1. Introduction

At the present stage of oil field development, a wide range of pumping equipment is used. The central part in the mechanized method of oil production is the sucker-rod pumps [

1] and the electrical submersible centrifugal pumps (ESPs) [

2]. Engineering developments aimed at improving the flow elements of the working stages have resulted in a vast series of small-sized impellers, characterized by their construction (outlet diameter

D2 = 70–80 mm) and the maximum possible values of the energy characteristics [

3].

When designing ESPs that operate on the hydrodynamic principle of action, special attention should be given to the working conditions of this pumping equipment, including increased wells’ depths, the need to pump highly viscous oil, the temperature of the pumped fluids, and small-diameter dimensions [

4]. In practice, such conditions are quite difficult to ensure, which highlights the need to create conceptually highly effective, small-sized, high-pressure pumping units [

5,

6].

Modern hydrodynamic submersible pumping units are made unregulated. Operation in variable conditions of the well, due to changes in the hydraulic network’s characteristics, results in a decrease in the reliability, durability, and energy efficiency of the considered pumping units. For the efficient operation of oil wells using submersible centrifugal pumps, a technologically feasible method for matching the pump’s characteristics to those of the well is to adjust the rotational speed. The task of creating the specified technique is complicated by the issue of submersible vane pump operational quality within the well hydraulic network and auxiliary equipment, as well as by the significant influence of the pumped medium’s viscosity [

7].

The composition and properties of the pumped fluids significantly affect the performance characteristics of the pumps in question. Determining it at the pump design stage is a challenging task. The generally accepted practice in pump engineering for addressing this issue is as follows: the calculation is performed for the case of pumping technically pure water, with subsequent corrections applied to account for the composition and properties of the actual pumped medium. One of the kinds of such corrections is a correction that considers the viscosity of the pumped medium. As of this time, none of the existing techniques considers only individual conditions characteristic of the operation of highly specialized pumping units [

8,

9].

As a result, the direction of scientific research has shifted towards identifying external factors that contribute to improving the performance of this pumping equipment to a higher level. The search for better solutions to the existing problem led to the creation of turbine-driven well dynamic pumps-turbo-pump units (TPUs) [

10,

11] and pumps with electric high-frequency drives [

12,

13]. They provide the ability to operate in a relatively wide range of operating modes, allowing for the regulation of power consumption in response to changes in the viscosity of the pumped medium and automatically ensuring that the pump’s rated operating point is within the zone of maximum energy efficiency [

14]. The TPU has the property of self-regulating the rotational speed under the influence of a changing external load. The developed borehole turbo-pump units allow operation in a wide range of rotational speeds of the drive rotor, from 3000 rpm to 10,000 rpm and higher. In addition, the starting torque characteristic of the turbine drive, compared to asynchronous electric motors, does not lead to overloads and, accordingly, eliminates the possibility of TPU failure during frequent starts and stops. Thus, it becomes possible to find a high-quality solution to the problem of creating high heads with small diametrical dimensions of its working parts, particularly for pumping highly viscous media.

Many researchers have considered the problem of pumping highly viscous oil. Various techniques have been developed for recalculating the performance curves of centrifugal pumps from water to high-viscosity liquids [

8]. Each method was developed for specific, narrowly defined conditions of pumping highly viscous media. Their application to recalculation for a separately selected impeller size gives results with significant discrepancies between them.

The potential for using TPU has heightened the need for a high-quality solution to the problem of predicting the performance characteristics of hydrodynamic pumps that pump highly viscous media at high rotor speeds and small working parts. To unify the design of TPU for oil production, it is advisable to utilize the pump stages of submersible pumping units based on already standardized serial sizes.

The implementation of a borehole pump unit with a high rotational speed enables a reduction in the influence of the viscosity of the pumped medium on the pump parameters, as the Reynolds number increases for Newtonian fluids and the dynamic viscosity decreases with an increase in the velocity gradient.

An analysis of scientific publications has shown that it is impossible to develop a technique for recalculating the performance characteristics of water in highly viscous media using only a calculation-analytical method, due to the multifactorial influence of physical properties and the complex structure of the flow of the pumped viscous liquid in the pump’s flow channels. Based on the completed information and analytical review of sources on the topic under consideration, it was established that existing techniques for recalculating the performance characteristics of hydrodynamic pumps operating from water to high-viscosity liquid are only empirical in nature and provide a sufficiently acceptable calculation accuracy only in the case of using medium-sized and large-sized impellers D2 > 150 mm at a standard pump rotation speed up to n = 3000 rpm. To predict the performance characteristics of ESP (D2 < 100 mm) with the possibility of operation at high drive rotor rotation speeds (n > 3000 rpm), calculations using existing techniques yield significant errors that exceed the permissible limits.

The analysis of the authors’ work, conducted over a long period of research in this area, reveals a constant relevance and novelty in the scientific and engineering field of research. The established problem of the lack of an acceptable technique for predicting the performance characteristics of small-sized pump stages of ESPs pumping highly viscous liquids at high rotational speeds of the drive rotor became the aim of the presented scientific research.

To achieve this goal, the following tasks have been formulated:

- –

to determine the peculiarities of the flow of high-viscosity liquid in the flow path elements of small-sized centrifugal pump stages;

- –

to study the issue of the peculiarities of applying the formulas of the theory of similarity, considering the influence of factors of high rotation speed of the rotor of a pump with small-sized centrifugal wheels when it operates on a high-viscosity liquid;

- –

to develop a refined technique for recalculating the operating characteristics of centrifugal pump stages with small-sized working elements at high rotor speeds from water to high-viscosity liquid.

2. Materials and Methods

2.1. Analytical Study

The solution to the set problems was carried out using the calculation-analytical method and the physical modeling method to study the working process of industrial samples of flow parts in submersible pumping equipment on an experimental stand.

