Large Eddy Simulation Approaches for Trailing-Edge Heat Transfer in Gas Turbine Blades: A Review

Abstract

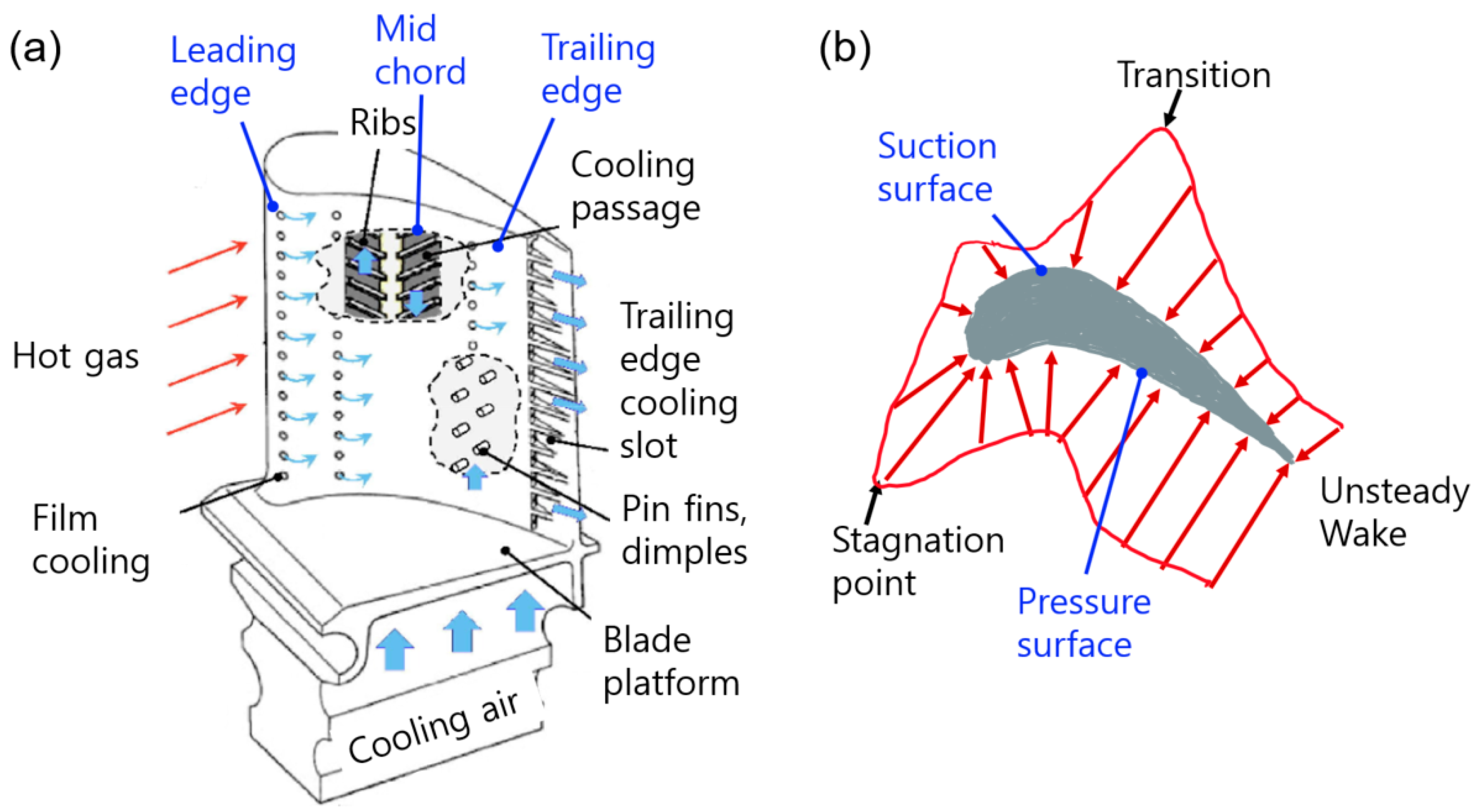

1. Introduction

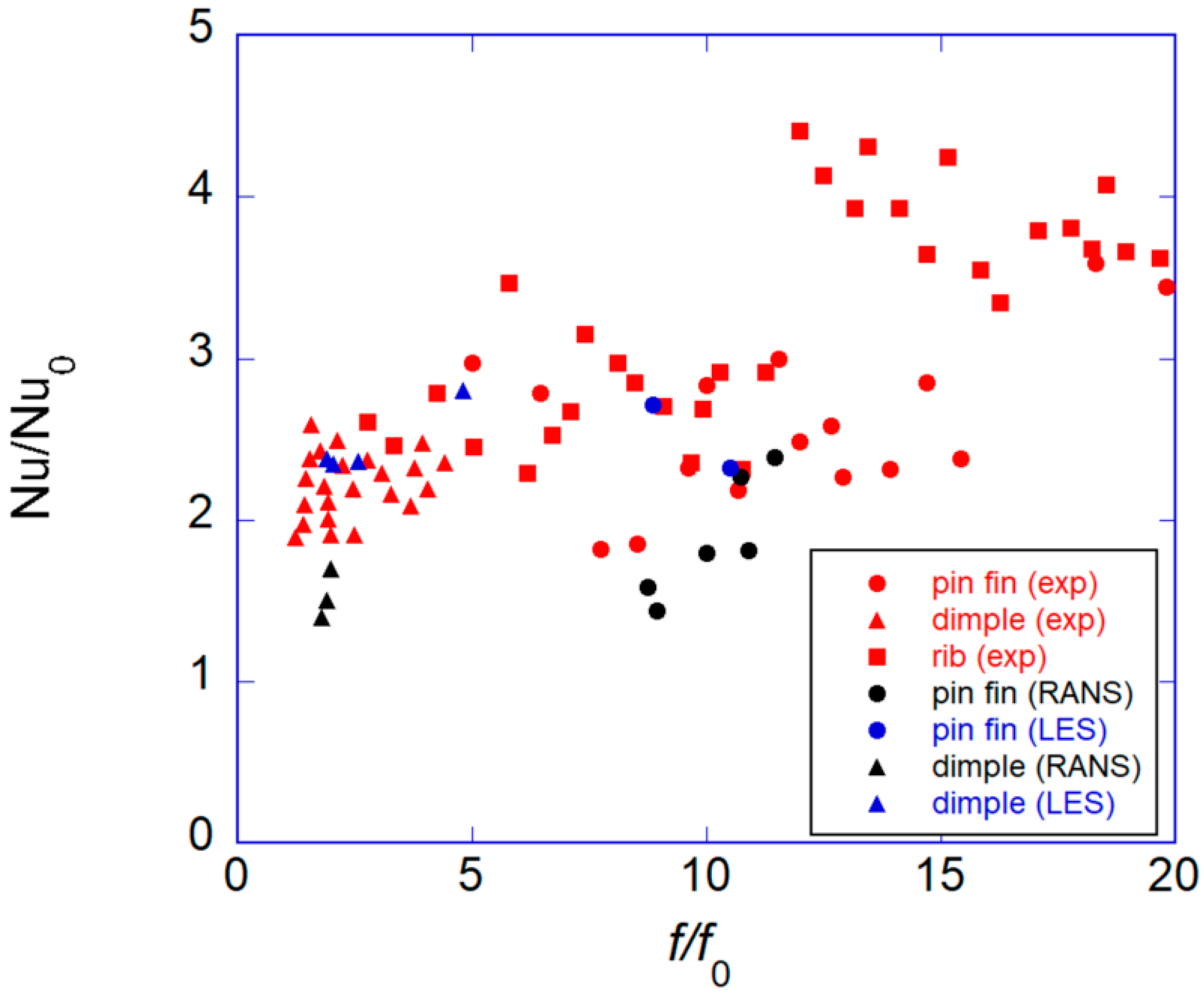

2. Large Eddy Simulation of Flow and Heat Transfer in Pin Fin Ducts

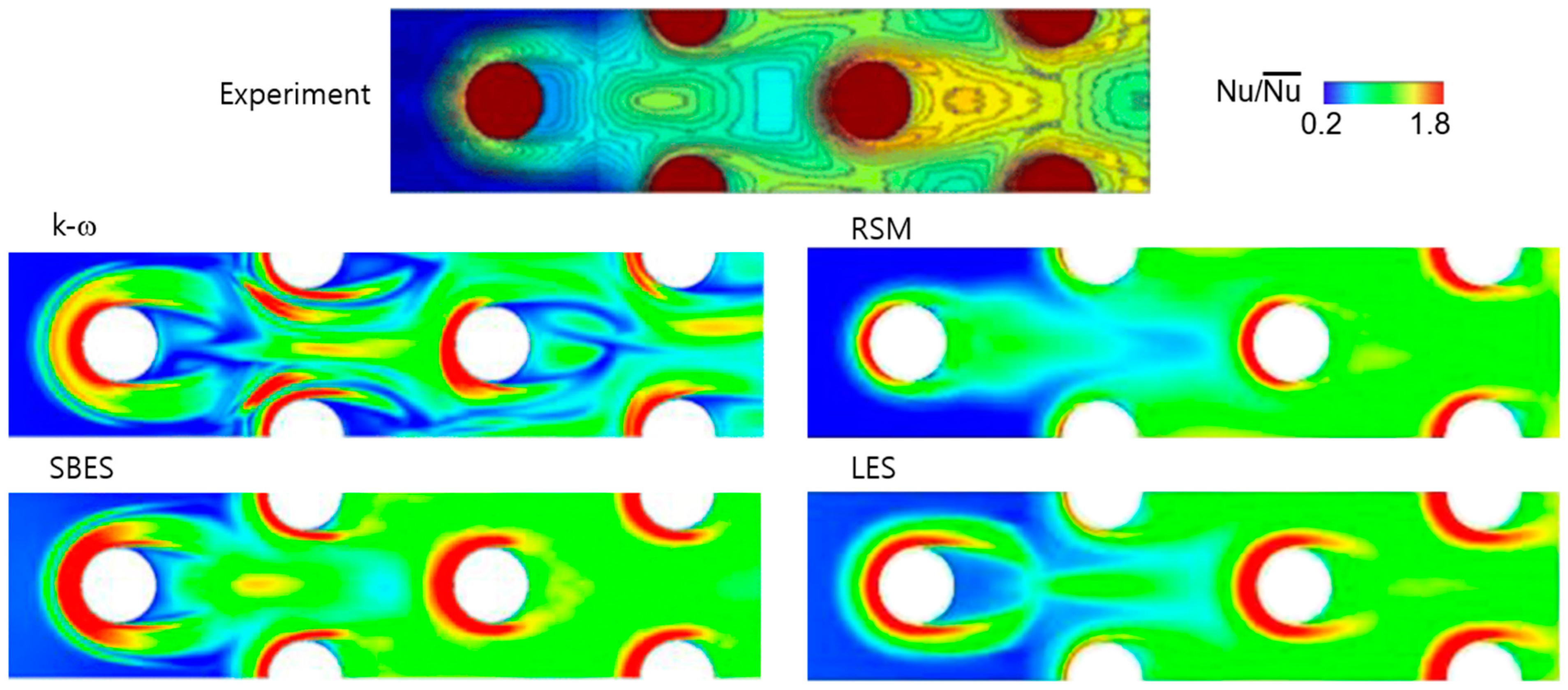

2.1. Comparative Study of Modeling Approaches (RANS, LES, Hybrid)

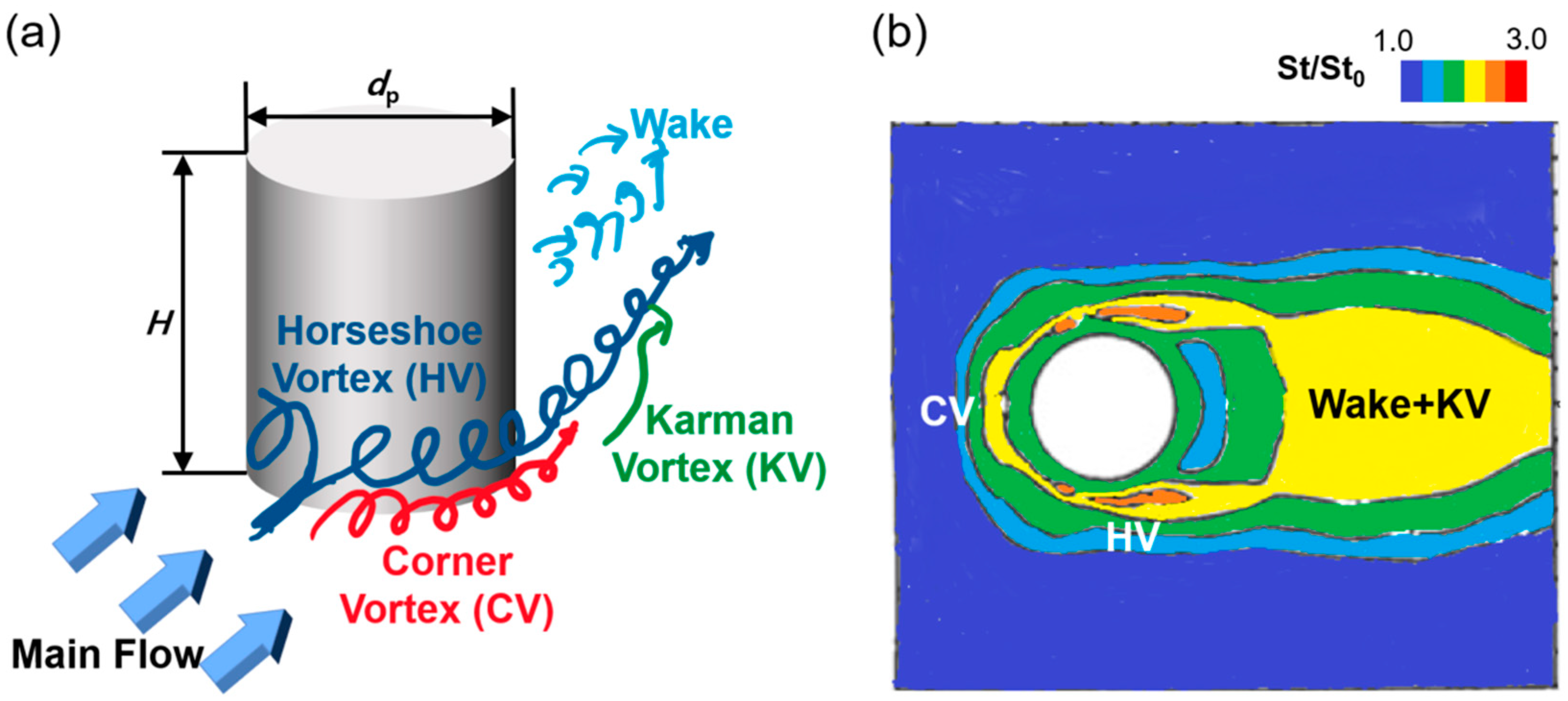

2.2. Detailed Flow and Vortex Structures

2.3. Thermal Performance Analysis

2.4. Pin Fin Channel with Film Cooling

2.5. Conjugate Heat Transfer Analysis

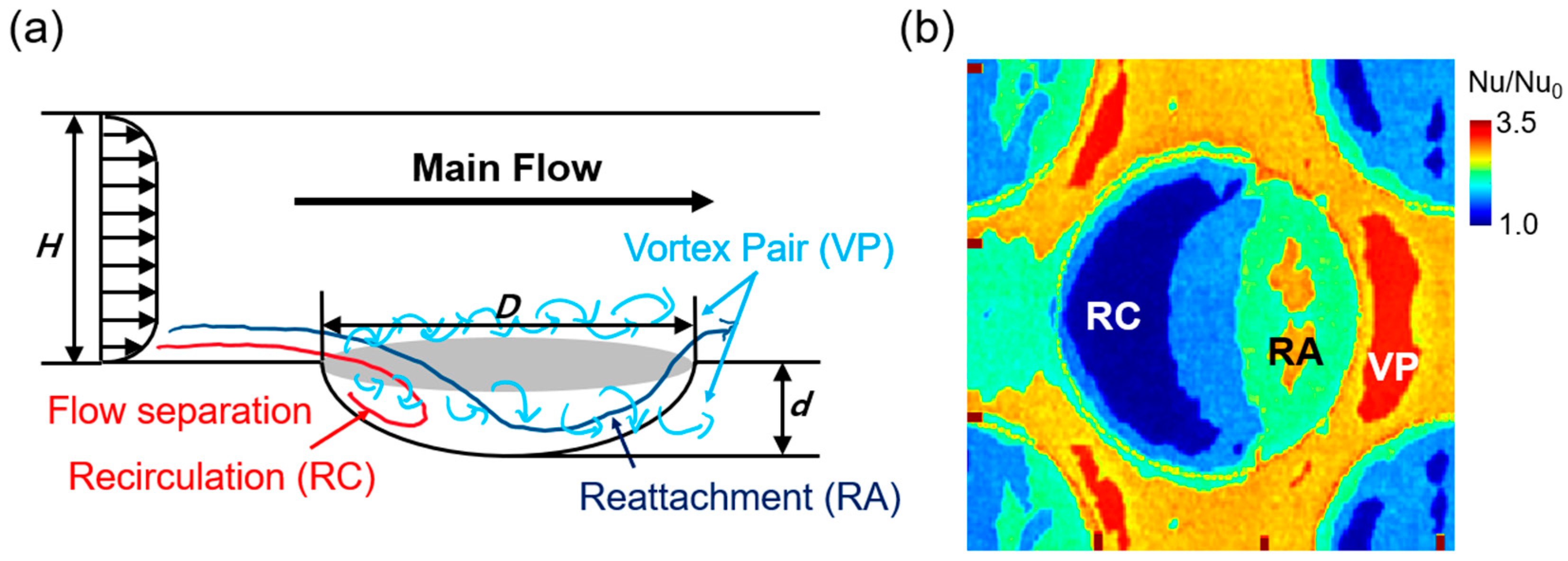

3. Large Eddy Simulation of Flow and Heat Transfer in Dimpled Channels

3.1. Flow Structure and Mechanisms of Heat Transfer Enhancement

3.2. Geometric Variations and Their Effects on Heat Transfer

3.3. Dimples with Protrusions or Turbulence Enhancers

3.4. Influence of Rotation and Flow Pulsations

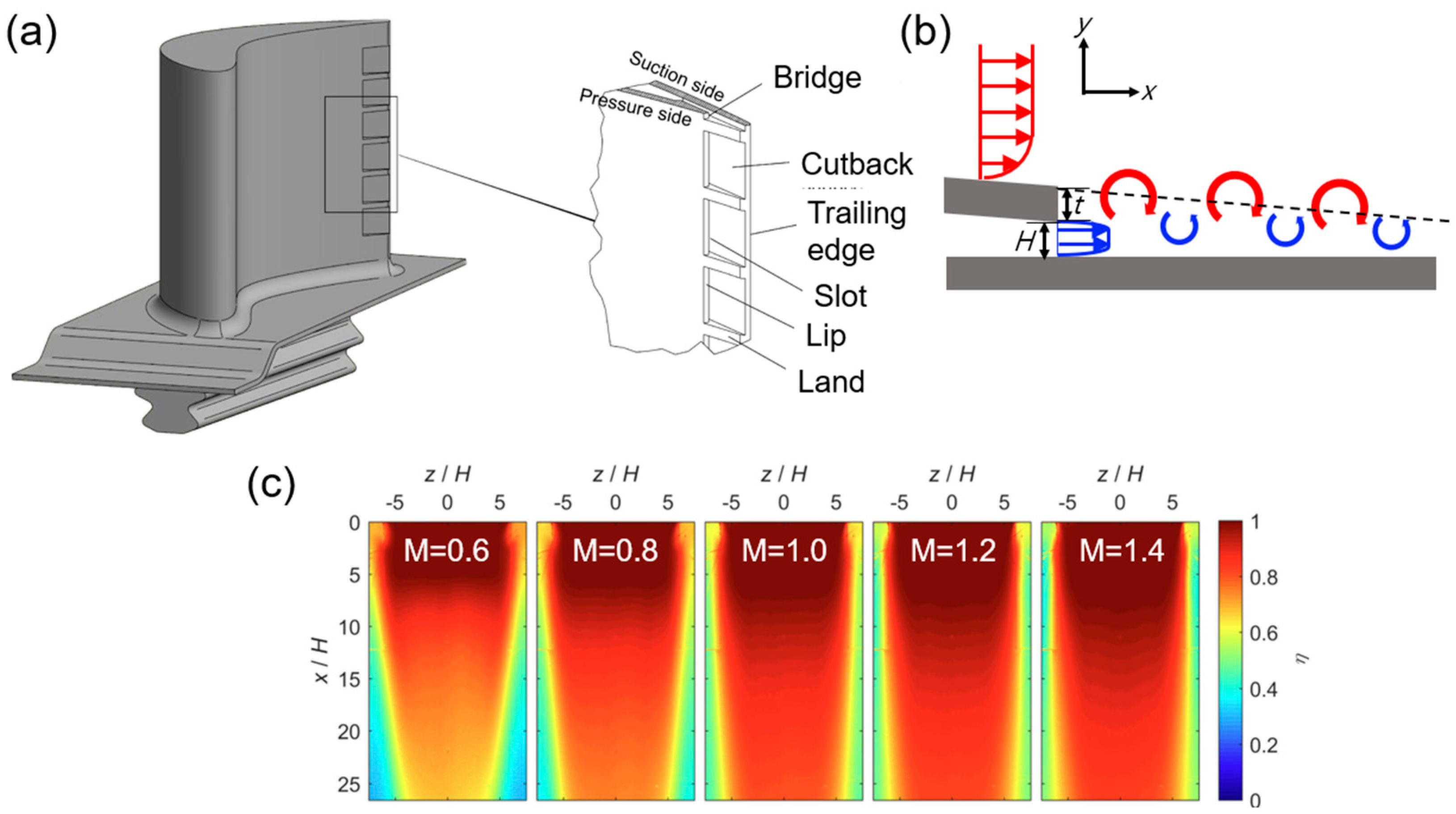

4. Large Eddy Simulation of Film Cooling at the Trailing Edge

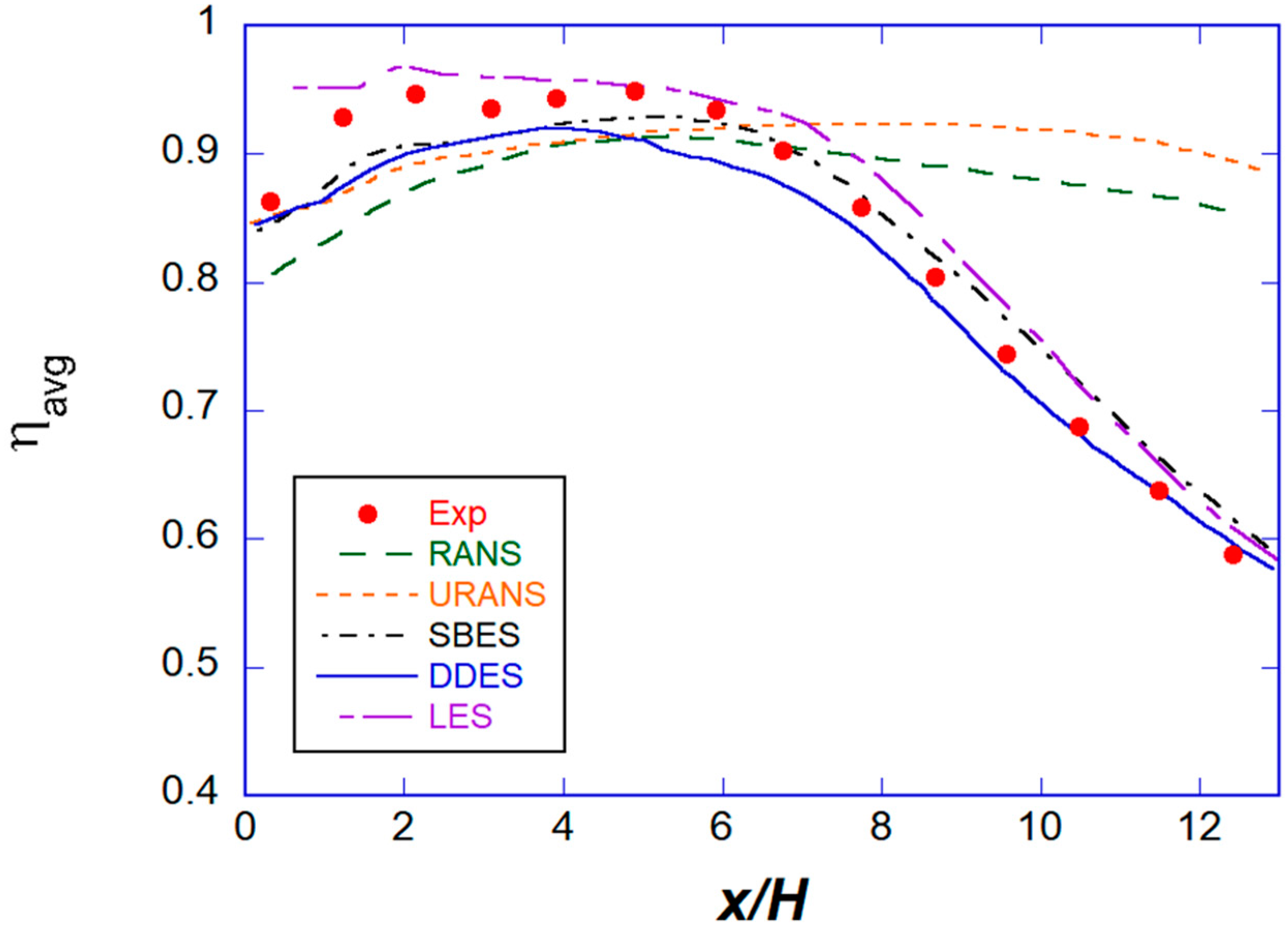

4.1. Comparative Study of Modeling Approaches (RANS, LES, Hybrid)

4.2. Influence of Blowing Ratio on Flow Structure and Film Cooling Effectiveness

4.3. Impact of Lip and Land Geometry on Cutback Film Cooling Performance

4.4. Combined Effects of Internal Rib Configurations or Novel Internal Structures

4.5. Interaction with Upstream Film Cooling

5. Future Works

5.1. LES Investigations of Advanced Trailing Edge Cooling Geometries

5.2. Multi-Physics Simulations Integrating Thermal and Structural Behavior

5.3. Effects of Rotation and Unsteady Flow on the Trailing Edge Cooling

6. Conclusions

- Large eddy simulation (LES) has proven its capability in resolving flow features that are often inadequately captured by Reynolds-Averaged Navier–Stokes (RANS) simulations. It has effectively modeled key phenomena, including horseshoe and corner vortices in pin fin arrays, shear layer vortices in dimples, complex interactions between dimple exit flows and the main flow, and shear layer-generated vortices in cutback film cooling. These insights have greatly advanced the understanding of heat transfer mechanisms and the distribution of film cooling effectiveness, which is particularly crucial for cooling the trailing edge due to its more complex geometry compared to the mid-chord region;

