Analysis of Rail Pressure Stability in an Electronically Controlled High-Pressure Common Rail Fuel Injection System via GT-Suite Simulation

Abstract

1. Introduction

2. Bosch HPCR Fuel Injection System Control Model and Boundary Condition

2.1. Fluid Control Model

2.2. Boundary Model of the Three Major Components of the HPCR Fuel Injection System

2.2.1. Fuel Pump Mathematical Model

- (1)

- The Continuity Equation of the Plunger Chamber

- (2)

- The motion equation of the outlet valve

- (3)

- The continuity equation of the outlet valve chamber

2.2.2. Common Rail Mathematical Model

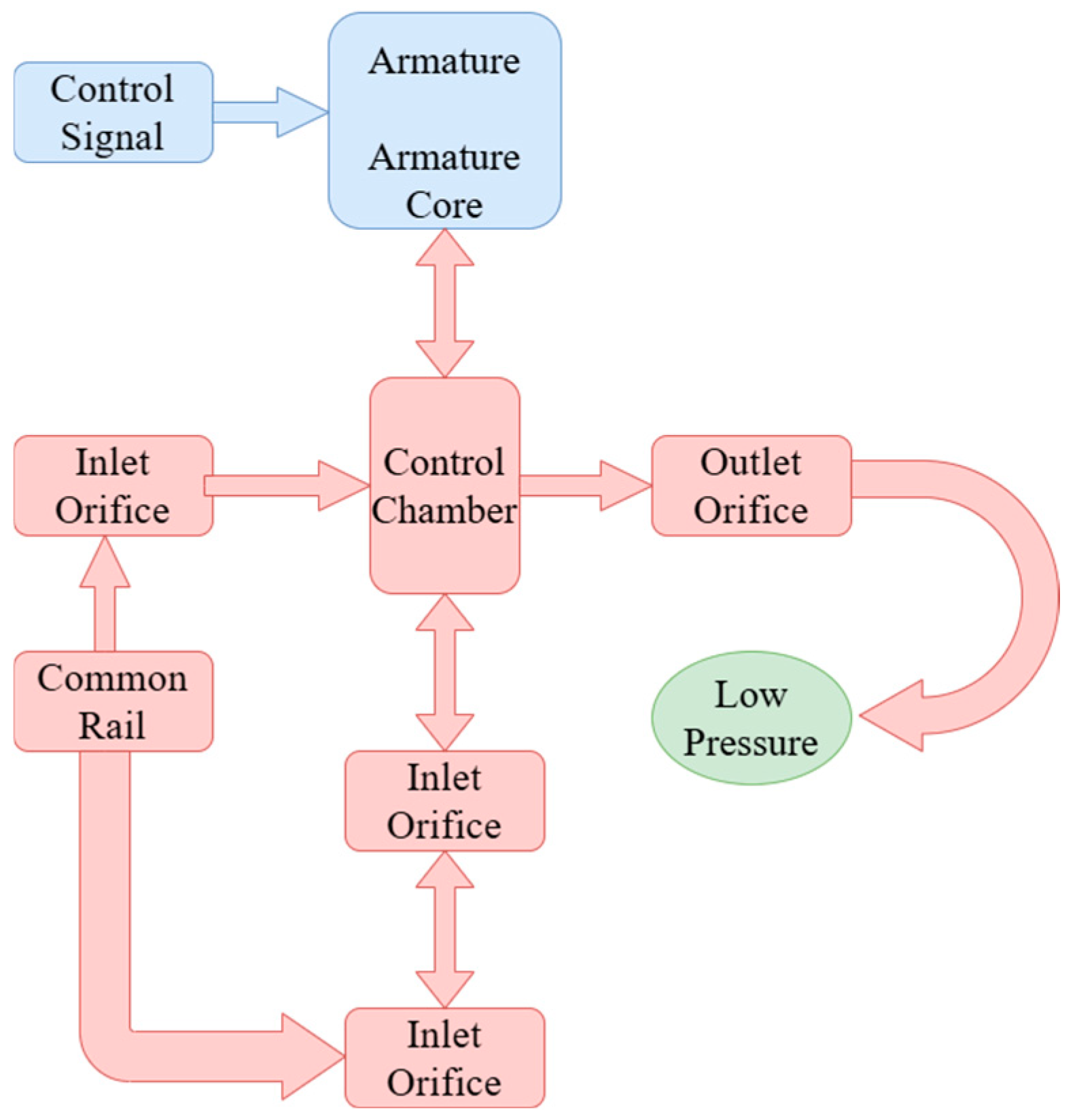

2.2.3. Fuel Injector Mathematical Model

- (1)

- Continuity Equation for the Fuel Injector Control Chamber

- (2)

- The Continuity Equation of the Injector’s Oil Chamber

- (3)

- Continuity Equation of the Pressure Chamber

- (4)

- The Needle Valve Motion Equation

- (5)

- Fuel Flow Process in Injector Nozzle

2.3. Calculation of Parameters in Simulation Models

Calculation of Fuel Property Parameters

- (1)

- Calculation of Fuel Sound Velocity

- (2)

- Calculation of Fuel Density

- (3)

- Calculation of Fuel Bulk Modulus

- (4)

- Calculation of Fuel Kinematic Viscosity

- (5)

