Experimental Analysis of Heat Transfer in Multi-Mini-Channel Module: A Comparison with CFD Simulations

Abstract

1. Introduction

- Conventional Channels: dh > 3 mm

- Minichannels: 3 mm ≥ dh > 200 µm

- Microchannels: 200 µm ≥ dh > 10 µm

- Transitional Channels:

- Transitional Microchannels: 10 µm ≥ dh > 1 µm

- Transitional Nanochannels: 1 µm ≥ dh > 0.1 µm

- Molecular Nanochannels: dh ≤ 0.1 µm

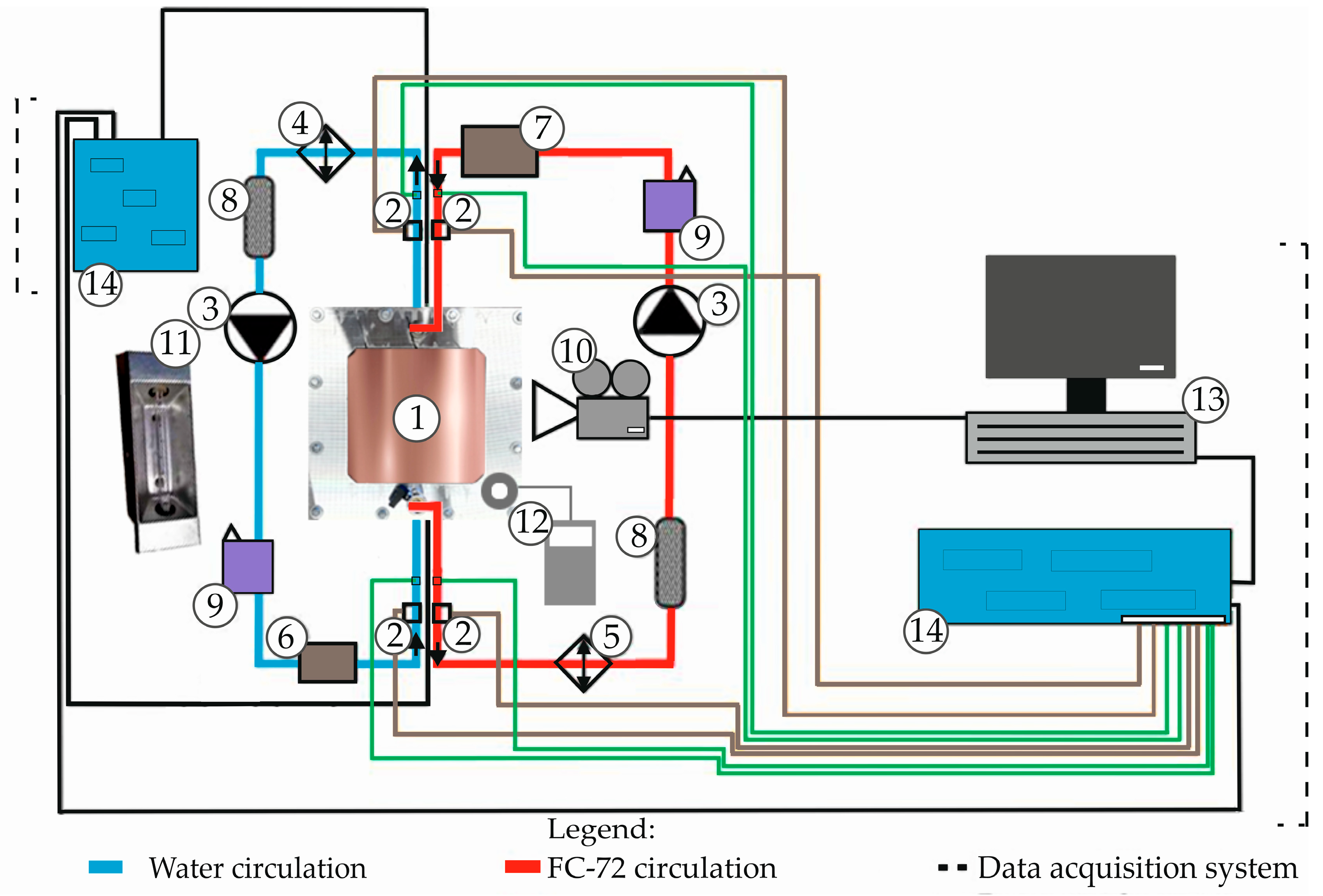

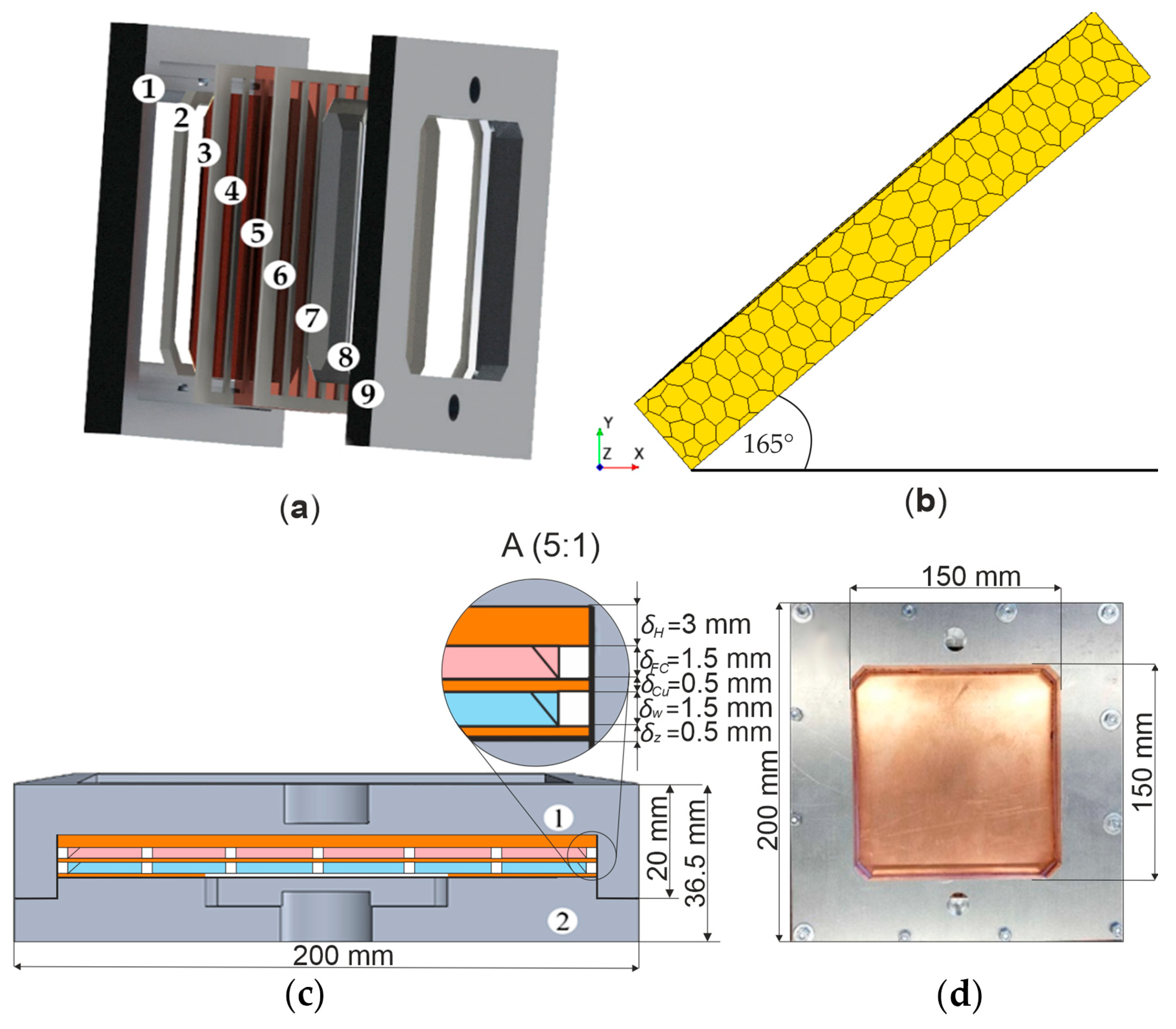

- The innovative test module was constructed with two groups of mini-channels (MCHs) (hot and cold), and copper heating, separation, and closing plates. The components were significantly modified from earlier designs, which relied on alternative plate materials such as tempered glass, solar cells, and Haynes-230 alloy.

- Each MCH measured 140 mm in length, 18.3 mm in width, and 1.5 mm in depth, with a hydraulic diameter of dh = 2.77 mm.

- A copper hot plate, coated with a high-emissivity paint (ε = 0.97), was heated using a 1000 W halogen lamp.

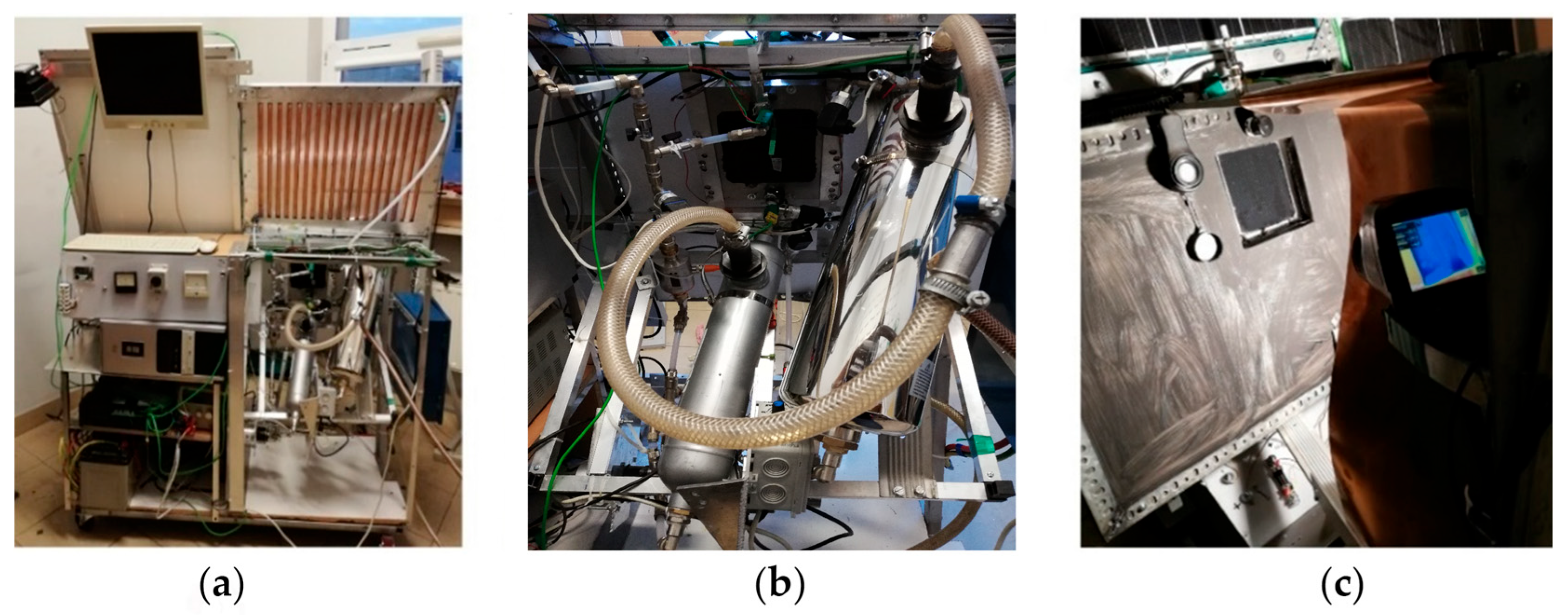

- Experimental data were collected for three distinct heat flux densities transferred to the fluid within the MCH: 1000 W/m2, 2000 W/m2, and 8000 W/m2. The measurements were conducted at an inclination of 165° relative to the horizontal plane, with two different mass flow rates of the fluids in countercurrent flow at 0.008 kg/s.

- The study encompassed experimental, analytical (1D approach), and numerical (CFD) analyses of heat transfer phenomena occurring during the countercurrent flow of Fluorinert FC-72 and distilled water within a multi-mini-channels (MMCH) module under steady-state conditions.

- The heating system on the upper wall of the external copper component includes a halogen lamp.

