Analysis and Research on the Flow Characteristics of Ice-Containing Filling Slurry Based on the Population Balance Model

Abstract

1. Introduction

2. Theoretical Model

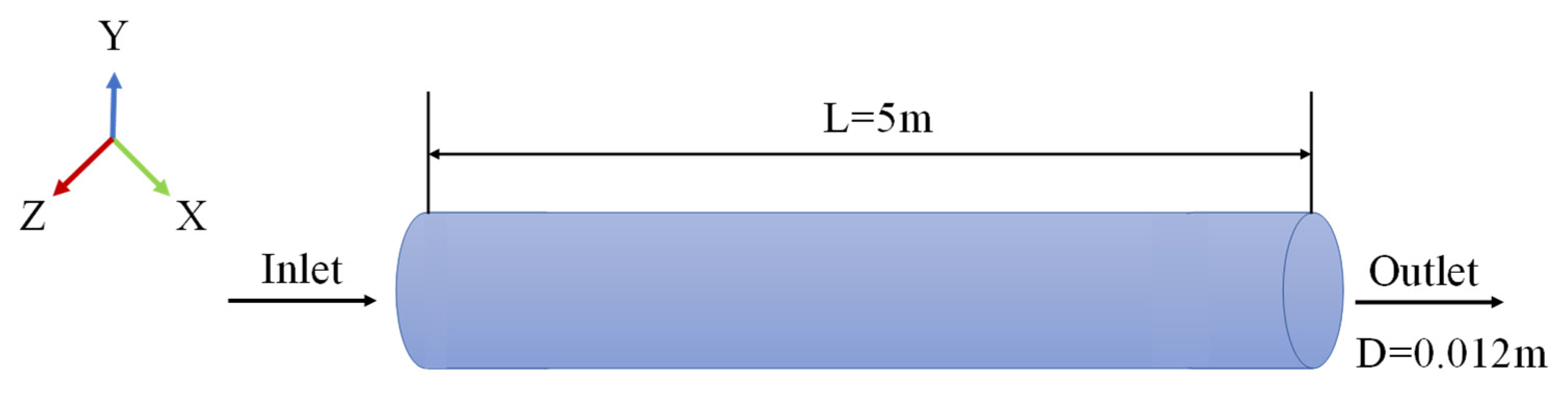

2.1. Geometric Model

2.2. Governing Equations

- (1)

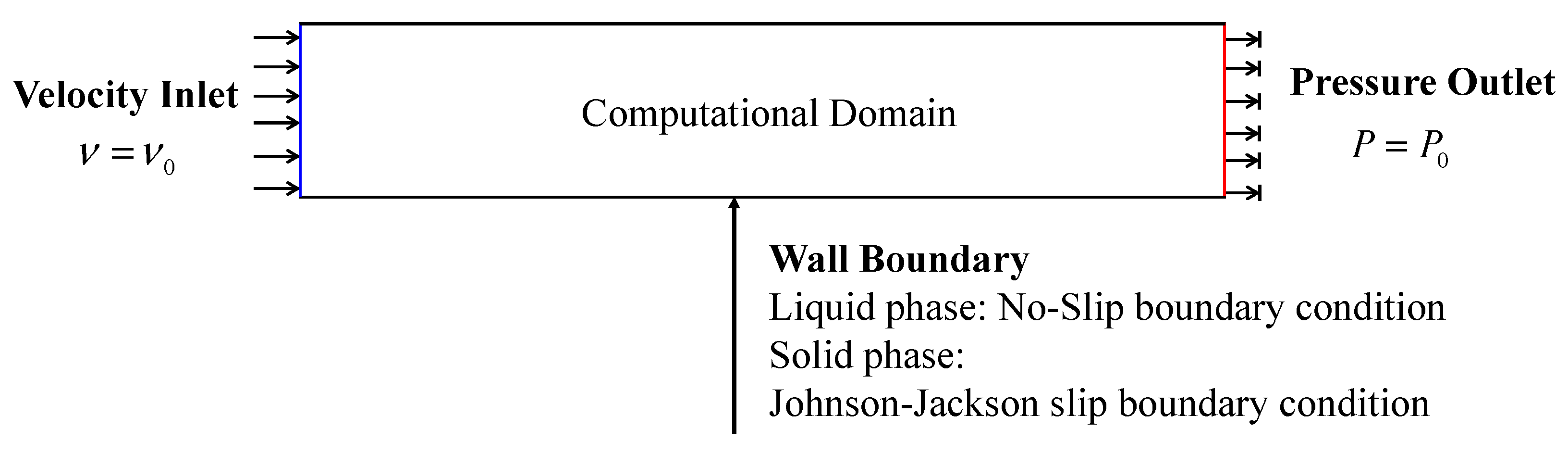

- When the ice particle-containing slurry flows in a circular tube, it is assumed that the inlet velocity remains constant;

- (2)

- It is assumed that the flow of fillers containing ice particles in the pipeline is in a heterogeneous isothermal flow state.

