Bian, T.; Li, C.; Cheng, L.; Chen, Y.; Yan, S.; Dukashin, D.; Wang, L.; Shen, J.; Senin, P. Gradient hydrophobic evaporator based on ODT modified Co3O4/NF enables efficient desalination and thermoelectric power generation. Sep. Purif. Technol. 2025, 358, 130344. [Google Scholar] [CrossRef]

- Mehrenjani, J.R.; Shirzad, A.; Adouli, A.; Gharehghani, A. Data-driven optimization of two novel geothermal-powered systems integrating LNG regasification with thermoelectric generation for eco-friendly seawater desalination and data center cooling. Energy 2024, 313, 133846. [Google Scholar] [CrossRef]

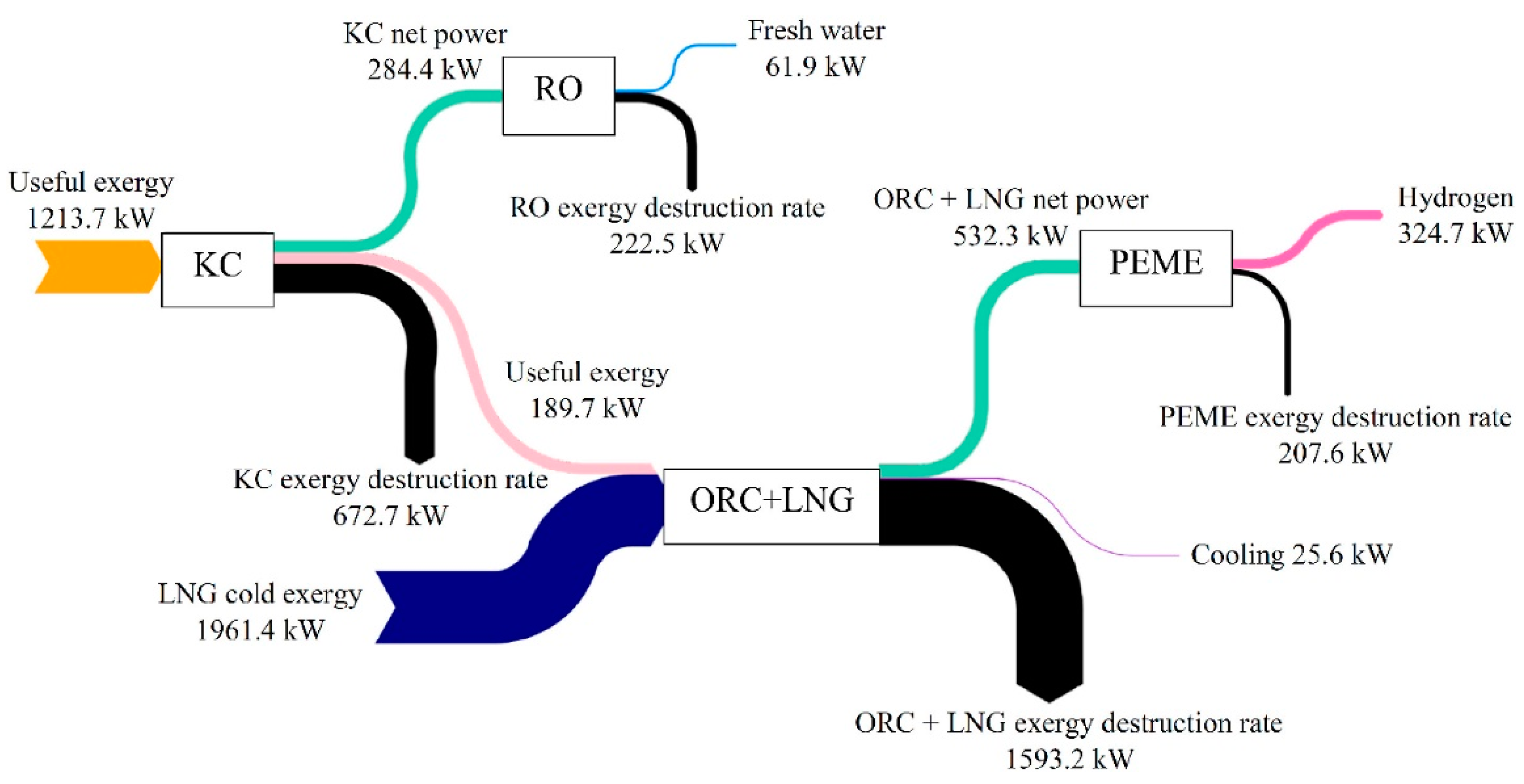

- Musharavati, F.; Khanmohammadi, S.; Pakseresht, A. Proposed a new geothermal based poly-generation energy system including Kalina cycle, reverse osmosis desalination, elecrolyzer amplified with thermoelectric: 3E analysis and optimization. Appl. Therm. Eng. 2021, 187, 116596. [Google Scholar] [CrossRef]