- Calculation of Fuel Flow Resistance

2.4. Solution Steps and Convergence Criteria

3. Establishment and Validation of Diesel Engine Simulation Models for Electronically Controlled HPCR Systems

3.1. Establishment of High-Pressure Pump Model

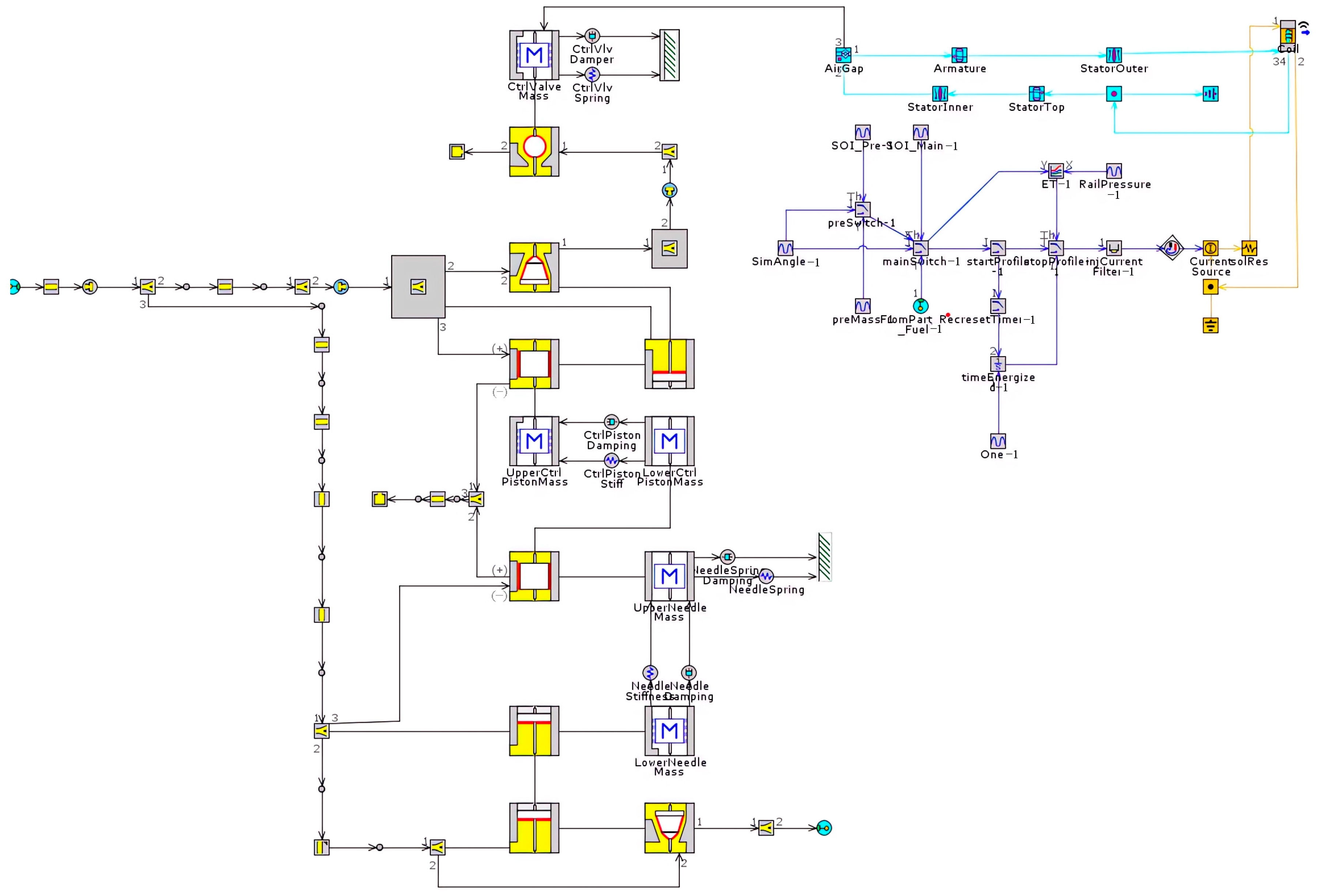

3.2. Establishment of Fuel Injector Model

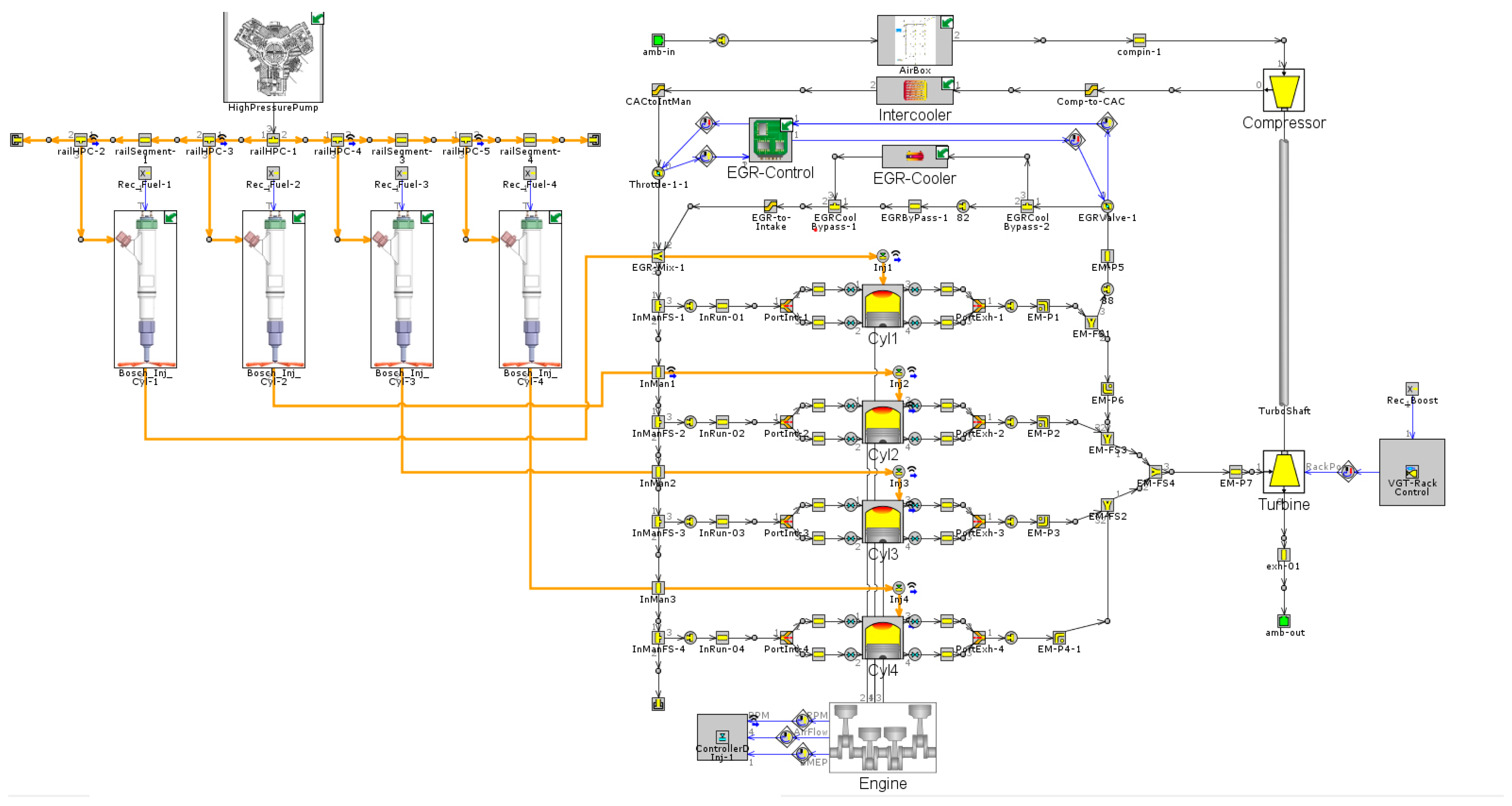

3.3. Overall Simulation Model of Electronically Controlled HPCR Fuel Injection System

