Dual-Stage Energy Recovery from Internal Combustion Engines

Abstract

1. Introduction

2. Materials and Methods

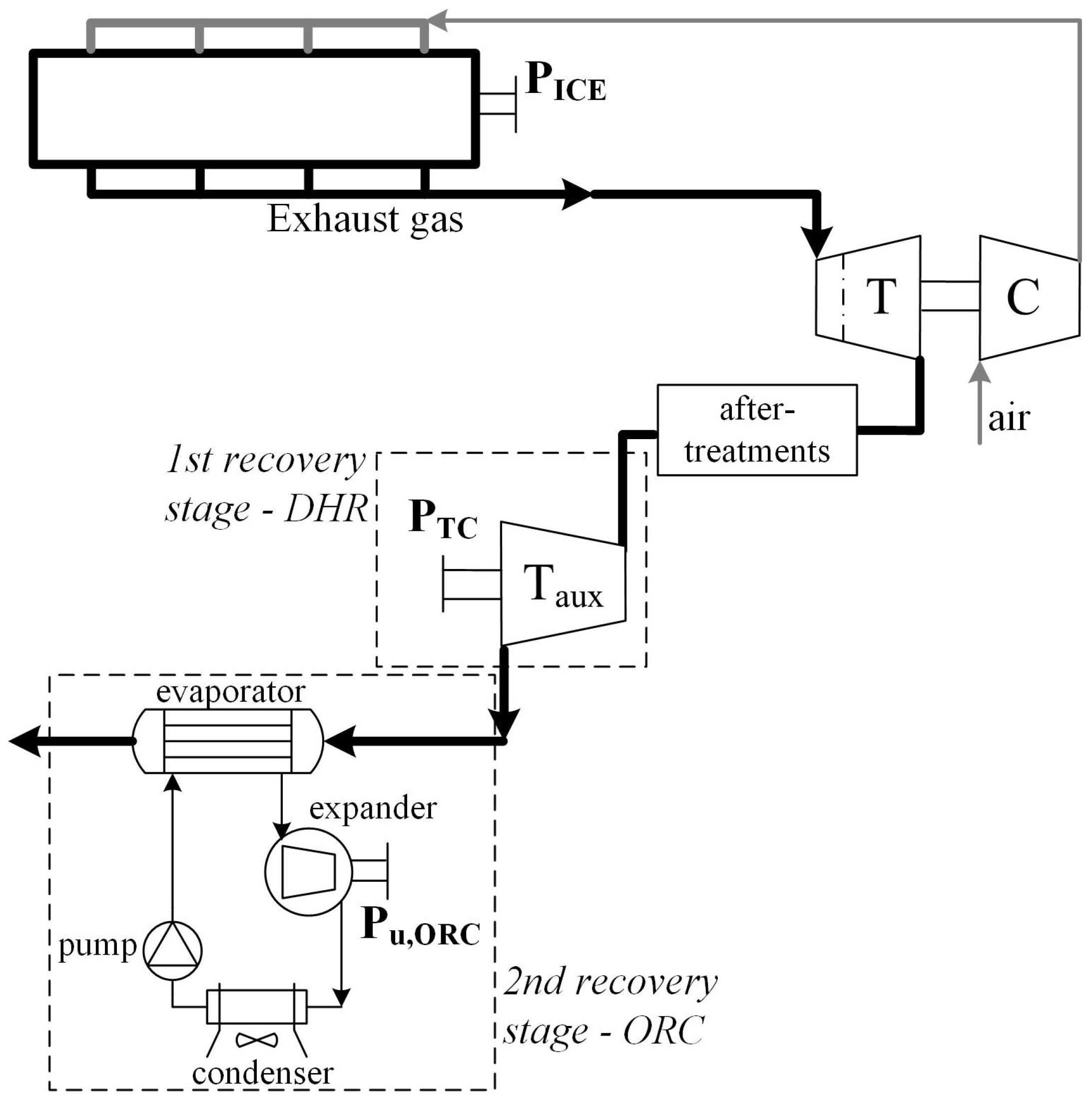

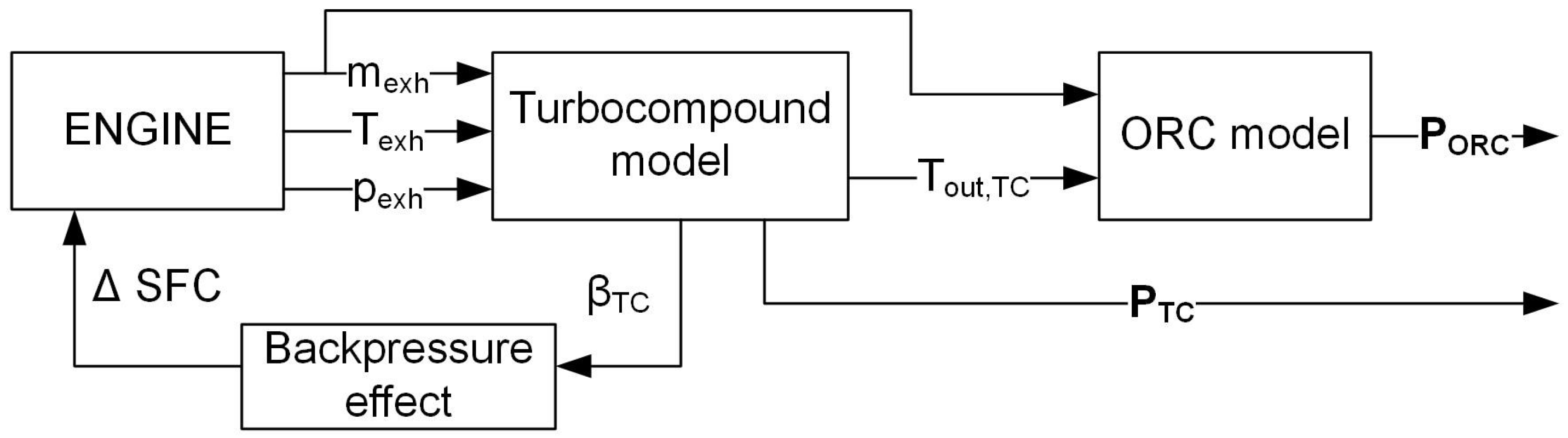

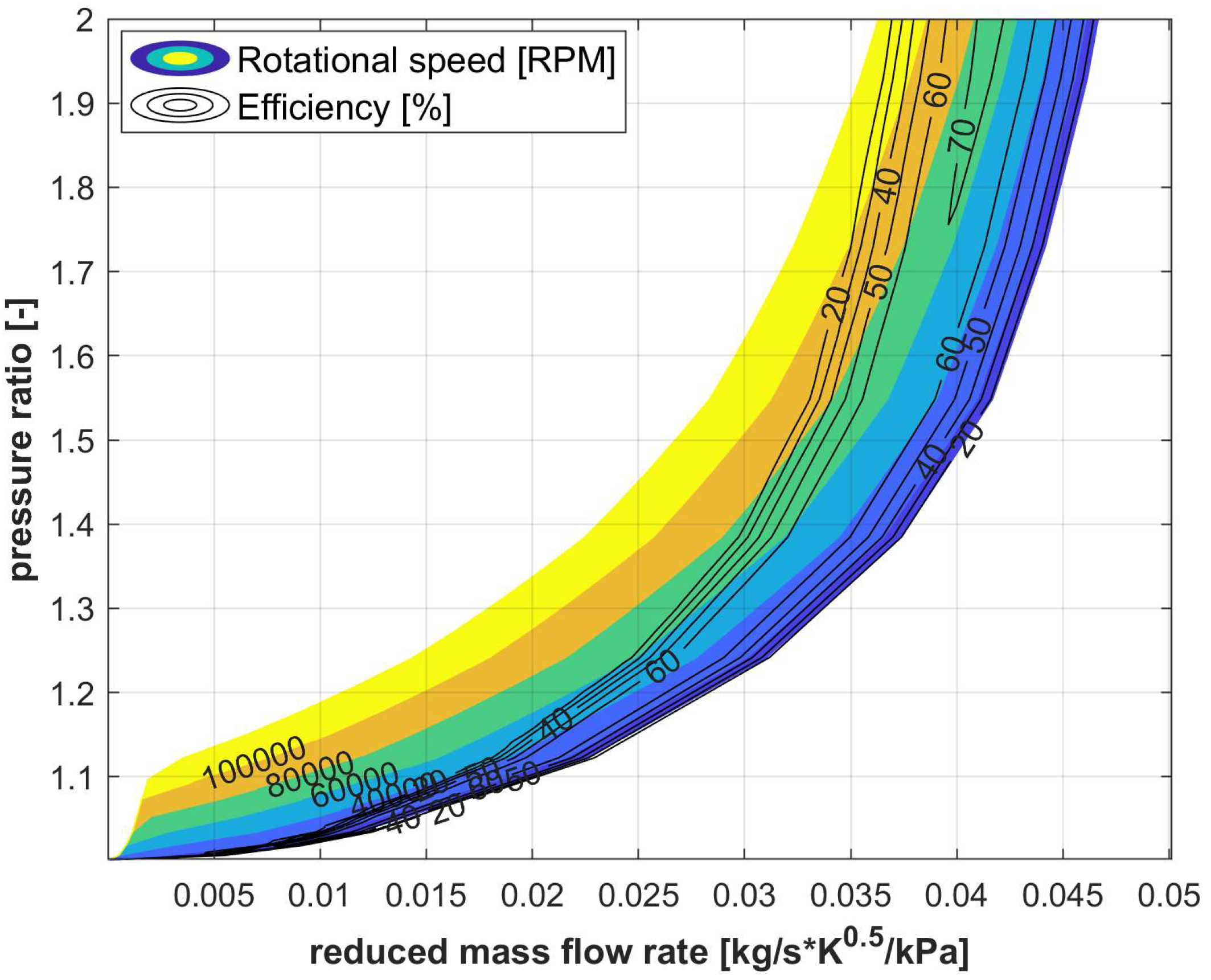

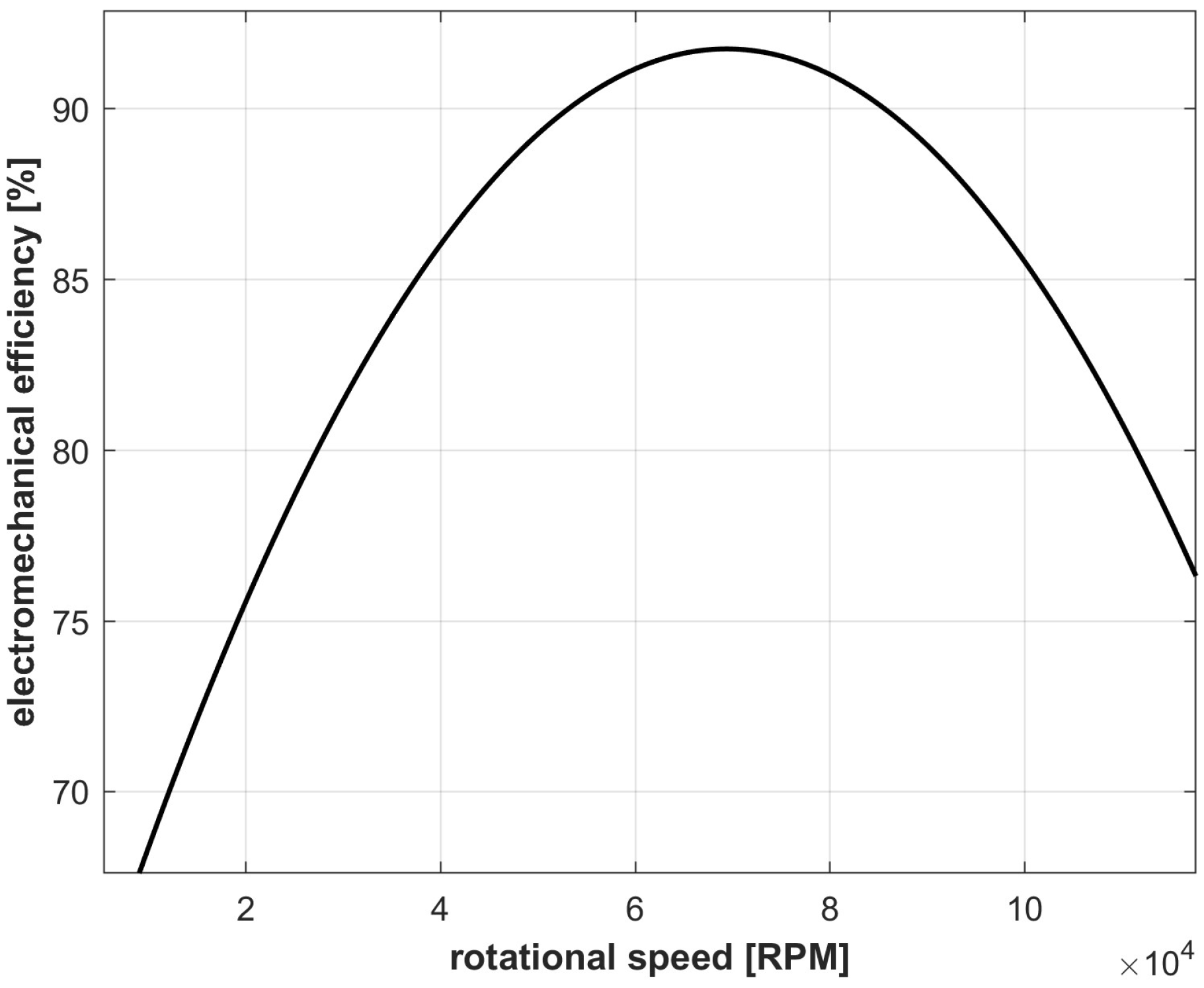

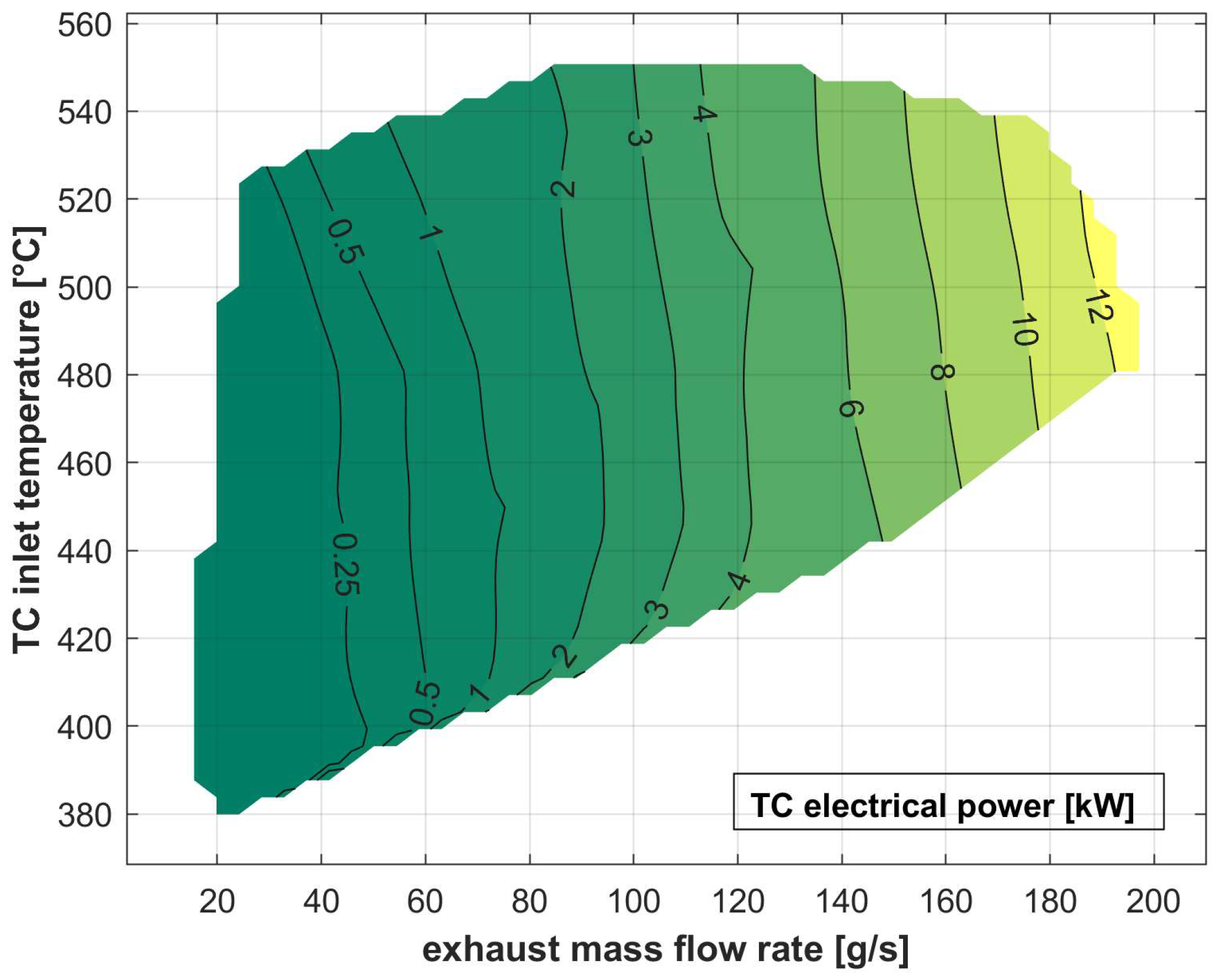

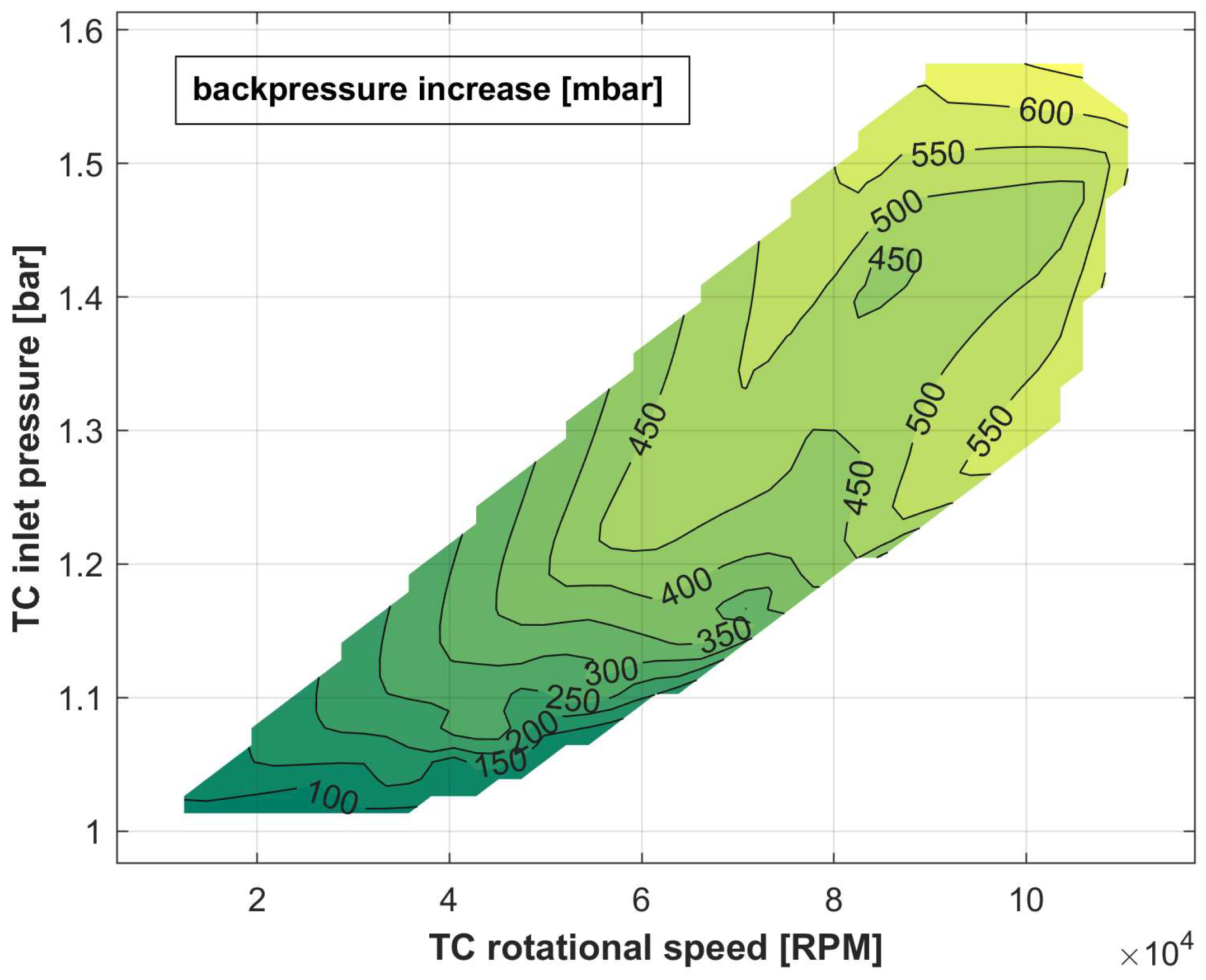

2.1. Direct Recovery Modeling

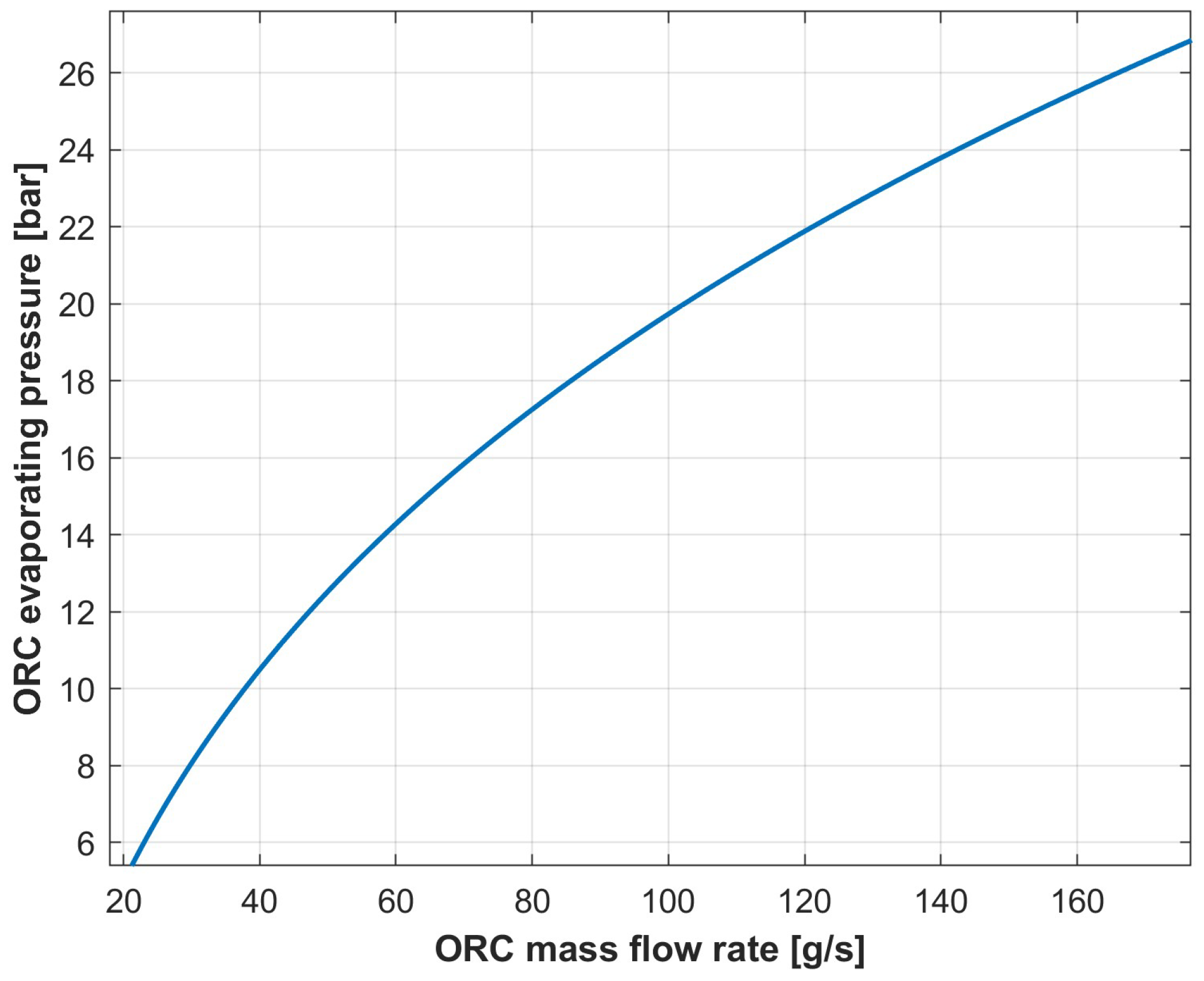

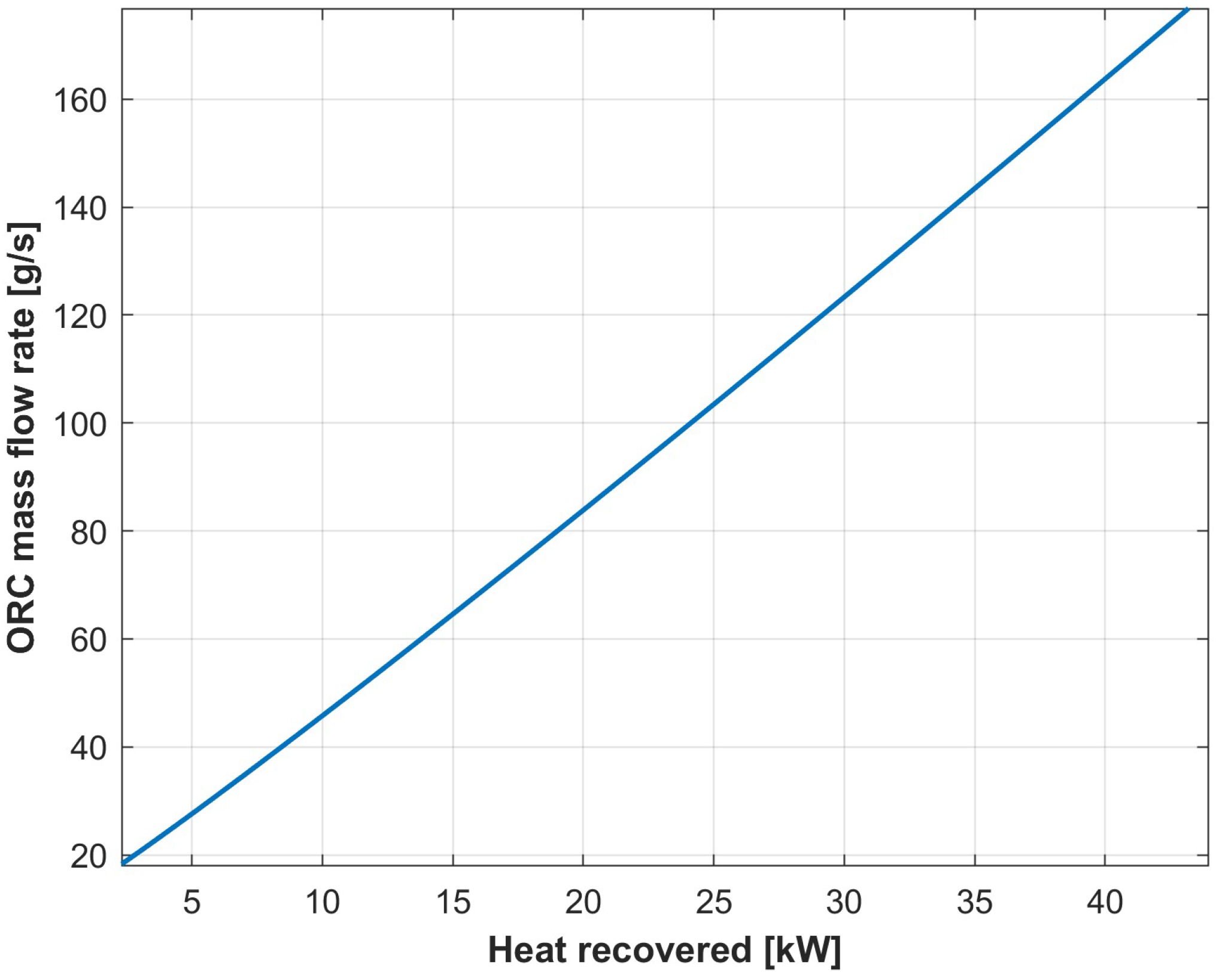

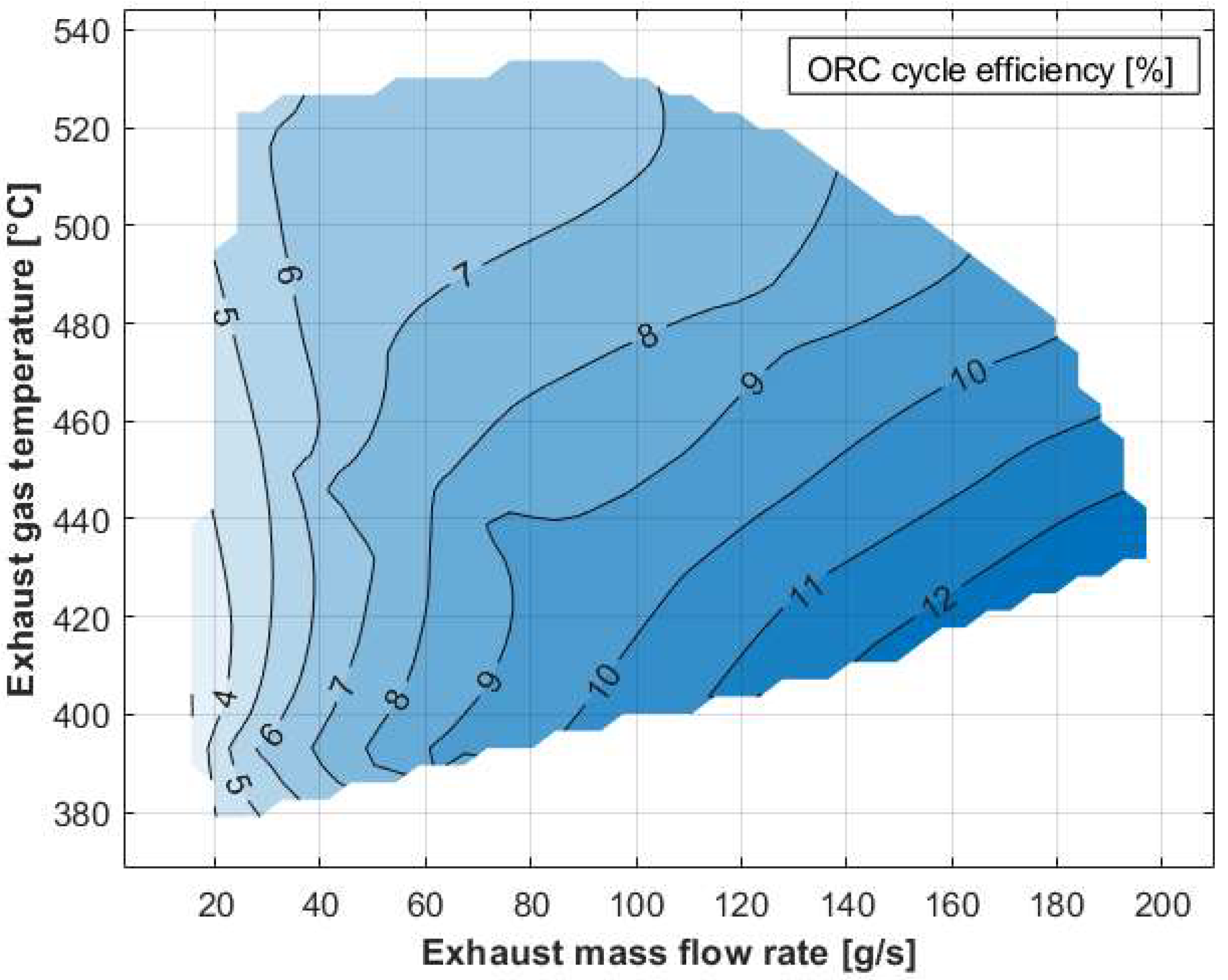

2.2. Indirect Heat Recovery Section

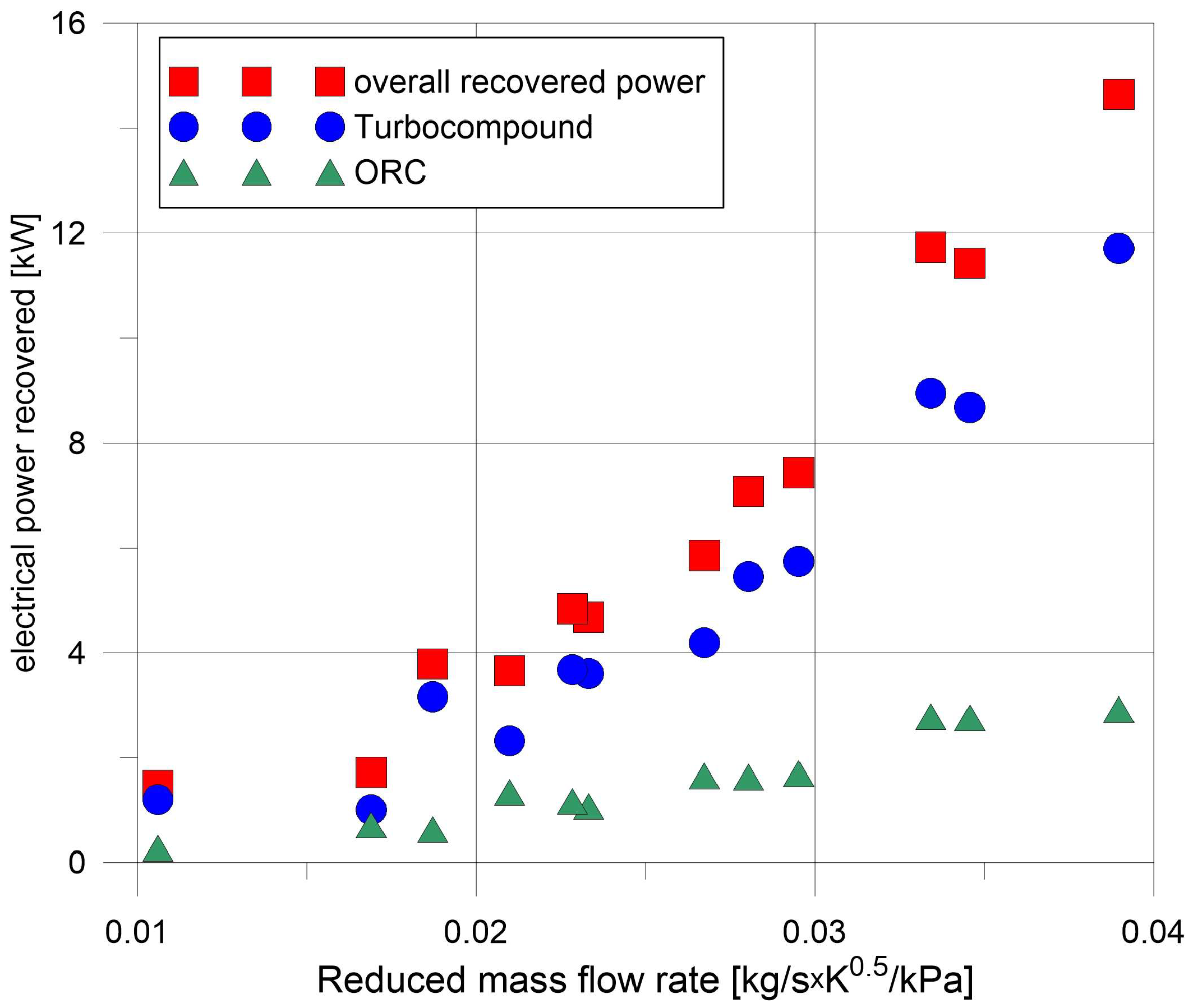

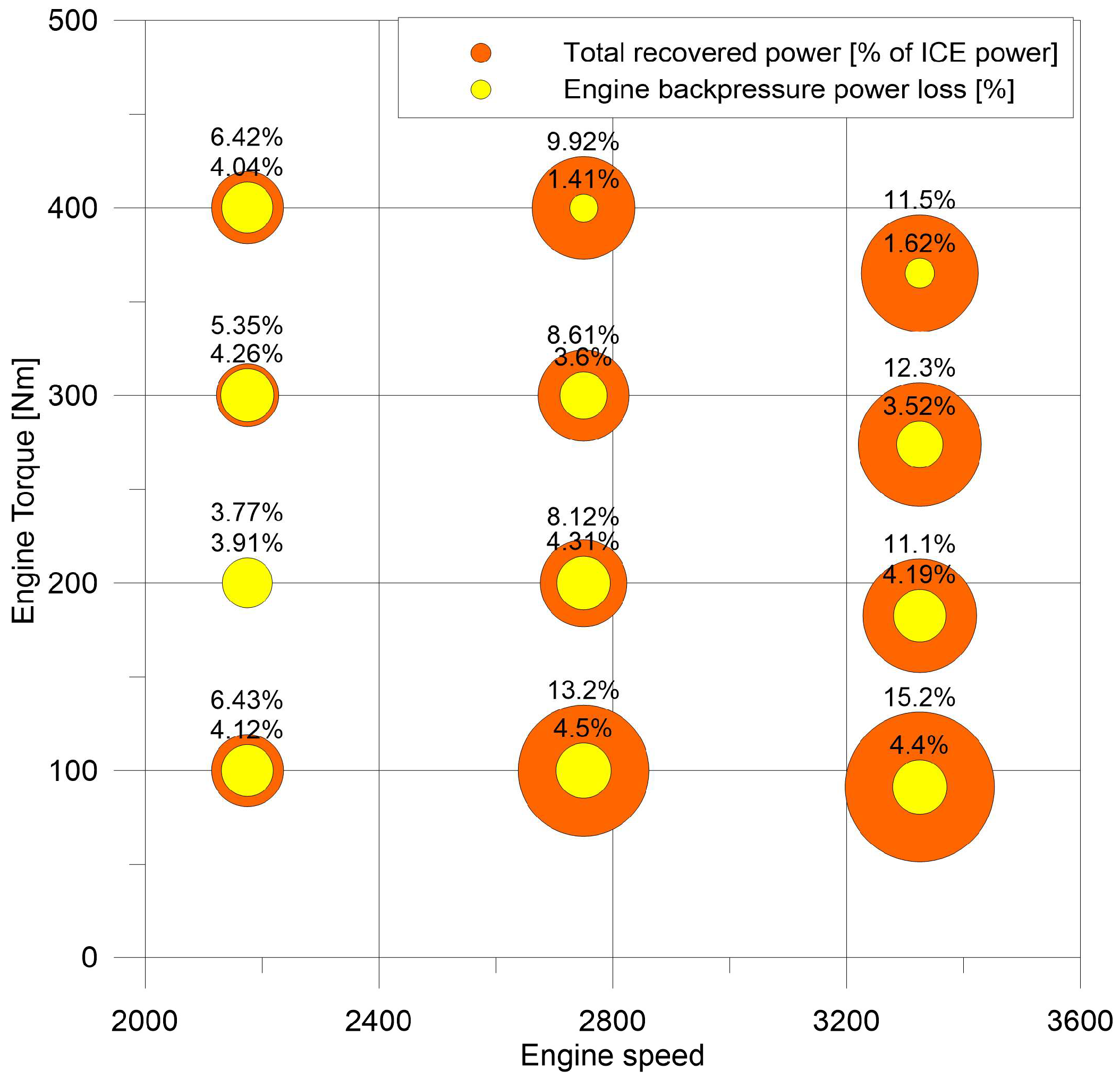

3. Results

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Acronyms | |

