Assessment of the Impact of Direct Water Cooling and Cleaning System Operating Scenarios on PV Panel Performance

Abstract

:1. Introduction

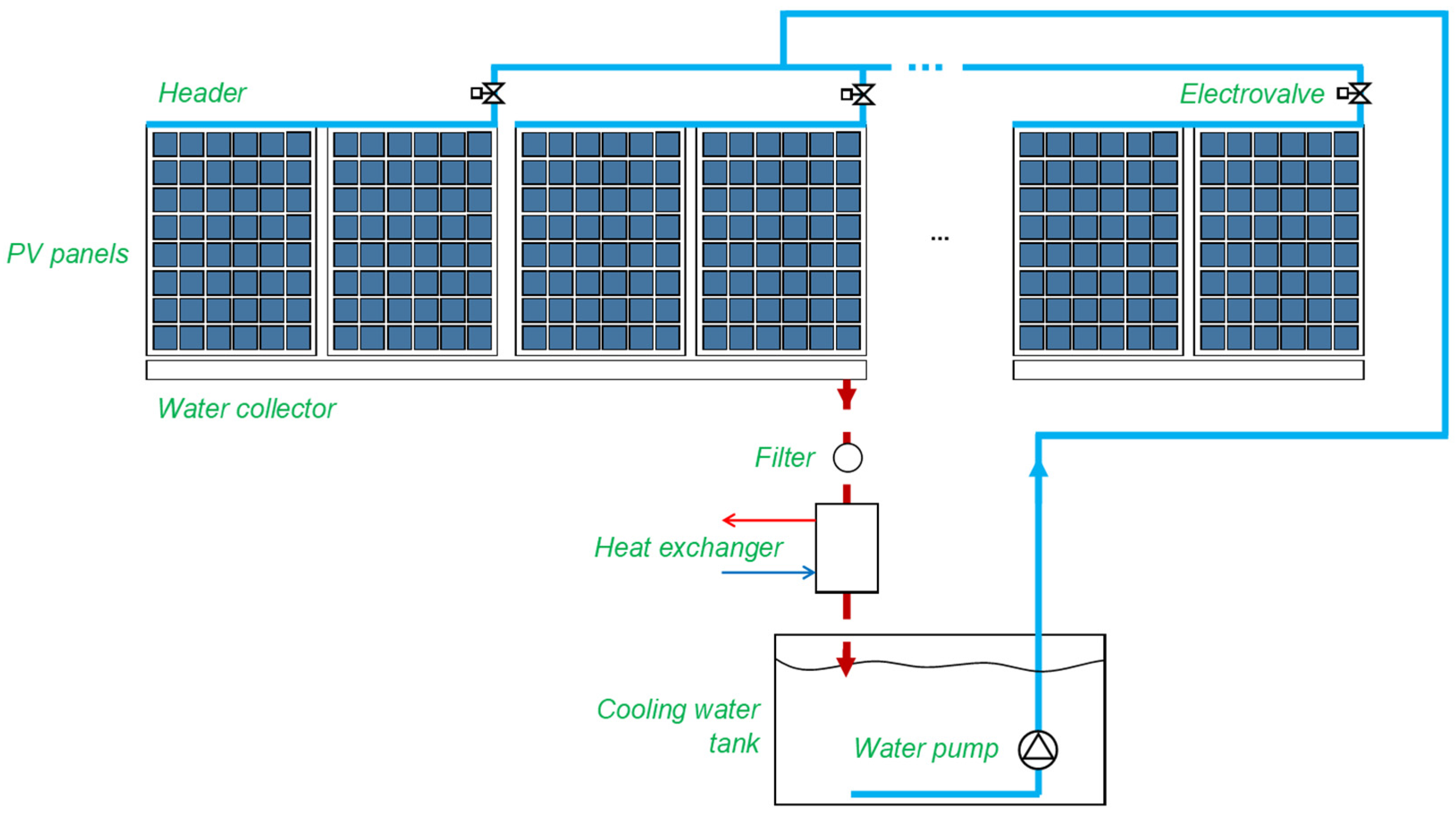

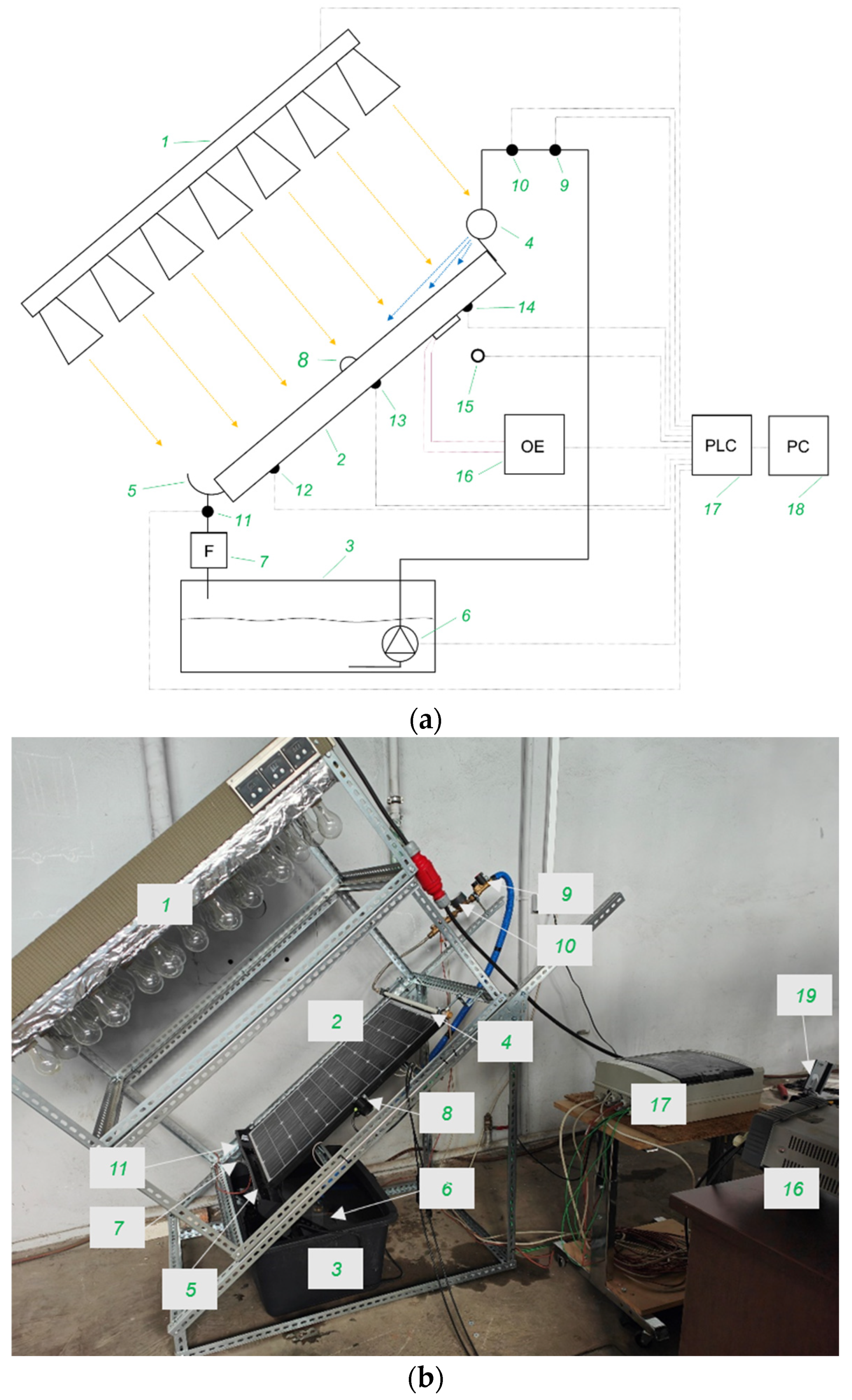

2. Materials and Methods

2.1. Internal Experimental Rig

2.2. External Experimental Rig

2.3. Experimental Procedure

