Abstract

The transition to a sustainable energy system is crucial to meet climate targets and reduce fossil fuel dependence. Solar hydrogen systems offer a promising route for renewable hydrogen production. This study presents a techno-economic assessment of hydrogen production using integrated solar hydrogen panels combined with balance-of-plant equipment such as compressors. The analysis combines detailed Aspen Plus process design with an hourly solar model to capture the impact of system scale and hydrogen storage under intermittent operation. Results show that large-scale integrated systems can achieve costs comparable to photovoltaic–electrolyzer setups, suggesting a feasible and streamlined alternative. System scale is the dominant factor influencing the levelized cost of hydrogen (LCOH). At a small scale (1000 panels), the LCOH is about 49 €/kg. Including hydrogen storage reduces costs by up to 40% through better utilization of capital-intensive components. At larger scales, costs decrease substantially: 100,000 panels yield an LCOH of 9.1 €/kg, and 10 million panels reach 7.3 €/kg. In these large systems, storage slightly increases costs because added capital expenditures outweigh operational gains. If solar-to-hydrogen efficiency improves to 23% and panel costs drop to 120 €/m2, hydrogen could be produced at around 3.8 €/kg. These findings emphasize the importance of scale, efficiency gains, and cost reduction to enable affordable renewable hydrogen directly from sunlight and water.

1. Introduction

To meet the objectives of the Paris Agreement, there is a strong focus on reducing greenhouse gas emissions and transitioning from fossil fuels to more sustainable alternatives. This transition involves the adoption of renewable energy sources [1], increased circularity [2,3,4], and renewable energy carriers such as hydrogen (H2). Hydrogen is a versatile energy carrier, suitable for transportation, heat supply, seasonal energy storage, and as an industrial feedstock, making it an important component of the future energy system [5]. Renewable H2 is expected to play a key role in the energy transition, both as a fuel and as a base reagent for the chemical industry. At the broader energy-system level, several recent studies examine the role of hydrogen and energy storage in sustainable transport, multi-energy microgrids with green hydrogen, and long-duration storage in capacity markets [6,7,8].

The global annual demand for H2 reached approximately 97 million tonnes (Mt) in 2023 [9,10]. This hydrogen is mainly used in industry, for example, in refining operations and the production of ammonia and methanol. Currently, almost all H2 is produced from fossil resources through natural gas steam reforming (SMR), coal gasification, or hydrocarbon cracking. This production results in around 920 Mt of CO2 emissions each year. Without CO2 capture or a carbon tax, the production costs of fossil-based H2 range from approximately 1 to 5 € per kg of H2, with cost fluctuations largely driven by fossil energy price volatility [10].

To reduce the carbon footprint of H2 production, technologies that use renewable energy need to be deployed at scale and should be as cost effective as possible. Water electrolysis is currently the leading technology [11], although its production costs are relatively high and reported to range globally from around 4 € per kg to over 12 € per kg [10], and approximately 12 to 14 € per kg in the Netherlands [12]. Future production costs are expected to decrease thanks to reductions in renewable energy costs, economies of scale, and technological innovation. Long-term cost trajectories may, however, also be influenced by the availability of critical materials (such as platinum and iridium) [13] and potential regulatory constraints, including restrictions on per- and polyfluoroalkyl substances (PFAS), which are used in some membrane materials [14,15].

The EU Fit for 55 package includes legislative proposals that mandate the use of renewable fuels of non-biological origin (RFNBOs), such as H2, in industry and transport, thus supporting growing demand [16]. In the Net Zero Emissions by 2050 scenario of the International Energy Agency (IEA), low-carbon hydrogen demand is projected to reach 420 Mt per year by 2050, with 80% derived from renewable sources [17,18]. In the IEA’s Announced Pledges Scenario (APS), which reflects current national climate pledges, hydrogen demand reaches about 130 Mt per year by 2050, with a substantial share still expected to come from low-carbon production routes [17,18]. Similar projections are echoed by the Hydrogen Council, which estimates that global hydrogen demand could reach 660 Mt per year by 2050 under an ambitious decarbonization trajectory. To ensure sufficient H2 supply, alternative production technologies beyond electrolysis could be of significant interest to the market, provided they can compete with electrolysis in terms of cost and efficiency.

Integrated solar hydrogen panels are an alternative technology under development. Unlike photovoltaic (PV) panels that generate electricity to power a separate electrolyzer, these panels produce hydrogen and oxygen directly from water using sunlight in a single device. They combine light absorption, charge separation, and electrochemical water splitting into one module, and usually operate at low pressure. However, to make hydrogen suitable for storage or distribution, further compression is often needed. These downstream steps, including compression, storage, and other balance-of-plant components, are critical for assessing system performance but are often left out of cost estimates. In this study, the term “Integrated Solar Hydrogen Systems” refers to arrays of solar hydrogen panels that are connected to centralized balance-of-plant (BoP) equipment, including water pre-treatment and recycling, gas–liquid separation, gas purification and compression. Integrated systems may offer benefits such as more efficient land use, fewer energy conversion steps, lower current densities, and the potential for fast cost reductions thanks to steep learning curves in small-scale devices [19]. Although solar hydrogen production has been studied for decades, module-level prototypes have only recently been demonstrated [20,21,22,23,24]. Still, like PV-electrolyzer systems, the costs remain high and market readiness is limited.

To understand the cost-related challenges and opportunities for solar hydrogen production, techno-economic assessments provide valuable insights to determine appropriate development targets. Many of these assessments focus on electricity production by photovoltaic (PV) systems coupled with electrolysis (PV-E) to produce hydrogen [25,26,27,28,29]. However, few techno-economic studies evaluate integrated solar hydrogen concepts. An early techno-economic study assessed four different direct processes (two photocatalytic and two photoelectrochemical (PEC) approaches) for producing hydrogen from solar energy with a capacity of 10 tH2 per day [30,31]. While these early studies reported relatively low hydrogen production costs, with 10.4 $/kg for PEC systems and 4.0 $/kg with light concentration, these values are based on simplified assumptions and do not represent the full cost of a deployable system. In particular, the estimates exclude important elements such as hydrogen purification, compression to delivery pressures, and downstream infrastructure like storage and distribution. Balance-of-plant (BoP) components, including water purification, gas and liquid separation, thermal management, and control systems, are either highly simplified or not included. The analysis also focuses on idealized component level performance and does not account for challenges related to scaling, intermittency, or durability under real operating conditions, or geographical variation in solar irradiance. These estimates are useful as early-stage benchmarks but underestimate full system costs and should be interpreted with caution when compared to more complete techno-economic assessments.

Shaner et al. (2016) [32] conducted a techno-economic comparison of PEC and PV-E systems for a hydrogen production capacity of 10 tH2 per day. Production costs for PEC systems ranged between 9.2 and 11.4 $/kg, with the lowest costs achieved using concentrated light, while PV-E systems were slightly more expensive at 12.1 $/kg. Detz et al. [33] estimated the base case hydrogen production cost for PEC systems at 10.8 $/kg in 2015. Projected costs based on learning curve analysis were significantly lower, reaching 2.2 $/kg by 2050.

Grimm et al. (2020) [34] analyzed PEC and PV-E systems for a capacity of 10 tH2 per day. The study concluded that the potential techno-economic benefits of PEC systems over traditional PV-E systems are uncertain, as reflected by higher levelized production costs for PEC at 8.4 $/kg compared to 6.2 $/kg for PV-E. The authors acknowledged the impact of solar irradiance variations across locations on levelized production costs. However, their calculations were based on average daily irradiation data without considering hourly variations [34].

Frowijn and Van Sark [35] analyzed several routes, including PEC, for renewable hydrogen production in the Netherlands. They reported that at a capacity of 10 tH2 per day, the levelized cost was approximately 19 €/kg, decreasing to 11 €/kg in sunnier regions. Schneidewind [36] applied a Monte Carlo-based development distance methodology to assess how technological progress affects hydrogen production costs for PEC and PV-E systems. The analysis indicated that current PEC base case levelized costs are very high, exceeding 100 $/kg. These costs decrease exponentially with increasing development distance, reaching targets of 1.5 to 1.6 $/kg, but only for systems using solar concentrators.

In 2024, Cattry et al. [37] reported an extensive techno-economic assessment of PEC and PV-E systems for hydrogen and carbon monoxide production. The study combined system-level analysis based on physical performance models with stochastic methods for uncertainty assessment, targeting a hydrogen production capacity of 1 tH2 per day. The results showed that systems with light concentration achieved the lowest costs, 3.6 $/kg compared to 6.3 $/kg without concentration. PV-E systems had production costs ranging from 3.9 to 4.2 $/kg. The authors estimated that production costs could decrease to around 2 $/kg by 2040.