2. Experimental

2.1. Experimental Apparatus with the Test Section

2.2. Data Reduction, Thermal and Flow Parameters

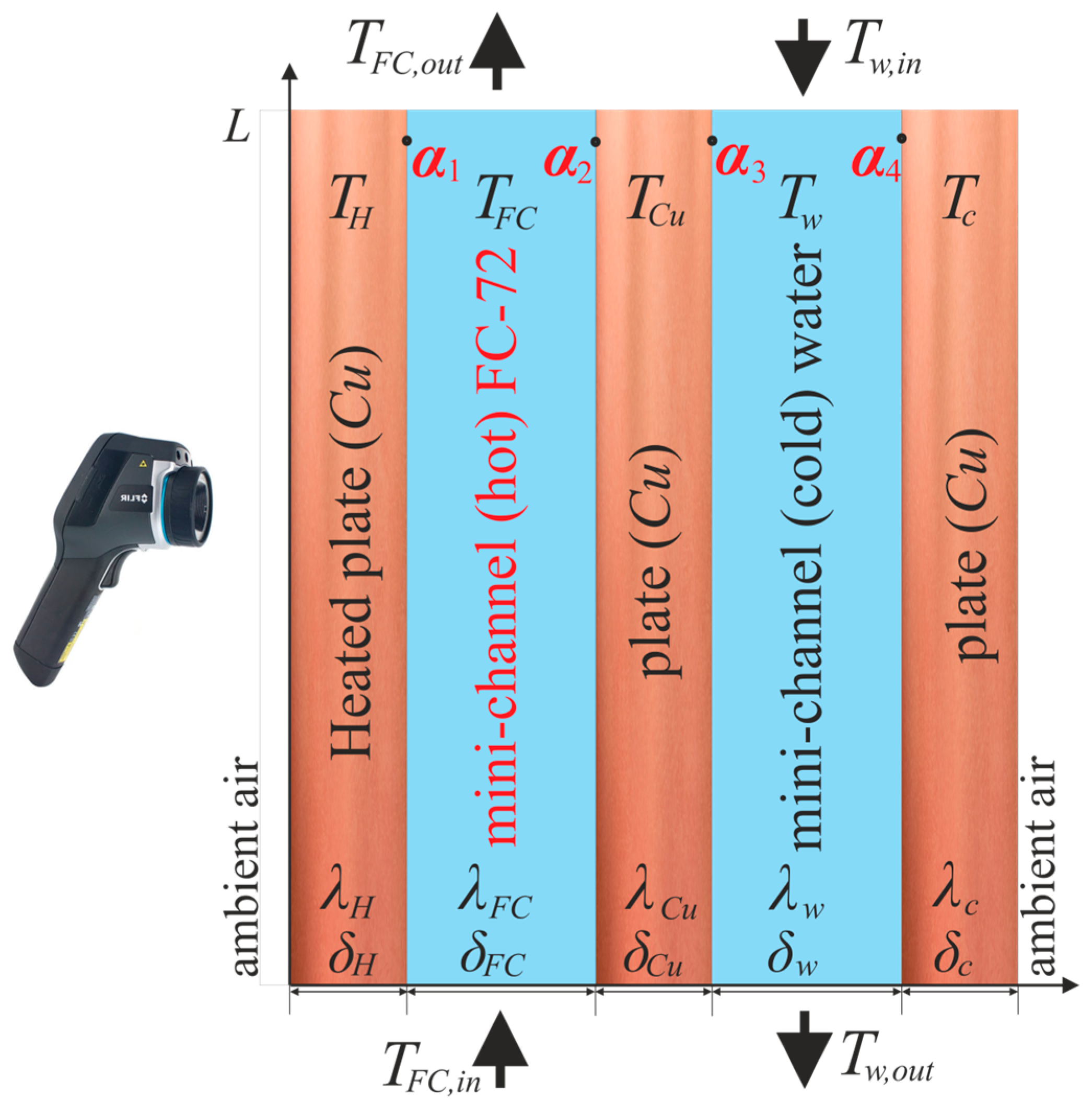

3. Calculations of the Heat Transfer Coefficients—A One-Dimensional (1D) Approach

- The flow of the two fluids (water and FC-72) was parallel, laminar, and countercurrent.

- Both fluids had a constant mass flow rate of 0.008 kg/s on either side of the copper plate.

- Heat transfer was modeled as one-dimensional, occurring perpendicular to the flow direction and the width of the mini-channel (MCH), and restricted to one direction: perpendicular to both the flow path and the MCH width.

- Local heat transfer coefficients (HTCs) were used to determine the interface conditions between the heated plate and HMCHs, HMCHs and the separating plate, the separating plate and CMCHs, as well as between the CMCHs and the closing plate.

- The system was insulated, so heat losses (radiative and convective) to the environment through the external surfaces of the test section were considered negligible.

- The temperature independence of the physical parameters of the test section’s elements, with known temperatures at the inlets and outlets of the MCHs.

- q—heat flux density,

- EIR—the radiation intensity for the copper heated plate.

- —the temperature of the external surface of the copper plate (measured by infrared camera),

- —thermal conductivity of the copper plate,

- —thickness of the copper plate.

- —refrigerant FC-72 temperature calculated from Equation (3):

- L—the mini-channel length.

- —heat flux reaching the refrigerant FC-72,

- —surface area of the copper separating plate.

- —thermal conductivity of the copper plate,

- —thickness of the copper plate.

- —heat flux reaching the refrigerant FC-72,

4. CFD—Simcenter STAR-CCM+ Software

4.1. Calculation of CFD—Simcenter STAR-CCM+

- E—the total energy,

- H—the total enthalpy,

- V—volume,

- a—the area vector,

- ρ—the density,

- v—the velocity vector,

- fb—the resultant of body forces,

- q”—the heat flux vector,

- T—the viscous stress tensor,

- hi—the total enthalpy of components i,

- Ji—the diffusive flux of components i.

- t—time,

- Sui—user-specified source term.

- p—pressure,

- I—identity tensor.

- Cp—the specific heat,

- T—the temperature,

- vs—the solid convective velocity.

- Sai—the mass source term of phase i.

- R—thermal resistance,

- —the heat flux from the fluid through boundary0,

- —the heat flux leaves through boundary1 into the solid,

- A, B, C, D—linearized heat flux coefficients,

- Tc0, Tc1—are the cell temperatures next to boundary0 and boundary1 respectively,

- —the interface temperatures on the fluid side (boundary0) and on the solid side (boundary1), respectively.

4.2. Validation of Numerical CFD Results

- Comparison of numerical results with experimental data.

- Examination of the quality of the adopted computational meshes.

5. Results

5.1. One-Dimensional Approach

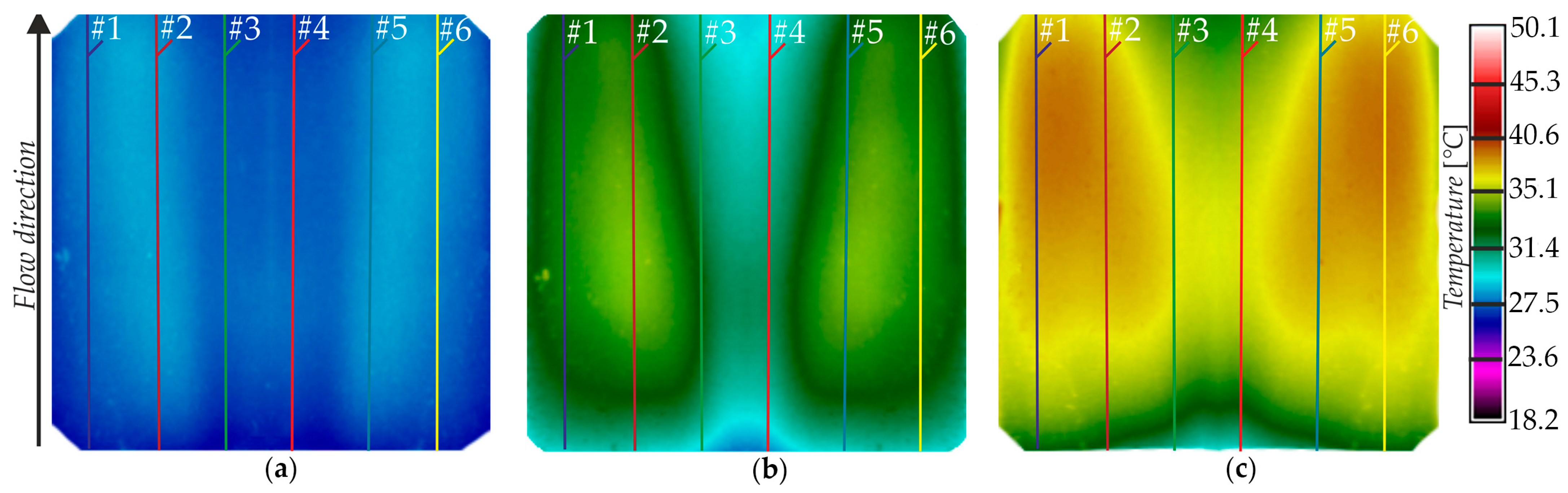

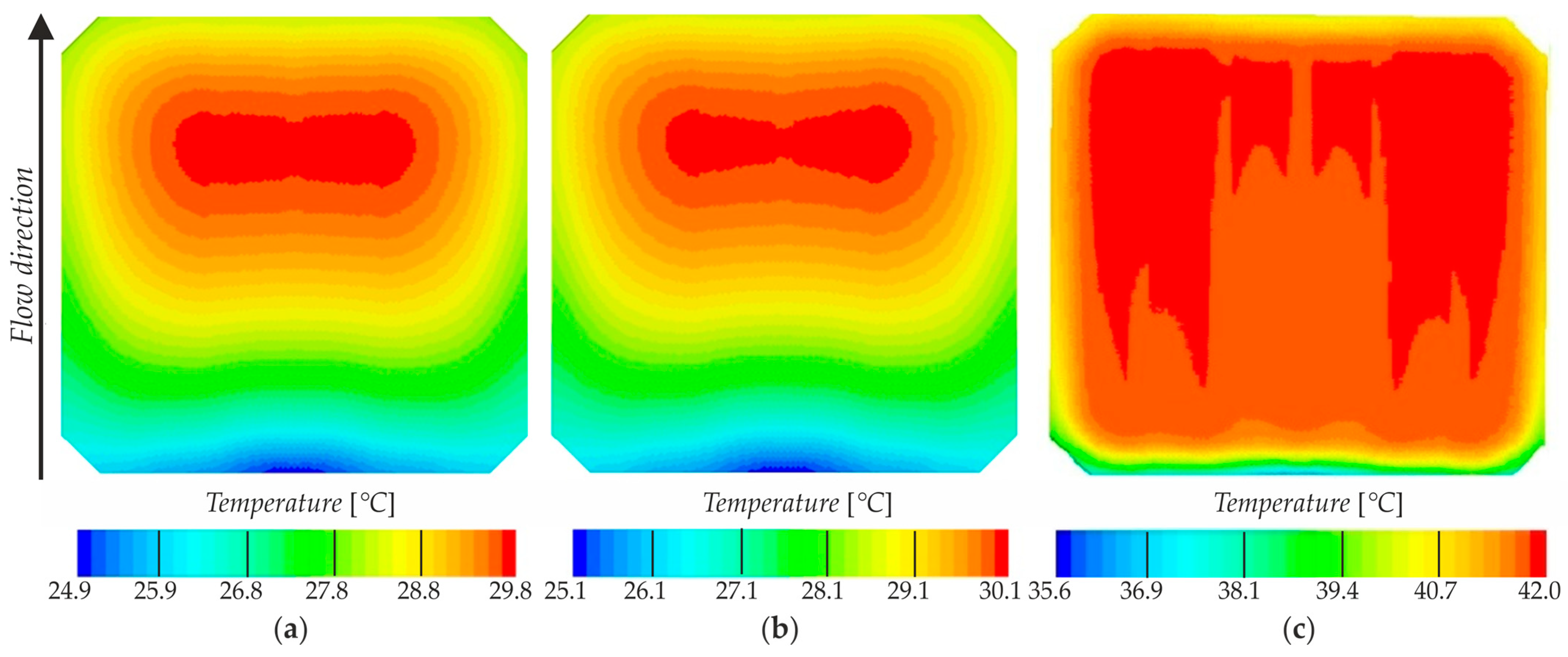

- A thermogram obtained from the infrared camera program on the external surface of the heated plate for three heat flux densities: 1000 W/m2 (a), 2000 W/m2 (b), and 8000 W/m2 (c). Six channels are labeled from #1 to #6 (Figure 5).

