Water–Energy Co-Production by Coupling Photothermal Membrane Distillation with Thermal-Osmotic Energy Conversion

Abstract

1. Introduction

2. Experimental Procedure

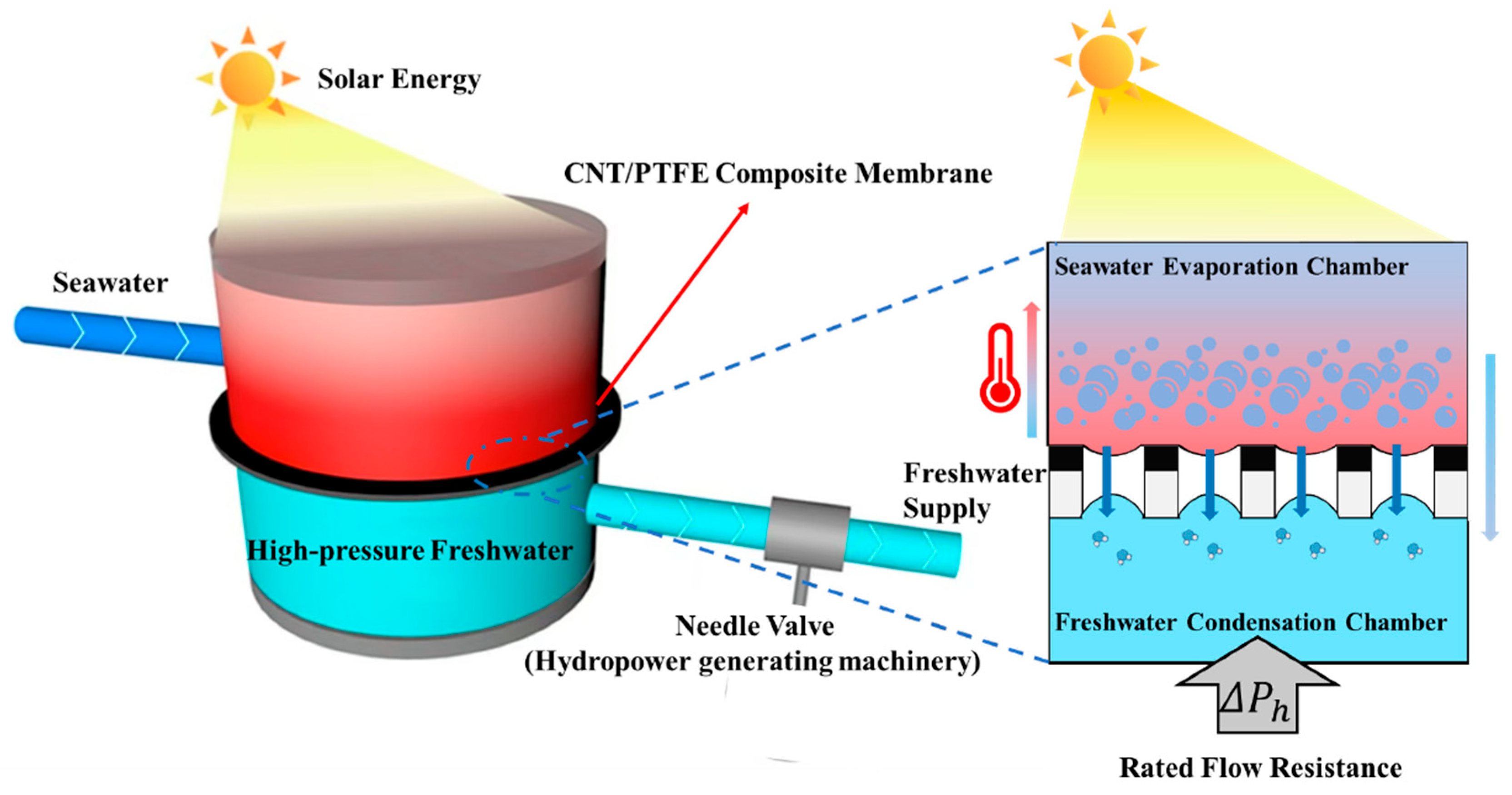

2.1. Design Concept

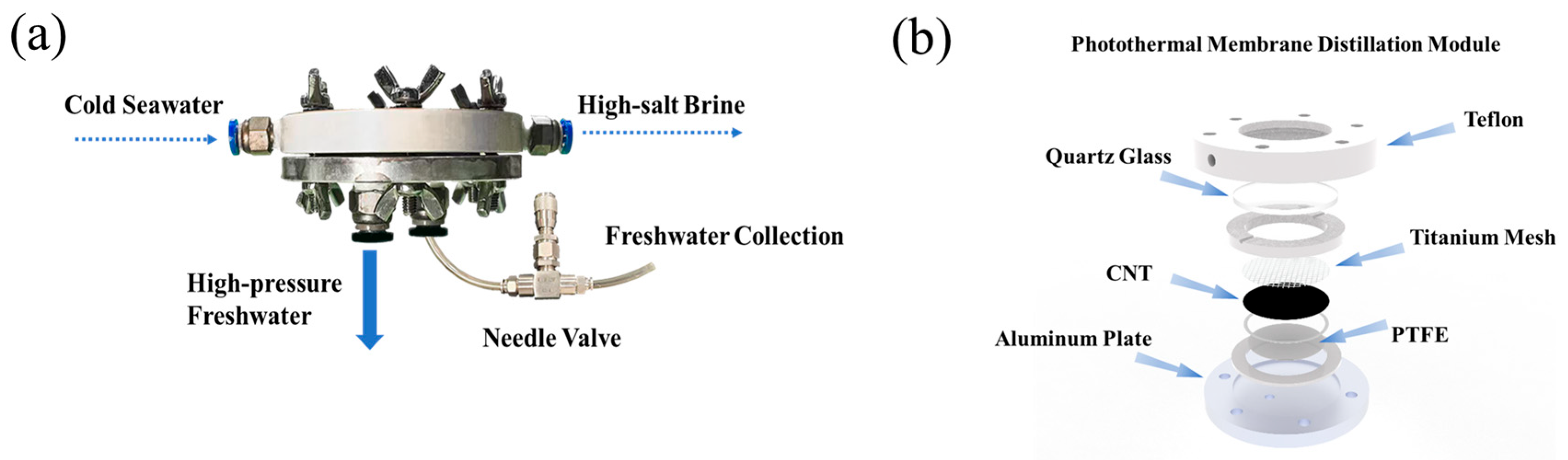

2.2. Experimental Device Construction and Testing

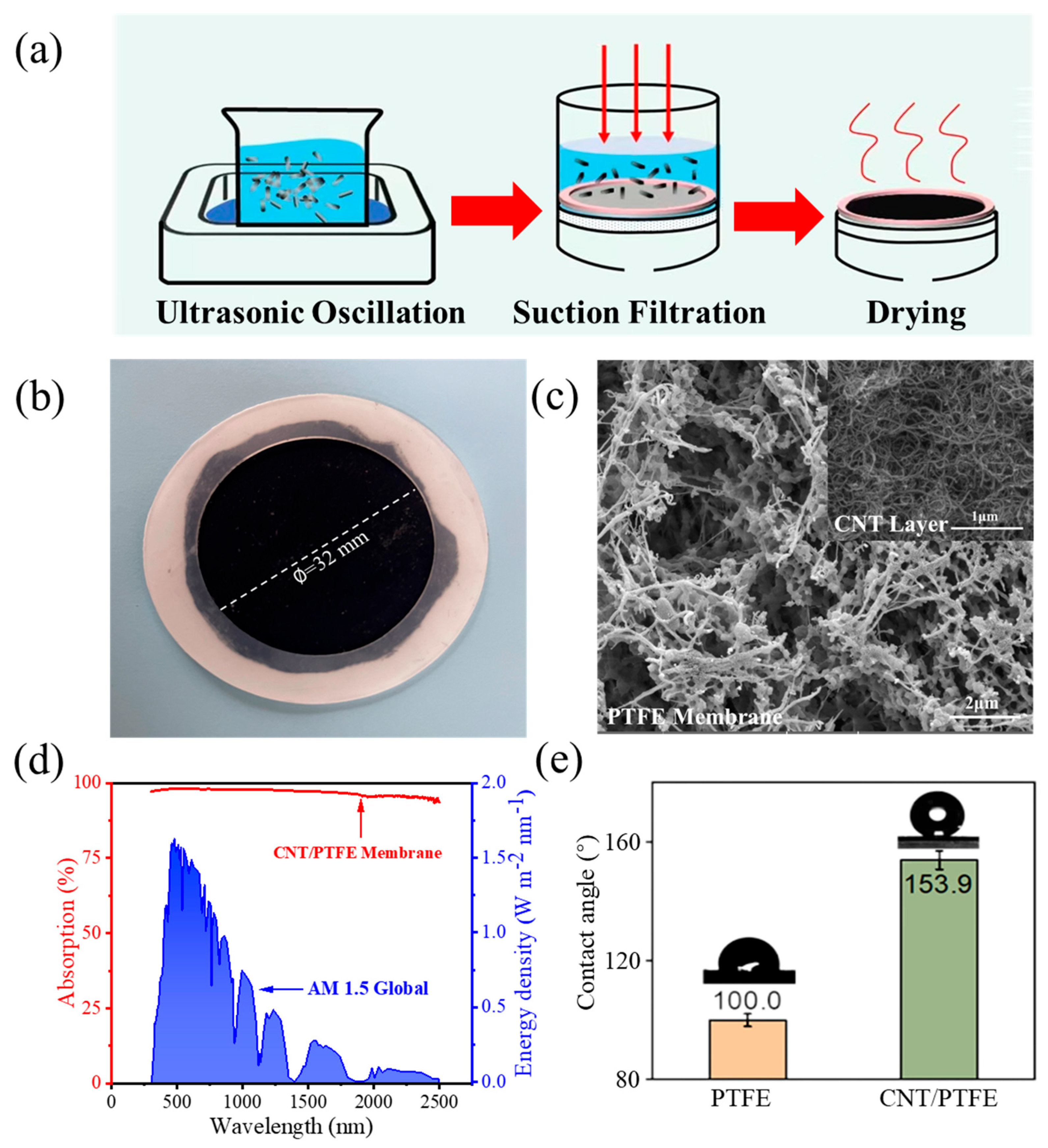

2.3. Preparation and Characterization of Experimental Materials

3. Results and Discussion

3.1. Experimental Results and Performance Evaluation

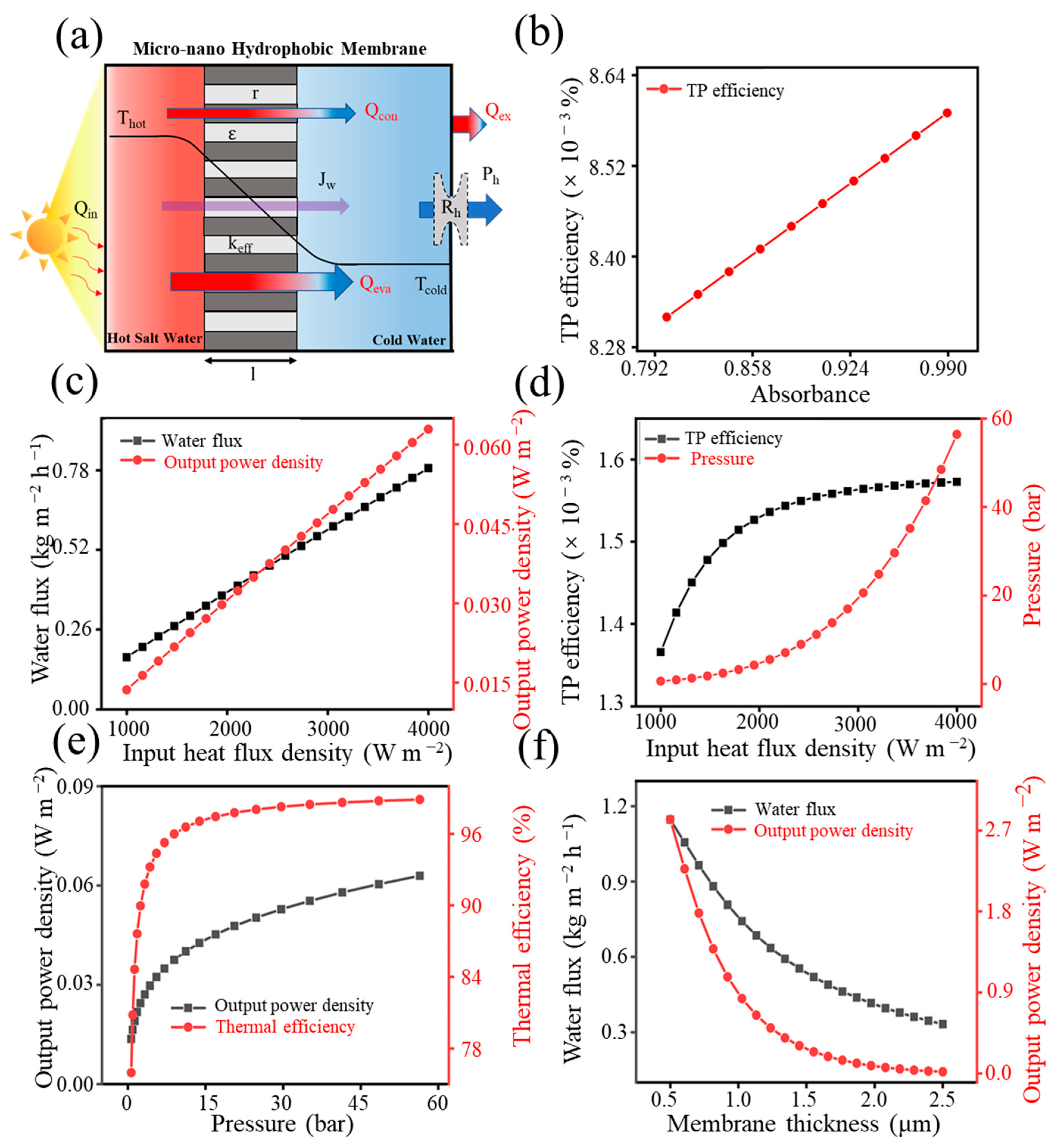

3.2. Analysis of Theoretical Calculation Results

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, H.; Ma, J.; Chen, H.; Hong, W.; Lan, J.; Chang, Y.; Zhang, H.; Zhang, L.; Niu, X.; Li, Y.; et al. Interfacial photothermal membrane distillation for direct solar water production. Adv. Funct. Mater. 