Numerical Analysis of Heavy Oil-Water-Air Flow in a Horizontal Pipe Using Core Annular Flow Adapting Large Eddy Simulations

Abstract

1. Introduction

2. Methodology and Numerical Formulation

2.1. LES for CAF Simulation Using CFD in the Horizontal Pipe

2.2. VOF Model

2.3. Development of Model and LES Method

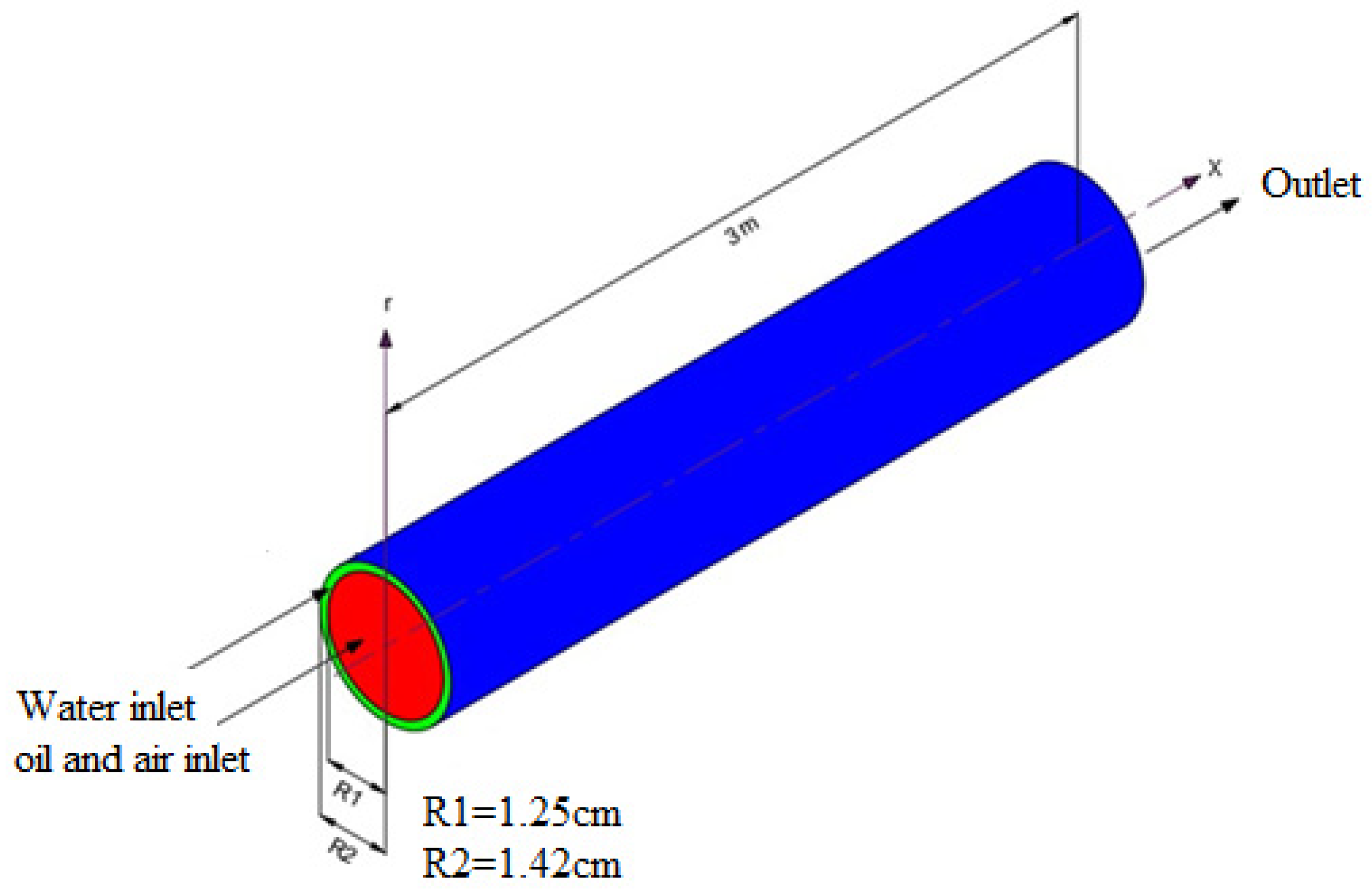

Physical Model

2.4. Governing Equations

- The model should be incompressible and support transient flow.

- There should be no chemical reactions between the oil and water during the simulation.

- Gravitational and drag impacts should be presented.

- The viscosities of the heavy oil, air, and water should be presented as temperature functions.

- The interfacial transport of mass between the oil, water, and air phases is zero.

2.5. Numerical Methodology

2.6. Selected Boundary Conditions

- At pipe inletIn the present model, high-density oil and air velocities are indicated in the core space of the horizontal pipe. Simultaneously, the water velocity is indicated in the horizontal pipe’s annular space as shown in Figure 2.The inlet boundary conditions are:

- (a)

- In the annular space representing the water inlet, the mean velocity and volume fraction of water in the direction of x are presented as follows:where u, v, e, v denote vector components of velocity in the x, y, and directions, w, o, and a denote water, oil, and air phases, respectively, and T is the temperature.

- (b)

- The core space representing the oil inlet, the mean velocity component, and the volume fraction of oil and air in the x-axis was taken as:

- At pipe outlet

- 3.

- Pipe wall boundary conditions.

