Research on the Liquid Helium Insulation Characteristics of an Experimental System

Abstract

1. Introduction

2. Theoretical Design of Experimental System for Liquid Helium Insulation Characteristics

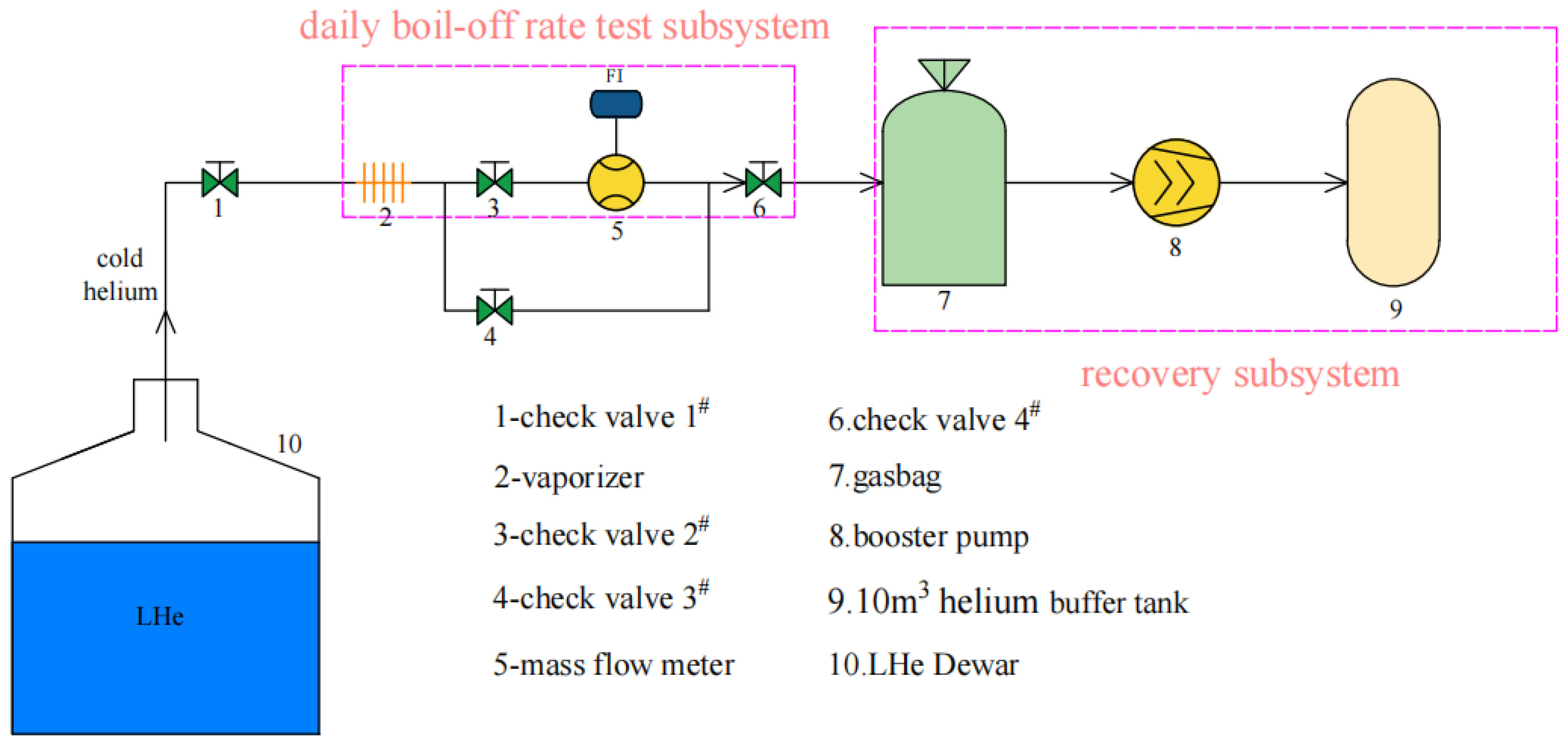

2.1. PFD of Experimental System for Liquid Helium Insulation Characteristics