2025, e15845. [Google Scholar] [CrossRef]

- Huang, J.; Zheng, H.; Kong, H. Key pathways for efficient solar thermal desalination. Energy Convers. Manag. 2024, 299, 117806. [Google Scholar] [CrossRef]

- Shannon, M.A.; Bohn, P.W.; Elimelech, M.; Georgiadis, J.G.; Mariñas, B.J.; Mayes, A.M. Science and technology for water purification in the coming decades. Nature 2008, 452, 301–310. [Google Scholar] [CrossRef]

- Al-Othman, A.; Darwish, N.N.; Qasim, M.; Tawalbeh, M.; Darwish, N.A.; Hilal, N. Nuclear desalination: A state-of-the-art review. Desalination 2019, 457, 39–61. [Google Scholar] [CrossRef]

- Ghazi, Z.M.; Rizvi, S.W.F.; Shahid, W.M.; Abdulhameed, A.M.; Saleem, H.; Zaidi, S.J. An overview of water desalination systems integrated with renewable energy sources. Desalination 2022, 542, 116063. [Google Scholar] [CrossRef]

- Zhao, Y.; Li, M.; Long, R.; Liu, Z.; Liu, W. Review of osmotic heat engines for low-grade heat harvesting. Desalination 2022, 527, 115571. [Google Scholar] [CrossRef]

- Long, R.; Zhao, Y.; Li, M.; Pan, Y.; Liu, Z.; Liu, W. Evaluations of adsorbents and salt-methanol solutions for low-grade heat driven osmotic heat engines. Energy 2021, 229, 120798. [Google Scholar] [CrossRef]

- Zhao, Y.; Li, M.; Long, R.; Liu, Z.; Liu, W. Dynamic modeling and analysis of an advanced adsorption-based osmotic heat engines to harvest solar energy. Renew. Energy 2021, 175, 638–649. [Google Scholar] [CrossRef]

- Kalogirou, S.A. Seawater desalination using renewable energy sources. Prog. Energy Combust. Sci. 2005, 31, 242–281. [Google Scholar] [CrossRef]

- Ginsberg, M.; Zhang, Z.; Atia, A.A.; Venkatraman, M.; Esposito, D.V.; Fthenakis, V.M. Integrating solar energy, desalination, and electrolysis. Sol. RRL 2022, 6, 2100732. [Google Scholar] [CrossRef]

- Elbarbary, S.; Zaher, M.A.; Saibi, H.; Fowler, A.-R.; Saibi, K. Geothermal renewable energy prospects of the African continent using GIS. Geotherm. Energy 2022, 10, 8. [Google Scholar] [CrossRef]

- Drożdż, W.; Bilan, Y.; Rabe, M.; Streimikiene, D.; Pilecki, B. Optimizing biomass energy production at the municipal level to move to low-carbon energy. Sustain. Cities Soc. 2022, 76, 103417. [Google Scholar] [CrossRef]