2.7. Discretization Result Systems and Computational Set-Up

3. Results and Discussion

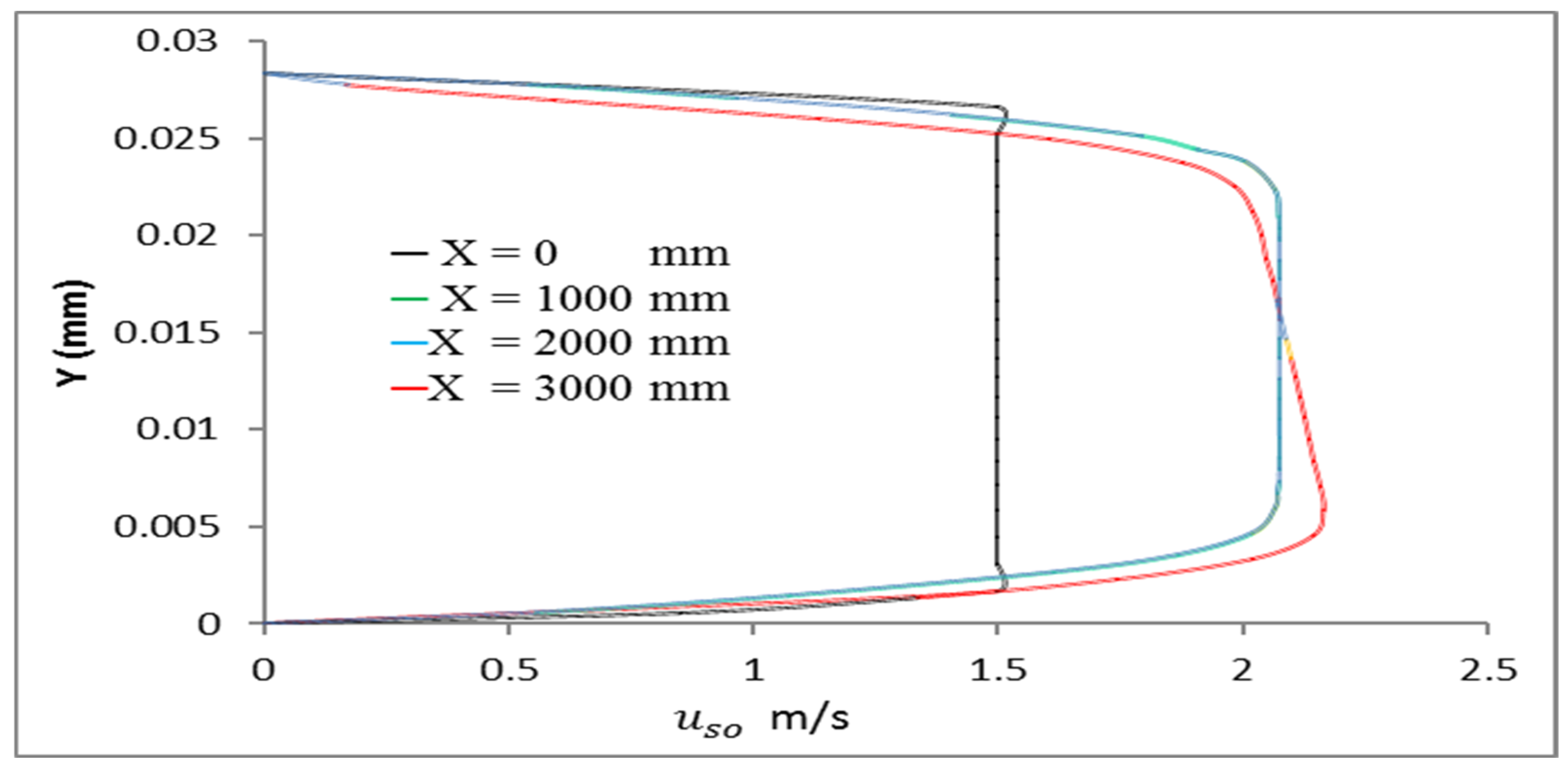

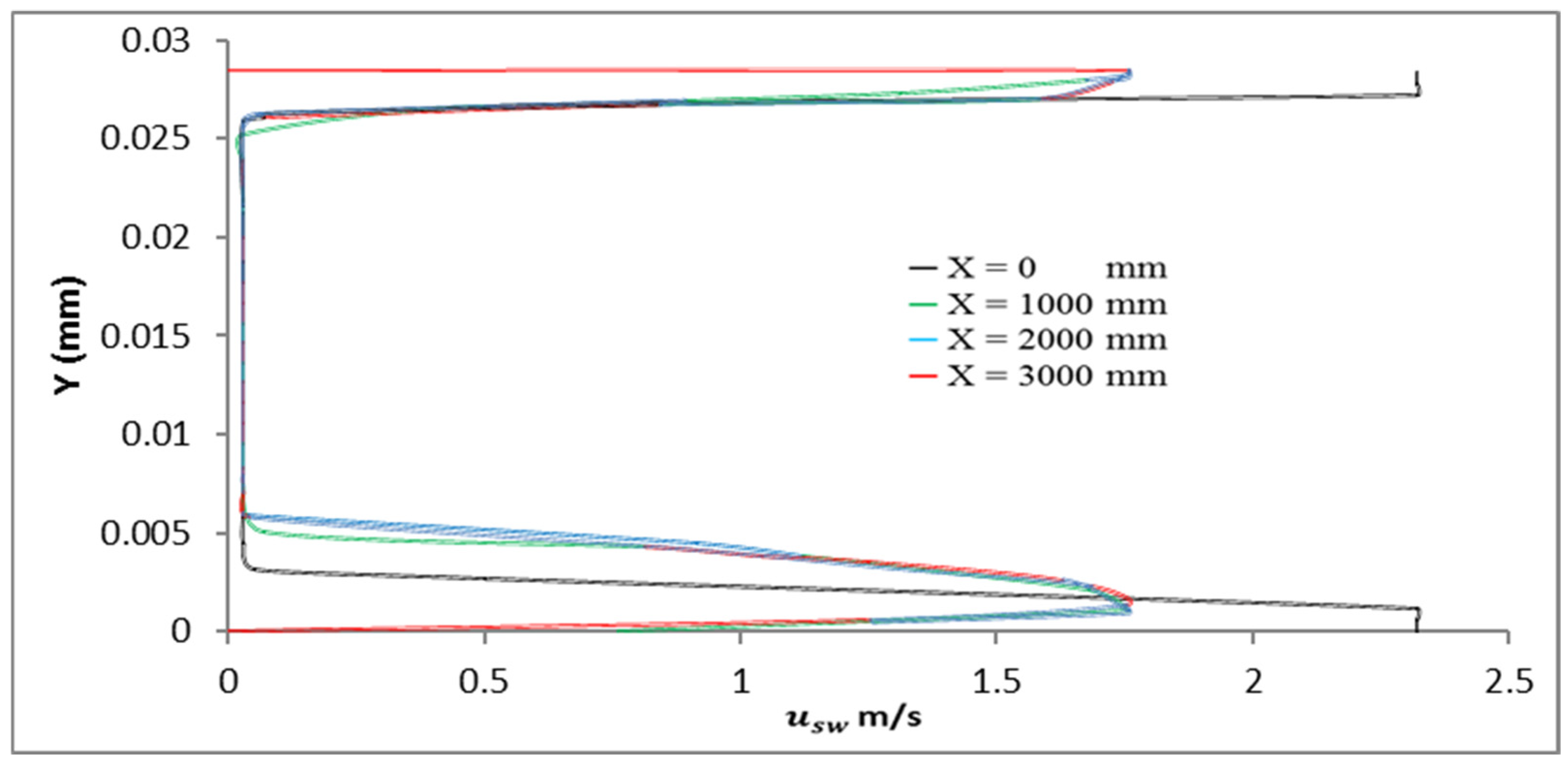

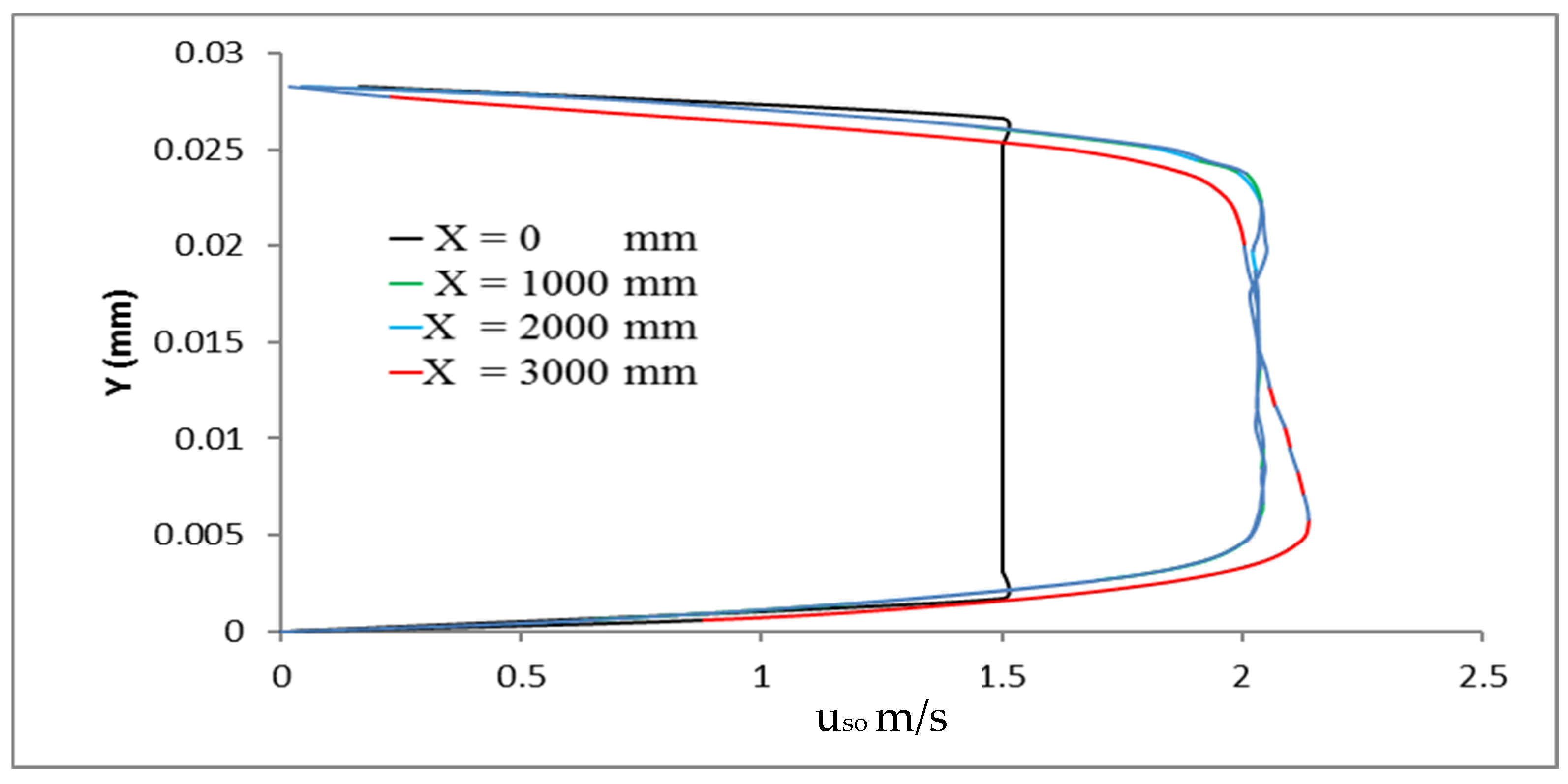

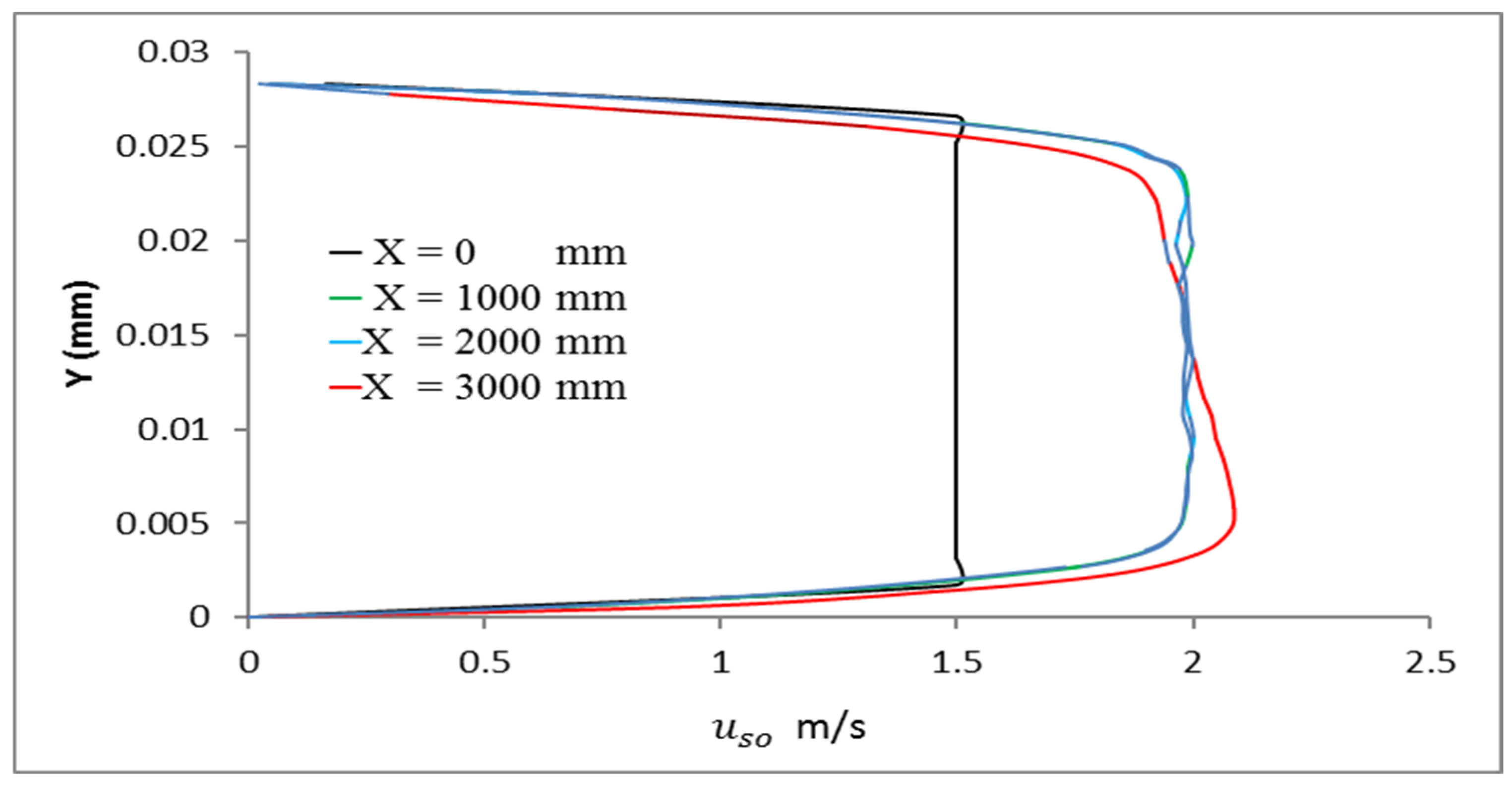

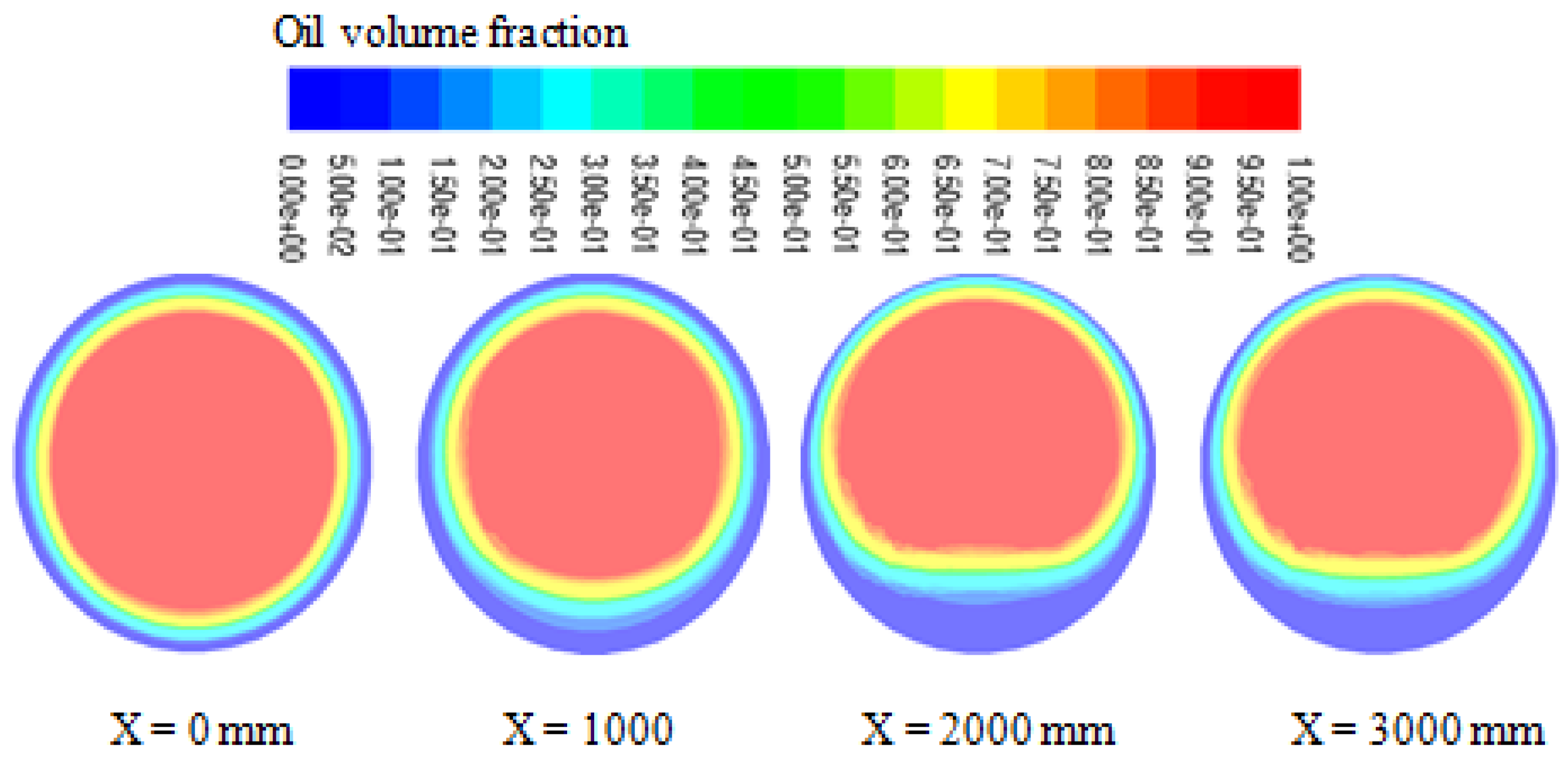

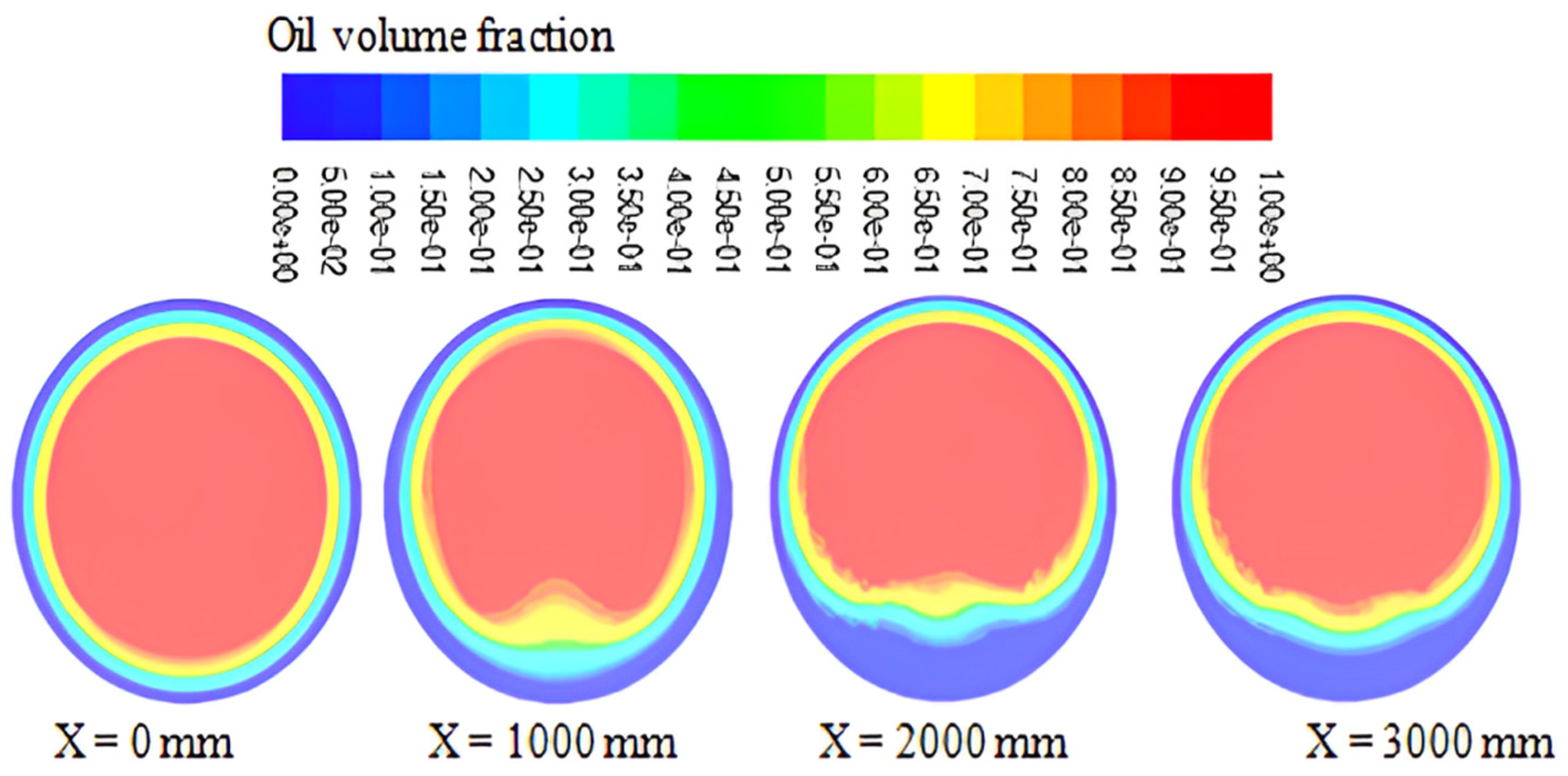

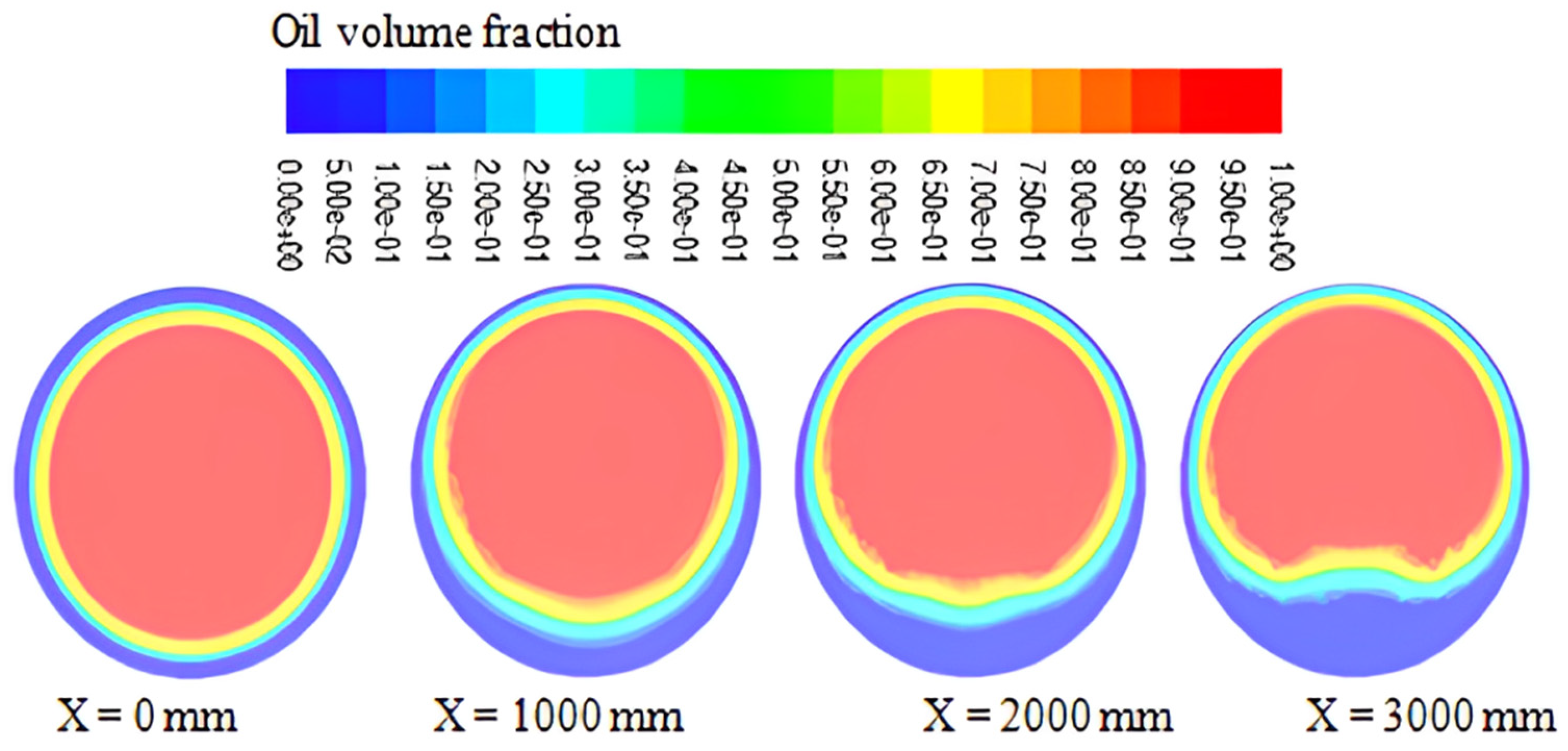

3.1. Air Phase Impact

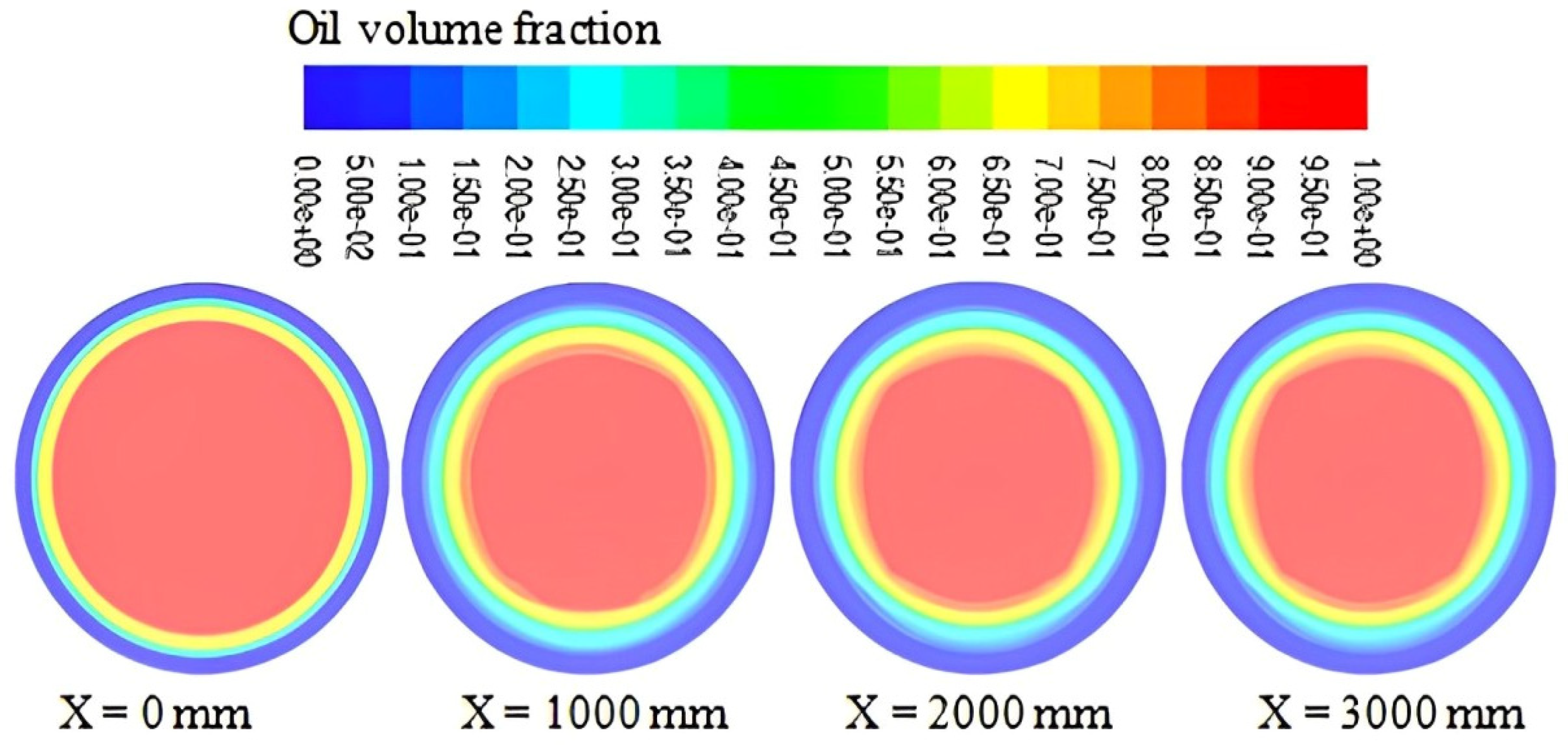