- LES has consistently outperformed RANS in predicting heat transfer within pin fin and dimpled channels, which are commonly used for cooling the trailing edge of turbine blades. RANS often underestimates the heat transfer rate in these configurations, whereas LES provides a distribution that more closely matches experimental observations, with reduced sensitivity to boundary conditions and turbulence models. For example, LES avoids the asymmetric or experimentally unobserved local heat transfer peaks that can appear in RANS results depending on the turbulence model, demonstrating its greater reliability across different subgrid-scale (SGS) models;

- Similar to film cooling through discrete holes in the mid-chord region, LES has provided more accurate predictions of cutback film cooling effectiveness, whereas RANS tends to overestimate it. Although LES has yet to achieve fully accurate heat transfer predictions for film cooling in the mid-chord, we anticipate more successful results for cutback film cooling, where the flow is relatively less complex. This advancement will be crucial for conjugate heat transfer analysis, which accounts for both cutback film cooling and internal heat transfer enhancement;

- LES has provided precise predictions of turbulence statistics, an area where RANS often fall short in trailing-edge cooling scenarios. While RANS struggles to accurately capture turbulence within the shear layer inside dimples or in cutback film cooling—often showing deviations depending on the turbulence model—LES reliably predicts these flow features regardless of the SGS model. This capability has deepened the understanding of heat transfer characteristics and significantly contributed to turbulence model development. As data-driven approaches, such as machine learning, integrate with LES, further advancements in turbulence modeling and heat transfer prediction are expected;