- random covering of the surface of the PV panel with 15 g sand (series S_2A),

- random covering of the surface of the PV panel with 30 g sand (series S_2B),

- random covering of the surface of the PV panel with 50 g sand (series S_2C).

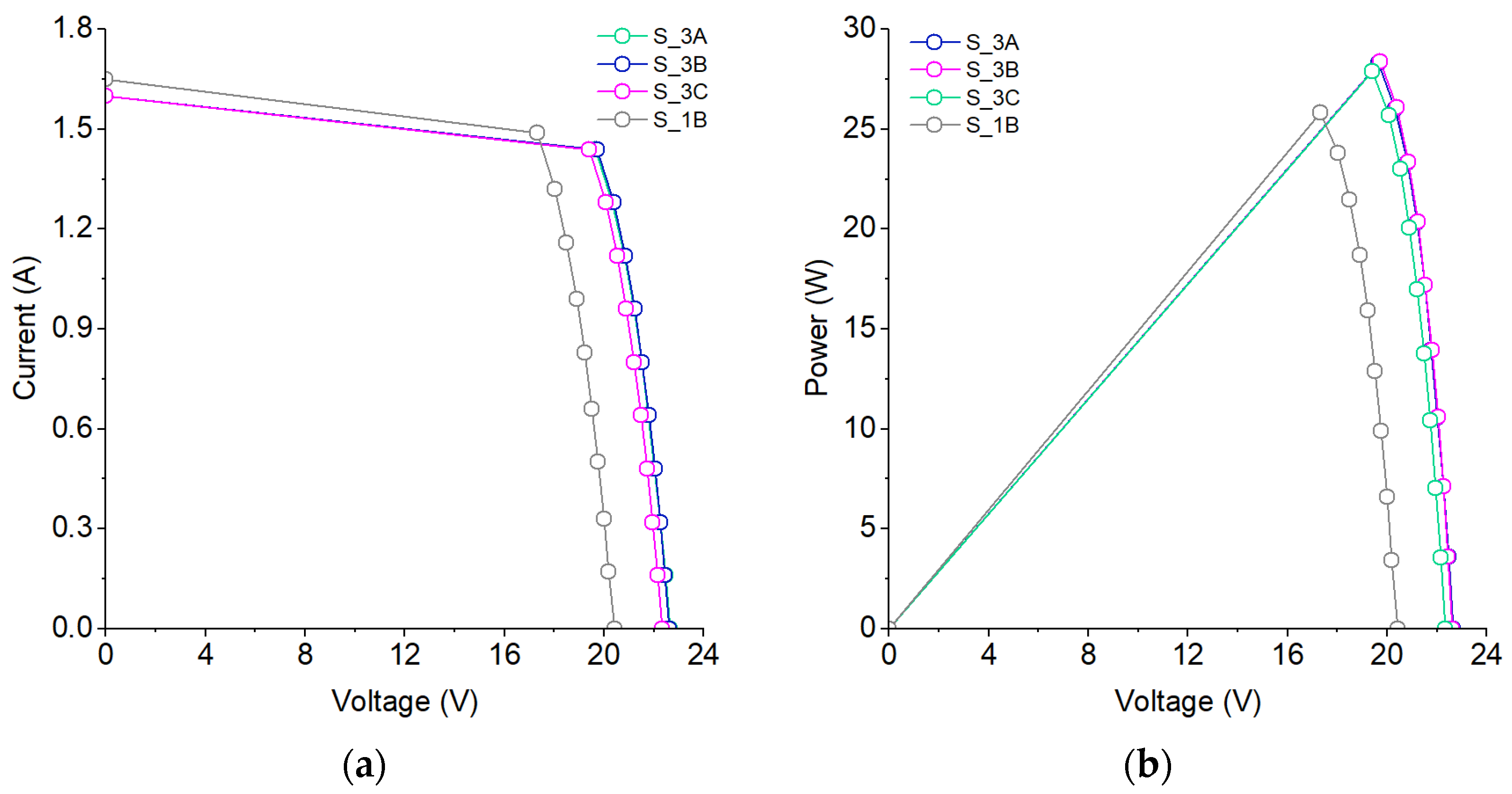

- 2.0 L/min (series S_3A),

- 3.0 L/min (series S_3B),

- 4.0 L/min (series S_3C).