2.2.1. Multiphase Flow Model

2.2.2. Turbulence Model

2.2.3. Particle Dynamics Model

2.2.4. PBM Model

2.2.5. Agglomeration and Fragmentation Model

2.3. Boundary Condition

2.4. The Coupling Mechanism of CFD and PBM Models

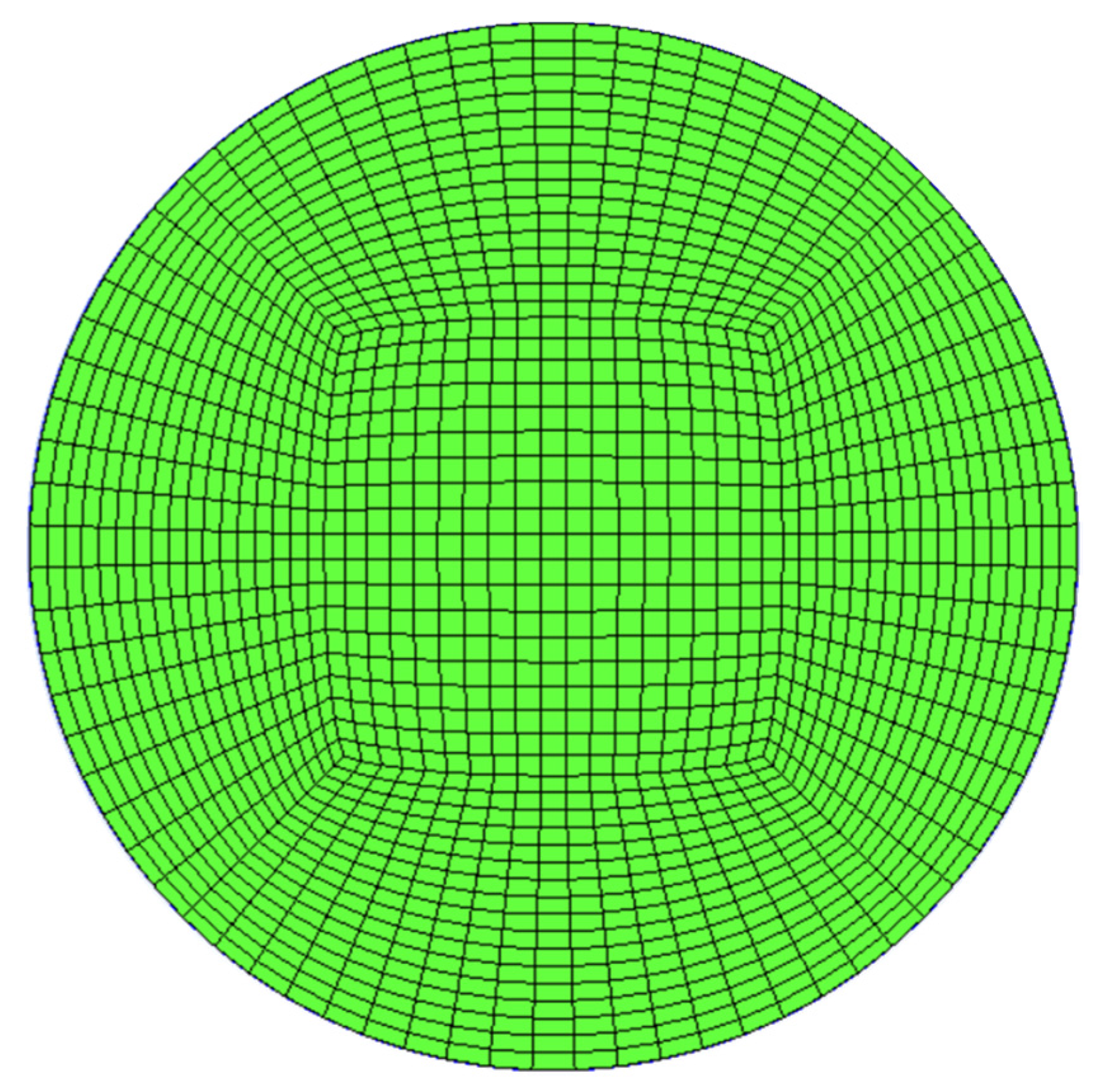