These studies indicate that the production costs of solar hydrogen, whether through integrated panels or photovoltaic systems coupled with electrolyzers, vary significantly, ranging from approximately 3 to 19 €/kg, with one study reporting even higher production costs. There is no consensus on which concept achieves the lowest production costs. However, several gaps remain. First, most assessments of solar hydrogen concepts, and integrated panels in particular, give limited attention to the design and cost of the balance of plant, especially purification and compression units needed to deliver hydrogen at pressure. Second, the impact of hourly and seasonal solar intermittency on plant design, utilization, and production costs is often represented using average irradiation values rather than time series. Third, scale effects and the role of intermediate hydrogen or electricity storage are not yet systematically assessed across a wide range of plant sizes with a consistent comparison to photovoltaic–electrolyzer (PV–E) systems. Reuß et al. [38] showed that the level of integration in solar hydrogen panels can strongly influence efficiency under varying weather conditions, which underlines the importance of analyzing intermittency and system integration together. This study addresses these gaps by analyzing an integrated solar hydrogen system at plant scale and linking detailed process design to the effects of solar intermittency, system scale, and storage. The main contributions are as follows:

- It develops a plant-scale techno-economic model of an integrated solar hydrogen system that includes water conditioning and recycling, gas–liquid separation, gas purification and compression in the balance of plant.

- It combines detailed Aspen Plus process design with an hourly Python 3.10.9 operation model driven by measured solar irradiance data for Huelva (Spain), with and without intermediate hydrogen and electricity storage, to capture the effects of diurnal and seasonal variability on hydrogen production and equipment utilization.

- It evaluates three system scales (1000, 100,000, and 10 million panels) and quantifies how system size and storage options influence capital use, operating hours, and the levelized cost of hydrogen, including a consistent comparison with a PV–E reference configuration.

The goal is to provide insights and guidelines for evaluating the techno-economic feasibility of standalone solar hydrogen systems that rely on intermittent solar energy. To support this, the analysis focuses on the following four central questions: What is the levelized cost of hydrogen (LCOH) that can be achieved with solar hydrogen plants under varying design conditions? How do key cost drivers, such as the cost of solar hydrogen panels and balance-of-plant components, affect the LCOH? What are the required targets for panel cost, solar-to-hydrogen efficiency, and plant size to reach cost parity with hydrogen from photovoltaic-electrolyzer (PV-E) systems? Finally, under what conditions can solar hydrogen production reach a cost below 5 €/kg?

2. Materials and Methods

2.1. Process Design and Modelling

This study examines a facility for hydrogen production powered by solar energy. The facility consists of integrated solar hydrogen panels that generate hydrogen when exposed to sunlight. After production, the hydrogen undergoes collection, purification, and pressurization before being delivered at the plant gate. The plant design and process parameters are described in Section 2.3 and Section 2.4.

The process is developed using Aspen Plus v12 (Aspen Technology, Inc., Bedford, MA, USA), which serves as the basis for determining the plant installation size. The Electrolyte Non-Random Two-Liquid (NRTL) thermodynamic model is used to calculate the activity coefficients of the liquid phase, while the Peng-Robinson equation of state describes the vapour and gas phases. Aspen Plus modelling provides detailed mass and energy balances of the process, excluding intermediate storage, and is applied to size equipment based on the maximum hydrogen production rate. The maximum capacity is determined by the hydrogen flow produced under a solar irradiance design condition of 1000 W/m2 (equivalent to AM 1.5 solar spectrum) and the number of panels considered. The equipment sizing data obtained are essential for cost estimation of key operations, such as DeOXO units and compressors.

To account for the variability of solar irradiance throughout the day and across seasons, the hourly performance of the plant is modelled in Python. While Aspen Plus defines the plant design capacity under peak irradiance, the Python model estimates actual hydrogen production rates based on hourly solar irradiance data. This dynamic modelling approach captures the effects of diurnal and seasonal fluctuations in solar input, using average daily irradiation profiles for each month. The hourly hydrogen production and storage balance are implemented in Python as a simple forward calculation, where the compressor flow is limited by its capacity and the difference between production and compression accumulates as intermediate storage. Solar irradiation data for Huelva, Spain, is sourced from the European Joint Research Centre (JRC) Photovoltaic Geographical Information System (PVGIS) [39]. Additional details on the solar irradiation data are provided in the Supplementary Information (see Table S1).

When intermediate energy storage is integrated, the capacities of process sections prior to storage remain the same as in cases without storage. However, the inclusion of storage introduces a trade-off between storage capacity and the capacity of downstream equipment, indicating that buffering capacity can increase the number of operating hours. This trade-off is evaluated from both operational and economic perspectives. In cases that include energy storage, the trade-offs are also modelled in Python. For both cases, with and without storage, the dynamic modelling is conducted over a two-year operational period starting in July. The Python model uses an hourly resolution and is supported by economic metrics, which are explained in detail in the following section. The results of this modelling reveal the storage capacity requirements and the capacities of equipment located downstream from storage.

A reference PV-E system, where photovoltaic panels generate electricity used in separate (centralized) electrolyzers to produce hydrogen, is also examined for comparison with the integrated solar hydrogen panel system (see Supplementary Information).

2.2. Economic Analysis

The economic assessment provides insights into the total capital expenditure (CAPEX) and operations and maintenance (O and M) costs, which are later used as inputs to estimate the levelized cost of hydrogen production (LCOH). All values are expressed in constant 2023 euros (EUR2023).

CAPEX is estimated for the main components of the integrated solar hydrogen system, which consists of solar hydrogen panels, PV panels, balance of plant, hydrogen storage tanks, and batteries. The balance of plant includes all additional equipment required to operate the process under the correct conditions (see Section 3), such as compressors, heat exchangers, mixers, gas–liquid separators, dryers, deoxygenation units, pumps, reverse osmosis systems, and ion exchange units. For all components, the investment cost includes the following four elements: direct costs, indirect and owner’s costs, working capital, and contingency.

For the balance of plant, bare equipment costs were determined from the process mass and energy flows using Aspen Plus v12 and estimated using Aspen Economic Analyzer v12. The conversion of bare equipment costs into total installed costs followed standard cost estimation methodologies described by Peters et al. [40]. Specifically, direct costs were calculated as 260% of bare equipment cost, indirect and owner’s costs as 100%, working capital as 10% of the combined direct and indirect costs, and contingency as 20% of that same base. This cost structure was applied consistently across all components to ensure methodological consistency. Further details are provided in the Supplementary Information.

To enable flexible scaling, polynomial cost functions of the form y = b2X2 + b1X + a were derived for each balance-of-plant component, where X represents the hydrogen flow rate. These functions are based on cost estimations for eight discrete capacities (1 k, 10 k, 100 k, 500 k, 1 M, 2.5 M, 5 M, and 10 M panels), obtained by running Aspen Plus and Aspen Economic Analyzer simulations for each case. The resulting scaling equations are used in the optimization framework to determine equipment sizing dynamically. This approach also supports the assessment of maximum equipment capacities (e.g., when multiple compressors or heat exchangers are required in parallel). The same methodology was applied to estimate the CAPEX of hydrogen storage tanks.

For solar hydrogen panels, a direct cost of 260 €/m2 is used, based on a panel area of 1.8 m2. This value is not a single assumed number, but the result of a bottom-up estimate based on the material and component costs listed in Section S7. In brief, the PV part of the panel is costed at 50 €/m2, identical to the value assumed for separate PV modules, and the remaining 210 €/m2 corresponds to the additional electrolysis-related components, assembly, and manufacturing. The following additional components contribute to the CAPEX: the balance of module, which includes wiring, piping, electronics, and mounting, adds 50 €/m2 (accounted as direct cost). Indirect and owner’s costs are also estimated at 50 €/m2, based on the cost structure for conventional PV panels reported in [41]. Working capital and contingency are then applied as described above. These costs are scaled linearly with panel count.

The cost structure for PV panels (used to power auxiliary systems such as compressors and pumps and to charge the batteries in the storage case) is similar to that of the solar hydrogen panels. Direct costs include 50 €/m2 for the PV module and 50 €/m2 for balance of module (the balance of module accounts for the electronics to connect the PV panels, for example, to batteries). Indirect and owner’s costs are also assumed to be 50 €/m2 [41], while working capital and contingency are again 10% and 20%, respectively, of the combined direct and indirect costs. The costs are scaled linearly with installed area.

Battery CAPEX (for intermediate electricity storage, when applicable) was estimated using the literature values from [42], with a total specific cost of 270 €/kWh. This figure was decomposed into its cost components as follows: direct costs (156 €/kWh), indirect and owner’s costs (52 €/kWh), working capital (21 €/kWh), and contingency (42 €/kWh). No scaling effects were applied to battery costs.

For the case of a detached PV and electrolyzer system (used as the reference for comparison), a direct cost of 900 €/kW was used for the electrolyzer, based on the data from [12]. Indirect and owner costs were estimated at 485 €/kW, also following the descriptions in [12]. Working capital was set at 10% of the sum of direct and indirect costs. Contingency was estimated at 20% of that same sum. The electrolyzer CAPEX does not include scaling effects.