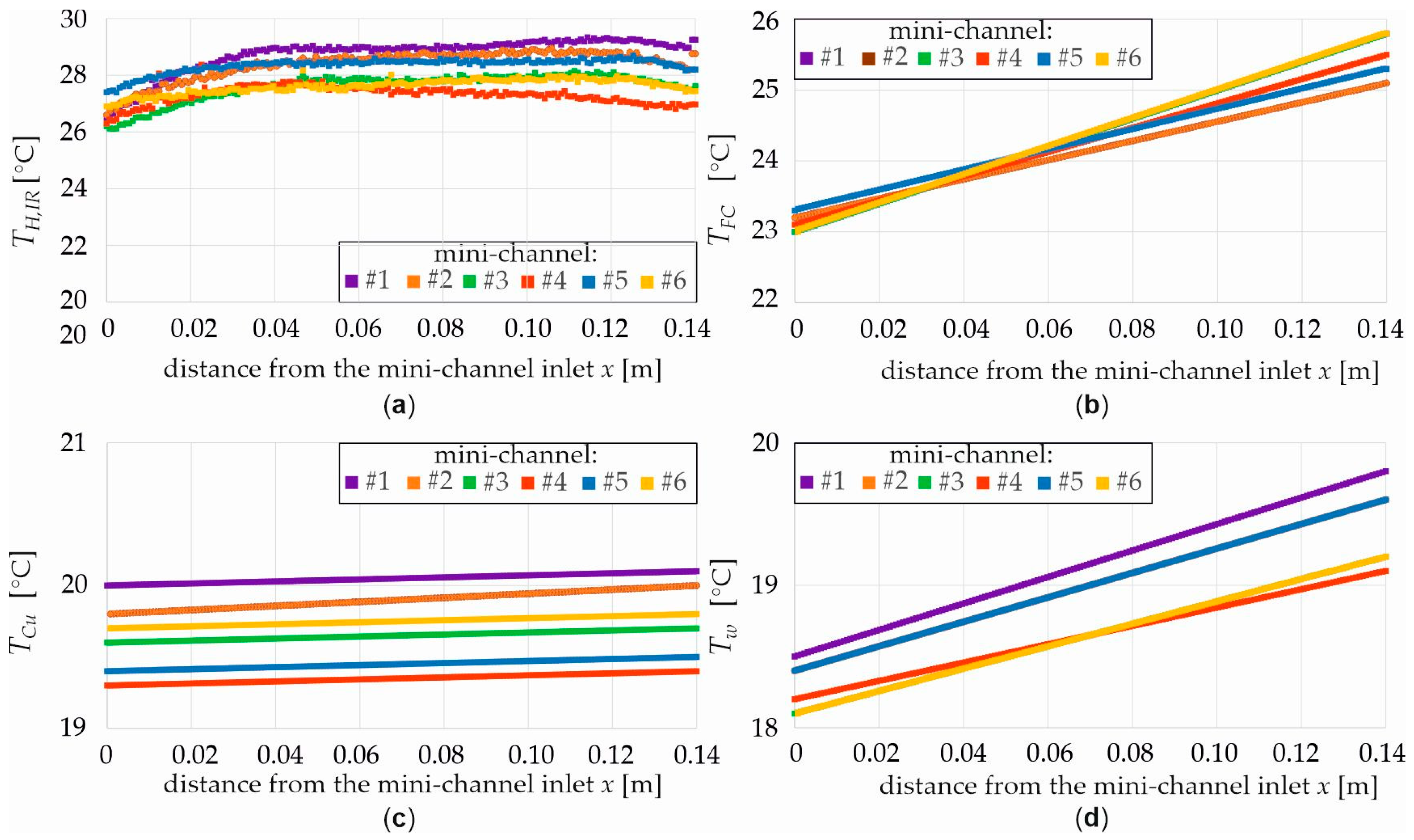

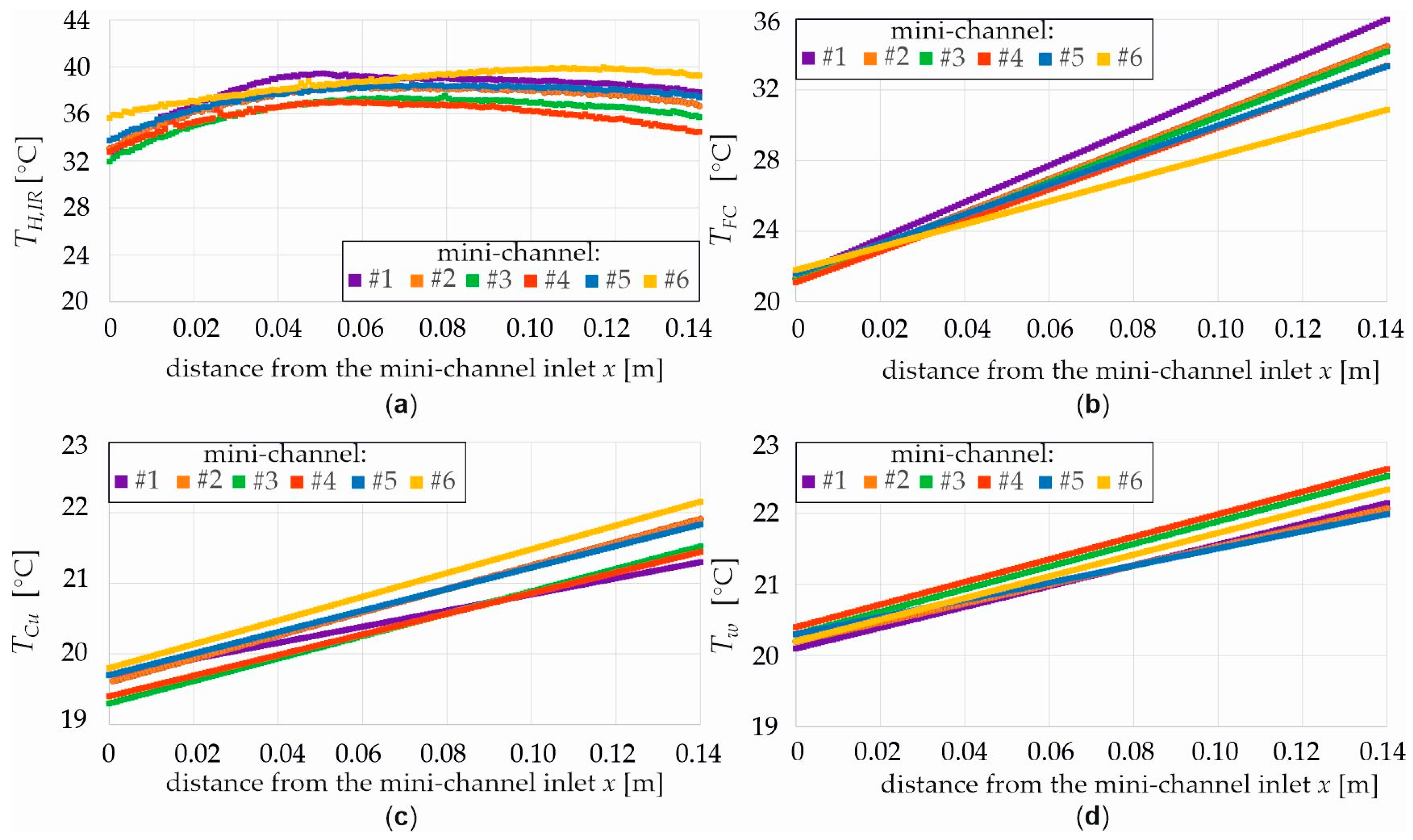

- Dependencies for the temperature as a function of distance from the MCH (a) copper heated plate, (b) FC-72 fluid, (c) copper separate plate, (d) distilled water for three heat flux densities 1000, 2000, and 8000 W/m2, and six channels labeled from #1 to #6 (Figure 6, Figure 7, Figure 8 and Figure 9).

