Comparative Analysis of Solar Photovoltaic/Thermal Assisted Heat Pump Systems Coupled with PCM Storage and EV Charging with Reference to the UK’s National Carbon Intensity

Abstract

1. Introduction

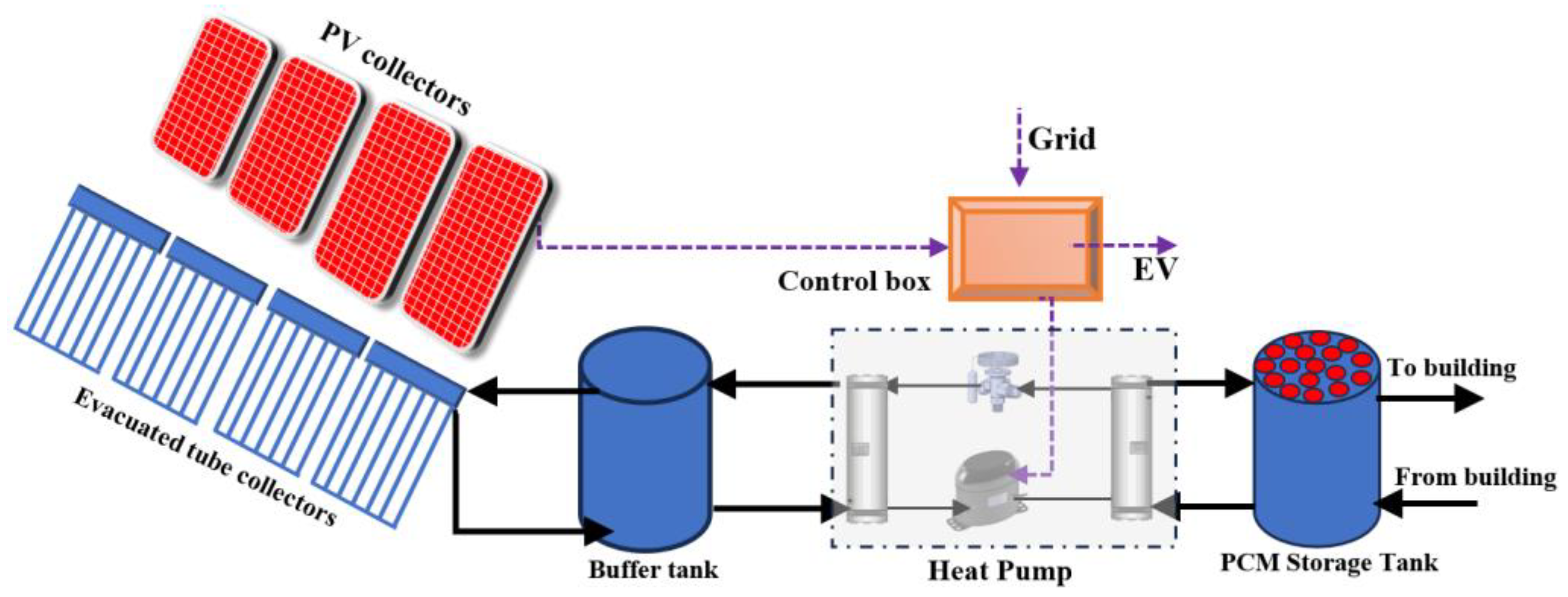

2. Concept Description and Method

Building Energy Simulation

3. System Modeling for Simulations

3.1. Modeling of Solar HP Components

- The constant pressure is assumed for condensation and evaporation;

- The 3 °C subcooling ( and superheating ( temperatures are given;

- The evaporation temperature in the evaporator depends on the buffer tank temperature. An 8 K pinch temperature difference is selected;

- In order to charge the PCM, the condensation temperature is chosen as 70 °C [29].

