Research on Vibration and Noise of Oil Immersed Transformer Considering Influence of Transformer Oil

Abstract

1. Introduction

- (1)

- Ultrasonic partial discharge detection

- (2)

- Acousto-electrical joint detection

- (3)

- Noise pattern analysis

- (4)

- Vibration monitoring

- (5)

- Voiceprint (acoustic fingerprint) diagnostics

- (6)

- Digital twin for intelligent O&M

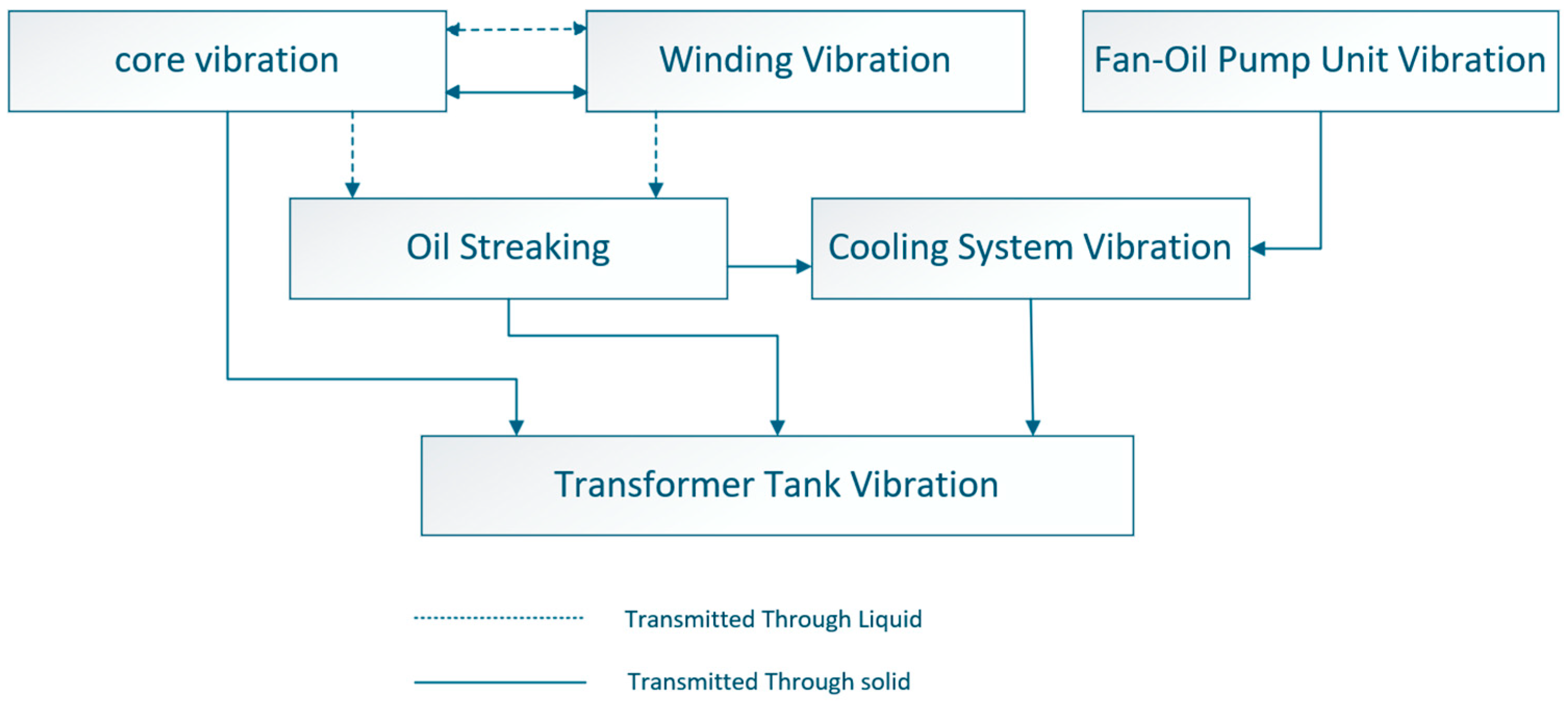

2. Structure of Oil Immersed Transformer and Composition of Vibration of Structural Parts

2.1. Structural Composition and Vibration Constituents of Oil-Immersed Power Transformers

- (1)

- Structural conduction through the core-limb/yoke assembly followed by fluid coupling into the tank wall;

- (2)

- Direct fluid-borne transmission through the oil volume.

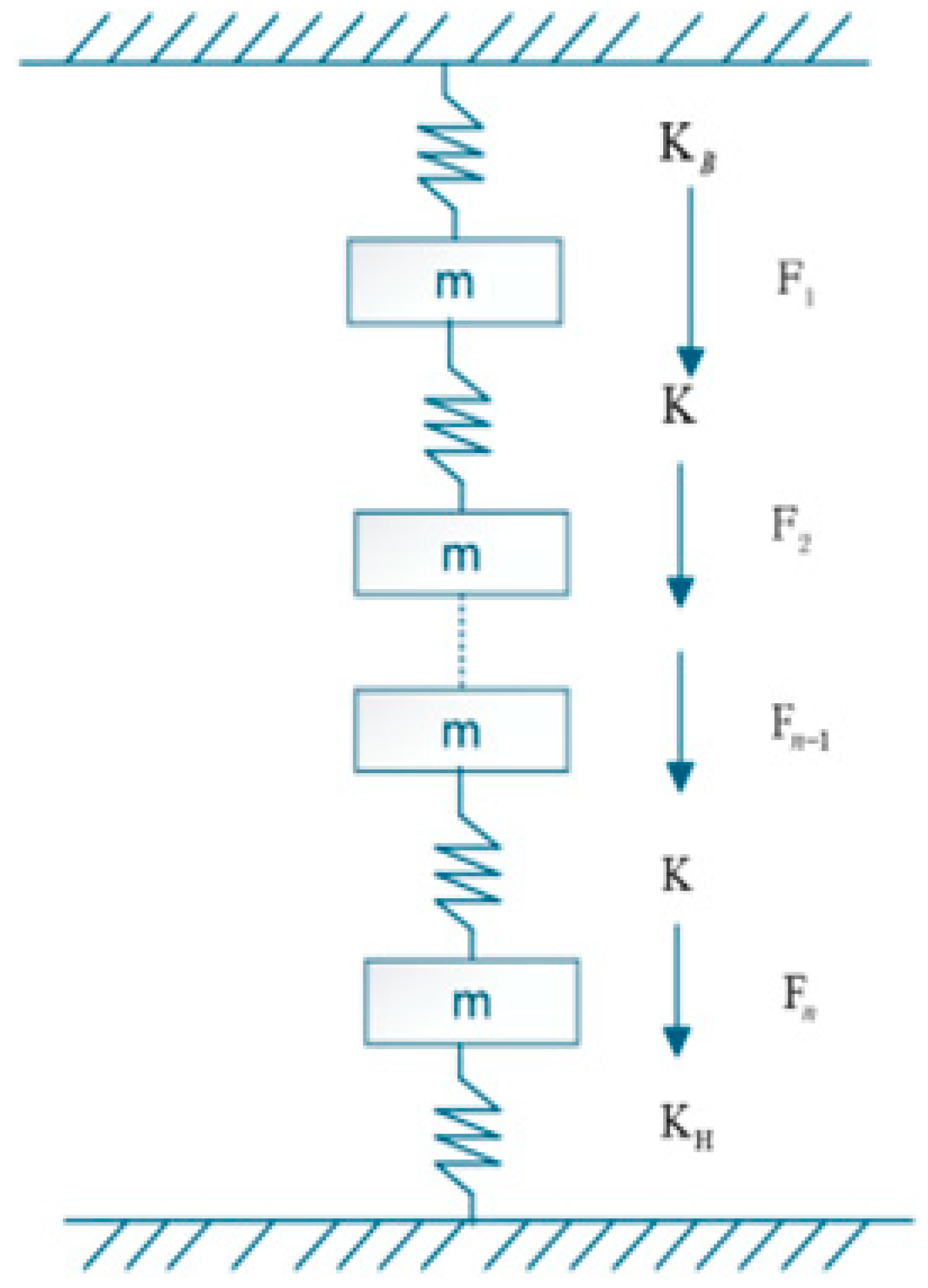

2.2. Modelling of Core and Winding Vibrations in Power Transformers

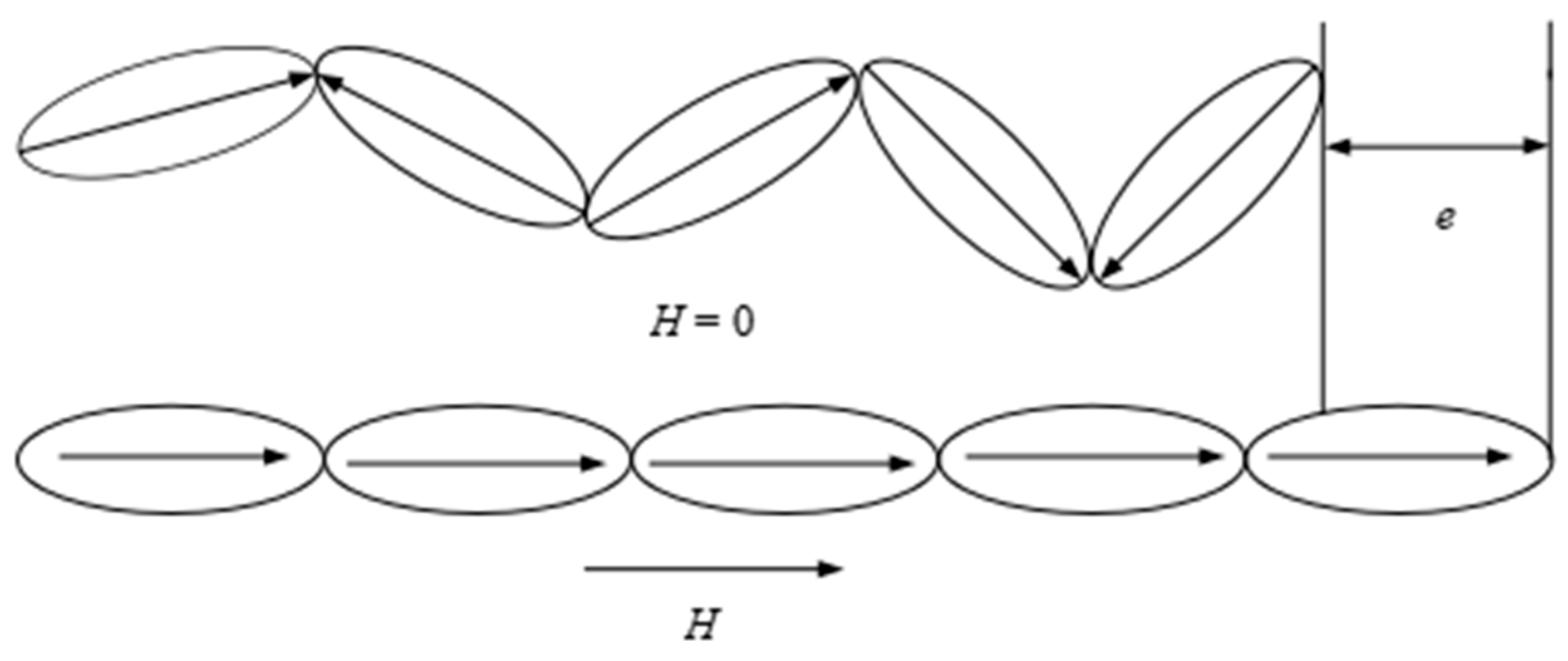

2.3. Modelling of Fluid–Structure Interaction Damping Between Transformer Oil and Structural Components

- (1)

- Excitation frequency

- (2)

- Damping coefficient

- (3)

- Vibration correction factor

- (4)