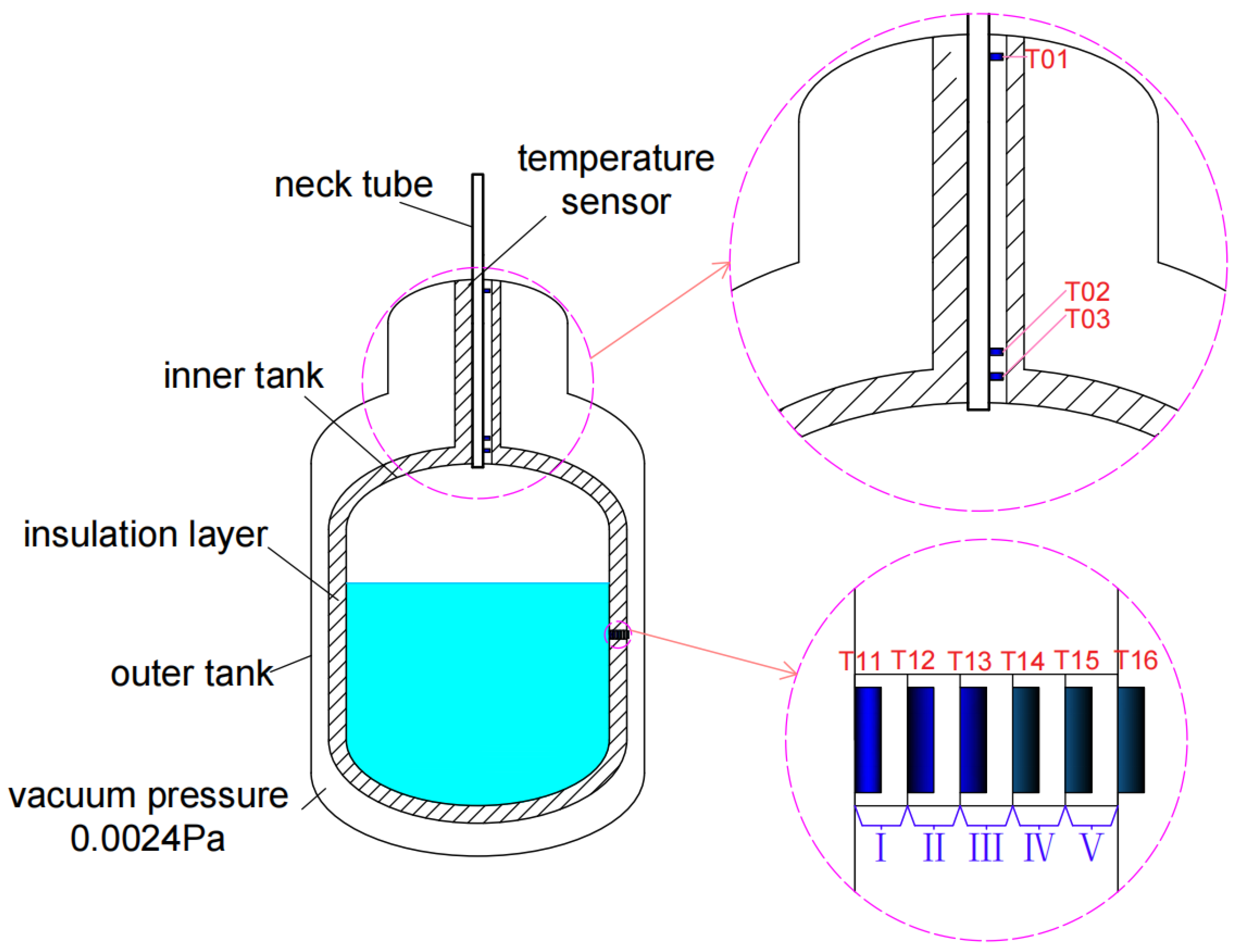

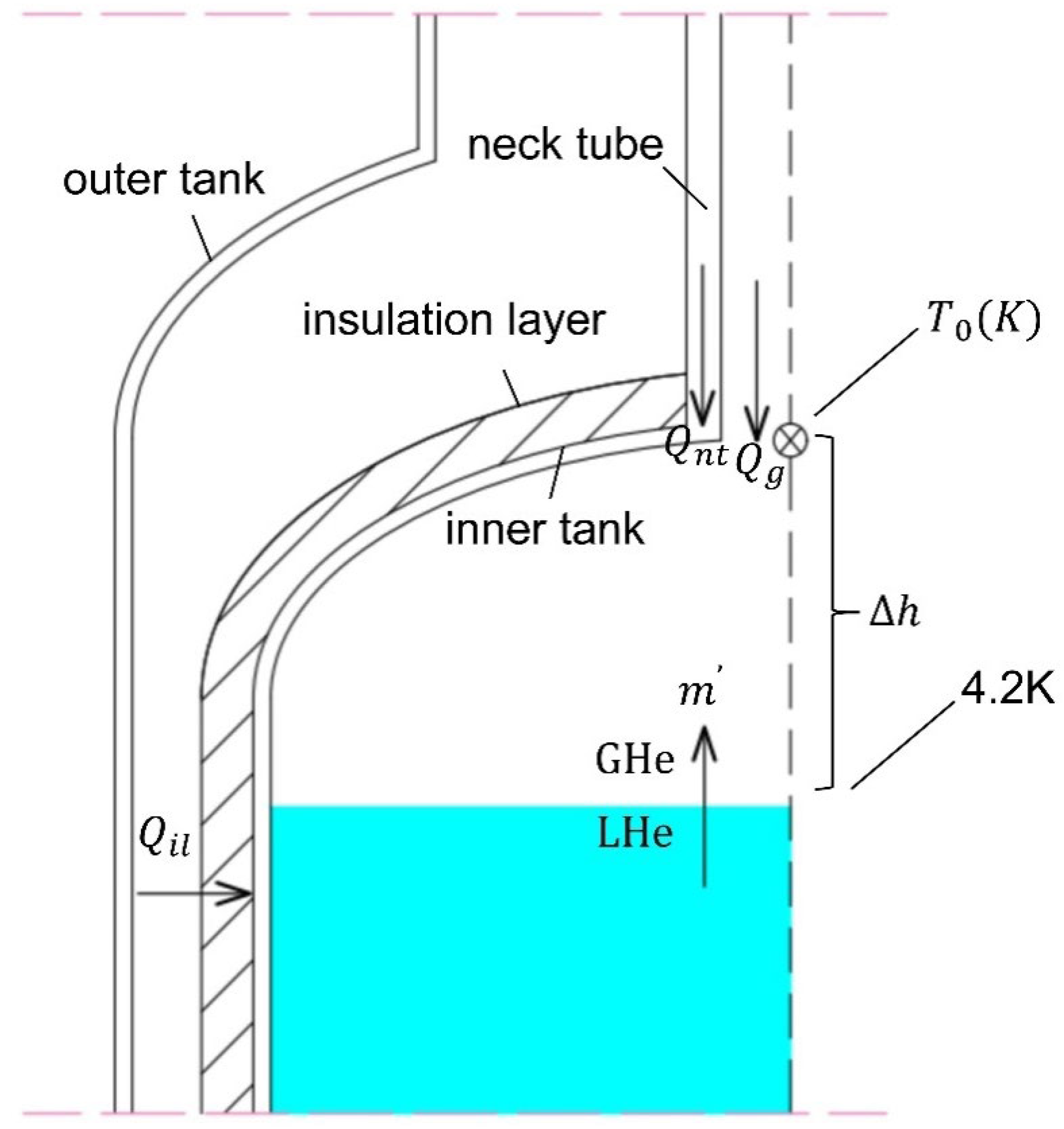

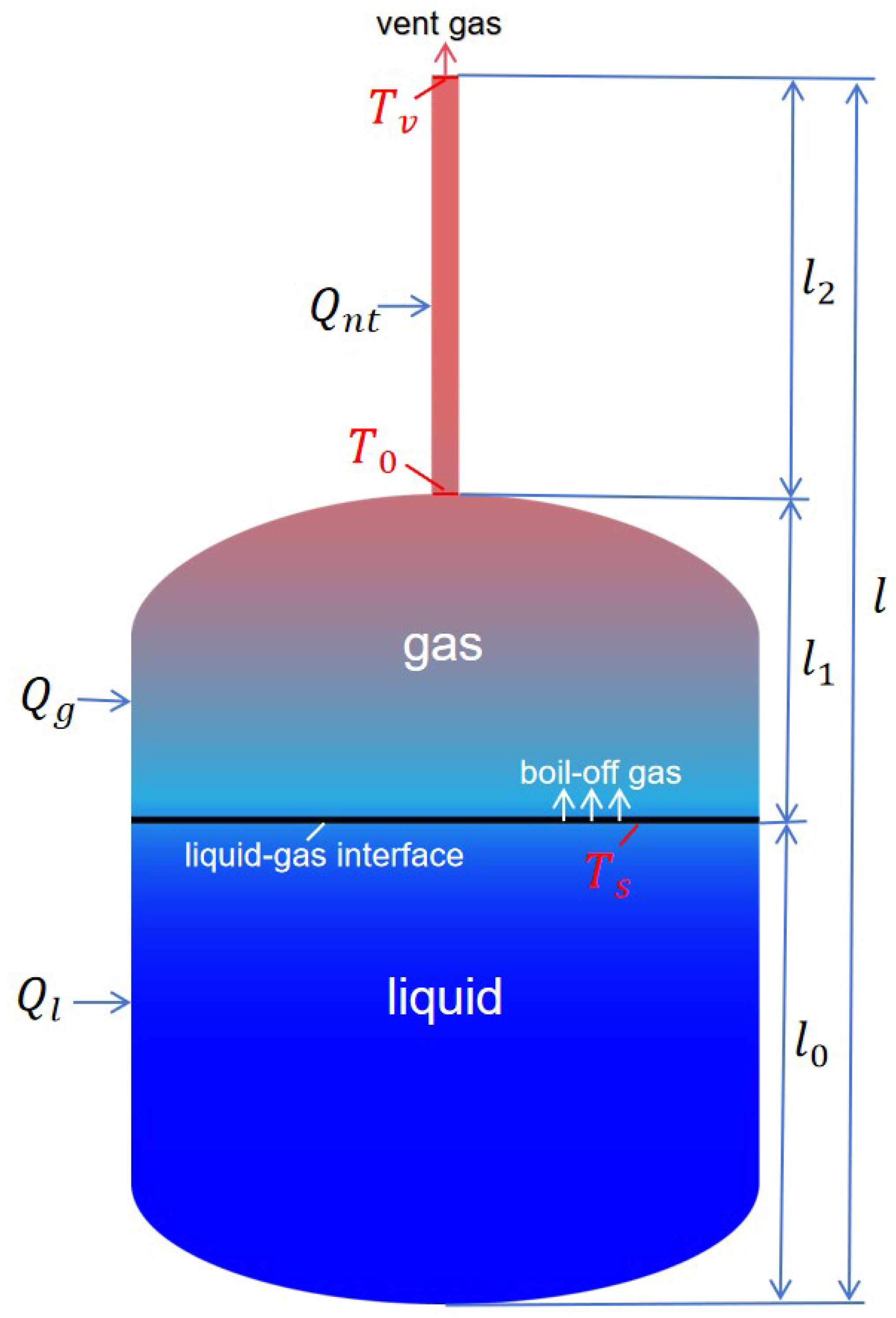

2.2. Theoretical Analysis of Heat Leakage from a Liquid Helium Dewar

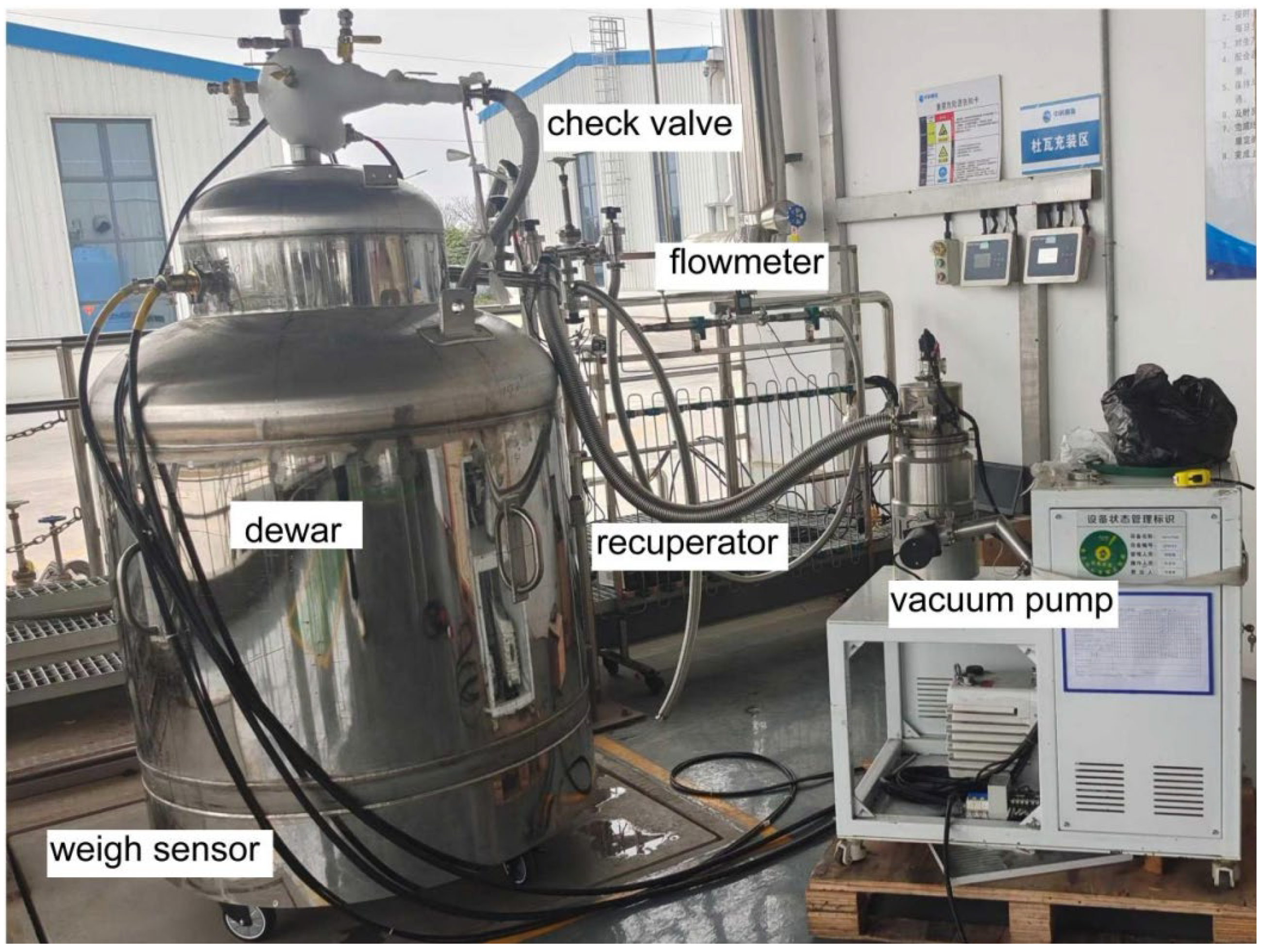

3. Experimental System for Liquid Helium Insulation Characteristics