The computational and analytical portion of the work was based on the fundamental principles of fluid and gas mechanics, the basic tenets of similarity theory, and the theory of turbomachines. Considering the complexity of the issue under examination, semi-empirical relationships were employed, followed by verification through physical experimentation.

Due to the incomplete understanding of this problem, a semi-empirical technique for predicting the performance characteristics of small-sized centrifugal pump stages operating on high-viscosity liquids was designed at the Research Laboratory of Hydrodynamic Drives and Installations of Sumy State University [

15]. The developed technique is intended for submersible electric pump units. This is due to the increased demand for this technique for the oil and gas production complex.

Ultimately, a refined semi-empirical recalculation technique was developed for high rotation speed values. It is a system of analytical equations for determining the recalculation coefficients for pump capacity

kQ, pump head

kH, pump power

kN, and energy efficiency

kη:

where

nreq—required rotation speed of the pump drive rotor, rpm;

nm = 2910 rpm—model rotation speed;

α—a structural parameter that links the determinable recalculation coefficients together;

kρ—the density ratio.

The method for determining the structural parameter

α is described in great detail in a previous scientific work [

15], which indicates that it depends on empirical coefficients that were determined in the process of experimental studies for a specific design of pump impellers and the viscosity range of the pumped liquid, as well as on the Reynolds number, in the calculation of which the main geometric parameters of the impeller outlet are included.

The peculiarity of its calculation is that the technique considers the central geometric values of the impeller, which directly determine the qualitative value of the primary energy parameters. In case if at practical calculations, it is not possible to determinate the value of the initial parameters of the impeller geometry from the ESP standard series, the following recommendation can be used for the calculation, namely, taking into account the accumulated experimental material on the design features of the centrifugal stages of the ESP series pumps, the geometric coefficient which taking into account the main geometric parameters of the impeller outlet with an acceptable error of kg = 0.13.

After determining the recalculation coefficients, the predicted values of the primary energy parameters for the selected pump are finally obtained for its operation at the required viscosity of the liquid, corresponding to the nominal region of its operation in terms of energy efficiency. The calculation is carried out according to the following dependencies:

where

Qv,

Qw—pump capacity, m

3/s;

Hv,

Hw—pump head, m;

Nv,

Nw—pump power, W;

ηv,

ηw—energy efficiency. Indexes “

w” and “

v” indicate water and high-viscosity liquid, respectively.

Next, to construct graphical performance curves of the predicted parameters of the pump in question, the values of the main parameters corresponding to the operating rate range of the expected performance characteristics are determined. For this purpose, Equation (2) is used, which considers the values of the parameters for the water. According to international requirements [

16,

17], the operating rate range of the pump capacity falls within 70–120% of the optimal pump capacity,

Qopt.

The developed technique for predicting the performance characteristics of well submersible electric centrifugal oil pumps does not account for the influence of the hydraulic network itself. In practice, the oil production complex network has its own operational parameters for pressure, which are maintained at a constant value. Thus, the variable value is the well parameters. Therefore, to improve the developed technique, it is necessary to predict the pump performance characteristics under specific operating conditions of the borehole. The specified factor is the justification for the operating regime of a correctly selected pumping unit within the operating rate range, which yields maximum energy efficiency values. These values, in turn, determine the maximum energy efficiency in its performance, with minimal energy losses and costs over the long term.

The following assumptions are considered. First, the speed of the pumped oil at the pump outlet and at the wellhead is taken to be approximately equal: v1 ≈ v2, m/s. Second, the coefficient of local resistance along the length of the oil-well tubing pressure is assumed to be zero: ξ = 0.