- Implementation procedure

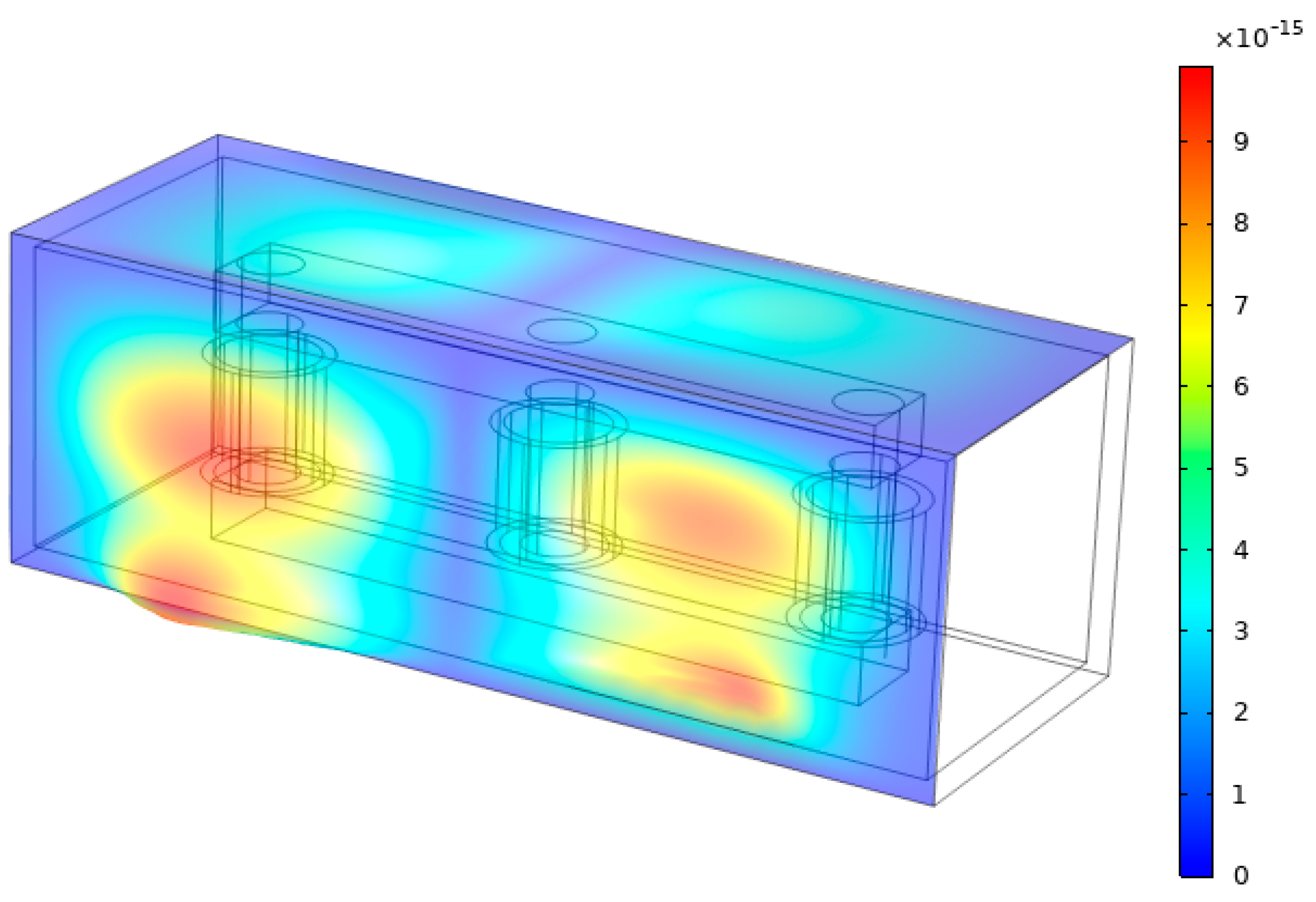

3. Simulation of Vibration and Noise of Oil Immersed Transformer

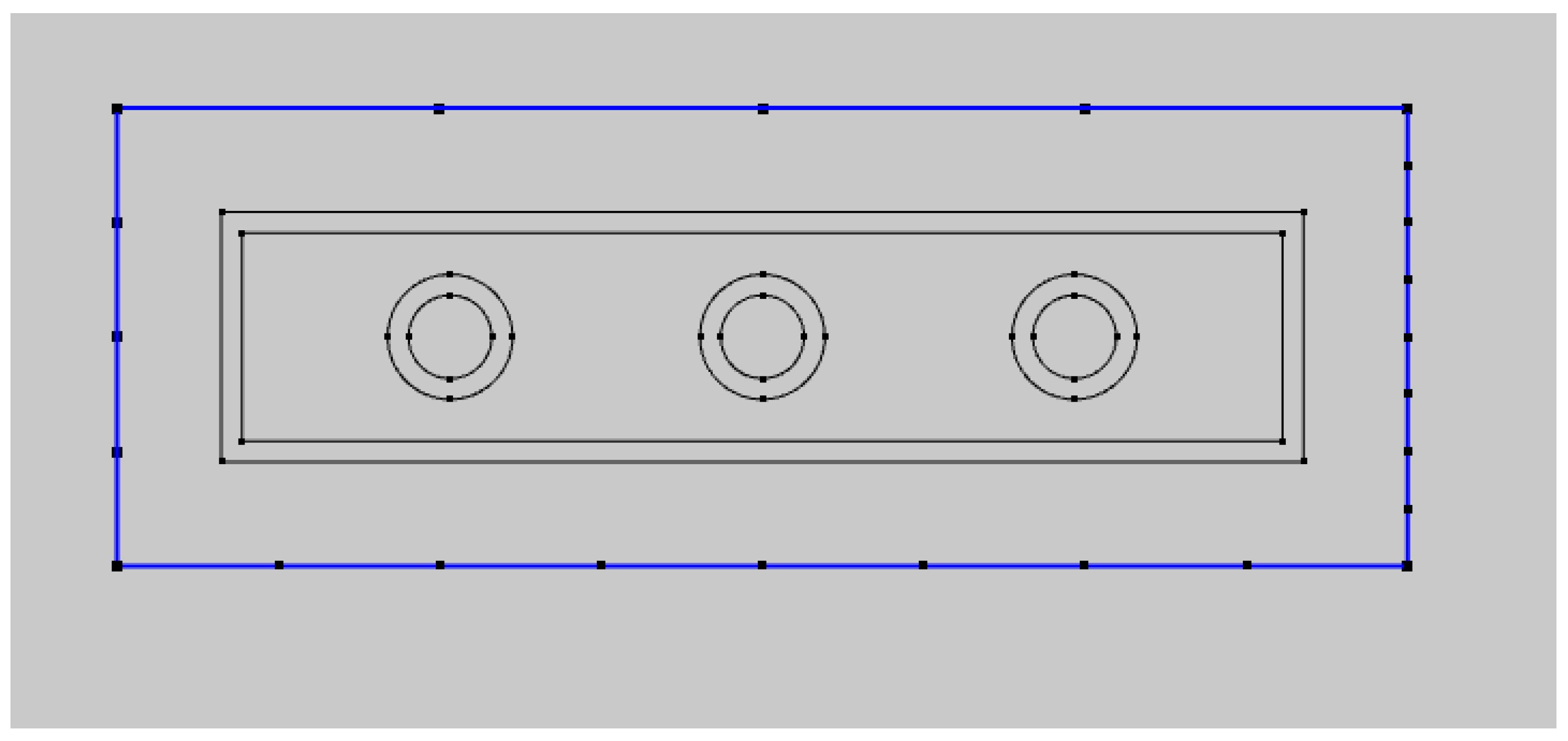

3.1. Vibration Simulation of the Active Part–Tank Assembly

3.1.1. Fundamental Assumptions and Boundary Conditions

- (1)

- Simplifications of the structural modelThe transformer core–winding system is a high-order multi-degree-of-freedom (MDOF) structure; however, for linear modal analysis, the following simplifications are introduced:

- All sub-domains are treated as homogeneous continua; the laminated core is regarded as a monolithic solid, and inter-laminar joints as well as yoke–limb interfaces are neglected.

- Material nonlinearities are excluded from the modal solver.

- (2)

- Material properties

- (3)

- Boundary constraintsTwo boundary sets are prescribed:

- Free-free for all surfaces without mechanical contact;

- Fixed constraints (all six DOFs set to zero) at the upper locating lugs and lower foot pads that anchor the core inside the tank.

- (4)

- Frequency range

- (5)

- Multi-physics coupling strategy

- (6)

- Magnetostrictive excitation

- (7)

- Fluid modelling assumptionsTo accelerate convergence while preserving accuracy, the oil is idealized as:

- (a)

- Weakly compressible (small pressure perturbations);

- (b)

- Inviscid (negligible viscous dissipation);

- (c)

- Laminar (natural-circulation pressure ≪ pump pressure);

- (d)

- Homogeneous.