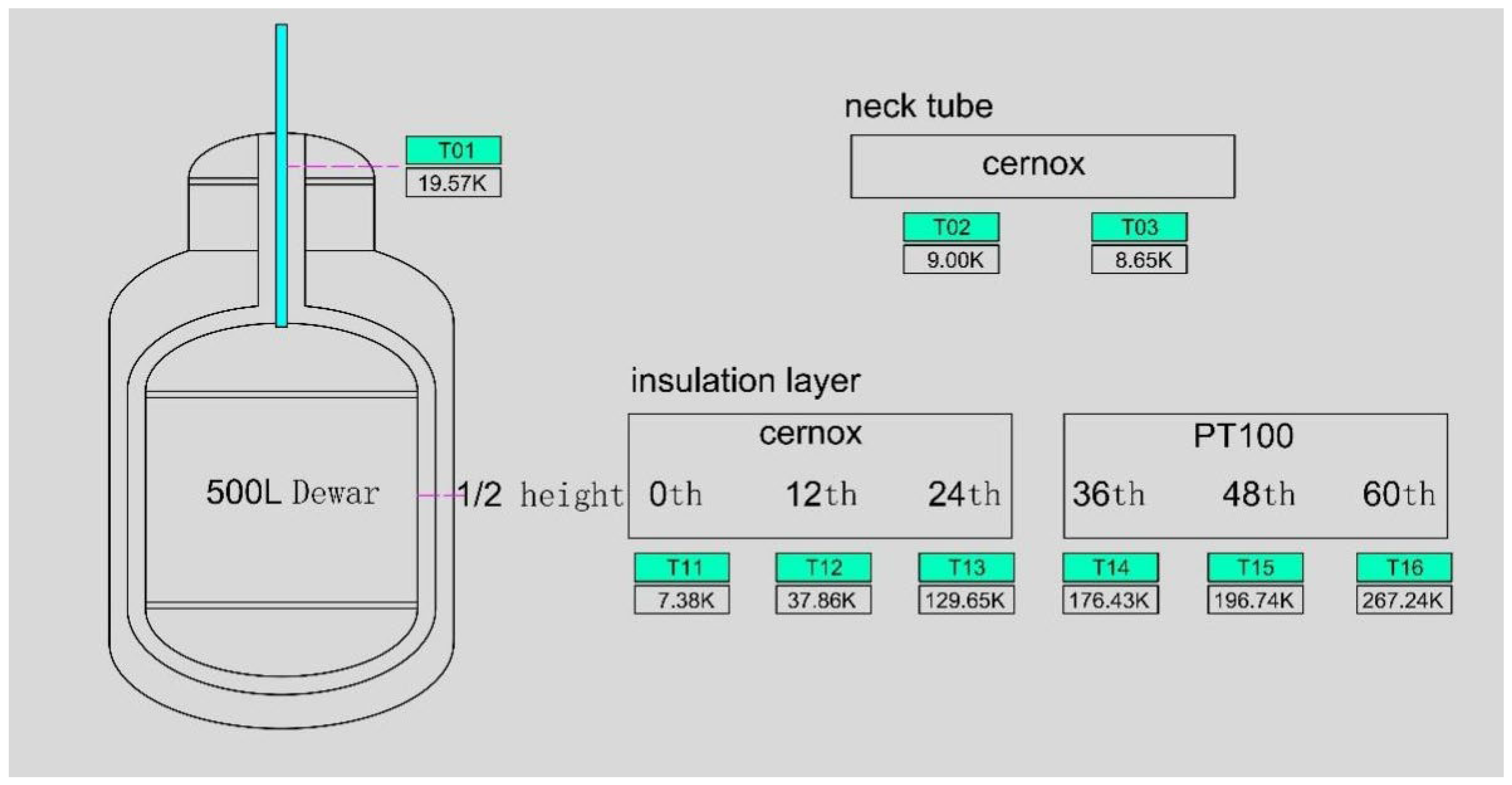

4. Results and Discussion

4.1. Uncertainty Analysis of Experimental System

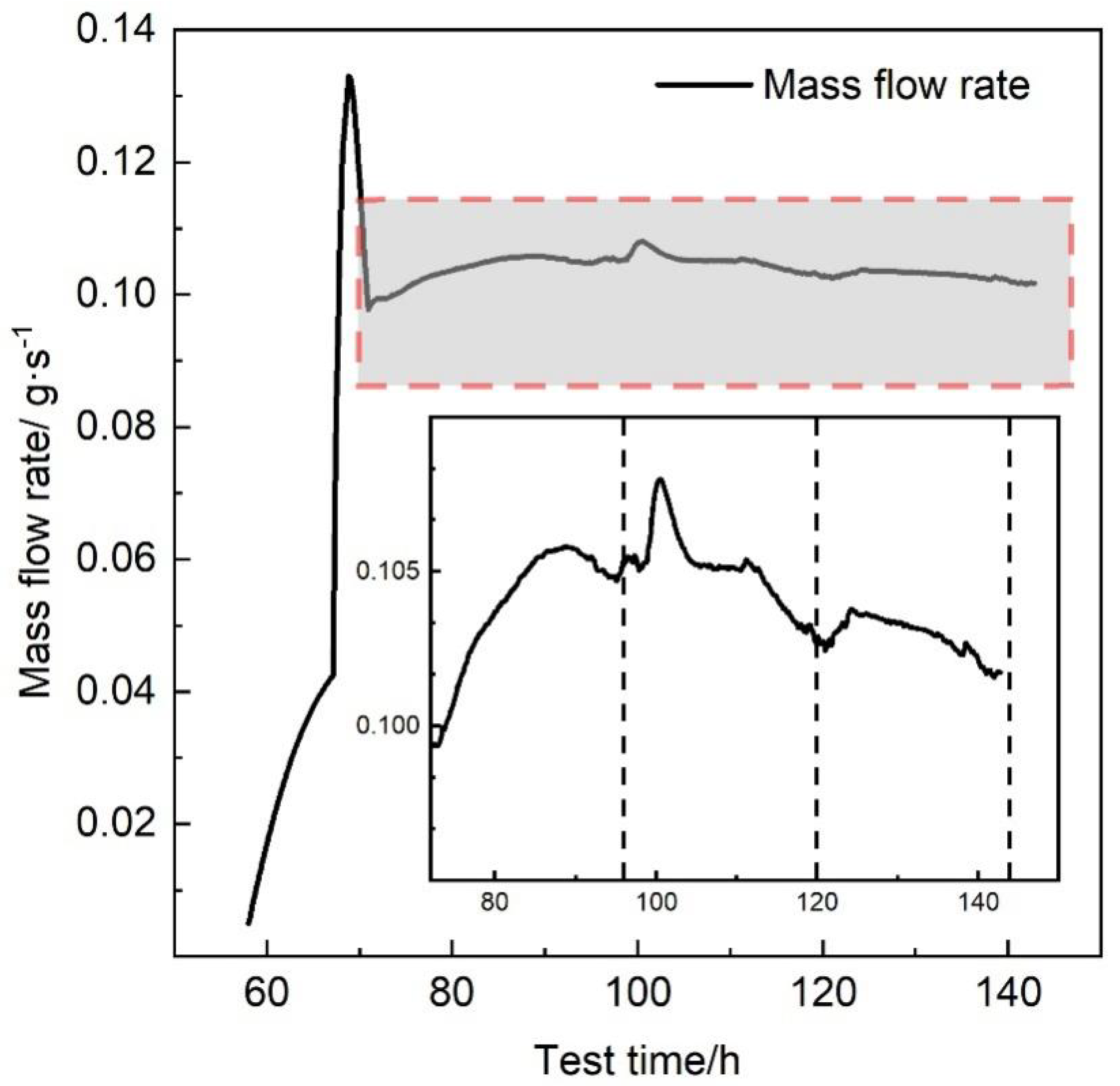

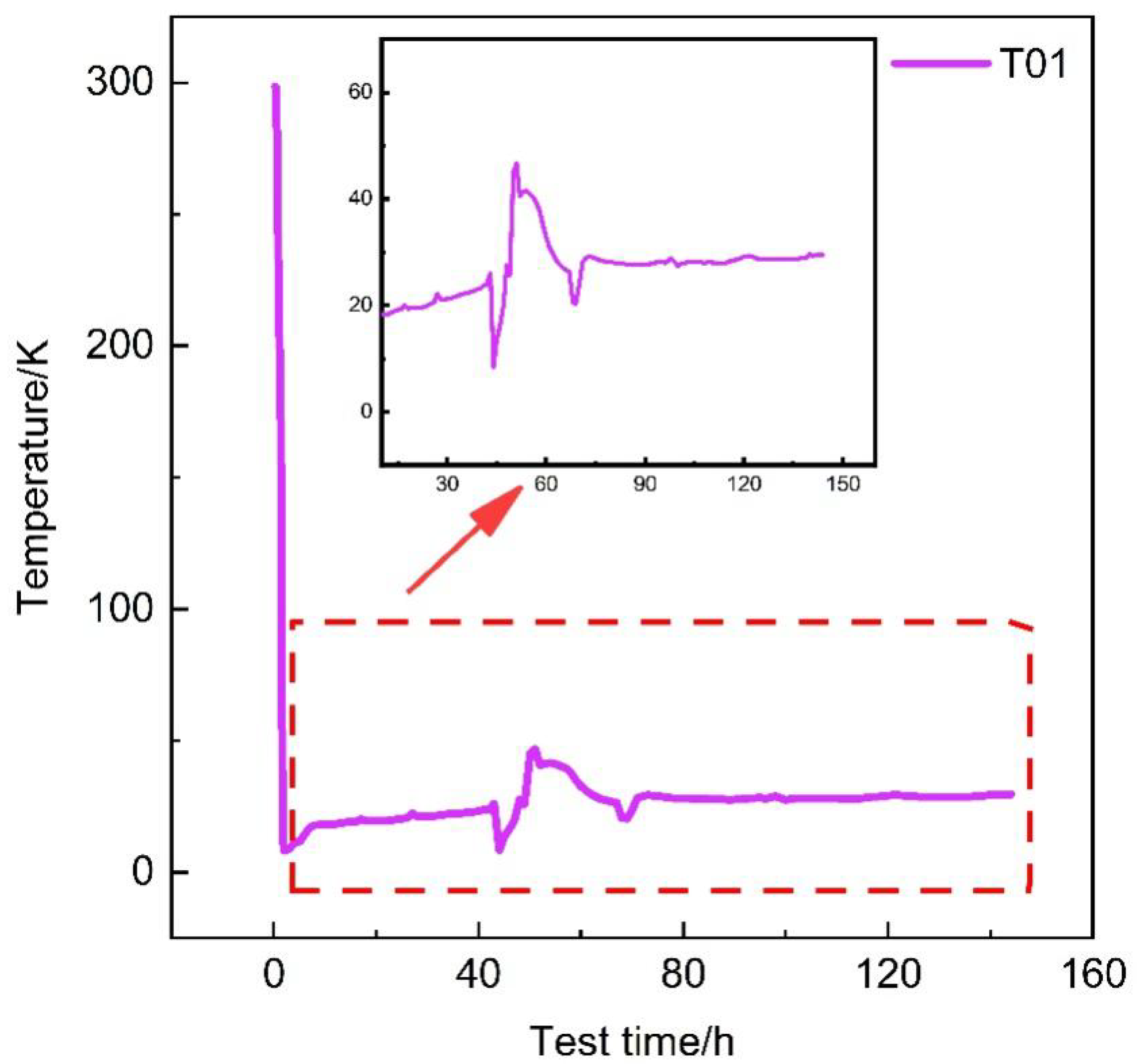

4.2. Analysis of the Daily Boil-Off Rate of the Liquid Helium Dewar

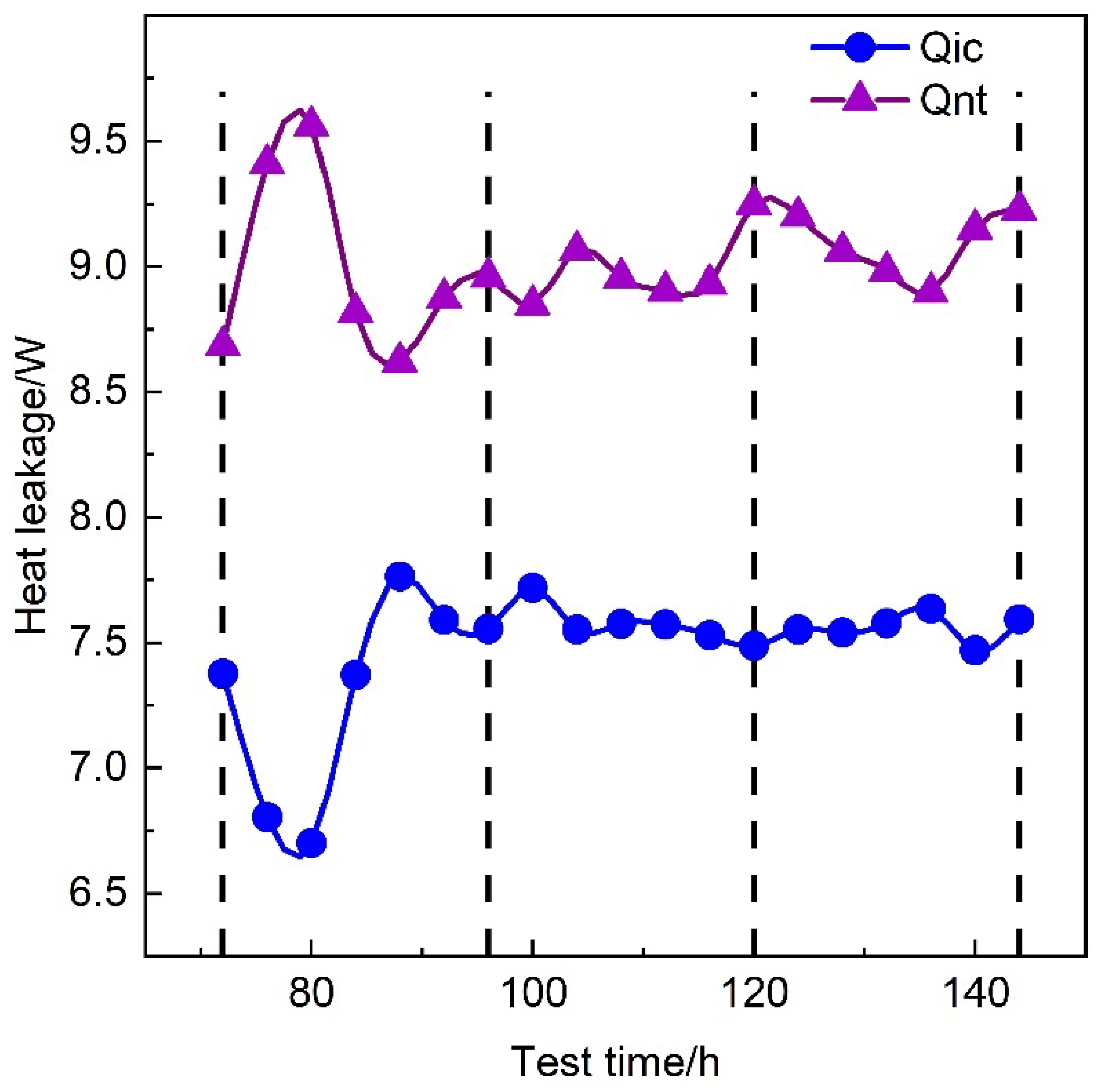