In this work, the value of 900 €/kW for the Proton Exchange Membrane (PEM) electrolyzer and the value of 260 €/m2 for the solar hydrogen panels both represent direct equipment costs. The total CAPEX of each component is obtained by applying the same factors for indirect and owner’s costs, working capital and contingency, as described above and in the Supplementary Information. This results in a total electrolyzer CAPEX of 1800 €/kW and a total solar hydrogen panel CAPEX of 468 €/m2, consistent with the component breakdown in Tables S2–S4.

Full breakdowns of CAPEX estimations are provided in Section S4 of the Supplementary Information.

The levelized cost of hydrogen is estimated using Equation (1).

The annualized CAPEX is estimated utilizing Equation (2), where “i” represents the discount rate and “t” signifies the lifetime of the project. In this scenario, a discount rate of 10% and a project lifetime of 20 years are assumed. The operation and maintenance (O and M) costs are presumed to be 5% of the initial CAPEX [43]. The project lifetime of 20 years is applied consistently to all configurations, including the PV–electrolyzer reference system. For the integrated solar hydrogen panels, this value represents a long-term technological target for durability rather than a performance that has already been demonstrated. Therefore, a sensitivity analysis on the lifetime of the solar hydrogen panels (and the electrolyzer in the reference system) was carried out to assess the impact of this parameter on the LCOH.

For cases involving intermediate energy storage, we use a simulation-based techno-economic analysis rather than a formal optimization model. The hourly model described in Section 2.1 provides hourly hydrogen production from the panels, intermediate storage levels, and hydrogen flow to the compressors for a given compressor capacity. These flows, together with the design flow at 1000 W/m2, are used to scale all balance-of-plant equipment based on Aspen Plus cost correlations, and to compute annual hydrogen output, operating hours, and capital investments. The levelized cost of hydrogen (LCOH) is then calculated from annualized CAPEX and O and M using Equations (1) and (2).

The compressor capacity is treated as a design variable. We evaluate a range of possible capacities, covering from 10% of the design hydrogen flow up to the full design flow, using an incremental search. For each candidate capacity, the hourly simulation is run and the corresponding LCOH is computed. The capacity that yields the lowest LCOH within this range is taken as the cost-optimal design for the given number of panels. An analogous procedure is applied to the reference PV–electrolyzer system, where the electrolyzer power capacity is varied. All input data and assumptions required to reproduce these calculations are provided in Section 2.1, Section 2.2, Section 2.3, Section 2.4 and in the Supplementary Information.

2.3. System Description

The system boundaries defined for this analysis follow a gate-to-gate approach. The focus is solely on the hydrogen production process and system operations. Aspects such as upstream operations beyond the plant gate were not considered. In addition, downstream operations beyond the plant gate, including hydrogen transport, distribution, and handling, are excluded from the scope of this study. For the base case, hydrogen is assumed to be delivered at a purity above 99.9% and at a pressure of 60 bar. This pressure is selected as a typical value for hydrogen injection into a pipeline network [44]. The plant is assumed to be located in Huelva, Spain, to represent a region in Europe with high solar irradiance, such as southern Spain, enabling the analysis of a near-optimal location. Plant capacities are defined based on the number of panels installed: 1000, 100,000, and 10 million, corresponding to hydrogen production scales in the range of kW, MW, and GW, respectively.

For both the integrated solar hydrogen system and the PV–electrolyzer reference, the BoP encompasses water conditioning and recycling, gas–liquid separation, deoxygenation, drying and compression to 60 bar. Thus, the overall BoP complexity is comparable in both concepts (see Section 2.4). The main difference lies in whether the water-splitting function is provided by an integrated solar hydrogen panel or by a separate PV + electrolyzer system (see also Section 3.4.2 and Figure S2 for the PV–E configuration).

2.4. Plant Design

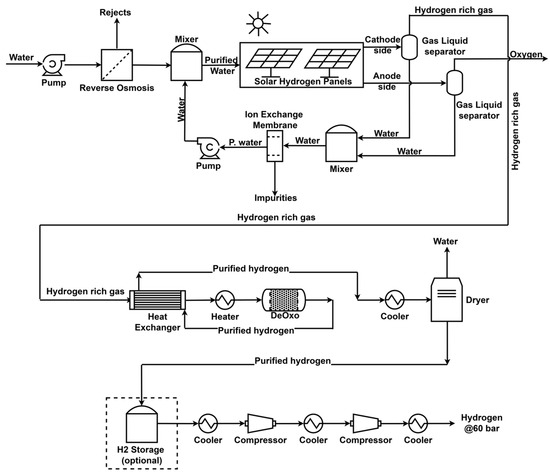

The system consists of the following four main sections (see Figure 1): (i) water conditioning and recycling, (ii) solar hydrogen production, (iii) hydrogen purification, and (iv) hydrogen compression. The process starts with conditioning the water to be supplied to the solar hydrogen panel system. The water pressure is first increased to 10.3 bar, which is the operating pressure of the reverse osmosis unit [45]. The water is then purified to remove impurities, as the electrolysis process requires high-purity water. Reverse osmosis is used for purification, with an efficiency of 80% on a mass basis [45], meaning that 20% of the water initially supplied is discarded along with the impurities. The purified water is directed to a mixer, where it is combined with water recycled from the panel system after hydrogen production. From the mixer, the water is fed into the solar hydrogen panels. Hydrogen production in the panels occurs at 10 bar and an average operating temperature of 40 °C. The solar hydrogen panels operate with a solar-to-hydrogen (STH) efficiency of 18%, calculated as the ratio of hydrogen output (LHV) to solar energy input. The solar hydrogen efficiency is based on a 25% energy conversion efficiency from the light harvesting, which is typical for silicon-perovskite tandem approach, combined with a 72% energy efficiency for the water splitting reaction.

Figure 1.

Simplified flowsheet of the integrated solar hydrogen system, showing the four main process sections (water conditioning and recycling, solar hydrogen production, hydrogen purification, and hydrogen compression) and the location of intermediate hydrogen storage.

Each panel produces two output streams. The first originates from the cathode side and contains unconverted water and hydrogen-rich gas. This stream is directed to a gas–liquid separator, where water is separated from the gas. The liquid fraction flows into a mixer, while the hydrogen-rich stream proceeds to the purification stage. The anode side generates liquid water and oxygen-rich gas. This stream is sent to a gas–liquid separator, where oxygen is collected as the top product, and the liquid fraction is combined in a mixer with water recovered from the separator that treated the cathode side stream. Both gas–liquid separators operate at 10 bar. The oxygen stream has a purity of 99.6 wt% (output from the Aspen Plus simulation) and is assumed to have no added value and is vented to the atmosphere after appropriate dilution and safety measures. The water recovered from the gas–liquid separators is directed to an ion exchange membrane unit to remove impurities. It is then pressurized using a pump before being mixed with fresh water from the reverse osmosis process and fed back into the panels (refer to Figure 1).

The hydrogen-rich stream obtained from the gas–liquid separation unit contains 92.4% hydrogen, 1.5% oxygen, and 6.1% water (results from Aspen Plus Simulation; values on a mass basis). To meet product specifications and ensure safety, the hydrogen undergoes further purification. The first step in this process involves the removal of oxygen through a catalytic reaction, known as DeOxo, where oxygen reacts with hydrogen to form water. The DeOxo process is exothermic and operates at 200 °C and 10 bar. Heat exchangers are used for heat recovery to reduce the need for externally sourced energy (refer to Figure 1). Removing oxygen from the hydrogen stream is essential due to the significant safety risk it poses to the system [46].

The stream leaving the catalytic process, containing water and hydrogen, is cooled to 30 °C and passed through a dryer to remove water. After purification, gas compressors increase the hydrogen pressure from 10 to 60 bar using a two-stage compression system with intermediate cooling. The compressors are assumed to operate with an isentropic efficiency of 60% and a mechanical efficiency of 95% as described in [47].

To address the intermittency caused by variations in solar irradiance throughout the day, month, and season, the inclusion of intermediate hydrogen storage is analyzed. Due to safety considerations, the storage of hydrogen containing even small amounts of oxygen should be avoided. Therefore, the most suitable location for intermediate storage is between the drying process and the compression train. The system follows the previously provided descriptions, with the exception of the addition of a spherical hydrogen storage tank (striped square in Figure 1). It is assumed that hydrogen is stored at a pressure of 10 bar. Additional PV panels are required to generate the electricity needed for various balance-of-plant processes. To meet the energy demands of processes operating during non-sunlight hours, the model includes the option to store electricity in batteries.

3. Results and Discussion

3.1. Operational Results

Table 1 presents the technical results from the modelling at different process capacities, based on a peak solar irradiance of 1000 W/m2. The results show that hydrogen production capacity increases from the kilowatt level with 1000 panels to the megawatt level with 100,000 panels, and up to the gigawatt level with 10 million panels. The plant operates for an average of 2264 full load hours per year, corresponding to an average annual capacity utilization of 26% (see discussion below). The installed capacity is therefore significantly higher than the actual annual production. It is not feasible to reduce the balance-of-plant size as a whole without intermediate storage, as this would limit the ability to capture peak irradiance during summer months (see solar irradiance input values used in the modelling for Huelva in the Supplementary Materials).