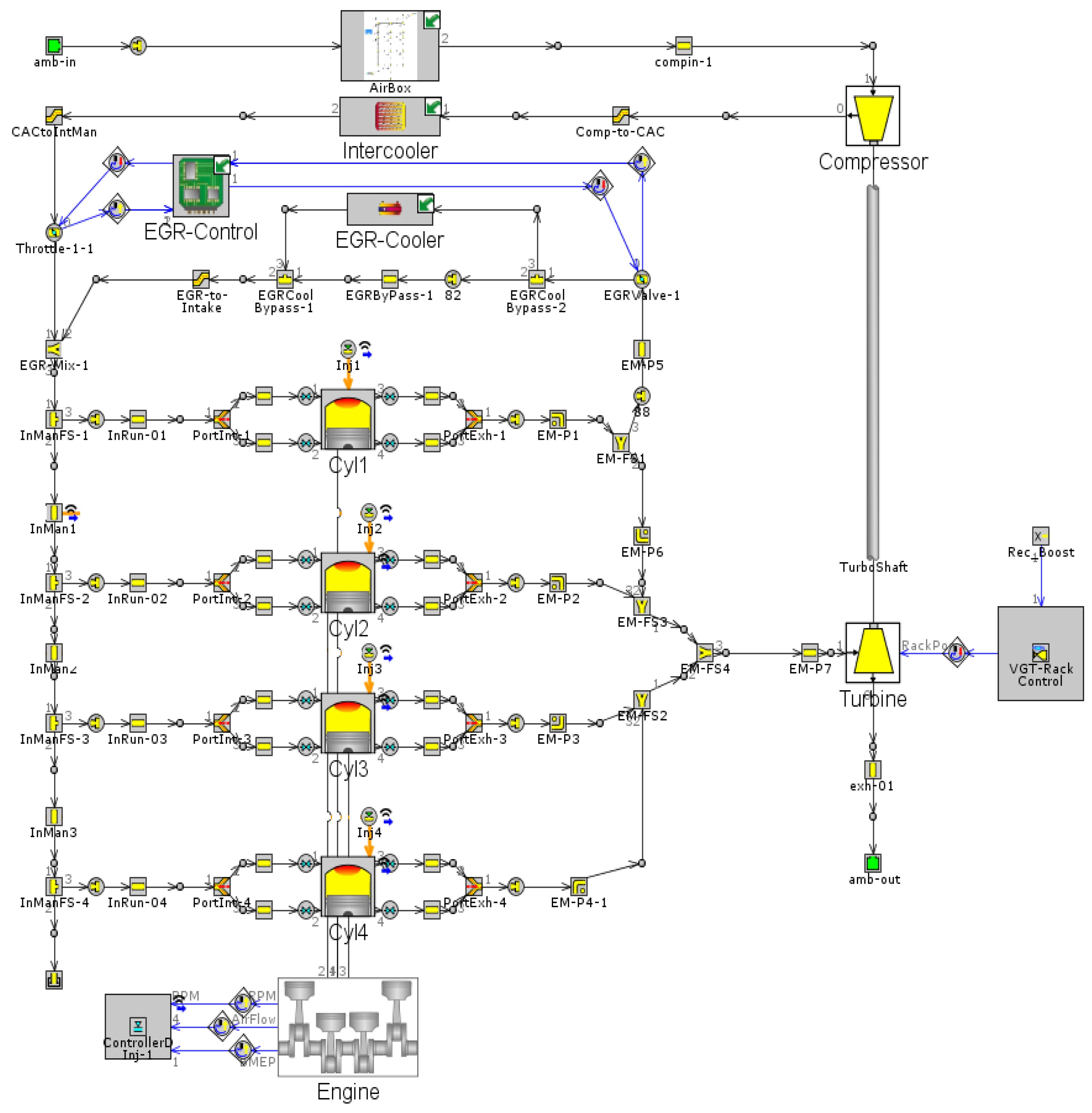

3.4. Establishment of Diesel Engine Simulation Model

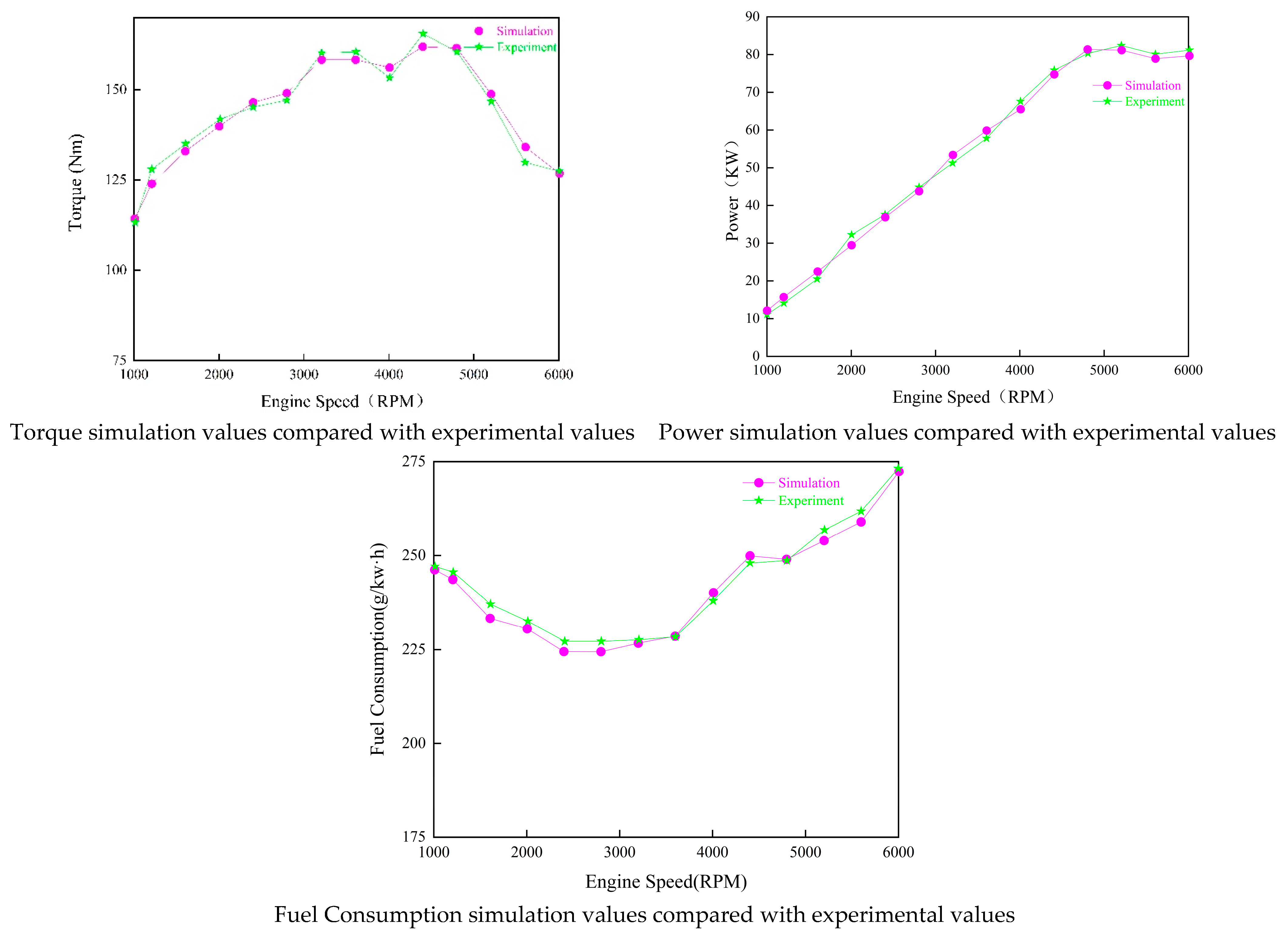

3.5. Coupled Simulation Model and Validation of Electronically Controlled HPCR Fuel Injection System and Diesel Engine System

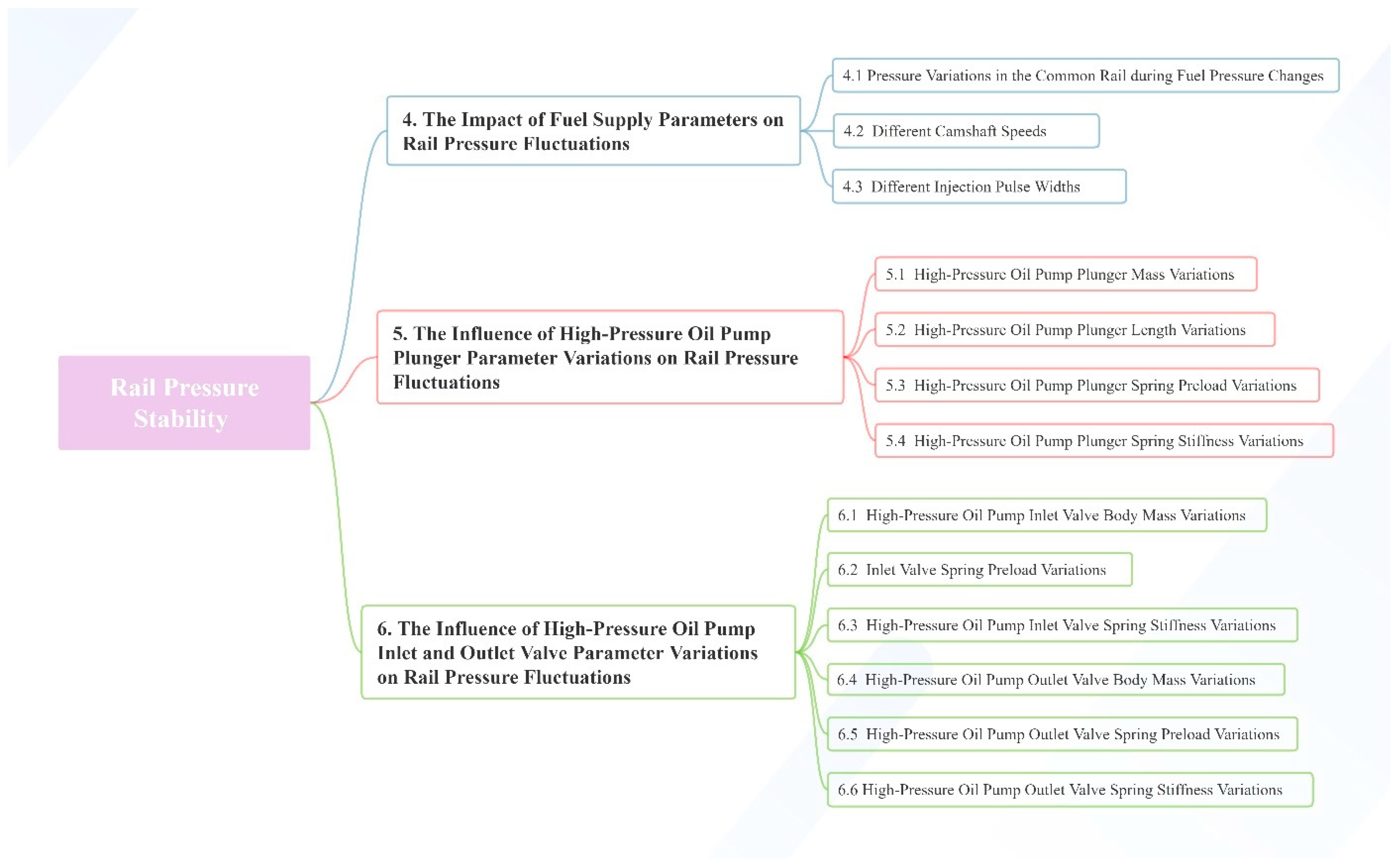

4. The Impact of Fuel Supply Parameters in Electronically Controlled HPCR Injection Systems on Rail Pressure Fluctuations