4.3. Heat Leakage from the Experimental Liquid Helium Dewar

Thermal Analysis of Dewar

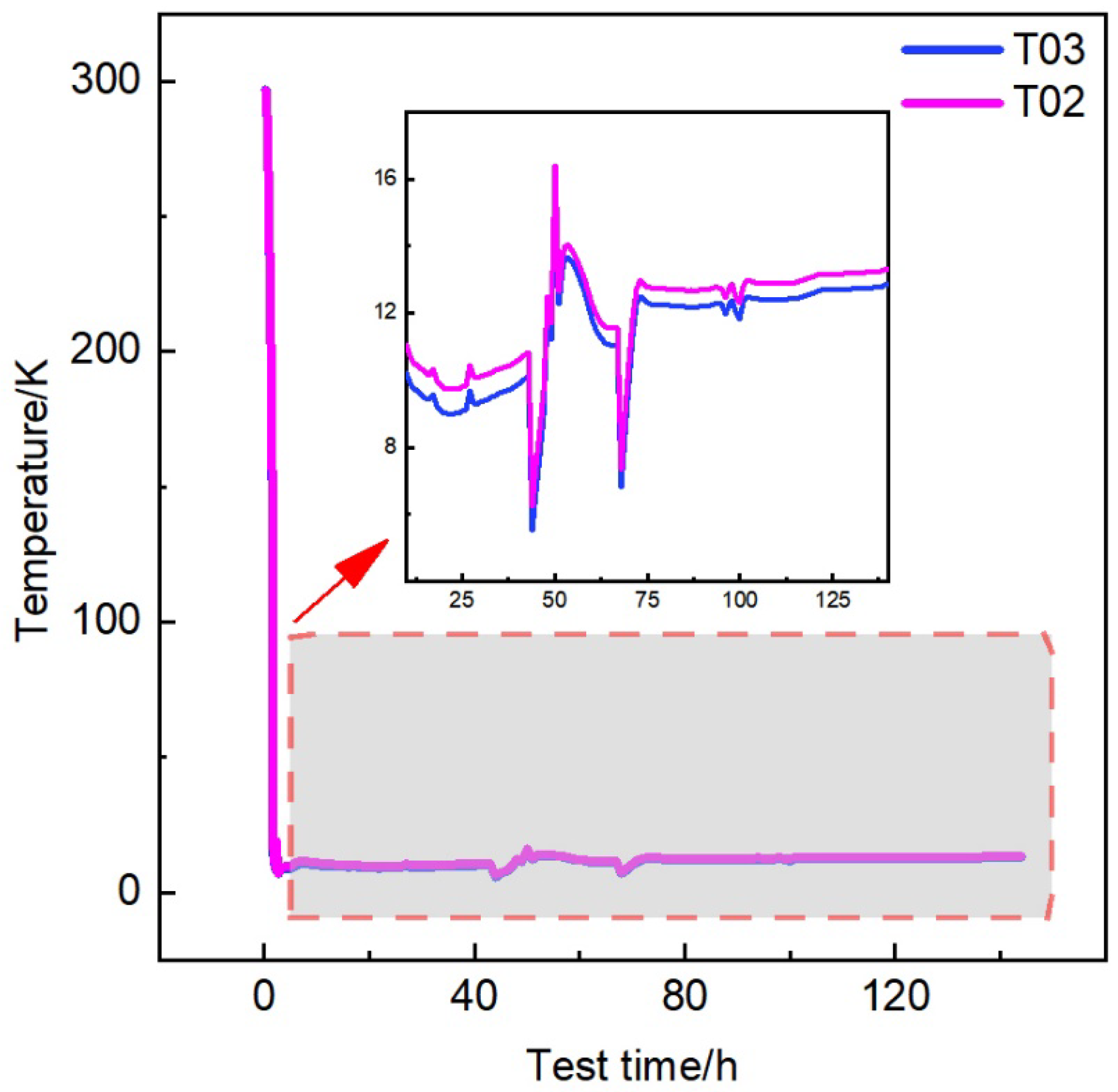

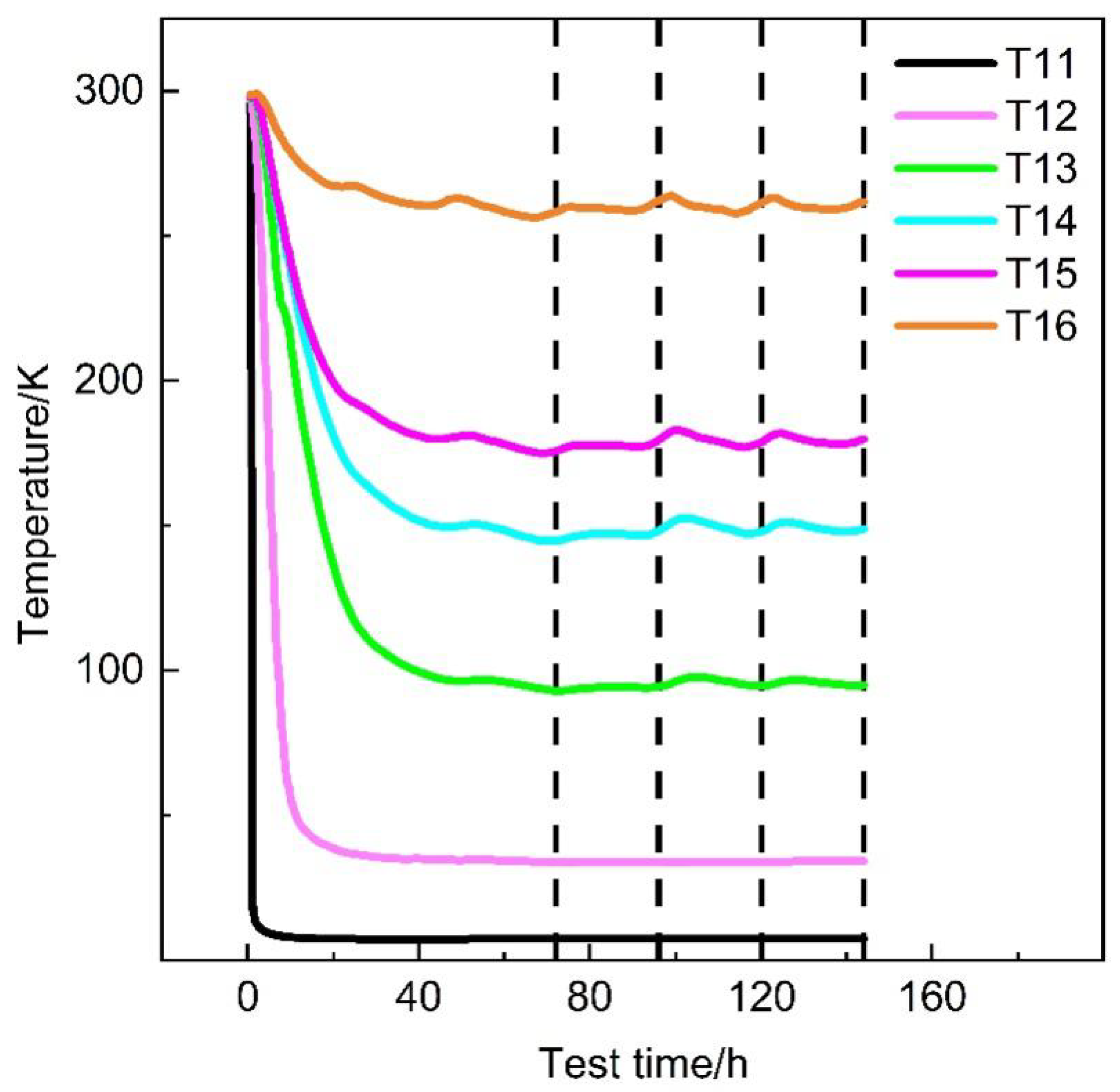

- The pressure remains constant throughout the test, and steady-flow conditions are achieved during the 72–144 h period.