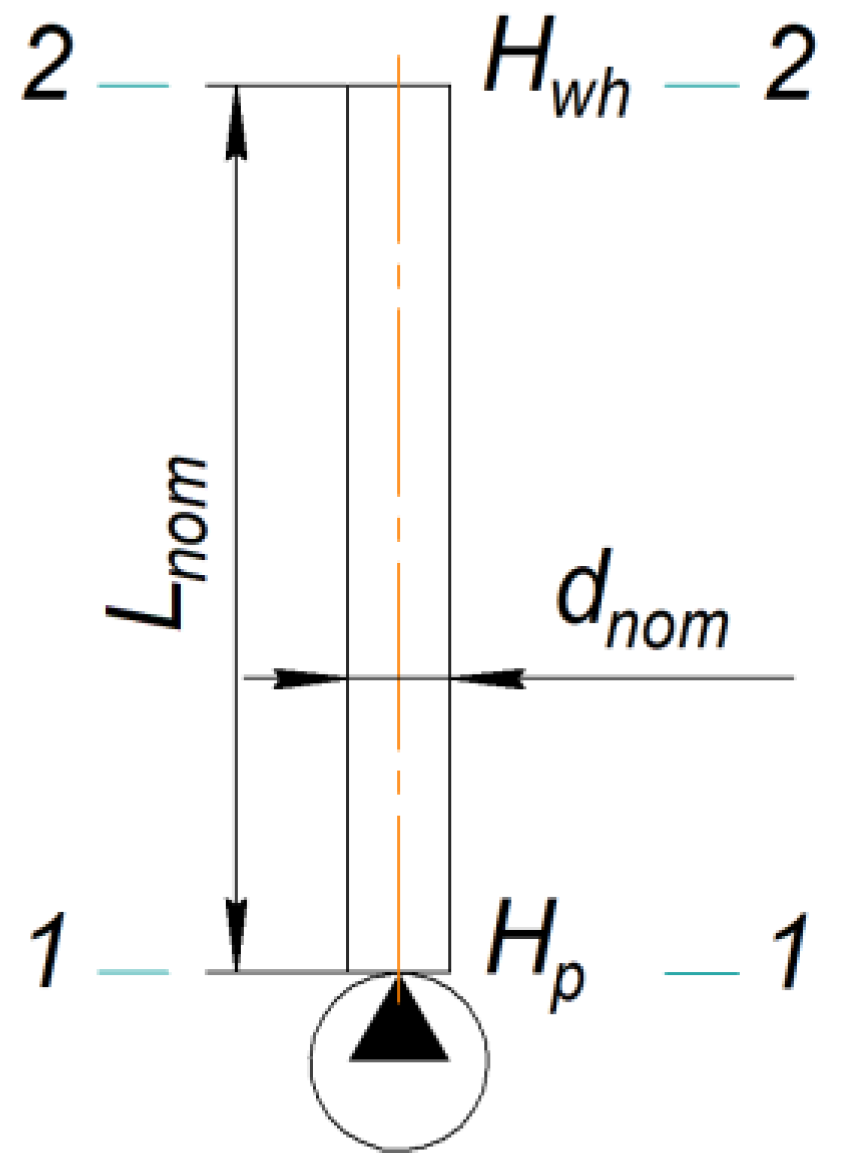

Under these conditions, after using the continuity equation for the pump-well hydraulic network (

Figure 1), a calculation formula was obtained for determining the required head at the outlet of an oil electric pump unit:

where

Hp—the required pump head, m;

Hwh—actual value of the production network head at the wellhead, m;

λ—the coefficient of hydrodynamic losses along the length of the pipeline;

Qv—required well’s flow rate, m

3/s;

dnom—nominal diameter of the pressure oil-well tubing, m;

L—installation depth of the pumping part in the well, m.

The coefficient of hydrodynamic losses λ along the pipeline length is determined using known methods in the theory of hydraulic machines.

Thus, from the calculated value of the head at the outlet of the pumping part Hp, which for the case of pumping a highly viscous liquid is Hp = Hv, using the conversion expressions (2) of the technique for predicting the performance characteristic of oil electric dynamic submersible pump units. The parameters of the specified dynamic pumping unit on water are determined by reverse calculation. After this, the selection of appropriate pumping equipment from the existing product range is carried out.

2.2. Physical Experimentation

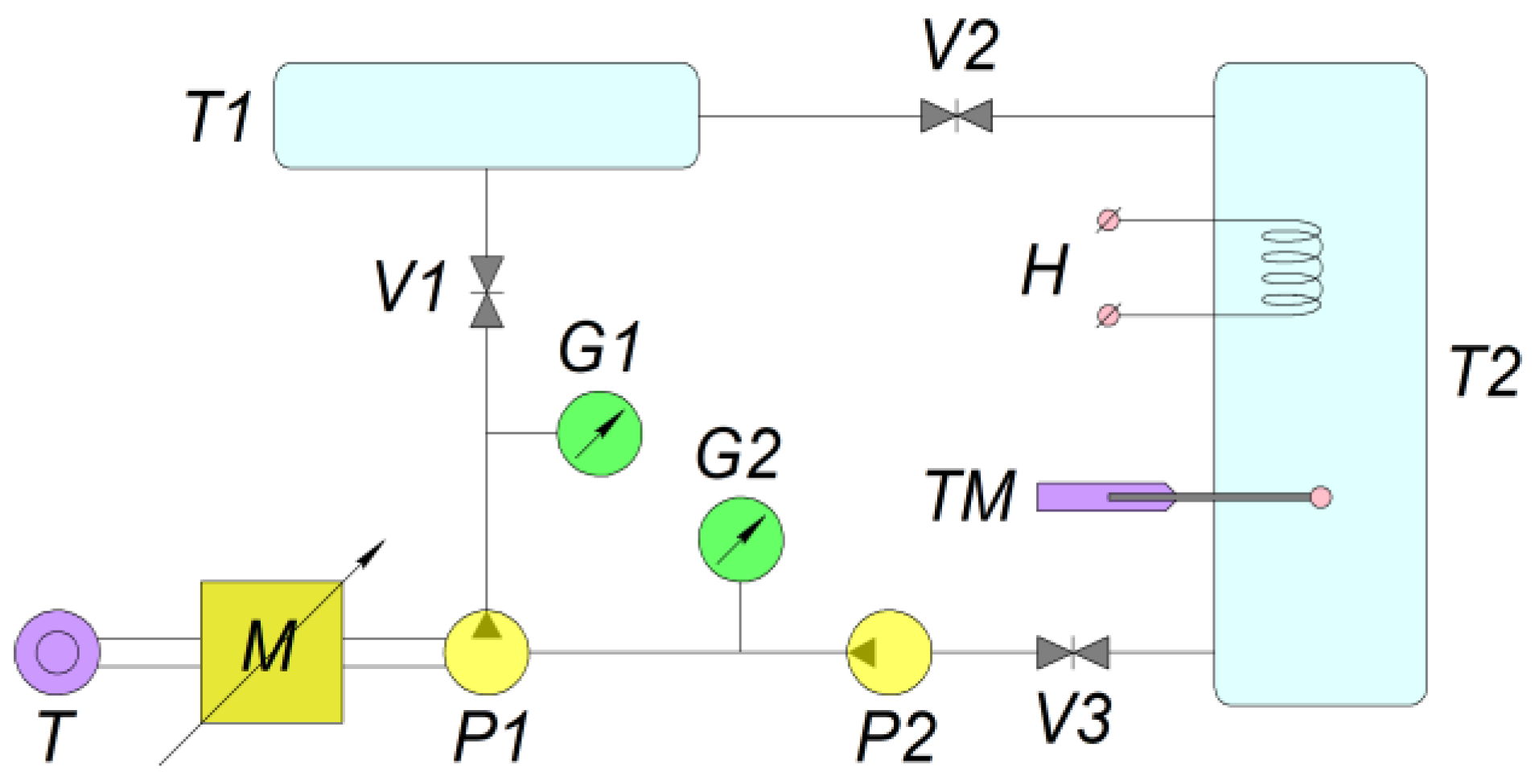

To investigate the peculiarities of ESP-type submersible pumps operating on high-viscosity liquids, an experimental stand was constructed at the Research Laboratory of Hydrodynamic Drives and Installations of Sumy State University. It enables energy efficiency tests to be conducted within a specified range of geometric parameters of pump stages, allowing for the simultaneous examination of the impact of viscosity and high rotation speed on their operating characteristics. A basic hydraulic scheme of the experimental setup is illustrated in

Figure 2.