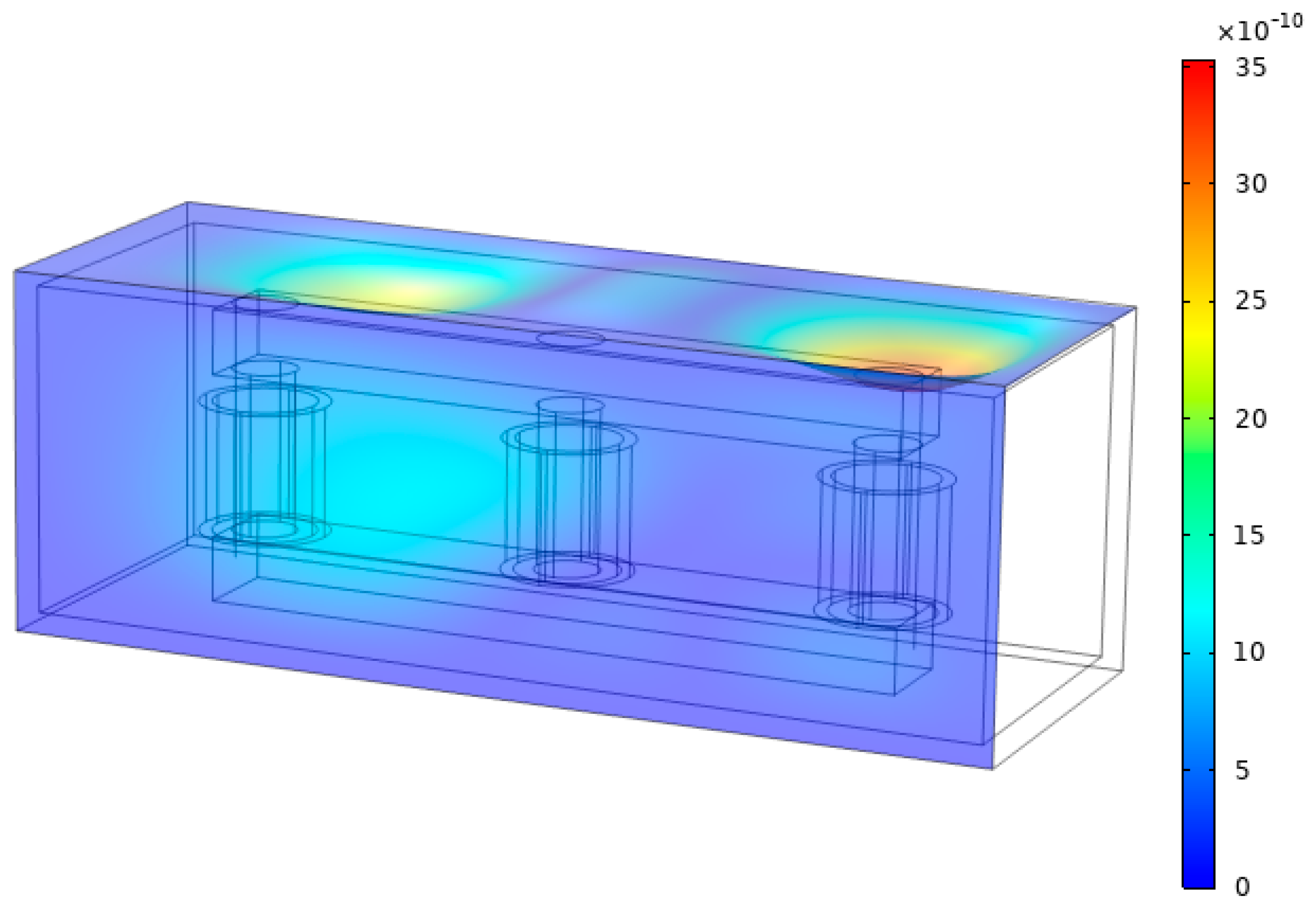

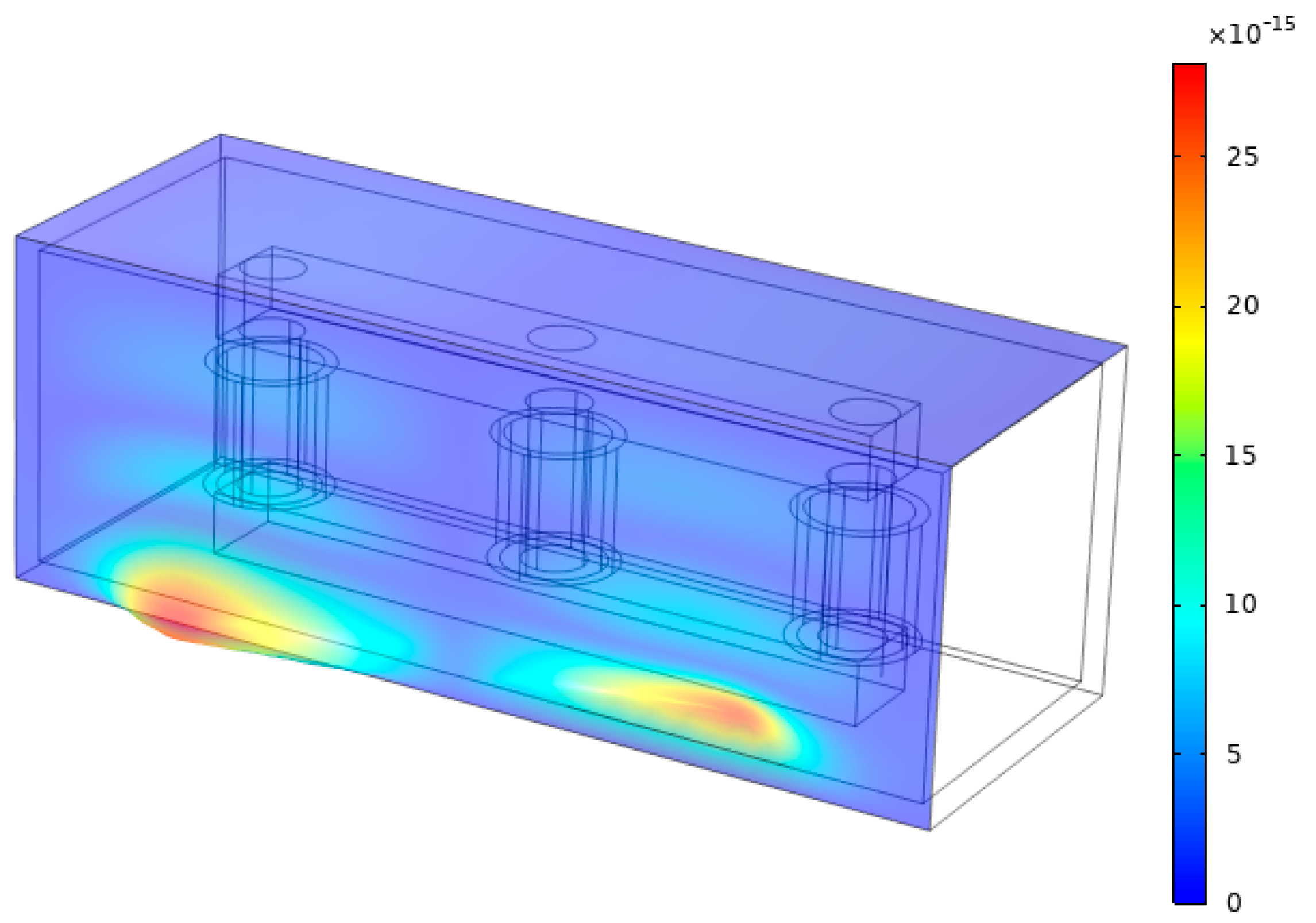

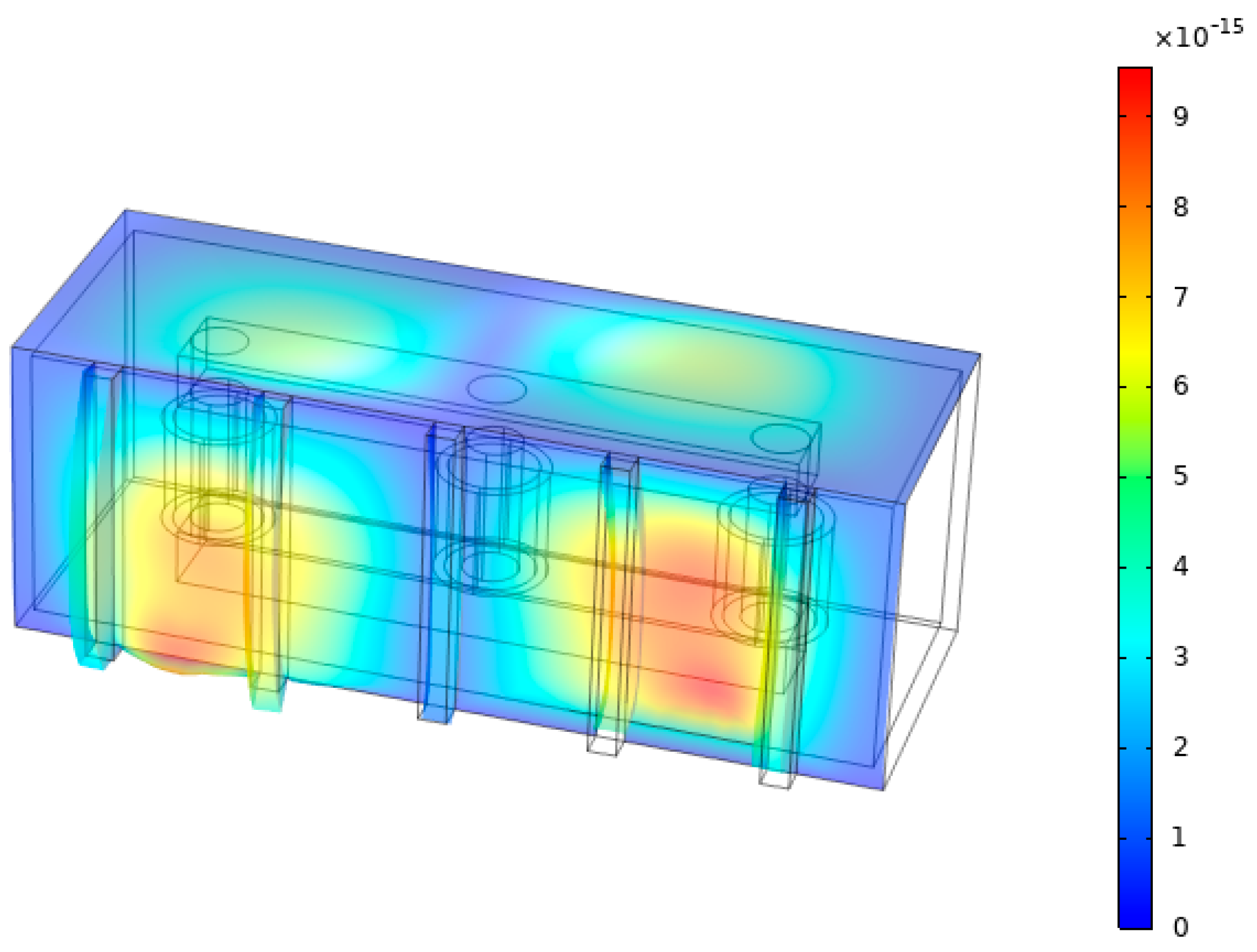

3.1.2. Vibration Characteristics of the Active Part

- (1)

- Simultaneous winding and core excitation

- (2)

- Winding-only excitation

- (3)