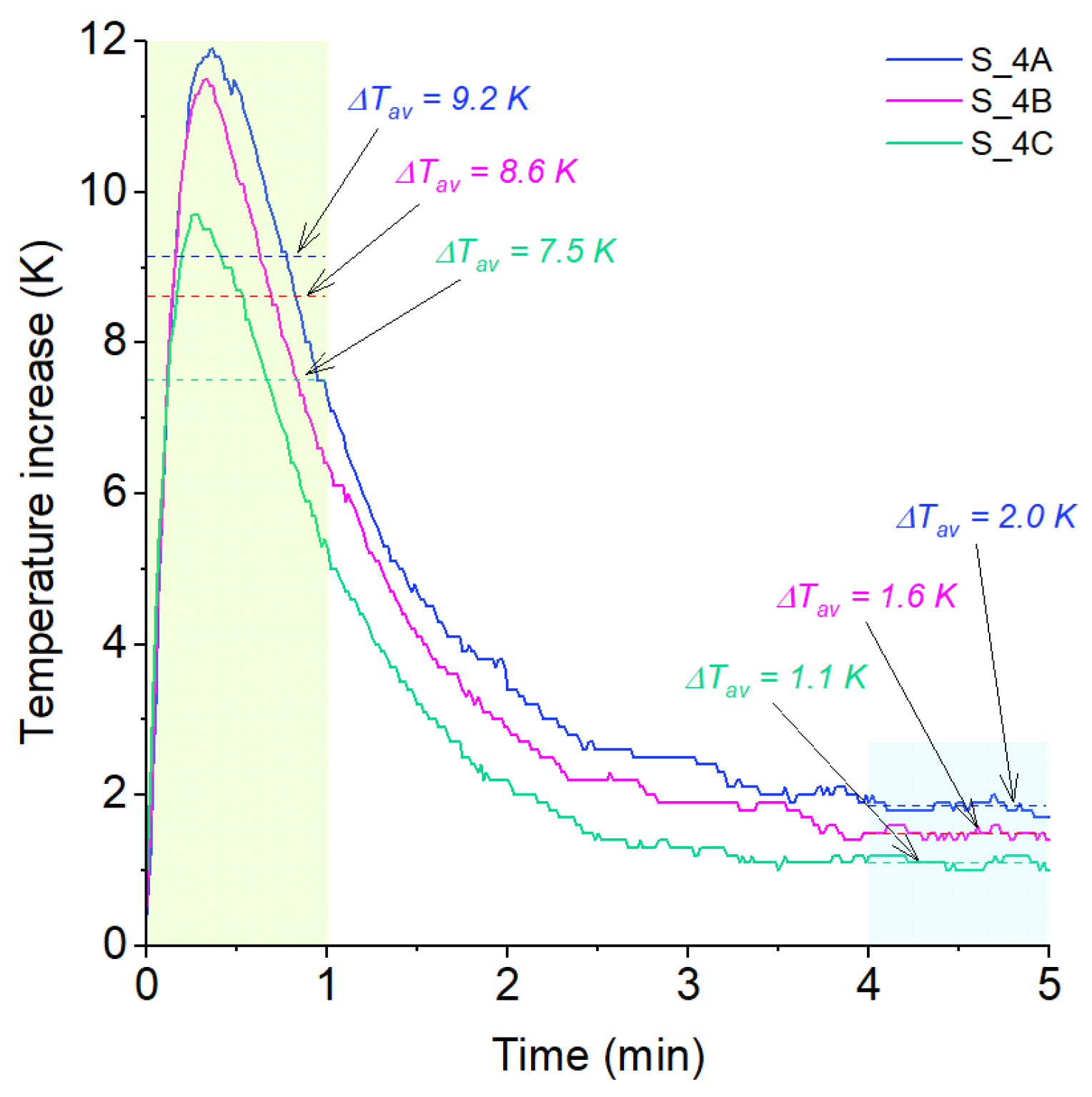

- a 2 min cooling mode with 5 min interruptions (series S_4A),

- a 1 min cooling mode with 5 min interruptions (series S_4B),

- a 1 min cooling mode with 9 min interruptions (series S_4C).

2.4. Calculations of Temperature Coefficients of Power, Voltage, and Current

- Pmax—the maximum power generated in the hot PV panel [W],

- Pmax,ref—the maximum power generated in the cold PV panel (reference value) [W],

- Isc—the short-circuit current generated in the hot PV panel [A],

- Isc,ref—the short-circuit current generated in the cold PV panel (reference value) [A],

- Voc—the open-circuit voltage generated in the hot PV panel [V],

- Voc,ref—the open-circuit voltage generated in the cold PV panel (reference value) [V],

- T—the temperature of the hot PV panel [K],

- Tref—the reference temperature (the initial temperature of the cold PV panel) [K].

2.5. Economic Analysis

- IC—initial costs [EUR],

- ES—energy savings [EUR/year].

- CFt—net cash flow during a single period t [EUR/year],

- α—discount rate [-],

- t—number of periods [years].

