Experimental Investigation of Heat Transfer Coefficients in a Plate Heat Exchange for an Organic Rankine Cycle

Abstract

1. Introduction

2. Materials and Methods

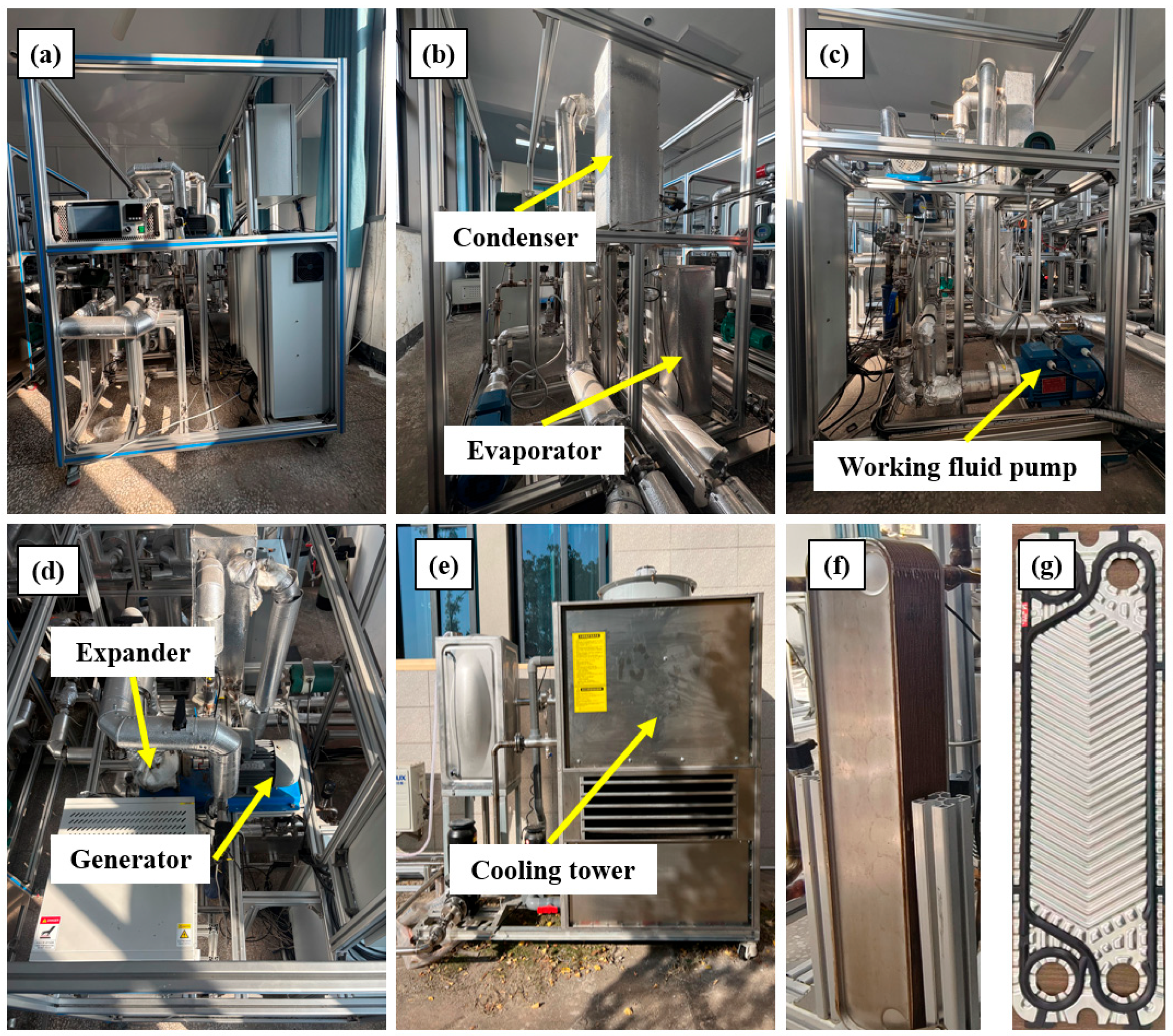

2.1. Experimental Apparatus

2.2. Data Reduction

2.3. Uncertainty Analysis

2.4. Review of Existing Heat Transfer Correlations

2.4.1. Amalfi Prediction Method

2.4.2. Han Prediction Method

2.4.3. Zheng Prediction Method

2.4.4. Hsieh Prediction Method

2.4.5. Longo Prediction Method