3.2. Modeling of EV Behavior and Charging Operations

4. Results and Discussions

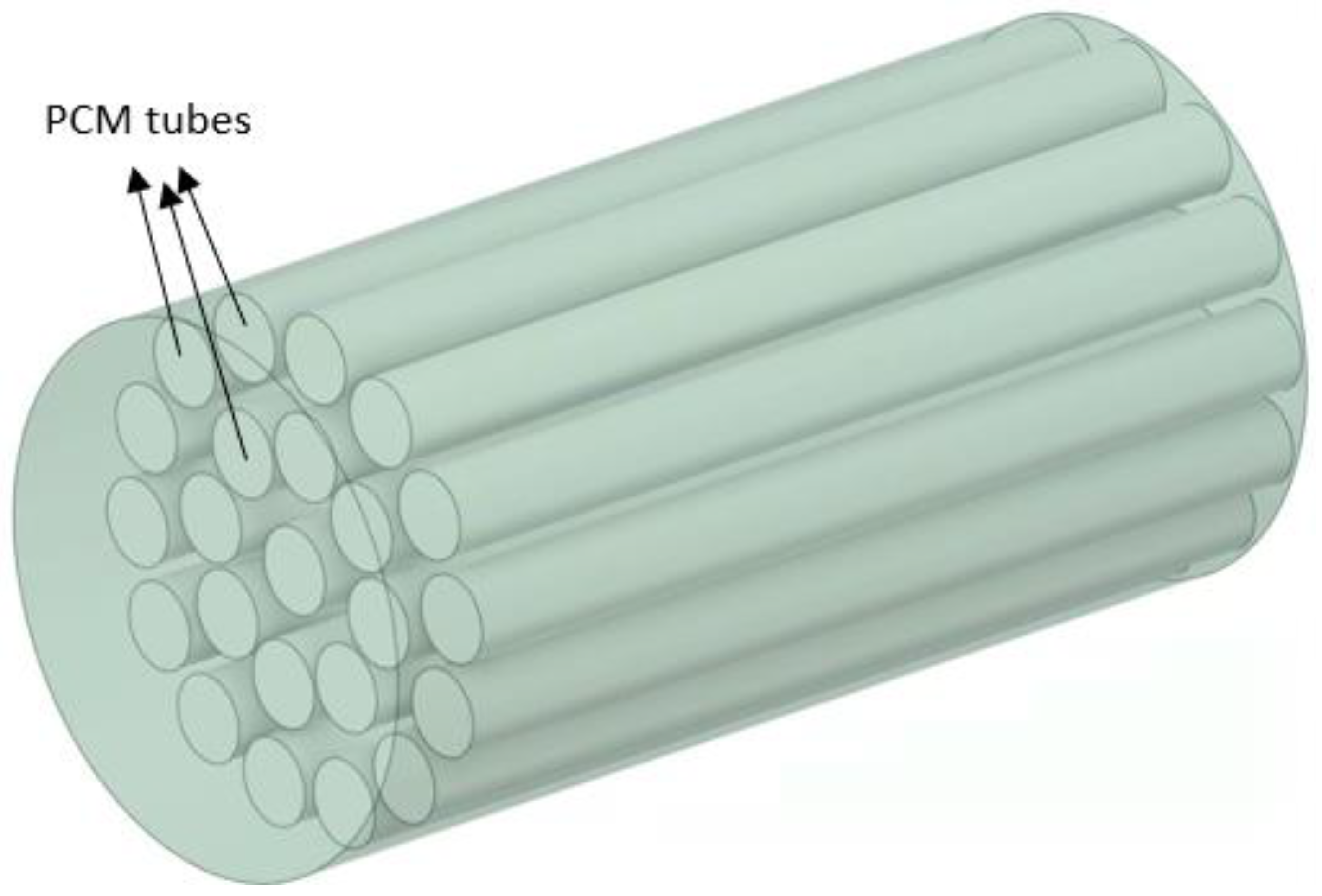

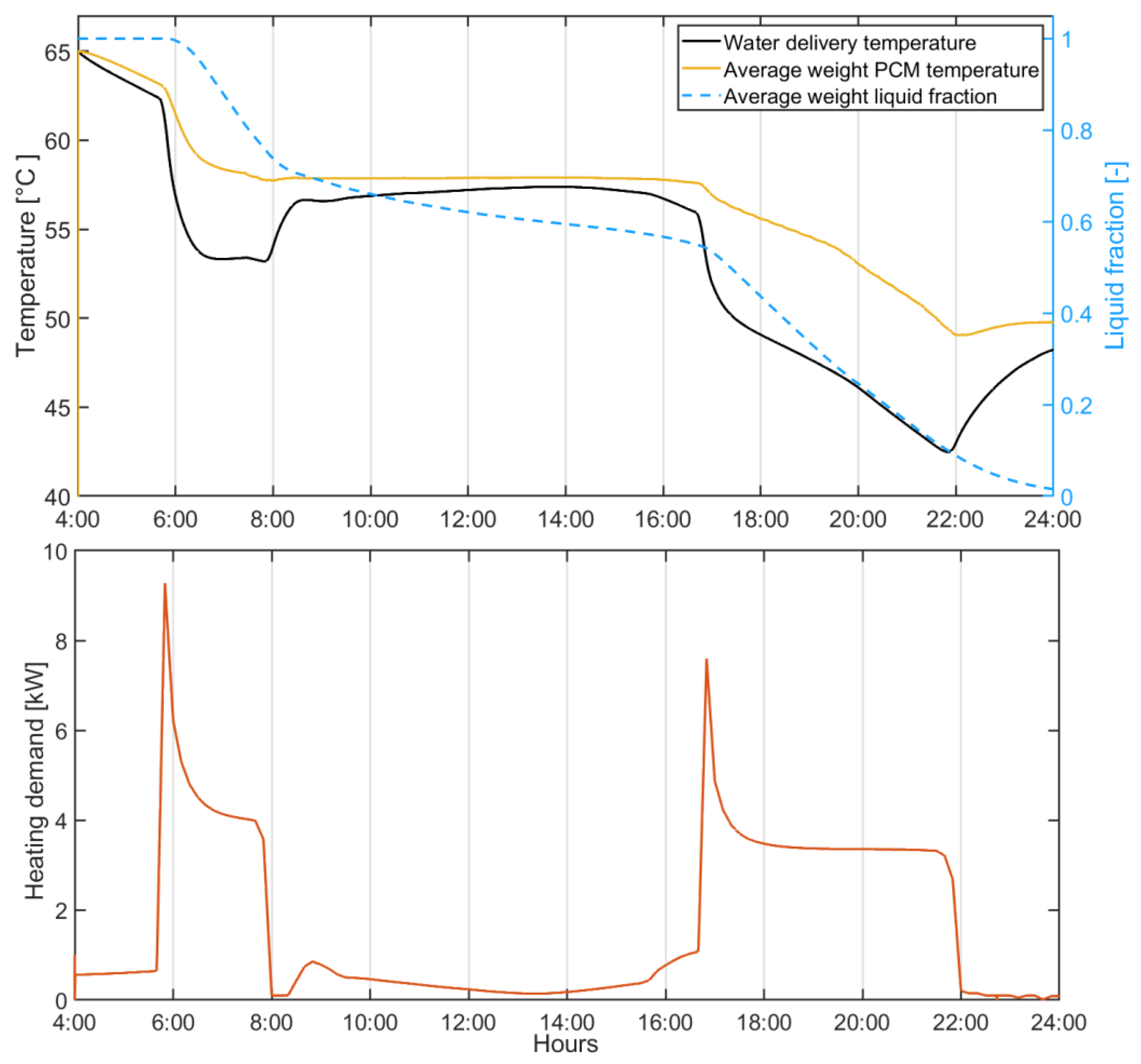

4.1. Heat Supply Performance of the PCM Storage Tank

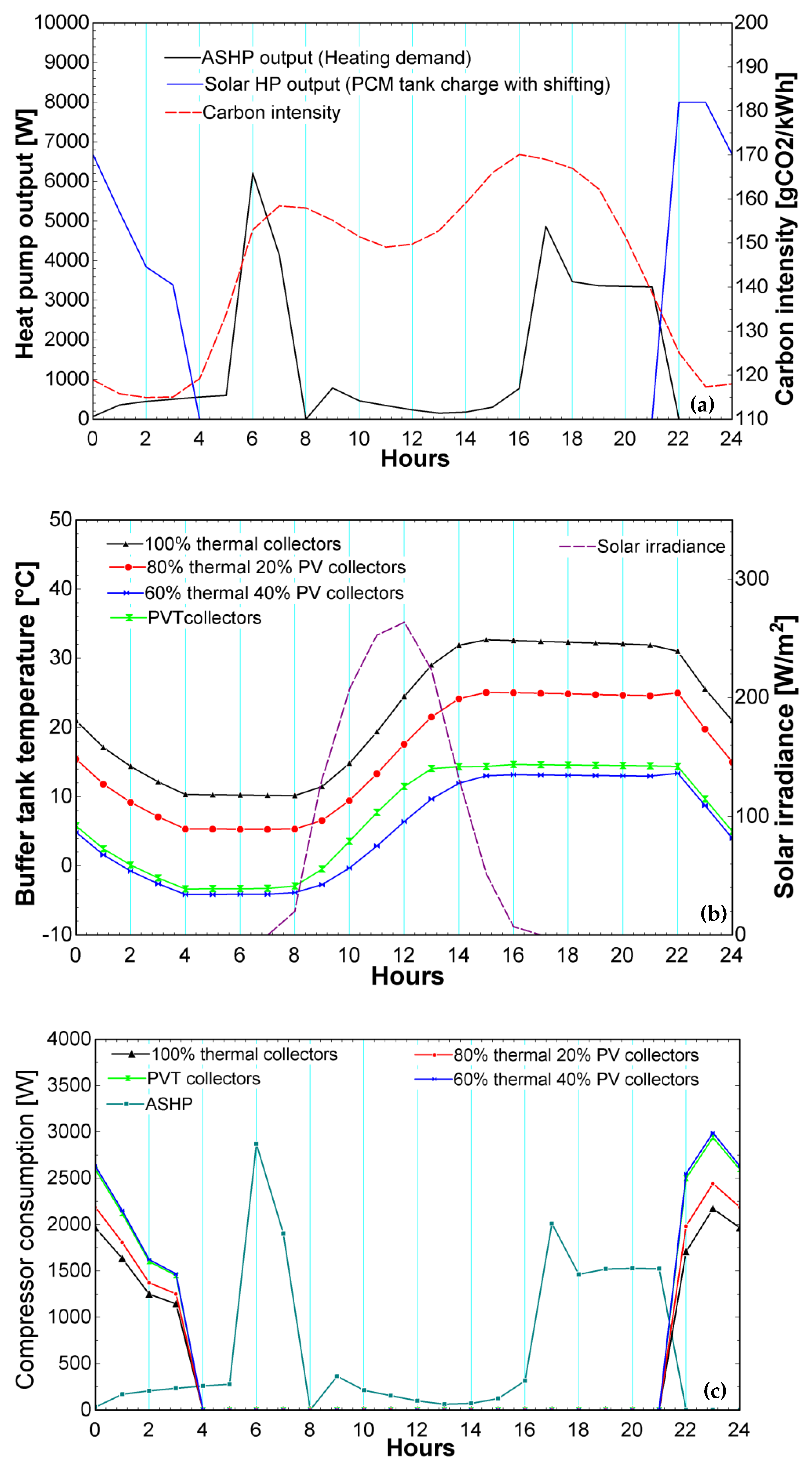

4.2. Heat Pump Operation

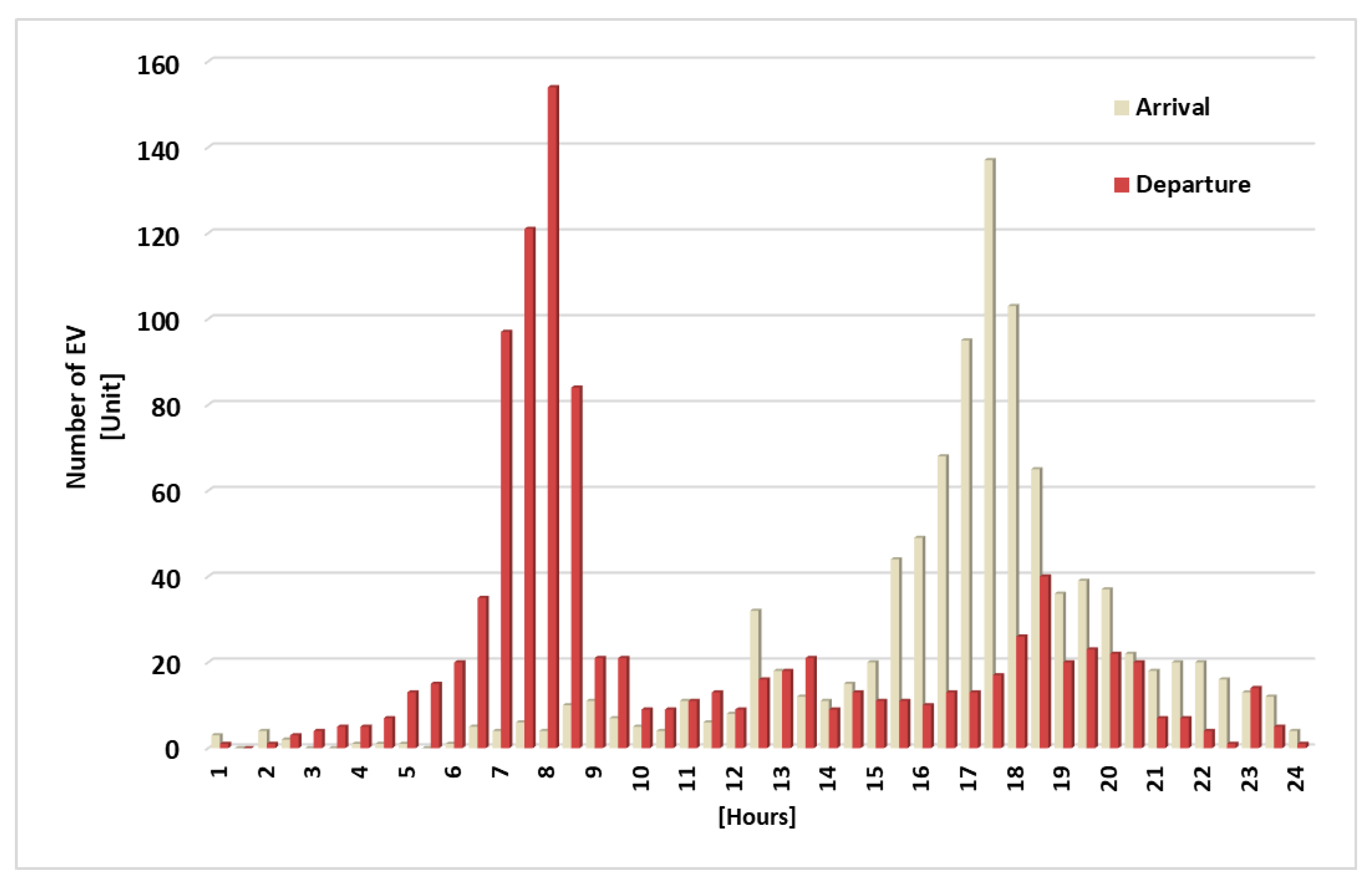

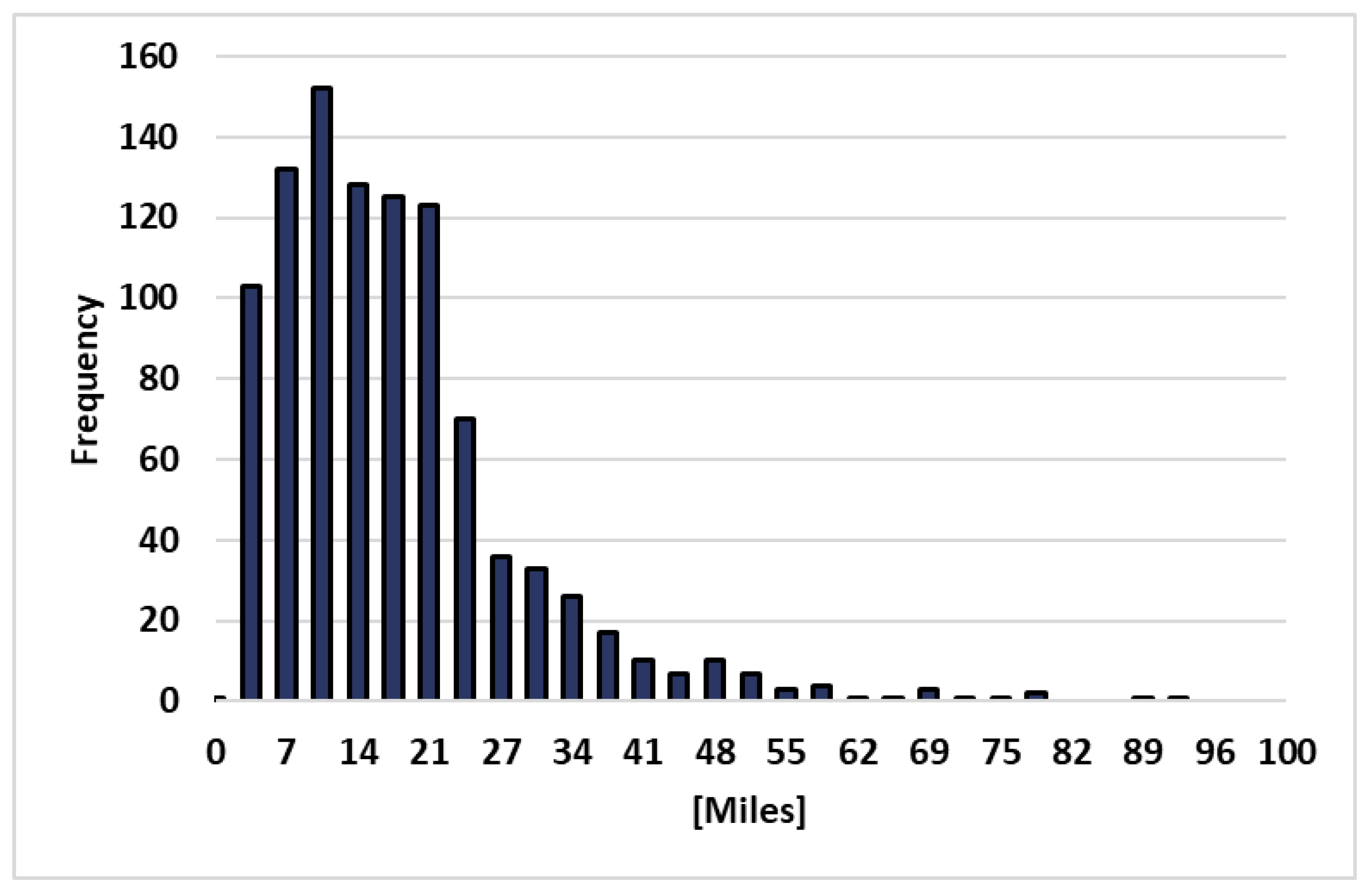

4.3. Analysis of EV Behavior and Travel Patterns

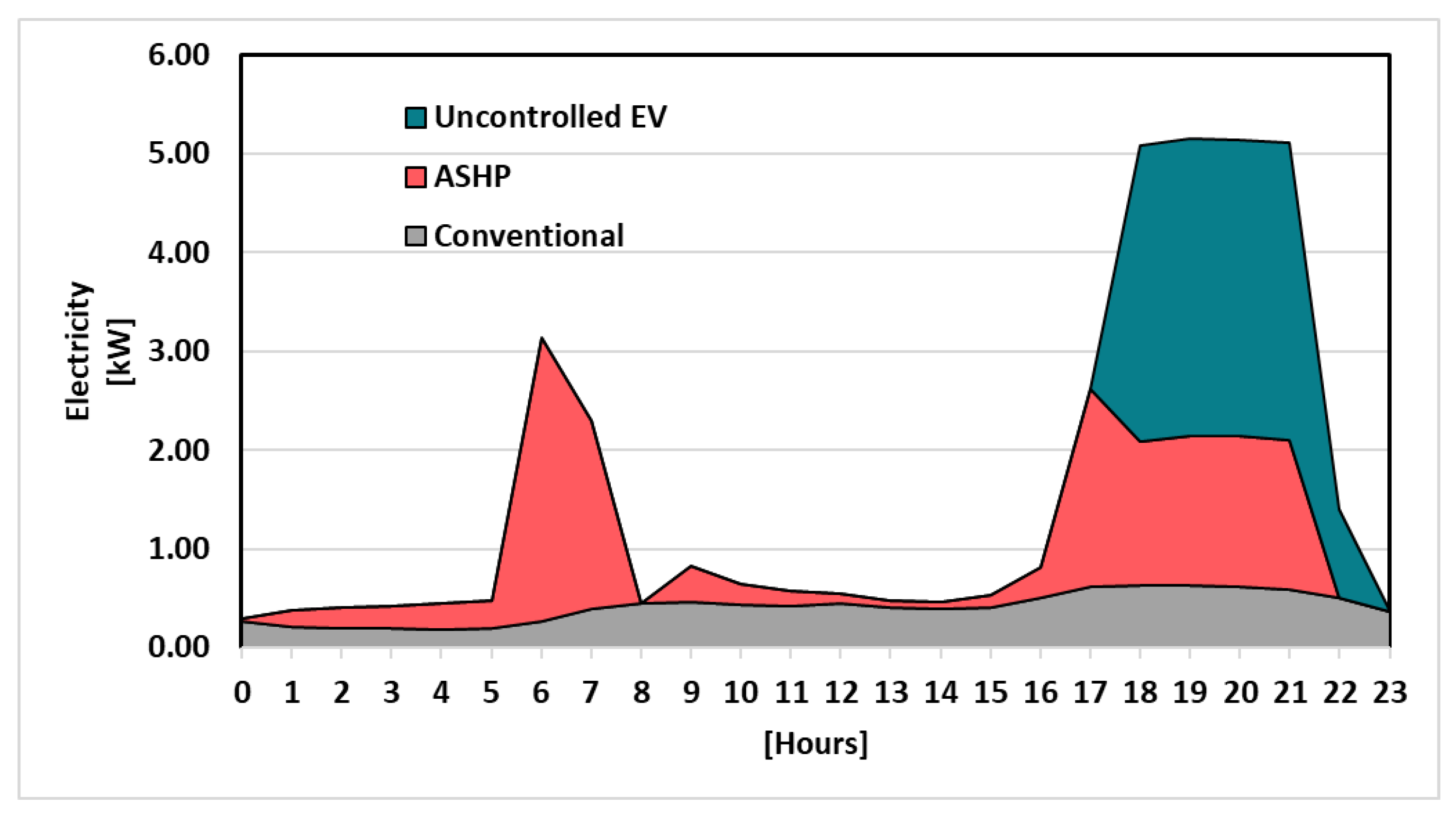

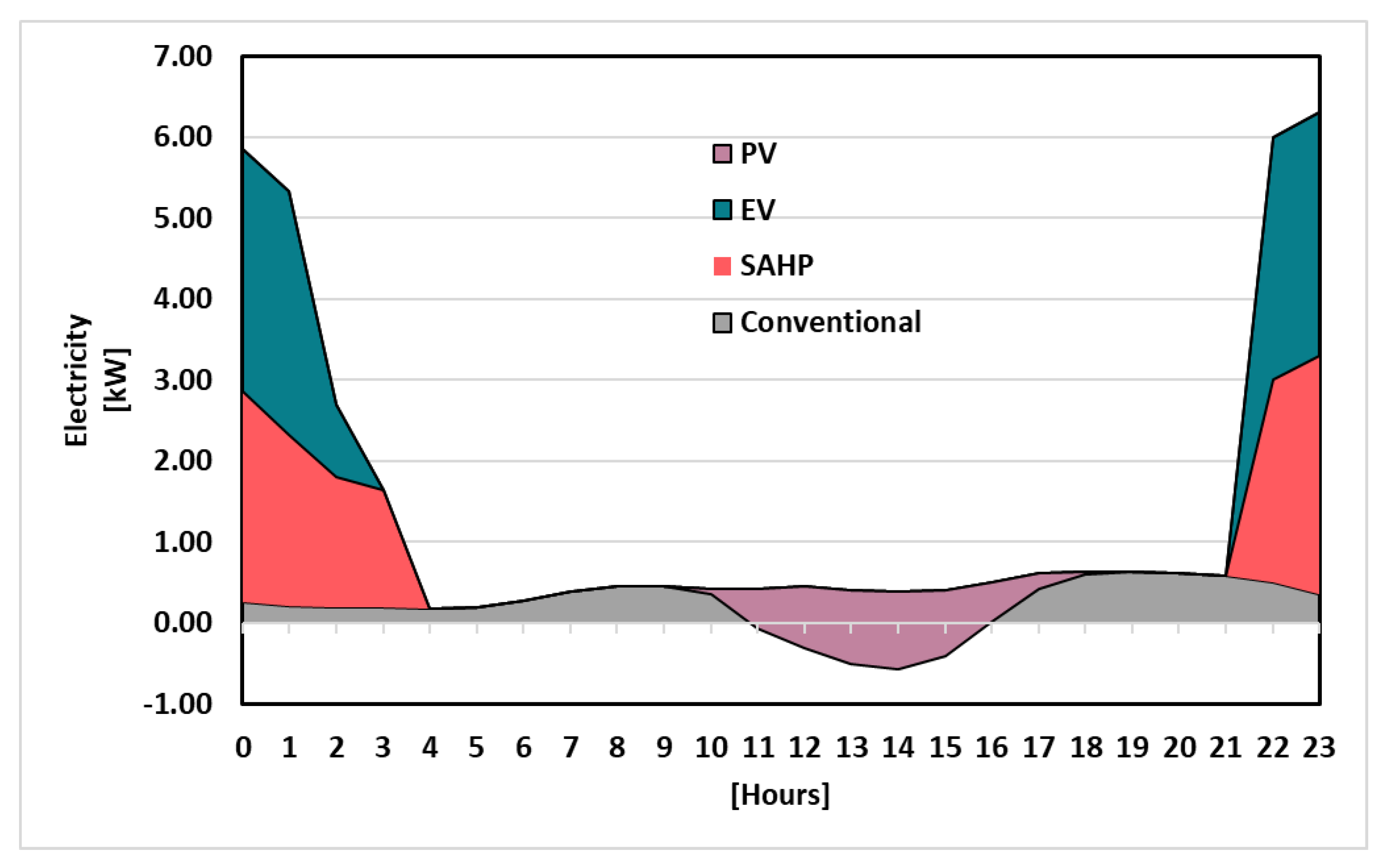

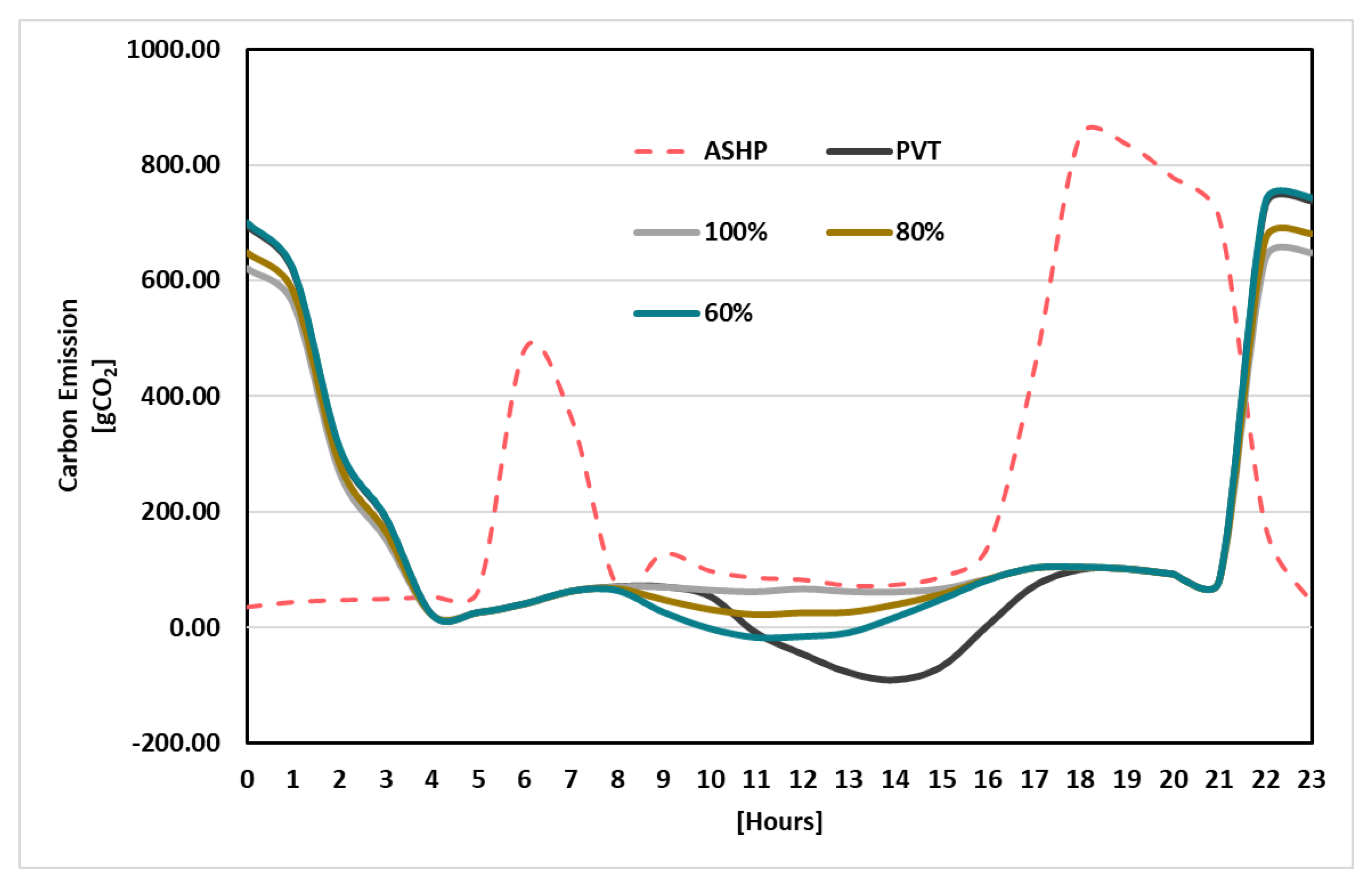

4.4. Overall Energy Consumptions and CO2 Emissions

5. Conclusions

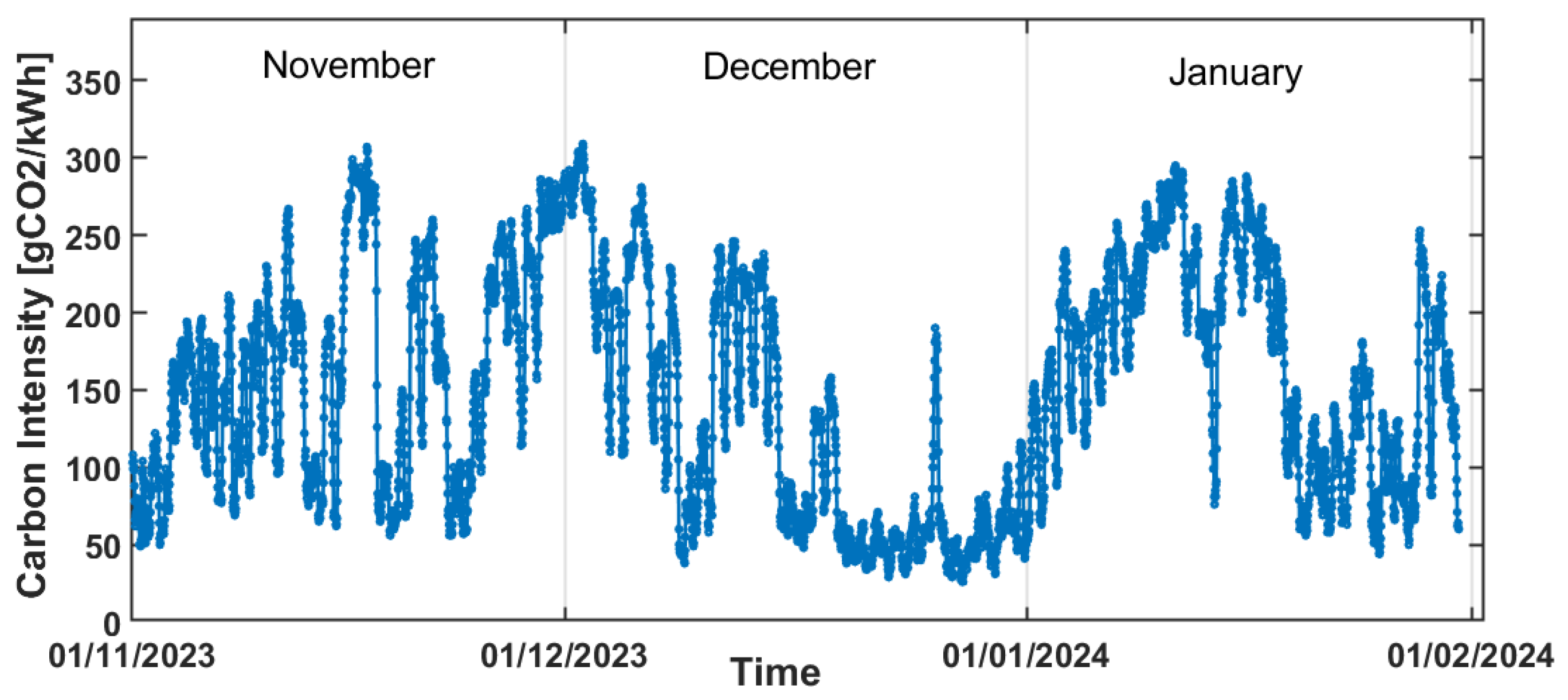

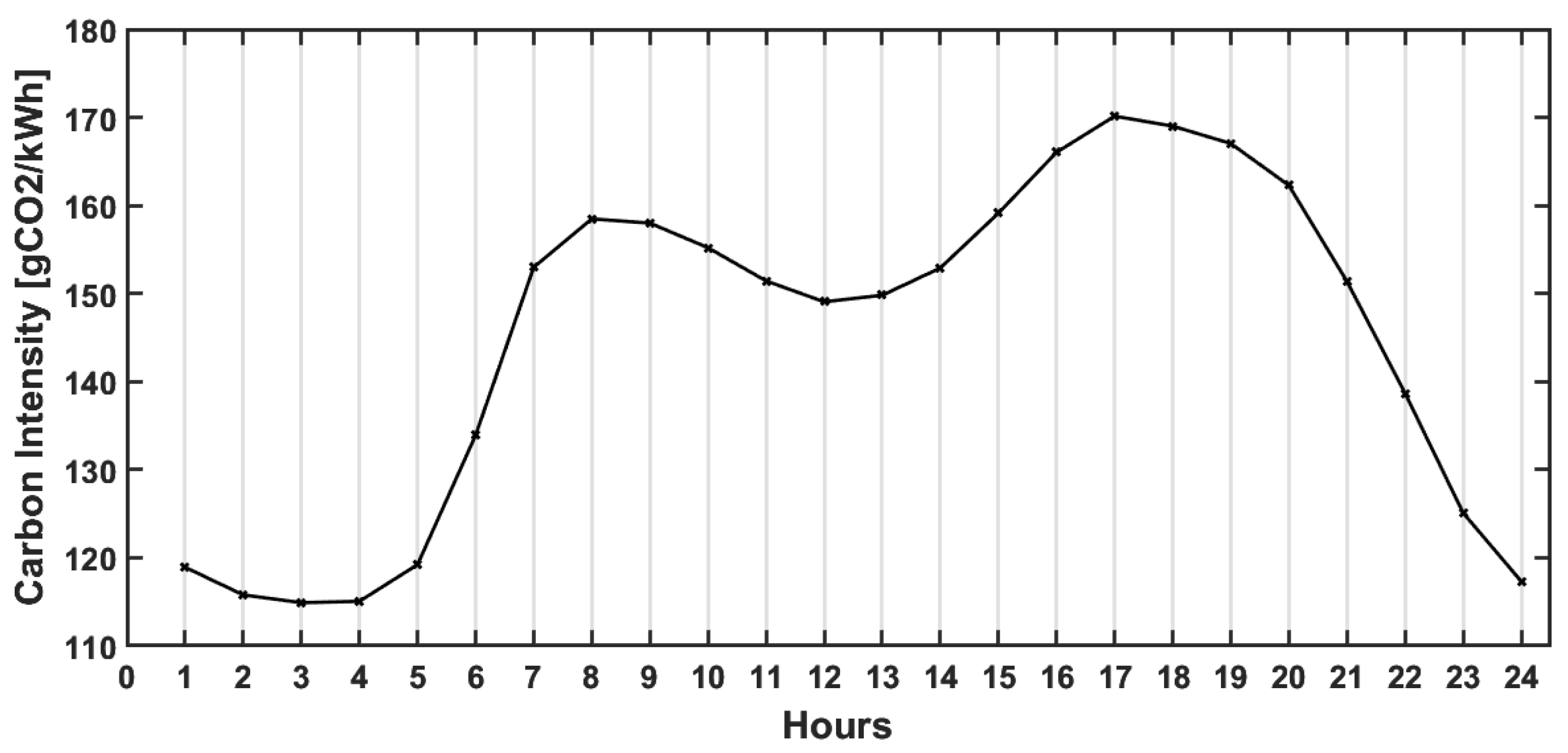