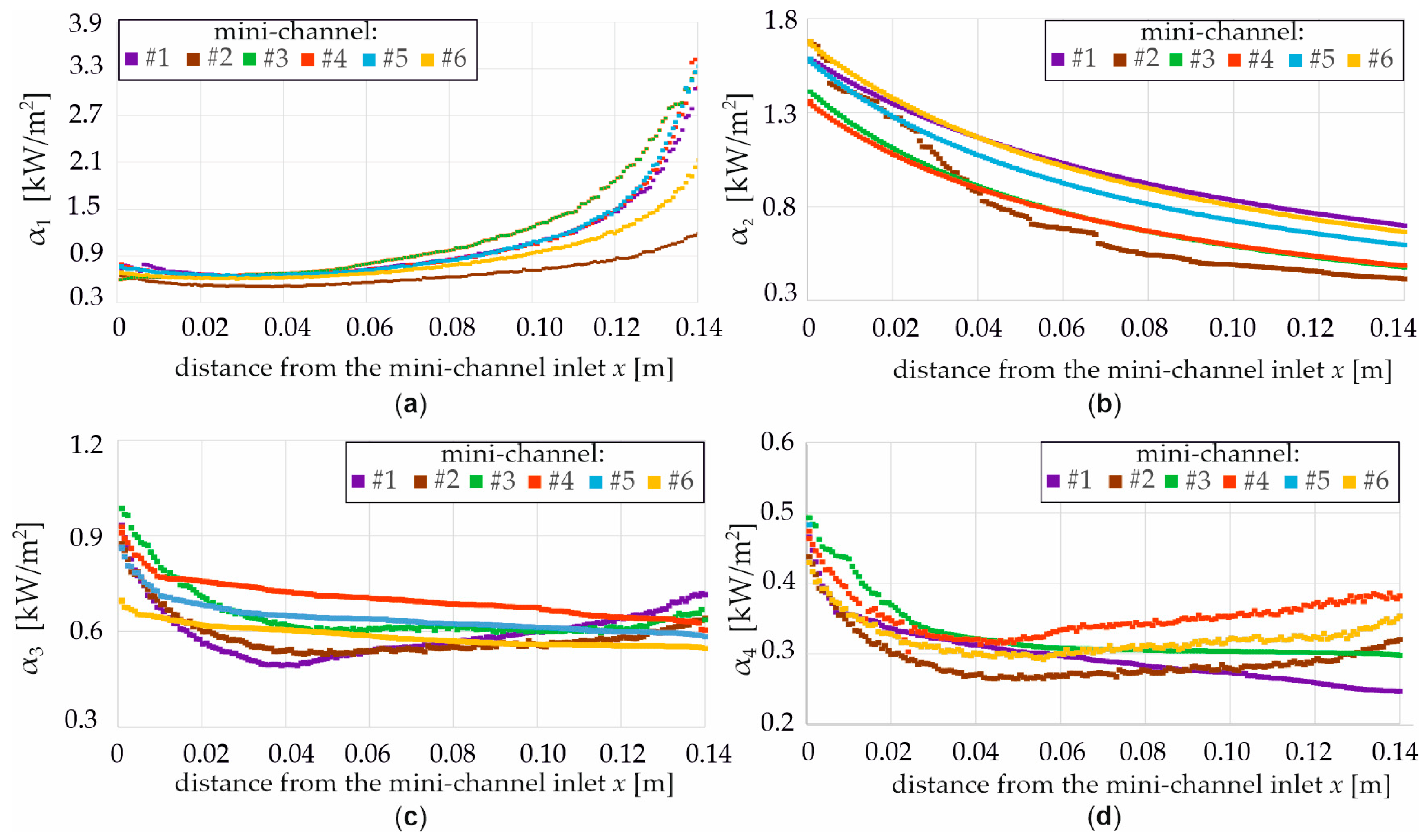

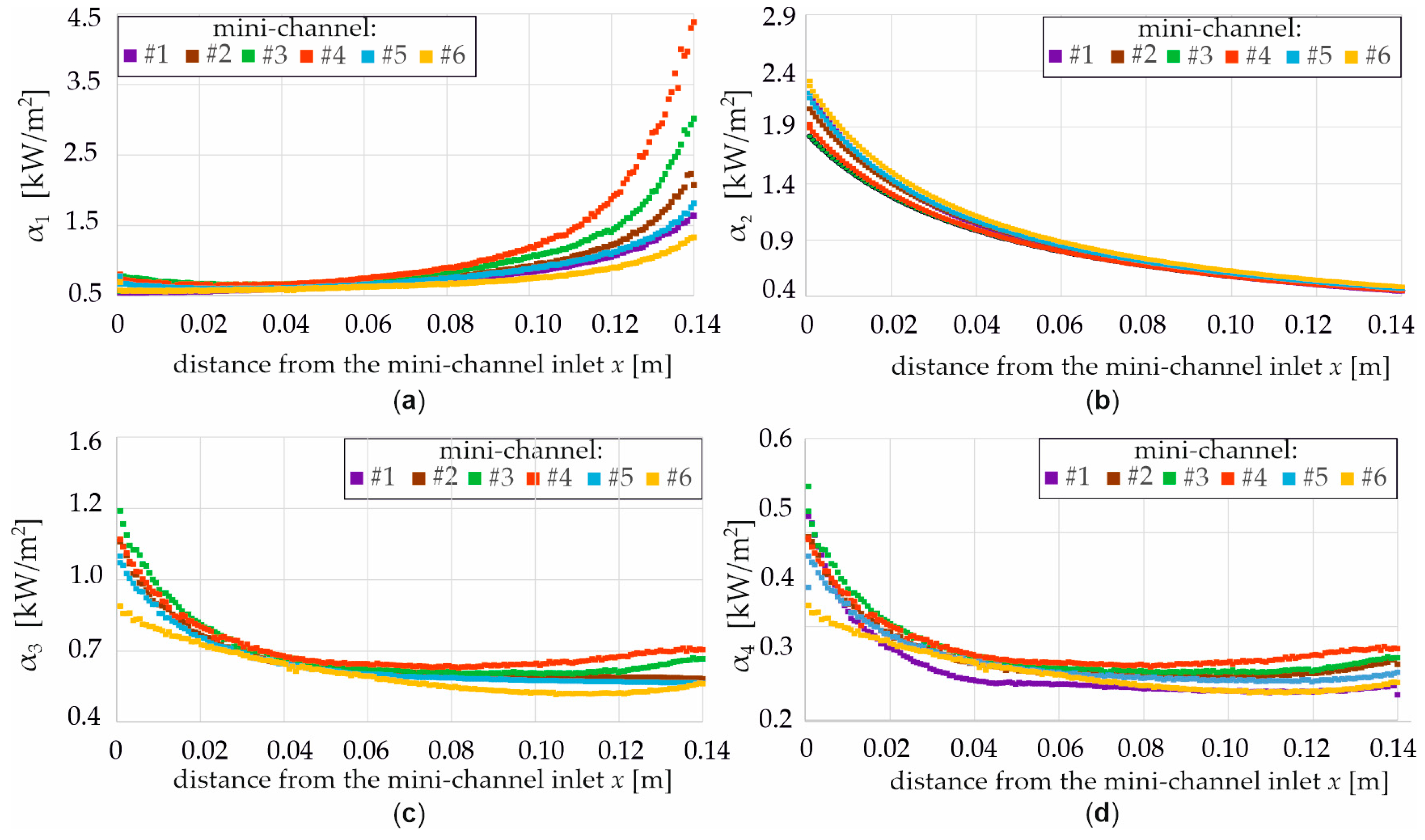

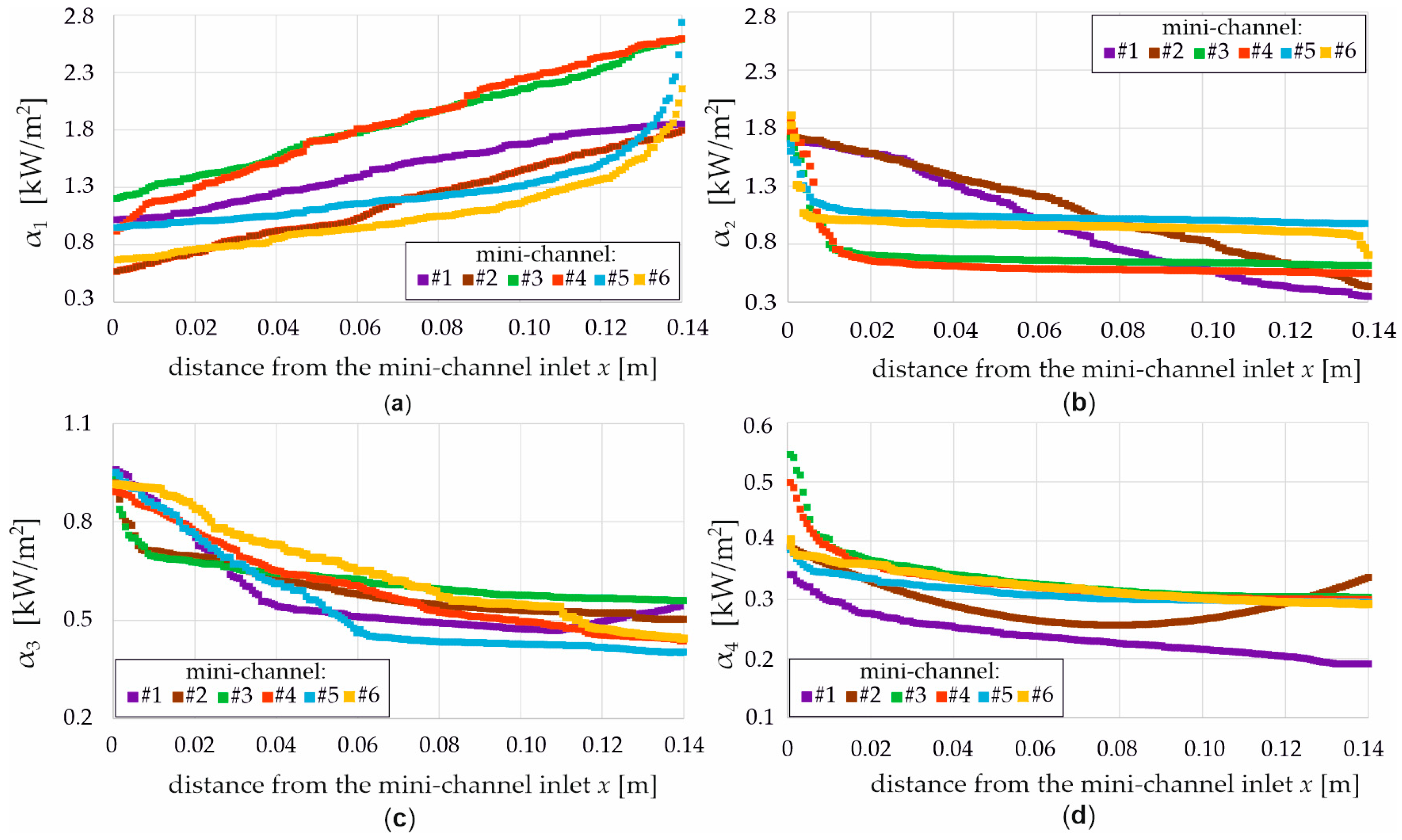

- Dependencies for the HTC as a function of the distance from the MCH inlet from 1D approach for three flux densities 1000, 2000, and 8000 W/m2: (a) α1—heated plate and FC-72, (b) α2—FC-72 and copper separating plate, (c) α3—copper separating plate and water, (d) α4—water and copper closing plate, for six MCH (from #1 to #6) (Figure 10 and Figure 11).

