Computational Fluid Dynamic Modeling of Pack-Level Battery Thermal Management Systems in Electric Vehicles

Abstract

1. Introduction

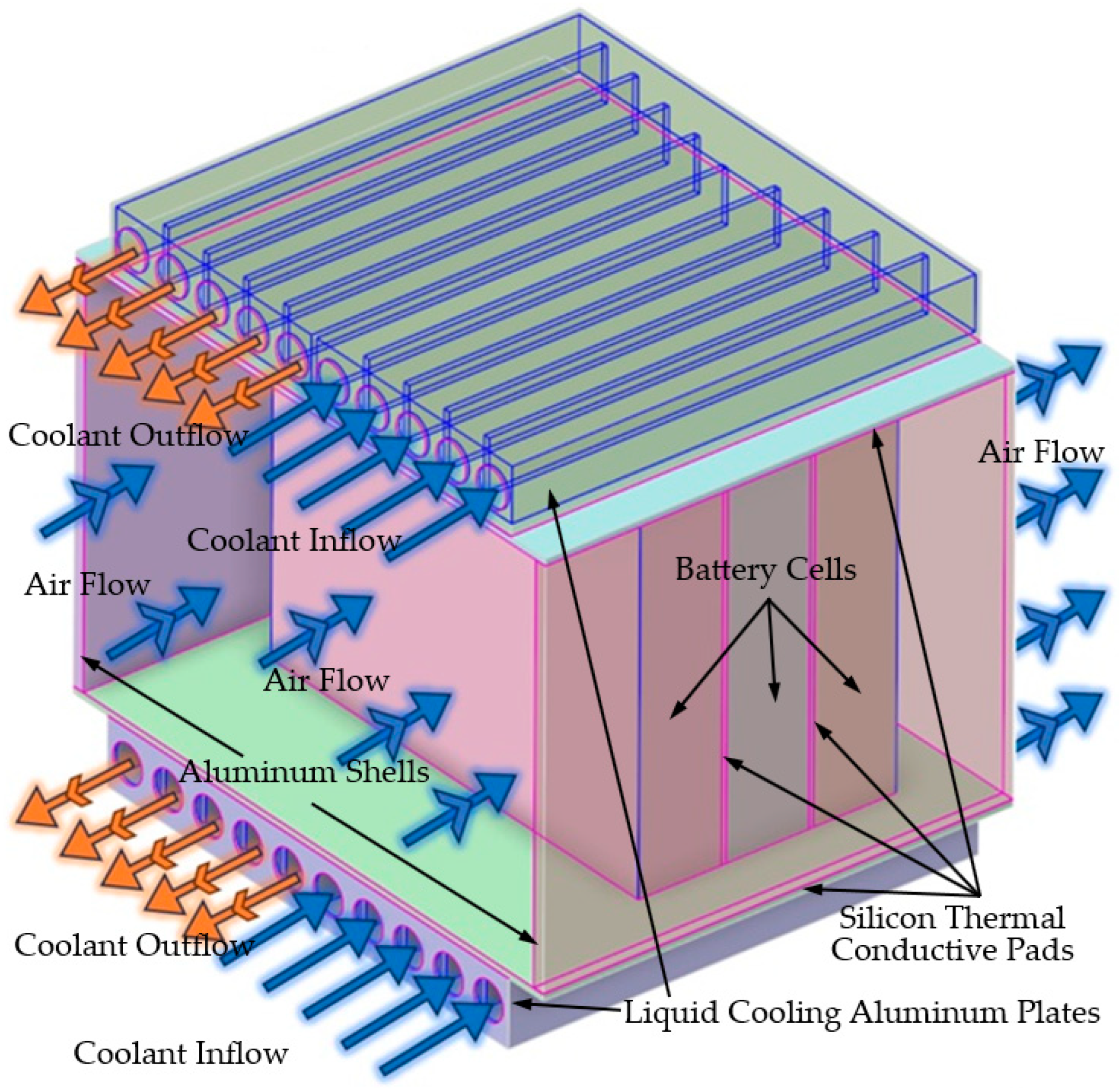

2. Method and Model Used for Evaluating BTMSs

2.1. Experimental and Computational Methods for Evaluating BTMSs

2.2. Fundamentals of CFD and Thermal Models of BTMS in This Study

2.3. Physical Parameters, and Boundary and Working Conditions in Modeling

- (1)

- The density, thermal conductivity, and specific heat of each material do not change with temperature and SOC.

- (2)

- The thermal conductivity of battery materials is anisotropic and changes in different directions, while the thermophysical parameters in the same direction are constant.

- (3)

- The heat generation rate of the battery remains unchanged, and the current density is evenly distributed.

- (4)

- Ignore radiation during heat transfer.

- (5)

- The coolant (water) is considered an incompressible Newtonian fluid. Since heat conduction plays a major role in the BTMS heat transfer process, its natural convection is ignored.

- (6)

- Based on the principle of a simplified model, the battery only retains the structural dimensions and the function of heating part of the battery core by ignoring the details of the positive and negative electrode tabs and busbar.