4.1. Pressure Fluctuations Within the Common Rail During Variations in Fuel Supply Pressure

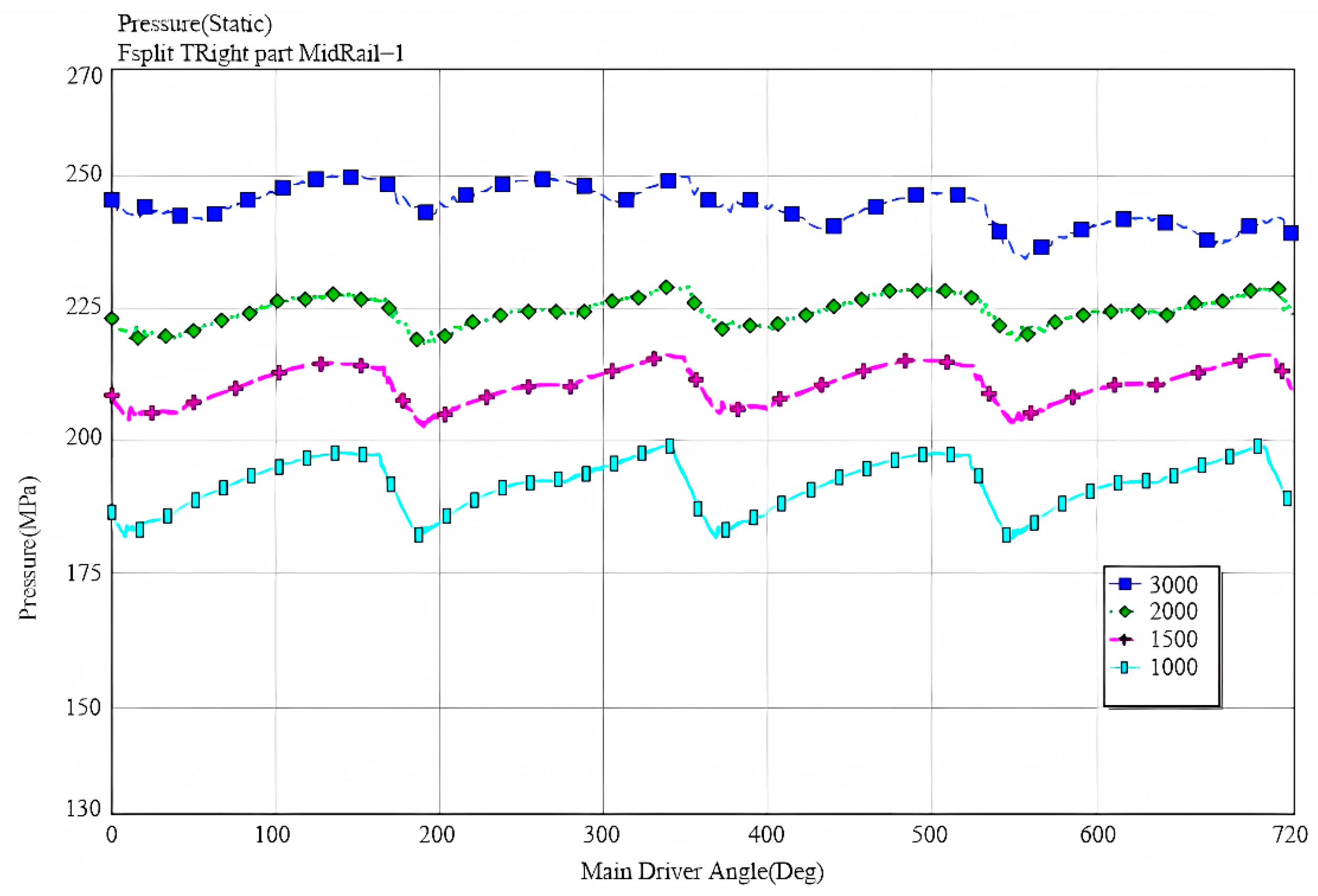

4.2. The Influence of Camshaft Speed on Common Rail Pressure

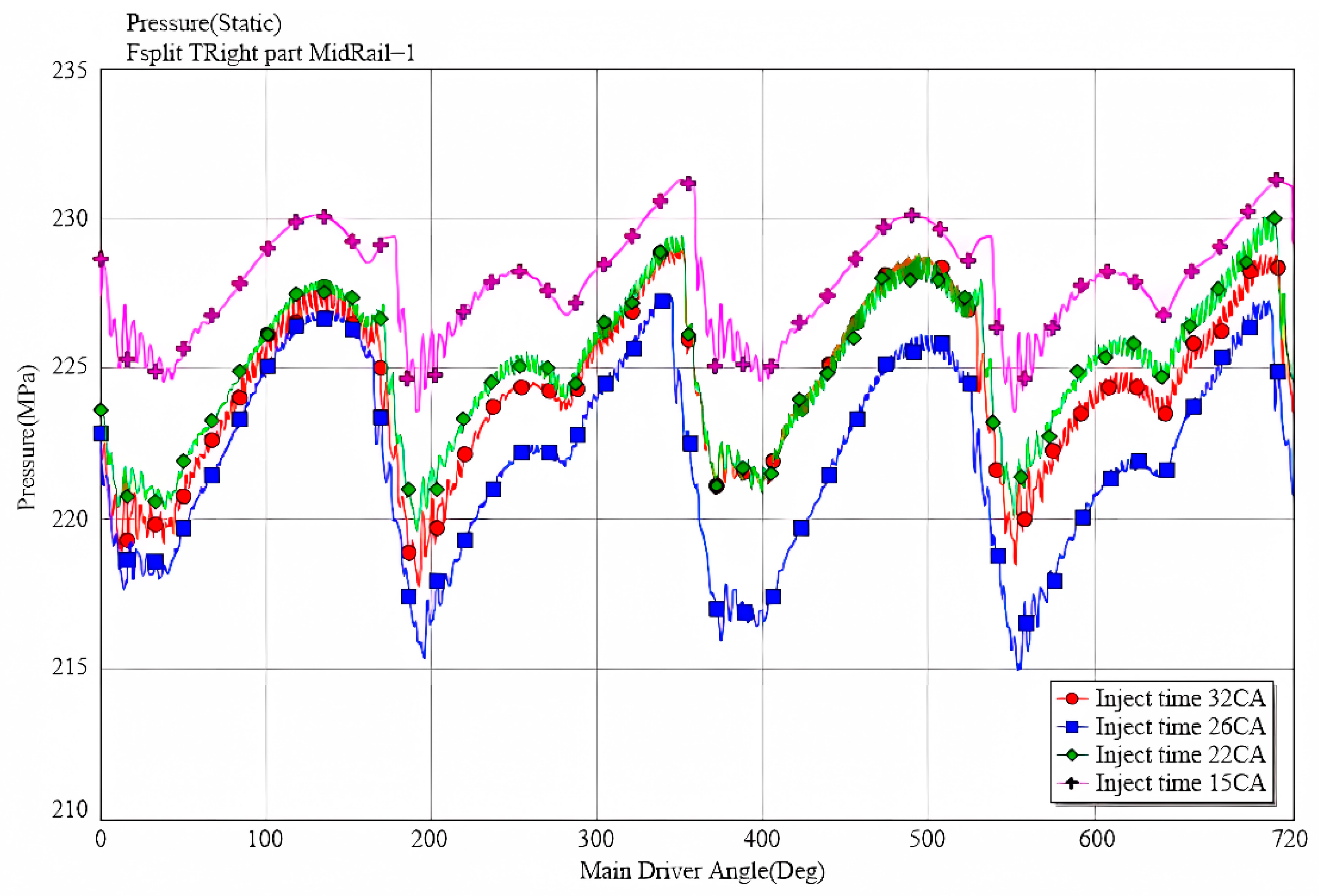

4.3. The Influence of Fuel Injection Pulse Width on Common Rail Pressure

5. The Impact of High-Pressure Oil Pump Plunger Parameter Variations on Rail Pressure Fluctuations

5.1. The Impact of High-Pressure Oil Pump Plunger Mass Variations on Rail Pressure Fluctuations

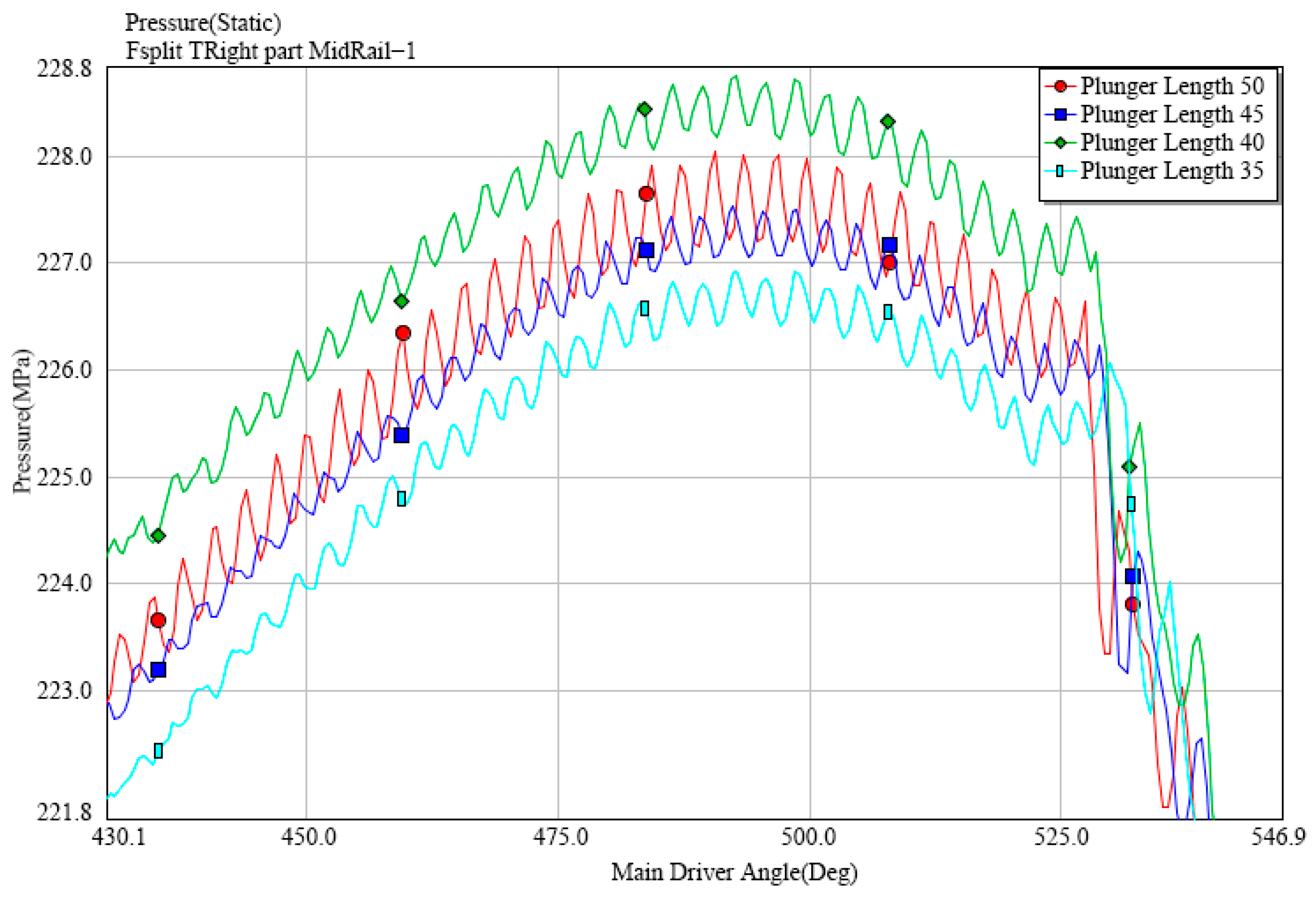

