3.4.1. Technical Characteristics

The comparison of HAWT and VAWT in the technical characteristic category is shown in

Table 3 and explained in more detail in this subchapter.

The efficiency coefficient measures the overall efficiency of a turbine in converting wind energy into electrical energy. In contrast, the Cp coefficient represents the ratio of actual power extracted to the theoretical maximum power available in the wind. The efficiency coefficient includes all losses (mechanical, electrical), whereas Cp focuses on aerodynamic efficiency [

35,

36].

HAWTs generally have a higher efficiency coefficient than VAWTs, often exceeding VAWT efficiency by approximately 25% under similar conditions [

40]. Due to design limitations, VAWTs tend to have lower Cp [

41].

HAWTs typically have a more complex design and installation process. The main components, including the generator, gearbox, and rotor, are housed in a nacelle at the top of a tall tower. This configuration requires the installation of specialized equipment, such as cranes, especially for larger turbines. HAWTs require a yaw mechanism to maintain the rotor’s orientation in the wind direction, which adds to their complexity. The installation process often involves more time and resources due to the height and weight of components [

37].

In the case of VAWTs, the generator and key components are located at ground level, enabling installation without the need for cranes. A simpler design, omnidirectional operation, and lower height reduce installation complexity, making VAWTs particularly suitable for urban or confined spaces with turbulent or shifting wind conditions [

36]. VAWTs can capture wind from any direction without requiring yaw mechanisms, which reduces mechanical complexity and minimizes the need for operational adjustments [

36,

38].

Utility-scale projects (1–26 MW turbines) dominate in the case of HAWTs due to higher efficiency and proven technology. The trend is a continuous increase in rotor diameter, which expands the swept area, enabling greater energy capture [

33]. China’s most extensive offshore HAWT, with a 26 MW capacity, a rotor diameter of approximately 310 m, and a tower height of around 185 m, is being built [

39].

VAWTs are associated with limited scalability, as most designs are under 100 m in height, with smaller rotor diameters (~50 m), resulting in typical power ratings of 1–10 MW. However, innovations like coaxial counter-rotating systems and MagLev bearings aim to enhance their capacity [

4,

36,

38].

CFD-based optimization studies have demonstrated that hybrid VAWT designs, which combine lift- and drag-based rotors, can extend the operational range and improve scalability [

42]. Recent research shows that VAWTs have potential for scalability in grid-connected systems, especially in hybrid configurations incorporating solar PV and energy storage [

43,

44]. Research from Pagnini et al. showed that VAWTs have potential for small-scale distributed generation and can attract attention for both standalone and grid-connected configurations, supporting their scalability for local grids and integration with the broader electricity network [

45].

VAWTs perform better in turbulent or variable wind conditions. Operational speeds range from 2 to 20 m/s [

4]. HAWTs require more stable wind conditions for optimal performance (3–4 m/s), with “cut-out” being app. 25 m/s [

35].

The management of VAWT is easier as it captures wind from any direction without adjustment [

4]. HAWT requires active yaw mechanisms for alignment with the wind direction, which increases operational complexity [

35].

The lifespan of VAWT is typically 15–20 years, though advancements in materials and design are extending the lifespan [

4]. HAWT is proven technology with a typical lifespan of 20–25 years [

35].

VAWTs have a lower capacity factor (~20–35%), limited by lower efficiency in converting wind energy into electricity. One disadvantage of VAWT is that they must be installed close to the ground. Since the wind blows at a higher speed and evenly at greater heights, an installation not on a mast loses lots of efficiency [

4]. HAWTs have higher capacity factor (~30–45%), depending on location and wind conditions [

35].

