Impact of Electric Motor Selection on the Efficiency and Reliability of Level Crossing Gate Drives in Polish Railway Infrastructure

Abstract

1. Introduction

2. Materials and Methods

2.1. General Approach

2.2. Description of Motor Designs

- PRMOa90-90 motor—A classic commutator DC motor with ferrite magnets, commonly used in EEG drives, with a rated voltage of 24 V and a power of 170 W. Its main advantages are its simple design and low production costs, while its limitations include relatively low efficiency, low torque reserve, and susceptibility to brush wear.

- Prototype commutator motor with neodymium magnets—Proprietary design with rectangular N38 magnets, enabling higher flux density and torque with limited dimensions. It is distinguished by greater load resistance, the ability to operate without a gearbox, and easier installation due to the placement of magnets in special slots. Potential disadvantages of this design include higher production costs compared to solutions with ferrite magnets and the closure of part of the flux by the walls between the magnets.

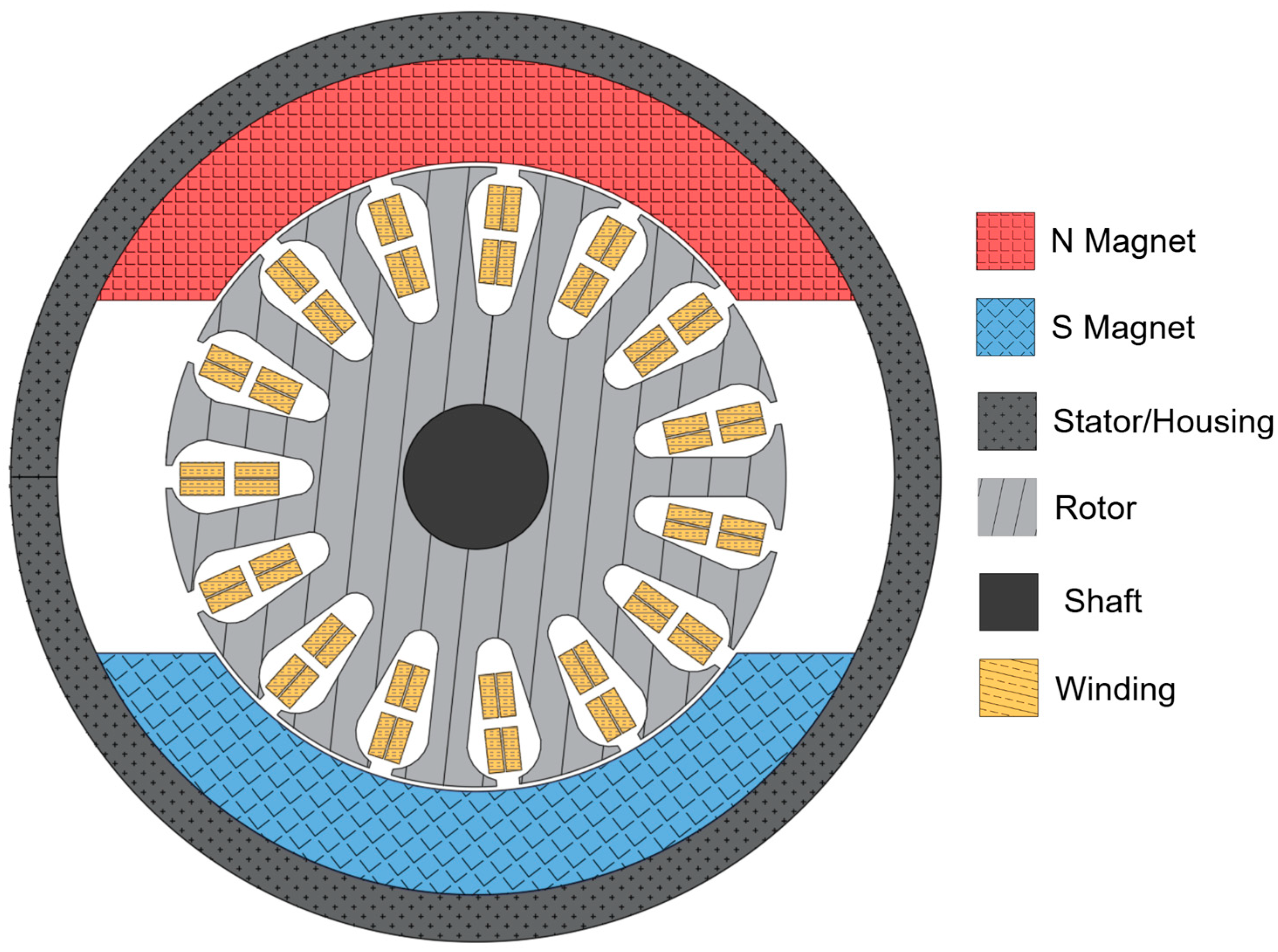

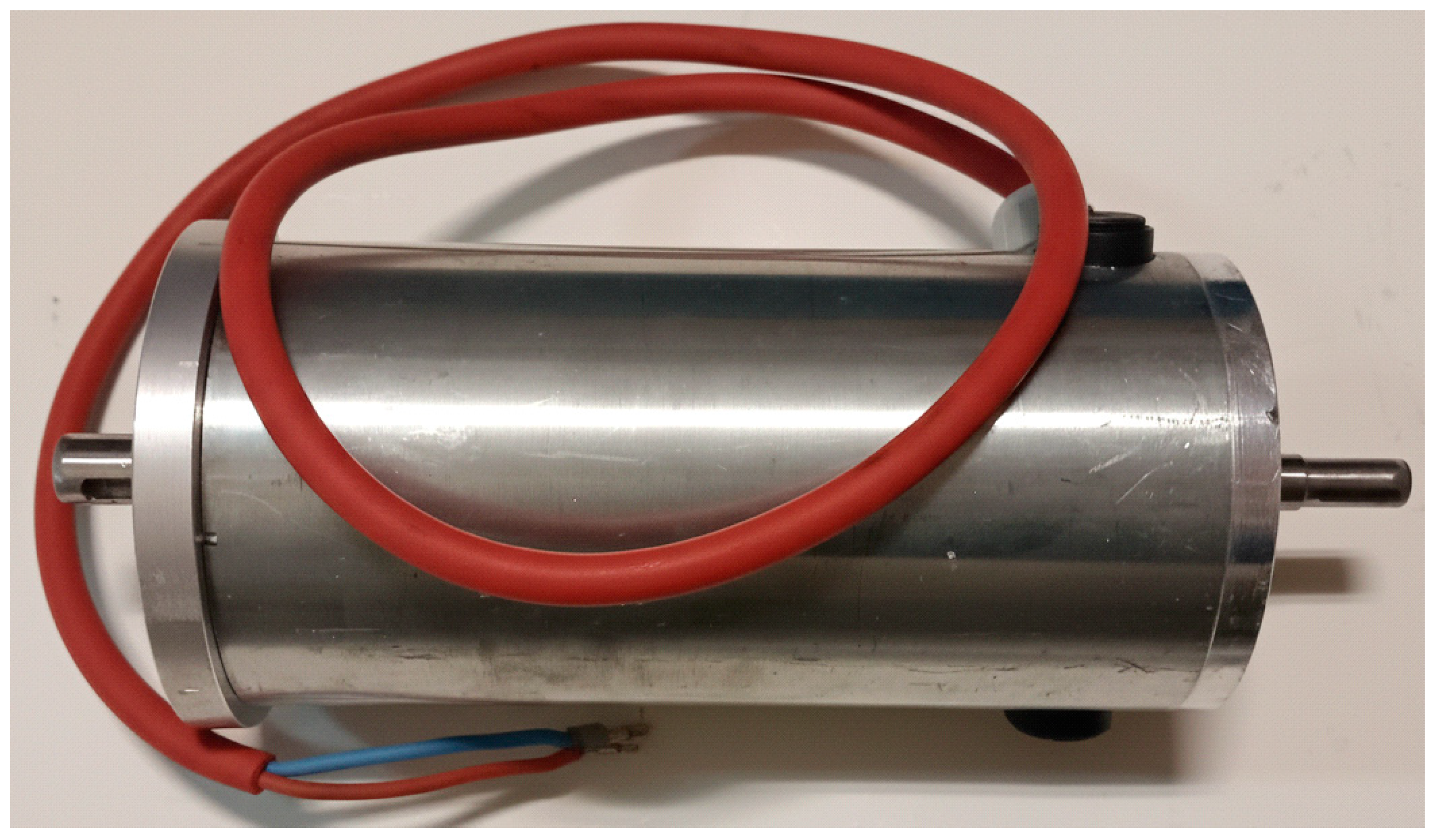