Table 1.

Results of Aspen Plus modelling of the solar hydrogen plant at different system capacities (without intermediate storage).

To provide clarity on seasonal variations in capacity utilization by hour of the day and by month, an average day for each month was used to model the effect of intermittency (see Supplementary Information, Table S1). The results show that hydrogen production generally peaks during the warmer months, from May to August, and between 11 a.m. and 2 p.m. each day. During these periods, the capacity utilization rate ranges from 84% to 96% of the installed capacity (see Figure S1 in the Supplementary Information). The capacity utilization rate decreases during the darker months and at times of the day when irradiance is low, reaching zero during dark hours. These results illustrate the monthly and hourly variations in plant performance depending on the time of year (Figure S1 in the Supplementary Information). This pattern is typical for processes that rely solely on intermittent resources such as solar energy. The resulting penalty is the need to oversize the process, leading to an investment that is not continuously utilized. Consequently, there are many hours when the plant remains idle. This is a critical issue because many industrial processes cannot be easily shut down and restarted on an hourly basis.

The impact and technical challenges of turning the plant on and off, as well as the ramp-up and ramp-down times, are not fully addressed in this study. Some studies cover certain aspects of flexible operation [48,49]. However, based on this work, future research is recommended to look more closely at the consequences of intermittent operation in this specific context. However, one aspect that may improve process stability is evaluated, namely the intermediate storage of hydrogen. The integration of intermediate hydrogen storage after the deoxygenation and drying stages results in a more stable hydrogen input for the downstream compression system (see Figure 1). This allows for a smaller compression train because the utilization rate can be significantly increased. The relative cost contributions of both storage and compression determine the cost-optimal storage and compression capacities. Upstream from the hydrogen storage section, the process operates on the same hourly basis as the base case system without intermediate storage, corresponding to 2264 h per year.

The modelling results indicate that for a system with 1000 panels, the annual operating hours of the compressors can reach up to 6939, which is approximately three times higher than the operating time of a compression system without intermediate hydrogen storage. For larger systems with 100,000 and 10 million panels, the annual compression time is roughly similar to the base case, at 2267 h. These findings suggest that incorporating downstream storage has a greater effect on small-scale systems compared to large-scale systems, where the number of operating hours is similar to those without intermediate storage. The primary reason for this behaviour in large-scale systems will be discussed in the following sections. Profiles of intermediate hydrogen storage are provided in Figure S3 in the Supplementary Information.

3.2. Investment Costs

The integrated solar hydrogen panels represent the most novel component of the analyzed hydrogen production plant. These panels are not yet commercial, and cost estimates from the literature vary substantially depending on factors such as the type of panel, the materials used, and the level of light concentration. The techno-economic assessment relies primarily on parameters such as overall efficiency, costs, and panel lifetime. The cost of the panel becomes less dominant in the production cost when light concentrators are used. In such systems, the costs of light concentrator systems, secondary optics, and tracking installations become more significant. In this analysis, no concentration factor is applied to focus on the direct costs and performance of an integrated solar hydrogen panel (panel costs amount to 260 €/m2, see Section 2.2).

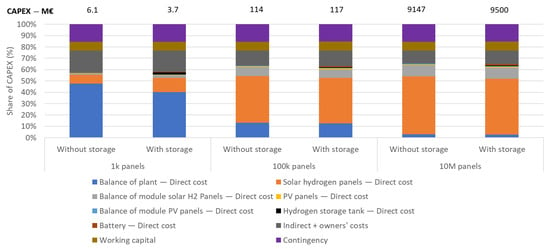

Figure 2 shows the CAPEX distribution for different system sizes of the integrated solar hydrogen system. For the case of 1000 panels and no hydrogen storage, the balance of plant, which includes compressors, makes up almost 48% of total CAPEX. This confirms that at small scale, the cost of supporting equipment, especially compression, is a major part of the investment. When intermediate hydrogen storage is included, it allows for more stable operation and a smaller compressor size. As a result, total CAPEX decreases from 6.1 M€ to 3.7 M€, a reduction of about 2.4 M€. In this case, the balance of plant share falls to 40%, and battery and storage tank costs appear in the CAPEX breakdown. Still, compression and related equipment remain among the largest cost items at this scale.

Figure 2.

Total capital investments and cost distribution for a solar hydrogen plant at the different installed capacities (with and without intermediate hydrogen storage).

As system capacity increases, the relative impact of the balance of plant, including compressors, on total CAPEX decreases. For a system with 100,000 panels, total CAPEX is about 114 M€ without storage. At this scale, solar hydrogen panels and their balance of module represent nearly 49% of the investment. When intermediate hydrogen storage is added, total CAPEX rises slightly to 117 M€, mainly due to the cost of electricity storage. The balance of plant contributes around 13% for both cases without storage and with storage, showing the effect of economies of scale.

A similar trend appears in the 10 million-panel system. In this case, solar hydrogen panels and their balance of module make up more than 59% of the total CAPEX, which reaches around 9.1 billion € without storage. Including storage leads to a small CAPEX increase, mostly due to the battery. At this capacity, the balance of plant contributes only 3.5% to total CAPEX, confirming the reduced cost share of supporting equipment at large scale.

For all system sizes, the combined share of indirect and owner’s costs, working capital, and contingency remains relatively steady, between 35% and 38% of total CAPEX. These components scale with direct costs and are not strongly affected by system size or storage. Their stable share reflects their structural role in total investment rather than being linked to specific equipment.

3.3. Hydrogen Production Costs

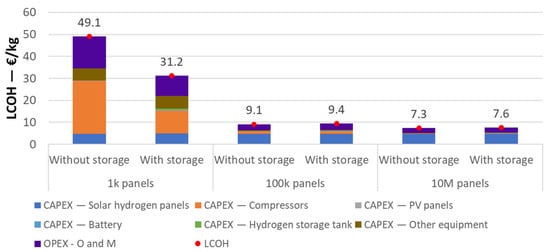

After estimating the total investment costs, the hydrogen production costs (LCOH) are calculated for facilities of different scales, both without and with intermediate storage (Figure 3). The LCOH primarily depends on the CAPEX. The OPEX is influenced by the CAPEX as it is represented as a fraction of it. Other variable operating costs are minimal, as the plant relies solely on water input of which the costs are relatively minor and excluded from the analysis. All the energy required to operate the system, including electricity for compressors and utilities for heating and cooling, is supplied by dedicated on-site photovoltaic (PV) panels. Notably, the cost estimation excludes the cost of panel replacement, which would require a stable performance for at least 45,000 operational hours. Such a performance for integrated solar hydrogen panels has not been demonstrated so far and, thus, can be considered as an optimistic assumption (sensitivity analysis was carried out on the solar hydrogen panel lifetime).

Figure 3.

Levelized cost of hydrogen production of a solar hydrogen plant at different system capacities (without and with storage).

For a system with 1000 panels, the LCOH is 49 €/kg-H2 without storage. In this configuration, the CAPEX of compressors and the solar hydrogen panels are the main contributors to the high cost. When intermediate storage is included, the LCOH drops to 31 €/kg-H2, a reduction of nearly 40%. This improvement is primarily due to the ability of intermediate storage to smooth and extend the operating hours of downstream equipment, particularly compressors. By buffering hydrogen and storing electricity (needed to operate the compressors mostly), the system can downsize the compression train while keeping it in operation for longer periods, leading to better utilization and lower CAPEX. Without storage, the compressor must be sized for short-lived peak flows, resulting in poor utilization of the equipment and higher costs. For 1000 panels, the CAPEX breakdown in Tables S8–S10 shows that adding storage reduces BoP CAPEX from 5.2 M€ to 2.7 M€, while the tank and battery CAPEX remain modest (0.13 M€ and 0.03 M€), which explains why storage significantly lowers the LCOH.

At larger scales, this effect becomes negligible. The contribution of compressors to total CAPEX drops sharply thanks to economies of scale, while the cost of solar hydrogen panels increases proportionally with system size. As a result, the overall cost is dominated by the panels, and further optimization of the downstream equipment (such as compressors) has little impact on the LCOH. For a system with 100,000 panels, the LCOH is 9.1 €/kg-H2 without storage and slightly increases to 9.4 €/kg-H2 with storage. Similarly, at 10 million panels, the LCOH rises from 7.3 €/kg-H2 to 7.6 €/kg-H2 when storage is included. These increases reflect the added cost of hydrogen storage tank and batteries for electricity storage (electricity is stored to be able to run compressors in non-sunny hours), which are not offset by proportional reductions in equipment size. At these scales, the impact of storage on cost is minimal or counterproductive. At this 10 million panel scale, the CAPEX breakdown in Table S10 shows that total CAPEX increases from about 9.15 to 9.50 billion €, with the hydrogen storage tank and the battery contributing approximately 97 M€ and 210 M€, respectively (Tables S8–S10), so the extra storage CAPEX is only weakly compensated by additional operating hours.