The stand operates on a closed circuit, circulating the working fluid. These studies were conducted for a fluid that is adequate for Newtonian ones. The influence of the viscosity of the pumped liquid on the pump parameters was investigated over a wide range of rotor rotation speeds. Full-scale operating parameters of centrifugal stages of well pumps used in the oil production complex were obtained.

The experimental pump allows, without altering its basic design, for conducting tests of working stages for four versions of pump stages, according to the standard size range of ESPs. The measuring equipment enabled the measurement of the energy characteristics of the stage under study in accordance with existing requirements [

18].

To measure the temperature of the pumped liquid, a mercury thermometer of accuracy class 0.1 with a measurement range of 0–100 °C was used in the circuit of the experimental stand to measure the temperature of the working liquid in the system; its readings were used to determine the start time of the tests for the selected value of the viscosity of the pumped liquid.

Considering Venn’s approach to defining the general domain where the selected research model simultaneously satisfies physical, kinematic, and geometric assumptions, appropriate parameter ranges for the design, viscosity of the pumped fluid, and rotational speed of the drive rotor were determined to solve the assigned tasks. Each set of tested pump stages of the selected pump size range, ESP 5-50, ESP 5-80, and ESP 5-125 (where 5 is the diameter dimensions of the pump, in inches; 50, 80, and 125 are the flow rate m3/day), worked on pumped highly viscous liquid with variable viscosity. The viscosity change range corresponded to the most common values in the practice of the oil production complex: 10–40 cSt, 40–70 cSt, and 70–110 cSt.

Additionally, the problem of determining the corresponding rotation speeds for each range of viscosity values was solved. The tests were conducted at rotation speeds ranging from 3000 rpm to 8000 rpm, with an increment of 1000 rpm.

The design of the research object pertains to a small-sized type of centrifugal pump, specifically its working stages. This requirement precludes obtaining high-quality experimental results when operating with a single stage, as significant errors occur when transitioning from low to high power levels. Furthermore, the characteristics of the first and intermediate stages may differ significantly due to the influence of flow swirl at the inlet of the intermediate stage impeller. In practice, when testing multistage pumps, the intermediate stage characteristic is obtained by conducting tests using a multistage configuration. The characteristics of the pump with the smaller design (one stage) are then subtracted from those of the pump with the larger design (one stage). This eliminates the influence of the inlet and outlet of the experimental setup. The method discussed is preferable for this study. If tests are conducted with 4-stage and 3-stage assemblies, the intermediate stage characteristic can be obtained with minimal error.

When performing numerous tests on serial pump stages of various sizes, the necessary material was obtained to develop a technique that predicts the performance characteristics of submersible electric centrifugal pumps, ranging from water to high-viscosity liquids. For example,

Table 1 presents some test results of the ESP 5-50 stage, corresponding to the operating range of pump capacity (0.7–1.2)·

Qopt.

The chosen methodology for conducting the experimental portion of the study allowed for an assessment of the accuracy of the experimental data obtained by comparing the results of three repeated experiments under identical operating conditions. This makes it possible to assert that the methodology and errors in determining the measured physical quantities during testing on the created stand satisfy the requirements of the relevant standards currently in force.

When calculating the errors in determining the main parameters of the pump (pump capacity, head, power, and energy efficiency), the analytical dependencies presented were used in accordance with the ISO 9906:2012 requirements [

18]. The results of determining the error values of indirect measurements are presented in

Table 2.

The maximum relative error (MRE) and the root mean square error (RMSE) are calculated as follows:

where

N—the total number of experiments;

i—experiment number (

i = 1, 2, …,

N);

—

i-th experimental data;

—

i-th estimated data;

—mean value.

The reliability of the obtained experimental results is substantiated using a generally accepted method for conducting the relevant tests in pump engineering practice, as well as a satisfactory measurement error of the physical parameters during the experimental part of the study.