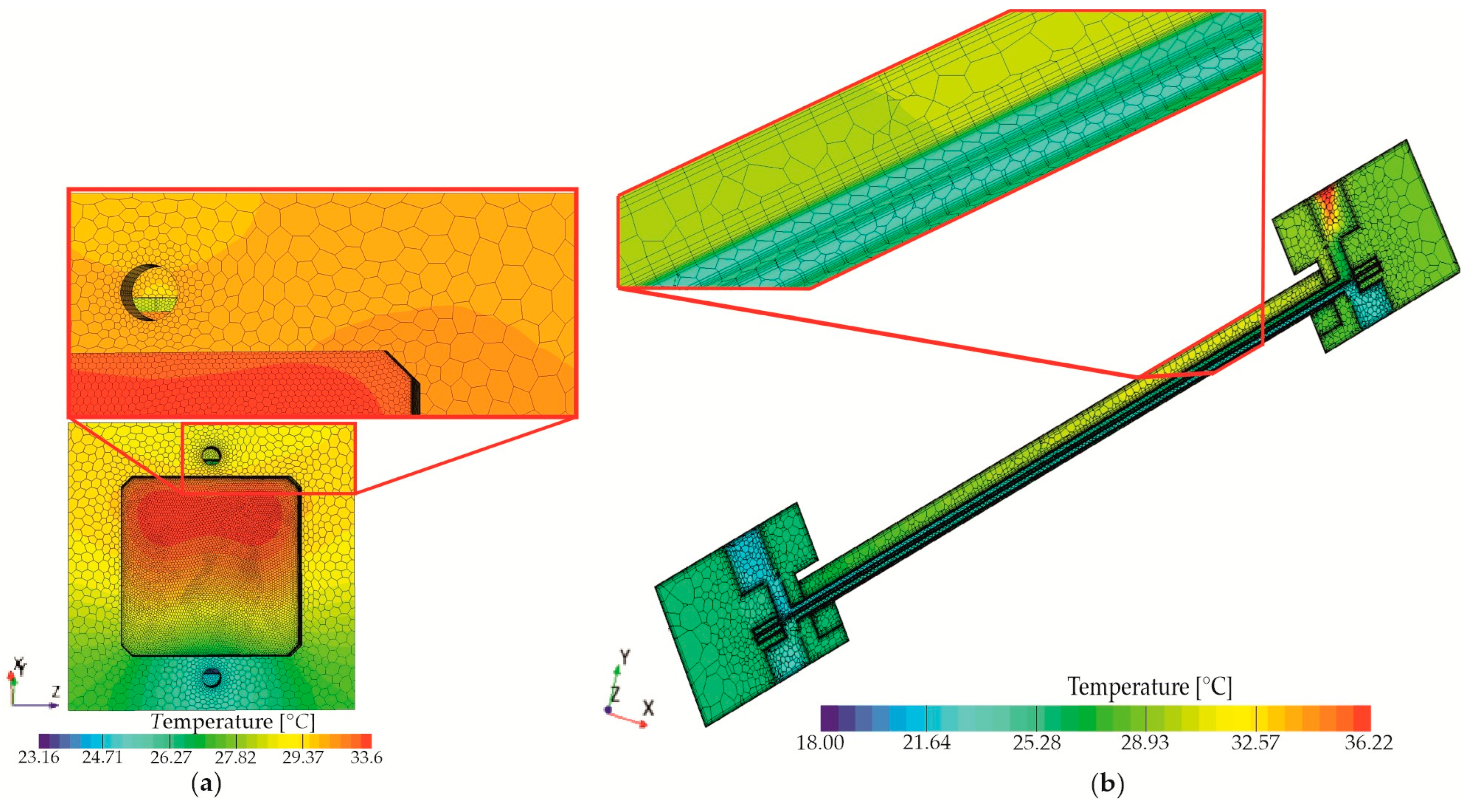

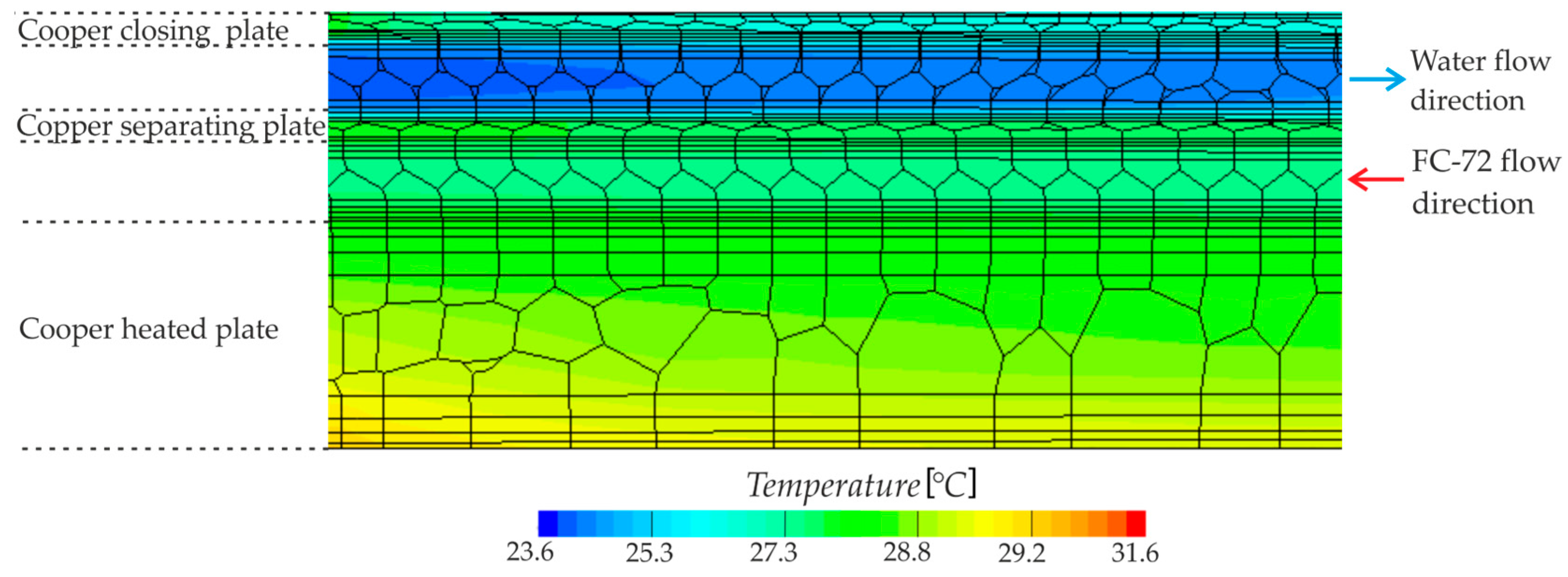

5.2. Simcenter STAR CCM+ CFD Results

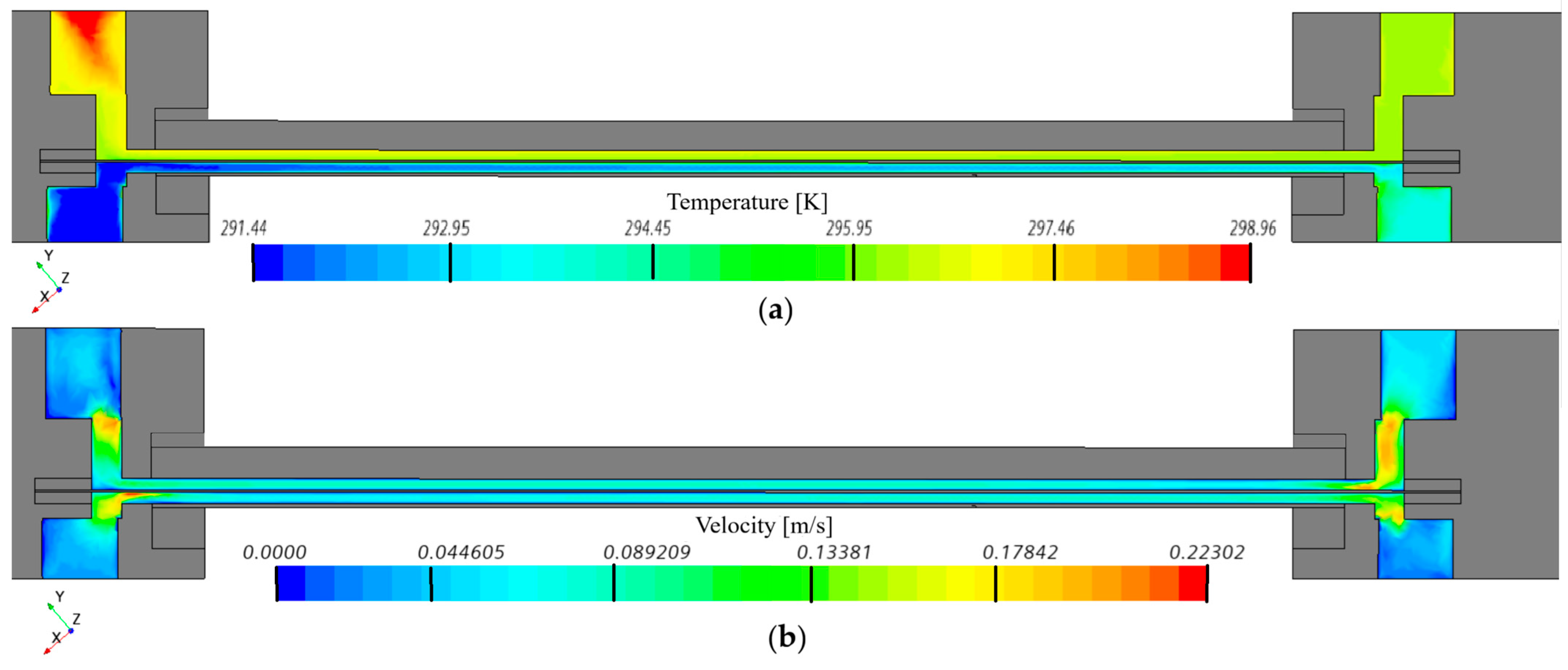

- Two-dimensional calculation results illustrating velocity distributions: (a) temperature, (b) velocity, generated by the STAR-CCM+ software—Figure 14.

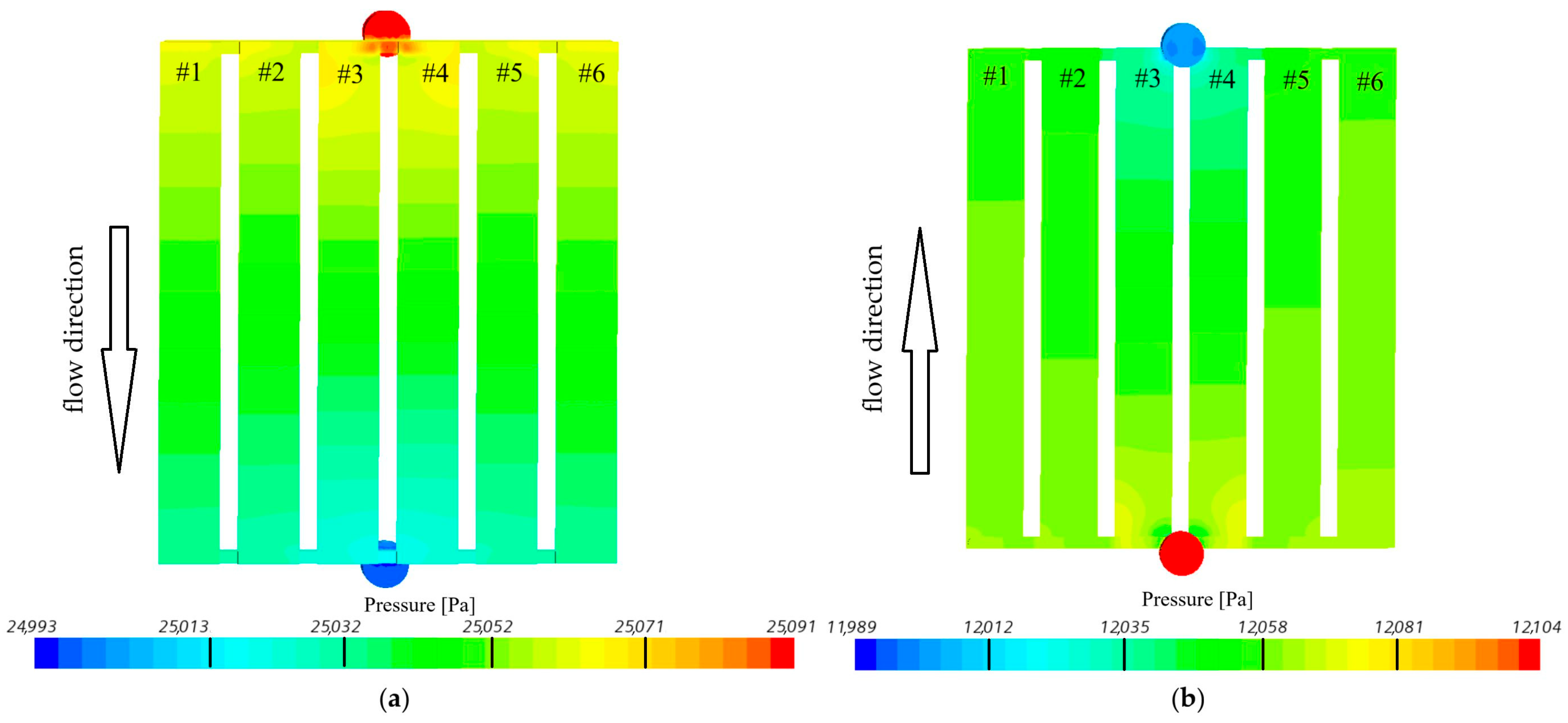

- Two-dimensional calculation results illustrating pressure on the (a) hot wall, (b) cold wall generated by the STAR-CCM+ software—Figure 15.

- Two-dimensional temperature distribution generated by the STAR-CCM+ software depicting the external surface of the heated plate for three distinct heat flux densities: (a) q = 1000 W/m2, (b) q = 2000 W/m2, and (c) q = 8000 W/m2, as illustrated in Figure 16.

- Dependencies for the HTC as a function of the distance from the MCH inlet, derived from the STAR-CCM+ program for: (a) α1—heated plate and FC-72, (b) α2—FC-72 and copper separating plate, (c) α3—copper separating plate and water, d) α4—water and copper closing plate for a heat flux density of 2000 W/m2—Figure 17.

5.3. Comparison of the 1D Approach and STAR-CCM+ Simulations

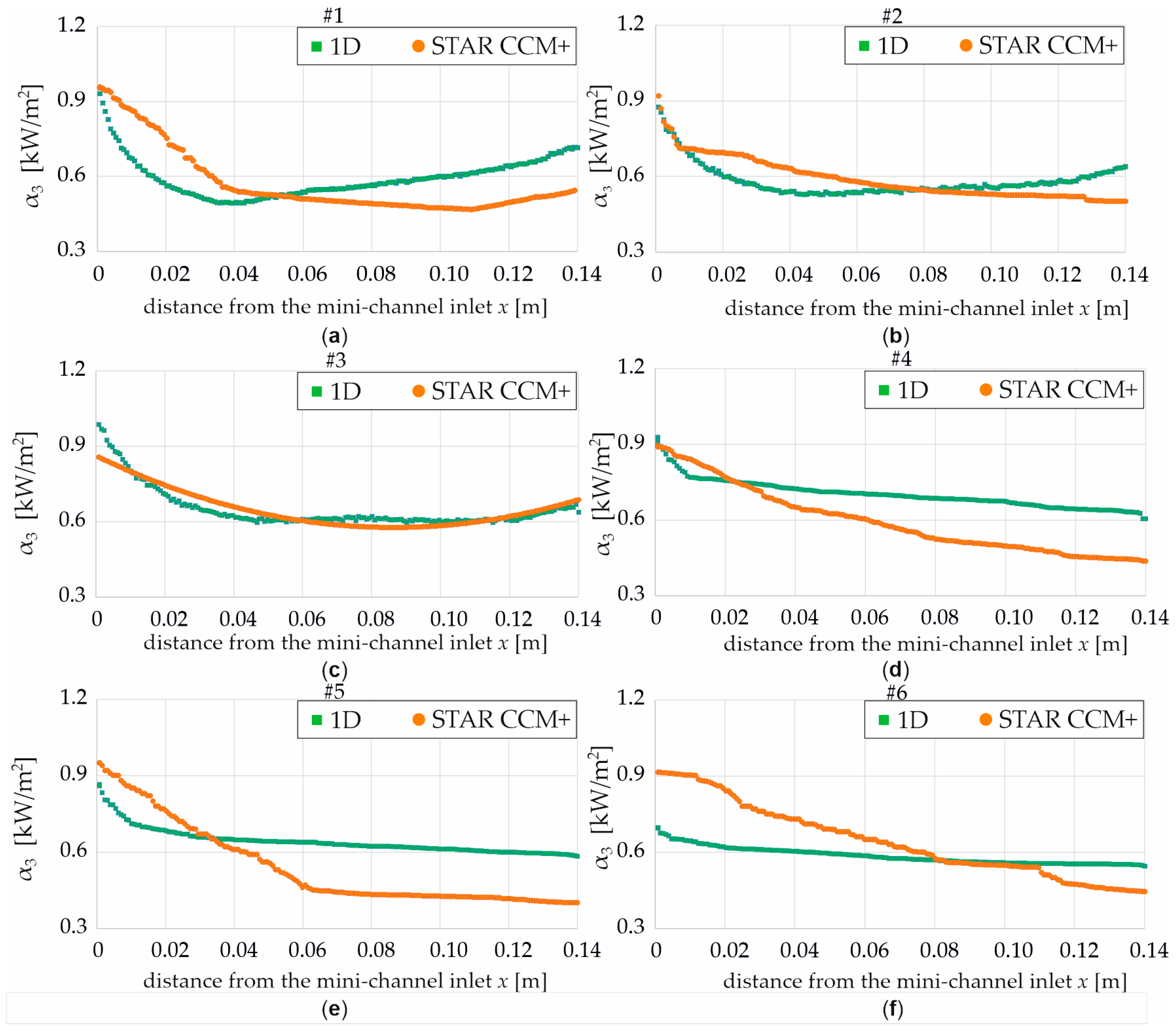

- Relationships for the HTC as a function of the distance from the MCH inlet, derived from the STAR-CCM+ program and 1D approach, for a heat flux density of 2000 W/m2 and α3—copper separating plate/water—Figure 18.