2.5. Computational Grid and Independence Verification

3. Verification and Analysis of the Model

4. Results and Discussion

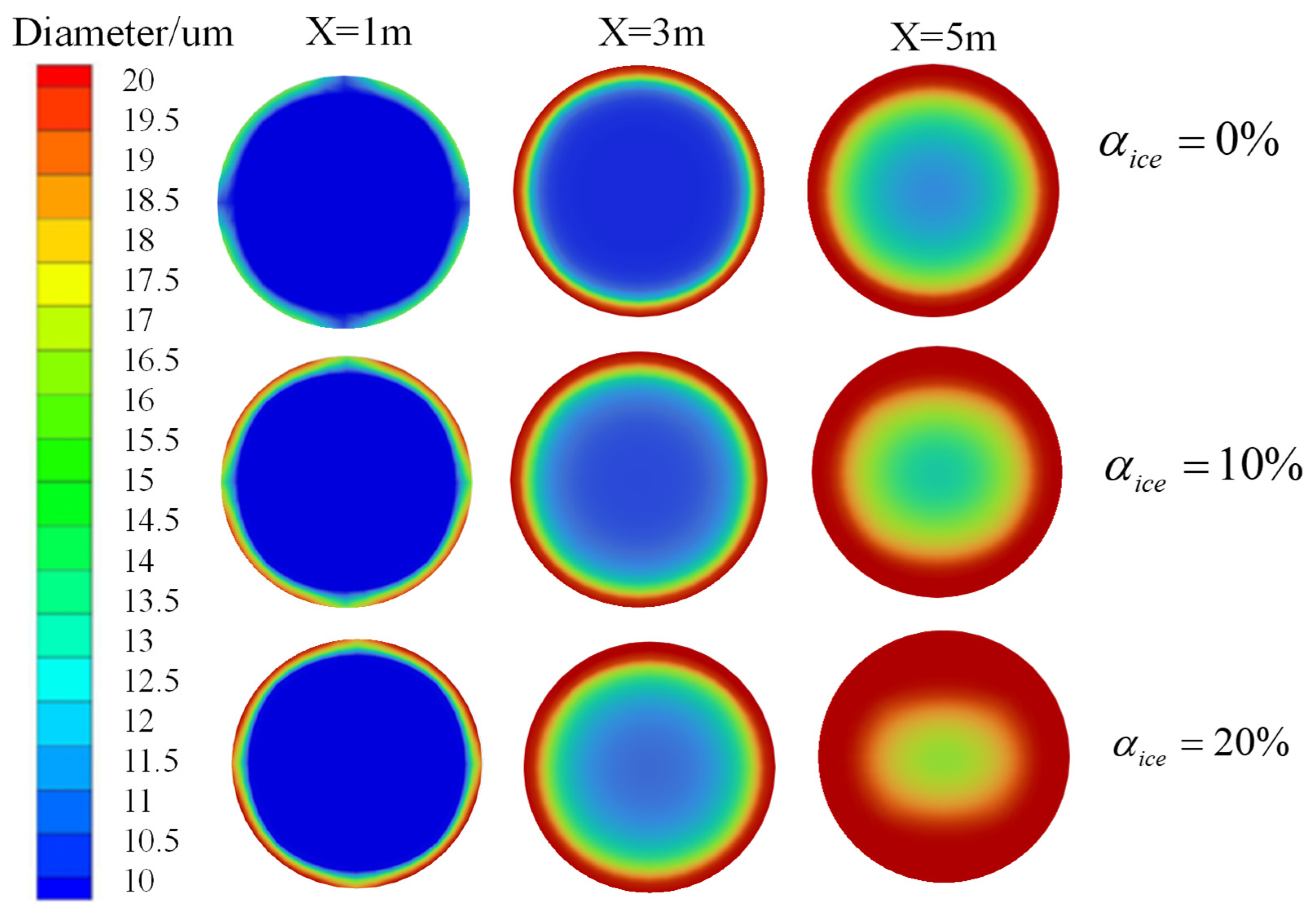

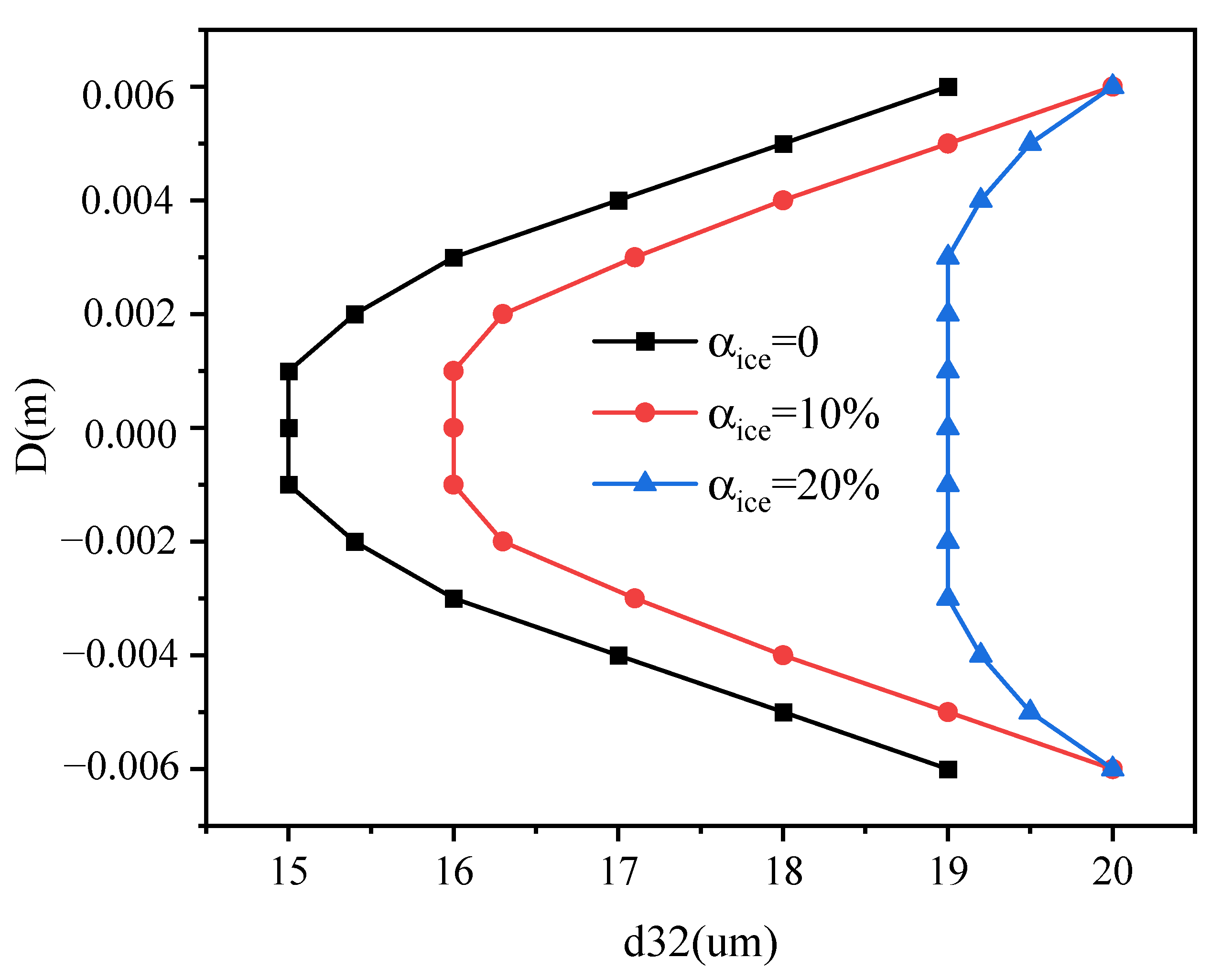

4.1. Ice Content in the Filling Slurry