3. Results

3.1. Experimental Results

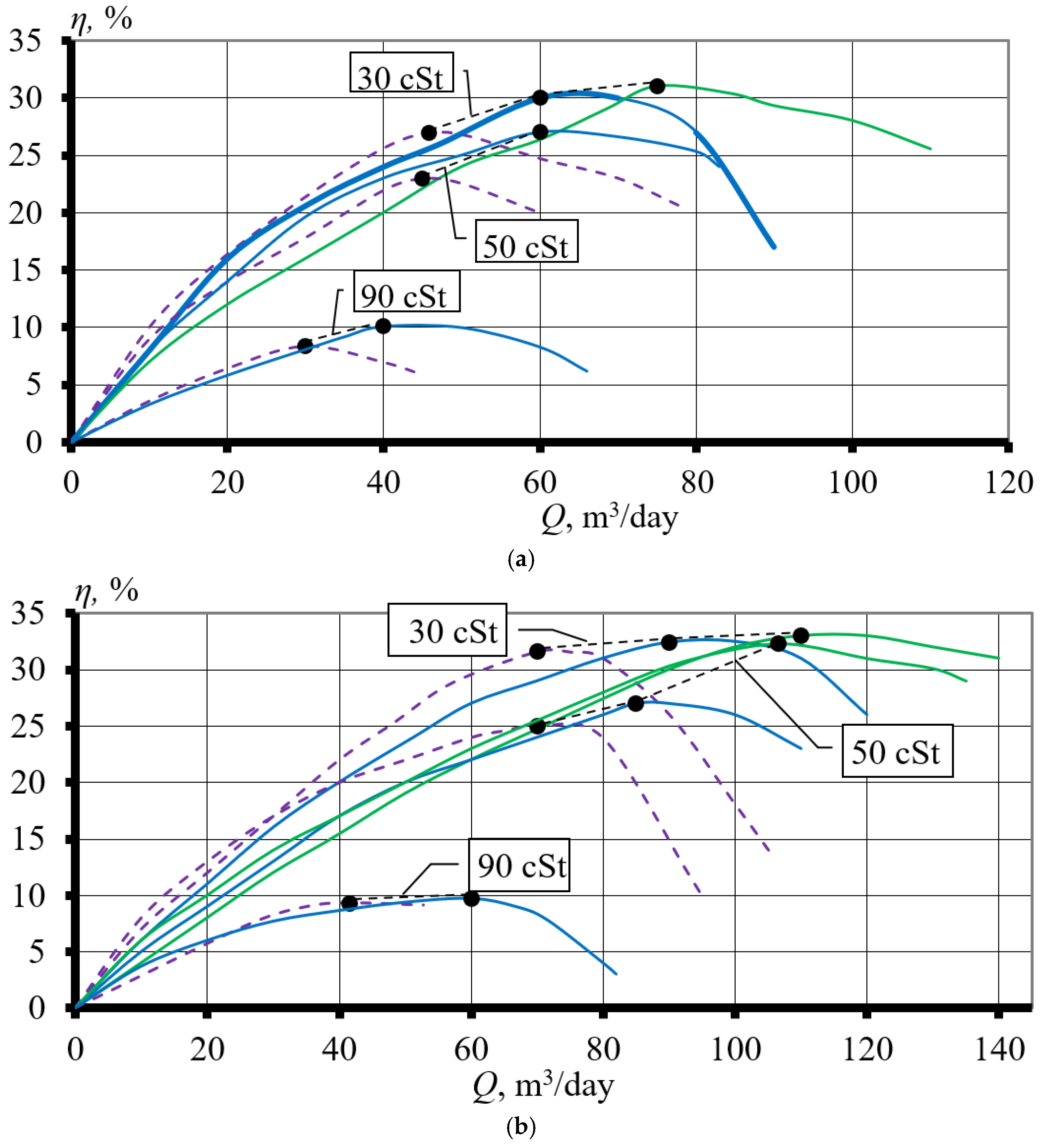

The operating characteristics obtained from the experimental setup confirm the absence of transient flow regimes in the flow structure of the pumped viscous medium. In the physical model of viscous fluid flow in the proposed small-size centrifugal stages, the laminar flow regime prevails (

Table 3), which corresponds to the experimental result—the absence of recessed sections in the head characteristics of the tested pump stages (

Figure 3).

As can be seen from the presented table of Reynolds number calculation results, our assertions about the prevalence of the laminar flow regime in the flow structure of the small-sized working stage of the dynamic pump are confirmed by the calculation method.

This result substantiates the presence of a stable flow regime for high-viscosity liquids during pumping within the operating range. This enables the application of the model recalculation technique, yielding a satisfactory result in terms of accuracy, by utilizing the similarity theory in today’s pump engineering practice.

Based on the given characteristics, it is evident from some of the accumulated experimental data that increasing the rotation speed has a positive effect on the energy efficiency of the pump stage when pumping highly viscous liquids. This fact is confirmed by a noticeable shift in the optimal rated point of the studied stages to the right with an increase in rotational speed for a given flow rate.

Based on the results obtained from the experimental work, the following general conclusions can be drawn. First, all the optimal energy efficiency operating regions correspond to almost identical values of the specific speed. It can be assumed that these regimes are kinematically similar. This conclusion is consistent with the similar theory for vane machines.

Second, at low productivity and high viscosity, due to the pump’s low energy efficiency, rapid heating of the pumped liquid in the flow channels occurs at high rotational speeds. As a result, the viscosity of the pumped medium decreases, which leads to a subsequent reduction in energy losses in the pump. Obviously, this is connected, first, with changes in the value of energy losses due to disk friction.

Third, it has been established that when the rotation speed changes during the process of pumping highly viscous liquids with small working stages, the technique of recalculating the rotation speed, as described in the theory of vane machines, undergoes some modifications. The studied phenomenon confirms the hypothesis regarding the structure of the flow of high-viscosity liquids in the flow channels of the centrifugal pump stages [

19,

20,

21].