3. Results and Discussion

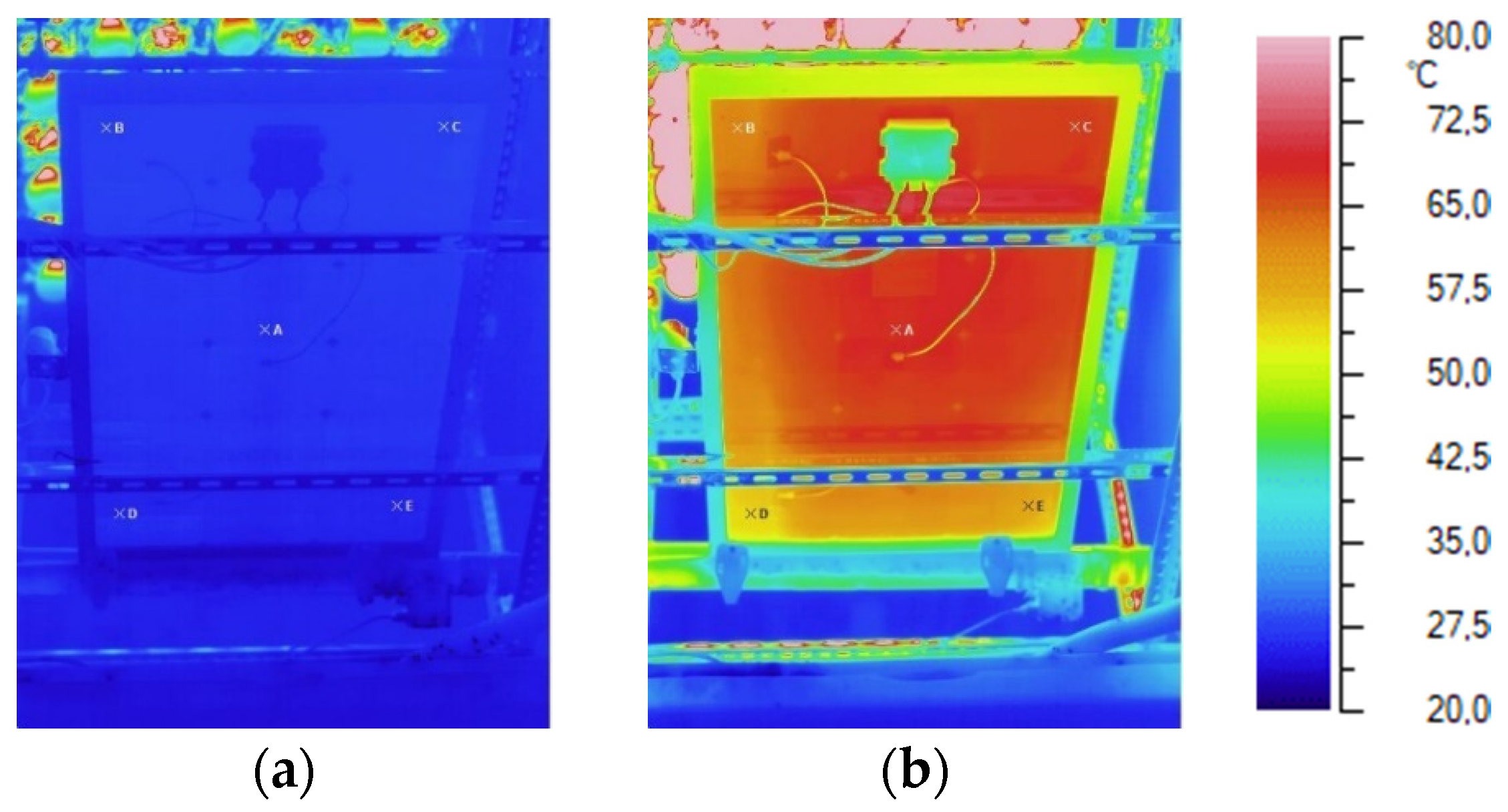

3.1. Assessing the Impact of Temperature on the Performance of the 70 Wp PV Panel

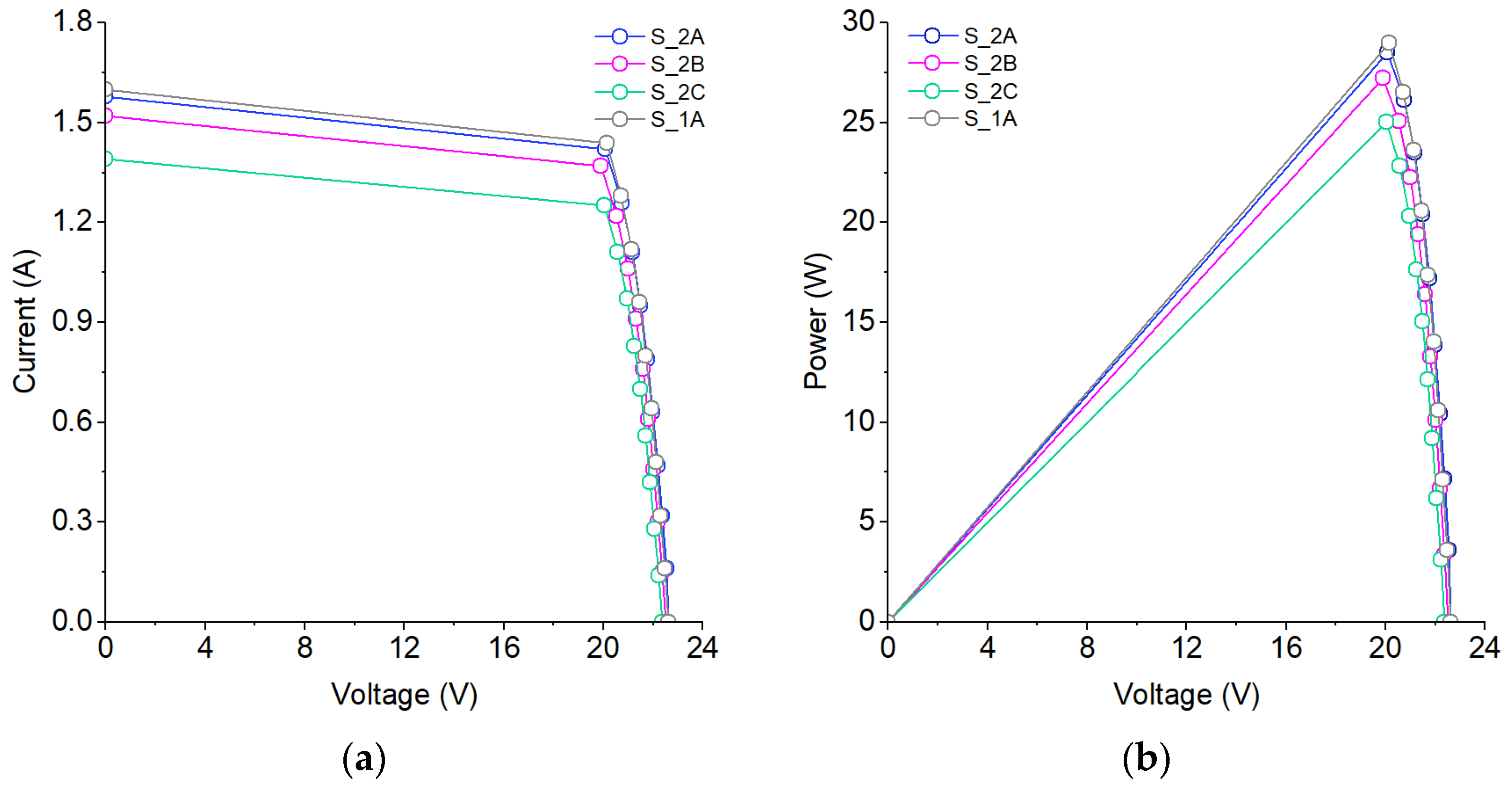

3.2. Assessing the Impact of Soiling on the Performance of the 70 Wp PV Panel

3.3. Assessing the Impact of Water Flow on the Performance of the 70 Wp PV Panel

3.4. Assessing the Amount of Heat Received from the Cooled 70 Wp PV Panel

3.5. Assessing the Impact of Interval Operation of the Cooling System on the Performance of the 70 Wp PV Panel

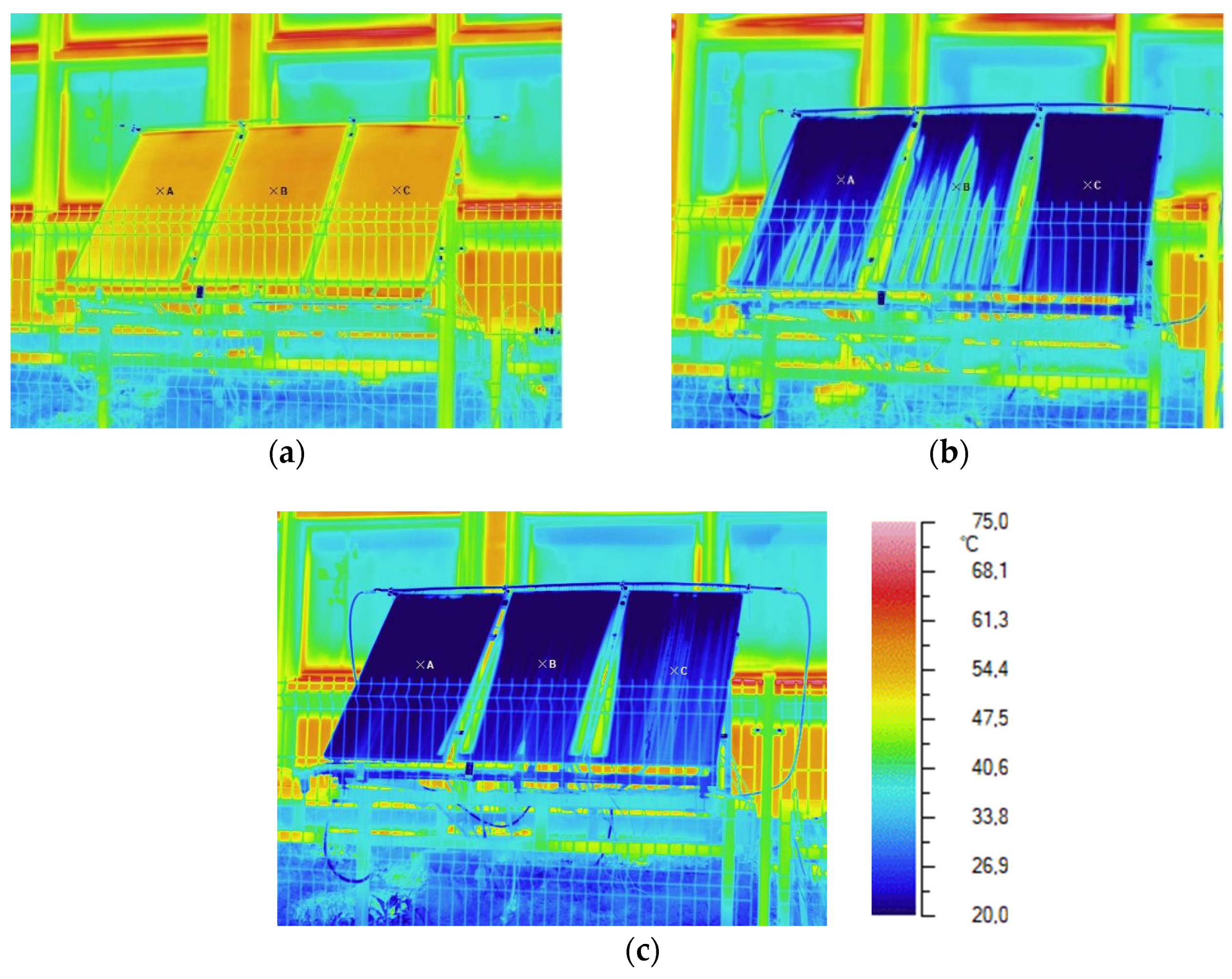

3.6. Assessing the Operation Parameters of the 160 Wp PV Panels Under Real Conditions

3.7. Assessing the Economic Aspects of Installing the Developed Direct Cooling and Cleaning System to the PV Installation

- the installed power of the PV system would be 5 kWp (ten 500 Wp PV panels) or 10 kWp (twenty 500 Wp PV panels);

- the investment cost of implementing the cooling and water cleaning system was assumed to be 1400 EUR (for the 5 kWp installation) and 2100 EUR (for the 10 kWp installation);

- sequential cooling was assumed—the PV installations were divided into sections of two PV panels each. Each section was assumed to be cooled for 60 s at 5-min intervals, so one water pump was assumed for variant A, and two water pumps were assumed for variant B;

- the energy required by the cooling pump, cooler, and controller would be covered by PV panels;

- the cost of water can be omitted because it is possible to use rainwater;

- PV panels would operate in Polish climatic conditions characterized by insolation of 1000–1100 kWh/(m2·year) [50];

- the electricity price was assumed at EUR 0.2847/kWh (based on the average price in the EU27 area in the second half of 2023) [51];

- an annual increase in electricity generation yield of 7 and 10% was assumed.

4. Conclusions

- the power generated in the PV panel dropped from 28.99 W to 25.87 W (a decrease of 10.8% was observed) when the panel’s temperature increased from approx. 26.5 to approx. 59.8 °C;

- the performance of the cooled PV panel was close to the performance of the cold unit and higher by 9.63–11.25% compared to the performance of the heated unit;

- the average temperature increase of the cooling water flowing through the PV panel surface in the first minute of the cooling process ranged from 7.5 to 8.4 K, while in the fifth minute of the process, it ranged from 1.6 to 1.8 K. Consequently, the average values of thermal power received by the cooling water from the PV panel’s surface ranged from 1461.8 to 1727.2 W (minute 1) and from 307.3 to 342.2 W (minute 5);

- to limit the amount of electrical energy consumed by the cooling water pump, the direct cooling and cleaning system can operate in an interval mode;

- cooling for one minute with interruptions of 4–5 min allowed to obtain the average temperature of the tested PV panel at a level lower than 40 °C. In comparison, the temperature of the uncooled panel in the same operating conditions was close to 60 °C;