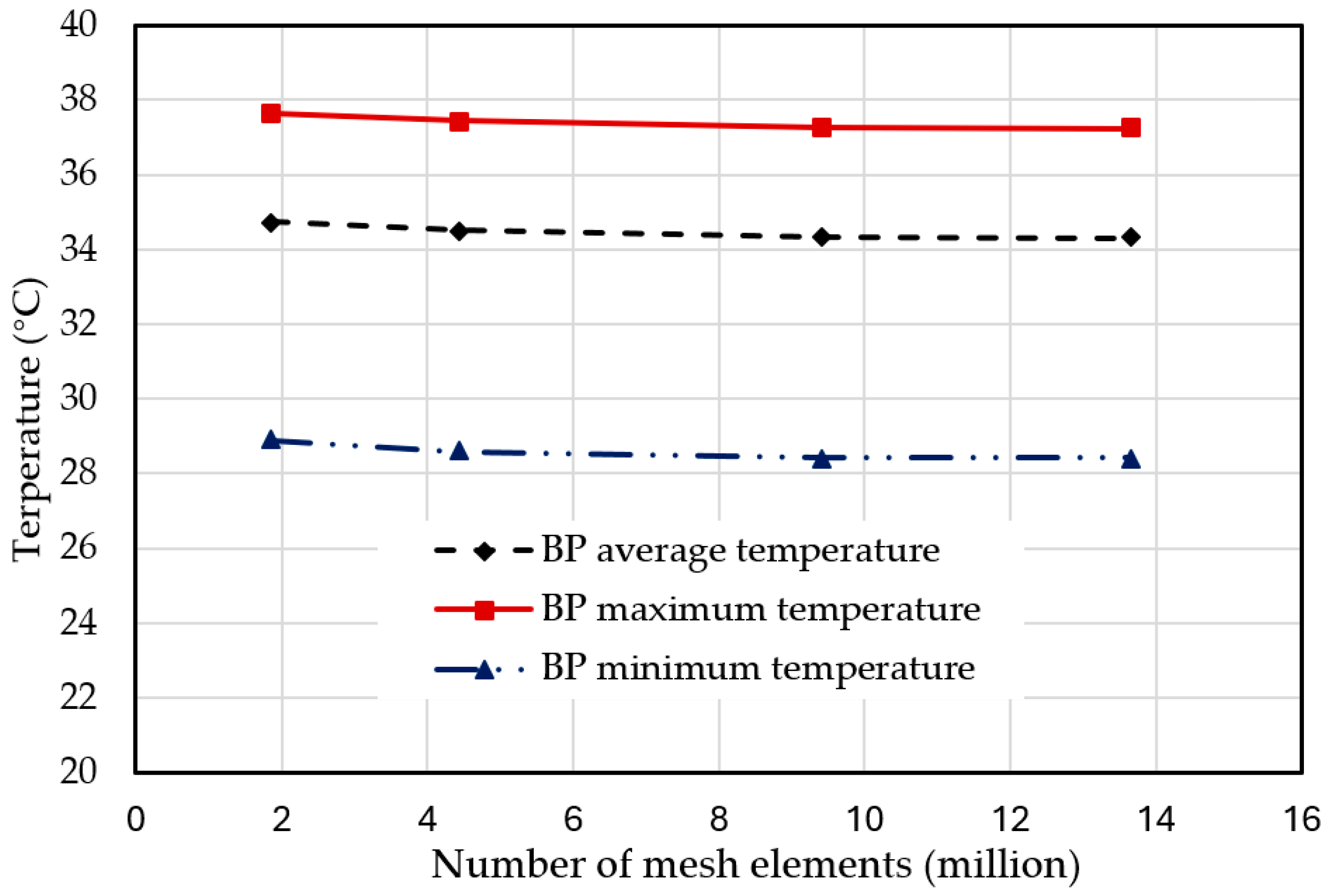

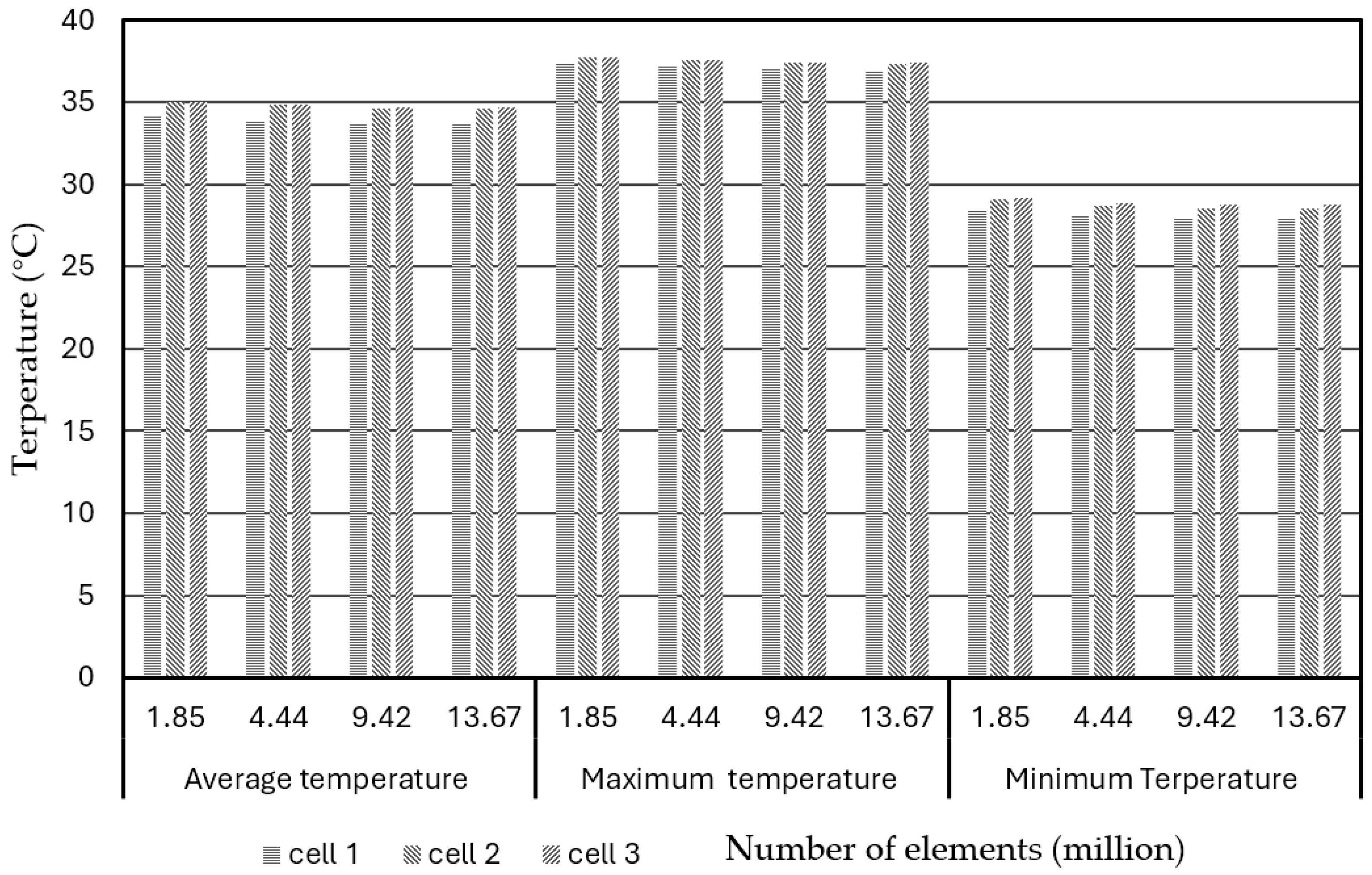

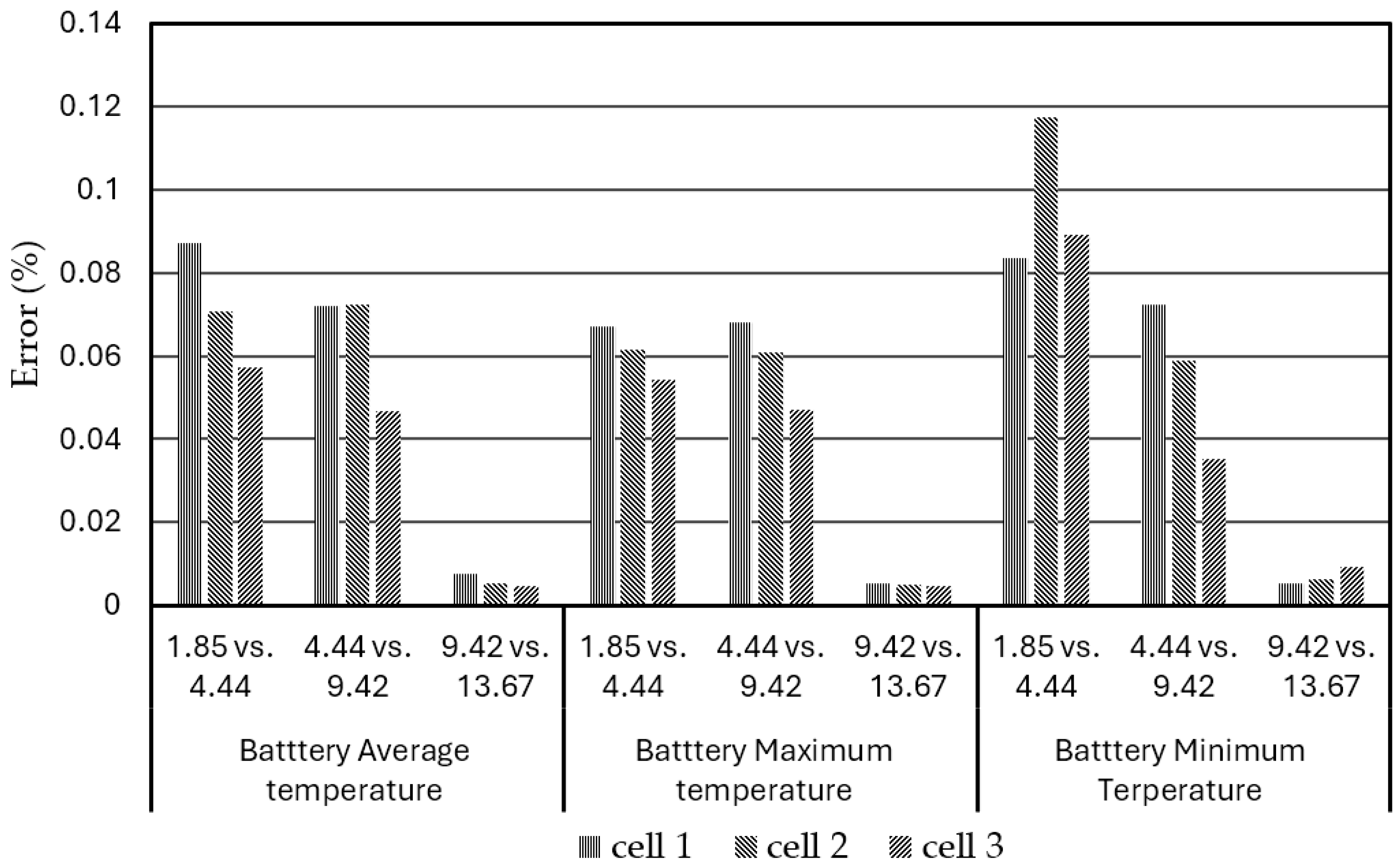

2.4. Mesh Convergence Study

- Create a mesh using a minimum or reasonable number of elements and reasonable element size and analyze a specific convergence output variable or variables, such as maximum displacement of the problem in the solid mechanics problems or maximum, minimum, or average temperature in the thermal problem in this study.

- Recreate the mesh with a denser element distribution or finer elements, re-analyze the specific output variable/s, and compare the results with those of the previous solutions.

- Keep increasing the mesh density and re-analyzing the modeling results until the specific output variable/s from the modeling result converge satisfactorily.