| DHR | Direct heat recovery |

| HDV | Heavy-duty vehicle |

| HRVG | Heat recovery vapor generator |

| IBC | Inverted Brayton cycle |

| ICE | Internal combustion engine |

| IHR | Indirect heat recovery |

| ORC | Organic Rankine cycle |

| SFC | Specific fuel consumption |

| Taux | Auxiliary turbine |

| TC | Turbocompound |

| WHR | Waste heat recovery |

| Symbols | |

| P | Power |

| cp | Specific heat at constant pressure |

| h | Enthalpy |

| m | Mass flow rate |

| p | Pressure |

| Qrec | Recovered thermal power |

| T | Temperature |

| β | Pressure ratio |

| η | Efficiency |

| Subscripts | |

| ad | Adiabatic |

| el | Electric |

| exh | Exhaust |

| exp | Expander |

| u | Useful |

| wf | Organic working fluid |

References

- Crippa, M.; Guizzardi, D.; Pagani, F.; Banja, M.; Muntean, M.; Schaaf, E.; Monforti-Ferrario, F.; Becker, W.E.; Quadrelli, R.; Risquez Martin, A.; et al. GHG Emissions of All World Countries; Publications Office of the European Union: Luxembourg, 2024. [Google Scholar] [CrossRef]

- U.S. Energy Information Administration. International Energy Outlook 2023. Available online: https://www.eia.gov/outlooks/ieo/ (accessed on 28 November 2024).

- IEA. Road Transport; IEA: Paris, France, 2023; Available online: https://www.iea.org/reports/road-transport (accessed on 15 December 2024).