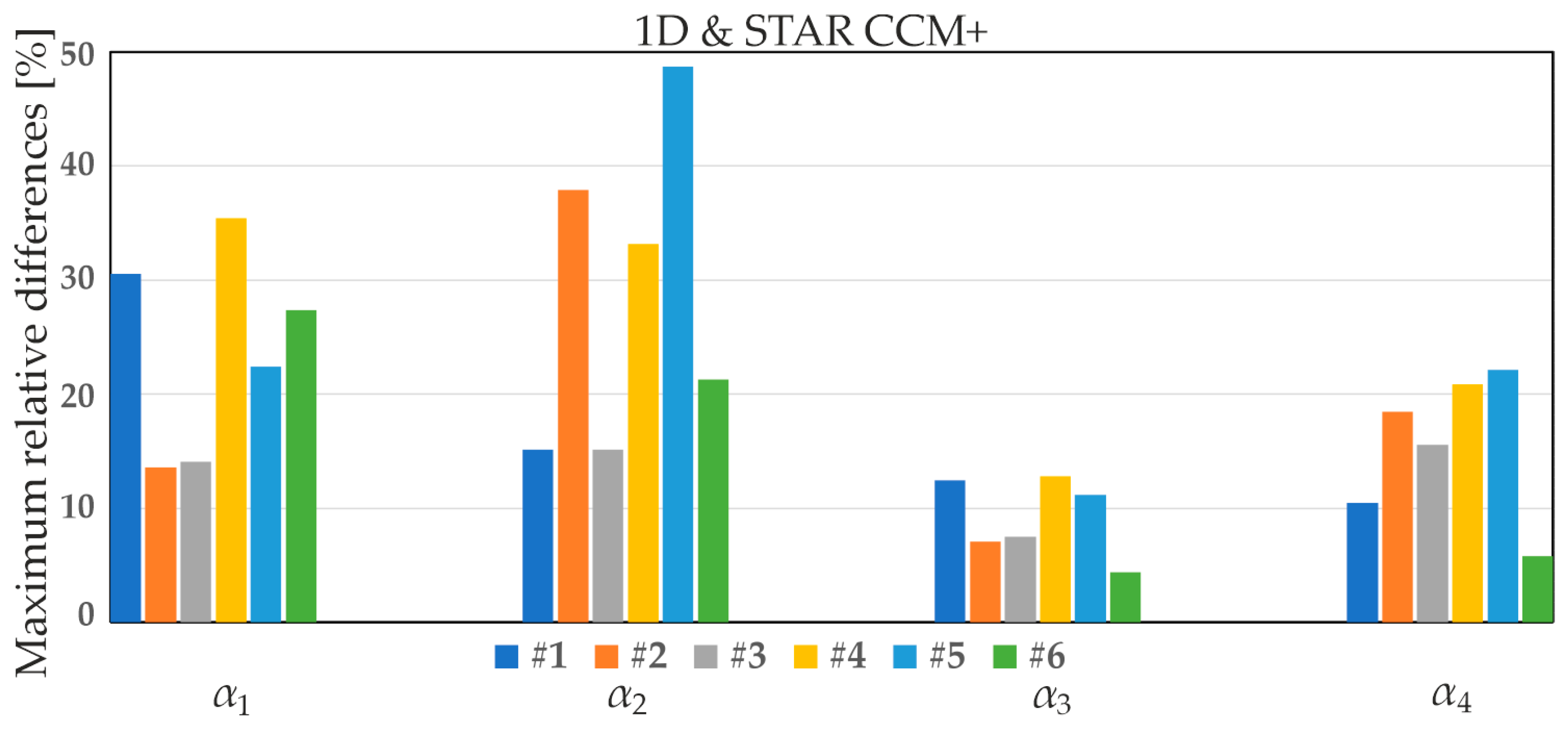

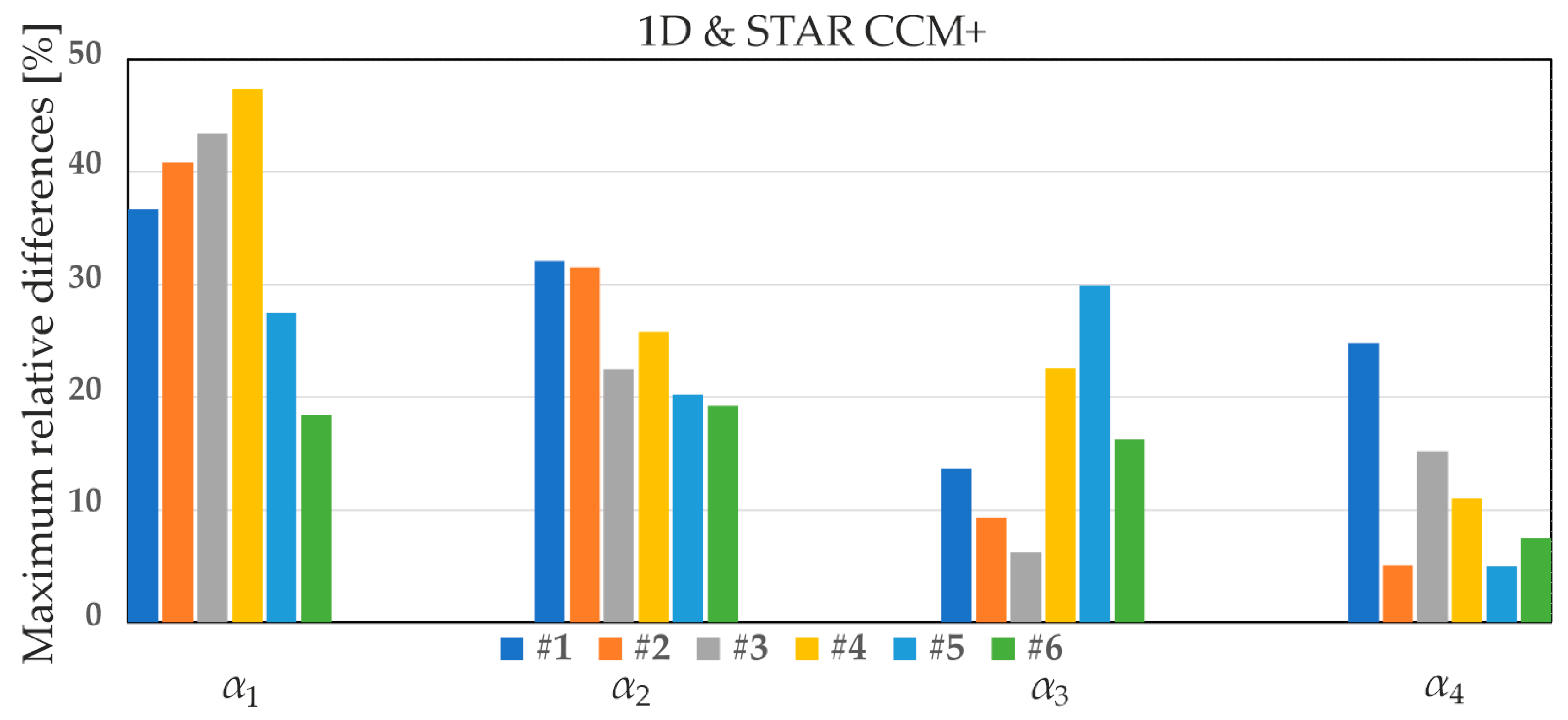

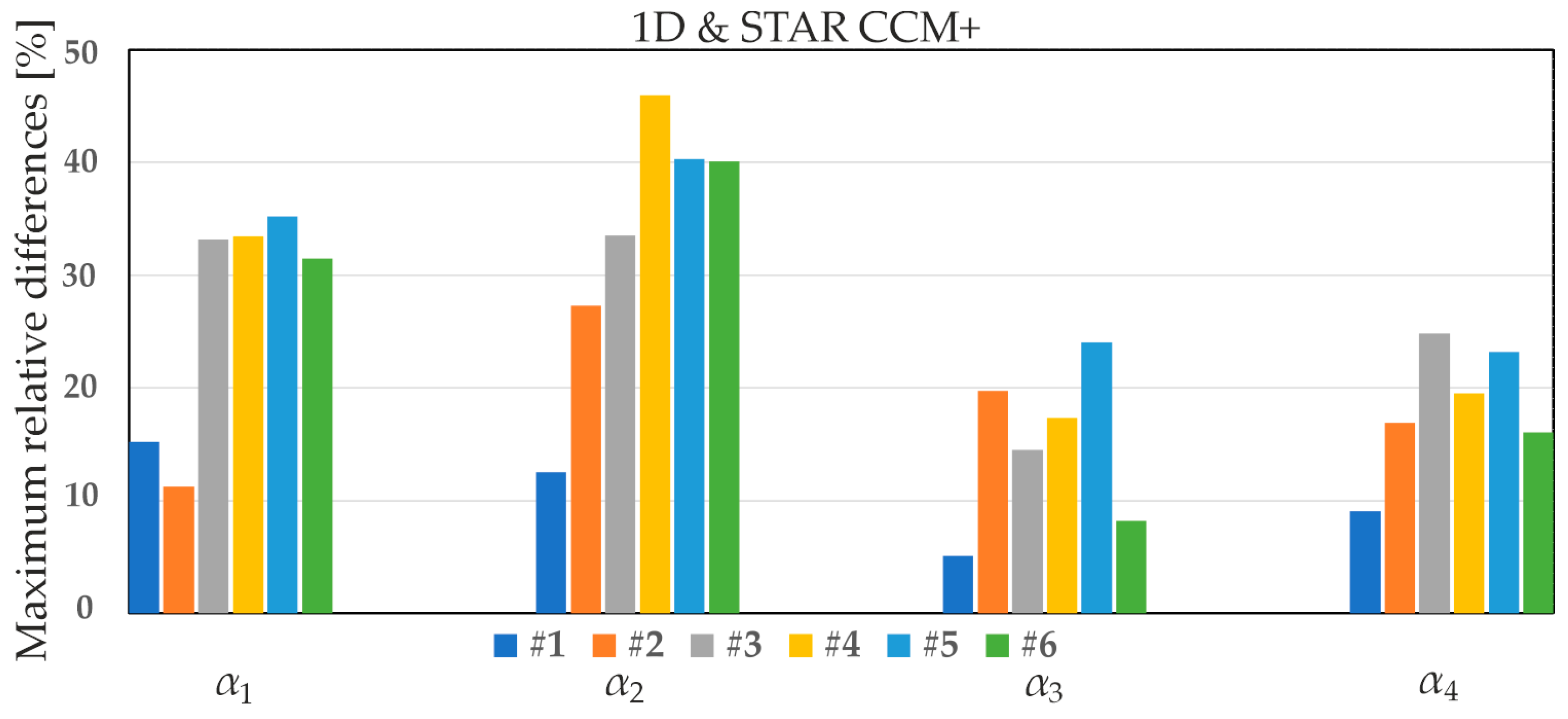

- Maximum relative differences between the values of the HTC α1, calculated from Equation (2), and α2, α3, α4, derived from Equations (4), (5), and (7), respectively, including a comparison with HTCs obtained from the STAR CCM+ software for all MCHs (from #1 to #6) at heat flux densities of 1000 W/m2 (Figure 19), 2000 W/m2 (Figure 20), and 8000 W/m2 (Figure 21).

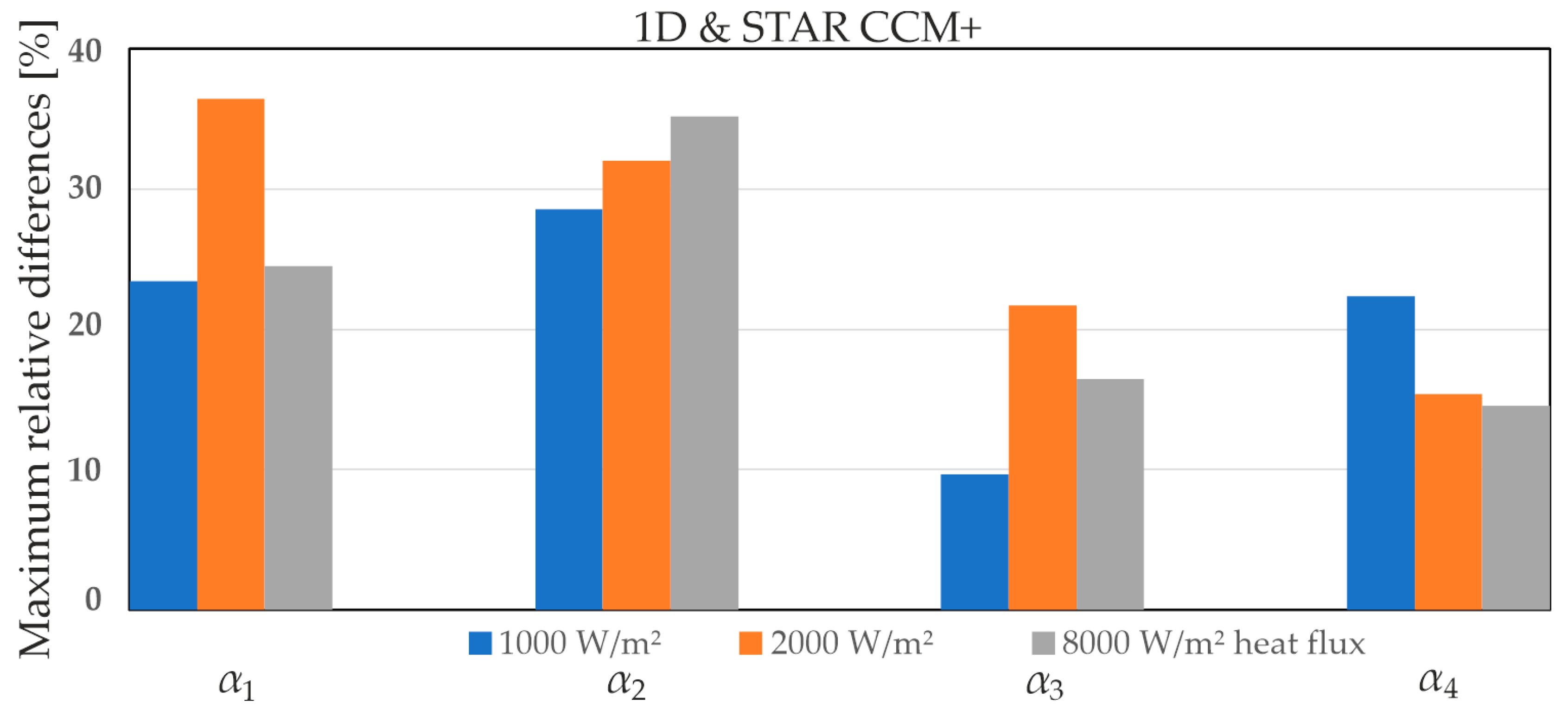

- Maximum relative differences between the values of the HTC α1, calculated from Equation (2), and α2, α3, α4, derived from Equations (4), (5), and (7), respectively, are presented, along with a comparison of HTCs obtained from the STAR-CCM+ software for average values of all MCHs at heat flux densities of 1000, 2000, and 8000 W/m2 (Figure 22).