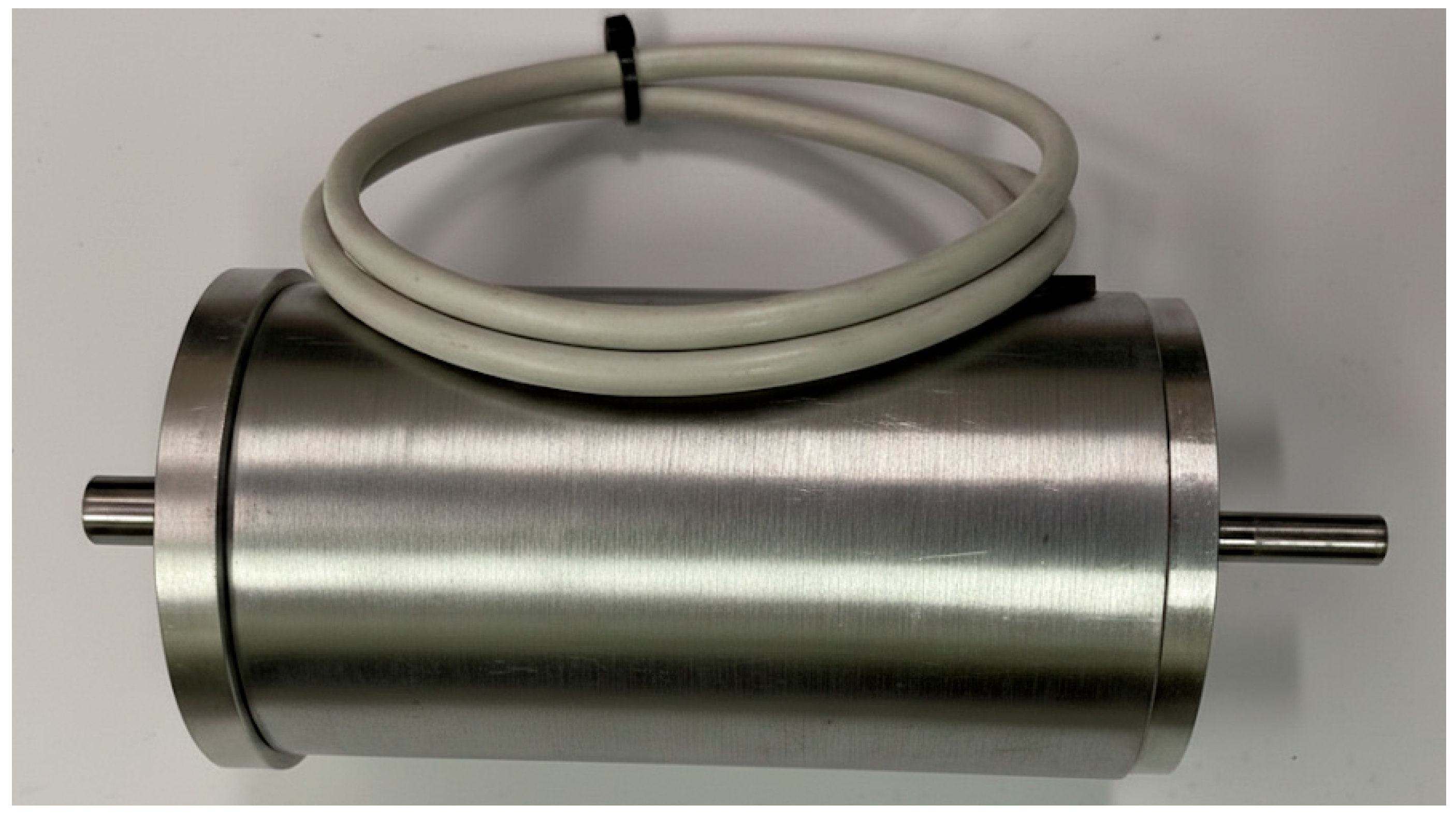

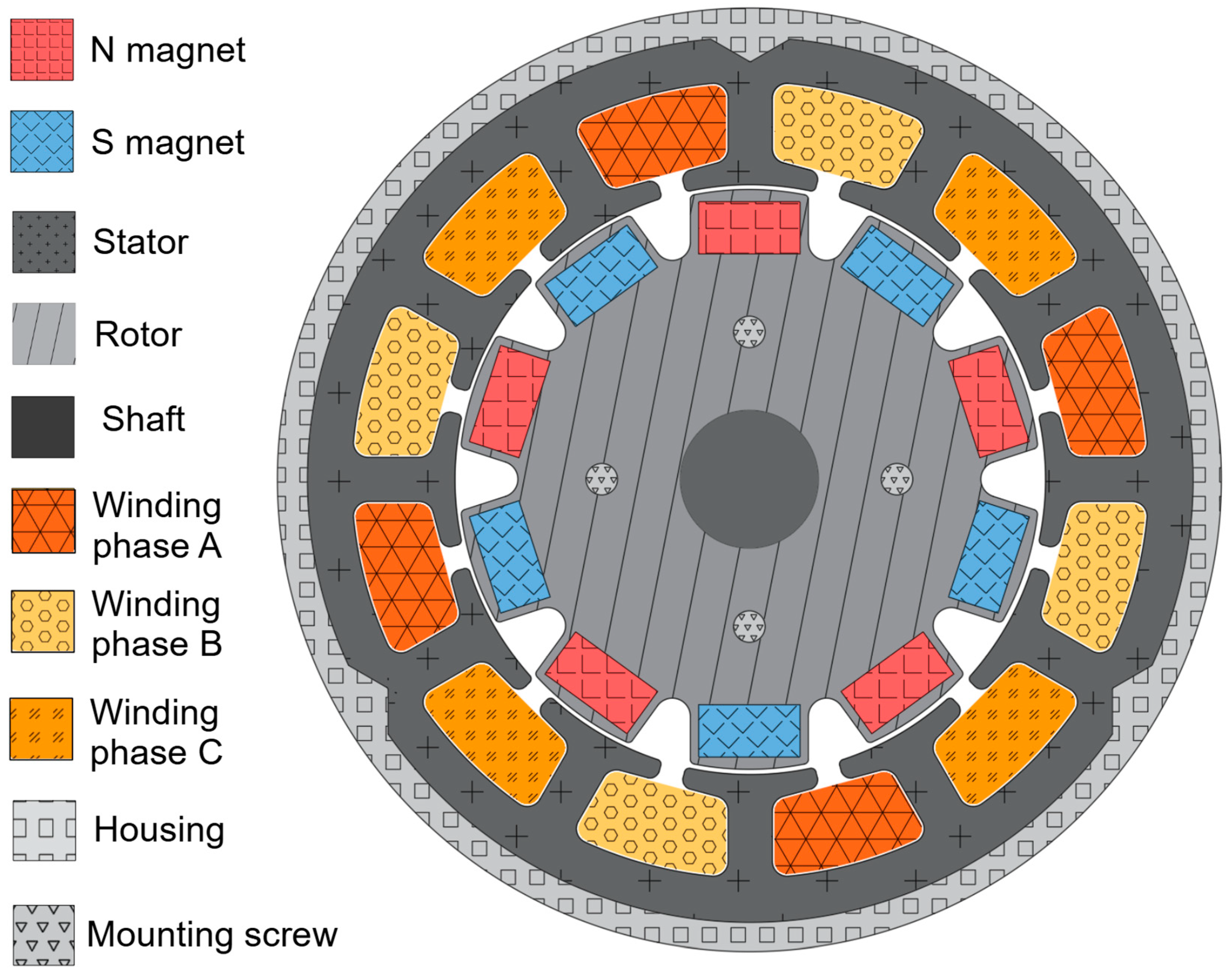

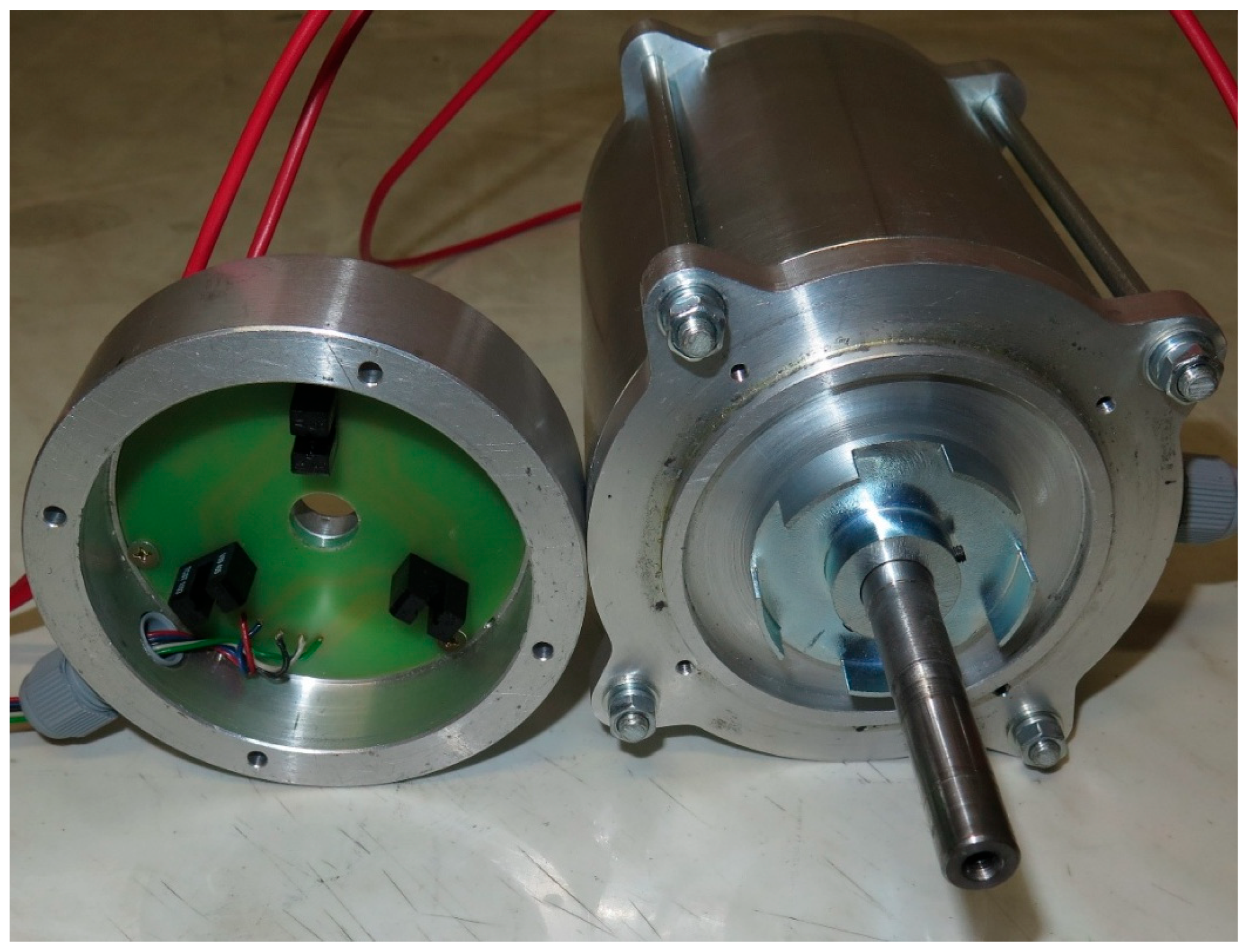

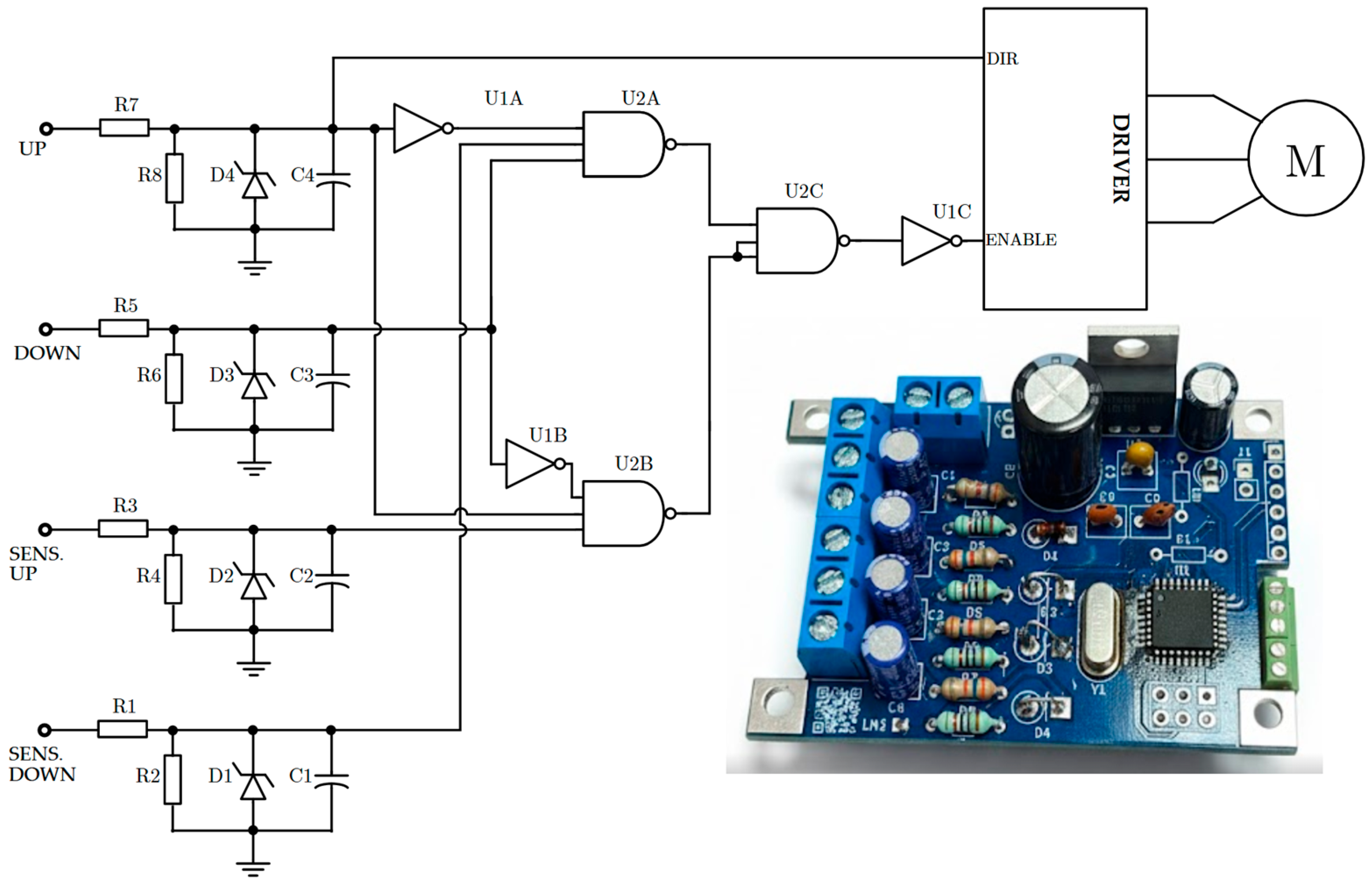

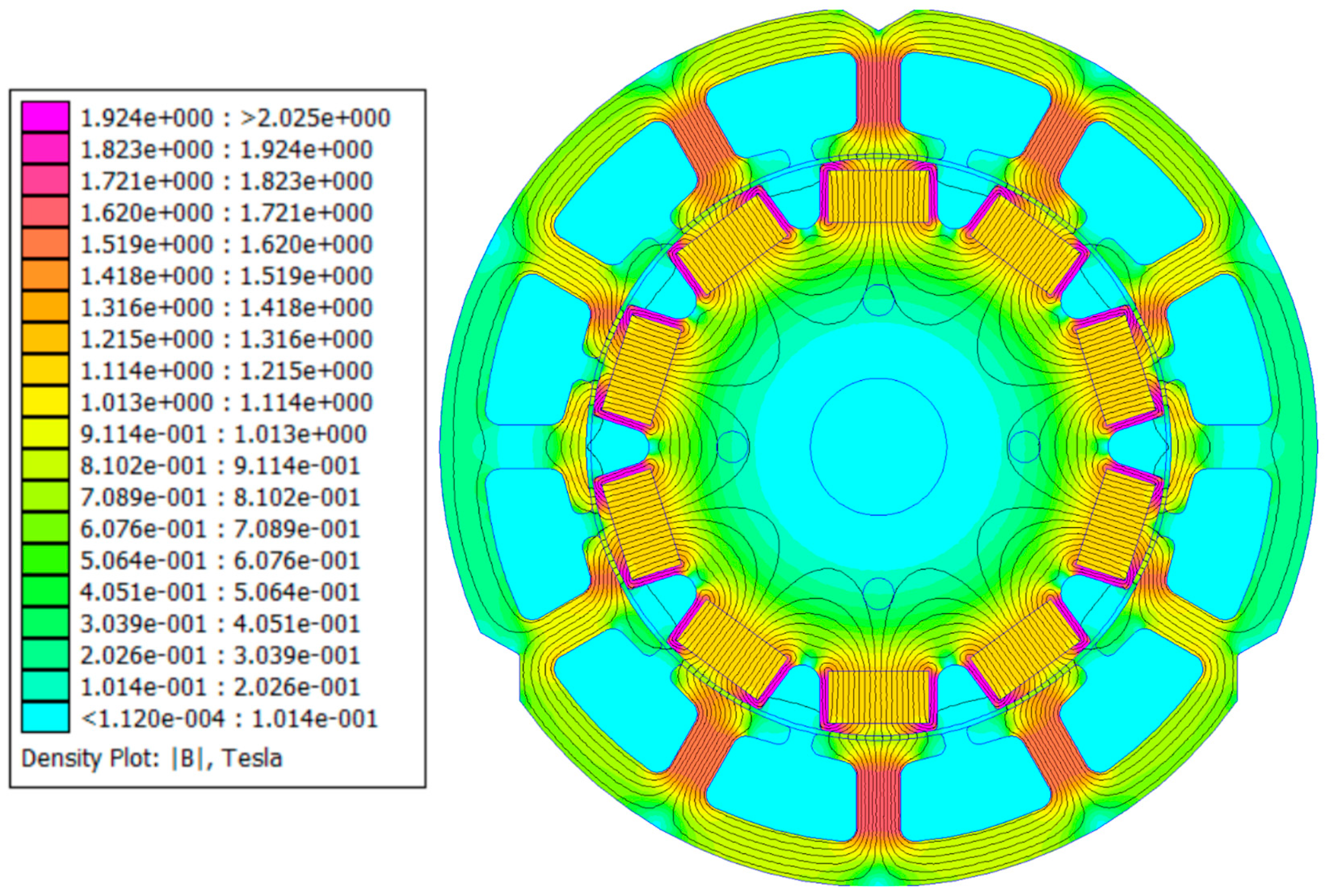

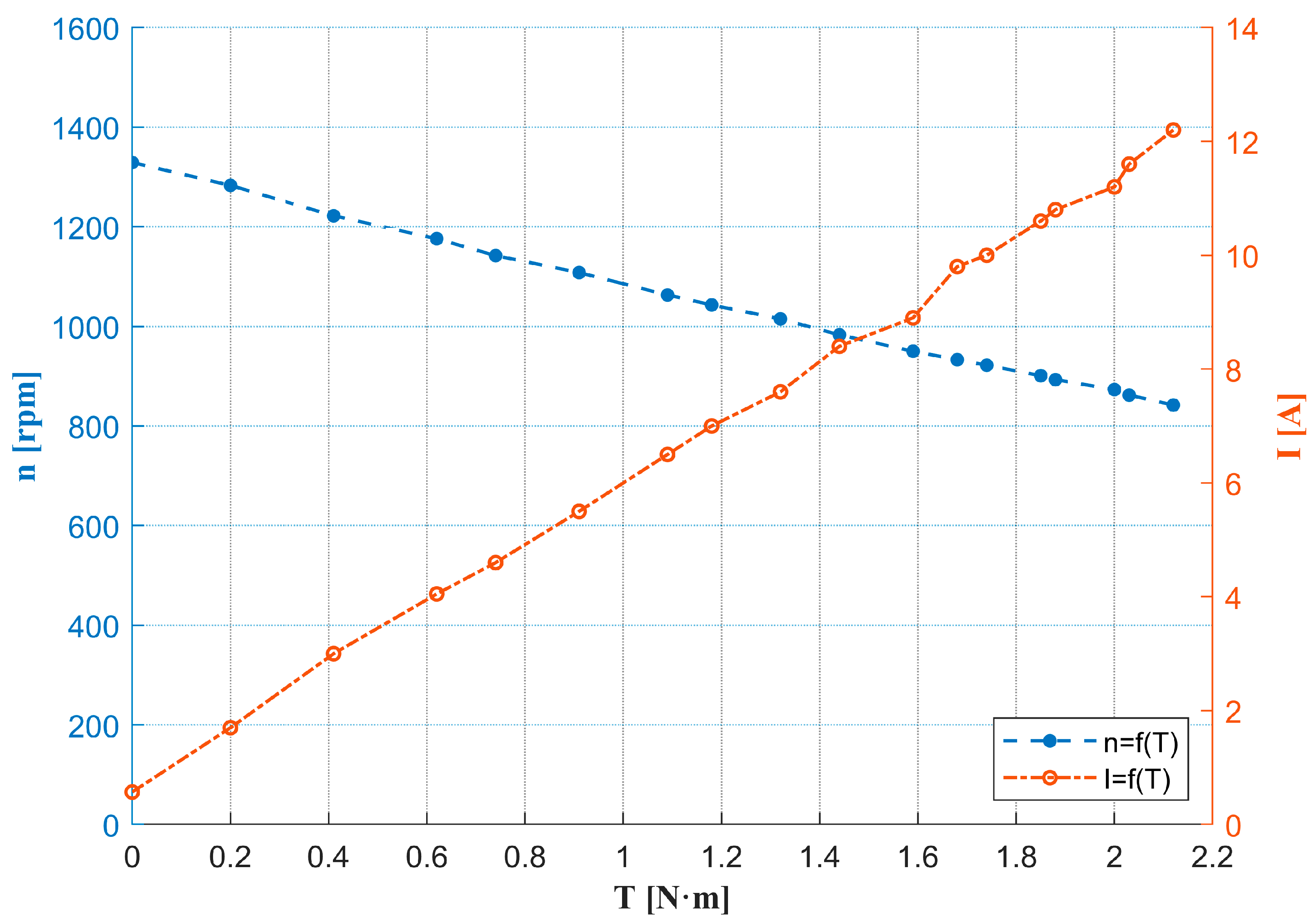

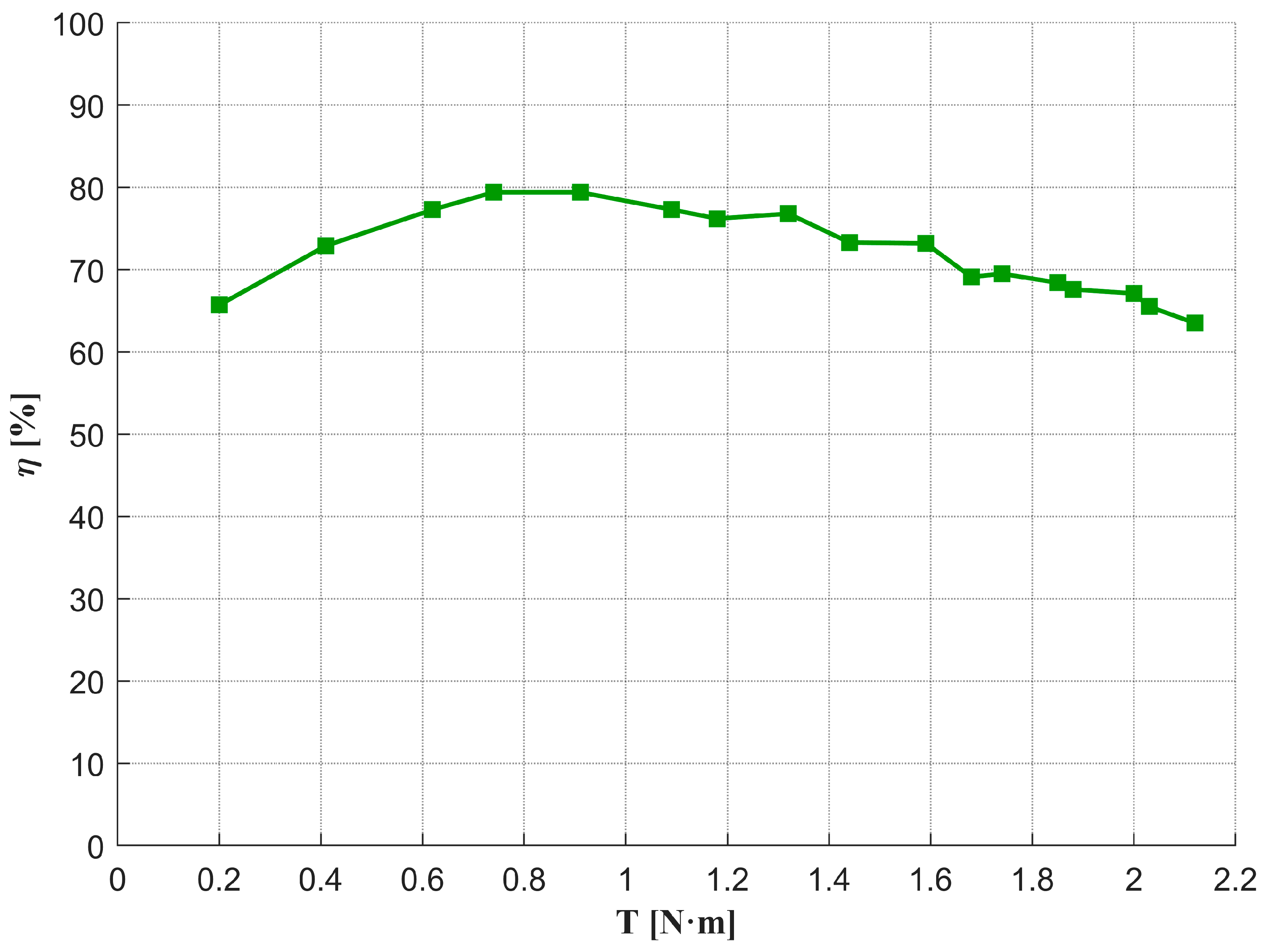

- Prototype BLDC motor—A brushless DC machine with a ten-pole rotor and a twelve-slot stator, in which commutation is performed electronically. It offers the highest efficiency and almost maintenance-free operation, but requires the use of an electronic controller and involves higher production costs.