- Hu, J.; Huang, J.; Chen, Y.; Xu, L.; Wu, B.; Yue, H.; Ji, H.; Li, H.; Jin, J. Achieving efficient water-electricity ensemble via using easily obtainable hydrovoltaic-thermoelectric hybrid generators. Desalination 2025, 596, 118330. [Google Scholar] [CrossRef]

- Shoeibi, S.; Saemian, M.; Khiadani, M.; Kargarsharifabad, H.; Ali Agha Mirjalily, S. Influence of PV/T waste heat on water productivity and electricity generation of solar stills using heat pipes and thermoelectric generator: An experimental study and environmental analysis. Energy Convers. Manag. 2023, 276, 116504. [Google Scholar] [CrossRef]

- Jin, B.; Lu, Y.; Zhang, X.; Zhang, X.; Li, D.; Liu, Q.; Deng, B.; Li, H. Iceberg-inspired solar water generator for enhanced thermoelectricity–freshwater synergistic production. Chem. Eng. J. 2023, 469, 143906. [Google Scholar] [CrossRef]

- Sun, J.; Xin, Y.; Sun, B.; Yang, Q.; Fan, X. Plasma-assisted synthesis of Janus multifunctional solar evaporator for ultra-long-duration freshwater and thermoelectric co-generation. Chem. Eng. J. 2024, 497, 154621. [Google Scholar] [CrossRef]

- Zeng, L.; Deng, D.; Zhu, L.; Zhang, Z.; Gu, X.; Wang, H.; Jiang, Y. Multi-scale CuS-rGO pyramidal photothermal structure for highly efficient solar-driven water evaporation and thermoelectric power generation. Nano Energy 2024, 125, 109531. [Google Scholar] [CrossRef]

- Asadabadi, M.J.R.; Moghimi, M. Direct waste heat recovery from a solid oxide fuel cell through Kalina cycle, two-bed adsorption chiller, thermoelectric generator, reverse osmosis, and PEM electrolyzer: 4E analysis and ANN-assisted optimization. Appl. Therm. Eng. 2024, 236, 121307. [Google Scholar] [CrossRef]

- Li, S.G.; Leng, Y.C.; Nutakki, T.U.K.; Abdullaev, S.; Fouad, Y.; Alhadrawi, M. Intelligent optimization of eco-friendly H2/freshwater production and CO2 reduction layout integrating GT/rankine cycle/absorption chiller/TEG unit/PEM electrolyzer/RO section. Process Saf. Environ. 2024, 189, 204–218. [Google Scholar] [CrossRef]

- Kumar, P.; Singh, O. Investigations on Integrating SOFC with Gas Turbine for Performance Enhancement and Sustainable Energy. J. Energy Environ. Sustain. 2019, 7, 42–46. [Google Scholar] [CrossRef]

| Year Range 2013–2024 | |||

|---|---|---|---|

| Queries/Keywords | Science Direct Total Articles (Review Articles) | Scopus Total Articles (Review Articles) | Google Scholar Total Articles (Review Articles) |

| Desalination | 15,326 (1252) | 33,861 (2552) | 338,000 (37,800) |

| Thermoelectric generator | 2935 (159) | 9908 (418) | 24,000 (8920) |

| Combined power generation and Desalination | 278 (17) | 445 (27) | 30,200 (17,000) |

| Thermoelectric AND Desalination | 160 (19) | 366 (32) | 15,800 (2690) |

| Thermoelectric generator AND Desalination | 89 (5) | 127 (8) | 8320 (1450) |

| Combined thermoelectric power generation AND desalination | 23 (1) | 39 (3) | 13,000 (2180) |

| Material | Operating Temperature Range (°C) | Figure of Merit (ZT) | Characteristics and Applications | References |

|---|---|---|---|---|

| Bismuth Telluride (Bi2Te3) | 0–150 | ~1 at 300 K | High thermoelectric performance at room temperature, but limited thermal stability at higher temperatures. Effective for low-temperature applications. Cooling devices, low-temperature power generation. | [27] |

| Lead Telluride (PbTe) | 300–600 | ~0.8–2.5 at 600 K | Suitable for mid-temperature applications with good thermoelectric performance. Environmental concerns are due to lead toxicity. Waste heat recovery, mid-temperature power generation. | [28] |