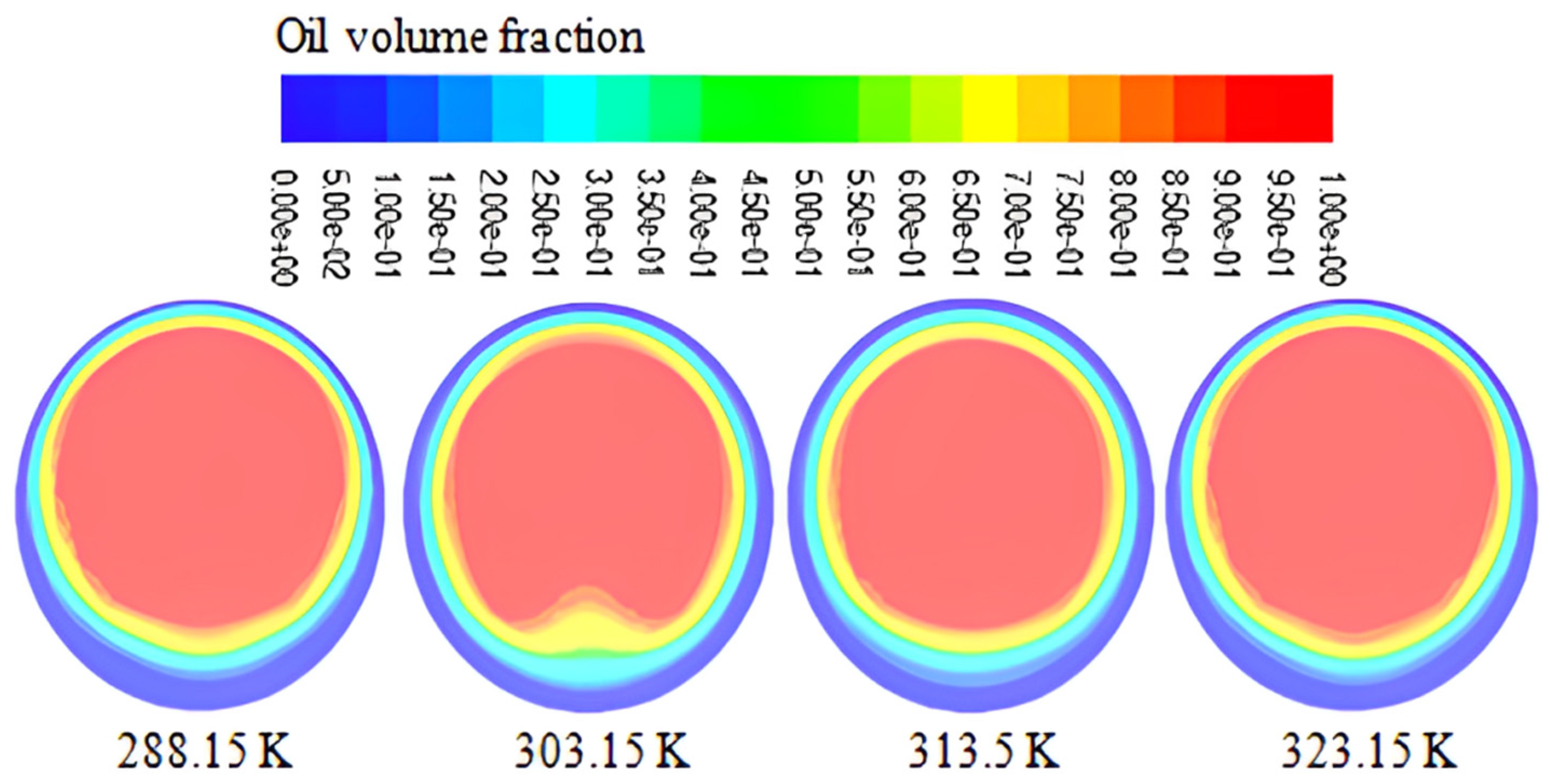

3.2. Temperature Change Impact

3.3. Effect of Temperature and the Presence of Air on Pressure Drop

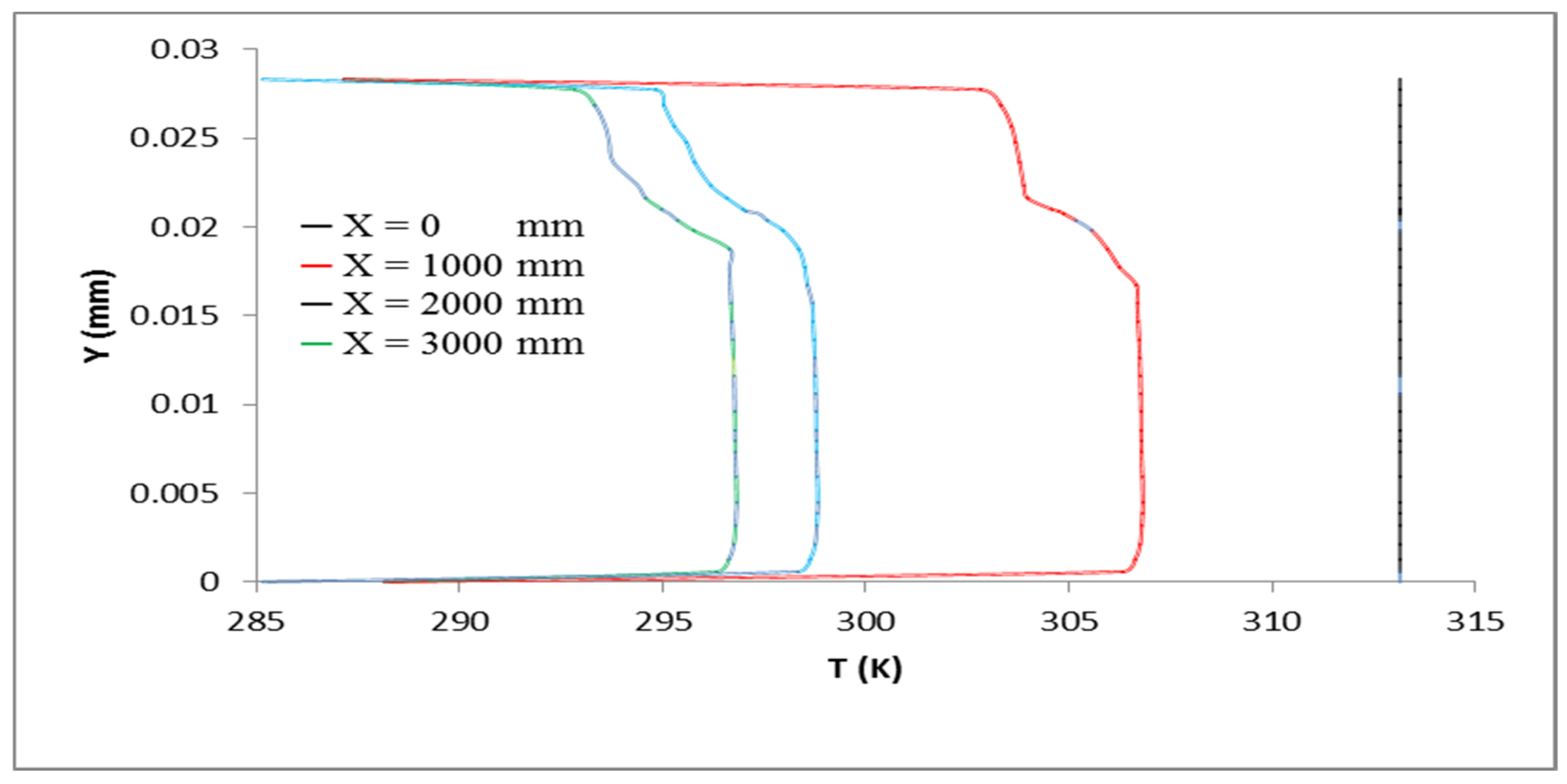

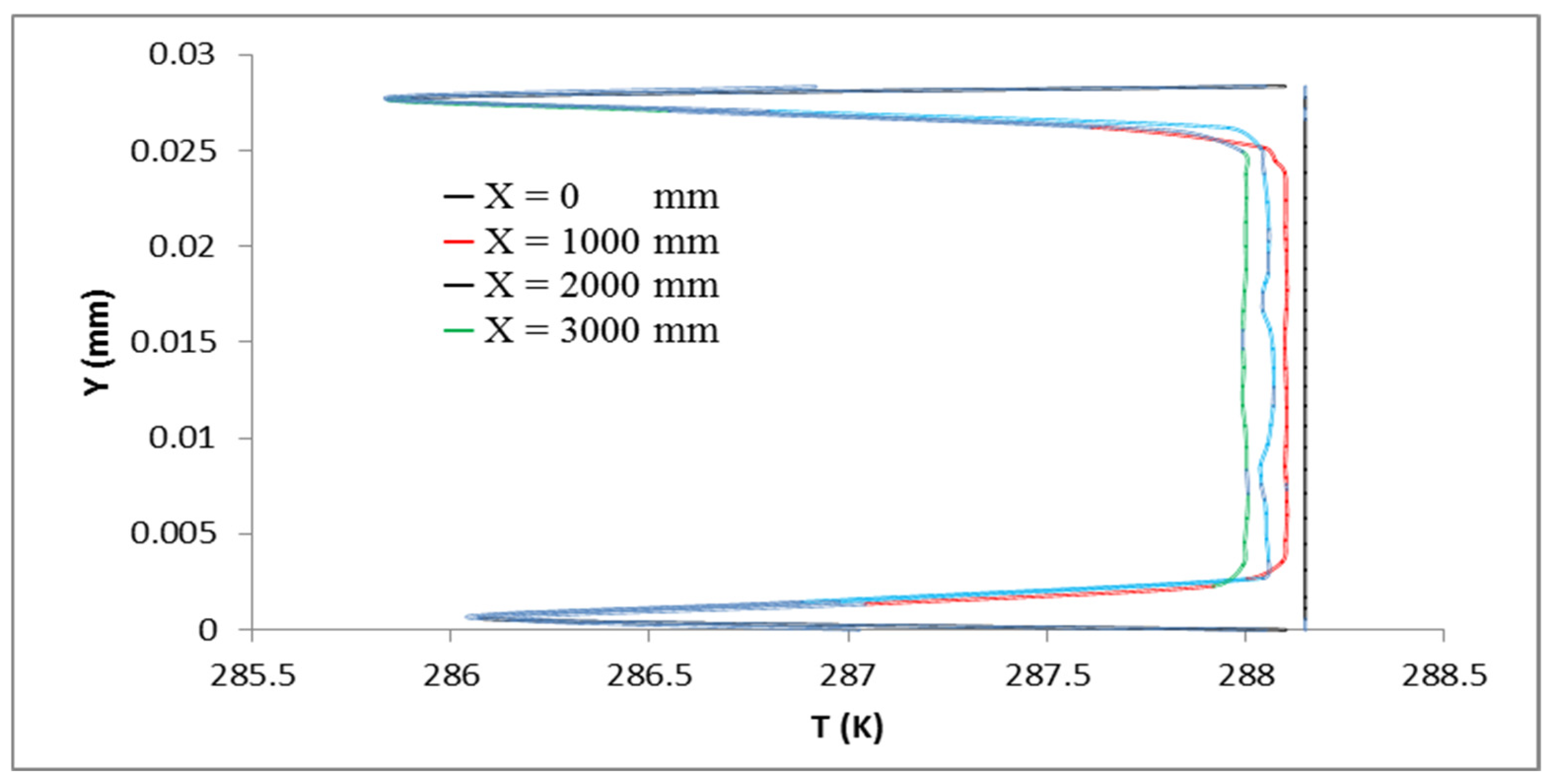

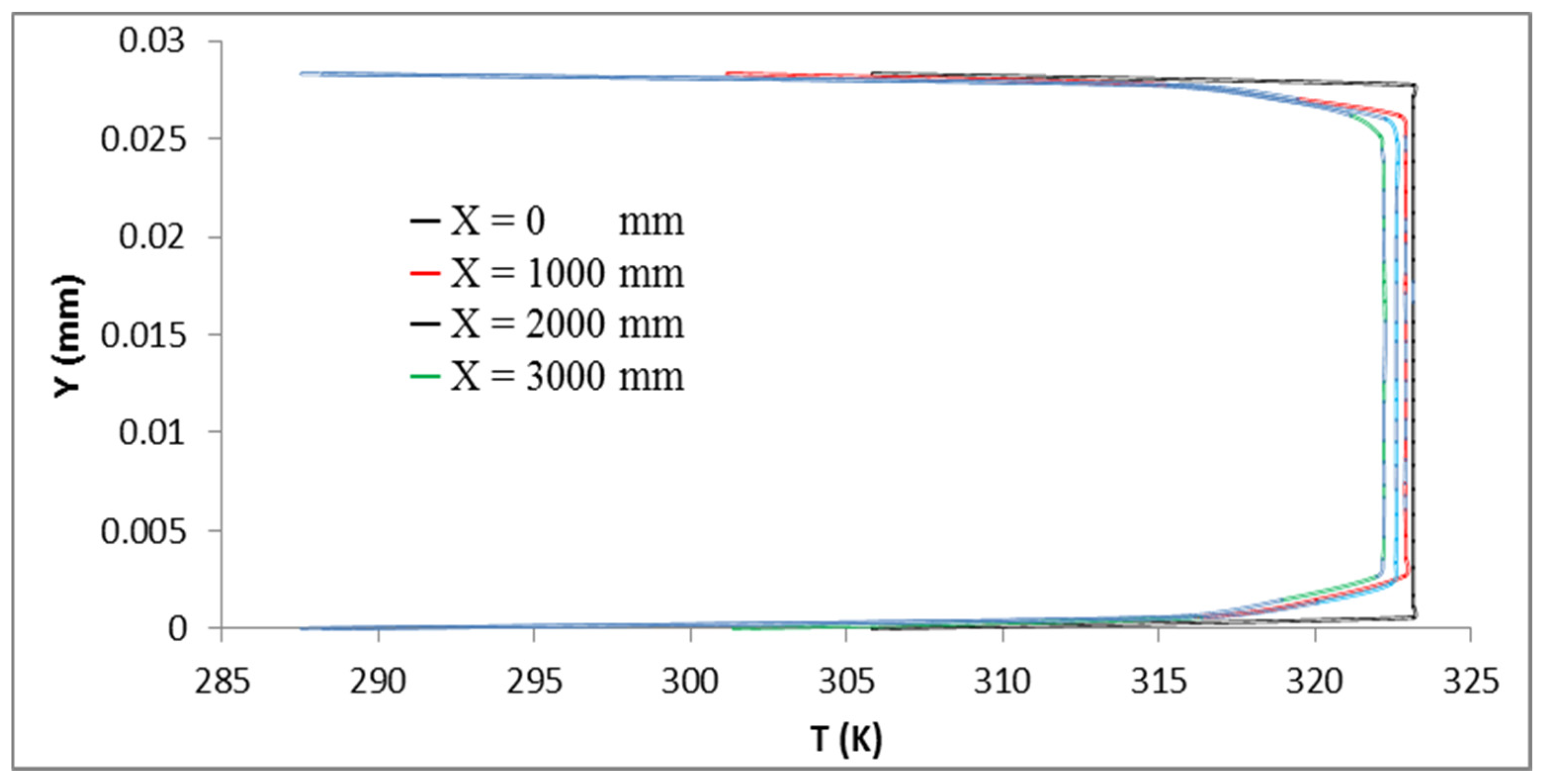

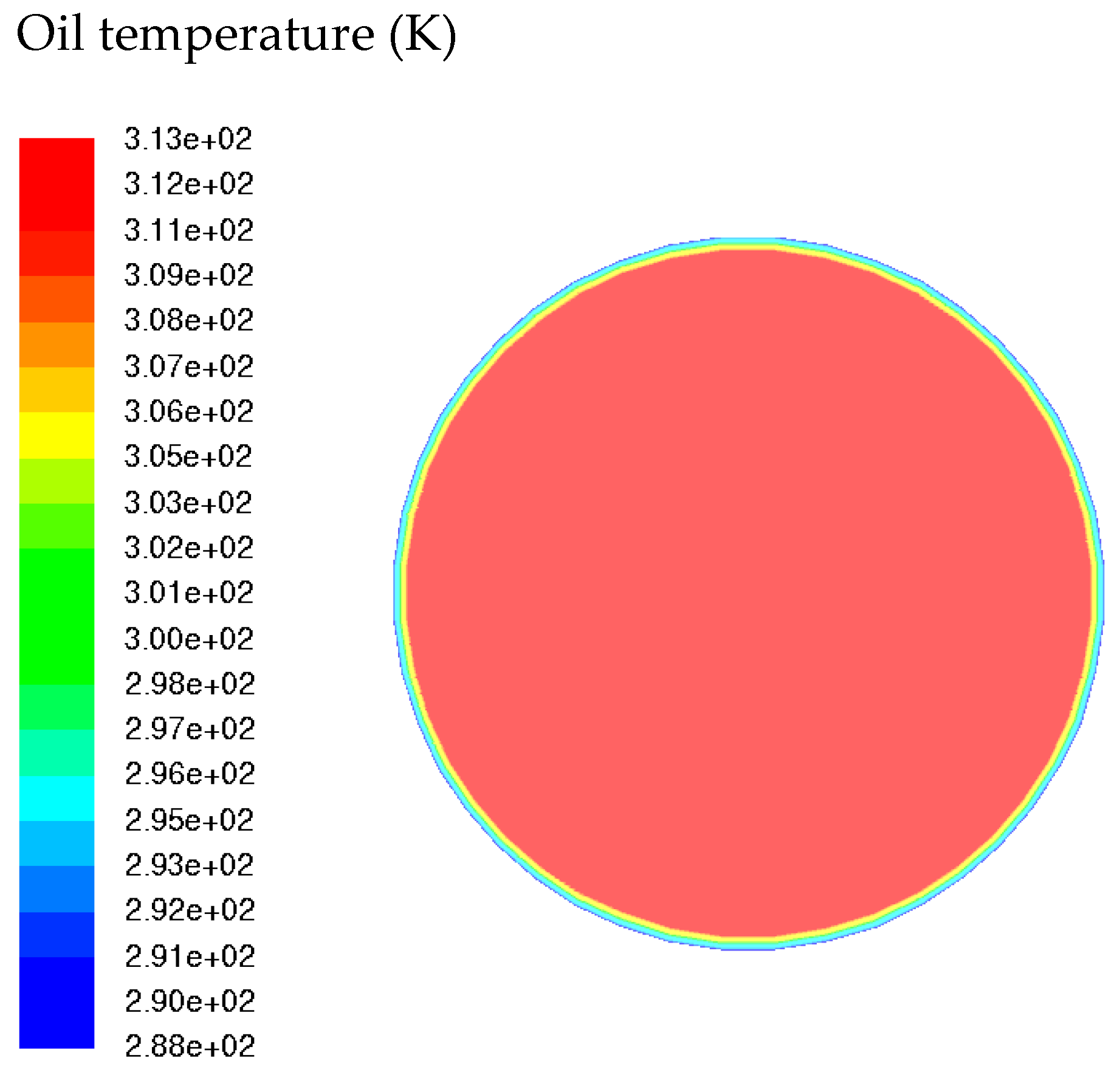

3.4. Temperature Profile Fields

4. Summary

- (1)

- The developed numerical model predicts how a non-isothermal three-phase flow of water, oil, and air behaves in a straight pipe.