3. Results

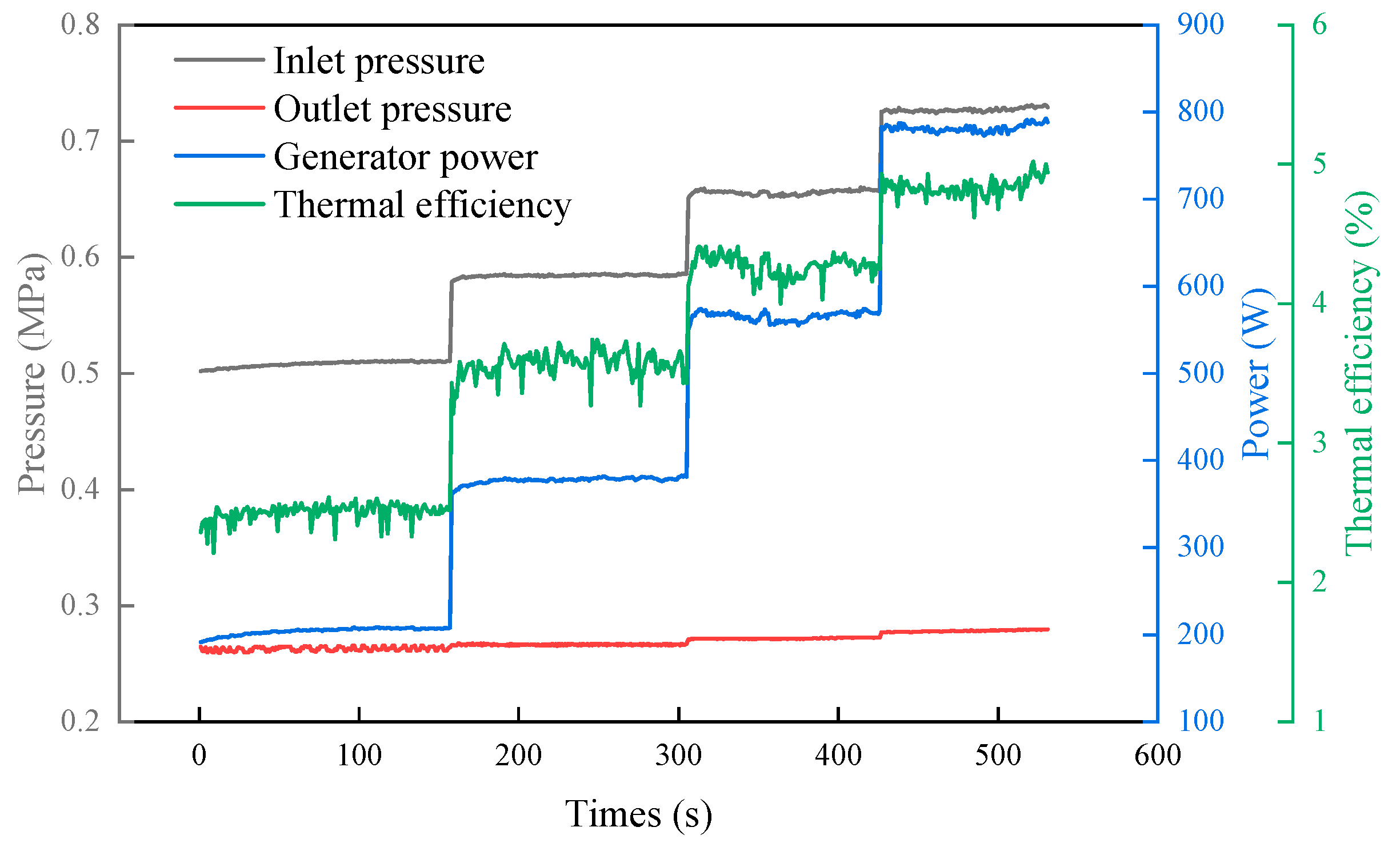

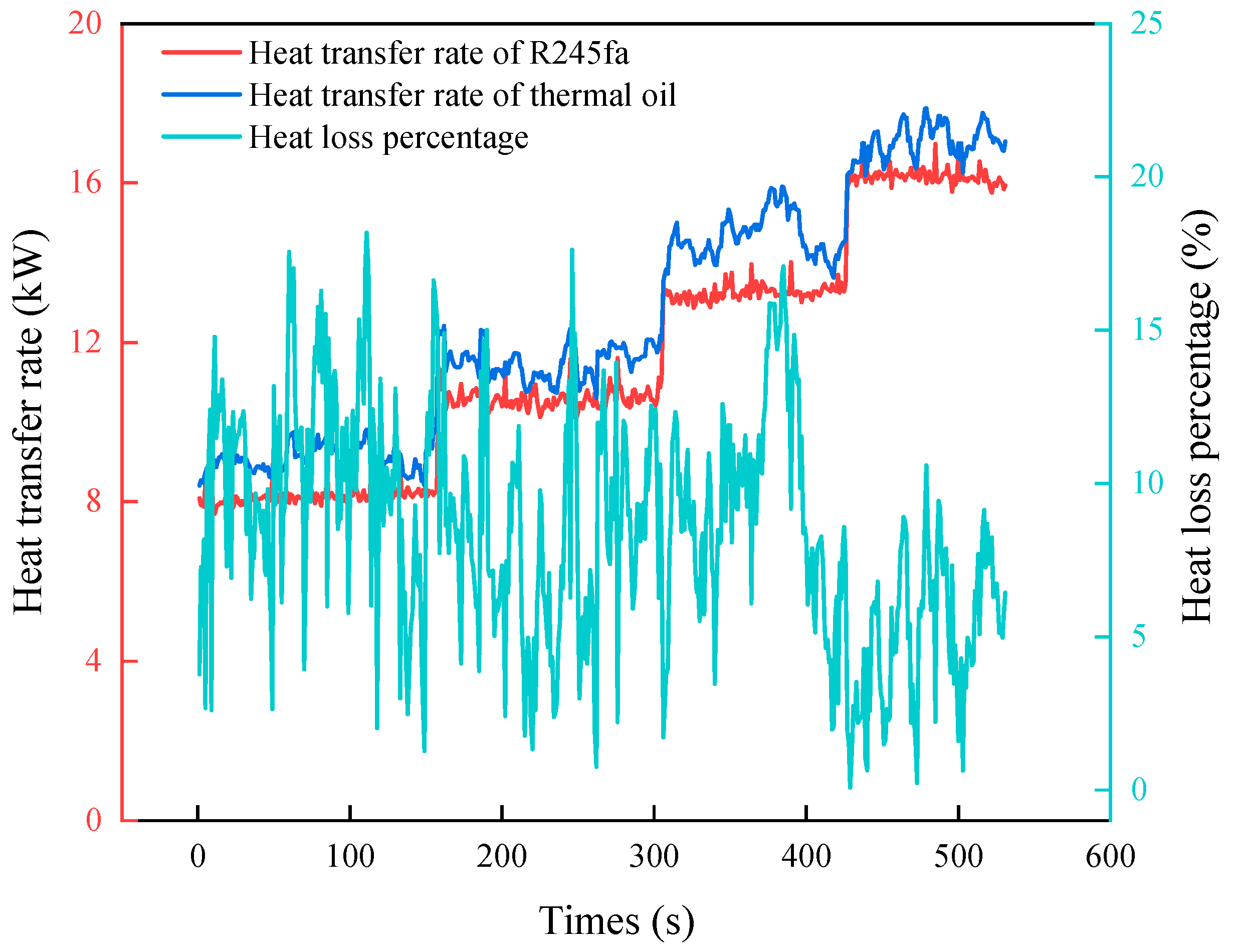

3.1. Steady-State Operation Test

3.2. Heat Source Temperature and Mass Flux Effects

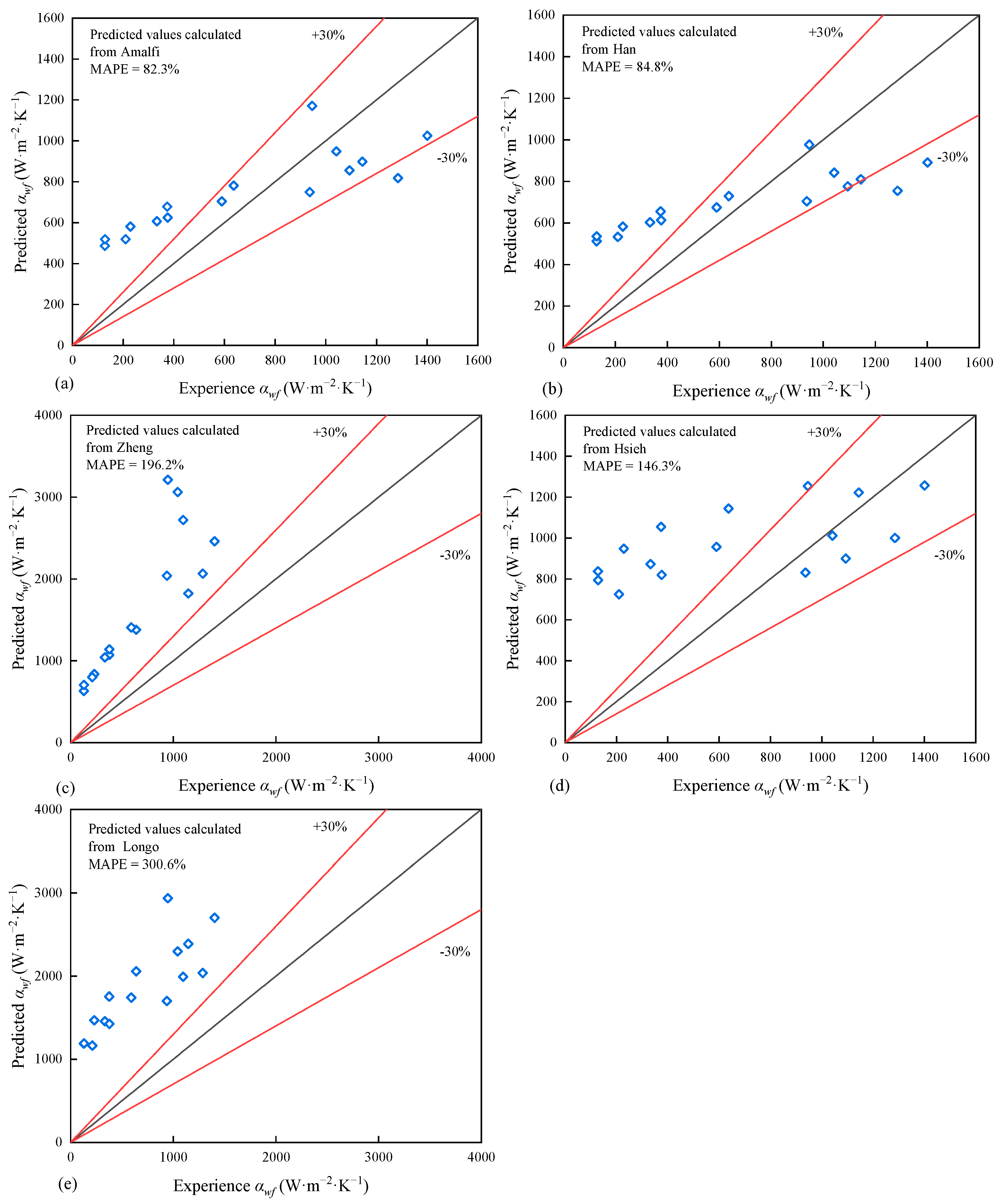

3.3. Evaluation of Prediction Methods

3.4. Development of a New Predictive Correlation

4. Conclusions

- (1)

- The heat flux exhibited only a slight increase with rising heat source temperature because the heat absorbed in the superheating region was relatively limited compared with that in the saturated two-phase region. In contrast, both generator power and thermal efficiency increased significantly with mass flux, primarily due to enhanced convection and greater refrigerant circulation through the subcooled and saturated two-phase regions. This enhancement promoted more efficient vaporization, resulting in higher vapor quality and enthalpy at the expander inlet, improving system performance.

- (2)

- Both the overall and refrigerant heat transfer coefficients increased with rising mass flux and heat source temperature, reaching peak values under moderate conditions. This trend is primarily attributed to intensified convective boiling and improved thermal coupling between the heat source and the refrigerant. With a further rise in mass flux, the heat transfer area demand increased within the subcooled and saturated two-phase regions, leading to insufficient energy exchange in the superheated region and consequently lowering the heat transfer coefficients.