The results confirm that scaling up the system is the most effective strategy to reduce hydrogen production costs. While small-scale systems suffer from high unit costs dominated by compressors and balance-of-plant equipment, large-scale systems benefit from economies of scale. For capacities above 100,000 panels, production costs fall below 10 €/kg-H2. However, the solar hydrogen panel remains the dominant cost component, especially in large-scale systems.

These results show that the scale of the solar hydrogen system is a key factor in its economic performance, an aspect often overlooked in other studies. Most studies focus on hydrogen production capacities around 14 MW and do not examine the effects of larger (GW scale) or smaller capacities (kW scale) [30,32,34,37].

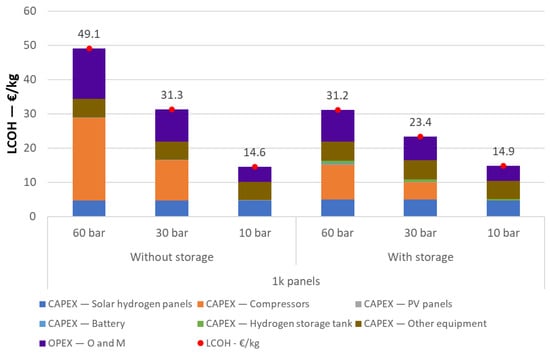

Effect of Hydrogen Delivery Pressure on LCOH

Given the significant impact of the CAPEX for compressors on the LCOH, the effect of hydrogen delivery at 30 bar and 10 bar has been evaluated for the 1000 panel scenario by comparing hydrogen production costs (see Figure 4).

Figure 4.

Levelized cost of hydrogen at different hydrogen delivery pressures for a 1000 panel system.

The calculated LCOH for different delivery pressures shows a clear cost reduction trend (see Figure 3). For a system with 1000 panels and no storage, lowering the compression pressure from 60 bar to 30 bar reduces the LCOH by about 36%, from 49 €/kg-H2 to 31 €/kg-H2. If no compression is needed and hydrogen is delivered at 10 bar, the LCOH drops further to 15 €/kg-H2, which is a total cost reduction of over 70%. A similar trend appears when storage is added, although the reductions are smaller: 25% at 30 bar and 52% at 10 bar, compared to the 60 bar case. These results show that delivery pressure has a strong impact on cost, at least for small-scale systems. The effect of hydrogen delivery pressure for large-scale systems is presented in Section S5.2 of the Supplementary Materials.

Compared to the target LCOH of 5 €/kg H2, the system without compression still shows production costs about three times higher, even in the most favourable case. This means that although removing the compression train leads to a significant cost reduction, more cost cuts are still needed at this scale. The results also show that without compression, the CAPEX from other equipment including heat exchangers, tanks, pumps, water purification systems, gas–liquid separators, and deoxygenation units becomes the main cost driver, even higher than the CAPEX of the solar hydrogen panels (these items are grouped as Other Equipment in Figure 3; see Section S4 of the Supplementary Information for a full breakdown). A detailed redesign of compressors and other auxiliary systems is outside the scope of this study, but the results point to the need to focus on those components for future cost optimization in small-scale systems.

The hydrogen delivery pressure is an important parameter when evaluating the system at a broader level. For example, if a small-scale system produces hydrogen at 10 bar, this hydrogen will likely require further compression to a higher pressure for applications such as injection into a high-pressure transmission network. Hydrogen from small-scale systems can, however, first be delivered into a low-pressure distribution network and then directed to a centralized compression stage. This approach may be more advantageous than using a standalone compression system for small-scale capacities. This scenario requires further evaluation from a system-level perspective to assess the trade-offs of using a distribution grid before centralized compression.

This consideration is important because the definition of system boundaries can significantly influence the overall outcomes of an assessment. Reducing the pressure at the point of production may require accounting for hydrogen pressurization at a different stage of the solar hydrogen system value chain. Therefore, it is essential to adopt a more comprehensive value chain evaluation in future studies to clearly communicate the challenges of hydrogen mobilization when compression is not considered.

3.4. Development Targets and Competitivity

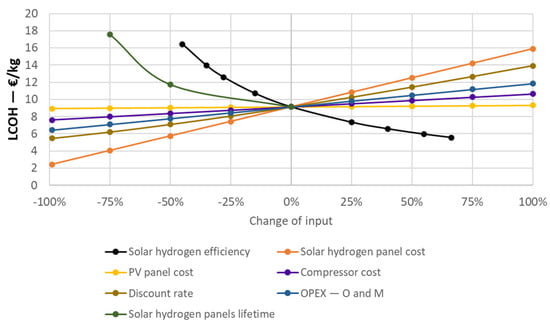

3.4.1. Sensitivity Analysis

Figure 5 shows the results of a sensitivity analysis for a 100,000 panel system without energy storage. It evaluates how changes in six input parameters affect the LCOH. The efficiency of the solar hydrogen panels is the most influential factor. Reducing the efficiency by 45% from its base value of 18%, down to 10%, causes a steep rise in LCOH, reaching up to 16.4 €/kg. In contrast, doubling the efficiency to 36% lowers the LCOH to about 5.6 €/kg. This confirms the strong and asymmetric impact of panel efficiency on system economics. The penalty from reduced efficiency is larger than the benefit from efficiency gains. This strong sensitivity also indicates the potential influence of operating conditions and weather-related performance losses on the cost of hydrogen. Solar hydrogen panel cost is the second most important factor. A 50% drop in panel cost brings the LCOH below 6 €/kg. While this is still above the cost of fossil hydrogen, it shows that reducing panel costs, especially when combined with higher efficiency, is key to making the system more competitive. Because the panel direct cost includes the electrolysis stack and its catalysts, the ±50% variation in panel cost also provides an indication of how uncertainties in catalyst loading and noble-metal price volatility would affect the LCOH.

Figure 5.

Sensitivity analysis of LCOH to change in input parameters for a 100,000 solar hydrogen panel system without storage.

Figure 5 also highlights the impact of the assumed solar hydrogen panel lifetime on the hydrogen production costs. For the 100,000-panel integrated system, reducing the lifetime from 20 to 10 and 5 years increases the LCOH from 9.1 to 11.7 and 17.6 €/kg H2 in the case without storage, and from 9.4 to 12.0 and 17.8 €/kg H2 when storage is included (Figure S9). The corresponding PV–electrolyzer benchmark shows a similar trend, with LCOH rising from 11.7 to 14.2 and 19.8 €/kg H2 without storage and from 11.3 to 12.1 and 14.0 €/kg H2 with storage (Figures S10 and S11). These results underline that the systems are strongly CAPEX-driven, as shorter solar hydrogen panel lifetimes (electrolyzer lifetimes for the reference case) substantially increase the annualized capital cost and therefore the LCOH, even when all other parameters remain unchanged.

The CAPEX of PV panels for auxiliary electricity has a substantially smaller effect on total cost. Compressor and O and M costs have moderate, linear effects. Since O and M is modelled as a fixed % of CAPEX, its impact scales with system size and complexity. These parameters shift the LCOH but not dramatically. The discount rate also influences the LCOH. Lowering it from 10% to 5% reduces the LCOH by about 2 €/kg to 7 €/kg. Since solar hydrogen systems have high upfront costs, financing conditions matter. Lower perceived risk, policy support, and long-term contracts can help reduce the cost of capital and improve the economics of the system.

For the 100,000-panel system, similar trends are observed when intermediate storage is included (see Figure S9 in Supplementary Information). The efficiency of the solar hydrogen panels has an even greater impact in this case. Small decreases in efficiency lead to an immediate increase in the LCOH, while higher efficiency reduces costs, though not as significantly as the cost increases caused by efficiency losses. The cost of solar hydrogen panels remains the second most influential parameter. As in the case without storage, a reduction in panel cost results in a linear decrease in the LCOH. The influence of compression cost is present but less significant compared to the cost of the solar hydrogen panels and the O and M cost.

The sensitivity analysis shows that specific conditions, such as simultaneous reductions in solar hydrogen panel and compressor costs combined with improvements in solar-to-hydrogen efficiency, can significantly lower the LCOH. For example, setting solar hydrogen panel direct costs to 120 €/m2, reducing compressor costs by 50%, and increasing solar hydrogen efficiency from 18% (base case) to 23%, while keeping other parameters unchanged, results in an LCOH of 3.8 €/kg-H2 without storage and 3.7 €/kg-H2 with storage for a system of 100,000 panels. The system with storage leads to a similar cost despite the additional CAPEX required for storage tanks and batteries which are barely deployed. These results indicate that storage does not provide a significant cost advantage over the case without storage. However, the impact of flexible operation on system robustness and the potential requirement for continuous hydrogen delivery is not assessed in this study.