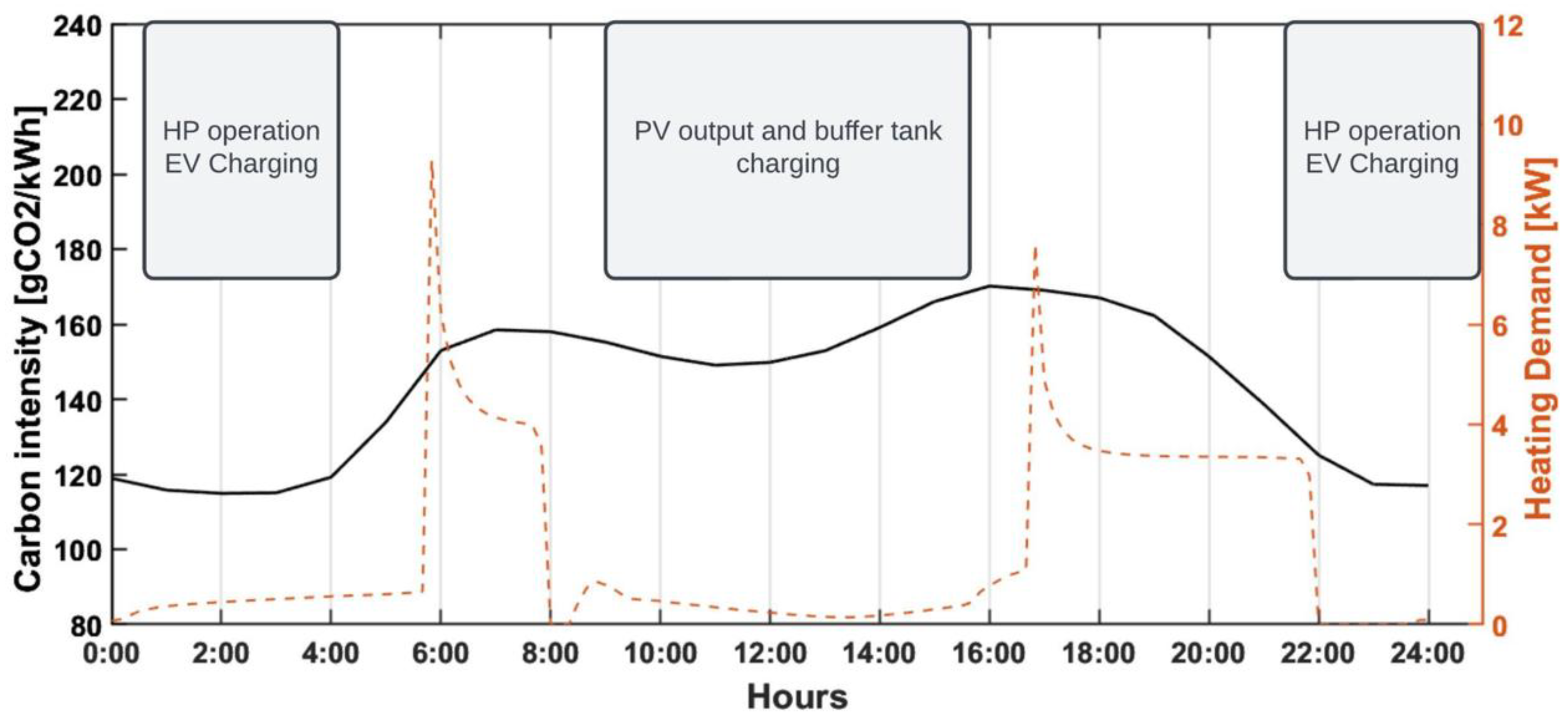

- Based on published data on carbon emissions from electricity generation in the UK during November, December, and January, the national carbon intensity is lowest between 11 p.m. and 5 a.m. Therefore, demand shifting should be prioritized during this period.

- To provide 34.5 kWh heating to the building, a storage tank with 380 kg of PCM tubes was selected. The tank is designed to be charged within 5–6 h, aligning with periods of low carbon intensity.

- The performance of the HP system is directly influenced by the thermal collector area, as it enhances solar energy utilization. For a system with 100% thermal collectors, the SAHP achieves a daily COP of 3.49. When the thermal collectors