3. Results and Discussion

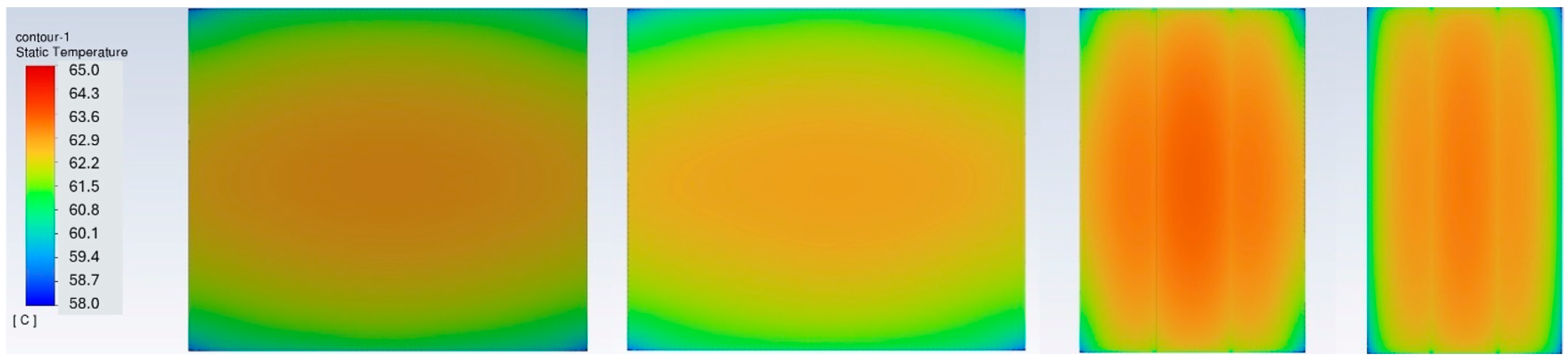

3.1. BP Thermal Performance Without BTMS

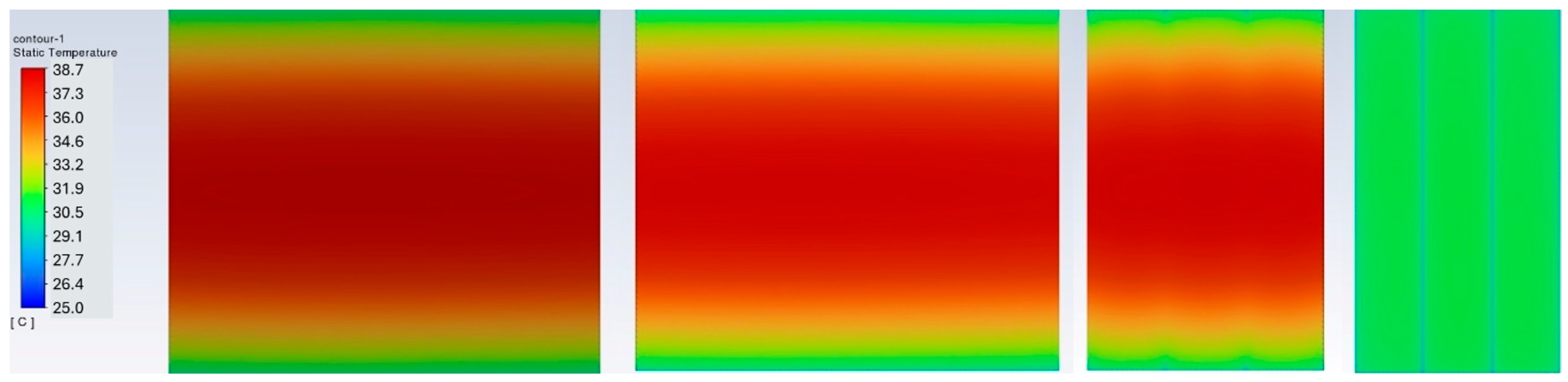

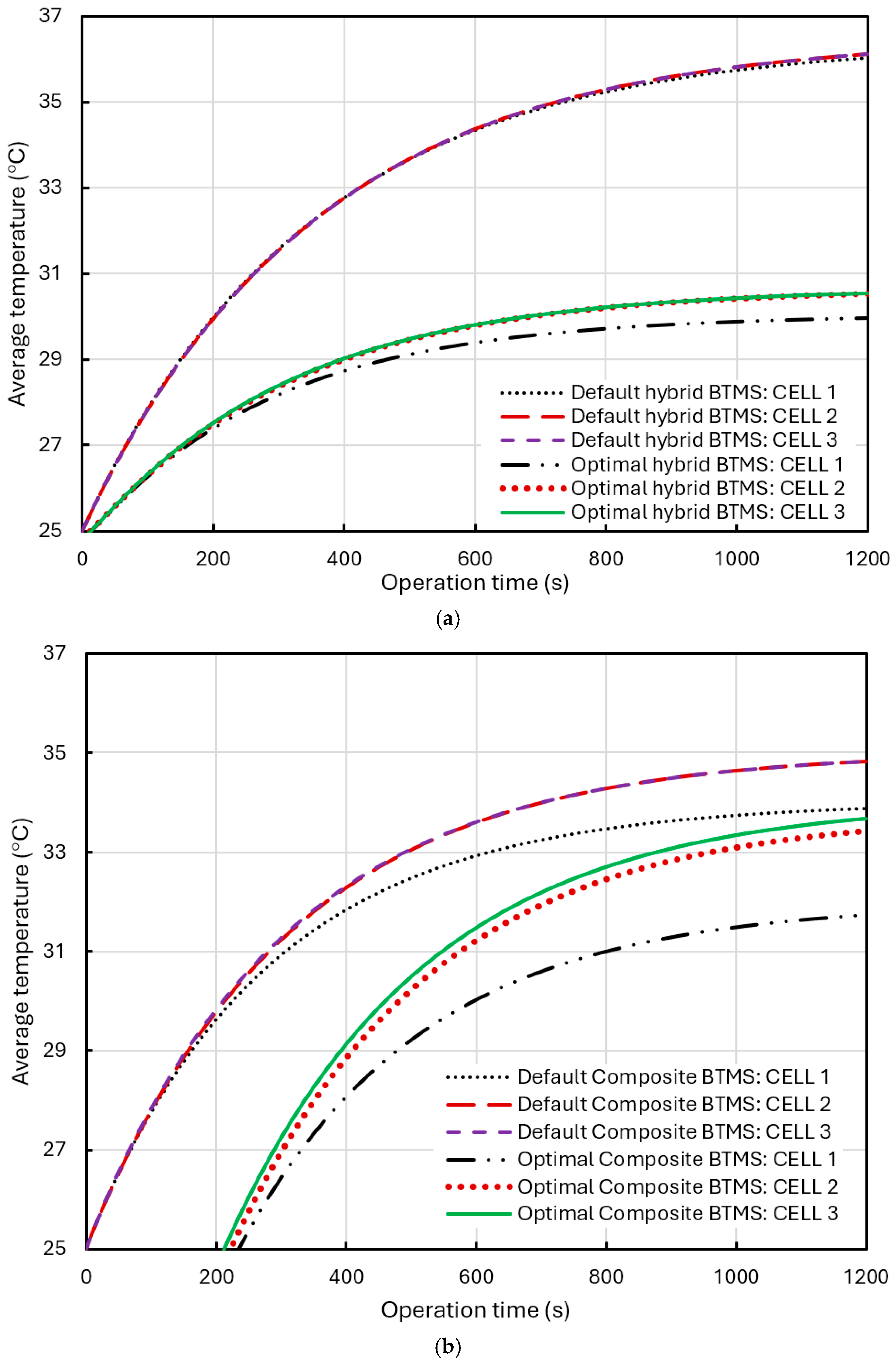

3.2. Effect of a Hybrid BTMS (Water Cooling) on BP Thermal Performance

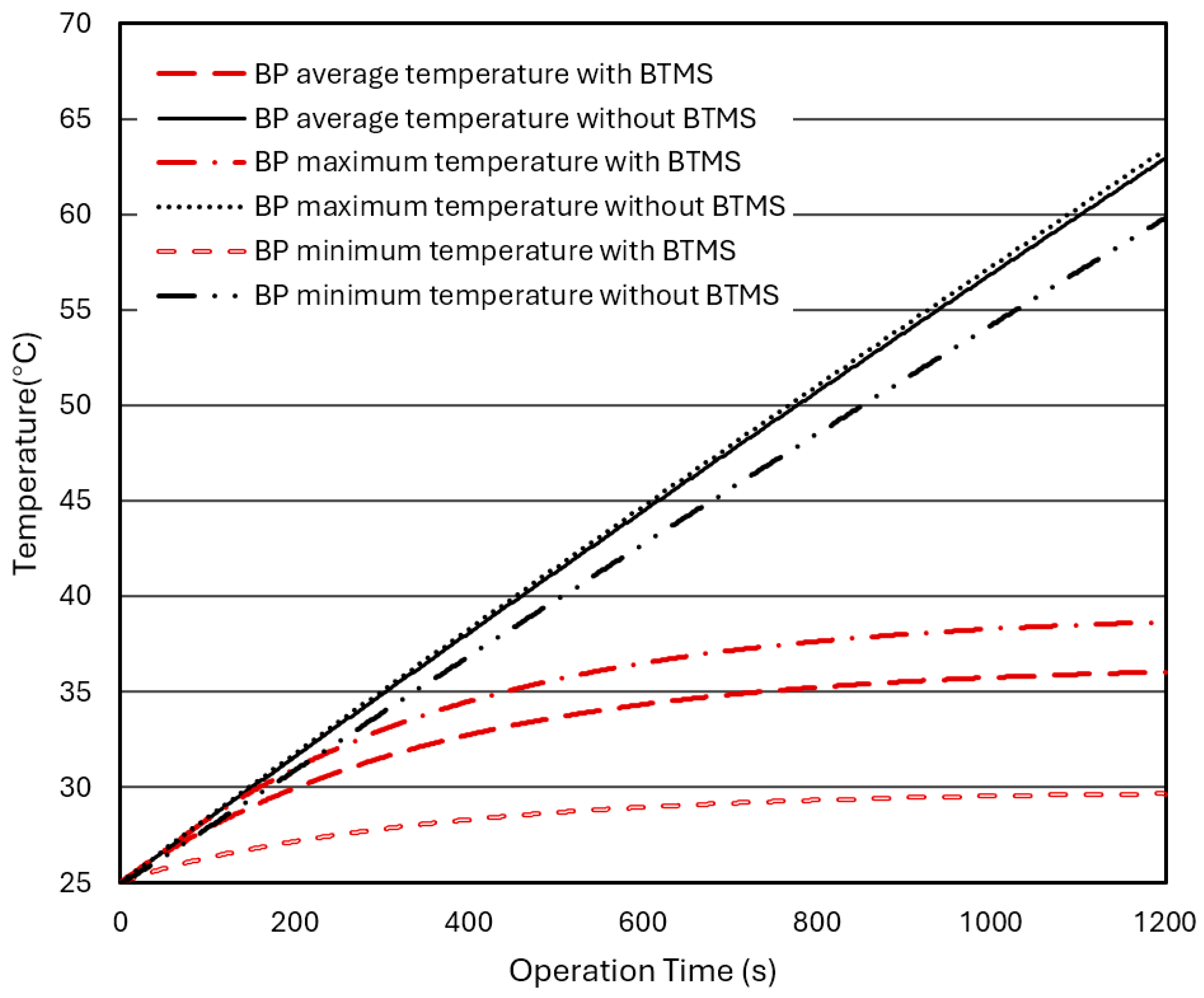

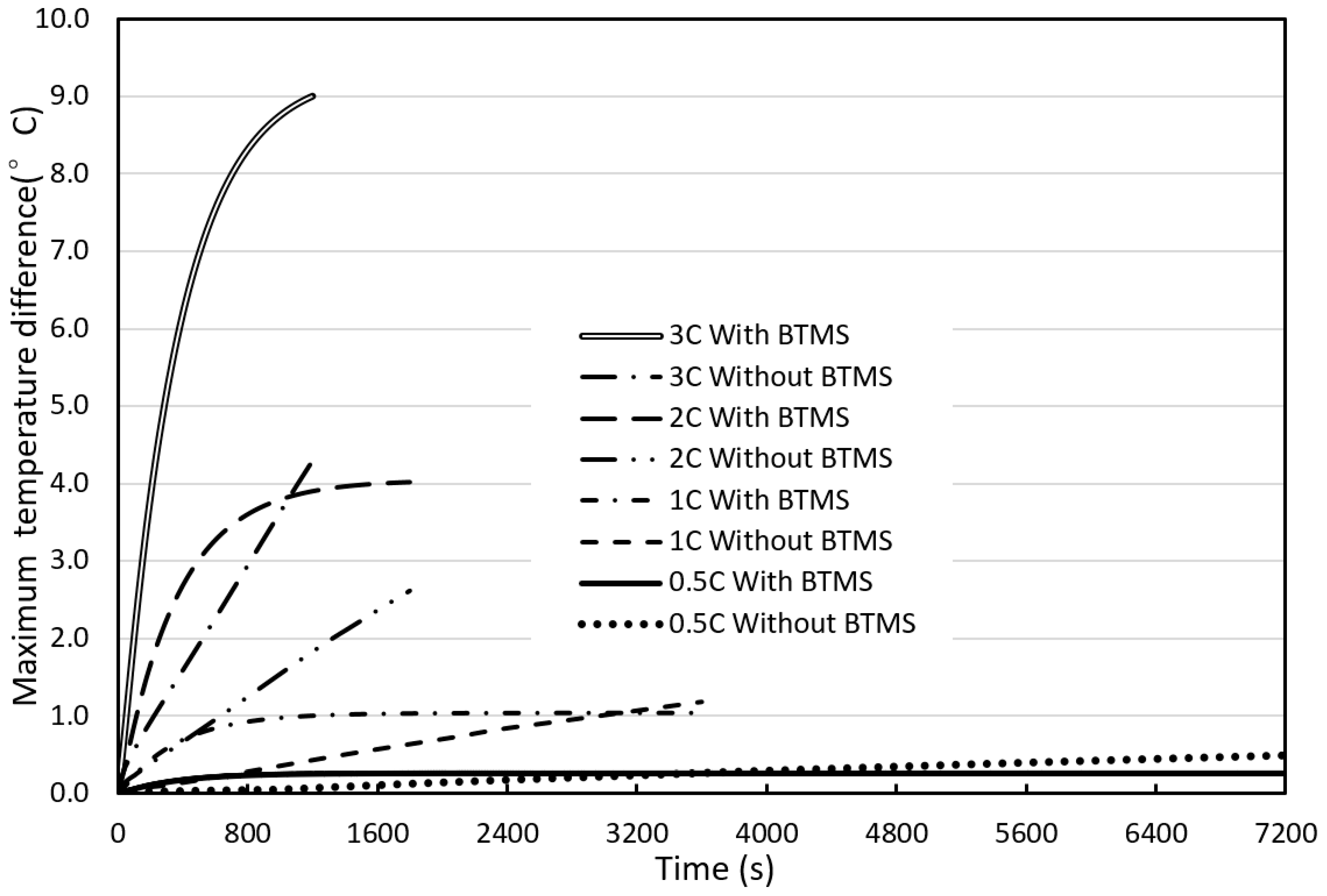

3.3. Effect of Discharge Rate on BP Thermal Performance

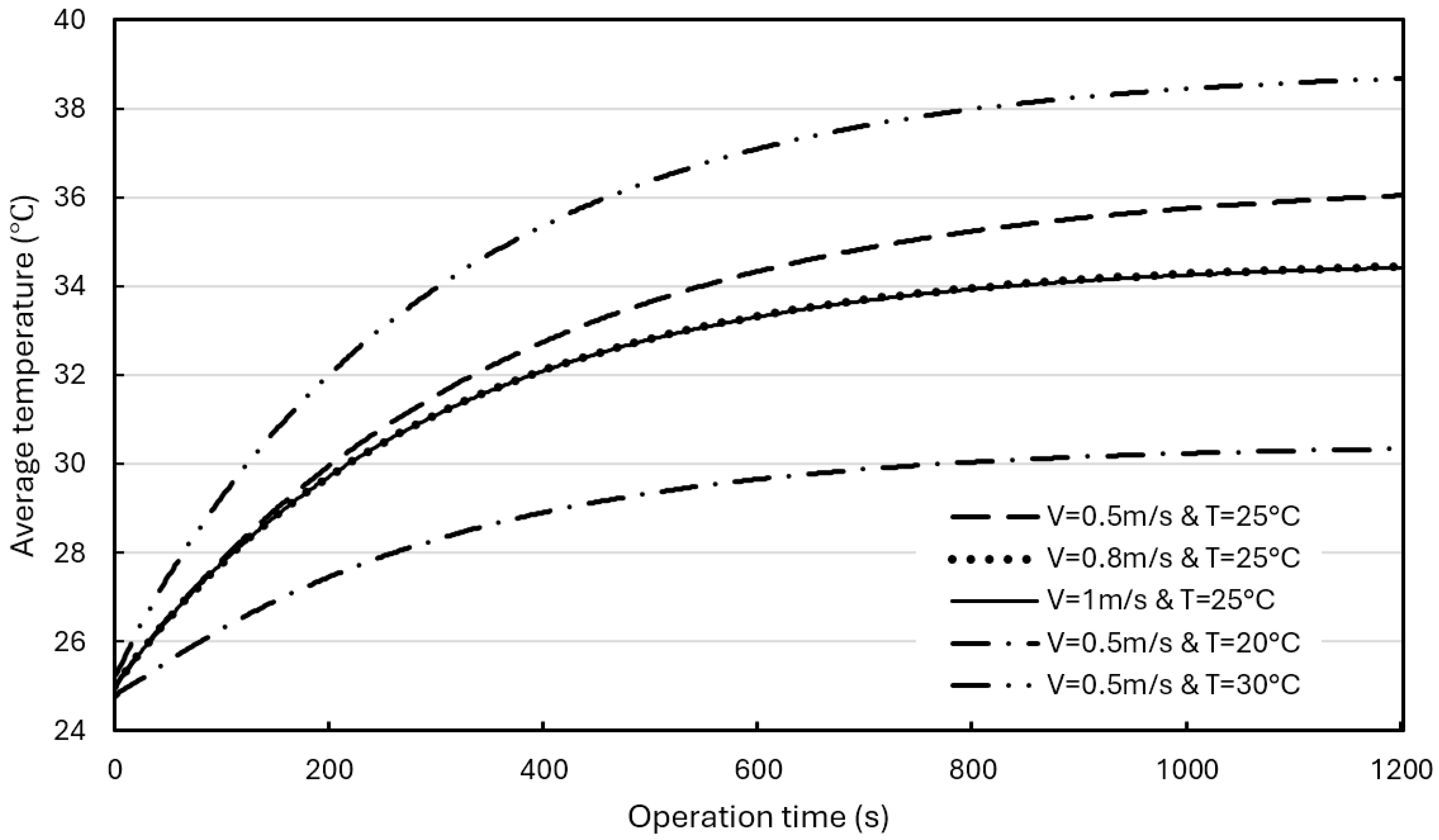

3.4. Effect of Water Coolant Flow Rate and Initial Temperature on BP Thermal Performance

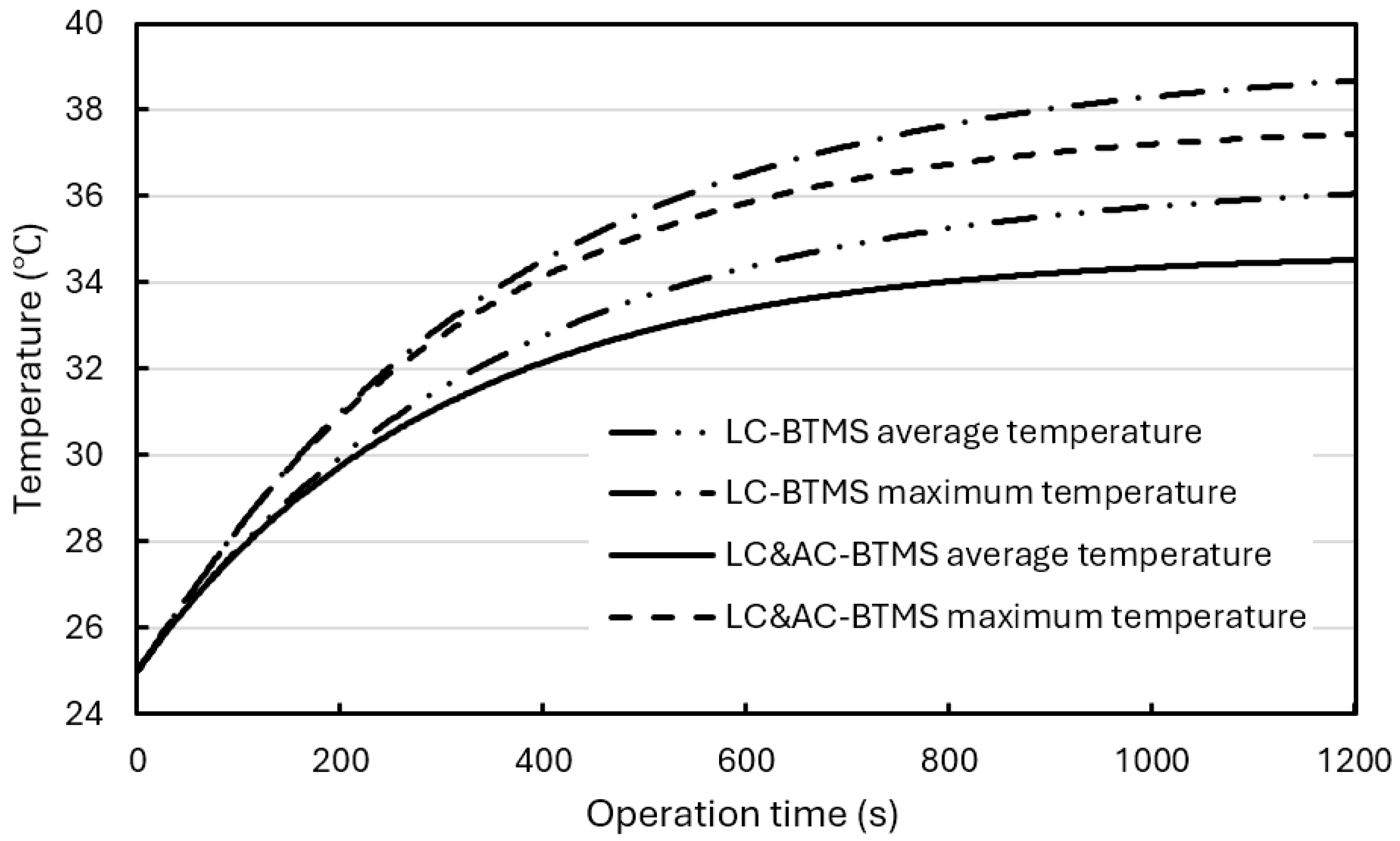

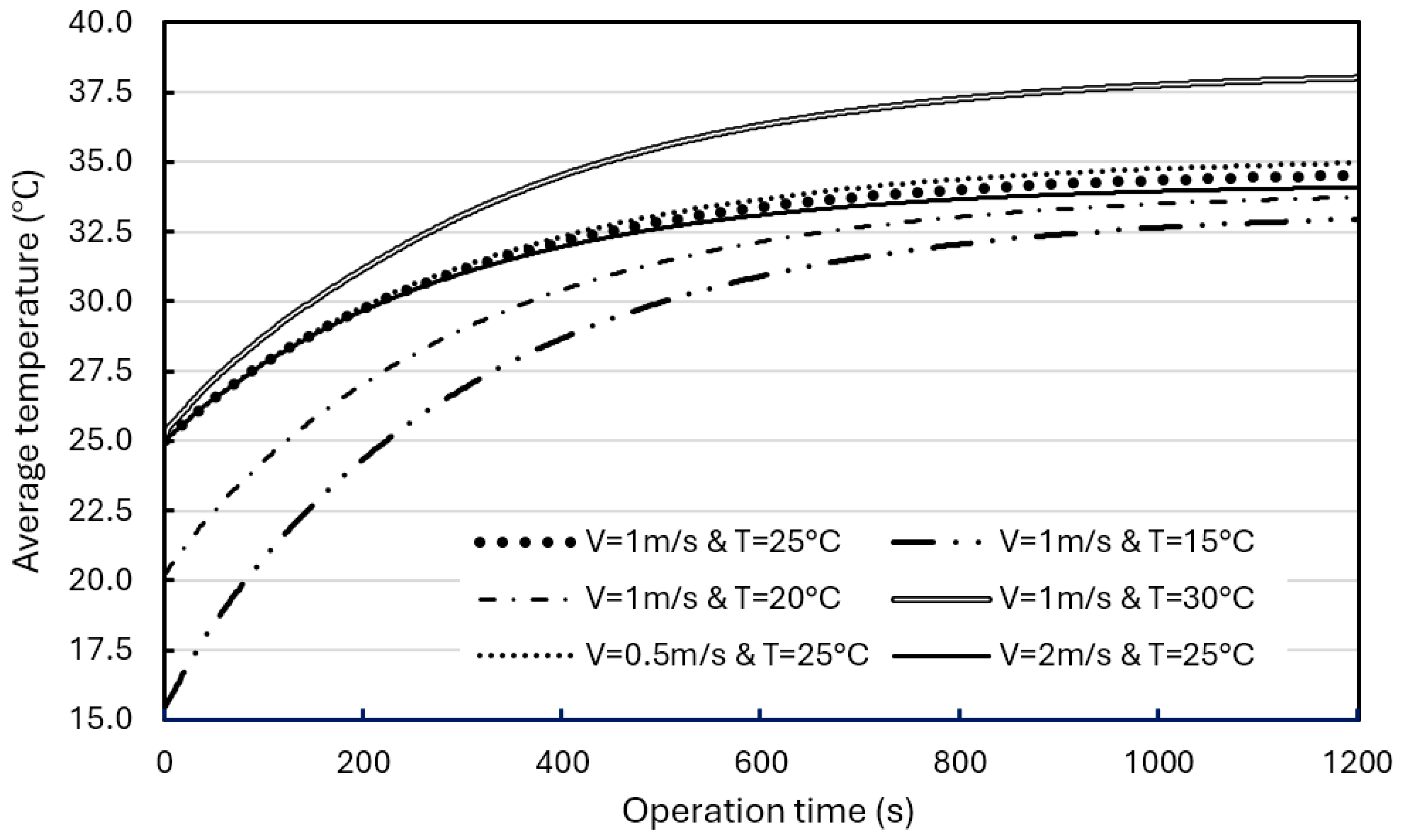

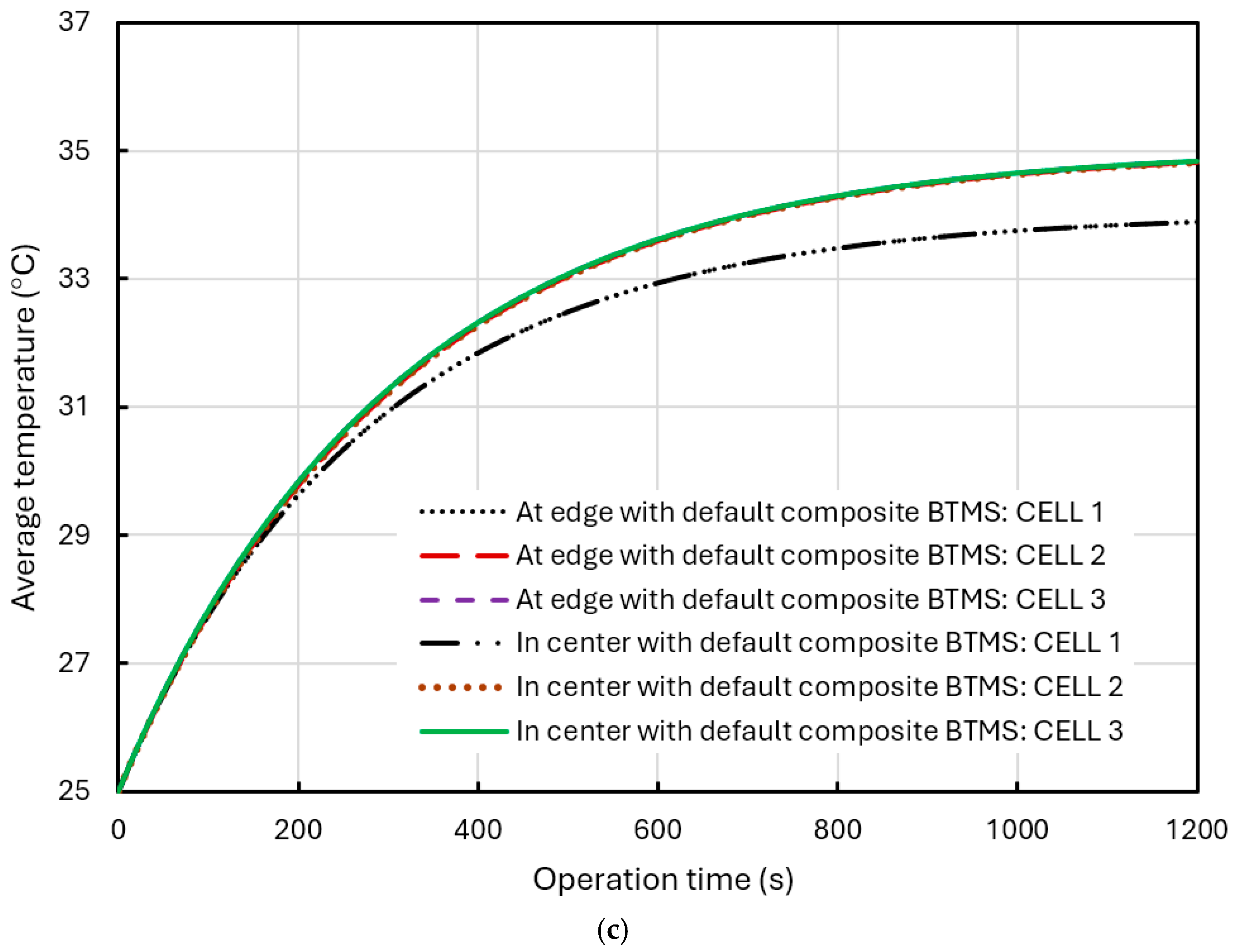

3.5. Effect of Composite BTMS (Forced Air Cooling Combined with Water Ccooling) on BP Thermal Performance

3.6. Summarizing Thermal Performance Comparison of Different BTMS Designs

4. Conclusions

- (1)

- For the BP without a BTMS (Scenario 1—natural air convection cooling only), the temperature in the BP rises rapidly and continuously to reach 63.8 °C, much higher than the upper bound of the ROTR (+20 °C~+35 °C) under the extreme discharge rate of 3 C and even if the discharge rate is 2 C.

- (2)

- For the BP with a hybrid BTMS (Scenario 2—water coolant cooling plus natural air cooling), the temperature in the BP rises much slower and tends to reach converging values after a certain operation time (after 1000 s). The maximum temperature in the BP at the steady state rises to about 38.7 °C, slightly