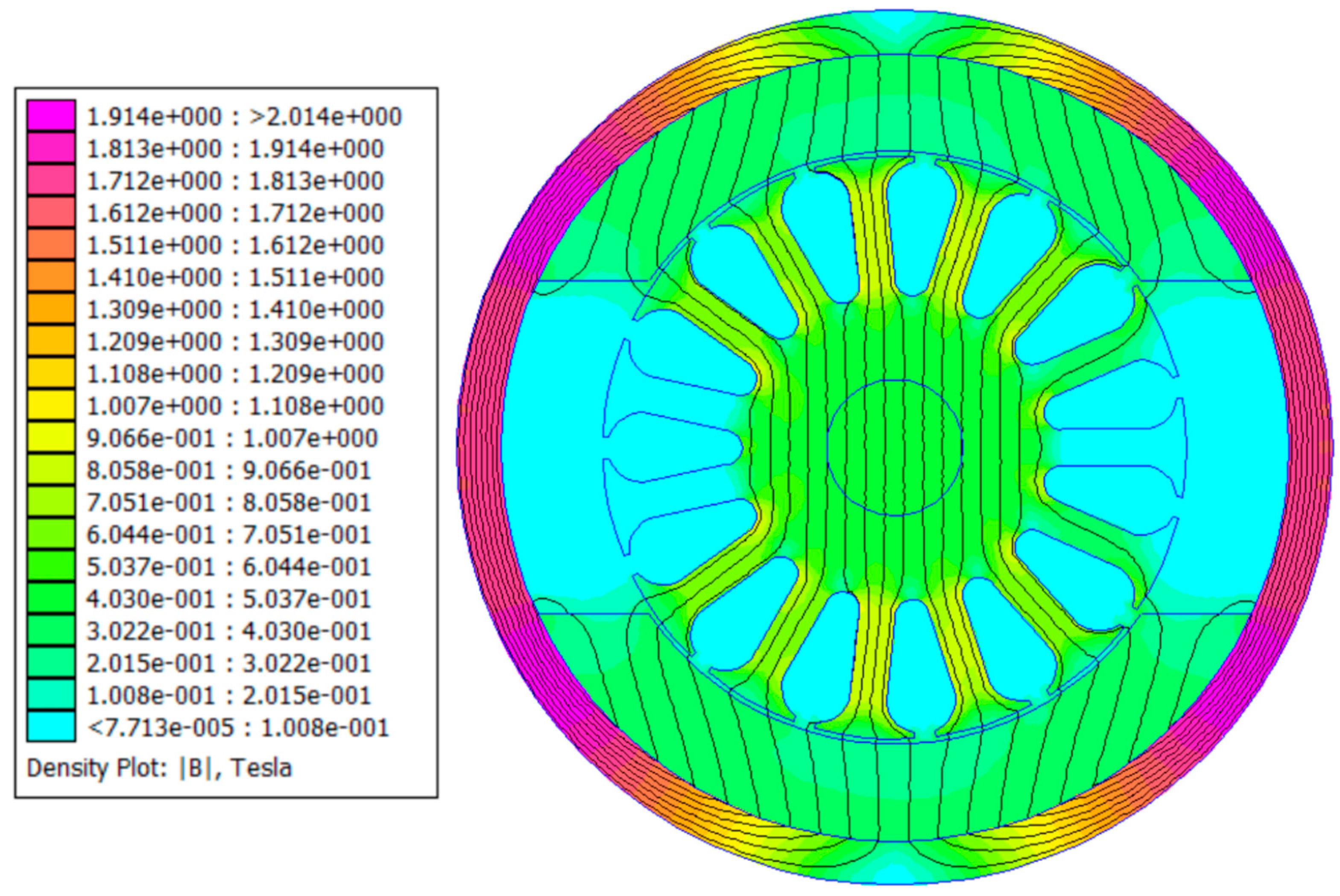

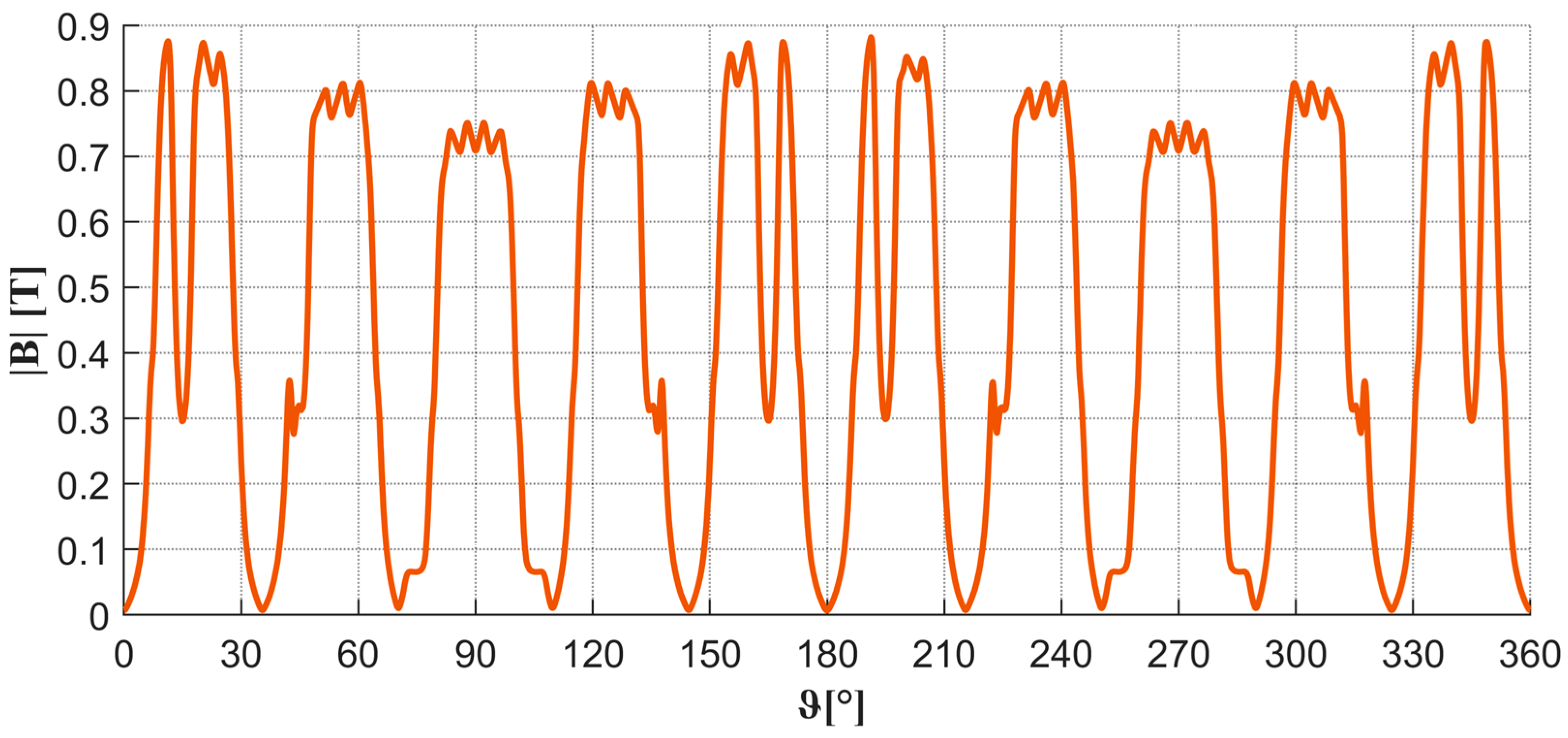

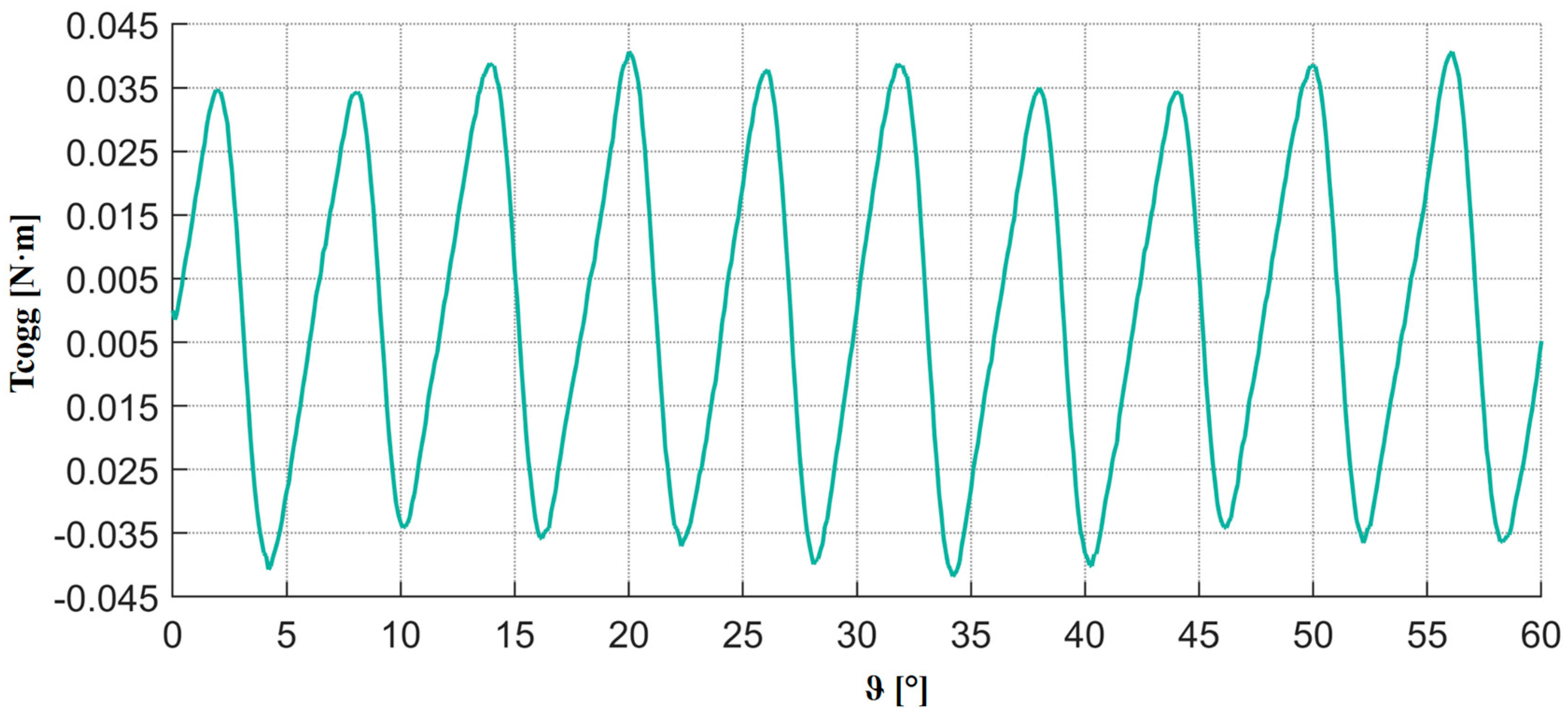

2.3. Finite Element Method (FEM) Simulations

- Calculation grid: a basic element size of 1 mm was used, with additional grid refinement in the air gap area to improve the accuracy of flux and torque calculations.

- Boundary conditions: a Dirichlet condition (magnetic potential equal to zero) was assumed on the model boundary.

- Material parameters: the magnetic cores were described by nonlinear B-H characteristics of electrical steel, and the