- Recent LES studies have successfully combined internal and external flow simulations for trailing-edge cooling, providing a comprehensive understanding of these interconnected systems. With ongoing advancements in computational capabilities, future research is expected to delve into multi-physics simulations. These will integrate CHT and flow-structure interactions, addressing the thermal and mechanical demands of next-generation turbine designs.

Funding

Data Availability Statement

Conflicts of Interest

References

- Takeishi, K. Evolution of turbine cooled vanes and blades applied for large industrial gas turbines and its trend toward carbon neutrality. Energies 2022, 15, 8935. [Google Scholar] [CrossRef]

- Mohamed, O.; Khalil, A. Progress in modeling and control of gas turbine power generation systems: A survey. Energies 2020, 13, 2358. [Google Scholar] [CrossRef]

- Stefanizzi, M.; Capurso, T.; Filomeno, G.; Torresi, M.; Pascazio, G. Recent combustion strategies in gas turbines for propulsion and power generation toward a zero-emissions future: Fuels, burners, and combustion techniques. Energies 2021, 14, 6694. [Google Scholar] [CrossRef]

- Chowdhury, T.S.; Mohsin, F.T.; Tonni, M.M.; Mita, M.N.H.; Ehsan, M.M. A critical review on gas turbine cooling performance and failure analysis of turbine blades. Int. J. Thermofluids 2023, 18, 100329. [Google Scholar] [CrossRef]

- Haque, M.A.; Nemitallah, M.A.; Abdelhafez, A.; Mansir, I.B.; Habib, M.A. Review of fuel/oxidizer-flexible combustion in gas turbines. Energy Fuels 2020, 34, 10459–10485. [Google Scholar] [CrossRef]

- Han, J.C. Fundamental gas turbine heat transfer. J. Therm. Sci. Eng. Appl. 2013, 5, 021007. [Google Scholar] [CrossRef]

- Ligrani, P. Heat transfer augmentation technologies for internal cooling of turbine components of gas turbine engines. Int. J. Rotating Mach. 2013, 2013, 275653. [Google Scholar] [CrossRef]