5.2. The Influence of Plunger Length Variations on Rail Pressure Fluctuations

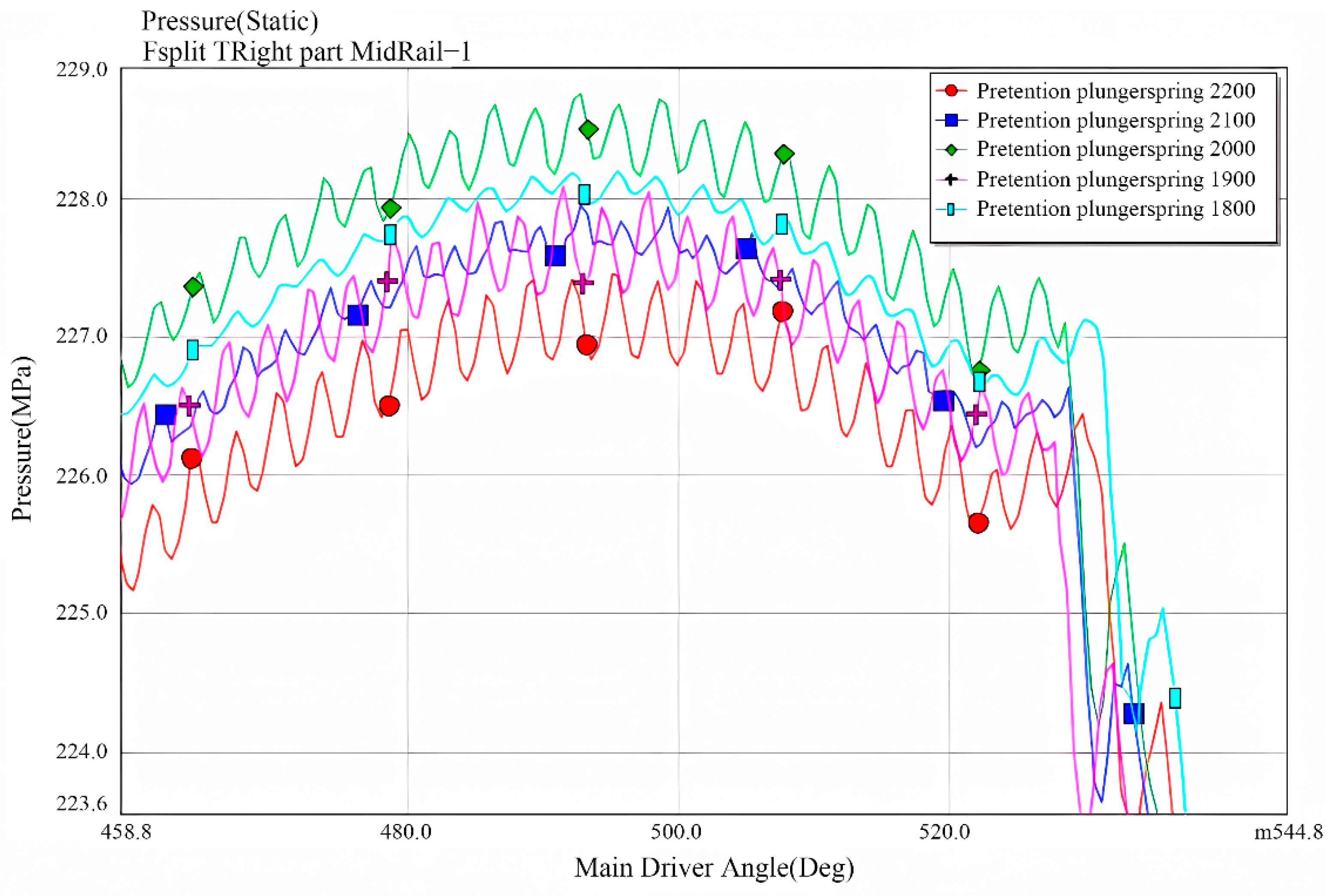

5.3. The Influence of Plunger Spring Preload on Rail Pressure Fluctuations

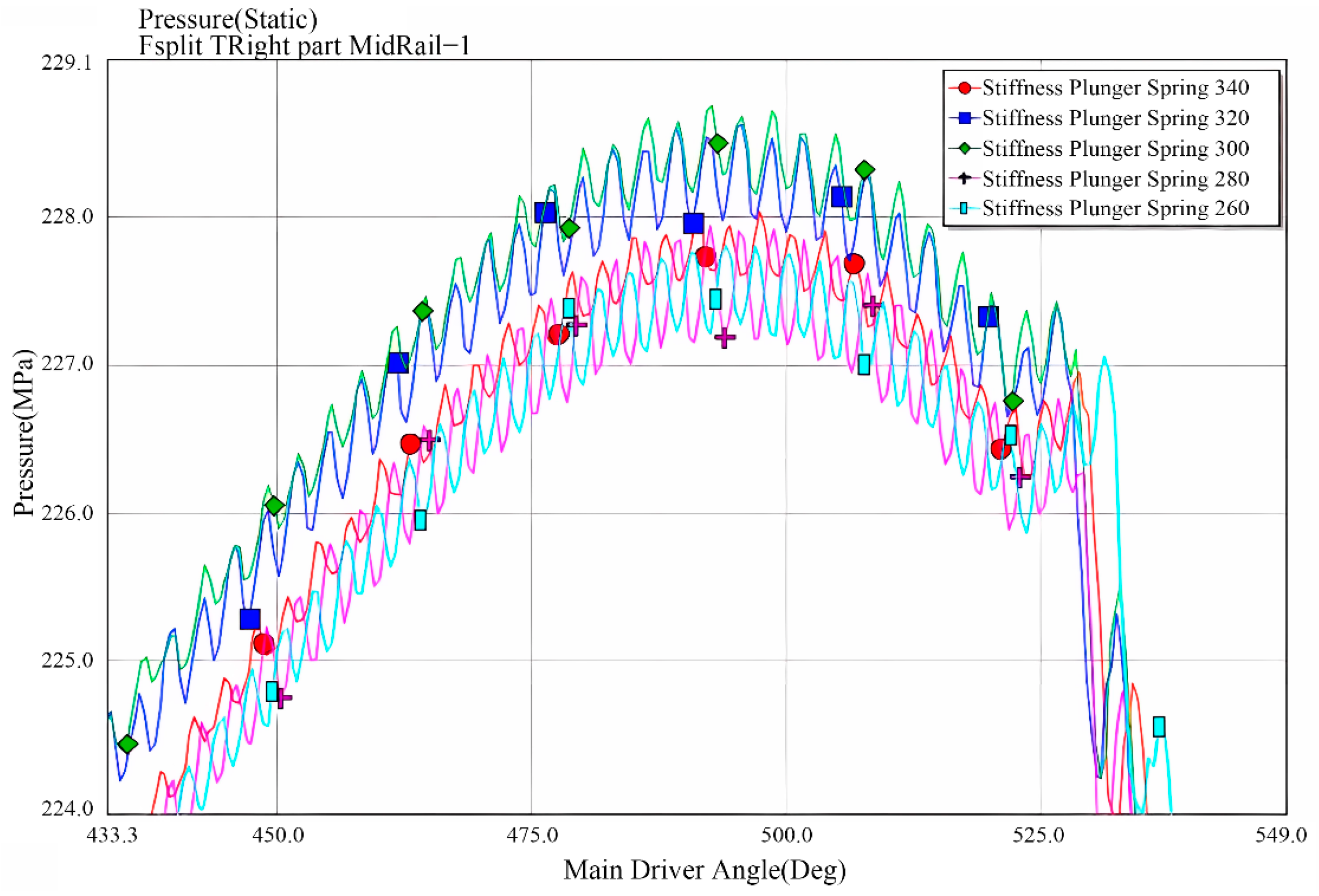

5.4. The Impact of Plunger Spring Stiffness Variation on Rail Pressure Fluctuations

6. The Impact of Inlet and Outlet Valve Parameters on Pressure Fluctuations Within the HPCR System

6.1. Influence of Mass Variation of the Inlet Valve of High-Pressure Fuel Pump on Common Rail Pressure Fluctuation