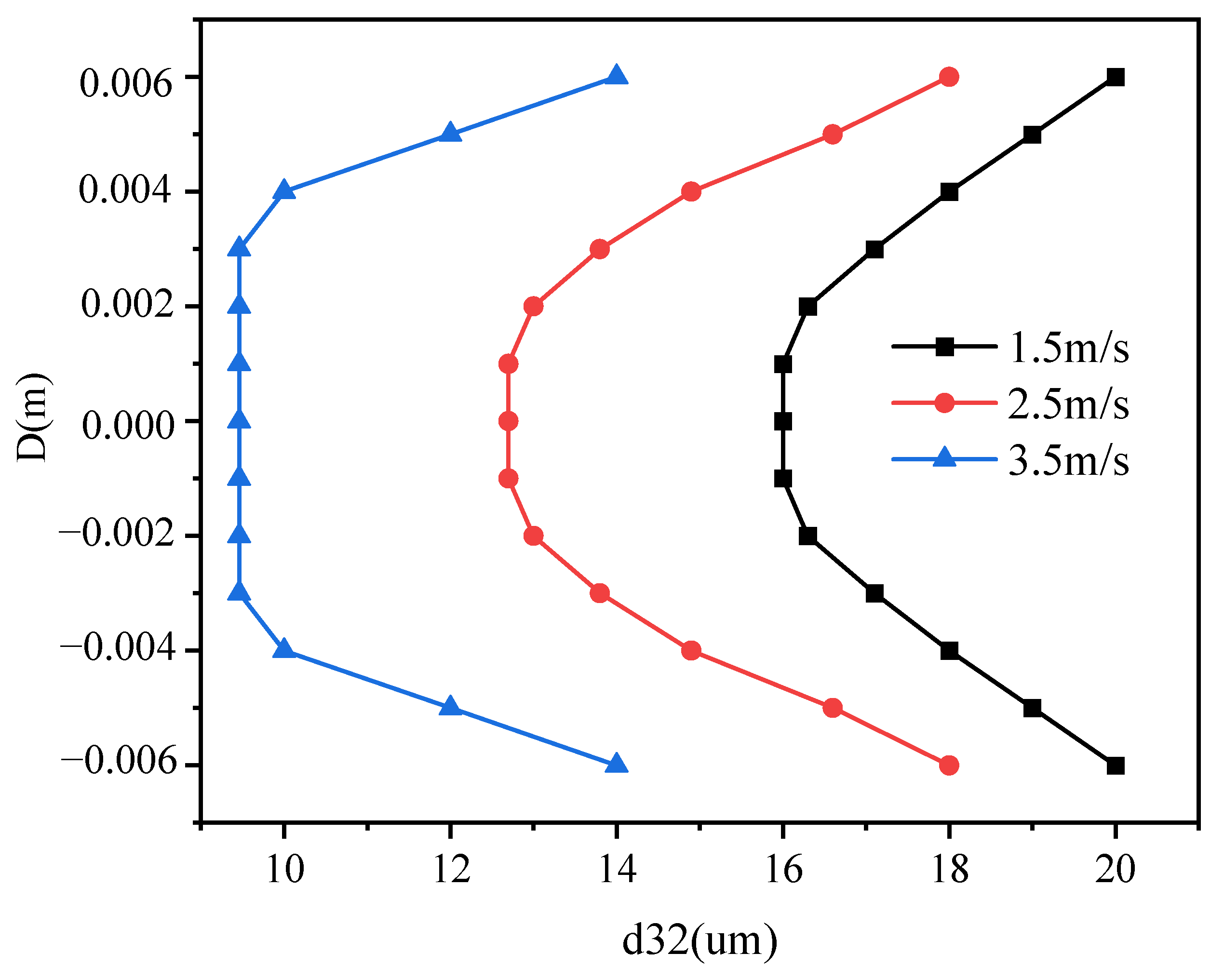

4.2. Pipe Inlet Velocity

4.3. Initial Particle Size of Tailings

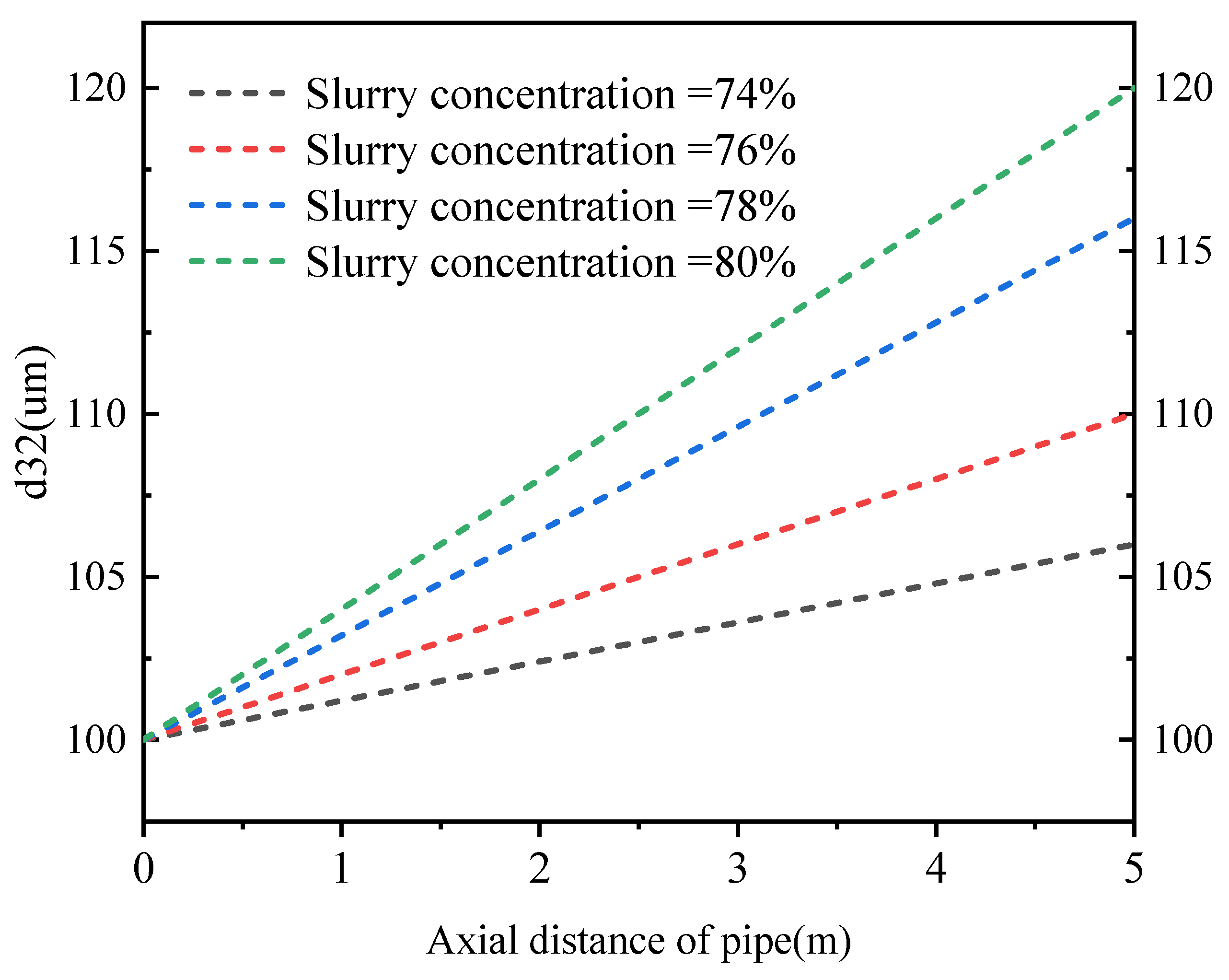

4.4. The Concentration of Filling Slurry

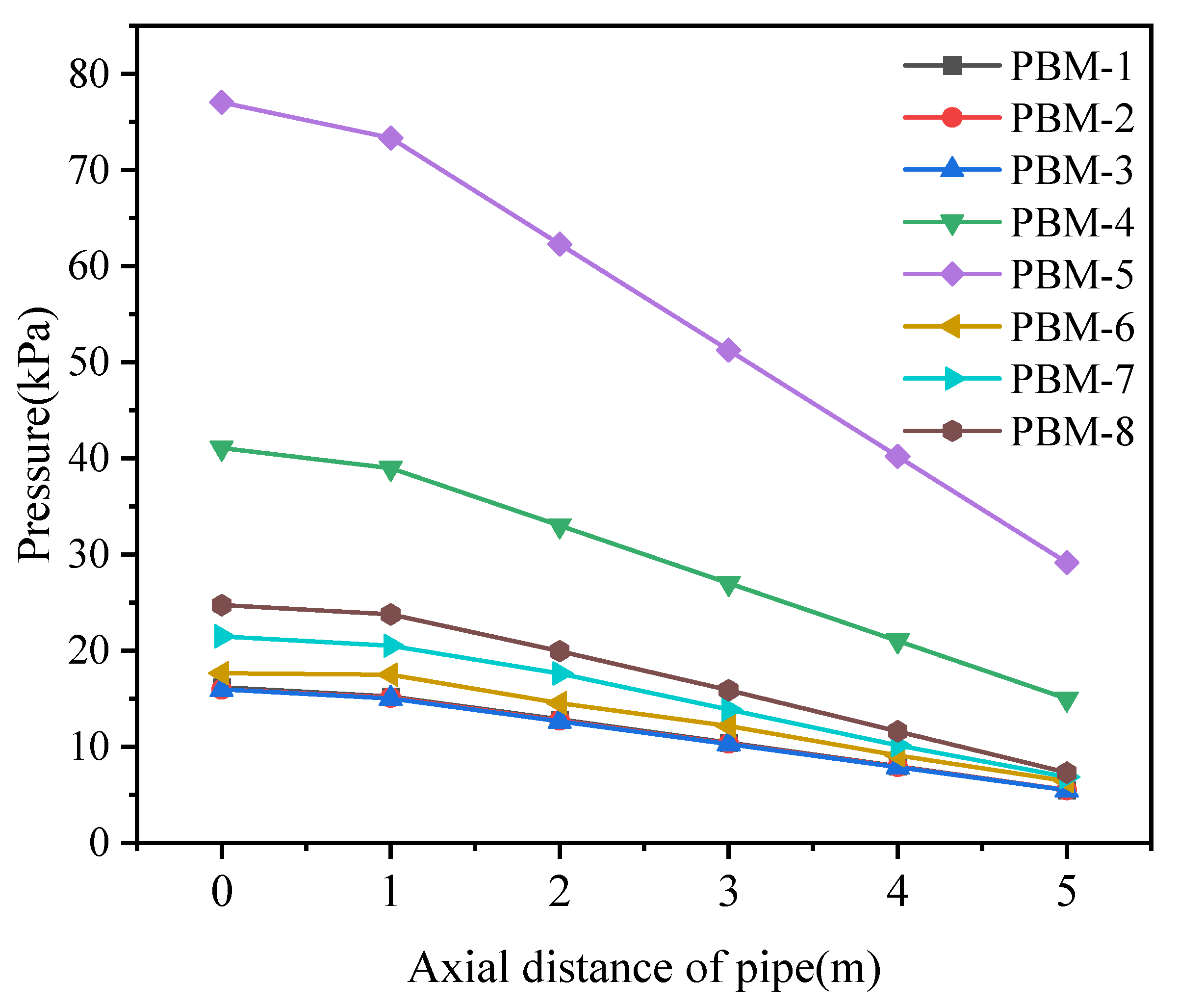

4.5. Pressure Drop Along the Pipeline

5. Conclusions

- (1)

- With the increase in ice content, the risk of agglomeration of the ice-containing filling slurry significantly increases during pipeline transportation. It is recommended to control the ice content to within 20% to reduce the occurrence of caking.