- Influence of oil and stiffening ribs

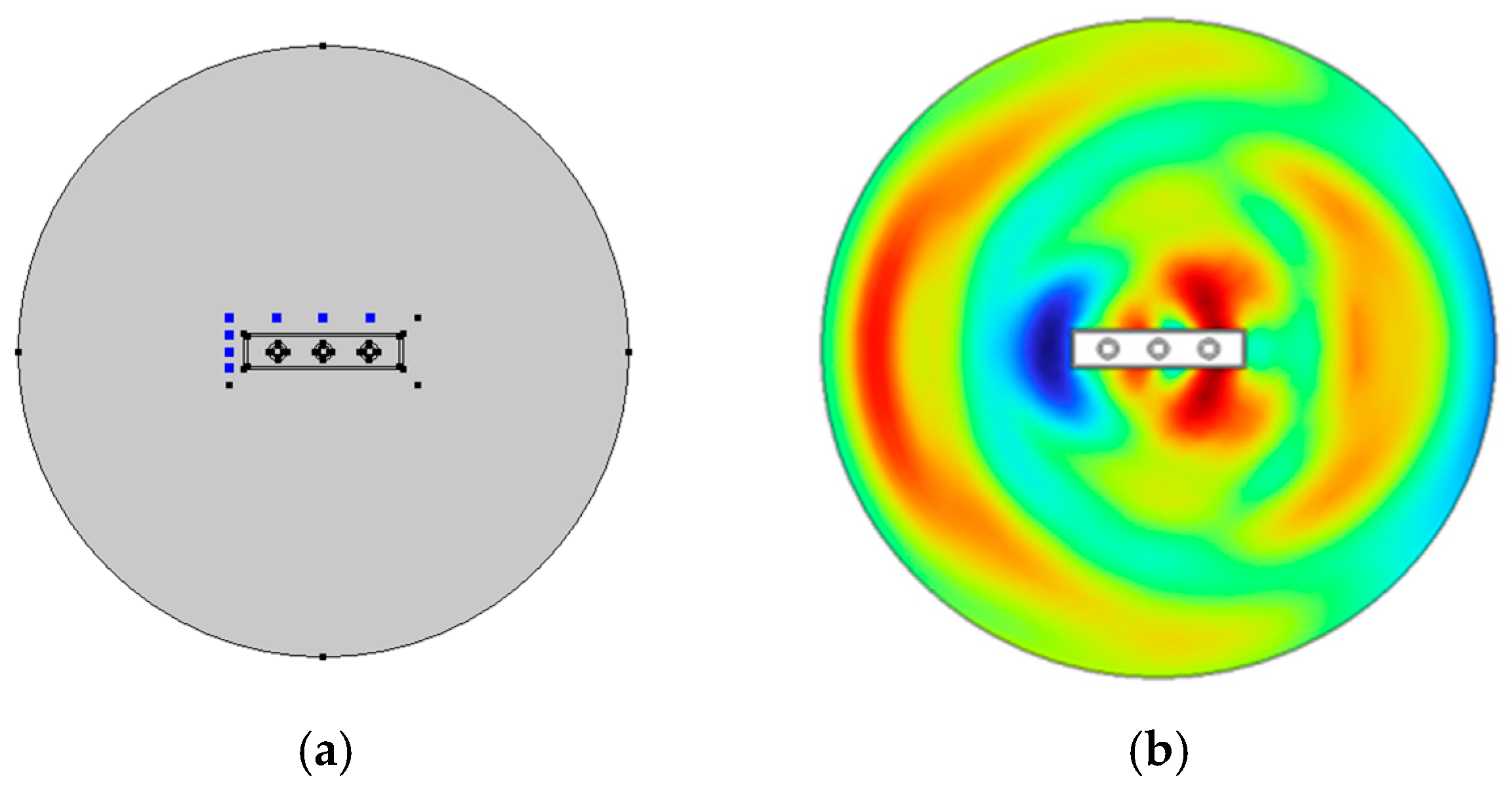

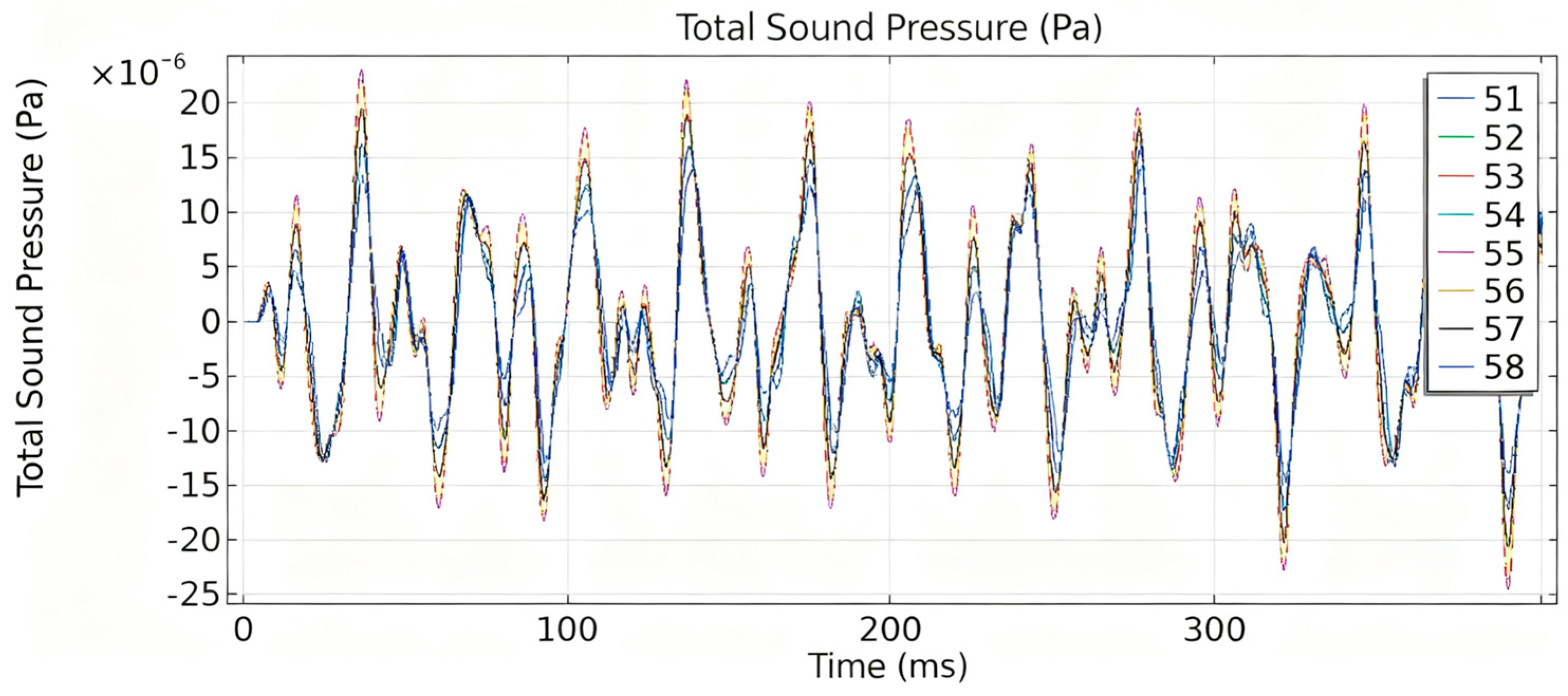

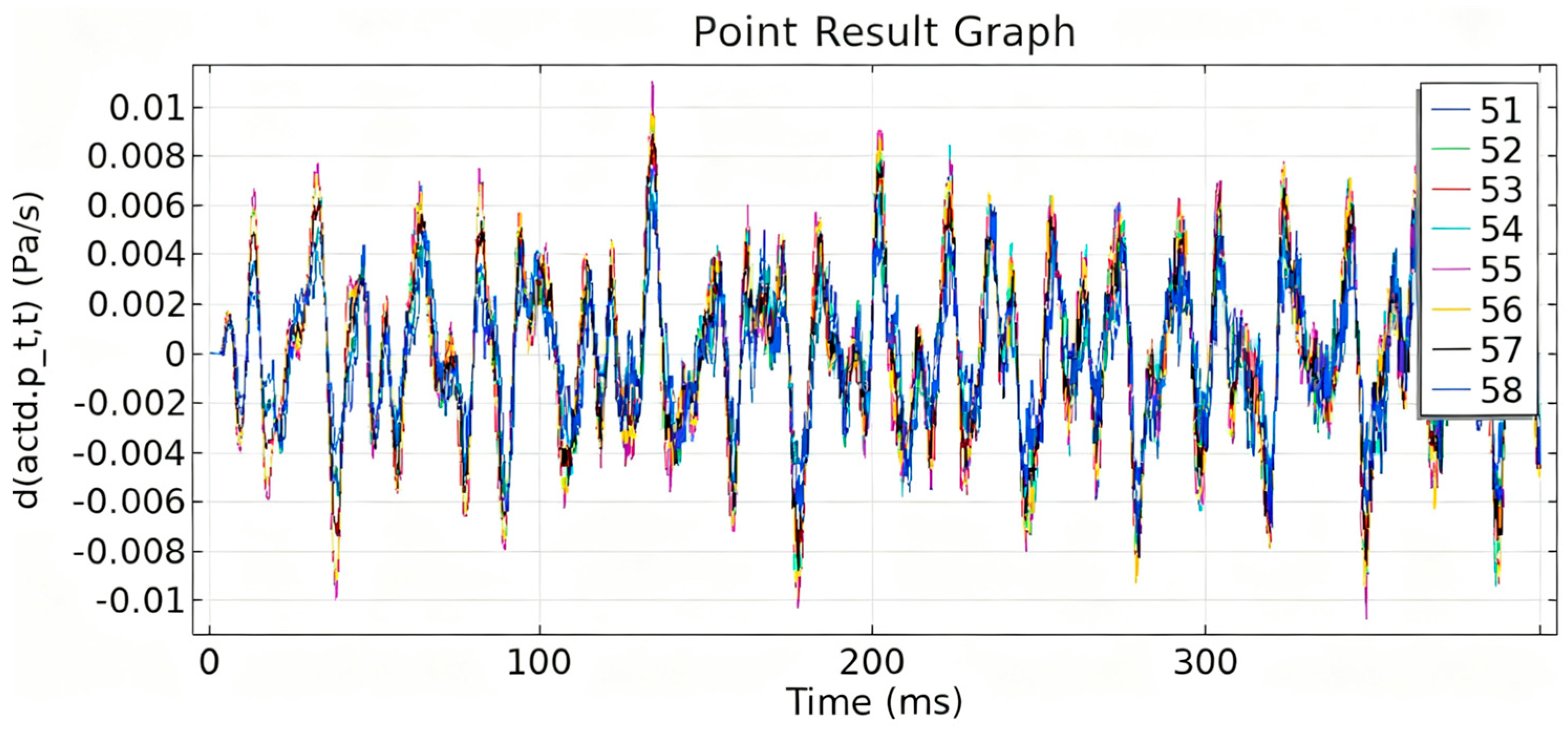

3.2. Noise Simulation for Oil-Immersed Transformers

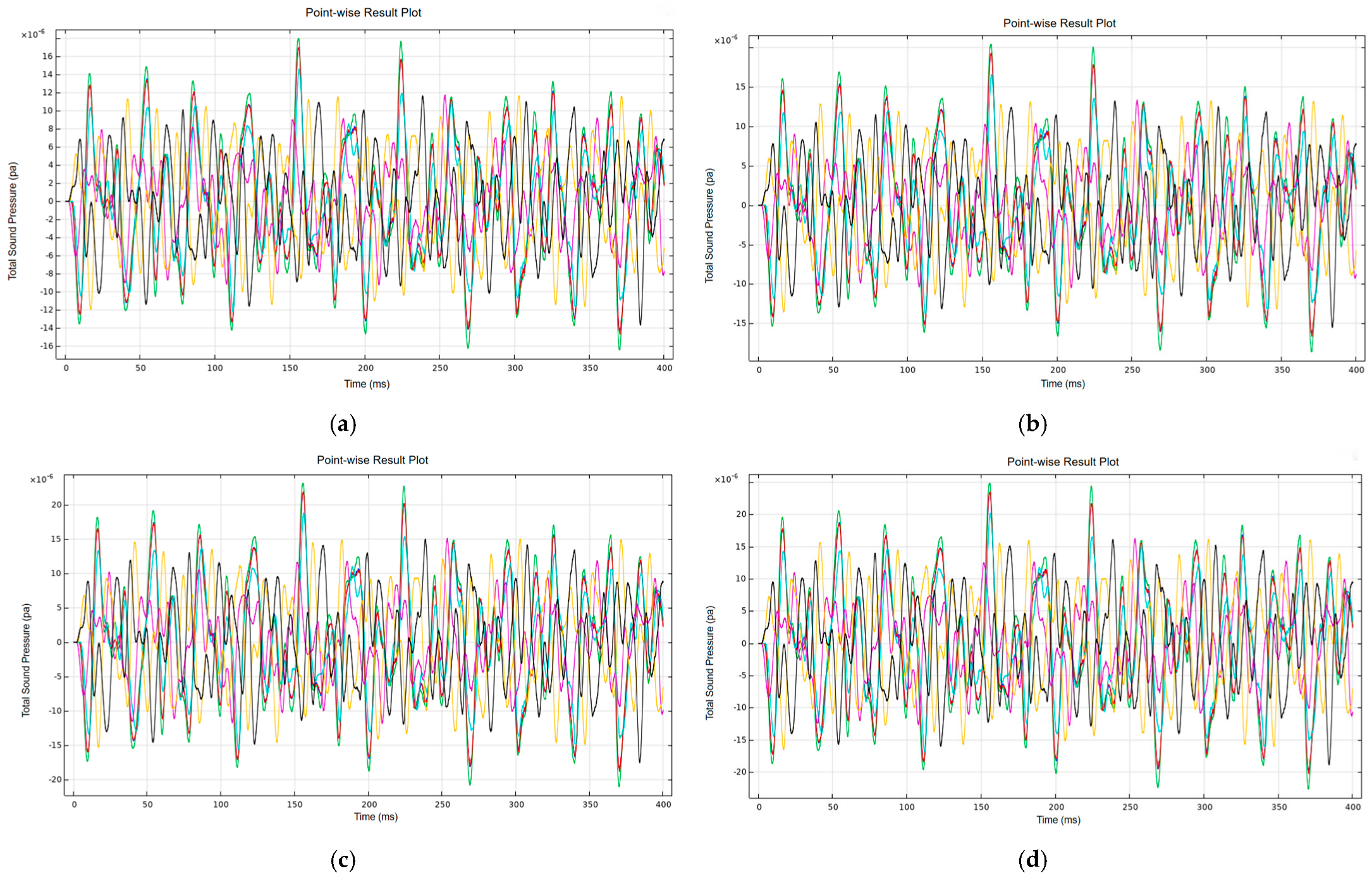

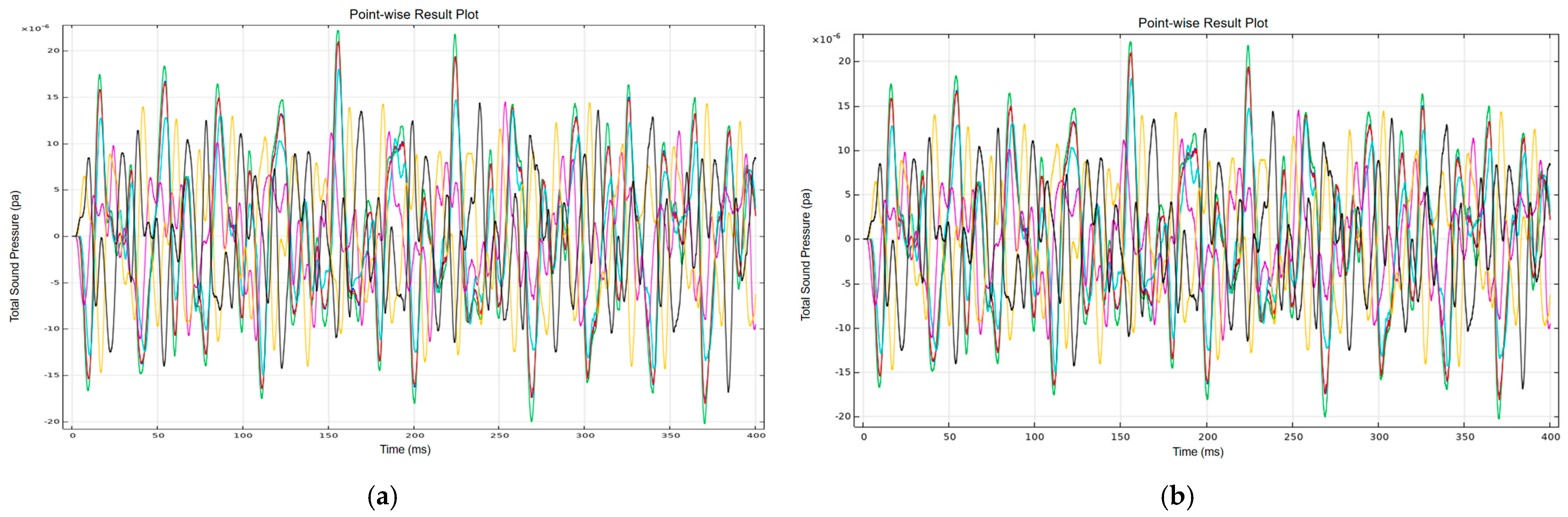

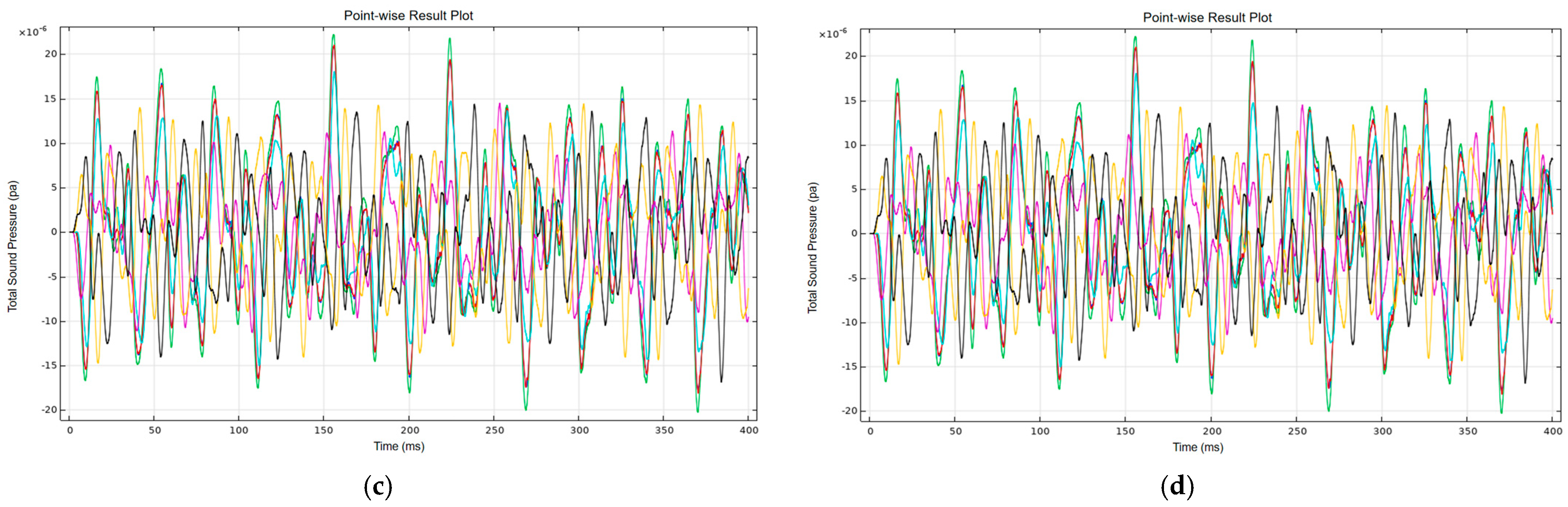

3.2.1. Overload and Underload

3.2.2. Voltage Fluctuation

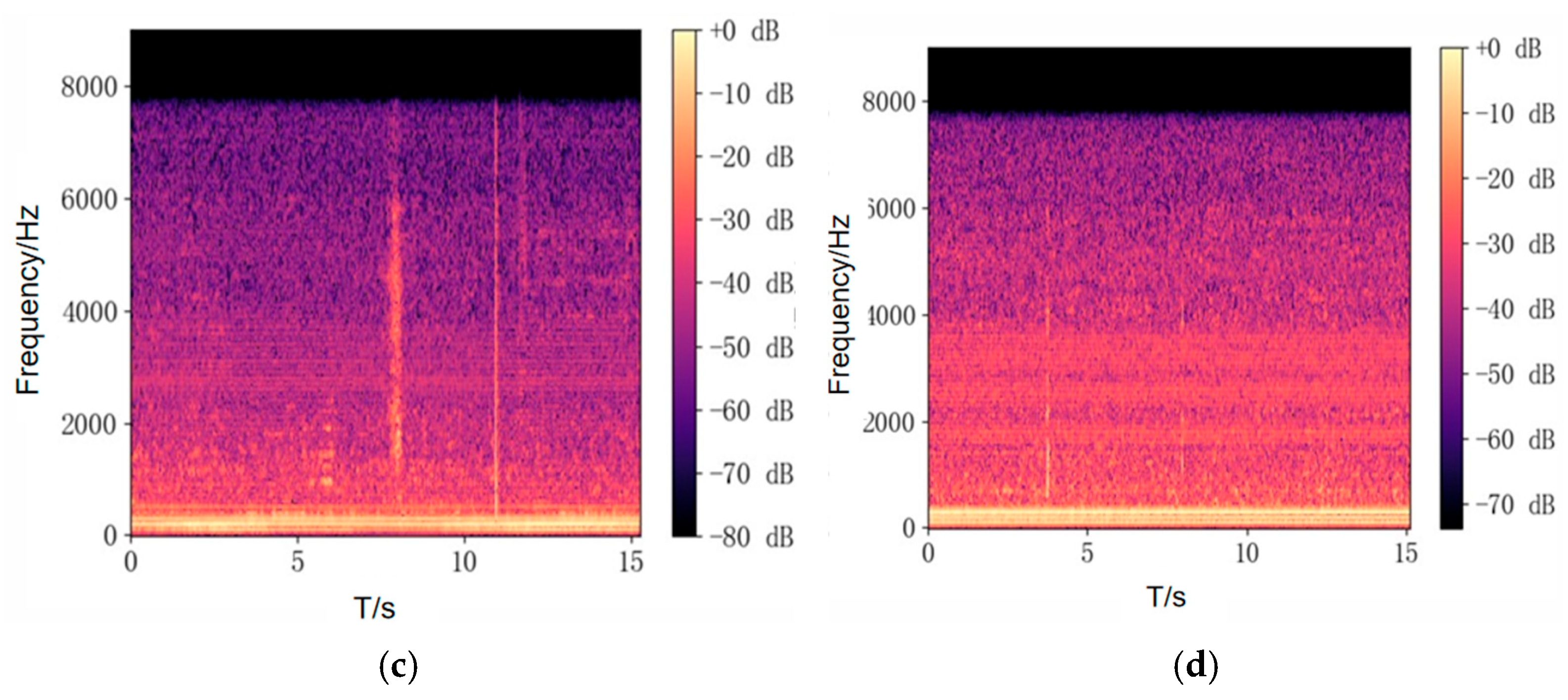

3.2.3. Iron Core Looseness