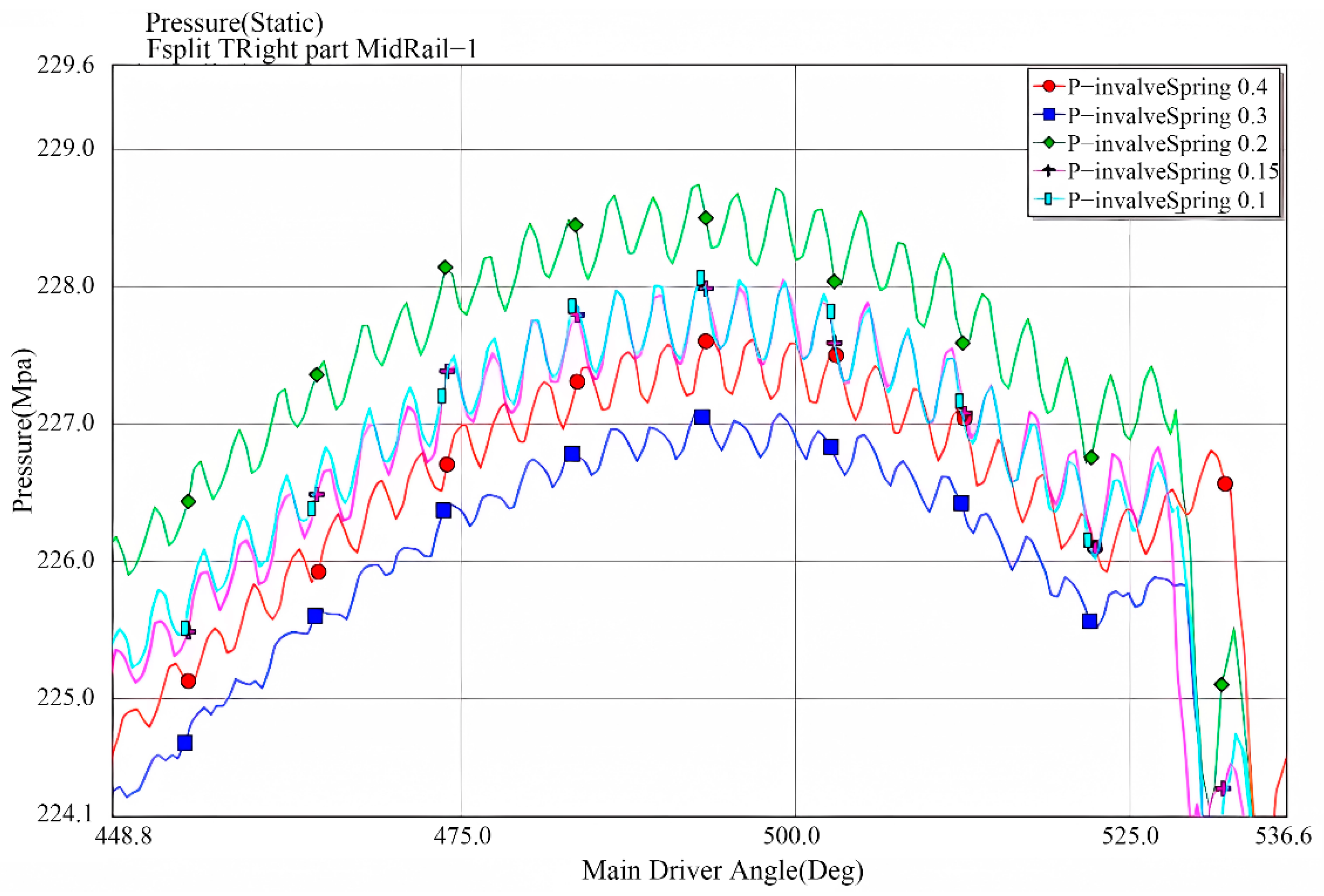

6.2. The Impact of Inlet Valve Spring Preload Variations on Rail Pressure Fluctuations

6.3. The Influence of Inlet Valve Spring Stiffness Variations on Rail Pressure Fluctuations

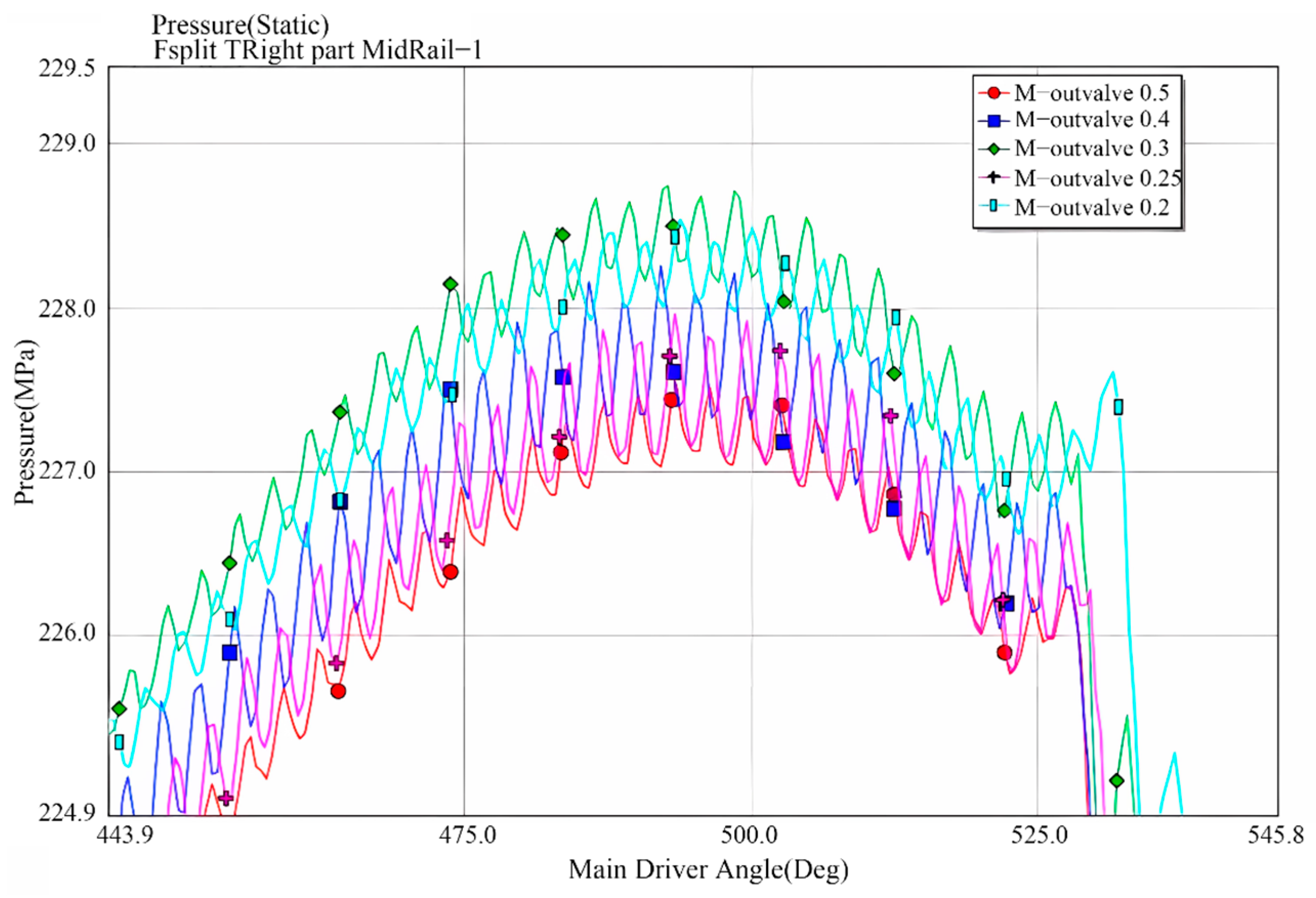

6.4. The Impact of Outlet Valve Body Mass Variations on Rail Pressure Fluctuations in High-Pressure Oil Pumps

6.5. The Impact of Outlet Valve Spring Pre-Tightening Force Variations on Rail Pressure Fluctuations in High-Pressure Oil Pumps