- (2)

- When the inlet velocity of the round pipe is high, due to the effects of turbulent shear forces and particle breakage, the caking phenomenon is less likely to occur during the transport of the filling slurry in the pipe. Additionally, the higher the flow velocity, the smaller the increase in the particle size of the tailings.

- (3)

- The larger the size of the tailings, the weaker the agglomeration effect. To ensure the safe transportation of filling slurry containing ice particles, it is recommended to select tailings with a particle size greater than 300 microns.

- (4)

- Filling slurry with a high concentration exhibits a strong agglomeration effect. Therefore, on the basis of meeting the fluidity and strength requirements of the filling slurry, a lower concentration should be used to ensure smooth transportation.

- (5)

- The pressure drop along the pipeline is proportional to the inlet velocity and the particle size of the tailings. The addition of ice particles to the filling slurry has almost no effect on the pipeline pressure drop.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Pressure | |

| Force | |

| Turbulent kinetic energy | |

| Coefficient of resistance | |

| Length | |

| The diameter of the Pipe | |

| Horizontal coordinates of the node | |

| Density | |

| volume fraction | |

| Velocity vector | |

| Gravitational acceleration | |

| Shear stress | |

| Turbulent dissipation rate | |

| Particle temperature | |

| Shear viscosity | |

| Volume viscosity | |

| The diameter of the particle | |

| Collision restitution coefficient | |

| Radial distribution function | |

| Diffusion and exchange coefficients | |

| Prandtl coefficient | |

| Reynolds number | |

| The birth moment of particle aggregation | |

| The death moment of particle aggregation | |

| The birth moment of particle breakage | |

| The death moment of particle breakage | |

| The order of the moment | |

| Weighting | |

| Solid phase (particle phase) | |

| Liquid phase (fluid phase) | |

| D | Resistance |

| si | Fluctuation |

| eff | Effective |

| t | Average eddy current |

| tl | Turbulence |

| PBE | The population balance equation |

| PBM | The population balance model |

| EEM | Euler–Euler model |

| PSD | Particle size distribution |

References

- Panão, M.R.O.; Franco, P.A.G.; Costa, J.J. Effect of Atomizer Geometry on Particle Formation in Dry-Ice Sprays. Int. J. Multiph. Flow 2020, 130, 103358. [Google Scholar] [CrossRef]

- Wang, M.; Liu, P.; Shang, S.; Chen, Q.; Zhang, B.; Liu, L. Numerical and Experimental Studies on the Cooling Performance of Backfill Containing Phase Change Materials. Build. Environ. 2022, 218, 109155. [Google Scholar] [CrossRef]

- Wang, M.; Liu, P.; Liu, L.; Geng, M.; Wang, Y.; Zhang, Z. The Impact of the Backfill Direction on the Backfill Cooling Performance Using Phase Change Materials in Mine Cooling. Renew. Energy 2022, 201, 1026–1037. [Google Scholar] [CrossRef]

- Wang, M.; Wang, Y.; Geng, M.; Shang, S.; Zhang, B.; Liu, L.; Wen, G. Effect of Cold Storage Backfill on Thermal Comfort of Mine Stope Based on Standard Effective Temperature. Energy Build. 2023, 300, 113632. [Google Scholar] [CrossRef]

- Wang, M.; Geng, M.; Liu, L.; Wang, Y.; Shang, S.; Wen, G. Numerical and Experimental Study on the Cooling Performance of Cold Load Storage Functional Backfill Considering the Coupled Heat and Moisture Transfer. J. Build. Eng. 2023, 78, 107673. [Google Scholar] [CrossRef]

- Onokoko, L. Experimental and Numerical Investigation of Isothermal Ice Slurry Flow. Int. J. Therm. Sci. 2018, 126, 82–95. [Google Scholar] [CrossRef]

- Wang, J.; Wang, S.; Zhang, T.; Battaglia, F. Numerical and Analytical Investigation of Ice Slurry Isothermal Flow through Horizontal Bends. Int. J. Refrig. 2018, 92, 37–54. [Google Scholar] [CrossRef]

- Bordet, A.; Poncet, S.; Poirier, M.; Galanis, N. Flow Visualizations and Pressure Drop Measurements of Isothermal Ice Slurry Pipe Flows. Exp. Therm. Fluid Sci. 2018, 99, 595–604. [Google Scholar] [CrossRef]

- Zhang, Q.; Xie, S.; Zheng, J.; Wang, X. Research on the Settlement Law of Filling Slurry and Feasibility Analysis of Transportation. J. Chongqing Univ. 2011, 34, 105–109. [Google Scholar]

- Wang, H.; Zhang, A.; He, M. Experimental Study on the Proportion and Transportation Characteristics of High-Sulfur Ultra-Fine Full Tailings Filling Materials. China Mine Eng. 2014, 43, 4. [Google Scholar]

- Zhang, L.; Luo, T.; Xu, Y.; Chen, Z.; Liu, J. Research on Rheological Properties of High Concentration Filling Slurry and Simulation Optimization of Pipeline Transportation. Min. Res. Dev. 2016, 36, 36–41. [Google Scholar] [CrossRef]

- Guo, J.; Liu, M.; Zhang, B. Settlement mechanism of two-phase flow pipeline in deep well filling. Gold Sci. Technol. 2016, 24, 86–93. [Google Scholar]

- Capecelatro, J.; Desjardins, O. Eulerian–Lagrangian Modeling of Turbulent Liquid–Solid Slurries in Horizontal Pipes. Int. J. Multiph. Flow 2013, 55, 64–79. [Google Scholar] [CrossRef]