- the results of the experimental study conducted under laboratory conditions were confirmed under real conditions. Tests of the PV panels equipped with the prototype of the direct water cooling and cleaning system showed an increase in their efficiency by up to 15.3% compared to uncooled panels, while the average values were measured at a level of 3.63% in May, 7.48% in July, and 2.51% in September, respectively;

- the calculated simple payback period varied from 6.9 to 13.1 years, depending on the assumed installed power of the PV system and the potential increase in module efficiency. Calculated for a period of 15 years, the net present value was a maximum of 518.4 EUR, while the corresponding profitability index was 1.247;

- further research will include, in particular, studies of the seasonal performance of PV panels under real operating conditions. In addition, the research will take into account issues related to the parameters of cooling and cleaning water (e.g., its mineralization, pH, and content of gaseous and solid contaminants). The potential corrosive effect of the water on the PV plant’s structural elements will also be considered, as well as the potential growth of algae and other organisms. Moreover, based on the experimental results, mathematical models describing the operating parameters of PV panels equipped with the direct water cooling and cleaning system will be prepared and introduced to the dynamic simulations.

Funding

Data Availability Statement

Conflicts of Interest

References

- Alami, A.H. Effects of Evaporative Cooling on Efficiency of Photovoltaic Modules. Energy Convers. Manag. 2014, 77, 668–679. [Google Scholar] [CrossRef]

- Manju, S.; Sagar, N. Progressing towards the Development of Sustainable Energy: A Critical Review on the Current Status, Applications, Developmental Barriers and Prospects of Solar Photovoltaic Systems in India. Renew. Sustain. Energy Rev. 2017, 70, 298–313. [Google Scholar] [CrossRef]

- Matusz-Kalász, D.; Bodnár, I. Operation Problems of Solar Panel Caused by the Surface Contamination. Energies 2021, 14, 5461. [Google Scholar] [CrossRef]

- Su, D.; Jia, Y.; Alva, G.; Liu, L.; Fang, G. Comparative Analyses on Dynamic Performances of Photovoltaic–Thermal Solar Collectors Integrated with Phase Change Materials. Energy Convers. Manag. 2017, 131, 79–89. [Google Scholar] [CrossRef]

- Muneeshwaran, M.; Sajjad, U.; Ahmed, T.; Amer, M.; Ali, H.M.; Wang, C.C. Performance Improvement of Photovoltaic Modules via Temperature Homogeneity Improvement. Energy 2020, 203, 117816. [Google Scholar] [CrossRef]

- Kozak-Jagieła, E.; Cisek, P.; Ocłoń, P. Cooling Techniques for PV Panels: A Review. Sci. Radices 2023, 2, 47–68. [Google Scholar] [CrossRef]

- Mahdavi, A.; Farhadi, M.; Gorji-Bandpy, M.; Mahmoudi, A. A Review of Passive Cooling of Photovoltaic Devices. Clean. Eng. Technol. 2022, 11, 100579. [Google Scholar] [CrossRef]