- Yeranee, K.; Rao, Y. A review of recent studies on rotating internal cooling for gas turbine blades. Chin. J. Aeronaut. 2021, 34, 85–113. [Google Scholar] [CrossRef]

- Han, J.C. Advanced cooling in gas turbines 2016 Max Jakob memorial award paper. J. Heat Transf. 2018, 140, 113001. [Google Scholar] [CrossRef]

- Zhang, G.; Zhu, R.; Xie, G.; Li, S.; Sundén, B. Optimization of cooling structures in gas turbines: A review. Chin. J. Aeronaut. 2022, 35, 18–46. [Google Scholar] [CrossRef]

- Yang, X.; Hao, Z.; Feng, Z. An experimental study on turbine vane Leading-Edge film cooling with deposition. Appl. Therm. Eng. 2021, 198, 117447. [Google Scholar] [CrossRef]

- Dutta, S.; Singh, P. Opportunities in jet-impingement cooling for gas-turbine engines. Energies 2021, 14, 6587. [Google Scholar] [CrossRef]

- Unnikrishnan, U.; Yang, V. A review of cooling technologies for high temperature rotating components in gas turbine. Propuls. Power Res. 2022, 11, 293–310. [Google Scholar] [CrossRef]

- Cunha, F.J.; Chyu, M.K. Trailing-edge cooling for gas turbines. J. Propul. Power 2006, 22, 286–300. [Google Scholar] [CrossRef]

- Joo, J.; Durbin, P. Simulation of turbine blade trailing edge cooling. J. Fluids Eng. 2009, 131, 021102. [Google Scholar] [CrossRef]

- Casarsa, L.; Arts, T. Experimental investigation of the aerothermal performance of a high blockage rib-roughened cooling channel. J. Turbomach. 2005, 127, 580–588. [Google Scholar] [CrossRef]

- Murata, A.; Yano, K.; Hanai, M.; Saito, H.; Iwamoto, K. Arrangement effects of inclined teardrop-shaped dimples on film cooling performance of dimpled cutback surface at airfoil trailing edge. Int. J. Heat Mass Transf. 2017, 107, 761–770. [Google Scholar] [CrossRef]

- Horbach, T.; Schulz, A.; Bauer, H.J. Trailing edge film cooling of gas turbine airfoils—External cooling performance of various internal pin fin configurations. J. Turbomach. 2011, 133, 041006. [Google Scholar] [CrossRef]

- Kumar, S.; Amano, R.S. An investigation in the numerical approach to solve the heat transfer phenomenon in gas turbine. J. Energy Resour. Technol. 2021, 143, 080805. [Google Scholar] [CrossRef]