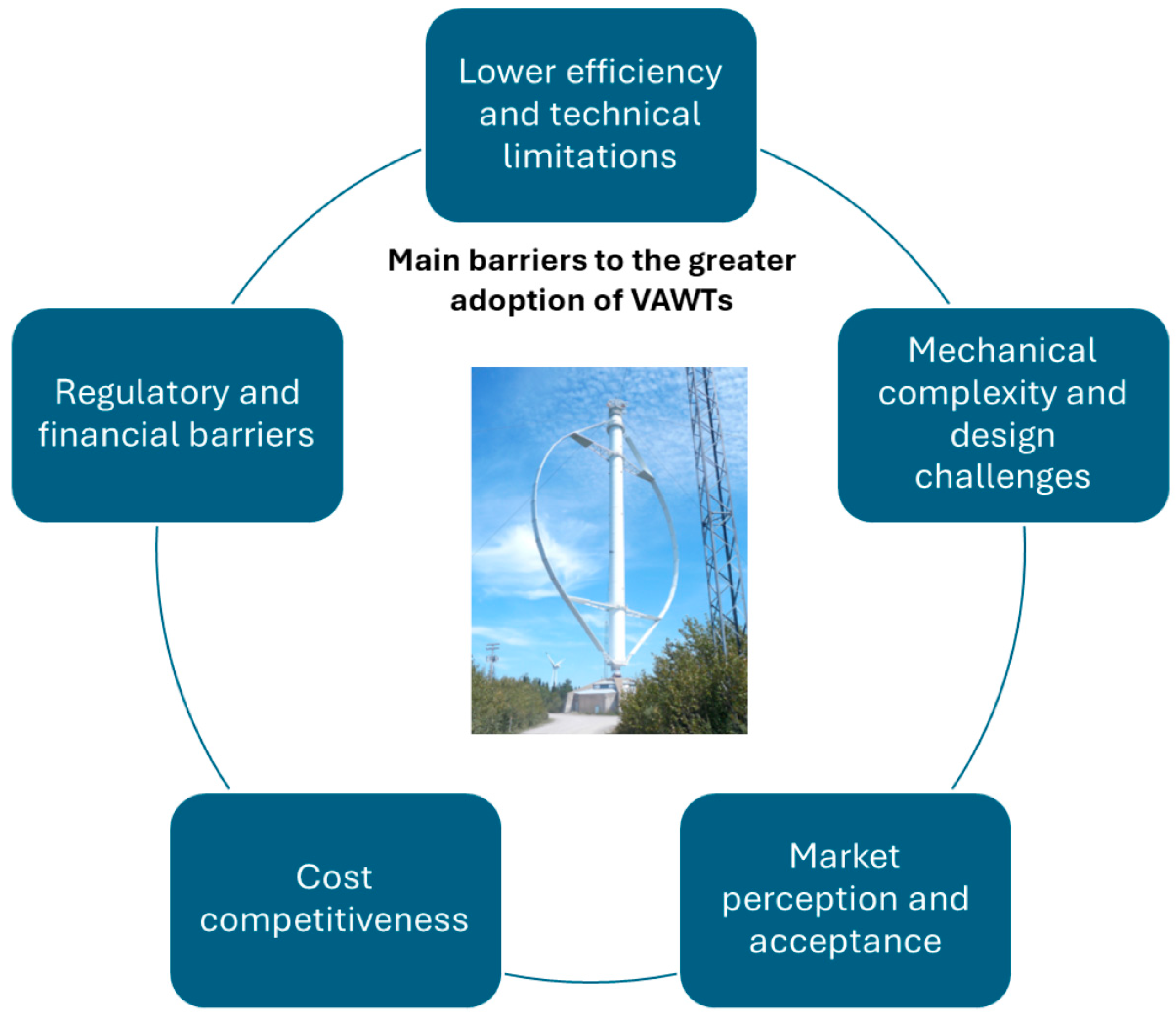

VAWTs have limited potential for significant improvements. Technology improvements are associated with the development of magnetic bearings, modular systems, and contra-rotating rotors [

6]. For HAWTs, continuous advancements in materials and design are being undertaken. Optimization through AI and smart grid integration is also one of the potentials for technology improvement [

6,

33].

3.4.2. Economic Characteristics

The comparison of HAWTs and VAWTs in the economic characteristic category is shown in

Table 4 and explained in more detail in this subchapter.

VAWTs generally require a higher material mass per swept area unit than HAWTs. For example, large Darrieus VAWTs exhibit a specific mass (kg/m

2) up to 10 times higher than equivalent HAWTs due to structural reinforcements needed to handle cyclic loads and blade fatigue [

47].

The varied designs of VAWTs (e.g., Savonius, Darrieus, helical) demand specialized fabrication for components like curved blades and magnetic levitation (MAGLEV) systems, increasing labor costs. For instance, MAGLEV VAWTs require precision aligning neodymium magnets and custom rotor brackets, often necessitating advanced 3D printing or CNC machining [

32,

48]. Lack of standardized components (e.g., blade profiles, support arms) further complicates mass production, unlike HAWTs, which benefit from aviation-derived modular designs [

47,

48]. HAWTs use lightweight composite materials (e.g., carbon fiber) optimized for lift-driven blades, reducing mass and material costs per MW capacity [

47]. Standardized three-blade designs and automated manufacturing processes lower labor costs (economies of scale). HAWT blade production leverages established aerospace techniques, enabling cost-effective mass production [

4,

48].