- Pang, W.; Cui, Y.; Zhang, Q.; Wilson, G.J.; Yan, H. A Comparative Analysis on Performances of Flat Plate Photovoltaic/Thermal Collectors in View of Operating Media, Structural Designs, and Climate Conditions. Renew. Sustain. Energy Rev. 2020, 119, 109599. [Google Scholar] [CrossRef]

- Gharzi, M.; Arabhosseini, A.; Gholami, Z.; Rahmati, M.H. Progressive Cooling Technologies of Photovoltaic and Concentrated Photovoltaic Modules: A Review of Fundamentals, Thermal Aspects, Nanotechnology Utilization and Enhancing Performance. Sol. Energy 2020, 211, 117–146. [Google Scholar] [CrossRef]

- Zhao, B.; Yang, J.; Cao, S.; Lv, C.; Fan, S.; Sun, T.; Chen, N. Design of a Vacuum-Type PV Module Cleaning Robot Based on an Auxiliary Mobile Frame. Sol. Energy 2024, 275, 112634. [Google Scholar] [CrossRef]

- Syafiq, A.; Balakrishnan, V.; Ali, M.S.; Dhoble, S.J.; Rahim, N.A.; Omar, A.; Bakar, A.H.A. Application of Transparent Self-Cleaning Coating for Photovoltaic Panel: A Review. Curr. Opin. Chem. Eng. 2022, 36, 100801. [Google Scholar] [CrossRef]

- Aljaghoub, A.; Abumadi, F.; AlMallahi, M.N.; Obaideen, K.; Alami, A.H. Solar PV cleaning techniques contribute to Sustainable Development Goals (SDGs) using Multi-criteria decision-making (MCDM): Assessment and review. Int. J. Thermofluids 2022, 16, 100233. [Google Scholar] [CrossRef]

- Antonelli, M.G.; Beomonte Zobel, P.; De Marcellis, A.; Palange, E. Autonomous Robot for Cleaning Photovoltaic Panels in Desert Zones. Mechatronics 2020, 68, 102372. [Google Scholar] [CrossRef]

- Al-Amri, F.; Saeed, F.; Mujeebu, M.A. Novel Dual-Function Racking Structure for Passive Cooling of Solar PV Panels –Thermal Performance Analysis. Renew. Energy 2022, 198, 100–113. [Google Scholar] [CrossRef]

- Hernandez-Perez, J.G.; Carrillo, J.G.; Bassam, A.; Flota-Banuelos, M.; Patino-Lopez, L.D. A New Passive PV Heatsink Design to Reduce Efficiency Losses: A Computational and Experimental Evaluation. Renew. Energy 2020, 147, 1209–1220. [Google Scholar] [CrossRef]

- Hamed, M.H.; Hassan, H.; Ookawara, S.; Nada, S.A. PV Thermal Regulation and Water Harvesting Hybrid System Using Evaporative Cooling of Silica Gel Layer. Process Saf. Environ. Prot. 2024, 181, 243–265. [Google Scholar] [CrossRef]

- Hussien, A.; Eltayesh, A.; El-Batsh, H.M. Experimental and Numerical Investigation for PV Cooling by Forced Convection. Alex. Eng. J. 2023, 64, 427–440. [Google Scholar] [CrossRef]

- Bevilacqua, P.; Bruno, R.; Rollo, A.; Ferraro, V. A Novel Thermal Model for PV Panels with Back Surface Spray Cooling. Energy 2022, 255, 124401. [Google Scholar] [CrossRef]

- Kabeel, A.E.; Abdelgaied, M.; Sathyamurthy, R. A Comprehensive Investigation of the Optimization Cooling Technique for Improving the Performance of PV Module with Reflectors under Egyptian Conditions. Sol. Energy 2019, 186, 257–263. [Google Scholar] [CrossRef]

- Madurai Elavarasan, R.; Nadarajah, M.; Pugazhendhi, R.; Gangatharan, S. An Experimental Investigation on Coalescing the Potentiality of PCM, Fins and Water to Achieve Sturdy Cooling Effect on PV Panels. Appl. Energy 2024, 356, 122371. [Google Scholar] [CrossRef]

- Faheem, M.; Abu Bakr, M.; Ali, M.; Majeed, M.A.; Haider, Z.M.; Khan, M.O. Evaluation of Efficiency Enhancement in Photovoltaic Panels via Integrated Thermoelectric Cooling and Power Generation. Energies 2024, 17, 2590. [Google Scholar] [CrossRef]

- Choi, S.M.; Kwon, H.G.; Kim, T.; Moon, H.K.; Cho, H.H. Active Cooling of Photovoltaic (PV) Cell by Acoustic Excitation in Single-Dimpled Internal Channel. Appl. Energy 2022, 309, 118466. [Google Scholar] [CrossRef]

- Yildirim, M.A.; Cebula, A.; Sułowicz, M. A Cooling Design for Photovoltaic Panels—Water-Based PV/T System. Energy 2022, 256, 124654. [Google Scholar] [CrossRef]

- Wang, J.; Li, Y.; Yang, B.; Jiang, L. Multi-Optimized Reconfiguration of Hybrid Photovoltaic-Thermoelectric Generation (PV-TEG) System for Performance Enhancement. Energy Convers. Manag. 2024, 307, 118373. [Google Scholar] [CrossRef]

- Arnaoutakis, G.E.; Busko, D.; Richards, B.S.; Ivaturi, A.; Gordon, J.M.; Katz, E.A. Ultra-Broadband near-Infrared Upconversion for Solar Energy Harvesting. Sol. Energy Mater. Sol. Cells 2024, 269, 112783. [Google Scholar] [CrossRef]

- Papis-Frączek, K.; Żołądek, M.; Filipowicz, M. The Possibilities of Upgrading an Existing Concentrating Solar Thermal System —Case Study. Energy Rep. 2021, 7, 28–32. [Google Scholar] [CrossRef]

- Sornek, K.; Żołądek, M.; Papis-Frączek, K.; Szram, M.; Filipowicz, M. Experimental Investigations of the Microscale Concentrated Photovoltaic/Thermal System Based on a Solar Parabolic Trough Concentrator. Energy Rep. 2023, 9, 86–97. [Google Scholar] [CrossRef]

- Sornek, K.; Filipowicz, M.; Jasek, J. The Use of Fresnel Lenses to Improve the Efficiency of Photovoltaic Modules for Building-Integrated Concentrating Photovoltaic Systems. J. Sustain. Dev. Energy Water Environ. Syst. 2018, 6, 415–426. [Google Scholar] [CrossRef]

- Micheli, L.; Senthilarasu, S.; Reddy, K.S.; Mallick, T.K. Applicability of Silicon Micro-Finned Heat Sinks for 500× Concentrating Photovoltaics Systems. J. Mater. Sci. 2015, 50, 5378–5388. [Google Scholar] [CrossRef]