permanent magnets by magnetization vectors consistent with the data for magnetic materials—Ferrite and neodymium N38.

- The distribution of magnetic induction in the air gap and in the cross-section;

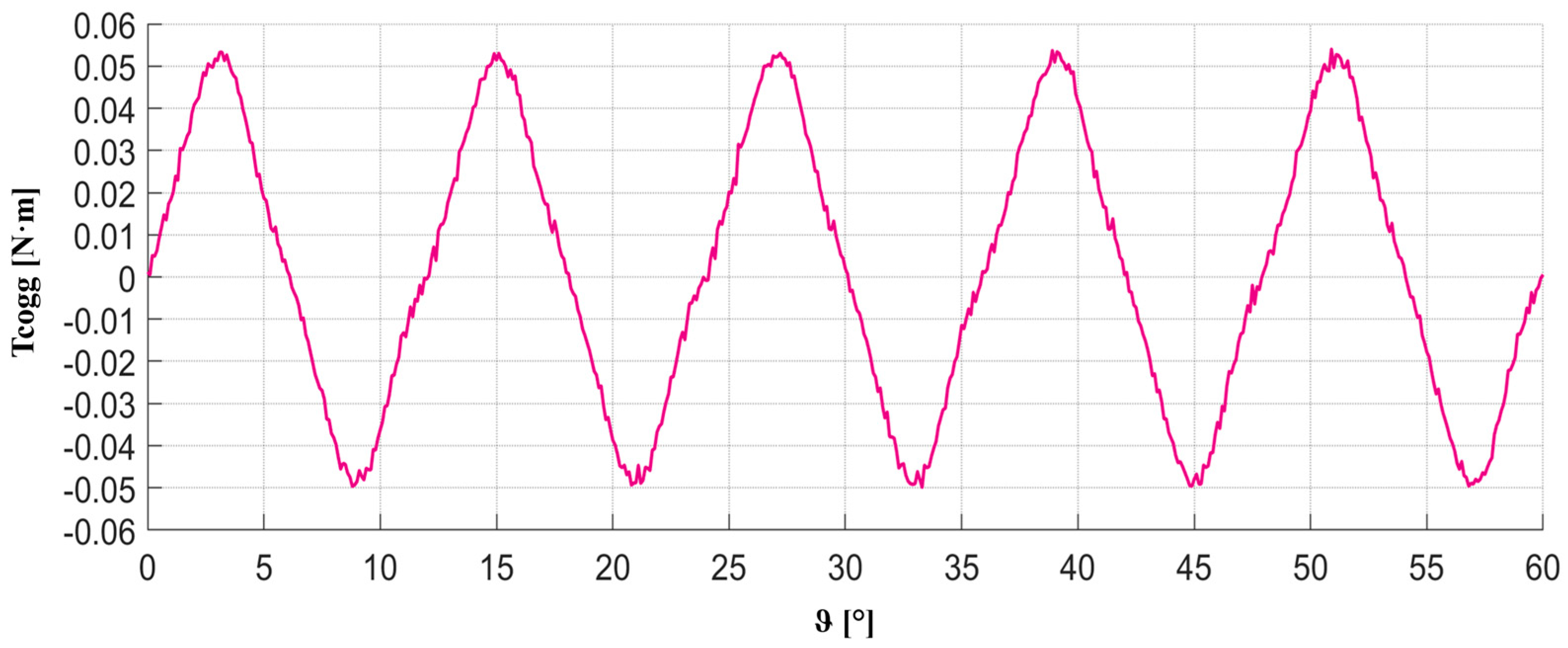

- The cogging torque as a function of the angle of rotation.

2.4. Prototyping and Experimental Setup

2.5. Data Processing and Comparison

- Efficiency was determined at a constant torque of 1.4 N·m,

- Efficiency was evaluated at the rated points of each motor,

- The values of cogging torque and load torque reserve were analyzed.