VAWTs incur 15–25% higher initial rotor costs due to material mass and fabrication complexity, but savings in drivetrain and maintenance costs partially offset this. VAWTs often require larger foundations due to ground-level generator placement, increasing installation costs in soft soils or urban settings. However, their compact design allows installation in constrained spaces (e.g., rooftops), reducing land use expenses [

48]. HAWTs require tall towers (up to 150+ m offshore) and active yaw systems to align with wind direction, increasing material and labor expenses. Offshore installations face additional challenges like marine infrastructure and crane logistics [

4,

47]. Large-scale HAWT farms need extensive electrical infrastructure, whereas VAWTs can integrate into decentralized urban grids with lower upfront costs.

HAWT requires frequent maintenance of components mounted atop tall towers, necessitating specialized equipment and safety protocols, increasing operational complexity [

38]. On the other hand VAWT requires lower maintenance costs (20–30%) as most components are ground-level, simplifying access and repair work [

4]. VAWTs house critical components like generators and gearboxes near the base, reducing downtime and making maintenance easier. This design eliminates the need for climbing tall towers, a significant operational advantage in urban or remote settings [

38]. Many VAWTs use direct-drive systems (e.g., magnetic levitation bearings), which reduce mechanical wear and maintenance frequency compared to HAWTs’ complex gearboxes [

38,

46].

3.4.3. Environmental and Human Impact

The comparison of HAWT and VAWT in land occupancy, bird/wildlife impact and human impact is shown in

Table 5 and explained in detail below.

HAWTs require large spacing (typically 5–10 rotor diameters apart) to minimize wake interference, which reduces turbulence and efficiency losses between turbines. In general, the total area of a wind farm includes the perimeter surrounding all the turbines, consisting of the direct impact area, the undisturbed land between turbines, and the buffer zone for residential buildings [

1]. It is important to note that wind farm turbines can be arranged in different layouts, such as long rows, several irregular rows, parallel rows, or separate power plants. Each configuration results in land occupancy per installed MW of turbine capacity [

1].

VAWTs can be clustered more densely (3–4 rotor diameters apart) due to omnidirectional operation and reduced wake effects, enabling higher energy density per unit area [

36,

49]. VAWTs are particularly suitable for constrained spaces (e.g., urban rooftops and mountainous terrain) where land availability is limited [

36].

Large HAWT farms fragment habitats and displace wildlife, and their placement in migratory bird corridors leads to significant risks—especially for raptors and other sensitive species [

51,

52]. Empirical research, including a study in Karnataka, India, found an annual animal fatality rate of 0.26 per turbine, with raptor declines linked to cascading ecosystem impacts, such as increased prey populations [

48,

50,

53].

VAWTs, by contrast, can be installed in urban and agricultural zones with minimal land disruption, and their lower height and slower blade speeds generally reduce avian and wildlife collisions. Studies by Roy et al. and Thaxter et al. have shown that when VAWTs are deployed in dispersed clusters and outside migration corridors, they pose a lower risk to birds and wildlife. Nonetheless, no wind turbine is impact-free; effective siting, selective curtailment, and local risk assessment remain essential for both VAWT and HAWT projects. VAWTs typically offer reduced bird collision and disturbance rates, but these benefits are context-dependent and require ongoing ecological monitoring. [

51,

52].

VAWTs, when deployed in smaller, more dispersed clusters, show reduced collision rates per unit energy produced and lower aggregate wildlife disturbance. Research from Roy et al. indicates that, while overall infrastructure-related bird mortality can be significant, VAWTs—due to their lower height, slower blade speeds, and flexibility in siting—can be placed in urban/agricultural areas, as well as outside major migration corridors, further mitigating the risk [

52].

However, it is essential to note that no wind energy technology is entirely free from impacts on wildlife. The literature suggests site-specific risk assessments and best-practice mitigation—such as selective curtailment during peak migration and informed siting—remain necessary for both HAWT and VAWT projects. Claims of reduced impact must always be contextualized: VAWTs generally exhibit lower bird collision rates and ecosystem disturbance across a range of installations, but local effects depend on turbine density, landscape, and species composition. Monitoring programs, adaptive management, and further ecological research are needed to validate these benefits under diverse regional conditions [

51].