- Arolla, S.K.; Desjardins, O. Transport Modeling of Sedimenting Particles in a Turbulent Pipe Flow Using Euler–Lagrange Large Eddy Simulation. Int. J. Multiph. Flow 2015, 75, 1–11. [Google Scholar] [CrossRef]

- Liu, L.; Xin, J.; Zhang, B.; Zhang, X.; Wang, M.; Qiu, H.; Chen, L. Basic Theory and Application Exploration of Functional Backfilling in Mines. J. China Coal Soc. 2018, 43, 1811–1820. [Google Scholar] [CrossRef]

- Wang, M.; Liu, L.; Chen, L.; Zhang, X.; Zhang, B.; Ji, C. Cold Load and Storage Functional Backfill for Cooling Deep Mine. Adv. Civ. Eng. 2018, 2018, 5435214. [Google Scholar] [CrossRef]

- Wang, M.; Liu, L.; Zhang, B.; Zhang, X.; Xun, C.; Zhao, Y.; Tu, B. Basic Theory of Cold-Carrying/Storage Functional Backfilling in Mines. J. China Coal Soc. 2020, 45, 1336–1347. [Google Scholar] [CrossRef]

- Liu, L.; Fang, Z.; Qi, C.; Zhang, B.; Guo, L.; Song, K.I.-I.L. Numerical Study on the Pipe Flow Characteristics of the Cemented Paste Backfill Slurry Considering Hydration Effects. Powder Technol. 2019, 343, 454–464. [Google Scholar] [CrossRef]

- Liu, L.; Fang, Z.Y.; Wu, Y.P.; Lai, X.P.; Wang, P.; Song, K.-I. Experimental Investigation of Solid-Liquid Two-Phase Flow in Cemented Rock-Tailings Backfill Using Electrical Resistance Tomography. Constr. Build. Mater. 2018, 175, 267–276. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, T.; Wang, S. Heterogeneous Ice Slurry Flow and Concentration Distribution in Horizontal Pipes. Int. J. Heat Fluid Flow 2013, 44, 425–434. [Google Scholar] [CrossRef]

- Rezaei, M.; Pakravan, H.A. Numerical Study of Ice Slurry Flow and Heat Transfer in Successive U-Bends as Part of Tubular Heat Exchangers. Int. J. Therm. Sci. 2023, 191, 108357. [Google Scholar] [CrossRef]

- Kamyar, A.; Aminossadati, S.M.; Leonardi, C.R.; Sasmito, A.P.; Poncet, S. Flow Characterisation of Monopropylene Glycol Ice Slurry through a Horizontal U-Bend: A Numerical Approach. Eur. J. Mech. B/Fluids 2020, 82, 93–105. [Google Scholar] [CrossRef]

- Cai, L.; Liu, Z.; Mi, S. Investigation on Flow Characteristics of Ice Slurry in Horizontal 90° Elbow Pipe by a CFD-PBM Coupled Model. Adv. Powder Technol. 2019, 30, 2299–2310. [Google Scholar] [CrossRef]

- Mi, S.; Geng, S.; Cai, L.; Xu, C. Investigation on the Flow Characteristics of a Phase Change Material Slurry in Horizontal and U-Shaped Tubes Based on CFD-PBM. Chem. Eng. Res. Des. 2024, 201, 409–424. [Google Scholar] [CrossRef]

- Du, Q.; Chen, M.; Song, W.; Qin, K.; Feng, Z. Investigation on the Evolution of Ice Particles and Ice Slurry Flow Characteristics during Subcooling Release. Int. J. Heat Mass Transf. 2023, 209, 124008. [Google Scholar] [CrossRef]

- Xu, D.; Liu, Z.; Cai, L.; Tang, Y.; Yu, Y.; Xu, A. A CFD-PBM Approach for Modeling Ice Slurry Flow in Horizontal Pipes. Chem. Eng. Sci. 2018, 176, 546–559. [Google Scholar] [CrossRef]

- Jin, T.; Li, Y.; Wu, S.; Liu, Y. Numerical Modeling for the Flow and Heat Transfer of Slush Nitrogen in a Horizontal Pipe Based on Population Balance Equations. Appl. Therm. Eng. 2017, 123, 301–309. [Google Scholar] [CrossRef]

- Gao, Y.; Ning, Y.; Xu, M.; Wu, C.; Mujumdar, A.S.; Sasmito, A.P. Numerical Investigation of Aqueous Graphene Nanofluid Ice Slurry Passing through a Horizontal Circular Pipe: Heat Transfer and Fluid Flow Characteristics. Int. Commun. Heat Mass Transf. 2022, 134, 106022. [Google Scholar] [CrossRef]

- Van De Ven, T.G.M.; Mason, S.G. The Microrheology of Colloidal Dispersions VII. Orthokinetic Doublet Formation of Spheres. Colloid Polym. Sci. 1977, 255, 468–479. [Google Scholar] [CrossRef]

- Wang, X.; Cui, B.; Wei, D.; Song, Z.; He, Y.; Bayly, A.E. Effect of Feed Solid Concentration on Tailings Slurry Flocculation in a Thickener by a Coupled CFD-PBM Modelling Approach. J. Environ. Chem. Eng. 2021, 9, 106385. [Google Scholar] [CrossRef]

- Yao, Y.; Su, J.-W.; Luo, Z.-H. CFD-PBM Modeling Polydisperse Polymerization FBRs with Simultaneous Particle Growth and Aggregation: The Effect of the Method of Moments. Powder Technol. 2015, 272, 142–152. [Google Scholar] [CrossRef]

- Zhang, P.; Shi, X.J. Thermo-Fluidic Characteristics of Ice Slurry in Horizontal Circular Pipes. Int. J. Heat Mass Transf. 2015, 89, 950–963. [Google Scholar] [CrossRef]