comprise only 60% of the solar array, the daily COP decreases to 2.57. The SAHP system utilizing PV/T collectors demonstrates a relatively low heating COP of 2.6, although this still represents a 16% improvement over the COP of the ASHP.

- SAHP systems with thermal collectors achieve significant reductions in total energy consumption and carbon emissions compared to conventional ASHP systems. A 100% thermal collector SAHP reduces total energy consumption by 22% compared to the baseline ASHP configuration.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| ASHP | air-sourced heat pump |

| BEVs | battery electric vehicles |

| CIBSE | Chartered Institution of Building Services Engineers |

| COP | coefficient of performance |

| DfT | Department for Transport |

| EV | electric vehicle |

| HP | heat pump |

| IEA | International Energy Agency |

| IES VE | Integrated Environmental Solutions Virtual Environment |

| ITS | inverse transform sampling |

| NTS | National Travel Survey |

| PHEVs | plug-in hybrid electric vehicles |

| PV/T | photovoltaic–thermal |

| RBS | randomized behavior simulation |

| SAHP | solar-assisted heat pump |

| SAT | sodium acetate trihydrate |

| SOC | state of charge |

| URS | uniform random sampling |

| WRS | weighted random sampling |

| Nomenclature | |

| collector area, m2 | |

| specific heat, J kg−1K−1 | |

| solar irradiance, W m−2 | |

| specific enthalpy, J/kg | |

| mass flow rate, kg s−1 | |

| refrigerant mass flow rate, kg s−1 | |

| NOCT | normal operating cell temperature |

| Nusselt number | |

| Prandtl number | |

| heat rate, W | |

| Reynolds number | |

| temperature, | |

| power, W | |

| Subscripts | |

| ambient | |

| col | collector |

| compressor | |

| condenser | |

| evaporator | |

| heat transfer fluid | |

| inlet | |

| mean | |

| reference | |

| tank | |

| thermal | |

References

- Hassan, Q.; Algburi, S.; Sameen, A.Z.; Salman, H.M.; Jaszczur, M. A Review of Hybrid Renewable Energy Systems: Solar and Wind-Powered Solutions: Challenges, Opportunities, and Policy Implications. Results Eng. 2023, 20, 101621. [Google Scholar] [CrossRef]