- Heat leakage is assumed to solely originate from the surrounding environment.

- The liquid phase is treated as an incompressible fluid, maintaining a saturated and uniform phase.

- While the temperature gradients in the gas phase within the container and neck tube differ, both are assumed to follow a linear distribution.

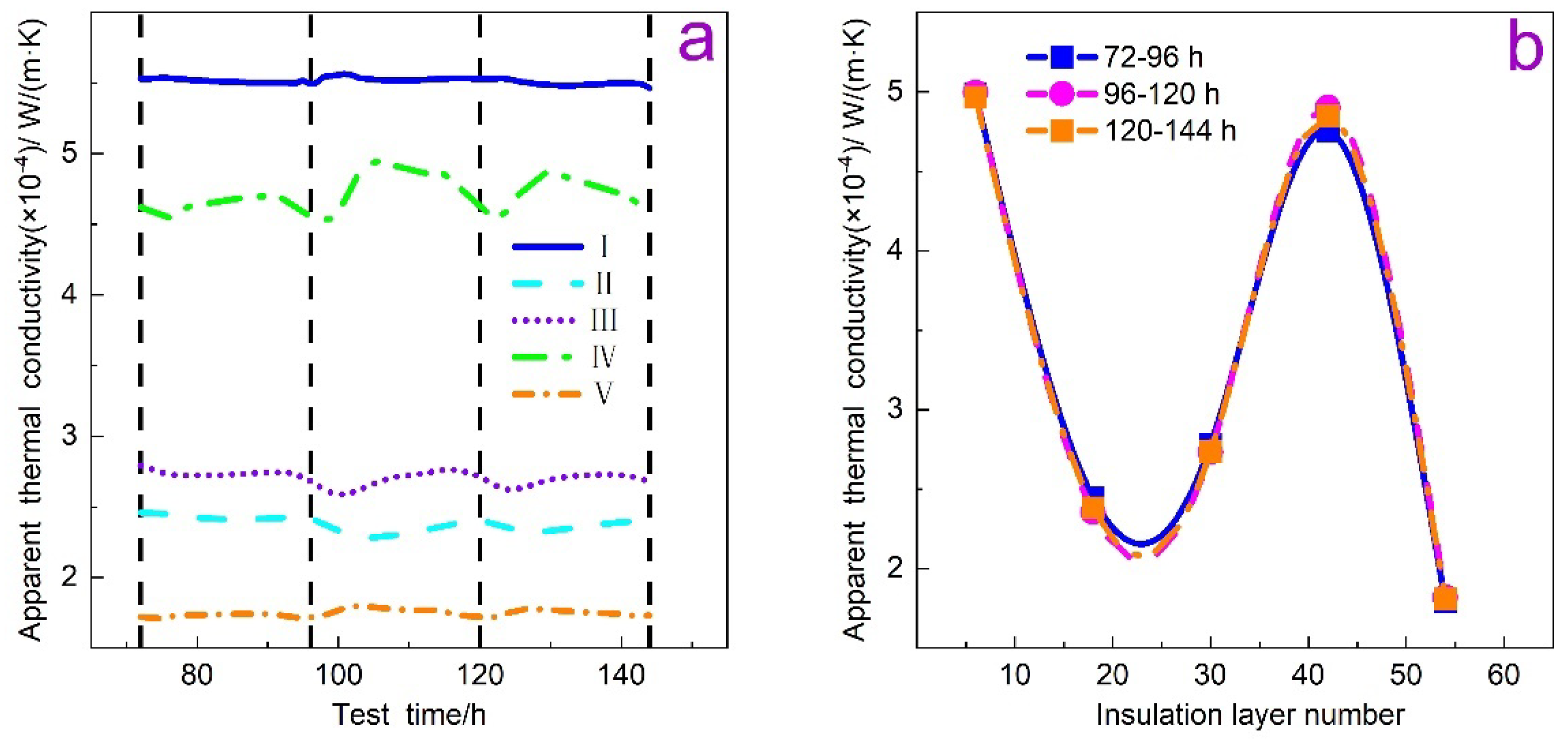

4.4. Thermal Insulation Characteristics of MLI

5. Conclusions

- (1)

- The experimental system utilizing the MLI–SP presented an average daily boil-off rate of 14.4%, heat leakage of 6.6 W, and a heat flux of 2.254 W/m2 from the inner container.

- (2)