3.2. Practical Results

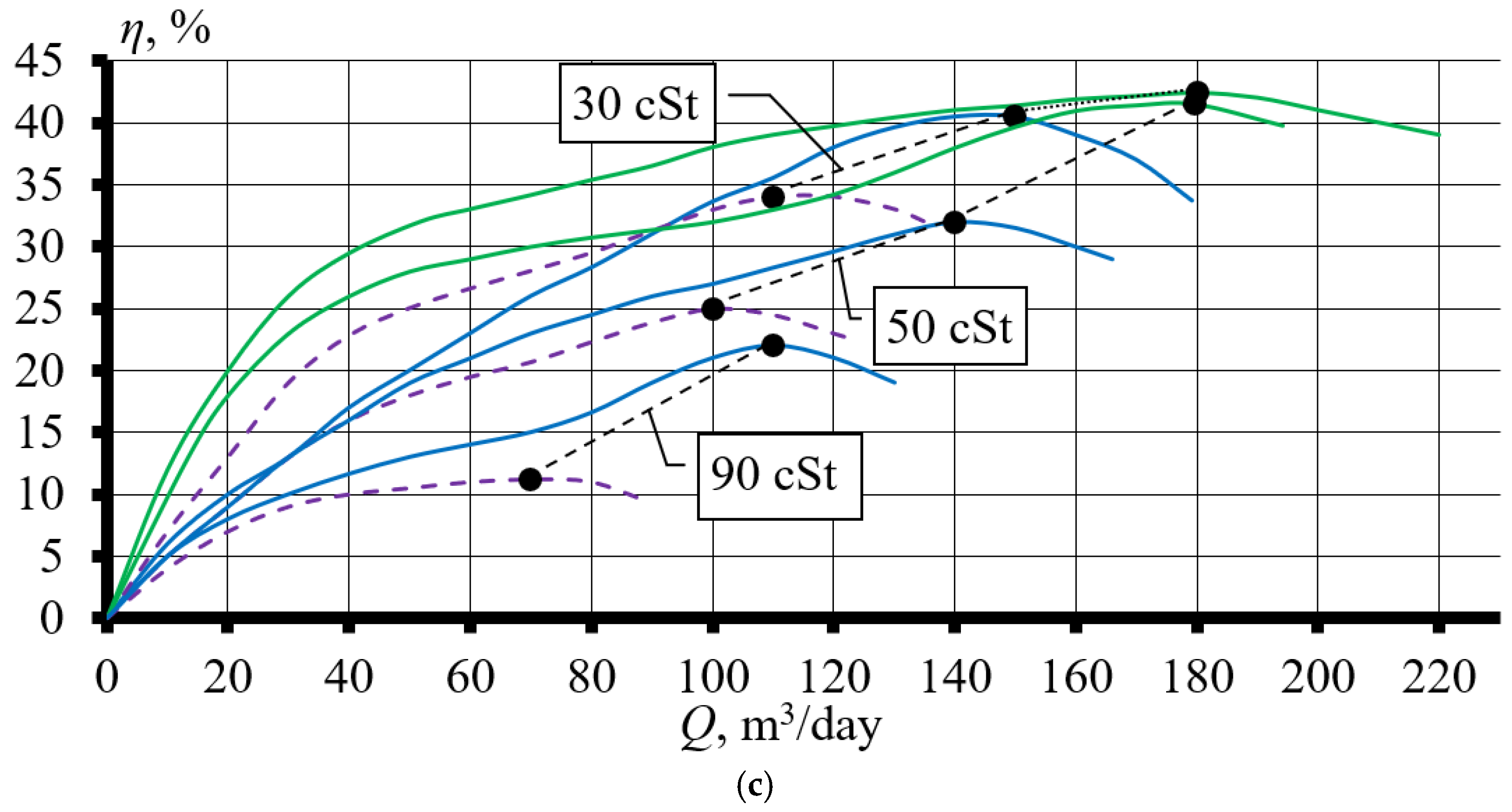

As a result of subsequent research work in the application of the developed technique for conditions of high rotation speed of the drive rotor when pumping highly viscous liquids, as applied to the pumping part of the TPU with a small-sized type of pump stages, refined analytical expressions were obtained for calculating the working rate range of the performance characteristic of the corresponding pumps, which provide satisfactory agreement between the calculated and experimental data.

First, talking about the dependence of the value of power consumed by the pump on the rotation speed of its rotor. It has been experimentally determined that in the case of pumping a highly viscous liquid, the value of the water purity degree m, when changing the rotation speed of the pump rotor, can change from m = 3 (technically pure water) to m < 3 (highly viscous liquid). Within the specified limits of change in viscosity of the pumped medium, the average value m = 2.7 can be taken.

Additionally, for high-speed conditions, there is an error in calculating the pump stage head. To eliminate it, an empirical coefficient of 0.85 is introduced into the head conversion ratio. In this case, as applied to the pump stages of the ESP 5-50, ESP 5-80, and ESP 5-125 types, the calculated results are consistent with the experimental data within the limits that satisfy regulatory requirements.

As has been established by experimental studies, in the process of pumping a highly viscous liquid, the similarity theory is maintained in the values of the primary energy parameters when the rotation speed changes in the range of the result of the ratio of changing rotation frequencies n1/n2 ≤ 2, which is also in good agreement with the generally accepted principles of the theory of vane machines.