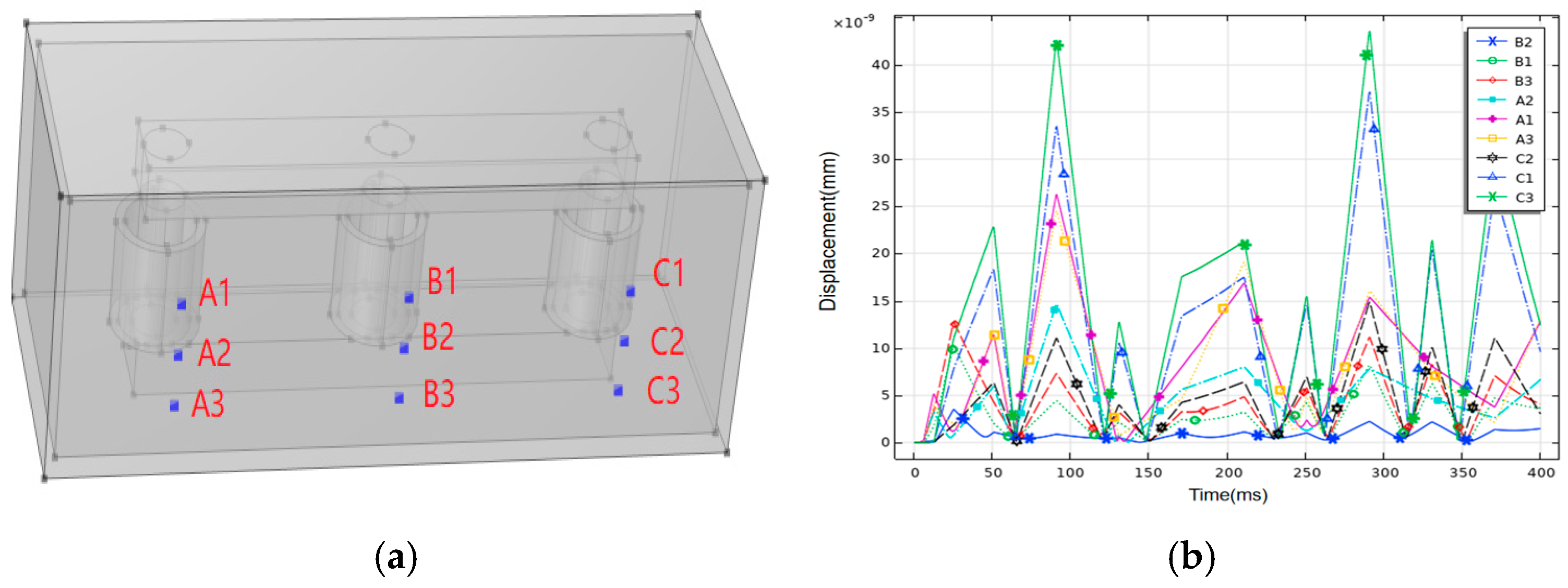

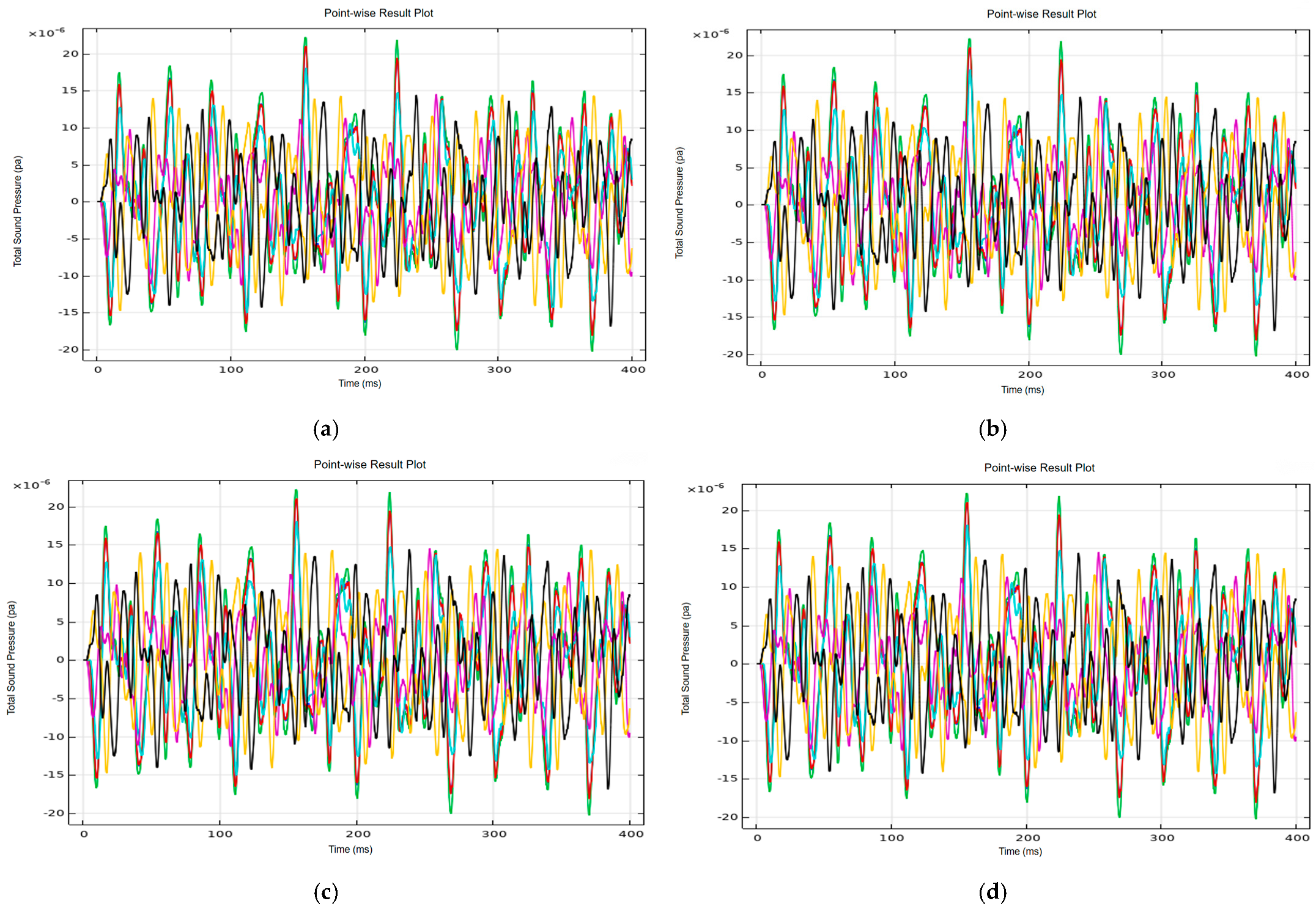

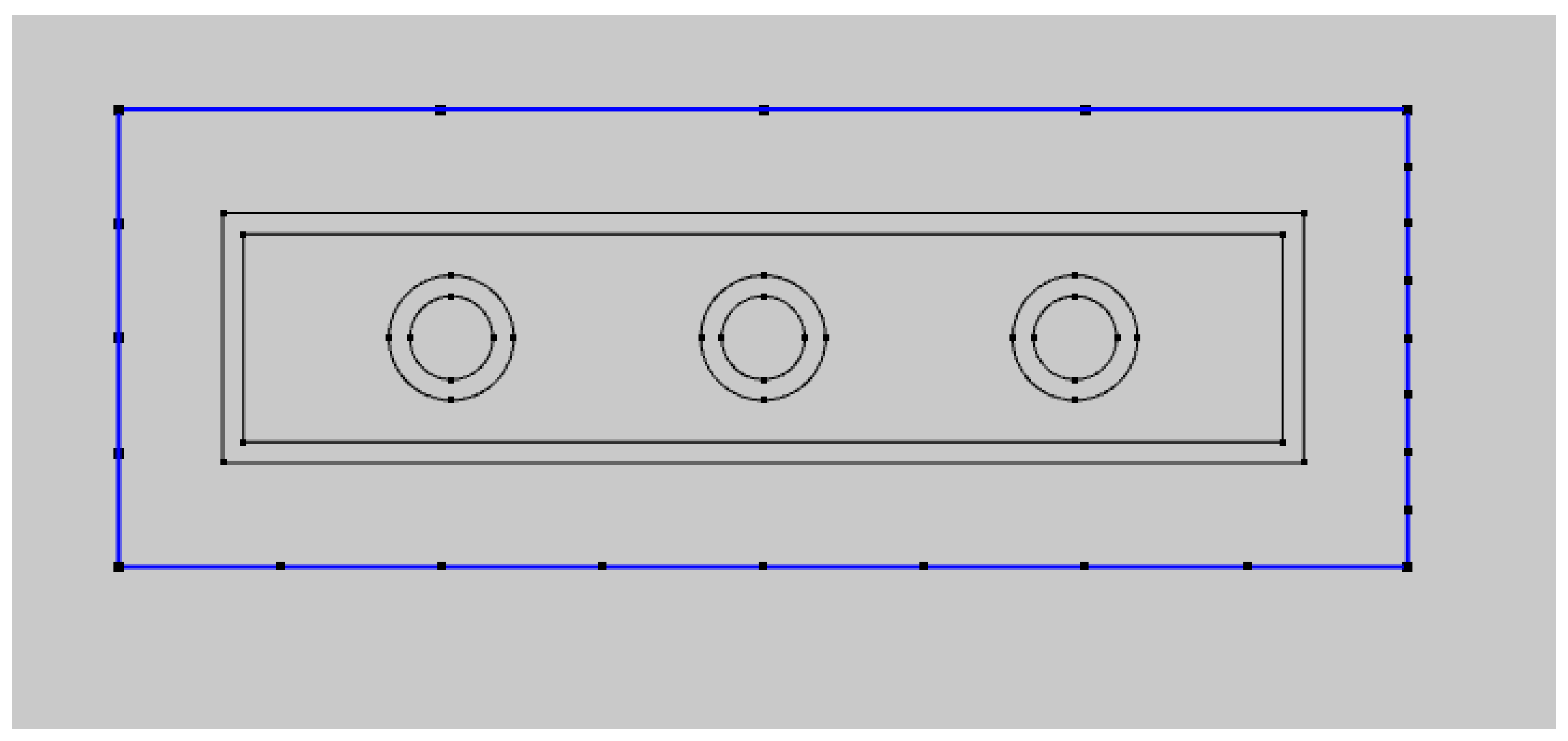

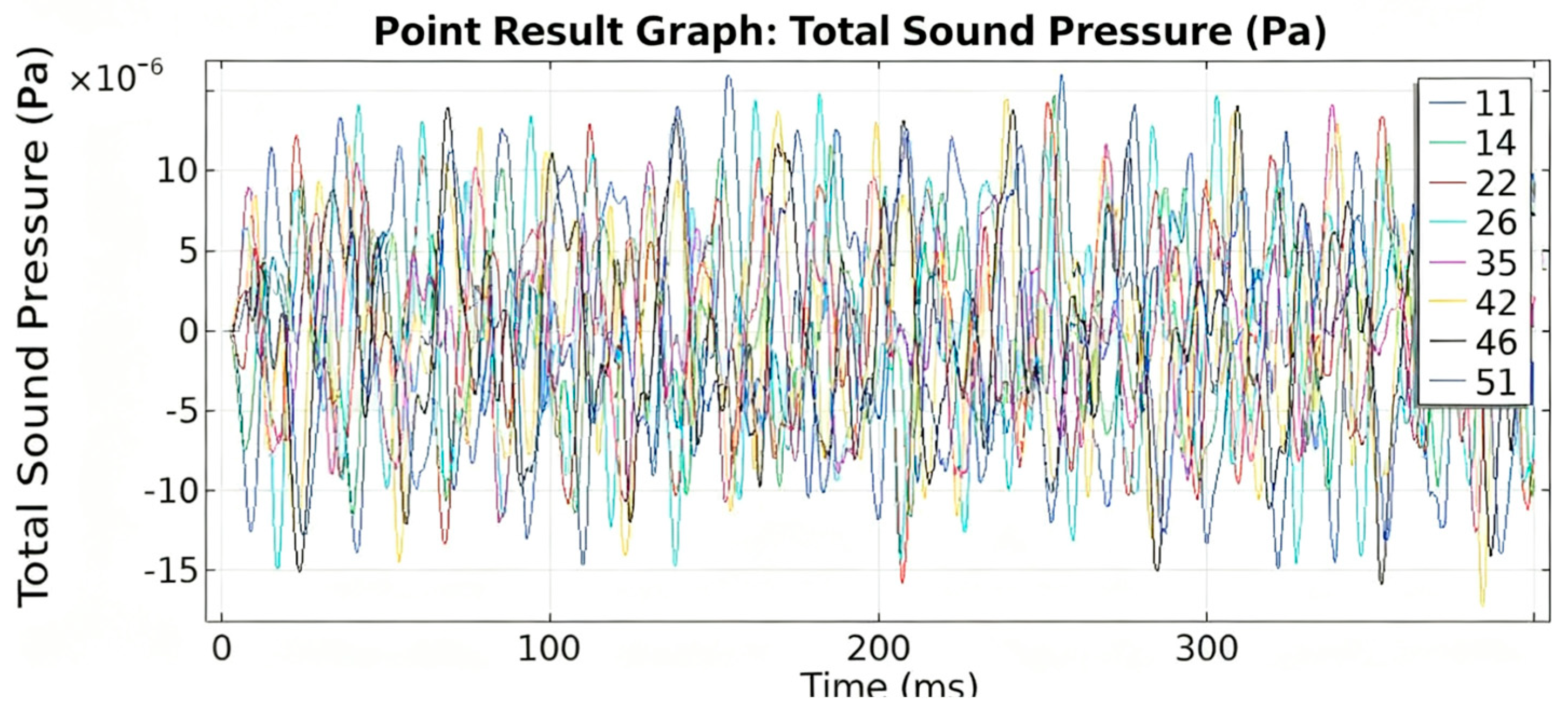

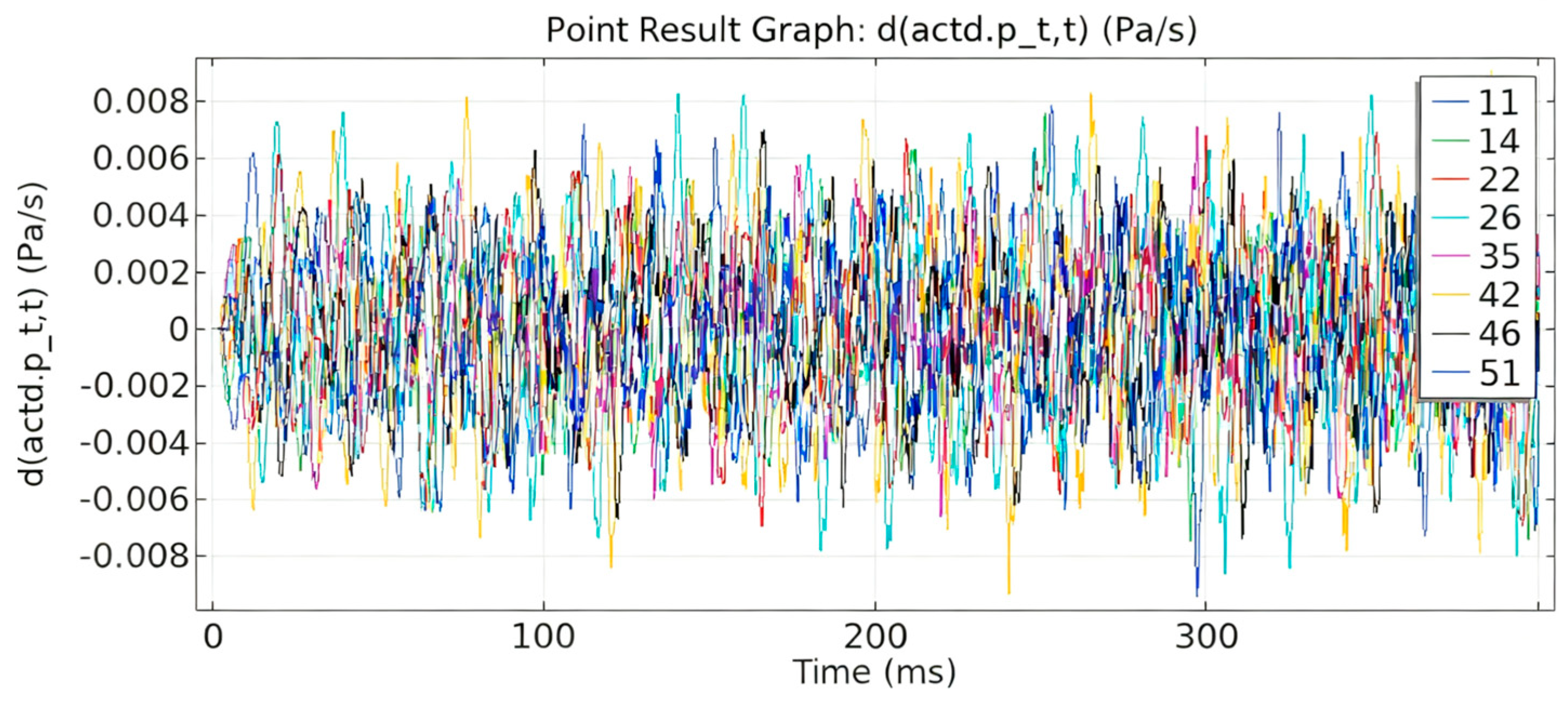

3.2.4. Analysis of Sensor Network Deployment Scheme

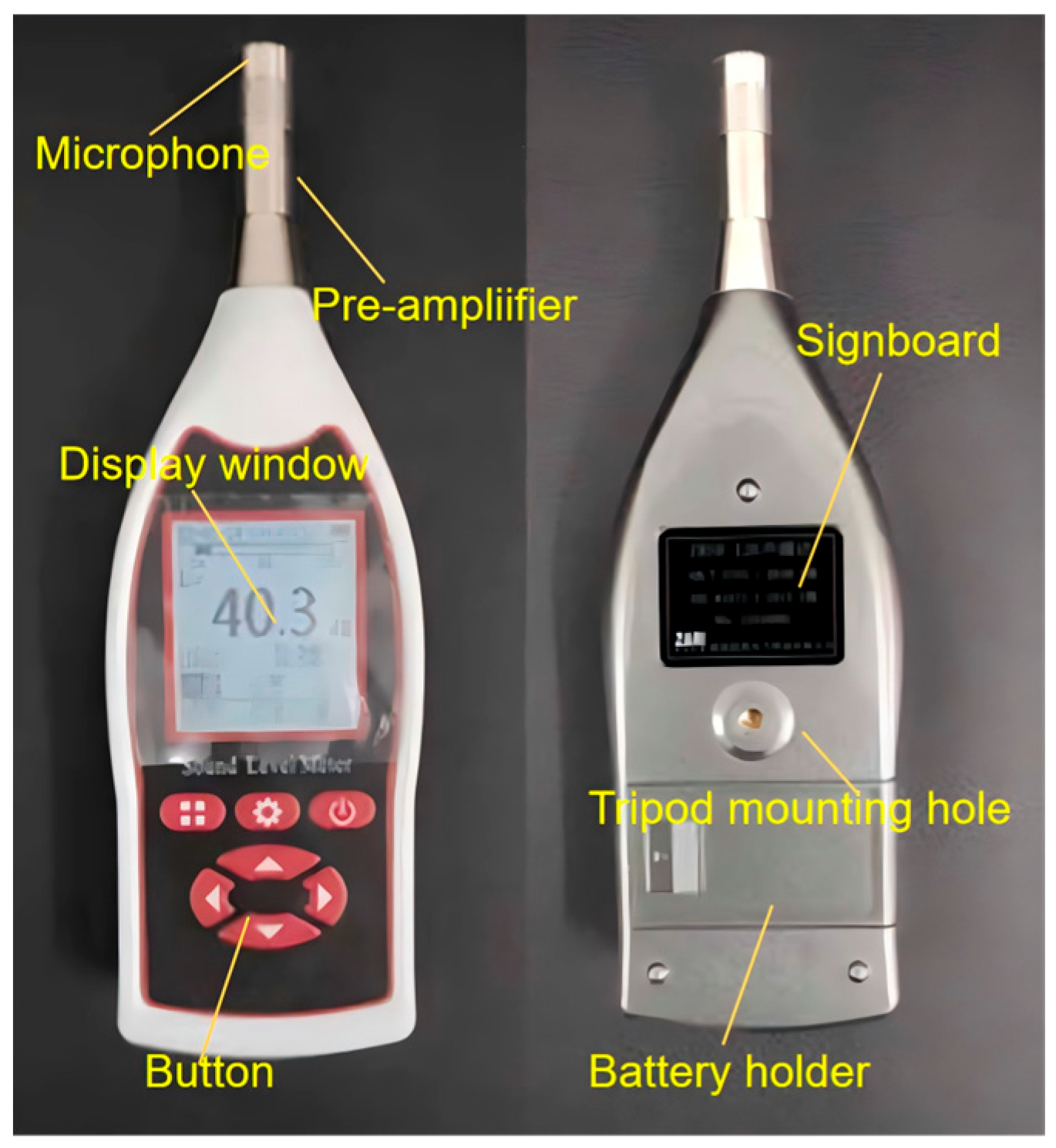

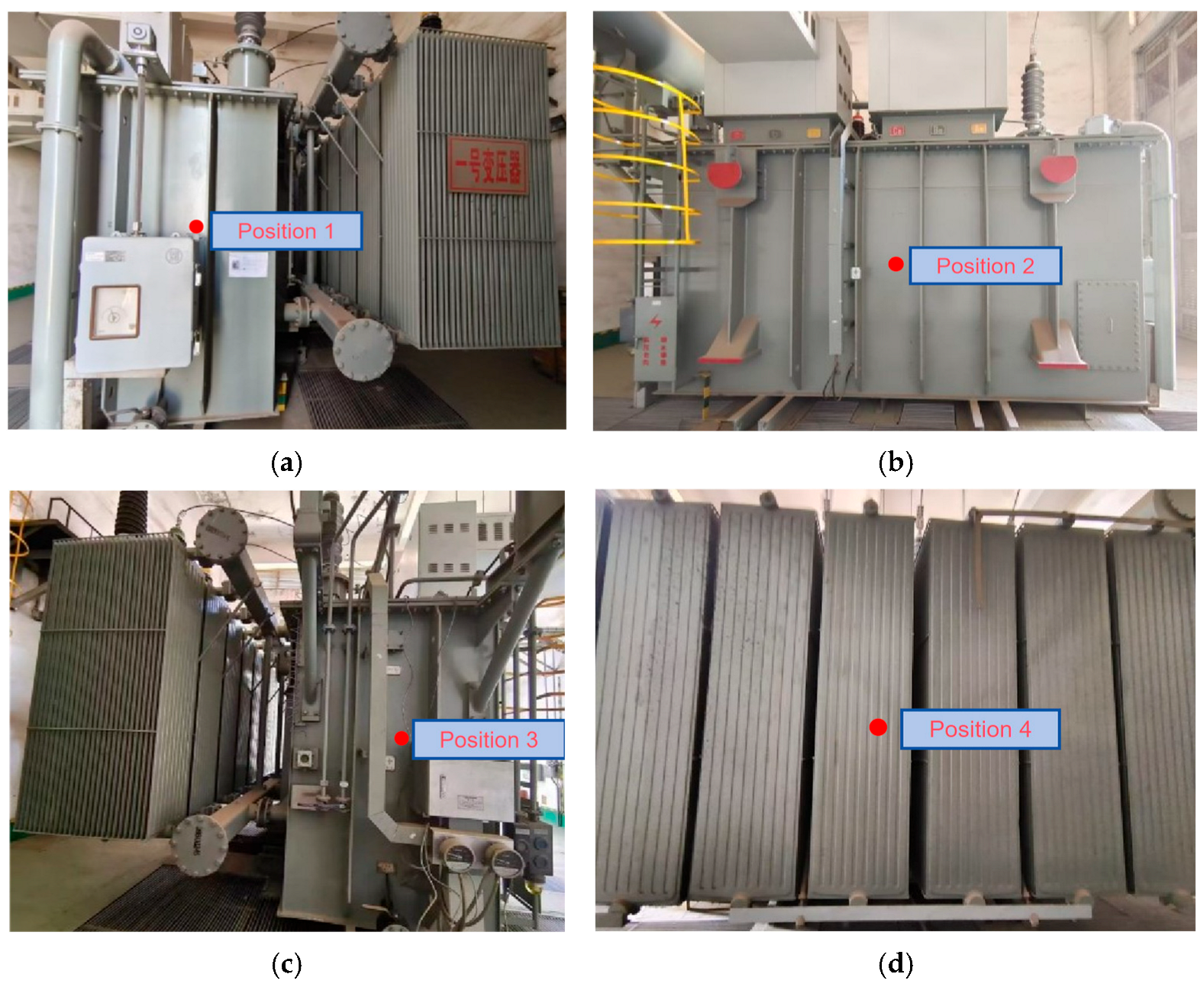

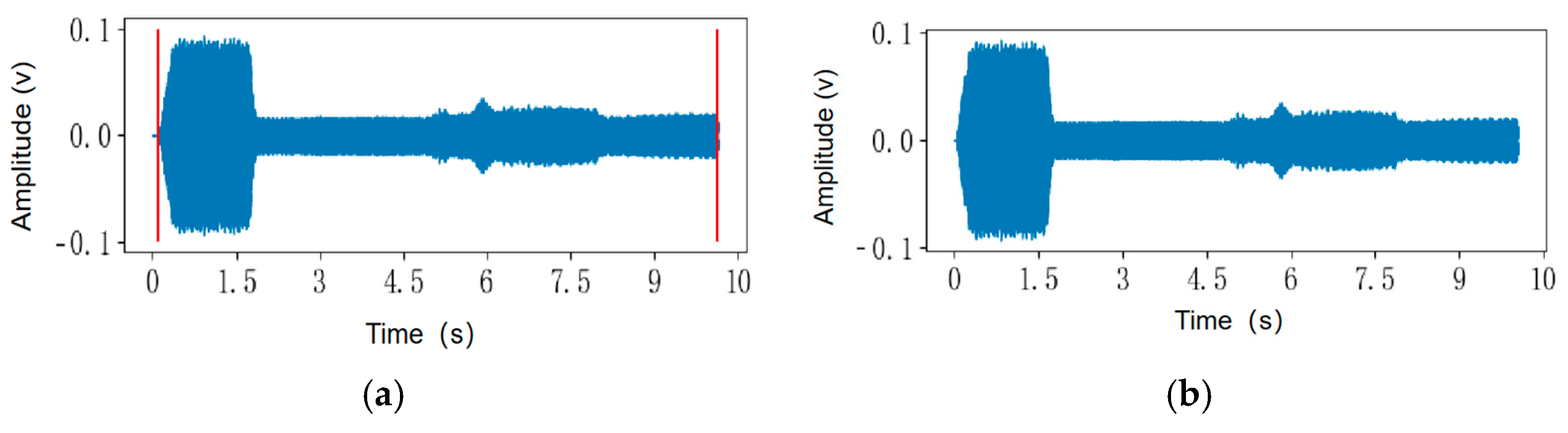

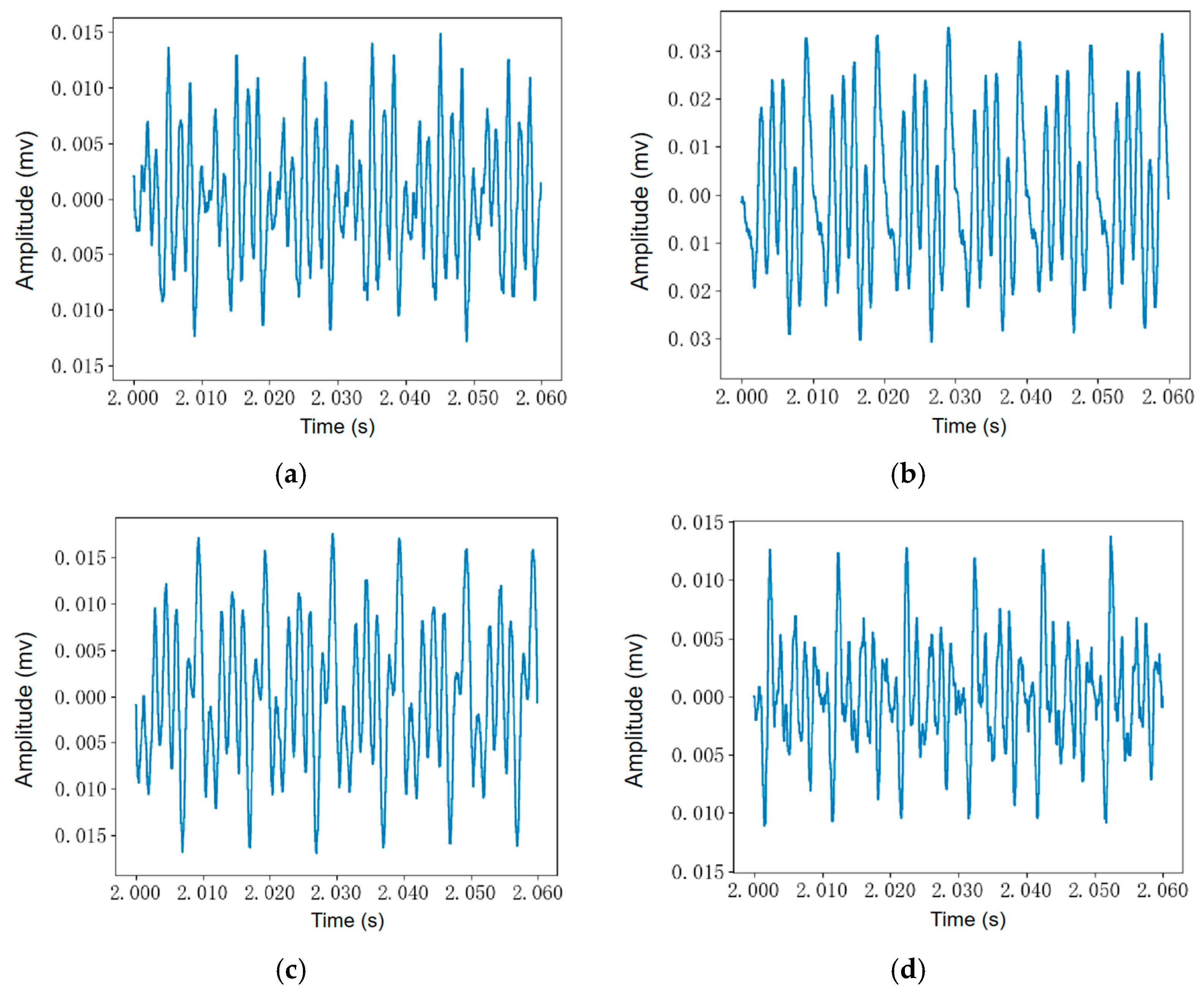

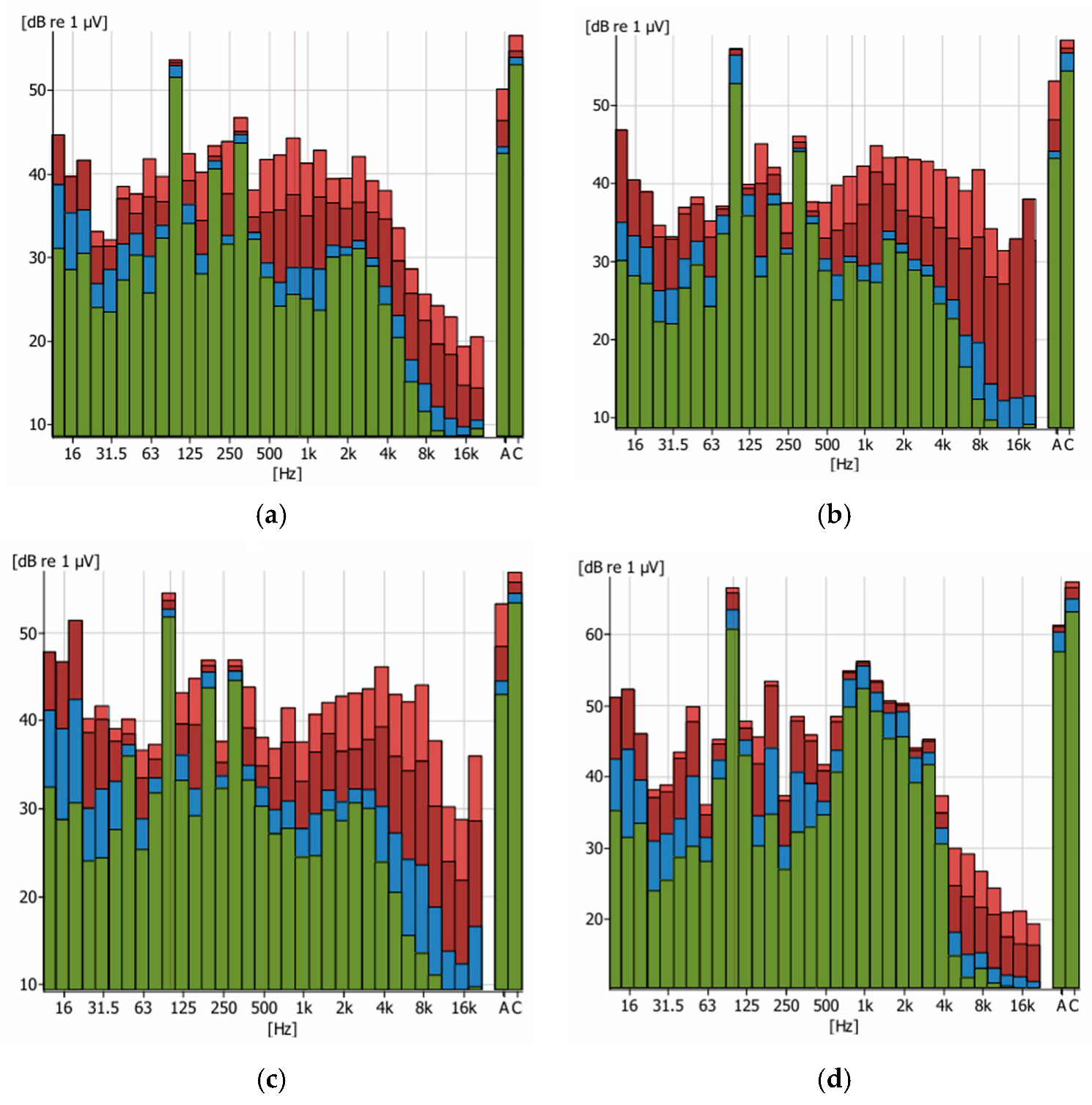