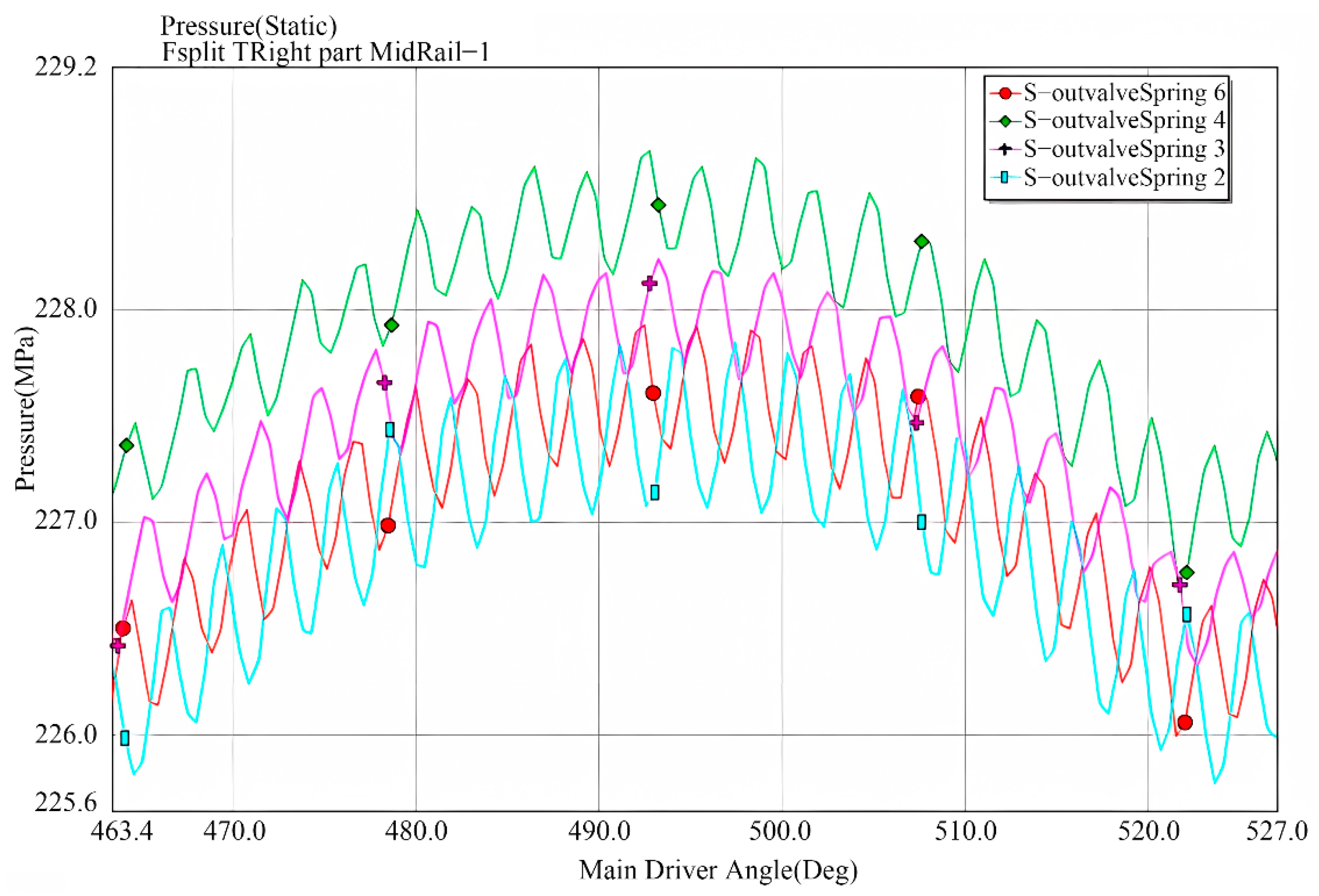

6.6. The Impact of Outlet Valve Spring Stiffness Variations on Rail Pressure Fluctuations

7. Gray Relation Analysis (GRA)

- (1)

- Determine the Analysis Sequence

- (2)

- Data Preprocessing of Variables

- (3)

- Calculating the Correlation Coefficients between Subsequence Indicators and the Reference Sequence

- (4)

- Calculation of Gray Relational Degree

8. Conclusions

- (1)

- Through the analysis of the impact of fuel supply parameters in the high-pressure common rail fuel injection system on the rail pressure fluctuation, it was found that the fuel supply pressure, camshaft speed, and injection pulse width all have significant effects on rail pressure fluctuations. At different fuel supply pressures, the pressure fluctuation frequency during the fuel supply phase is higher than that during the injection phase. As the camshaft speed increases, the common rail pressure increases proportionally, with the fluctuation frequency rising and the amplitude decreasing. Specifically, the ratio of the common rail pressure at a camshaft speed of 3000 rpm to that at 2000 rpm is approximately 1.11. Increasing the injection pulse width results in a reduction in the pressure fluctuation amplitude within the common rail. When the injection pulse width is 32 CA, the amplitude of pressure fluctuation decreases by approximately 3 MPa compared to when the pulse width is 26 CA.

- (2)

- By analyzing the influence of plunger parameter variations in a high-pressure fuel pump on rail pressure fluctuations, it was found that changes in the plunger’s mass and length affect rail pressure oscillations. An increase in plunger mass results in a reduction in the rail pressure. When the plunger length increases, both the frequency and amplitude of rail pressure fluctuations rise slightly, with a maximum amplitude increase of approximately 1 MPa. Simultaneously, the increased plunger length elevates the fluctuation frequency and amplitude of rail pressure, though the amplitude increase is limited to around 0.1 MPa. Additionally, an increase in the preload of the plunger spring leads to a decreasing trend in rail pressure, with the reduction varying between 0.5 MPa and 2 MPa, while the amplitude of pressure fluctuations also decreases. Conversely, variations in the plunger spring stiffness exhibit a relatively minor effect on rail pressure fluctuations.

- (3)

- Examination of the effects of inlet and outlet valve parameter variations in the high-pressure fuel pump on rail pressure fluctuations demonstrated that the valve body mass, spring preload, and spring stiffness of the valves all influence rail pressure fluctuations. Gray correlation analysis indicated that the spring preload of the inlet valve has the highest correlation with rail pressure fluctuations (0.815), followed by the spring stiffness of the inlet valve (0.625), while the spring preload (0.551) and spring stiffness (0.527) of the outlet valve have relatively lower correlations. This suggests that optimizing the inlet valve spring preload is the most critical factor for reducing rail pressure fluctuations.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| The Cross-sectional Area | |

| The Flow Velocity | |

| The Speed of Sound | |

| The Coefficient of Viscous Resistance | |

| The Kinematic Viscosity | |

| The Flow Coefficient | |

| The Plunger Stroke | |

| The Pipeline Pressure | |

| The Plunger Pair Oil Leakage | |

| The Outlet Valve Body Mass | |

| The Outlet Valve Spring Stiffness | |

| Outlet Valve Spring Compressibility | |

| Outlet Valve Spring Pre-compressibility | |

| Outlet Valve Body Action Area | |

| Outlet Valve Exit Flow Area | |

| The Outlet Valve Orifice Diameter | |

| The Outlet Valve Body Diameter | |

| The Valve Body and Outlet Valve Orifice Contact Angle | |

| The Mass Flow Rate | |

| The Control Chamber Inlet Orifice Area | |

| The Needle Valve Upper Head Area | |

| The Needle Lift | |

| The Control Chamber Inlet Mass Flow Rate | |

| The Needle Valve Control Chamber Outflow Area | |

| The Needle Valve Control Chamber Flow Coefficient | |

| The Needle Valve Guide Contact Area | |

| The Needle Valve Head Area | |

| The Needle Valve Mass | |

| The Needle Valve Lift | |

| The Needle Valve Spring Stiffness | |

| The Needle Valve Spring Pre-compression | |

| The Needle Valve Lower Pressure-bearing Area | |

| The Needle Valve Upper Pressure-bearing Area | |

| The Needle Valve Taper Contact Area | |

| The Needle Valve Control Chamber Oil Pressure | |

| The Bulk Modulus of the Fuel. | |

| The Fuel Density | |

| The Reference Pressure | |

| The Pressure Inside the Common Rail Pipe | |

| The Friction Drag Coefficient of the Fuel | |

| The Inside Diameter of the Fuel Pipe | |

| The Time Step | |

| The Discretization Length | |

| The Default Convergence Criterion | |

| The Variable From the Previous Cycle Within the Same Control Volume |

References

- Ahire, V.; Shewale, M.; Razban, A. A review of the state-of-the-art emission control strategies in modern diesel engines. Arch. Comput. Methods Eng. 2021, 28, 4897–4915. [Google Scholar] [CrossRef]

- Hoang, A.T. Applicability of fuel injection techniques for modern diesel engines. In Proceedings of the AIP Conference Proceedings; AIP Publishing: Melville, NY, USA, 2020. [Google Scholar]

- Varshil, P.; Deshmukh, D. A comprehensive review of waste heat recovery from a diesel engine using organic rankine cycle. Energy Rep. 2021, 7, 3951–3970. [Google Scholar]

- Alwi, E.; Amin, B.; Afnison, W. Electric turbo compounding (ETC) as exhaust energy recovery system on vehicle. GEOMATE J. 2020, 19, 228–234. [Google Scholar]

- Jiang, F.; Zhou, J.; Hu, J.; Tan, X.; Mo, Q.; Cao, W. Performance Comparison and Optimization of 16V265H Diesel Engine Fueled with Biodiesel Based on Miller Cycle. Processes 2022, 10, 1412. [Google Scholar] [CrossRef]

- Song, L.; Liu, T.; Fu, W.; Lin, Q. Experimental study on spray characteristics of ethanol-aviation kerosene blended fuel with a high-pressure common rail injection system. J. Energy Inst. 2018, 91, 203–213. [Google Scholar] [CrossRef]

- Shatrov, M.G.; Dunin, A.U.; Dushkin, P.V.; Yakovenko, A.L.; Golubkov, L.N.; Sinyavski, V.V. Influence of pressure oscillations in common rail injector on fuel injection rate. Facta Univ. Ser. Mech. Eng. 2020, 18, 579–593. [Google Scholar] [CrossRef]

- Hu, Y.; Yang, J.; Hu, N. Experimental study and optimization in the layouts and the structure of the high-pressure common-rail fuel injection system for a marine diesel engine. Int. J. Engine Res. 2021, 22, 1850–1871. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, Y.-T.; Qiu, T.; Ding, X.; Xiong, Q. Optimization research for a high pressure common rail diesel engine based on simulation. Int. J. Automot. Technol. 2010, 11, 625–636. [Google Scholar] [CrossRef]

- Yang, X.; Dong, Q.; Song, J.; Zhou, T. Investigation of a method for online measurement of injection rate for a high-pressure common rail diesel engine injector under multiple-injection strategies. Meas. Sci. Technol. 2021, 33, 025301. [Google Scholar] [CrossRef]

- Qi, B.; Zhang, Y.; Guo, D. Study on seal performance of injector nozzle in high-pressure common rail injection system. J. Braz. Soc. Mech. Sci. Eng. 2018, 40, 1–10. [Google Scholar] [CrossRef]

- Gao, Z.-G.; Li, G.-X.; Xu, C.-l.; Li, H.-M.; Wang, M. Simulation study on pressure fluctuation characteristics of a high-pressure common rail system. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2023, 237, 2645–2663. [Google Scholar] [CrossRef]