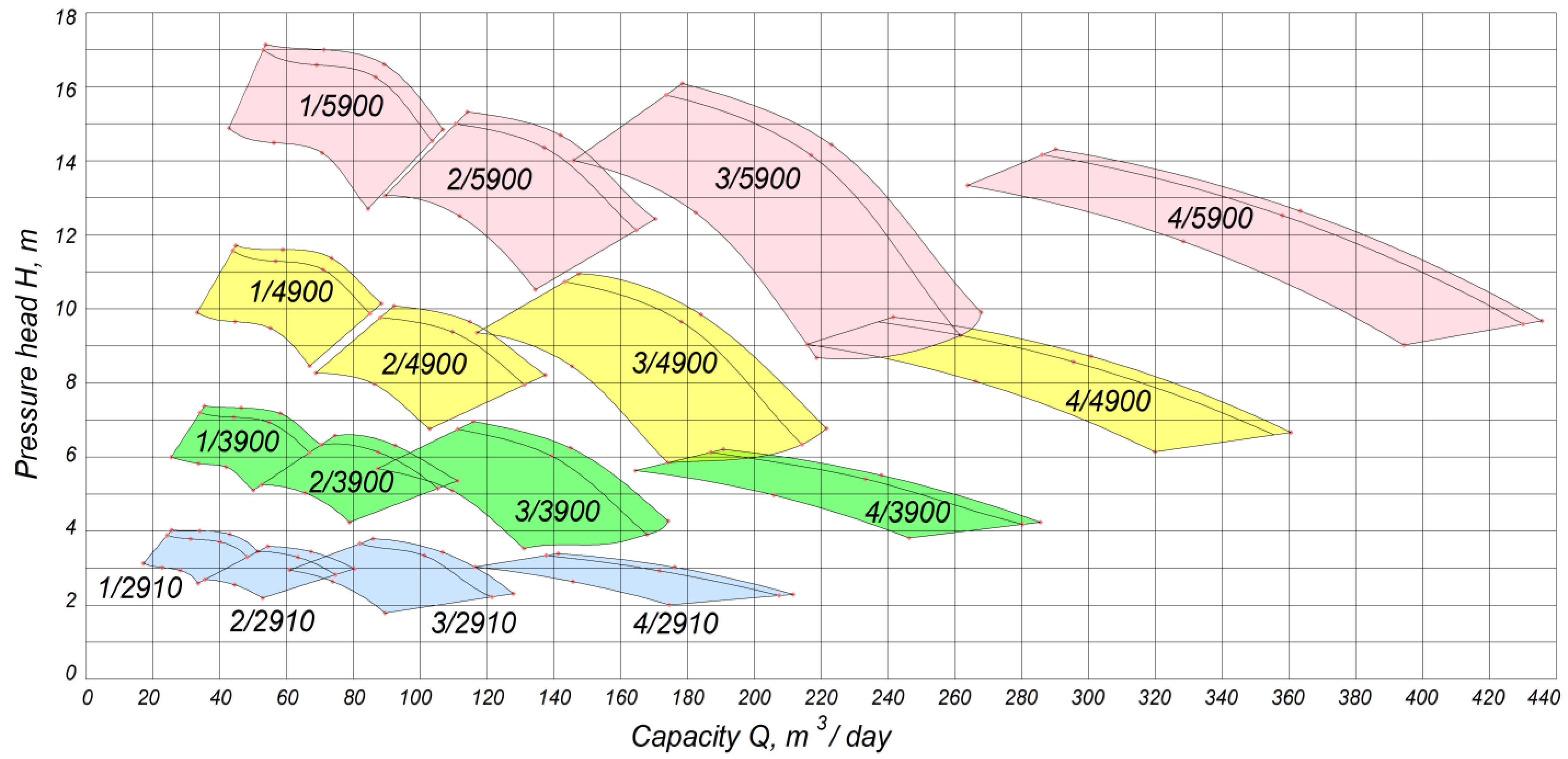

To provide more information and clarity, the recommendations are presented in graphical form, indicating changes in the main parameters within the pump’s operating range, depending on the required performance at a specified range of viscosity and rotor rotation speed (

Figure 4).

According to the graphic information provided, the initial selection of the required pumping unit is as follows:

- –

the required performance or its range is selected from the scale of pump capacity;

- –

the required head of the pump stage is determined using the head scale;

- –

the desired field of parameters is determined based on the kinematic viscosity of the pumped medium, based on the condition of the most efficient operation of the selected pumping unit;

- –

the required pump rotation speed is set to achieve the required parameters and the corresponding energy efficiency value;

- –

after the initial determination of the pump unit size, its performance characteristics are specified using the developed technique.

4. Discussion

The calculated values of the performance characteristics of the pumps in the above-mentioned size range, obtained based on the developed technique, are quite close to the actual operating values. From the perspective of convenience for engineering calculations, this technique does not require a complex sequence of mathematical calculations. A similar approach to developing a method for predicting the performance of centrifugal pumps handling highly viscous fluids was used by the authors in a scientific study that correlated the head conversion factor with the modified Reynolds number [

8], but the proposed method, unlike ours, does not take into account the influence of high rotor speed.

A completely different approach to solving the problem under consideration has been implemented by some researchers, who have explored the relationship between the impeller geometry of a centrifugal pump and the viscosity of the pumped liquids to design the impeller for a specific liquid viscosity [

3]. This approach, in contrast to our proposed method, requires significantly more labor-intensive and time-consuming work in predicting the operating characteristics of dynamic pumps, and also does not allow the use of ready-made serial sizes of ESP stages.

Due to the variety of standard sizes of well dynamic pumps for oil production, both in design and in terms of operating conditions, the presented technique, naturally, cannot cover and consider all the objectively existing factors that make up the work process of pumping highly viscous and multiphase media [

22,

23,

24]. About of the complex nature of the flow of highly viscous media in the flow channels of multistage pumps of a number of ESPs is very well and scientifically substantiatedly presented in a research paper, which studied the influence of the flow of Newtonian and non-Newtonian fluids on the general characteristics of ESPs (secondary flows, recirculation zones, vortex flows, pressure drop losses, rheological properties of liquids, etc.) [

25].

Consequently, it is necessary to establish acceptable intervals for the factors that determine satisfactory performance when applying the specified recalculation technique.

This technique was developed based on the results of scientific research into the influence of three main criteria on the characteristics of changes in the energy parameters of centrifugal pumps, including high viscosity of the pumped liquid, high rotation speed, and small-sized design of the working stages.

The experimental results showed the absence of an equidistant increase in the power characteristics of the pump when it operates on a viscous medium in relation to its characteristics when it operates on water, which can be explained by a significant increase in the forces of energy loss due to disk friction with an increase in pump flow due to the small axial dimensions between the impeller disks and the pump casing. This results in a disproportionate increase in power when pumping highly viscous fluids, relative to the power required for pumping water. This phenomenon, in our opinion, is typical of pumping highly viscous liquids using small-sized pump stages. It can be argued that there is a limit to the viscosity of the pumped fluid, up to which the use of the studied pump stages is justified. It has been established that with increasing viscosity above 110 cSt, resistance in the flow channels increases to a level of power loss comparable to, or even greater than, the power of the stage itself. Ultimately, this affects the consistency of calculated and experimental results.