- (3)

- The correlations proposed by Zheng, Longo, and Hsieh showed considerable discrepancies, particularly overestimating the heat transfer coefficient under nucleate boiling conditions. In contrast, the dimensionless correlations proposed by Amalfi and Han demonstrated higher predictive accuracy, although they tend to slightly overestimate at lower mass fluxes and underestimate at higher mass fluxes.

- (4)

- A unified predictive correlation, applicable to the subcooled boiling, saturated two-phase, and superheating regions, was developed using nondimensional analysis combined with multivariate regression. The resulting correlation yielded a mean absolute percentage error of 15.9%, demonstrating its ability to accurately capture the heat transfer characteristics across all regions of the evaporator. This correlation provides a reliable theoretical basis for performance prediction, and system optimization of evaporators of ORC systems.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| ORC | Organic Rankine cycle |

| PHE | Plate heat exchanger |

| HTC | Heat transfer coefficient |

| LMTD | Log mean temperature difference |

| Re | Reynolds number |

| Pr | Prandtl number |

| Bd | Bond number |

| Bo | Boiling number |

| Fr | Froude number |

| Ja | Jakob number |

| Nu | Nusselt number |

| MAPE | Mean absolute percentage error |

References

- Liu, G.; Ji, D.; Markides, C.N. Progress and prospects of low-grade thermal energy utilization technologies. Appl. Therm. Eng. 2024, 254, 123859. [Google Scholar] [CrossRef]

- Obiora, S.C.; Bamisile, O.; Hu, Y.; Ozsahin, D.U.; Adun, H. Assessing the decarbonization of electricity generation in major emitting countries by 2030 and 2050: Transition to a high share renewable energy mix. Heliyon 2024, 10, e28770. [Google Scholar] [CrossRef]

- Forman, C.; Muritala, I.K.; Pardemann, R.; Meyer, B. Estimating the global waste heat potential. Renew. Sustain. Energy Rev. 2016, 57, 1568–1579. [Google Scholar] [CrossRef]

- Oh, J.; Han, U.; Jung, Y.; Kang, Y.T.; Lee, H. Advancing waste heat potential assessment for net-zero emissions: A review of demand-based thermal energy systems. Renew. Sustain. Energy Rev. 2024, 202, 114693. [Google Scholar] [CrossRef]

- Lecompte, S.; Huisseune, H.; van den Broek, M.; Vanslambrouck, B.; De Paepe, M. Review of organic Rankine cycle (ORC) architectures for waste heat recovery. Renew. Sustain. Energy Rev. 2015, 47, 448–461. [Google Scholar] [CrossRef]

- Zhao, Y.; Liu, G.; Li, L.; Yang, Q.; Tang, B.; Liu, Y. Expansion devices for organic Rankine cycle (ORC) using in low temperature heat recovery: A review. Energy Convers. Manag. 2019, 199, 111944. [Google Scholar] [CrossRef]

- Shi, L.; Shu, G.; Tian, H.; Deng, S. A review of modified Organic Rankine cycles (ORCs) for internal combustion engine waste heat recovery (ICE-WHR). Renew. Sustain. Energy Rev. 2018, 92, 95–110. [Google Scholar] [CrossRef]

- Zhang, C.; Liu, C.; Wang, S.; Xu, X.; Li, Q. Thermo-economic comparison of subcritical organic Rankine cycle based on different heat exchanger configurations. Energy 2017, 123, 728–741. [Google Scholar] [CrossRef]

- Joy, J.; Chowdhury, K. Appropriate number of stages of an ORC driven by LNG cold energy to produce acceptable power with reasonable surface area of heat exchangers. Cryogenics 2022, 128, 103599. [Google Scholar] [CrossRef]

- Chen, Q.; Xu, J.; Chen, H. A new design method for Organic Rankine Cycles with constraint of inlet and outlet heat carrier fluid temperatures coupling with the heat source. Appl. Energy 2012, 98, 562–573. [Google Scholar] [CrossRef]