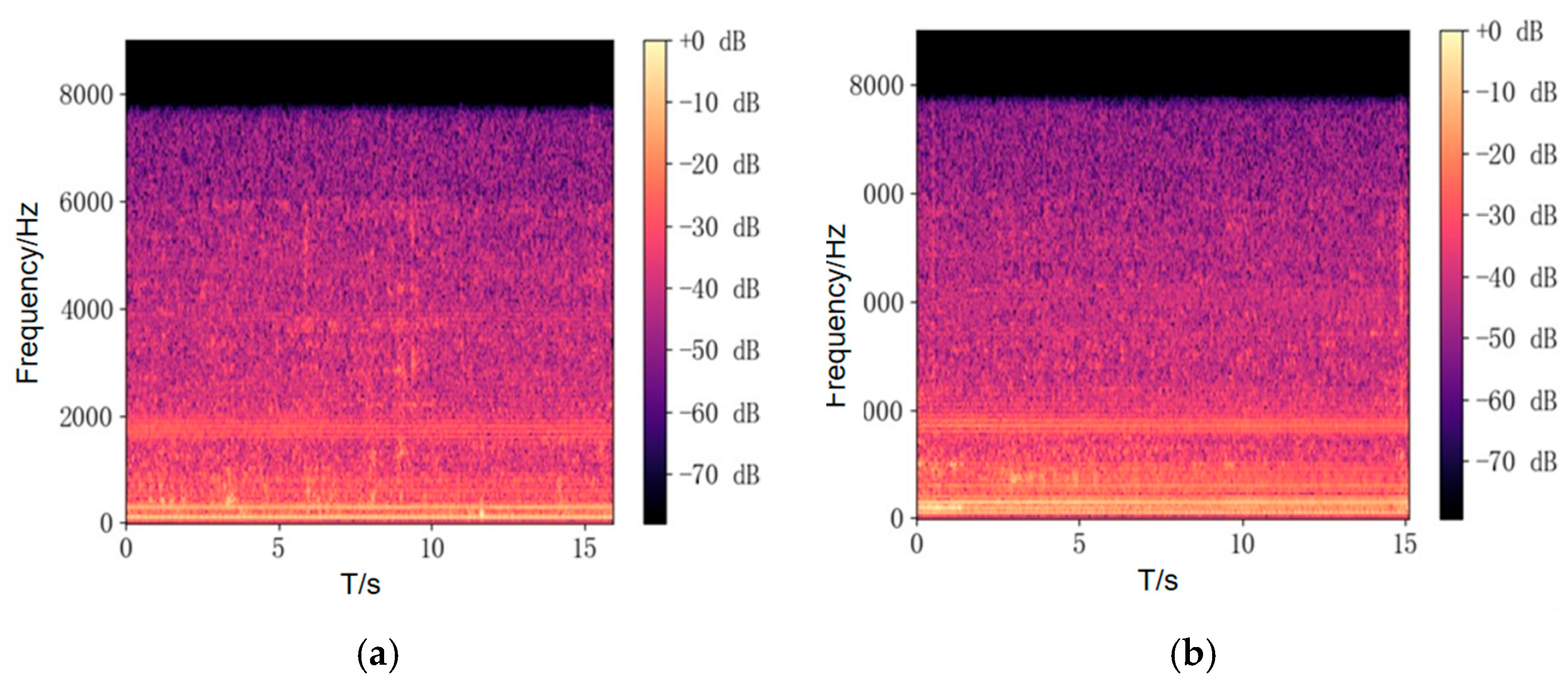

4. Vibration and Noise Measurement and Analysis on Oil-Immersed Transformers

5. Conclusions

- Oil significantly influences vibration transmission, particularly by facilitating fluid-borne energy transfer from the windings to the tank wall. This highlights the importance of incorporating fluid–structure interaction in predictive models.

- Magnetostriction remains the primary source of core noise, with its harmonic content sensitive to operational parameters such as load and voltage. This supports the use of acoustic harmonic analysis for early fault detection.

- Simulation and experimental results align well, validating the proposed models and demonstrating the spatial variability of vibration and sound pressure across the transformer surface.

- Sensor placement strategies must account for structural features such as stiffening ribs and clamping points, which can locally amplify or attenuate vibration signals.