- Xu, L.; Bai, X.-S.; Jia, M.; Qian, Y.; Qiao, X.; Lu, X. Experimental and modeling study of liquid fuel injection and combustion in diesel engines with a common rail injection system. Appl. Energy 2018, 230, 287–304. [Google Scholar] [CrossRef]

- Wei, Y.; Fan, L.; Wu, Y.; Gu, Y.; Xu, J.; Fei, H. Research on transmission and coupling characteristics of multi-frequency pressure fluctuation of high pressure common rail fuel system. Fuel 2022, 312, 122632. [Google Scholar] [CrossRef]

- Agarwal, A.K.; Singh, A.P.; Maurya, R.K.; Shukla, P.C.; Dhar, A.; Srivastava, D.K. Combustion characteristics of a common rail direct injection engine using different fuel injection strategies. Int. J. Therm. Sci. 2018, 134, 475–484. [Google Scholar] [CrossRef]

- Jiang, H.; Wang, H.; Jiang, F.; Hu, J.; Hu, L. Research on the Optimization of a Diesel Engine Intercooler Structure Based on Numerical Simulation. Processes 2024, 12, 276. [Google Scholar] [CrossRef]

- Danilevičius, A.; Karpenko, M.; Křivánek, V. Research on the noise pollution from different vehicle categories in the urban area. Transport 2023, 38, 1–11. [Google Scholar] [CrossRef]

- Bai, Y.; Lan, Q.; Fan, L.; Ma, X.; Liu, H. Investigation on the fuel injection stability of high pressure common rail system for diesel engines. Int. J. Engine Res. 2021, 22, 616–631. [Google Scholar] [CrossRef]

- Li, P.; Zhang, Y.; Li, T.; Xie, L. Elimination of fuel pressure fluctuation and multi-injection fuel mass deviation of high pressure common-rail fuel injection system. Chin. J. Mech. Eng. 2015, 28, 294–306. [Google Scholar] [CrossRef]

- Niklawy, W.; Shahin, M.; Amin, M.; Elmaihy, A. Modelling and experimental investigation of high–pressure common rail diesel injection system. In Proceedings of the IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2020; p. 012037. [Google Scholar]

- Lan, Q.; Bai, Y.; Fan, L.; Gu, Y.; Wen, L.; Yang, L. Investigation on fuel injection quantity of low-speed diesel engine fuel system based on response surface prediction model. Energy 2020, 211, 118946. [Google Scholar] [CrossRef]

- Wang, D.; Xu, Z.; Su, C.; Hu, J. Pressure Control Strategy and Simulation of High Pressure Common Rail System. J. Phys. Conf. Ser. 2020, 1624, 022061. [Google Scholar]

- Li, Z.; Wang, Y.; Yin, Z.; Gao, Z.; Wang, Y.; Zhen, X. An exploratory numerical study of a diesel/methanol dual-fuel injector: Effects of nozzle number, nozzle diameter and spray spacial angle on a diesel/methanol dual-fuel direct injection engine. Fuel 2022, 318, 123700. [Google Scholar] [CrossRef]

- Balz, R.; von Rotz, B.; Sedarsky, D. In-nozzle flow and spray characteristics of large two-stroke marine diesel fuel injectors. Appl. Therm. Eng. 2020, 180, 115809. [Google Scholar] [CrossRef]

- Gupta, P.; Rajak, U.; Verma, T.N.; Arya, M.; Singh, T.S. Impact of fuel injection pressure on the common rail direct fuel injection engine powered by microalgae, kapok oil, and soybean biodiesel blend. Ind. Crops Prod. 2023, 194, 116332. [Google Scholar] [CrossRef]

- He, Z.; Zhou, H.; Duan, L.; Xu, M.; Chen, Z.; Cao, T. Effects of nozzle geometries and needle lift on steadier string cavitation and larger spray angle in common rail diesel injector. Int. J. Engine Res. 2021, 22, 2673–2688. [Google Scholar] [CrossRef]

- Ning, L.; Duan, Q.; Chen, Z.; Kou, H.; Liu, B.; Yang, B.; Zeng, K. A comparative study on the combustion and emissions of a non-road common rail diesel engine fueled with primary alcohol fuels (methanol, ethanol, and n-butanol)/diesel dual fuel. Fuel 2020, 266, 117034. [Google Scholar] [CrossRef]

- Liu, J.; Liu, Z.; Wang, L.; Wang, P.; Sun, P.; Ma, H.; Wu, P. Effects of PODE/diesel blends on particulate matter emission and particle oxidation characteristics of a common-rail diesel engine. Fuel Process. Technol. 2021, 212, 106634. [Google Scholar] [CrossRef]

- Bai, Y.; Chen, Z.; Dou, W.; Kong, X.; Yao, J.; Ai, C.; Zhai, F.; Zhang, J.; Yang, L. Pressure Fluctuation Characteristics of High-Pressure Common Rail Fuel Injection System. Diesel Engines Biodiesel Engines Technol. 2022, 2022, 229. [Google Scholar]

- Li, R.; Yuan, W.; Xu, J.; Wang, L.; Chi, F.; Wang, Y.; Liu, S.; Lin, J.; Zhang, Q.; Chen, L. Study of the Optimization of Rail Pressure Characteristics in the High-Pressure Common Rail Injection System for Diesel Engines Based on the Response Surface Methodology. Processes 2023, 11, 2626. [Google Scholar] [CrossRef]

- Fayad, M.A.; Al-Salihi, H.A.; Dhahad, H.A.; Mohammed, F.M.; Al-Ogidi, B.R. Effect of post-injection and alternative fuels on combustion, emissions and soot nanoparticles characteristics in a common-rail direct injection diesel engine. Energy Sources Part A Recovery Util. Environ. Eff. 2021, 3, 1–15. [Google Scholar] [CrossRef]

- Chen, G.; Chen, C.; Yuan, Y.; Zhu, L. Modelling and simulation analysis of high-pressure common rail and electronic controlled injection system for diesel engine. Appl. Math. Nonlinear Sci. 2020, 5, 345–356. [Google Scholar] [CrossRef]

- Wenbin, C.; Ruilin, M.; Yinshui, L.; Defa, W.; Xiaowen, C. Effects of distribution valve spring stiffness and opening pressure on the volumetric efficiency of micro high-pressure plunger pump. Adv. Mech. Eng. 2024, 16, 16878132241288404. [Google Scholar] [CrossRef]

- Abifarin, J.; Ofodu, J. Modeling and grey relational multi-response optimization of chemical additives and engine parameters on performance efficiency of diesel engine. Int. J. Grey Syst. 2022, 2, 16–26. [Google Scholar] [CrossRef]

- Muqeem, M.; Sherwani, A.F.; Ahmad, M.; Khan, Z.A. Taguchi based grey relational analysis for multi response optimisation of diesel engine performance and emission parameters. Int. J. Heavy Veh. Syst. 2020, 27, 441–460. [Google Scholar] [CrossRef]

| Parameter | Specification |

|---|---|

| Injector Needle Valve Diameter (mm) | 10 |

| Injector Nozzle Number × Orifice Diameter (mm) | 6 × 0.2 |

| Injector Nozzle Length (mm) | 1.5 |

| Injector Injection Pulse Width (ms) | 1.8 |

| Injector Pressure Chamber Volume (mm3) | 6 |

| Injector Oil Reservoir Volume (mm3) | 180 |

| Needle Valve Seat Cone Angle | 60° |

| Name of Engine | Diesel Engine |

|---|---|

| Fuel | Diesel Fuel |

| Number of Cylinders | 4 |

| Displacement (Volume) | 2.149 |

| Max Power | 87 kW (Net Power) |

| Rpm of Max Power | 5500 |

| Max Torque | 170 Nm (Net Torque) |

| Rpm of Max Torque | 4000 rpm~4400 rpm |

| Stroke/Diameter | 82/91.5 |

| Compression Ratio | 18:1 |

| Exhaust Backpressure at Specific Engine RPM (Excluding Converter) | 45 kpa@5500 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, H.; Li, Z.; Jiang, F.; Zhang, S.; Huang, Y.; Hu, J. Analysis of Rail Pressure Stability in an Electronically Controlled High-Pressure Common Rail Fuel Injection System via GT-Suite Simulation. Energies 2025, 18, 550. https://doi.org/10.3390/en18030550

Jiang H, Li Z, Jiang F, Zhang S, Huang Y, Hu J. Analysis of Rail Pressure Stability in an Electronically Controlled High-Pressure Common Rail Fuel Injection System via GT-Suite Simulation. Energies. 2025; 18(3):550. https://doi.org/10.3390/en18030550

Chicago/Turabian StyleJiang, Hongfeng, Zhejun Li, Feng Jiang, Shulin Zhang, Yan Huang, and Jie Hu. 2025. "Analysis of Rail Pressure Stability in an Electronically Controlled High-Pressure Common Rail Fuel Injection System via GT-Suite Simulation" Energies 18, no. 3: 550. https://doi.org/10.3390/en18030550

APA StyleJiang, H., Li, Z., Jiang, F., Zhang, S., Huang, Y., & Hu, J. (2025). Analysis of Rail Pressure Stability in an Electronically Controlled High-Pressure Common Rail Fuel Injection System via GT-Suite Simulation. Energies, 18(3), 550. https://doi.org/10.3390/en18030550