| Silicon–Germanium (SiGe) | 500–1000 | ~0.5–0.7 at 900 K | Excellent thermal stability for high-temperature applications but lower efficiency compared to other materials. Cost remains a limiting factor. High-temperature power generation, space applications. | [29] |

| Skutterudites | 300–700 | ~1.0–1.5 at 700 K | High electrical conductivity with complex synthesis. Promising for automotive waste heat recovery, but challenging scalability. Waste heat recovery, automotive applications. | [30] |

| Tin Selenide (SnSe) | 300–800 | 0.8 to 2.6 at 923 K | Outstanding thermoelectric performance with high ZT value, but anisotropic properties and challenging large-scale production. Power generation, waste heat recovery. | [31,33] |

| Magnesium Silicide (Mg2Si) | 300–600 | ~0.6–1.45 at 600 K | Abundant, cost-effective, and environmentally friendly. Efficiency improvements are required for competitive performance. Automotive waste heat recovery, power generation. | [32,34] |

| DCMD Direct Contact Membrane Distillation | AGMD Air Gap Membrane Distillation | VMD Vacuum Membrane Distillation | SGMD Sweeping Gas Membrane Distillation | |

|---|---|---|---|---|

| Unique feature | Feed and permeate in direct contact with the membrane | Air gap between membrane and condensation surface | Vacuum applied to the permeate side for vapor removal | Gas sweeps vapor from membrane surface |

| Advantage | Simplest configuration, high flux | Less conductive heat loss, volatile compounds elimination | Conductive heat loss is negligible | No membrane wetting |

| Disadvantage | Highest heat loss | Lower permeate flux | Membrane wetting | Cost of sweep gas |

| STEC | 1500 to 4580 kWh/m3 | ~1110 kWh/m3 | 160 to 3550 kWh/m3 | 1090 to 1450 kWh/m3 |

| Membrane Modules | Material | Membrane Physical Properties | Operating Conditions and Performance | Reference(s) |

|---|---|---|---|---|

| Flat Sheet | PVDF | Pore size: 0.2–0.45 µm Contact angle: 100–162° Thickness: 35–330 µm | DCMD, feed: 1–2 wt% NaCl, Tf: 60 °C, Tp: 21.1 °C, Qf: 4 cm3/s; flux: 7.5–32.8 L/m2h; rejection: 99.5–100%; LEP: 150–280 kPa | [63,64,71,72] |

| Hollow Fiber | PP/PVDF | Pore size: 0.3–0.35 µm Contact angle: 90–100° Thickness: 130–150 µm | DCMD, feed: 3.5 wt% NaCl, Tf: 80 °C, vf: 0.5 m/s; flux: 35–40 L/m2h; rejection: 99.9–99.99%; LEP: 300–320 kPa | [65,66,73,74,75,76] |

| Spiral Wound | PTFE/PP/PE | Pore size: 0.1–0.2 µm Contact angle: 105–115° Thickness: 120–130 µm | DCMD/AGMD, feed: city water, Tf: 70 °C, A: 14 m2; flux: 2.0–2.5 L/m2h; rejection: 99–99.9%; LEP: 150–250 kPa | [67,68,77,78] |

| Tubular | Alumina | Pore size: 0.2–0.8 µm Contact angle: 140–150° Thickness: 1500–2000 | VMD, feed: 3 wt% NaCl, Tf: 70 °C, P: 5 kPa; flux: 28–60 L/m2h; rejection: 99.8–99.9%; LEP: 550–570 kPa | [69,70,79,80,81] |

| Technology (Study Type) | Energy Source/Temperature | Power Generation Capacity | Feed Source/Salinity | Desalination System Performance | Freshwater Generation Capacity | Reference |

|---|---|---|---|---|---|---|

| Kalina cycle + HDH-D + TEG | Solar pond 25–96 °C | 8.75 kW | 35,000 ppm | GOR 0.5 to 1.8 | 0.152 to 0.586 m3/h | [108] |

| HDH-D + TEG | Solar pond 25–96 °C | 3.5 kW | Seawater 35,000 ppm | GOR 1.56 | 4.5 m3/day | [109] |

| HDH-D + TEG | Solar parabolic collectors (nanofluid) 120–140 °C | 1.785 kW | 35,000 ppm | Combined GOR 1.2 to 1.6 | 0.36 m3/h | [110] |

| Brayton cycle + Rankine cycle + ORC + RO + TEG | Heliostat solar collector 80–800 °C | 3.59 to 9.48 MW | 35,000 ppm | 3 to 6 kWhe/m3 | 450 m3/h to 1166 m3/h | [111] |

| Stirling engine + TEC + single-stage flash desal | Dish solar collector 500 °C | 506 W | 3.5% (35,000 ppm) | N/A | 28 kg/day | [98] |