above the upper bound of the ROTR even under the discharge rate of 3 C. Lowering the coolant (water) initial temperature can effectively lower the temperature up to 5.7 °C in the BP, but the water flow rate cannot since the turbulence model.

- (3)

- For the BP with a composite BTMS (Scenario 3—water coolant cooling plus forced air cooling), the temperature in the BP rises much slower and tends to reach converging values after a certain operation time (after 1000 s). Compared with Scenario 2, the temperature at the steady state is lowered up to 1.5 °C under the extreme discharge rate of 3 C. Lowering the coolant initial temperature and air initial temperature can effectively lower the temperatures up to 5.1 °C and 1.0 °C, respectively, in the BP, but the coolant flow rate (due to the turbulence model) and the air flow rate cannot.

- (4)

- Therefore, a hybrid BTMS can meet the cooling needs in BP to some extent. A composite BTME can be slightly better to serve the cooling needs of the BP compared to the hybrid BTMS. In future study, more thermal process parameters, such as pressure-drop, pumping-power, heat generation rate, energy efficiency, and laminar flow and transitional flow models can be analyzed, and experiments should be conducted for comparison and validation. The approach to integrate multiple cooling methods and select/develop new cooling media for further comprehensive improvement of the BTMS should be considered.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

References

- Friedlingstein, P.; O’Sullivan, M.; Jones, M.W.; Andrew, R.M.; Bakker, D.C.E.; Hauck, J.; Landschützer, P.; Le Quéré, C.; Luijkx, I.T.; Peters, G.P.; et al. Global carbon budget 2023. Earth Syst. Sci. Data 2023, 15, 5301–5369. [Google Scholar] [CrossRef]

- Mehmood, K.A.; Hassan, J.; Hassan, A.; Arshad, M.W.; Batool, S. Consumer’s automobile purchase: A concept. Qlantic J. Soc. Sci. Humanit. 2024, 5, 203–207. [Google Scholar] [CrossRef]

- International Energy Agency. Global EV Outlook 2023—Catching Up with Climate Ambitions. 2023. Available online: www.iea.org (accessed on 15 October 2024).

- Xia, G.; Cao, L.; Bi, G. A review on battery thermal management in electric vehicle application. J. Power Sources 2017, 367, 90–105. [Google Scholar] [CrossRef]

- Waldmann, T.; Wilka, M.; Kasper, M.; Fleischhammer, M.; Wohlfahrt-Mehrens, M. Temperature dependent ageing mechanisms in Lithium-ion batteries—A post-mortem study. J. Power Sources 2014, 262, 129–135. [Google Scholar] [CrossRef]

- Song, L.; Zheng, Y.; Xiao, Z.; Wang, C.; Long, T. Review on thermal runaway of lithium-ion batteries for electric vehicles. J. Electron. Mater. 2022, 51, 30–46. [Google Scholar] [CrossRef]

- Shim, J.; Kostecki, R.; Richardson, T.; Song, X.; Striebel, K. Electrochemical analysis for cycle performance and capacity fading of a lithium-ion battery cycled at elevated temperature. J. Power Sources 2022, 112, 222–230. [Google Scholar] [CrossRef]