- Du, B.; Hu, E.; Kolhe, M. Performance Analysis of Water Cooled Concentrated Photovoltaic (CPV) System. Renew. Sustain. Energy Rev. 2012, 16, 6732–6736. [Google Scholar] [CrossRef]

- Zorrilla-Casanova, J.; Piliougine, M.; Carretero, J.; Bernaola, P.; Carpena, P.; Mora-Lopez, L.; Sidrach-de-Cardona, M. Analysis of Dust Losses in Photovoltaic Modules. In Proceedings of the World Renewable Energy Congress—Sweden, Linköping, Sweden, 8–13 May 2011; Volume 57, pp. 2985–2992. [Google Scholar] [CrossRef]

- Tripanagnostopoulos, Y. Aspects and Improvements of Hybrid Photovoltaic/Thermal Solar Energy Systems. Sol. Energy 2007, 81, 1117–1131. [Google Scholar] [CrossRef]

- Aste, N.; Del Pero, C.; Leonforte, F.; Manfren, M. Performance Monitoring and Modeling of an Uncovered Photovoltaic-Thermal (PVT) Water Collector. Sol. Energy 2016, 135, 551–568. [Google Scholar] [CrossRef]

- Shyam; Tiwari, G.N.; Al-Helal, I.M. Analytical Expression of Temperature Dependent Electrical Efficiency of N-PVT Water Collectors Connected in Series. Sol. Energy 2015, 114, 61–76. [Google Scholar] [CrossRef]

- Moharram, K.A.; Abd-Elhady, M.S.; Kandil, H.A.; El-Sherif, H. Influence of Cleaning Using Water and Surfactants on the Performance of Photovoltaic Panels. Energy Convers. Manag. 2013, 68, 266–272. [Google Scholar] [CrossRef]

- Dahlioui, D.; Traore, L.; Laarabi, B.; Barhdadi, A. Ecological Cleaning of PV Panels by Exploitation of Dew Water in Morocco. Mater. Today Proc. 2022, 66, 130–134. [Google Scholar] [CrossRef]

- Zhao, W.; Lv, Y.; Dong, Z.; Zhao, F.; Lv, F.; Yan, W. Effect of Self-Cleaning Superhydrophobic Coating on Dust Deposition and Performance of PV Modules. Renew. Energy 2024, 227, 120576. [Google Scholar] [CrossRef]

- Singh, U.P.; Chandra, S. Optimal Cleaning Schedule in Solar PV Using the Biography-Based Helianthus Optimization Enabled Coupled Deep Network. Sol. Energy 2023, 266, 112138. [Google Scholar] [CrossRef]

- Zhang, C.; Ma, Y.; Mi, Z.; Yang, F.; Zhang, L. A Rolling-Horizon Cleaning Recommendation System for Dust Removal of Industrial PV Panels. Appl. Energy 2024, 353, 122168. [Google Scholar] [CrossRef]

- You, S.; Lim, Y.J.; Dai, Y.; Wang, C.H. On the Temporal Modelling of Solar Photovoltaic Soiling: Energy and Economic Impacts in Seven Cities. Appl. Energy 2018, 228, 1136–1146. [Google Scholar] [CrossRef]

- Rodrigo, P.M.; Gutiérrez, S.; Micheli, L.; Fernández, E.F.; Almonacid, F.M. Optimum Cleaning Schedule of Photovoltaic Systems Based on Levelised Cost of Energy and Case Study in Central Mexico. Sol. Energy 2020, 209, 11–20. [Google Scholar] [CrossRef]

- Sornek, K.; Goryl, W.; Głowacka, A. Improving the Performance of Photovoltaic Panels Using a Direct Water Cooling System. J. Sustain. Dev. Energy Water Environ. Syst. 2023, 11, 1–24. [Google Scholar] [CrossRef]

- Sornek, K.; Goryl, W.; Figaj, R.; Dąbrowska, G.D.; Brezdeń, J. Development and Tests of the Water Cooling System Dedicated to Photovoltaic Panels. Energies 2022, 15, 5884. [Google Scholar] [CrossRef]

- Available online: https://imgw.pl/wydarzenia/charakterystyka-wybranych-elementow-klimatu-w-polsce-w-2022-roku-podsumowanie (accessed on 21 August 2023).

- Available online: https://re.jrc.ec.europa.eu/pvg_tools/en/ (accessed on 20 August 2024).

- Micheli, L.; Fernández, E.F.; Aguilera, J.T.; Almonacid, F. Economics of Seasonal Photovoltaic Soiling and Cleaning Optimization Scenarios. Energy 2021, 215, 119018. [Google Scholar] [CrossRef]

- Tina, G.M.; Bontempo Scavo, F.; Micheli, L.; Rosa-Clot, M. Economic Comparison of Floating Photovoltaic Systems with Tracking Systems and Active Cooling in a Mediterranean Water Basin. Energy Sustain. Dev. 2023, 76, 101283. [Google Scholar] [CrossRef]

- Szafranko, E. Assessment of the Economic Efficiency of Energy-Saving Projects, Methodology Based on Simple and Compound Methods. Energy Sci. Eng. 2022, 10, 423–438. [Google Scholar] [CrossRef]

- EN 60038; CENELEC Standard Voltages. European Committee for Standards-Electrical: Brussels, Belgium, 2011.

- Olczak, P.; Komorowska, A. An Adjustable Mounting Rack or an Additional PV Panel? Cost and Environmental Analysis of a Photovoltaic Installation on a Household: A Case Study in Poland. Sustain. Energy Technol. Assess. 2021, 47, 101496. [Google Scholar] [CrossRef]

- Electricity Price Statistics—Statistics Explained. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Electricity_price_statistics#Electricity_prices_for_household_consumers (accessed on 27 July 2024).

| Position | Additional Information |

|---|---|

| Photovoltaic panel | The unit 4SUN 70 W Maxx |

| Artificial light source | A set of 25 bulbs |

| Direct water cooling and cleaning system | The prototype composed of the header, water collector, water tank, and water pump |

| Programable logic controller | The modular unit WAGO PFC200 with a set of input and output modules |

| PC with CoDeSys software | CoDeSys in version 2.9 |

| Electronic artificial load | The unit Array 3721A with measuring range from 0 to 400 W for power and accuracy 0.1% +600 mW |

| Pyranometer | The unit UICPAL PYR20 with a measuring range from 0 to 2000 W/m2 and an accuracy of 5% |

| Pt100 sensors | Resistance sensors Termo-Precyzja T-101 with a measuring range from −50 °C to 400 °C and tolerance ±0.3 +0.005 × [t] |

| PTTK sensors | Thermocouple sensors UNI-T UT-T10K with a measuring range from −40 °C to 260 °C and tolerance ±2.0 °C or ±0.0075 × [t] |

| Infrared camera | The unit NEC ThermoTracer H2640 with measuring range from −40 to 120 °C, and accuracy ±2 °C or ±2% of reading |