- Tucker, P.G. Trends in turbomachinery turbulence treatments. Prog. Aerosp. Sci. 2013, 63, 1–32. [Google Scholar] [CrossRef]

- Ali, U.; Kamran, M.S. Geometric optimization of a gas turbine blade cooling passage using CFD. Int. J. Therm. Environ. Eng. 2020, 17, 105–114. [Google Scholar]

- Tyacke, J.; Vadlamani, N.R.; Trojak, W.; Watson, R.; Ma, Y.; Tucker, P.G. Turbomachinery simulation challenges and the future. Prog. Aerosp. Sci. 2019, 110, 100554. [Google Scholar] [CrossRef]

- Tyacke, J.C.; Tucker, P.G. Future use of large eddy simulation in aero-engines. J. Turbomach. 2015, 137, 081005. [Google Scholar] [CrossRef]

- Ahn, J. Large eddy simulation of film cooling: A review. Energies 2022, 15, 8876. [Google Scholar] [CrossRef]

- Ahn, J. Large eddy simulation of flow and heat transfer in a ribbed channel for the internal cooling passage of a gas turbine blade: A review. Energies 2023, 16, 3656. [Google Scholar] [CrossRef]

- Holgate, J.; Skillen, A.; Craft, T.; Revell, A. A review of embedded large eddy simulation for internal flows. Arch. Comp. Methods Eng. 2019, 26, 865–882. [Google Scholar] [CrossRef]

- Du, W.; Luo, L.; Jiao, Y.; Wang, S.; Li, X.; Sunden, B. Heat transfer in the trailing region of gas turbines–A state-of-the-art review. Appl. Therm. Eng. 2021, 199, 117614. [Google Scholar] [CrossRef]

- Ravanji, A.; Lee, A.; Mohammadpour, J.; Cheng, S. Critical review on thermohydraulic performance enhancement in channel flows: A comparative study of pin fins. Renew. Sustain. Energy Rev. 2023, 188, 113793. [Google Scholar] [CrossRef]

- Ligrani, P.M.; Oliveira, M.M.; Blaskovich, T. Comparison of heat transfer augmentation techniques. AIAA J. 2003, 41, 337–362. [Google Scholar] [CrossRef]

- Chyu, M.K.; Natarajan, V. Heat transfer on the base surface of three dimensional protruding elements. Int. J. Heat Mass Transf. 1996, 39, 2925–2935. [Google Scholar] [CrossRef]

- Saha, A.K.; Acharya, S. Unsteady simulation of turbulent flow and heat transfer in a channel with periodic array of cubic pin-fins. Numer. Heat Transf. A 2004, 46, 731–763. [Google Scholar] [CrossRef]

- Delibra, G.; Hanjalić, K.; Borello, D.; Rispoli, F. Vortex structures and heat transfer in a wall-bounded pin matrix: Les with a RANS wall-treatment. Int. J. Heat Fluid Flow 2010, 31, 740–753. [Google Scholar] [CrossRef]

- Carnevale, M.; Salvadori, S.; Martelli, F.; Manna, M. A comparative study of rans, urans and nles approaches for flow prediction in pin fin array. In Proceedings of the 10th European Conference on Turbomachinery Fluid Dynamics & Thermodynamics, Lappeenranta, Finland, 15–19 April 2013; European Turbomachinery Society: Naples, Italy, 2013. [Google Scholar]

- Paniagua, L.; Lehmkuhl, O.; Oliet, C.; Pérez-Segarra, C.D. Large eddy simulations (LES) on the flow and heat transfer in a wall-bounded pin matrix. Numer. Heat Transf. B 2014, 65, 103–128. [Google Scholar] [CrossRef]

- Hao, Z.; Gorlé, C. Large eddy simulations of forced heat convection in a pin-fin array with a priori examination of an eddy-viscosity turbulence model. Int. J. Heat Fluid Flow 2019, 77, 73–83. [Google Scholar] [CrossRef]

- Hao, Z.; Gorlé, C. Quantifying turbulence model uncertainty in Reynolds-averaged Navier–Stokes simulations of a pin-fin array. Part 1: Flow field. Comput. Fluids 2020, 209, 104641. [Google Scholar] [CrossRef]

- Hao, Z.; Gorlé, C. Quantifying turbulence model uncertainty in Reynolds-averaged Navier–Stokes simulations of a pin-fin array. Part 2: Scalar transport. Comput. Fluids 2020, 209, 104642. [Google Scholar] [CrossRef]

- Effendy, M.; Yao, Y.; Sugati, D.; Tjahjono, T. Numerical study of pin-fin cooling on gas turbine blades. AIP Conf. Proc. 2019, 2114, 060022. [Google Scholar]

- Jamaldi, A.; Hassan, H.K. Performance prediction of trailing-edge cooling system of gas turbine blade using detached eddy simulation. Appl. Res. Smart Technol. (ARSTech) 2020, 1, 16–21. [Google Scholar] [CrossRef]

- Kim, B.-C.; Chang, K. Assessment of hybrid RANS/LES models in heat and fluid flows around staggered pin-fin arrays. Energies 2020, 13, 3752. [Google Scholar] [CrossRef]

- Benhamadouche, S.; Afgan, I.; Manceau, R. Numerical simulations of flow and heat transfer in a wall-bounded pin matrix. Flow Turbul. Combust. 2020, 104, 19–44. [Google Scholar] [CrossRef]

- Wan, P.; Han, X.; Mao, J. Very Large Eddy Simulation of turbulent flow and heat transfer for single cylinder and cylindrical pin matrix. Appl. Therm. Eng. 2020, 169, 114972. [Google Scholar] [CrossRef]

- Bauer, J.; Tyacke, J. Comparison of low Reynolds number turbulence and conjugate heat transfer modelling for pin-fin roughness elements. Appl. Math. Modell. 2022, 103, 696–713. [Google Scholar] [CrossRef]

- Jogee, S.; Anupindi, K. Evaluation of flow and thermal characteristics for flow through a wall-confined array of pin-fins using large-eddy simulation. Int. J. Heat Mass Transf. 2022, 196, 123214. [Google Scholar] [CrossRef]

- Lee, C.S.; Tom, I.; Shih, P. Effects of heat loads on flow and heat transfer in the entrance region of a cooling duct with a staggered array of pin fins. Int. J. Heat Mass Transf. 2021, 175, 121302. [Google Scholar] [CrossRef]

- Lee, C.S.; Shih, T.I.P.; Bryden, K.M.; Dalton, R.P.; Dennis, R.A. Strongly heated turbulent flow in a channel with pin fins. Energies 2023, 16, 1215. [Google Scholar] [CrossRef]

- Ames, F.E.; Nordquist, C.A.; Klennert, L.A. Endwall heat transfer measurements in a staggered pin fin array with an adiabatic pin. In Proceedings of the Turbo Expo: Power for Land, Sea, and Air, Montreal, QC, Canada, 14–17 May 2007; ASME: New York, NY, USA, 2007. [Google Scholar]

- Ligrani, P.M.; Harrison, J.L.; Mahmmod, G.I.; Hill, M.L. Flow structure due to dimple depressions on a channel surface. Phys. Fluids 2001, 13, 3442–3451. [Google Scholar] [CrossRef]

- Mahmood, G.I.; Ligrani, P.M. Heat transfer in a dimpled channel: Combined influences of aspect ratio, temperature ratio, Reynolds number, and flow structure. Int. J. Heat Mass Transf. 2002, 45, 2011–2020. [Google Scholar] [CrossRef]

- Elyyan, M.A.; Tafti, D.K. Large eddy simulation investigation of flow and heat transfer in a channel with dimples and protrusions. J. Turbomach. 2008, 130, 041016. [Google Scholar] [CrossRef]

- Elyyan, M.A.; Tafti, D.K. Effect of Coriolis forces in a rotating channel with dimples and protrusions. Int. J. Heat Fluid Flow 2010, 31, 1–18. [Google Scholar] [CrossRef]

- Lee, Y.O.; Ahn, J.; Lee, J.S. Effects of dimple depth and Reynolds number on the turbulent heat transfer in a dimpled channel. Prog. Comp. Fluid Dyn. Int. J. 2008, 8, 432–438. [Google Scholar] [CrossRef]