- Lv, S.; Wang, X.; Lu, W.; Zhang, J.; Ni, H. The influence of temperature on the capacity of lithium ion batteries with different anodes. Energies 2022, 15, 60. [Google Scholar] [CrossRef]

- Al-Zareer, M.; Dincer, I.; Rosen, M.A. A novel approach for performance improvement of liquid to vapor based battery cooling systems. Energy Convers. Manag. 2019, 187, 191–204. [Google Scholar] [CrossRef]

- Song, W.; Chen, M.; Bai, F.; Lin, S.; Chen, Y.; Feng, Z. Non-uniform effect on the thermal/aging performance of Lithium-ion pouch battery. Appl. Therm. Eng. 2018, 128, 1165–1174. [Google Scholar] [CrossRef]

- Klein, M.; Tong, S.; Park, J.W. In-plane nonuniform temperature effects on the performance of a large-format lithium-ion pouch cell. Appl. Energy 2016, 165, 639–647. [Google Scholar] [CrossRef]

- Thawkar, V.; Dhoble, A.S. A review of thermal management methods for electric vehicle batteries based on heat pipes and PCM. J. Braz. Soc. Mech. Sci. Eng. 2023, 45, 90. [Google Scholar] [CrossRef]

- Ma, S.; Jiang, M.; Tao, P.; Song, C.; Wu, J.; Wang, J.; Deng, T.; Shang, W. Temperature effect and thermal impact in lithium-ion batteries: A review. Prog. Nat. Sci. Mater. Int. 2018, 28, 653–666. [Google Scholar] [CrossRef]

- Wu, W.; Wang, S.; Wu, W.; Chen, K.; Hong, S.; Lai, Y. A critical review of battery thermal performance and liquid based battery thermal management. Energy Convers. Manag. 2019, 182, 262–281. [Google Scholar] [CrossRef]