- Liu, S.-S.; Xiao, W.-D. Numerical Simulations of Particle Growth in a Silicon-CVD Fluidized Bed Reactor via a CFD–PBM Coupled Model. Chem. Eng. Sci. 2014, 111, 112–125. [Google Scholar] [CrossRef]

- Shi, X.J.; Zhang, P. Two-Phase Flow and Heat Transfer Characteristics of Tetra-n-Butyl Ammonium Bromide Clathrate Hydrate Slurry in Horizontal 90° Elbow Pipe and U-Pipe. Int. J. Heat Mass Transf. 2016, 97, 364–378. [Google Scholar] [CrossRef]

- Huilin, L.; Gidaspow, D.; Bouillard, J.; Wentie, L. Hydrodynamic Simulation of Gas–Solid Flow in a Riser Using Kinetic Theory of Granular Flow. Chem. Eng. J. 2003, 95, 1–13. [Google Scholar] [CrossRef]

- Lee, D.W.; Yoon, E.S.; Joo, M.C.; Sharma, A. Heat Transfer Characteristics of the Ice Slurry at Melting Process in a Tube Flow. Int. J. Refrig. 2006, 29, 451–455. [Google Scholar] [CrossRef]

- Nayak, B.B.; Chatterjee, D.; Mullick, A.N. Numerical Prediction of Flow and Heat Transfer Characteristics of Water-Fly Ash Slurry in a 180° Return Pipe Bend. Int. J. Therm. Sci. 2017, 113, 100–115. [Google Scholar] [CrossRef]

- Ekambara, K.; Sanders, R.S.; Nandakumar, K.; Masliyah, J.H. Hydrodynamic Simulation of Horizontal Slurry Pipeline Flow Using ANSYS-CFX. Ind. Eng. Chem. Res. 2009, 48, 8159–8171. [Google Scholar] [CrossRef]

- Shi, X.J.; Zhang, P. Conjugated Heat and Mass Transfer during Flow Melting of a Phase Change Material Slurry in Pipes. Energy 2016, 99, 58–68. [Google Scholar] [CrossRef]

- Hulburt, H.M.; Katz, S. Some Problems in Particle Technology. Chem. Eng. Sci. 1964, 19, 555–574. [Google Scholar] [CrossRef]

- John, V.; Angelov, I.; Öncül, A.A.; Thévenin, D. Techniques for the Reconstruction of a Distribution from a Finite Number of Its Moments. Chem. Eng. Sci. 2007, 62, 2890–2904. [Google Scholar] [CrossRef]

- Marchisio, D.L.; Vigil, R.D.; Fox, R.O. Implementation of the Quadrature Method of Moments in CFD Codes for Aggregation–Breakage Problems. Chem. Eng. Sci. 2003, 58, 3337–3351. [Google Scholar] [CrossRef]

- Peng, S.J.; Williams, R.A. Direct Measurement of Floc Breakage in Flowing Suspensions. J. Colloid Interface Sci. 1993, 166, 321–332. [Google Scholar] [CrossRef]

- Vuarnoz, D.; Sari, O.; Egolf, P.W.; Liardon, H. Ultrasonic velocity profiler uvp-xw for ice- slurry flow characterisation. In Proceedings of the ISUD 3: Third International Symposium on Ultrasonic Doppler Methods for Fluid Mechanics and Fluid Engineering, Lausanne, Switzerland, 9–11 September 2002. [Google Scholar]

- Cai, L.; Mi, S.; Liu, Z. Experimental study on the evolution law of ice crystal particle size during the flow of ice slurry. J. Refrig. 2023, 44, 131–138. [Google Scholar]

| Constituent Elements | Parameter | Value | Unit |

|---|---|---|---|

| water | Density | 913 | |

| Viscosity | 8.90 × 10−4 | ||

| Ice | Density | 1000 | |

| Tailings | Density | 3500 |

| Operating Condition Name | Inlet Velocity (m/s) | Initial Size of Tailings (μm) | Ice Content (%) |

|---|---|---|---|

| PBM-1 | 1.5 | 10 | 0 |

| PBM-2 | 1.5 | 10 | 10% |

| PBM-3 | 1.5 | 10 | 20% |

| PBM-4 | 2.5 | 10 | 10% |

| PBM-5 | 3.5 | 10 | 10% |

| PBM-6 | 1.5 | 100 | 10% |

| PBM-7 | 1.5 | 200 | 10% |

| PBM-8 | 1.5 | 300 | 10% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, M.; Zhang, F.; Liu, L.; Wen, G.; Ni, W.; Kong, D. Analysis and Research on the Flow Characteristics of Ice-Containing Filling Slurry Based on the Population Balance Model. Energies 2025, 18, 1430. https://doi.org/10.3390/en18061430

Wang M, Zhang F, Liu L, Wen G, Ni W, Kong D. Analysis and Research on the Flow Characteristics of Ice-Containing Filling Slurry Based on the Population Balance Model. Energies. 2025; 18(6):1430. https://doi.org/10.3390/en18061430

Chicago/Turabian StyleWang, Mei, Fan Zhang, Lang Liu, Guoming Wen, Wanying Ni, and Deyang Kong. 2025. "Analysis and Research on the Flow Characteristics of Ice-Containing Filling Slurry Based on the Population Balance Model" Energies 18, no. 6: 1430. https://doi.org/10.3390/en18061430

APA StyleWang, M., Zhang, F., Liu, L., Wen, G., Ni, W., & Kong, D. (2025). Analysis and Research on the Flow Characteristics of Ice-Containing Filling Slurry Based on the Population Balance Model. Energies, 18(6), 1430. https://doi.org/10.3390/en18061430