| Water flowmeter | The unit Apator Powogaz JS 4-NK 1 L/IMP |

| Position | Additional Information |

|---|---|

| Photovoltaic panels | The units 3P 160 W |

| Direct water cooling system | The preliminary unit composed of the header, water collector, water tank, and water pump |

| Solar charge controller | The unit Array 3721A with measuring range from 0 to 400 W for power and accuracy 0.1% +600 mW |

| Batteries | A set of units Volt Polska AGM VRLA 12 V 20 Ah |

| Programable logic controller | The modular unit WAGO PFC200 with a set of input and output modules |

| PC with CoDeSys software | CoDeSys in version 2.9 |

| Pyranometer | The unit UICPAL PYR20 with a measuring range from 0 to 2000 W/m2 and an accuracy of 5% |

| Pt100 sensors | Resistance sensors Termo-Precyzja T-101 with a measuring range from −50 °C to 400 °C and tolerance ±0.3 + 0.005 × [t] |

| Infrared camera | The unit NEC ThermoTracer H2640 with measuring range from −40 to 120 °C, and accuracy ±2 °C or ±2% of reading |

| Water flowmeter | The unit Apator Powogaz JS 4-NK 1 L/IMP |

| Configuration | Series | Operating Scenario |

|---|---|---|

| PV panel without an installed cooling system | S_1A | Cold PV panel characterized by an average surface temperature of approx. 26.5 °C |

| S_1B | Heated PV panel characterized by an average surface temperature of approx. 59.8 °C | |

| PV panel covered by the sand | S_2A | Cold PV panel covered with approx. 15 g sand |

| S_2B | Cold PV panel covered with approx. 30 g sand | |

| S_2C | Cold PV panel covered with approx. 30 g sand | |

| PV panel with installed cooling system | S_3A | The PV panel cooled continuously when the water flow was set to 2.0 L/min |

| S_3B | The PV panel cooled continuously when the water flow was set to 3.0 L/min | |

| S_3C | The PV panel cooled continuously when the water flow was set to 4.0 L/min | |

| S_4A | PV panel cooled intermittently (a 2 min cooling mode with 5-min interruptions) | |

| S_4B | PV panel cooled intermittently (a 1 min cooling mode with 5-min interruptions) | |

| S_4C | PV panel cooled intermittently (a 1 min cooling mode with 9-min interruptions) |

| Parameter | Unit | Series S_1A | Series S_1B |

|---|---|---|---|

| The average temperature of the PV panel surface, tPV | °C | 26.5 | 59.8 |

| The open circuit voltage, VOC | V | 22.62 | 20.42 |

| The short circuit current, ISC | A | 1.60 | 1.67 |

| The maximum power, PMPP | W | 28.99 | 25.87 |

| Matched voltage, VMPP | V | 20.13 | 17.36 |

| Matched current, IMPP | A | 1.44 | 1.49 |

| Parameter | Unit | Series S_2A | Series S_2B | Series S_2C |

|---|---|---|---|---|

| The open circuit voltage, VOC | V | 22.60 | 22.52 | 22.37 |

| The short circuit current, ISC | A | 1.58 | 1.52 | 1.39 |

| The maximum power, PMPP | W | 28.33 | 27.41 | 24.86 |

| Matched voltage, VMPP | V | 20.09 | 20.01 | 19.89 |

| Matched current, IMPP | A | 1.41 | 1.37 | 1.25 |

| Power loss due to the presence of contamination, ΔPMPP | % | 2.28 | 5.55 | 14.25 |

| Parameter | Unit | Series S_3A | Series S_3B | Series S_3C |

|---|---|---|---|---|

| The open circuit voltage, VOC | V | 22.80 | 22.54 | 22.61 |

| The short circuit current, ISC | A | 1.58 | 1.62 | 1.62 |

| The maximum power, PMPP | W | 28.36 | 28.56 | 28.78 |

| Matched voltage, VMPP | V | 19.97 | 19.56 | 19.71 |

| Matched current, IMPP | A | 1.42 | 1.46 | 1.46 |

| PV panel performance improvement, ΔPMPP | % | 9.63 | 10.40 | 11.25 |

| Series | Scenario Description | The Minimum Temperature of the PV Panel, °C | The Maximum Temperature of the PV Panel, °C | The Average Temperature of the PV Panel, °C |

|---|---|---|---|---|

| S_4A | 2-min cooling mode with 5-min interruptions | 29.9 | 43.5 | 37.2 |

| S_4B | 1-min cooling mode with 5-min interruptions | 33.2 | 45.1 | 39.5 |

| S_4C | 1-min cooling mode with 9-min interruptions | 35.5 | 50.1 | 42.6 |

| Case | Month | Energy Generated in PV Panel, W | The Increase in Energy Generation, % | |

|---|---|---|---|---|

| Uncooled PV Panel | Cooled PV Panel | |||

| A | May 2022 | 7169.6 | 7430.3 | 3.63 |

| B | July 2022 | 13,370.6 | 14,370.0 | 7.48 |

| C | September 2022 | 4553.3 | 4667.9 | 2.51 |

| Parameter | 5.0 kWp PV System | 10 kWp PV System | ||

|---|---|---|---|---|

| The estimated investment costs, EUR | 1400.0 | 2100.0 | ||

| Estimated annual electricity production (without cooling and water cleaning system), kWh/a | 5373.2 | 10,746.3 | ||

| The estimated annual increase in generated energy, % | 7.0 | 10.0 | 7.0 | 10.0 |

| Estimated annual electricity production (with cooling and water cleaning system), kWh/a | 5749.3 | 5910.5 | 11,498.5 | 11,820.9 |

| Estimated increase in electricity generated, kWh/a | 376.1 | 537.3 | 752.2 | 1074.6 |

| The estimated economic benefits, EUR/a | 107.1 | 153.0 | 214.2 | 305.9 |

| SPBT, years | 13.1 | 9.2 | 9.8 | 6.9 |

| NPV (15 years, α = 8%), EUR | −483.3 | −90.4 | −266.6 | 518.4 |

| PI (15 years, α = 8%), EUR | 0.655 | 0.935 | 0.873 | 1.247 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sornek, K. Assessment of the Impact of Direct Water Cooling and Cleaning System Operating Scenarios on PV Panel Performance. Energies 2024, 17, 4392. https://doi.org/10.3390/en17174392

Sornek K. Assessment of the Impact of Direct Water Cooling and Cleaning System Operating Scenarios on PV Panel Performance. Energies. 2024; 17(17):4392. https://doi.org/10.3390/en17174392

Chicago/Turabian StyleSornek, Krzysztof. 2024. "Assessment of the Impact of Direct Water Cooling and Cleaning System Operating Scenarios on PV Panel Performance" Energies 17, no. 17: 4392. https://doi.org/10.3390/en17174392

APA StyleSornek, K. (2024). Assessment of the Impact of Direct Water Cooling and Cleaning System Operating Scenarios on PV Panel Performance. Energies, 17(17), 4392. https://doi.org/10.3390/en17174392