- Li, K.; Yan, J.; Chen, H.; Wang, Q. Water cooling based strategy for lithium-ion battery pack dynamic cycling for thermal management system. Appl. Therm. Eng. 2018, 132, 575–585. [Google Scholar] [CrossRef]

- Kabir, M.M.; Demirocak, D.E. Degradation mechanisms in Li-ion batteries: A state-of-the-art review. Int. J. Energy Res. 2017, 41, 1963–1986. [Google Scholar] [CrossRef]

- Arora, S. Selection of thermal management system for modular battery packs of electric vehicles: A review of existing and emerging technologies. J. Power Sources 2018, 400, 621–640. [Google Scholar] [CrossRef]

- Andwari, A.M.; Pesiridis, A.; Rajoo, S.; Martinez-Botas, R.; Esfahanian, V. A review of Battery Electric Vehicle technology and readiness levels. Renew. Sustain. Energy Rev. 2017, 78, 414–430. [Google Scholar] [CrossRef]

- Kim, J.; Oh, J.; Lee, H. Review on battery thermal management system for electric vehicles. Appl. Therm. Eng. 2018, 149, 192–212. [Google Scholar] [CrossRef]

- Khan, M.R.; Swierczynski, M.J.; Kær, S.K. Towards an ultimate battery thermal management system: A review. Batteries 2017, 3, 9. [Google Scholar] [CrossRef]

- Garud, K.S.; Tai, L.D.; Hwang, S.-G.; Nguyen, N.-H.; Lee, M.-Y. A review of advanced cooling strategies for battery thermal management systems in electric vehicles. Symmetry 2023, 15, 1322. [Google Scholar] [CrossRef]

- Hwang, F.S.; Confrey, T.; Reidy, C.; Picovici, D.; Callaghan, D.; Culliton, D.; Nolan, C. Review of battery thermal management systems in electric vehicles. Renew. Sustain. Energy Rev. 2024, 192, 114171. [Google Scholar] [CrossRef]

- Battery Design—From Chemistry to Pack. Available online: https://www.BatteryDesign.net (accessed on 19 January 2025).

- Rahmani, A.; Dibaj, M.; Akrami, M. Recent advancements in battery thermal management systems for enhanced performance of Li-ion batteries: A comprehensive review. Batteries 2024, 10, 265. [Google Scholar] [CrossRef]

- Tai, L.D.; Garud, K.S.; Hwang, S.-G.; Lee, M.-Y. A review on advanced battery thermal management systems for fast charging in electric vehicles. Batteries 2024, 10, 372. [Google Scholar] [CrossRef]

- Zhao, C.; Zhang, B.; Zheng, Y.; Huang, S.; Yan, T.; Liu, X. Hybrid battery thermal management system in electric vehicles: A review. Energies 2020, 13, 6257. [Google Scholar] [CrossRef]

- Jomde, A.; Patane, P.; Nadgire, A.; Patil, C.; Kolas, K.; Bhojwani, V. Battery Thermal Management System for EVs: A Review. In Energy Storage Systems. Engineering Optimization: Methods and Applications; Mathew, V.K., Hotta, T.K., Ali, H.M., Sundaram, S., Eds.; Springer: Singapore, 2023. [Google Scholar]

- Lin, Y.; Chen, Y.-W.; Yang, J.-T. Optimized thermal management of a battery energy-storage system (BESS) inspired by air-cooling inefficiency factor of data centers. Int. J. Heat Mass Transf. 2023, 200, 123388. [Google Scholar] [CrossRef]

- Al-Zareer, M.; Dincer, I.; Rosen, M.A. Electrochemical modeling, and performance evaluation of a new ammonia-based battery thermal management system for electric and hybrid electric vehicles. Electrochim. Acta 2017, 247, 171–182. [Google Scholar] [CrossRef]

- Zhang, S.; Zhao, R.; Liu, J.; Gu, J. Investigation on a hydrogel based passive thermal management system for lithium-ion batteries. Energies 2014, 68, 854–861. [Google Scholar] [CrossRef]

- Wang, J.; Gan, Y.; Liang, J.; Tan, M.; Li, Y. Sensitivity analysis of factors influencing a heat pipe-based thermal management system for a battery module with cylindrical cells. Appl. Therm. Eng. 2019, 151, 475–485. [Google Scholar] [CrossRef]

- Wu, W.; Liu, J.; Liu, M.; Rao, Z.; Deng, H.; Wang, Q.; Qi, X.; Wang, S. An innovative battery thermal management with thermally induced flexible phase change material. Energy Convers. Manag. 2020, 221, 113145. [Google Scholar] [CrossRef]

- Yue, Q.; He, C.; Jiang, H.; Wu, M.; Zhao, T. A hybrid battery thermal management system for electric vehicles under dynamic working conditions. Int. J. Heat Mass Transf. 2021, 164, 120528. [Google Scholar] [CrossRef]

- Ma, K.; Liu, J. Liquid metal cooling in thermal management of computer chips. Front. Energy Power Eng. China 2007, 1, 384–402. [Google Scholar] [CrossRef]

- Ma, K.-Q.; Liu, J. Heat-driven liquid metal cooling device for the thermal management of a computer chip. J. Phys. D Appl. Phys. 2007, 40, 4722–4729. [Google Scholar] [CrossRef]

- Huo, Y.; Rao, Z. The numerical investigation of nanofluid based cylinder battery thermal management using lattice Boltzmann method. Int. J. Heat Mass Transf. 2015, 91, 374–384. [Google Scholar] [CrossRef]

- Sui, Z.; Lin, H.; Sun, Q.; Dong, K.; Wu, W. Multi-objective optimization of efficient liquid cooling-based battery thermal management system using hybrid manifold channels. Appl. Energy 2024, 371, 123766. [Google Scholar] [CrossRef]

- Wang, J.; Feng, X.; Yu, Y.; Huang, H.; Zheng, M.; Xu, Y.; Wu, J.; Yang, Y.; Lu, J. Rapid temperature-responsive thermal regulator for safety management of battery modules. Nat. Energy 2024, 9, 939–946. [Google Scholar] [CrossRef]

- Zuo, W.; Zhang, Y.; E, J.; Li, J.; Li, Q.; Zhang, G. Performance comparison between single S-channel and double S-channel cold plate for thermal management of a prismatic LiFePO4. Renew. Energy 2022, 192, 46–57. [Google Scholar] [CrossRef]

- Zhang, Y.; Zuo, W.; E, J.; Li, J.; Li, Q.; Sun, K.; Zhou, K.; Zhang, G. Performance comparison between straight channel cold plate and inclined channel cold plate for thermal management of a prismatic LiFePO4 battery. Energy 2022, 248, 123637. [Google Scholar] [CrossRef]

- Wang, T.; Tseng, K.J.; Zhao, J.; Wei, Z. Thermal investigation of lithium-ion battery module with different cell arrangement structures and forced air-cooling strategies. Appl. Energy 2014, 134, 229–238. [Google Scholar] [CrossRef]

- Tang, Y.; Jia, M.; Li, J.; Lai, Y.; Cheng, Y.; Liu, Y. Numerical Analysis of Distribution and Evolution of Reaction Current Density in Discharge Process of Lithium-Ion Power Battery. J. Electrochem. Soc. 2014, 161, E3021–E3027. [Google Scholar] [CrossRef]

- Chacón, X.C.A.; Laureti, S.; Ricci, M.; Cappuccino, G. A review of non-destructive techniques for lithium-ion battery performance analysis. World Electr. Veh. J. 2023, 14, 305. [Google Scholar] [CrossRef]

- Ping, P.; Wang, Q.; Huang, P.; Sun, J.; Chen, C. Thermal behaviour analysis of lithium-ion battery at elevated temperature using deconvolution method. Appl. Energy 2014, 129, 261–273. [Google Scholar]

- Feng, X.; Sun, J.; Ouyang, M.; He, X.; Lu, L.; Han, X.; Fang, M.; Peng, H. Characterization of large format lithium ion battery exposed to extremely high temperature. J. Power Sources 2014, 272, 457–467. [Google Scholar] [CrossRef]

- Aruna, P.; Vasan Prabhu, V.; Krishnakumar, V.; Velmurugan, P. Review on Lithium-Ion Battery Modeling Techniques for Electric Vehicle Applications. In Advances in Communication, Devices and Networking; ICCDN 2022. Lecture Notes in Electrical, Engineering; Dhar, S., Do, D.-T., Sur, S.N., Liu, C.-M., Eds.; Springer: Singapore, 2023; Volume 1037, pp. 551–565. [Google Scholar] [CrossRef]

- Olsen, N.R.B. CFD Algorithms for Hydraulic Engineering; Department of Hydraulic and Environmental Engineering, The Norwegian University of Science and Technology: Trondheim, Norway, 2000; 80p. [Google Scholar]

- Versteeg, H.K.; Malalasekera, W. An Introduction to Computational Fluid Dynamics, 1st ed.; Longman Science & Technical: Harlow, England, 1995. [Google Scholar]