The resulting volume of experimental data allowed us to determine the values of the empirical coefficients. By analyzing the changes in their numerical values, taking into account the changing data during pumping, acceptable ranges were established within which the specified values were constant or had minor discrepancies. Thus, within the selected viscosity range, the resulting average numerical value of the experimental coefficients in question matched the experimental results, thereby determining the operating characteristics of the centrifugal pump stages under study.

When considering the physical model of the flow of a viscous liquid in small-sized centrifugal pump stages, it can be assumed that viscous friction forces dominate the flow structure, which determines the nature of the change in the operating parameters of the stages under consideration. Under the conditions under consideration, the inertial forces in the flow of viscous liquid have virtually no effect on the change in its structure and, over a sufficiently large range of changes in the viscosity of the pumped medium, have an almost constant value. In our opinion, this occurs due to the disproportionality of the friction coefficient change due to the viscous nature of the flow, as well as its functional dependence on the Reynolds number. Consequently, it becomes advisable to establish the actual values of the proportionality indices in the accepted relationships.

Using the calculation method, while adhering to the above-mentioned principles, expressions were obtained that resulted in a discrepancy between the calculated and experimental data, resulting in an error in the pump stage head calculation. To eliminate this, an empirical coefficient of 0.85 was introduced into the head conversion formula. In this case, for ESP-type pump stages, the calculated results agree with the experimental data within limits that meet regulatory requirements.

As a result, based on the experimental data obtained, the range of values of these criteria, in which the technique gives adequate calculated results with the actual ones, is as follows:

- –

in terms of design features of the working stages, it covers the model range of submersible electric centrifugal pumps with floating type impellers (from ESP 5-30 to ESP 5-200);

- –

the acceptable range of rotation speed of the drive rotor is between 2910 rpm and 8000 rpm. As stated above, the value of the ratio of variable rotation speed for the recalculation conditions should not exceed a numerical value equal to 2.0;

- –

the range of change in viscosity of the pumped liquid, for conditions of efficient operation of pumping equipment from the point of view of energy consumption, is limited by the viscosity of 10–110 cSt;

- –

the change in head is proportional to the change in rotation speed to the degree of 2.1–2.2, but for viscosities exceeding 150 cSt.

For viscosities in the range from 10 cSt to 120 cSt, the degree of proportionality with sufficient accuracy for recalculation is taken to be equal to 2.0. The pump power changes proportionally to the change in rotation speed to the degree of 2.7.

It is also advisable to provide the necessary recommendations for the most effective use of the results of predicting the performance characteristics of the specified series of pumping units.

When selecting a pump from the recommended ESP product range, it is essential to consider the operational requirements, including the flow rate of the pumped viscous liquid and the required head value. Preference should be given to pumps with predicted parameters that are as close as possible to the required ones.

For pumping liquids with maximum viscosity values (relative to the technique’s allocated area of applicability), recalculation should be carried out for pumps with higher productivity and energy efficiency, as obtained on water.

When operating this type of pump at high rotation speeds, it is necessary to create a pressure head of at least 0.15 MPa at the inlet of the first stage.

When performing model recalculation for pump stages that are adequately sized according to the standard size range established by the technique, the impellers with the maximum energy parameters obtained in water should be used as the model.

5. Conclusions

An analysis of scientific publications revealed the absence of an accepted technique for recalculating the operating characteristics of centrifugal pump stages for water to high-viscosity media, considering their small-sized design and high rotation speeds. This fact defined the concept of scientific novelty for this work, which is formed from several components in its scientific solution.

The conducted research has yielded new scientific and practical results that significantly enhance the theoretical understanding and engineering application of small-sized high-speed centrifugal pumps operating with viscous fluids.

The scientific novelty of the study lies in the following. First, the mechanism of the combined influence of rotor speed and fluid viscosity on the performance characteristics of small-scale hydrodynamic pumps has been established. Second, the effect of geometric scaling on the flow behavior of viscous media within the flow path of centrifugal pumps has been revealed. Also, the application features of similarity theory for recalculating performance characteristics of centrifugal pumps operating with high-viscosity liquids at various rotor speeds have been determined. Finally, a generalized functional relationship between the main types of energy losses in a centrifugal pump has been proposed, accounting for both the viscosity of the pumped medium and the rotational speed.

The practical significance of the results is as follows. First, a semi-empirical methodology has been developed to recalculate the head and energy characteristics of centrifugal pumps when transitioning from water to high-viscosity liquids, considering high rotor speeds and reduced dimensions of the flow elements. Second, experimental validation was conducted on serial pump stages of ESP-type submersible units, confirming the reliability and accuracy of the proposed recalculation method. Based on the data obtained, practical recommendations have been developed for selecting pump unit sizes for specific operating conditions. Also, the energy-efficient viscosity ranges for the working fluid have been determined for submersible electric pump units of the ESP series (from ESP 5-30 to ESP 5-200). Finally, practical guidelines have been formulated for selecting pump configurations that ensure optimal energy performance under predetermined operational parameters.

The results of the scientific work were tested in predicting the performance characteristics of the ESP 5-80-1200 pump located in Bugrevate’s field of the Okhtyrka oil production complex at JSC “Ukrnafta” (Okhtyrka, Sumy Region, Ukraine).

The obtained scientific and methodological results contribute to improving the energy efficiency of industrial hydraulic systems, particularly in oil and gas applications, and enhance their technical and economic indicators. Therefore, the proposed technique for predicting the performance characteristics of submersible centrifugal pumping units possesses both scientific and practical significance, expanding the fundamentals of vane machine design and enabling its practical application in modern engineering practice.