VAWTs operate at lower rotational speeds (~60 rpm vs. HAWTs at 10–20 rpm, but with higher tip speeds), reducing aerodynamic noise and making them preferable for noise-sensitive areas [

54,

55]. VAWTs produce lower noise at low-to-moderate wind speeds (5–8 m/s). For example, a 200 kW VAWT emits ~94.1 dBA at 6 m/s, compared to HAWTs of similar capacity (~96.7–100.2 dBA) [

56]. HAWTs generate higher noise due to blade-tip vortices and mechanical components. Larger HAWTs (>1 MW) generate >100 dBA at rated wind speeds [

56]. The installation of wind turbines can affect house prices in the vicinity, causing potential loss of revenue. Research by Dröes and Koster [

57] showed that constructing a wind turbine leads to a 1.8% decrease in local house prices. A turbine taller than 150 m decreases prices within 2 km by 5.4%, while the effect of small turbines (<50 m) is statistically insignificant. Also, the impact of tall wind turbines does not extend significantly beyond 2 km. Wind farms should be placed carefully, as the total loss in housing wealth can increase if turbines are built too close to residential properties [

57].

Although wind turbines are recognized as a clean and renewable source of electricity generation, the challenges of the energy required for manufacturing and their environmental impact remain. Wind turbines do not produce emissions during their operational stages; however, emissions are generated during manufacturing, transportation, and disposal [

58]. Life cycle analysis (LCA) is a method that quantifies the energy use, emissions, and environmental impacts of a product, system, or process throughout its life cycle stages, encompassing the extraction of materials, transportation, manufacture, installation, and disposal, as well as recycling [

58].

Martínez et al. conducted an LCA study of a 2 MW wind turbine. The results showed that the manufacturing process of wind turbine components is the greatest contributor to environmental impact [

59]. Tremeac and Menuier compared a 4.5 MW and 250 W wind turbines and conducted a sensitivity analysis. The results showed that energy use primarily occurs at the manufacturing stage, accounting for 75% for the 4.5 MW wind turbine and 96% for the 250 W wind turbine, respectively [

60]. Similarly, the results of the LCA performed on a large-scale (400 MW) offshore wind farm with large wind turbine units (5 MW) in China showed that manufacturing contributes the most to the environmental impact, which is in accordance with the results published in other studies [

61,

62,

63].

Rashedi et al. conducted an LCA of three types of 50 MW wind farms: onshore-HAWT, offshore-HAWT, and VAWT. The results showed that VAWT generated the lowest impact per unit of electricity, followed by offshore-HAWT and onshore-HAWT. The impact of onshore- and offshore-HAWT on human health was 1.72 and 1.54 times higher compared to the onshore VAWT farm. Similarly, ecosystem quality onshore and offshore values were 1.27 and 1.14 times higher compared to VAWT, with a similar trend observed in the resources category. The results showed that offshore HAWT exhibits higher impact values than onshore HAWT [

64].

On the other hand, the capacity factor of offshore HAWT is almost 50% higher than that of onshore HAWT per unit electricity profile, making it more eco-friendly and cost-effective than onshore HAWT [

64]. Uddin and Kumar performed an LCA of VAWT and HAWT for three potential applications in Thailand, analyzing the life cycle embodied energy, emissions (air and water), environmental impacts, energy payback time, and performance indexes. Research has shown that VAWT is more energy- and emission-intensive compared to HAWT for base case system design. The environmental impact could be reduced using thermoplastics or fiberglass turbines, with an average reduction in more than 15% [

58]. The findings are supported by recent research from Cao et al., which emphasizes that the capacity factor significantly influences the environmental performance of offshore wind plants, followed by the importance of site selection and maintenance of offshore wind farms. Results from scenario-based dynamic modeling suggest that selecting glass fiber-reinforced plastic and carbon fiber-reinforced plastic as materials could significantly reduce global warming potential and other environmental impacts [

63].

LCA is an instrument for assessing environmental performance and decision support; however, it only considers environmental impact. Sustainability assessment also includes social and economic performance. In decision-making, different considerations play important roles, and products or activities should be economically viable, environmentally benign, and socially just to be qualified as the most sustainable [

65]. Talluri et al. [

66] conducted a techno-economic and environmental analysis of installing two VAWT on the deck of a ship in conjunction with conventional power plants. The results showed that the installation of the WAVT is still not profitable for all the routes, given the current policy and fuel prices. The environmental gain is significant, but considering the economic features, it is still not recommended for routes that do not experience strong wind conditions. Results showed that the installation of the VAWT could be advantageous when carried out on vessels that travel the Atlantic Ocean [

66]. Recently, Ramalho et al. [

67] researched the externalities associated with wind energy. Even though the environmental advantages are significant, the wind turbines may alter the environment, create noise pollution, cast shadows, and cause flashing. The negative effects are felt mainly by inhabitants living closer to the wind turbines [

57,

67,

68].