- Quoilin, S.; Broek, M.V.D.; Declaye, S.; Dewallef, P.; Lemort, V. Techno-economic survey of Organic Rankine Cycle (ORC) systems. Renew. Sustain. Energy Rev. 2013, 22, 168–186. [Google Scholar] [CrossRef]

- Nematollahi, O.; Abadi, G.B.; Kim, D.Y.; Kim, K.C. Experimental study of the effect of brazed compact metal-foam evaporator in an organic Rankine cycle performance: Toward a compact ORC. Energy Convers. Manag. 2018, 173, 37–45. [Google Scholar] [CrossRef]

- Lee, D.; Kim, D.; Yun, S.; Kim, Y. Two-phase flow patterns and pressure drop of a low GWP refrigerant R-1234ze(E) in a plate heat exchanger under adiabatic conditions. Int. J. Heat Mass Transf. 2019, 145, 118816. [Google Scholar] [CrossRef]

- Zheng, X.; Luo, X.; Luo, J.; Chen, J.; Liang, Y.; Yang, Z.; Chen, Y.; Wang, H. Experimental investigation of operation behavior of plate heat exchangers and their influences on organic Rankine cycle performance. Energy Convers. Manag. 2020, 207, 112528. [Google Scholar] [CrossRef]

- Luo, J.; Lu, P.; Chen, K.; Luo, X.; Chen, J.; Liang, Y.; Yang, Z.; Chen, Y. Experimental and simulation investigation on the heat exchangers in an ORC under various heat source/sink conditions. Energy 2023, 264, 126189. [Google Scholar] [CrossRef]

- Peris, B.; Navarro-Esbrí, J.; Mateu-Royo, C.; Mota-Babiloni, A.; Molés, F.; Gutiérrez-Trashorras, A.J.; Amat-Albuixech, M. Thermo-economic optimization of small-scale Organic Rankine Cycle: A case study for low-grade industrial waste heat recovery. Energy 2020, 213, 118898. [Google Scholar] [CrossRef]

- Zhang, J.; Hu, X.; Wu, D.; Huang, X.; Wang, X.; Yang, Y.; Wen, C. A comparative study on design and performance evaluation of Organic Rankine Cycle (ORC) under different two-phase heat transfer correlations. Appl. Energy 2023, 350, 121724. [Google Scholar] [CrossRef]

- Hsieh, Y.Y.; Chiang, L.J.; Lin, T.F. Subcooled flow boiling heat transfer of R-134a and the associated bubble characteristics in a vertical plate heat exchanger. Int. J. Heat Mass Transf. 2002, 45, 1791–1806. [Google Scholar] [CrossRef]

- Agostini, B.; Thome, J.R.; Fabbri, M.; Michel, B.; Calmi, D.; Kloter, U. High heat flux flow boiling in silicon multi-microchannels—Part II: Heat transfer characteristics of refrigerant R245fa. Int. J. Heat Mass Transf. 2008, 51, 5415–5425. [Google Scholar] [CrossRef]

- Imran, M.; Usman, M.; Yang, Y.; Park, B.-S. Flow boiling of R245fa in the brazed plate heat exchanger: Thermal and hydraulic performance assessment. Int. J. Heat Mass Transf. 2017, 110, 657–670. [Google Scholar] [CrossRef]

- Longo, G.A.; Mancin, S.; Righetti, G.; Zilio, C. A new model for refrigerant boiling inside Brazed Plate Heat Exchangers (BPHEs). Int. J. Heat Mass Transf. 2015, 91, 144–149. [Google Scholar] [CrossRef]

- Longo, G.A.; Mancin, S.; Righetti, G.; Zilio, C. Hydrocarbon refrigerants boiling local heat transfer coefficients inside a Brazed Plate Heat Exchanger (BPHE). Int. J. Refrig. 2023, 156, 113–122. [Google Scholar] [CrossRef]

- Huang, X.; Zhang, J.; Haglind, F. An experimental study of flow boiling heat transfer and pressure drop of hydrofluoroolefin and hydrocarbon mixtures in a plate heat exchanger. Int. J. Therm. Sci. 2025, 212, 109762. [Google Scholar] [CrossRef]

- Amaranatha Raju, M.; Ashok Babu, T.P.; Ranganayakulu, C. Investigation of flow boiling heat transfer and pressure drop of R134a in a rectangular channel with wavy fin. Int. J. Therm. Sci. 2020, 147, 106055. [Google Scholar] [CrossRef]