- Dornoff, J. CO2 Emission Standards for New Passenger Cars and Vans in the European Union; International Council on Clean Transportation: Washington, DC, USA, 2023; Available online: https://theicct.org/publication/eu-co2-standards-cars-vans-may23/ (accessed on 30 November 2024).

- ACEA. Fact Sheet: CO2 Standards for Heavy-Duty Vehicles. February 2023. Available online: https://www.acea.auto/fact/fact-sheet-co2-standards-for-heavy-duty-vehicles/ (accessed on 30 November 2024).

- Mulholland, E.; Rodriguez, F. The Revised CO2 Standards for Heavy-Duty Vehicles in the European Union; International Council on Clean Transportation: Washington, DC, USA, 2024; Available online: https://theicct.org/publication/revised-co2-standards-hdvs-eu-may24/ (accessed on 30 November 2024).

- Berube, M. Director, Vehicle Technologies Office. Vehicle Technologies Office Overview. In Proceedings of the 2017 Annual Merit Review and Peer Evaluation Meeting, Washington, DC, USA, 5–9 June 2017. [Google Scholar]

- Winkelmann, J.; Spinler, S.; Neukirchen, T. Green transport fleet renewal using approximate dynamic programming: A case study in German heavy-duty road transportation. Transp. Res. Part E Logist. Transp. Rev. 2024, 186, 103547. [Google Scholar] [CrossRef]

- Geng, P.; Cao, E.; Tan, Q.; Wei, L. Effects of alternative fuels on the combustion characteristics and emission products from diesel engines: A review. Renew. Sustain. Energy Rev. 2017, 71, 523–534. [Google Scholar] [CrossRef]

- Guido, C.; Beatrice, C.; Di Iorio, S.; Fraioli, V.; Di Blasio, G.; Vassallo, A.; Ciaravino, C. Alternative Diesel Fuels Effects on Combustion and Emissions of an Euro5 Automotive Diesel Engine. SAE Int. J. Fuels Lubr. 2010, 3, 107–132. [Google Scholar] [CrossRef]

- Di Blasio, G.; Ianniello, R.; Beatrice, C. Hydrotreated vegetable oil as enabler for high-efficient and ultra-low emission vehicles in the view of 2030 targets. Fuel 2022, 310, 122206. [Google Scholar] [CrossRef]

- Wouters, C.; Burkardt, P.; Steeger, F.; Fleischmann, M.; Pischinger, S. Comprehensive assessment of methanol as an alternative fuel for spark-ignition engines. Fuel 2023, 340, 127627. [Google Scholar] [CrossRef]