3. Results and Discussion

3.1. PRMOa90-90 Ferrite Permanent Magnet Motor

3.2. Commutator Motor with Rectangular Neodymium Magnets

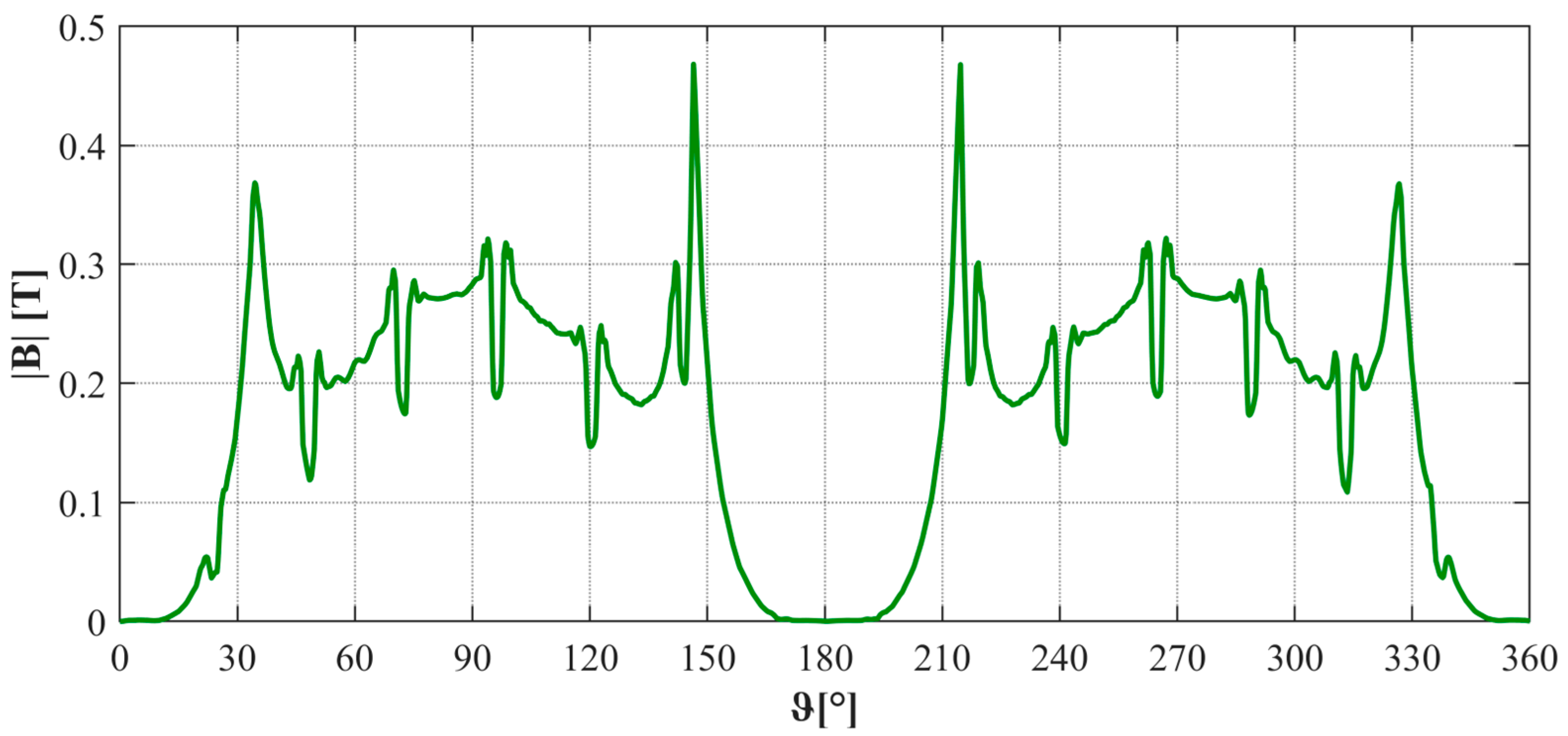

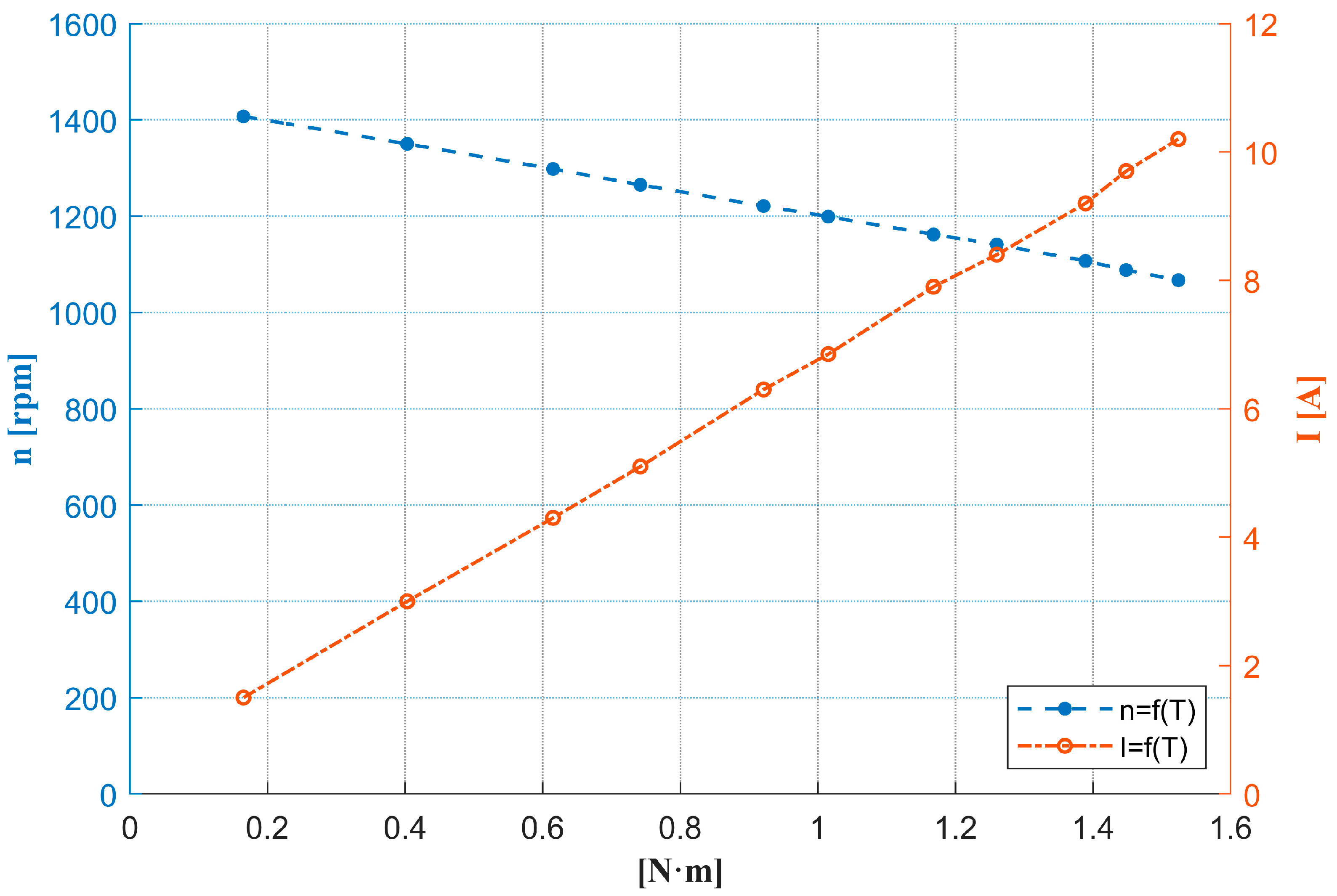

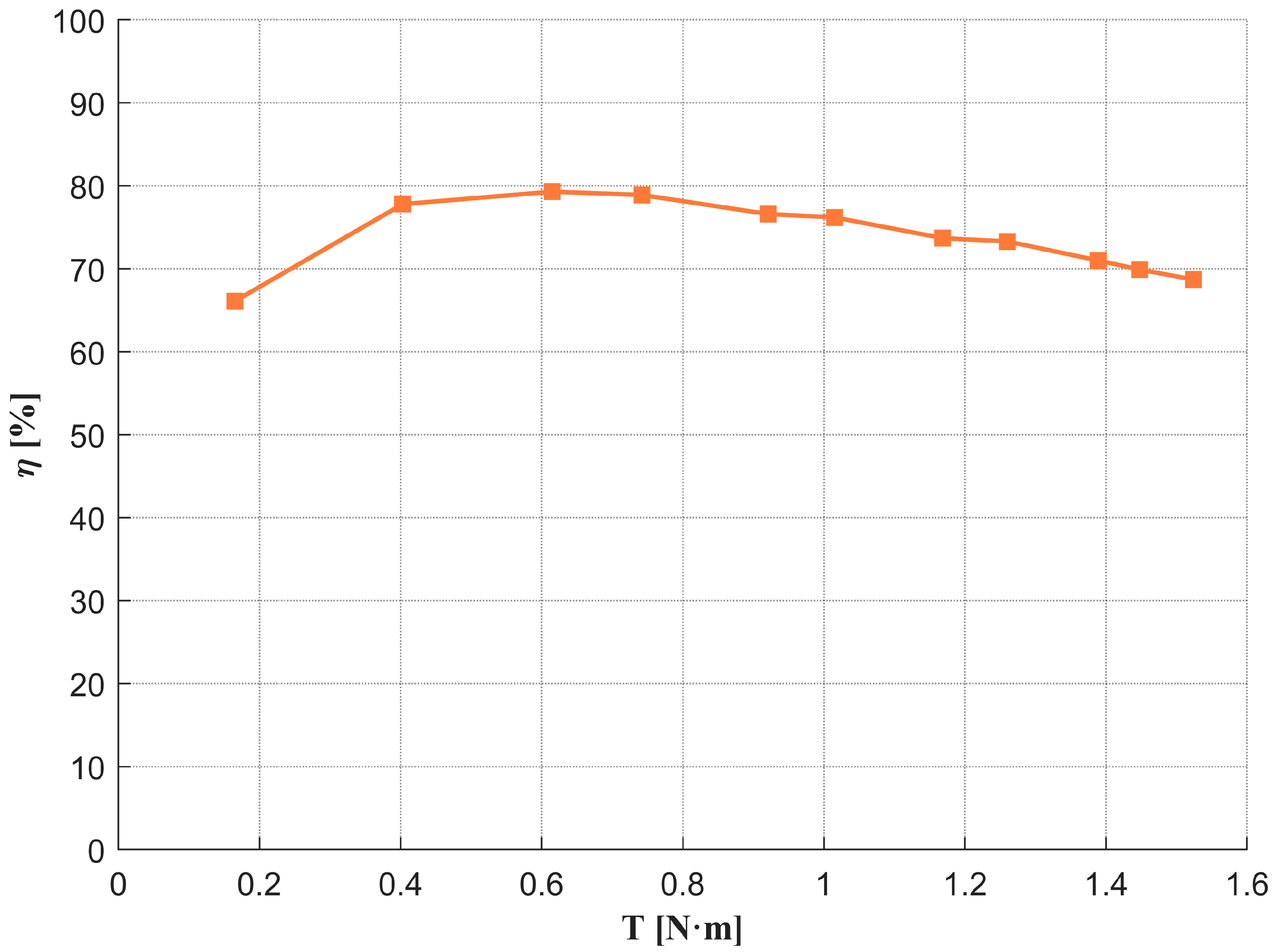

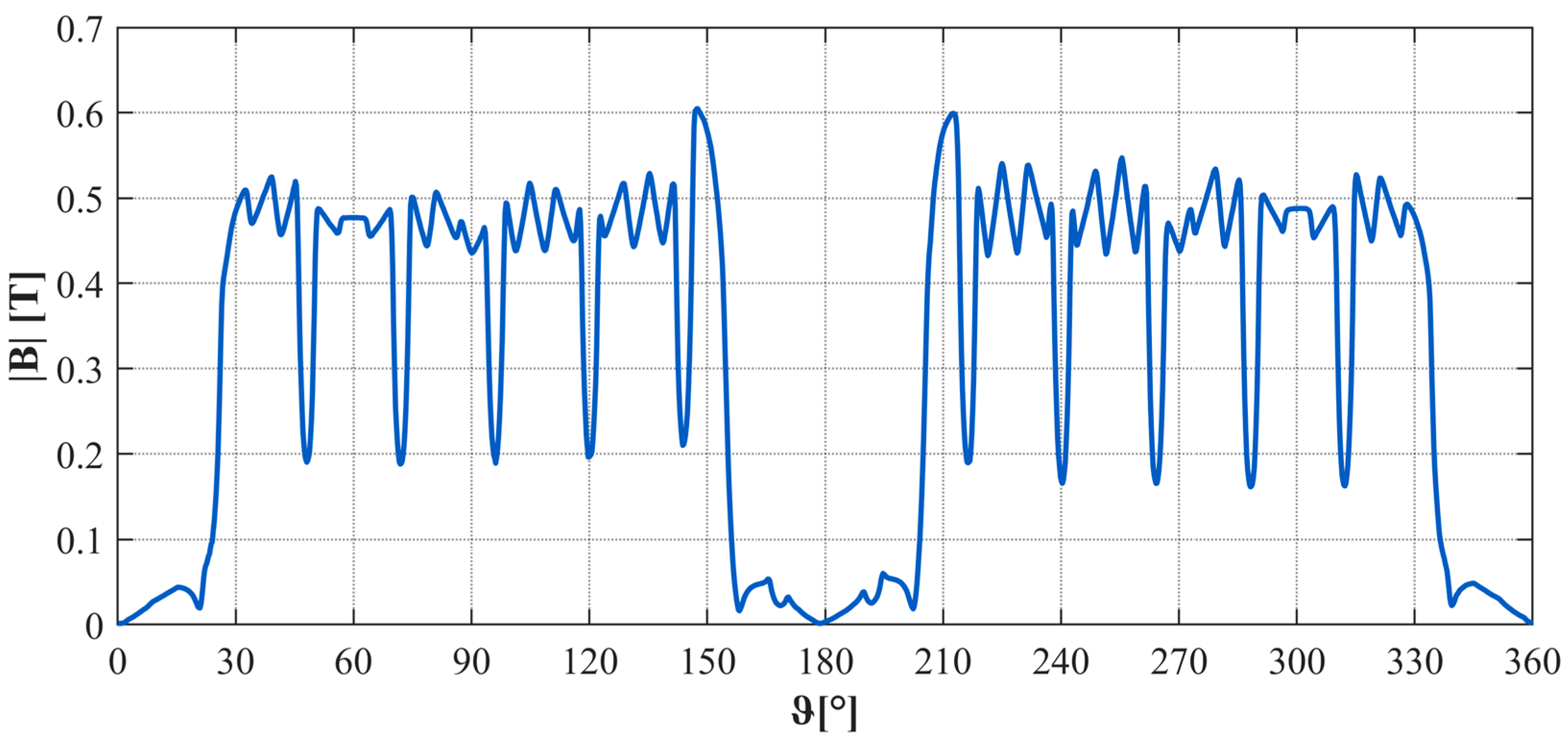

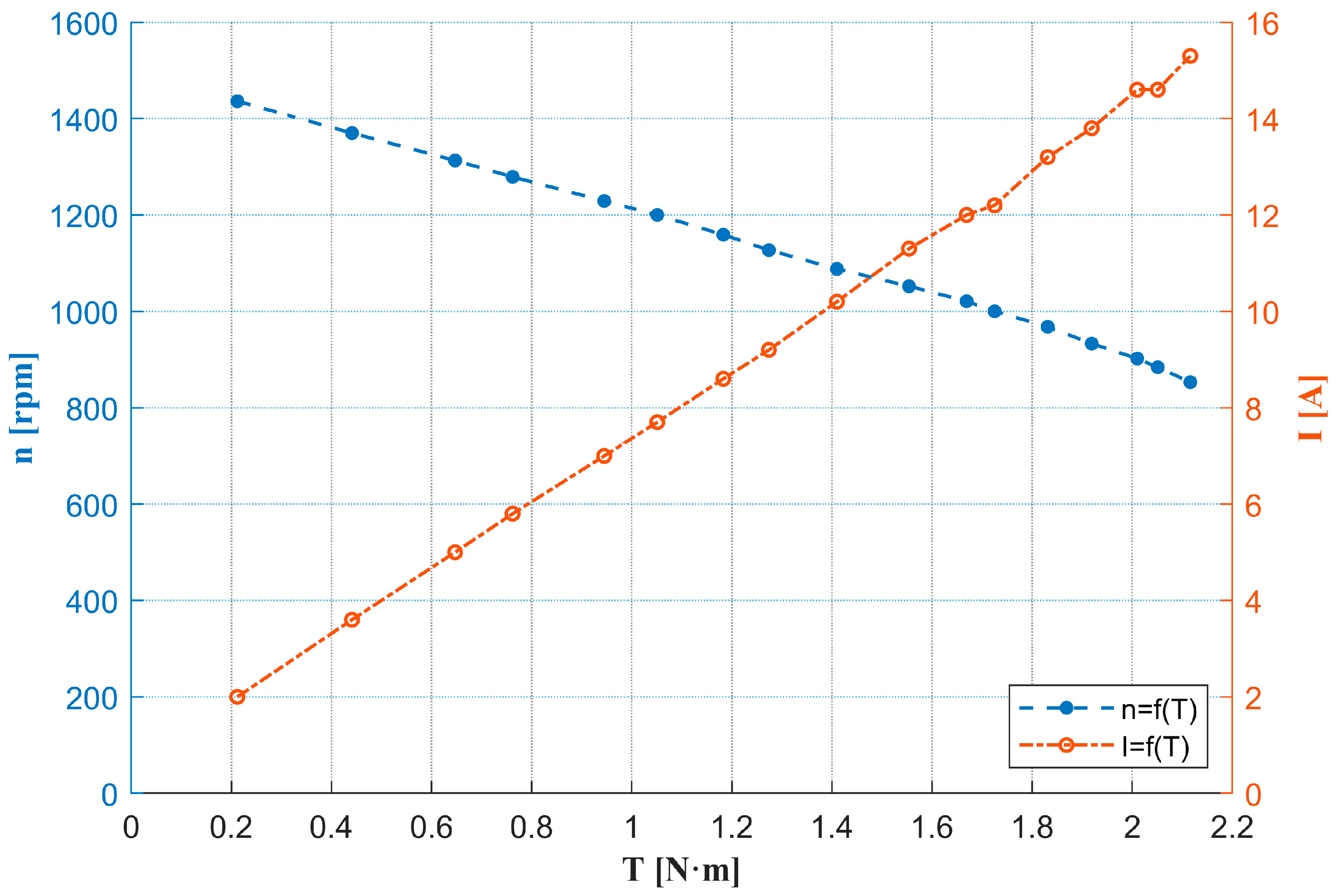

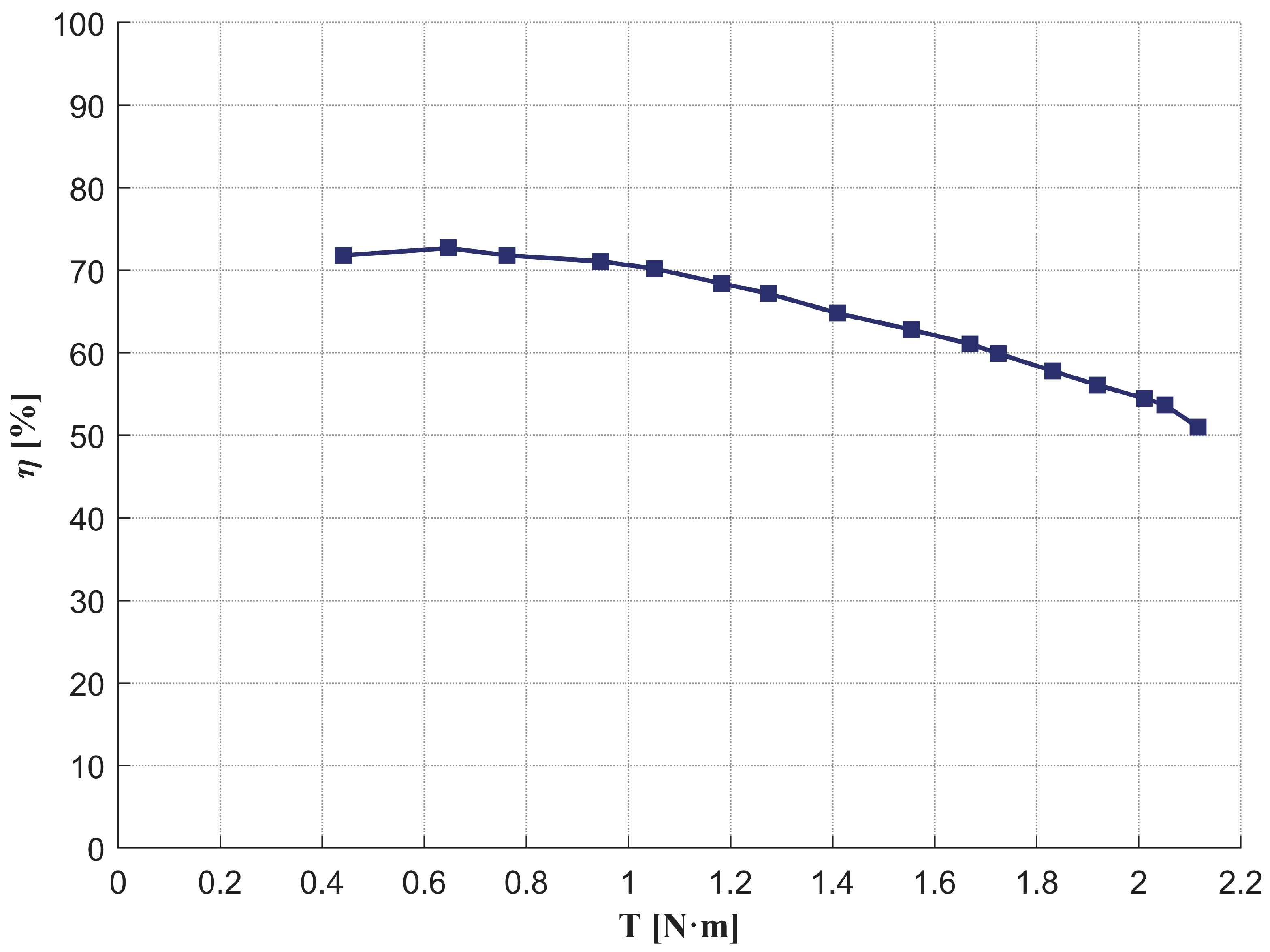

3.3. Brushless DC (BLDC) Motor

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- PKP Polskie Linie Kolejowe S.A. Wymagania na Systemy Zabezpieczenia Ruchu na Przejazdach Kolejowo—Drogowych i Przejściach Ie-119; PKP PLK: Warszawa, Poland, 2019. [Google Scholar]

- PKP Polskie Linie Kolejowe S.A. Instrukcja Ir-7—Przejazdy Kolejowo-Drogowe; PKP PLK: Warszawa, Poland, 2019. [Google Scholar]

- EN 50126-1:2017; Railway Applications—The Specification and Demonstration of Reliability, Availability, Maintainability and Safety (RAMS)—Part 1: Generic RAMS Process. CENELEC: Brussels, Belgium, 2017.