- Lao, W.-C.; Fang, Y.-D.; Chen, Q.-H.; Xu, L.-J.; Yang, H.-N.; Huang, Y.-Q. Experimental investigation on the flow boiling of R134a in a plate heat exchanger with mini-wavy corrugations. Int. J. Refrig. 2024, 162, 53–63. [Google Scholar] [CrossRef]

- Longo, G.A.; Mancin, S.; Righetti, G.; Zilio, C. Local heat transfer coefficients of R32 and R410A boiling inside a brazed plate heat exchanger (BPHE). Appl. Therm. Eng. 2022, 215, 118930. [Google Scholar] [CrossRef]

- Zhang, J.; Desideri, A.; Kærn, M.R.; Ommen, T.S.; Wronski, J.; Haglind, F. Flow boiling heat transfer and pressure drop characteristics of R134a, R1234yf and R1234ze in a plate heat exchanger for organic Rankine cycle units. Int. J. Heat Mass Transf. 2017, 108, 1787–1801. [Google Scholar] [CrossRef]

- Desideri, A.; Zhang, J.; Kærn, M.R.; Ommen, T.S.; Wronski, J.; Lemort, V.; Haglind, F. An experimental analysis of flow boiling and pressure drop in a brazed plate heat exchanger for organic Rankine cycle power systems. Int. J. Heat Mass Transf. 2017, 113, 6–21. [Google Scholar] [CrossRef]

- Zheng, X.; Zhang, J.; Kærn, M.R.; Kabelac, S.; Haglind, F. Experimental analysis of quasi-local non-equilibrium boiling heat transfer with the refrigerants R1234ze(E) and R1234yf in a gasketed plate heat exchanger. Int. J. Refrig. 2025, 170, 453–467. [Google Scholar] [CrossRef]

- Tsai, Y.-C.; Feng, Y.-Q.; Shuai, Y.; Lai, J.-H.; Leung, M.K.H.; Wei, Y.; Hsu, H.-Y.; Hung, T.-C. Experimental validation of a 0.3 kW ORC for the future purposes in the study of low-grade thermal to power conversion. Energy 2023, 285, 129422. [Google Scholar] [CrossRef]

- Lin, C.-H.; Hsu, P.-P.; He, Y.-L.; Shuai, Y.; Hung, T.-C.; Feng, Y.-Q.; Chang, Y.-H. Investigations on experimental performance and system behavior of 10 kW organic Rankine cycle using scroll-type expander for low-grade heat source. Energy 2019, 177, 94–105. [Google Scholar] [CrossRef]

- Galindo Noguera, A.L.; Mendoza Castellanos, L.S.; Pedraza-Corzo, H.D.; Rua, D.J.; Silva Lora, E.E.; Melian Cobas, V.R. Comprehensive methodology for the integrating of the organic rankine Cycle-ORC with diesel generators in off-grid areas: Application to a Colombian case study. Clean. Eng. Technol. 2024, 23, 100828. [Google Scholar] [CrossRef]

- Fatigati, F.; Coletta, A.; Di Bartolomeo, M.; Cipollone, R. The dynamic behaviour of ORC-based power units fed by exhaust gases of internal combustion engines in mobile applications. Appl. Therm. Eng. 2024, 240, 122215. [Google Scholar] [CrossRef]

- Martin, H. A theoretical approach to predict the performance of chevron-type plate heat exchangers. Chem. Eng. Process. Process Intensif. 1996, 35, 301–310. [Google Scholar] [CrossRef]

- Li, T.; Yuan, Z.; Li, W.; Yang, J.; Zhu, J. Strengthening mechanisms of two-stage evaporation strategy on system performance for organic Rankine cycle. Energy 2016, 101, 532–540. [Google Scholar] [CrossRef]

- Luo, X.; Huang, R.; Yang, Z.; Chen, J.; Chen, Y. Performance investigation of a novel zeotropic organic Rankine cycle coupling liquid separation condensation and multi-pressure evaporation. Energy Convers. Manag. 2018, 161, 112–127. [Google Scholar] [CrossRef]

- Moffat, R.J. Describing the uncertainties in experimental results. Exp. Therm. Fluid Sci. 1988, 1, 3–17. [Google Scholar] [CrossRef]