- (2)

- Despite temperature variations, the continuous aqueous film (CAF) is created and sustained. The unconventional core of the oil-air mixture tends towards stratification, avoiding the pipe wall and forming due to a fine water film.

- (3)

- This investigation demonstrated that the presence and proximity of air in a dense two-phase flow of water and oil significantly influence the distribution of oil inside the straight pipe and the velocity profiles of the phases. However, the CAF maintains its characteristic formation.

- (4)

- The viscosity of the water and oil decreases with increasing temperature during fluid flow through the pipe, resulting in a reduced pressure drop. Conversely, the presence of air causes an increase in pressure drop.

- (5)

- The profiles of the temperature of the water, heavy oil, and air phases alongside the pipe revealed an expected lesser temperature near the pipe surface, which lowers the temperature of the liquids by the time they depart the pipe. Due to its proximity to the pipe wall, annular water experiences this temperature drop more dramatically.

- (6)

- The research outcomes, backed by simulations and experimental evidence from existing literature, consistently show results that enhance our understanding of how well LES can model intricate flow dynamics like those studied in this investigation.

- (7)

- Comprehending the characteristics of heavy oil-water-air flows is essential for numerous industrial uses, including the transportation and processing of oil. Improved design and operational techniques for pipelines and processing facilities handling heavy oils under multi-phase flow circumstances may result from the study’s conclusions.