- Villforth, J.; Casal, K.A.; Rossi, E.; Vacca, A.; Cupo, F.; Chiodi, M.; Bargende, M. Experimental and Numerical Identification and Optimization of eFuel Potentials on Combustion Behavior and Engine Efficiency. Tongji Daxue Xuebao/J. Tongji Univ. 2021, 49, 83–95. [Google Scholar] [CrossRef]

- Bicer, Y.; Dincer, I. Life cycle environmental impact assessments and comparisons of alternative fuels for clean vehicles. Resour. Conserv. Recycl. 2018, 132, 141–157. [Google Scholar] [CrossRef]

- Oktar, H.E.; Tonyali, I.H.; Apaydin, A.H. A cost-effective and sustainable path to a green future: Retrofitting internal combustion engines for hydrogen fuel utilization. Int. J. Hydrogen Energy, 2024; in press. [Google Scholar] [CrossRef]

- Pramuanjaroenkij, A.; Kakaç, S. The fuel cell electric vehicles: The highlight review. Int. J. Hydrogen Energy 2023, 48, 9401–9425. [Google Scholar] [CrossRef]

- Razali, H.; Sopian, K.; Mat, A.S. Hydrogen as an alternative: Life cycle cost analysis between hydrogen internal combustion engine (Al+Hci) and gasoline engine based on brake specific fuel consumption. Appl. Mech. Mater. 2013, 315, 423–427. [Google Scholar] [CrossRef]

- Lehmann, J.; Winkenbach, M. Technology and energy choices for fleet asset decarbonization under cost uncertainty. Transp. Res. Part D Transp. Environ. 2025, 139, 104525. [Google Scholar] [CrossRef]

- .Singh, D.V.; Pedersen, E. A review of waste heat recovery technologies for maritime applications. Energy Convers. Manag. 2016, 111, 315–328. [Google Scholar] [CrossRef]

- SUPERTRUCK 2: Empowering Future Trucking; North American Council for Freight Efficiency (NACFE): Fort Wayne, IN, USA, 2024.

- Feng, D.J.; Tang, Y.; Zhu, S.; Deng, K.; Bai, S.; Li, S. Design of a combined organic Rankine cycle and turbo-compounding system recovering multigrade waste heat from a marine two-stroke engine. Energy 2024, 309, 133151. [Google Scholar] [CrossRef]

- Pasini, G.; Lutzemberger, G.; Frigo, S.; Marelli, S.; Ceraolo, M.; Gentili, R.; Capobianco, M. Evaluation of an electric turbo compound system for SI engines: A numerical approach. Appl. Energy 2016, 162, 527–540. [Google Scholar] [CrossRef]

- Fisher, R.; Ciappi, L.; Niknam, P.; Braimakis, K.; Karellas, S.; Frazzica, A.; Sciacovelli, A. Innovative waste heat valorisation technologies for zero-carbon ships—A review. Appl. Therm. Eng. 2024, 253, 123740. [Google Scholar] [CrossRef]

- Fu, J.; Liu, J.; Wang, Y.; Deng, B.; Yang, Y.; Feng, R.; Yang, J. A comparative study on various turbocharging approaches based on IC engine exhaust gas energy recovery. Appl. Energy 2014, 113, 248–257. [Google Scholar] [CrossRef]

- Jääskeläinen, H.; Majewski, W.A. Waste Heat Recovery for Heavy-Duty Diesel Engines: A Review of Mechanical Turbocompounding. In Proceedings of the ASME 2017 Internal Combustion Engine Division Fall Technical Conference, Seattle, WA, USA, 15–18 October 2017; Volume 1: Large Bore Engines, p. V001T01A012. [Google Scholar] [CrossRef]

- Teo Sheng Jye, A.; Pesiridis, A.; Rajoo, S. Effects of Mechanical Turbo Compounding on a Turbocharged Diesel Engine; SAE Technical Paper 2013-01-0103; SAE: Warrendale, PA, USA, 2013. [Google Scholar] [CrossRef]

- Katsanos, C.O.; Hountalas, D.T.; Zannis, T.C. Simulation of a heavy-duty diesel engine with electrical turbocompounding system using operating charts for turbocharger components and power turbine. Energy Convers. Manag. 2013, 76, 712–724. [Google Scholar] [CrossRef]

- Leng, L.; Cheng, J.; Shi, L.; Deng, K. Thermodynamic analysis on the effect of altitude on the exhaust energy recovery of electric turbocompound engines. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2024. [Google Scholar] [CrossRef]

- Di Battista, D.; Di Bartolomeo, M.; Di Prospero, F.; Di Diomede, D.; Carapellucci, R.; Cipollone, R. Turbocompound energy recovery option on a turbocharged diesel engine. J. Phys. Conf. Ser. 2023, 2648, 012078. [Google Scholar] [CrossRef]

- Aghaali, H.; Ångström, H.-E. A review of turbocompounding as a waste heat recovery system for internal combustion engines. Renew. Sustain. Energy Rev. 2015, 49, 813–824. [Google Scholar] [CrossRef]

- Hountalas, D.; Katsanos, C.; Lamaris, V. Recovering Energy from the Diesel Engine Exhaust Using Mechanical and Electrical Turbocompounding; SAE Technical Paper 2007-01-1563; SAE: Warrendale, PA, USA, 2007. [Google Scholar] [CrossRef]

- Leng, L.; Ma, Z.; Cheng, J.; Shi, L.; Deng, K. Research on exhaust energy distribution regulation for fuel economy improvement of turbocompound diesel engine. Appl. Therm. Eng. 2023, 220, 119708. [Google Scholar] [CrossRef]

- Brancaleoni, P.P.; Corti, E.; Ravaglioli, V.; Moro, D.; Silvagni, G. Innovative torque-based control strategy for hydrogen internal combustion engine. Int. J. Hydrogen Energy 2024, 73, 203–220. [Google Scholar] [CrossRef]

- Di Battista, D.; Carapellucci, R.; Cipollone, R. Integrated evaluation of Inverted Brayton cycle recovery unit bottomed to a turbocharged diesel engine. Appl. Therm. Eng. 2020, 175, 115353. [Google Scholar] [CrossRef]

- Chagnon-Lessard, N.; Copeland, C.; Mathieu-Potvin, F.; Gosselin, L. Maximizing specific work output extracted from engine exhaust with novel inverted Brayton cycles over a large range of operating conditions. Energy 2020, 191, 116350. [Google Scholar] [CrossRef]

- Karabacak, M.; Turan, O. Off-design analysis of the inverted Brayton cycle engine. Aircr. Eng. Aerosp. Technol. 2024, 96, 954–963. [Google Scholar] [CrossRef]

- Butrymowicz, D.; Gagan, J.; Łukaszuk, M.; Śmierciew, K.; Pawluczuk, A.; Zieliński, T.; Kędzierski, M. Experimental validation of new approach for waste heat recovery from combustion engine for cooling and heating demands from combustion engine for maritime applications. J. Clean. Prod. 2021, 290, 125206. [Google Scholar] [CrossRef]

- de Araújo, L.R.; Morawski, A.P.; Barone, M.A.; Rocha, H.R.O.; Donatelli, J.L.M.; Santos, J.J.C.S. Response surface methods based in artificial intelligence for superstructure thermoeconomic optimization of waste heat recovery systems in a large internal combustion engine. Energy Convers. Manag. 2022, 271, 116275. [Google Scholar] [CrossRef]