- Lee, Y.O.; Ahn, J.; Kim, J.; Lee, J.S. Effect of dimple arrangements on the turbulent heat transfer in a dimpled channel. J. Enhanced Heat Transf. 2012, 19, 359–367. [Google Scholar] [CrossRef]

- Turnow, J.; Kornev, N.; Isaev, S.; Hassel, E. Vortex mechanism of heat transfer enhancement in a channel with spherical and oval dimples. Heat Mass Transf. 2011, 47, 301–313. [Google Scholar] [CrossRef]

- Turnow, J.; Kornev, N.; Zhdanov, V.; Hassel, E. Flow structures and heat transfer on dimples in a staggered arrangement. Int. J. Heat Fluid Flow 2012, 35, 168–175. [Google Scholar] [CrossRef]

- Turnow, J.; Kasper, R.; Kornev, N. Flow structures and heat transfer over a single dimple using hybrid URANS-LES methods. Comput. Fluids 2018, 172, 720–727. [Google Scholar] [CrossRef]

- Chen, Y.; Chew, Y.T.; Khoo, B.C. Enhancement of heat transfer in turbulent channel flow over dimpled surface. Int. J. Heat Mass Transf. 2012, 55, 8100–8121. [Google Scholar] [CrossRef]

- Chen, Y.; Chew, Y.T.; Khoo, B.C. Heat transfer and flow structure on periodically dimple–protrusion patterned walls in turbulent channel flow. Int. J. Heat Mass Transf. 2014, 78, 871–882. [Google Scholar] [CrossRef]

- Yoon, H.S.; Park, S.H.; Choi, C.; Ha, M.Y. Numerical study on characteristics of flow and heat transfer in a cooling passage with a tear-drop dimple surface. Int. J. Therm. Sci. 2015, 89, 121–135. [Google Scholar] [CrossRef]

- Jeong, M.; Ha, M.Y.; Park, Y.G. Numerical investigation of heat transfer enhancement in a dimpled cooling channel with different angles of the vortex generator. Int. J. Heat Mass Transf. 2019, 144, 118644. [Google Scholar] [CrossRef]

- Xie, Y.; Rao, Y.; Li, W.; Qin, J. Experiments and Stress-Blended Eddy Simulations of turbulent flow over edge-rounded dimples. Int. J. Therm. Sci. 2020, 154, 106380. [Google Scholar] [CrossRef]

- Zhang, P.; Rao, Y.; Xie, Y.; Zhang, M. Turbulent flow structure and heat transfer mechanisms over surface vortex structures of micro V-shaped ribs and dimples. Int. J. Heat Mass Transf. 2021, 178, 121611. [Google Scholar] [CrossRef]

- Li, M.; Chen, X.; Ruan, X. Investigation of flow structure and heat transfer enhancement in rectangular channels with dimples and protrusions using large eddy simulation. Int. J. Therm. Sci. 2020, 149, 106207. [Google Scholar] [CrossRef]

- Nourin, F.N.; Amano, R.S. Experimental and large eddy simulation study for visualizing complex flow phenomena of gas turbine internal blade cooling channel with no bend. J. Energy Resour. Technol. 2022, 144, 062104. [Google Scholar] [CrossRef]

- İlter, Y.K.; Çetinkaya, A.; Ünal, U.O. Large eddy simulations of the turbulent channel flow over dimpled surfaces. J. Turbul. 2023, 24, 2186415. [Google Scholar] [CrossRef]

- Yamamoto, T.; Murata, A.; Inokuma, K.; Iwamoto, K. Heat transfer augmentation due to flow pulsation in a channel with teardrop-shaped dimples investigated by large eddy simulation. Int. J. Heat Fluid Flow 2024, 110, 109579. [Google Scholar] [CrossRef]

- Inokuma, K.; Yawata, Y.; Murata, A.; Iwamoto, K. Effects of flow pulsation and surface geometry on heat transfer performance in a channel with teardrop-shaped dimples investigated by large eddy simulation. ASME J. Heat Mass Transf. 2024, 146, 061801. [Google Scholar] [CrossRef]

- Amsha, K.A.; Craft, T.J.; Iacovides, H. Computational modelling of the flow and heat transfer in dimpled channels. Aeronaut. J. 2017, 121, 1066–1086. [Google Scholar] [CrossRef]

- Kwon, H.G.; Hwang, S.D.; Cho, H.H. Measurement of local heat/mass transfer coefficients on a dimple using naphthalene sublimation. Int. J. Heat Mass Transf. 2011, 54, 1071–1080. [Google Scholar] [CrossRef]

- Rao, Y.; Li, B.; Feng, Y. Heat transfer of turbulent flow over surfaces with spherical dimples and teardrop dimples. Exp. Therm. Fluid Sci. 2015, 61, 201–209. [Google Scholar] [CrossRef]

- Isaev, S.A.; Kornev, N.V.; Leontiev, A.I.; Hassel, E. Influence of the Reynolds number and the spherical dimple depth on turbulent heat transfer and hydraulic loss in a narrow channel. Int. J. Heat Mass Transf. 2010, 53, 178–197. [Google Scholar] [CrossRef]

- Katkhaw, N.; Vorayos, N.; Kiatsiriroat, T.; Khunatorn, Y.; Bunturat, D.; Nuntaphan, A. Heat transfer behavior of flat plate having 45 ellipsoidal dimpled surfaces. Case Stud. Therm. Eng. 2014, 2, 67–74. [Google Scholar] [CrossRef]

- Jordan, C.N.; Wright, L.M. Heat transfer enhancement in a rectangular (AR = 3:1) channel with V-shaped dimples. In Turbo Expo: Power for Land, Sea, and Air; ASME: New York, NY, USA, 2011; Volume 54655. [Google Scholar]

- Hwang, S.D.; Kwon, H.G.; Cho, H.H. Heat transfer with dimple/protrusion arrays in a rectangular duct with a low Reynolds number range. Int. J. Heat Fluid Flow 2008, 29, 916–926. [Google Scholar] [CrossRef]

- Choi, E.Y.; Choi, Y.D.; Lee, W.S.; Chung, J.T.; Kwak, J.S. Heat transfer augmentation using a rib–dimple compound cooling technique. Appl. Therm. Eng. 2013, 51, 435–441. [Google Scholar] [CrossRef]

- Mironov, A.; Isaev, S.; Skrypnik, A.; Popov, I. Numerical and physical simulation of heat transfer enhancement using oval dimple vortex generators—Review and recommendations. Energies 2020, 13, 5243. [Google Scholar] [CrossRef]

- Choi, S.M.; Kwon, H.G.; Bang, M.; Moon, H.K.; Cho, H.H. Heat transfer from a dimple-imprint downstream of boundary-layer trip-wire. Int. J. Heat Mass Transf. 2021, 173, 121242. [Google Scholar] [CrossRef]

- Wong, T.H.; Ireland, P.T.; Self, K.P. Film cooling effectiveness downstream of trailing edge slots including cutback surface protuberances. Int. Power 2016, 1, 4. [Google Scholar] [CrossRef]

- Schneider, H.; von Terzi, D.; Bauer, H.J. Large-Eddy Simulations of trailing-edge cutback film cooling at low blowing ratio. Int. J. Heat Fluid Flow 2010, 31, 767–775. [Google Scholar] [CrossRef]

- Schneider, H.; Von Terzi, D.; Bauer, H.J. Turbulent heat transfer and large coherent structures in trailing-edge cutback film cooling. Flow Turbul. Combust. 2012, 88, 101–120. [Google Scholar] [CrossRef]

- Schneider, H.; Von Terzi, D.A.; Bauer, H.J.; Rodi, W. Coherent structures in trailing-edge cooling and the challenge for turbulent heat transfer modelling. Int. J. Heat Fluid Flow 2015, 51, 110–119. [Google Scholar] [CrossRef]

- Ravelli, S.; Barigozzi, G. Application of unsteady computational fluid dynamics methods to trailing edge cutback film cooling. J. Turbomach. 2014, 136, 121006. [Google Scholar] [CrossRef]

- Ravelli, S.; Barigozzi, G. Stress-blended eddy simulation of coherent unsteadiness in pressure side film cooling applied to a first stage turbine vane. J. Heat Transf. 2018, 140, 092201. [Google Scholar] [CrossRef]

- Ravelli, S.; Barigozzi, G. Dynamics of coherent structures and random turbulence in pressure side film cooling on a first stage turbine vane. J. Turbomach. 2019, 141, 011003. [Google Scholar] [CrossRef]