- (8)

- Overall, this work is novel because it uses an integrated approach to apply advanced numerical techniques, such as LES, to heavy oil, water, and air flows in a horizontal pipe. This approach advances both fundamental understanding and real-world applications in industrial contexts.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Bannwart, A.C.; Rodriguez, O.M.H.; Trevisan, F.E.; Vieira, F.F.; de Carvalho, C.H.M. Experimental investigation on liquid-liquid-gas flow: Flow patterns and pressure-gradient. J. Pet. Sci. Eng. 2009, 65, 1–13. [Google Scholar] [CrossRef]

- Trevisan, F.E. Flow Patterns and Pressure Drop in three Phase Horizontal Flow of Heavy Oil, Water and Air. Master’s Thesis, Petroleum Science and Engineering, Faculty of Mechanical Engineering, State University of Campinas (UNICAMP), Campinas, Brazil, 2003. [Google Scholar]

- Bannwart, A.C. Modelling aspects of oil-water core annular flows. J. Pet. Sci. Eng. 2001, 32, 127–143. [Google Scholar] [CrossRef]

- Desamala, A.B.; Dasamahapatra, A.K.; Mandal, T.K. Oil-water two-phase flow characteristics in horizontal pipeline—A comprehensive CFD Study. Int. J. Chem. Nucl. Mater. Metall. Eng. 2014, 8, 336–340. [Google Scholar]

- Bensakhria, A.; Peysson, Y.; Antonini, G. Experimental study of the pipeline lubrication for heavy oil transport. Oil Gas Sci. Technol.—Rev. IFP 2004, 59, 523–533. [Google Scholar] [CrossRef]

- Crivelaro, K.C.O.; Damacena, Y.T.; Andrade, T.H.F.; Lima, A.G.B.; Farias, S.R. Numerical simulation of heavy oil flows in pipes using the core-annular flow technique. WIT Trans. Eng. Sci. 2009, 63, 193–203. [Google Scholar]

- Ghosh, S.; Mandal, T.K.; Das, G.; Das, P.K. Review of oil water core annular flow. Renew. Sustain. Energy Rev. 2009, 13, 1957–1965. [Google Scholar] [CrossRef]

- Gupta, R.; Turangan, C.K.; Manica, R. Oil-water coreannular flow in vertical pipes: A CFD study. Can. J. Chem. Eng. 2016, 94, 980–987. [Google Scholar] [CrossRef]

- Rodriguez, O.; Bannwart, A.C.; de Carvalho, C. Pressure loss in core-annular flow: Modelling, experimental investigation and full-scale experiments. J. Ofpetroleum Sci. Eng. 2009, 65, 67–75. [Google Scholar] [CrossRef]

- Gadelha, A.J.F.; de Farias Neto, S.R.; Swarnakar, R.; de Lima, A.G.B. Thermo-hydrodynamics of core-annular flow of water heavy oil and air using CFX. Adv. Chem. Eng. Sci. 2013, 3, 37–45. [Google Scholar] [CrossRef]

- Poesio, P.; Sotgia, G.; Strazza, D. Experimental investigation of three-Phase oil-water-air flow through a pipeline. Multiph. Sci. Technol. 2009, 21, 107–122. [Google Scholar] [CrossRef]

- Strazza, D.; Chiecchi, D.; Poesio, P. High viscosity oil-water-air three phase flows: Flow maps, pressure drops and bubble dynamics. In Proceedings of the 7th International Conference on Multiphase Flow—ICMF, Tampa, FL, USA, 30 May–4 June 2010; pp. 1–7. [Google Scholar]

- Kreith, F.; Bohn, M.S. Principles of Heat Transfer; Editora Edgard Blücher: São Paulo, Brazil, 1977. (In Portuguese) [Google Scholar]

- Santana, C.W.S.; Tôrres, E.G.; de Lacerda, I.S. Adjustment equations for kinematic viscosity of petroleum products depending on the temperature. In Proceedings of the 3rd Brazilian Congress of R & D in Petroleum and Gas 3rd PDPETRO, Rio de Janeiro, Portuguese, 2–5 October 2004. [Google Scholar]

- Versteeg, H.K.; Malalasekera, W. Introduction to Computational Fluid Dynamics, 2nd ed.; Pearson Education: Harlow, UK, 2007. [Google Scholar]

- Leonard, A. Energy cascade in large-eddy simulations of turbulent fluid flows. Adv. Geophys. 1974, 18 Pt A, 237–248. [Google Scholar]

- Poesio, P.; Strazza, D.; Sotgia, G. Two- and three-phase mixtures of highly-viscous-oil/water/air in a 50 mm id. pipe. Appl. Therm. Eng. 2011, 49, 41–47. [Google Scholar] [CrossRef]

- Poesio, P.; Strazza, D.; Sotgia, G. Very-viscous-oil/water/air flow through horizontal pipes: Pressure drop measurement and prediction. Chem. Eng. Sci. 2009, 64, 1136–1142. [Google Scholar] [CrossRef]

| Property | Water Phase | Oil Phase | Air Phase |

|---|---|---|---|

| Density (ρ), kg/m3 | 997.2 | 971 | 0.778 |

| Viscosity (μ), Pa·s | 0.001375 | 0.64 | 1.794e−0.5 |

| Specific heat (J/kg·K) | 4,181,700 | 1,800,000 | 1025,766 |

| Interfacial Tension N/m | 0.019 | 0.019 | 0.019 |

| Length | Diameter |

|---|---|

| 3 m | 0.0284 m |

| Phases | Equations | Units |

|---|---|---|

| Heavy oil | Pa·s | |

| Water | ) | Pa·s |

| Air | Pa·s |

| Motion | Stationary |

|---|---|

| Shear condition | No slip |

| Momentum Explicit Relaxation Factor | 0.3 |

| Pressure Explicit Relaxation Factor | 0.3 |

| Turbulent Model | LES, Smagorinsky-Lilly model |

| Material | oil, water, and air |

| Numerical Details | |

| Pressure-Velocity Coupling | PISO |

| Descretisation Momentum | Bounded Central differencing |

| Pressure | PRESTO |

| Gradient | Least square cells based |

| Time | Bounded second order implicit |

| Boundary conditions | |

| Inlet | velocity |

| outlet | pressure |

| Simulation factor | |

| Total simulation time | 80–190 s |

| Start data sampling | 40 s |

| Time step | 0.001 |

| courant number | Between 0.5–0.85 in all simulations |

| Residual Criteria | 1 × 107 |

| Cases | To, Tw and Ta (K) | ΔP Pa/m |

|---|---|---|

| Two-phase | 313.15 (To and Tw) | 1191.15 |

| Three-phase | 288.15 | 1582.81 |

| Three-phase | 303.15 | 1469.338 |

| Three-phase | 313.15 | 1462.23 |

| Three-phase | 313.15 | 1434.72 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al. Jadidi, S.; Anbalagan, S.; Moolya, S. Numerical Analysis of Heavy Oil-Water-Air Flow in a Horizontal Pipe Using Core Annular Flow Adapting Large Eddy Simulations. Energies 2025, 18, 6188. https://doi.org/10.3390/en18236188

Al. Jadidi S, Anbalagan S, Moolya S. Numerical Analysis of Heavy Oil-Water-Air Flow in a Horizontal Pipe Using Core Annular Flow Adapting Large Eddy Simulations. Energies. 2025; 18(23):6188. https://doi.org/10.3390/en18236188

Chicago/Turabian StyleAl. Jadidi, Salim, Satheesh Anbalagan, and Shivananda Moolya. 2025. "Numerical Analysis of Heavy Oil-Water-Air Flow in a Horizontal Pipe Using Core Annular Flow Adapting Large Eddy Simulations" Energies 18, no. 23: 6188. https://doi.org/10.3390/en18236188

APA StyleAl. Jadidi, S., Anbalagan, S., & Moolya, S. (2025). Numerical Analysis of Heavy Oil-Water-Air Flow in a Horizontal Pipe Using Core Annular Flow Adapting Large Eddy Simulations. Energies, 18(23), 6188. https://doi.org/10.3390/en18236188