- Lecompte, S.; Huisseune, H.; Van Den Broek, M.; Vanslambrouck, B.; De Paepe, M. Review of organic Rankine cycle (ORC) architectures for waste heat recovery. Renew. Sustain. Energy Rev. 2015, 47, 448–461. [Google Scholar] [CrossRef]

- Li, G.; Ying, J.; Zheng, Y.; Guo, W.; Tang, Y.; Ye, C. Analytical design model for waste heat thermoelectric generator and experimental verification. Energy Convers. Manag. 2022, 252, 115034. [Google Scholar] [CrossRef]

- Liao, Y.; Wang, R.; Fane, A.G. Fabrication of bioinspired composite nanofiber membranes with robust super hydrophobicity for direct contact membrane distillation. Environ. Sci. Technol. 2014, 48, 6335–6341. [Google Scholar] [CrossRef]

- Zhao, S.; Jiang, C.; Fan, J.; Hong, S.; Mei, P.; Yao, R.; Liu, Y.; Zhang, S.; Li, H.; Zhang, H.; et al. Hydrophilicity gradient in covalent organic frameworks for membrane distillation. Nat. Mater. 2021, 20, 1551–1558. [Google Scholar] [CrossRef]

- Razaqpur, A.G.; Wang, Y.; Liao, X.; Liao, Y.; Wang, R. Progress of photothermal membrane distillation for decentralized desalination: A review. Water Res. 2021, 201, 117299. [Google Scholar] [CrossRef]

- Guo, A.; Ming, X.; Fu, Y.; Wang, G.; Wang, X. Fiber-based, double-sided, reduced graphene oxide films for efficient solar vapor generation. ACS Appl. Mater. Interfaces 2017, 9, 29958–29964. [Google Scholar] [CrossRef]

- Wang, W.; Shi, Y.; Zhang, C.; Hong, S.; Shi, L.; Chang, J.; Li, R.; Jin, Y.; Ong, C.; Zhuo, S.; et al. Simultaneous production of fresh water and electricity via multistage solar photovoltaic membrane distillation. Nat. Commun. 2019, 10, 3012. [Google Scholar] [CrossRef]

- Wu, X.; Cao, S.; Ghim, D.; Jiang, Q.; Singamaneni, S.; Jun, Y.-S. A thermally engineered polydopamine and bacterial nanocellulose bilayer membrane for photothermal membrane distillation with bactericidal capability. Nano Energy 2021, 79, 105353. [Google Scholar] [CrossRef]

- Jawed, A.S.; Hegab, H.M.; Kharraz, J.; Banat, F.; Al Marzooqi, F.; Hasan, S.W. Enhancement of photothermal membrane distillation efficiency with octylamine-functionalized copper oxide nanoparticles. Sep. Purif. Technol. 2025, 375, 133801. [Google Scholar] [CrossRef]

- Yu, J.; Sun, D.; Yue, D.; Li, B.; Zhu, T.; Liu, P. CuMOF-functionalized PVDF membrane with hierarchical structure for photothermal vacuum membrane distillation. J. Membr. Sci. 2024, 706, 122967. [Google Scholar] [CrossRef]

- Deshmukh, A.; Boo, C.; Karanikola, V.; Lin, S.; Straub, A.P.; Tong, T.; Warsinger, D.M.; Elimelech, M. Membrane distillation at the water-energy nexus: Limits, opportunities, and challenges. Energy Environ. Sci. 2018, 11, 1177–1196. [Google Scholar] [CrossRef]

- Wang, Z.; Horseman, T.; Straub, A.P.; Yip, N.Y.; Li, D.; Elimelech, M.; Lin, S. Pathways and challenges for efficient solar-thermal desalination. Sci. Adv. 2019, 5, eaax0763. [Google Scholar] [CrossRef]

- Jun, Y.S.; Wu, X.; Ghim, D.; Jiang, Q.; Cao, S.; Singamaneni, S. Photothermal membrane water treatment for two worlds. Acc. Chem. Res. 2019, 52, 1215–1225. [Google Scholar] [CrossRef]

- Lu, H.; Price, L.; Zhang, Q. Capturing the invisible resource: Analysis of waste heat potential in Chinese industry. Appl. Energy 2016, 161, 497–511. [Google Scholar] [CrossRef]

- Zuo, X.; Zhu, C.; Xian, W.; Meng, Q.; Guo, Q.; Zhu, X.; Wang, S.; Wang, Y.; Ma, S.; Sun, Q. Thermo-osmotic energy conversion enabled by Covalent-Organic-Framework membranes with record output power density. Angew. Chem. Int. Ed. 2022, 61, e202116910. [Google Scholar] [CrossRef] [PubMed]