- Herrando, M.; Markides, C.N.; Hellgardt, K. A UK-Based Assessment of Hybrid PV and Solar-Thermal Systems for Domestic Heating and Power: System Performance. Appl. Energy 2014, 122, 288–309. [Google Scholar] [CrossRef]

- Herrando, M.; Ramos, A. Photovoltaic-Thermal (PV-T) Systems for Combined Cooling, Heating and Power in Buildings: A Review. Energies 2022, 15, 3021. [Google Scholar] [CrossRef]

- Kazem, H.A.; Chaichan, M.T.; Al-Waeli, A.H.A.; Sopian, K. A Systematic Review of Photovoltaic/Thermal Applications in Heat Pumps Systems. Sol. Energy 2024, 269, 112299. [Google Scholar] [CrossRef]

- Herrando, M.; Ramos, A.; Freeman, J.; Zabalza, I.; Markides, C.N. Technoeconomic Modelling and Optimisation of Solar Combined Heat and Power Systems Based on Flat-Box PVT Collectors for Domestic Applications. Energy Convers. Manag. 2018, 175, 67–85. [Google Scholar] [CrossRef]

- Wang, K.; Herrando, M.; Pantaleo, A.M.; Markides, C.N. Technoeconomic Assessments of Hybrid Photovoltaic-Thermal vs. Conventional Solar-Energy Systems: Case Studies in Heat and Power Provision to Sports Centres. Appl. Energy 2019, 254, 113657. [Google Scholar] [CrossRef]

- Le, K.X.; Huang, M.J.; Wilson, C.; Shah, N.N.; Hewitt, N.J. Tariff-Based Load Shifting for Domestic Cascade Heat Pump with Enhanced System Energy Efficiency and Reduced Wind Power Curtailment. Appl. Energy 2020, 257, 113976. [Google Scholar] [CrossRef]

- Tyagi, V.V.; Buddhi, D. PCM Thermal Storage in Buildings: A State of Art. Renew. Sustain. Energy Rev. 2007, 11, 1146–1166. [Google Scholar] [CrossRef]

- Sinha, R.; Chaudhary, S.K.; Bak-Jensen, B.; Golmohamadi, H. Smart Operation Control of Power and Heat Demands in Active Distribution Grids Leveraging Energy Flexibility. Energies 2024, 17, 2986. [Google Scholar] [CrossRef]

- Department for Energy Security and Net Zero (DESNZ). Final UK Greenhouse Gas Emissions National Statistics: 1990 to 2022. Contains Public Sector Information Licensed Under the Open Government Licence v3.0. 2024. Available online: https://www.gov.uk/government/statistics/final-uk-greenhouse-gas-emissions-national-statistics-1990-to-2022 (accessed on 18 December 2024).

- Arowolo, W.; Perez, Y. Rapid Decarbonisation of Paris, Lyon and Marseille’s Power, Transport and Building Sectors by Coupling Rooftop Solar PV and Electric Vehicles. Energy Sustain. Dev. 2023, 74, 196–214. [Google Scholar] [CrossRef]

- Barman, P.; Dutta, L.; Bordoloi, S.; Kalita, A.; Buragohain, P.; Bharali, S.; Azzopardi, B. Renewable Energy Integration with Electric Vehicle Technology: A Review of the Existing Smart Charging Approaches. Renew. Sustain. Energy Rev. 2023, 183, 113518. [Google Scholar] [CrossRef]

- Lauvergne, R.; Perez, Y.; Françon, M.; Tejeda De La Cruz, A. Integration of Electric Vehicles into Transmission Grids: A Case Study on Generation Adequacy in Europe in 2040. Appl. Energy 2022, 326, 120030. [Google Scholar] [CrossRef]

- Zap-Map. EV Market Stats 2025: Tracking the Growth in EV Sales in the UK over Time. Available online: https://www.zap-map.com/ev-stats/ev-market (accessed on 10 February 2025).

- National Grid ESO (now NESO). Future Energy Scenarios (FES) 2023. Supported by National Energy SO Open Data. Licensed under NESO Open Data Licence v1.0. Available online: https://www.neso.energy/publications/future-energy-scenarios-fes/fes-documents (accessed on 10 February 2025).

- Department for Transport (DfT). Taking Charge: The Electric Vehicle Infrastructure Strategy; Contains Public Sector Information Licensed Under the Open Government Licence v3.0.; HM Government: London, UK, 2022. Available online: https://www.gov.uk/government/publications/uk-electric-vehicle-infrastructure-strategy (accessed on 18 December 2024).

- Tasnim, M.N.; Akter, S.; Shahjalal, M.; Shams, T.; Davari, P.; Iqbal, A. A Critical Review of the Effect of Light Duty Electric Vehicle Charging on the Power Grid. Energy Rep. 2023, 10, 4126–4147. [Google Scholar] [CrossRef]

- Dik, A.; Kutlu, C.; Sun, H.; Calautit, J.K.; Boukhanouf, R.; Omer, S. Towards Sustainable Urban Living: A Holistic Energy Strategy for Electric Vehicle and Heat Pump Adoption in Residential Communities. Sustain. Cities Soc. 2024, 107, 105412. [Google Scholar] [CrossRef]

- National Grid ESO (now NESO). National Carbon Intensity Forecast. Supported by National Energy SO Open Data. Licensed under NESO Open Data Licence v1.0. Available online: https://www.nationalgrideso.com/data-portal/national-carbon-intensity-forecast/national_carbon_intensity_forecast (accessed on 1 July 2024).

- Hall, M.R.; Casey, S.P.; Loveday, D.L.; Gillott, M. Analysis of UK Domestic Building Retrofit Scenarios Based on the E.ON Retrofit Research House Using Energetic Hygrothermics Simulation—Energy Efficiency, Indoor Air Quality, Occupant Comfort, and Mould Growth Potential. Build Environ. 2013, 70, 48–59. [Google Scholar] [CrossRef]

- Chartered Institution of Building Services Engineers (CIBSE). Guide A: Environmental Design; Chartered Institution of Building Services Engineers (CIBSE): London, UK, 2016. [Google Scholar]

- Freeman, J.; Guarracino, I.; Kalogirou, S.A.; Markides, C.N. A Small-Scale Solar Organic Rankine Cycle Combined Heat and Power System with Integrated Thermal Energy Storage. Appl. Therm. Eng. 2017, 127, 1543–1554. [Google Scholar] [CrossRef]

- Yu, Q.; Chan, S.; Chen, K.; Zhao, B.; Ren, X.; Pei, G. Numerical and Experimental Study of a Novel Vacuum Photovoltaic/Thermal (PV/T) Collector for Efficient Solar Energy Harvesting. Appl. Therm. Eng. 2024, 236, 121580. [Google Scholar] [CrossRef]

- Mattei, M.; Notton, G.; Cristofari, C.; Muselli, M.; Poggi, P. Calculation of the Polycrystalline PV Module Temperature Using a Simple Method of Energy Balance. Renew. Energy 2006, 31, 553–567. [Google Scholar] [CrossRef]

- Kutlu, C.; Li, J.; Su, Y.; Wang, Y.; Pei, G.; Riffat, S. Investigation of an Innovative PV/T-ORC System Using Amorphous Silicon Cells and Evacuated Flat Plate Solar Collectors. Energy 2020, 203, 117873. [Google Scholar] [CrossRef]

- Ungureşan, P.; Petreuş, D.; Pocola, A.; Bălan, M. Potential of Solar ORC and PV Systems to Provide Electricity under Romanian Climatic Conditions. Energy Procedia 2016, 85, 584–593. [Google Scholar] [CrossRef]