| Solar still + TEG | Evacuated tube solar collectors 80–120 °C | 1.4 W per TEG cell | N/A | N/A | 0.97 kg/m2/h | [112] |

| Co3O4/NF hydrophobic membrane + TEG | Direct sunlight | 0.74 W/m−2 | 3.5 wt% NaCl solution | N/A | 1.76 kg/m2/h | [113] |

| ORC + ARCs + RO + LNG + TEG | Geothermal 160 K | ORCs 4.324 to 6.135 MW LNG 0.457 to 0.578 MW | Seawater 35,000 ppm | N/A | 32,488 m3/day | [114] |

| Kalina cycle + RO + PEM + TEG | Geothermal water 230 °C | 50 kW at 30 bar of geo-fluid pressure | 45,000 ppm | N/A | ~70 m3/h at 30 bar of geo-fluid pressure | [115] |

| CB/PVDF@BFP + TEG | Direct sunlight | ~1600.43 mW/m2 under 1 sun | 0.8–20 wt% | N/A | ~1.41 kg/m2/h | [116] |

| Solar still + heat pipe + TEG | Photovoltaic panel 57.6 °C | 75 W at 1 pm | N/A | N/A | 1162 mL/m2 | [117] |

| TEG coated by photothermal agent + bilayer nonwoven fabric + passive cooling vapor condenser | Direct sunlight | 0.47 W | ~102 to 104 mg/L | N/A | 1.02 kg/m2/h | [118] |

| DBD plasma treatment + TEG | Direct sunlight | 1.65 W/m2 | 3.5 wt% NaCl | N/A | Up to 1.82 kg/m2/h | [119] |

| Photothermal material + TEG | Direct sunlight | 5.55 W/m2 | ~103 to 104 mg/L | N/A | 12.1 kg/m2 | [120] |

| Technology (Study Type) | Power Generation Capacity | Water Production Capacity | Water Production Cost | Electrical Production Cost | Reference |

|---|---|---|---|---|---|

| SS-TEG-WI-M configuration | 2.5 W | 796 mL/m2/day | USD 0.071/kg (i.e., USD 71/m3) | - | [82] |

| Solar + geothermal + TEGs | 9146.7 kW | 240.226 m3/day | - | USD 0.037/kWh | [88] |

| Solar/biomass + multi-generation plant + TEG | 33.03 MW | 16.09 m3/h | - | USD 0.065/kWh | [89] |

| SOFC-GT | 4.9 MW | 85.2 m3/h | USD 0.223/m3 | USD 0.029/kWh | [92] |

| ORC + MED | 10 MW | 38.51 m3/h | USD 0.4225/m3 | USD 0.008087/kWh | [94] |

| Gasification combined cycle + MED | 8.347 MW | 11.7 kg/s | - | USD 0.051/kWh | [96] |

| Solar still + TEG | 1.4 W per TEG cell | 0.97 kg/m2/h | USD 0.0106/kg (i.e., USD 10.6/m3) | - | [112] |

| ORC + ARCs + RO + LNG + TEG | ORCs 4.324 to 6.135 MW LNG 0.457 to 0.578 MW | 32,488 m3/day | USD 0.2205–0.3/m3 | USD 0.0424–0.0521/kWh | [114] |

| Solar still + heat pipe + TEG | 75 W at 1 pm | 1162 mL/m2/day | 0.042 USD/kg (i.e., USD 42/m3) | USD 0.061/kWh | [117] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Traisak, O.; Kumar, P.; Vahaji, S.; Zhang, Y.; Date, A. Advancements in Integrated Thermoelectric Power Generation and Water Desalination Technologies: A Comprehensive Review. Energies 2025, 18, 1454. https://doi.org/10.3390/en18061454

Traisak O, Kumar P, Vahaji S, Zhang Y, Date A. Advancements in Integrated Thermoelectric Power Generation and Water Desalination Technologies: A Comprehensive Review. Energies. 2025; 18(6):1454. https://doi.org/10.3390/en18061454

Chicago/Turabian StyleTraisak, Oranit, Pranjal Kumar, Sara Vahaji, Yihe Zhang, and Abhijit Date. 2025. "Advancements in Integrated Thermoelectric Power Generation and Water Desalination Technologies: A Comprehensive Review" Energies 18, no. 6: 1454. https://doi.org/10.3390/en18061454

APA StyleTraisak, O., Kumar, P., Vahaji, S., Zhang, Y., & Date, A. (2025). Advancements in Integrated Thermoelectric Power Generation and Water Desalination Technologies: A Comprehensive Review. Energies, 18(6), 1454. https://doi.org/10.3390/en18061454