- Straub, A.P.; Yip, N.Y.; Lin, S.; Lee, J.; Elimelech, M. Harvesting low-grade heat energy using thermo-osmotic vapour transport through nanoporous membranes. Nat. Energy 2016, 1, 16090. [Google Scholar] [CrossRef]

- Brogioli, D.; La Mantia, F. Innovative technologies for energy production from low temperature heat sources: Critical literature review and thermodynamic analysis. Energy Environ. Sci. 2021, 14, 1057–1082. [Google Scholar] [CrossRef]

- Fu, L.; Merabia, S.; Joly, L. Understanding fast and robust thermo-osmotic flows through carbon nanotube membranes: Thermodynamics meets hydrodynamics. J. Phys. Chem. Lett. 2018, 9, 2086–2092. [Google Scholar] [CrossRef]

- Marbach, S.; Bocquet, L. Osmosis, from molecular insights to large-scale applications. Chem. Soc. Rev. 2019, 48, 3102–3144. [Google Scholar] [CrossRef]

- Park, K.; Kim, D.Y.; Yang, D.R. Theoretical Analysis of Pressure Retarded Membrane Distillation (PRMD) Process for Simultaneous Production of Water and Electricity. Ind. Eng. Chem. Res. 2017, 56, 14888–14901. [Google Scholar] [CrossRef]

- Li, J.; Zhang, Z.; Zhao, R.; Zhang, B.; Liang, Y.; Long, R.; Liu, W.; Liu, Z. Stack thermo-osmotic system for low-grade thermal energy conversion. ACS Appl. Mater. Interfaces 2021, 13, 21371–21378. [Google Scholar] [CrossRef]

- Xiao, T.; Lin, Z.; Liu, C.; Liu, L.; Li, Q. Integration of desalination and energy conversion in a thermo-osmotic system using low-grade heat: Performance analysis and techno-economic evaluation. Appl. Therm. Eng. 2023, 223, 120039. [Google Scholar] [CrossRef]

- Rahimi, M.; Straub, A.P.; Zhang, F.; Zhu, X.; Elimelech, M.; Gorski, C.A.; Logan, B.E. Emerging electrochemical and membrane-based systems to convert low-grade heat to electricity. Energy Environ. Sci. 2018, 11, 276–285. [Google Scholar] [CrossRef]

- Yuan, Z.; Wei, L.; Afroze, J.D.; Goh, K.; Chen, Y.; Yu, Y.; She, Q.; Chen, Y. Pressure-retarded membrane distillation for low-grade heat recovery: The critical roles of pressure-induced membrane deformation. J. Membr. Sci. 2019, 579, 90–101. [Google Scholar] [CrossRef]

- Zhao, R.; Li, J.; Zhang, Z.K.; Long, R.; Liu, W.; Liu, Z. Harvesting net power and desalinating water by pressure-retarded membrane distillation. Sci. China Technol. Sci. 2022, 65, 214–220. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, R.; Wang, J.; Huang, L.; Zhang, Y.; He, H.; Yin, X.; Luo, S.; Huang, B.; Pei, J.; Hu, X. Water–Energy Co-Production by Coupling Photothermal Membrane Distillation with Thermal-Osmotic Energy Conversion. Energies 2025, 18, 6297. https://doi.org/10.3390/en18236297

Gao R, Wang J, Huang L, Zhang Y, He H, Yin X, Luo S, Huang B, Pei J, Hu X. Water–Energy Co-Production by Coupling Photothermal Membrane Distillation with Thermal-Osmotic Energy Conversion. Energies. 2025; 18(23):6297. https://doi.org/10.3390/en18236297

Chicago/Turabian StyleGao, Ruiying, Jinzhao Wang, Lu Huang, Ying Zhang, Hanhua He, Xinxing Yin, Shan Luo, Baolin Huang, Junxian Pei, and Xuejiao Hu. 2025. "Water–Energy Co-Production by Coupling Photothermal Membrane Distillation with Thermal-Osmotic Energy Conversion" Energies 18, no. 23: 6297. https://doi.org/10.3390/en18236297

APA StyleGao, R., Wang, J., Huang, L., Zhang, Y., He, H., Yin, X., Luo, S., Huang, B., Pei, J., & Hu, X. (2025). Water–Energy Co-Production by Coupling Photothermal Membrane Distillation with Thermal-Osmotic Energy Conversion. Energies, 18(23), 6297. https://doi.org/10.3390/en18236297