3.4.2. Comparison with PV Coupled to Electrolysis

The integrated solar hydrogen panel system is compared with a similar system design in which the integrated panels are replaced by PV panels coupled to electrolyzers (PV-E (System 2), see Section S2 in Supplementary Information for more details). In this system, intermediate storage is only available in the form of batteries. For the PV-E system, with PV panel direct costs of approximately 50 €/m2 [41] (for a 25% efficiency tandem cell) and electrolyzer equipment costs of 900 €/kWe [12] (for a PEM stack including power electronics operating at 72% efficiency), the LCOH of a 100,000 PV panel system is 11.7 €/kg-H2. When electricity is stored in a battery after the PV panels (with a base case CAPEX of around 270 €/kWh [42]), the LCOH slightly decreases to 11.3 €/kg-H2. Although the storage option allows for a lower capacity and, therefore, lower cost of the electrolyzer system, the additional costs of the battery prevent larger reduction in production costs. This situation may change if battery costs decline.

Using the same irradiance and PV efficiency assumptions, the electrolyzer direct cost of 900 €/kW corresponds to roughly 225 €/m2 of illuminated area, which, when added to the 50 €/m2 PV module cost, gives a combined PV + electrolyzer direct cost of about 275 €/m2; this is slightly higher than the 260 €/m2 direct cost assumed for the solar hydrogen panels and indicates that the panel cost used here is comparable to, and not more optimistic than, the PV–electrolyzer cost assumption.

The comparison between the integrated solar hydrogen system and the PV-E system reveals clear differences in levelized cost of hydrogen. For a 100,000-panel facility without storage, the LCOH of the solar hydrogen system is 9.1 €/kg-H2, while the LCOH of the PV-E system reaches 11.7 €/kg-H2 (see Figure 3 and Figure S6 in Supplementary Materials). This represents a 22% higher cost for the PV-E system under the same scale and operating conditions. When intermediate storage is included, the solar hydrogen system achieves an LCOH of 9.4 €/kg-H2, compared to 11.3 €/kg-H2 for the PV-E configuration, maintaining a similar cost advantage. These findings indicate that the integrated system is more cost-efficient under the base case assumptions. This difference in LCOH is mainly driven by the cost structure of each configuration. In the integrated system, hydrogen production occurs directly within the panel, which is priced at 260 €/m2 for the active module and follows a PV-like cost structure. This enables relatively low costs per unit of hydrogen-generating area. By contrast, the PV-E system includes separate PV panels and an external PEM electrolyzer. The electrolyzer, together with the associated balance of plant and power supply components, represents a major share of the total CAPEX, particularly at this scale. When the cost of the electrolyzer system is added to that of the PV panels, the total investment becomes substantially higher, increasing the LCOH.

While the PV-E system is more technologically mature and already benefits from commercial experience with PV panels and electrolyzers, the integrated solar hydrogen panel system is still in an earlier development stage and may face scaling challenges. However, under the assumptions used in this study and at the analyzed scale, the integrated system potentially has some economic advantages. Further research is needed to assess the scalability and long-term performance of integrated panels, as well as to better understand the trade-offs between modular integration and the greater flexibility offered by the PV-E configuration to operate for longer hours when intermediate electricity storage is incorporated.

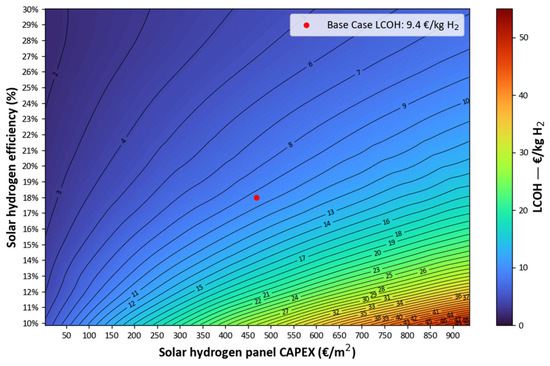

Looking deeper at the parameters that influence the LCOH the most for the two systems, Figure 6 shows the influence of two key parameters, solar hydrogen panel CAPEX (€/m2) and efficiency (%), on the Levelized Cost of Hydrogen (LCOH) for an integrated solar hydrogen panel system with intermediate storage. Both parameters are varied to illustrate their combined impact on LCOH. A clear trend is observed, where increasing panel costs lead to higher LCOH, particularly at lower efficiency levels. In these cases, even a modest increase in solar hydrogen panel CAPEX results in significantly higher hydrogen production cost. In contrast, reducing solar hydrogen panel CAPEX results in the lowest LCOH values, especially when combined with a higher efficiency. This indicates that cost reductions are most effective when accompanied by efficiency improvements.

Figure 6.

Impact of solar hydrogen panel cost and efficiency on the levelized cost of hydrogen (LCOH) in the integrated solar hydrogen panel system with intermediate storage for 100,000 panels.

From the base case (468 €/m2 (this value corresponds to total CAPEX of solar hydrogen panels, with a direct solar hydrogen panel cost of 260 €/m2) and 18% efficiency, corresponding to 9.4 €/kg-H2), both reducing panel CAPEX and increasing efficiency independently result in significant cost reductions. Lowering panel CAPEX to 200 €/m2, while keeping efficiency constant, reduces the LCOH to about 5.7 €/kg-H2, a drop of approx. 40%. Increasing efficiency to 25% at the same CAPEX also reduces the LCOH by around 40% to 5.6 €/kg-H2. When both parameters are improved at once (200 €/m2 and 25% efficiency), the LCOH reaches about 3.8 €/kg-H2. This means a total reduction of 5.6 €/kg-H2 (60%) compared to the base case. These results show that both cost and performance play a key role in improving the economics, and the highest gains come when they are improved together.

At the other extreme, the figure also shows how quickly hydrogen costs rise when efficiency is low and CAPEX is high. If the panel efficiency drops to 10% and CAPEX goes above 800 €/m2, the LCOH exceeds 50 €/kg-H2. In this region, the system becomes economically unfeasible, and even large savings in other components will not help. This highlights the obvious need to avoid design options that combine poor conversion performance with high capital cost. Early-stage technologies must focus on both scalable production and solid efficiency to avoid getting stuck with very high production costs. Overall, the findings support the need for a combined development approach. Improving panel performance and cutting solar hydrogen panels CAPEX must go hand in hand to bring solar hydrogen closer to competitive levels.

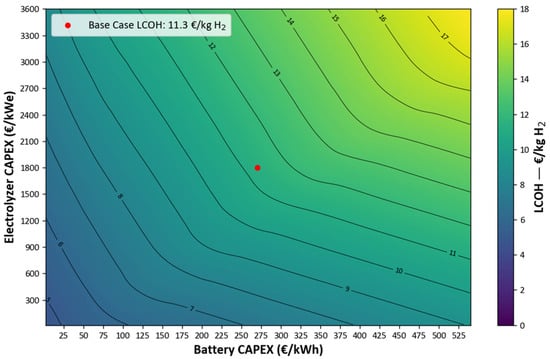

Figure 7 shows how battery and electrolyzer CAPEX affect the levelized cost of hydrogen (LCOH) in the PV-E system with intermediate energy storage. The base case, shown in the figure, considers a battery CAPEX of 270 €/kWh and an electrolyzer CAPEX of 1800 €/kW (this value corresponds to the total CAPEX of electrolyzers which includes a direct cost of 900 €/kW as described above). This results in an LCOH of 11.3 €/kg-H2. Lowering the cost of either component leads to noticeable reductions in LCOH. For example, at fixed electrolyzer CAPEX, reducing battery CAPEX from 270 €/kWh to 100 €/kWh brings LCOH down to about 9.2 €/kg-H2, a decrease of 19%. The shape of the contour lines shows that battery CAPEX has a stronger impact when electrolyzer CAPEX is also high, and the same happens the other way around.

Figure 7.

Influence of battery and electrolyzer costs on the levelized cost of hydrogen (LCOH) in a PV-E with intermediate storage for 100,000 panels.

Overall, electrolyzer CAPEX has a larger influence on LCOH than battery CAPEX. If battery CAPEX stays at 270 €/kWh, reducing electrolyzer CAPEX from 1800 €/kW to 900 €/kW lowers LCOH to just under 8 €/kg-H2, a cost cut of around 27%. Even if battery CAPEX is relatively high, up to 500 €/kWh, an electrolyzer CAPEX of 600 €/kW can still keep LCOH below 10 €/kg-H2. However, when both components are expensive (above 400 €/kWh for batteries and 3000 €/kW for the electrolyzer) LCOH rises above 16 €/kg-H2. This shows that lowering the cost of just one component is not enough to bring hydrogen into a competitive range.

The base case falls in an area with moderate cost sensitivity, which means the system can still benefit from improvements in both battery and electrolyzer technology. While reducing electrolyzer costs gives a stronger LCOH reduction, battery cost cuts still matter, especially in setups that rely heavily on storage. The contour map confirms that both components need to be targeted together to achieve deeper cost reductions. Focusing on only one component will likely hit a point of diminishing returns if the other remains expensive. For PV-E systems with intermediate storage, a combined strategy to cut costs is needed to close the gap with fossil-based hydrogen. Cost reductions for the PV component of the system can further reduce the hydrogen production costs, although not shown in the figure.