- Amalfi, R.L.; Vakili-Farahani, F.; Thome, J.R. Flow boiling and frictional pressure gradients in plate heat exchangers. Part 2: Comparison of literature methods to database and new prediction methods. Int. J. Refrig. 2016, 61, 185–203. [Google Scholar] [CrossRef]

- Han, D.-H.; Lee, K.-J.; Kim, Y.-H. Experiments on the characteristics of evaporation of R410A in brazed plate heat exchangers with different geometric configurations. Appl. Therm. Eng. 2003, 23, 1209–1225. [Google Scholar] [CrossRef]

- Gungor, K.E.; Winterton, R.H.S. A general correlation for flow boiling in tubes and annuli. Int. J. Heat Mass Transf. 1986, 29, 351–358. [Google Scholar] [CrossRef]

- Chen, J.C. Correlation for Boiling Heat Transfer to Saturated Fluids in Convective Flow. Ind. Eng. Chem. Process Des. Dev. 1966, 5, 322–329. [Google Scholar] [CrossRef]

- Dittus, F.W.; Boelter, L.M.K. Heat transfer in automobile radiators of the tubular type. Int. Commun. Heat Mass Transf. 1985, 12, 3–22. [Google Scholar] [CrossRef]

- Cooper, M.G. Saturation Nucleate Pool Boiling—A Simple Correlation. In First U.K. National Conference on Heat Transfer; Simpson, H.C., Hewitt, G.F., Boland, D., Bott, T.R., Furber, B.N., Hall, W.B., Heggs, P.J., Rowe, P.N., Saunders, E.A.D., Spalding, D.B., Eds.; Pergamon: Oxford, UK, 1984; pp. 785–793. [Google Scholar]

- Zhang, J.; Haglind, F. Experimental analysis of high temperature flow boiling heat transfer and pressure drop in a plate heat exchanger. Appl. Therm. Eng. 2021, 196, 117269. [Google Scholar] [CrossRef]

- Zhang, Y.-F.; Li, M.-J.; Ren, X.; Duan, X.-Y.; Wu, C.-J.; Xi, H.; Feng, Y.-Q.; Gong, L.; Hung, T.-C. Effect of heat source supplies on system behaviors of ORCs with different capacities: An experimental comparison between the 3 kW and 10 kW unit. Energy 2022, 254, 124267. [Google Scholar] [CrossRef]

- Thonon, B.; Vidil, R.; Marvillet, C. Recent Research and Developments in Plate Heat Exchangers. J. Enhanc. Heat Transf. 1995, 2, 149–155. [Google Scholar] [CrossRef]

| Type | Measurement Range | Device Uncertainty | |

|---|---|---|---|

| Temperature | K-type | 0–200 °C | ±0.5% |

| Pressure | Diffused silicon | 0–1 MPa | ±0.5% |

| R245fa flow rate | Coriolis | 0–2250 kg/h | ±0.2% |

| Thermal oil flow rate | Vortex | 2–6 m3/h | ±1% |

| Condensation flow rate | Electromagnetic | 0.3–14 m3/h | ±0.5% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Y.; Wen, C.; Zhang, J.; Sakai, H. Experimental Investigation of Heat Transfer Coefficients in a Plate Heat Exchange for an Organic Rankine Cycle. Energies 2025, 18, 6573. https://doi.org/10.3390/en18246573

Chen Y, Wen C, Zhang J, Sakai H. Experimental Investigation of Heat Transfer Coefficients in a Plate Heat Exchange for an Organic Rankine Cycle. Energies. 2025; 18(24):6573. https://doi.org/10.3390/en18246573

Chicago/Turabian StyleChen, Yanqi, Chuang Wen, Ji Zhang, and Hideyuki Sakai. 2025. "Experimental Investigation of Heat Transfer Coefficients in a Plate Heat Exchange for an Organic Rankine Cycle" Energies 18, no. 24: 6573. https://doi.org/10.3390/en18246573

APA StyleChen, Y., Wen, C., Zhang, J., & Sakai, H. (2025). Experimental Investigation of Heat Transfer Coefficients in a Plate Heat Exchange for an Organic Rankine Cycle. Energies, 18(24), 6573. https://doi.org/10.3390/en18246573