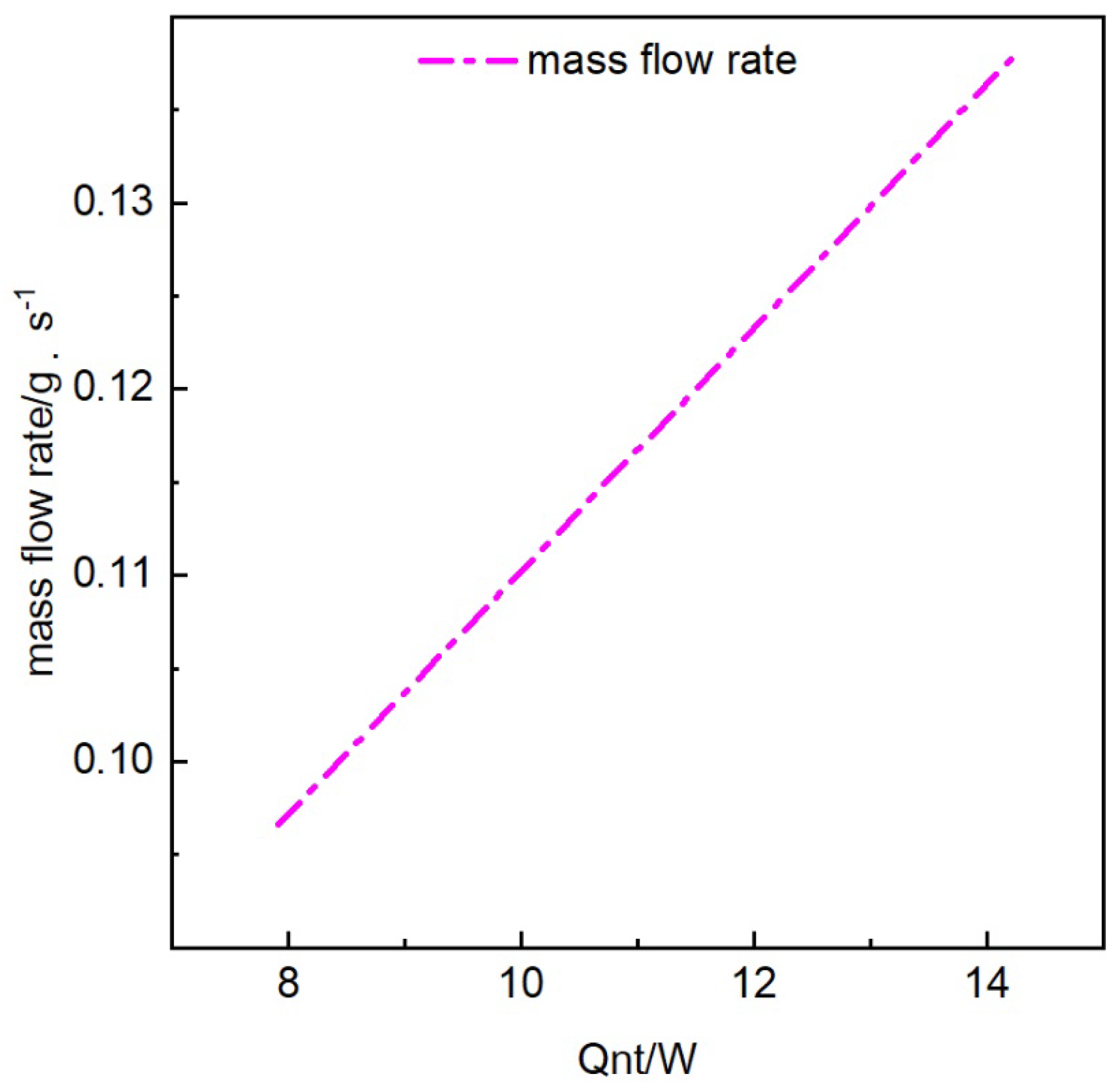

- A theoretical thermal analysis of the experimental Dewar was performed, leading to the derivation of a relationship between the heat leakage, evaporation rate, enthalpy, and internal energy. The heat leakage of the neck tube has a significant effect on the evaporation.

- (3)

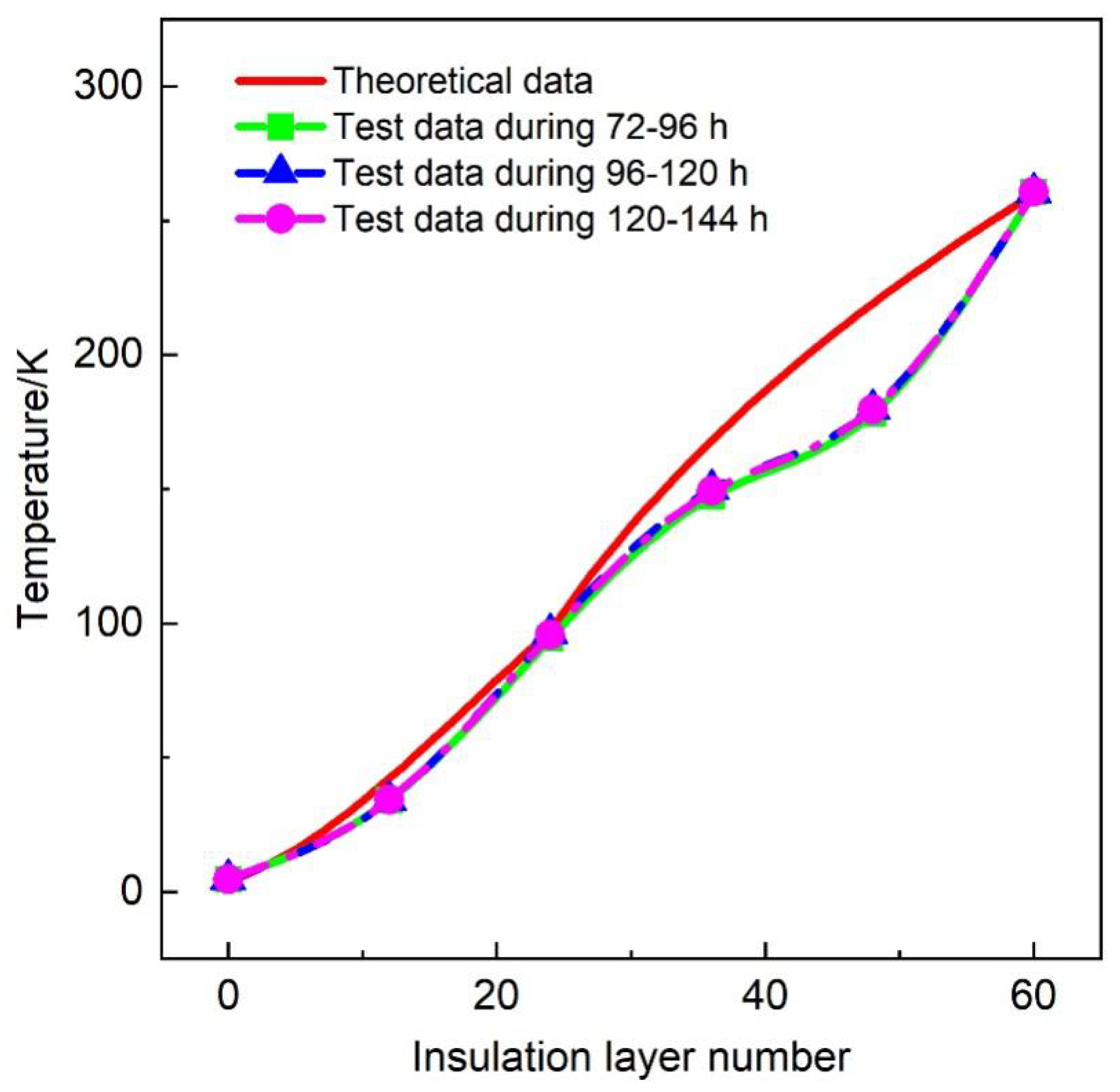

- The uncertainty of the temperature sensors is 1.16%, while the comprehensive measurement uncertainty of the system is 2.78%. There exists a certain degree of discrepancy between the simulated and experimental results of the interlayer temperature distribution of the insulation layer, with an overall error of 14.3% and a maximum error of 22.3%.

- (4)

- The apparent thermal conductivity of different layers of MLI is temperature-dependent, as supported by extensive literature indicating a unidirectional increase in apparent thermal conductivity with increasing temperature. In this system, experimental analysis revealed that the overall apparent thermal conductivity of the 60-layer MLI, operating at a cold end of 4.63 K and an ambient temperature of 286 K, was . The apparent thermal conductivity between the layers of insulation exhibited significant fluctuations with temperature, ranging from a maximum of to a minimum of .

- (5)

- During the heat transfer process in MLI with spherical particle, the dominant heat transfer mechanisms are likely to vary with temperature. This phenomenon is potentially associated with the non-uniform distribution of pressure following complete cooling.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Nomenclature | |

| Q | heat leakage, |

| equivalent area, | |

| L | length of neck tube, |

| thermal conductivity, | |

| equivalent length, | |

| curvature radius of multilayer insulation, | |

| T | absolute temperature, |

| mass flow rate, | |

| daily average mass flow rate, | |

| inner container volume | |

| daily boil-off rate | |

| volumetric flow rate under standard conditions, | |

| density of helium gas under standard conditions, | |

| enthalpy of helium vent gas under actual conditions, | |

| specific heat capacity at constant pressure of helium, | |

| enthalpy of cold helium gas leaving neck tube under actual conditions, | |

| heat leakage of inner container, | |

| heat leakage of neck tube, | |

| effective emissivity | |

| dynamic viscosity | |

| molecular free path | |

| Knudsen number | |

| specific heat ratio related to the gas between layers, 1.4 for air | |

| gas constant, | |

| Stefan-Boltzmann constant, | |

| molar mass related to gas between layers, for air, 29 | |

| characteristic temperature between layers, | |

| characteristic pressure between layers, | |

| constant related to gas | |

| constant related to multilayer insulation | |

| spacer sparsity of multilayer insulation | |

| D | distance between layers |

| apparent thermal conductivity, | |

| total heat flux, | |

| PFD | process flow diagram |

| Subscripts | |

| nt | neck tube |

| il | insulation layer |

| g | gas |

| h | hot boundary |

| c | cold boundary |

| radiation conduction | |

| gas conduction | |

| solid conduction | |

| Dacron net | |

| SP | spherical particle |

References

- Van Sciver, S.W.; Timmerhaus, K.D.; Clark, A.F. Helium Cryogenics; Springer: New York, NY, USA, 2012. [Google Scholar]