- Mulcué-Nieto, L.F.; Mora-López, L. A New Model to Predict the Energy Generated by a Photovoltaic System Connected to the Grid in Low Latitude Countries. Solar Energy 2014, 107, 423–442. [Google Scholar] [CrossRef]

- Duffie, J.A.; Beckman, W.A. Solar Engineering of Thermal Processes; John Wiley: Hoboken, NJ, USA, 2013. [Google Scholar]

- Kutlu, C.; Su, Y.; Lyu, Q.; Riffat, S. Thermal Management of Using Crystallization-Controllable Supercooled PCM in Space Heating Applications for Different Heating Profiles in the UK. Renew. Energy 2023, 206, 848–857. [Google Scholar] [CrossRef]

- Kutlu, C.; Erdinc, M.T.; Dik, A.; Chen, Z.; Lyu, Q.; Su, Y.; Riffat, S. A Study on the Combination of Crystallization-Controllable Phase Change Materials and Solar-Assisted Heat Pump for Electricity Demand Shifting in Space Heating. Energy Convers. Manag. 2025, 324, 119260. [Google Scholar] [CrossRef]

- Taborek, J. Longitudinal Flow in Tube Bundles with Grid Baffles. AIChE Symp. Ser. 1989, 85, 72–78. [Google Scholar]

- Kutlu, C.; Tapia-Brito, E.; Agbonaye, O.; Su, Y.; Smith, S.T.; Hughes, B.; Riffat, S. Incorporation of Controllable Supercooled Phase Change Material Heat Storage with a Solar Assisted Heat Pump: Testing of Crystallization Triggering and Heating Demand-Based Modelling Study. J. Energy Storage 2022, 55, 105744. [Google Scholar] [CrossRef]

- International Energy Agency (IEA). Global EV Outlook 2024; Licence: CC BY 4.0; IEA: Paris, France, 2024; Available online: https://www.iea.org/reports/global-ev-outlook-2024 (accessed on 18 December 2024).

- Department for Transport (DfT). Licensed Ultra Low Emission Vehicles by Body Type and Propulsion or Fuel Type. Contains Public Sector Information Licensed Under the Open Government Licence v3.0. Available online: https://www.gov.uk/government/statistical-data-sets/vehicle-licensing-statistics-data-tables (accessed on 18 December 2024).

- EV-Database. Current and Upcoming Electric Vehicles. Available online: https://ev-database.org/ (accessed on 18 December 2024).

- Department for Transport (DfT). Electric Charge Point Analysis 2017: Domestics Report. 2018. Contains Public Sector Information Licensed Under the Open Government Licence v3.0. Available online: https://www.gov.uk/government/statistics/electric-chargepoint-analysis-2017-domestics (accessed on 18 December 2024).

- Zap-Map. EV Charging Statistics. 2024. Available online: https://www.zap-map.com/ev-stats/how-many-charging-points (accessed on 18 December 2024).

- Wang, Y.; Infield, D. Markov Chain Monte Carlo Simulation of Electric Vehicle Use for Network Integration Studies. Int. J. Electr. Power Energy Syst. 2018, 99, 85–94. [Google Scholar] [CrossRef]

- Department for Transport (DfT). Annual Mileage Band of Cars, England: 2002 Onwards (NTS0904). Contains Public Sector Information Licensed Under the Open Government Licence v3.0. Available online: https://www.gov.uk/government/statistical-data-sets/nts09-vehicle-mileage-and-occupancy (accessed on 19 December 2024).

- Hao, X.; Wang, H.; Lin, Z.; Ouyang, M. Seasonal Effects on Electric Vehicle Energy Consumption and Driving Range: A Case Study on Personal, Taxi, and Ridesharing Vehicles. J. Clean Prod. 2020, 249, 119403. [Google Scholar] [CrossRef]

- Kostopoulos, E.D.; Spyropoulos, G.C.; Kaldellis, J.K. Real-World Study for the Optimal Charging of Electric Vehicles. Energy Rep. 2020, 6, 418–426. [Google Scholar] [CrossRef]

- Dik, A.; Kutlu, C.; Omer, S.; Boukhanouf, R.; Su, Y.; Riffat, S. An Approach for Energy Management of Renewable Energy Sources Using Electric Vehicles and Heat Pumps in an Integrated Electricity Grid System. Energy Build. 2023, 294, 113261. [Google Scholar] [CrossRef]

- Owen, P.; Foreman, R. Powering the Nation: Household Electricity Using Habits Revealed; Energy Saving Trust/DECC/DEFRA: London, UK, 2012. [Google Scholar]

| Roof (W/m2K) | Floor (W/m2K) | External Wall (W/m2K) | Window (W/m2K) | Door (W/m2K) |

|---|---|---|---|---|

| 0.13 | 0.12 | 0.54 | 0.7 | 3 |

| EVs | Capacity [kWh] | Consumption Rate [kWh/mile] |

|---|---|---|

| TESLA MODEL 3 | 60 | 0.232 |

| NISSAN LEAF | 40 | 0.269 |

| KIA NIRO | 68 | 0.27 |

| RENAULT ZOE | 54.7 | 0.274 |

| VOLKSWAGEN ID3 | 62 | 0.264 |

| JAGUAR I-PACE | 90 | 0.36 |

| TESLA MODEL Y | 60 | 0.267 |

| AUDI E-TRON | 93.4 | 0.34 |

| BMW I3 | 42.2 | 0.261 |

| HYUNDAI KONA | 67.5 | 0.261 |

| Heat Pump System | Daily Compressor Consumption (kWh) | Daily COP |

|---|---|---|

| ASHP | 15.4 | 2.24 |

| 100% Thermal Collector SAHP | 9.87 | 3.49 |

| 80% Thermal 20% PV Collector SAHP | 11 | 3.12 |

| 70% Thermal 30% PV Collector SAHP | 11.98 | 2.88 |

| 60% Thermal 40% PV Collector SAHP | 13.41 | 2.57 |

| PV/T Collector SAHP | 13.29 | 2.6 |

| Heat Pump System | PV Output | Total Consumption | Carbon Emission |

|---|---|---|---|

| ASHP | - | 25.15 kWh | 5800 g |

| SAHP with 100% thermal collector | - | 19.61 kWh | 4141 g |

| SAHP with 80% thermal 20% PV collector | 1.86 kWh | 19.42 kWh | 4070 g |

| SAHP with 70% thermal 30% PV collector | 1.36 kWh | 19.66 kWh | 4073 g |

| SAHP with 60% thermal 40% PV collector | 2.73 kWh | 20.42 kWh | 4137 g |

| SAHP with PV/T collector | 4.7 kWh | 18.25 kWh | 3789 g |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kutlu, C.; Dik, A.; Erdinc, M.T.; Su, Y.; Riffat, S. Comparative Analysis of Solar Photovoltaic/Thermal Assisted Heat Pump Systems Coupled with PCM Storage and EV Charging with Reference to the UK’s National Carbon Intensity. Energies 2025, 18, 920. https://doi.org/10.3390/en18040920

Kutlu C, Dik A, Erdinc MT, Su Y, Riffat S. Comparative Analysis of Solar Photovoltaic/Thermal Assisted Heat Pump Systems Coupled with PCM Storage and EV Charging with Reference to the UK’s National Carbon Intensity. Energies. 2025; 18(4):920. https://doi.org/10.3390/en18040920

Chicago/Turabian StyleKutlu, Cagri, Abdullah Dik, Mehmet Tahir Erdinc, Yuehong Su, and Saffa Riffat. 2025. "Comparative Analysis of Solar Photovoltaic/Thermal Assisted Heat Pump Systems Coupled with PCM Storage and EV Charging with Reference to the UK’s National Carbon Intensity" Energies 18, no. 4: 920. https://doi.org/10.3390/en18040920

APA StyleKutlu, C., Dik, A., Erdinc, M. T., Su, Y., & Riffat, S. (2025). Comparative Analysis of Solar Photovoltaic/Thermal Assisted Heat Pump Systems Coupled with PCM Storage and EV Charging with Reference to the UK’s National Carbon Intensity. Energies, 18(4), 920. https://doi.org/10.3390/en18040920