3.5. Limitations and Future Considerations for Technology Development

While this study provides a comprehensive techno-economic assessment of integrated solar hydrogen systems, several operational aspects have not been included, which may influence the long-term feasibility, cost effectiveness, and safety of the technologies analyzed. These limitations should be addressed in future research to support the continued development of solar hydrogen systems.

The analysis does not consider detailed operational dynamics, such as start-up and shutdown cycles, transient responses, and system ramp rates. These factors are important for identifying potential bottlenecks and operational inefficiencies that may emerge during real-world deployment. Understanding these dynamics can help to optimize system design and reduce unforeseen operational costs. In addition, the potential effects of intermittent operation on materials and balance-of-plant (BoP) components are not explored. Frequent cycling due to solar irradiance variability can lead to accelerated material degradation, particularly in components exposed to thermal and mechanical stresses, such as electrolyzers, compressors, and hydrogen storage systems. This may affect both performance and safety, as well as increase maintenance requirements over time.

Furthermore, the study does not address the implications of operating the system to deliver hydrogen continuously at a steady flow over the entire year. Achieving such high annual operating hours would require significant buffering strategies or hybrid systems to mitigate the effects of solar intermittency. Under current conditions, large buffering systems would result in high costs, as shown in the analysis, particularly in the PV-E configuration, where battery storage contributes noticeably to overall system costs. Achieving continuous operation through storage alone remains economically challenging under current assumptions.

For photovoltaic-electrolyzer (PV-E) systems, the option to produce electricity in addition to hydrogen was not evaluated in detail. While PV-E systems are more technologically mature and offer greater design flexibility, including the potential to produce electricity when hydrogen demand is low, these features were not quantified in this study. Future work could explore the trade-offs between hydrogen and electricity co-production, considering both grid interactions and on-site energy demands.

The distribution of hydrogen versus electricity within the plant and its effect on overall costs has also not been examined in detail (although some aspects are part of the costs such as piping, wiring and power electronics). The choice between distributing hydrogen or electricity can influence infrastructure requirements, energy losses, and operational flexibility. This is particularly relevant for large-scale systems, where distribution efficiency and infrastructure costs may significantly affect the levelized cost of hydrogen (LCOH).

Furthermore, this study does not explicitly model the long-term availability and price volatility of critical materials, in particular noble-metal catalysts such as platinum and iridium used in electrolysis components. These materials are already recognized as potential bottlenecks for large-scale deployment of PEM electrolyzers, and integrated solar hydrogen panels that rely on similar components will face comparable constraints. In our analysis, uncertainties in catalyst and membrane costs are represented implicitly through the sensitivity of LCOH to panel direct cost, but a dedicated assessment of future supply chain risks is beyond the scope of this work. In addition, possible regulatory changes such as restrictions on PFAS-containing membranes and differences in life-cycle impacts between integrated panels and PV–electrolyzer systems also warrant further study.

A limitation of this study is that the oxygen stream is not valorized. In the present analysis, oxygen is assumed to have no economic value and is simply vented, which is appropriate for a generic large-scale plant without a nearby, stable oxygen demand. In specific locations, however, co-utilization of oxygen (for example in industrial or wastewater treatment processes) could improve overall project economics. Assessing such site-specific opportunities falls outside the scope of this work and is left for future studies.

A further important limitation is the uncertainty in long-term durability of integrated solar hydrogen panels. While module scale prototypes are being studied, lifetimes comparable to those assumed at system level have not yet been demonstrated. The sensitivity analysis for the project lifetime shows that a reduction from 20 to 10 or 5 years can increase the LCOH by 20–100%, depending on the configuration. This means that achieving lifetimes in the order of one to two decades is a crucial development target for integrated panels if they are to compete with PV–electrolyzer systems.

Additional indicators of system robustness, such as guaranteed continuous hydrogen delivery or statistics over several weather years, are not included, since analyzing them would require a more detailed operational optimization framework beyond the scope of this study.

Addressing these limitations in future research will be important for refining cost estimates, improving system design, and supporting the broader deployment of solar hydrogen technologies. Understanding the interactions between operational flexibility, material durability, and system integration will help identify opportunities for cost reduction and performance improvement. This is particularly important for integrated solar hydrogen panels, which are still at an early development stage. The development trajectory will undoubtedly face scalability and manufacturability challenges but it also provides the opportunity to include the identified design aspects from an early stage.

4. Conclusions

This study presents a techno-economic assessment of integrated solar hydrogen production systems, examining how scale, solar intermittency, and intermediate energy storage influence production costs. The results provide detailed answers to four central research questions.

4.1. Levelized Cost of Hydrogen (LCOH) Across System Designs

Hydrogen production costs vary significantly with system size and storage configuration. In a system with 1000 integrated panels, the LCOH is approximately 49 €/kg without intermediate storage. Including hydrogen storage reduces the LCOH to around 31 €/kg, a cost decrease of 36%. This reduction stems from increased utilization of compressors and other equipment thanks to smoother operation. As system scale increases, costs decrease thanks to economies of scale. At 100,000 panels, the LCOH drops to 9.1 €/kg without storage and increases slightly to 9.4 €/kg when storage is added. At 10 million panels, the LCOH reaches 7.3 €/kg without storage and 7.6 €/kg with storage. The impact of storage becomes negligible or even counterproductive at these scales, where the additional costs of hydrogen storage tanks and batteries are not offset by improved equipment utilization. Overall, scaling up from kilowatt- to gigawatt-level systems is the most effective approach for reducing hydrogen production costs, especially by reducing the relative cost of the BoP. Nevertheless, reductions on solar hydrogen panel costs have become imperative to reduce hydrogen costs.

4.2. Key Cost Drivers and Their Influence on LCOH

Panel efficiency and panel cost are the most influential parameters affecting the LCOH. For a system with 100,000 panels, increasing solar-to-hydrogen (STH) efficiency from 18% to 36% reduces the LCOH from 9.1 €/kg to 5.6 €/kg. Reducing panel direct cost by 50% (from ~260 €/m2 to ~130 €/m2) lowers the LCOH to just under 6 €/kg. These effects are more significant than those of other variables, such as auxiliary electricity or O and M costs.

Balance-of-plant (BoP) costs, particularly for compression, are important at a small scale. For example, in the 1000-panel system, compression is a major cost contributor. Reducing the hydrogen delivery pressure from 60 bar to 10 bar lowers the LCOH from 49 €/kg to approximately 15 €/kg, a 70% cost reduction. In systems with 100,000 panels or more, the contribution of BoP costs (including compression) is relatively small, and panel-related costs become the dominant driver.

4.3. Cost, Efficiency, and Scale Requirements for Parity with PV-E Systems

In a 100,000-panel configuration, the integrated solar hydrogen system achieves an LCOH of 9.1 €/kg without storage, which is about 22% lower than that of a comparable PV-E system under the same assumptions (11.7 €/kg). With storage, the integrated system reaches 9.4 €/kg, versus 11.3 €/kg for the PV-E case. This cost advantage results from the simpler design of the integrated system, which avoids the separate electrolyzer unit required in PV-E setups.

For integrated solar hydrogen systems to reach an LCOH value closer to the low side of the cost range of PV-E (around 5 €/kg), a combination of performance and cost improvements is necessary. For instance, reducing panel cost to 200 €/m2 or increasing STH efficiency to 25% individually reduces the LCOH to about 5.7–5.6 €/kg. When both changes are combined, the LCOH drops to around 3.8 €/kg. These parameter combinations define quantitative targets that would enable integrated solar hydrogen systems to approach or surpass the cost levels of PV-E systems. Whether such targets are achievable depends on future developments that are not assessed in this study. In addition to efficiency and cost, long-term durability is essential. If panel lifetimes remain limited to about 5–10 years, the levelized cost of hydrogen stays well above 10 €/kg even at large scale, which significantly reduces the competitiveness of integrated solar hydrogen systems.

4.4. Conditions for Achieving LCOH Below 5 €/Kg

The costs of fossil-based H2 range roughly between 1 and 5 € per kg of H2 (mainly depending on the fossil fuel price) and renewable approaches, such as electrolysis and solar hydrogen, should likely be able to produce at costs lower than 5 € per kg to become economically feasible. The base case results show that LCOH remains above 5 €/kg, even at the 10 million panel scale (LCOH = 7.3 €/kg without storage). Achieving a cost below 5 €/kg requires a combination of favourable conditions. For a 100,000 panel system, reducing panel direct cost to 120 €/m2, improving STH efficiency to 23%, and halving the cost of compressors and other BoP equipment results in an LCOH between 3.7 and 3.8 €/kg, both with and without storage. For context, this best-case value of about 3.8 €/kg-H2 lies in the upper part of the 1–5 €/kg-H2 cost range reported for hydrogen produced from fossil fuels. As a simple illustrative calculation, if solar hydrogen can achieve a 90% reduction in lifecycle CO2 emissions compared to grey hydrogen, a carbon price in the range of 100–200 €/t-CO2 would increase the effective cost of grey hydrogen (grey hydrogen emission factor assumed as 10 kg CO2eq/kg H2 [10]) by roughly 1–2 €/kg-H2 relative to solar hydrogen. Under such carbon prices, the best-case integrated solar hydrogen scenario considered here would be broadly competitive with fossil-based hydrogen, although a detailed life-cycle assessment of the integrated systems is beyond the scope of this techno-economic study.