- International Union of Railways UIC. Leaflet 761: Addendum: Safety Measures on Lines Operated from 120 to 200 Km/h; UIC: Chicago, IL, USA, 2005. [Google Scholar]

- International Union of Railways UIC. Leaflet 761: Guidance on the Automatic Operation of Level Crossings; UIC: Chicago, IL, USA, 2004. [Google Scholar]

- Di Graziano, A.; Marchetta, V. Application of a Quantitative Risk-Based Decision Tool for Local Railway Level Crossing Management. Appl. Sci. 2024, 14, 8630. [Google Scholar] [CrossRef]

- Zawodny, M.; Kruszyna, M.; Szczepanek, W.K.; Korzeń, M. A New Form of Train Detection as a Solution to Improve Level Crossing Closing Time. Sensors 2023, 23, 6619. [Google Scholar] [CrossRef] [PubMed]

- Blagojević, A.; Kasalica, S.; Stević, Ž.; Tričković, G.; Pavelkić, V. Evaluation of Safety Degree at Railway Crossings in Order to Achieve Sustainable Traffic Management: A Novel Integrated Fuzzy MCDM Model. Sustainability 2021, 13, 832. [Google Scholar] [CrossRef]

- Anagnostopoulos, A. Assessing Safety and Infrastructure Design at Railway Level Crossings Through Microsimulation Analysis. Future Transp. 2025, 5, 24. [Google Scholar] [CrossRef]

- Pamuła, T.; Pamuła, W. Detection of Safe Passage for Trains at Rail Level Crossings Using Deep Learning. Sensors 2021, 21, 6281. [Google Scholar] [CrossRef] [PubMed]

- Kornaszewski, M.; Nowak, A. Analiza techniczna napędów rogatkowych stosowanych na przejazdach kolejowo-drogowych w Polsce. Autobusy Tech. Eksploat. Syst. Transp. 2017, 18, 974–977. [Google Scholar]

- WAMEL Silniki Elektryczne Sp. z o.o. Silnik Prądu Stałego z Magnesami Trwałymi. Typ PRMOa 90-90. Karta Katalogowa nr 393. WAMEL Silniki Elektryczne: Warszawa, Poland, 2019. Available online: https://www.wamel.com.pl/wp-content/uploads/2019/07/karta-katalogowa-PRMOa-90-90-393.pdf (accessed on 4 September 2025).

- Suriano-Sánchez, S.I.; Ponce-Silva, M.; Olivares-Peregrino, V.H.; De León-Aldaco, S.E. A Review of Torque Ripple Reduction Design Methods for Radial Flux PM Motors. Eng 2022, 3, 646–661. [Google Scholar] [CrossRef]

- Marcos-Andrade, D.; Beltran-Carbajal, F.; Castelan-Perez, A.; Rivas-Cambero, I.; Hernández, J.C. Online Algebraic Estimation of Parameters and Disturbances in Brushless DC Motors. Machines 2025, 13, 16. [Google Scholar] [CrossRef]

- Abouseda, A.I.; Doruk, R.O.; Amini, A. Parameter Identification and Speed Control of a Small-Scale BLDC Motor: Experimental Validation and Real-Time PI Control with Low-Pass Filtering. Machines 2025, 13, 656. [Google Scholar] [CrossRef]

- Goryca, Z.; Straczynski, P.; Cygon, P. Brushless DC Motor and Control System for EEG-3 Crossing Barier Drive. Autom. Elektr. Zakloc. 2025, 16, 42–50. [Google Scholar] [CrossRef]

- Kyosan Electric Mfg. Co. Ltd. Napęd Rogatkowy. Rogatki z Udoskonalonym Mocowaniem. 2018. Available online: https://kyosan.com.pl/wp-content/uploads/2023/09/Leaflet_Gate_Mechanism_PL.pdf (accessed on 4 September 2025).

- Strączyński, P.; Różowicz, S.; Baran, K. Automated Laboratory Stand for Determining the Cogging Torque of a Small Permanent Magnet Electric Machine Using the MATLAB Environment. Energies 2025, 18, 1047. [Google Scholar] [CrossRef]

- Strączyński, P. Analiza Wpływu Wybranych Zmian Obwodu Magnetycznego Na Parametry Silnika Komutatorowego z Magnesami Trwałymi. Ph.D. Thesis, Kielce University of Technology, Kielce, Poland, 2024. [Google Scholar]

- Gieras, J.F. Electrical Machines; CRC Press: Boca Raton, FL, USA, 2020; ISBN 978-0-367-73694-1. [Google Scholar]

- Gieras, J.F.; Shen, J.-X. Modern Permanent Magnet Electric Machines: Theory and Control; CRC Press: Boca Raton, FL, USA, 2022; ISBN 978-1-000-77700-0. [Google Scholar]

- Hanselman, D. Brushless Permanent Magnet Motor Design; Magna Physics Publishing: Lebanon, OH, USA, 2006; ISBN 1-881855-15-5. [Google Scholar]

| Parameter | Value |

|---|---|

| Machine type | PMDC (commutator motor with permanent magnets) |

| Magnet type | Ferrite |

| Machine length | 90 mm |

| Outer diameter | 90 mm |

| Inner diameter of the stator | 80 mm |

| Magnet height | 10 mm |

| Number of rotor slots | 15 |

| Winding type | Lap winding |

| Rated power | 170 W |

| Rated voltage | 24 V |

| Rated current | 10 A |

| Rated speed | 1100 rpm |

| Parameter | Value |

|---|---|

| Machine type | PMDC (commutator motor with permanent magnets) |

| Magnet type | NdFeB (N38) |

| Machine length | 60 mm |

| Outer diameter | 90 mm |

| Inner diameter of stator | 57 mm |

| Magnet dimensions | 5 mm × 20 mm × 60 mm |

| Number of rotor slots | 15 |

| Winding type | Lap winding |

| Rated voltage | 24 V |

| Rated speed | 850 rpm |

| Parameter | Value |

|---|---|

| Machine type | BLDC |

| Magnet type | NdFeB (N38) |

| Machine length | 60 mm |

| Outer diameter | 90 mm |

| Inner diameter of stator | 60 mm |

| Outer diameter of rotor | 59.5 mm |

| Magnet dimensions | 5 mm × 10 mm × 60 mm |

| Number rotor magnets | 10 |

| Number of stator slots | 12 |

| Rotor type | Inset permanent magnet rotor |

| Magnet arrangement | Alternating N–S–N–S around the rotor circumference |

| Winding type | Three-phase concentrated winding |

| Rotor position sensor | Optical slot sensors |

| Feature/Parameter | PRMOa90-90 (PMDC, Ferrite Magnet) | Commutator Motor with Rectangular N38 Magnets | Brushless DC (BLDC) |

|---|---|---|---|

| Rated power | ≈160 W | ≈ 190 W | ≈145 W |

| Supply voltage | 24 V | 24 V | 24 V |

| Maximum efficiency/ operating point | ≈79.3%; ~1298 rpm, 0.62 N·m | ≈72.7%; ~1313 rpm, 0.65 N·m | ≈79.4%; ~1108 rpm, 0.91 N·m |

| Cogging torque (max) | 0.052 N·m | 0.040 N·m | 0.040 N·m |

| Wear-prone components | Brushes, commutator | Brushes, commutator | None |

| Resistance to environmental conditions | Limited | Good | Very good |

| Drive system notes | Insufficient torque for reliable winter operation | Possible direct drive (no gearbox required) | Requires electronic commutation controller |

| Manufacturing cost | Low | Medium | High |

| Maintenance | Frequent | Frequent | Rare |

| Life-cycle cost | High—frequent service, downtime | High—frequent service, downtime | Low (lowest LCC—no replacement of parts, minimal downtime) |

| Motor | Voltage U [V] | Speed n [rpm] | Torque T [N·m] | Current I [A] | Mech. Power Pmech [W] | El. power Pel [W] | Efficiency η [%] |

|---|---|---|---|---|---|---|---|

| PRMOa90-90 | 24.4 | 1103 | 1.40 | 8.5 | 161.8 | 226.1 | 71.6 |

| DC motor with N38 rect. | 24.2 | 1091 | 1.40 | 9.5 | 159.9 | 246.0 | 65.0 |

| BLDC motor | 24.1 | 994 | 1.40 | 8 | 145.7 | 195.5 | 74.5 |

| Motor | Voltage U [V] | Speed n [rpm] | Torque T [N·m] | Current I [A] | Mechanical Power Pmech [W] | Electrical Power Pel [W] | Efficiency η [%] |

|---|---|---|---|---|---|---|---|

| PRMOa90-90 | 24.1 | 1100 | 1.40 | 9.85 | 161.0 | 236.4 | 68.1 |

| DC motor with N38 rect. | 24.2 | 850 | 2.12 | 16.21 | 193.0 | 389.0 | 51.0 |

| BLDC motor | 24.3 | 1000 | 1.38 | 8.0 | 144.5 | 192.0 | 75.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Goryca, Z.; Strączyński, P.; Różowicz, S.; Suchenia, K.; Woszczyna, B. Impact of Electric Motor Selection on the Efficiency and Reliability of Level Crossing Gate Drives in Polish Railway Infrastructure. Energies 2025, 18, 6050. https://doi.org/10.3390/en18226050

Goryca Z, Strączyński P, Różowicz S, Suchenia K, Woszczyna B. Impact of Electric Motor Selection on the Efficiency and Reliability of Level Crossing Gate Drives in Polish Railway Infrastructure. Energies. 2025; 18(22):6050. https://doi.org/10.3390/en18226050

Chicago/Turabian StyleGoryca, Zbigniew, Paweł Strączyński, Sebastian Różowicz, Karol Suchenia, and Bartosz Woszczyna. 2025. "Impact of Electric Motor Selection on the Efficiency and Reliability of Level Crossing Gate Drives in Polish Railway Infrastructure" Energies 18, no. 22: 6050. https://doi.org/10.3390/en18226050

APA StyleGoryca, Z., Strączyński, P., Różowicz, S., Suchenia, K., & Woszczyna, B. (2025). Impact of Electric Motor Selection on the Efficiency and Reliability of Level Crossing Gate Drives in Polish Railway Infrastructure. Energies, 18(22), 6050. https://doi.org/10.3390/en18226050