- Naqavi, I.Z.; Tucker, P.G.; Liu, Y. Large-eddy simulation of the interaction of wall jets with external stream. Int. J. Heat Fluid Flow 2014, 50, 431–444. [Google Scholar] [CrossRef]

- Effendy, M.; Yao, Y.F.; Yao, J.; Marchant, D.R. DES study of blade trailing edge cutback cooling performance with various lip thicknesses. Appl. Therm. Eng. 2016, 99, 434–445. [Google Scholar] [CrossRef]

- Effendy, M.; Yao, Y.F.; Yao, J.; Marchant, D.R. Detached eddy simulation of blade trailing-edge cutback cooling performance at various ejection slot angles. Int. J. Heat Fluid Flow 2019, 80, 108487. [Google Scholar] [CrossRef]

- Sandberg, R.D.; Tan, R.; Weatheritt, J.; Ooi, A.; Haghiri, A.; Michelassi, V.; Laskowski, G. Applying machine learnt explicit algebraic stress and scalar flux models to a fundamental trailing edge slot. J. Turbomach. 2018, 140, 101008. [Google Scholar] [CrossRef]

- Khalil, A.; Kayed, H.; Hanafi, A.; Nemitallah, M.; Habib, M. Numerical Predictions of Three-Dimensional Unsteady Turbulent Film-Cooling for Trailing Edge of Gas-Turbine Blade Using Large Eddy Simulation. J. Energy Resour. Technol. 2019, 141, 042206. [Google Scholar] [CrossRef]

- Wang, R.; Yan, X. Delayed-detached eddy simulations of film cooling effect on trailing edge cutback with land extensions. J. Eng. Gas Turbines Power 2021, 143, 111004. [Google Scholar] [CrossRef]

- Luo, Y.; Wen, F.; Sullivan, P.; Wang, S.; Wang, Z. Large eddy simulation study on trailing edge cutback cooling with a whisker lip. Int. J. Heat Mass Transf. 2022, 194, 123079. [Google Scholar] [CrossRef]

- Du, W.; Luo, L.; Wang, S.; Jiao, Y.; Sunden, B. Film cooling in the cutback for trailing edge with different incident angles. J. Energy Resour. Technol. 2023, 145, 053201. [Google Scholar] [CrossRef]

- Luo, Y.; Wen, F.; Wang, S.; Wang, Z. DDES study on a pressure-side cutback cooling turbine blade with a whisker lip and a whisker trailing edge. Numer. Heat Transf. A 2024, 85, 739–760. [Google Scholar] [CrossRef]

- Jia, Q.; Du, W.; Luo, L.; Yan, H.; Li, X.; Jiao, Y.; Wang, S. DES study of the unsteady flow and film cooling at trailing edge cutback with various internal rib configurations. Aerosp. Sci. Technol. 2024, 145, 108865. [Google Scholar] [CrossRef]

- Jia, Q.; Du, W.; Li, X.; Luo, L.; Jiao, Y.; Yan, H. Effects of blowing ratios and lip thicknesses on film cooling for trailing edge cutback with latticework ducts. Appl. Therm. Eng. 2024, 252, 123640. [Google Scholar] [CrossRef]

- Xu, Q.; Wang, P.; Du, Q. DDES investigation of the cooling performance and turbulence characteristics of the turbine vane trailing edge cutback slot with fan-shaped holes. Int. Commun. Heat Mass Transf. 2022, 138, 106405. [Google Scholar] [CrossRef]

- Wang, P.; Xu, Q.; Liu, J.; Wang, P.; Du, Q.; Wang, Z. Experimental and unsteady numerical investigations on cooling characteristics of trailing-edge cutback with effect of upstream film holes. Int. J. Therm. Sci. 2023, 193, 108423. [Google Scholar] [CrossRef]

- Li, Y.; Rao, Y.; Liu, Y.; Terzis, A. Film cooling enhancement over oblong-dimpled cutback surfaces for the trailing edge of turbine blades. Int. J. Heat Fluid Flow 2024, 108, 109450. [Google Scholar] [CrossRef]

- Martini, P.; Schulz, A.; Bauer, H.J. Film cooling effectiveness and heat transfer on the trailing edge cutback of gas turbine airfoils with various internal cooling designs. J. Turbomach. 2006, 128, 196–205. [Google Scholar] [CrossRef]

- Tariq, A.; Prajapati, A.N. Heat transfer characteristics within the matrix cooling channels. J. Turbomach. 2021, 143, 051007. [Google Scholar] [CrossRef]

- Chen, Z.; Mao, Y.; Hu, K.; Su, X.; Yuan, X. 2-D prediction method for multi-row film cooling effectiveness. Appl. Therm. Eng. 2021, 199, 117607. [Google Scholar] [CrossRef]

- Li, X.; Ren, J.; Jiang, H. Multi-row film cooling characteristics on a vane endwall. Int. J. Heat Mass Transf. 2016, 92, 23–33. [Google Scholar] [CrossRef]

- Li, B.; Liu, C.; Ye, L.; Zhou, T.; Zhang, F. Evaluation of film cooling effect in multi-row hole configurations on turbine blade leading edge. Energy 2024, 309, 132908. [Google Scholar] [CrossRef]

- Siw, S.C.; Chyu, M.K.; Alvin, M.A. Heat transfer enhancement of internal cooling passage with triangular and semi-circular shaped pin-fin arrays. In Turbo Expo: Power for Land, Sea, and Air; ASME: New York, NY, USA, 2012. [Google Scholar]

- Jin, W.; Wu, J.; Jia, N.; Lei, J.; Ji, W.; Xie, G. Effect of shape and distribution of pin-fins on the flow and heat transfer characteristics in the rectangular cooling channel. Int. J. Therm. Sci. 2021, 161, 106758. [Google Scholar] [CrossRef]

- Bianchini, C.; Facchini, B.; Simonetti, F.; Tarchi, L.; Zecchi, S. Numerical and experimental investigation of turning flow effects on innovative pin fin arrangements for trailing edge cooling configurations. J. Turbomach. 2012, 134, 021005. [Google Scholar] [CrossRef]

- Chang, S.W.; Yang, T.L.; Huang, C.C.; Chiang, K.F. Endwall heat transfer and pressure drop in rectangular channels with attached and detached circular pin-fin array. Int. J. Heat Mass Transf. 2008, 51, 5247–5259. [Google Scholar] [CrossRef]

- Srinivasan, D.; Ananth, K. Recent advances in alloy development for metal additive manufacturing in gas turbine/aerospace applications: A review. J. Indian Inst. Sci. 2022, 102, 311–349. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, J.; Zhang, Y.; Zhang, J.; Ma, S.; Sunden, B.; Xie, G. Effect of shape and placement of twisted pin fins in a rectangular channel on thermo-hydraulic performance. J. Therm. Sci. 2024, 33, 1773–1793. [Google Scholar] [CrossRef]

- Zhang, W.; Chen, L.; Feng, H.; Ge, Y. Adding branched fin angle as degree-of-freedom improves performance of a TY-shaped fin. Case Stud. Therm. Eng. 2024, 61, 105031. [Google Scholar] [CrossRef]

- Cui, H.; Wang, L.; Li, X.; Ren, J. Data-driven conjugate heat transfer analysis of a gas turbine vane. Processes 2022, 10, 2335. [Google Scholar] [CrossRef]

- Ubulom, I. Influence of fluid-structure interaction modelling on the stress and fatigue life evaluation of a gas turbine blade. Proc. Inst. Mech. Eng. A J. Power Energy 2021, 235, 1019–1038. [Google Scholar] [CrossRef]