- Shih, T.-H.; Liou, W.W.; Shabir, A.; Yang, A.; Zhu, J. A new k-ε Eddy-viscosity model for high Reynolds number turbulent flows-model development and validation. Comput. Fluids 1995, 24, 227–238. [Google Scholar] [CrossRef]

- Bulat, M.P.; Bulat, P.V. Comparison of turbulence models in the calculation of supersonic separated flows. World Appl. Sci. J. 2013, 27, 1263–1266. [Google Scholar]

- ANSYS, Inc. Ansys Fluent Theory Guide 2022/R1; Ansys, Inc.: Canonsburg, PA, USA, 2022. [Google Scholar]

- Sun, J.; Dan, D.; Wei, M.; Cai, S.; Zhao, Y.; Wright, E. Pack-level modeling and thermal analysis of a battery thermal management system with phase change materials and liquid cooling. Energies 2023, 16, 5815. [Google Scholar] [CrossRef]

- Ye, J.; Aldaher AY, M.; Tan, G. Thermal performance analysis of 18,650 battery thermal management system integrated with liquid-cooling and air-cooling. J. Energy Storage 2023, 72, 108766. [Google Scholar] [CrossRef]

- Xia, B.; Liu, Y.; Huang, R.; Yang, Y.; Lai, Y.; Zheng, W.; Wang, H.; Wang, W.; Wang, M. Thermal analysis and improvements of the power battery pack with liquid cooling for electric vehicles. Energies 2019, 12, 3045. [Google Scholar] [CrossRef]

- EVE, LF50F. Available online: https://evemall.com/ (accessed on 19 April 2024).

- Bernardi, D.; Pawlikowski, E.; Newman, J. A general energy balance for battery systems. J. Electrochem. Soc. 1985, 132, 5–12. [Google Scholar] [CrossRef]

- Sagar, P.; Teotia, P.; Sahlot, A.D.; Thakur, H.C. Heat transfer analysis and optimization of engine fins of varying surface roughness. Mater. Today Proc. 2017, 4, 8565–8570. [Google Scholar] [CrossRef]

- Yu, M.; Modesti, D.; Pirozzoli, S. Direct numerical simulation of flow in open rectangular ducts. J. Fluid Mech. 2023, 977, A32. [Google Scholar] [CrossRef]

- Wang, X.; Liang, X.; Hao, Z.; Chen, R. Comparison of electrical and mechanical water pump performance in internal combustion engine. Int. J. Veh. Syst. Model. Test. 2015, 10, 205–223. [Google Scholar] [CrossRef]

- Zhang, L.; Li, J.; Feng, Z.; Peng, S.; Zhao, S. Research on multi-objective optimization of automotive electronic water pump motor considering the factor of gap viscous loss. Struct. Multidiscip. Optim. 2022, 65, 243. [Google Scholar] [CrossRef]

- Bhagavathy, S.M.; Budnitz, H.; Schwanen, T.; McCulloch, M. Impact of charging rates on electric vehicle battery life. Findings 2021. [Google Scholar] [CrossRef]

| The Parameter | Value | Units |

|---|---|---|

| Air | ||

| Initial temperature | 25.0 | °C |

| Initial flow rate | 0.0 | m/s |

| Density | 1.225 | Kg/m3 |

| Specific heat | 1006 | J/(kg·K) |

| Thermal conductivity | 0.0242 | W/(m·K) |

| Kinematic viscosity | 1.789 × 10−5 | Kg/(m·s) |

| Silicone thermal conductive plate | ||

| Size (between batteries) | mm × mm × mm | |

| Size (between battery and liquid cooling plate) | mm × mm × mm | |

| Density | 1130 | Kg/m |

| Specific heat | 1320 | J/(kg·K) |

| Thermal conductivity | 2.0 | W/(m·K) |

| Liquid cooling plate and walls | ||

| Size of LCP | mm | |

| Density (Al) | 2719 | Kg/m3 |

| Specific heat (Al) | 871.0 | J/(kg·K) |

| Thermal conductivity (Al) | 202.4 | W/(m·K) |

| Heat convection coefficient | ||

| Wall | 5.0 | W/(m2·K) |

| Thermal pad | 5.0 | W/(m2·K) |

| The Parameter | Value | Units |

|---|---|---|

| Water | ||

| Initial temperature | 25.0 | °C |

| Initial flow rate | 0.5 | m/s |

| Thermal conductivity | 0.6 | W/(m·K) |

| Kinematic viscosity | 0.001003 | m2/s |

| Specific heat | 4182 | J/(kg·K) |

| Size (Between battery and liquid cooling plate) | mm × mm × mm | |

| Density | 998.2 | Kg/m3 |

| Other component temperature | 25.0 | °C |

| Changes in coolant (water) conditions | ||

| Temperature/flow rate/convection coefficient * | 30/0.5/128.5 | °C; m/s; W/(m2·K) |

| Temperature/flow rate/convection coefficient * | 20/0.5/701.9 | °C; m/s; W/(m2·K) |

| Temperature/flow rate/convection coefficient * | 25/0.8/225.9 | °C; m/s; W/(m2·K) |

| Temperature/flow rate/convection coefficient * | 25/1.0/279.4 | °C; m/s; W/(m2·K) |

| Heat convection coefficient | ||

| Wall | 5.0 | W/(m2·K) |

| Thermal pad | 5.0 | W/(m2·K) |

| The properties of natural air, silicone thermal conductive plates, liquid cooling plates, and walls are the same as in Table 1 | ||

| The Parameter | Value | Units |

|---|---|---|

| Water | ||

| Initial temperature | 25.0 | °C |

| Initial flow rate | 0.5 | m/s |

| Air | ||

| Initial temperature | 25.0 | °C |

| Initial velocity | 1.0 | m/s |

| Density | 1.225 | Kg/m3 |

| Specific heat | 1006 | J/(kg·K) |

| Thermal conductivity | 0.0242 | W/(m·K) |

| Kinematic viscosity | 1.789 × 10−5 | Kg/(m·s) |

| Changes in air conditions | ||

| Temperature/flow rate/convection coefficient * | 30/1/20.60 | °C; m/s; W/(m2·K) |

| Temperature/flow rate/convection coefficient * | 20/1/23.78 | °C; m/s; W/(m2·K) |

| Temperature/flow rate/convection coefficient * | 15/1/61.67 | °C; m/s; W/(m2·K) |

| Temperature/flow rate/convection coefficient * | 25/2/17.02 | °C; m/s; W/(m2·K) |

| Temperature/flow rate/convection coefficient * | 25/0.5/13.51 | °C; m/s; W/(m2·K) |

| The properties of silicone thermal conductive plates, liquid cooling plates, and walls are the same as in Table 1 | ||

| The Parameter | Value | Units |

|---|---|---|

| Battery | ||

| Nominal voltage | 3.20 | V |

| Nominal capacity | 50 | Ah |

| Standard cycle (at 25°) | 1500 (0.5 C) | |

| Internal resistance (1 KHz) | ≤2.0 | mΩ |

| Weight | 1035 ± 100 | g |

| Size (height × width × thickness) | 129.8 × 148.3 × 26.7 | mm × mm × mm |

| Distance between the adjacent battery cells | 1.5 | mm × mm × mm |

| Density | 2519 | Kg/m3 |

| Specific heat | 1022.8 | J/(kg·K) |

| Thermal conductivity (x-direction) | 1.062 | W/(m·K) |

| Thermal conductivity (y/z-direction) | 22.45 | W/(m·K) |

| Discharge | ||

| Discharge rate (C) | Total time steps | Time step size (s) |

| 0.5 | 3600 | 2 |

| 1.0 | 1800 | 2 |

| 2.0 | 900 | 2 |

| 3.0 | 600 | 2 |

| Discharge rate (C) | 0.5 | 1 | 2 | 3 |

| Volumetric heat source (W/m3) | 2486.1 | 9944.3 | 38,777.3 | 89,498.8 |

| Operation time (s) | 7200 | 3600 | 1800 | 1200 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Y.; Hu, Z. Computational Fluid Dynamic Modeling of Pack-Level Battery Thermal Management Systems in Electric Vehicles. Energies 2025, 18, 484. https://doi.org/10.3390/en18030484

Chen Y, Hu Z. Computational Fluid Dynamic Modeling of Pack-Level Battery Thermal Management Systems in Electric Vehicles. Energies. 2025; 18(3):484. https://doi.org/10.3390/en18030484

Chicago/Turabian StyleChen, Yifan, and Zhong Hu. 2025. "Computational Fluid Dynamic Modeling of Pack-Level Battery Thermal Management Systems in Electric Vehicles" Energies 18, no. 3: 484. https://doi.org/10.3390/en18030484

APA StyleChen, Y., & Hu, Z. (2025). Computational Fluid Dynamic Modeling of Pack-Level Battery Thermal Management Systems in Electric Vehicles. Energies, 18(3), 484. https://doi.org/10.3390/en18030484