6. Conclusions

- The temperature of the copper heated plate, FC-72 fluid, copper separating plate, and distilled water generally increased with both distance from the MCH inlet and heat flux density across the six MCHs, except for the copper heated plate outlet.

- In the cold mini-channel, only single-phase convection occurred across the entire MCH length, resulting in low temperature differences between the plates and the distilled water.

- The local HTCs at the interface between the copper heated plate and the FC-72 fluid increased with the distance from the MCH, except at the MCH inlet.

- Conversely, the HTCs at the copper separating plate/distilled water and distilled water/closing plate interfaces decreased in the inlet section (approximately the first one-third of the length) before showing a slight increase near the MCH outlet.

- Numerical CFD calculations were performed using Simcenter STAR-CCM+ to determine temperatures and HTCs for individual layers, analogously to the 1D analytical approach for selected experimental data.

- The two-dimensional temperature distribution generated by STAR-CCM+ for the heated copper plate demonstrated a similar external temperature distribution across all heat flux densities compared to the experimental infrared camera data.

- A pairwise comparison of the HTCs for the central heat flux density (q = 2000 W/m2) showed the most accurate agreement between the 1D analytical approach and CFD for MCH #3, while MCH #5 exhibited the least accurate agreement.

- The maximum relative differences between the 1D analytical approach and STAR-CCM+ were dependent on the MCH, the location, and the heat flux density. The highest average maximum relative differences across all heat flux densities were observed for α2 (29%), and the smallest were observed for α3 (13.5%).

- The employed numerical method demonstrated reliability and accuracy in validating simplified analytical models. The comparison between the CFD-based three-dimensional model and the one-dimensional analytical method affirmed the correctness and consistency of the 1D approach, thus corroborating its suitability for preliminary thermal design and analysis.

- At the maximum heat flux density (8000 W/m2), the first group of MCHs showed a significant temperature increase, indicating greater localized thermal heat exchange. The second section of the heat exchanger, however, maintained temperatures comparable to those observed at lower flux densities, suggesting the system can sustain relatively uniform thermal conditions in that region.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Symbols | |

| A | surface area, m2 |

| dh | hydraulic diameter, m |

| E | the radiation intensity for copper heated plate, W/m2 |

| G | mass flux, kg/(m2 s) |

| k | owerall heat transfer coefficient, W/(m2 K) |

| L | length of the mini-channel, m |

| p | pressure, Pa |

| Re | Reynolds number |

| Qm | mass flow rate, kg/s |

| q | heat flux density, W/m2 |

| T | temperature, K |

| x | coordinate in the direction of flow, m |

| Greek letters | |

| α | heat transfer coefficient, W/(m2 K) |

| Δ | difference, |

| δ | thickness, depth, m |

| λ | thermal conductivity, W/(m K) |

| µ | dynamic viscosity, Pa∙s |

| ρ | density, kg/m3 |

| σ | surface tension, N/m |

| Abbreviations | |

| 1D | one-dimensional approach |

| CFD | Computational Fluid Dynamics |

| CMCH | cold mini-channel |

| HMCH | hot mini-channel |

| HTC | heat transfer coefficient |

| MCH | mini-channel |

| MMCH | multi-mini-channel |

| Subscripts | |

| Cu | copper plate |

| f | fluid |

| FC | FC-72 fluid |

| H | heated plate |

| l | linear |

| IRT | infrared thermography |

| w | distilled water |

| in | inlet |

| out | outlet |

References

- Kandlikar, S.G.; Grande, W.J. Evolution of Microchannel Flow Passages—Thermohydraulic Performance and Fabrication Technology. Heat Transf. Eng. 2003, 24, 3–17. [Google Scholar] [CrossRef]

- Klemes, J.J.; Arsenyeva, O.; Kapustenko, P.; Tovazhnyanskyy, L. Compact Heat Exchangers for Energy Transfer Intensification Low Grade Heat and Fouling Mitigation; CRC Press: Boca Raton, FL, USA, 2015; ISBN 9781138748330. [Google Scholar]

- Shang, H.; Yan, Z.; Xia, G. Analysis of Influence of Inlet Vapor Quality on Heat Transfer and Flow Pattern in Mini-Channels during Flow Condensation Process. Appl. Therm. Eng. 2024, 236, 121864. [Google Scholar] [CrossRef]

- Li, T.; Luo, X.; Li, G. Instability Analysis of Pressure Drop and Flow Characteristics in Mini-Channel Heat Sink with Phase-Separated Configuration. Appl. Therm. Eng. 2024, 253, 123755. [Google Scholar] [CrossRef]

- Bao, Y.; Chen, J.; Shao, S. Comparison on Thermal and Hydraulic Performances of Transverse Mini-Channel Based on a Novel Comprehensive Evaluation Factor. Appl. Therm. Eng. 2024, 253, 123795. [Google Scholar] [CrossRef]

- Ma, X.; Hu, C.; Ji, X.; Yang, X.; Xu, N.; Zhang, Y.; Wei, J.; Feng, Y.; Sundén, B. Flow Boiling Frictional Pressure Drop inside Micro/Mini-Channels: A New General Model and Experimental Investigation. Appl. Therm. Eng. 2024, 247, 123111. [Google Scholar] [CrossRef]

- Zhang, J.; Luo, X.; Feng, Z. Effect of Pin Electrodes on Flow Boiling Heat Transfer and Bubble Dynamic Behaviors in Vertical Minichannels. Int. J. Therm. Sci. 2024, 200, 108964. [Google Scholar] [CrossRef]

- Zhang, J.; Luo, X.; Feng, Z. Compound Effect of EHD and Nanofluid on Flow Boiling Characteristics in Minichannels. Powder Technol. 2024, 442, 119895. [Google Scholar] [CrossRef]

- Yin, L.; Wang, Y.; Jia, L. Flow Boiling Instability of R134a in the Large-Area Heat Sink with Interconnected Parallel Multi-Minichannels. Int. J. Therm. Sci. 2024, 204, 109193. [Google Scholar] [CrossRef]

- Ye, H.; Lum, L.Y.X.; Kandasamy, R.; Zhao, H.; Ho, J.Y. Flow Boiling Heat Transfer Enhancement of R134a in Additively Manufactured Minichannels with Microengineered Surfaces. Appl. Therm. Eng. 2024, 256, 124150. [Google Scholar] [CrossRef]

- Luo, K.; Chang, W.; Foysal, F.; Santi, E.; Li, C. Hybrid-Featured Porous Pin-Fin Arrays to Enhance Flow Boiling in a Large Minichannel Heatsink. Int. J. Heat Mass Transf. 2025, 248, 127213. [Google Scholar] [CrossRef]

- Yang, R.; Fan, C.; Li, B.; Zhang, C.; Chen, Y. Role of Hypergravity in Minichannel Flow Boiling. Int. J. Heat Mass Transf. 2025, 237, 126429. [Google Scholar] [CrossRef]

- Shang, H.; Xia, G.; Li, R.; Miao, S. Experimental Study on Flow Boiling Heat Transfer of HFE-7100 in Minichannel Heat Sinks for Professional-Grade Server Chips Cooling. Int. Commun. Heat Mass Transf. 2025, 164, 108825. [Google Scholar] [CrossRef]

- Lan, Y.; Feng, Z.; Hu, Z.; Zheng, S.; Zhou, J.; Zhang, Y.; Huang, Z.; Zhang, J.; Lu, W. Experimental Investigation on the Effects of Swirling Flow on Flow Boiling Heat Transfer and Instability in a Minichannel Heat Sink. Appl. Therm. Eng. 2023, 219, 119512. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, J.; Huang, S. Vapor Separation in Minichannel Heat Sink Flow Boiling Application Using Gradient Porous Copper Ribs. Appl. Therm. Eng. 2025, 259, 124930. [Google Scholar] [CrossRef]

- Kokate, R.; Park, C.; Mitsingas, C.; Schroen, E. Flow Boiling in Parallel Microchannels in a Pumped Two-Phase Loop: Flow Visualization and Thermal Characteristics. Int. Commun. Heat Mass Transf. 2024, 155, 107566. [Google Scholar] [CrossRef]

- Zhang, Z.; Jia, L.; Dang, C.; Ding, Y. Experimental Study on Flow Boiling Characteristics of R134a inside High-Heat-Flux Microchannels. Int. J. Heat Fluid Flow 2024, 107, 109372. [Google Scholar] [CrossRef]

- Rohini, A.K.; Choi, W.W.; Kim, S.M. Subcooled Flow Boiling in Multiple Parallel Rectangular Micro-Channel Heat Sink: Development of Heat Transfer Correlation. Appl. Therm. Eng. 2024, 250, 123444. [Google Scholar] [CrossRef]

- Mutumba, A.; Coletti, F.; Reip, A.; Mahmoud, M.M.; Karayiannis, T.G. Experiments and Correlations for Single-Phase Convective Heat Transfer in Brazed Plate Heat Exchangers. Heat Transf. Eng. 2023, 44, 211–231. [Google Scholar] [CrossRef]

- Yaghoubi, M.S.; Ahmadpour, A.; Saffar-Avval, M. Geometrical Design of Minichannels with Rectangular Wall Cavities for Flow Boiling Heat Transfer Enhancement. Results Eng. 2025, 25, 103989. [Google Scholar] [CrossRef]

- Igaadi, A.; El Amraoui, R.; El Mghari, H. CFD Investigation on Heat Transfer Improvement of Subcooled Flow Boiling in a Vertical Upflow Minichannel with Straight and Enhanced Geometrical Structure. e-Prime-Adv. Electr. Eng. Electron. Energy 2023, 5, 100231. [Google Scholar] [CrossRef]

- Igaadi, A.; El Amraoui, R.; El Mghari, H. Thermo-Hydrodynamic Investigation into the Effects of Minichannel Configuration on the Thermal Performance of Subcooled Flow Boiling. Nucl. Eng. Technol. 2023, 56, 265–274. [Google Scholar] [CrossRef]

- Li, Q.; Avramova, M.; Jiao, Y.; Chen, P.; Yu, J.; Pu, Z.; Chen, J. CFD Prediction of Critical Heat Flux in Vertical Heated Tubes with Uniform and Non-Uniform Heat Flux. Nucl. Eng. Des. 2018, 326, 403–412. [Google Scholar] [CrossRef]

- Piasecka, M.; Hożejowska, S.; Maciejewska, B.; Pawińska, A. Time-Dependent Heat Transfer Calculations with Trefftz and Picard Methods for Flow Boiling in a Mini-Channel Heat Sink. Energies 2021, 14, 1832. [Google Scholar] [CrossRef]

- Piasecka, M.; Maciejewska, B.; Łabędzki, P. Heat Transfer Coefficient Determination during FC-72 Flow in a Minichannel Heat Sink Using the Trefftz Functions and ADINA Software. Energies 2020, 13, 6647. [Google Scholar] [CrossRef]

- Piasecka, M.; Piasecki, A.; Dadas, N. Experimental Study and CFD Modeling of Fluid Flow and Heat Transfer Characteristics in a Mini-Channel Heat Sink Using Simcenter STAR-CCM+ Software. Energies 2022, 15, 536. [Google Scholar] [CrossRef]

- Maciejewska, B.; Piasecka, M.; Dadas, N.; Strąk, K. Fluid Flow and Heat Transfer Characteristics in Minichannels—CFD Calculations in Simcenter STAR-CCM+. Heat Mass Transf. 2025, 61, 22. [Google Scholar] [CrossRef]

- Piasecka, M.; Hożejowska, S.; Pawińska, A.; Strąk, D. Heat Transfer Analysis of a Co-Current Heat Exchanger with Two Rectangular Mini-Channels. Energies 2022, 15, 1340. [Google Scholar] [CrossRef]

- 3M™ Fluorinert™ Electronic Liquid FC-72. Available online: https://multimedia.3m.com/mws/media/64892O/3m-fluorinert-electronic-liquid-fc-72.pdf (accessed on 11 November 2025).