- The study lays the groundwork for advanced diagnostic techniques, including voiceprint recognition and digital twin modelling, by establishing a robust link between observable surface signals and internal mechanical states.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Rashed, A.K.; Alshehawy, A.M.; Mansour, D.E.A.; Farade, R.A.; Ghali, M.; Megahed, T.F. Optical Spectroscopy Techniques for Condition Assessment and Fault Diagnosis of Power Transformer Insulation: A Critical Review on Technologies, Methods, and Standards. IEEE Trans. Dielectr. Electr. Insul. 2025, 32, 2162–2176. [Google Scholar] [CrossRef]

- Fofana, I.; Hadjadj, Y. Electrical-Based Diagnostic Techniques for Assessing Insulation Condition in Aged Transformers. Energies 2016, 9, 679. [Google Scholar] [CrossRef]

- Long, J.; Shenoi, A.R.; Jiang, W. A reliability-centred maintenance strategy based on maintenance-free operating period philosophy and total lifetime operating cost analysis. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 2009, 223, 711–719. [Google Scholar] [CrossRef]

- Lee, J.; Wu, F.; Zhao, W.; Ghaffari, M.; Liao, L.; Siegel, D. Prognostics and health management design for rotary machinery systems—Reviews, methodology and applications. Mech. Syst. Signal Process. 2014, 42, 314–334. [Google Scholar] [CrossRef]

- Bebbington, M.; Cronin, S.J.; Chapman, I.; Turner, M.B. Quantifying volcanic ash fall hazard to electricity infrastructure. J. Volcanol. Geotherm. Res. 2008, 177, 1055–1062. [Google Scholar] [CrossRef]

- Zhao, H.J.; Zhu, Y.; Wang, X.F.; Xing, Y.B.; Ding, S.M.; Chen, J. Research on Design and Application of Reactive Power Optimization Software for Distribution Network. In Proceedings of the 4th International Conference on Environmental and Energy Engineering (IC3E 2020), Sanya, China, 12 March 2020. [Google Scholar]

- Zhang, X.; Gockenbach, E. Asset-Management of Transformers Based on Condition Monitoring and Standard Diagnosis. IEEE Electr. Insul. Mag. 2008, 24, 26–40. [Google Scholar] [CrossRef]

- Jardinem, K.A.; Lin, D.; Banjevic, D. A review on machinery diagnostics and prognostics implementing condition-based maintenance. Mech. Syst. Signal Process. 2005, 20, 1483–1510. [Google Scholar] [CrossRef]

- Brown, R.E.; Humphrey, B.G. Asset management for transmission and distribution. IEEE Power Energy Mag. 2005, 3, 39–45. [Google Scholar] [CrossRef]

- Heng, A.; Zhang, S.; Tan, C.A.; Joseph, M. Rotating machinery prognostics: State of the art, challenges and opportunities. Mech. Syst. Signal Process. 2008, 23, 724–739. [Google Scholar] [CrossRef]

- Eugenio, B.; Cristiana, D.; Gianpio, L.M.D. Eigen-spectrograms: An interpretable feature space for bearing fault diagnosis based on artificial intelligence and image processing. Mech. Adv. Mater. Struct. 2023, 30, 4639–4651. [Google Scholar]

- Abu-Elanien, E.A.; Salama, M. Asset management techniques for transformers. Electr. Power Syst. Res. 2009, 80, 456–464. [Google Scholar] [CrossRef]

- Ayu, K.; Yunusa-Kaltungo, A. A Holistic Framework for Supporting Maintenance and Asset Management Life Cycle Decisions for Power Systems. Energies 2020, 13, 1937. [Google Scholar] [CrossRef]

- Xue, W.; Jia, D. A Novel Method for Winding Faults Diagnostic of Power Transformers Based on Parameter Estimation. IEEJ Trans. Electr. Electron. Eng. 2021, 16, 1563–1572. [Google Scholar] [CrossRef]

- Engin, B.; Varbak, S.N.; Erkan, D. Hybrid Condition Monitoring System for Power Transformer Fault Diagnosis. Energies 2023, 16, 1151. [Google Scholar] [CrossRef]

- Cui, Y.; Ma, H.; Saha, T.; Ekanayake, C.; Wu, G.N. Multi-physics modelling approach for investigation of moisture dynamics in power transformers. IET Gener. Transm. Distrib. 2016, 10, 1993–2001. [Google Scholar] [CrossRef]

- Gmati, G.; Fofana, I.; Picher, P.; Fernàndez, O.H.A.; Rebaine, D.; Meghnefi, F.; Brahami, Y.; Yapi, K.M.L. Effect of Moisture and Aging of Kraft Paper Immersed in Mineral Oil and Synthetic Ester on Bubbling Inception Temperature in Power Transformers. Energies 2025, 18, 4579. [Google Scholar] [CrossRef]

- Thango, A.B. Six Sigma-Based Frequency Response Analysis for Power Transformer Winding Deformation. Appl. Sci. 2025, 15, 3951. [Google Scholar] [CrossRef]

- Jingle Jabha, D.F.; Selvi, K.; Joselin, R. A Strategy to Determine Partial Discharge in XLPE Power Cables Using Acoustic Emission Detection Technique. J. Test. Eval. 2017, 46, 283–293. [Google Scholar] [CrossRef]

- Zarandi, D.F.; Behjat, V.; Gauvin, M.; Picher, P.; Ezzaidi, H.; Fofana, I. Power Transformers OLTC Condition Monitoring Based on Feature Extraction from Vibro-Acoustic Signals: Main Peaks and Euclidean Distance. Sensors 2023, 23, 7020. [Google Scholar] [CrossRef] [PubMed]

- Franciszek, W.; Zbigniew, O.; Grzegorz, S.; Maciej, S. The 8AE-PD computer measurement system for registration and analysis of acoustic emission signals generated by partial discharges in oil power transformers. Metrol. Meas. Syst. 2019, 26, 403–418. [Google Scholar] [CrossRef]

- MacAlpine, M.; Zhao, Z.; Demokan, M.S. Development of a fibre-optic sensor for partial discharges in oil-filled power transformers. Electr. Power Syst. Res. 2002, 63, 27–36. [Google Scholar] [CrossRef]

- Markalous, S.M.; Tenbohlen, S.; Feser, K. Detection and location of partial discharges in power transformers using acoustic and electromagnetic signals. IEEE Trans. Dielectr. Electr. Insul. 2008, 15, 1576–1583. [Google Scholar] [CrossRef]

- Hou, S.; Qin, Y.; Gao, J.; Lyu, F.; Li, X. Intelligent Monitoring System Based on Optical Fiber Acoustic Emission Sensor and Its Application in Partial Discharge Diagnosis of Gas-insulated Switchgear. Sens. Mater. 2021, 33, 1127–1136. [Google Scholar] [CrossRef]

- Si, W.; Fu, C.; Li, D.; Li, H.; Yuan, P.; Yu, Y. Directional Sensitivity of a MEMS-Based Fiber-Optic Extrinsic Fabry—Perot Ultrasonic Sensor for Partial Discharge Detection. Sensors 2018, 18, 1975. [Google Scholar] [CrossRef]

- Jiang, J.; Wang, K.; Wu, X.; Ma, G.; Zhang, C. Characteristics of the propagation of partial discharge ultrasonic signals on a transformer wall based on Sagnac interference. Plasma Sci. Technol. 2020, 22, 024002. [Google Scholar] [CrossRef]

- Liu, Y.; Peng, W.; Liang, Y.; Zhang, X.; Zhou, X.; Pan, L. Fiber-optic Mach-Zehnder interferometric sensor for high-sensitivity high temperature measurement. Opt. Commun. 2013, 300, 194–198. [Google Scholar] [CrossRef]

- Ma, G.M.; Shi, C.; Qin, W.Q.; Li, Y.B.; Zhou, H.Y.; Li, C.R. A Non-Intrusive Electrical Discharge Localization Method for Gas Insulated Line Based on Phase-Sensitive OTDR and Michelson Interferometer. IEEE Trans. Power Deliv. 2019, 34, 1324–1331. [Google Scholar] [CrossRef]

- Xin, X.; Luo, Y.; Tang, X.; Chen, P.; Li, Y. Relocatable Ultrasonic Array and UHF Combined Sensor Applied to PD Location in Oil. IEEE Sens. J. 2014, 14, 357–361. [Google Scholar]

- Sikorski, W. Active Dielectric Window: A New Concept of Combined Acoustic Emission and Electromagnetic Partial Discharge Detector for Power Transformers. Energies 2019, 12, 115. [Google Scholar] [CrossRef]

- Mingyong, L.; Olivier, H.; Xavier, M.; Frederic, B.; Laurent, B.; Thierry, W. Reduction of Power Transformer Core Noise Generation Due to Magnetostriction-Induced Deformations Using Fully Coupled Finite-Element Modeling Optimization Procedures. IEEE Trans. Magn. 2017, 53, 1–11. [Google Scholar]

- Sikorski, W.; Gielniak, J. Online Monitoring of Partial Discharges in Large Power Transformers Using Ultra-High Frequency and Acoustic Emission Methods: Case Studies. Energies 2025, 18, 1718. [Google Scholar] [CrossRef]

- Machado, B.B.; Casamayor, Á.H.; García, D.I.; Giner, E. Damage mechanism identification in additive manufactured extruded polymer via acoustic emission technique, experimental testing and pattern recognition models. Eng. Fail. Anal. 2025, 181, 109928. [Google Scholar] [CrossRef]

- Zhanlong, Z.; Yongye, W.; Sigong, Z.; Peiyu, J.; Huarui, Y. Online monitoring research of transformer vibration based on labview. J. Phys. Conf. Ser. 2019, 1168, 022083. [Google Scholar] [CrossRef]

- Bartoletti, C.; Desiderio, M.; Carlo, D.D.; Fazio, G.; Muzi, F.; Sacerdoti, G.; Salvatori, F. Vibro-Acoustic Techniques to Diagnose Power Transformers. IEEE Trans. Power Deliv. 2004, 19, 221–229. [Google Scholar] [CrossRef]

- Hong, L.; Zhang, R.; Zhang, R. Research on S-type fiber Bragg grating acceleration sensor for low-frequency vibration monitoring. Rev. Sci. Instrum. 2024, 95, 065006. [Google Scholar] [CrossRef]

- Simplice, A.; Issouf, F.; Zié, Y.; Brettschneider, S.; Peter, K.; Bekibenan, S. On the Feasibility of Monitoring Power Transformer’s Winding Vibration and Temperature along with Moisture in Oil Using Optical Sensors. Sensors 2023, 23, 2310. [Google Scholar] [CrossRef]

- Kinnunen, T.; Li, H.Z. An overview of text-independent speaker recognition: From features to supervectors. Speech Commun. Int. J. 2010, 52, 12–40. [Google Scholar] [CrossRef]

- Gryvill, H.; Grana, D.; Tjelmeland, H. Bayesian Ensemble Kalman Filter for Gaussian Mixture Models. Math. Geosci. 2024, 57, 153–192. [Google Scholar] [CrossRef]

- Kenny, P.; Ouellet, P.; Dehak, N.; Gupta, V.; Dumouchel, P. A Study of Interspeaker Variability in Speaker Verification. IEEE Trans. Audio Speech Lang. Process. 2008, 16, 980–988. [Google Scholar] [CrossRef]

- Xuan, X.; Han, R.; Ding, B. Research on Speaker Identification Models Based on CNN and Additive Angular Margin Loss. In Proceedings of the 2021 2nd International Conference on Electronics, Communications and Information Technology (CECIT 2021), Sanya, China, 27 December 2021. [Google Scholar]

- Ahmed, K.; Mohamed, D.; Ahmed, S.S. A novel hybrid feature method based on Caelen auditory model and gammatone filterbank for robust speaker recognition under noisy environment and speech coding distortion. Multimed. Tools Appl. 2022, 82, 16195–16212. [Google Scholar]

- Imam, S.A.; Lim, M.H.; Abdelrhman, A.M.; Ahmad, I.; Leong, M.S. Enhanced Blade Fault Diagnosis Using Hybrid Deep Learning: A Comparative Analysis of Traditional Machine Learning and 1D Convolutional Transformer Architecture. Eng. Rep. 2025, 7, 70202. [Google Scholar] [CrossRef]

- Fei, T.; Jiangfeng, C.; Qinglin, Q.; Meng, Z.; He, Z.; Fangyuan, S. Digital twin-driven product design, manufacturing and service with big data. Int. J. Adv. Manuf. Technol. 2018, 94, 3563–3576. [Google Scholar]

- Gabrielle, B.; Georges, A.N.; Dragan, K.; Stéphane, P. Multi-criteria prioritization of asset management investments in the power industry. IFAC Pap. Line 2022, 55, 1804–1809. [Google Scholar]

- Ramirez, I.; Pino, J.; Pardo, D.; Sanz, M.; Rio, L.; Ortiz, A.; Morozovska, K.; Aizpurua, I.J. Residual-based attention Physics-informed Neural Networks for spatio-temporal ageing assessment of transformers operated in renewable power plants. Eng. Appl. Artif. Intell. 2025, 139, 109556. [Google Scholar] [CrossRef]

- Guo, C.; Potekhin, V.V.; Li, P.; Kovalchuk, E.A.; Lian, J. MDFT-GAN: A Multi-Domain Feature Transformer GAN for Bearing Fault Diagnosis Under Limited and Imbalanced Data Conditions. Appl. Sci. 2025, 15, 6225. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hao, X.; Ma, S.; Zhu, X.; Zhang, Y.; Liu, R.; Zhang, B. Research on Vibration and Noise of Oil Immersed Transformer Considering Influence of Transformer Oil. Energies 2025, 18, 6155. https://doi.org/10.3390/en18236155

Hao X, Ma S, Zhu X, Zhang Y, Liu R, Zhang B. Research on Vibration and Noise of Oil Immersed Transformer Considering Influence of Transformer Oil. Energies. 2025; 18(23):6155. https://doi.org/10.3390/en18236155

Chicago/Turabian StyleHao, Xueyan, Sheng Ma, Xuefeng Zhu, Yubo Zhang, Ruge Liu, and Bo Zhang. 2025. "Research on Vibration and Noise of Oil Immersed Transformer Considering Influence of Transformer Oil" Energies 18, no. 23: 6155. https://doi.org/10.3390/en18236155

APA StyleHao, X., Ma, S., Zhu, X., Zhang, Y., Liu, R., & Zhang, B. (2025). Research on Vibration and Noise of Oil Immersed Transformer Considering Influence of Transformer Oil. Energies, 18(23), 6155. https://doi.org/10.3390/en18236155