- Sharma, O.P.; Pickett, G.F.; Ni, R.H. Assessment of unsteady flows in turbines. J. Turbomach. 1992, 114, 79–90. [Google Scholar] [CrossRef]

| Institution | Country | Year [Ref.] | Model | SGS | Software | Reynolds Number | H/dp | p/dp |

|---|---|---|---|---|---|---|---|---|

| Louisiana State Univ. | U.S.A. | 2004 [31] | LES, URANS | Dynamic | In-house | 13,280 | 1 | 2.5 |

| Sapienza Roma | Italia | 2010 [32] | LES, URANS | Dynamic | In-house | 10,000 | 2 | 2.5 |

| Univ. Firenze | Italia | 2013 [33] | LES, URANS | Smagorinsky | In-house | 10,000 | 2 | 2.5 |

| Univ. Politec. Catalunya | Spain | 2014 [34] | LES | WALE, QR, VMS | In-house | 3000–30,000 | 2 | 2.5 |

| Stanford Univ. | U.S.A. | 2019 [35] | LES | One-eq. | OpenFOAM | 10,000 | 2 | 2.5 |

| 2020 [36] | LES, RANS | One-eq. | OpenFOAM | 10,000 | 2 | 2.5 | ||

| 2020 [37] | LES, RANS | One-eq. | OpenFOAM | 10,000 | 2 | 2.5 | ||

| U.M.S.S. | Indonesia | 2019 [38] | DES | Smagorinsky | In-house | 250,000 | 1 | 2.5 |

| 2020 [39] | DES | Smagorinsky | In-house | 250,000 | 1 | 2.5 | ||

| Ulsan Univ. | Korea | 2020 [40] | DES, SBES, URANS | Fluent v. 18.2 | 10,000 | 2 | 2.5 | |

| Univ. Manchester | U.K. | 2020 [41] | URANS, LES | Dynamic | In-house | 3000–30,000 | 2 | 2.5 |

| Nanjing Aviation Univ. | China | 2020 [42] | LES, RANS, DES | Smagorinsky | Fluent v. 16.1 | 10,000 | 2 | 2.5 |

| Brunel Univ. | U.K. | 2022 [43] | RANS, LES | Yoshizawa | In-house | 13,000 | 3.4 | 2.5 |

| IIT Madras | India | 2022 [44] | LES | Yoshizawa | OpenFOAM | 5900 | 2 | 2.5 |

| Purdue Univ. | U.S.A. | 2021 [45] | LES | WALE | Fluent | 10,000 | 2 | 2.5 |

| 2023 [46] | LES | WALE | In-house | 10,000 | 2 | 2.5 |

| Institution | Country | Year [Ref.] | Model | SGS | SW | Re | d/D | H/d |

|---|---|---|---|---|---|---|---|---|

| Virginia Tech. | U.S.A. | 2008 [50] | LES | Dynamic | In-house | 200, 1000, 10,000 | 0.2 | 2.5 |

| 2010 [51] | LES | Dynamic | In-house | 10,000 | 0.2 | 2.5 | ||

| Seoul Nat’l Univ. | Korea | 2008 [52] | LES | Dynamic | In-house | 5000, 20,000 | 0.2, 0.3 | 2,2.5 |

| Seoul Nat’l Univ. | Korea | 2012 [53] | LES | Dynamic | In-house | 20,000 | 0.2 | 2.5 |

| Univ, Rostock | Germany | 2011 [54] | LES, URANS | DMM | OpenFOAM | 20,000 | 0.26 | 2.5 |

| 2012 [55] | LES | LDMM | OpenFOAM | 13,000 | 0.2, 0.3 | 2.5 | ||

| 2018 [56] | LES, IDDES | WMLES | OpenFOAM | 20,000, 50,000 | 0.26 | 2.5 | ||

| Nat’l Univ. Singapore | Singapore | 2012 [57] | DES | Smagorinsky | In-house | 5000 | 0.05–0.3 | 3–10 |

| 2014 [58] | DES | Smagorinsky | In-house | 6000 | 0.125 | 5 | ||

| Pusan Nat’l Univ. | Korea | 2015 [59] | DNS | In-house | 3000 | 0.2 | 2.5 | |

| 2019 [60] | DNS | In-house | 3000 | 0.2 | 2.5 | |||

| Shanghai Jiaotong | China | 2020 [61] | SBES | WMLES | Fluent | 10,000, 60,000 | 0.2 | 2 |

| 2021 [62] | DDES | Smagorinsky | Fluent v.16 | 50,000 | 0.2 | 2.5 | ||

| Jilin Univ. | China | 2020 [63] | LES | TKE | OpenFOAM | 5000, 20,000 | 0.2 | 2.5 |

| Univ. Wisconsin | U.S.A. | 2022 [64] | LES | WALE | StarCCM+ | 10,000, 50,000 | 0.25 | 4 |

| Univ. Strathclyde | U.K. | 2023 [65] | LES | WALE | StarCCM+ | 10,000 | 0.05, 0.1 | 10, 20 |

| Tokyo A&M | Japan | 2024 [66] | LES | Dynamic | OpenFOAM | 25,000 | 0.3 | 3 |

| Tokyo A&M | Japan | 2024 [67] | LES | Dynamic | OpenFOAM | 25,000 | 0.3 | 3 |

| Institution | Country | Year [Ref.] | Model | SGS | SW | M | Inflow | t/H | Supply |

|---|---|---|---|---|---|---|---|---|---|

| Karlsruhe Inst. Tech. | Germany | 2010 [79] | LES | Smagorinsky | In-house | 0.5, 1.1 | Profile + fluctuation | 1 | Plain |

| 2012 [80] | LES | Smagorinsky | In-house | 0.5, 0.8, 1.1 | Profile + fluctuation | 1 | Plain | ||

| 2015 [81] | LES | Smagorinsky | In-house | 0.5, 0.8, 1.1 | Rescale | 1 | Plain | ||

| Univ. Bergamo | Italia | 2014 [82] | SAS, URANS | WALE | Fluent 14.5 | 0.6–1.4 | Uniform | 1 | Diverging |

| 2018 [83] | SBES | WALE | Fluent 17 | 1 | Uniform | 1 | Diverging | ||

| 2019 [84] | SBES | WALE | Fluent 17 | 1 | Uniform | 1 | Diverging | ||

| Cambridge Univ. | U.K. | 2014 [85] | LES | Dynamic | In-house | 0.3–2.3 | Rescale | 1 | Plain |

| Univ. West England | U.K. | 2016 [86] | DES | Smagorinsky | Fluent | 0.5, 1.1 | Profile | 0.25–1.5 | Pin fin |

| 2019 [87] | DES | Smagorinsky | Fluent | 0.5, 1.1 | Profile | 1 | Pin fin | ||

| Univ. Melbourne | Australia | 2018 [88] | LES | ML | In-house | 1.26 | Profile | 1.14, 0.126 | Plain |

| King Fahd Univ. | Saudi Arabia | 2019 [89] | LES | WALE | Fluent 17.2 | 0.4–1.7 | Uniform | 1 | Diverging |

| Xian Jiaotong Univ. | China | 2021 [90] | DDES | Smagorinsky | CFX 18 | 0.5, 1.1 | Uniform | 1 | Pin fin |

| Harbin Inst. Tech | China | 2022 [91] | DES | Smagorinsky | CFX | 0.2,0.8,1.25 | Uniform | 1 | Pin fin |

| 2023 [92] | LES | WALE | Fluent | 0.6–1.1 | Uniform | 1 | Plain | ||

| 2024 [93] | DDES | Smagorinsky | Fluent | 0.8, 1.1 | Uniform | 1 | Diverging | ||

| 2024 [94] | DES | Smagorinsky | CFX | 0.2, 0.8 | Uniform | 0.5–2 | Rib, pin fin, lattice | ||

| 2024 [95] | DES | Smagorinsky | CFX | 0.2, 0.8 | Uniform | 0.5–2 | Lattice work | ||

| Chinese Academy Sci. | China | 2022 [96] | DDES | Smagorinsky | CFX | 0.75 | Profile | 3 | Rib, pin fin |

| 2023 [97] | DDES | Smagorinsky | CFX | 0.3–1.2 | Profile | 3 | Plain | ||

| Shanghai Jiaotong Univ. | China | 2024 [98] | SAS | Smagorinsky | Fluent | 0.5–2 | Uniform | 0.9 | Pin fin, dimple |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahn, J. Large Eddy Simulation Approaches for Trailing-Edge Heat Transfer in Gas Turbine Blades: A Review. Energies 2025, 18, 1386. https://doi.org/10.3390/en18061386

Ahn J. Large Eddy Simulation Approaches for Trailing-Edge Heat Transfer in Gas Turbine Blades: A Review. Energies. 2025; 18(6):1386. https://doi.org/10.3390/en18061386

Chicago/Turabian StyleAhn, Joon. 2025. "Large Eddy Simulation Approaches for Trailing-Edge Heat Transfer in Gas Turbine Blades: A Review" Energies 18, no. 6: 1386. https://doi.org/10.3390/en18061386

APA StyleAhn, J. (2025). Large Eddy Simulation Approaches for Trailing-Edge Heat Transfer in Gas Turbine Blades: A Review. Energies, 18(6), 1386. https://doi.org/10.3390/en18061386