- Novotny, V.; Spale, J.; Szucs, D.J.; Tsai, H.-Y.; Kolovratnik, M. Direct integration of an organic Rankine cycle into an internal combustion engine cooling system for comprehensive and simplified waste heat recovery. Energy Rep. 2022, 254, 124268. [Google Scholar] [CrossRef]

- Ping, X.; Yang, F.; Zhang, H.; Xing, C.; Yao, B.; Wang, Y. An outlier removal and feature dimensionality reduction framework with unsupervised learning and information theory intervention for organic Rankine cycle (ORC). Energy 2022, 254, 124268. [Google Scholar] [CrossRef]

- Pili, R.; Wieland, C.; Spliethoff, H.; Haglind, F. Numerical analysis of feedforward concepts for advanced control of organic Rankine cycle systems on heavy-duty vehicles. J. Clean. Prod. 2022, 351, 131470. [Google Scholar] [CrossRef]

- Sprouse, C.E., III. Review of Organic Rankine Cycles for Internal Combustion Engine Waste Heat Recovery: Latest Decade in Review. Sustainability 2024, 16, 1924. [Google Scholar] [CrossRef]

- Carapellucci, R.; Di Battista, D. Combined Supercritical CO2 Brayton Cycle and Organic Rankine Cycle for Exhaust Heat Recovery. ASME J. Energy Resour. Technol. 2024, 146, 062101. [Google Scholar] [CrossRef]

- Pan, M.; Zhu, Y.; Bian, X.; Liang, Y.; Lu, F.; Ban, Z. Theoretical analysis and comparison on supercritical CO2 based combined cycles for waste heat recovery of engine. Energy Convers. Manag. 2020, 219, 113049. [Google Scholar] [CrossRef]

- Fatigati, F.; Di Bartolomeo, M.; Di Battista, D.; Cipollone, R. A dual-intake-port technology as a design option for a Sliding Vane Rotary Expander of small-scale ORC-based power units. Energy Convers. Manag. 2020, 209, 112646. [Google Scholar] [CrossRef]

- Galindo, J.; Ruiz, S.; Dolz, V.; Royo-Pascual, L.; Haller, R.; Nicolas, B.; Glavatskaya, Y. Experimental and thermodynamic analysis of a bottoming Organic Rankine Cycle (ORC) of gasoline engine using swash-plate expander. Energy Convers. Manag. 2015, 103, 519–532. [Google Scholar] [CrossRef]

- Alshammari, F.; Karvountzis-Kontakiotis, A.; Pesyridis, A.; Usman, M. Expander Technologies for Automotive Engine Organic Rankine Cycle Applications. Energies 2018, 11, 1905. [Google Scholar] [CrossRef]

- Di Battista, D.; Cipollone, R. Experimental Analysis of an Organic Rankine Cycle Plant Bottoming a Heavy-Duty Engine Using Axial Turbine as Prime Mover. SAE Int. J. Engines 2017, 10, 1385–1397. [Google Scholar] [CrossRef]

- Di Battista, D.; Di Bartolomeo, M.; Villante, C.; Cipollone, R. A Model Approach to the Sizing of an ORC Unit for WHR in Transportation Sector. Commer. Veh. 2017, 10, 608–617. [Google Scholar] [CrossRef]

- Fatigati, F.; Di Battista, D.; Carapellucci, R. Model-based assessment of a feedforward-feedback control strategy for ORC-based unit in waste heat recovery application. Appl. Therm. Eng. 2025, 258, 124774. [Google Scholar] [CrossRef]

- Rosset, K.; Pajot, O.; Schiffmann, J. Experimental Investigation of a Small-Scale Organic Rankine cycle Turbo-Generator Supported on Gas-Lubricated Bearings. J. Eng. Gas Turbines Power 2021, 143, 051015. [Google Scholar] [CrossRef]

- T Gamma—Gamma Technologies Inc. GT-SUITE-Flow Theory Manual; Gamma Technologies: Westmont, IL, USA, 2020. [Google Scholar]

- Fatigati, F.; Coletta, A.; Di Bartolomeo, M.; Cipollone, R. The dynamic behaviour of ORC-based power units fed by exhaust gases of internal combustion engines in mobile applications. Appl. Therm. Eng. 2024, 240, 122215. [Google Scholar] [CrossRef]

- Lemmon, E.W.; Huber, M.L.; McLinden, M.O. REFPROP, NIST Standard Reference Database 23, version 8.0. Natl Std. Ref. Data Series (NIST NSRDS). National Institute of Standards and Technology: Gaithersburg, MD, USA, 2007.

- Fatigati, F.; Di Bartolomeo, M.; Di Battista, D.; Cipollone, R. Model based control of the inlet pressure of a sliding vane rotary expander operating in an ORC-based power unit. Appl. Therm. Eng. 2021, 193, 117032. [Google Scholar] [CrossRef]

- Fatigati, F.; Di Bartolomeo, M.; Di Battista, D.; Cipollone, R. Experimental characterization of a hermetic scroll expander operating in an ORC-based power unit bottoming an internal combustion engine. AIP Conf. Proc. 2019, 2191, 020069. [Google Scholar] [CrossRef]

- Fatigati, F.; Di Battista, D.; Cipollone, R. Permeability effects assessment on recovery performances of small-scale ORC plant. Appl. Therm. Eng. 2021, 196, 117331. [Google Scholar] [CrossRef]

| Engine Speed | Engine Torque | Engine Power | mexh | Texh | pexh |

|---|---|---|---|---|---|

| RPM | Nm | kW | g/s | °C | bar |

| 2175 | 400.2 | 91.2 | 122.9 | 501.9 | 1.279 |

| 2175 | 200.1 | 45.6 | 69.8 | 480.0 | 1.134 |

| 2175 | 300.15 | 68.4 | 92.1 | 519.7 | 1.235 |

| 2175 | 100.05 | 22.8 | 49.3 | 350.8 | 1.161 |

| 2750 | 200 | 57.6 | 114.0 | 432.6 | 1.299 |

| 2750 | 300 | 86.4 | 138.1 | 493.3 | 1.295 |

| 2750 | 400 | 115.2 | 157.5 | 553.2 | 1.310 |

| 2750 | 100 | 28.8 | 93.9 | 380.3 | 1.281 |

| 3325 | 365.2 | 127.2 | 181.8 | 619.7 | 1.394 |

| 3325 | 91.3 | 31.8 | 116.9 | 442.1 | 1.369 |

| 3325 | 273.9 | 95.4 | 159.9 | 548.8 | 1.372 |

| 3325 | 182.6 | 63.6 | 136.0 | 485.8 | 1.336 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Di Battista, D.; Di Prospero, F.; Di Giovine, G.; Fatigati, F.; Cipollone, R. Dual-Stage Energy Recovery from Internal Combustion Engines. Energies 2025, 18, 623. https://doi.org/10.3390/en18030623

Di Battista D, Di Prospero F, Di Giovine G, Fatigati F, Cipollone R. Dual-Stage Energy Recovery from Internal Combustion Engines. Energies. 2025; 18(3):623. https://doi.org/10.3390/en18030623

Chicago/Turabian StyleDi Battista, Davide, Federico Di Prospero, Giammarco Di Giovine, Fabio Fatigati, and Roberto Cipollone. 2025. "Dual-Stage Energy Recovery from Internal Combustion Engines" Energies 18, no. 3: 623. https://doi.org/10.3390/en18030623

APA StyleDi Battista, D., Di Prospero, F., Di Giovine, G., Fatigati, F., & Cipollone, R. (2025). Dual-Stage Energy Recovery from Internal Combustion Engines. Energies, 18(3), 623. https://doi.org/10.3390/en18030623