- Physical Characteristics of Water. Available online: https://www.thermexcel.com/english/tables/eau_atm.htm (accessed on 1 June 2003).

- Tang-Kwor, E.; Matteï, S. Emissivity Measurements for Nextel Velvet Coating 811-21 between −36 °C and 82 °C. High Temp. Press. 2001, 33, 551–556. [Google Scholar] [CrossRef]

- Dariusz, S. Performance Investigation of Hybrid Photovoltaic Thermal-Heat with Mini-Channels for Application in Electric Vehicles. Arch. Automot. Eng.-Arch. Motoryz. 2023, 100, 1–26. [Google Scholar] [CrossRef]

- Simcenter STAR-CCM+. Available online: https://plm.sw.siemens.com/en-US/simcenter/fluids-thermal-simulation/star-ccm/ (accessed on 25 April 2021).

- Residuals in Simcenter STAR-CCM+. Available online: https://volupe.com/Simcenter-Star-Ccm/Residuals-in-Simcenter-Star-Ccm/ (accessed on 26 April 2024).

| Boiling Point (K) | Critical Temperature (K) | Kinematic Viscosity (m2/s) | Liquid Density (kg/m3) | Vapor Pressure (Pa) | Liquid Specific Heat (J/(kg∙K)) | Liquid Thermal Conductivity (W/(m∙K)) | Surface Tension (N/m) |

|---|---|---|---|---|---|---|---|

| Refrigerant FC-72 [29] | |||||||

| 329 | 449 | 0.38 × 103 | 1680.0 | 30.9 × 103 | 1100 | 0.057 | 0.01 |

| Distilled water [30] | |||||||

| 373 | 647 | 0.89 × 103 | 997.1 | 3.17 × 103 | 4180 | 0.607 | 0.07 |

| Parameter | Device | Type/Model, Manufacturer, City, Country | Basic Technical Data (Measurement Range) | The Maximum Measurement Error |

|---|---|---|---|---|

| Mass flow rate | Turbine mass flow meter (water) | 0045BP01XA, Equflow, Oss, The Netherlands | Inner diameter 4.8 mm Medium temperature −20 to +80 °C (0.1…1.8 L/min) | 1% of reading * |

| Magnetic flow meter (FC-72) | SM6000, IFM, Essen, Germany | Analogue current output 4…20 mA Medium temperature −10 to +70 °C (0.1…25 L/min) | ±0.8% measured value +0.5% final value of the measuring range * | |

| Atmospheric pressure, overpressure at the inlet/outlet of the test section | Pressure meter | A-10, Wika, Klingenberg am Main, Germany | Output signal 4…20 mA, Temperature ranges 0 to +80 °C (0…2.5 bar) | 0.5% of full scale * |

| Temperature | Thermocouple | Type K 221 b, Czaki Thermo-Product, Rybie, Poland | NiCr-NiAl sensor with a galvanically isolated weld (−40…375 °C) | calibration tolerance 1.5 °C * |

| Thermal imaging camera | E60, FLIR, Wilsonville, OR, USA | Spectrum range 7.5…13 μm, resolution 320 × 240 pixels (−20…120 °C) | ±1 °C or ±1% in the range of 0…120 °C and ±2 °C or ±2% outside this range * | |

| Light radiation intensity | Luxmeter | D2102.1, Delta OHM, Caselle di Selvazzano, Italy | Visible light intensity measurement 380…780 nm (0…1999.9 W/m2) | ±0.02 W/m2 or ±2% * |

| Data acquisition station | DaqLab/2005, IOtech Norton, MA, USA | Analog Inputs (16 bit/200 kHz): 16 100% Digital Calibration 512 Location Channel/Gain FIFO | 0.5% * | |

| Heat exchanger | MF-200, Aquaviva, Vescovato, Italy | Pool heat exchanger output power 60 kW hot water flow: 1.8 m3/h maximum temperature: 110 °C * | - | |

| B130, SECESPOL, Gdańsk, Poland | Shell and tube heat exchanger output power 130 kW maximum water flow: 20.94 m3/h maximum temperature: 203 °C * | - |

| Parameter | Range of Values/Values |

|---|---|

| Heat Flux Density, q (W/m2) | 1000, 2000, 8000 |

| Inlet Pressure, pin (kPa) | 110–118 |

| Mass Flux, GFC (kg/(m2∙s)) | 277–286 |

| Mass Flux, GW (kg/(m2∙s)) | 279–296 |

| Inlet Liquid Subcooling, ΔTsub (K) | 60–64 |

| Overall HTC, k (W/(m2 K)) | 428–972 |

| Reynolds Number, Re,FC (-) | 1201–1299 |

| Reynolds Number, Re,W (-) | 1108–1226 |

| Component of the HTC | Absolute Error |

|---|---|

| Plate Temperature Measurement by Infrared Thermography | ∆TIRT(x) = 2.0 K |

| Fluid Temperature Measurement by K-Type Thermocouple | ∆Tf(x) = 0.32 K |

| Thermal Conductivity of the Copper Heated Plate | ΔλH = 0.1 W/(m∙K) |

| Thickness of the Heated Plate | ΔδH = 5 × 10−5 m |

| Heated Plate Area | ΔA = 2.9 × 10−5 m2 |

| Heat Flux Density | Δq,Cu = 0.323 kW/m2 |

| Main Experimental Data | ||||||

|---|---|---|---|---|---|---|

| Heat Flux | 1000 W/m2 | 2000 W/m2 | 8000 W/m2 | |||

| Working Fluid | FC-72 | Water | FC-72 | Water | FC-72 | Water |

| Temperature at Inlet (°C) | 23.12 | 18.13 | 21.32 | 19.33 | 21.84 | 20.25 |

| Temperature at Outlet (°C) | 25.81 | 20.41 | 27.22 | 21.61 | 36.22 | 22.63 |

| Temperature of Ambient Air (°C) | 20.00 | 20.00 | 20.00 | 20.00 | 20.00 | 20.00 |

| Atmospheric Pressure (bar) | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 |

| Overpressure at the Outlet (bar) | 0.12 | 0.08 | 0.16 | 0.14 | 0.22 | 0.12 |

| Region/Boundary | Type | Value/Setting |

|---|---|---|

| Aluminum Cover | Static Temperature | 20 °C…26.8 °C |

| Silicon Gasket | Solid Static Temperature Reference Values | Si-silicon 18 °C Minimum Allowable Temperature: 15 °C, Maximum Allowable Temperature: 60 °C |

| Fluid domain cold (MMCH) | Pressure | 100,000 Pa |

| Static Temperature | 15 °C | |

| Turbulence intensity | 0.01 | |

| Turbulence Specification | Intensity/Viscosity + Ratio | |

| Turbulent Velocity Scale | 0.01 m/s | |

| Turbulent Viscosity Ratio | 1.0 | |

| Velocity | [0.0; 0.0; 0.0] m/s | |

| Fluid domain hot (MMCH) | Pressure | 900,000 Pa |

| Static Temperature | 15 °C | |

| Turbulence Intensity | 0.01 | |

| Turbulence Specification | Intencity/Viscocity + Ratio | |

| Turbulent Velocity Scale | 0.01 m/s | |

| Turbulent Viscosity Ratio | 1.0 | |

| Velocity | [0.0; 0.0; 0.0] m/s | |

| Separated copper plate | Solid | Cu |

| Reference Values | Minimum Allowable Temperature: 15 °C | |

| Maximum Allowable Temperature: 40 °C | ||

| Initial Condition | 20 °C | |

| Closing copper plate | Solid | Cu |

| Reference Values | Minimum Allowable Temperature: 15 °C | |

| Maximum Allowable Temperature: 30 °C | ||

| Initial Condition | 18 °C |

| Material | Density (kg/m3) | Dynamic Viscosity (Pa·s) | Specific Heat (J/(kgK)) | Thermal Conductivity (W/(mK)) |

|---|---|---|---|---|

| Fluid | ||||

| FC-72 | 1680.00 | 6.4 × 10−4 | 1100.00 | 0.057 |

| Distilled water | 997.56 | 8.89 × 10−4 | 4181.72 | 0.59 |

| Solid | ||||

| Copper | 8940 | - | 386 | 398 |

| Aluminum | 2702 | - | 903 | 237 |

| Silicon | 2160 | - | 702 | 0.21 |

| Element | Cells | Faces | Verts | Cells | Faces | Verts | Cells | Faces | Verts |

|---|---|---|---|---|---|---|---|---|---|

| 2 mm Base Size | 3 mm Base Size | 5 mm Base Size | |||||||

| Aluminum Cover | 1,444,837 | 7,198,231 | 5,047,593 | 1,048,732 | 5,133,350 | 3,554,235 | 737,586 | 3,505,375 | 2,373,171 |

| Silicon Gasket | 97,157 | 391,672 | 229,140 | 96,092 | 383,557 | 222,136 | 95,930 | 381,481 | 220,118 |

| Copper Plate | 132,595 | 740,831 | 642,456 | 134,044 | 743,447 | 637,551 | 128,914 | 704,903 | 603,914 |

| Silicon Gasket (forming a MMCH) Fluid domain hot | 3,896,846 | 17,371,031 | 11,137,637 | 1,723,910 | 7,241,018 | 4,398,724 | 808,143 | 3,335,321 | 1,990,058 |

| Copper Plate | 4,312,342 | 19,487,666 | 12,644,100 | 1,992,480 | 8,426,307 | 5,149,921 | 903,676 | 3,736,072 | 2,232,098 |

| Silicon Gasket (forming a MMCH) | 10,145,734 | 42,547,329 | 26,298,048 | 3,451,828 | 14,479,207 | 8,942,527 | 997,684 | 4,304,519 | 2,970,490 |

| Fluid domain cold | 4,731,730 | 21,364,994 | 14,101,491 | 2,297,449 | 9,866,828 | 6,115,940 | 899,876 | 3,740,677 | 2,247,285 |

| Copper Plate | 6,544,397 | 30,299,974 | 20,035,056 | 3,588,714 | 15,205,321 | 9,813,470 | 1,123,780 | 4,701,081 | 2,839,070 |

| Silicon Gasket | 97,167 | 391,682 | 229,150 | 96,192 | 383,657 | 222,146 | 95,940 | 381,581 | 220,218 |

| h (-) | N (-) | (K) | r (-) | (-) | p (-) | ea (%) | GCI (%) |

|---|---|---|---|---|---|---|---|

| 2.00 × 10−3 (h1) | 37,051,628 (N1) [2 mm] | 300.241567 ( | 1.3607 | - | 4.67 | - | - |

| 2.55 × 10−3 (h2) | 17,896,414 (N2) [3 mm] | 300.9499 ( | 1.2745 | 0.7084 | 0.24 | 0.14 | |

| 3.54 × 10−3 (h3) | 6,707,410 (N3) [5 mm] | 297.950452 ( | 1.3869 | −2.9995 | 0.99 | 0.35 |

| Heat Flux (W/m2) | Fluid | Mass Flow Rate (kg/s) | Inlet Total Pressure (Pa) | Inlet Temperature (K) | Type of Flow |

|---|---|---|---|---|---|

| 1000 | Cold Fluid (6 mini-channels) | 0.008 | 118,000 | 291.28 | Countercurrent Flow |

| Hot Fluid (6 mini-channels) | 0.008 | 112,325 | 296.27 | ||

| 2000 | Cold Fluid (6 mini-channels) | 0.008 | 125,000 | 292.48 | Countercurrent Flow |

| Hot Fluid (6 mini-channels) | 0.008 | 116,325 | 294.47 | ||

| 8000 | Cold Fluid (6 mini-channels) | 0.008 | 114,000 | 293.40 | Countercurrent Flow |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Strąk, K.; Strąk, D. Experimental Analysis of Heat Transfer in Multi-Mini-Channel Module: A Comparison with CFD Simulations. Energies 2025, 18, 5992. https://doi.org/10.3390/en18225992

Strąk K, Strąk D. Experimental Analysis of Heat Transfer in Multi-Mini-Channel Module: A Comparison with CFD Simulations. Energies. 2025; 18(22):5992. https://doi.org/10.3390/en18225992

Chicago/Turabian StyleStrąk, Kinga, and Dariusz Strąk. 2025. "Experimental Analysis of Heat Transfer in Multi-Mini-Channel Module: A Comparison with CFD Simulations" Energies 18, no. 22: 5992. https://doi.org/10.3390/en18225992

APA StyleStrąk, K., & Strąk, D. (2025). Experimental Analysis of Heat Transfer in Multi-Mini-Channel Module: A Comparison with CFD Simulations. Energies, 18(22), 5992. https://doi.org/10.3390/en18225992