Kouloumpis et al. [

69] investigated developing a smaller-scale VAWT to mitigate climate change. The results showed that most impacts are accredited to the supporting infrastructure, especially the mast and the foundations. The turbine itself accounted for only 30% of the global warming potential impact category. The results showed that environmental performance is susceptible to the fluctuations of the capacity factor.

Key aspects of wind turbine implementation, that should be considered for the reduction in life cycle environmental impact are shown in

Table 6.

Recycling can be challenging as wind turbine blades are made from composite materials. In line with circular economy approaches, new circular value chains must be designed, and cutting and sectioning operations should be integrated into the value chain. Lund et al. [

71] applied multicriteria decision-making methodologies (MCDM) for sustainable decision-making to assess different technologies for the sectioning of wind turbines. The study identified that an excavator with a diamond saw blade is the preferred technology for sectioning wind turbine waste for later transportation and processing. Paulsen and Enevoldsen identified recycling through co-processing to produce cement as the most suitable method for handling end-of-life (EoL) wind turbine blades based on the current technology readiness level (TRL) of the various recycling methods [

72]. Recently, Xu et al. [

70] identified pyrolysis and chemical solvolysis as promising recycling methods for waste wind turbine blades to recover glass fibers for further use as reinforcing materials for structural components.

For all turbine types, the choice of recycling method (mechanical, co-processing for cement, pyrolysis, or chemical solvolysis) influences total life cycle emissions and waste management challenges. Moreover, LCA results are sensitive to the capacity factor, site selection, and maintenance frequency, which vary with turbine design and installation environment. Recent dynamic modeling indicates that optimizing glass or carbon fiber composites, in conjunction with operational and maintenance protocols, can reduce the global warming potential for both onshore and offshore wind farms. Continued improvements in blade design, material innovation, and recycling are essential for optimizing life cycle sustainability of both VAWTs and HAWTs. An integrated approach addressing technical, economic, and circularity aspects can significantly improve the long-term environmental profile of vertical-axis wind technologies.

Operational safety is assessed through several factors, shown in

Table 7.

VAWTSs are characterized by lower rotational inertia, and proximity to the ground reduces the risk of catastrophic blade failure. However, composite materials like carbon fiber-reinforced polymer (CFRP) significantly lower stress (150 MPa vs. 215 MPa in structural steel) and fatigue damage (0.12 fatigue ratio vs. 0.21 in steel), enhancing blade durability [

73,

74]. Dynamic stall effects and turbulent wind conditions near the ground can increase cyclic loads, accumulating fatigue over time. Structural optimizations mitigate these risks by improving stress distribution uniformity (88% in optimized designs) [

74,

76]. Larger HAWT blades (up to 100+ m) experience higher centrifugal forces and bending stresses, increasing the likelihood of blade fractures or delamination [

1]. Blade failures in HAWTs can spread debris over large areas due to their height [

38]. Advanced materials and pitch-control systems reduce risks, but blade failures remain a critical safety concern, especially in high-wind conditions [

38,

73].

VAWTs’ lower tip speeds (typically 15–30 m/s) reduce the distance ice or debris can be thrown. Their vertical design also limits ice accumulation on blades in turbulent urban or marine environments [

73]. HAWTs’ high tip speeds (60–90 m/s) can propel ice fragments over 300 m, posing risks to nearby infrastructure and personnel. Ice detection systems and de-icing technologies are mandatory for HAWTs in cold climates [

38,

73].

VAWTs’ lower center of gravity and compact designs (e.g., monopile foundations) improve resistance to overturning. Structural simulations show monopiles reduce deflection by 30% compared to piled foundations under dynamic loads [

74]. Offshore VAWTs benefit from reduced wave-induced stresses, with fatigue damage ratios 20% lower than HAWTs in marine environments [

74]. HAWTs’ taller towers (80–150 m) are more susceptible to extreme wind gusts and foundation instability. Offshore HAWTs require complex floating platforms, increasing overturning risks in rough seas [

38,

73]. It can be concluded that HAWTs dominate in efficiency and capacity, but VAWTs offer advantages in urban areas [

75].