Overall, the analysis shows that current costs of solar hydrogen production through integrated solar hydrogen panels (but also via PV combined with electrolysis) are high. The sensitivity analysis indicates that if the solar hydrogen panel costs can be reduced while an efficiency of around 20% is sustained, the costs of hydrogen production may go below 5 €/kg. Research and development should, thus, particularly focus on reducing solar hydrogen panel costs, improving STH efficiency, and designing and demonstrating full systems that operate under outdoor conditions for prolonged time to facilitate further learning and scale up of the technology.

Supplementary Materials

The following supporting information can be downloaded at https://www.mdpi.com/article/10.3390/en18226069/s1.

Author Contributions

Conceptualization, J.M., B.d.G., J.v.d.H., P.B. and R.J.D.; methodology, J.M., R.J.D. and B.d.G.; software, J.M.; validation, J.M., B.d.G. and R.J.D.; formal analysis, J.M.; investigation, J.M., B.d.G., R.J.D. and J.v.d.H.; resources, N.M. and P.B.; data curation, J.M., R.J.D. and B.d.G.; writing—original draft preparation, J.M. and R.J.D.; writing—review and editing, all authors; visualization, J.M. and R.J.D.; supervision, B.d.G. and R.J.D.; project administration, N.M.; funding acquisition, P.B., R.J.D. and B.d.G. All authors have read and agreed to the published version of the manuscript.

Funding

This research has received funding from The Netherlands Organisation for Applied Scientific Research (TNO) Early Research Program (ERP, 060.63713) on Solar-2-Hydrogen and the EU Interreg Flanders-The Netherlands project FOTON.

Data Availability Statement

The data and analyses that support the conclusions of this work are fully included in this article. Additional details can be obtained from the corresponding author upon request.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- IEA. Tracking Clean Energy Progress 2023; IEA: Paris, France, 2023; Available online: https://www.iea.org/reports/tracking-clean-energy-progress-2023 (accessed on 16 May 2024).

- Razmjoo, A.; Gakenia Kaigutha, L.; Vaziri Rad, M.A.; Marzband, M.; Davarpanah, A.; Denai, M. A Technical analysis investigating energy sustainability utilizing reliable renewable energy sources to reduce CO2 emissions in a high potential area. Renew. Energy 2021, 164, 46–57. [Google Scholar] [CrossRef]

- Palm, E.; Tilsted, J.P.; Vogl, V.; Nikoleris, A. Imagining circular carbon: A mitigation (deterrence) strategy for the petrochemical industry. Environ. Sci. Policy 2024, 151, 103640. [Google Scholar] [CrossRef]

- Detz, R.J.; van der Zwaan, B. Transitioning towards negative CO2 emissions. Energy Policy 2019, 133, 110938. [Google Scholar] [CrossRef]

- Capurso, T.; Stefanizzi, M.; Torresi, M.; Camporeale, S.M. Perspective of the role of hydrogen in the 21st century energy transition. Energy Convers. Manag. 2022, 251, 114898. [Google Scholar] [CrossRef]

- Zhao, A.P.; Li, S.; Xie, D.; Wang, Y.; Li, Z.; Hu, P.J.-H.; Zhang, Q. Hydrogen as the nexus of future sustainable transport and energy systems. Nat. Rev. Electr. Eng. 2025, 2, 447–466. [Google Scholar] [CrossRef]

- Jia, X.; Xia, Y.; Yan, Z.; Gao, H.; Qiu, D.; Guerrero, J.M.; Li, Z. Coordinated operation of multi-energy microgrids considering green hydrogen and congestion management via a safe policy learning approach. Appl. Energy 2025, 401, 126611. [Google Scholar] [CrossRef]

- Qi, N.; Pinson, P.; Almassalkhi, M.R.; Zhuang, Y.; Su, Y.; Liu, F. Capacity credit evaluation of generalized energy storage considering strategic capacity withholding and decision-dependent uncertainty. Appl. Energy 2025, 397, 126310. [Google Scholar] [CrossRef]

- IEA. Global Hydrogen Review 2023; IEA: Paris, France, 2023; Available online: https://www.iea.org/reports/global-hydrogen-review-2023 (accessed on 21 May 2024).

- IEA. Global Hydrogen Review 2024; IEA: Paris, France, 2024; Available online: https://www.iea.org/reports/global-hydrogen-review-2024 (accessed on 21 May 2024).

- Shiva Kumar, S.; Lim, H. An overview of water electrolysis technologies for green hydrogen production. Energy Rep. 2022, 8, 13793–13813. [Google Scholar] [CrossRef]

- Eblé, L.; Weeda, M. Evaluation of the Levelised Cost of Hydrogen Based on Proposed Electrolyser Projects in The Netherlands. Renewable Hydrogen Cost Element Evaluation Tool (RHyCEET); TNO Report R10766; TNO: The Hague, The Netherlands, 2024. [Google Scholar]

- Clapp, M.; Zalitis, C.M.; Ryan, M. Perspectives on current and future iridium demand and iridium oxide catalysts for PEM water electrolysis. Catal. Today 2023, 420, 114140. [Google Scholar] [CrossRef]

- Améduri, B. Fluoropolymers as Unique and Irreplaceable Materials: Challenges and Future Trends in These Specific Per or Poly-Fluoroalkyl Substances. Molecules 2023, 28, 7564. [Google Scholar] [CrossRef]

- Sinha, P.; Cypher, S.M. Life Cycle Fluoropolymer Management in Proton Exchange Membrane Electrolysis. Hydrogen 2024, 5, 710–722. [Google Scholar] [CrossRef]

- EC. Hydrogen. European Commission. 2024. Available online: https://energy.ec.europa.eu/topics/energy-systems-integration/hydrogen_en (accessed on 22 May 2024).

- PWC. Quantifying the Opportunity in Green Hydrogen. 2024. Available online: https://www.pwc.com/gx/en/industries/energy-utilities-resources/future-energy/green-hydrogen-cost.html (accessed on 3 June 2024).

- IEA. Net Zero Roadmap. A Global Pathway to Keep the 1.5 °C Goal in Reach. Update 2023. 2023. Available online: https://www.iea.org/reports/net-zero-roadmap-a-global-pathway-to-keep-the-15-c-goal-in-reach (accessed on 3 June 2024).

- Sweerts, B.; Detz, R.J.; van der Zwaan, B. Evaluating the Role of Unit Size in Learning-by-Doing of Energy Technologies. Joule 2020, 4, 967–970. [Google Scholar] [CrossRef]

- Jacobsson, T.J.; Fjällström, V.; Edoff, M.; Edvinsson, T. CIGS based devices for solar hydrogen production spanning from PEC-cells to PV-electrolyzers: A comparison of efficiency, stability and device topology. Sol. Energy Mater. Sol. Cells 2015, 134, 185–193. [Google Scholar] [CrossRef]

- Holmes-Gentle, I.; Tembhurne, S.; Suter, C.; Haussener, S. Kilowatt-scale solar hydrogen production system using a concentrated integrated photoelectrochemical device. Nat. Energy 2023, 8, 586–596. [Google Scholar] [CrossRef]

- Gutiérrez-Martín, F.; Díaz-López, J.A.; Caravaca, A.; Dos Santos-García, A.J. Modeling and simulation of integrated solar PV-hydrogen systems. Int. J. Hydrogen Energy 2024, 52, 995–1006. [Google Scholar] [CrossRef]

- SunHydrogen. SunHydrogen Technology. 2024. Available online: https://www.sunhydrogen.com/news-posts/ctf?utm (accessed on 6 June 2024).

- Bloomenergy. Heliogen and Bloom Energy Lead the Way to Produce Low-Cost, Green Hydrogen Following Successful Demonstration. 2024. Available online: https://www.bloomenergy.com/resource/heliogen-and-bloom-energy-lead-the-way-to-produce-low-cost-green-hydrogen-following-successful-demonstration/?utm (accessed on 12 June 2024).

- Achour, Y.; Berrada, A.; Arechkik, A.; El Mrabet, R. Techno-Economic Assessment of hydrogen production from three different solar photovoltaic technologies. Int. J. Hydrogen Energy 2023, 48, 32261–32276. [Google Scholar] [CrossRef]

- Vartiainen, E.; Breyer, C.; Moser, D.; Román Medina, E.; Busto, C.; Masson, G.; Bosch, E.; Jäger-Waldau, A. True Cost of Solar Hydrogen. Sol. RRL 2022, 6, 2100487. [Google Scholar] [CrossRef]

- Hassan, Q.; Abdulrahman, I.S.; Salman, H.M.; Olapade, O.T.; Jaszczur, M. Techno-Economic Assessment of Green Hydrogen Production by an Off-Grid Photovoltaic Energy System. Energies 2023, 16, 744. [Google Scholar] [CrossRef]