- Balibar, S. Laszlo Tisza and the two-fluid model of superfluidity. Comptes Rendus. Phys. 2017, 18, 586–591. [Google Scholar]

- Hastings, L.J.; Plachta, D.W.; Salerno, L.; Kittel, P. An overview of NASA efforts on zero boiloff storage of cryogenic propellants. Cryogenics 2001, 41, 833–839. [Google Scholar]

- Tseng, C.; Yamaguchi, M.; Ohmori, T. Thermal conductivity of polyurethane foams from room temperature to 20 K. Cryogenics 1997, 37, 305–312. [Google Scholar]

- Liu, Z.; Li, Y.; Xie, F.; Zhou, K. Thermal performance of foam/MLI for cryogenic liquid hydrogen tank during the ascent and on orbit period. Appl. Therm. Eng. 2016, 98, 430–439. [Google Scholar] [CrossRef]

- Allen, M.S.; Baumgartner, R.G.; Fesmire, J.E.; Augustynowicz, S.D. Advances in microsphere insulation systems. AIP Conf. Proc. 2004, 710, 619–626. [Google Scholar]

- Naes, L.G., Jr.; Dammann, R. Multilayer insulation performance at low cold boundary temperatures. In Proceedings of the Cryogenic Optical Systems and Instruments IX, Seattle, WA, USA, 8 July 2002; Volume 4822, pp. 94–103. [Google Scholar]

- Vanderlaan, M.; Stubbs, D.; Ledeboer, K.; Ross, J.; Van Sciver, S.; Guo, W. Repeatability Measurements of Apparent Thermal Conductivity of Multilayer Insulation (MLI). IOP Conf. Ser. Mater. Sci. Eng. 2017, 278, 012195. [Google Scholar] [CrossRef]

- Shu, Q.S.; Fast, R.W.; Hart, H.L. Heat flux from 277 to 77 K through a few layers of multilayer insulation. Cryogenics 1986, 26, 671–677. [Google Scholar] [CrossRef]

- Sun, P.J.; Wu, J.Y.; Zhang, P.; Xu, L.; Jiang, M.L. Experimental study of the influences of degraded vacuum on multilayer insulation blankets. Cryogenics 2009, 49, 719–726. [Google Scholar] [CrossRef]

- Bapat, S.L.; Narayankhedkar, K.G.; Lukose, T.P. Experimental investigations of multilayer insulation. Cryogenics 1990, 30, 711–719. [Google Scholar] [CrossRef]

- Hastings, L.J.; Martin, J.J. Experimental testing of a foam/multilayer insulation (FMLI) thermal control system (TCS) for use on a cryogenic upper stage. AIP Conf. Proc. 1998, 420, 331–341. [Google Scholar]

- Hastings, L.J.; Hedayat, A.; Brown, T.M. Analytical Modeling and Test Correlation of Variable Density Multilayer Insulation for Cryogenic Storage. 2004. Available online: https://ntrs.nasa.gov/api/citations/20040121015/downloads/20040121015.pdf (accessed on 16 December 2024).

- Zheng, J.; Chen, L.; Wang, J.; Xi, X.; Zhu, H.; Zhou, Y.; Wang, J. Thermodynamic analysis and comparison of four insulation schemes for liquid hydrogen storage tank. Energy Convers. Manag. 2019, 186, 526–534. [Google Scholar]

- Zhang, C.; Li, C.; Jia, W.; Pang, Y. Thermodynamic study on thermal insulation schemes for liquid helium storage tank. Appl. Therm. Eng. 2021, 195, 117185. [Google Scholar]

- Zheng, J.; Chen, L.; Wang, P.; Zhang, J.; Wang, J.; Zhou, Y. A novel cryogenic insulation system of hollow glass microspheres and self-evaporation vapor-cooled shield for liquid hydrogen storage. Front. Energy 2020, 14, 570–577. [Google Scholar] [CrossRef]

- Wawryk, R.; Rafałowicz, J. Heat transfer in microsphere insulation. J. Therm. Anal. Calorim. 1988, 34, 249–257. [Google Scholar]

- Wang, P.; Liao, B.; An, Z.; Yan, K.; Zhang, J. Measurement and calculation of cryogenic thermal conductivity of HGMs. Int. J. Heat Mass Transf. 2019, 129, 591–598. [Google Scholar]

- Fesmire, J.E.; Augustynowicz, S.D. Thermal performance testing of glass microspheres under cryogenic vacuum conditions. AIP Conf. Proc. 2004, 710, 612–618. [Google Scholar]

- Rugaiganisa, B.M.; Yoshihara, T.; Yoshiwa, M.; Nakagawa, S.; Hirai, A. Experimental investigation on heat leak into a liquid helium Dewar. Cryogenics 1990, 30, 942–946. [Google Scholar]

- Zuo, Z.; Jiang, W.; Qin, X.; Huang, Y. A numerical model for liquid–vapor transition in self-pressurized cryogenic containers. Appl. Therm. Eng. 2021, 193, 117005. [Google Scholar] [CrossRef]

- McIntosh, G.E. Layer by layer MLI calculation using a separated mode equation. In Advances in Cryogenic Engineering; Springer: Boston, MA, USA, 1994; pp. 1683–1690. [Google Scholar]

- Yin, L.; Yang, H.; Ju, Y. Review on the key technologies and future development of insulation structure for liquid hydrogen storage tanks. Int. J. Hydrogen Energy 2024, 57, 1302–1315. [Google Scholar] [CrossRef]

- Wang, P.; Ji, L.; Yuan, J.; An, Z.; Yan, K.; Zhang, J. Modeling and optimization of composite thermal insulation system with HGMs and VDMLI for liquid hydrogen on orbit storage. Int. J. Hydrogen Energy 2020, 45, 7088–7097. [Google Scholar] [CrossRef]

- Sundén, B.; Fu, J. Heat Transfer in Aerospace Applications; Academic Press: Cambridge, MA, USA, 2016. [Google Scholar]

| Model | Cernox | PT100 |

|---|---|---|

| Temperature | ||

| 4.2 K | ±4 mK | — |

| 10 K | ±4 mK | — |

| 20 K | ±8 mK | ±9 mK |

| 30 K | ±9 mK | ±9 mK |

| 50 K | ±12 mK | ±10 mK |

| 100 K | ±16 mK | ±11 mK |

| 300 K | ±45 mK | ±24 mK |

| Source of Error | Uncertainty |

|---|---|

| Geometry of insulation layer | 2.05% |

| Temperature measurement | 1.16% |

| Mass flowmeter | 0.5% |

| Combined standard uncertainty | 2.78% |

| Working Fluid | Precooling Duration | Static Duration | Vacuum Degree | Warm Boundary | Cold Boundary | Stability Criterion |

|---|---|---|---|---|---|---|

| He | 72 h | 72 h | Ambient temperature | 4.2 K | delta T < 0.02 degrees C/min |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Y.; Guo, L.; Jia, Q.; Xie, X.; Zhu, W.; Wang, P. Research on the Liquid Helium Insulation Characteristics of an Experimental System. Energies 2025, 18, 1349. https://doi.org/10.3390/en18061349

Chen Y, Guo L, Jia Q, Xie X, Zhu W, Wang P. Research on the Liquid Helium Insulation Characteristics of an Experimental System. Energies. 2025; 18(6):1349. https://doi.org/10.3390/en18061349

Chicago/Turabian StyleChen, Ye, Liang Guo, Qiming Jia, Xiujuan Xie, Weiping Zhu, and Ping Wang. 2025. "Research on the Liquid Helium Insulation Characteristics of an Experimental System" Energies 18, no. 6: 1349. https://doi.org/10.3390/en18061349

APA StyleChen, Y., Guo, L., Jia, Q., Xie, X., Zhu, W., & Wang, P. (2025). Research on the Liquid Helium Insulation Characteristics of an Experimental System. Energies, 18(6), 1349. https://doi.org/10.3390/en18061349